Fully-automatic production line for producing wooden pier

A production line, fully automatic technology, applied in the direction of wood processing appliances, circular saws, nailing tools, etc., can solve the problems of reduced production efficiency, low nailing efficiency, and the process of nailing and transmission cannot be carried out continuously, so as to improve production efficiency. , high production efficiency, good promotion and application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

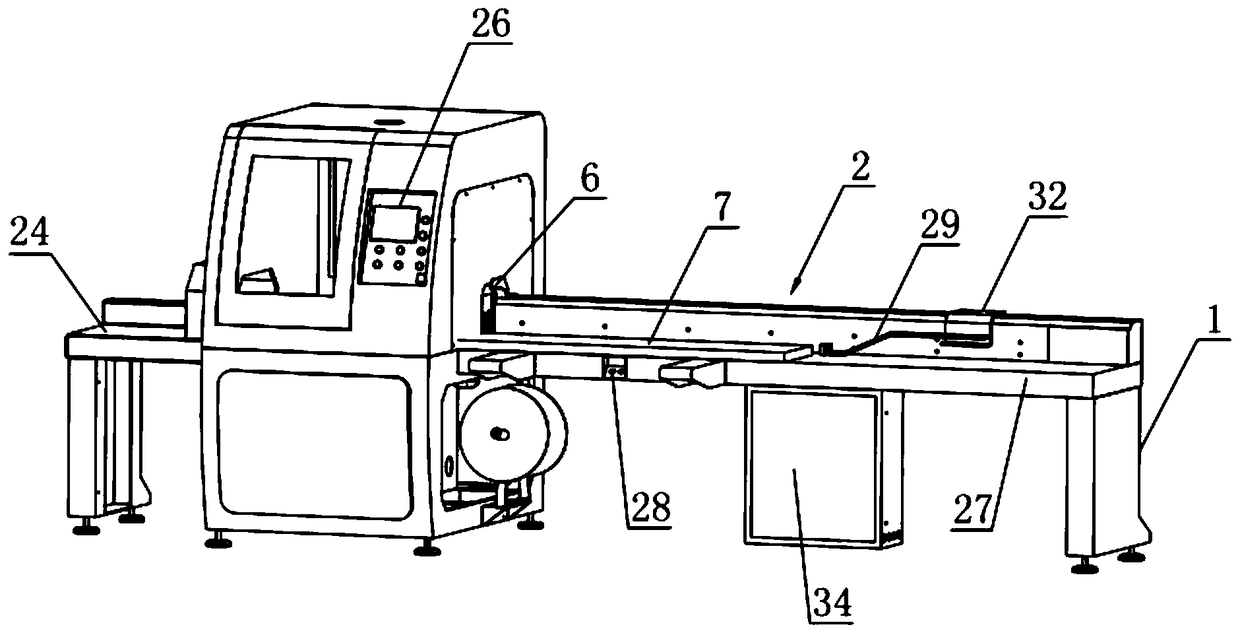

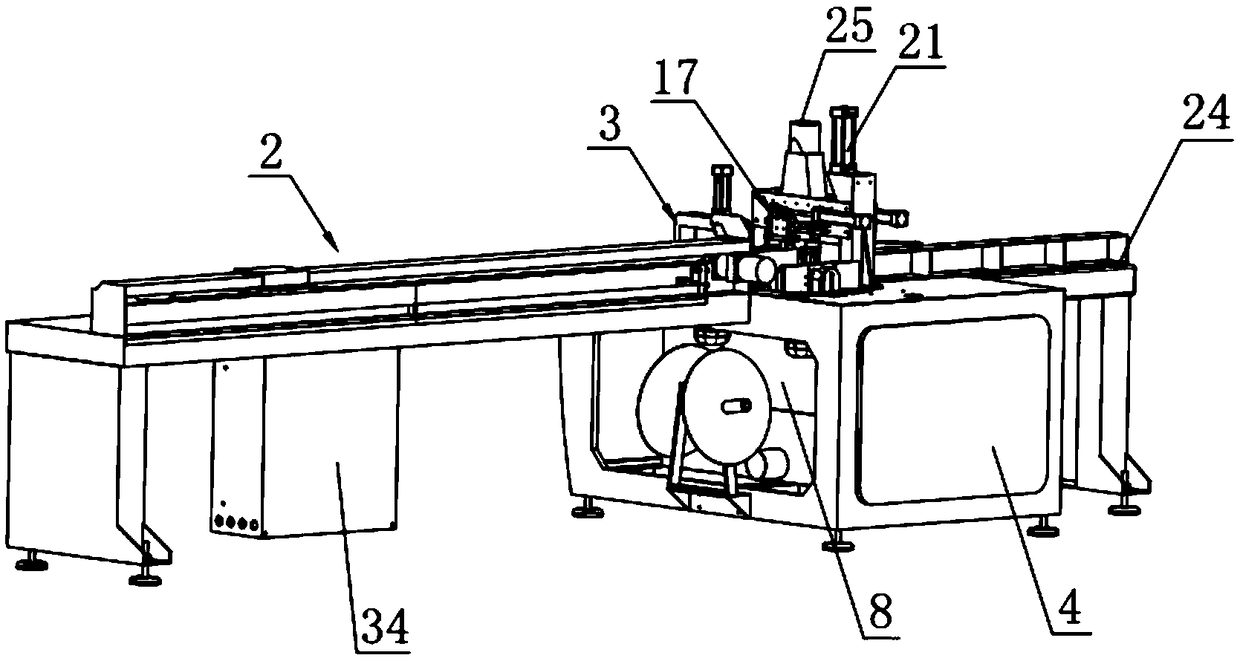

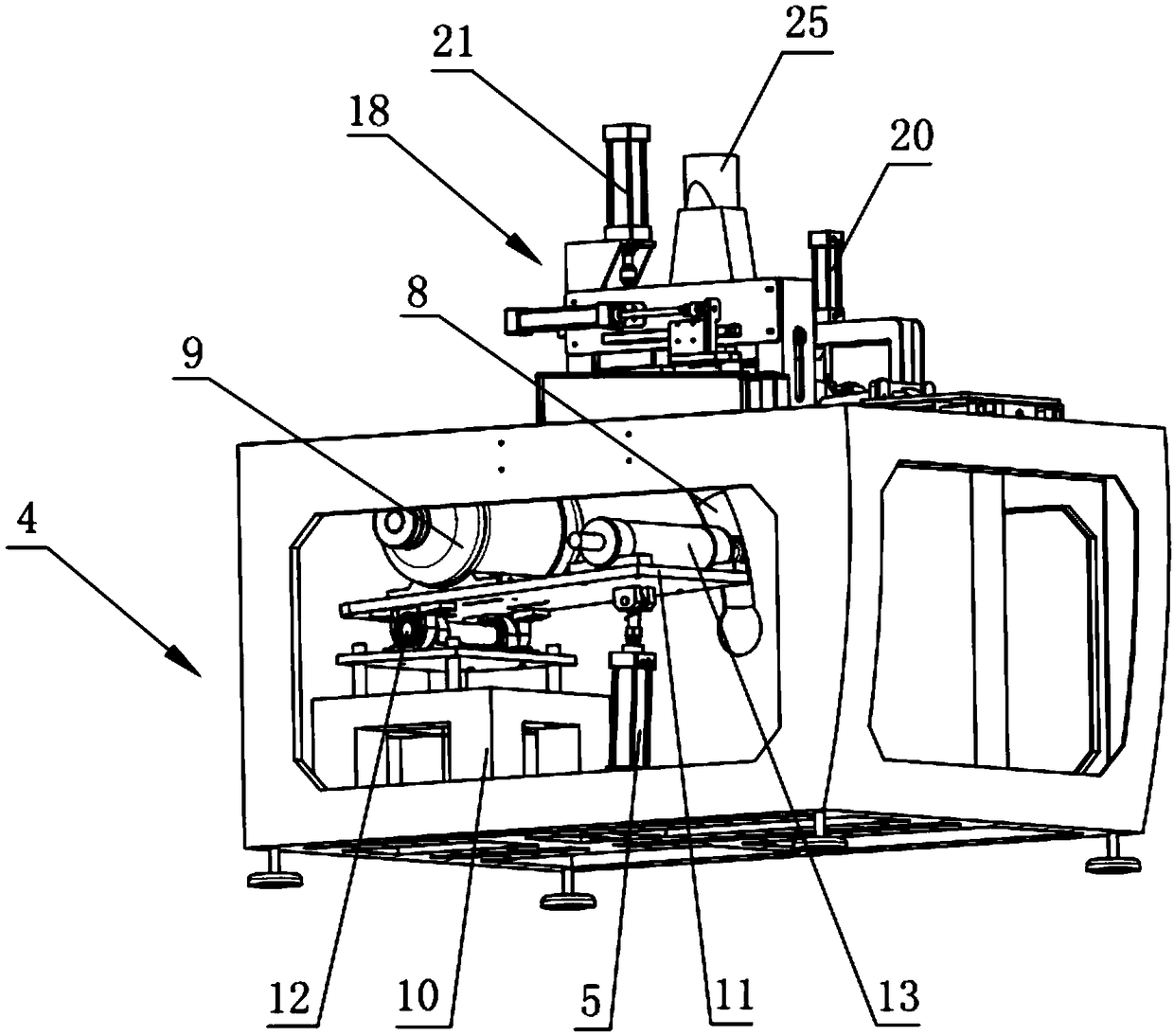

[0023] Such as figure 1 , 2 , 3, and 4, a fully automatic production line for producing wooden piers, including a workbench 1, on which a feeder 2 for conveying planks 7 raw materials is provided, along the feeding device 2 There is a nailing device 3 for binding the raw materials of multi-layer wood boards into wooden piers in the direction, and a cutting device 4 for cutting the wooden piers according to the required size and a lifting and lowering device for lifting and cutting the cutting device are installed under the workbench 1. The driving device 5 also includes a controller. The end of the feeding device 2 close to the nailing device is provided with a detection element 6 for detecting the wooden board. After detecting the wooden board 7, the detection element 6 sends a detection signal to the controller, and the controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com