Patents

Literature

498 results about "Nail device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

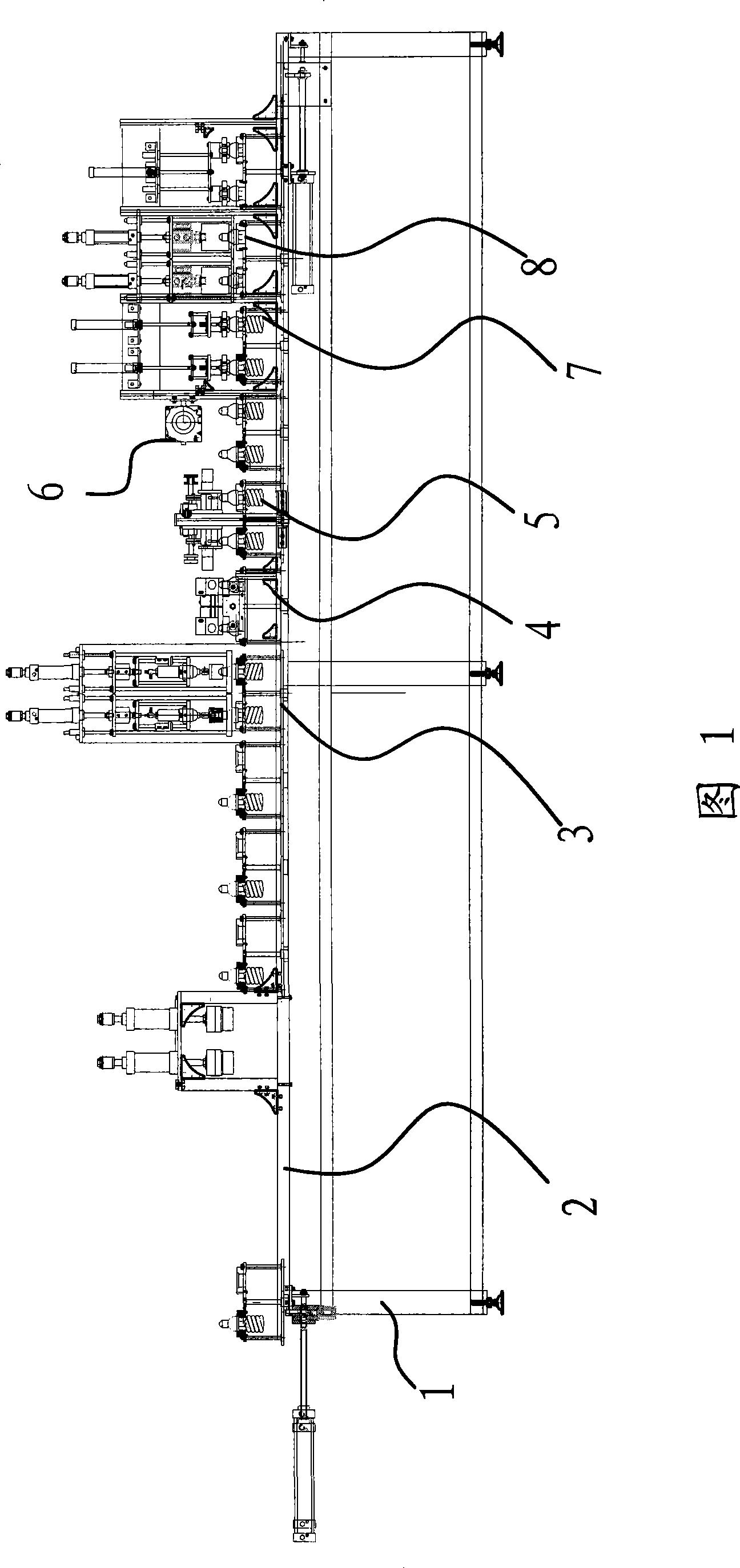

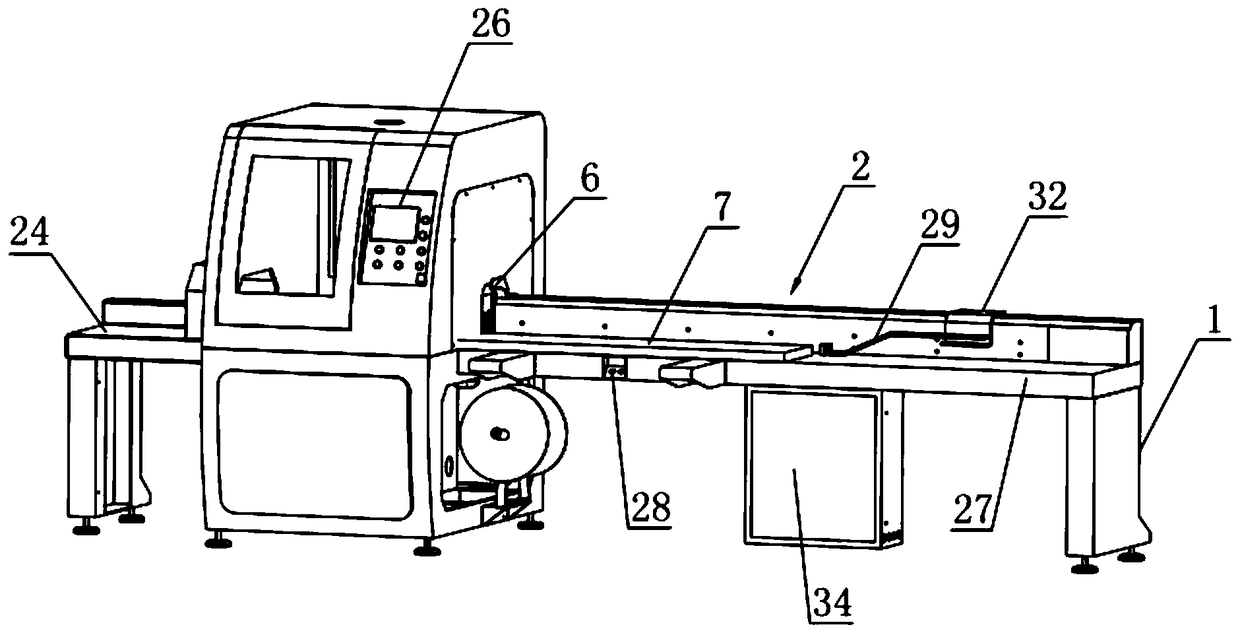

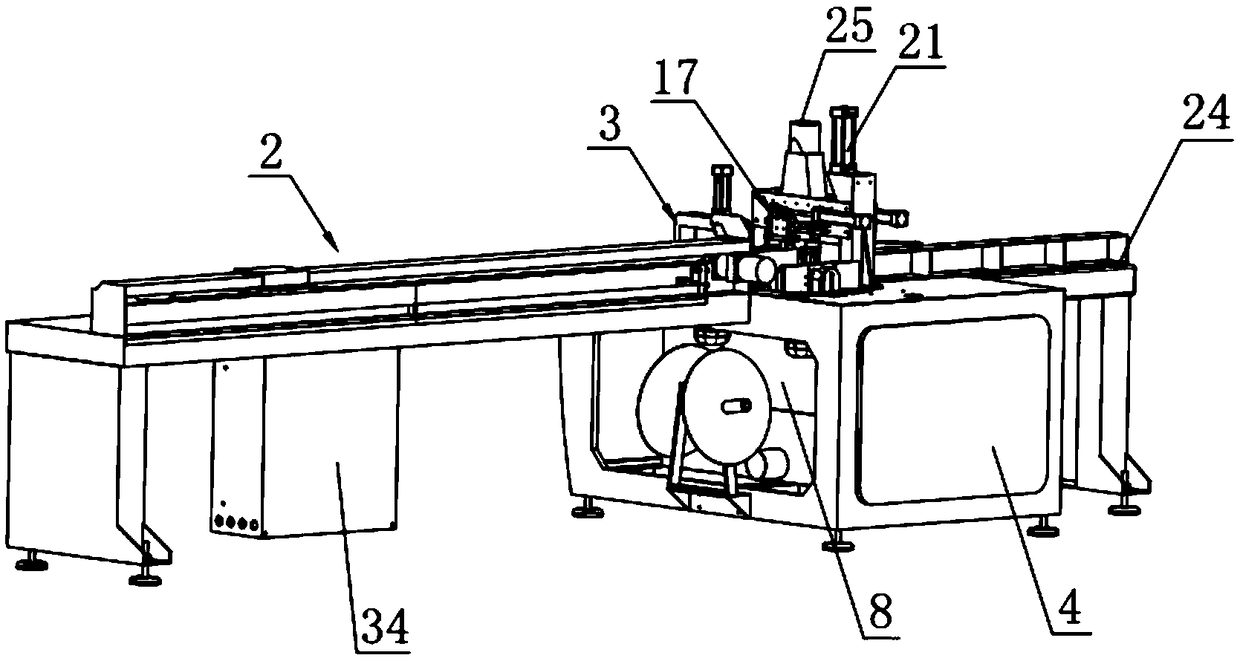

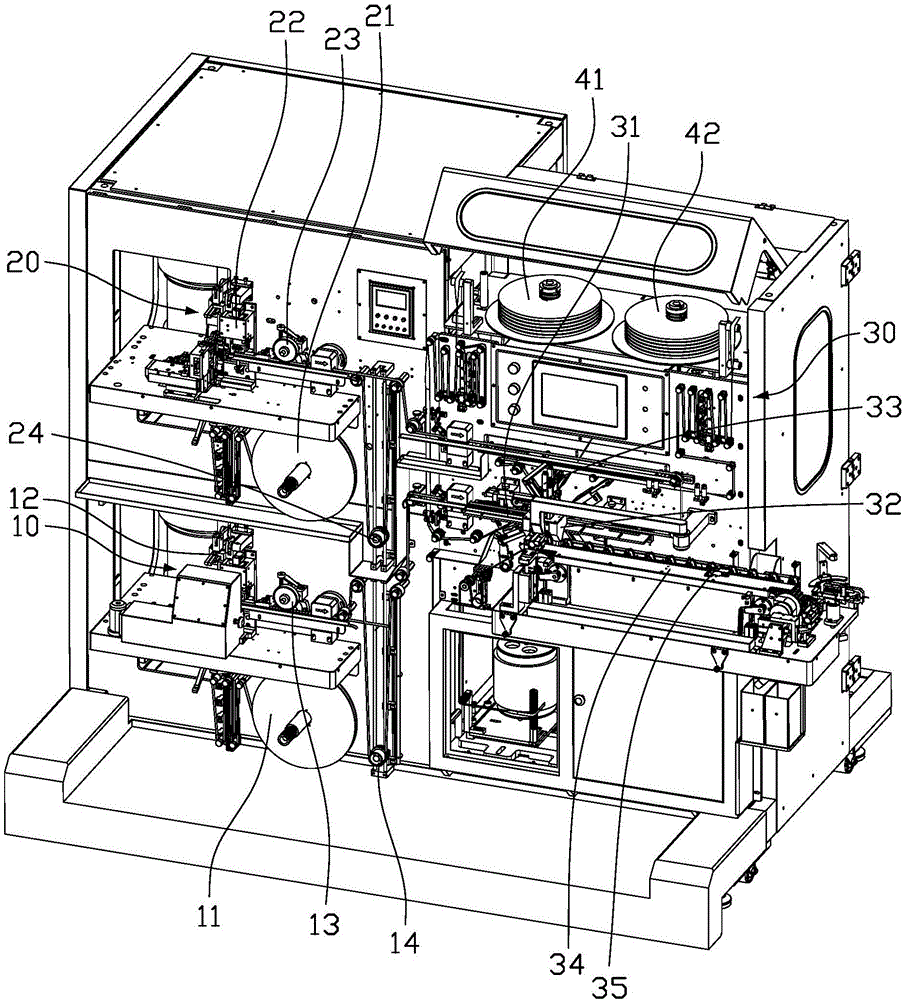

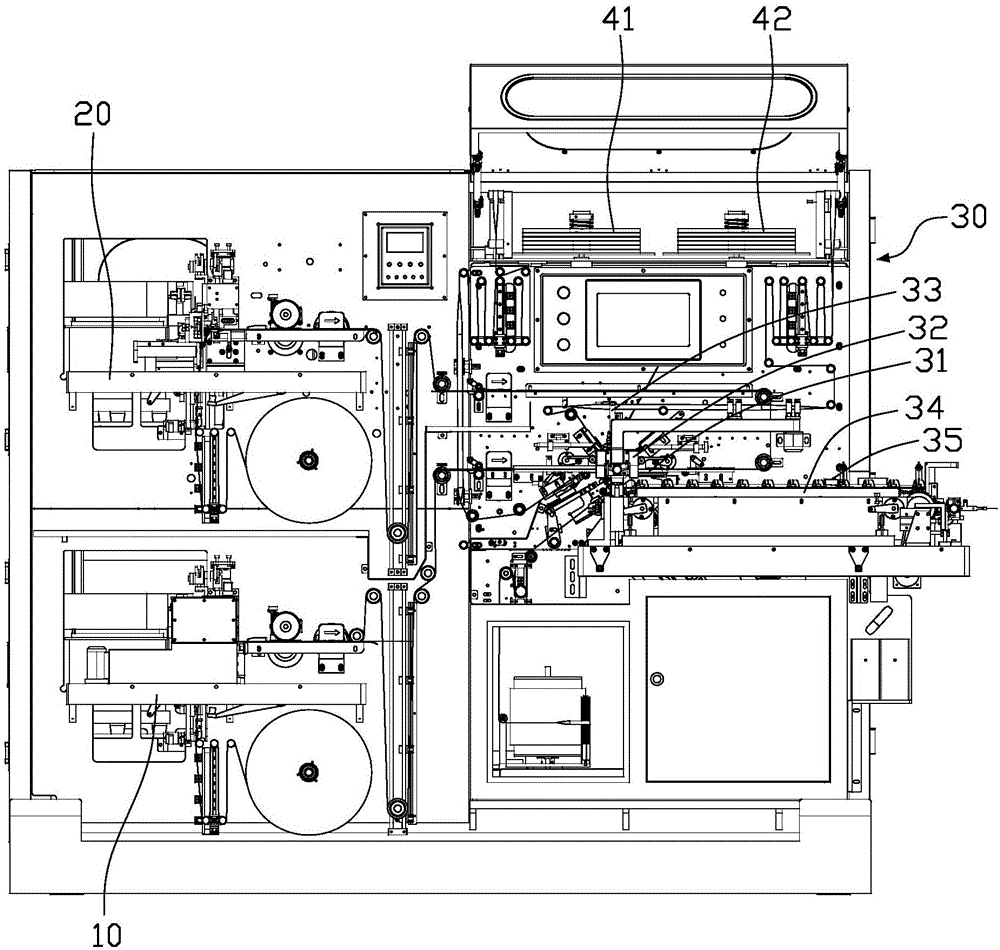

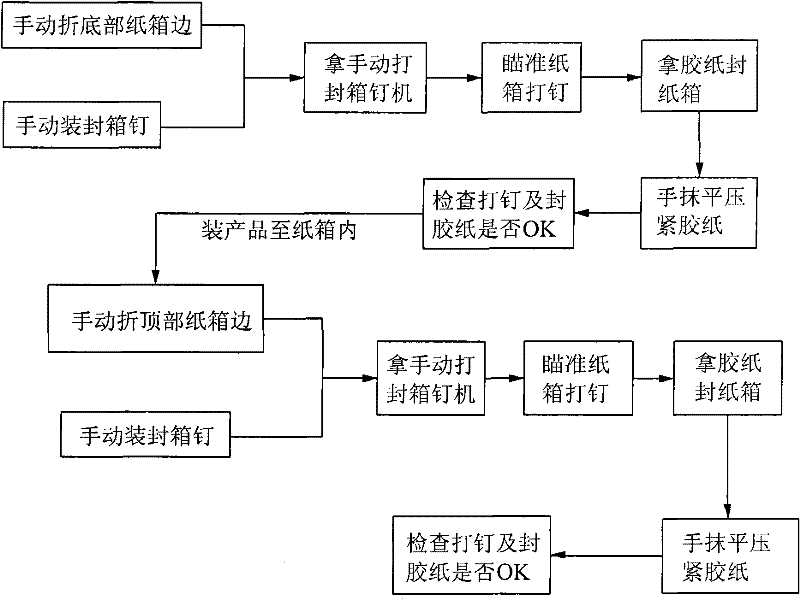

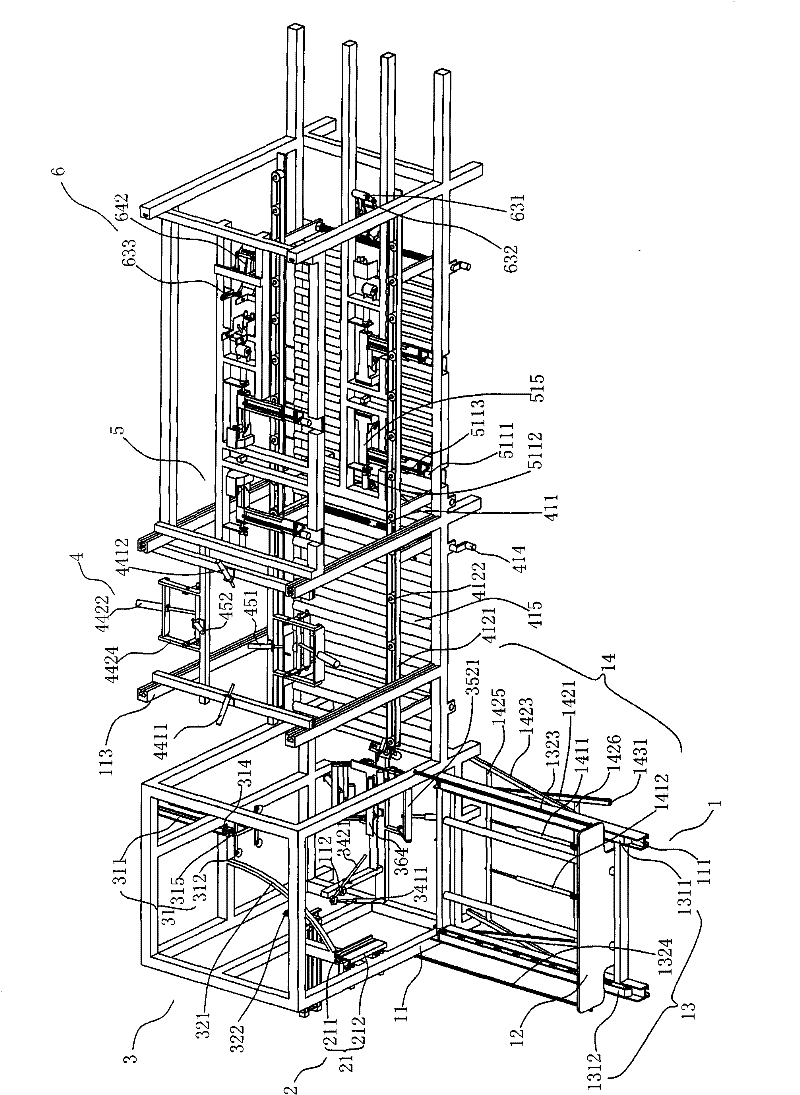

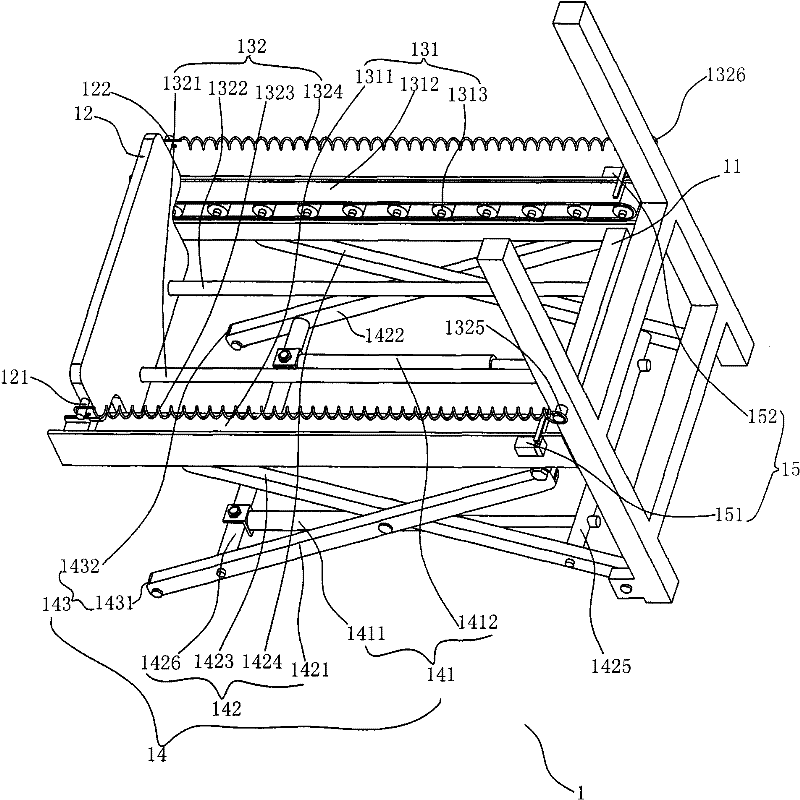

Full-automatic paper box forming machine

InactiveCN101786343ALabor savingRealize standardized operationBox making operationsPaper-makingDevice formCarton

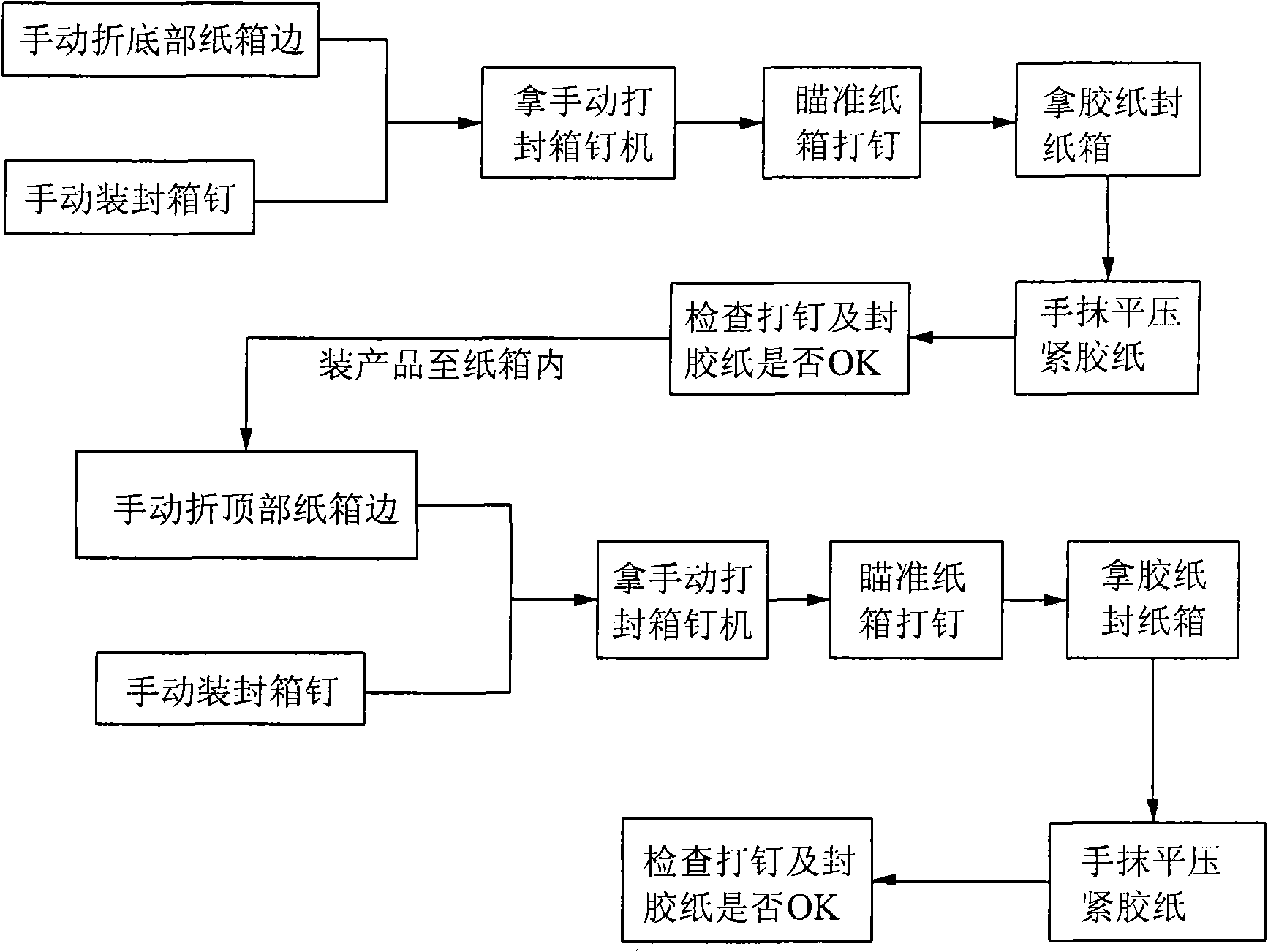

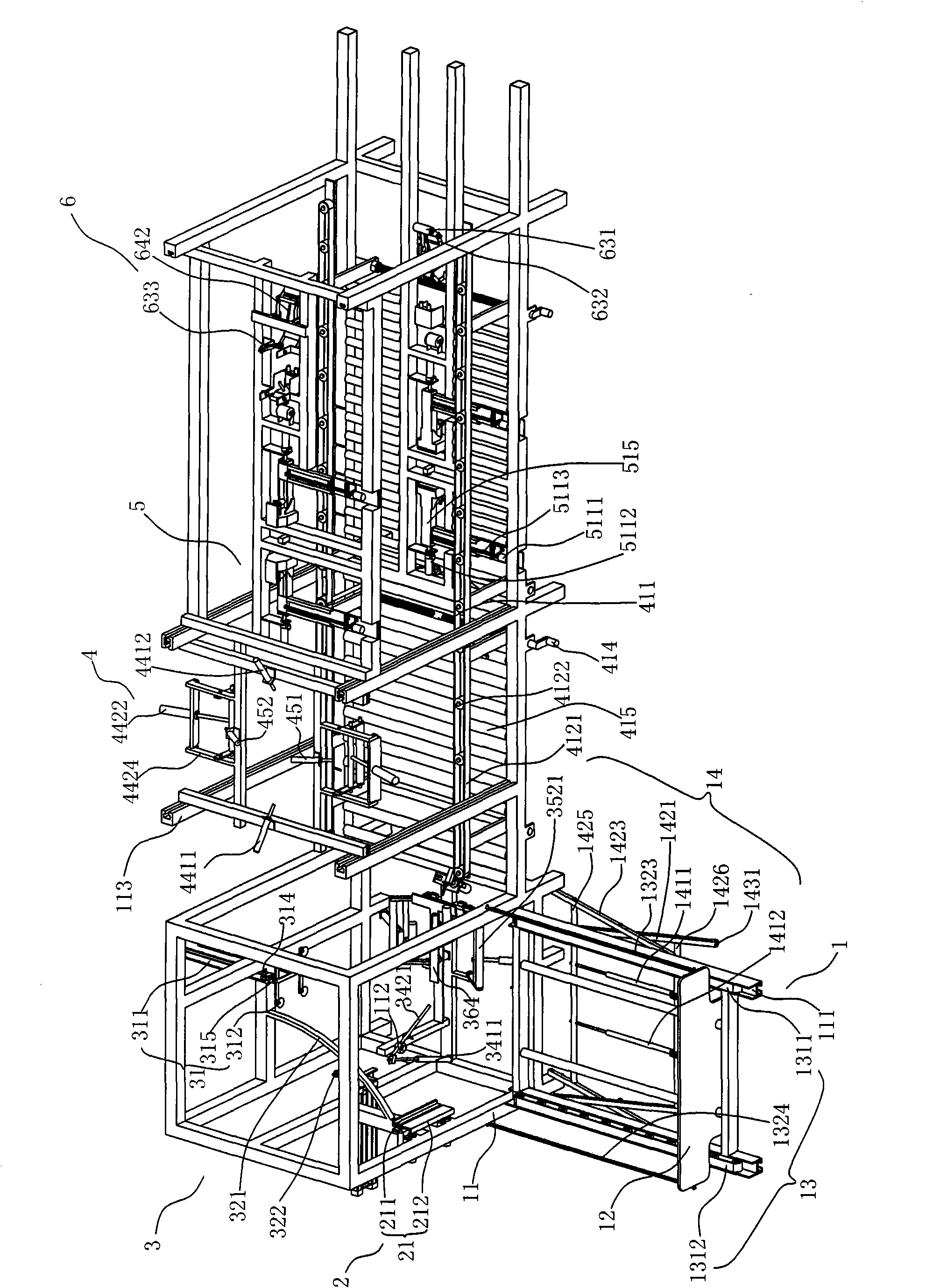

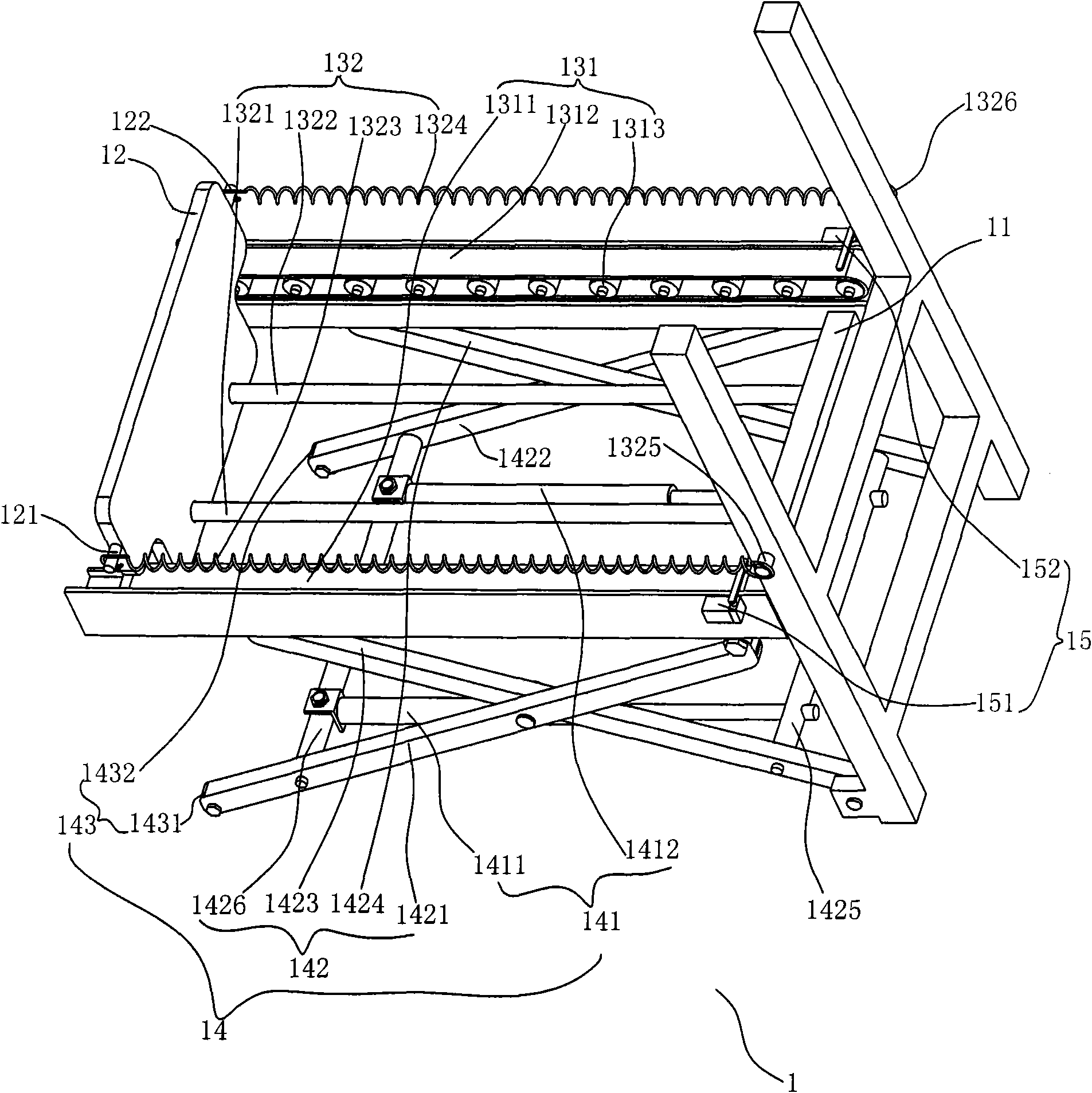

The invention provides a full-automatic paper box forming machine, which is applicable to the technical field of full atomization. The paper box forming machine comprises a machine frame, a paper box loading device, a releasing device, a paper box forming device, a top edge folding device, a feeding and nailing device, an adhesive tape sealing device and a controller, wherein the paper box loading device, the releasing device, the paper box forming device, the top edge folding device, the feeding and nailing device and the adhesive tape sealing device are sequentially arranged on the machine frame, the paper box loading device loads a paper box under the control of the controller, the release device moves the paper box into the paper box forming device, the paper box forming device forms the paper box, the feeding and nailing device binds the paper box, and the adhesive tape sealing device seals adhesive tapes on the bound paper box. Compared with the conventional paper box forming machine, the invention has the advantages that all flow processes are completed through controlling an automatic forming machine by the controller, the labor is saved, the standard operation is realized, and the invention can ensure that each product can be finished according to the technical requirements. In addition, the work efficiency is improved.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

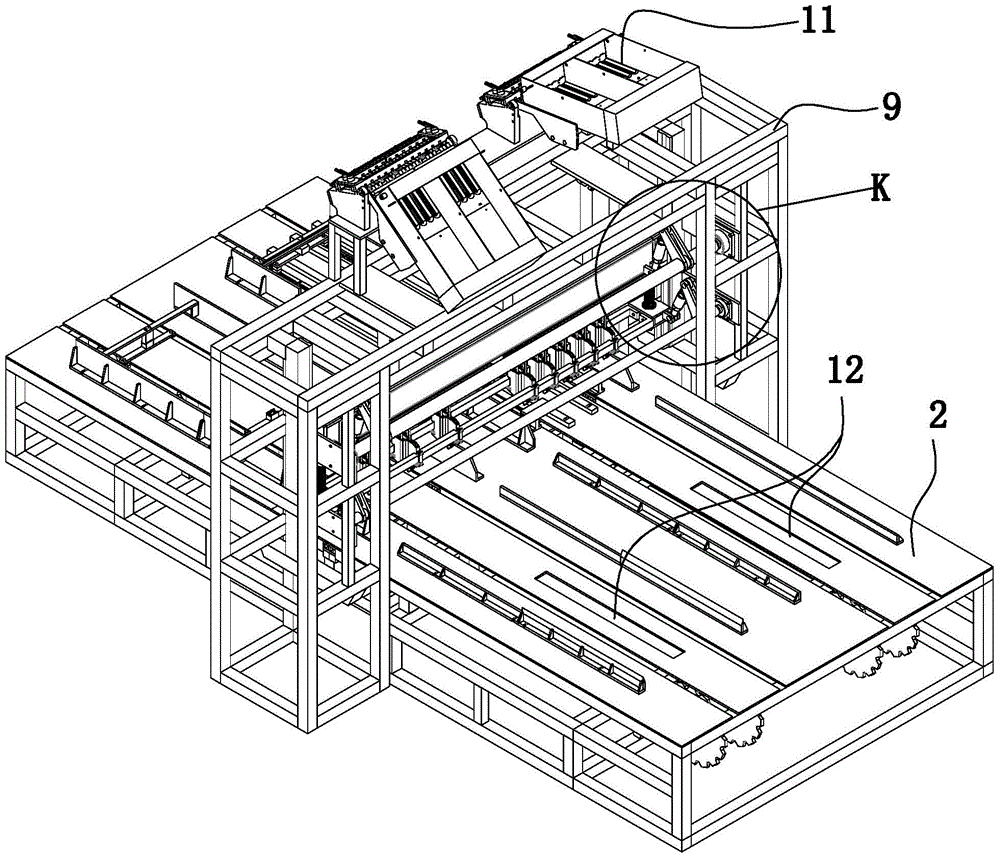

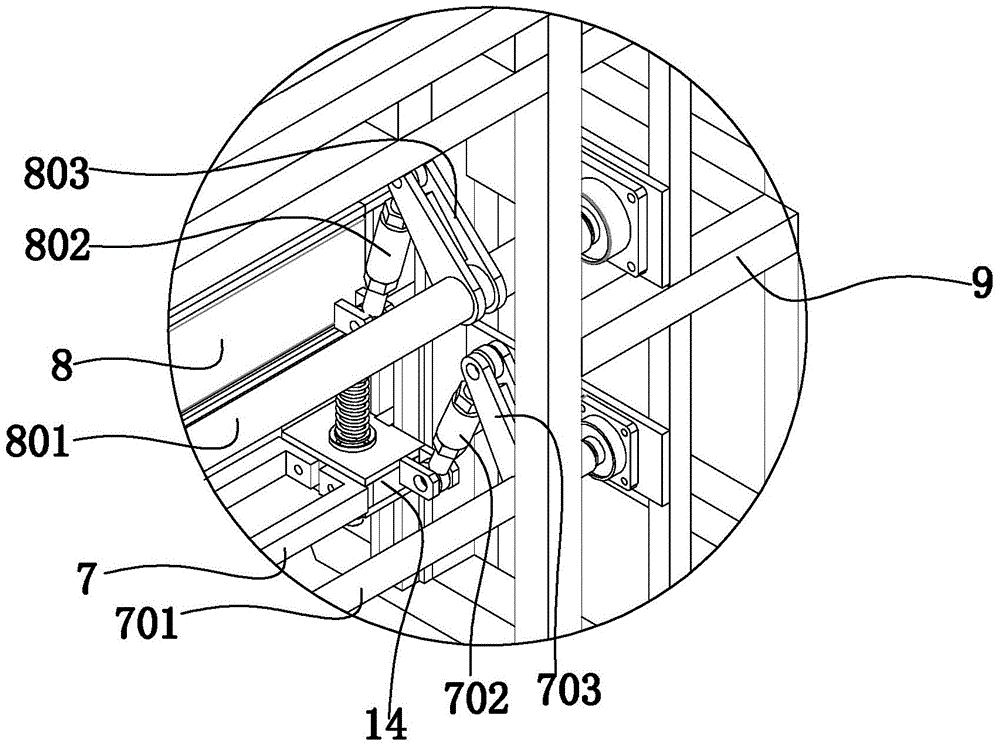

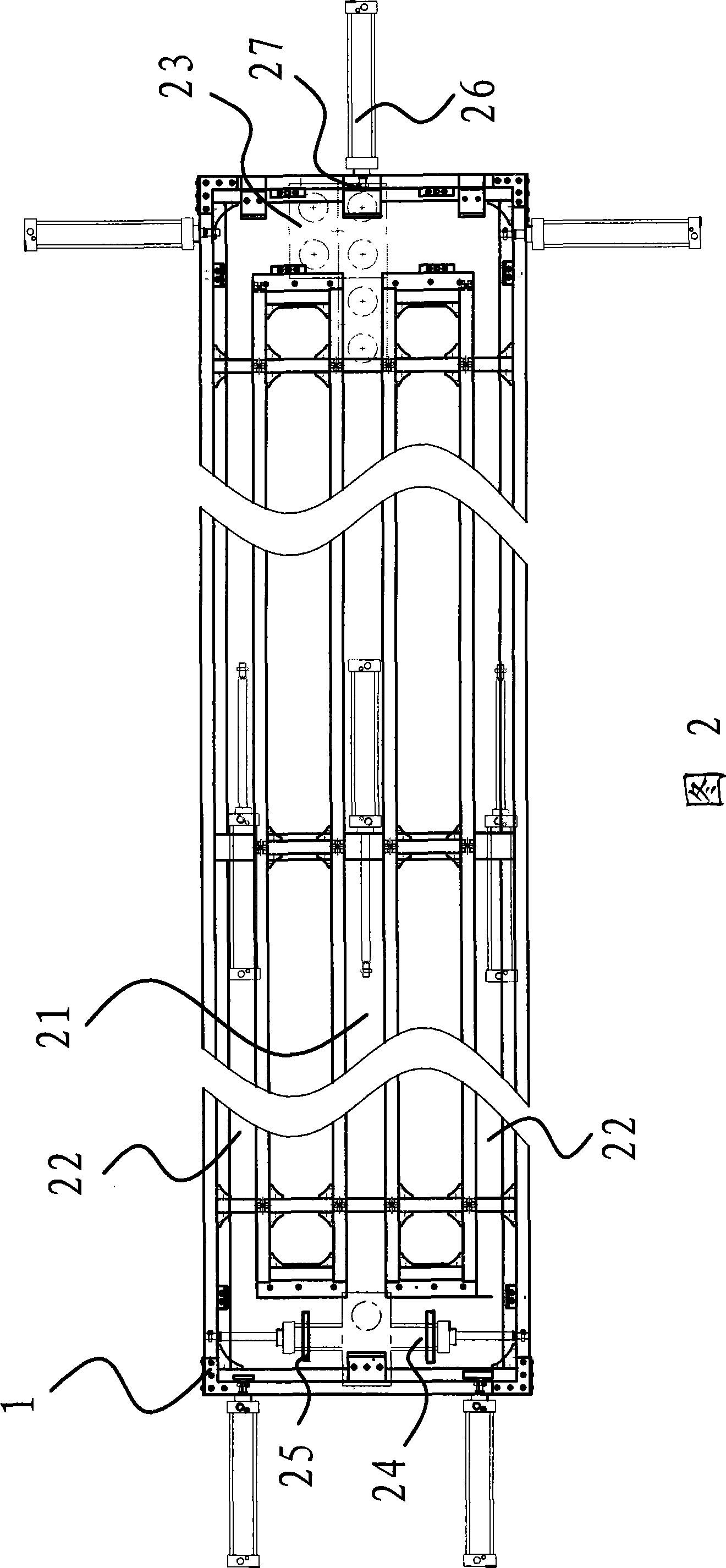

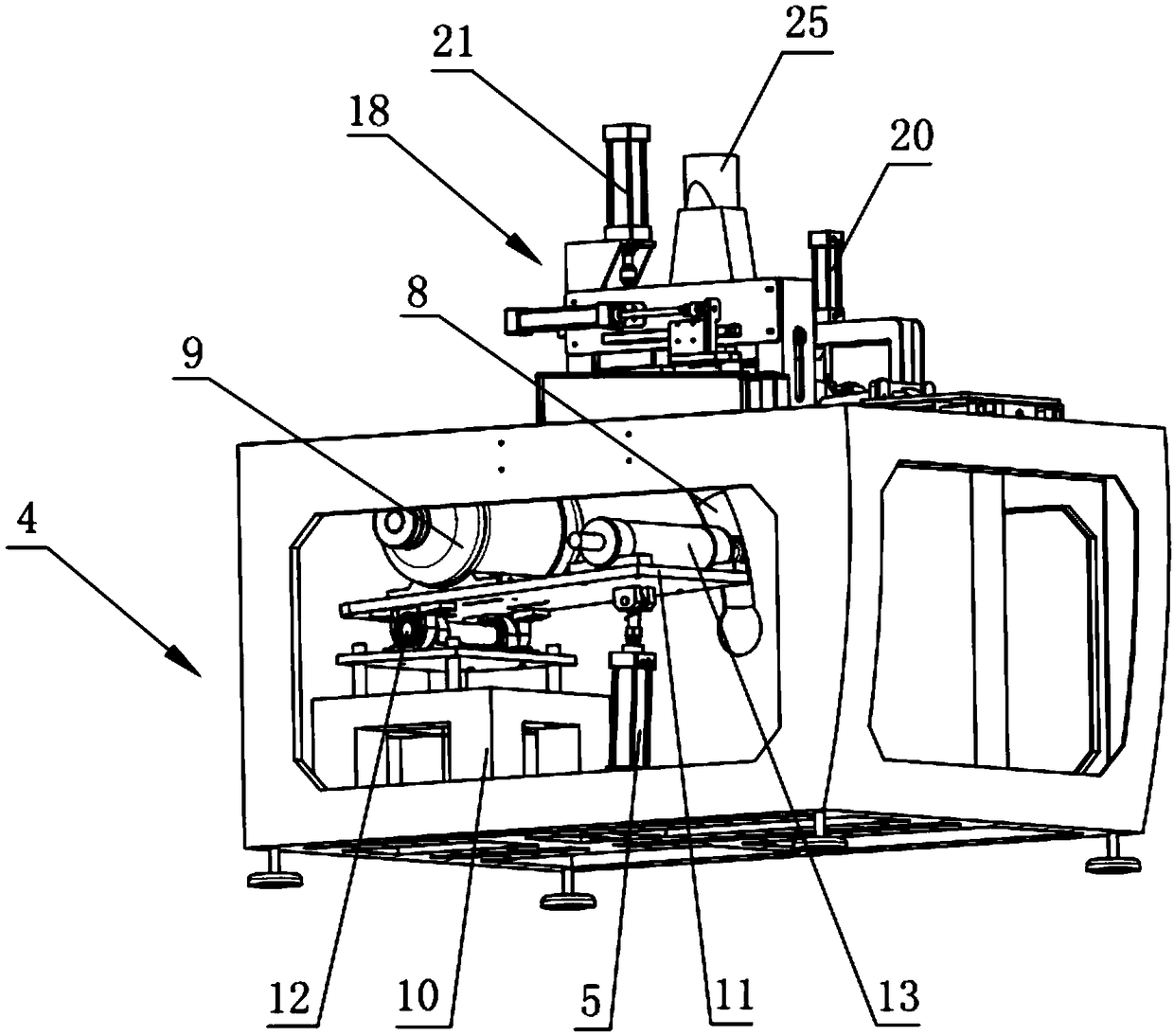

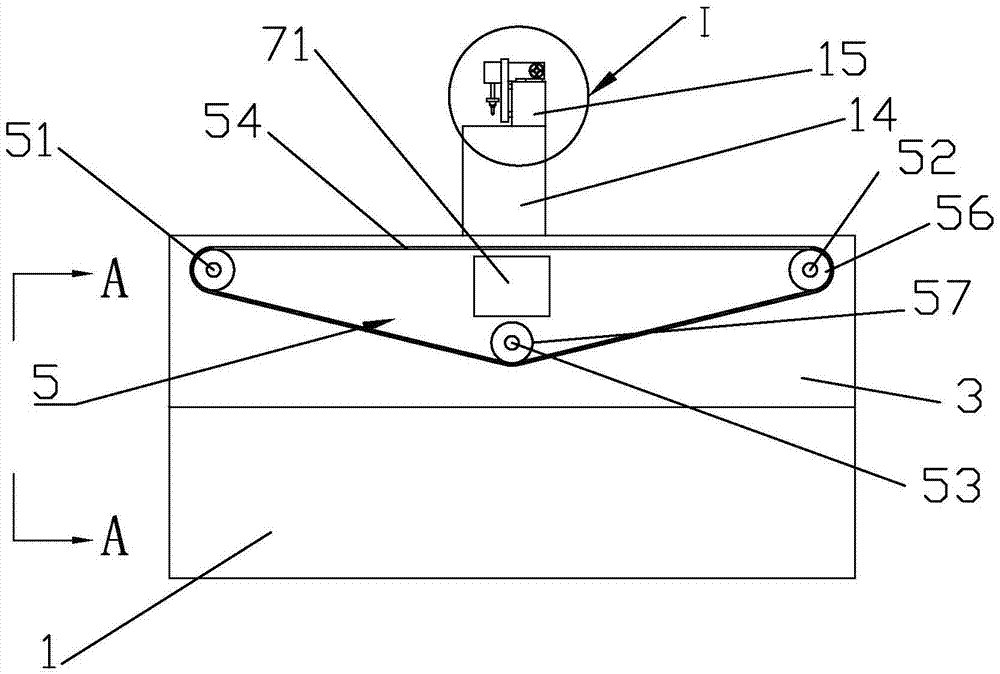

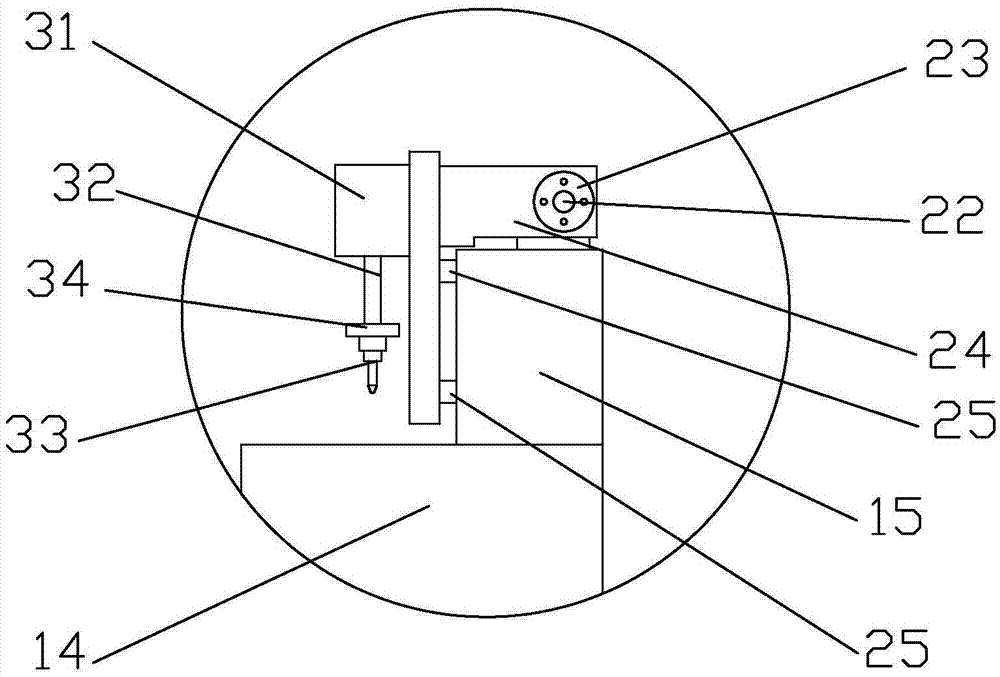

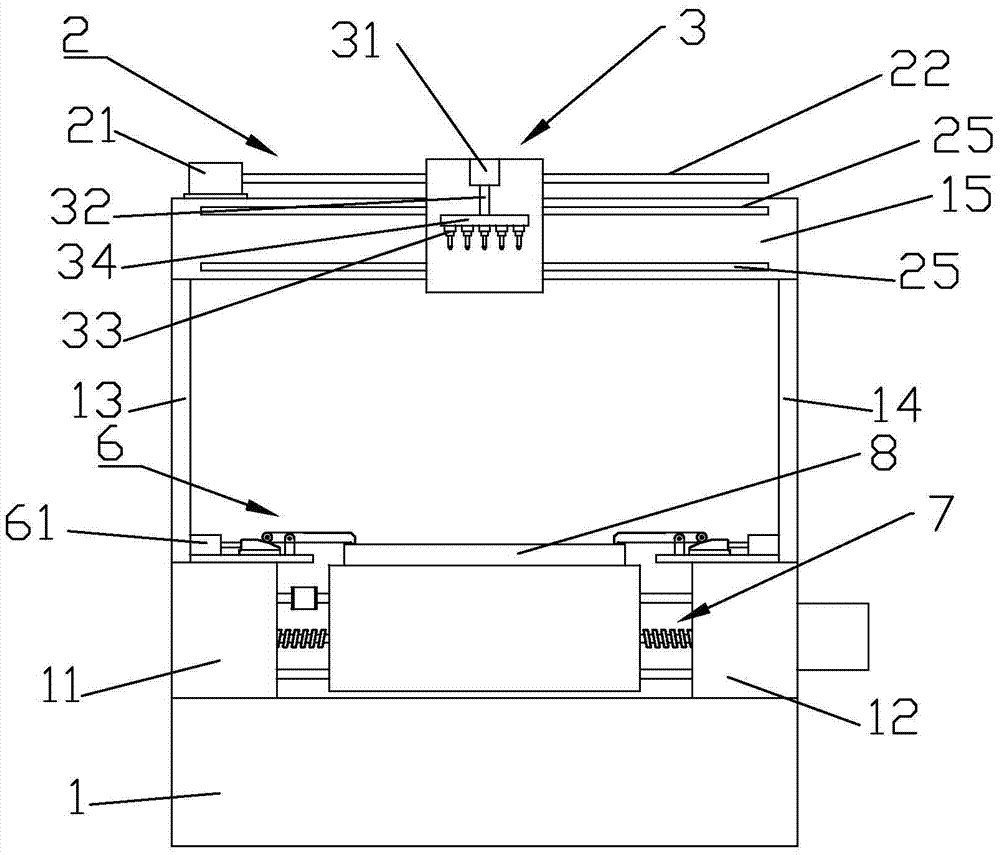

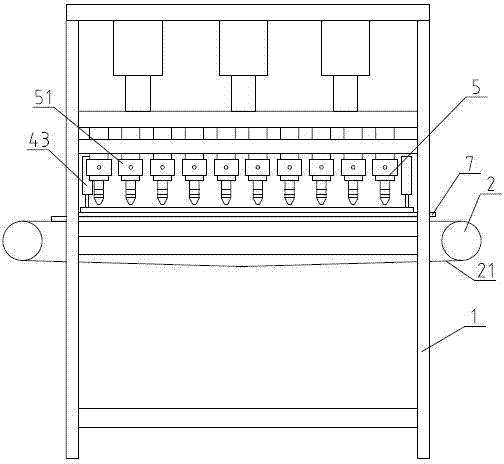

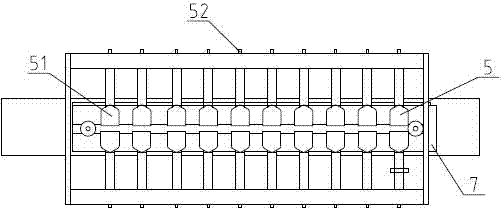

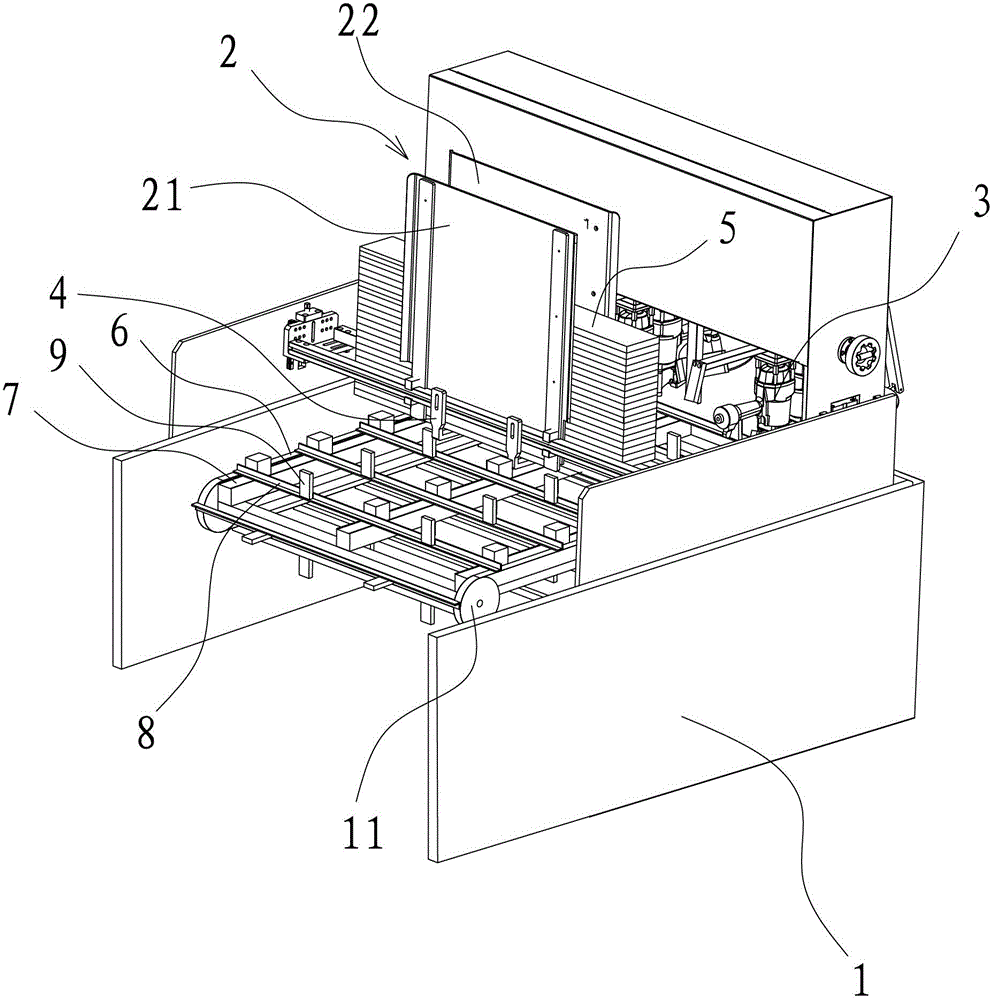

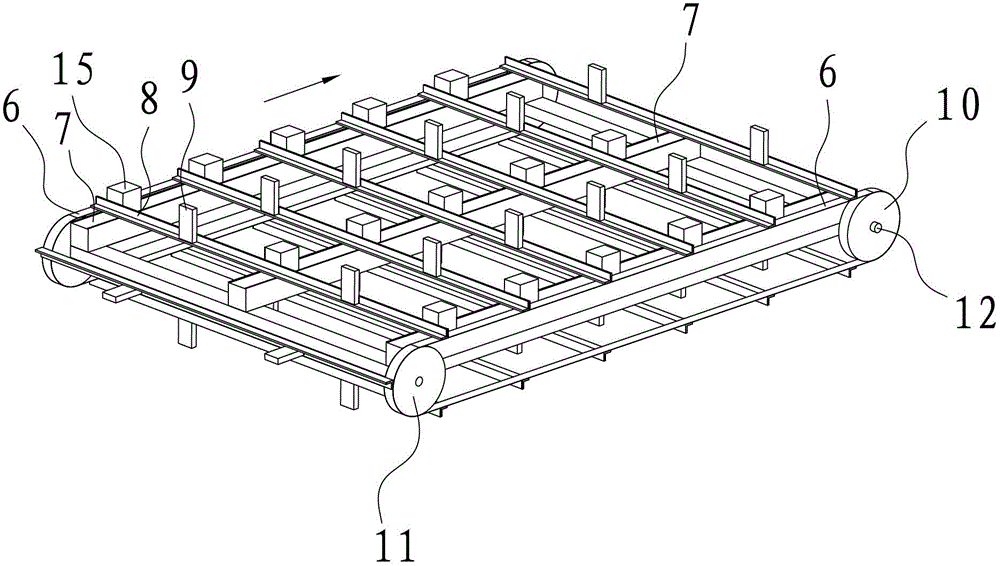

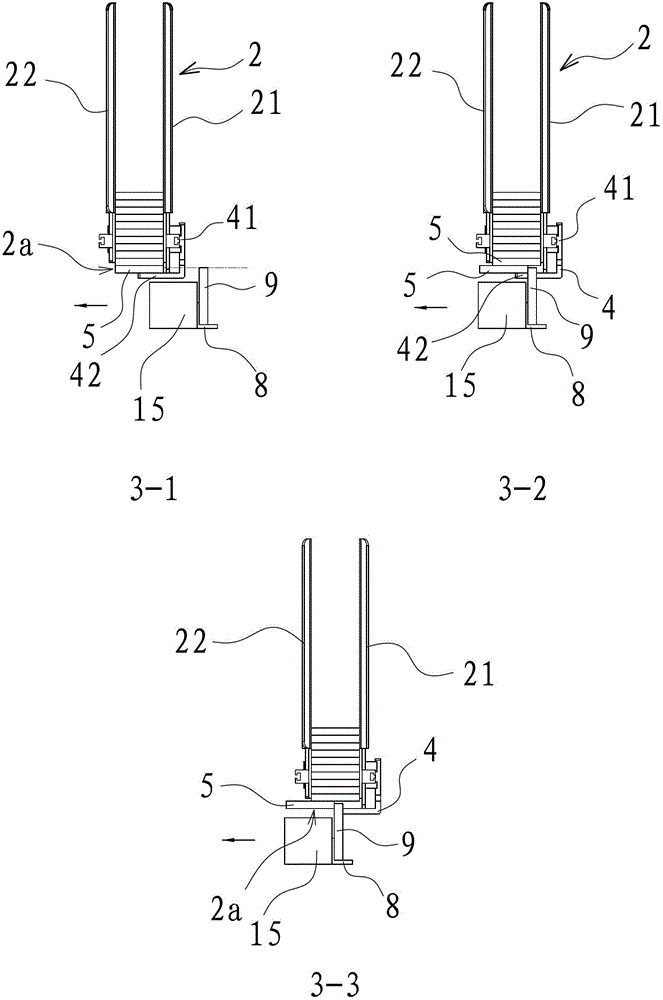

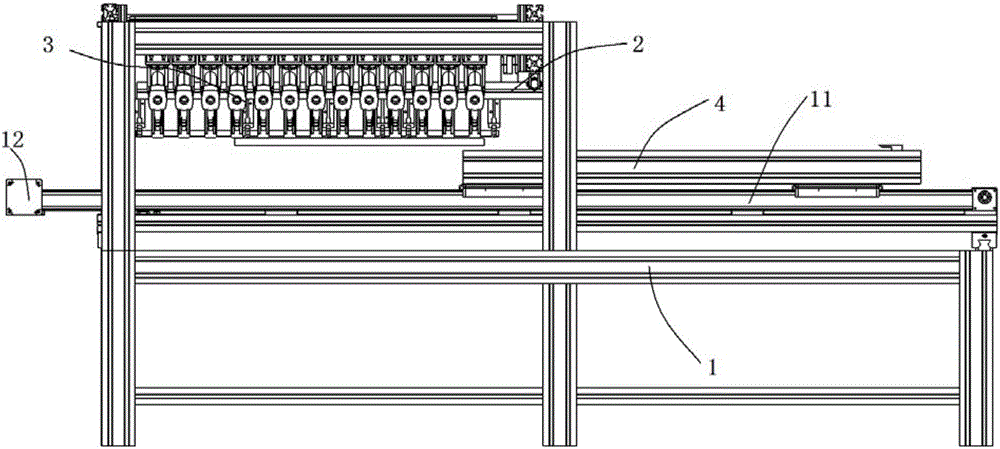

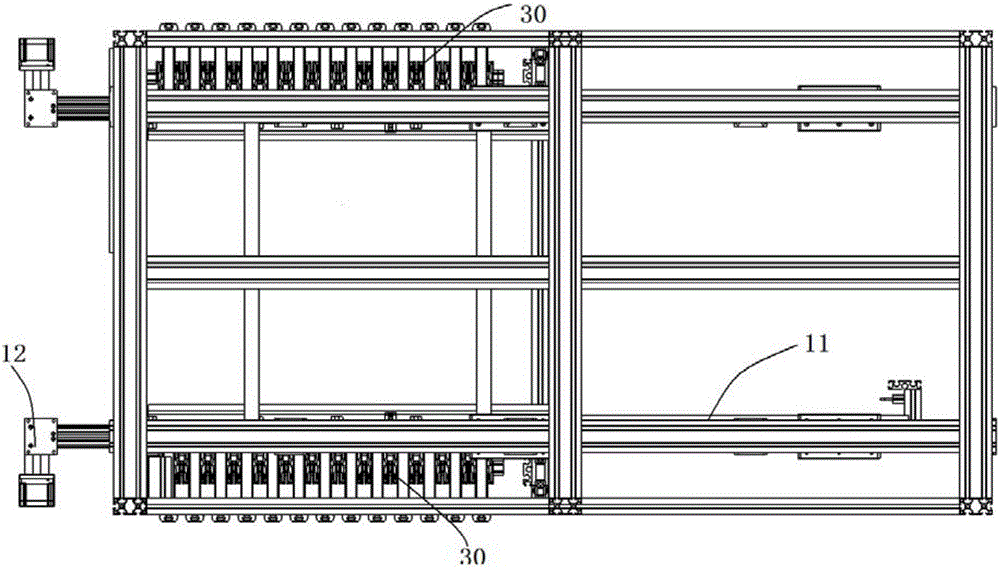

Production line for wood pallets

ActiveCN103600401AImprove production efficiencyImprove product qualityWood working apparatusProduction linePulp and paper industry

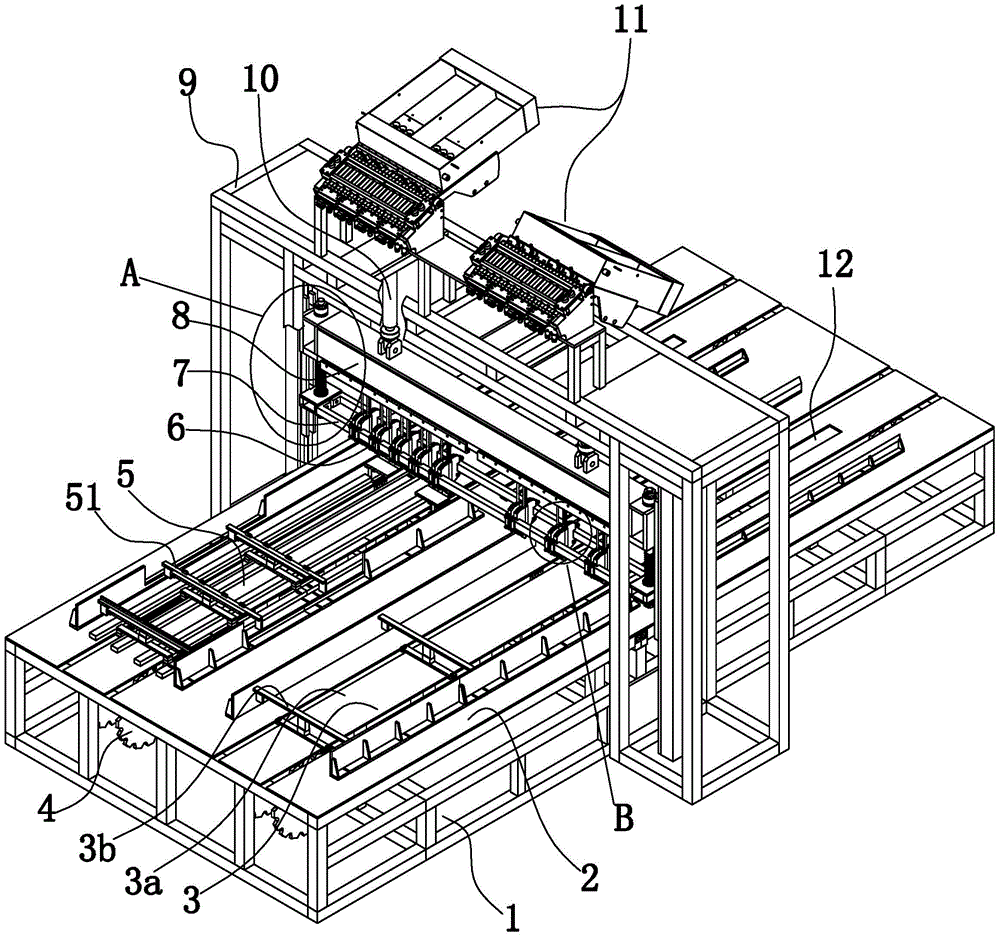

The invention discloses a production line for wood pallets and aims at providing the production line for wood pallets, which is capable of improving the wood pallet production efficiency and the product quality effectively and reducing labor costs. The production line comprises a rack, a wood pallet delivery device arranged on the rack and a nailing device which is arranged above the wood pallet delivery device. A material holding platform is arranged on the rack, and the wood pallet delivery device comprises a first wood pallet delivery line and a second wood pallet delivery line which are arranged in parallel on the material holding platform. The first wood pallet delivery line comprises a plurality of wood pier guide grooves formed in the material holding platform, a plurality of wood pier push rods perpendicular to the wood pier guide grooves and a first driving device for driving the wood pier push rods to move along the direction of the wood pier guide grooves. The second wood pallet delivery line comprises a plurality of wood pallet guide grooves formed in the material holding platform, a plurality of wood pallet push rods perpendicular to the wood pallet guide grooves and a second driving device for driving the wood pallet push rods to move along the direction of the wood pallet guide grooves.

Owner:WUHU ASIA PACIFIC GENERAL TRAY PACKING CO LTD

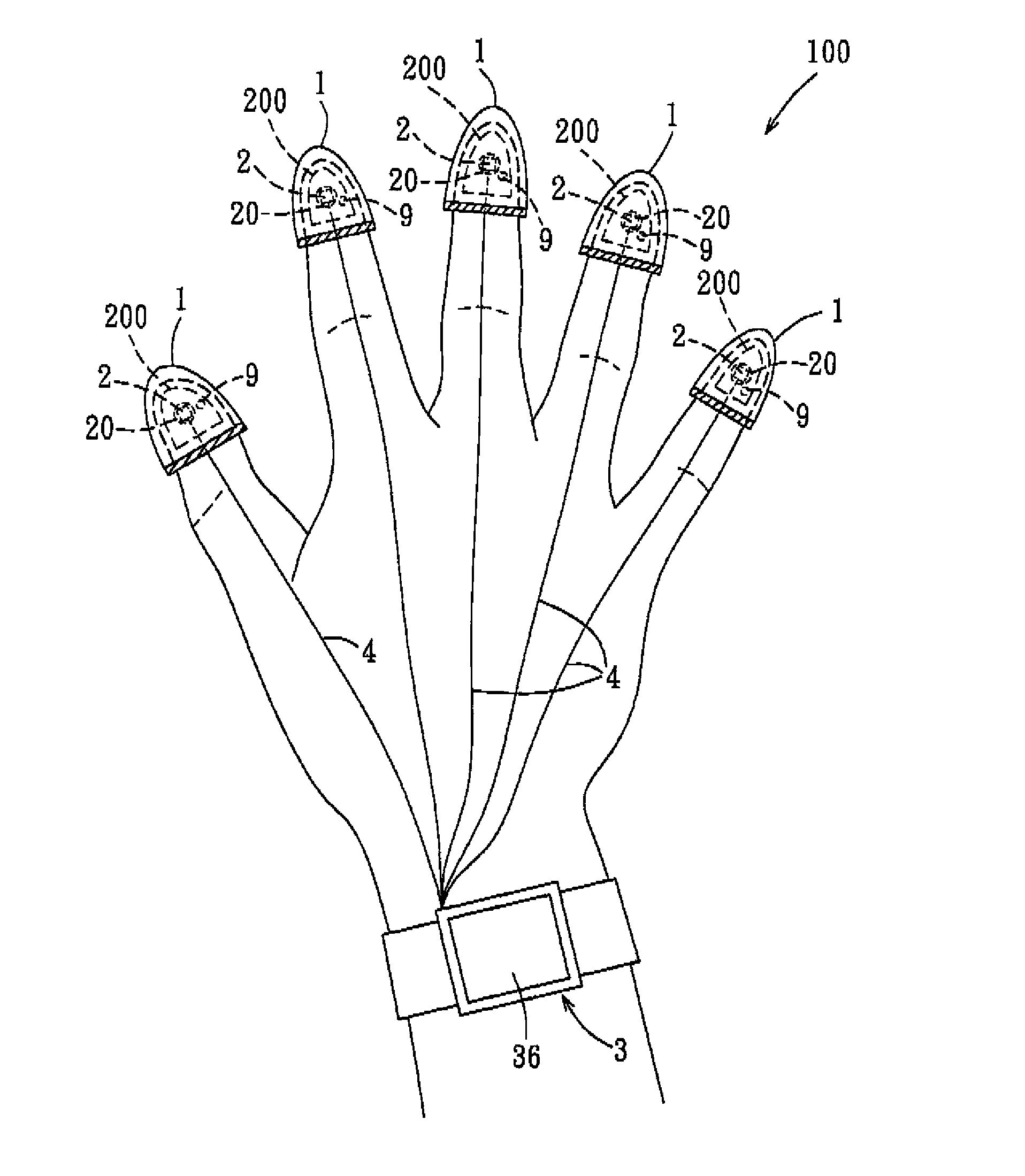

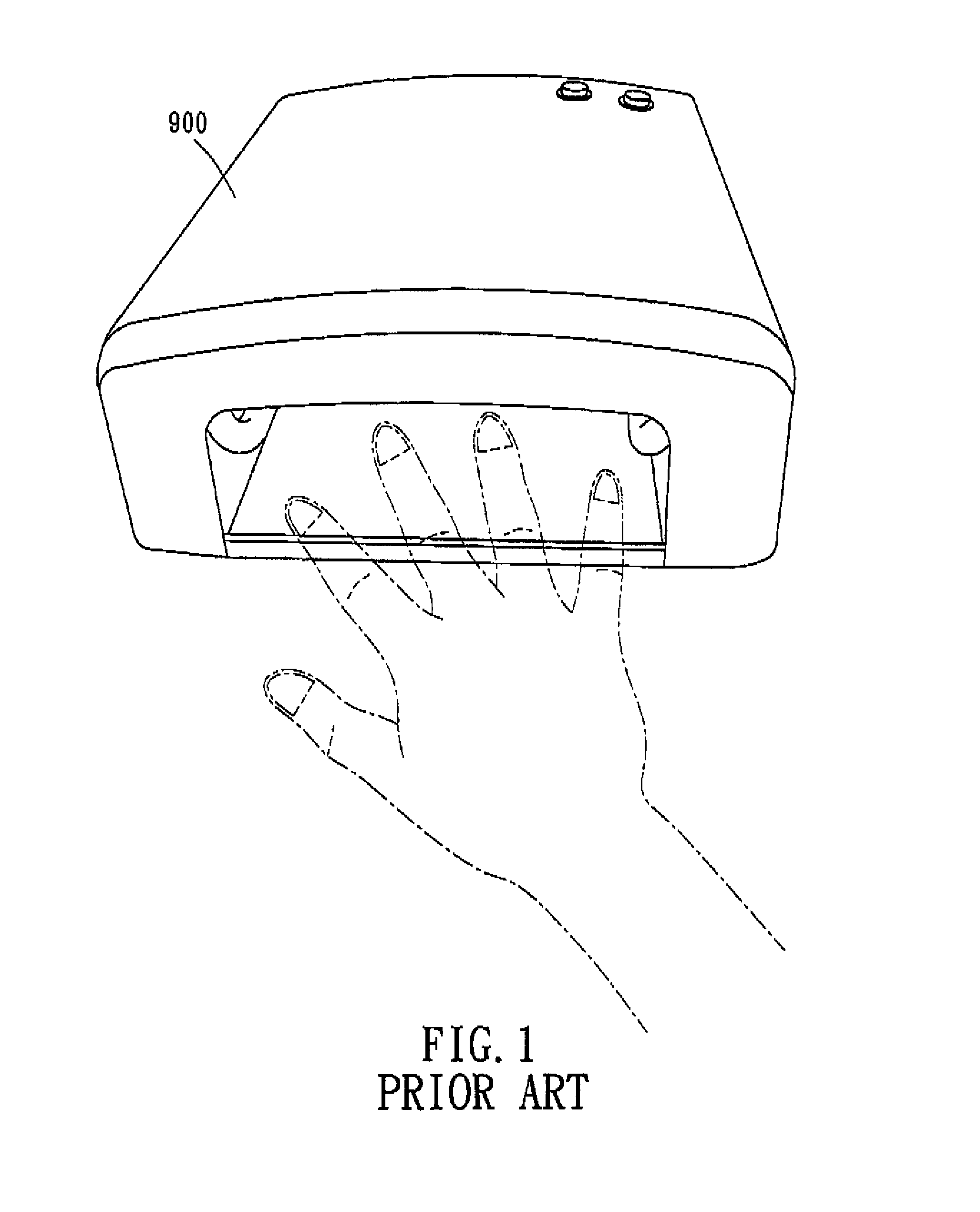

Nail care device

Owner:GENESIS PHOTONICS

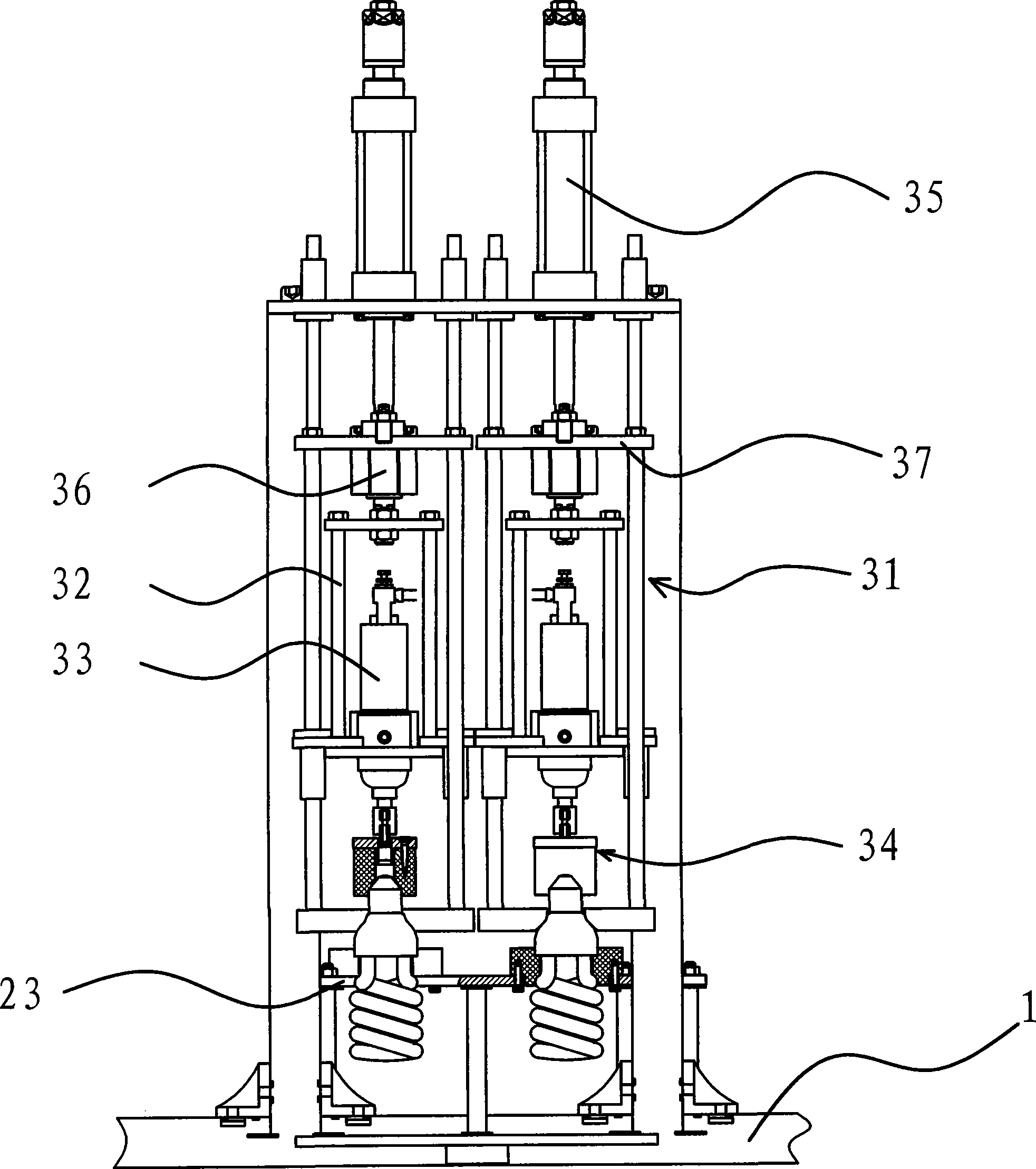

Energy-saving lamp automatic assembly line

InactiveCN101447382AReduce labor costsReduce manufacturing costSequential operation station machinesAutomatic transmissionControl system

The invention provides an energy-saving lamp automatic assembly line which belongs to the technical field of machine. The energy-saving lamp automatic assembly line solves the problem that the existing energy-saving lamp automatic assembly line adopts manual assembly and has low production efficiency. The energy-saving lamp automatic assembly line is provided with an energy-saving lamp assembly transmission system on a frame. The energy-saving lamp assembly transmission system comprises a middle transmission track and branch transmission tracks. Joint parts of one end of the middle transmission track with two branch transmission tracks are provided with distributing mechanisms which can distribute energy-saving lamps at the middle transmission track to two branch transmission tracks. Each branch transmission track is respectively provided with an automatic rotating energy-saving lamp cap device, an energy-saving lamp automatic filament-cutting device, an energy-saving lamp automatic tin soldering device, an energy-saving lamp automatic detecting and controlling system and an energy-saving lamp automatic nailing device. The energy-saving lamp automatic assembly line is equipped with two sets of assembly devices and realizes the advantages of automatic transmission and assembly, etc.

Owner:ZHEJIANG SHENDU OPTOELECTRONICS TECH

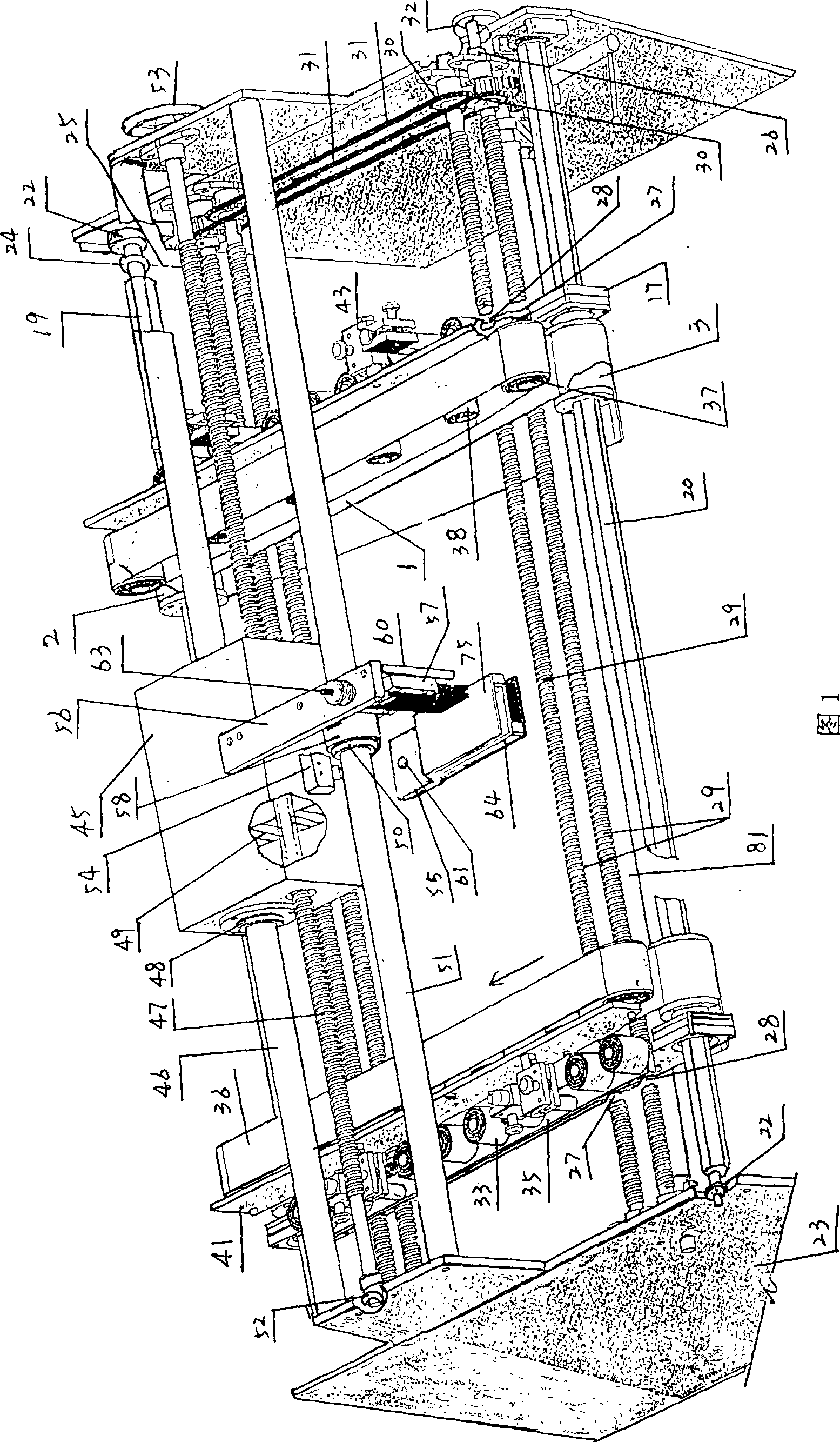

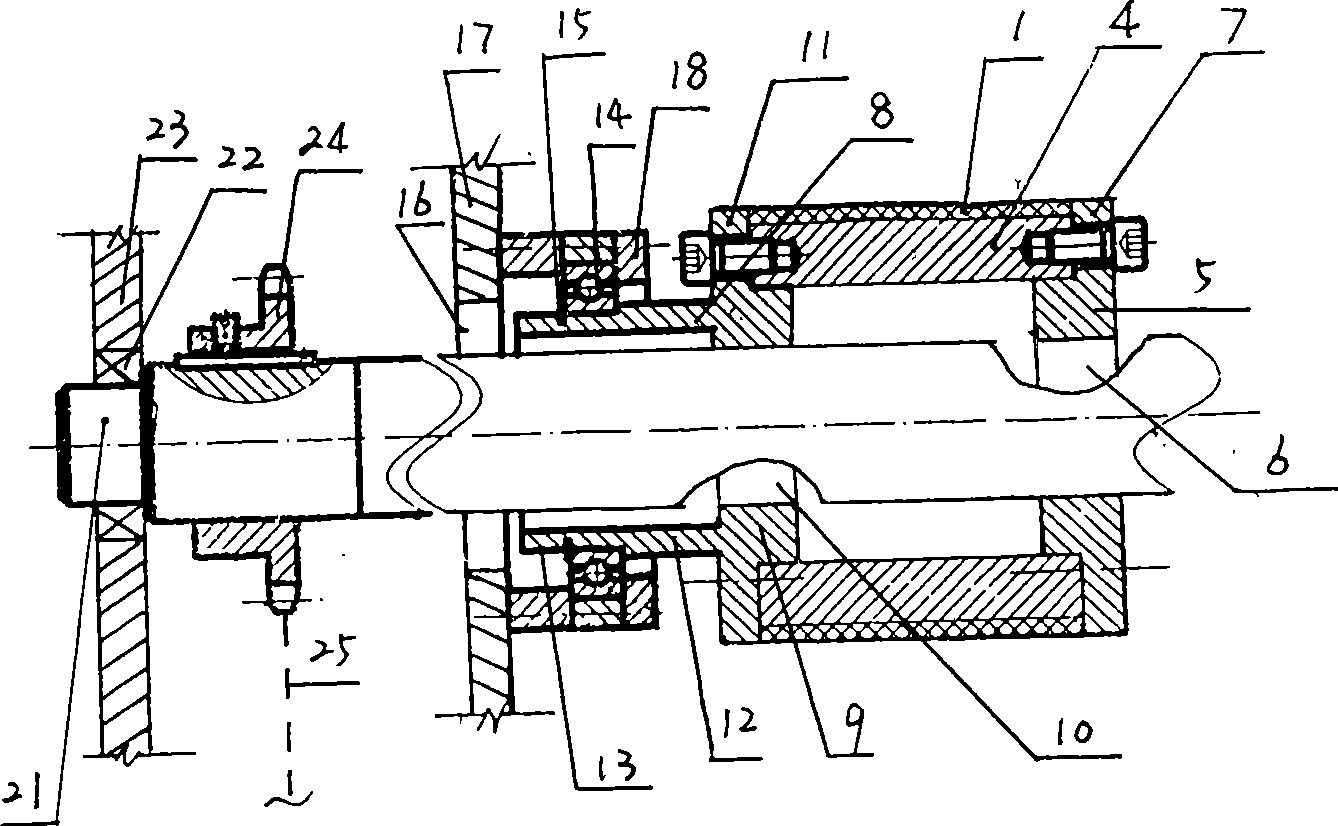

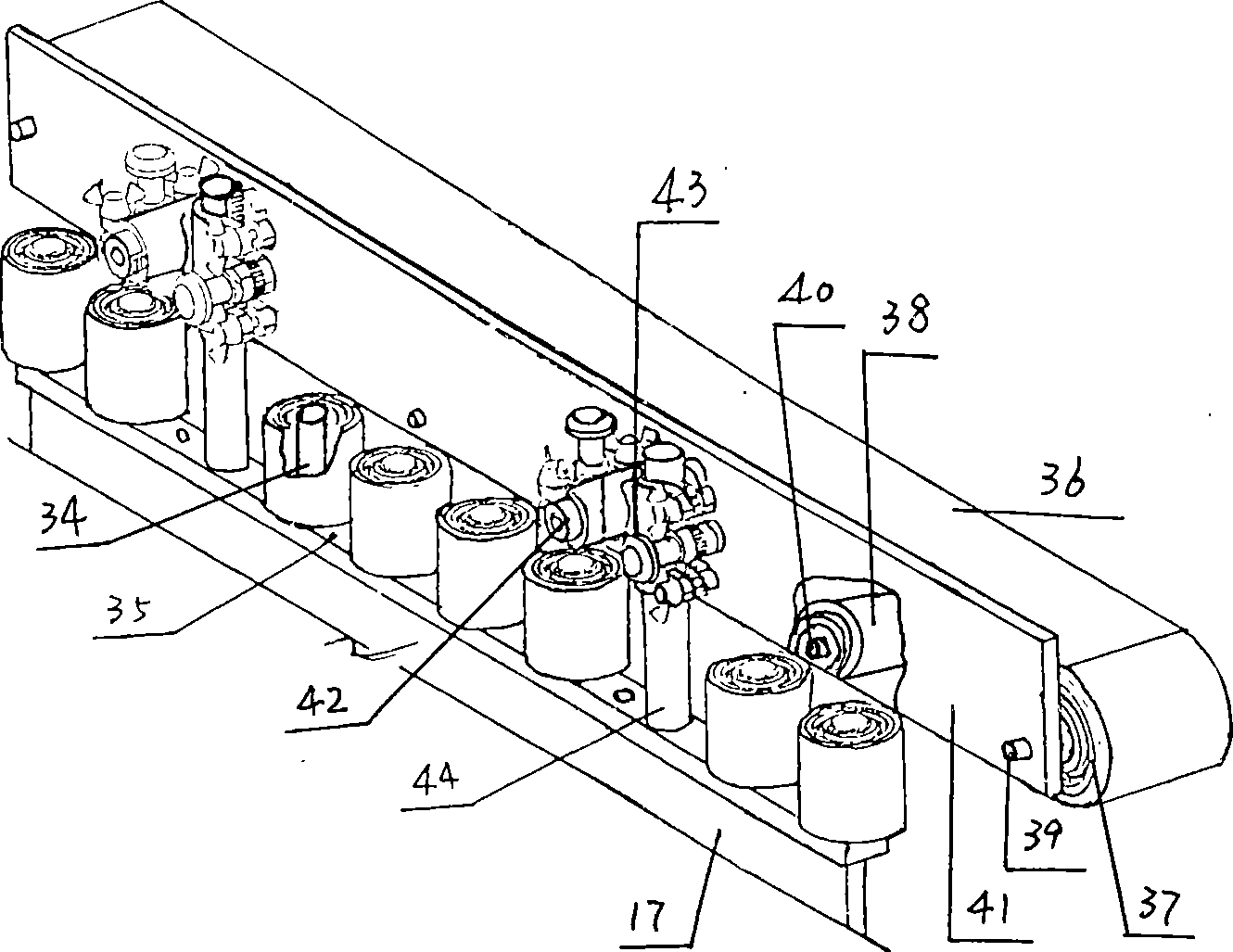

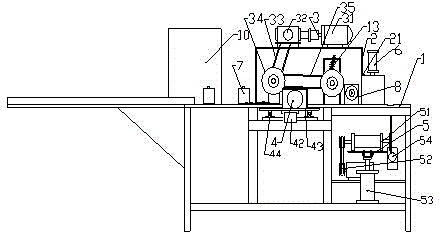

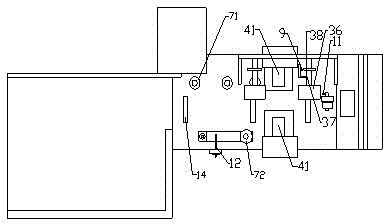

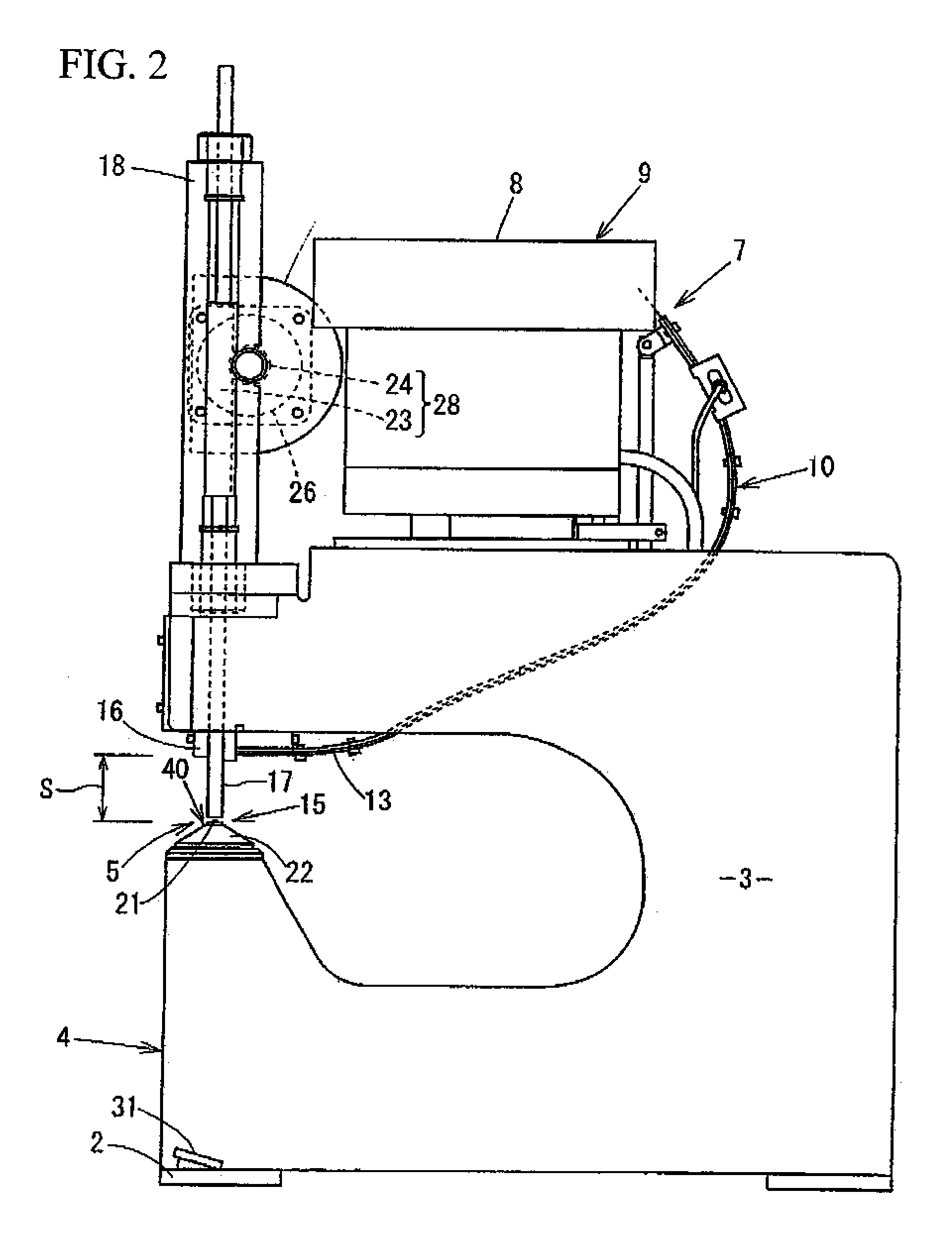

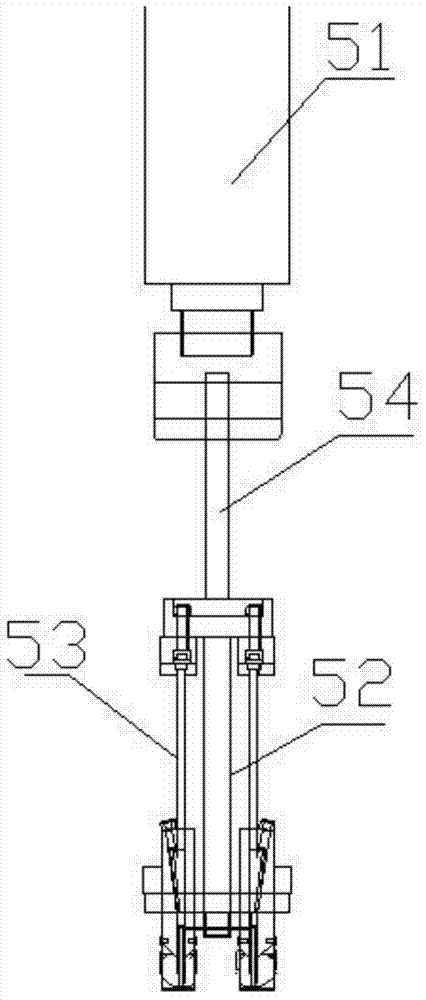

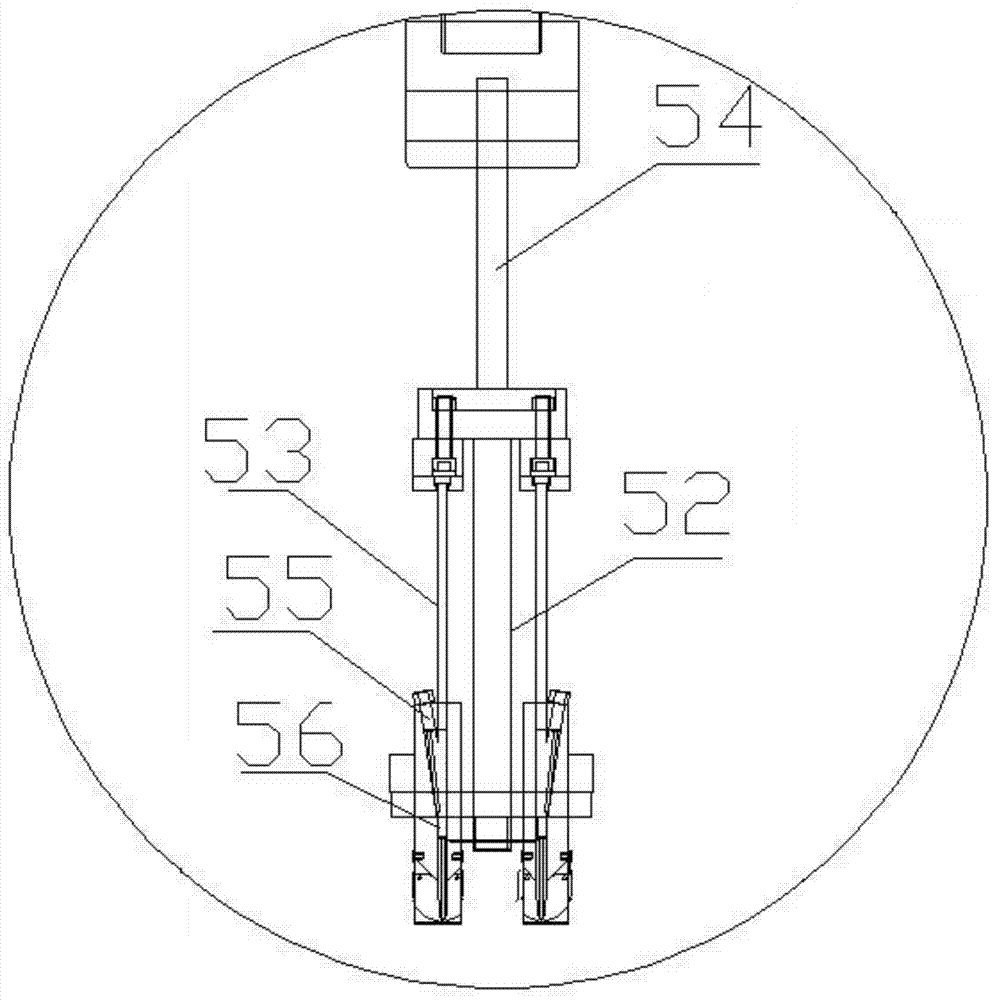

Nailing machine of corrugated case

InactiveCN101456265AQuality improvementAdjustable pressure partBox making operationsPaper-makingAxial displacementEngineering

The invention carton stapler for corrugated cases and belongs to the field of corrugated case manufacturing equipment. The carton stapler adopts a paper conveying mechanism which uses a hexagonal steel type transmission shaft to drive two small belts (1). A driving roller (2) and a driven roller (3) one each side of each small belt (1) are connected together through a small wall plate (17) on the same side, and each small belt (1) is also provided with a complete manual adjustment mechanism which adjusts axial displacement by using a threaded rod threaded rod shaft as well as an array roll type transverse positioning mechanism and a paper pressing belt (36) type paper pressing mechanism with a small roll (38), wherein the manual adjustment mechanism, the array roll type transverse positioning mechanism and the paper pressing belt (36) type paper pressing mechanism are all connected with the small wall plate (17) the transverse position of which can be adjusted. The carton stapler also adopts an automatic head nailing device which has a light controlled automatic system and is matched with the continuous paper conveying device. The transverse position of the automatic head nailing device is adjustable, the vertical position of a nail head holder (57) and the size of the paper pressure are adjustable, and a nail tongue (64) of a belt base plate (55) is changeable. The rollers can be changed easily and the transverse positions of the rollers can be adjusted conveniently, the friction is small, and the paper pressure is adjustable in terms of size. The carton stapler can not damage the surface of corrugaled board and the patterns on the surface of the corrugaled board, achieves excellent nailing quality, high efficiency and low energy consumption, and is convenient in adjustment and maintenance and is suitable to nail corrugaled boards with different thicknesses.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

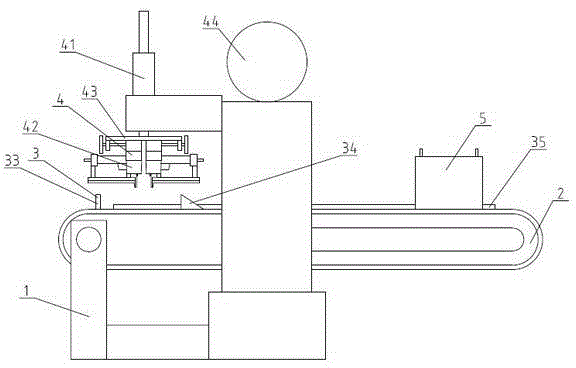

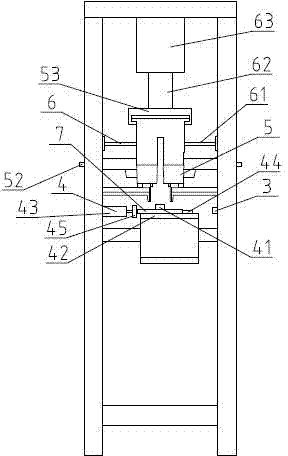

Automatic nailing device

ActiveCN103600385ANailing to achieveIncrease productivityStapling toolsNailing toolsDrive shaftEngineering

An automatic nailing device comprises a machine body, a conveying device, a positioning device and a nailing device. The conveying device comprises a transmission shaft and a conveying chain, the conveying chain is arranged on the transmission shaft, and the transmission shaft is arranged on the machine body. The positioning device comprises a supporting plate, a first cylinder, a fixed clamp, a movable clamp and a backup plate, wherein the supporting plate is vertical to the conveying direction of the conveying chain and is arranged on the machine body, the first cylinder is arranged above the supporting plate, the fixed clamp is arranged on the machine body on one side of the conveying device, the movable clamp and the fixed clamp are correspondingly arranged on the machine body on the other side of the conveying device, the movable clamp can move in the conveying direction of the conveying chain, and the backup plate is parallel with the conveying chain and is arranged on the machine body. The nailing device is arranged on the side where the fixed clamp is located and above the conveying device. According to the automatic nailing device, a floor can be automatically nailed, manual operations are replaced, production efficiency is greatly improved, and the automatic nailing device belongs to the technical field of floor production.

Owner:GUANGZHOU HOMEBON WOOD MFG +1

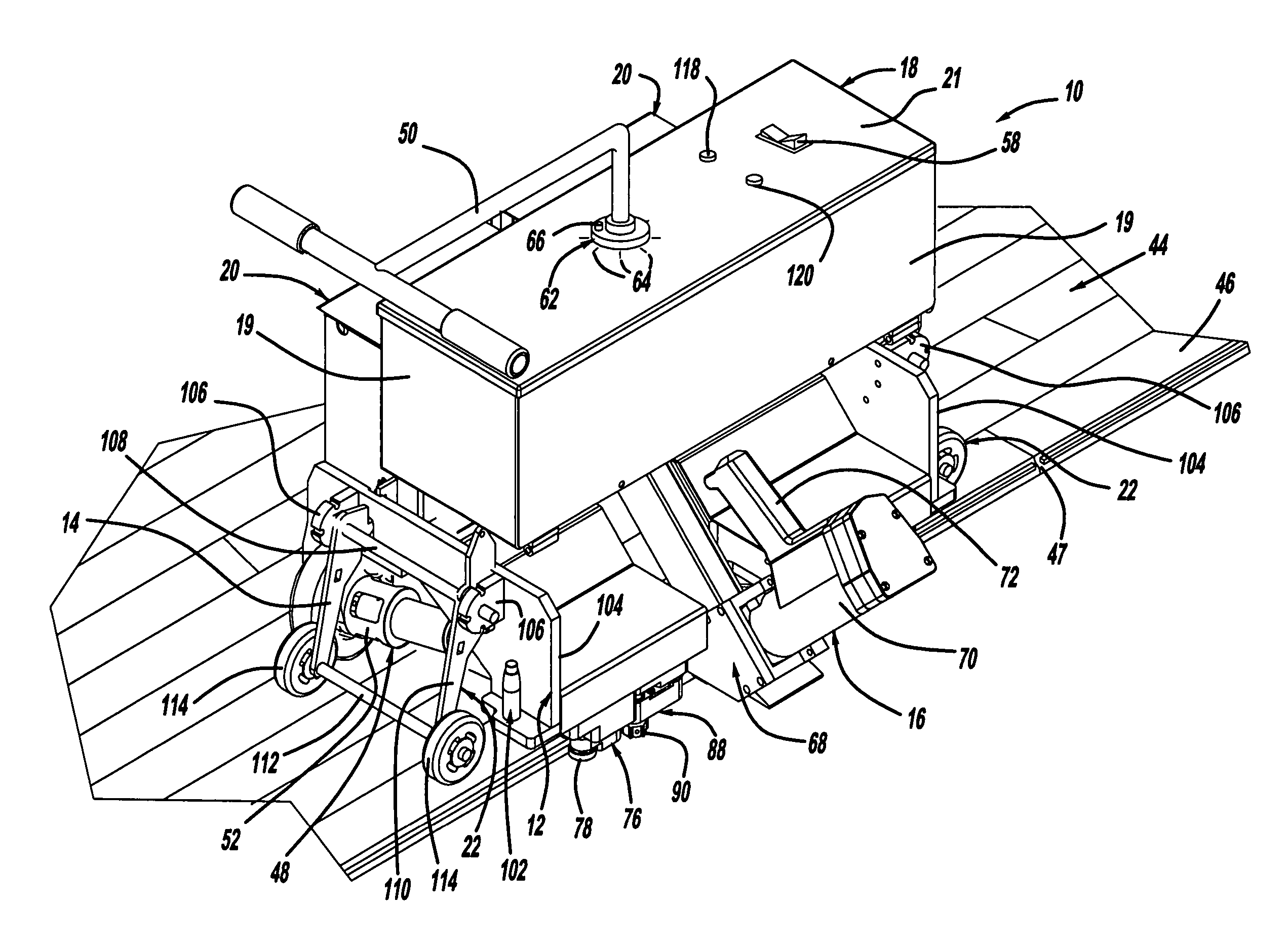

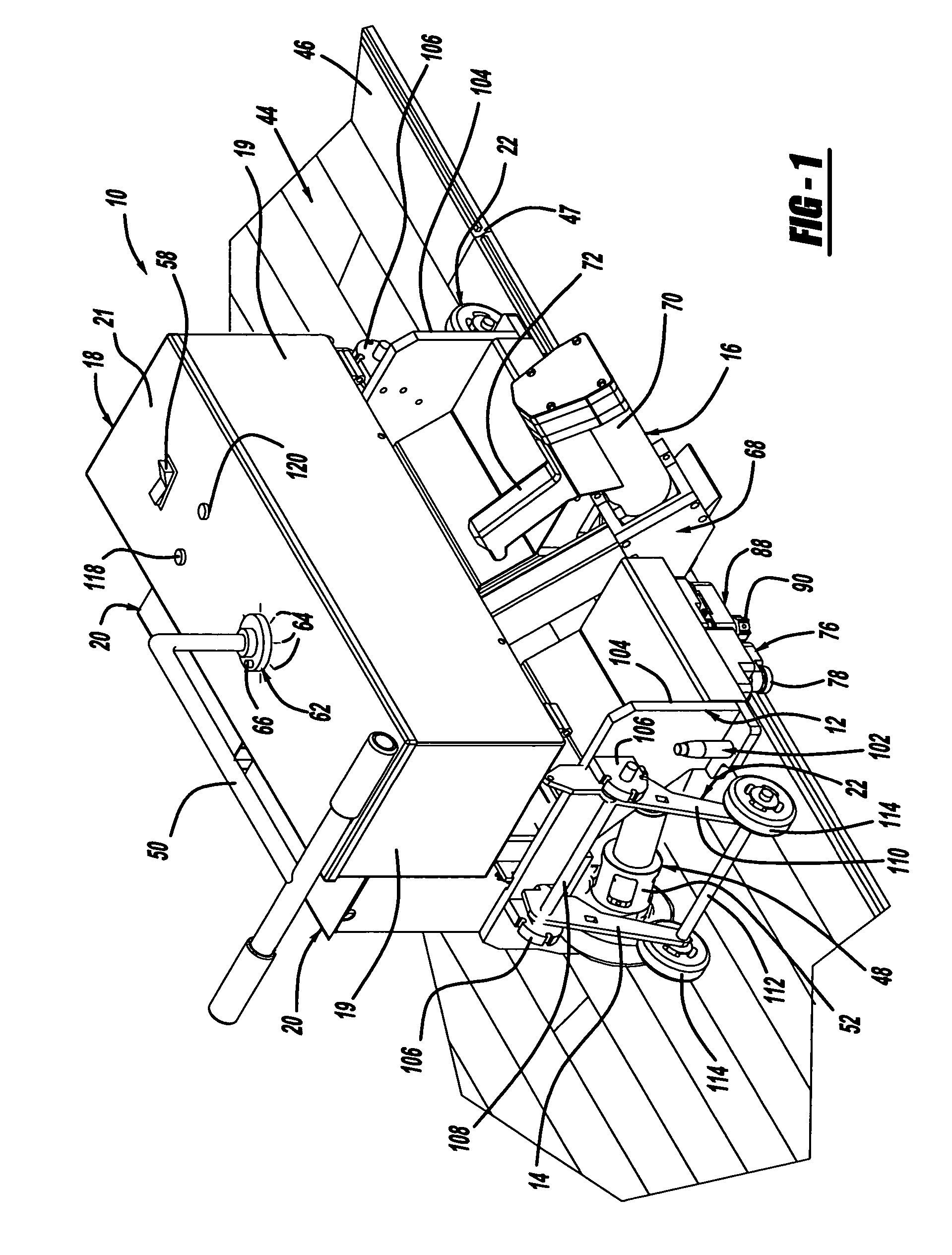

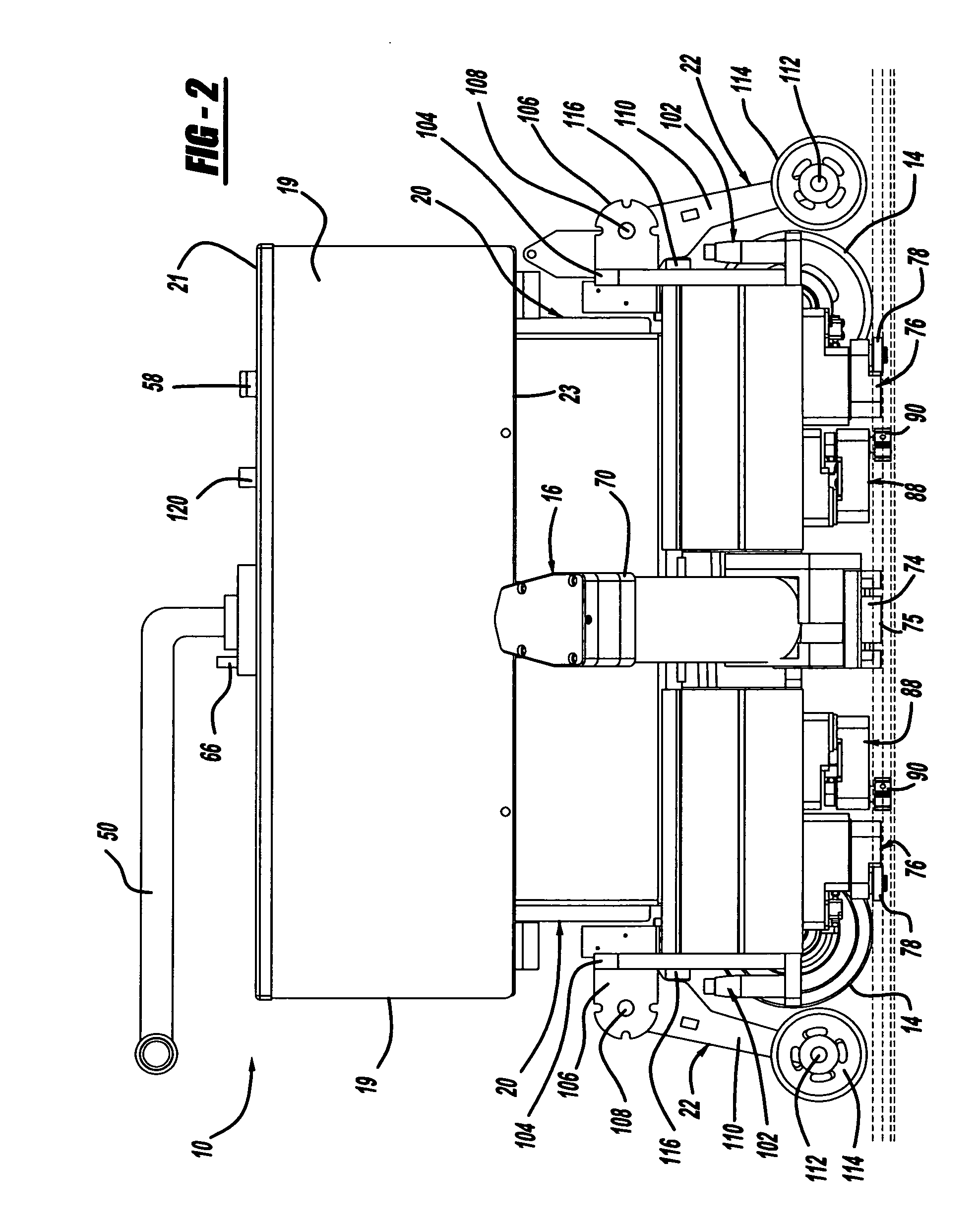

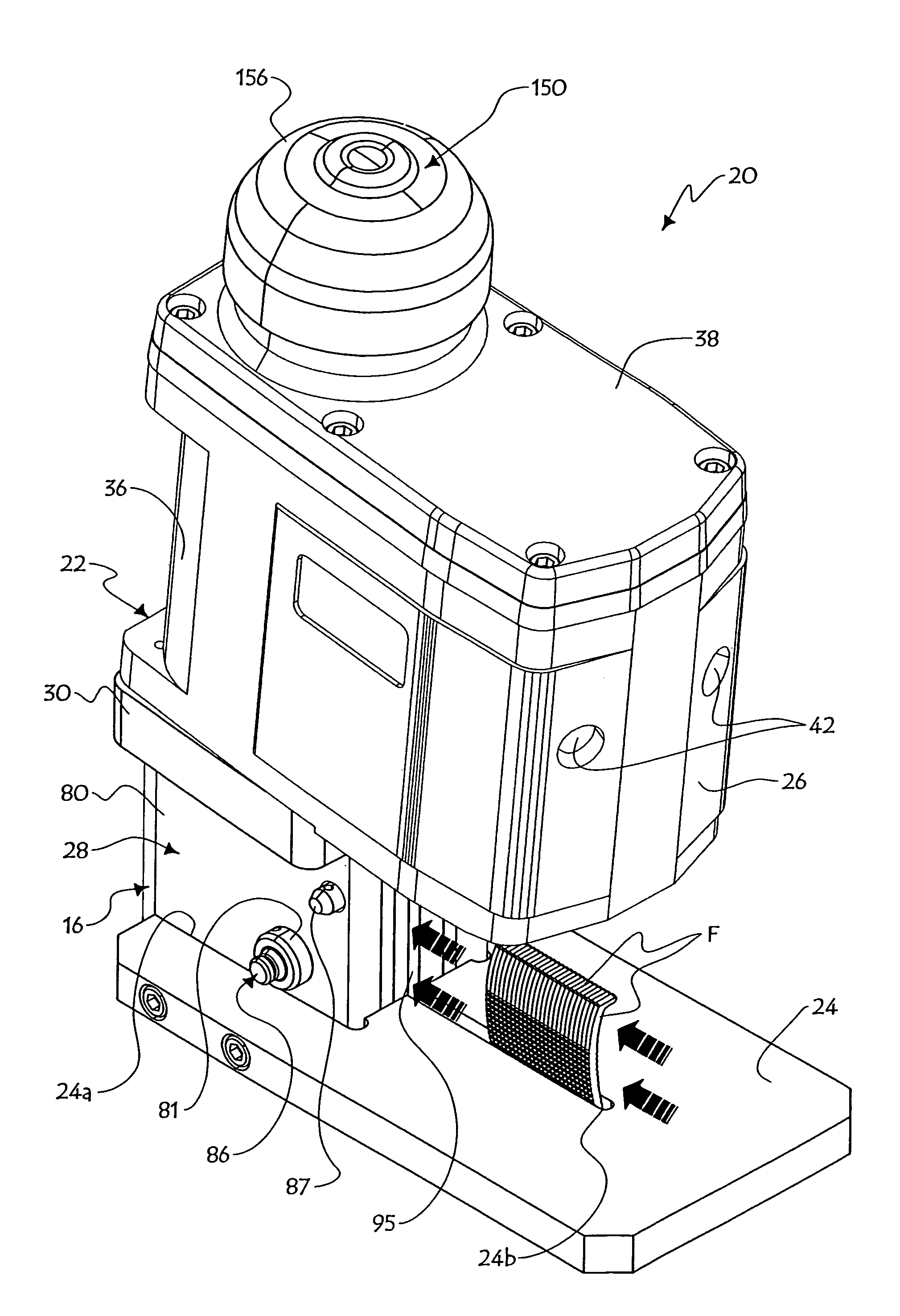

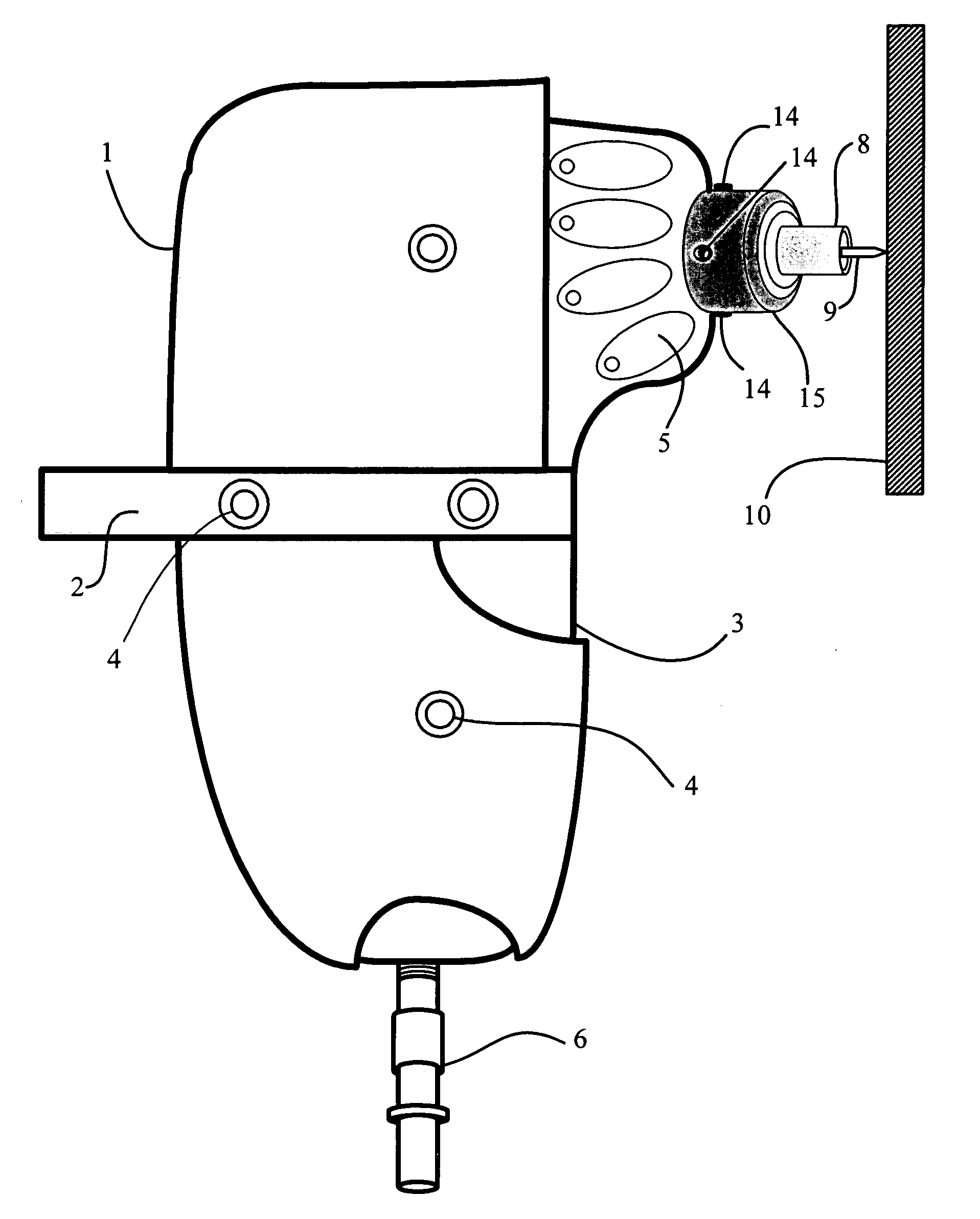

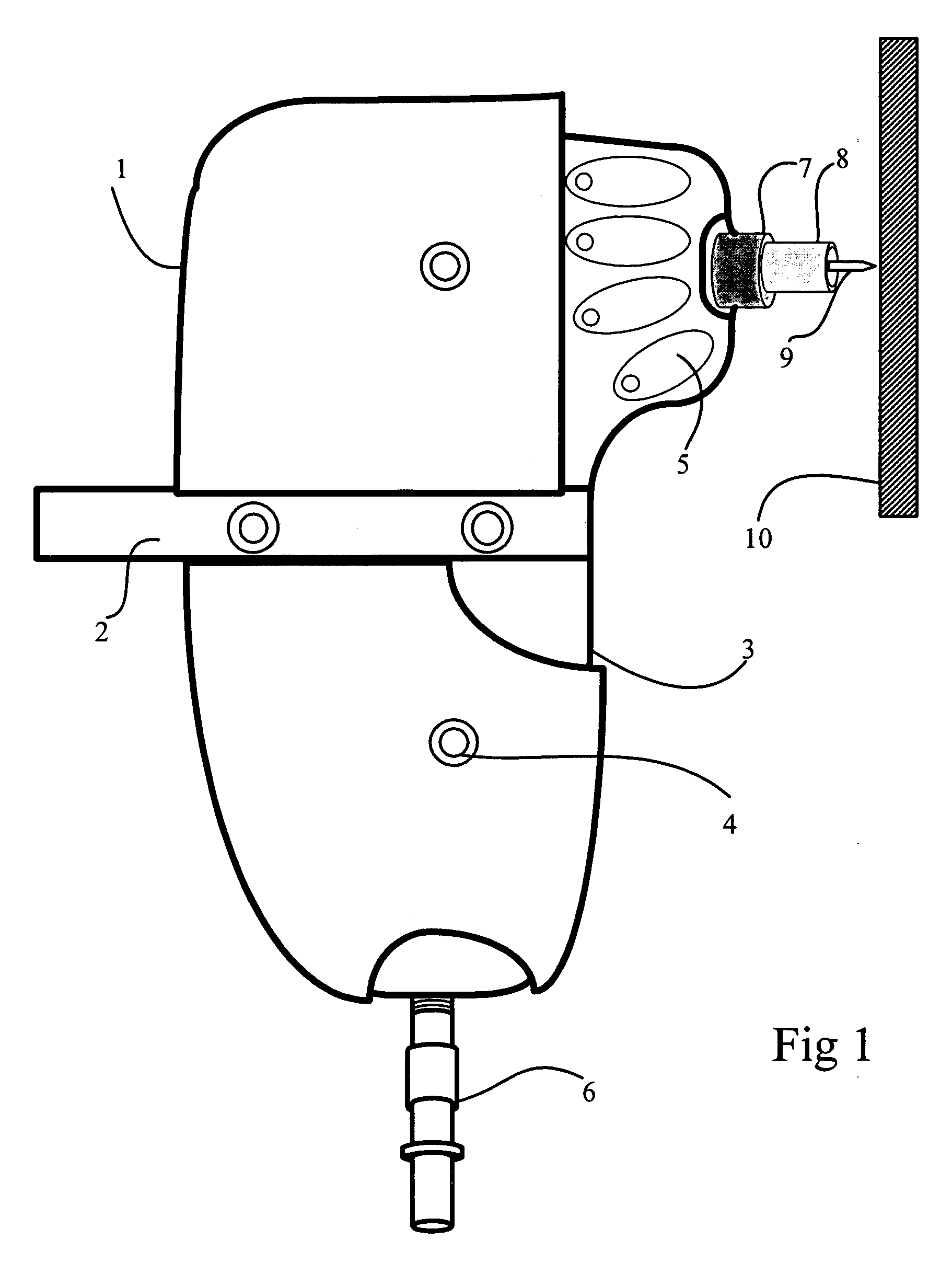

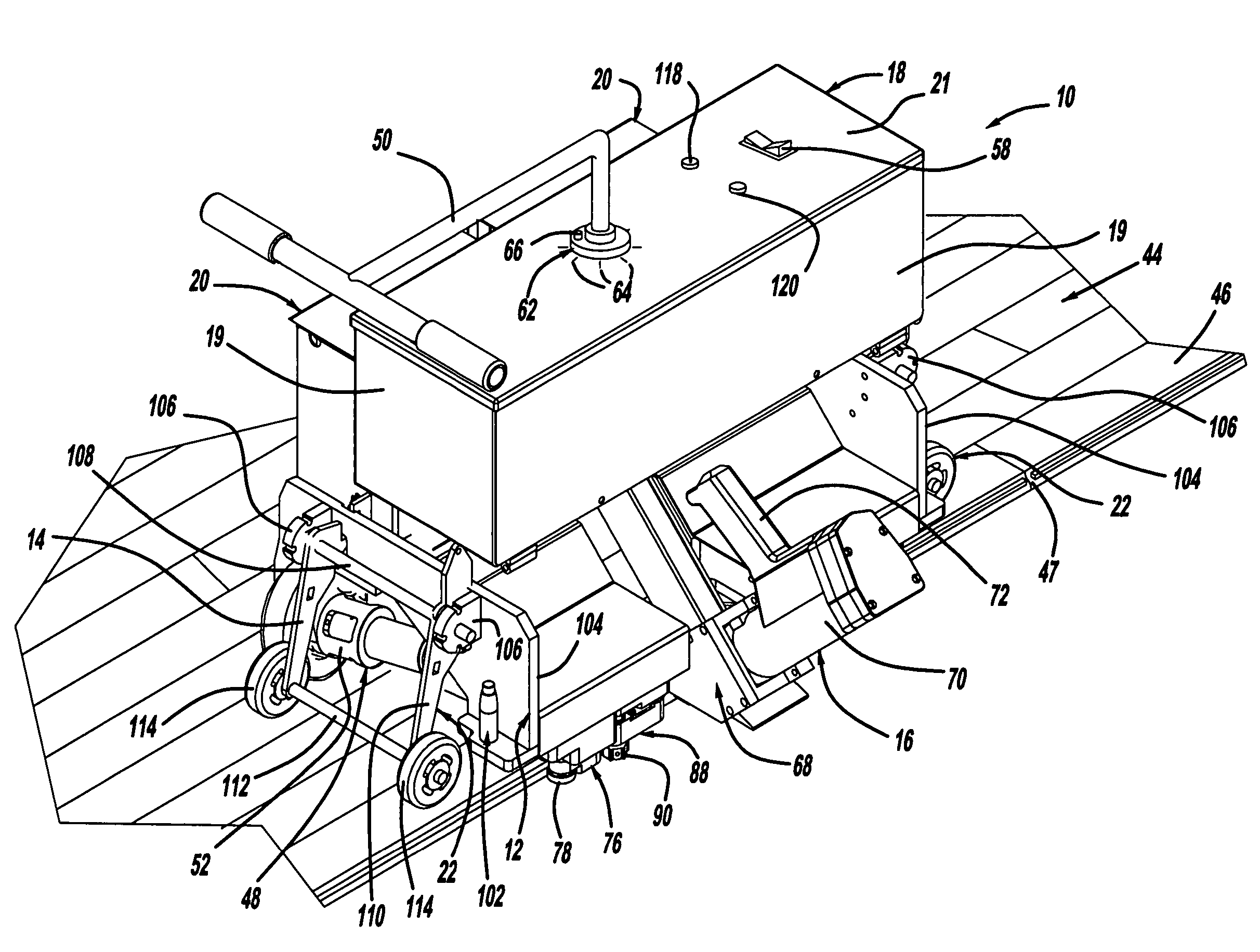

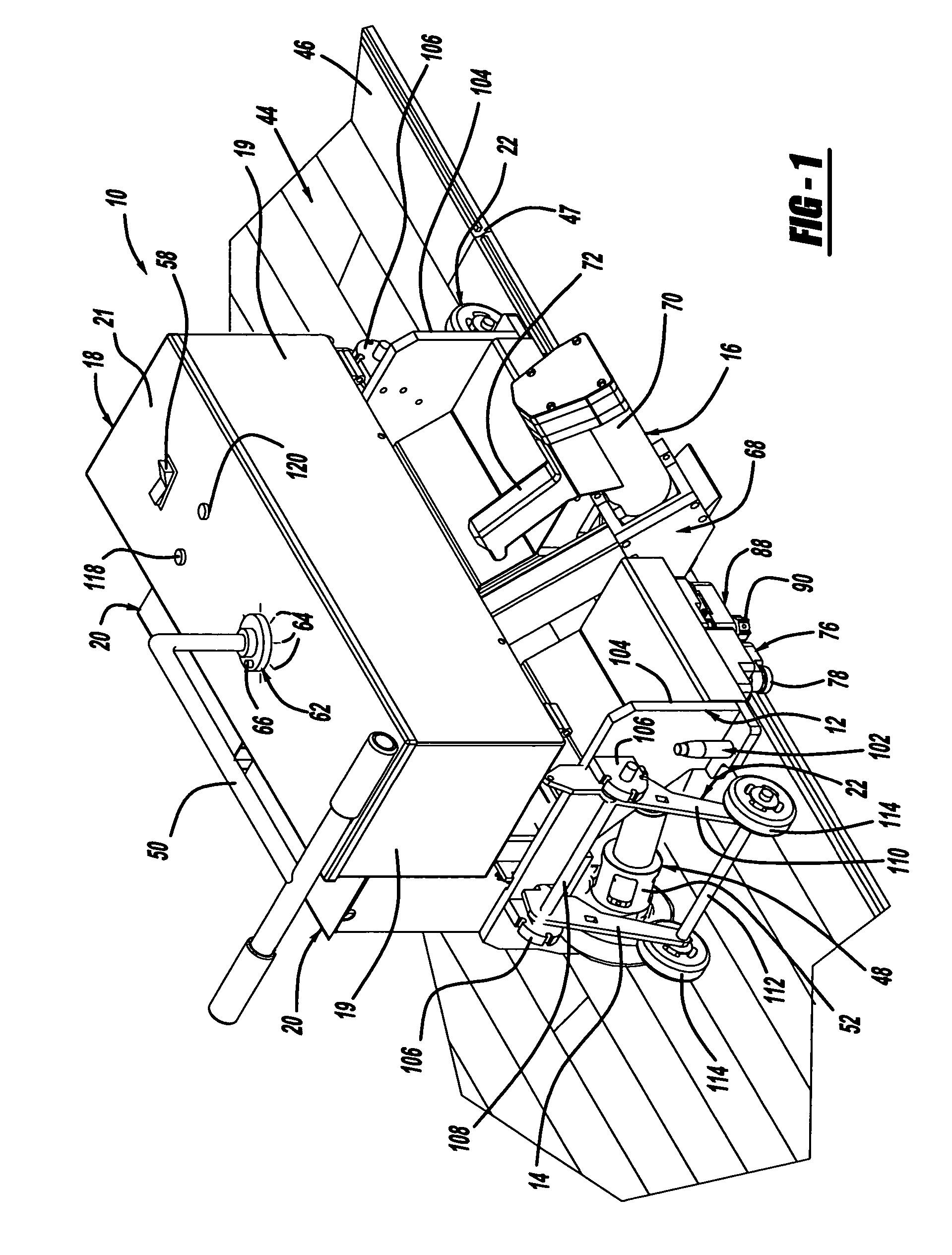

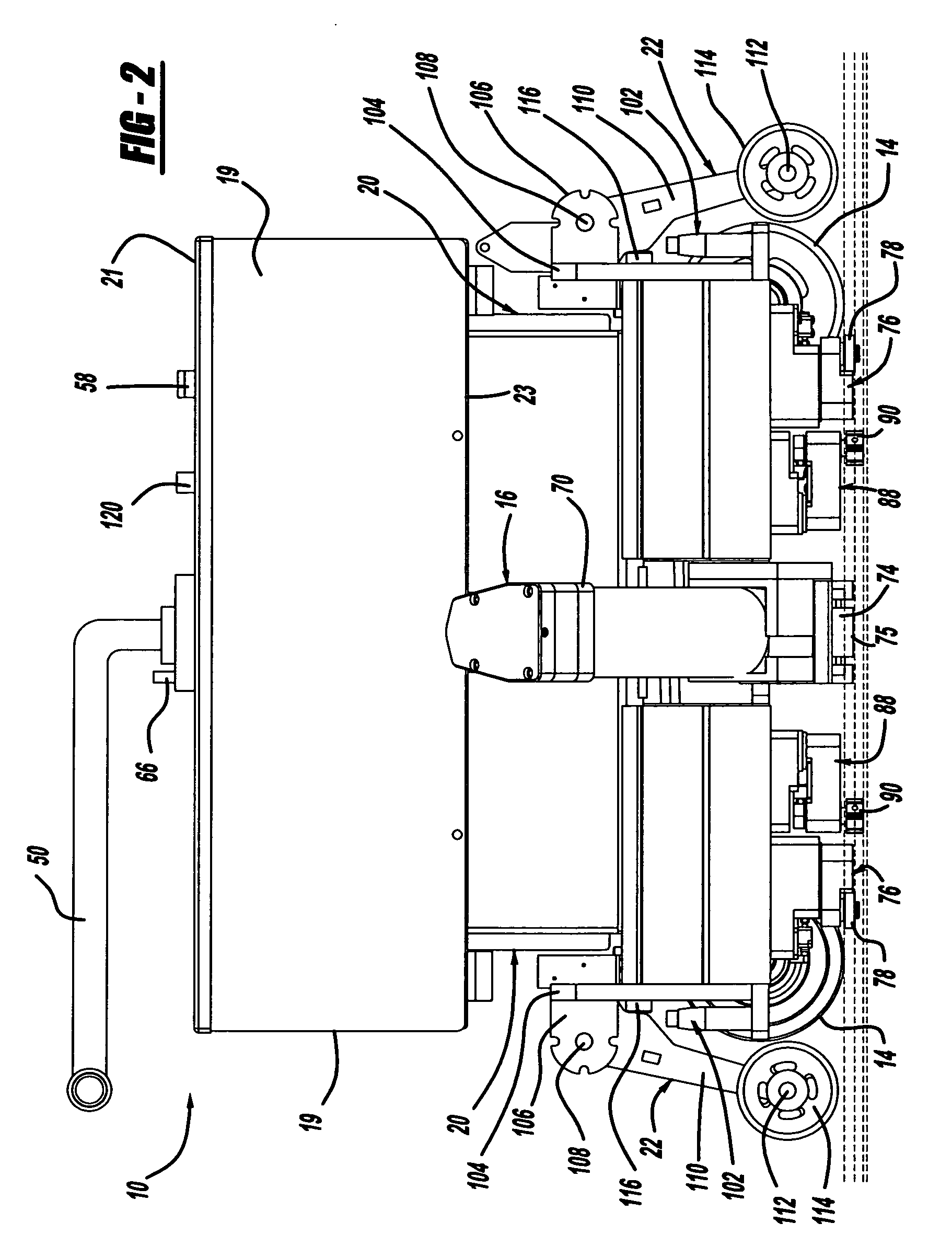

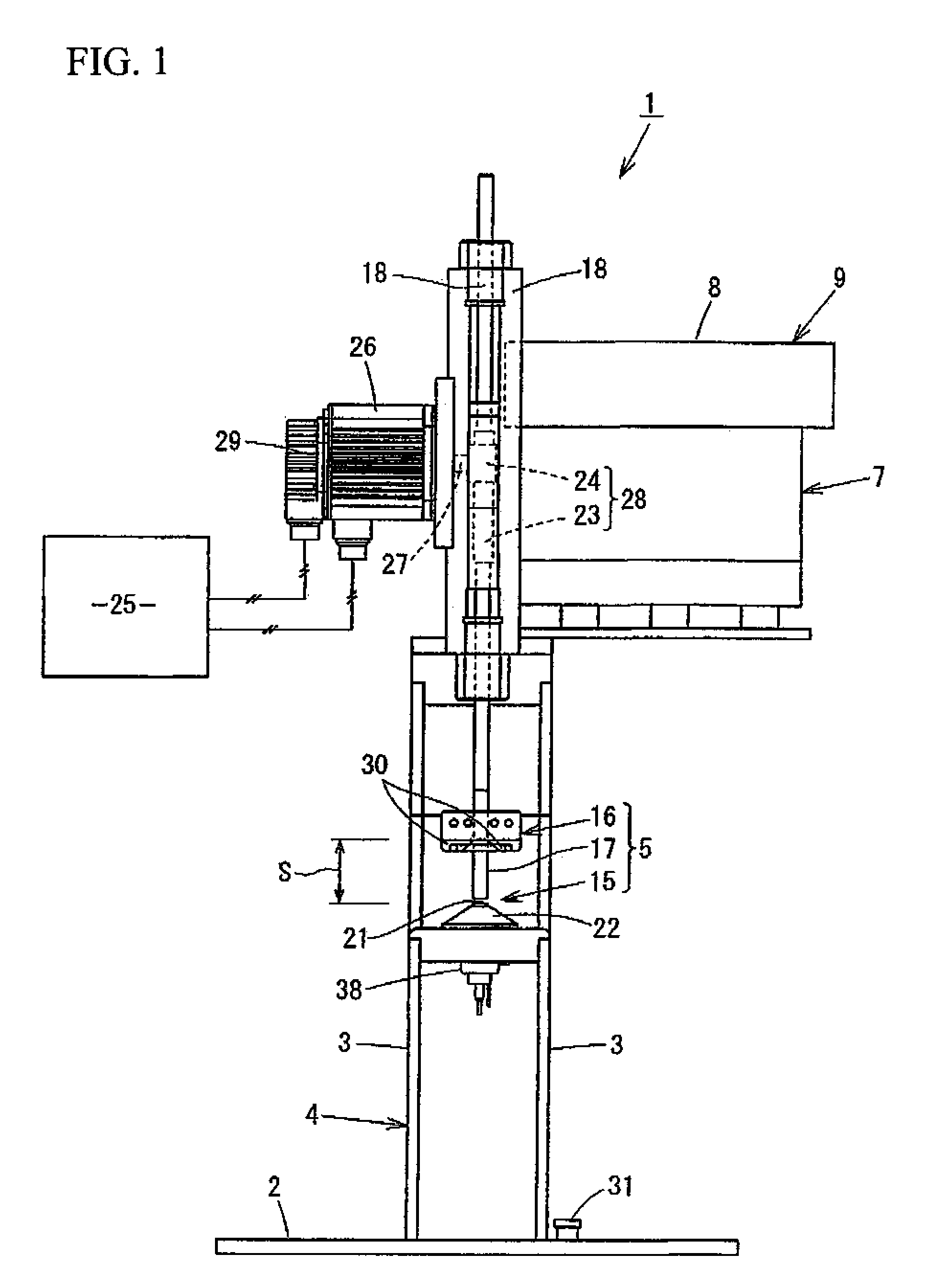

Nailing device

A nailer device having a carriage assembly, a pair of pivotal drive wheels, a nailer assembly and at least one end wheel. The pair of pivotal drive wheels are on the carriage assembly. The at least one end wheel is disposed adjacent an end of the carriage assembly. A drive motor can be associated with at least one of the pair of pivotal drive wheels when the nailer device is operating in an automatic mode. A handle disposed either intermediate of the pivotal drive wheels can be used to move or manually operate the nailer device and move the nailer device to an adjacent row of floorboards to be secured. A pair of adjustable wheels is also provided to adjust the height of the device.

Owner:HAMAR DOUGLAS J

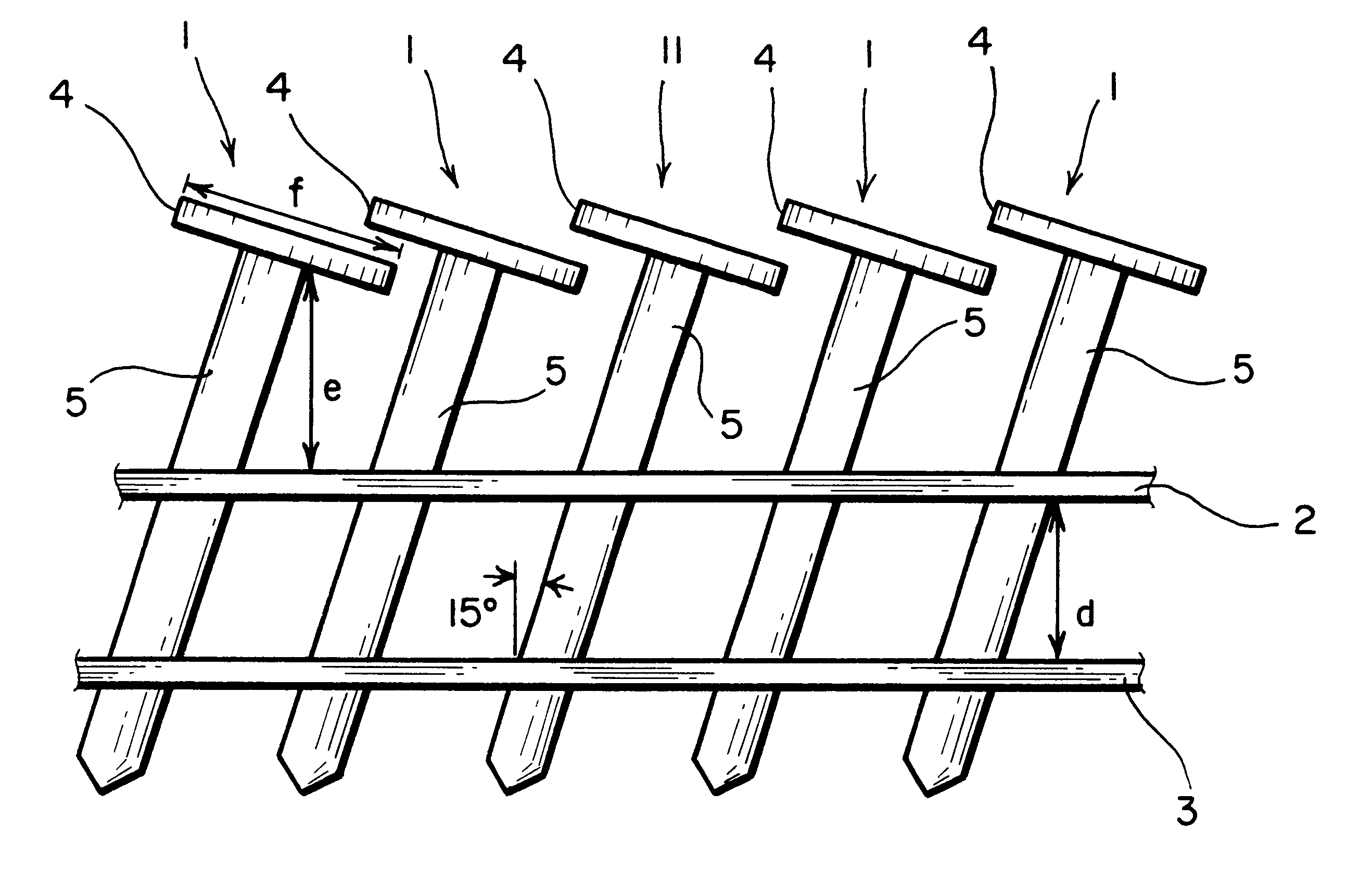

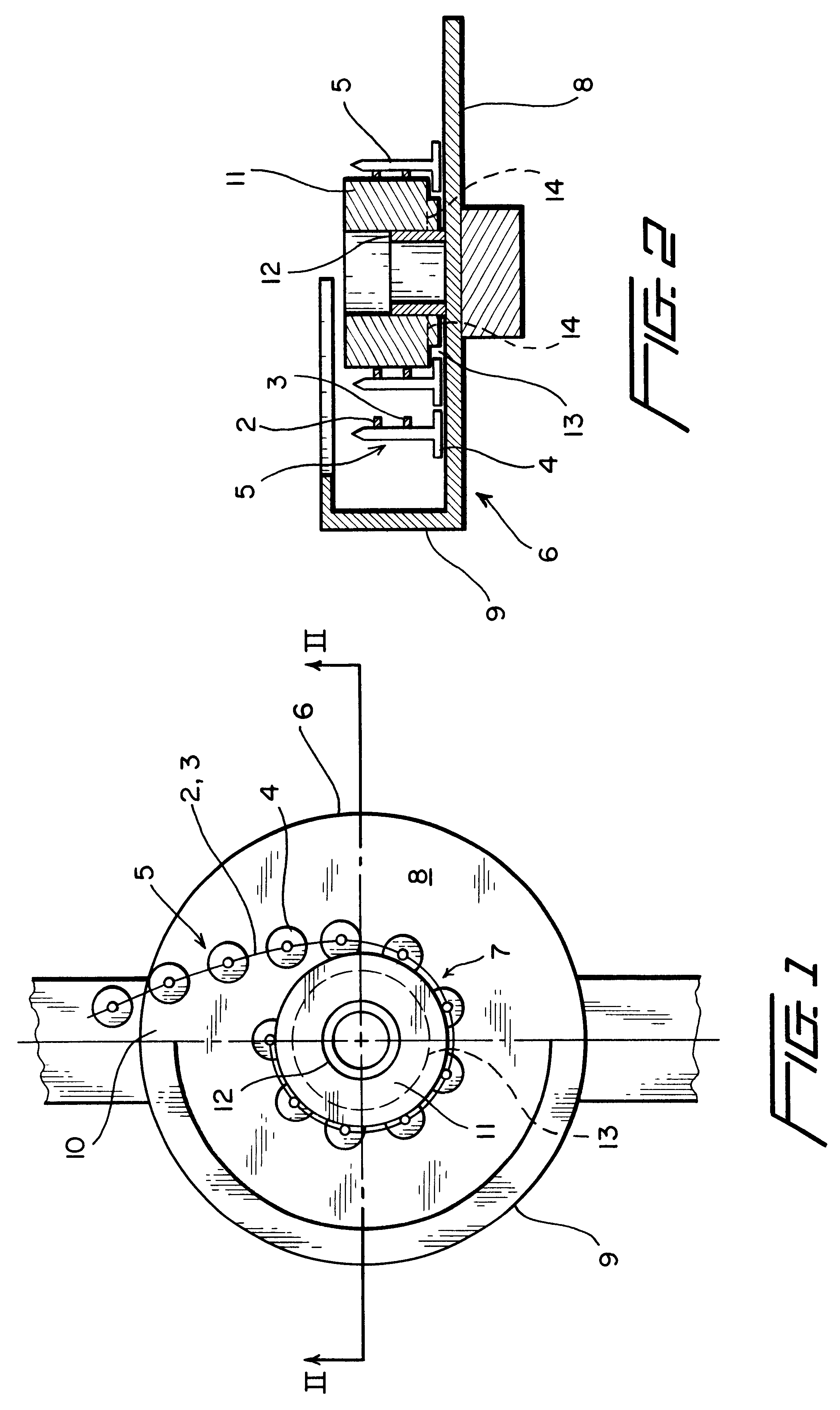

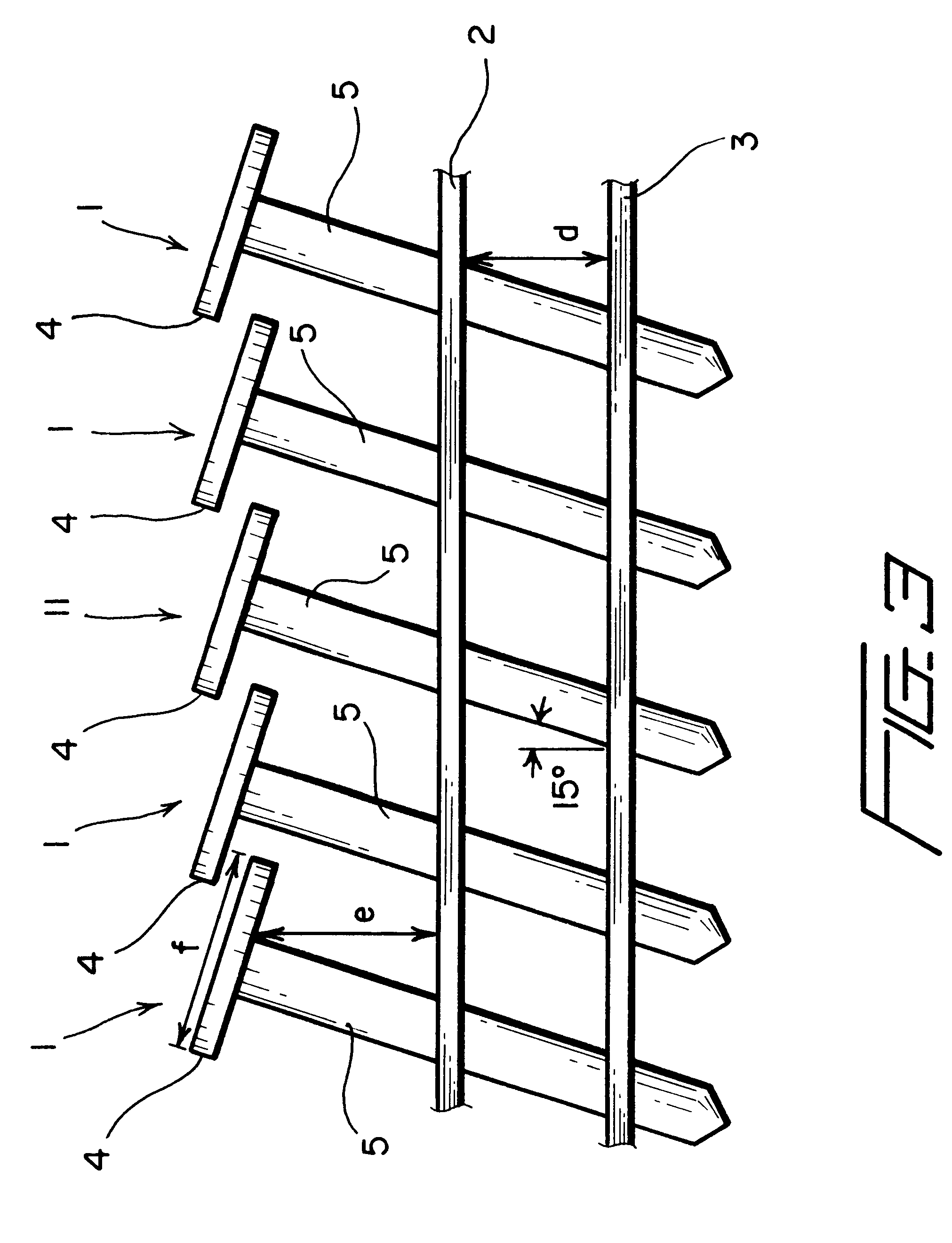

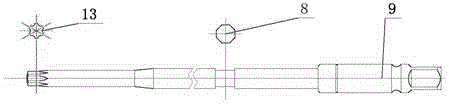

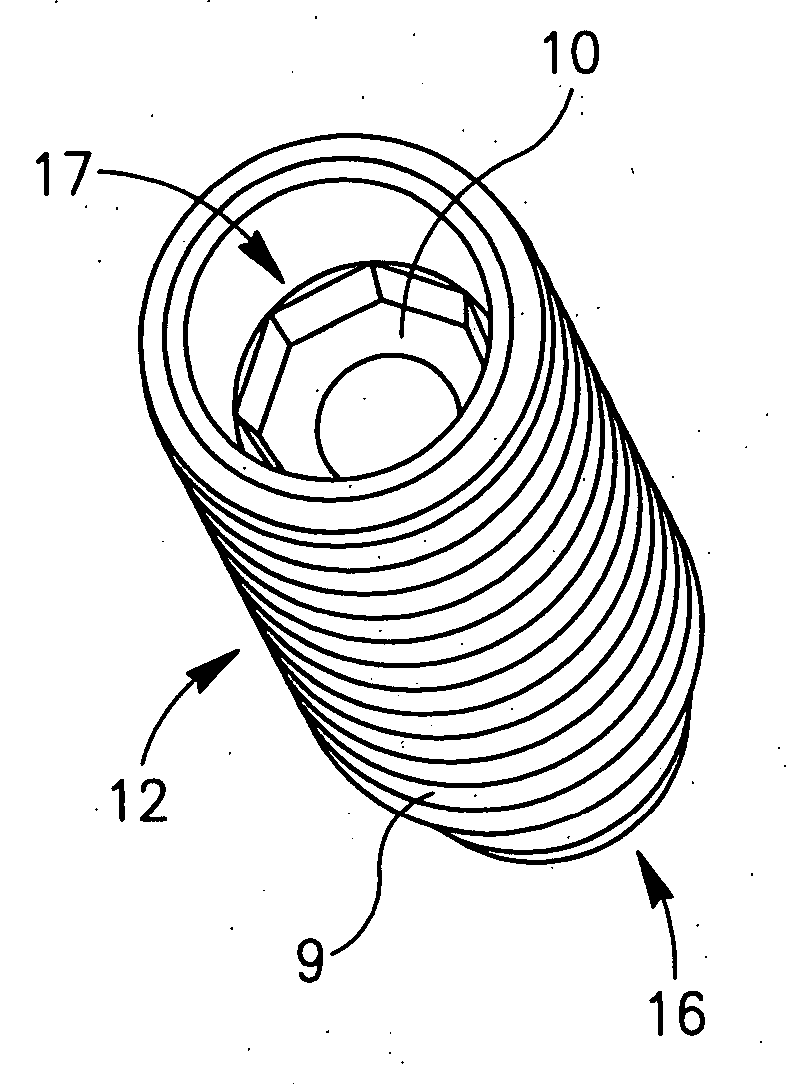

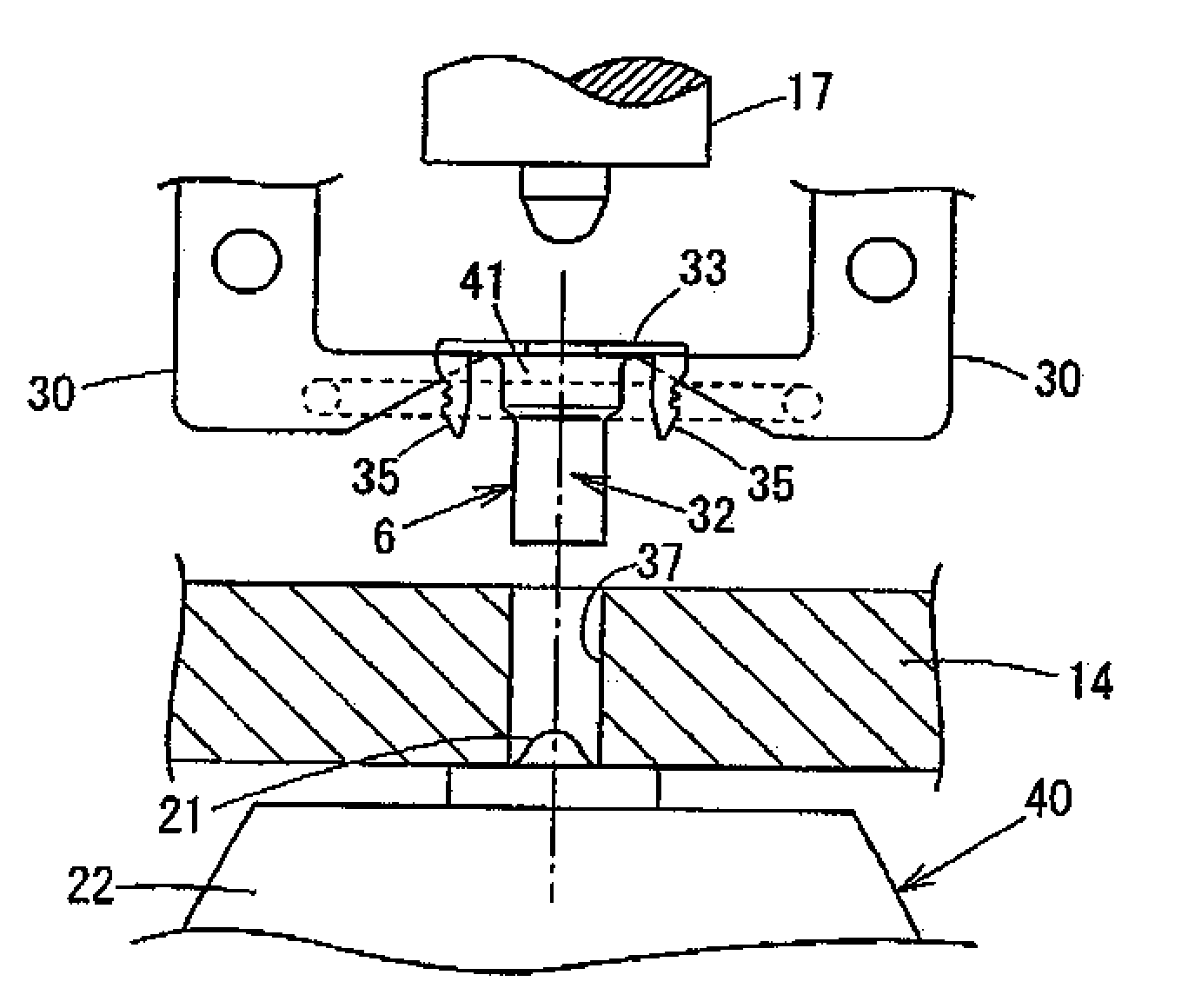

Coil strap with nails for use in a nail hammer

InactiveUS6557703B1Reliable separationTrouble free and fast workStaplesOther accessoriesMiddle lineBiomedical engineering

Coil strapped nails and a nailing device using coil strapped nails are provided. The coil may be provided with steel nails (1) having a length of 14 to 25 mm and a shaft diameter of 2 to 3 mm. The nails are held by wires (2,3) 6.5 to 7.5 mm apart, wherein the wires are preferably quenched and tempered. In the center of the coil a wrapping sleeve may be provided having due clearance for the nail heads.

Owner:LEITNER HELMUT

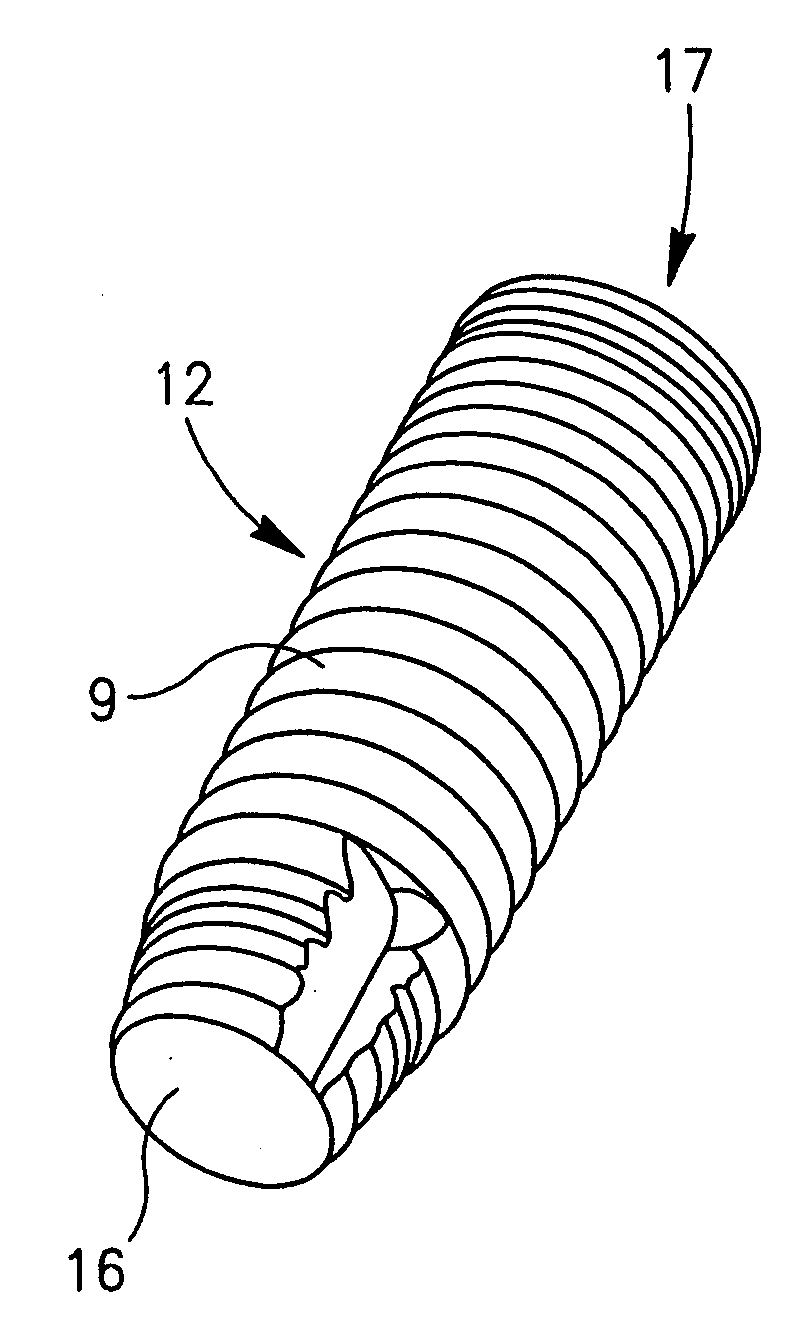

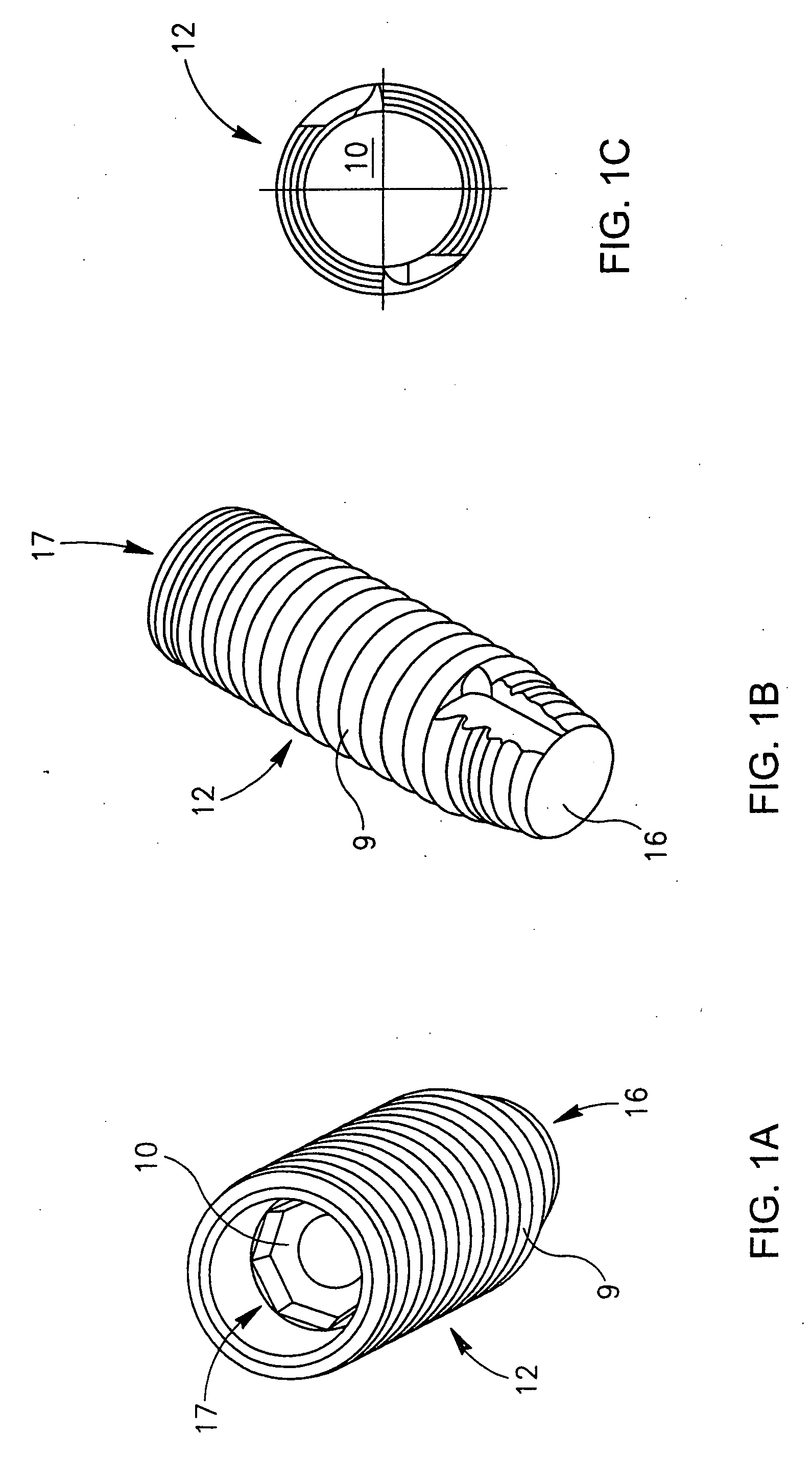

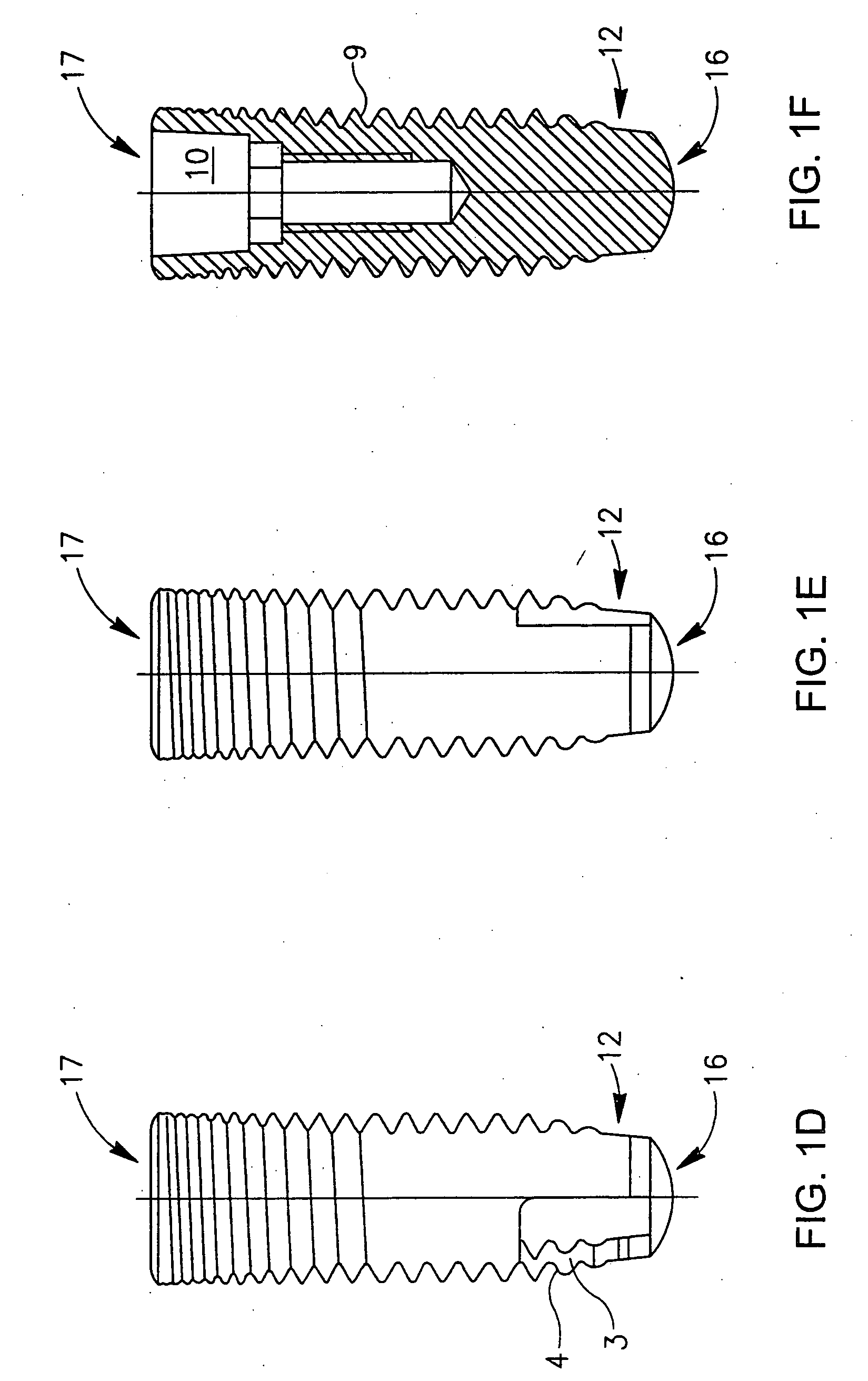

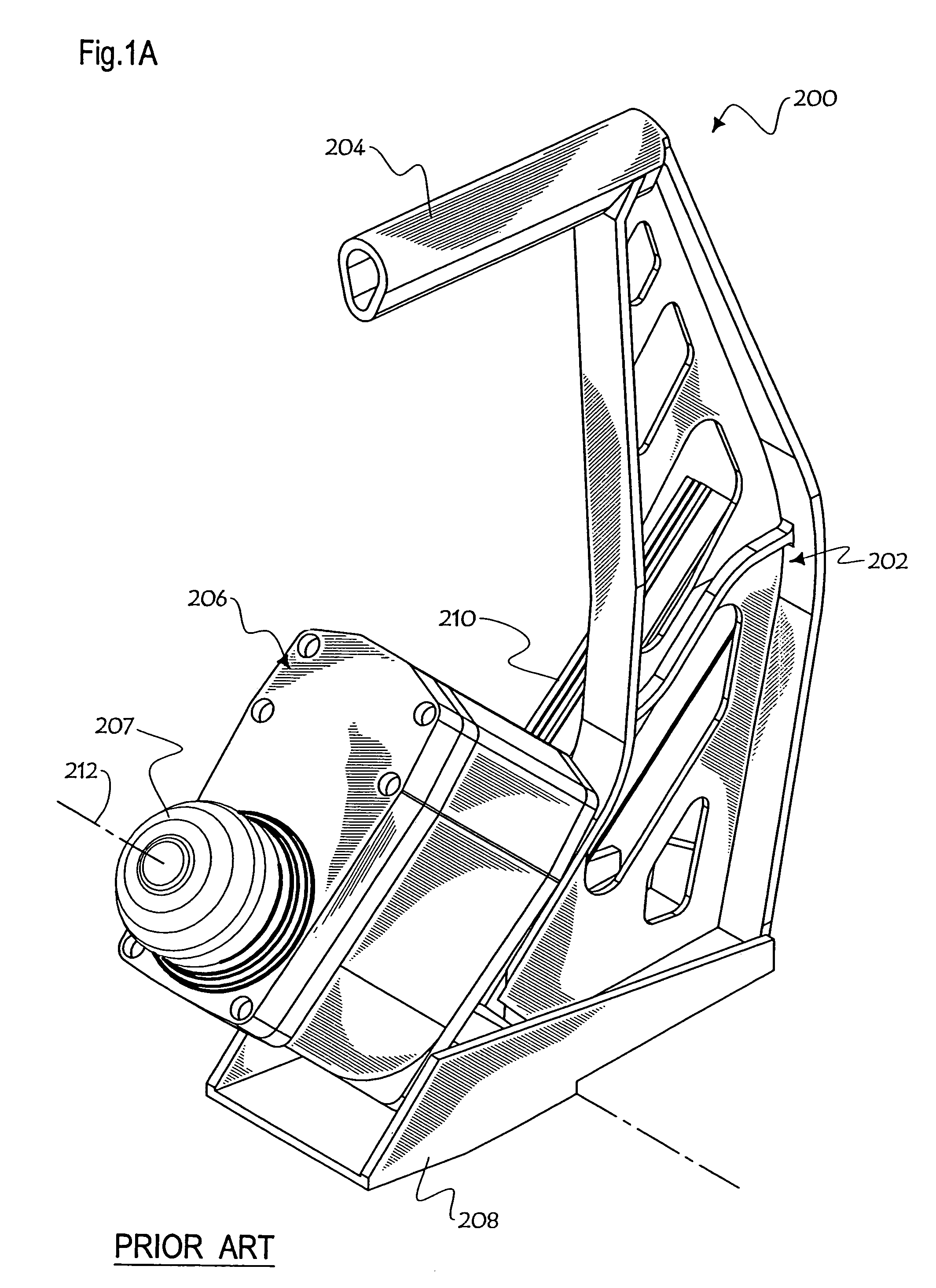

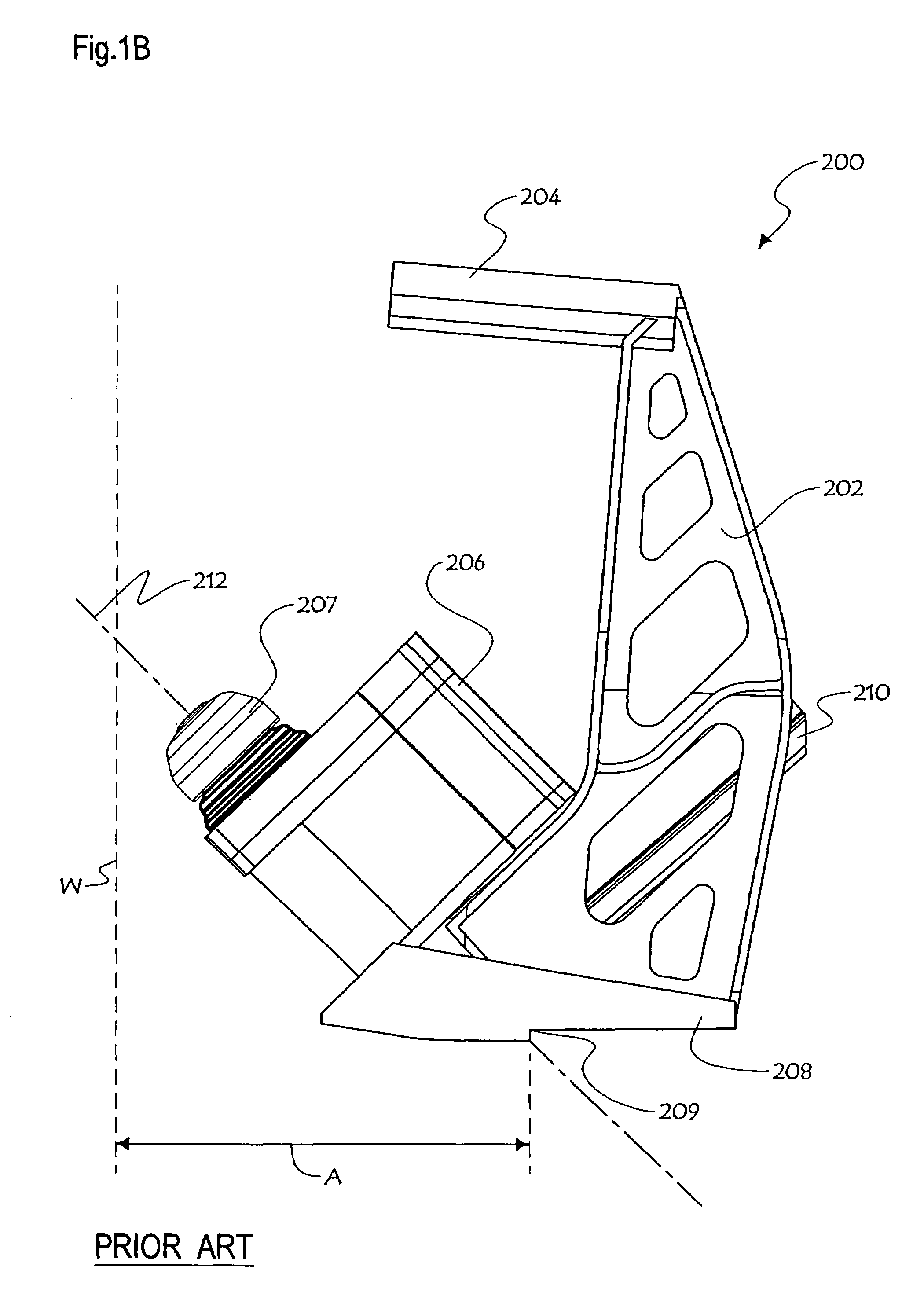

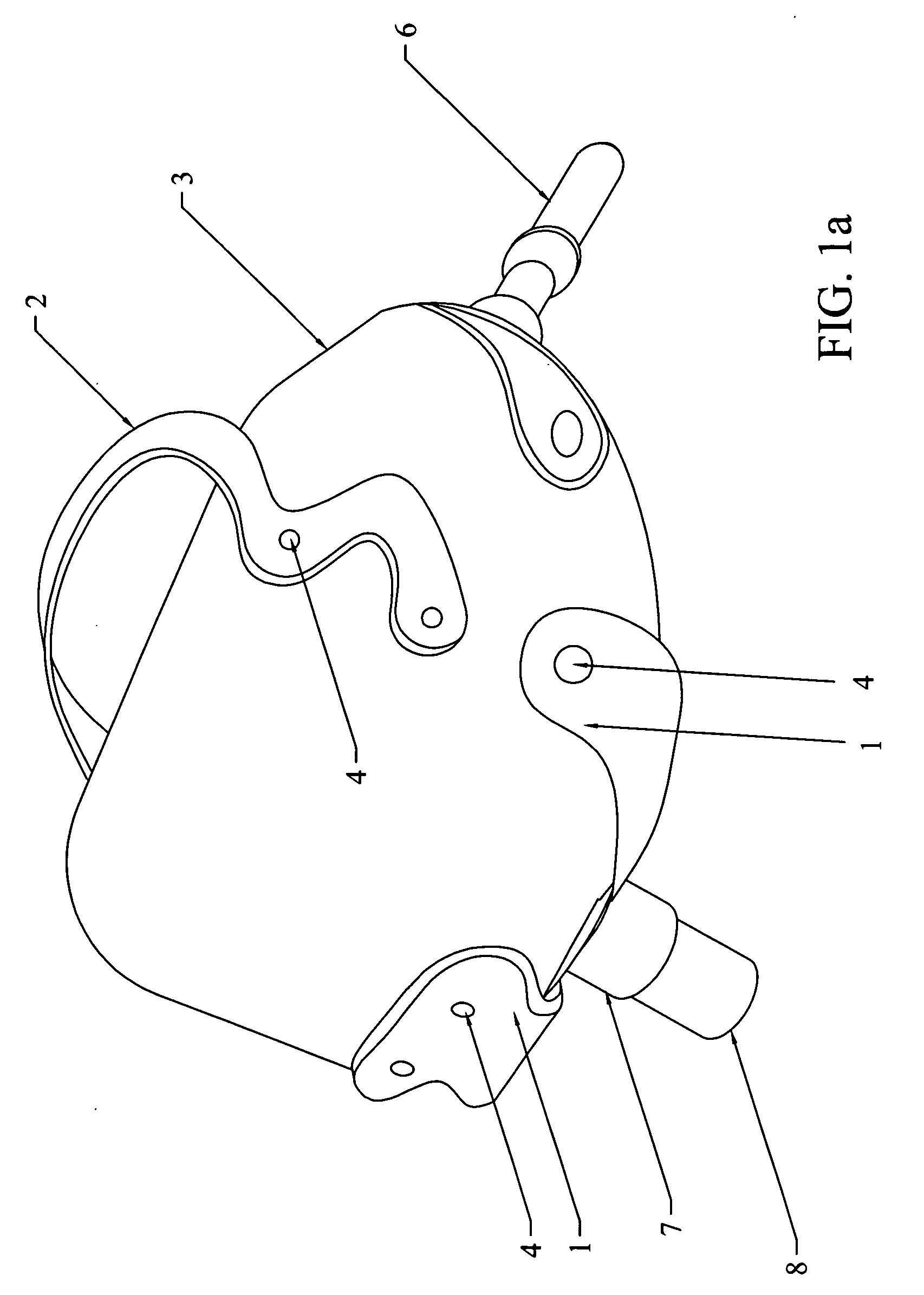

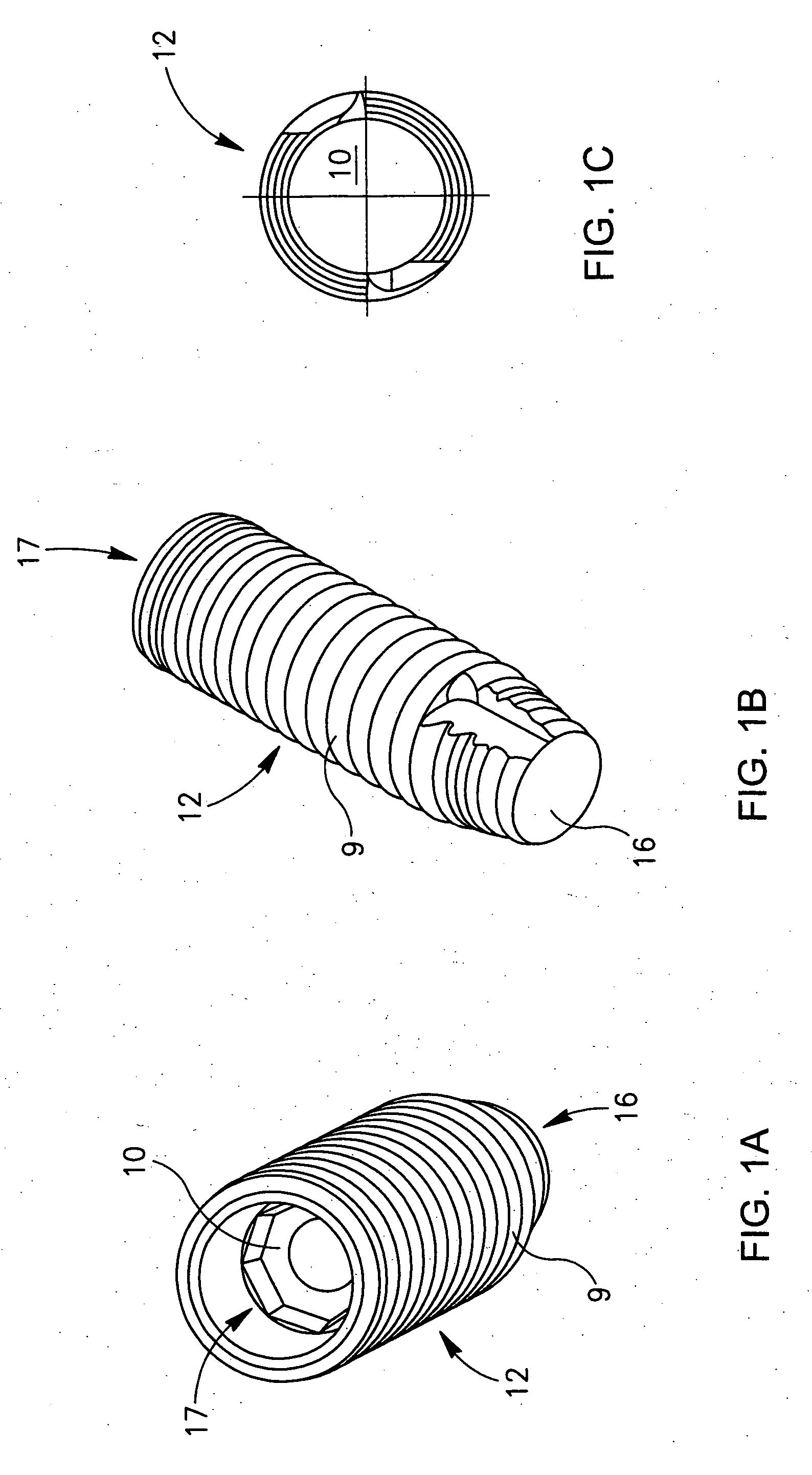

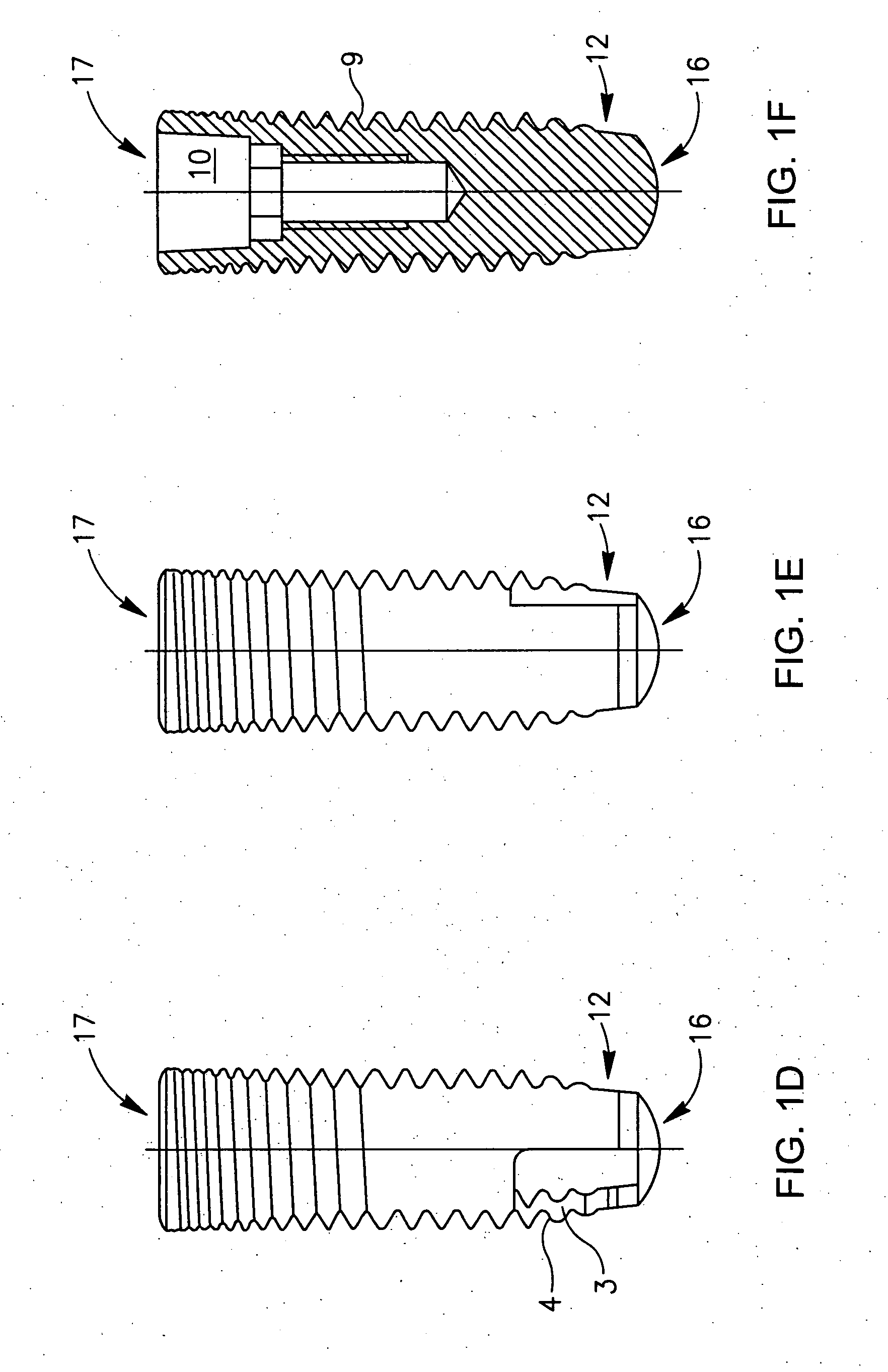

Orthodpedic or dental device

InactiveUS20050276676A1Relieve stressHigh pressureSuture equipmentsDental implantsDental EquipmentEngineering

A medical device having an outer surface, at least a portion of the outer surface being provided with a continuous thread. The thread has a feature that is not constant in the portion of the outer surface. The feature that is not constant may be, for example, the spacing between turns of the thread, the height of the thread, the thickness of the thread, or the pitch of the thread. The feature that varies may vary continuously or discontinuously. The device may be, for example, a screw, a dental implant, an orthopedic implant, a maxillo-facial device, an orthodontic device, a maxillo-facial fixation screw, a nailing device, or a sinous lift device. Varying a feature of the thread allows the device to be adapted for insertion in to bone having varying properties along the length of the device.

Owner:MARDINGER OFER +1

Fully-automatic production line for producing wooden pier

PendingCN109397453AGuaranteed cleanlinessGuaranteed accuracyStapling toolsCircular sawsProduction lineEngineering

The invention relates to the technical field of machining, in particular to a fully-automatic production line for producing a wooden pier. The production line includes a working table, the working table is provided with a feeding device, a nailing device, a cutting device, a lifting driving device and a controller, and a detecting component is arranged on the feeding device; the detecting component sends the detection signal to the controller after detecting a wooden board; the controller sends a driving signal for cutting off the wooden pier to the lifting drive device after receiving the detection signal and sends a signal for controlling the working state of the feeding device to the feeding device; after the wooden pier is cut, the controller sends a feeding signal for controlling thewooded board material to the feeding device. By setting the controller to control the cutting device, the feeding device and the nailing device, the automatic wooden board binding and the wooden piercutting are realized. The positioning is accurate, and the cutting precision is high. The fully-automatic production line for producing wooden pier can be used for feeding while binding, so that uninterrupted production is realized. The wooden board is cut from bottom to top in an arc mode, so that power and energy is saved. The production line has low production cost and high production efficiency and production precision is ensured.

Owner:QINGDAO MEIJIALONG PACKAGING MACHINERY

Arcuate fastener nailing device for hardwood flooring

Owner:LABE PRIMATECH

Full-automatic wood nailing machine

The invention discloses a full-automatic wood nailing machine. The full-automatic wood nailing machine comprises a frame; a conveying frame and a nailing bracket are arranged on the frame; the conveying frame includes a left conveying frame and a right conveying frame; the nailing bracket includes a nailing transverse frame and a nailing vertical frame; the nailing vertical frame includes a left nailing vertical frame and a right nailing vertical frame; the nailing transverse frame is positioned between the left nailing vertical frame and the right nailing vertical frame; a nailing device is arranged on the nailing transverse frame, and includes a moving mechanism and a nailing mechanism; the moving mechanism is connected with the nailing mechanism; the moving mechanism is mounted on the nailing transverse frame; a clamping device is mounted on the nailing vertical frame; a conveying device is arranged between the left conveying frame and the right conveying frame, and includes a conveying transmission mechanism and a conveying mechanism; and the conveying transmission mechanism is connected with the conveying mechanism. The machine is simple in structure, scientific, convenient, strong in pertinency and high in automation degree, can automatically transport and position nailed boards, and preferably solves the board nailing problem.

Owner:CHANGSHU YAHGEE MODULAR BUILDING CO LTD

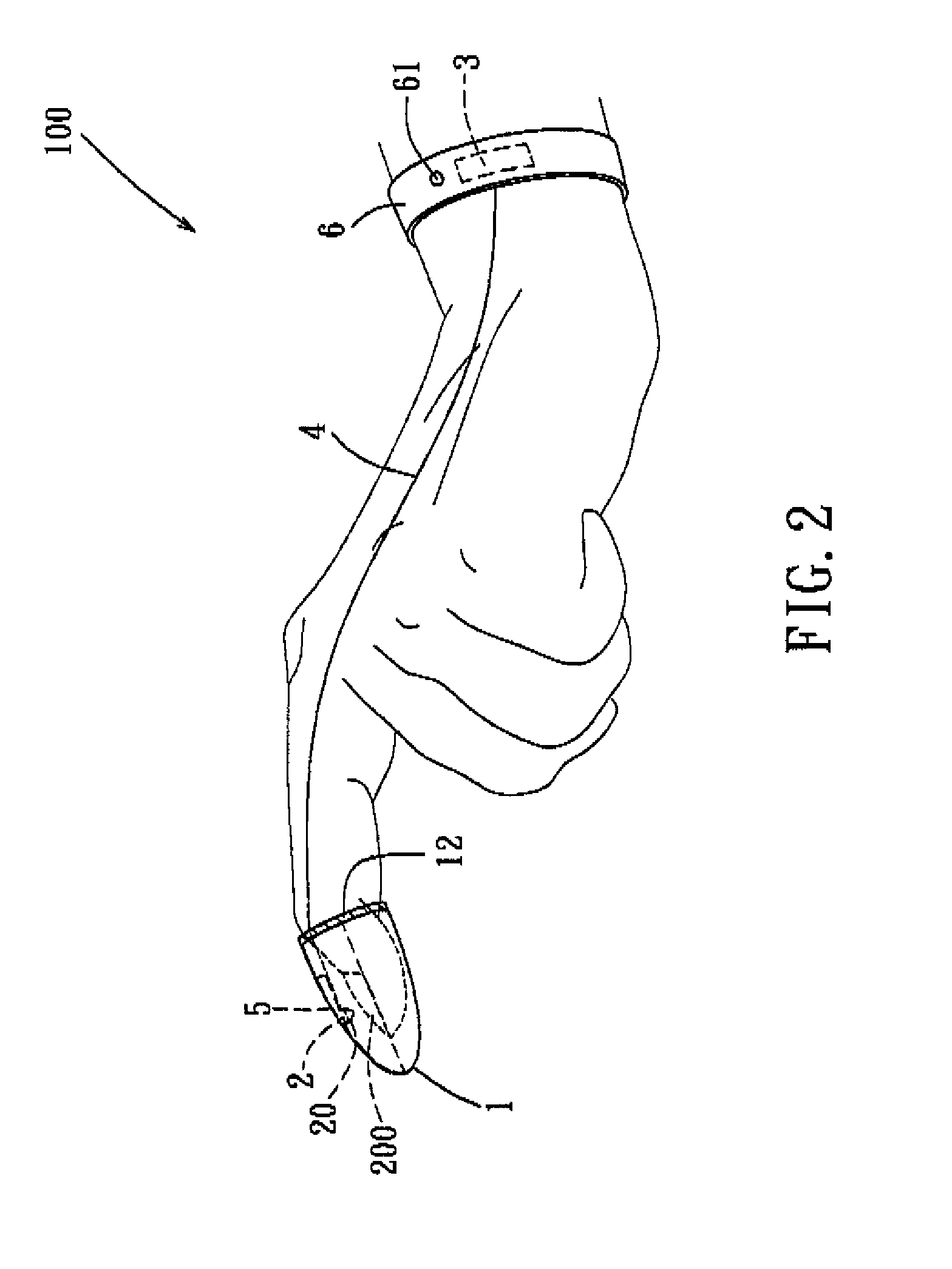

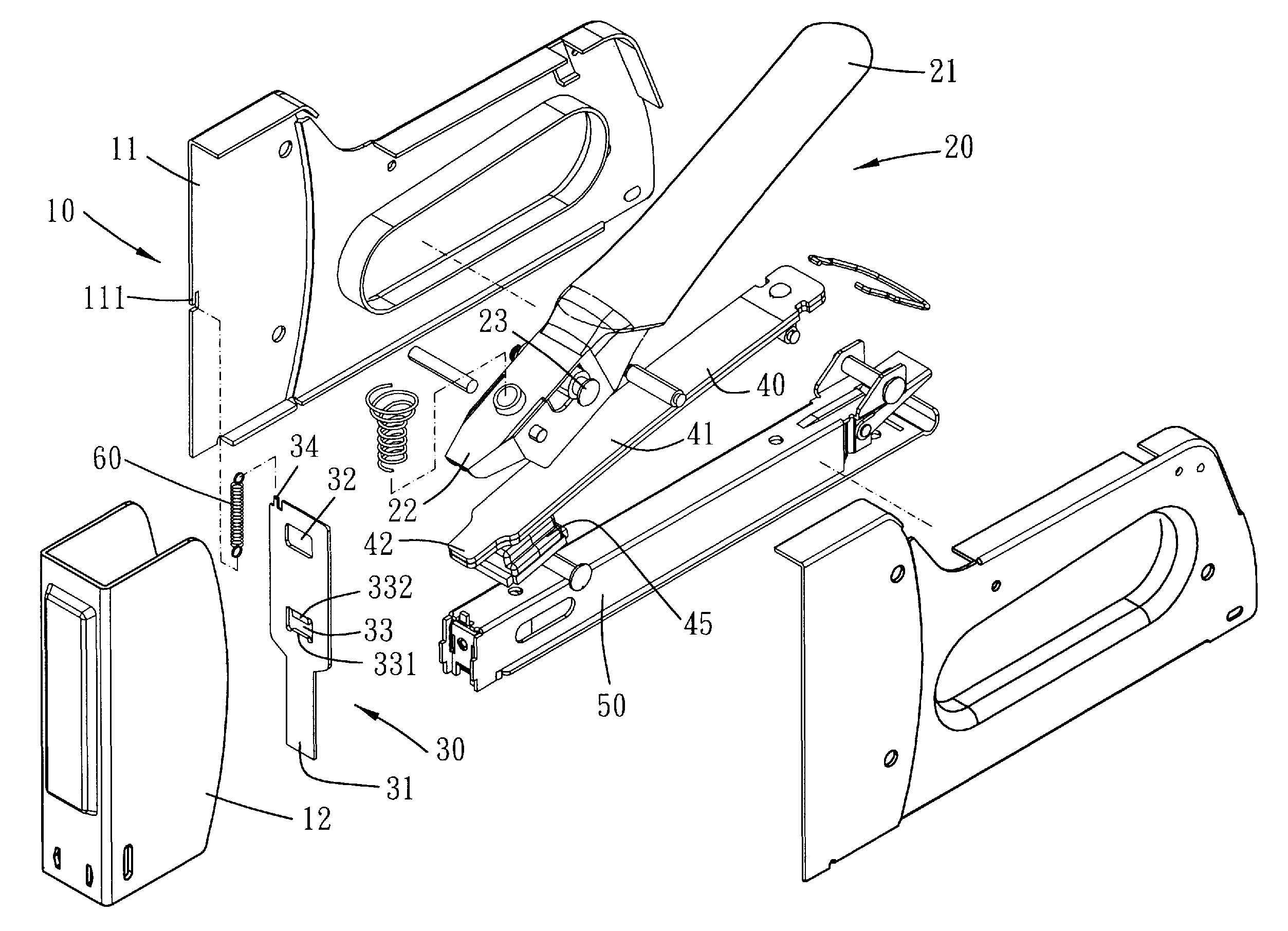

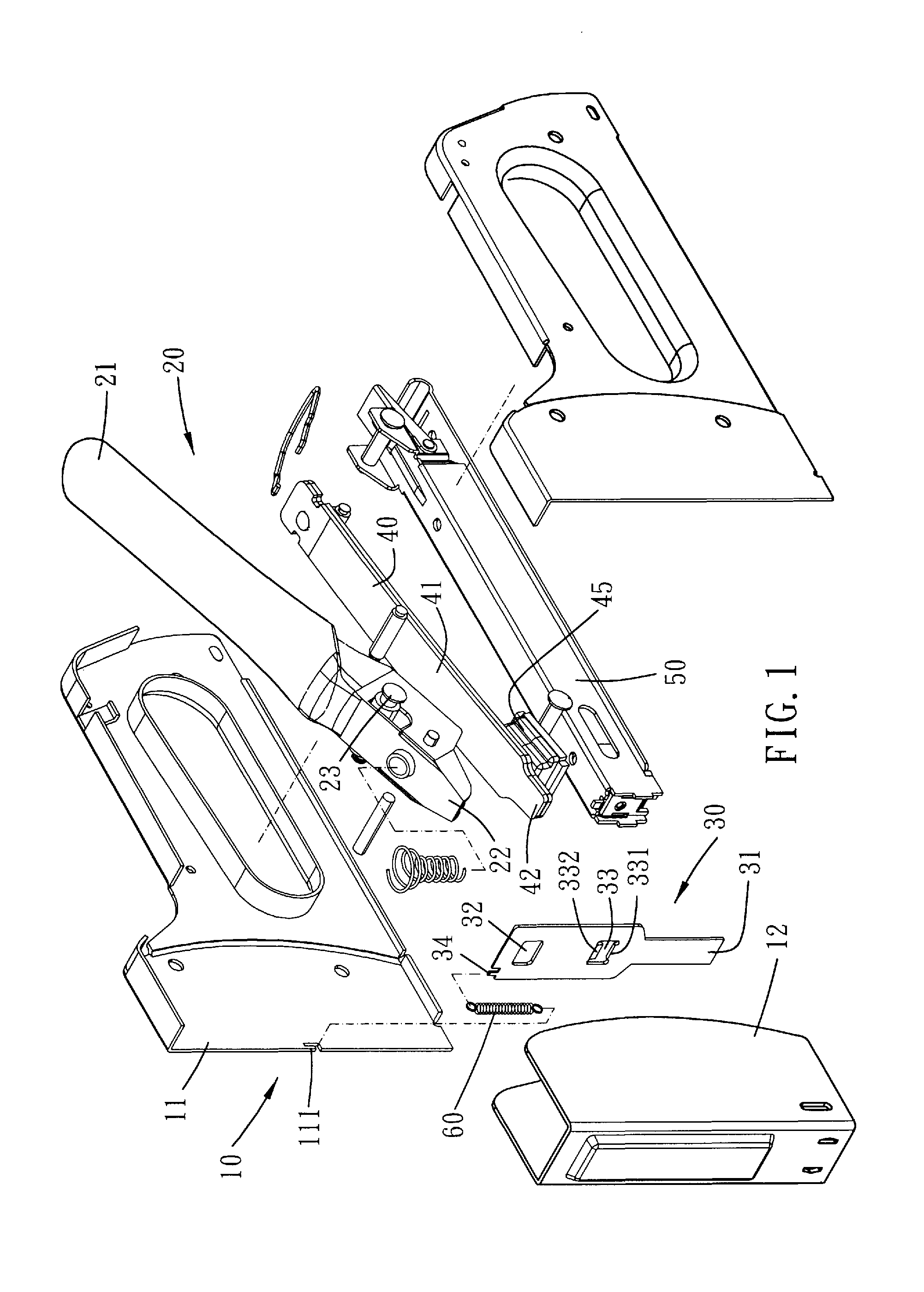

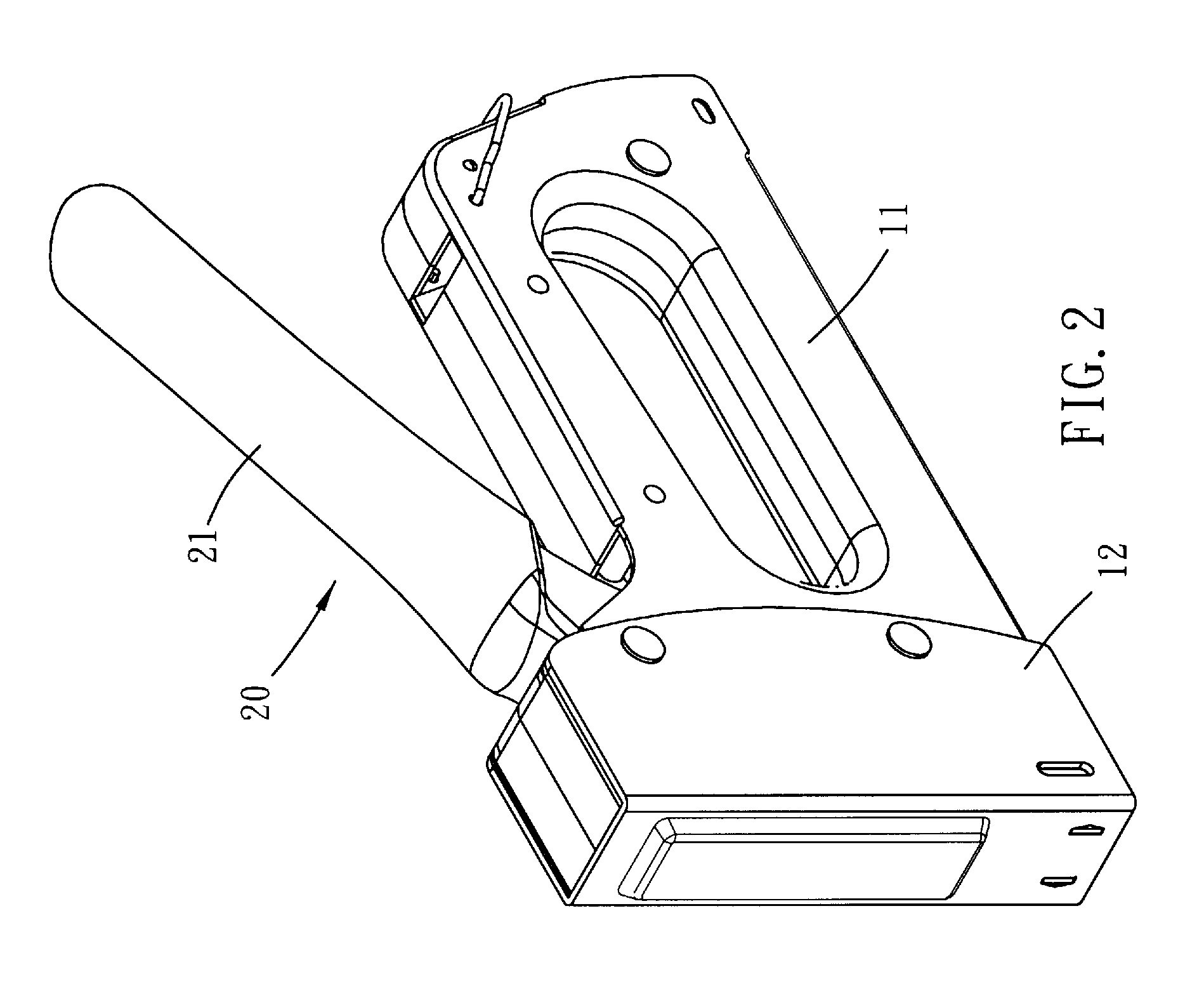

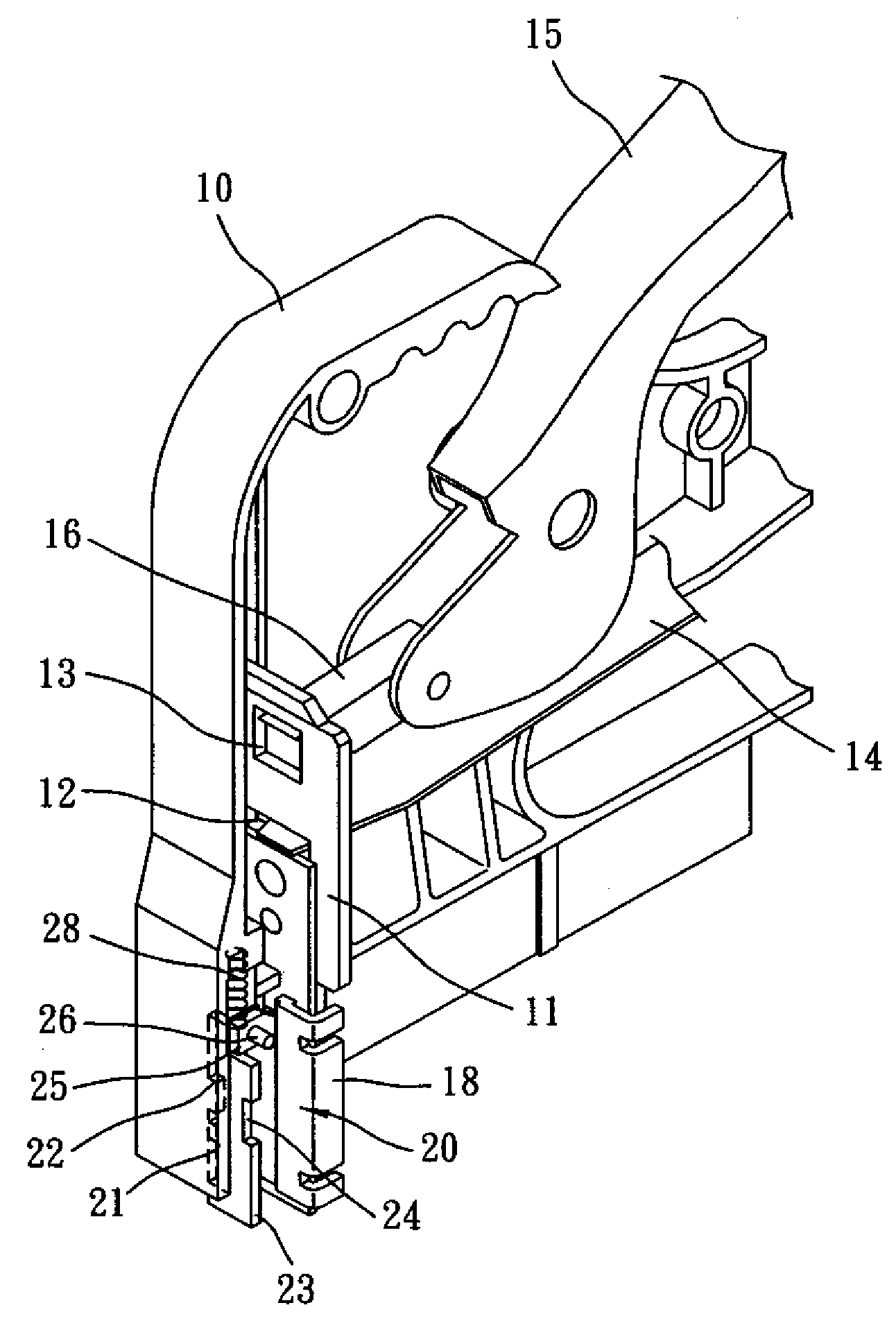

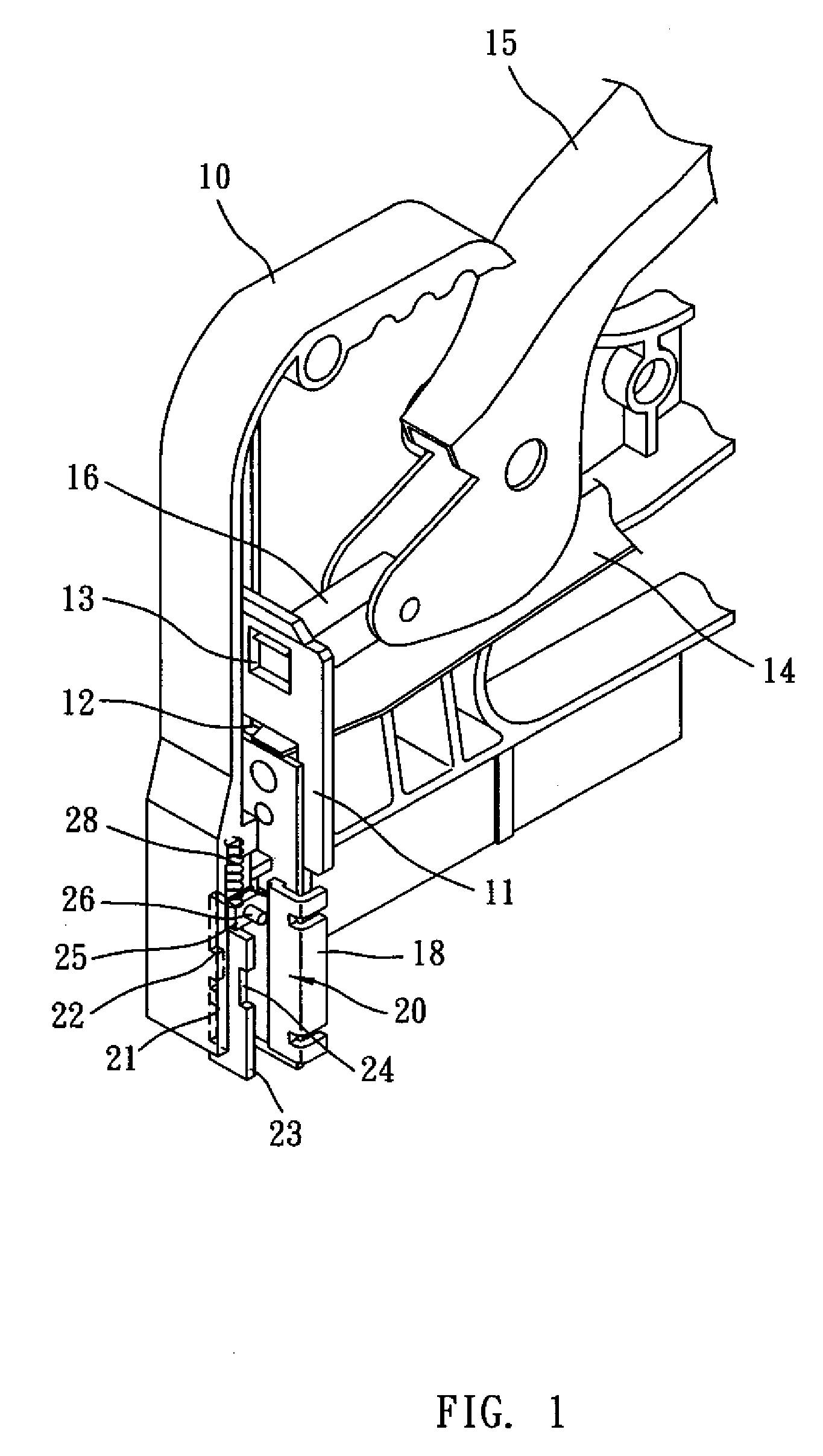

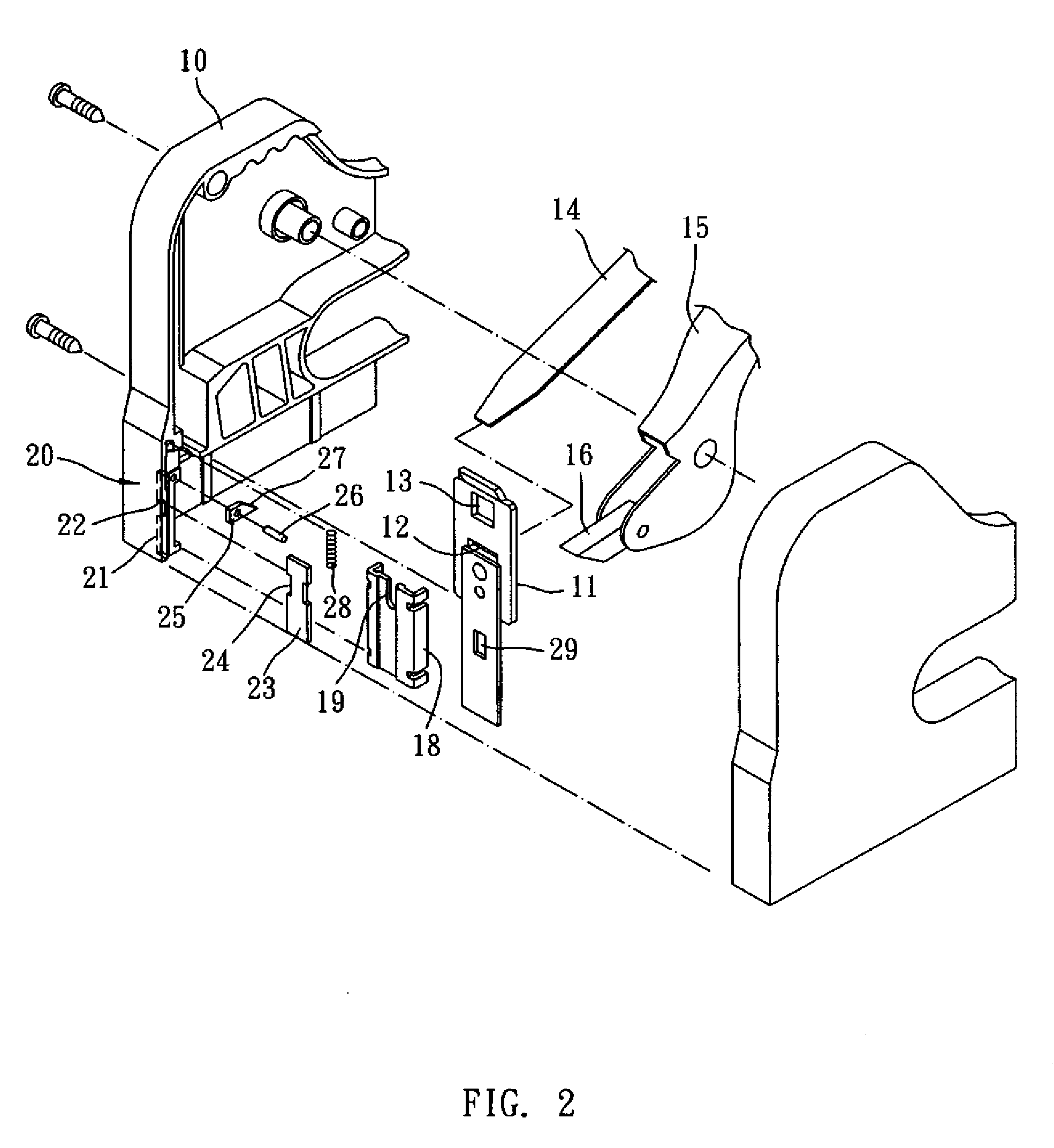

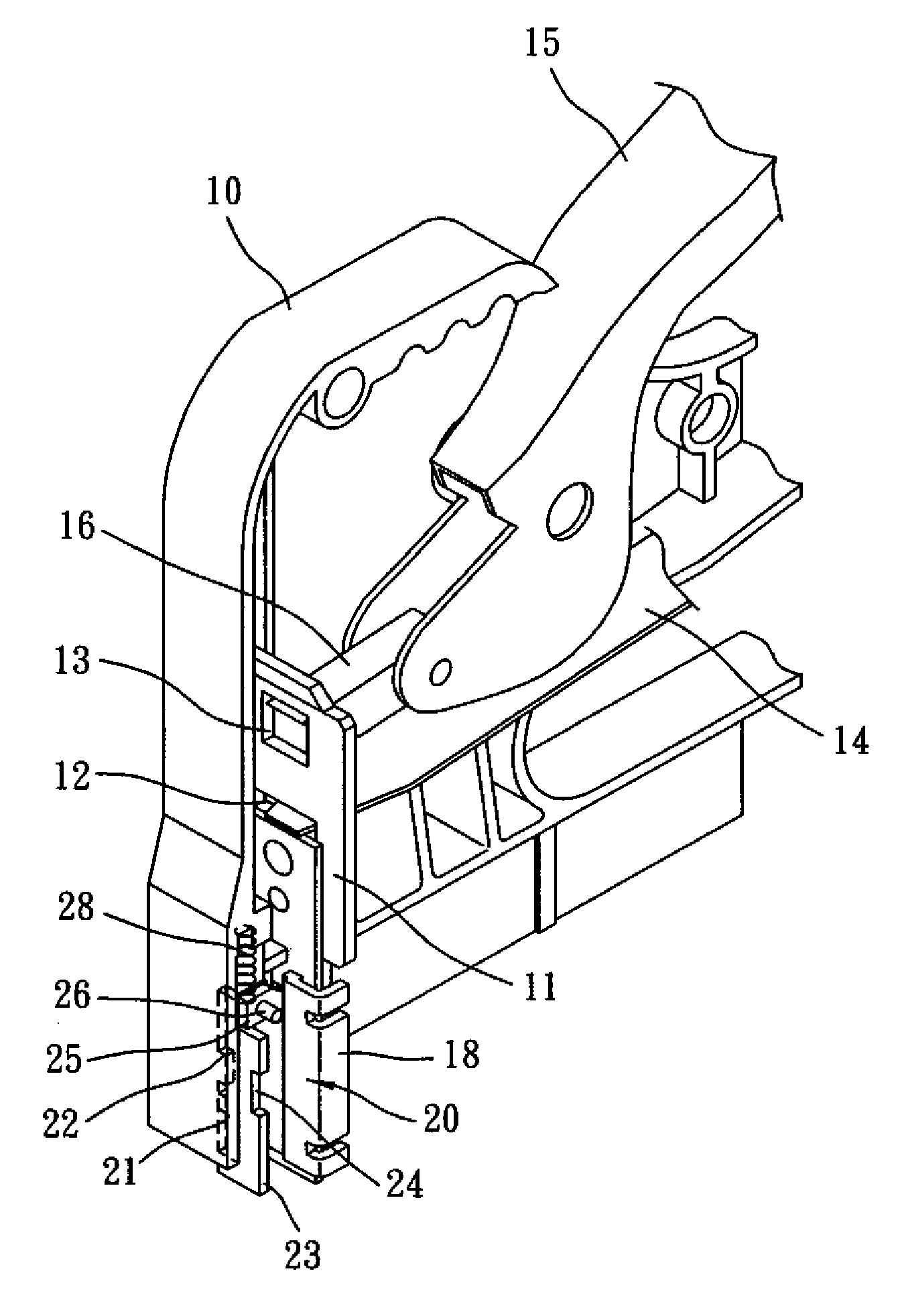

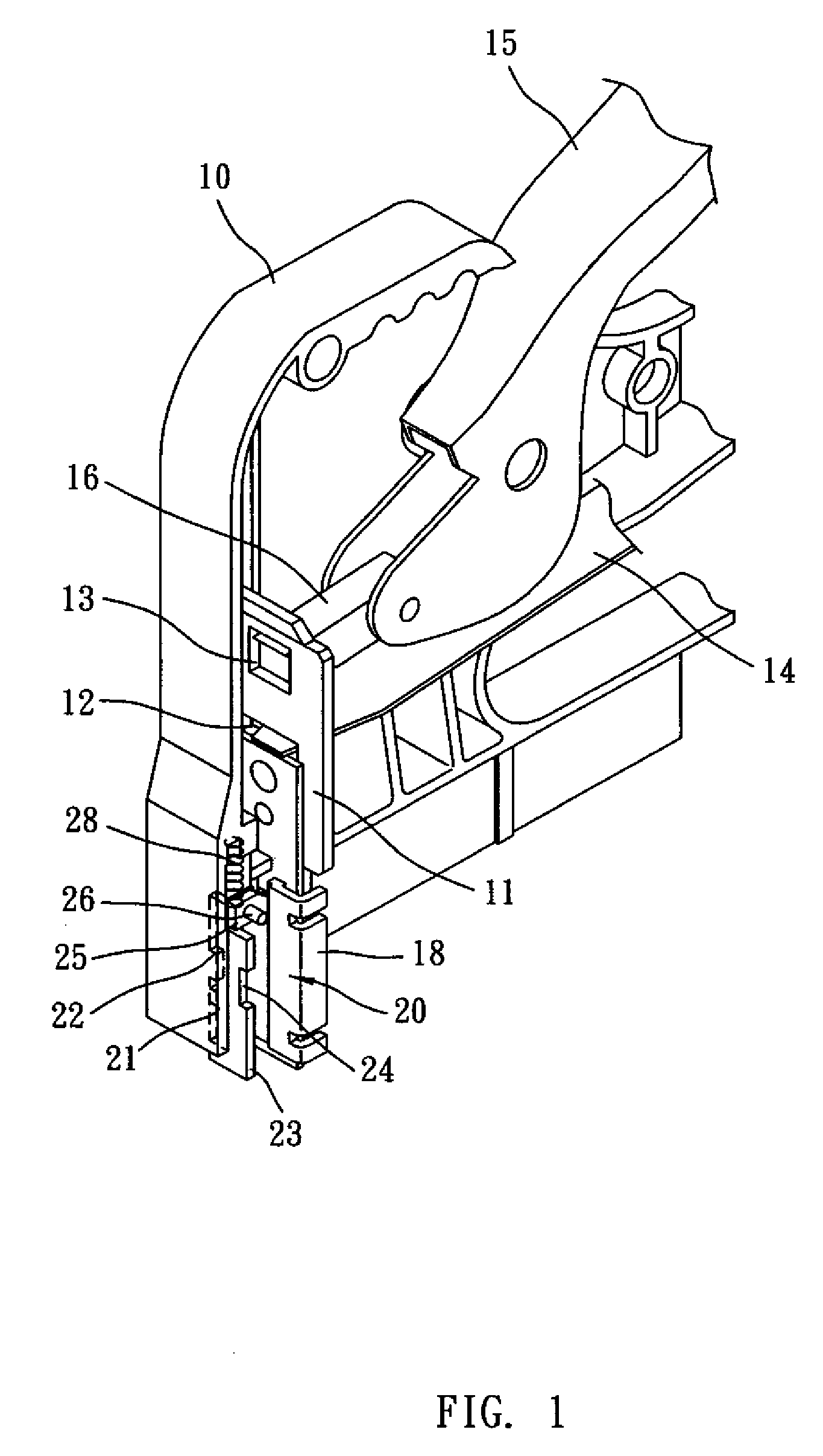

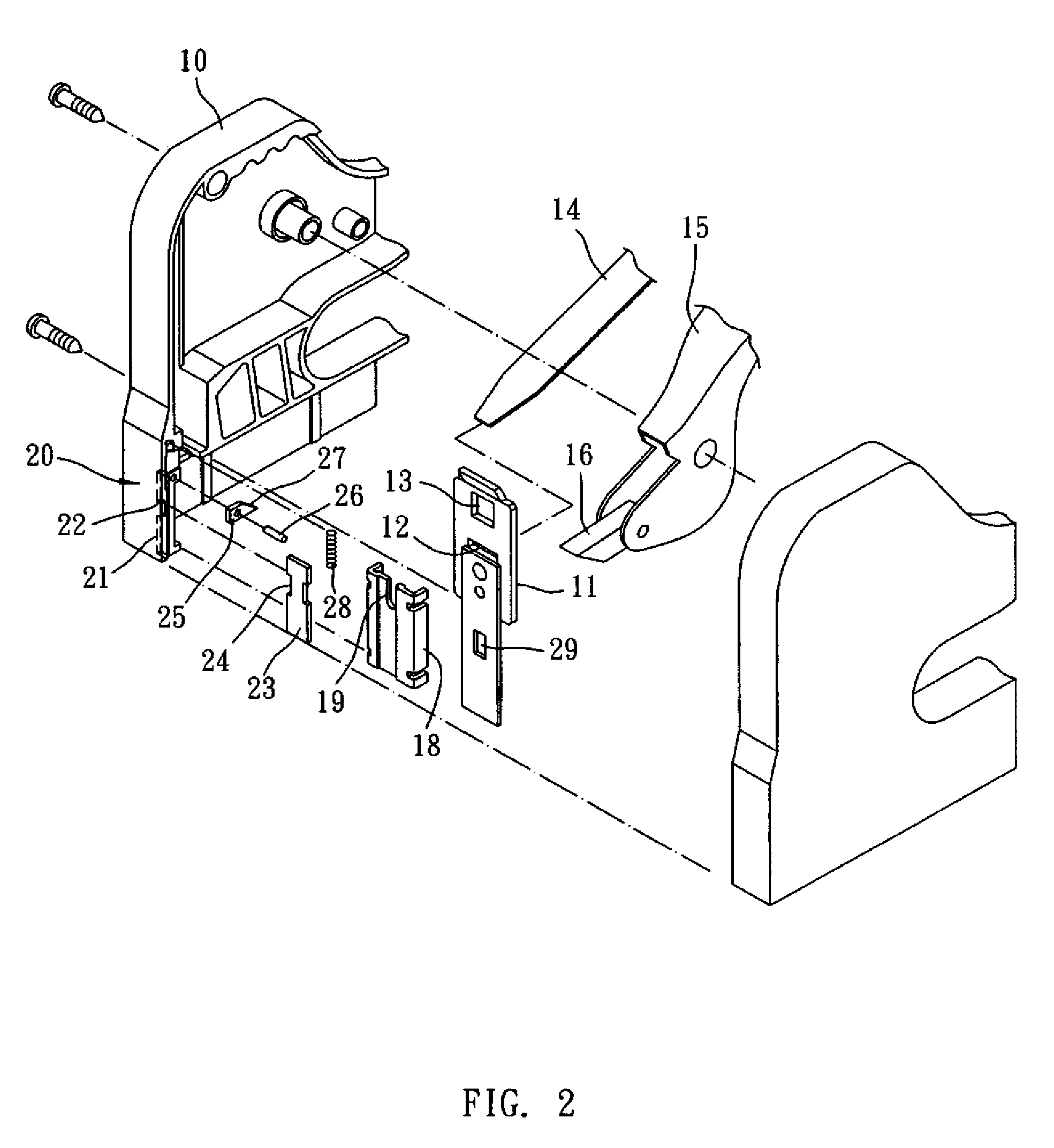

Safety nailing device

A safety nailing device of the present invention includes a main body, an actuator, a striking plate and a disengaging means. The main body defines a chamber therein, and an opening is defined on a bottom surface of the main body to communicate with the chamber. The actuator is disposed on the main body and has a controlling end. The striking plate is disposed in the chamber and is movable between a safety position, a starting position and a striking position. The striking plate has a protrusive end and a controlling groove. The protrusive end selectively protrudes out of the chamber from the opening, and the controlling groove is selectively engaged with the controlling end. The disengaging means is for moving the striking plate to the safety position to disengage the controlling end from the controlling groove, so that the travel of the actuator will not lift the striking plate.

Owner:APEX MFG

Floorboard nailing device

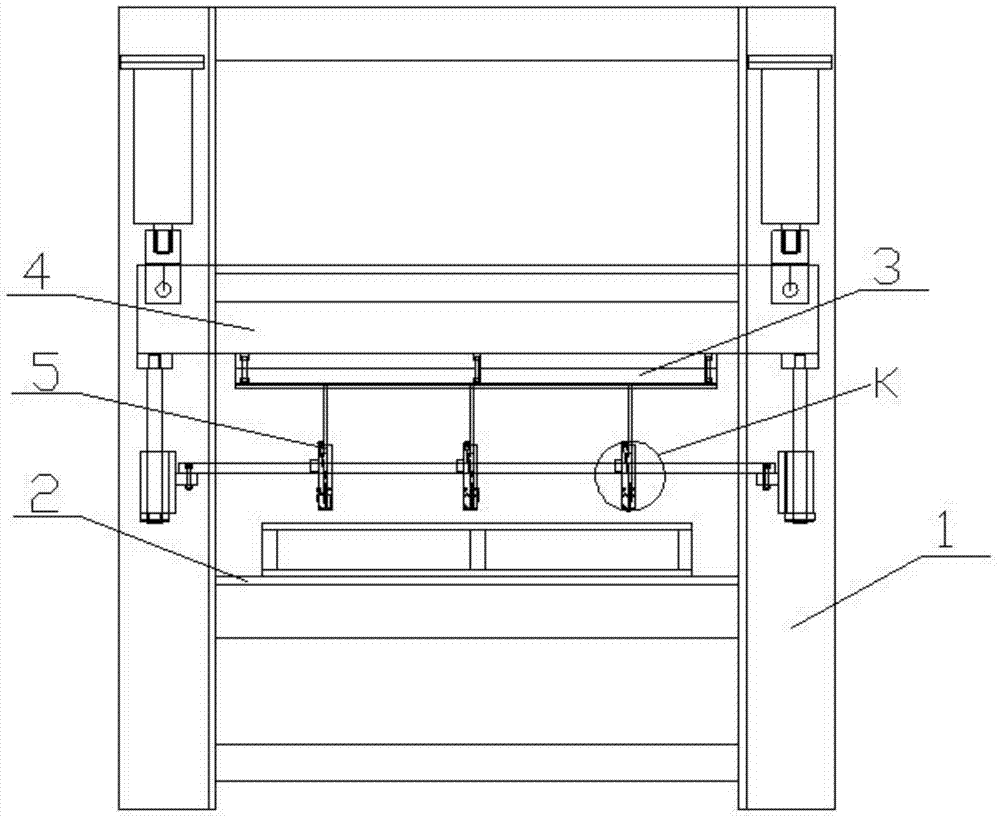

ActiveCN103612299AReduce quality accidentsReduce labor cost inputStapling toolsNailing toolsProcedural approachFuselage

The invention provides a floorboard nailing device which comprises a machine body, a conveying device, a sensing device, a positioning device, a nailing device body and a position regulation device. The conveying device, the sensing device, the positioning device, the nailing device body and the position regulation device are arranged on the machine body. The conveying device is used for conveying floorboards. The sensing device is used for controlling the conveying device. The positioning device is used for positioning and clamping the floorboards. The position regulation device is used for regulating the relative positions of the nailing device body and the floorboards. The floorboard nailing device can be used for completely replacing manual operation. Consequently, quality accidents caused by human factors are reduced, and investment of labor cost is also lowered. The floorboard nailing device is controlled by a computer program and can be perfectly connected with a device in a previous process and a device in a follow-up process in the operating process, so production efficiency is greatly improved. The floorboard nailing device belongs to the field of floorboard production technologies.

Owner:GUANGZHOU HOMEBON WOOD MFG +1

External Nailing Device Adaptor

InactiveUS20090166394A1Easy to installStapling toolsMetal working apparatusEngineeringTrial and error

An external adaptor for a palm nailer is disclosed. The adaptor acts as a spacer and allows controlling the depth of the nail pounded into siding or tiles. The adaptor is fitted onto a stationary extension sleeve that protrudes from the nailer and is clamped onto it using at least two threaded fasteners. A method for attaching and setting up the adaptor is also disclosed. The adaptor is moved up or down the stationary sleeve and the location that provides the optimum nail depth is established by trial and error.

Owner:GYORKOS LAWRENCE

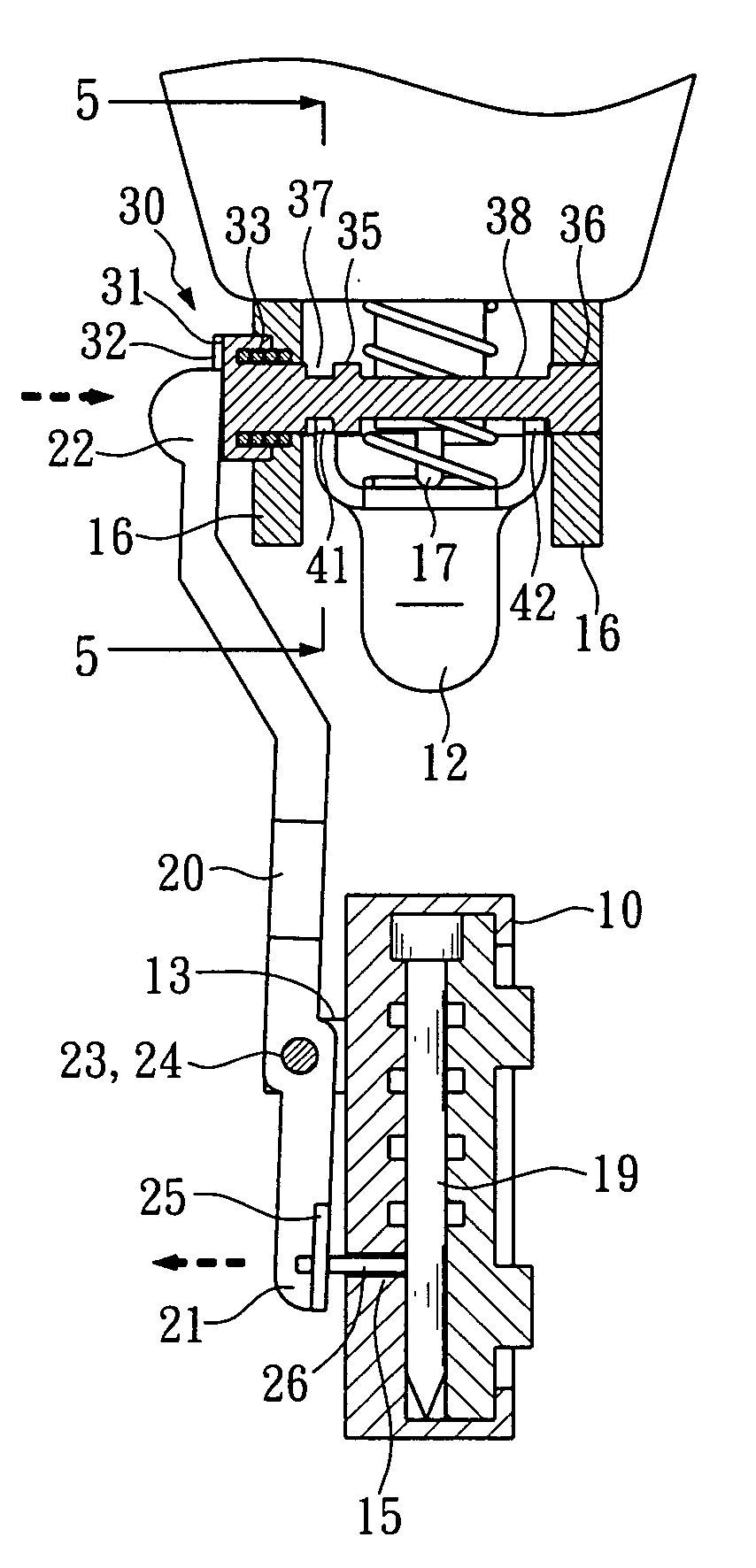

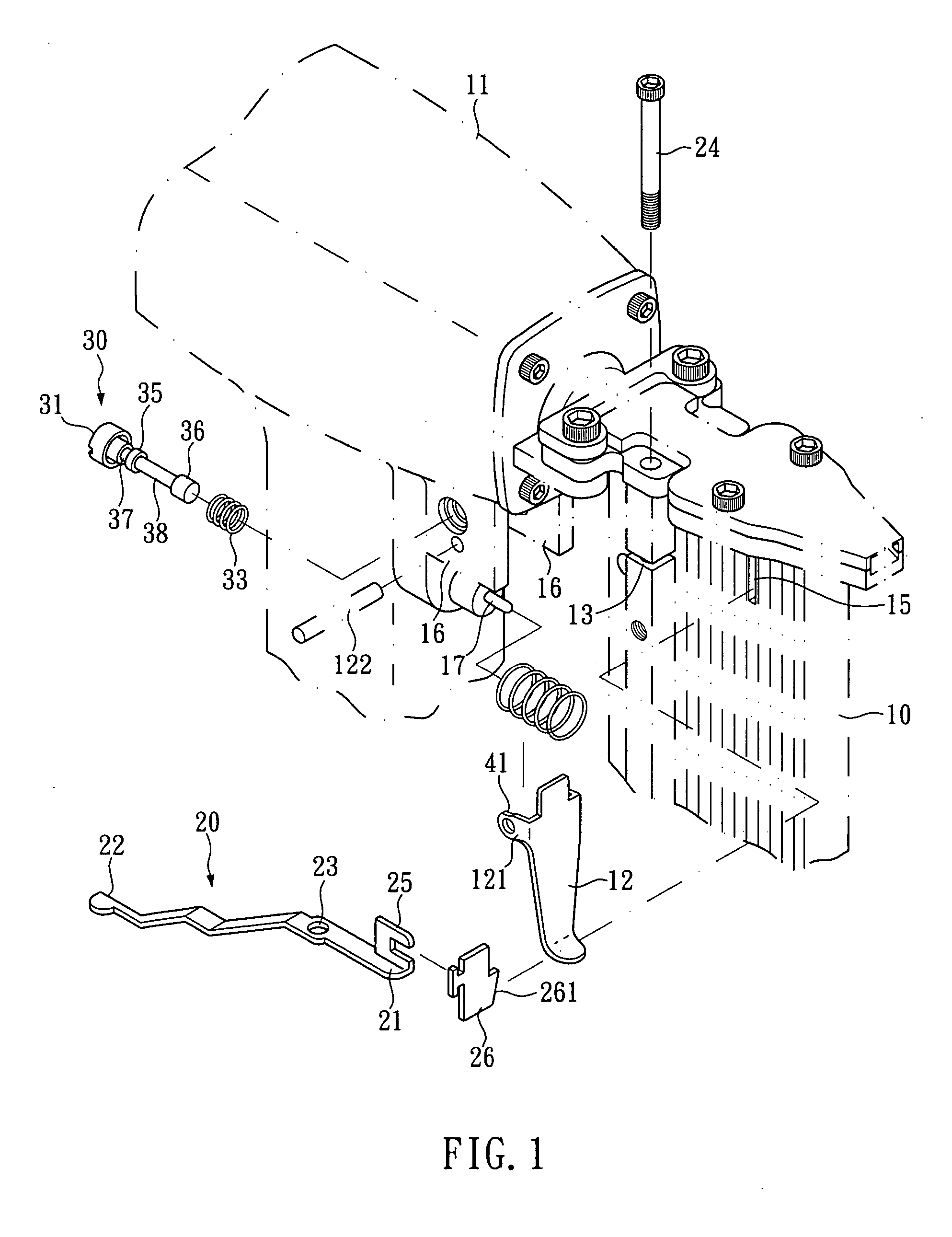

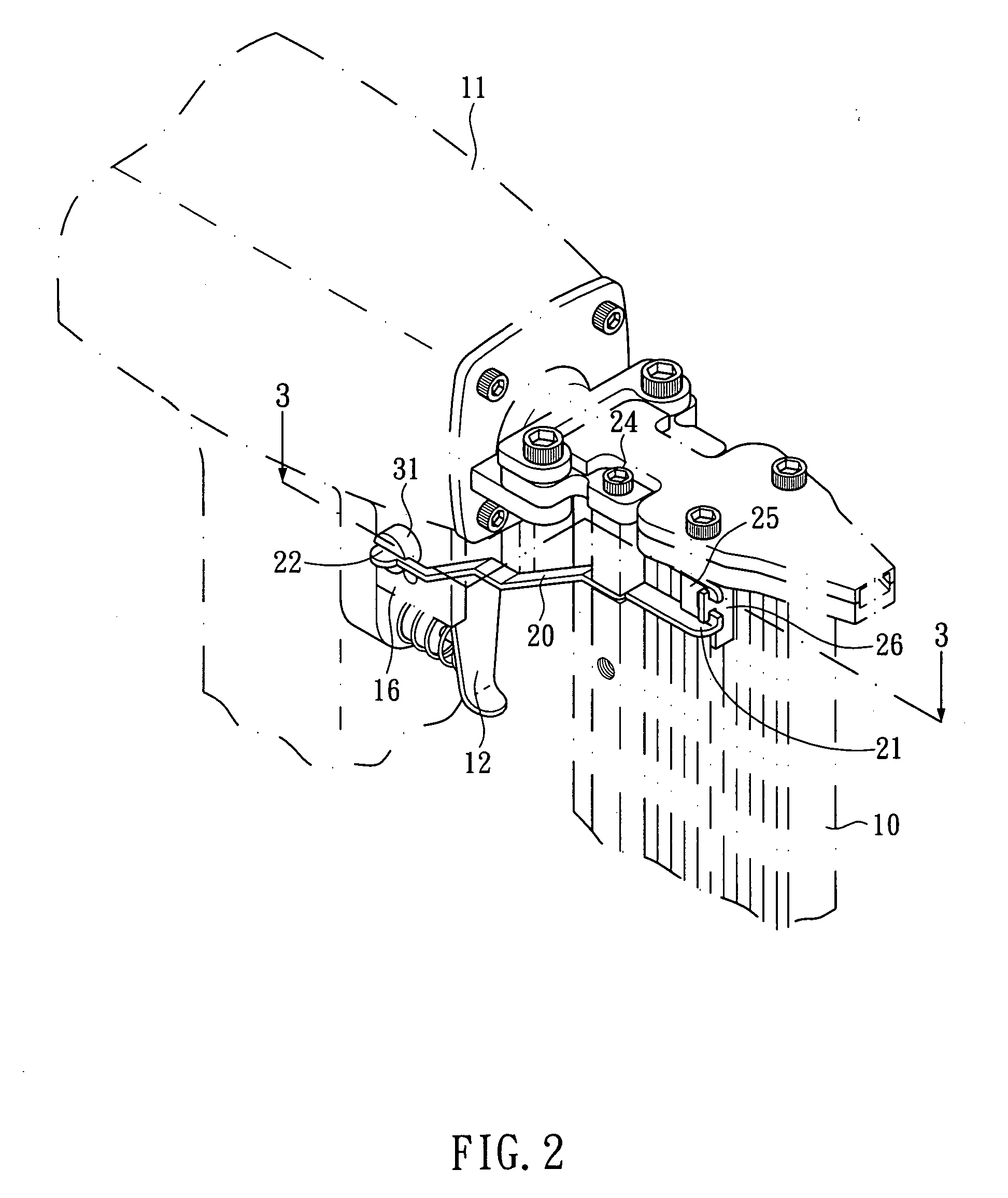

Structure of arresting mechanism for nail guns

A structure of an arresting mechanism for a nail gun, wherein the nail gun is composed of a nailing device. The nail gun further comprises a trigger, which is fastened between two pin plates of the nailing device and can be cocked to shoot nails. The arresting mechanism contains a reciprocating cotter pierced through the two pin plates; at lease one retaining part disposed on the trigger; a swinging sensing component, which is fastened together with the magazine, with its first end in the location corresponding to the magazine and further extending into the magazine to reach the nail and the second end reaching the head of the cotter. Accordingly to foregoing structure, when there is no nail loaded in the magazine, the trigger cannot be cocked by the users; contrarily, when nails are loaded in the magazine, the trigger can be cocked.

Owner:NAILERMATE ENTERPRISE

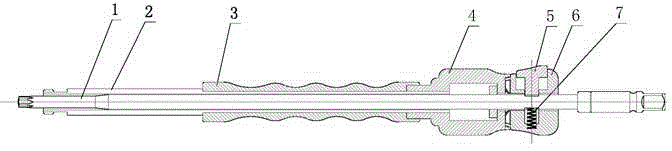

Pedicle screw nailing device

InactiveCN104688326AFirmly connectedFirm and effective lockingOsteosynthesis devicesEngineeringScrew thread

The invention provides a pedicle screw nailing device with which physicians can implant pedicle screws conveniently. The pedicle screw nailing device is convenient to operate and safe and reliable in use and characterized in that during use, a connecting head at the head part of a nailing rod is inserted into a pedicle screw, then the head part of a nailing sleeve pipe is screwed into the tail cap of the pedicle screw in a threaded manner to be fully locked through a screwing nut, and finally an anti-quit knob is pushed forwards until a lock button is bounced. The screwing nut is provided with a latch and matched with a neck in the anti-quit knob during work, and meanwhile the lock button is buckled into an octagon on the nailing rod, so that the nailing device and the pedicle screw are effectively connected into a whole and have firmness and no looseness under the action that locking force is not removed. Repeated experiments show that when the neck of the anti-quit knob is divided into 16 equal parts and the nailing rod is designed into the octagon at 30 degrees, the pedicle screw can be most effectively locked.

Owner:TIANJIN WALKMAN BIOMATERIAL CO LTD

Nailing device

A nailer device having a carriage assembly, a pair of pivotal drive wheels, a nailer assembly and at least one end wheel. The pair of pivotal drive wheels are on the carriage assembly. The at least one end wheel is disposed adjacent an end of the carriage assembly. A drive motor can be associated with at least one of the pair of pivotal drive wheels when the nailer device is operating in an automatic mode. A handle disposed either intermediate of the pivotal drive wheels can be used to move or manually operate the nailer device and move the nailer device to an adjacent row of floorboards to be secured. A pair of adjustable wheels is also provided to adjust the height of the device.

Owner:HAMAR DOUGLAS J

Base processing equipment for wooden pallet

The invention provides base processing equipment for a wooden pallet, belongs to the technical field of wooden pallets, and solves the problems that the traditional wooden pallet base has low processing efficiency. The base processing equipment for the wooden pallet comprises a rack and a conveying mechanism capable of conveying a plurality of foot piers side by side, wherein a bin and a nailing device are arranged above the conveying mechanism, and flitches are stacked in the bin; the bin and the nailing device are sequentially and fixedly arranged on the rack along the conveying direction of the foot piers, and a discharging mechanism is arranged between the conveying mechanism and the bin; and when each row of foot piers are conveyed to a position below the bin, the flitch rightly falling on the row of foot piers can be shifted from the bin by the discharging mechanism. According to the base processing equipment for the wooden pallet, the foot piers can be conveyed orderly, and supporting plates are accurately laid, so that the product quality is ensured, the degree of automation is high, and the production efficiency is greatly improved.

Owner:JINYUN XINYU METAL PROD

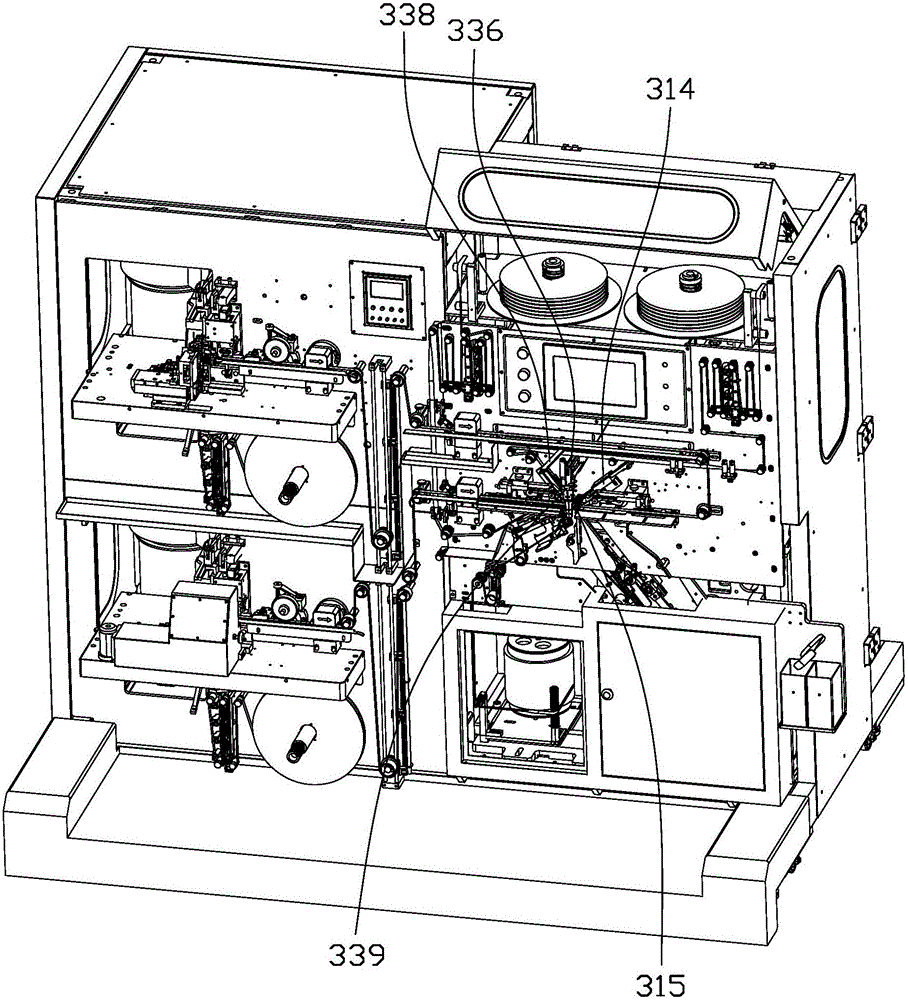

Nailing and winding integrated machine for producing electrolytic capacitor

ActiveCN106373791ACompact structureSmall footprintWinding capacitor machinesEngineeringElectrolytic capacitor

A nailing and winding integrated machine for producing an electrolytic capacitor comprises a winder as well as an anode nailing device and a cathode nailing device placed in the same side of the winder. The anode nailing device is placed over or under the cathode nailing device, and comprises an anode foil disk, a first nailing mechanism and a first foil drawing mechanism arranged successively; the cathode nailing device comprises a cathode foil disk, a second nailing mechanism and a second foil drawing mechanism arranged successively; the winder comprises a winding mechanism which is used to wind and glue an anode foil, a cathode foil and electrolytic paper; the first foil drawing mechanism draws the anode foil from the anode foil disk and nails the anode foil via the first nailing mechanism; the second foil drawing mechanism draws the cathode foil from the cathode foil disk and nails the anode foil via the second nailing mechanism; the nailed anode and cathode foils are transmitted to the winder via corresponding foil conveying wheels and wound and glued with the electrolytic paper to obtain a capacitor element. The nailing and winding integrated machine is compact in structure, small in occupation space and convenient to operate.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

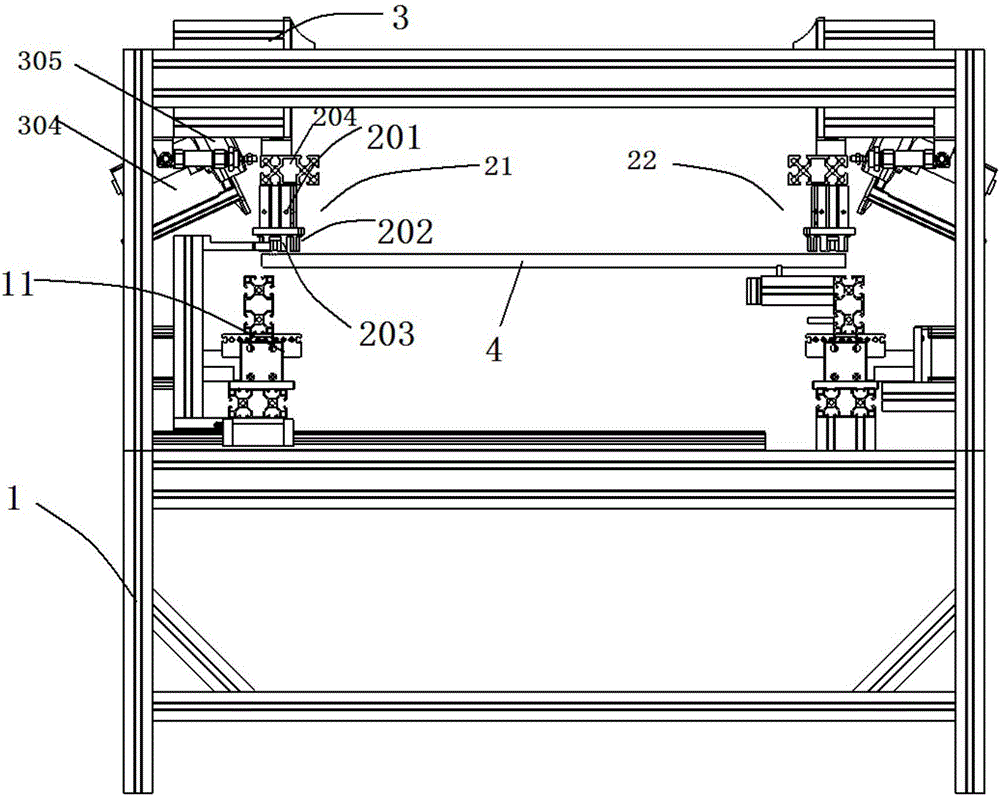

Full-automatic paper box forming machine

InactiveCN101786343BLabor savingRealize standardized operationBox making operationsPaper-makingDevice formCarton

The invention provides a full-automatic paper box forming machine, which is applicable to the technical field of full atomization. The paper box forming machine comprises a machine frame, a paper box loading device, a releasing device, a paper box forming device, a top edge folding device, a feeding and nailing device, an adhesive tape sealing device and a controller, wherein the paper box loading device, the releasing device, the paper box forming device, the top edge folding device, the feeding and nailing device and the adhesive tape sealing device are sequentially arranged on the machine frame, the paper box loading device loads a paper box under the control of the controller, the release device moves the paper box into the paper box forming device, the paper box forming device forms the paper box, the feeding and nailing device binds the paper box, and the adhesive tape sealing device seals adhesive tapes on the bound paper box. Compared with the conventional paper box forming machine, the invention has the advantages that all flow processes are completed through controlling an automatic forming machine by the controller, the labor is saved, the standard operation is realized, and the invention can ensure that each product can be finished according to the technical requirements. In addition, the work efficiency is improved.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

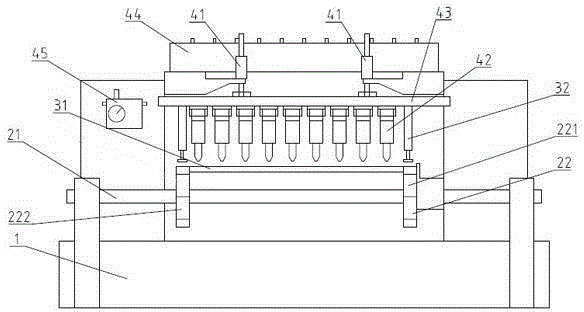

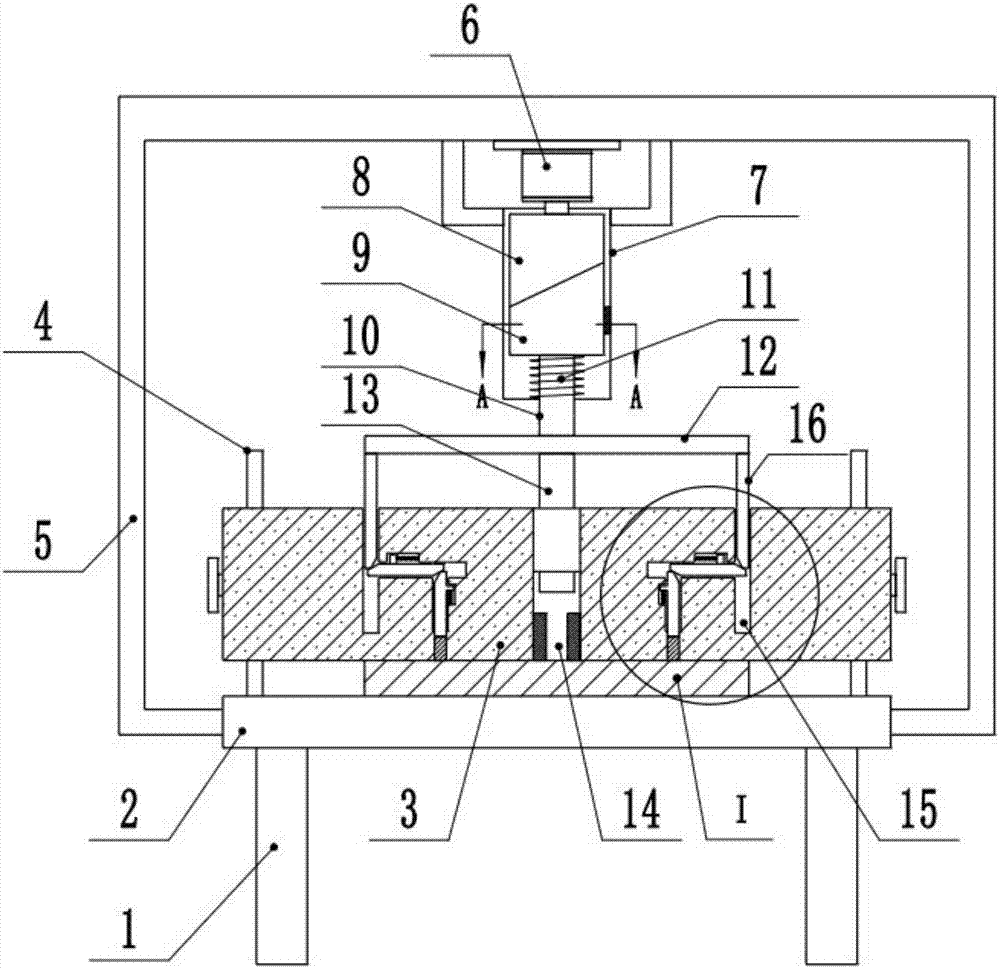

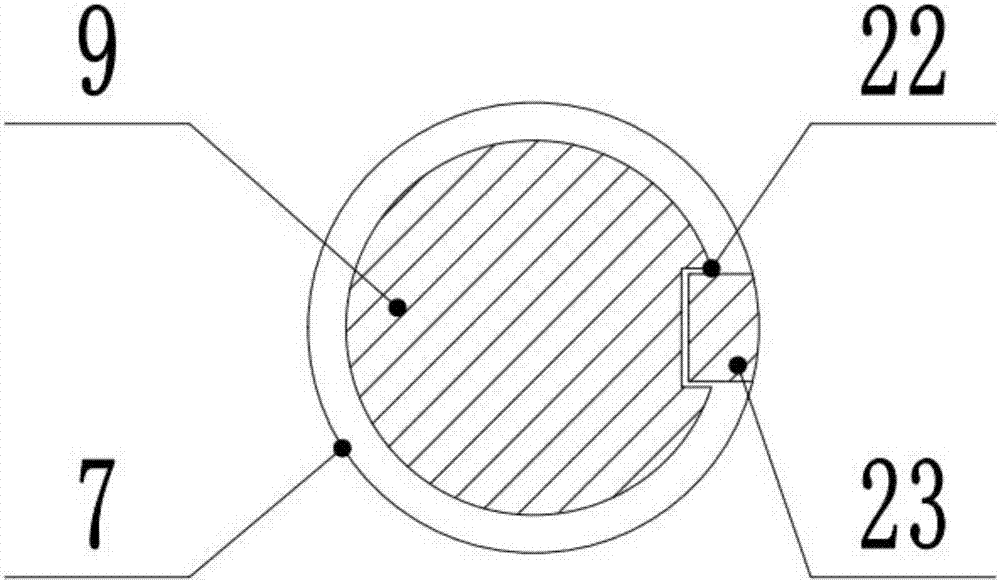

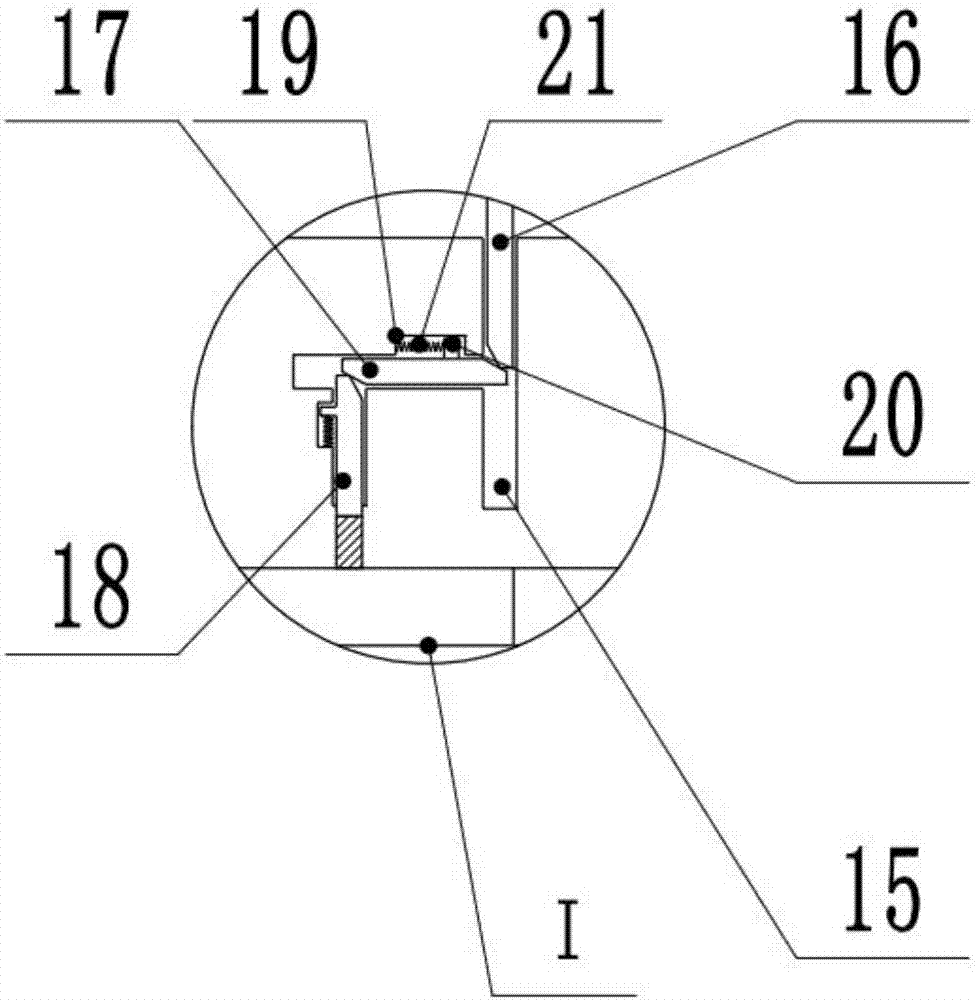

Full-automatic nailing machine for boards

ActiveCN104149144AImprove reliabilityPrecise positioningStapling toolsNailing toolsEngineeringControl unit

The invention discloses a full-automatic nailing machine for boards. The full-automatic nailing machine comprises an operating platform, a transmission device rack, a transmission device, nailing devices, a cutting mechanism, a squeezing cylinder, positioning wheels, a pressing plate wheel and a control unit. The transmission device rack is welded on the upper portion of the operating platform, the transmission device is arranged on the upper portion of the transmission device, the nailing devices are symmetrically arranged on the front and rear sides of the operating platform, the cutting mechanism is arranged on the lower portion of the operating platform, the squeezing cylinder is arranged on the upper left of the cutting device, the positioning wheels are arranged on the upper plane of the operating platform, the pressing wheel device is arranged on the right side of the transmission device, and the control unit is connected with the transmission device, the squeezing device, the cutting mechanism and the nailing mechanism. By the means, the full-automatic nailing machine has the advantages of high reliability, positioning accuracy, compact structure, high nailing efficiency, convenience in use and the like, completely substitutes for labor to nail the boards, and has good application prospect in the board processing industry.

Owner:沭阳县成基实业有限公司

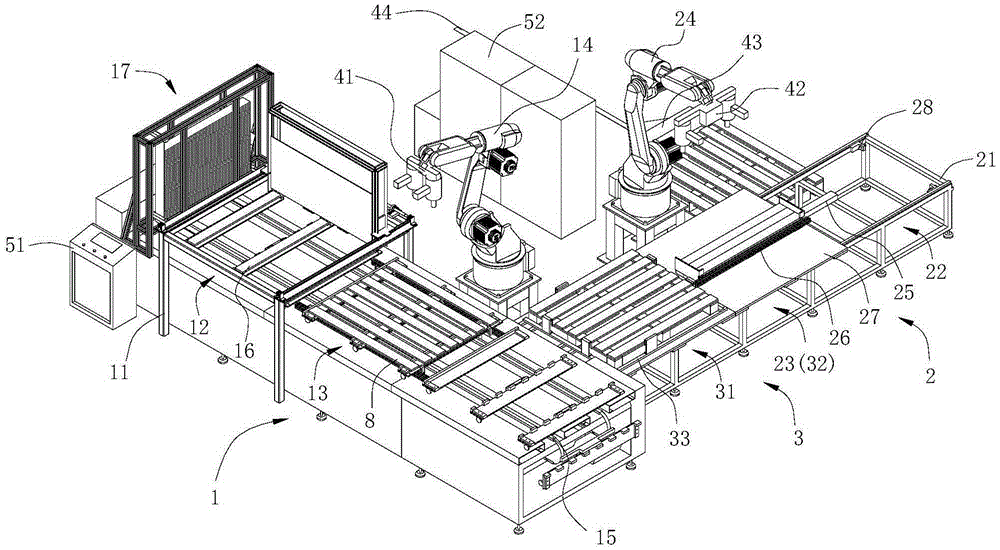

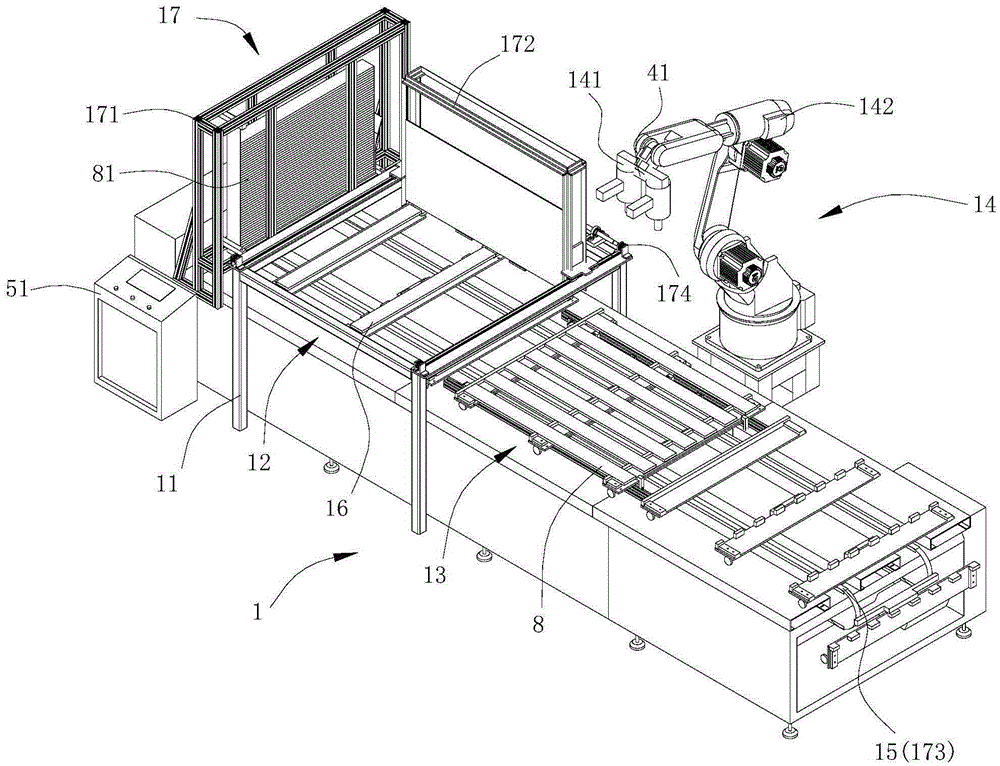

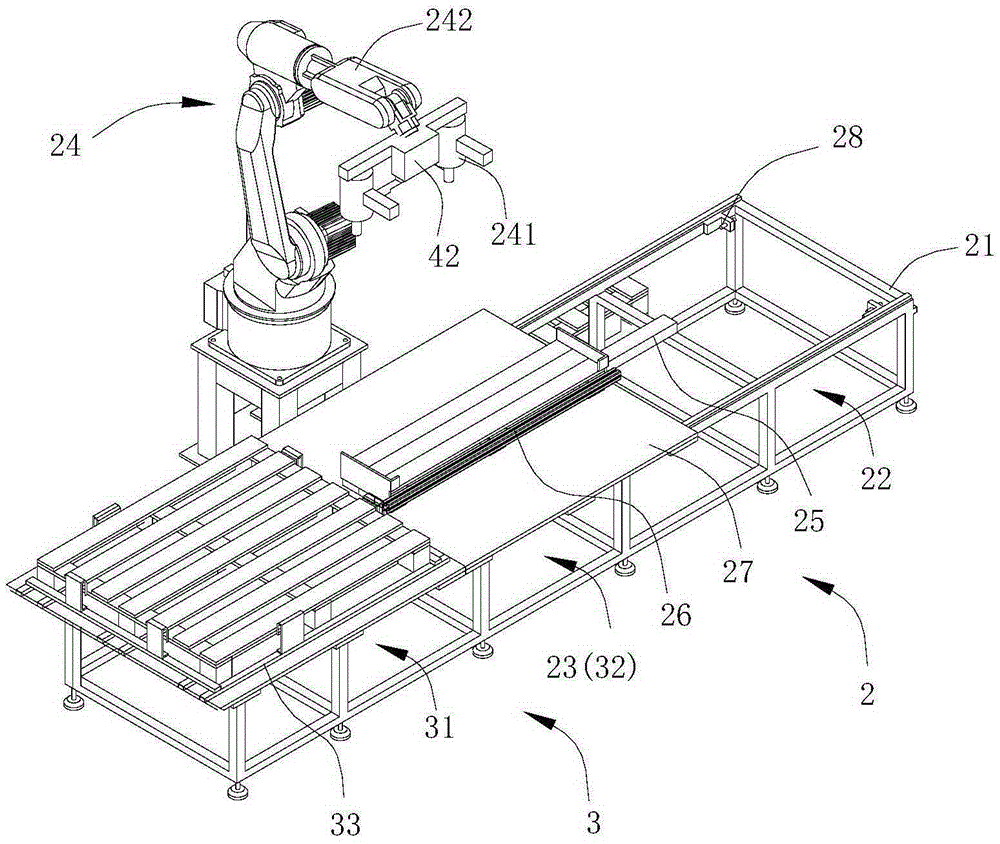

Wooden tray production line and wooden tray production process

ActiveCN106541483ARealize semi-automated assembly line operationIncrease productivityWood working apparatusProduction lineSemi automatic

The invention discloses a wooden tray production line and a wooden tray production process. The wooden tray production line comprises a panel production line, a base production line, an assembly line and a control device, wherein the panel production line comprises a first rack, a panel feeding station on the first rack, a panel nailing station, a feeding device at the panel feeding station, a first nailing device at the panel nailing station, and a first conveying device for conveying panels; the base production line comprises a second rack, a base feeding station on the second rack, a base nailing station, a second nailing device at the base nailing station, and a second conveying device for conveying bases; and the assembly line comprises a wooden tray assembling station and a wooden tray nailing station. The wooden tray production line can realize semi-automatic flow operation of a work process comprising feeding, nailing, conveying and discharging, so that the production efficiency and the product quality of wooden trays are improved, and the labor intensity of workers and the labor cost are lowered.

Owner:苏州维与智能科技有限公司

Orthodpedic or dental device

Owner:MARDINGER OFER +1

Apparatus for nailing t-nuts

There is provided an apparatus for nailing t-nut. The apparatus of the invention has a first nailing device. The first nailing device has a push bar; a rotation motion transmission mechanism; a first servo motor for moving the push bar up and down by means of the rotation motion transmission mechanism; a retaining portion to hold a t-nut; an alignment supplier to supply the t-nut to the retaining portion; and a receiving portion to hold a board. The apparatus further has a control device to control the rotation of the servo motor. The t-nut is release by the retaining portion when the push bar moves down. The upper end of the to-nut is pushed by the push bar. The push bar moves down at a speed faster than that of free fall of the t-nut when the retaining portion releases the t-nut, so as to nail the t-nut into the board.

Owner:NAGAYAMA ELECTRONICS IND

Safety of nailing device

InactiveUS20090114696A1Operational securityPrevent movementStapling toolsNailing toolsOperation safetyOperations security

A safety is incorporated in a nailing device, which ensures operation safety of the nailing device. The nailing device includes a housing in which a striker plate is mounted and movable to a ready-to-strike position for subsequently striking a nail out of the housing. The safety includes a retainer pivoted to the housing with an inner end engaging the striker plate to retain the striker plate against movement to the ready-to-strike position and an opposite outer end engaging a release plate that is biased by a spring to partially projecting beyond the housing. When the nailing device is properly set on a work piece, the release plate is forced against the biasing spring back into the housing and the inner end of the retainer is caused to disengage from and thus freeing the striker plate.

Owner:JANN YEI IND

Self-fixing plate nailing device for constructional engineering

ActiveCN107097308AAvoid misalignmentQuality improvementStapling toolsNailing toolsFixed frameIndustrial engineering

The invention discloses a self-fixing plate nailing device for constructional engineering. The self-fixing plate nailing device comprises a device body, the device body is provided with support frames, a workbench is arranged on the support frames, a positioning plate is arranged over the workbench, a nailing cavity is formed in the middle of the positioning plate, a fixing frame is arranged on the side face of the workbench, a motor is arranged on the top of the fixing frame, a sleeve is arranged at the bottom of the motor, a rotating block and a sliding block are arranged in the sleeve, a connecting rod is arranged at the bottom of the sliding block, a connecting support is arranged at the bottom of the connecting rod, a moving cavity is formed in the positioning plate, and a pressing rod is arranged in the middle of the bottom of the connecting support. According to the self-fixing plate nailing device for constructional engineering, the structure is simple, use is convenient, a workpiece can be fixed under the action of a device body while nailing is conducted, therefore, the workpiece is more stable, nailing operation is more stable, the condition that the workpiece is displaced is avoided, the working efficiency is effectively improved, the workpiece nailing quality is improved, and the practicability is high.

Owner:四川华映大地文化科技有限公司

Canvas stretching and nailing device

InactiveCN106347013AConsistent tightnessGuaranteed smoothSpecial ornamental structuresEngineeringNail gun

The invention discloses a canvas stretching and nailing device which comprises a bottom moving track, a clamping and pushing device and a stretching and nailing device, wherein the moving track pushes a canvas and a frame to the bottom of the clamping and pushing device, the canvas is delivered to an accommodating space between clamping jaws, a clamping cylinder drives the clamping jaws to clamp the edge of the canvas, a pushing cylinder pushes a pushing plate profile, the clamping cylinder moves along with the pushing plate profile, the clamping jaws wrap the edge of the canvas on the frame; a cylinder drives a heavy sliding block to drive an aluminium profile to move downwards, and a nail gun falls to the stretching and nailing position along with the aluminium profile, and stretches and nails the canvas on the frame. The device disclosed by the invention can automatically complete the process flows of wrapping the frame and stretching and nailing, realize uniform tightness of stretching and nailing, and ensure the levelness of stretching and nailing, thus improving the stretching and nailing efficiency and reducing investment of labor force.

Owner:ALLIO ROBOT TECH (CHANGSHU) CO LTD

Wooden tray nailing equipment

InactiveCN104275725AImprove work efficiencyReduce manufacturing costStapling toolsNailing toolsNail deviceEngineering

Owner:镇江市博业机械设备有限公司

Safety of nailing device

InactiveUS7594598B2Eliminates inadvertent percussionEnsure operational security issuesStapling toolsNailing toolsEngineeringOperation safety

A safety is incorporated in a nailing device, which ensures operation safety of the nailing device. The nailing device includes a housing in which a striker plate is mounted and movable to a ready-to-strike position for subsequently striking a nail out of the housing. The safety includes a retainer pivoted to the housing with an inner end engaging the striker plate to retain the striker plate against movement to the ready-to-strike position and an opposite outer end engaging a release plate that is biased by a spring to partially projecting beyond the housing. When the nailing device is properly set on a work piece, the release plate is forced against the biasing spring back into the housing and the inner end of the retainer is caused to disengage from and thus freeing the striker plate.

Owner:JANN YEI IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com