Composite mesophase negative electrode material, lithium ion secondary battery, preparation method and application

A technology of negative electrode material and mesophase, applied in the field of composite mesophase negative electrode material, can solve the problems of poor cycle performance and low discharge capacity of mesophase negative electrode material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

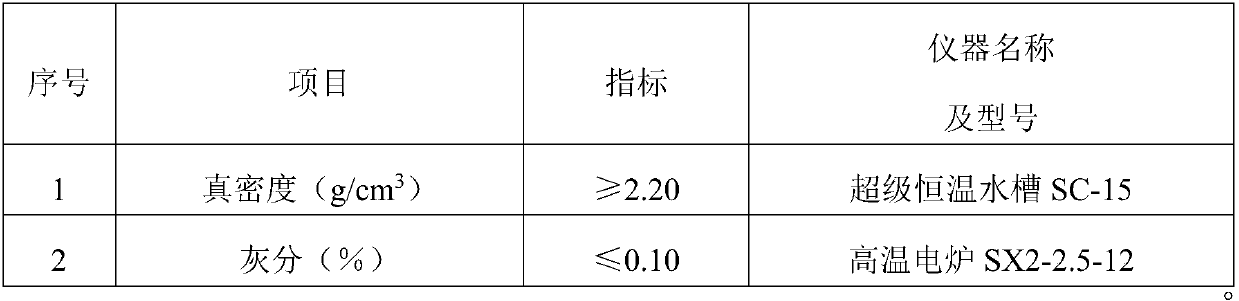

[0077] Petroleum pitch is crushed to below 0.1 mm, and 60 kg of petroleum coke calcined raw coke powder (D50 is 25.1 μm), 140 kg of mesocarbon microsphere green balls (D50 is 25.4 μm) and graphitization catalyst (SiO 2 ) 16kg, mixed evenly, mixed with pitch powder 60kg in a kneading pot, and kneaded for 1 hour at 160°C. After the kneading was completed, it was pressed into a sheet (4mm) in a tablet machine, and crushed into particles with a particle size of less than 100 μm. Briquetting is formed. Under the protection of nitrogen, carbonize at 1100°C for 2 hours, then cool the reaction product to room temperature, and then carry out high-temperature catalytic graphitization at 2800°C for 36 hours to obtain a composite with a particle size D50 of 17.8 μm. The intermediate phase negative electrode material has a half-battery capacity of 367.5mAh / g and an initial efficiency of 95.8%.

Embodiment 2

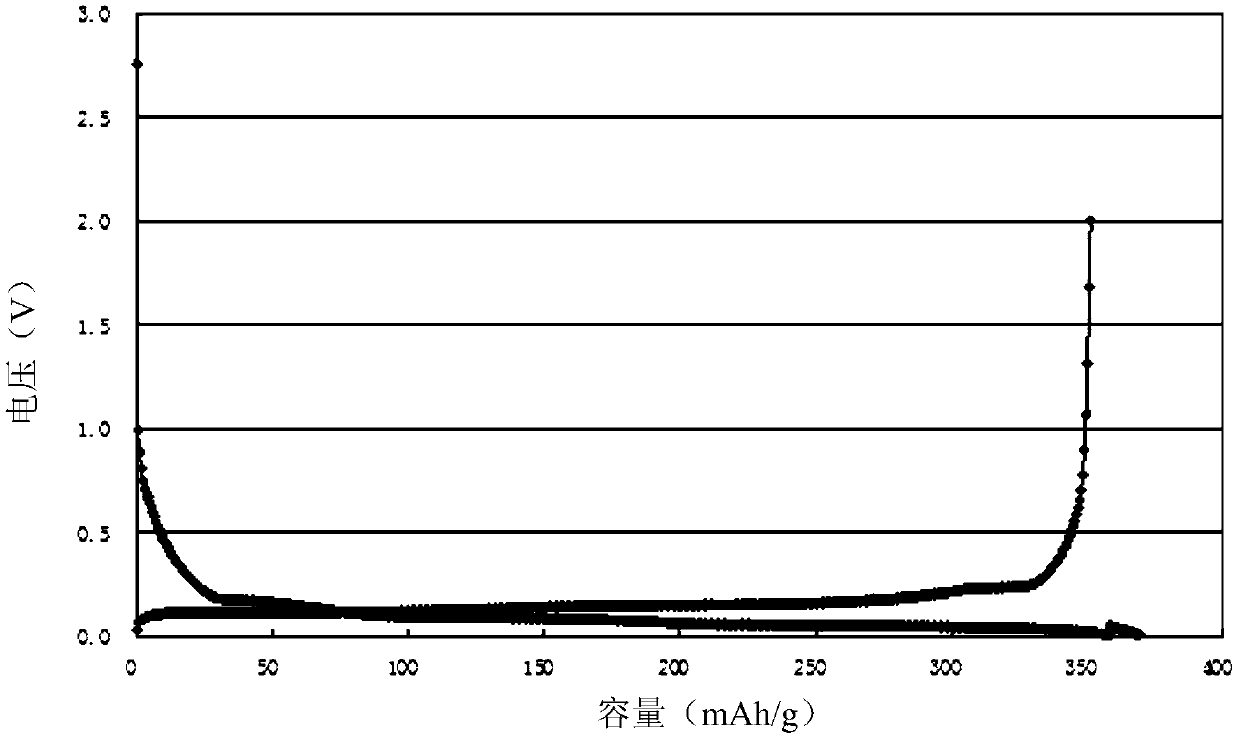

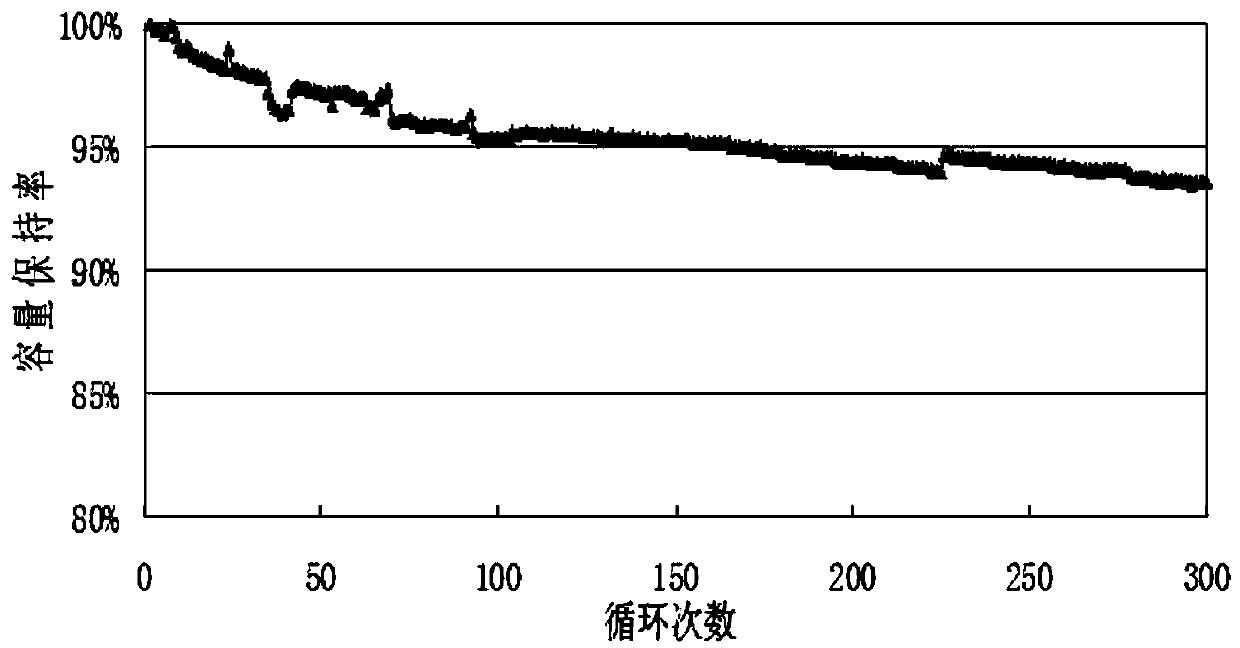

[0079] The petroleum pitch is crushed to less than 0.1mm, and 80kg of petroleum coke raw coke powder (D50 is 9.5μm), 120kg of mesophase carbon microspheres (D50 of 25.4μm) and graphitization catalyst (SiC) 6kg are added alternately under stirring Evenly, mix with asphalt powder 20kg in a kneading pot, and knead at 160°C for 1 hour. After kneading, press it into a tablet (3mm) in a tablet machine, crush it into particles with a particle size of less than 100μm, and briquette it. . Under the protection of nitrogen, carbonize at 800°C for 6 hours, then cool the reaction product to room temperature, and then carry out high-temperature catalytic graphitization at 3000°C for 48 hours to obtain a composite with a particle size D50 of 18.3 μm. The intermediate phase negative electrode material has a half-battery capacity of 368.1mAh / g and an initial efficiency of 95.2%. The first charge and discharge curve of the lithium secondary battery prepared in this embodiment is as follows: f...

Embodiment 3

[0081] Coal tar pitch is crushed to less than 0.1 mm, and 100 kg of green coke powder (D50 is 50.0 μm) before pitch coke calcining, 100 kg of mesocarbon microspheres (D50 is 20.5 μm) and graphitization catalyst (SiO 2 ) 10kg mixed evenly, mixed with pitch powder 40kg in a kneading pot, kneaded at 160°C for 1 hour, after the kneading was finished, pressed into flakes (5mm) in a tablet machine, and crushed into particles with a particle size of less than 100 μm. Briquetting is formed. Under the protection of nitrogen, carbonize at 1500°C for 3 hours, then cool the reaction product to room temperature, and then carry out high-temperature catalytic graphitization at 3200°C for 48 hours to obtain a composite with a particle size D50 of 17.4 μm. The intermediate phase negative electrode material has a half-battery capacity of 370.0mAh / g and an initial efficiency of 95.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com