Needle milling production process of powdery cell culture medium

A production process and culture medium technology, which is applied in the field of needle grinding production technology of powder cell culture medium, can solve the problems of reducing the annual production capacity of the culture medium, and achieve the effects of saving production time, production cost and large output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In Example 1, the pin mill production process was adopted, and the preparation of DMEM / F12 medium was taken as an example. The specific method steps are as follows.

[0028] Step 1. Weigh the raw materials by type and set aside; the raw materials are weighed by type as shown in Table 1-4:

[0029] Table 1: Inorganic salts in the formula

[0030] components

Content (mg / L)

116.6

0.0013

0.05

0.417

311.8

Magnesium chloride hexahydrate

28.64

48.84

Sodium chloride

6999.5

Anhydrous Sodium Dihydrogen Phosphate

54.35

Anhydrous Disodium Hydrogen Phosphate

71.02

0.432

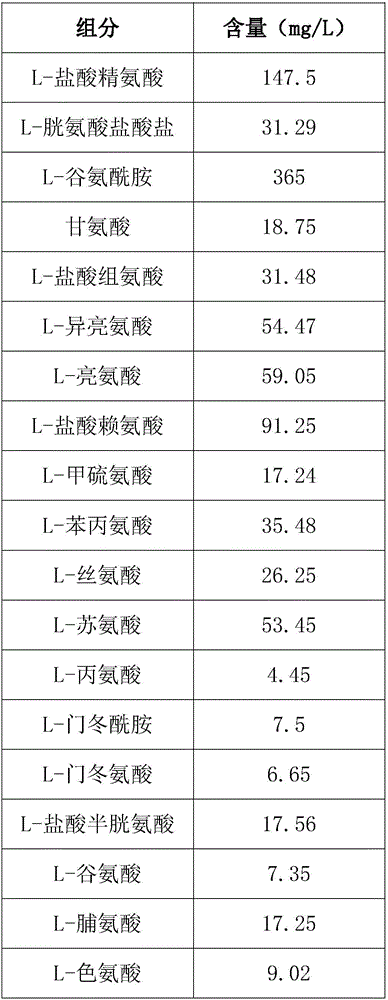

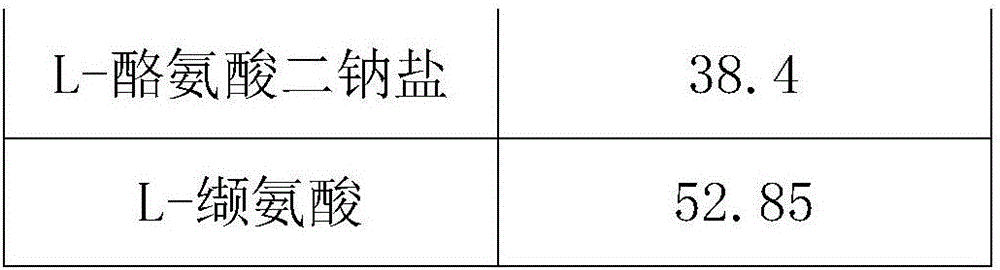

[0031] Table 2: Amino acids in the formula

[0032]

[0033]

[0034] Table 3: Vitamins in Formula

[0035] com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com