Patents

Literature

174results about How to "Save production time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

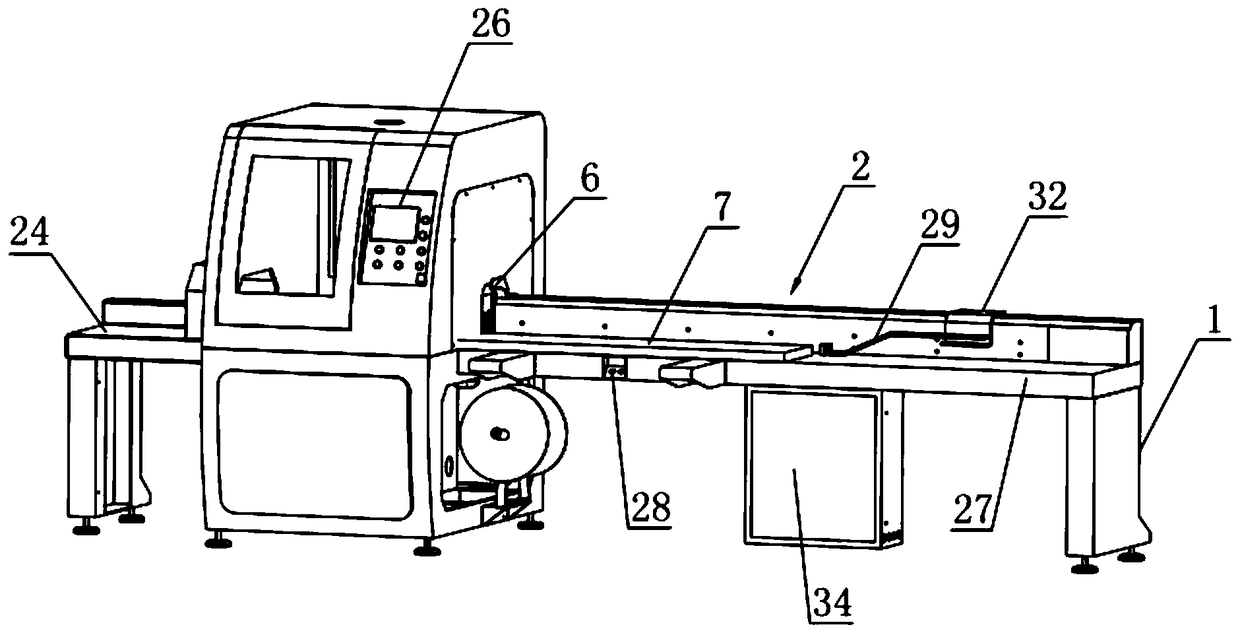

Automatic step steel plate cutting and welding device, and method thereof

ActiveUS20190358742A1Save production timeIncrease productivityLaser beam welding apparatusEngineeringFully automatic

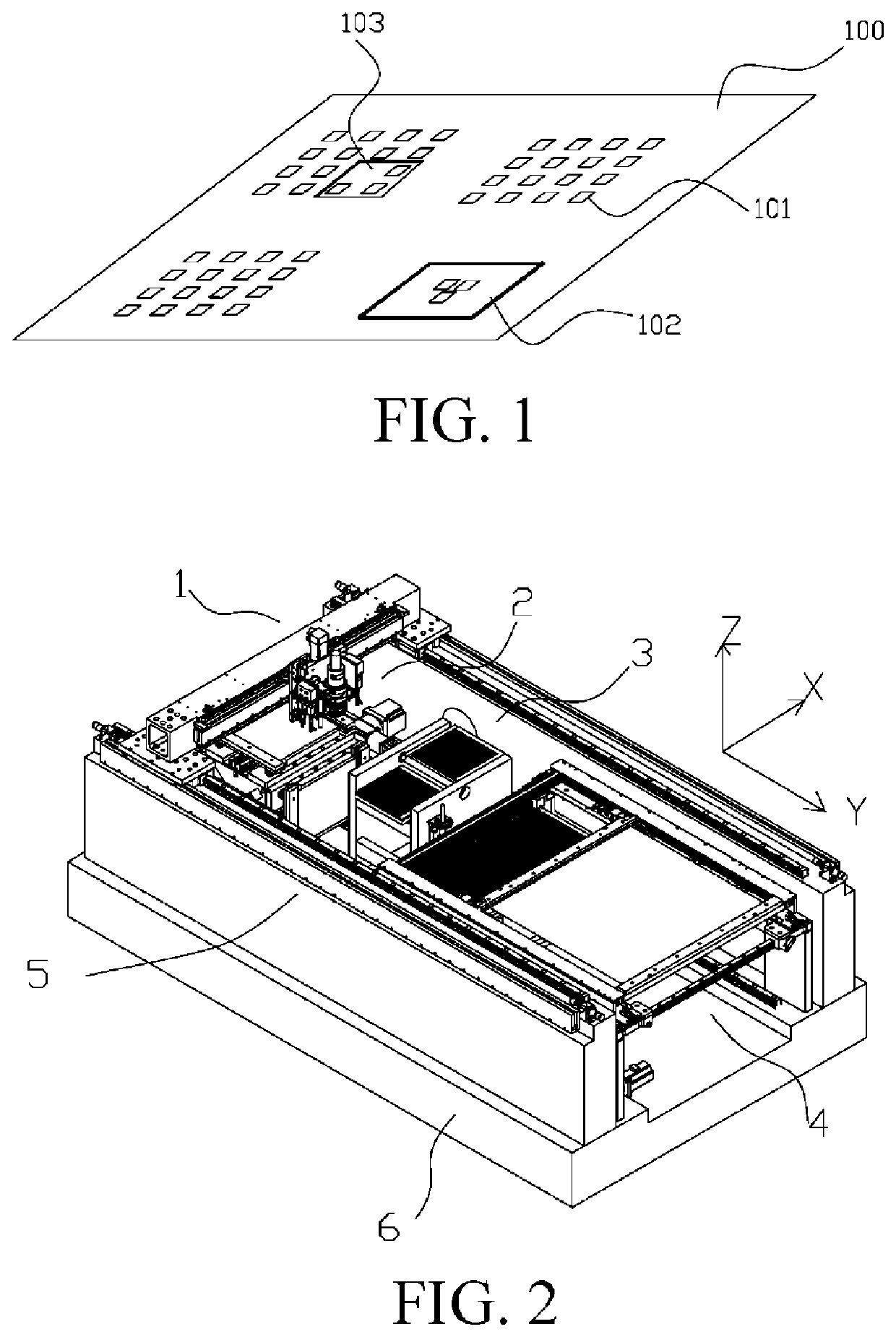

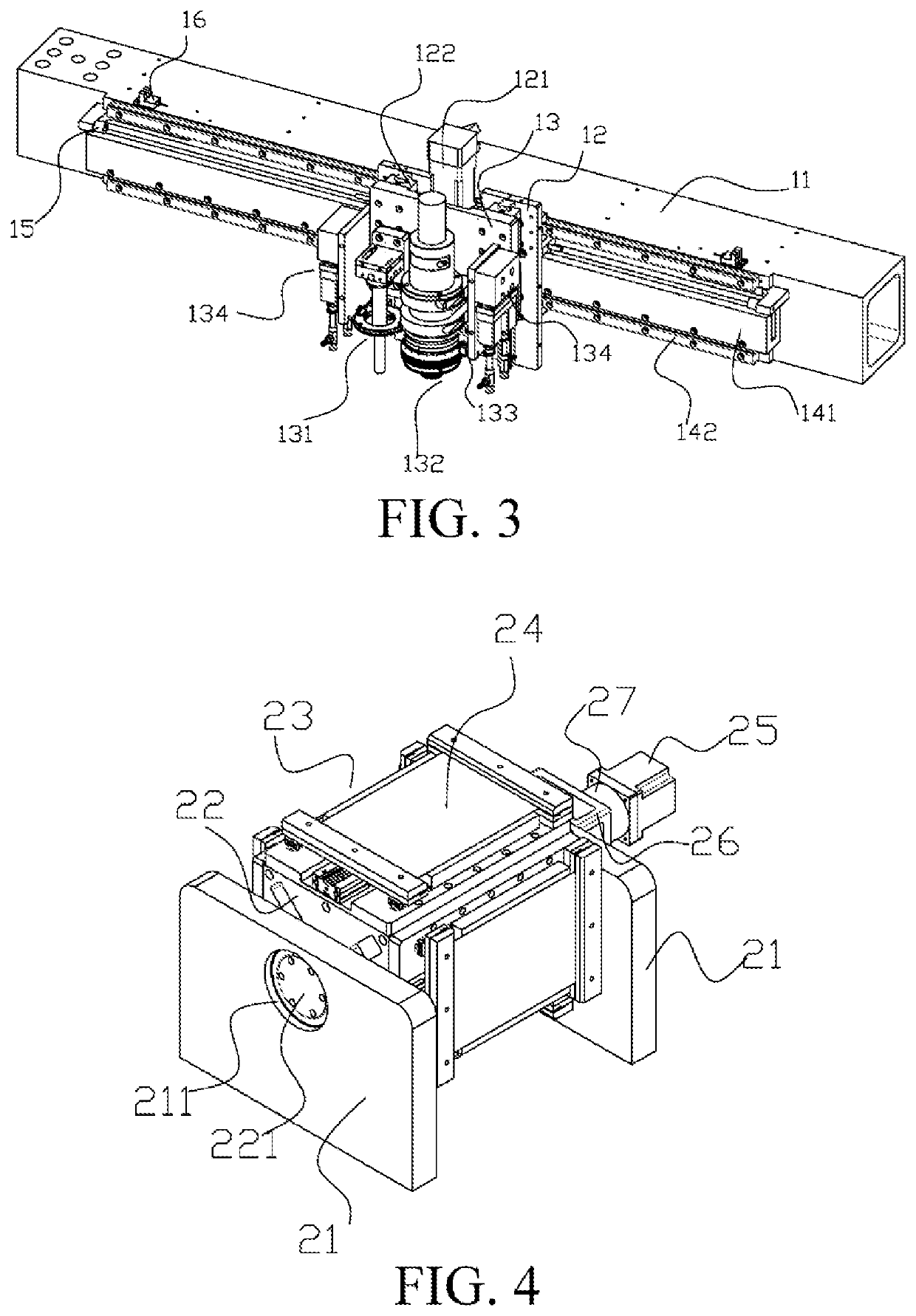

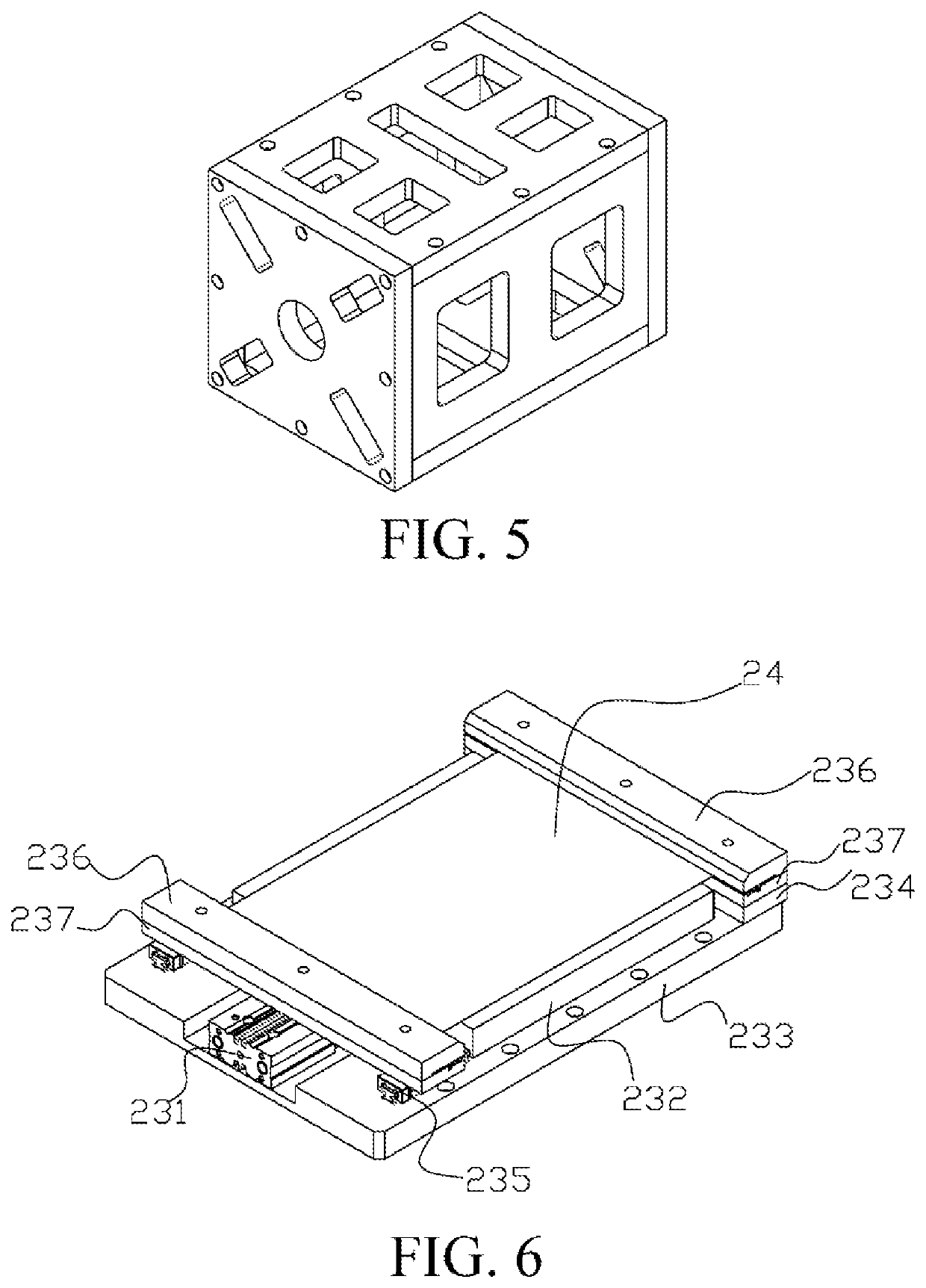

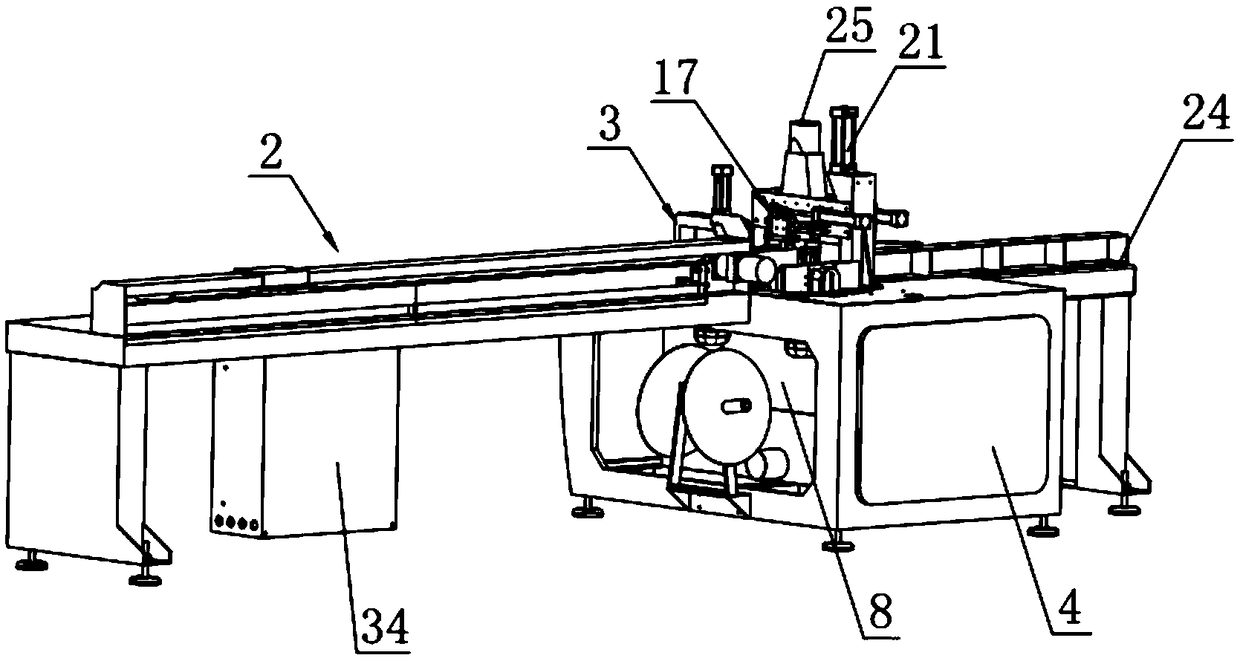

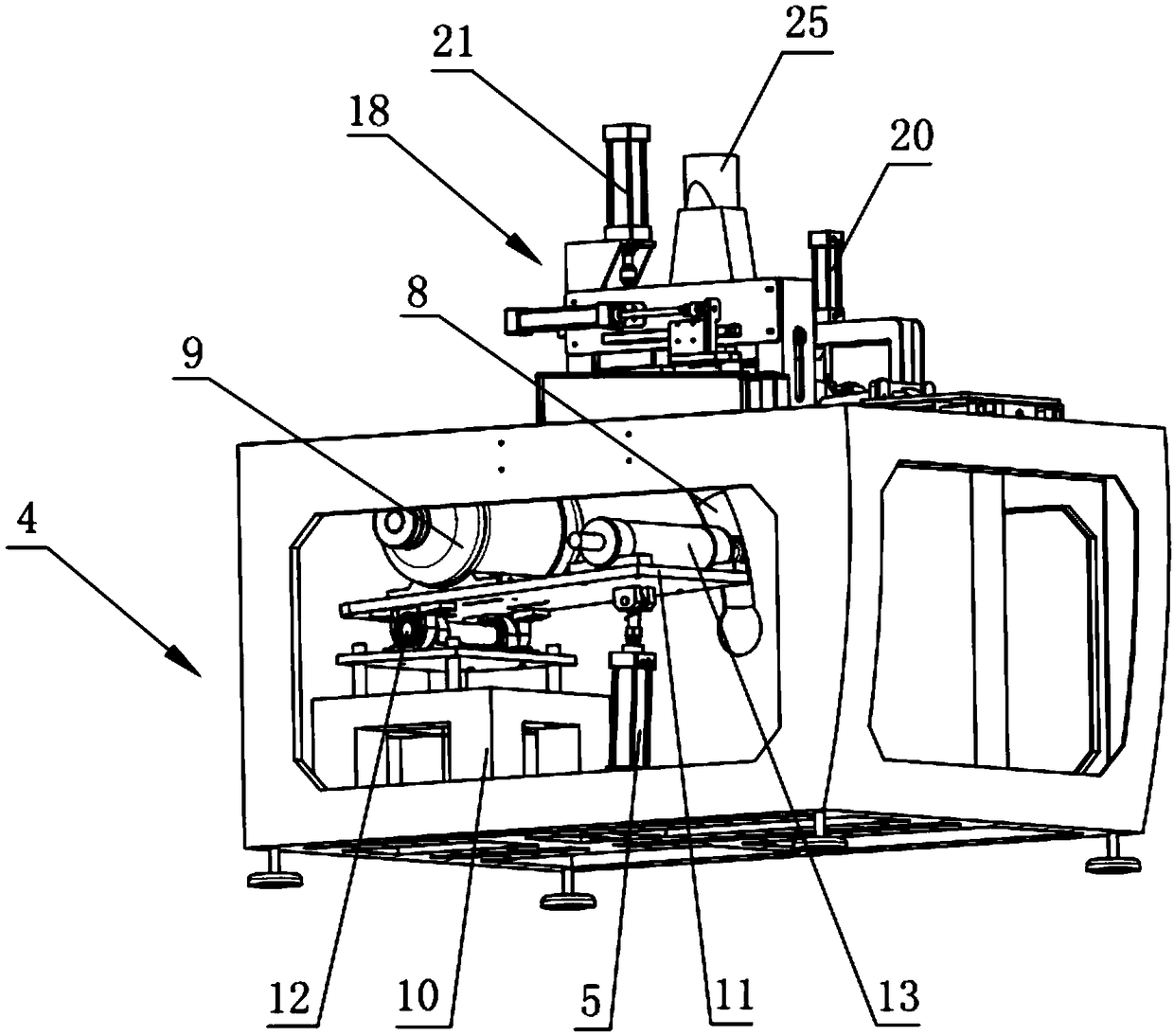

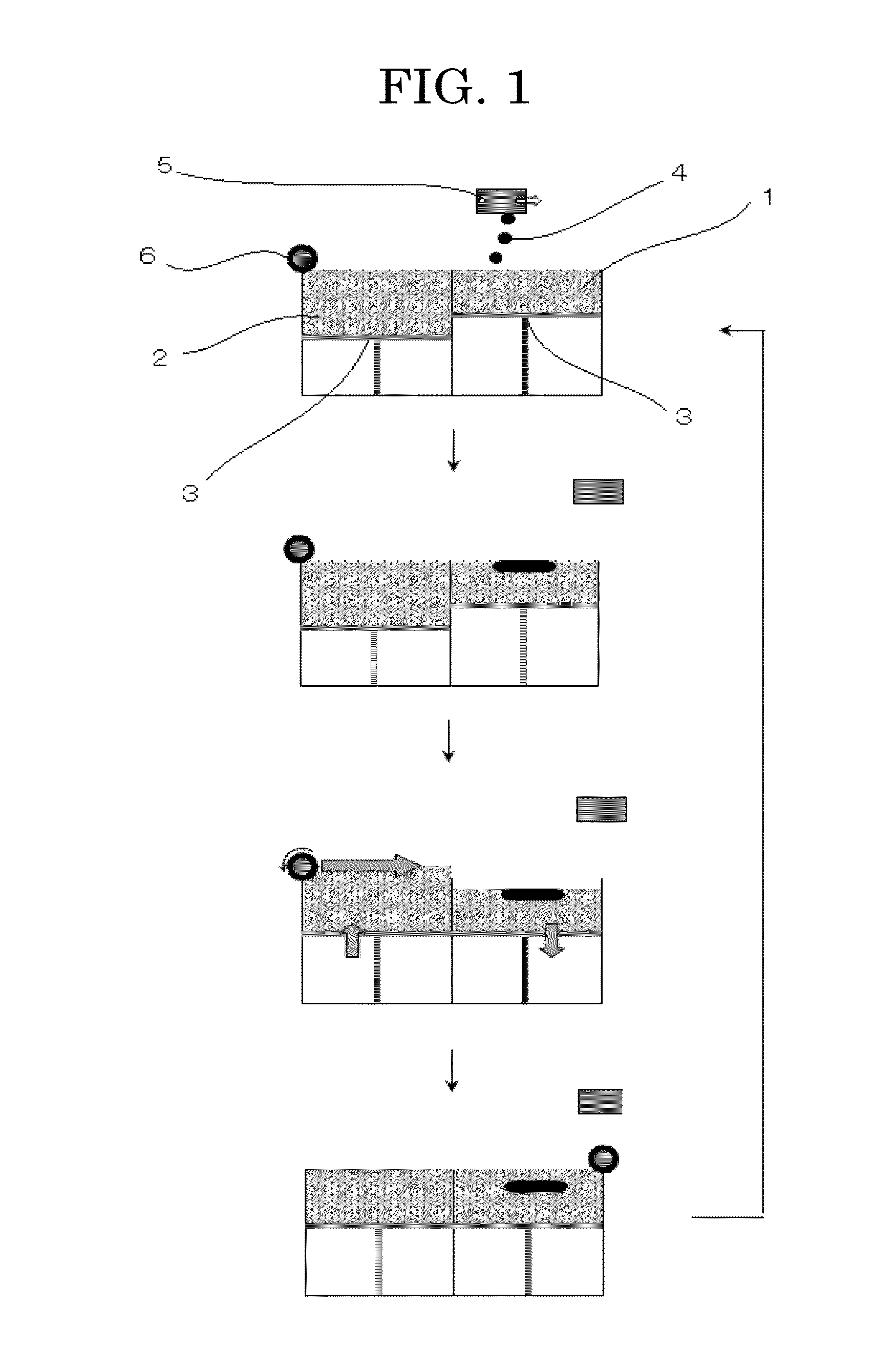

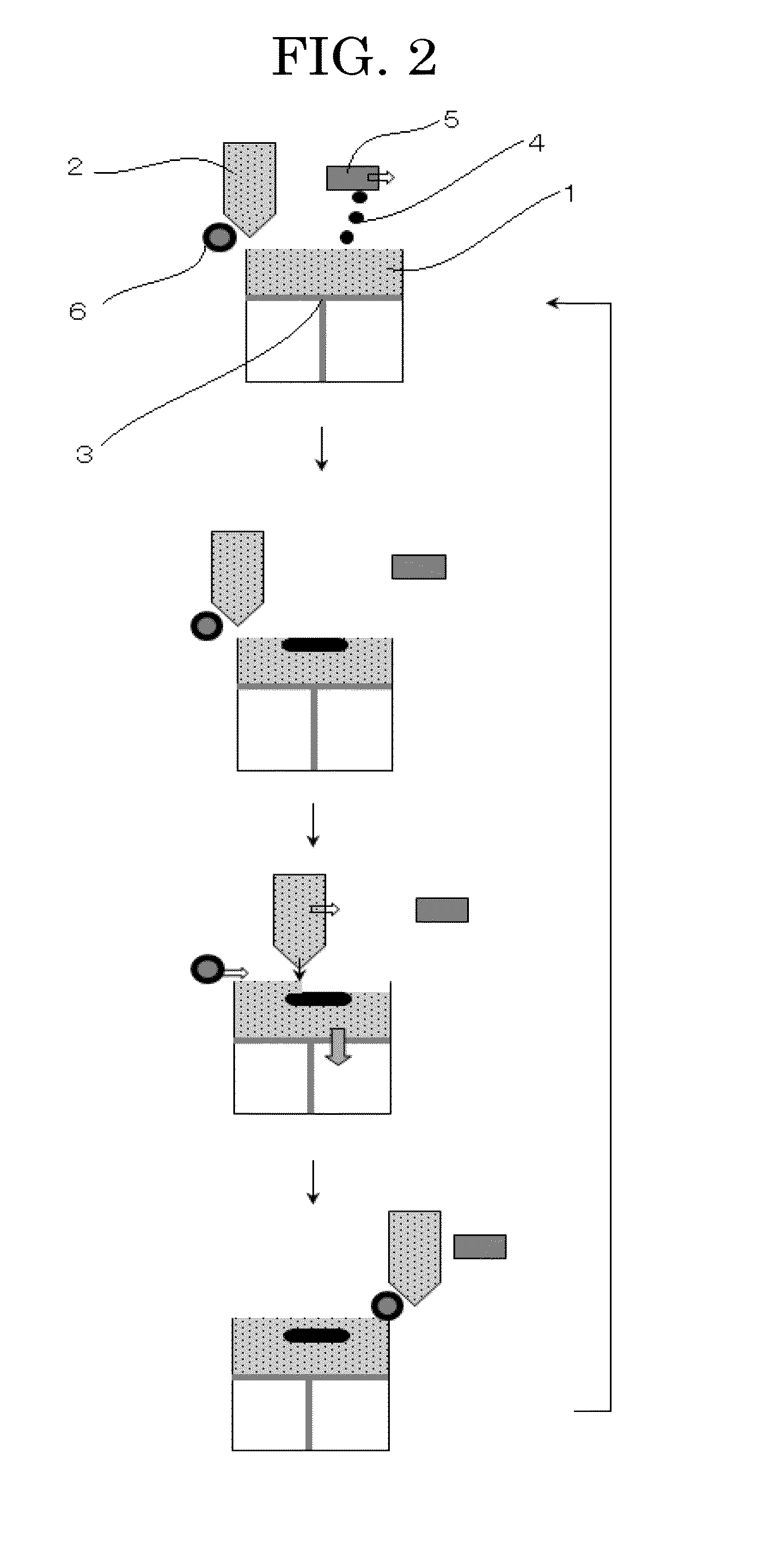

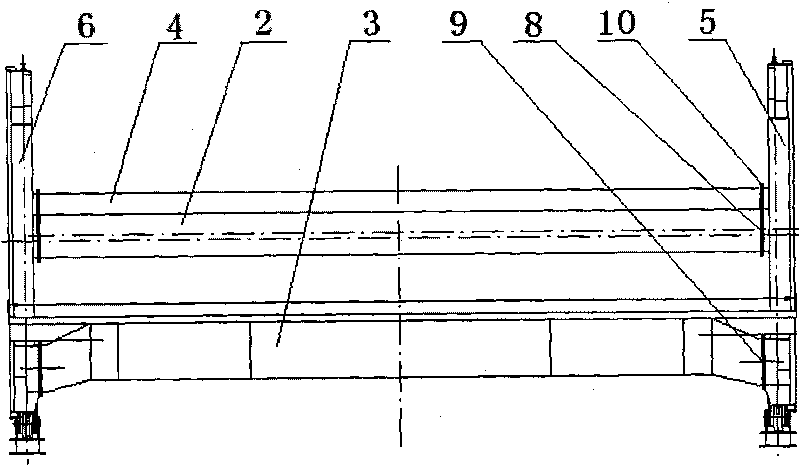

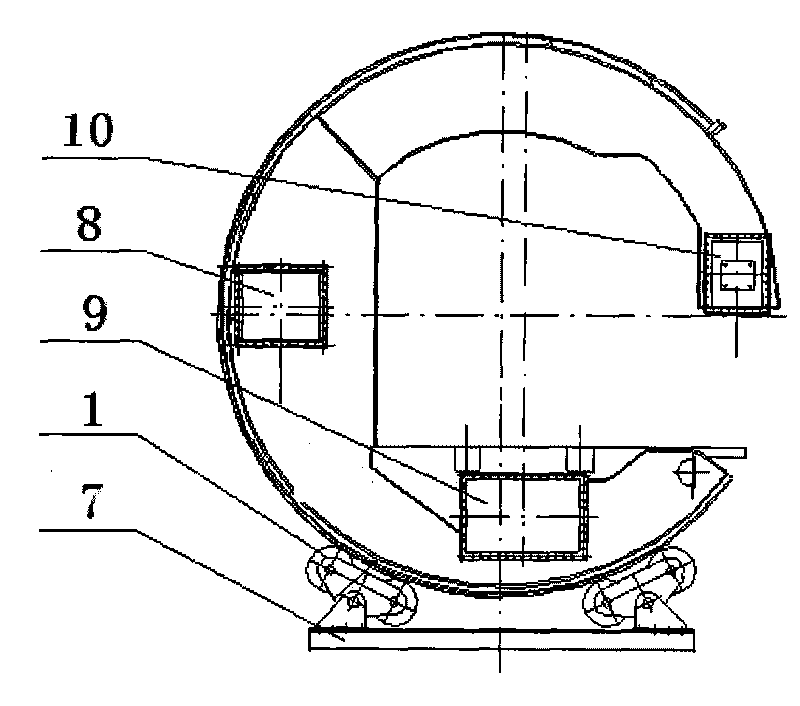

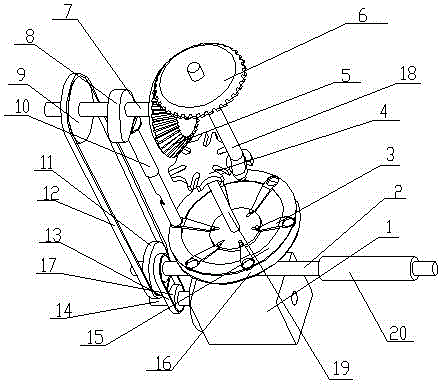

A fully-automatic cutting and welding apparatus for stepped steel plate, comprising a multi-function motion module (1), an automatic feed library turntable (2), a product flip platform (3), a steel plate bearing module (4), a pedestal (5), and a base (6). The multi-function motion module (1) is capable of performing motion in a Y-axis direction on the pedestal (5); the pedestal (5) is fixed on a surface edge of the base (6);the automatic feed library turntable (2) is fixed at one end of the base (6); the product flip platform (3) is disposed between the automatic feed library turntable (2) and the steel plate bearing module (4), and the steel plate bearing module (4) is fixed at the other end of the base (6) for bearing and fixing a steel plate, and is used as a welding platform for the final steel plate step part.

Owner:KUNSHAN THETA MICRO

Crystallization method of abamectin Bla

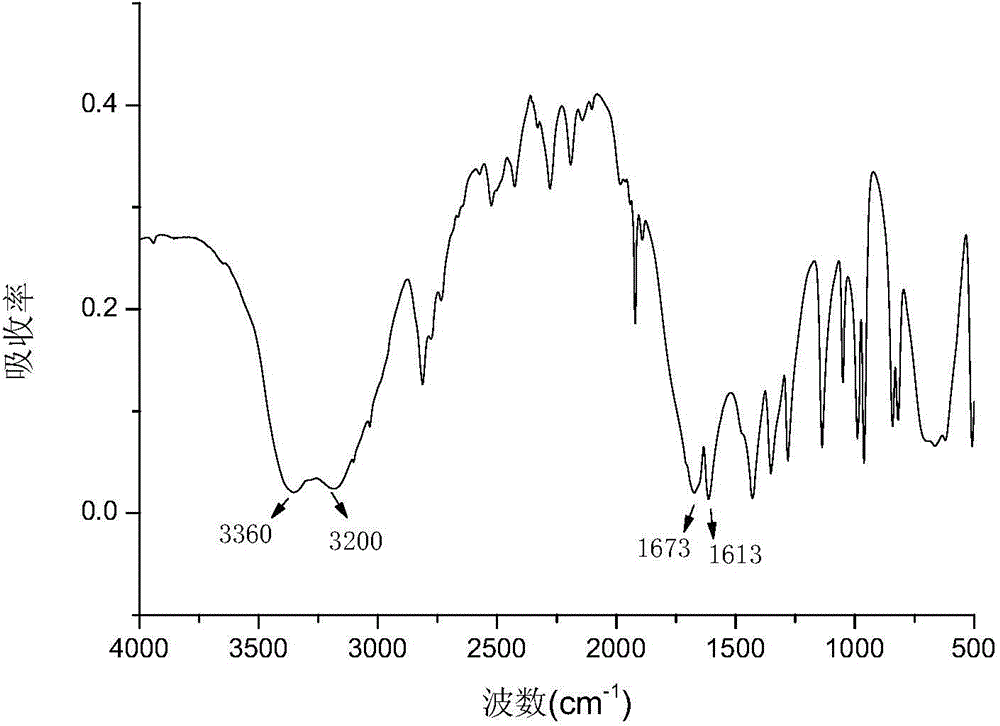

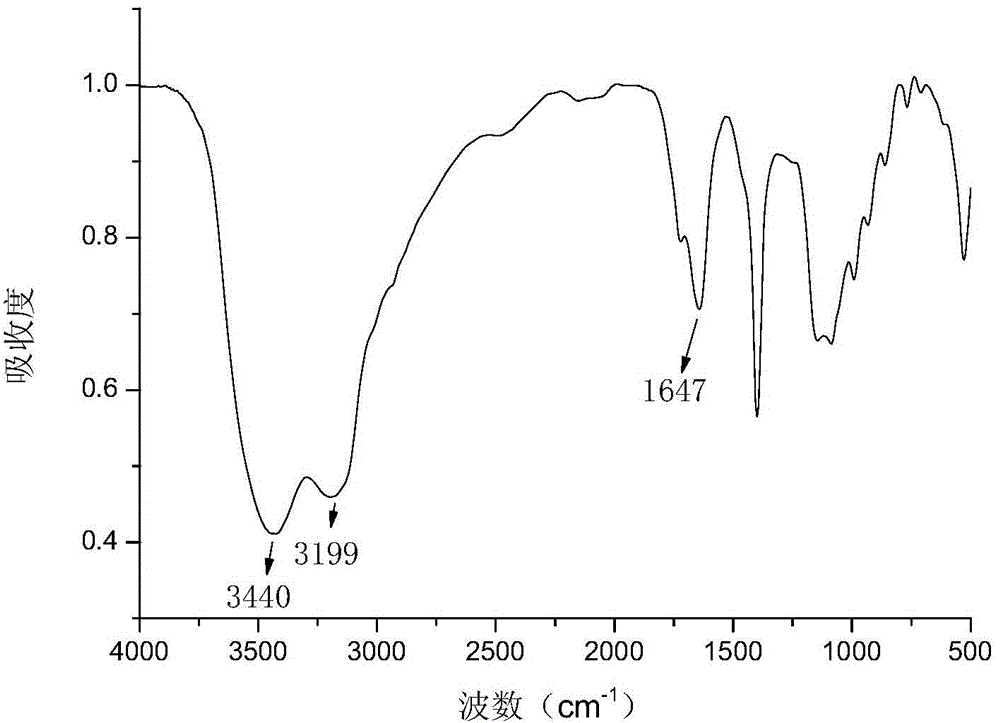

The present invention relates to a crystallization method of abamectin B 1a. Said method includes the following steps: using crystallization solvent n-butanol to stir and dissolve primary crude powder of abamectin B 1a at 75-100deg.C to saturation, filtering while the saturated solution is hot to obtain clear hot-saturated solution; slowly cooling said solution to that when the supersaturation degree is 1-3, adding crystal seeds, constant stirring for 20-60min, its stirring speed is 120-300rpm, and cooling to make crystallization, fitering crystal slurry or centrifugally-separating said crystal slurry, washing crystal and drying so as to obtain the invented abamectin B 1a.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process for extracting iodine from kelp

InactiveCN1840469ASave the drying processReduce manufacturing costHalogen/halogen-acidsMANNITOL/SORBITOLIodine

The disclosed method to extract I2 from kelp comprises: with fresh kelp as material, cutting up, adding 200wt% water to dip for 30-50min; putting soak into pond, adjusting pH value with alkali, while filling gas to stir and then filter to obtain the clear liquid with I2 and mannitol; acidifying and oxidizing to obtain dissociative I2 and then adsorb with basic anion exchange resin; desorbing the I2 on resin with Na2S2O3; adding strong H2SO4 and KClO3 to separate out coarse I2; cleaning, and refining with 25wt% strong H2SO4 at 140Deg to obtain the refined iodine. This invention reduces cost and source.

Owner:威海长青海洋科技股份有限公司

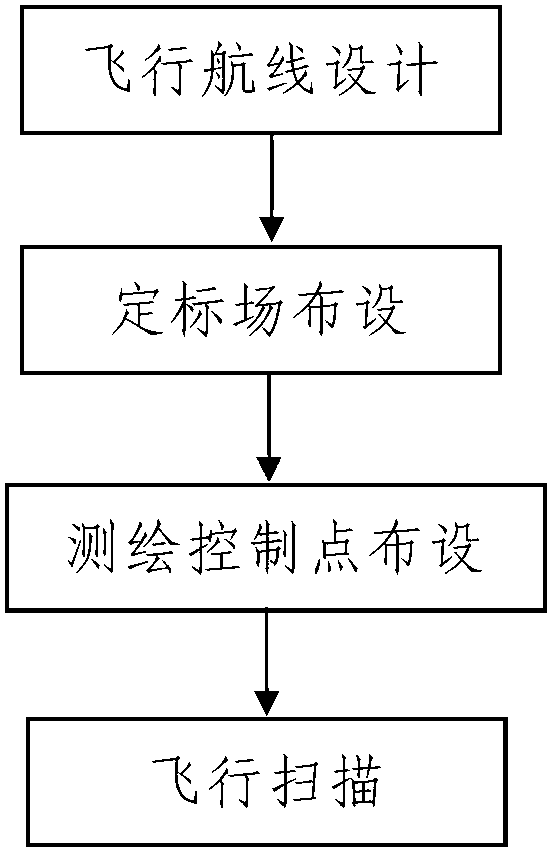

Ground control and measurement stationing method based on onboard interferometric synthetic aperture radar (InSAR)

InactiveCN102707284AThe method steps are simpleEasy to operateRadio wave reradiation/reflectionTerrainInterferometric synthetic aperture radar

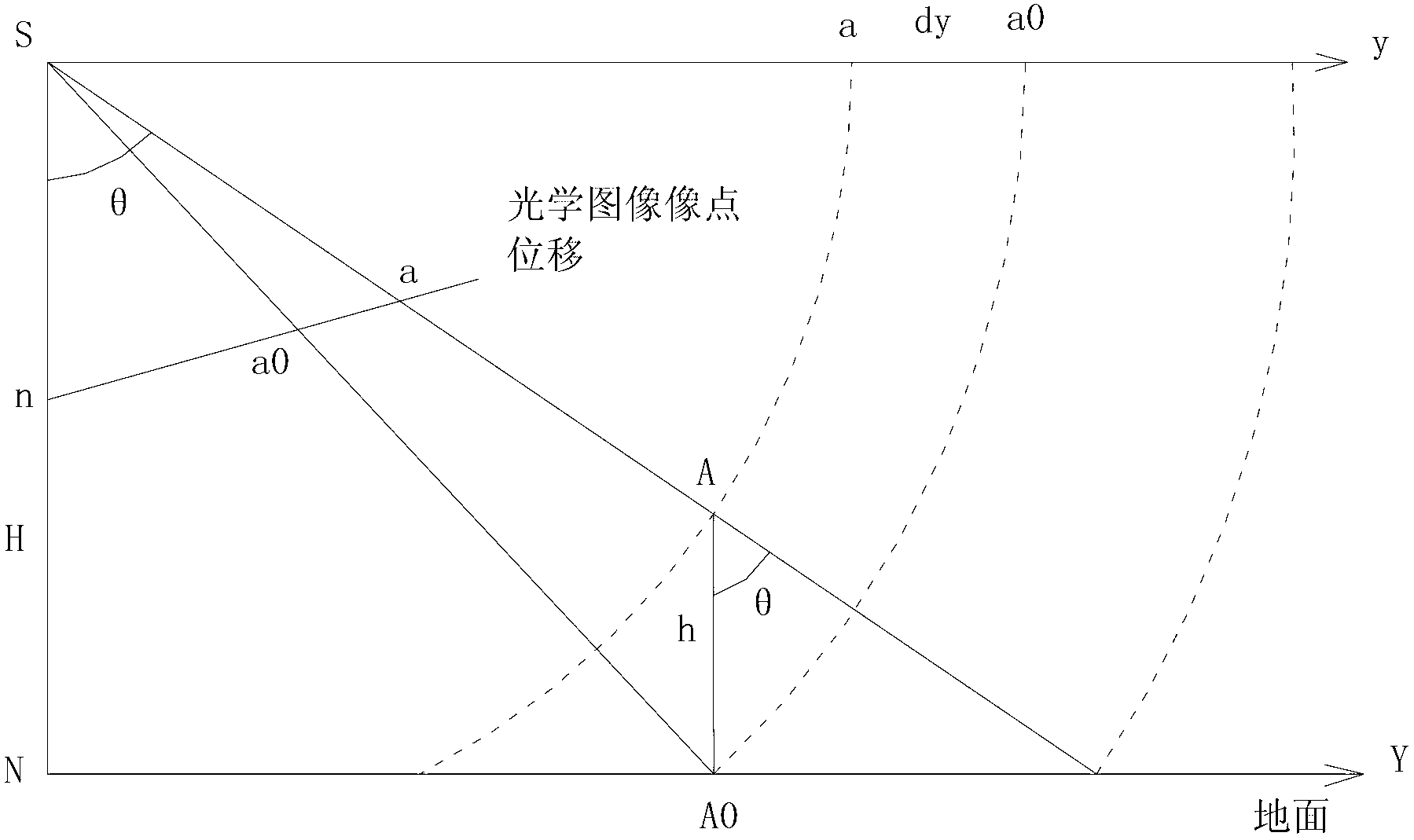

The invention discloses a ground control and measurement stationing method based on an onboard interferometric synthetic aperture radar (InSAR). The method comprises the following steps of: 1, designing a flight line, namely determining a range of a region to be plotted according to pre-collected information of a detection region terrain and designing the number N of sorties required to fly and the flight line of each sortie according to the determined range of the region to be plotted and flight parameters during plotting; 2, arranging calibration fields, namely arranging one or two calibration fields for radiating and geometrically calibrating an onboard InSAR system inside or outside the detection region; 3, stationing plotting control points; and 4, scanning flight, namely after the N sorties fly in the calibration fields and the detection region, acquiring InSAR measurement data in the region to be plotted. By the method, the steps are rational in design, the use operation is simple, and the using effect is good; and the shortcoming that the onboard InSAR terrain plotting control and measurement cannot be instructed according to the technical rule of the conventional optical system is overcome.

Owner:XIAN MEIHANG INFORMATION IND

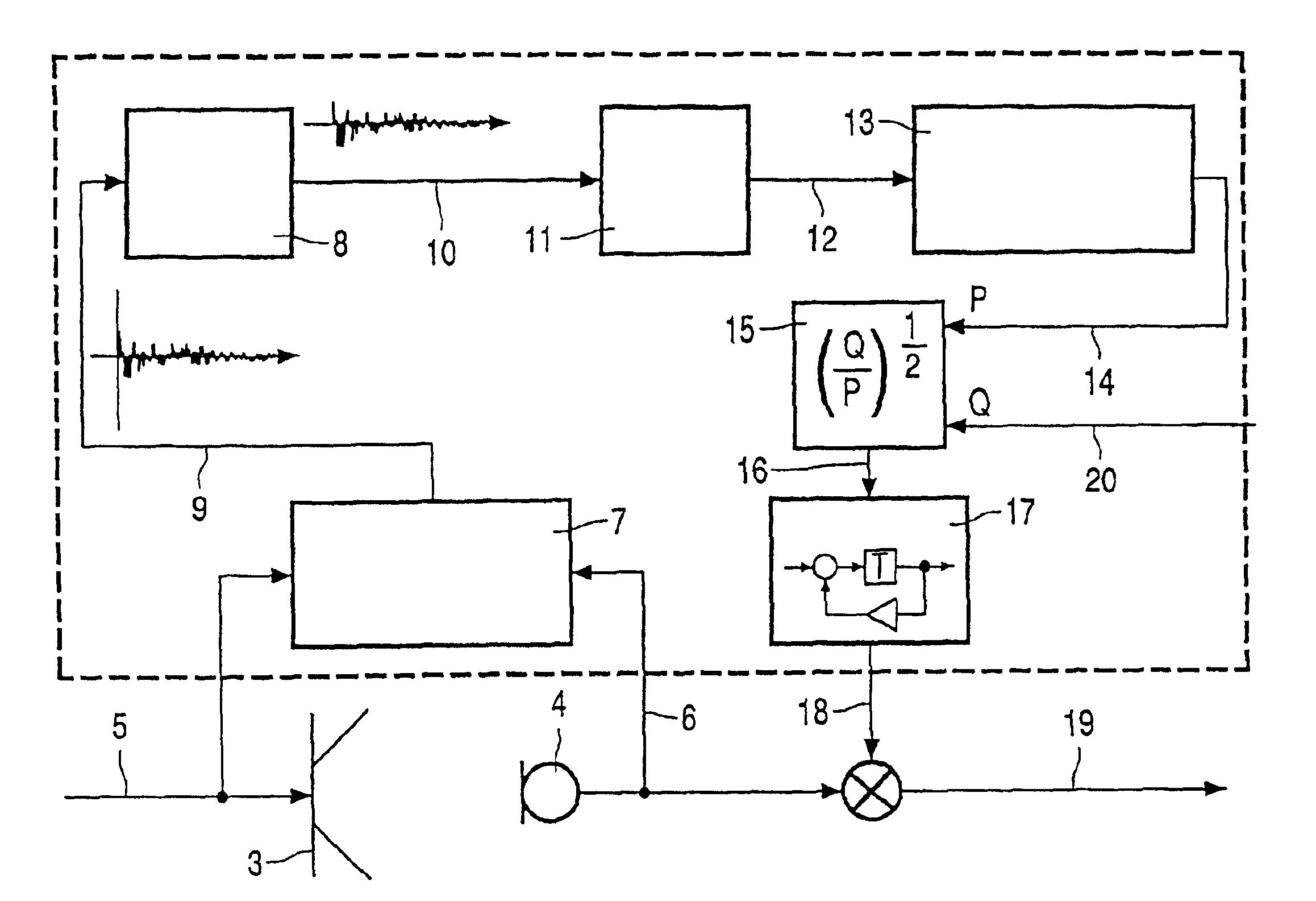

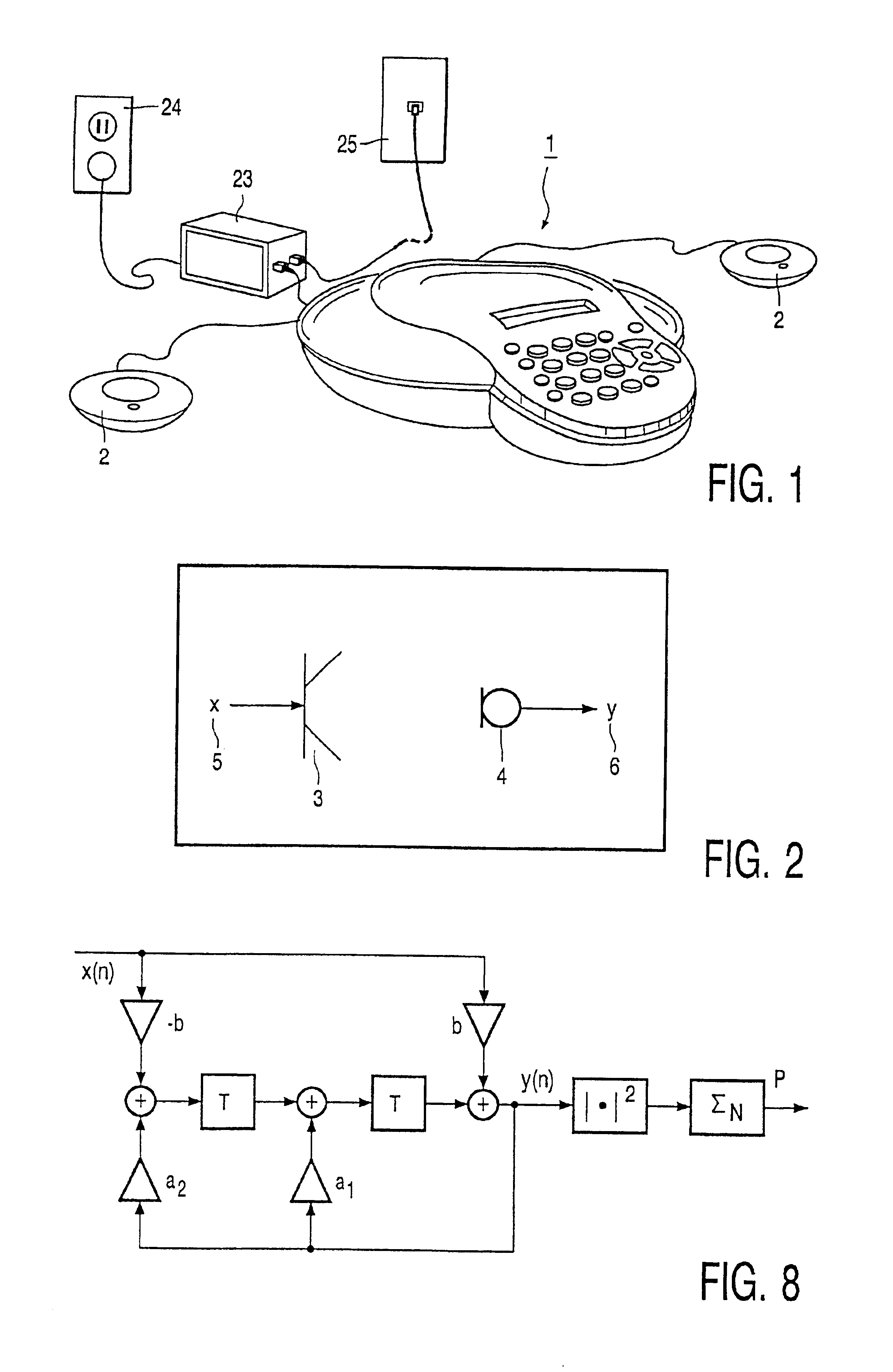

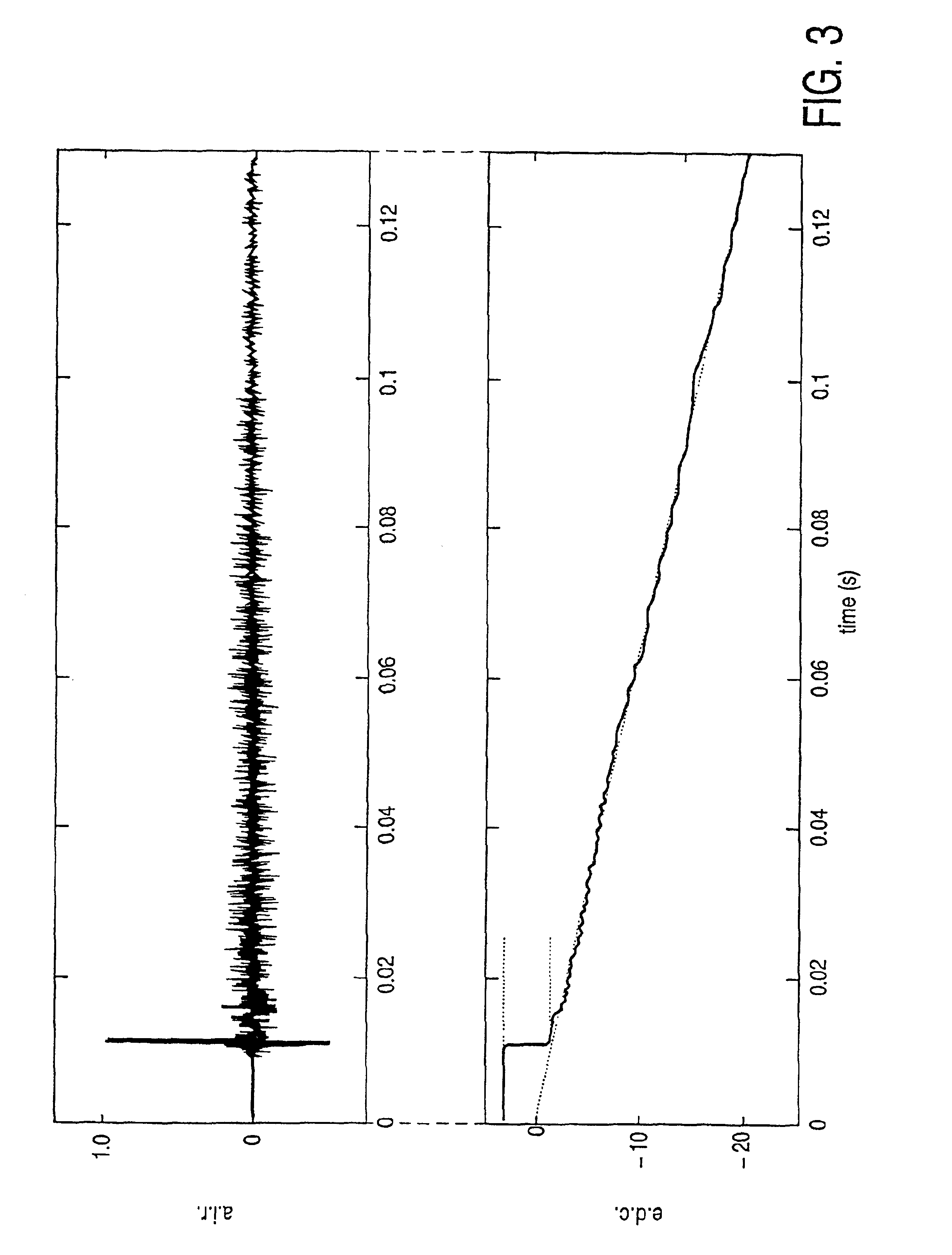

Device and method for calibration of a microphone

InactiveUS6914989B2Easy CalibrationImprove performanceMouthpiece/microphone attachmentsTransducer casings/cabinets/supportsEngineeringImpulse response

A device for and method of calibrating a microphone, includes a loudspeaker (3) for converting a loudspeaker input signal (5) into sound; a microphone (4) for converting received sound into a microphone output signal (16), and a calibration arrangement for calibrating an output power of the microphone relative to a desired power level. The calibration arrangement includes an impulse response estimating device (7) for estimating an acoustic impulse response of the microphone by correlating the microphone output signal (6) and the loudspeaker input signal (5) when the microphone (4) receives the sound from the loudspeaker (3), whereby the output power of the microphone (4) is estimated.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

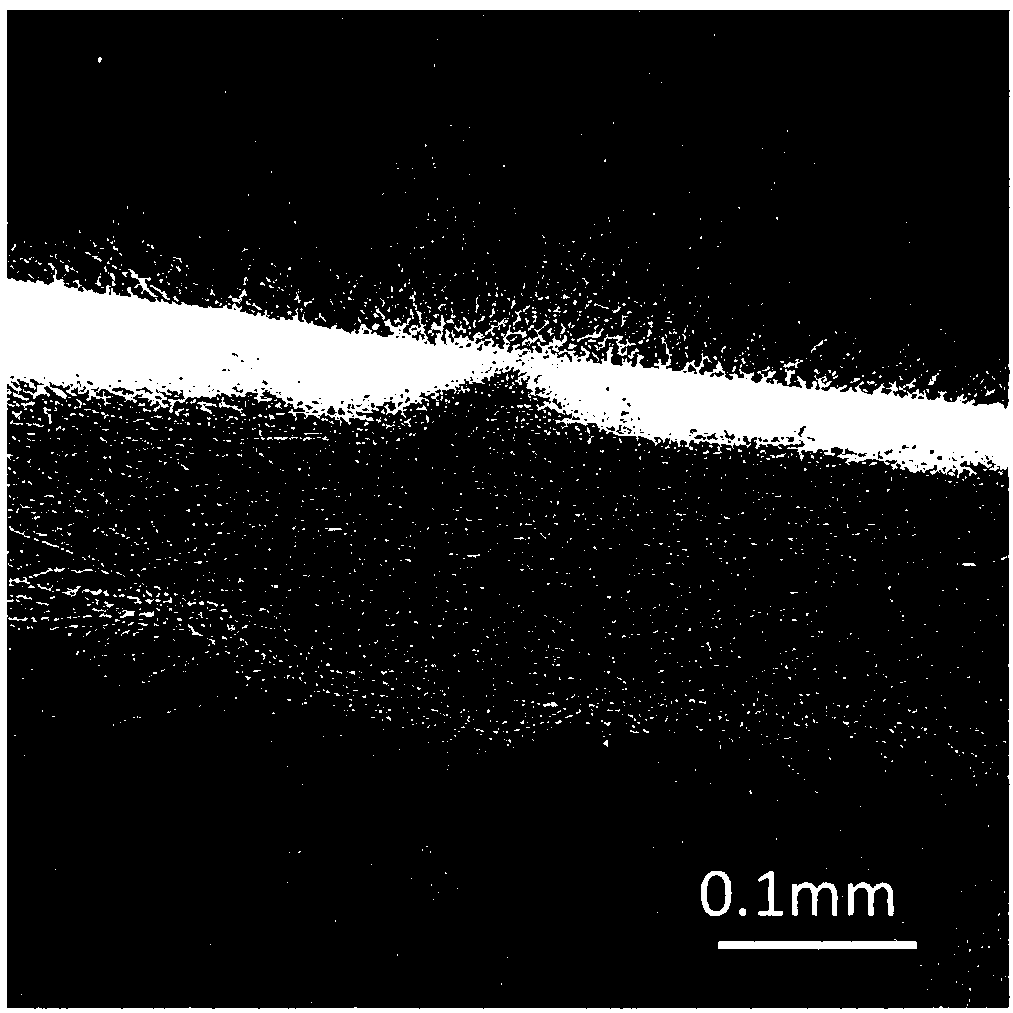

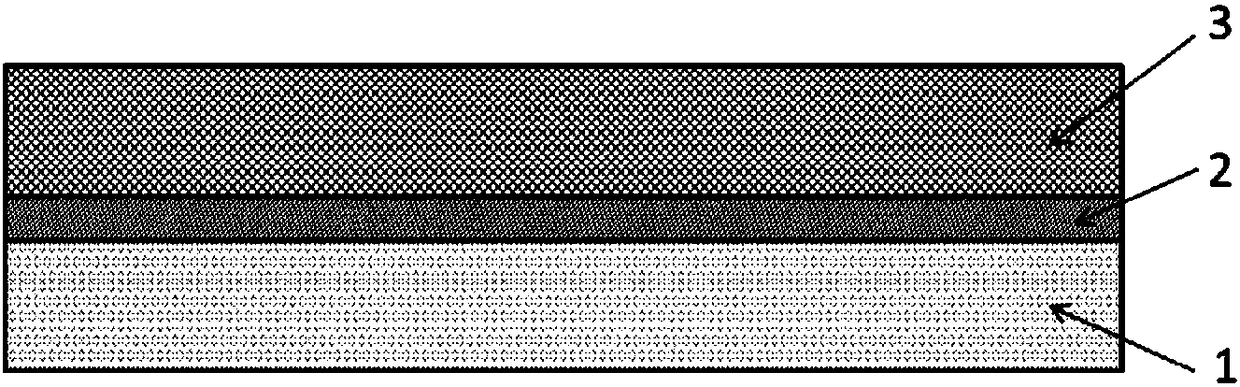

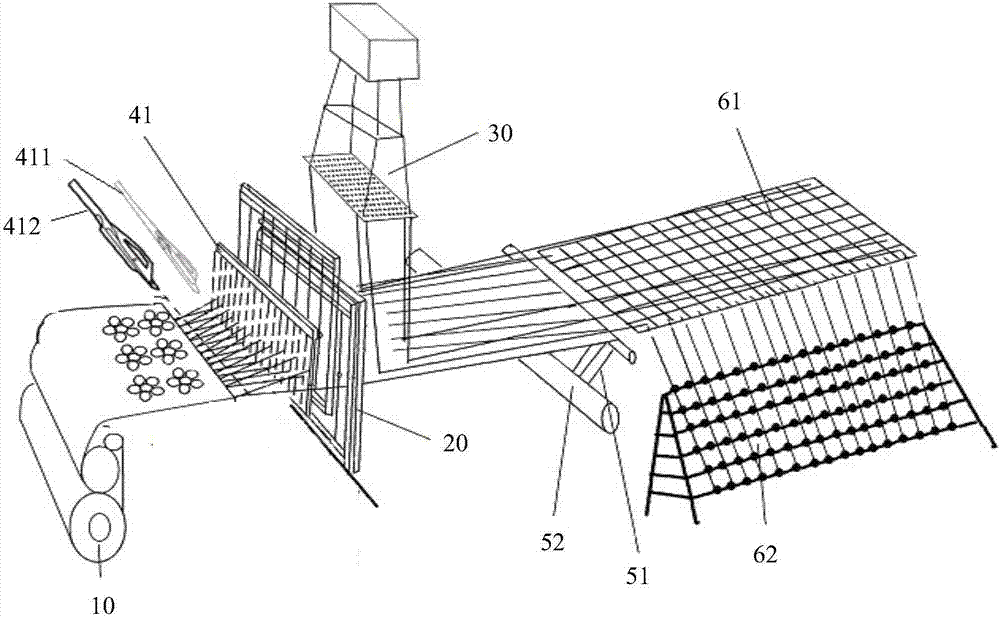

Anti-haze window screen based on electrospinning technology and preparation method thereof

ActiveCN108071332AThe overall thickness is thinHigh porosityDispersed particle filtrationInsect protectionParticulatesFiber

The invention discloses an anti-haze window screen based on an electrospinning technology and a preparation method thereof. The window screen is provided with a three-layer composite structure, a baselayer is a metal screen cloth, and a cyan ethyl acrylate viscous layer is compounded on the surface of the metal screen cloth in an electrostatic spray method. An intermediate layer is a nanofiber functional film directly electrospun on the surface of the metal screen cloth by electrospinning, and the nanofiber functional film is a nano-graphene / PVDF / PEO composite nanofiber film, a protective layer is compounded on the upper surface of the nanofiber functional film through a hot pressing method, and the protective layer is a nylon net. The window screen can filter outdoor air, effectively block dust and other particulate matter, and can ensure indoor and outdoor air circulation and indoor lighting. The preparation method is simple, suitable for large-scale production, and has a good application prospect.

Owner:聚纳达(青岛)科技有限公司

Coloring master batches for polyethylene and preparation method thereof

The invention discloses coloring master batches for polyethylene and a preparation method thereof. The coloring master batches for polyethylene disclosed by the invention comprise the following components in percentage by mass: 70%-90% of pigment, 10%-20% of polyethylene resin, 3%-5% of dispersant, 0.1%-1% of antioxidant and 0.1%-1% of antistatic agent. Compared with the prior art, the coloring master batches for polyethylene have the beneficial effects that the prepared coloring master batches for polyethylene are applied to coloring of polyethylene products, have the characteristics of good dispersibility, uniform coloring, high concentration, little dosage and no influence on the mechanical property of the polyethylene products, and are low in cost, easy to color, convenient to use and capable of saving production time and raw materials and the like.

Owner:QINGDAO SANLI ZHONGDEMEI WATER EQUIP

Instant nutritious black bone chicken and preparation method thereof

InactiveCN102370185AShorten marinating timeExtended shelf lifeClimate change adaptationFood preparationChinese traditionalPhysiological function

The invention relates to an instant nutritious black bone chicken and a preparation method thereof. The instant nutritious black bone chicken is prepared by the following steps of: injecting Chinese medicinal feed liquid into a black bone chicken body by using a bone brine injection machine; pouring injected curing auxiliary materials, the black bone chicken and remaining Chinese medicinal feed liquid into a vacuum rolling and kneading machine together to roll and knead for 50-70 minutes; statically salting at the temperature of 0-4 DEG C for 8-12 hours; and finally freezing to obtain the instant nutritious black bone chicken. The instant nutritious black bone chicken has the characteristics of improving physiological function, delaying aging, strengthening muscle and bone and the like of the black bone chicken; and since eight Chinese medicinal tonics such as yam, tuckahoe, medlar and the like are added, a product has the efficacy of the Chinese traditional medicines and achieves better tonic effectiveness.

Owner:天津宝迪农业科技股份有限公司

Fully-automatic production line for producing wooden pier

PendingCN109397453AGuaranteed cleanlinessGuaranteed accuracyStapling toolsCircular sawsProduction lineEngineering

The invention relates to the technical field of machining, in particular to a fully-automatic production line for producing a wooden pier. The production line includes a working table, the working table is provided with a feeding device, a nailing device, a cutting device, a lifting driving device and a controller, and a detecting component is arranged on the feeding device; the detecting component sends the detection signal to the controller after detecting a wooden board; the controller sends a driving signal for cutting off the wooden pier to the lifting drive device after receiving the detection signal and sends a signal for controlling the working state of the feeding device to the feeding device; after the wooden pier is cut, the controller sends a feeding signal for controlling thewooded board material to the feeding device. By setting the controller to control the cutting device, the feeding device and the nailing device, the automatic wooden board binding and the wooden piercutting are realized. The positioning is accurate, and the cutting precision is high. The fully-automatic production line for producing wooden pier can be used for feeding while binding, so that uninterrupted production is realized. The wooden board is cut from bottom to top in an arc mode, so that power and energy is saved. The production line has low production cost and high production efficiency and production precision is ensured.

Owner:QINGDAO MEIJIALONG PACKAGING MACHINERY

Starch grafted acrylamide and preparation method and application thereof

InactiveCN104086704ASimple processEasy to operateReinforcing agents additionUltimate tensile strengthReagent

The invention discloses starch grafted acrylamide and a preparation method and application thereof. The preparation method comprises the following steps: preparing waxy corn starch milk and adding an expansion inhibitor; adding alkali to adjust the starch milk to a certain pH value, adding a cationic reagent, and performing a cationic reaction at the temperature of 70-90 DEG C; taking acrylamide as a monomer, adding an initiating agent, performing a graft copolymerization reaction in a water phase of 40-80 DEG C, separating, drying and smashing to obtain the starch grafted acrylamide. By adding the prepared starch grafted acrylamide into the wet part of a papermaking machine in a certain mass ratio, the physical strength of produced paper can be enhanced.

Owner:SOUTH CHINA UNIV OF TECH

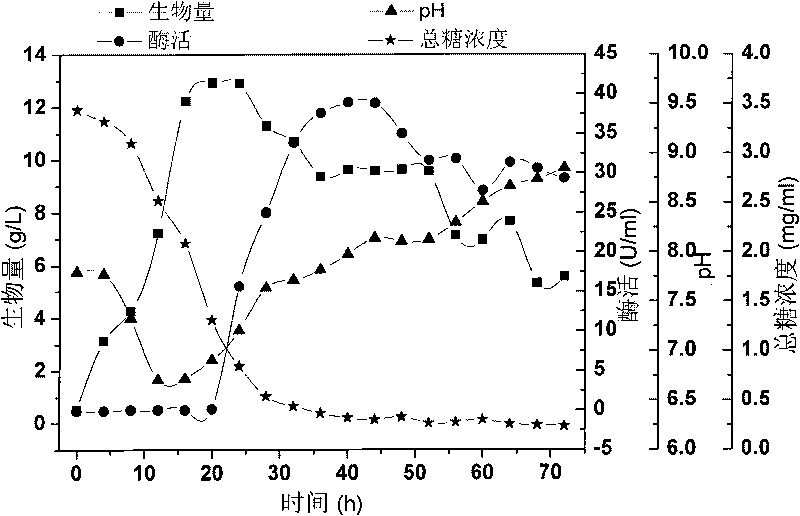

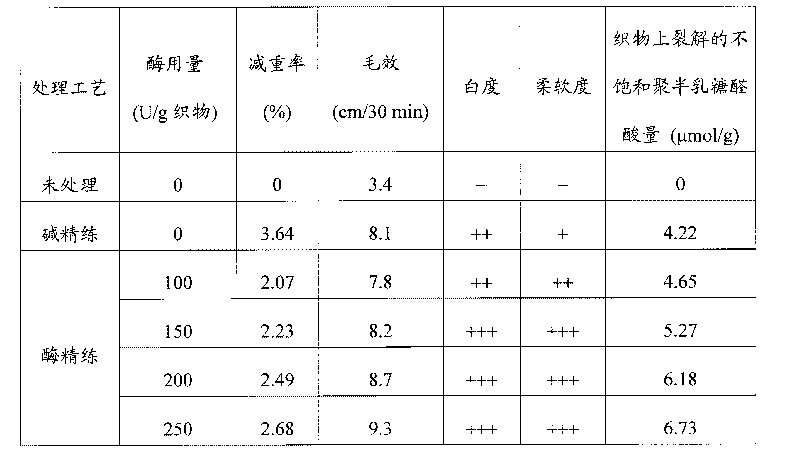

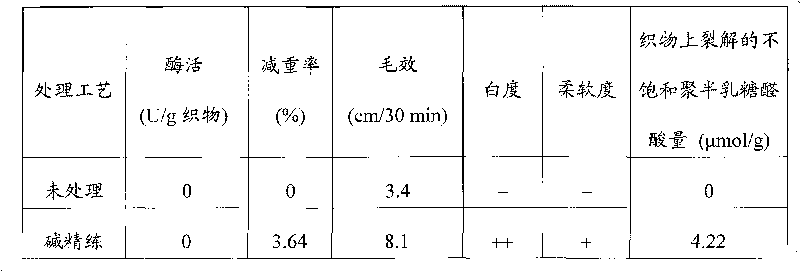

Compound enzyme preparation for textile fabrics and applications thereof

ActiveCN101713150AReduce processing costsReduce salt contentBacteriaBiochemical fibre treatmentPectinaseSolvent

The invention provides a high-efficiency compound enzyme preparation used for a pretreatment process of textile fabrics, particularly cotton fabrics, and application thereof. The compound enzyme preparation mainly comprises the following components by final concentration: 50 to 100g / L of polysiloxane, 50 to 100g / L of fatty alcohol-polyoxyethylene ether, 80 to 150g / L of Tween 20 to 80 series, 80 to 150g / L of Span 20 to 80 series, 30 to 80g / L of sorbitol, 3 to 10g / L of calcium chloride, 5 to 15g / L of sodium benzoate, 800 to 1,000U / mL of alkaline pectinase, 1,000 to 1,200U / nL of cellulase, and water serving as a solvent. The compound enzyme preparation is applied to the pretreatment of the textile fabrics to replace the conventional alkali boiling off process, can effectively reduce production cost, reduce labor intensity and enable the quality of the product to be obviously improved, can also reduce the salt content and BOD, COD and the like in the water discharged into the environment and obviously reduce the pollution to the environment, and is a green process route which accords with the sustainable development.

Owner:ZHEJIANG UNIV OF TECH

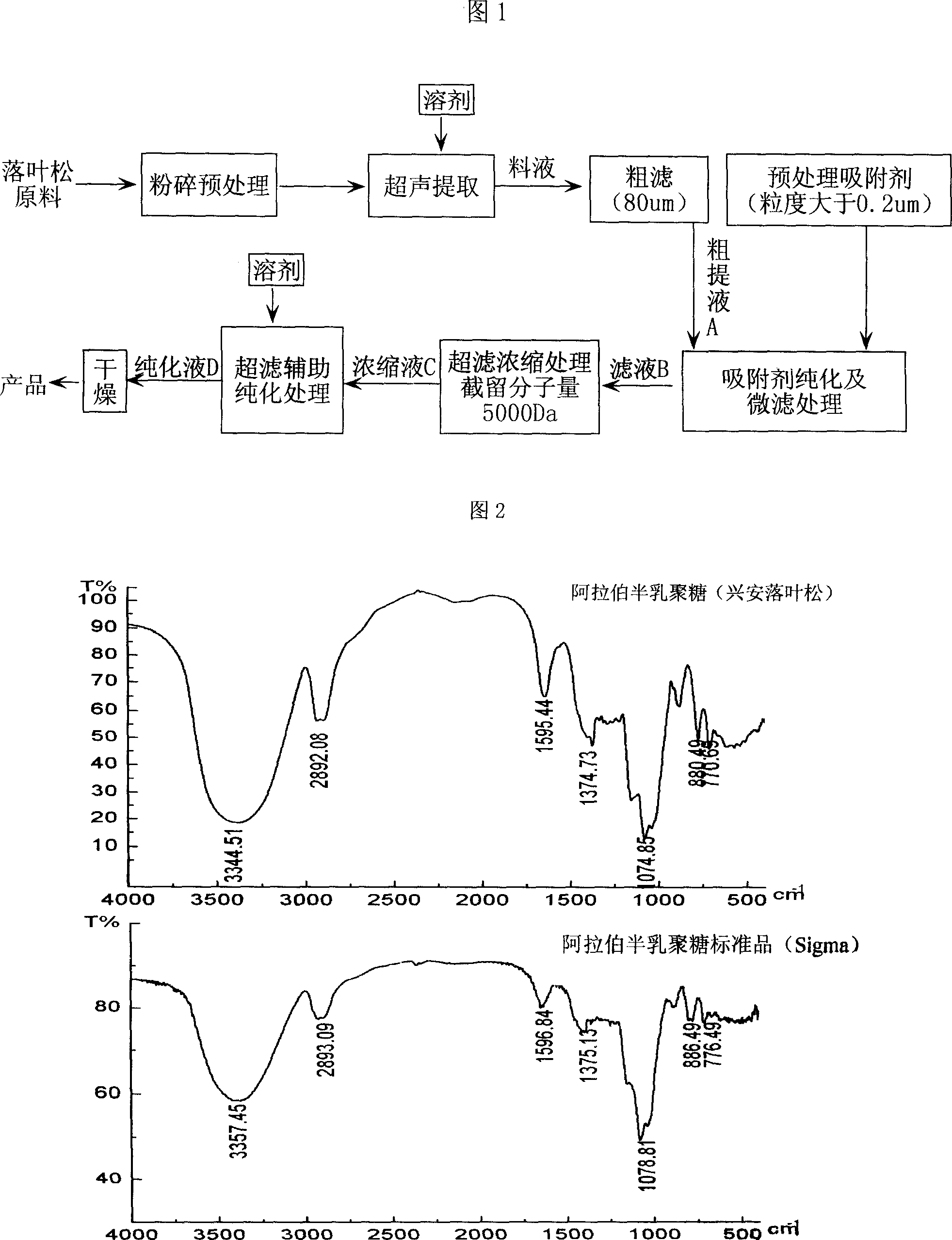

Method for preparing high-purity arabinogalactan

The invention discloses a technique which prepares high-purity arabogalactan from a dahuricia larch. The arabogalactan has effects of obvious increase of boy immunity, tumor resistance, mutation resistance, reduction of blood lipid, virus resistance and enhancement of the immunoreactive activity of monocytes, macrophages, T cells and natural killer cells in immune antigens. The preparation technique includes ultrasonic-assisted extraction, ultrafiltration concentration, washing purification and drying. The preprocessed dahuricia larch as a material is mixed with a designated solvent, extraction process is fulfilled in the energy field of ultrasonic energy, so that the crude extractant A of the arabogalactan is produced. The invention applies adsorbent to absorb the non-saccharide ingredients in the crude extractant A, and applies membrane separation techniques, such as microfiltration, ultrafiltration, etc., to separate arabogalactan, and after removing impurities in the crude extractant, small-molecule pigments and partial solvent, the purified arabogalactan solution D. The purified arabogalactan solution D is refrigerated and dried in order to obtain the white or light yellow powdery high-purity arabogalactan, and purity can reach over ninety five percent.

Owner:NORTHEAST FORESTRY UNIVERSITY +2

Method for making gallium nitride crystal

InactiveCN1434482AReduce the number of defectsSimple methodPolycrystalline material growthSemiconductor/solid-state device manufacturingSemiconductor materialsHeat deposition

This invention relates to a process method for semiconductor materials of gallium nitride crystals including the following steps: (1) epitaxial growth of Ga nitride or Al nitride on a substrate (2) heat-deposition of crystal particles of silicon, silicon carbide, silicon nitride or silicon oxide (3) continuation of epitaxial growth of Ga nitride further growing undoped and doped Ga nitride film Dor LED, LD, HEMT etc. photoelectronic and electronic apparatus. The said substraet can be sapphire, SiC SiL GaAs, ZnO, MgO, LiAlO2 or Li GaO2 effectively reducing dislocation, overcoming mismatch of the substrate and epitaxial layer.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Solid composition for preparing medical adhesive and medical adhesive prepared from solid composition

InactiveCN111905141AGreat application potentialWide variety of sourcesSurgical adhesivesPharmaceutical delivery mechanismAdhesiveBiocompatibility

The invention belongs to the technical field of biomedical materials, and particularly relates to a solid composition for preparing a medical adhesive and the medical adhesive prepared from the solidcomposition. Vegetable polysaccharide is selected, is modified with aldehyde groups through an oxidation reaction, and is further cross-linked with an amino-containing polymer material in the presenceof water or a buffer solution to prepare the medical adhesive. The used materials are widely applied to the fields of medical treatment, foods and the like, have good biocompatibility, can be degraded and metabolized in vivo, and are low in price and wide in source; and the formed hydrogel type medical adhesive of a three-dimensional network structure has good application potential in the aspectsof tissue adhesion, filling, sealing, hemostasis and the like.

Owner:江苏德威兰医疗器械股份有限公司

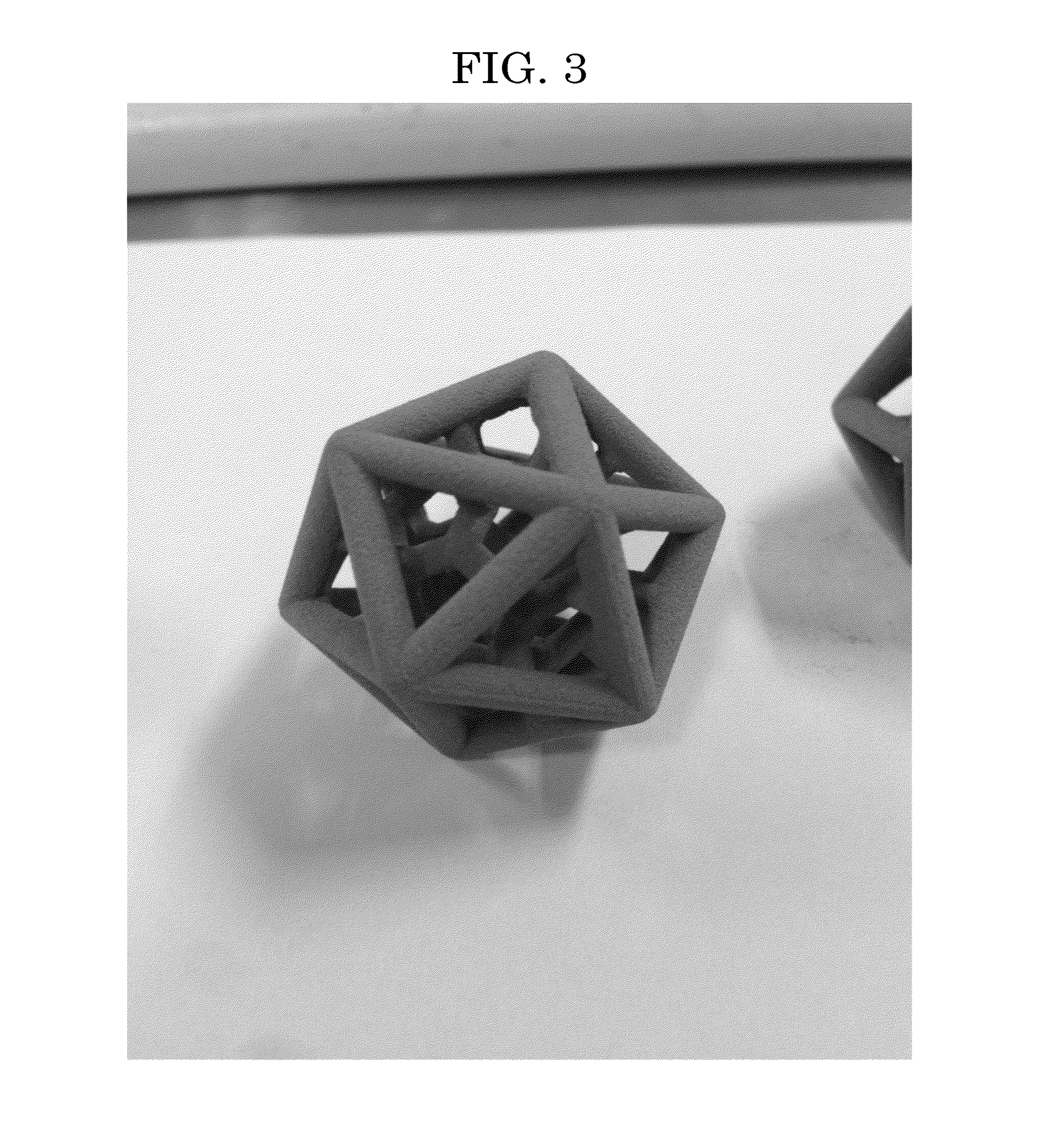

Liquid material for forming three-dimensional object and material set for forming three-dimensional object, and three-dimensional object producing method and three-dimensional object producing apparatus

ActiveUS20160200908A1Save timeWell dimensioningTransportation and packagingConfectioneryMetallurgyMelting point

Provided is a liquid material for forming a three-dimensional object, the liquid material adapted to be delivered to a powder material for forming a three-dimensional object to harden the powder material, the powder material containing an organic material and a base material, the liquid material including a cross-linking agent cross-linkable with the organic material and a resin having a glass transition temperature of 50° C. or higher or a melting point of 50° C. or higher.

Owner:RICOH KK

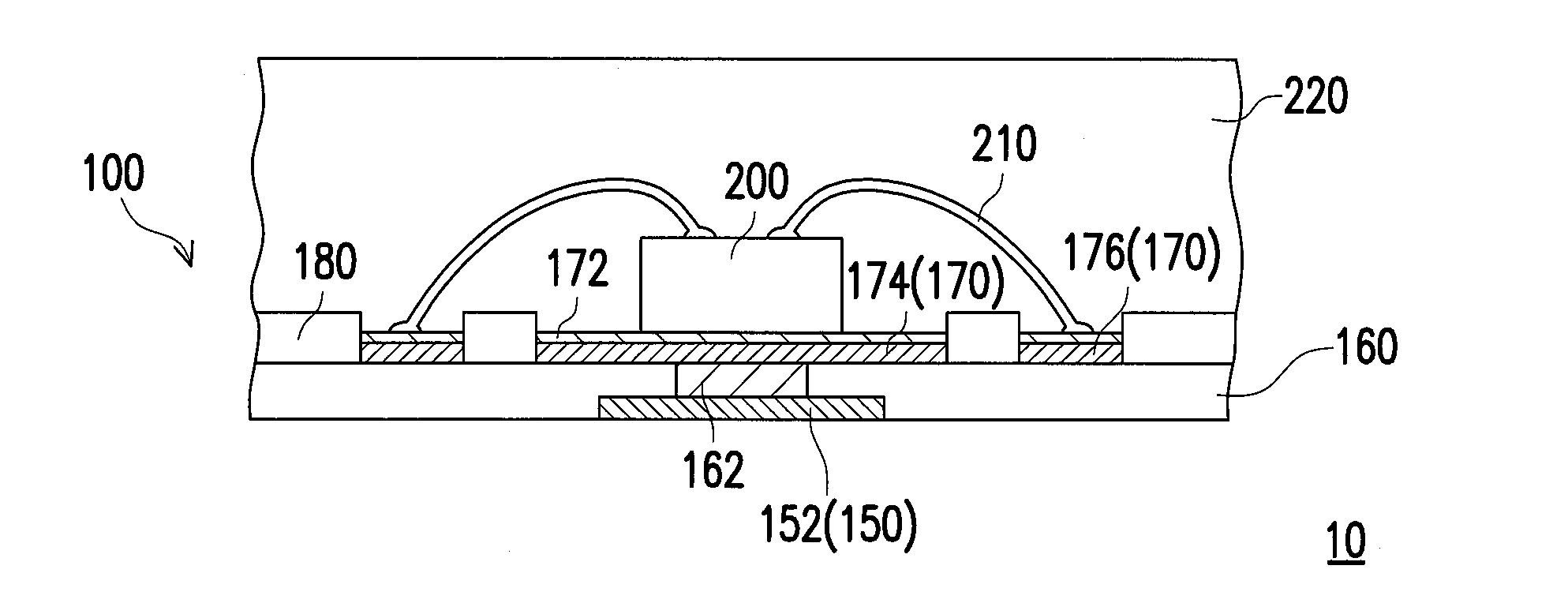

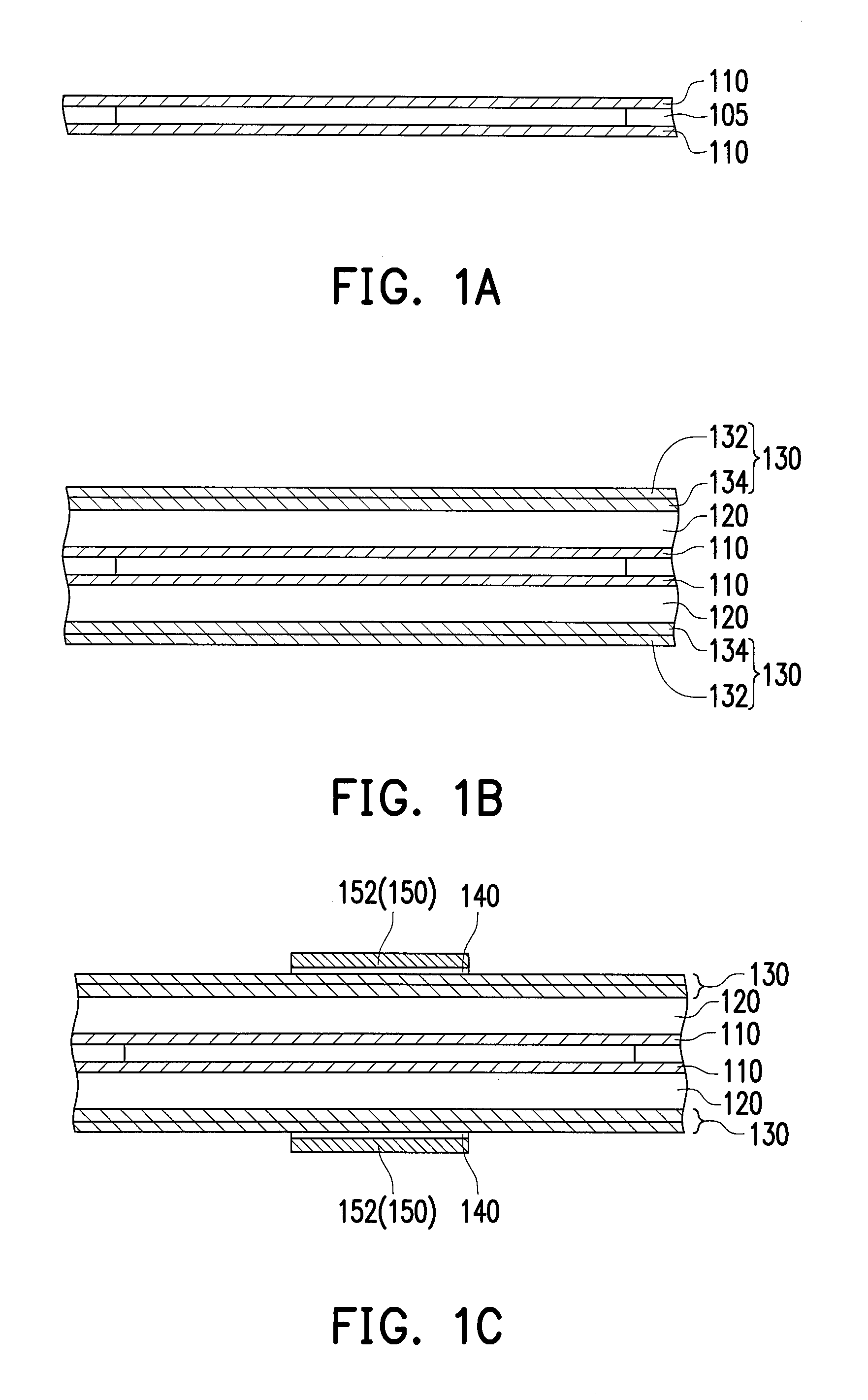

Package carrier and manufacturing method thereof

ActiveUS20150090476A1Reduce package thicknessEasy to disassemblePrinted circuit detailsSolid-state devicesDielectric layerMetal

A manufacturing method of a package carrier includes the following steps. Two base metal layers are bonded together. Two supporting layers are laminated onto the base metal layers respectively. Two release metal films are disposed on the supporting layers respectively. Each release metal film includes a first metal film and a second metal film separable from each other. Two first patterned metal layers are formed on the release metal films respectively. Each first patterned metal layer includes a pad pattern. Two dielectric layers are formed on the release metal films respectively and cover the corresponding first patterned metal layers. Each dielectric layer has a conductive via connecting to the corresponding pad pattern. Two second patterned metal layers are formed on the dielectric layers respectively. Each second patterned metal layer at least covers the conductive via. The base metal layers are separated from each other to form two independent package carriers.

Owner:SUBTRON TECH

Single-component middle coating can be used for wet-on-wet and dry jet wet, and preparation method thereof

InactiveCN109181433AExtension of timeImprove efficiencyPolyurea/polyurethane coatingsPriming paintsWater basedPolyol

The invention belongs to the technical field of paint, and more specifically relates to a single-component middle coating can be used for wet-on-wet and dry jet wet. The single-component middle coating can be used for wet-on-wet and dry jet wet comprises, by mass, 35 to 45% of a grinding component slurry, 15 to 25% of a water-based acrylic polyol dispersion, 5 to 15% of a water-based polyurethanedispersion, 3 to 7% of an aqueous auxiliary agent, 0.5 to 1.5% of an amine neutralizer, 0.5 to 2% of ethylene glycol monobutyl ether, 0.3 to 0.7% of a wetting leveling agent, 2 to 8% of a methylated amino resin, 0.3 to 0.7% of a thickening agent, and 8 to 14% of water. The single-component middle coating can be used for wet-on-wet and dry jet wet is capable of increasing production efficiency greatly, is universal in et-on-wet and dry jet wet, is capable of saving production time and baking energy consumption greatly, and reducing research and development cost.

Owner:GUANGDONG YATU CHEM

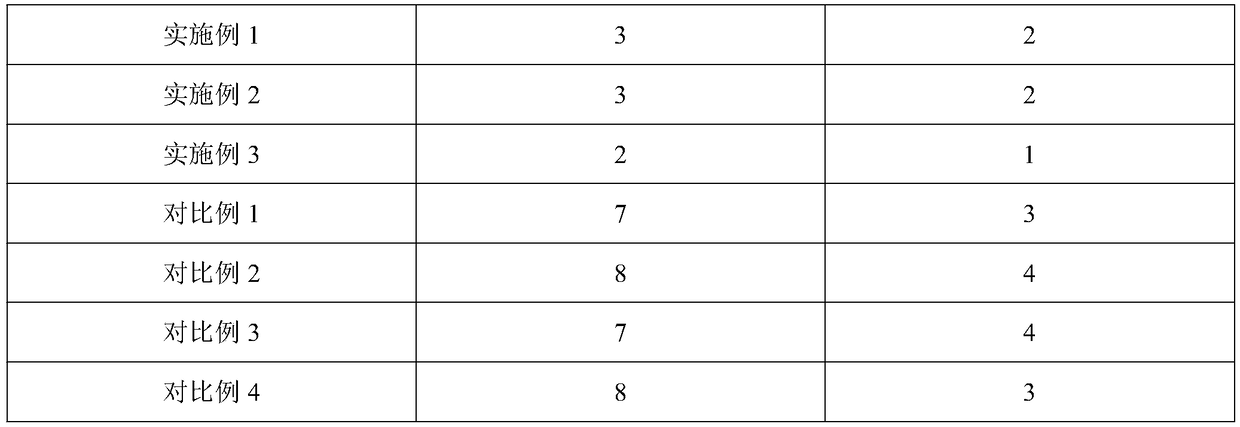

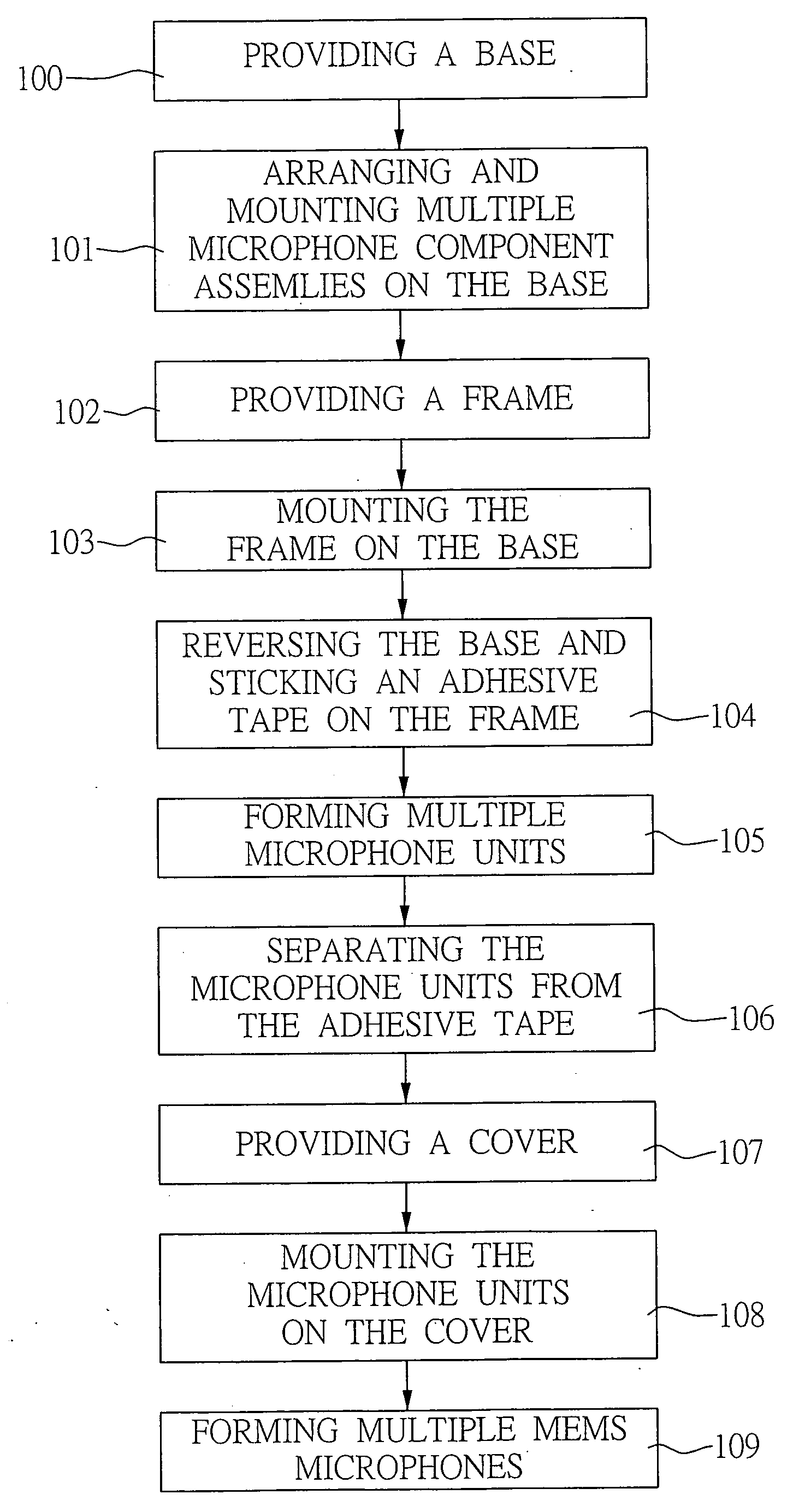

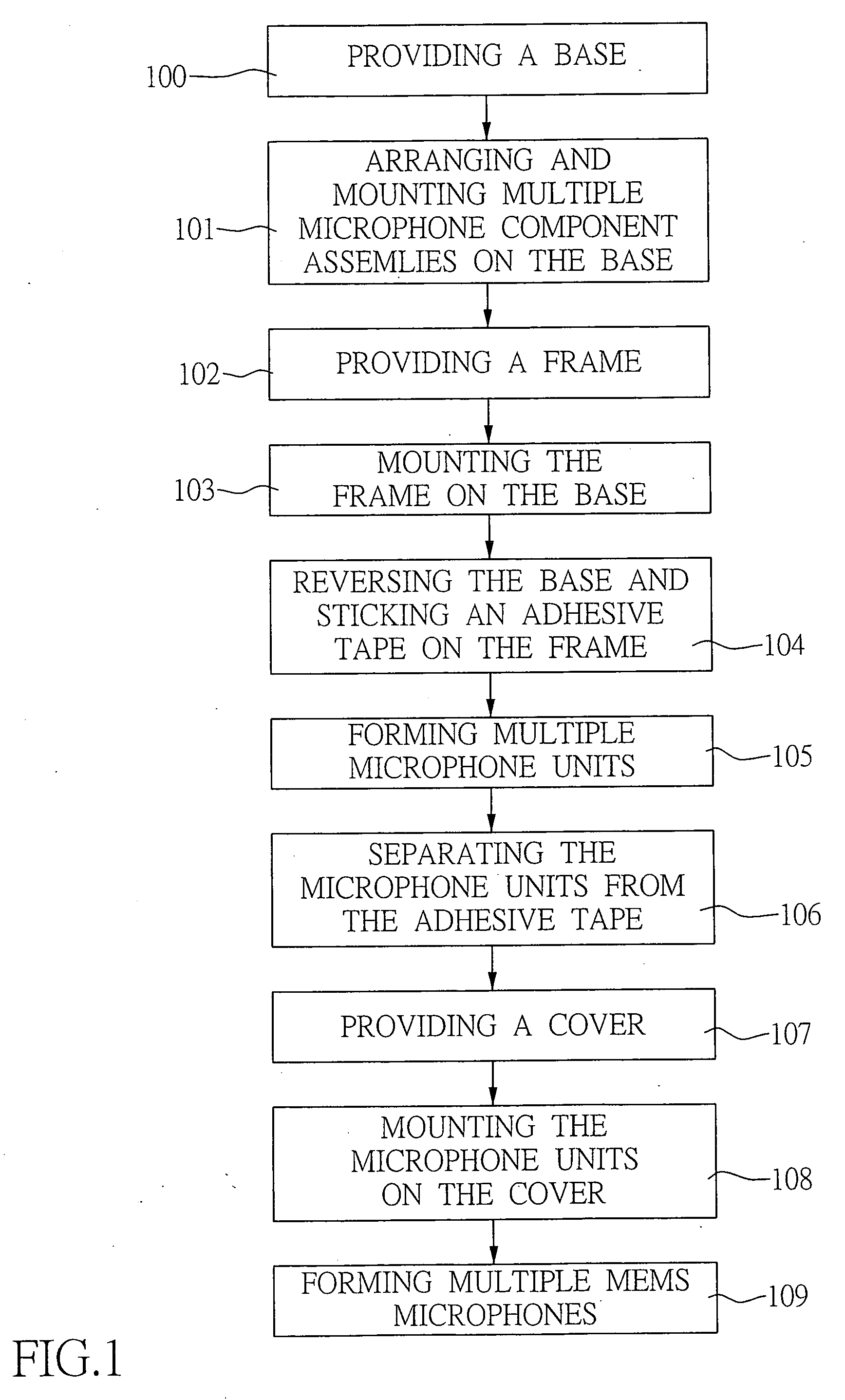

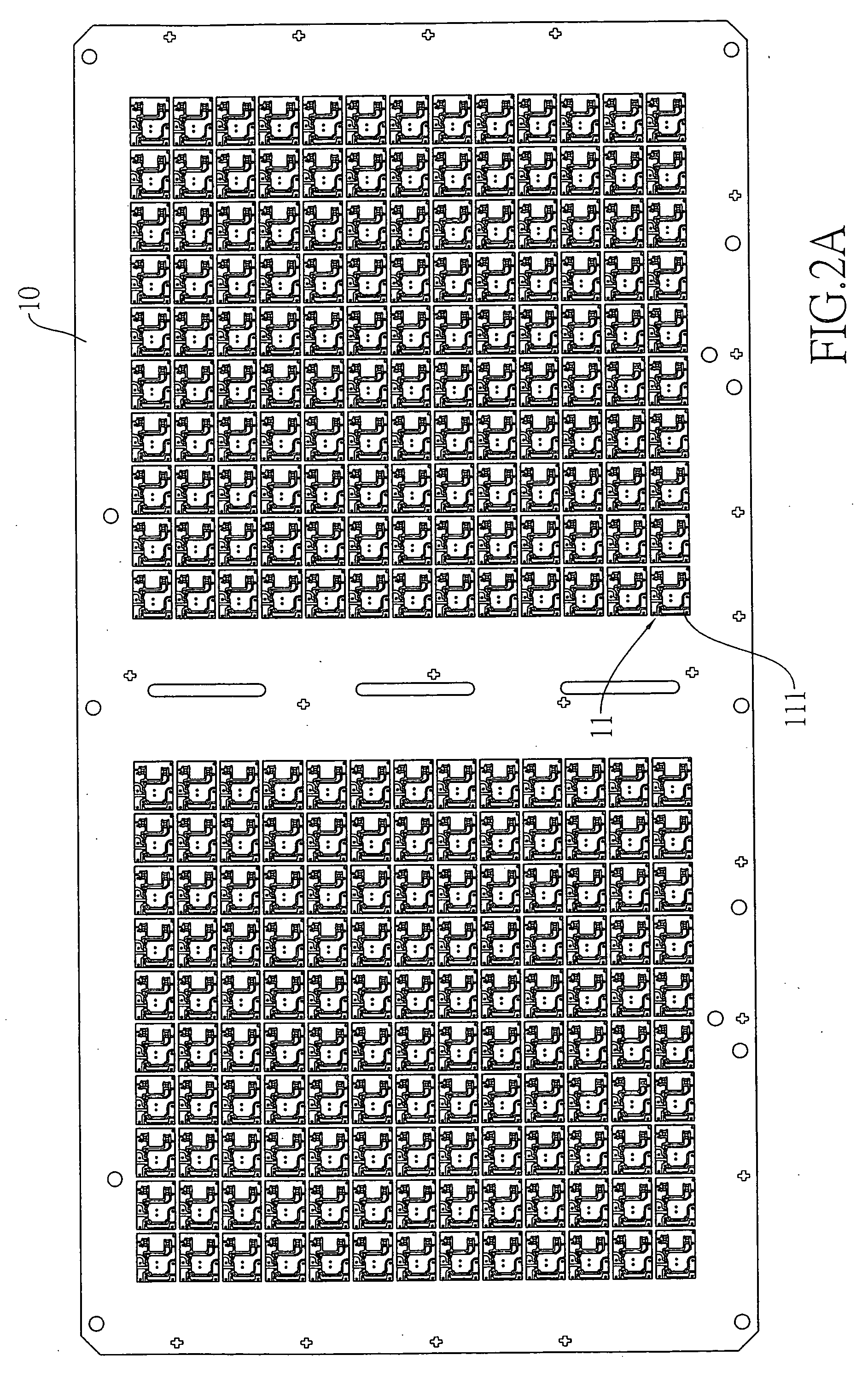

Method for packaging micro electromechanical systems microphone

InactiveUS20100175242A1Low costSave production timeAcceleration measurement using interia forcesPiezoelectric/electrostriction/magnetostriction machinesEngineeringMicrophone

A method for packaging micro electromechanical systems (MEMS) microphone has steps of providing a base, arranging and mounting multiple microphone component assemblies on the base, providing a frame, mounting the frame on the base, forming multiple microphone units, providing a cover; mounting the microphone units on the cover and forming multiple MEMS microphones. Therefore, the MEMS microphones can be produced once in large quantities to save production time and costs.

Owner:TONG HSING ELECTRONICS IND LTD

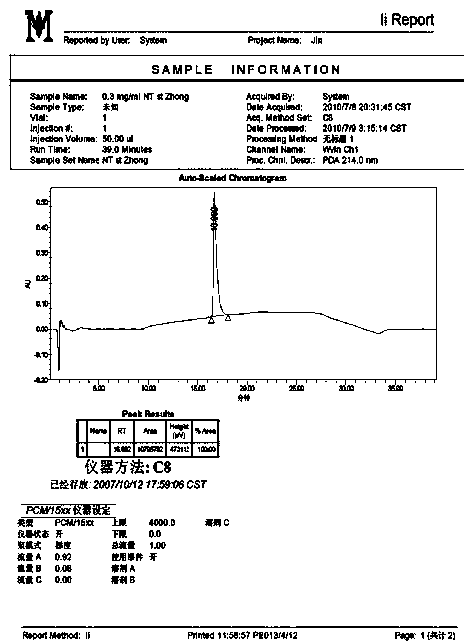

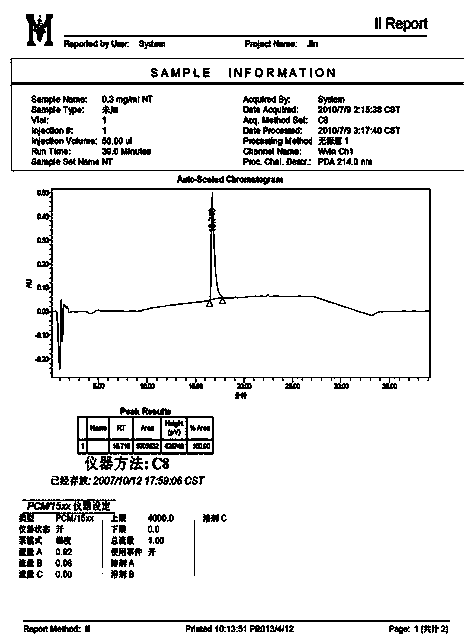

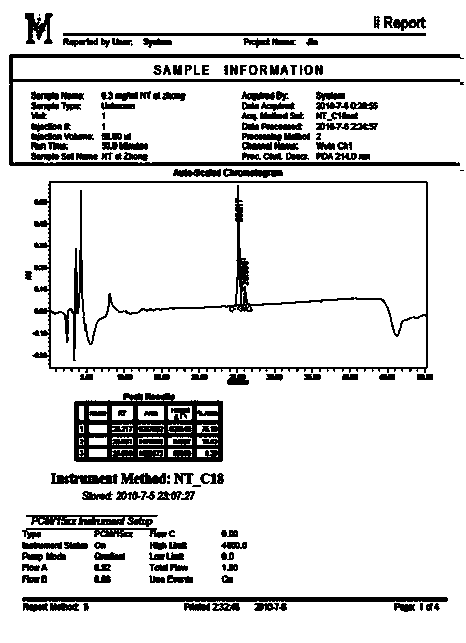

Method for separating and purifying cobra neurotoxin protein through dual-ion exchange chromatography, and preparation of cobra neurotoxin protein

ActiveCN103387610AHigh purityIncrease flow ratePeptide/protein ingredientsAntipyreticCobra venomHigh concentration

The invention provides a method for separating and purifying cobra neurotoxin protein through dual-ion exchange chromatography. The method comprises the following steps of: (1) first separation and purification through ion exchange chromatography, namely, a) dissolution of crude cobra venom, and b) separation and purification through an SP-Sephodex-C25 gel column; and (2) second separation and purification through ion exchange chromatography, namely, a) balance of a SourceS(XK5030) column having a column volume of 500 ml by using 1000 ml of liquid A for future use; and b) SourceS(XK5030) column purification, and then collection of the cobra neurotoxin protein purified twice according to a standard purification chromatogram. The method provided by the invention is scientific and rational in process; and no organic reagent, no high-concentration salt and no protein modification method are used in production, so that the biological activity of cobratide can be maintained to an utmost extent. The method provided by the invention is advanced in process and simple to operate; the production period can be greatly shortened, the production time can be saved and the production cost can be reduced; and the method is completely suitable for an industrial production line.

Owner:奔驰生物科技(云南)有限公司

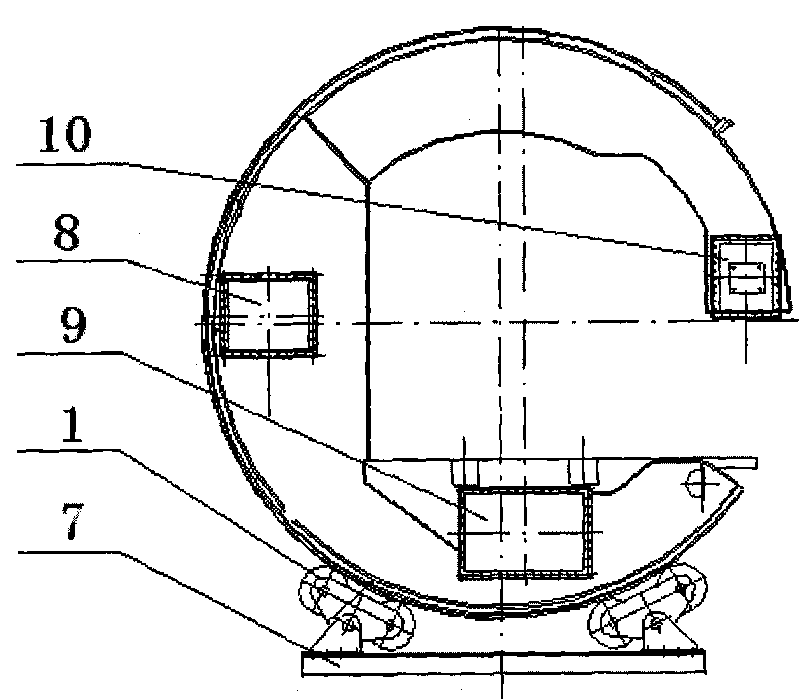

Integral assembling process for car tippler

The invention provides an integral assembling process for a car tippler. The integral assembling process comprises the following steps of: checking and making sure that the parts, which are needed in the integral assembly of the car tippler and comprise a supporting roller, leaning car beam, a supporting car beam, a small longitudinal beam, a charging end disk and a discharging end disk, are qualified, transferring the qualified parts to the pre-assembling field, centering the supporting roller on a pre-assembling platform so as to fix the end disks, taking fixed lengths of the leaning car beam, the supporting car beam and the small longitudinal beam, lifting the leaning car beam, the supporting car beam and the small longitudinal beam at a respective predetermined assembling position after fixed length taking,, connecting a No.1 flange with the leaning car beam, connecting a No.2 flange with the supporting car beam, and connecting a No.3 flange with the small longitudinal beam by bolts respectively, welding the outside welding lines, lifting down three main beams, welding the remaining welding lines, and fishing the integral assembly of the car tippler. The integral assembling process has the advantages of having convenient machining and simple structure, saving large machining equipment and a large amount of machining cost, reducing cost, and contributing to shortening production period and ensuring punctual delivery.

Owner:WUHAN POWER EQUIP WORKS

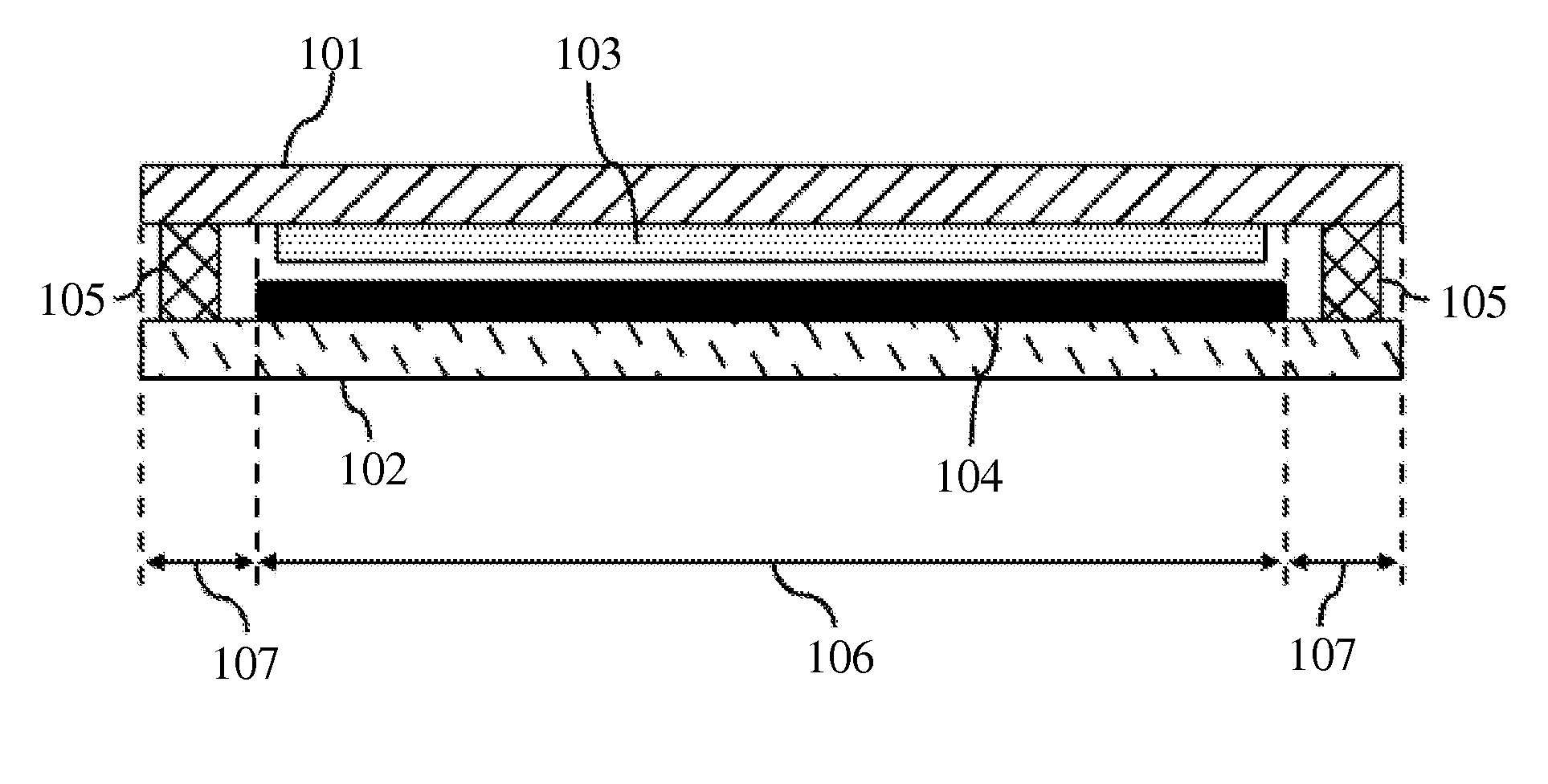

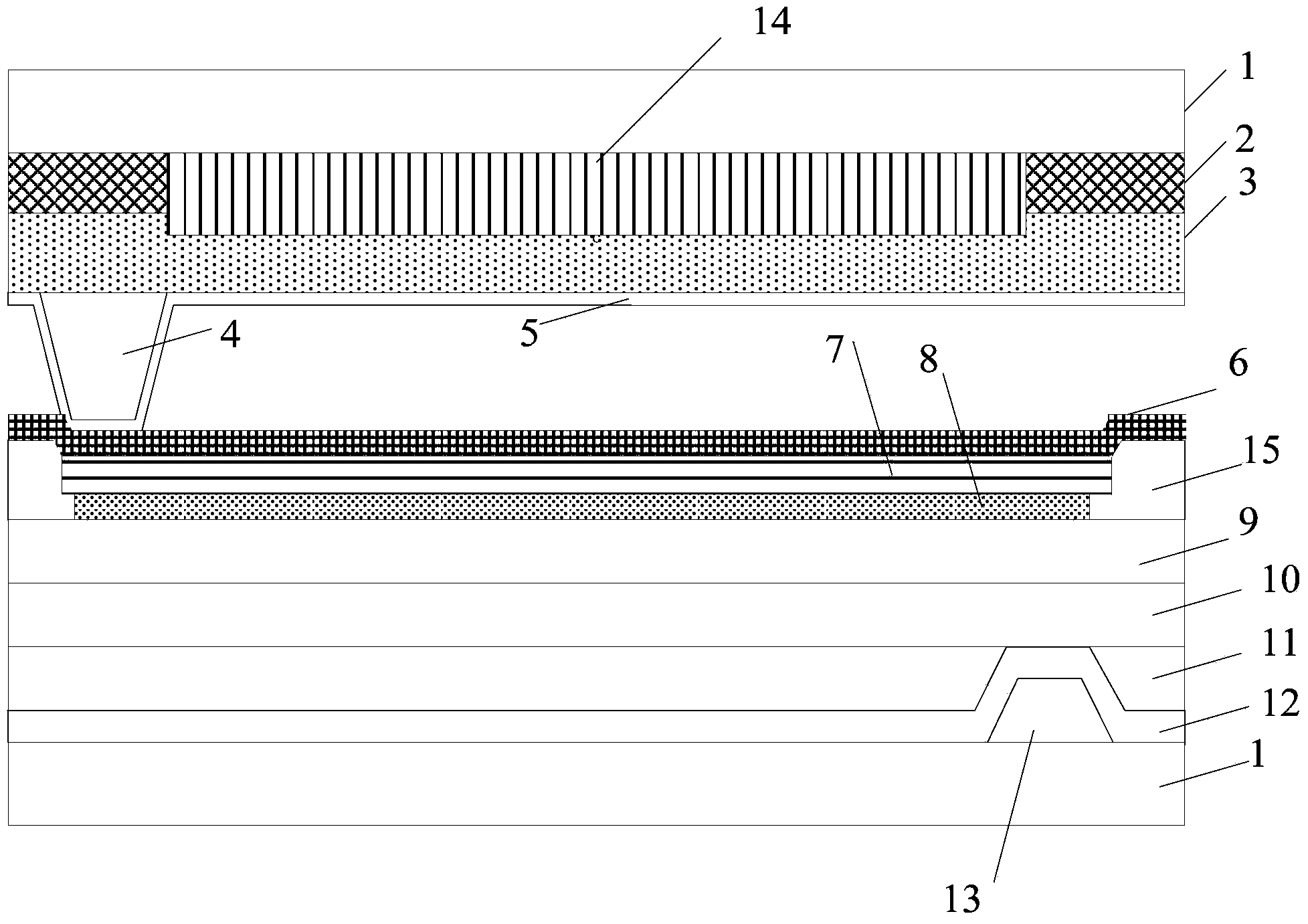

Display panel and method for manufacturing the same

ActiveUS20160020432A1Shorten the timeOmit processSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSealant

A display panel and a method for manufacturing the same are provided. The display panel comprises a substrate, an OLED device, a cover, at least one shielding element, and a sealant. The substrate has a first surface, and the OLED device is disposed on the first surface. The cover has a second surface, and the substrate and the cover are assembled into one piece, and the first surface and the second surface face each other. The shielding element is disposed on the second surface, and the sealant is disposed between the substrate and the cover.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

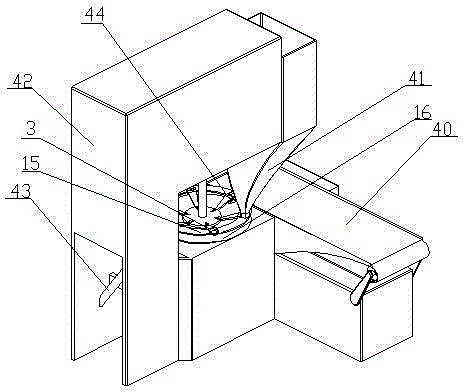

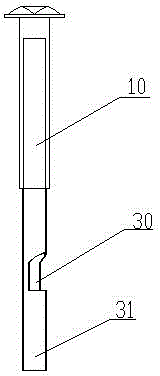

Full-automatic red date pitter

Disclosed is a full-automatic red date pitter. A first bevel gear is meshed with a second bevel gear to drive the second bevel gear, a geneva wheel is arranged under the second bevel gear, the second bevel gear and a third drive shaft are integrated, the second bevel gear drives the geneva wheel thereunder to intermittently rotate through the third drive shaft, the geneva wheel is integrated with a rotary plate thereunder through a fourth drive shaft, six red date holders with the included angle being 60 degrees are arranged on the rotary plate uniformly, a red date retaining piece is arranged on one side of the rotary plate. Plenty of manpower and production time are saved, pitting processing of red dates is completed automatically and quickly in batches, and the pitter is simple, effective, stable and safe.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Novel stamping part stamping process

InactiveCN106734464AStamping production is easy to realizeReasonable and scientific design processOriginal dataSheet metal stamping

The invention discloses a novel stamping part stamping process, and relates to the technical field of stamping. The novel stamping part stamping process comprises the steps of collecting and analyzing original data of design of sheet metal stamping parts; 2, analyzing the stamping manufacturability; 3, confirming a stamping scheme and process calculation, 4, choosing a mold type, 5, choosing stamping equipment, 6, compiling a stamping process card. The novel stamping part stamping process is simple and controllable in procedure, so that the stamping production of the sheet metal is easier to achieve, the product quality is guaranteed, and the yield of the product is increased.

Owner:宋世林

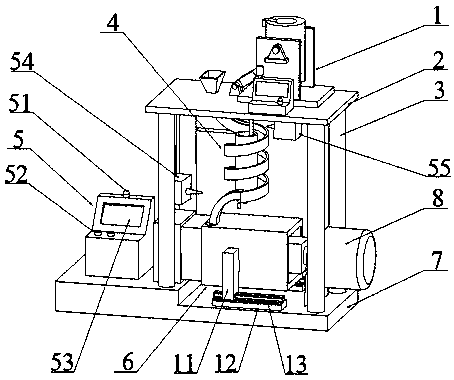

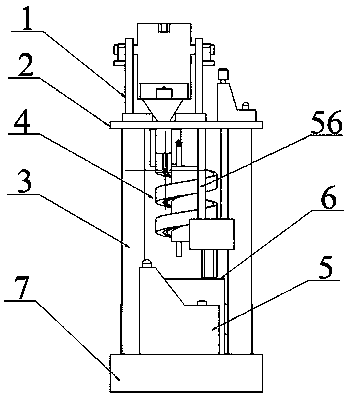

Semi-solid slurry preparation and forming integrated equipment

ActiveCN108273975AReduce manufacturing costReduce preparation energy consumptionNumerical controlSemi solid

The invention relates to semi-solid slurry preparation and forming integrated equipment, and belongs to the technical field of material processing. The equipment comprises a smelting device, a top plate, a supporting column, a slurry preparing device, a numerical control operation table, an extruding forming device and a base; the numerical control operation table is arranged on the base; the supporting column is arranged on the base and located on one side of the numerical control operation table; the top plate is horizontally arranged at the top end of the supporting column; the smelting device is arranged on the top plate; the extruding forming device is arranged on the base and located below the top plate; the pulp preparing device is arranged at the lower end of the top plate and located above the extruding forming device; and the smelting device, the slurry preparing device and the extruding forming device are sequentially communicated and are correspondingly connected with the numerical control operation table.

Owner:KUNMING UNIV OF SCI & TECH

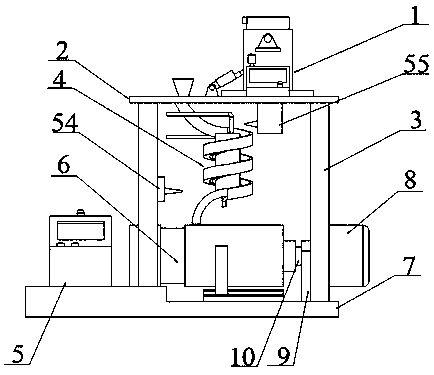

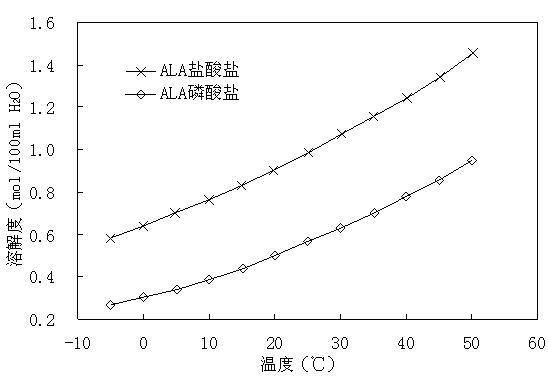

Crystallization method of 5-aminolevulinic acid phosphate

ActiveCN103265444AReduce usageHigh yieldOrganic compound preparationAmino-carboxyl compound preparationFiltrationIon exchange

The invention relates to a crystallization method of 5-aminolevulinic acid phosphate. The crystallization method comprises the following steps of carrying out ion-exchange of 5-aminolevulinate broth or other solutions containing 5-aminolevulinate to remove anions and a part of impurities, adding phosphoric acid into the treated solution according to a mole ratio of 1: 1 to 1.2: 1 to obtain a 5-aminolevulinic acid phosphate solution, carrying out decoloring and filtration of the 5-aminolevulinic acid phosphate solution, carrying out vacuum condensation of the 5-aminolevulinic acid phosphate solution to obtain 400 to 600g / l of the concentrated solution, gradually cooling the concentrated solution at a cooling rate of 10 to 15 DEG C / h with stirring at a stirring rate of 50 to 200rpm until crystal nucleuses are produced in the concentrated solution, carrying out constant-temperature crystal growing for 1 to 2h, sequentially carrying out stirring cooling until a temperature is in a range of -5 to 0 DEG C, carrying out filtration separation of the crystals, and drying at a temperature of 50 to 70 DEG C to obtain the 5-aminolevulinic acid phosphate crystals. The crystallization method does not adopt an organic solvent, avoids solvent residual and is conducive to use of 5-aminolevulinic acid phosphate in the medicine field.

Owner:ZHEJIANG UNIV

Rapier loom for producing Zhangzhou velvet satin and Zhangzhou velvet and weaving method thereof

ActiveCN107313158AReduce stepsIncrease productivityPile-fabric loomsEngineeringMechanical engineering

The invention discloses a rapier loom for producing Zhangzhou velvet satin and Zhangzhou velvet. The rapier loom comprises a front rack, a back rack and a cloth roller, the front rack is provided with weft insertion and beating-up mechanisms, a dobby shedding mechanism and a jacquard shedding mechanism, and the back rack comprises a dobby shedding mechanism loom off mechanism and a jacquard shedding mechanism loom off mechanism; the weft insertion and beating-up mechanisms comprise weft insertion mechanisms and beating-up mechanisms, the weft insertion mechanisms comprise a first weft insertion rapier mechanism which is used for conveying an inserted wire and a second weft insertion rapier mechanism which is used for conveying weft. The rapier loom for producing Zhangzhou velvet satin and Zhangzhou velvet substitutes the dobby shedding mechanism for a plain heddle device of an original wooden loom, substitutes the jacquard shedding mechanism for a draw loom (namely pattern tower portion) of the original wooden loom, mechanizes the Zhangzhou velvet satin and Zhangzhou velvet, and improves the production efficiency. Two sets of weft insertion mechanisms are adopted, one set is used for inserting the weft, and the other set is used for inserting the inserted wire, so that the rapier loom is convenient and fast, adopts the mechanical weft insertion mechanisms and further improves the production efficiency.

Owner:SUZHOU INST OF TRADE & COMMERCE

Bulbous flower tissue culture seedling cultivating process to form bulb inside container

InactiveCN1887051ASave production spaceSave production timeCultivating equipmentsPlant tissue cultureCulture mediumsRefrigerated temperature

The bulbous flower tissue culture seedling cultivating process for inducing formation of bulb inside a large container with high bulb forming speed includes the following steps: 1. preparing incubator with forced CO2 supplying system as the culture container; 2. selecting healthy secondary proliferous test tube plantlet as the material for inducing bulb; 3. inducing micro seed bulb with the test tube plantlet in no-sugar vermiculite culture medium comprising 1 / 2MS+NAA 0.1-0.3 mg / L+IBA0.-0.4 mg / L+PP333 5.0-10.0 mg / L or 1 / 2MS+IBA 0.2-0.4 mg / L+PP333 5.0-10.0 mg / L; and 4. air drying the collected the micro seed bulb at room temperature, storing in refrigerator, and treating at 4-10 deg.c for 4-8 weeks before planting in blooming bulb culturing land. The present invention is suitable for lily, color calla and other bulbous flower, and has saving in producing space and time.

Owner:甘肃省花卉工程技术研究中心

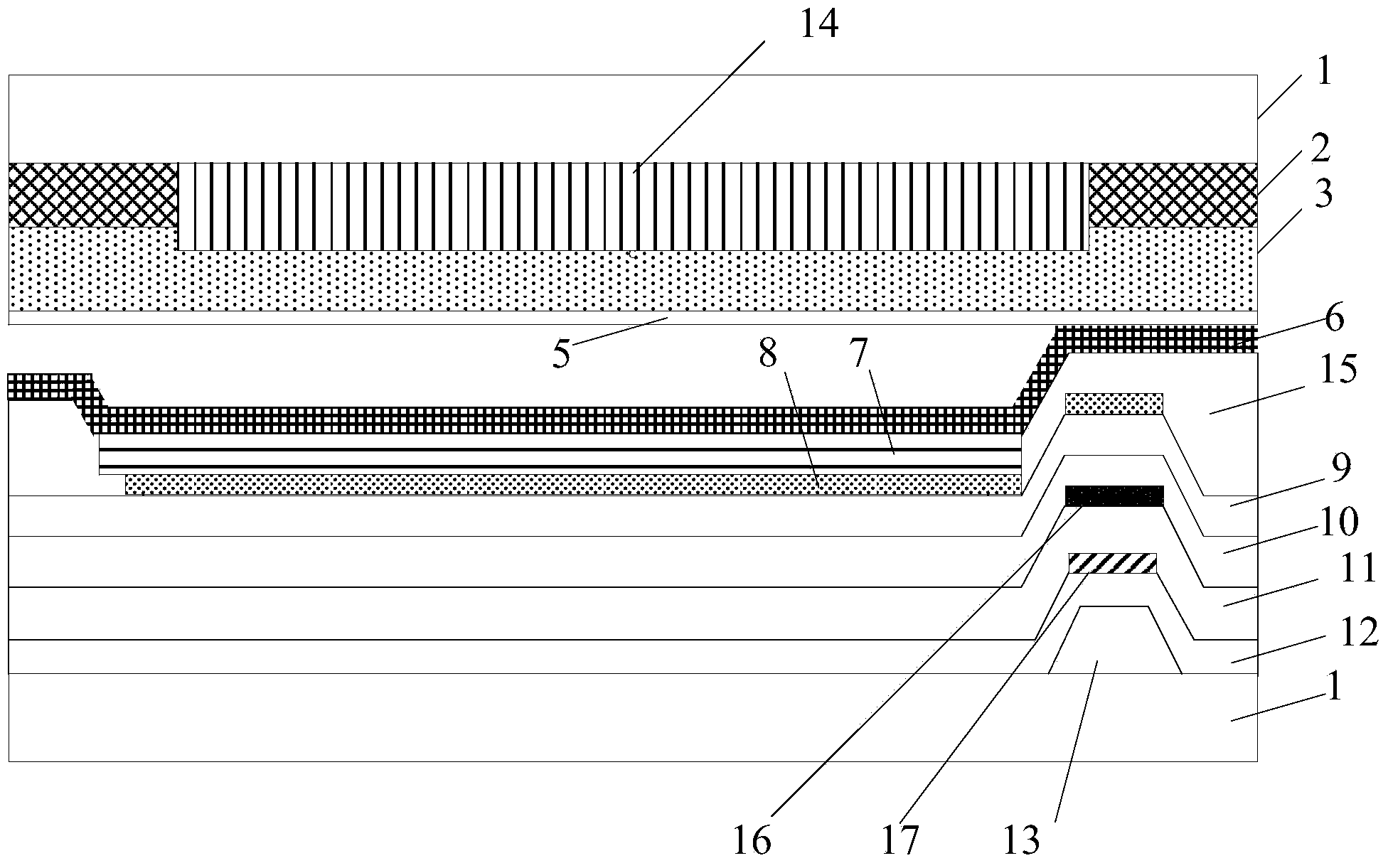

Display panel, manufacturing method thereof and display device

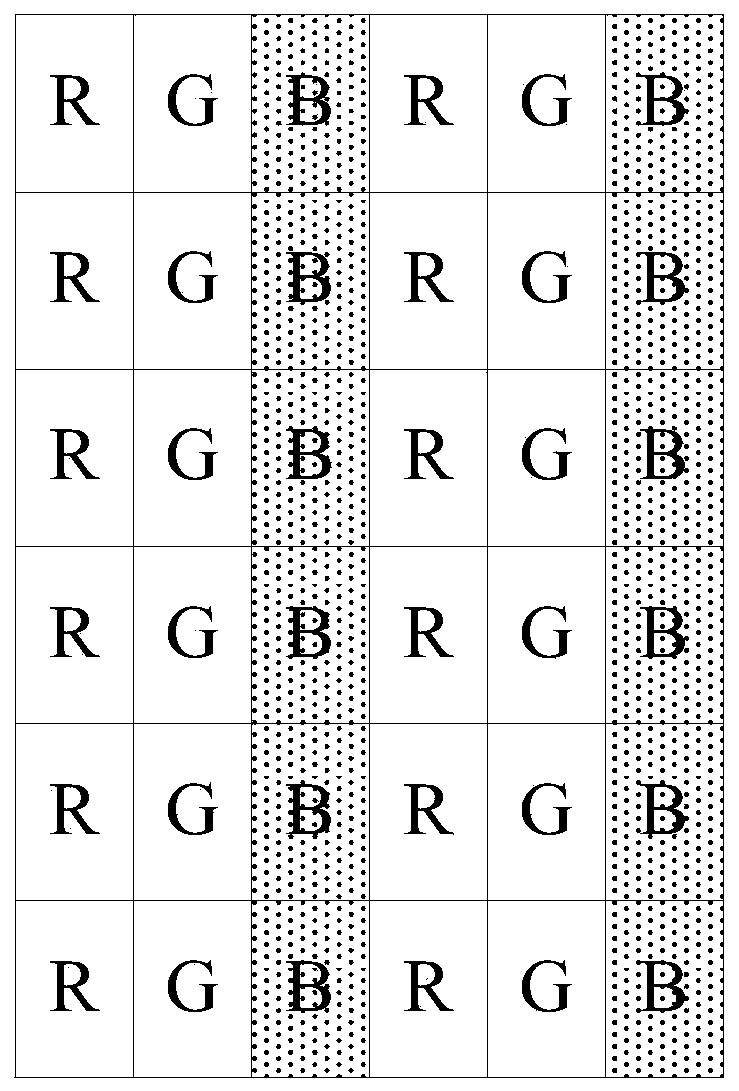

ActiveCN103681765ASave production timeSave productivitySolid-state devicesSemiconductor/solid-state device manufacturingManufacturing technologyDisplay device

The invention provides a display panel, a manufacturing method thereof and a display device, and belongs to the display field. The display panel comprises a colored film substrate and an array substrate opposite to the colored film substrate, wherein the colored film substrate is not provided with a spacer used for supporting the box thickness of the display panel. Protrusions used for supporting the box thickness of the display panel are arranged on the face, opposite to the colored film substrate, of the array substrate. According to the technical scheme, the manufacturing technology of the columnar spacer can be omitted, so that the production time and the production material of the display panel are saved, and the production cost of the display panel is lowered.

Owner:BOE TECH GRP CO LTD

Visible-light-activated photocatalyst and method for producing the same

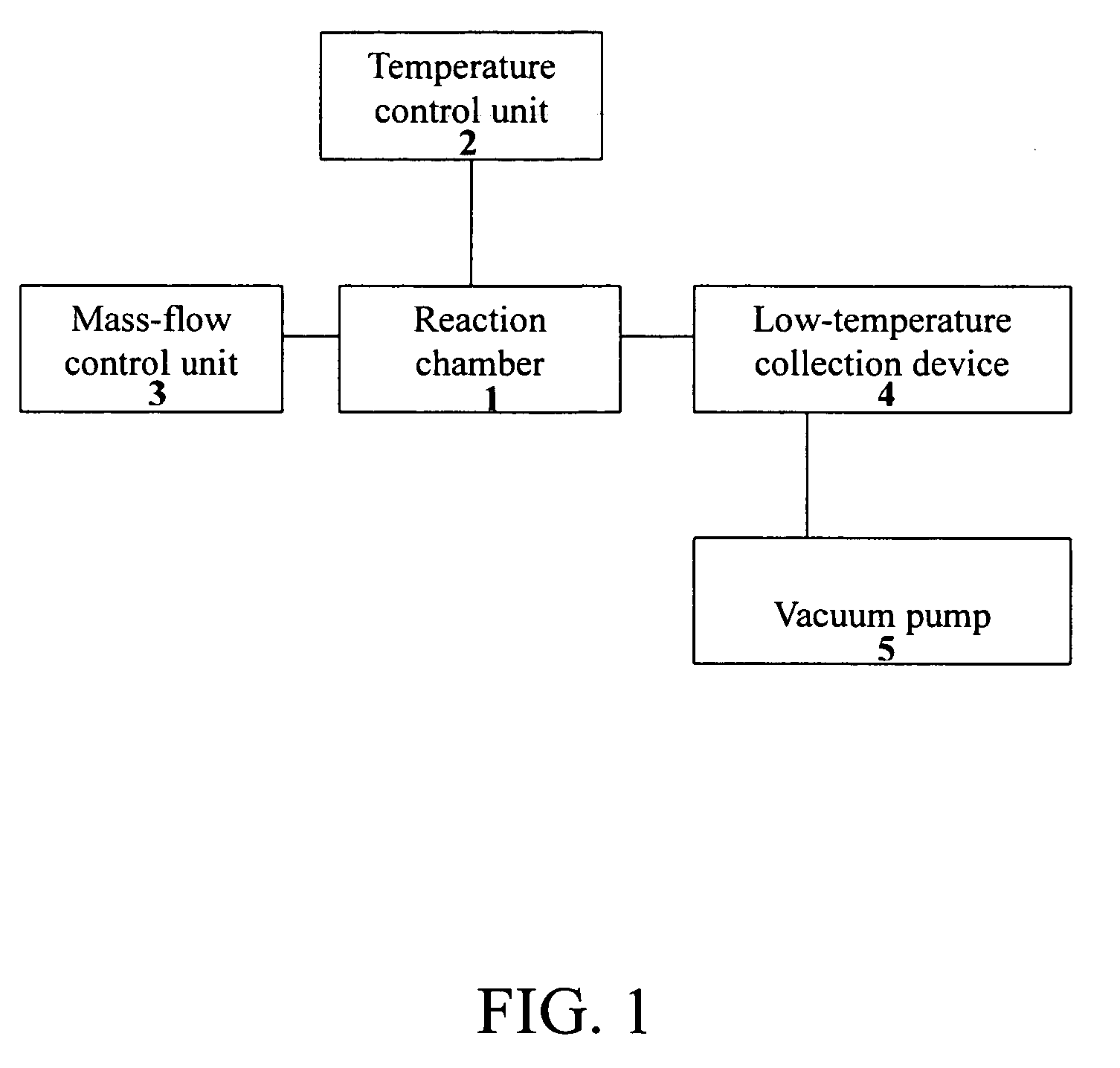

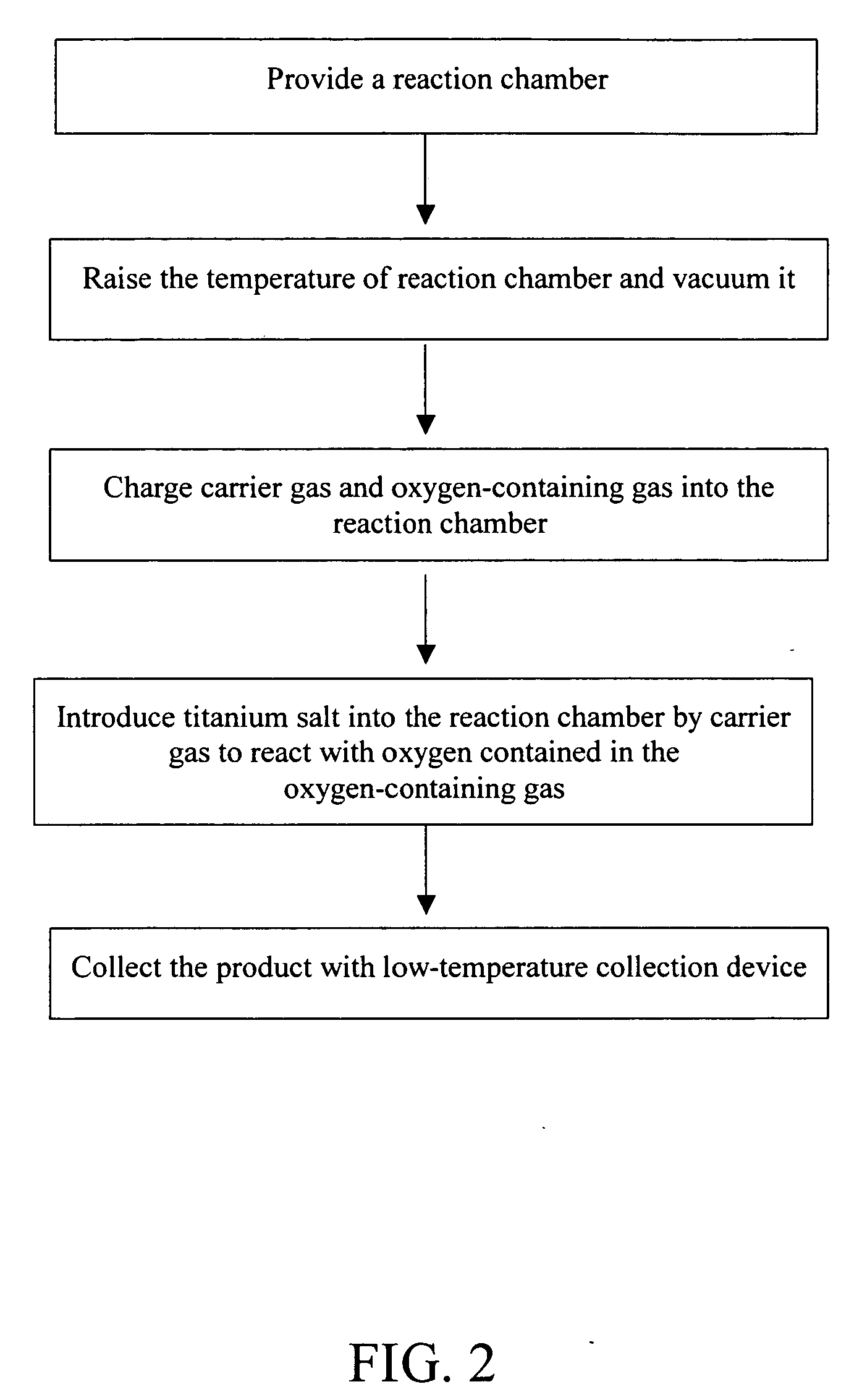

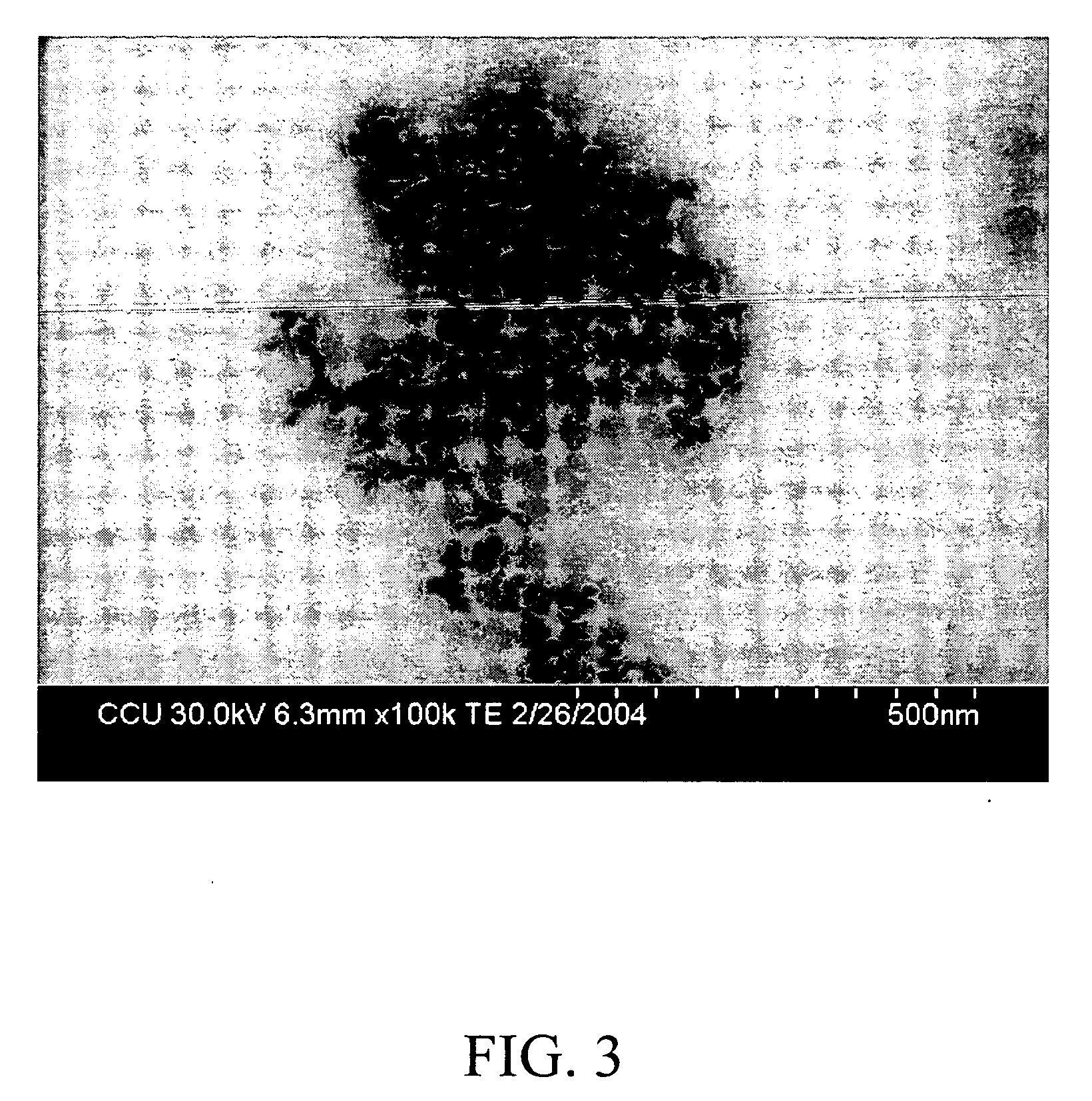

InactiveUS20060063668A1Inhibit aggregationSimple stepsMaterial nanotechnologyCatalyst activation/preparationAir contaminantCrystallinity

A photocatalyst powder and the method of chemical vapor deposition for producing the same are provided. Titanium salt is injected into a chamber by the carrier gas. After reaction with oxygen gas, the photocatalyst particle is introduced to a low temperature collection device. The synthesized titanium dioxide powder is nano-sized, well-dispersed and anatase-crystallinity. The air contaminant was degraded with this photocatalyst under 315 nm to 700 nm irradiation. The method enhances the conversion of sunlight irradiation to chemical energy.

Owner:IND TECH RES INST

Connector

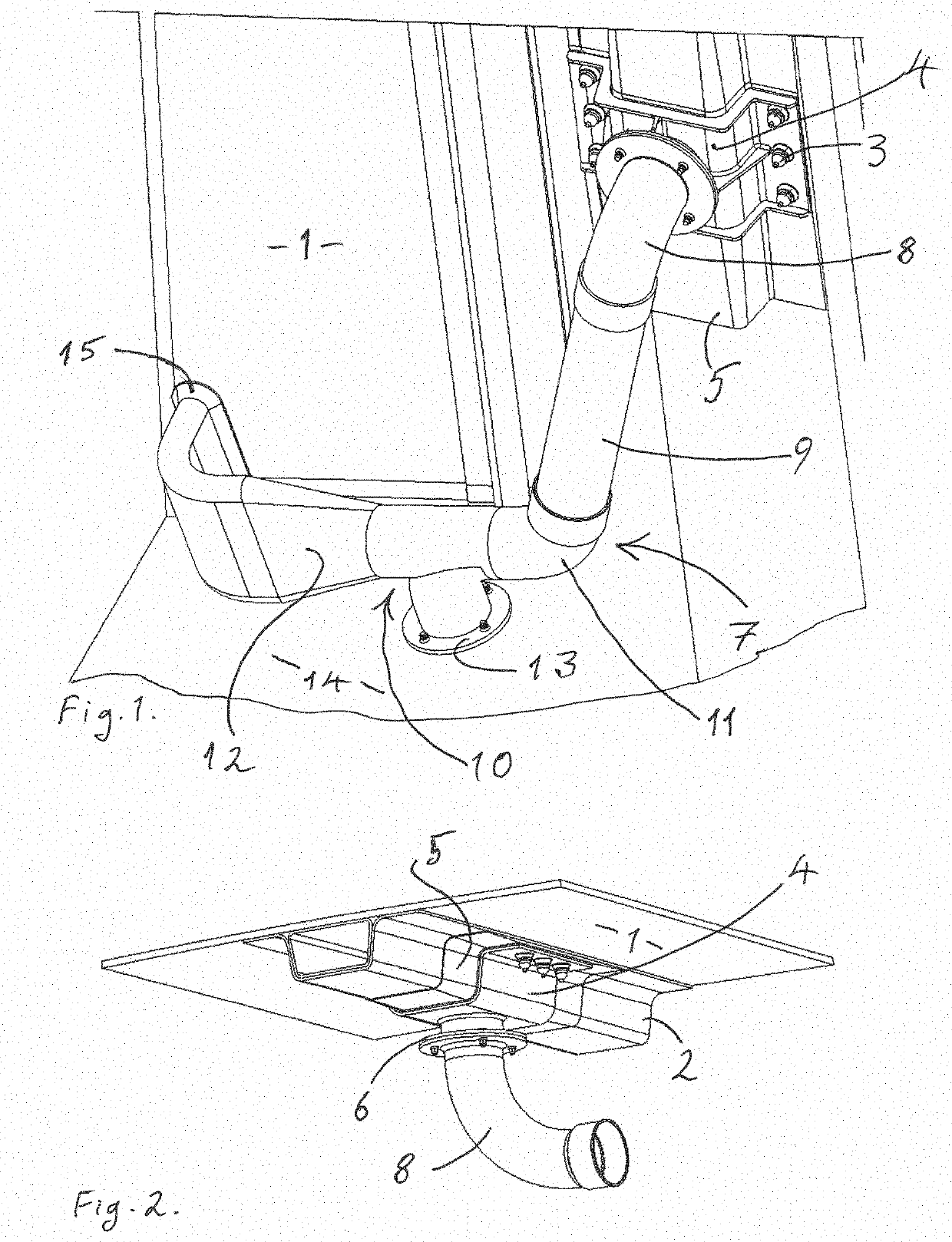

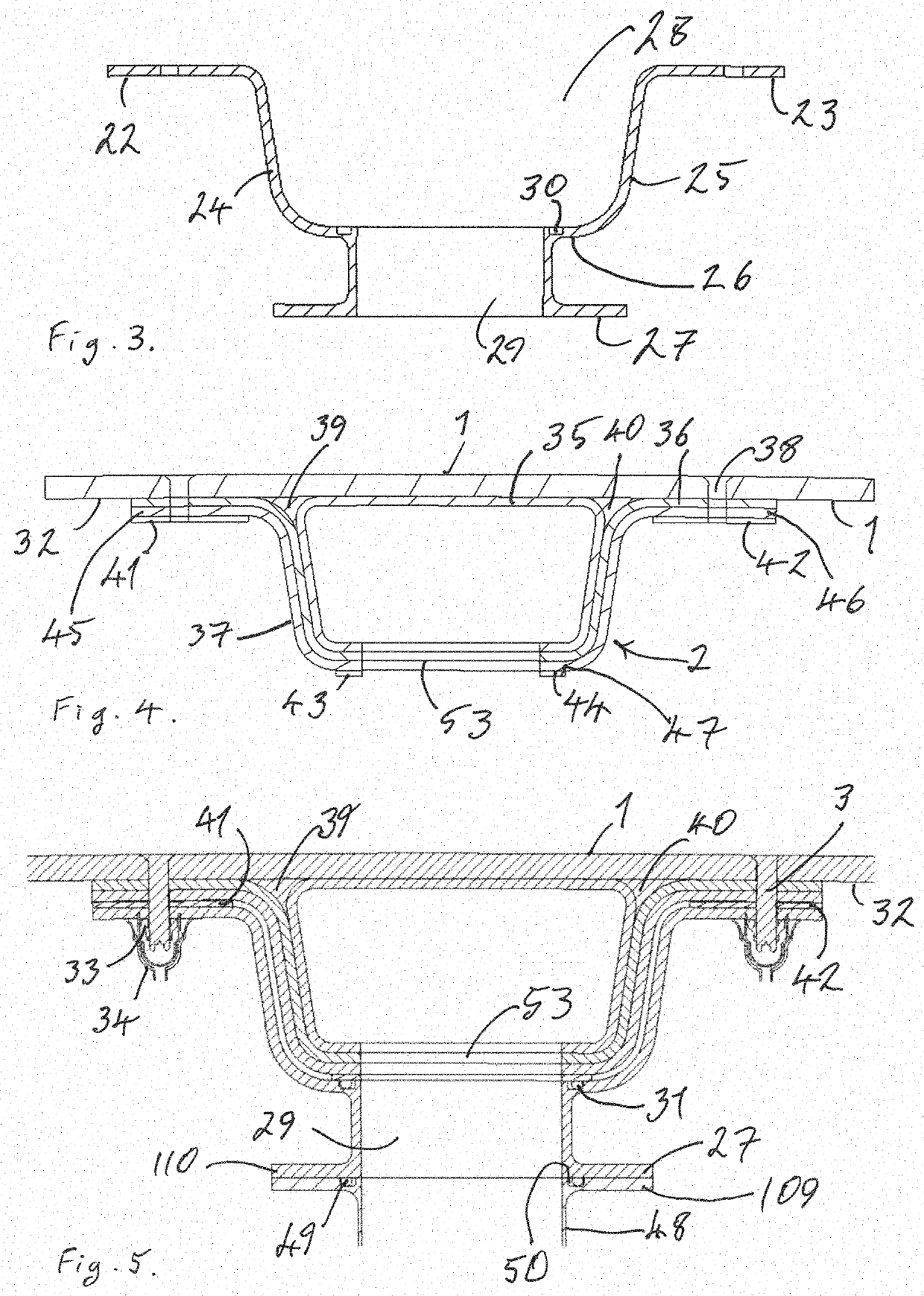

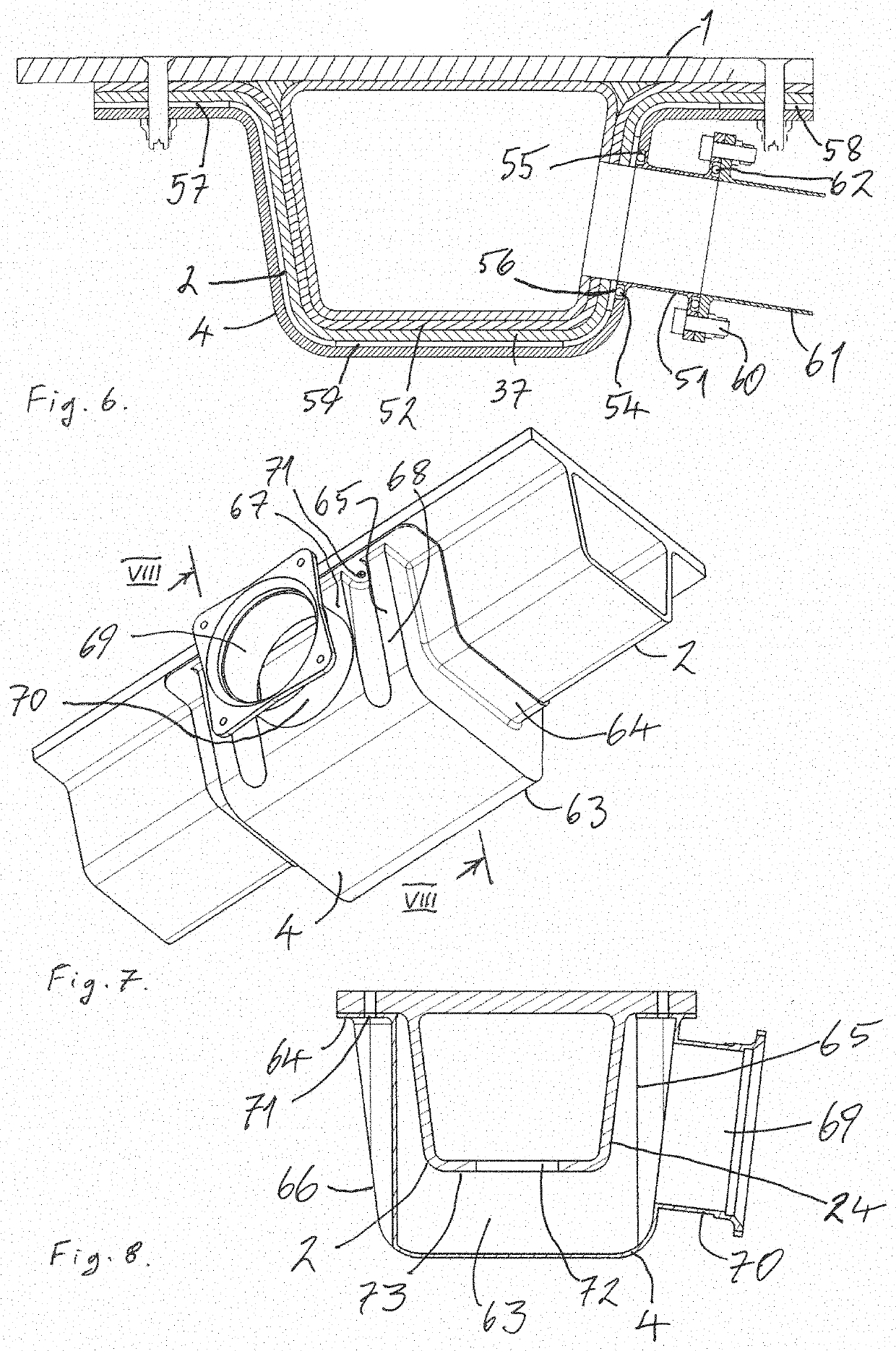

PendingUS20200010176A1Easy to disassembleMinimal spacePower plant fuel supplyWing adjustmentsFuel tankVentilator outlet

A connector, a connector assembly, an aircraft fuel breather system and an aircraft wing are disclosed. The connector connects a breather pipe or float valve to a hat section stringer duct attached to an aircraft panel. The connecter has a bridge to bridge over the duct and to cover an aperture in a wall of the duct. The bridge has a flange on either side for attachment of the connector to the panel. The connector has a seal to seal the bridge to the duct, an aperture defined in the bridge and a flow controller connector to connect and provide fluid connection between the connector and pipe or float valve. The assembly comprises the connector, the duct and aircraft panel and the fuel breather system includes one or more fuel tanks, a breather pipe and a vent to atmosphere.

Owner:AIRBUS OPERATIONS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com