Patents

Literature

46results about How to "Suppression of warping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

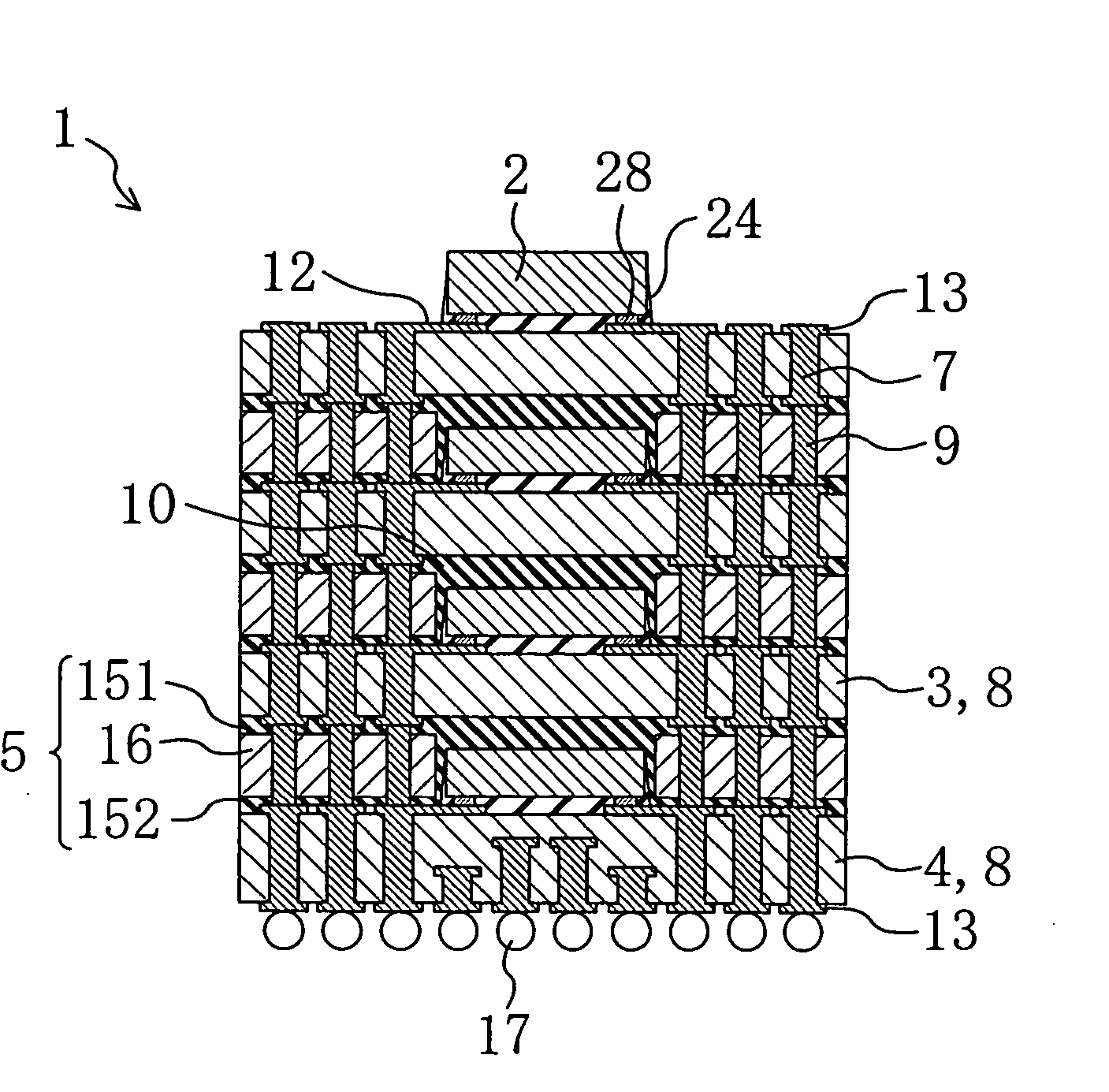

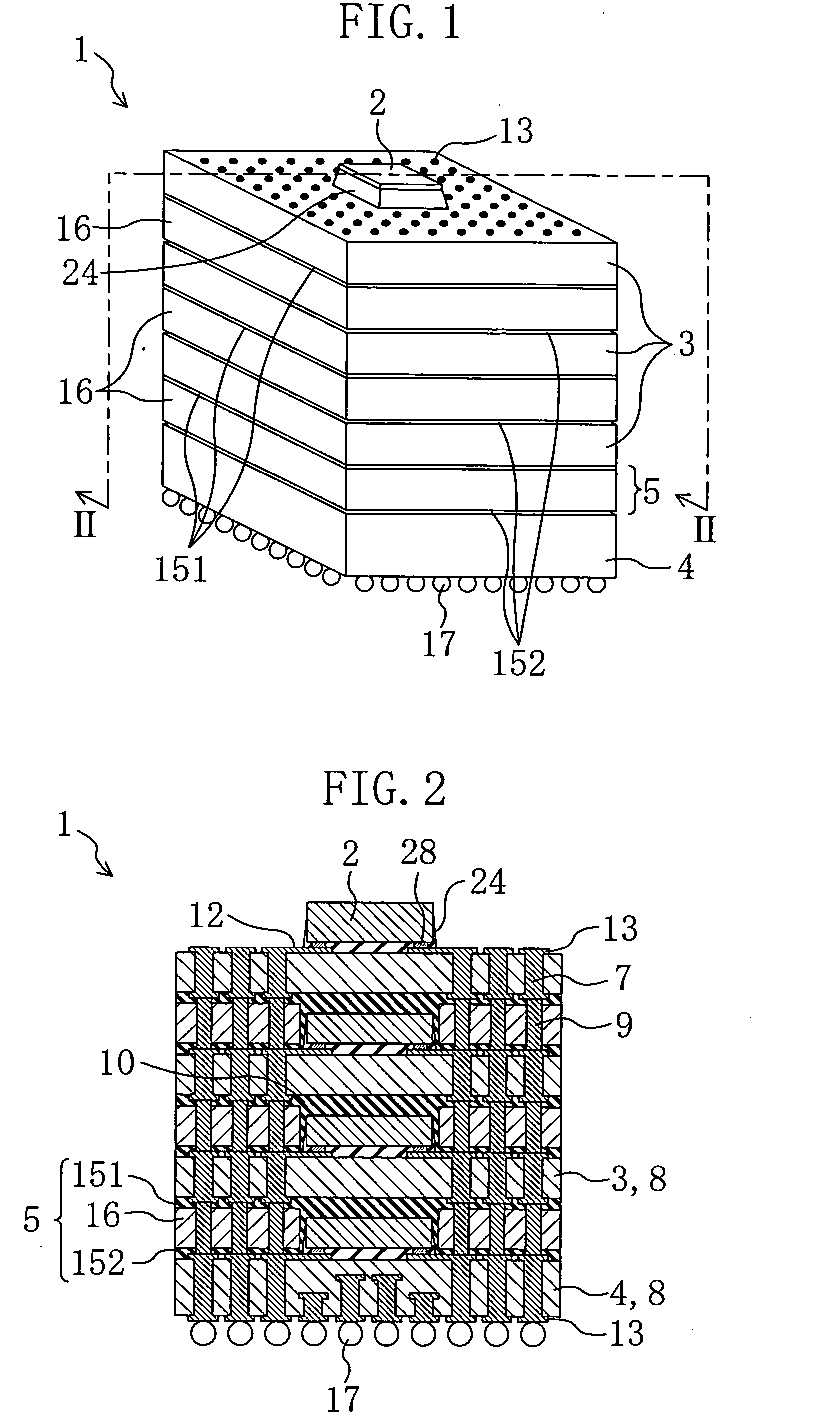

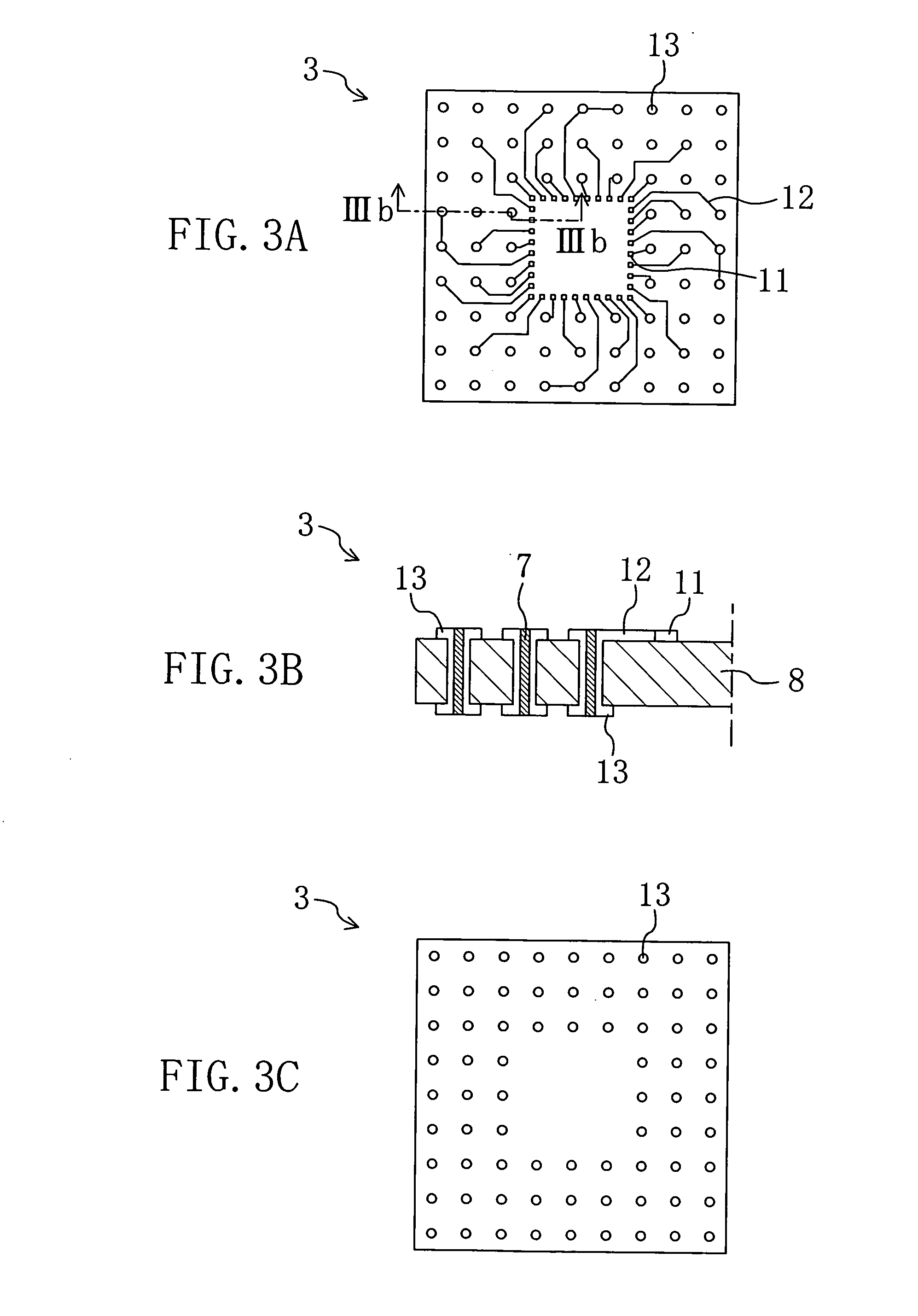

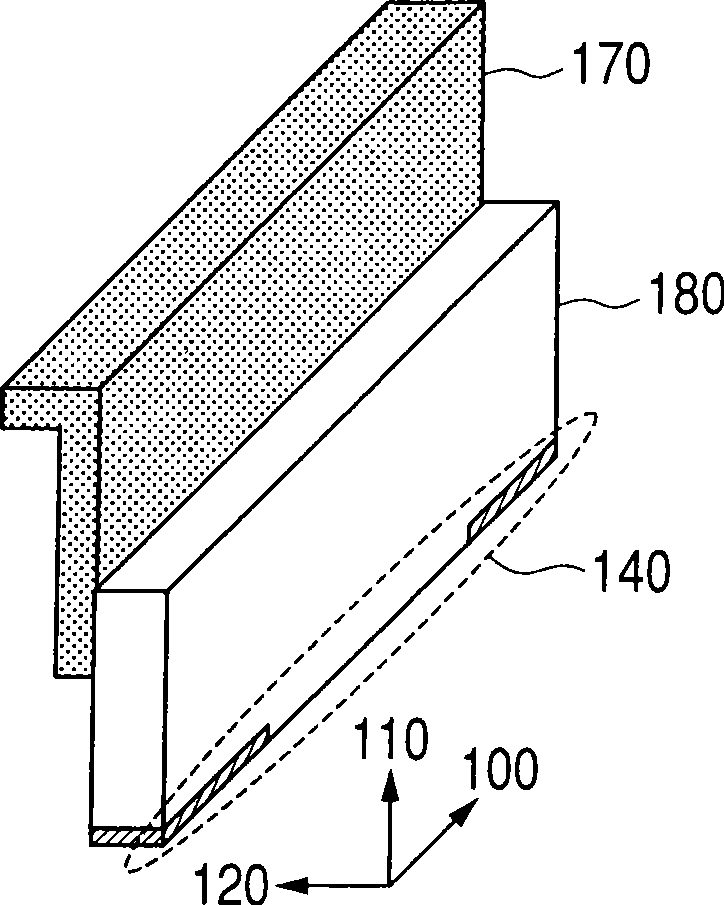

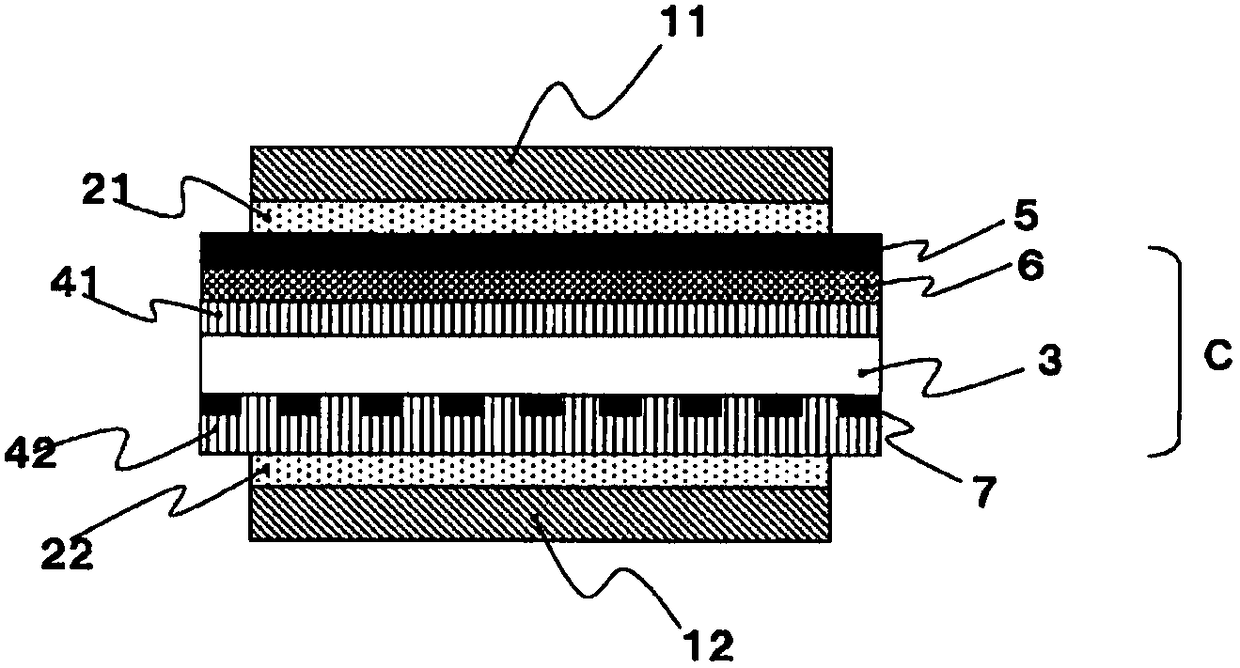

Multilevel semiconductor module and method for fabricating the same

InactiveUS20060231939A1InhibitionReduce thicknessSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor chip

A semiconductor module is formed by alternately stacking resin boards and sheet members. Each of the resin boards includes first buried conductors. A semiconductor chip is mounted on the upper face of each of the resin boards. Each of the sheet members having an opening for accommodating the semiconductor chip and including second buried conductors electrically connected to the first buried conductors. A first resin board located at the bottom is thicker than second resin boards. Each of the sheet members includes an adhesive member covering the upper and side faces of the semiconductor chip.

Owner:PANASONIC CORP

Auxiliary supporting structure capable of inhibiting thin-wall structure from deformation

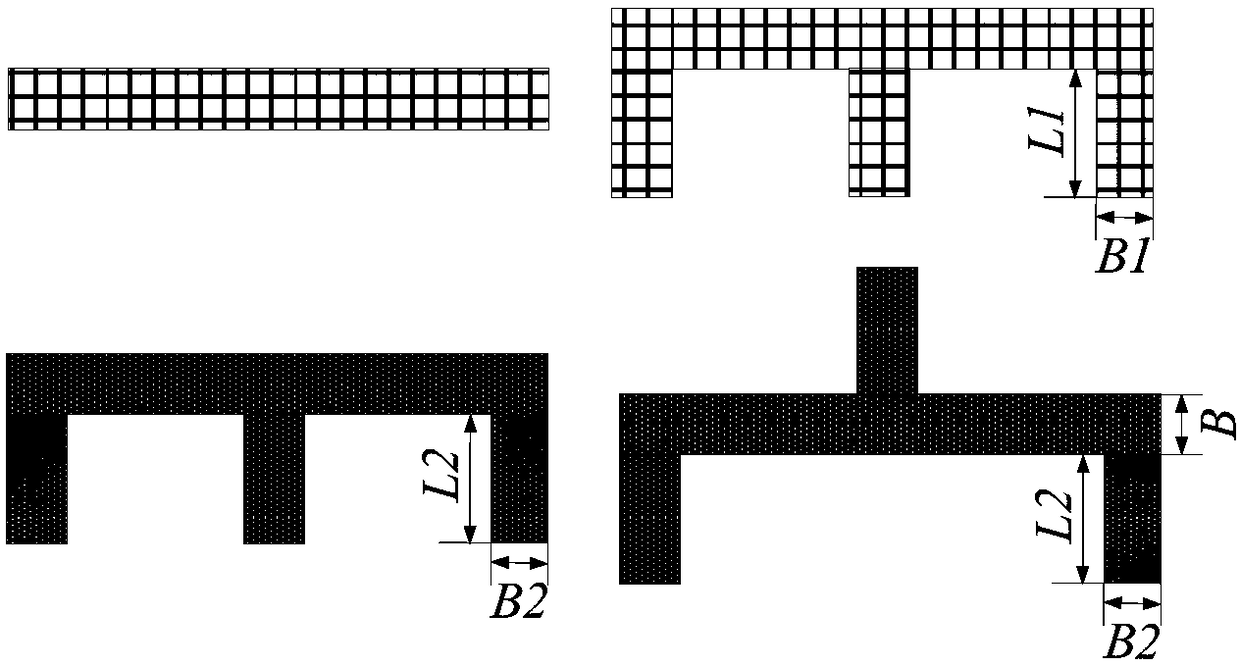

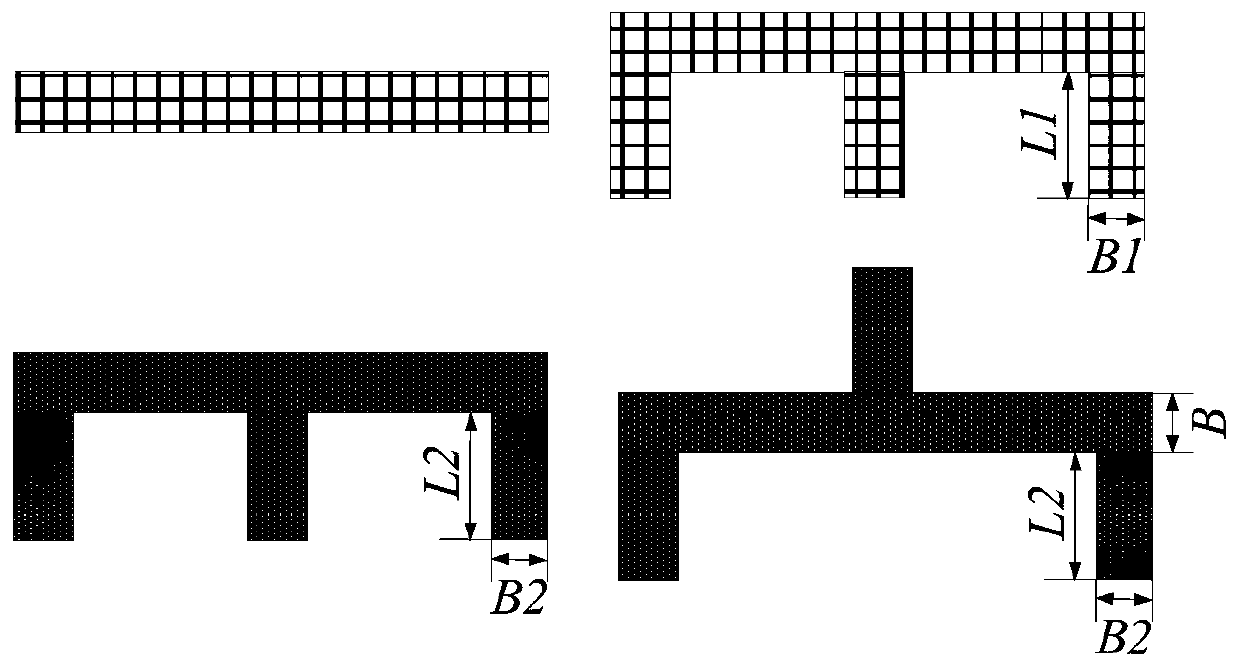

ActiveCN108145161AWarpage suppressionSuppresses warpingAdditive manufacturing apparatusIncreasing energy efficiencyOpen structureMesh grid

The invention provides an auxiliary supporting structure capable of inhibiting a thin-wall structure from deformation. The auxiliary supporting structure comprises a grid supporting part and a solid supporting part which are fixedly connected, i.e., the auxiliary supporting structure adopts integral type auxiliary support which has a section in a grid and solid form in a growth direction, whereina solid part is fixedly connected with a grid part; the lower end of the grid supporting part supports on the solid supporting part; support is formed between a suspending end of the thin-wall structure and the solid supporting part; the grid supporting part adopts a slice form or an epsilon type structural form; the upper end of the solid supporting part supports on the lower end surface of the grid supporting part, and the lower end of the solid supporting part supports on a forming base plate; and the solid supporting part adopts an epsilon type structural form or a Y-shaped structural form. The auxiliary supporting structure can effectively inhibit buckling deformation of an inclined thin-wall open structure and bulge deformation of a thin-wall open structure with relatively great breath, and guarantees thin-wall suspending precision and precision of an open structural molded surface.

Owner:CAPITAL AEROSPACE MACHINERY +1

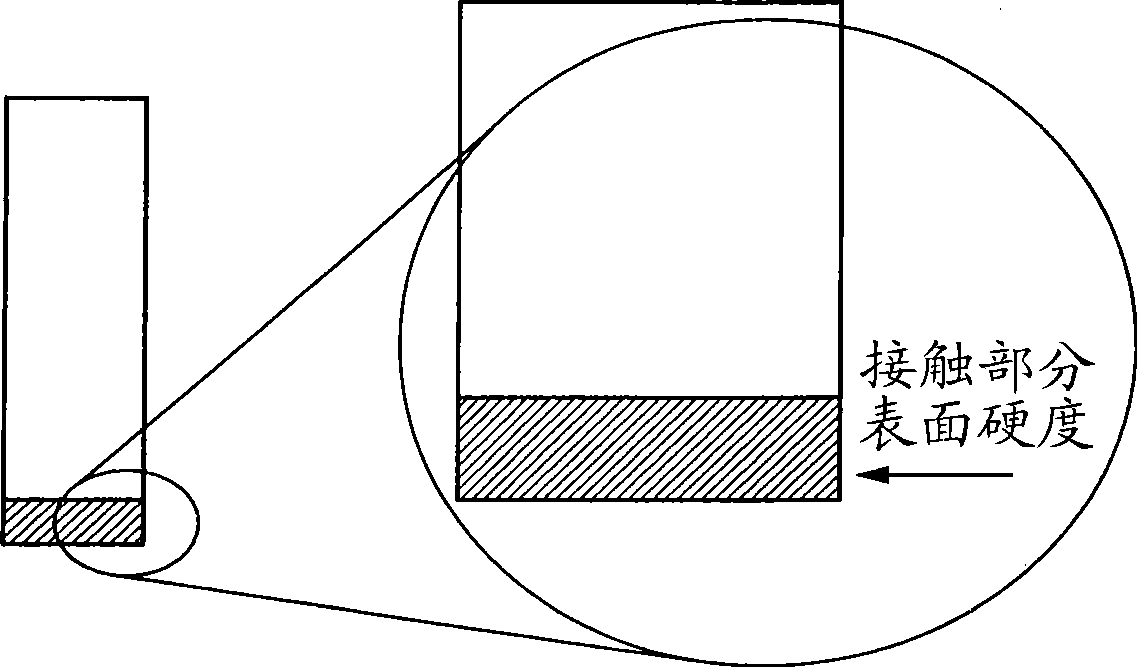

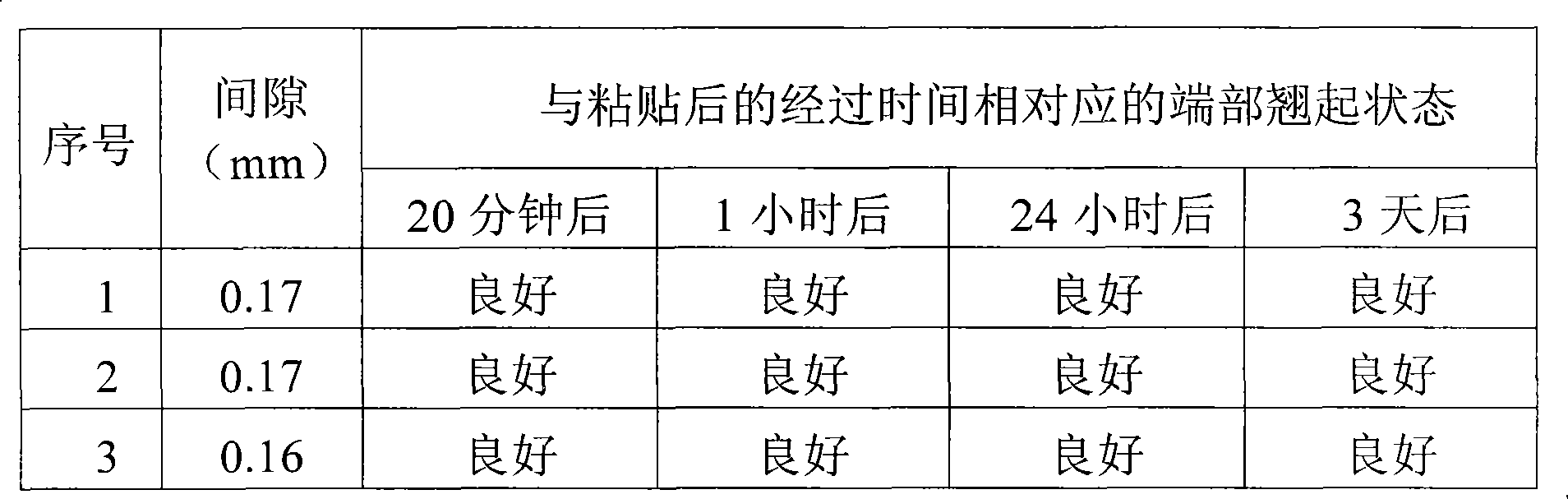

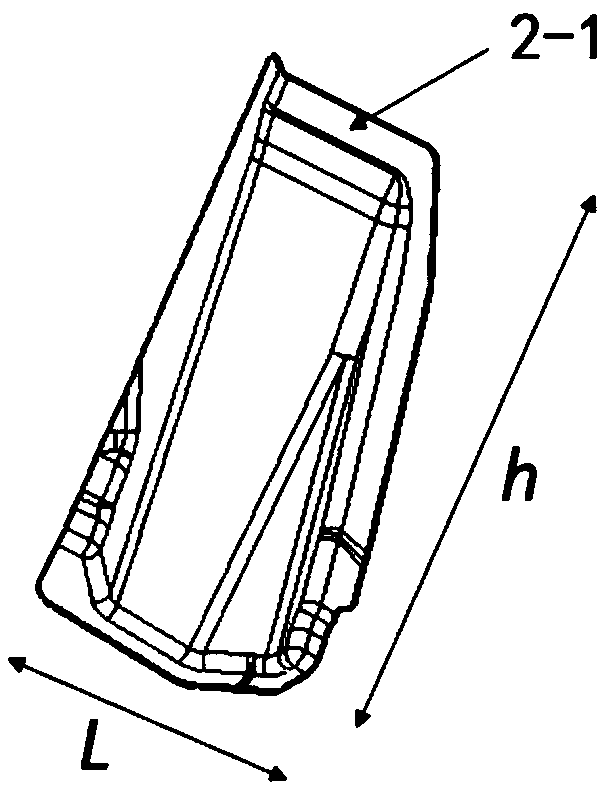

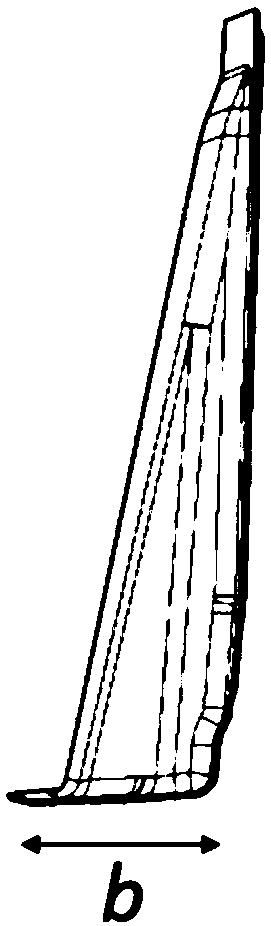

Electrophotographic cleaning blade, process for producing electrophotographic cleaning blade, and electrophotographic apparatus

ActiveCN101364076AImprove smoothnessSuppression of warpingElectrography/magnetographyHardnessMethods of production

The invention relates to an electrophotographic cleaning blade, process for producing electrophotographic cleaning blade and electrophotographic apparatus. The electrophotographic cleaning blade is provided which is free of blade turning-up coming from both end portions of the blade in its lengthwise direction. The cleaning blade having a blade formed of a polyurethane resin, which is to come into touch with the surface of a photosensitive drum of an electrophotographic apparatus to remove a toner remaining thereon, and a support member which holds the blade. The blade has a polyurethane resin portion having a dynamic hardness of 0.05 mN / mum2 or more and 0.16 mN / mum2 or less and a high-hardness portion having a dynamic hardness 1.3 times or more and 30 times or less the dynamic hardness of the polyurethane resin portion, provided at each end portion of the blade in its lengthwise direction at its part coming into touch with the photosensitive drum.

Owner:CANON KK

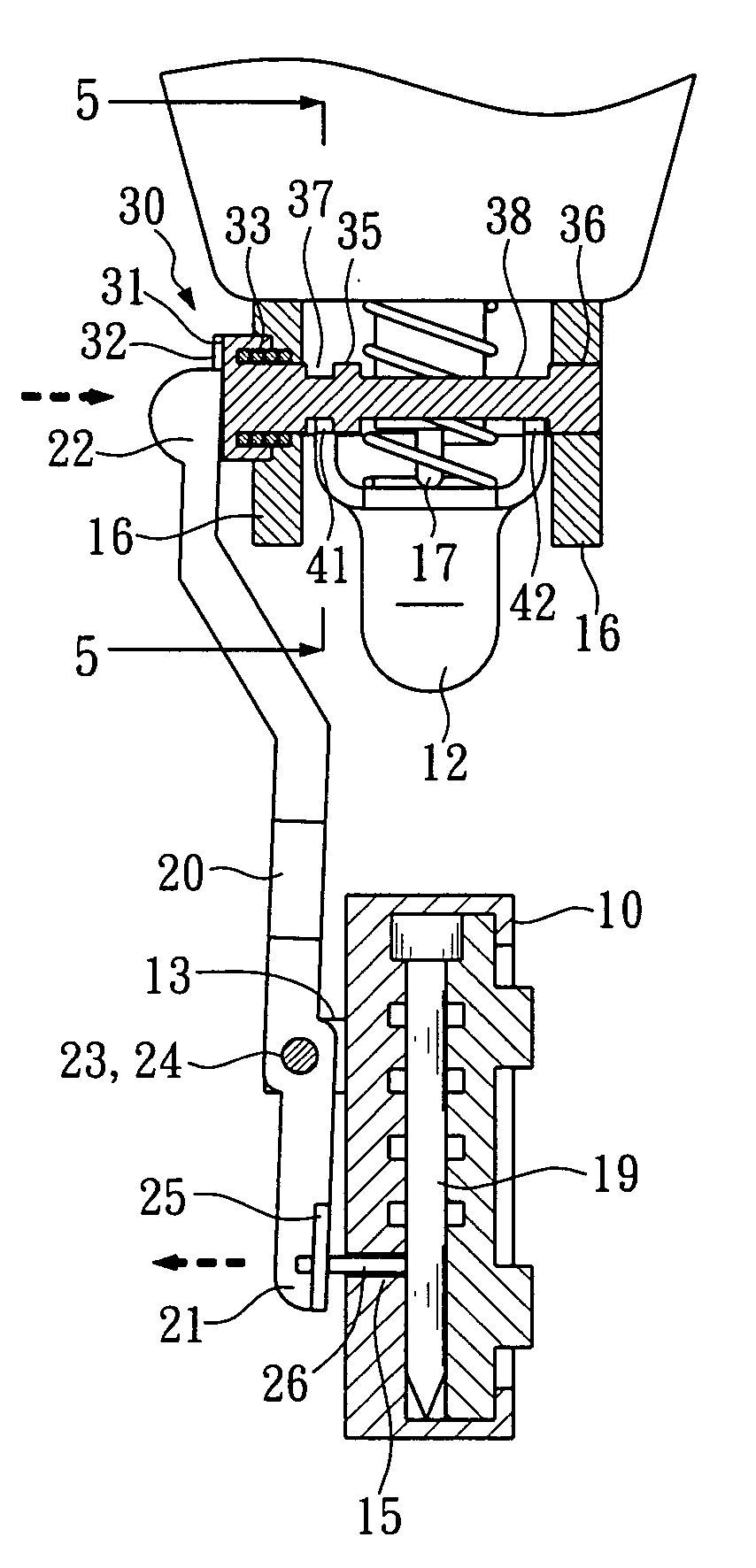

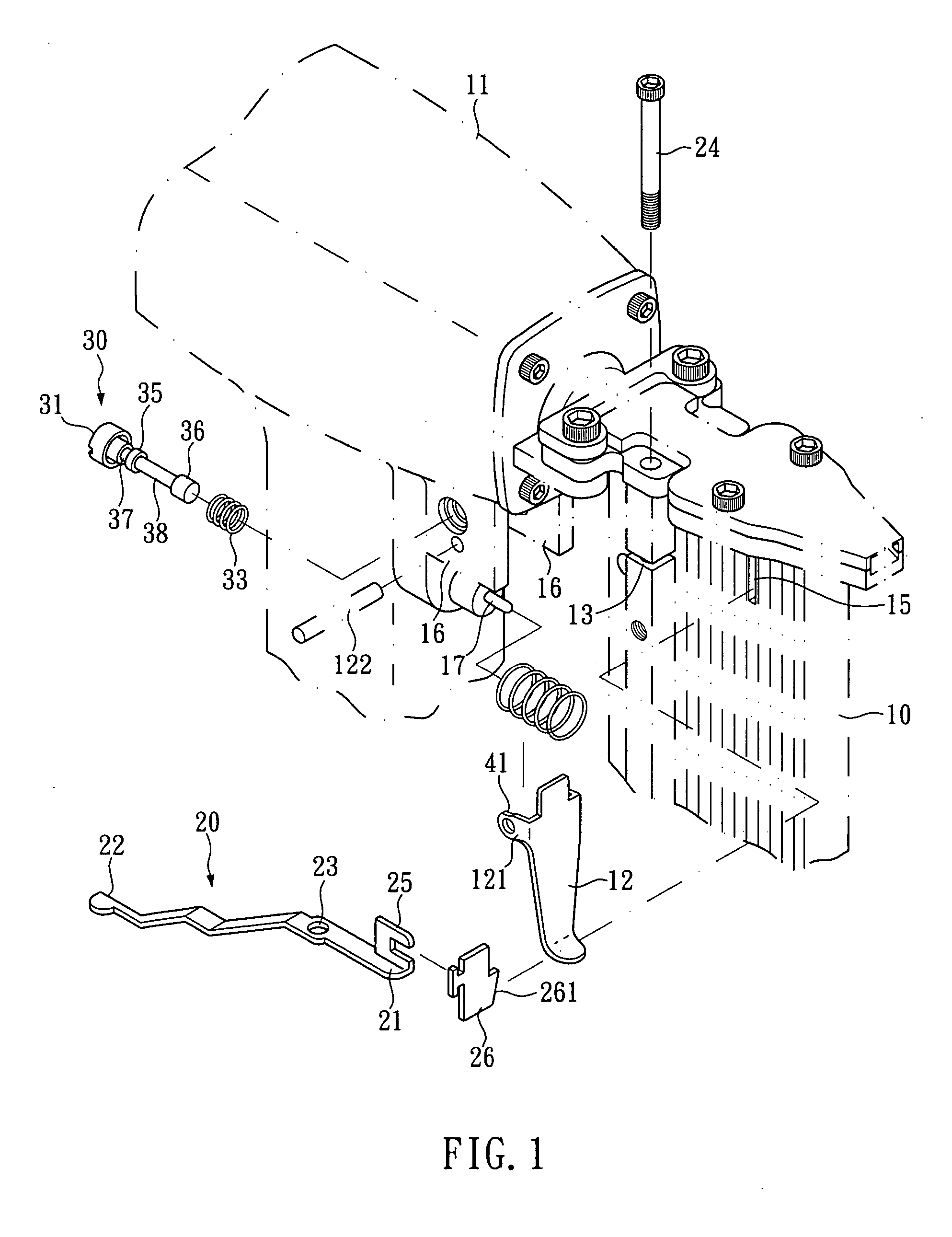

Structure of arresting mechanism for nail guns

A structure of an arresting mechanism for a nail gun, wherein the nail gun is composed of a nailing device. The nail gun further comprises a trigger, which is fastened between two pin plates of the nailing device and can be cocked to shoot nails. The arresting mechanism contains a reciprocating cotter pierced through the two pin plates; at lease one retaining part disposed on the trigger; a swinging sensing component, which is fastened together with the magazine, with its first end in the location corresponding to the magazine and further extending into the magazine to reach the nail and the second end reaching the head of the cotter. Accordingly to foregoing structure, when there is no nail loaded in the magazine, the trigger cannot be cocked by the users; contrarily, when nails are loaded in the magazine, the trigger can be cocked.

Owner:NAILERMATE ENTERPRISE

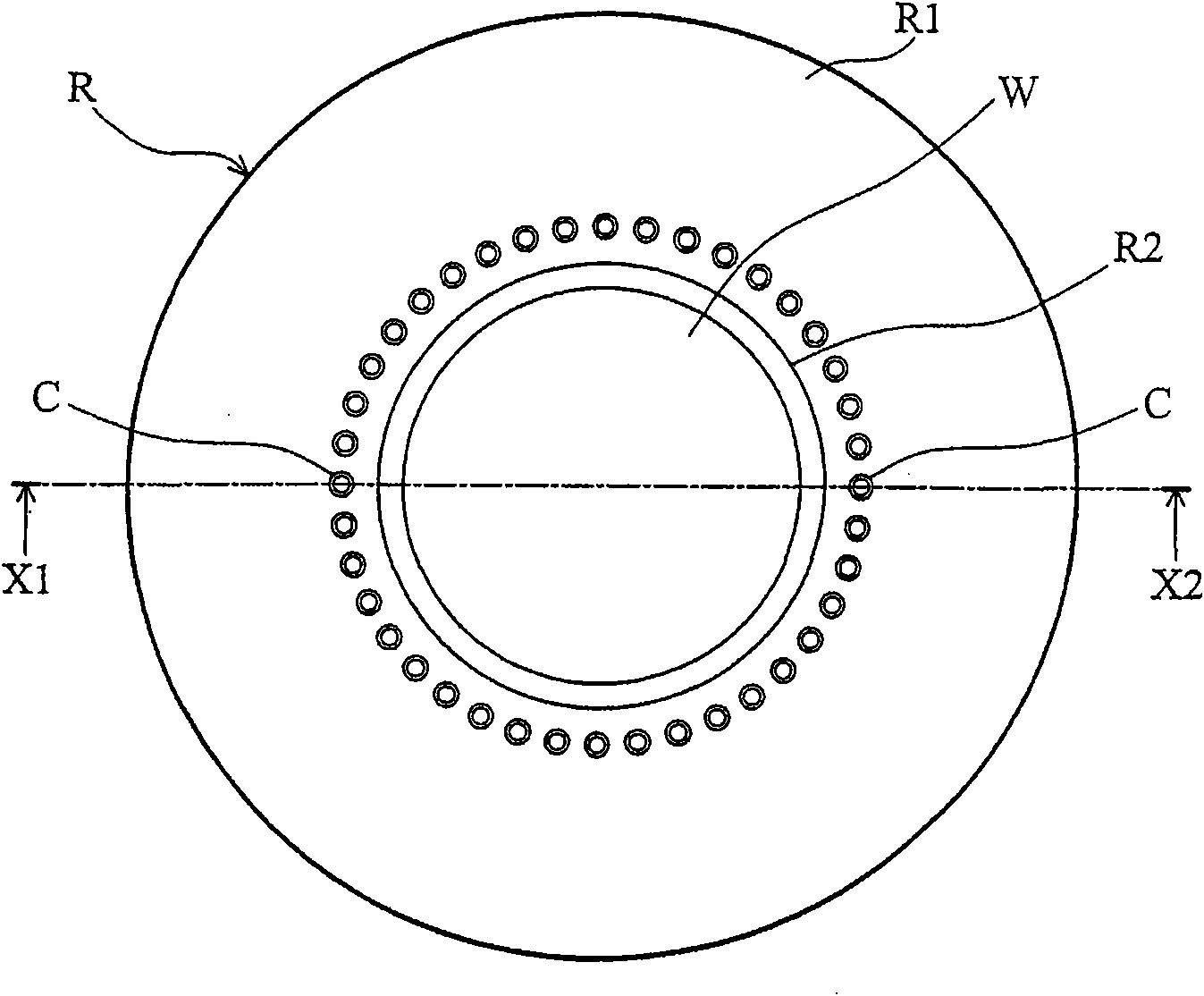

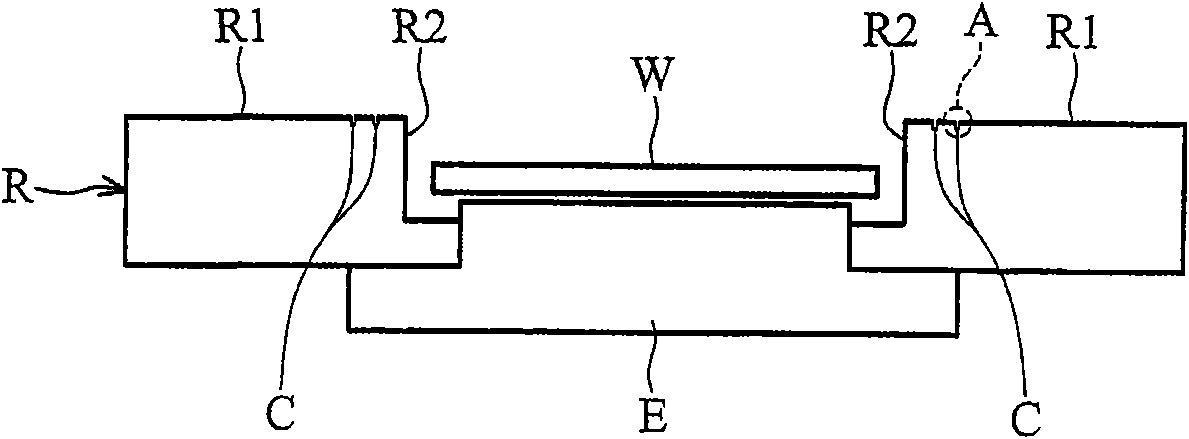

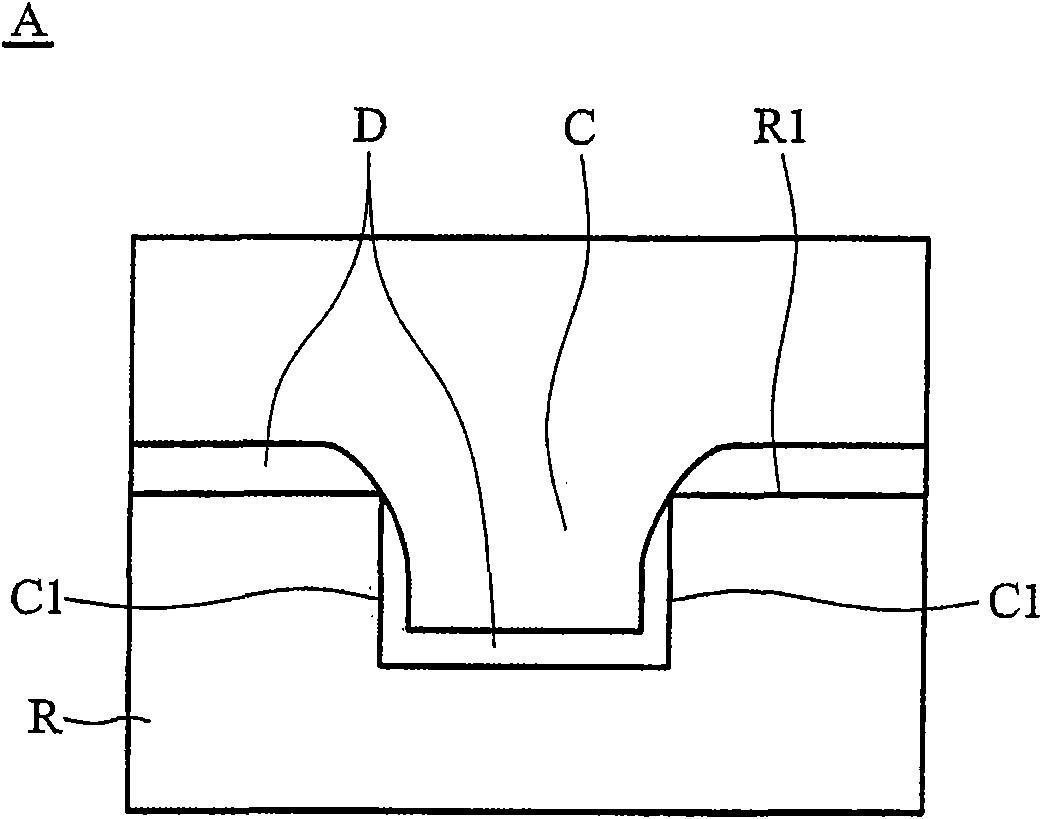

Semiconductor process unit and focusing ring thereof

InactiveCN101625958AImprove the excellent rateSuppression of warpingElectric discharge tubesSemiconductor/solid-state device manufacturingElectrical conductorEngineering

The invention discloses a focusing ring, which comprises an opening, an annular plane and a groove, wherein the opening is used for accommodating a semiconductor wafer; the annular plane surrounds the opening; and in particular, the groove is arranged on the annular plane in a mode of surrounding the annular plane. The focusing ring can prohibit contamination caused by the tilting of a deposited matter or the falling of the deposited matter from the focusing ring, thus the acceptance rate of the process can be greatly improved.

Owner:VANGUARD INTERNATIONAL SEMICONDUCTOR CORPORATION

Ink-jet recording device

Owner:BROTHER KOGYO KK

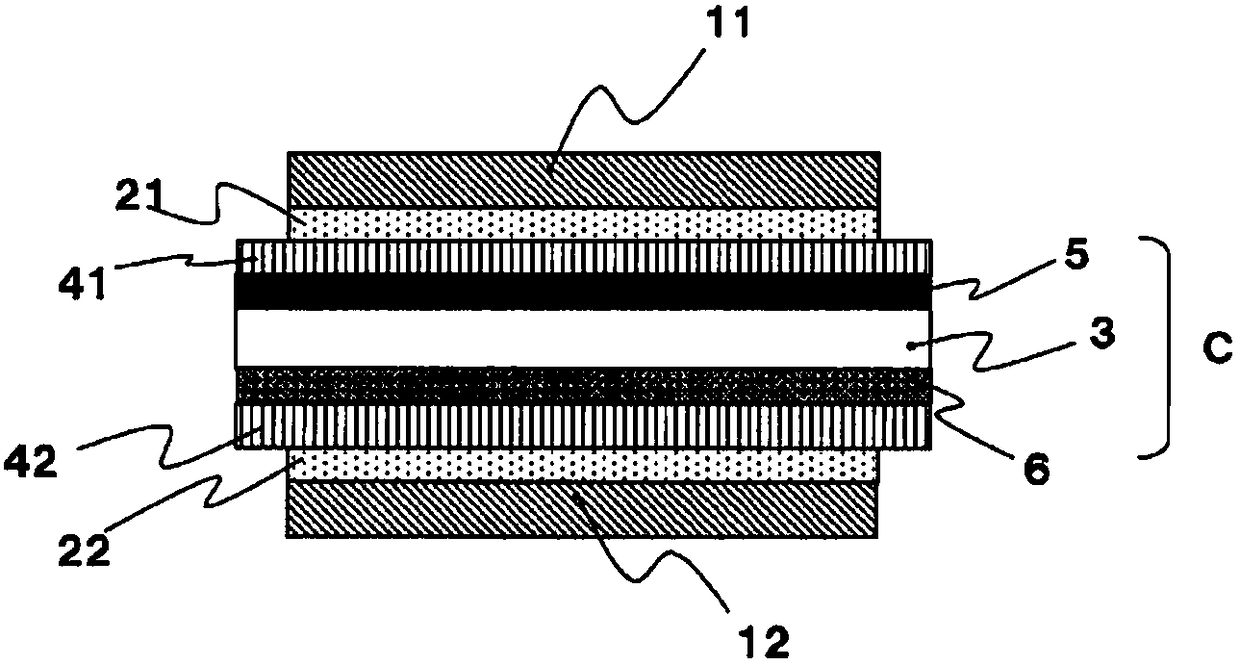

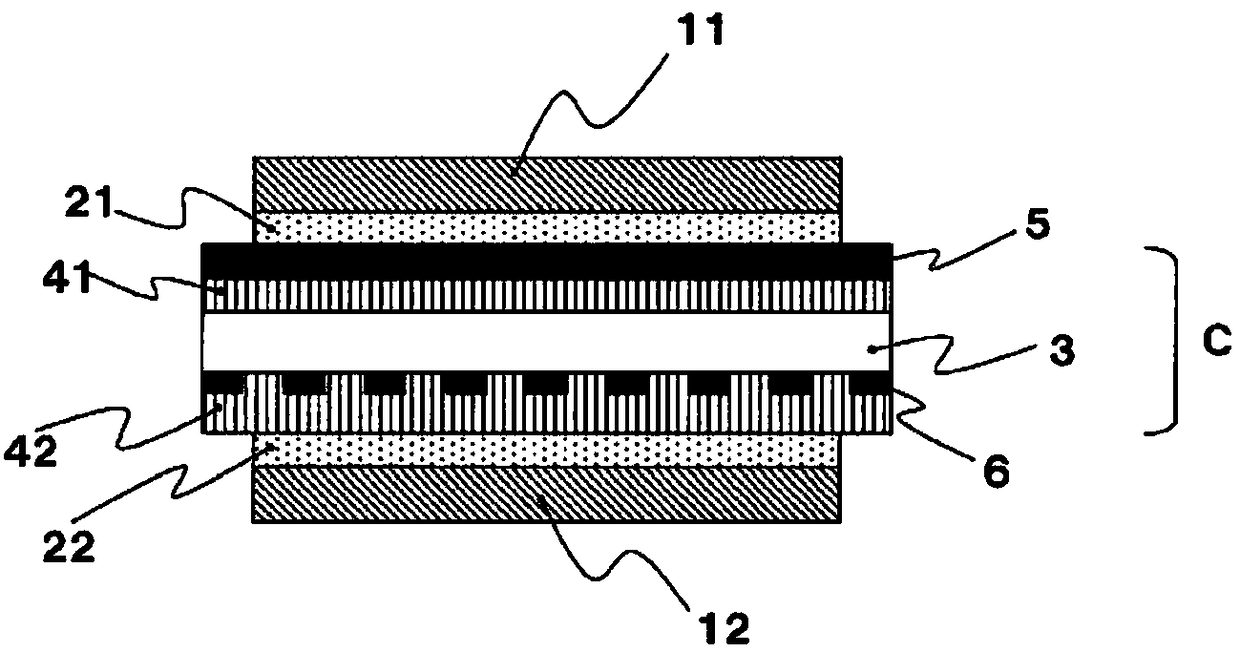

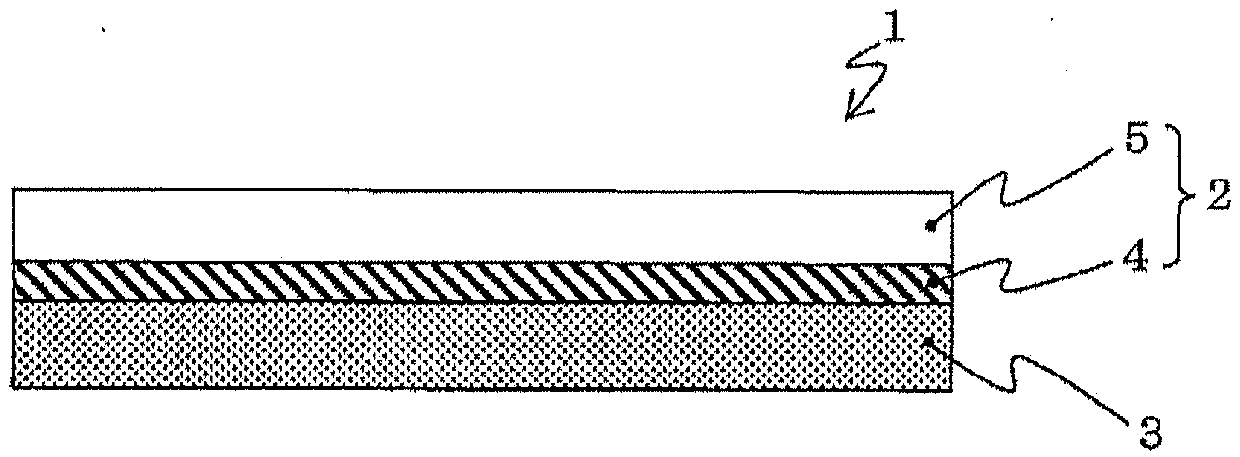

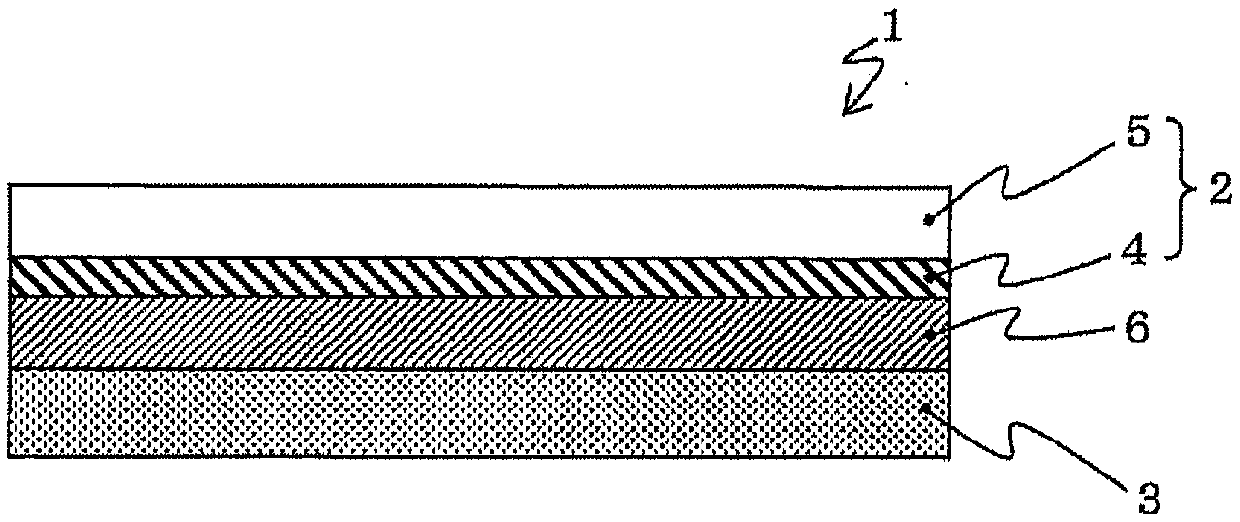

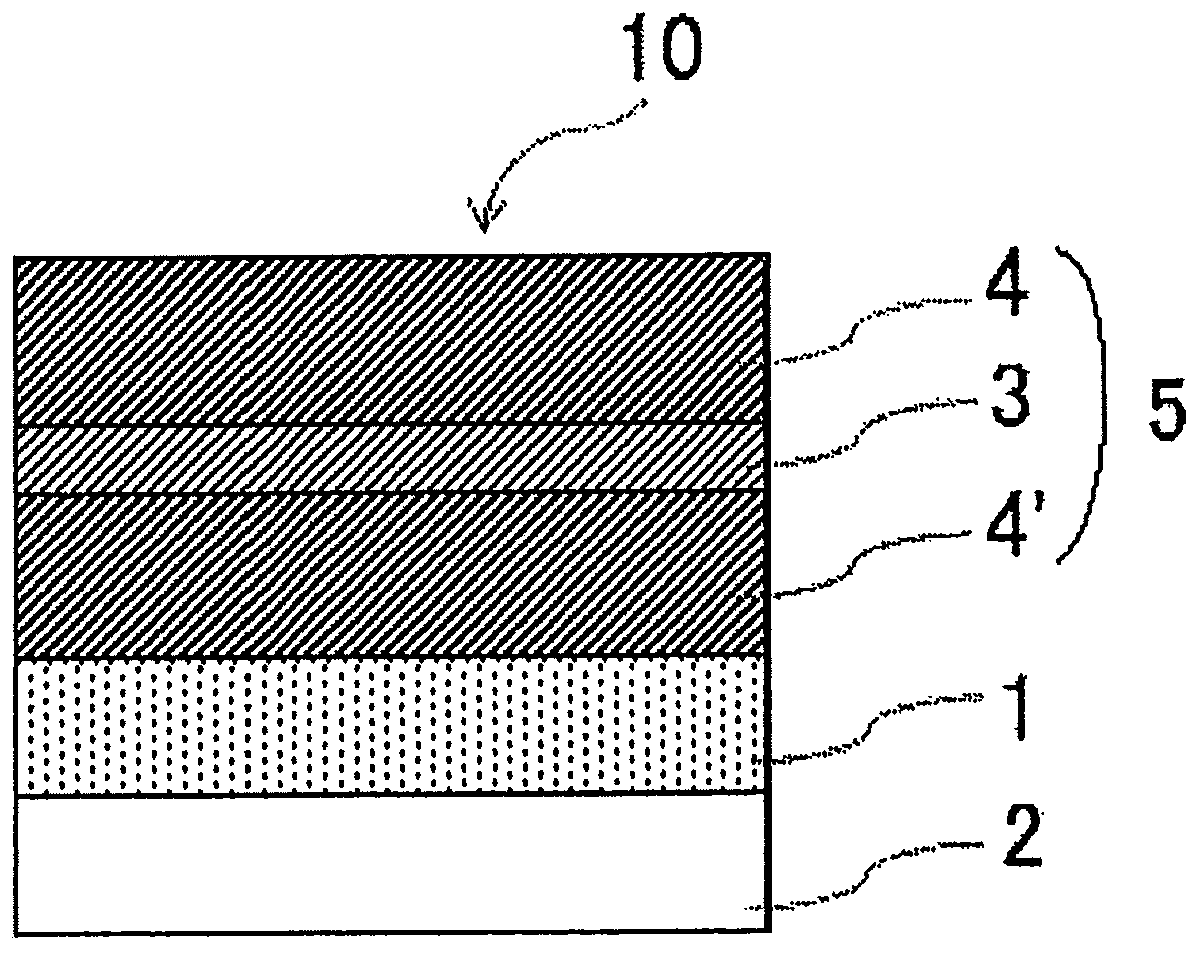

Liquid crystal panel with touch sensing function and liquid crystal display device

ActiveCN108139625ALower surface resistance valueInhibit static electricity generationSynthetic resin layered productsPolarising elementsMeth-Touch Senses

Owner:NITTO DENKO CORP

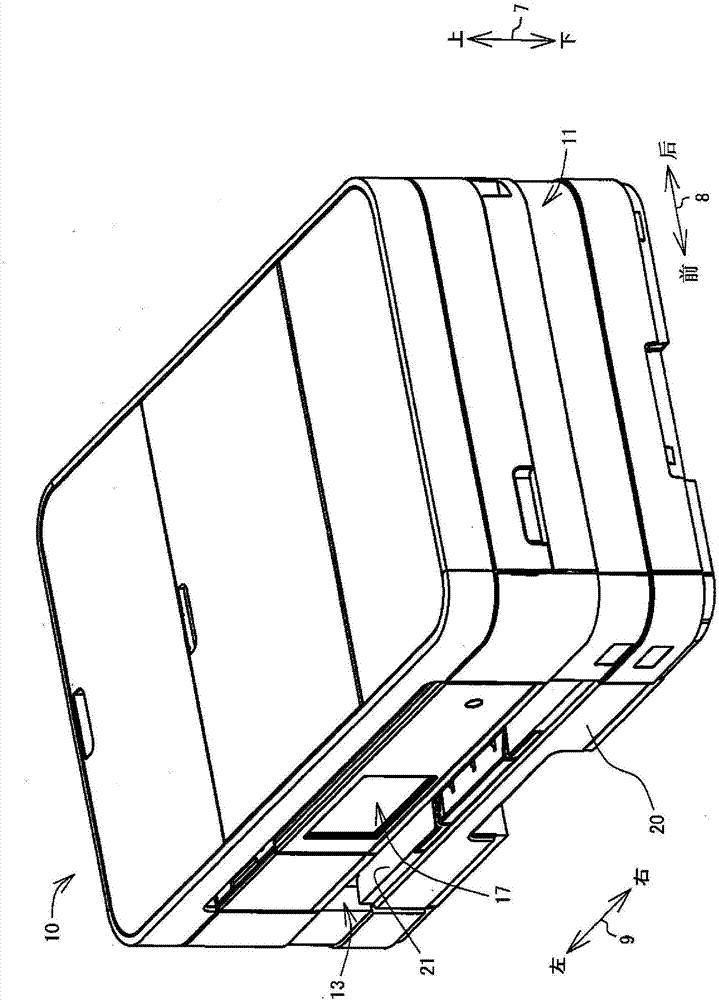

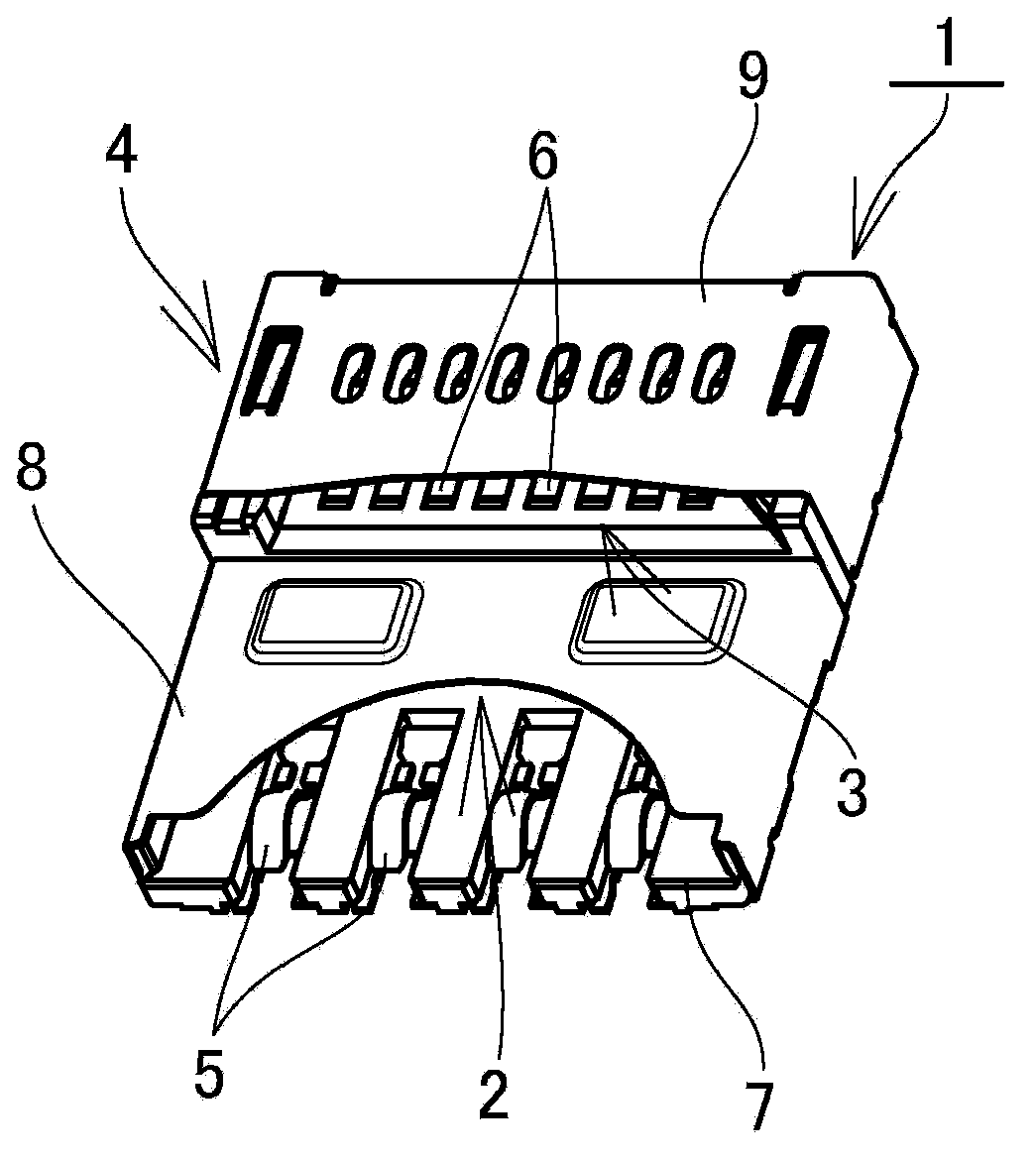

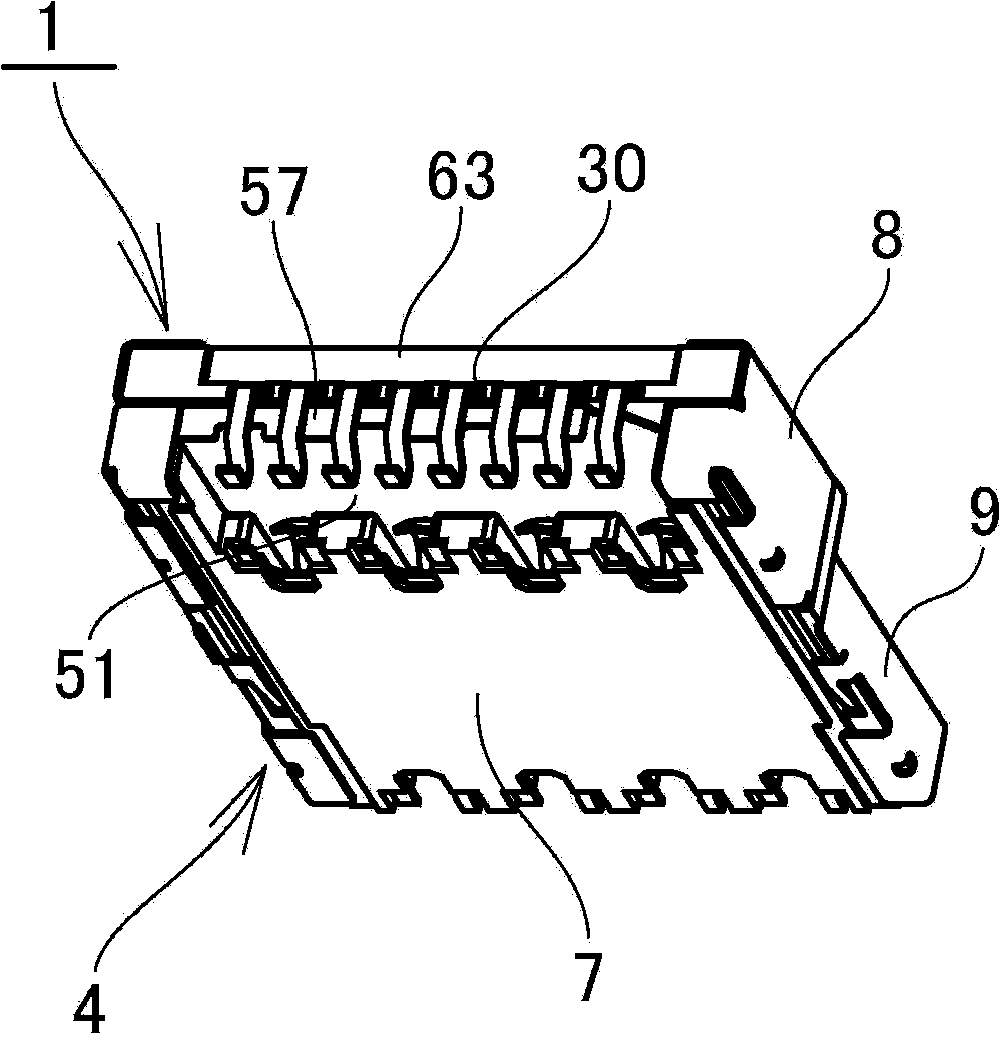

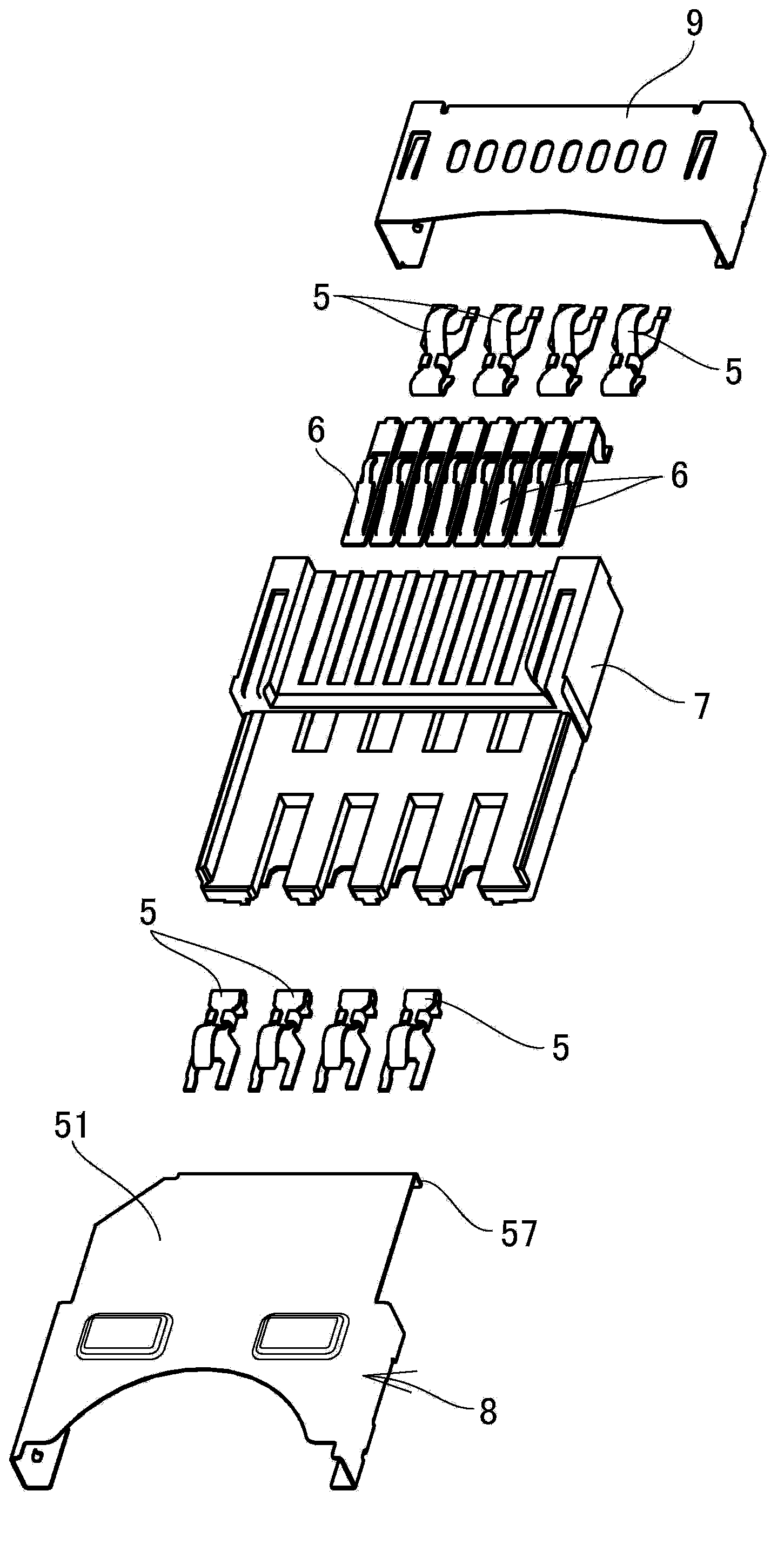

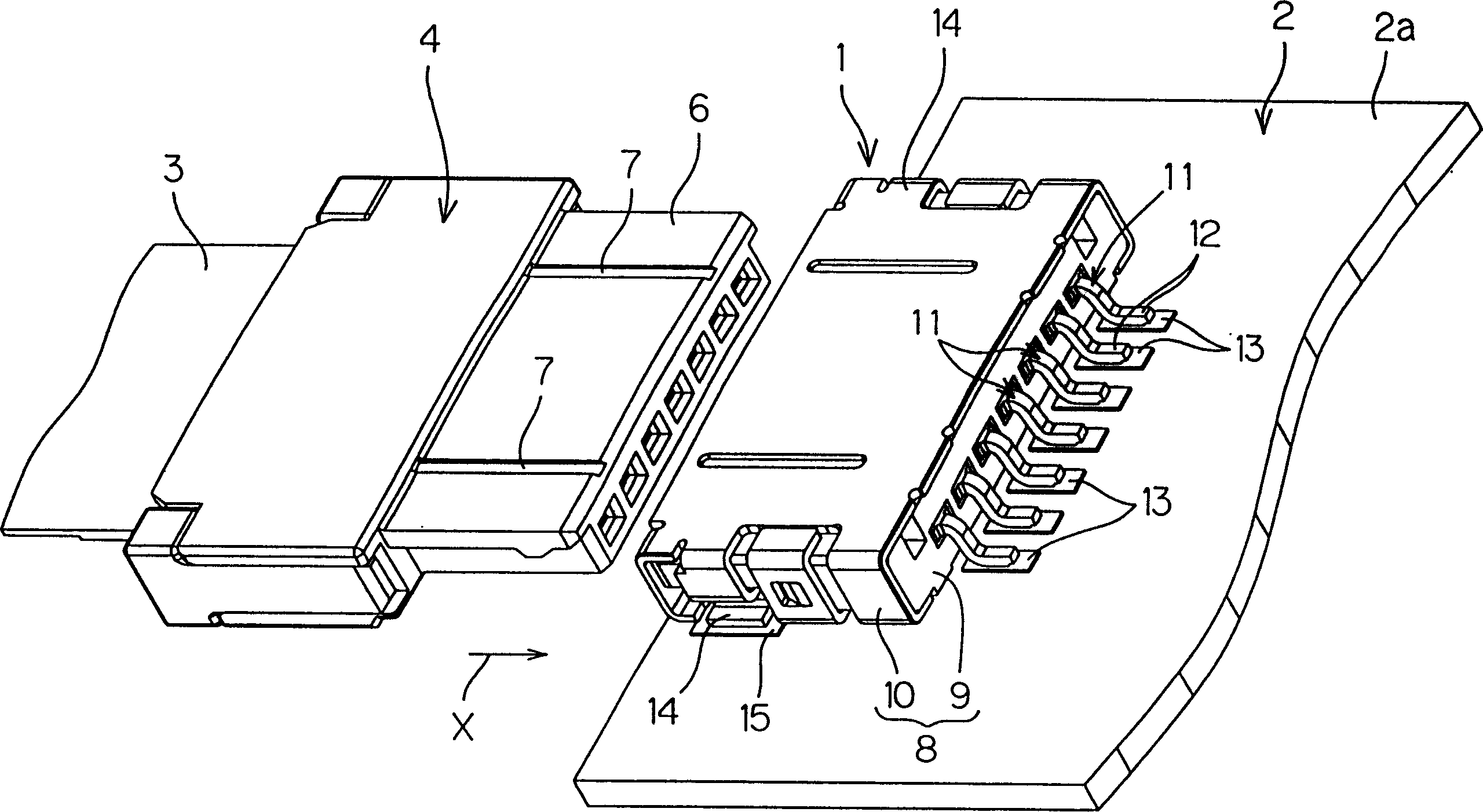

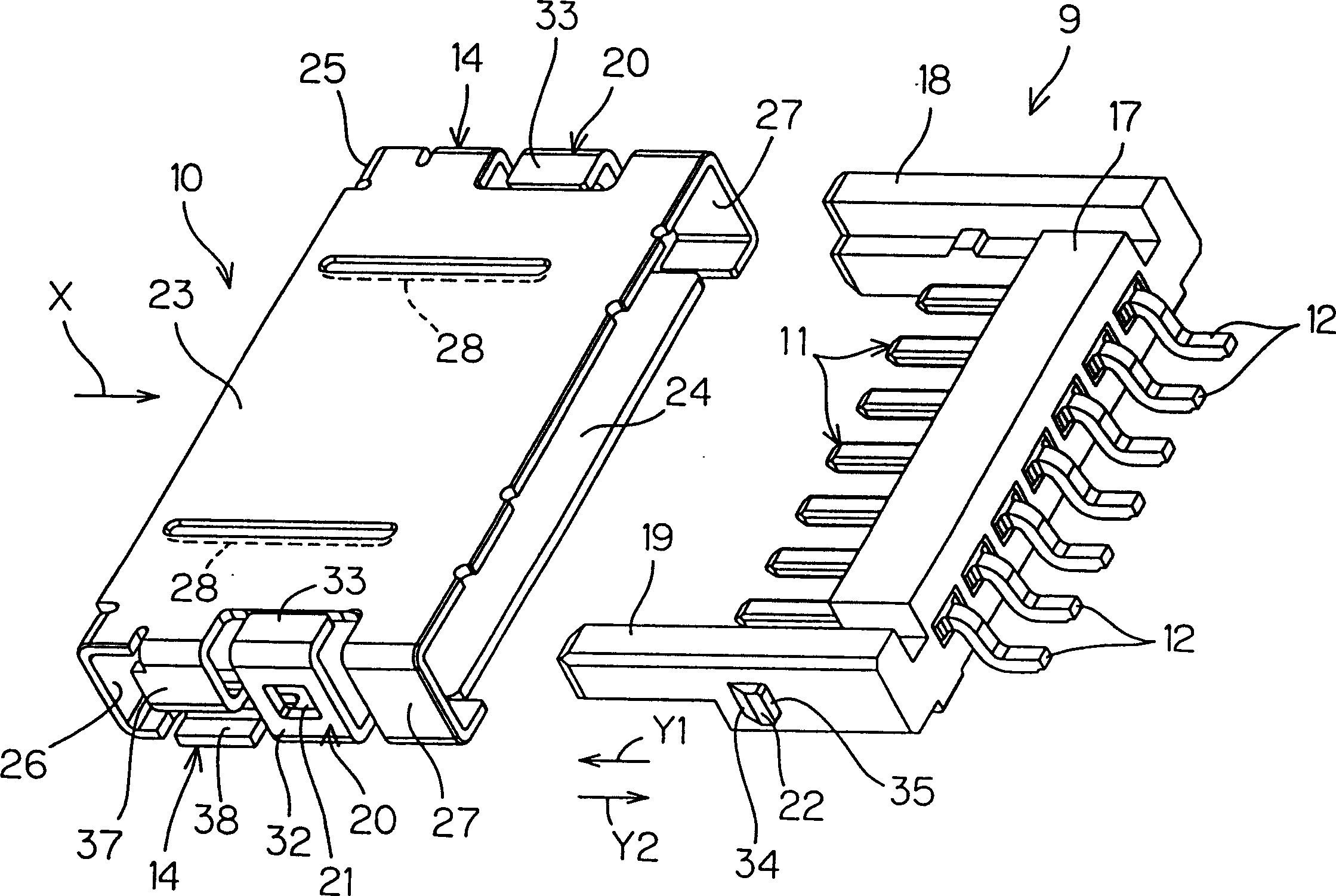

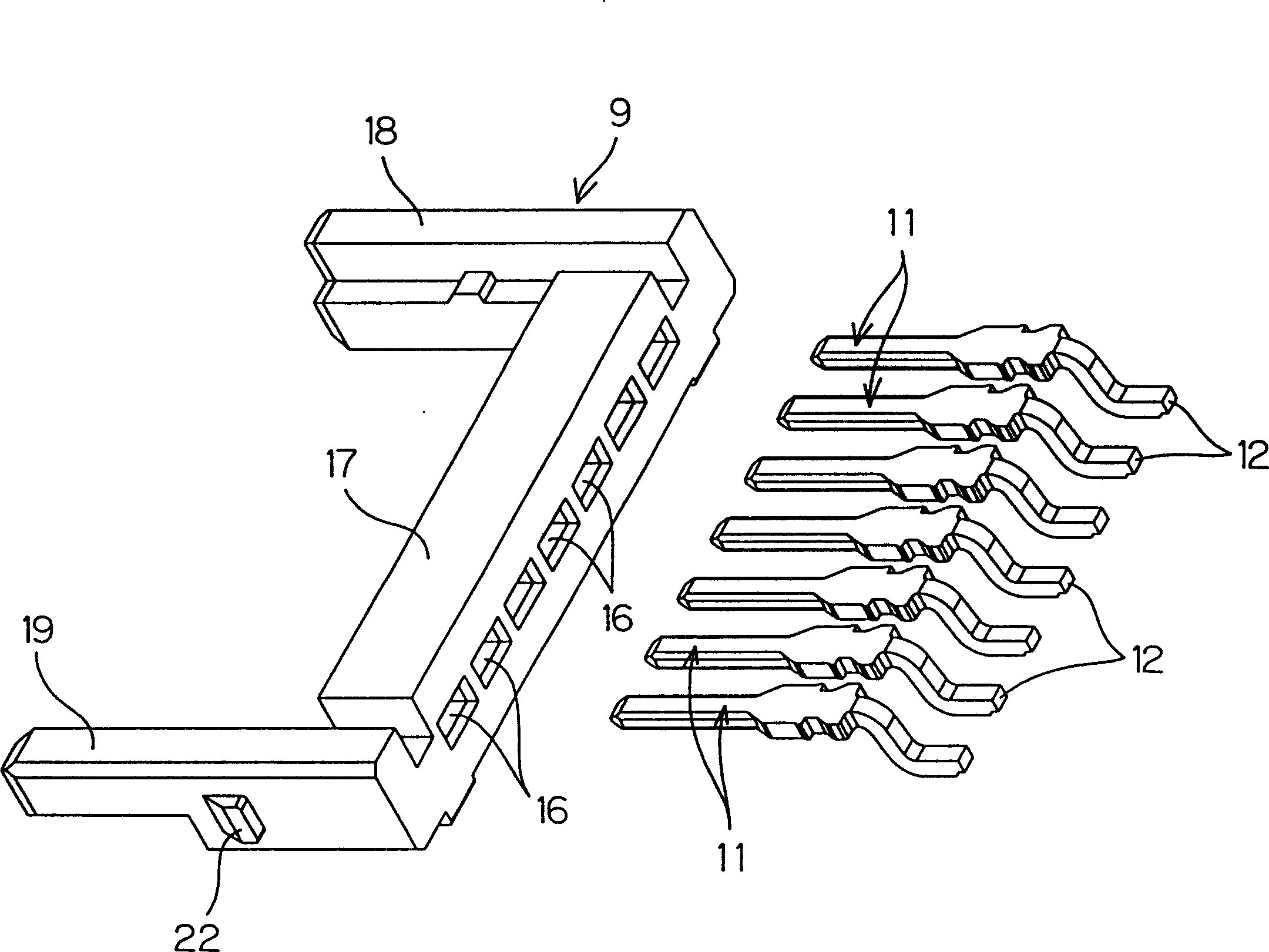

Card connector

InactiveCN103515759AShorten the overall lengthAchieve thinningCouplings bases/casesMiniaturizationEngineering

The invention provides a card connector which can connect with a plurality of cards by multilayer configuration, and the card connector can realize miniaturization and thinness. The card connector is provided with a housing (4) which has a plurality of card inserting portions (2,3) by multilayer configuration, and a plurality of contacts (5,5??,6,6??) contact with signal transmission terminals of cards (A,B) which are inserted in the card inserting portions (2,3), so that a plurality of cards can be connected in parallel configuration. The housing (4) is provided with a mould forming casing (7) made of insulating composite resin, and a lower layer cover component (8) made of metal. The mould forming casing (7) is provided with a lower layer baseplate portion (14) which forms the lower layer card inserting portion (2), and an upper layer baseplate portion (30) of the upper layer card inserting portion (3) which is formed on the lower layer baseplate portion (14) in parallel configuration at interval. The lower layer cover component (8) is provided with a bearing plate portion (51). The bearing plate portion (51) is inserted under the upper layer baseplate portion (30), and supports the lower surface of the upper layer baseplate portion (30).

Owner:SMK CO LTD

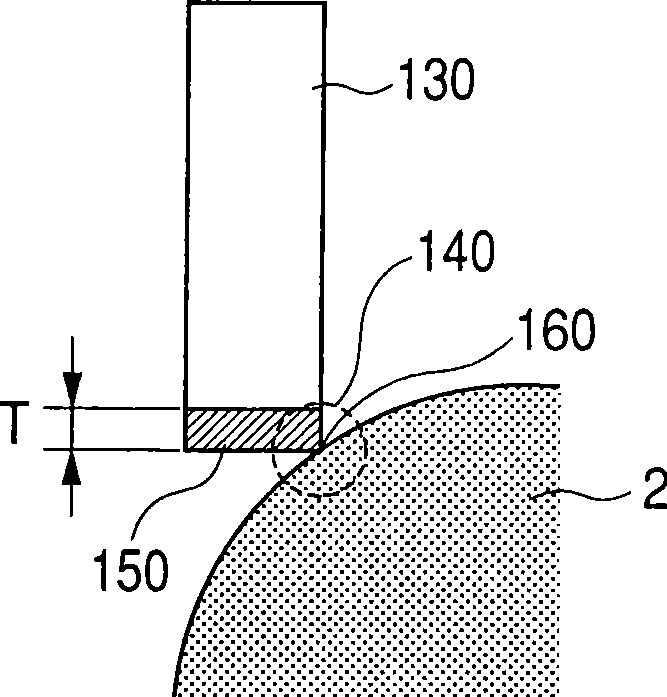

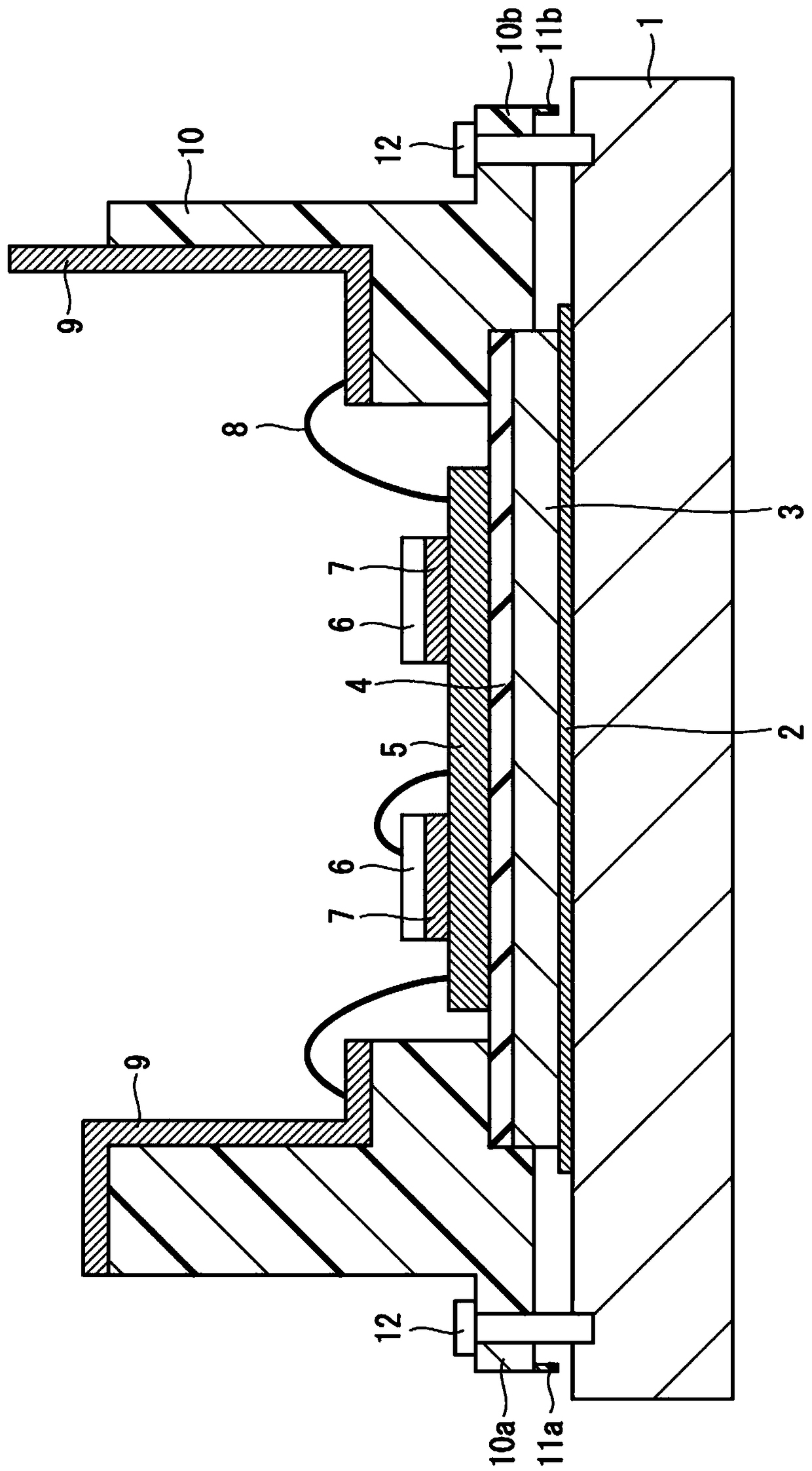

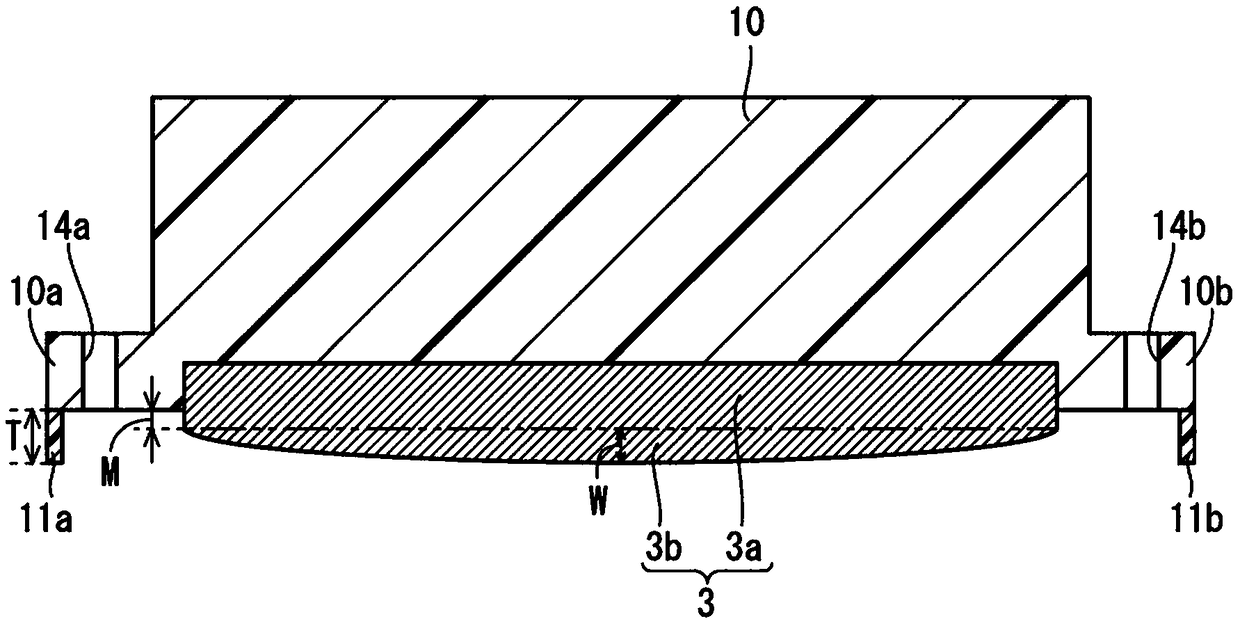

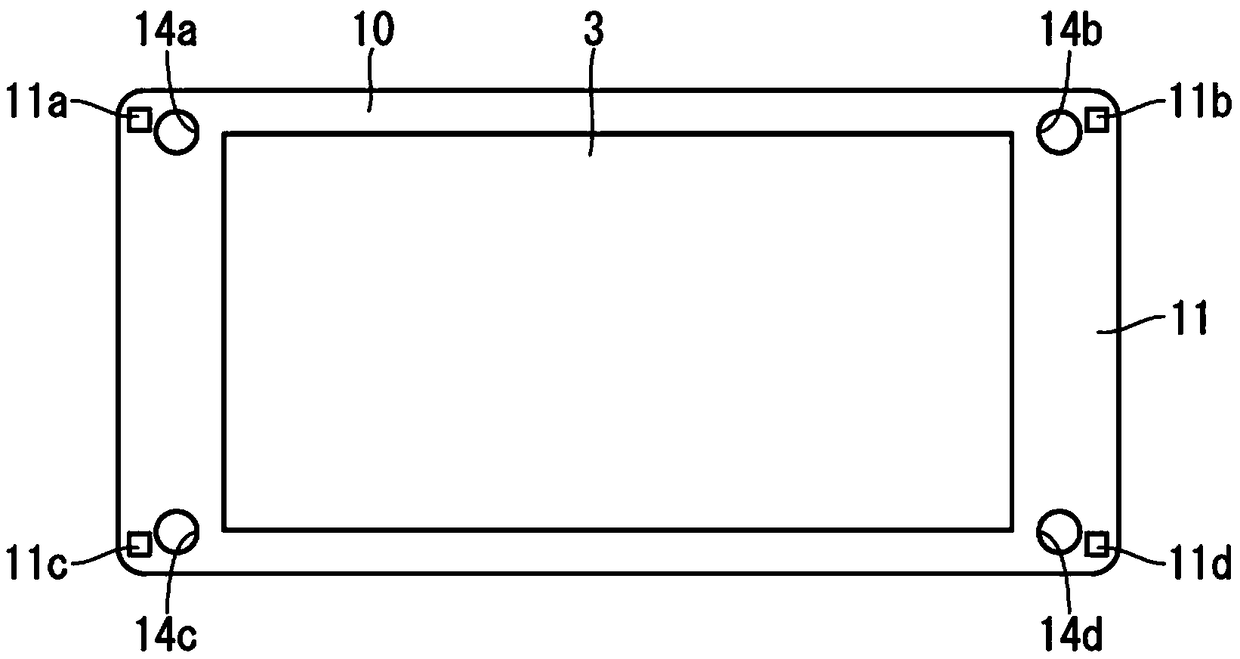

Semiconductor device

ActiveCN109461710ASuppression of warpingImprove the installation effectSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

Provided is a technique for improving product attachment. The distance between the lower end of the main body portion (3a) and the lower end of the casing (10) in a state where the semiconductor device fastens the screw (12) to the heat sink (1) via one mounting hole (14b, 14d) is set as M, the swelling amount of the swelling portion (3b) is W, and the projection height of the convex portion (11b)is T, the distance in the horizontal direction from the outer peripheral end of the casing (10) to the outer periphery of the heat dissipation plate (3) is L. The angle A formed by the imaginary line(B-B') and the imaginary line (C-C') satisfies 0<A<arctan((M+W-T) / L), the imaginary line (B-B') is an imaginary line connecting the two mounting holes (14b, 14c), and the imaginary line (C-C') is animaginary line connecting the following two points, that is, the lowest point (C) of one convex portion (11b) at the peripheral portion of one mounting hole (14b); the contact portion (C') of the bulging portion (3b) and the heat sink (1).

Owner:MITSUBISHI ELECTRIC CORP

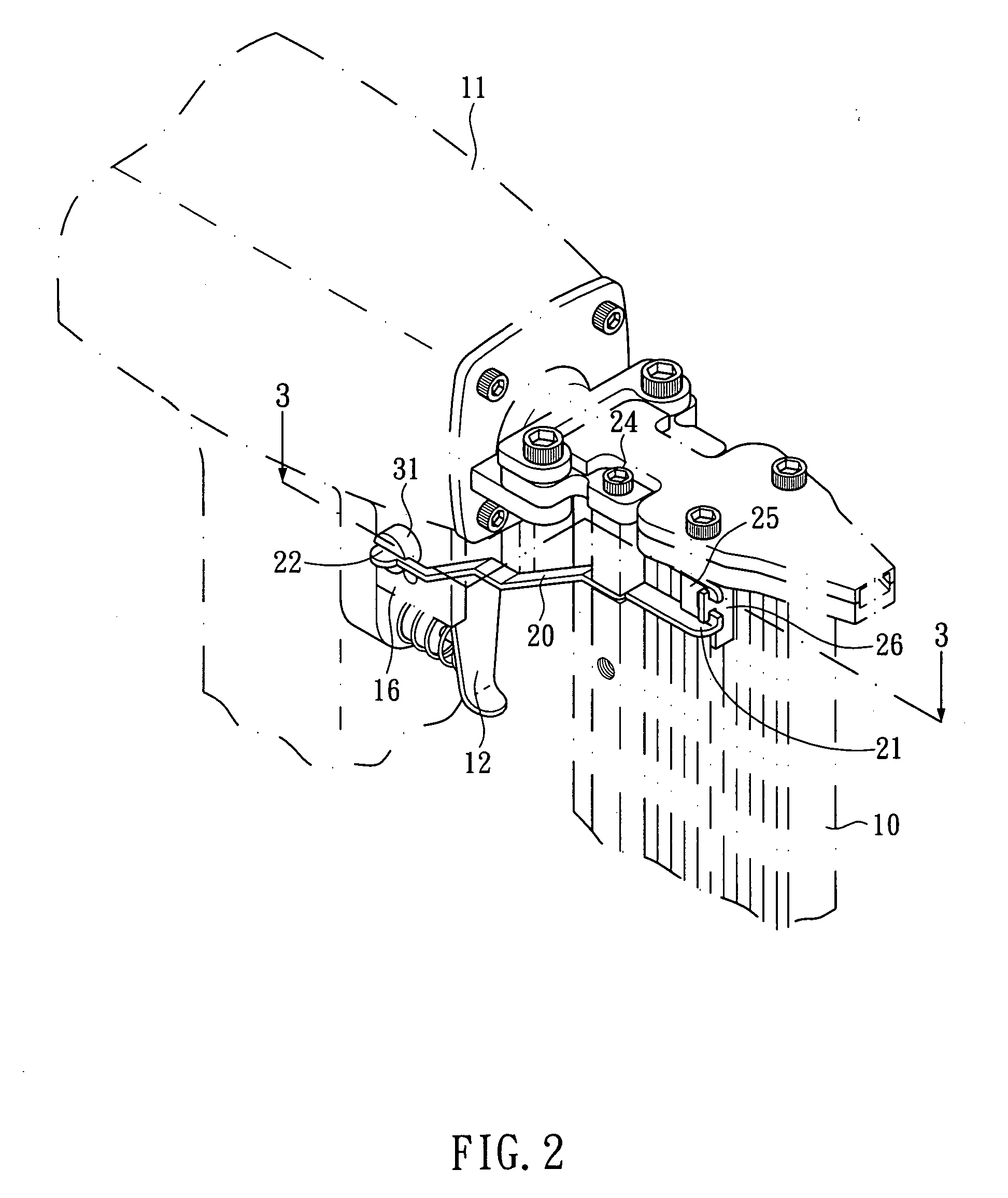

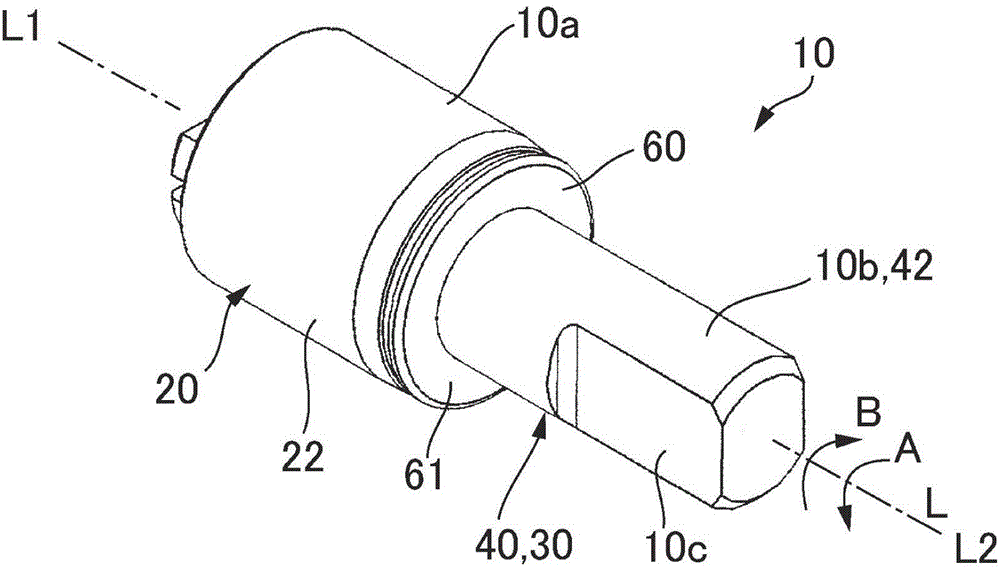

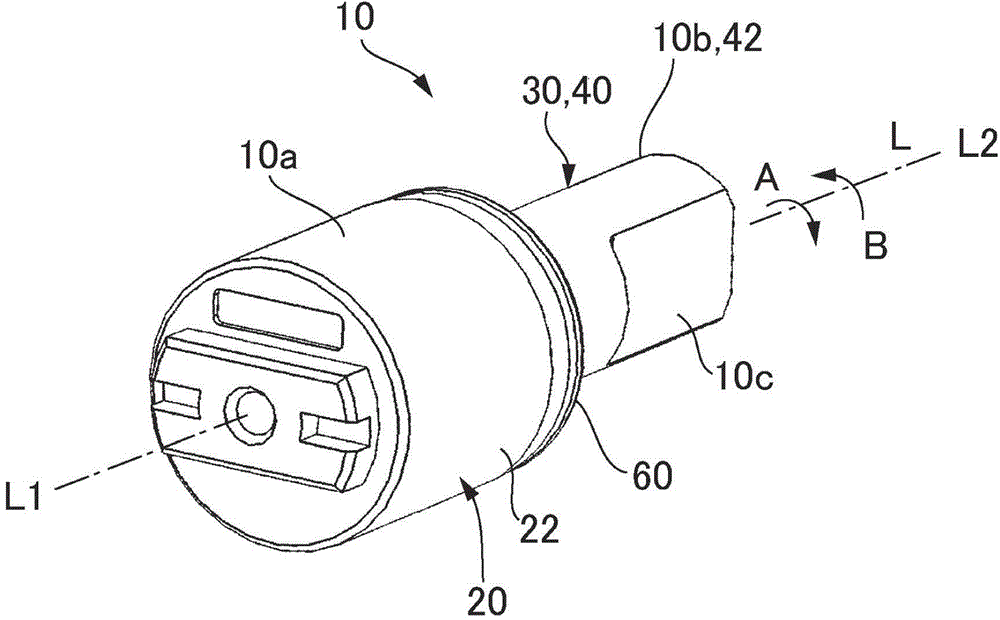

Fluid damper device and machine equipped with damper

ActiveCN105276058ASuppression of warpingIt is not easy to produce the situation that the contact position is the fulcrum rotationSpringsBuilding braking devicesRotational axisEngineering

The present invention provides a fluid damper device and a machine equipped with the fluid damper device. The fluid damper device can suppress lifting of a valve body from a rotary shaft when a rotor is rotated in the direction of opening. In a damper chamber of this fluid damper device, a protruding part of a valve body protrudes from a base part toward the outside in the radial direction of a rotary shaft, and toward one side (a first direction (A)) around the axial line of the rotary shaft, and a valve body support part of the rotary shaft is equipped with a base part support part between a first protruding part and a second protruding part. An inside portion of the protruding part of the valve body has a first portion and a second portion separated from each other in the direction in which the protruding part protrudes, and when the valve body is in the open position this first portion and second portion are supported by a seat part formed on the first protruding part of the rotary shaft. Therefore, even when the valve body is subjected to fluid pressure in the first direction, a situation in which the valve body rotates with the point of contact with the first protruding part as a fulcrum does not easily occur.

Owner:SANKYO SEIKI MFG CO LTD

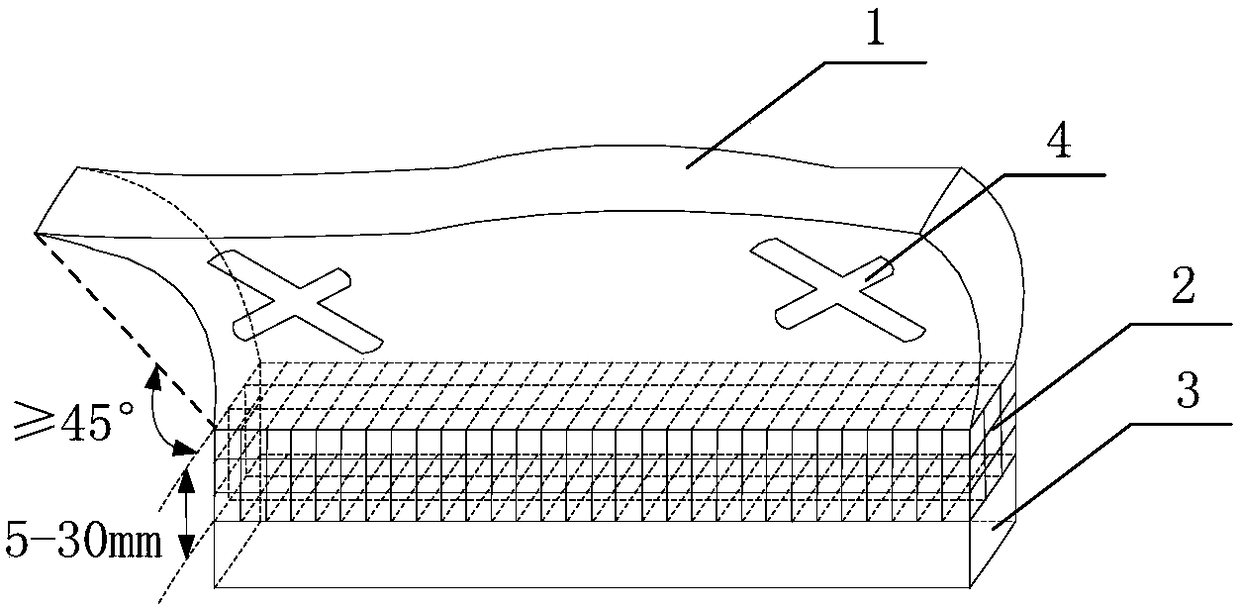

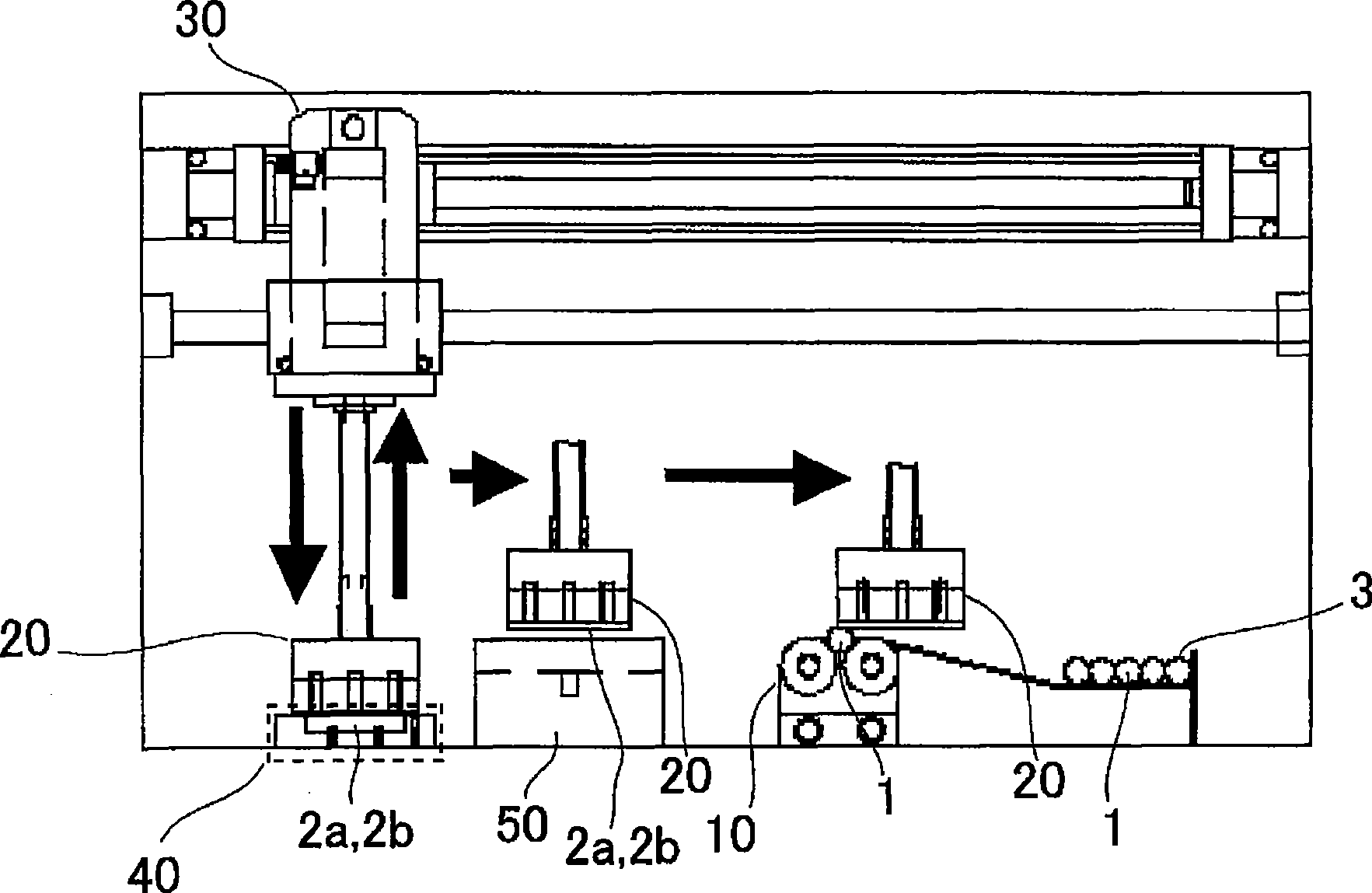

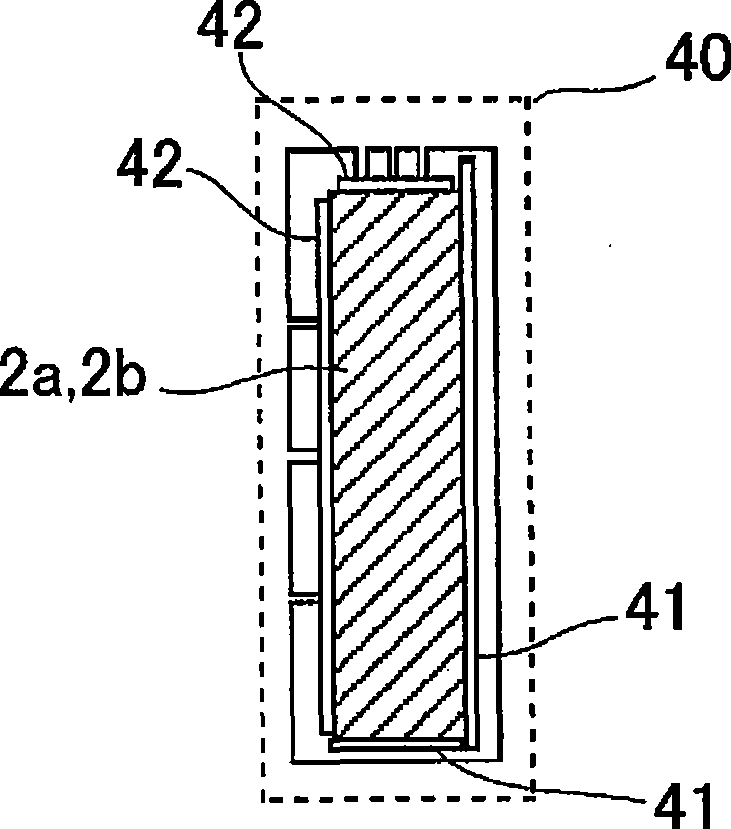

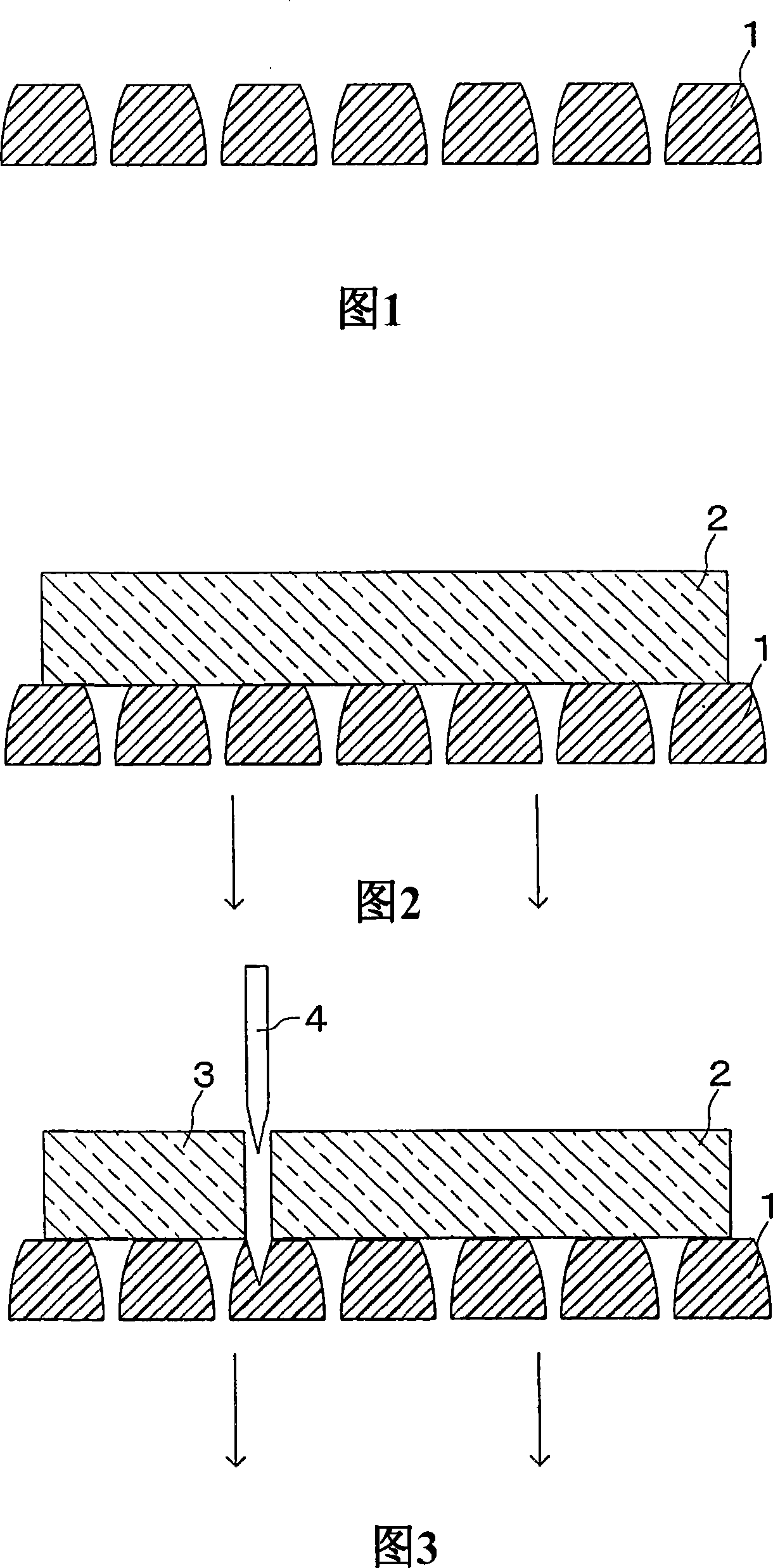

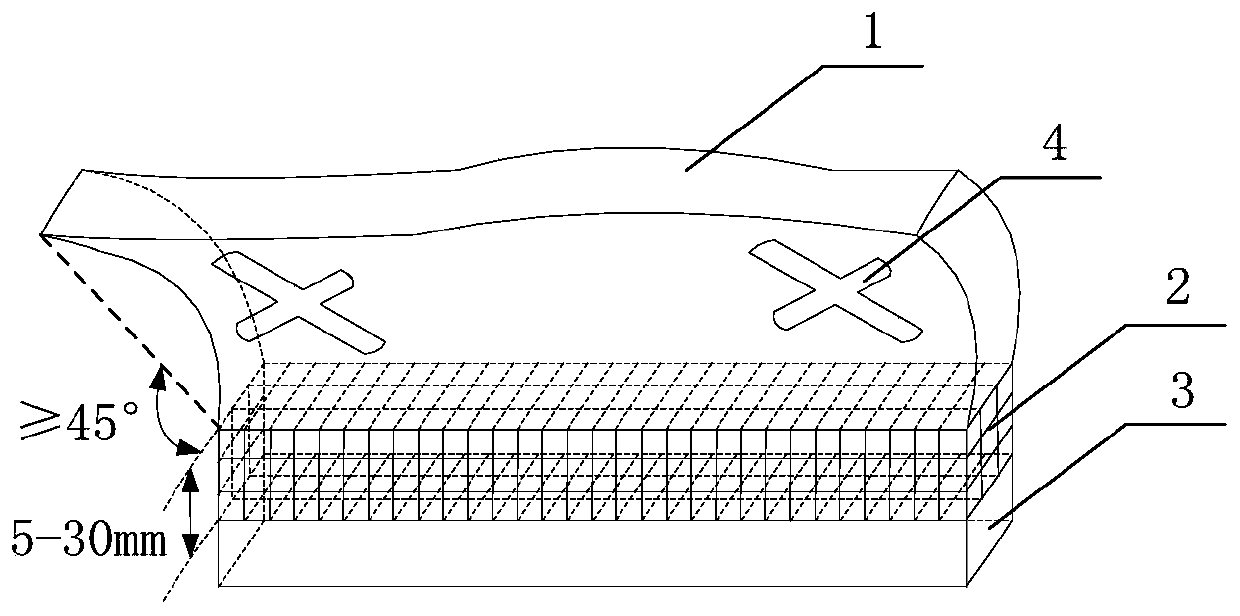

Device and method for forming a three-dimensional circuit board

InactiveCN101489354ASuppression of warpingFull landfillElectrographic process apparatusPrinted circuit manufactureBarrel ShapedEngineering

The present invention provides a forming device and forming method of stereo circuit board, which can accuracy paste circuit board in correct location on roller surface of cylinder-shape or barrel-shape, especially on the whole circle to make gaps being the smallest and most shallow. Forming device of the stereo circuit board includes rotary mechanism (10), which holding objects (1) of cylinder-shape or barrel-shape in horizontal status of central axis and rotating the object (1) around the central axis as rotating axle; holding mechanism (20) which holding adhesive film with isolation film with the exposed adhesive layer adown, and carrying horizontally; controlling mechanism (30), which can adjust relative position to make the carried adhesive film with isolation film (2a) or the circuit board (2b) contact with surface of the rotating object (1) and controlling the pressure pushed against the object (1) surface as constancy.

Owner:SUMITOMO METAL MINING CO LTD

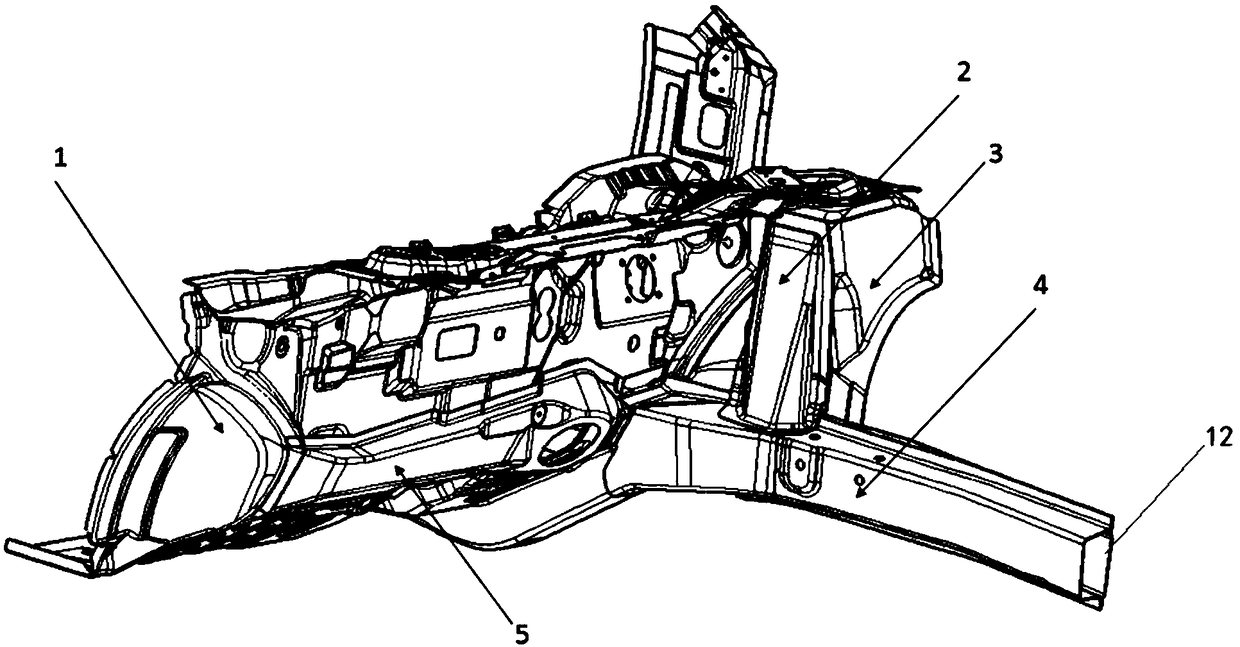

System structure capable of decreasing front dash panel intrusion amount, and automobile

The invention provides a system structure capable of decreasing the front dash panel intrusion amount, and an automobile. Through the design of four structures surrounding a front longitudinal beam and comprising a front damper tower supporting structure, a front dash panel and A pillar supporting structure, a front dash panel cross beam structure and a kickdown supporting structure, the phenomenaof root outward heaving, upward warping and bending of the front longitudinal beam are restrained, the root resisting capacity of the front longitudinal beam is improved, the anti-bending capacity ofa kick-down longitudinal beam is improved, and thus the effect of decreasing of the front dash panel intrusion amount is achieved. The system structure is comprehensively designed and is reasonable in design and high in security coefficient.

Owner:JIANGSU MINAN AUTOMOTIVE CO LTD

Connector for printed wiring board

InactiveCN1192463CSuppresses bending deformationSuppression of warpingPrinted circuit assemblingElectrically conductive connectionsEngineeringSynthetic resin

A connector includes a connector body having an insertion space for receiving its counterpart connector. The connector body includes a synthetic-resin housing for retaining contacts, and a metallic shell. A part of the insertion space is defined by an upper plate of the shell. The upper plate of the shell has extensions extended therefrom along corresponding side walls of the housing. The extensions include legs soldered to a conductive portion on a printed wiring board surface. The legs are outwardly extended and confined in an outline of the connector body as viewed in plan.

Owner:JST MFG CO LTD

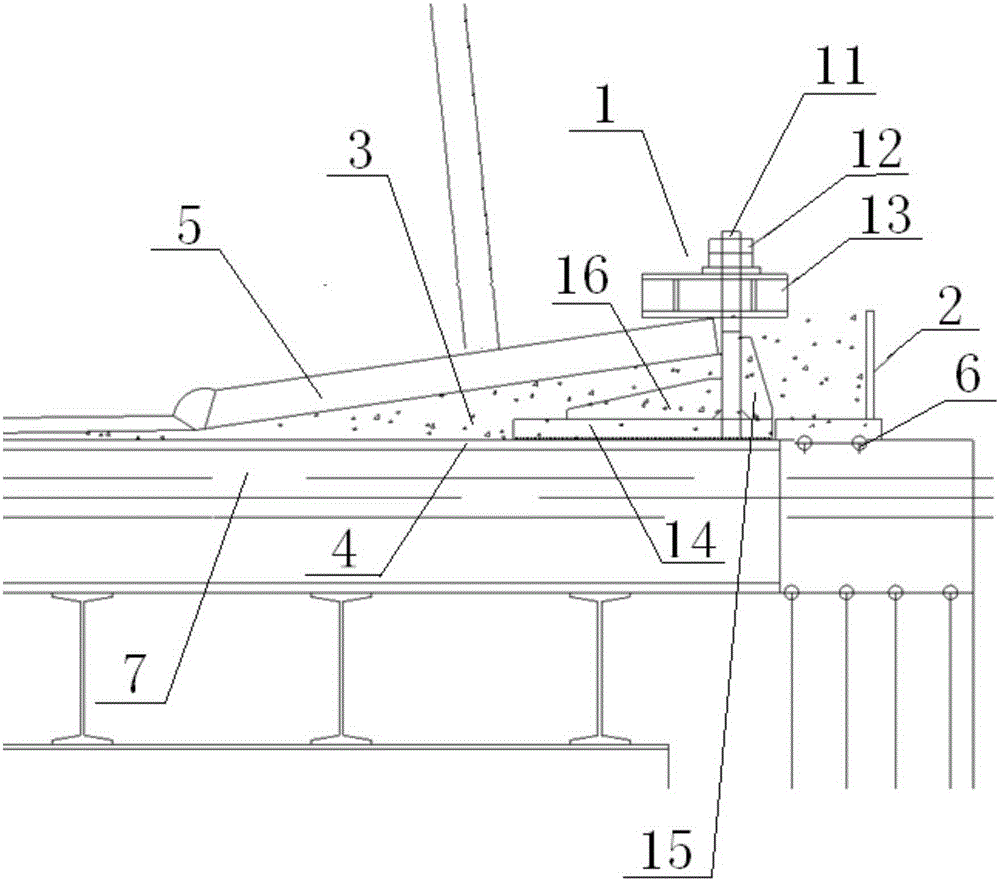

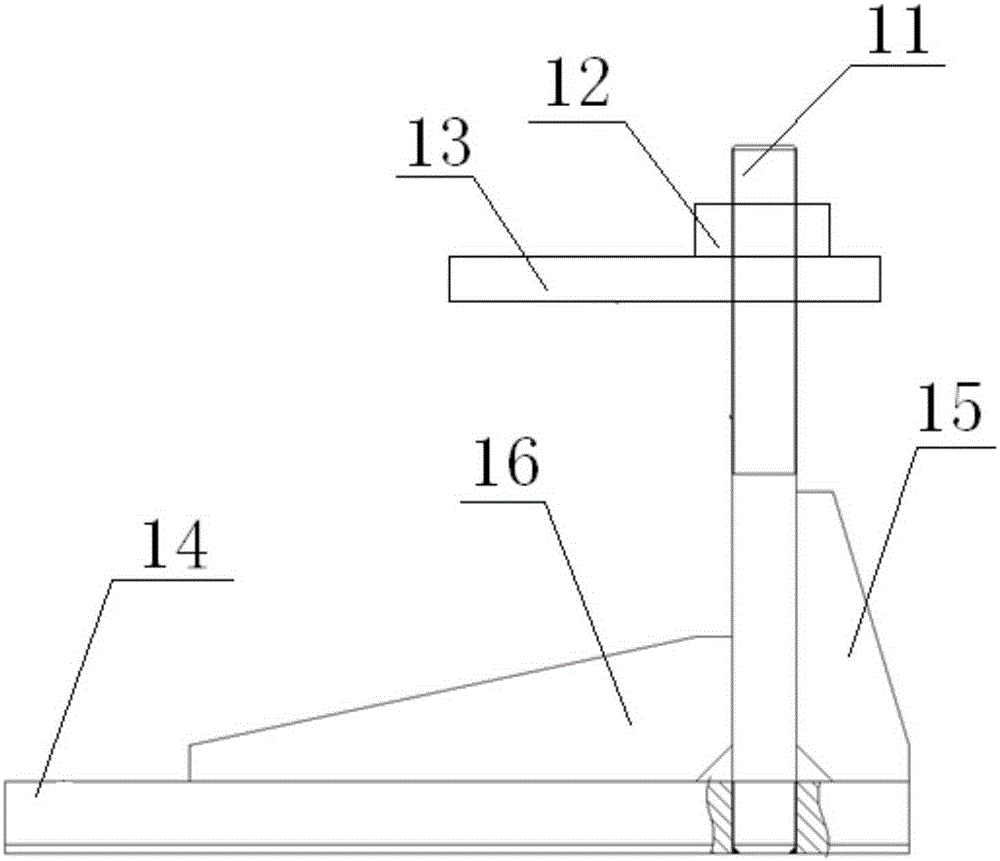

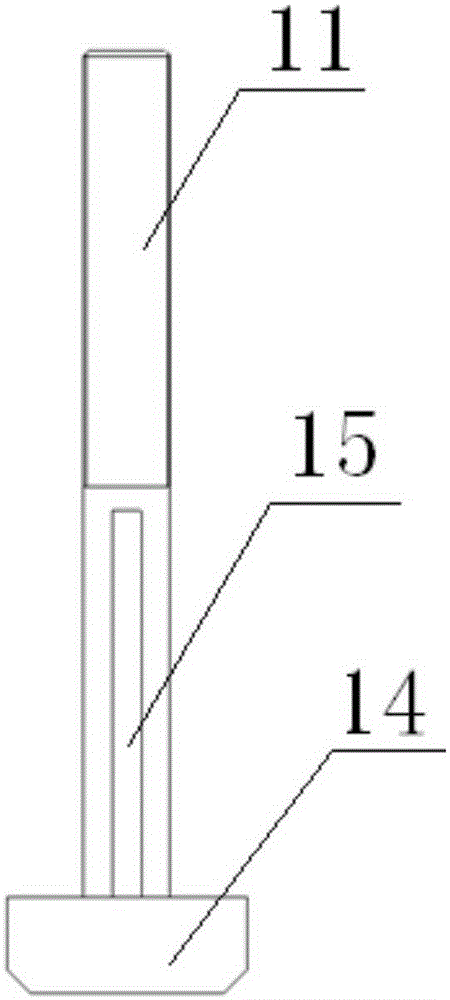

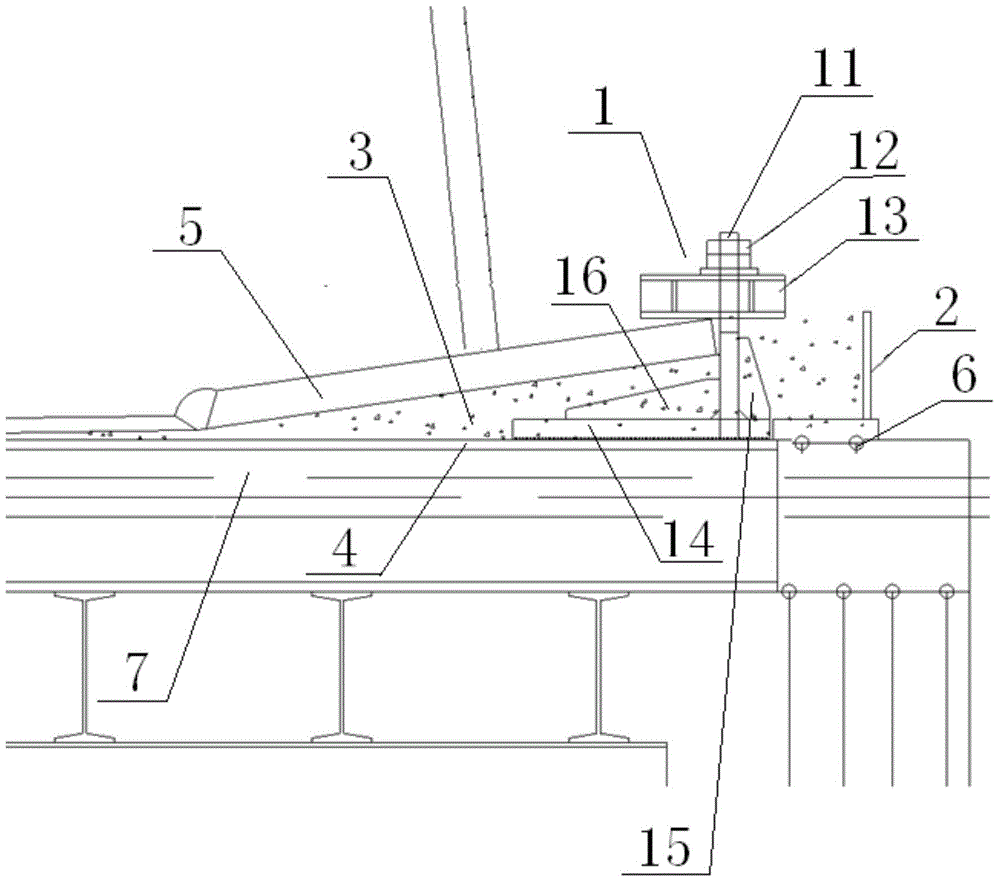

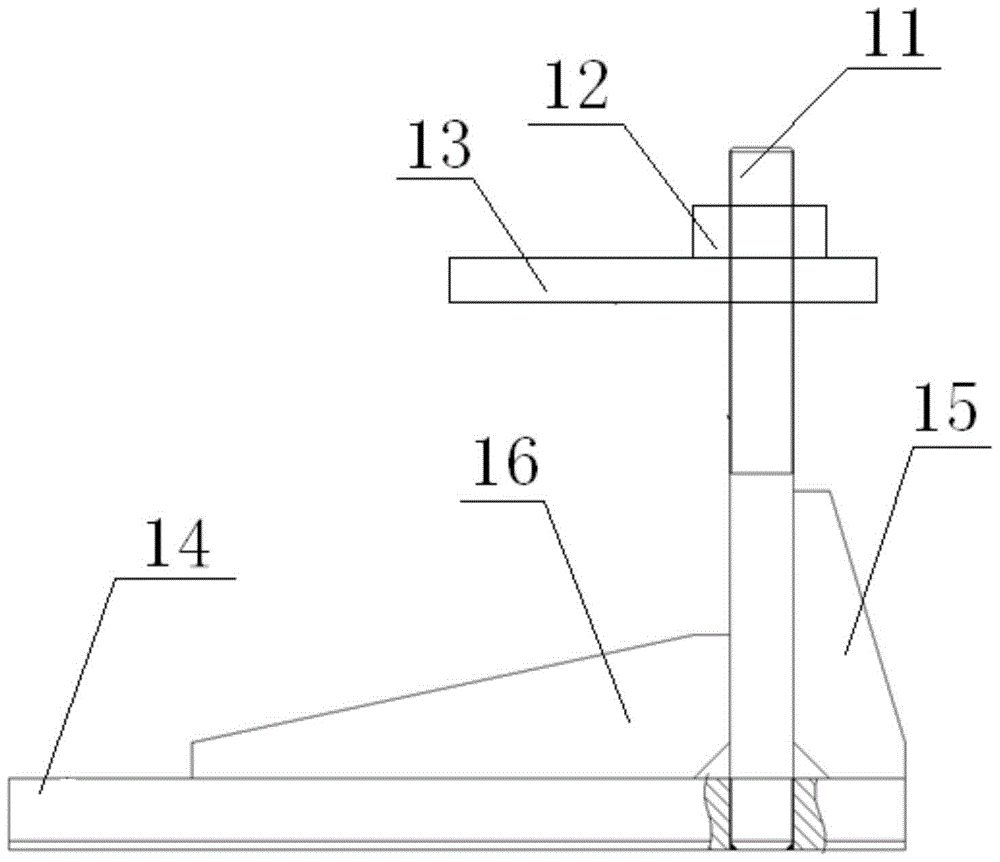

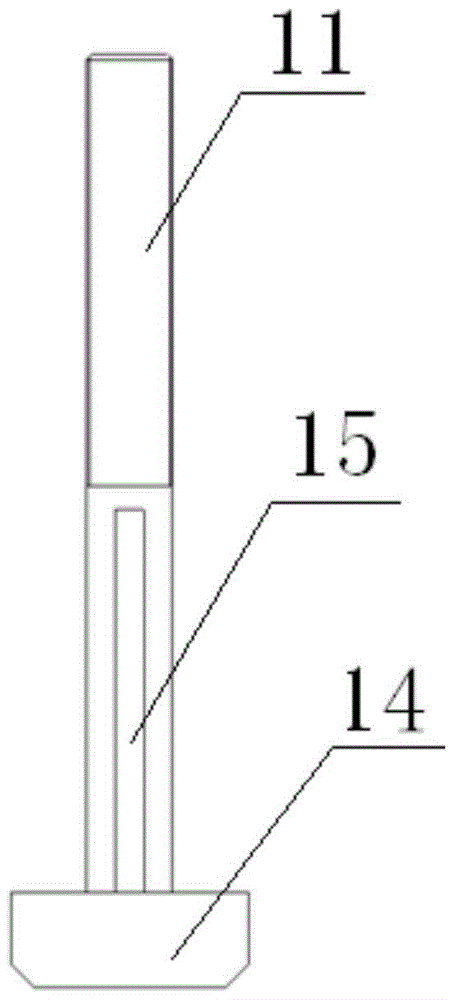

Pressing system restraining blast furnace hearth plate from warping upwards and application thereof

ActiveCN105238896AEliminate the effects ofStable productionBlast furnace componentsBlast furnace detailsChinese charactersEngineering

The invention discloses a pressing system restraining a blast furnace hearth plate from warping upwards and application thereof and belongs to the technical field of blast furnace equipment transformation. The pressing system comprises a pressing device, an annular check ring and castable material. The section of the main body of the pressing device is shaped like a Chinese character "tu" of a left-right asymmetry structure and comprises a pressing plate, a bottom plate and a bolt, wherein the pressing plate and the bottom plate are parallel, the bolt penetrates through the pressing plate so as to be fixedly connected to the bottom plate, and the height of the pressing plate is regulated by a nut. The bottom plate of the pressing device is inserted into the bottom of the blast furnace hearth plate warping upwards and presses on the top of a blast furnace hearth closing plate warping upwards through the pressing plate. The castable material fills the gap, formed by the blast furnace hearth closing plate warping upwards and the pressing device, in the furnace hearth. The annular check ring surrounds the outer side of the pressing device. According to the application of the pressing system, through the steps of calculating, laying, fixing, pressing, preparation before pouring, pouring, solidifying and the like, the influence caused by upward-warping of the blast furnace hearth closing plate is removed, production of a blast furnace is stabilized, various economic and technical indexes of production of the blast furnace are maintained, and the technological operation of the blast furnace is effectively guaranteed.

Owner:MAANSHAN IRON & STEEL CO LTD

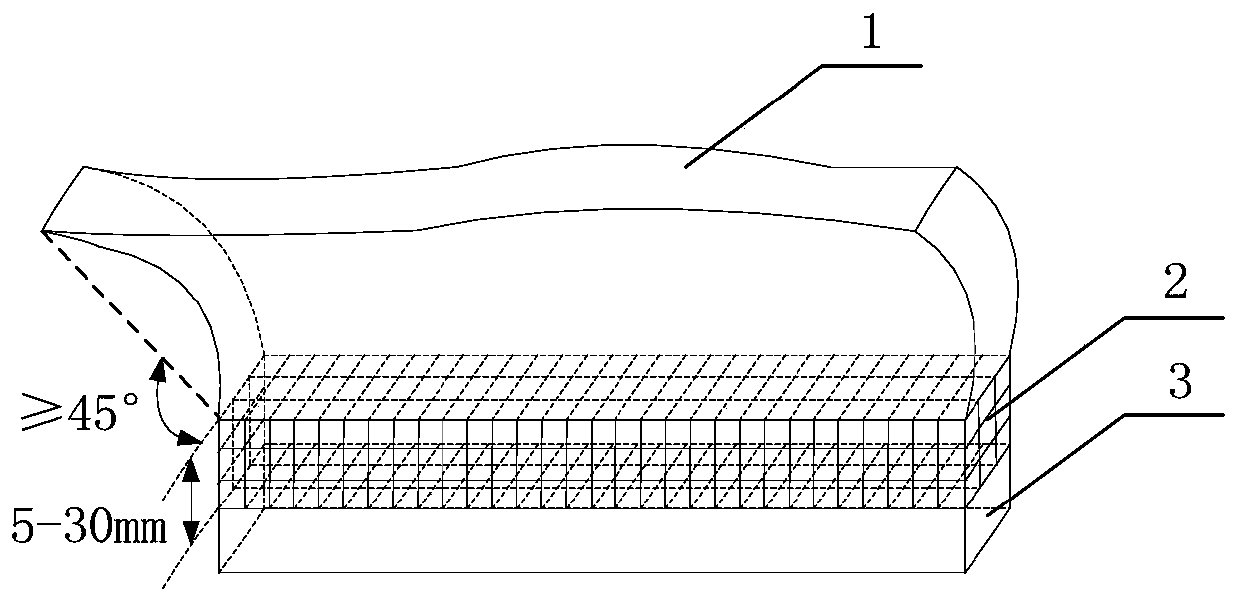

Method of manufacturing a polarizing plate, and a cutting mat used in the method

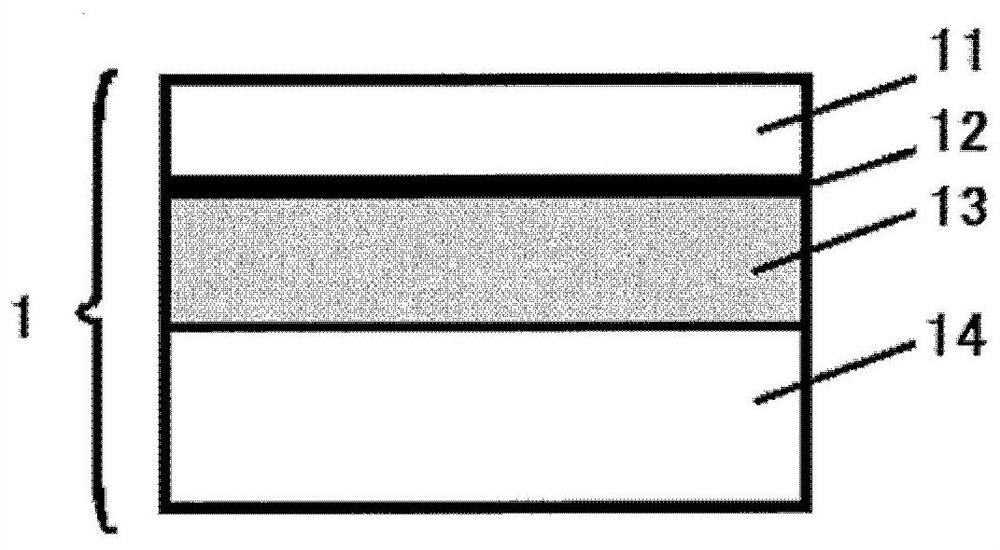

InactiveCN101101348AImprove wear resistanceNot easy to producePolarising elementsMetal working apparatusThin slabUltraviolet

A method of manufacturing a polarizing plate in which an original polarizing plate is cut accurately, cracks are not extended easily in a section and foreign substances are not attached easily on a polarizing plate to be obtained, and a cutting mat to be used in the method are provided. An original polarizing plate having a plurality of layers is fixed on a first principal surface of an ultrahigh molecular weight polyethylene porous sheet by drawing from the opposite side. The original polarizing plate is cut by a blade moving across the thickness of the original polarizing plate by using the porous sheet as a cutting mat to obtain a polarizing plate having a plurality of layers. A curable liquid, such as ultraviolet curable ink, is impregnated in vacant pores of the porous sheet, and is cured to obtain a sheet. The sheet thus obtained is particularly suitable for a cutting mat.

Owner:NITTO DENKO CORP

Continuous casting method capable of preventing head upwarp of casting blank

ActiveCN104889355ASuppression of warpingAvoid early disengagementMechanical engineeringContinuous caster

The invention discloses a continuous casting method capable of preventing head upwarp of a casting blank and belongs to the technical field of casting. The continuous casting method capable of preventing the head upwarp of the casting blank includes that using a curved spray continuous casting machine with 325-710 square centimeters square section or a curved spray continuous casting machine with 325-710 square centimeters round section; after starting the continuous casting machine, increasing a casting blank pull speed to a target pull speed according to the gradient of 0.1 m / min per 10 seconds; when the casting blank enters a secondary cooling region, closing the last two cooling water loops of the secondary cooling region; when the head of the casting blank passes through a withdrawal and straightening machine, controlling the pressure of a withdrawal and straightening roller at 70 to 100bar; after the head of the casting blank comes out of the withdrawal and straightening machine, opening the last two cooling water loops of the secondary cooling region, and controlling the water amount of the secondary cooling region at 0.28-0.32 L / kg. The continuous casting method capable of preventing the head upwarp of the casting blank avoids various accidents of high-nitrogen stainless steel due to the head upwarp of the casting blank in the continuous casting steel pouring process and enables the continuous casting production stability to be guaranteed.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

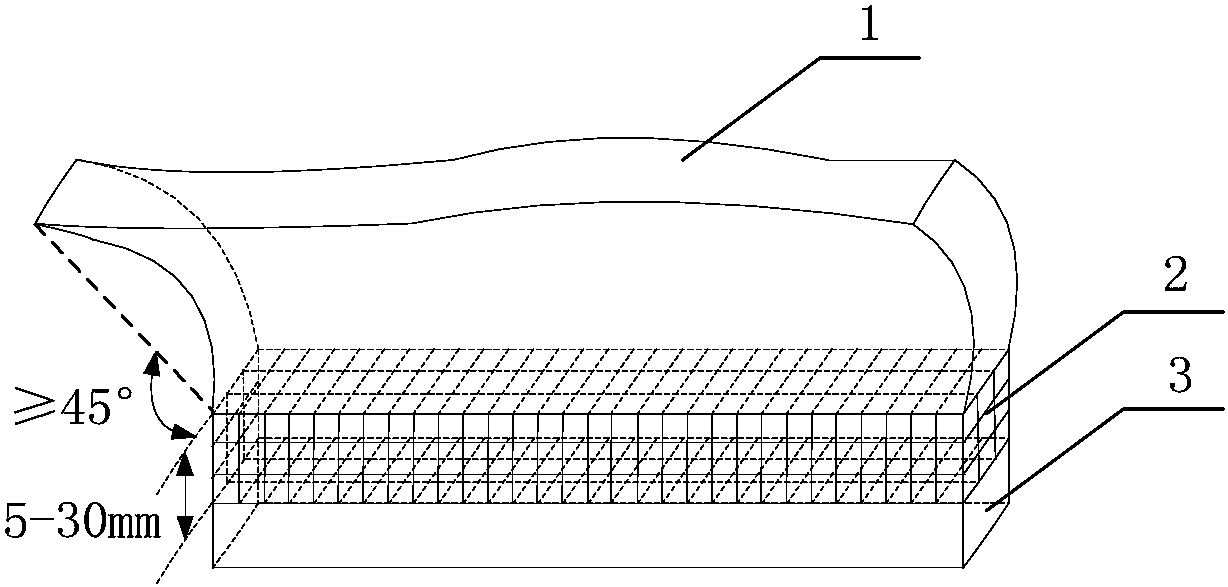

Auxiliary support structure for suppressing deformation of thin-walled structures

ActiveCN108145161BSuppression of warpingWarpage suppressionAdditive manufacturing apparatusIncreasing energy efficiencyClassical mechanicsMechanical engineering

The present invention provides an auxiliary support structure that suppresses deformation of thin-walled structures. The auxiliary support structure includes a fixedly connected grid support part and a solid support part, that is, the auxiliary support structure adopts an integral auxiliary support in which the section in the growth direction is in the form of "grid + solid" and the solid part and the grid part are firmly connected; The lower end of the grid support part is supported on the solid support part, and a support is formed between the suspended end of the thin-walled structure and the solid support part; the grid support part adopts a sheet-type or "mountain"-shaped structure; the The upper end of the solid support part is supported on the lower end surface of the grid support part, and the lower end is supported on the shaped substrate; the solid support part adopts a "mountain" or "Y" structure. The invention can effectively suppress the warping deformation of the inclined thin-walled open structure and the floating deformation of the relatively large-scale thin-walled open structure, and ensure the shape precision of the thin-walled suspended and open structure.

Owner:CAPITAL AEROSPACE MACHINERY +1

An oil pipeline traction and transfer device with anti-extrusion function

ActiveCN113697667BEasy dockingAvoid the effect of direct collision contactRunwaysTrolleysTraction systemTransportation technology

Owner:东营辰鑫应用技术开发有限公司

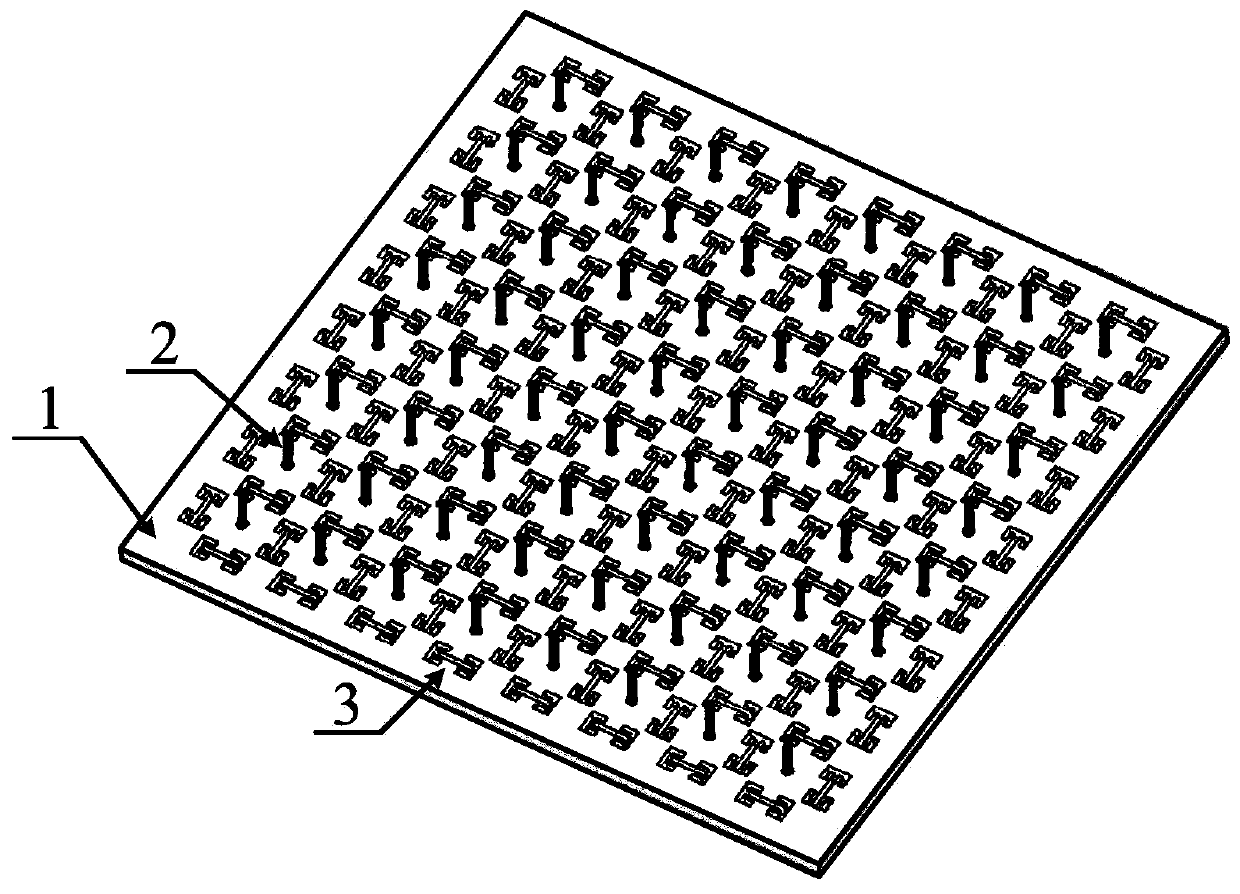

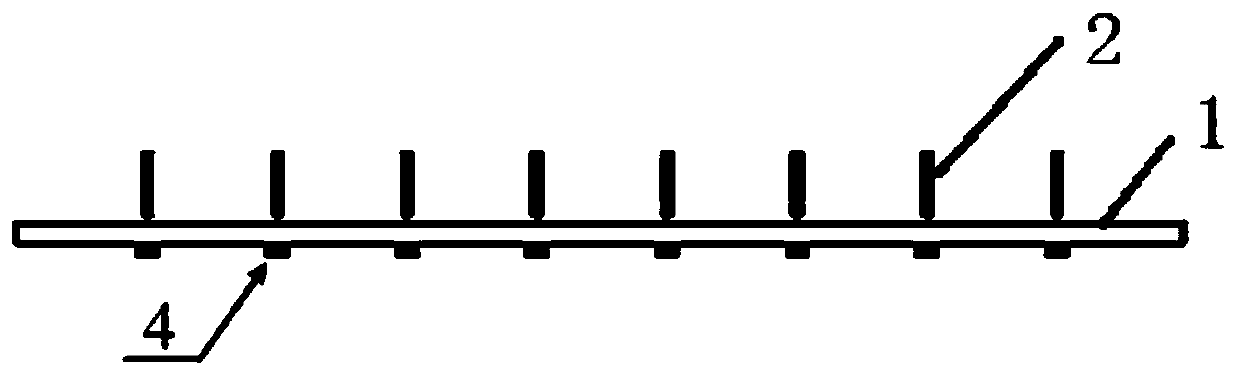

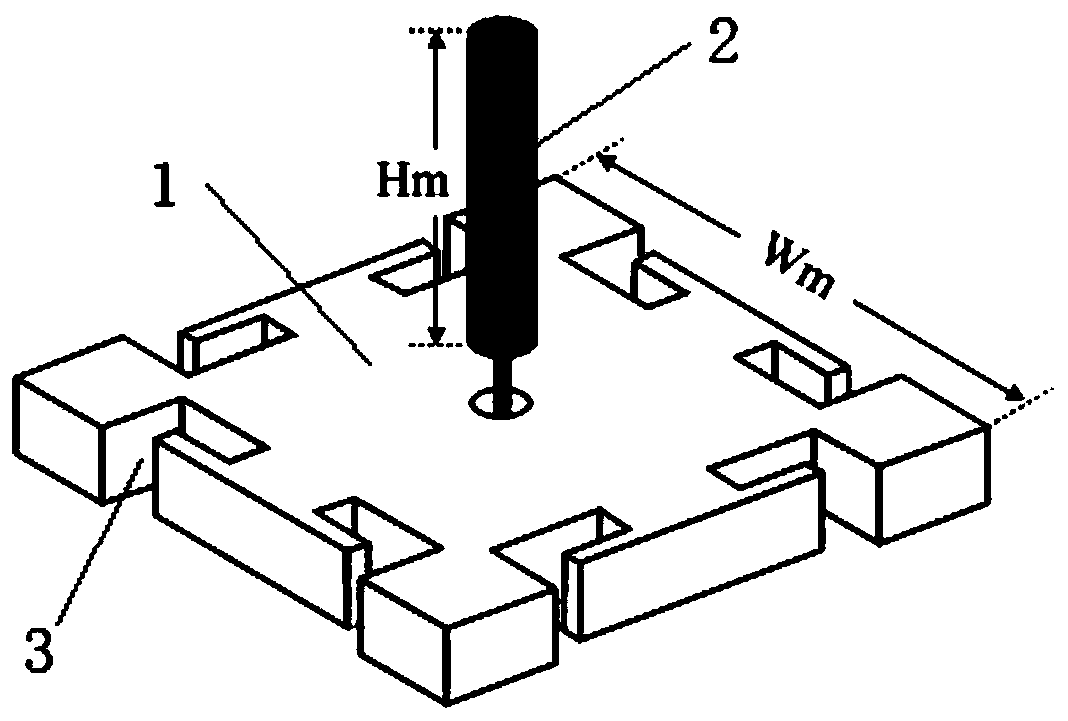

Omnidirectional scanning monopole end-fire array antenna of horizontal beam

ActiveCN111585020ASuppression of warpingAchieving Radiation BeamsParticular array feeding systemsIndividually energised antenna arraysEngineeringRadio frequency

The invention discloses an omnidirectional scanning monopole end-fire array antenna of a horizontal beam. The omnidirectional scanning monopole end-fire array antenna comprises a metal reflecting plate, end-fire array antenna units, slot structure units and a radio frequency connector, wherein the end-fire array antenna units are periodically arranged on the metal reflecting plate, the slot structure units are periodically arranged on the metal reflecting plate, and the slot structure units are arranged in the middle of the adjacent end-fire array antenna units. The monopole end-fire array antenna provided by the invention has beams which are completely radiated in the horizontal end direction, solves the problem that beams of a traditional end-fire array antenna are warped upwards, and issimple in structure, easy to process and manufacture and high in reliability.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

A pressing system and its application for restraining the warping of the bottom plate of blast furnace

ActiveCN105238896BInhibition of continuous upturningStable productionBlast furnace componentsBlast furnace detailsChinese charactersEngineering

The invention discloses a pressing system restraining a blast furnace hearth plate from warping upwards and application thereof and belongs to the technical field of blast furnace equipment transformation. The pressing system comprises a pressing device, an annular check ring and castable material. The section of the main body of the pressing device is shaped like a Chinese character "tu" of a left-right asymmetry structure and comprises a pressing plate, a bottom plate and a bolt, wherein the pressing plate and the bottom plate are parallel, the bolt penetrates through the pressing plate so as to be fixedly connected to the bottom plate, and the height of the pressing plate is regulated by a nut. The bottom plate of the pressing device is inserted into the bottom of the blast furnace hearth plate warping upwards and presses on the top of a blast furnace hearth closing plate warping upwards through the pressing plate. The castable material fills the gap, formed by the blast furnace hearth closing plate warping upwards and the pressing device, in the furnace hearth. The annular check ring surrounds the outer side of the pressing device. According to the application of the pressing system, through the steps of calculating, laying, fixing, pressing, preparation before pouring, pouring, solidifying and the like, the influence caused by upward-warping of the blast furnace hearth closing plate is removed, production of a blast furnace is stabilized, various economic and technical indexes of production of the blast furnace are maintained, and the technological operation of the blast furnace is effectively guaranteed.

Owner:MAANSHAN IRON & STEEL CO LTD

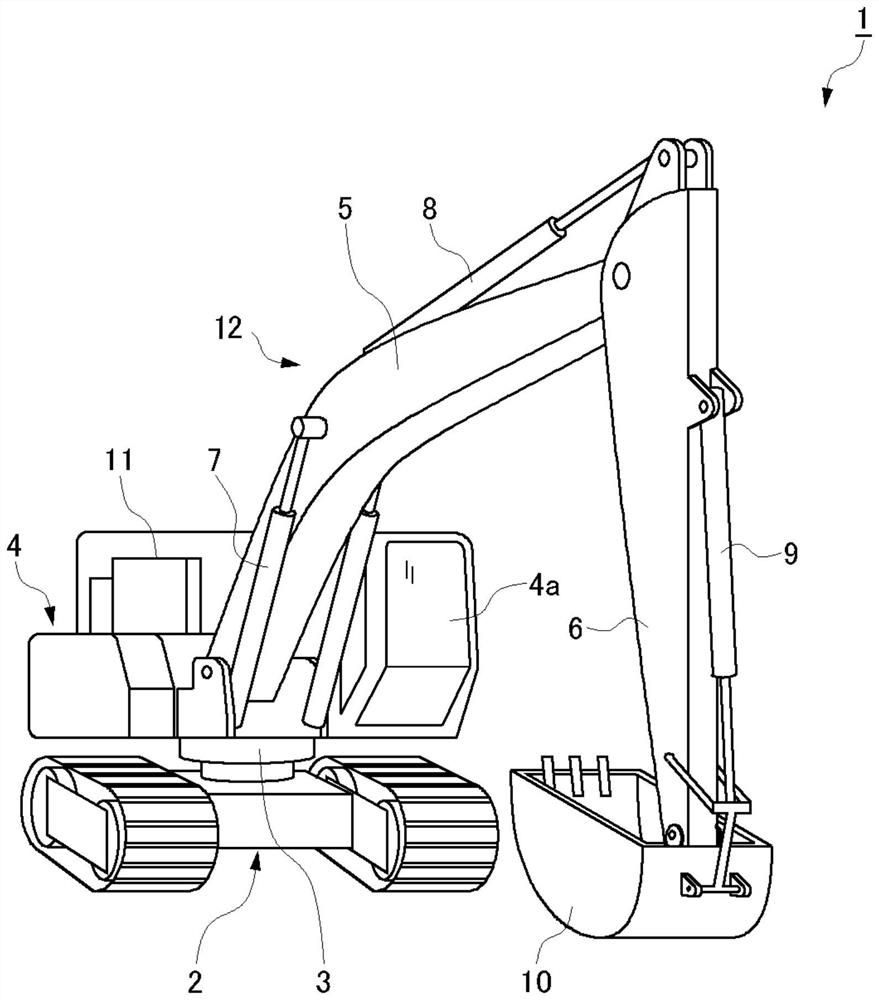

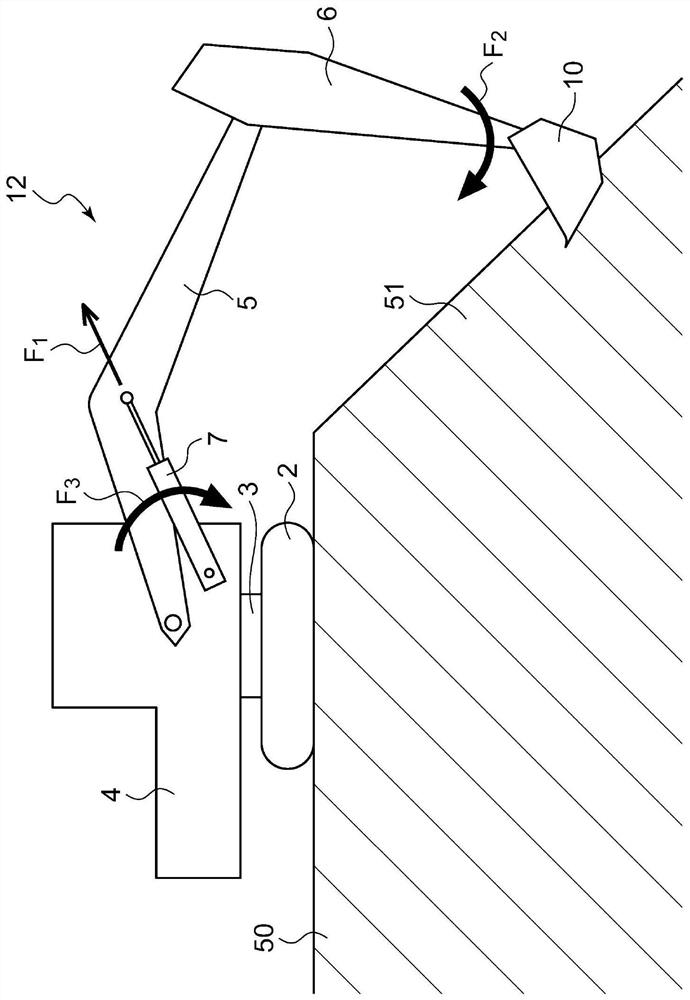

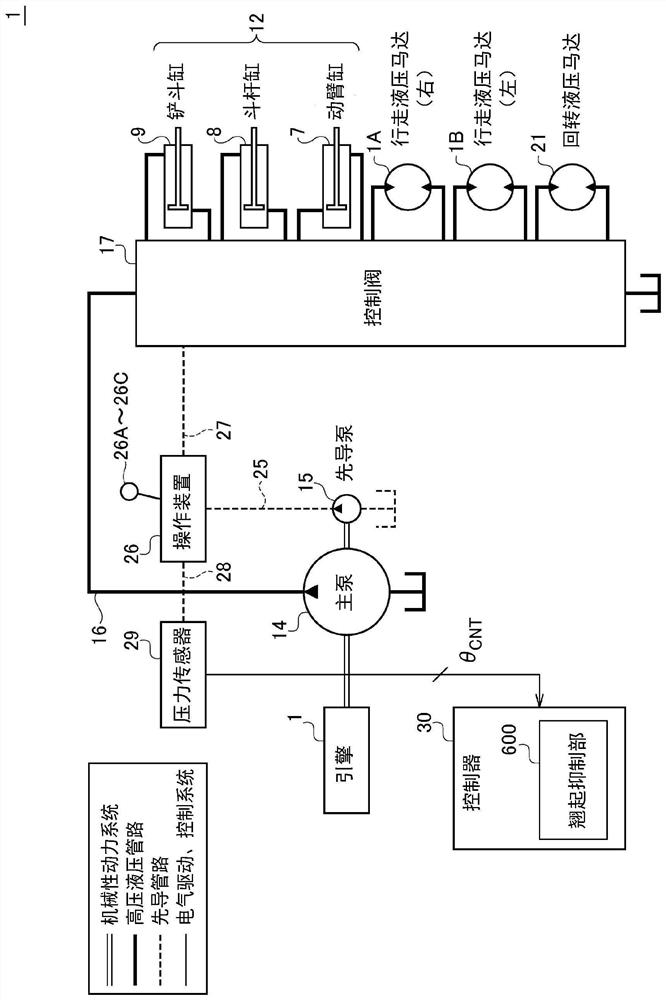

Excavator

ActiveCN109689980BSuppression of warpingMechanical machines/dredgersAdaptive controlClassical mechanicsExcavator

The excavator (1) of the present invention has: a traveling body; an upper revolving body rotatably mounted on the traveling body; and an accessory device including a boom, a bucket, and a bucket mounted on the upper revolving body. The tilting suppressing unit (600) corrects the operation of the boom cylinder (7) of the attachment so as to suppress tilting of the rear side of the traveling body with the front as the turning fulcrum.

Owner:SUMITOMO HEAVY IND LTD

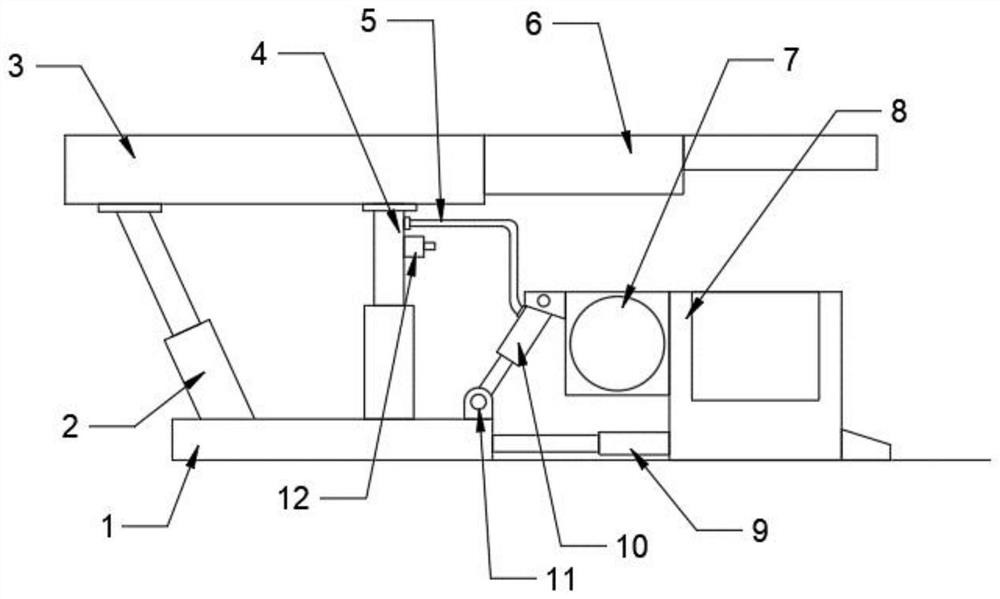

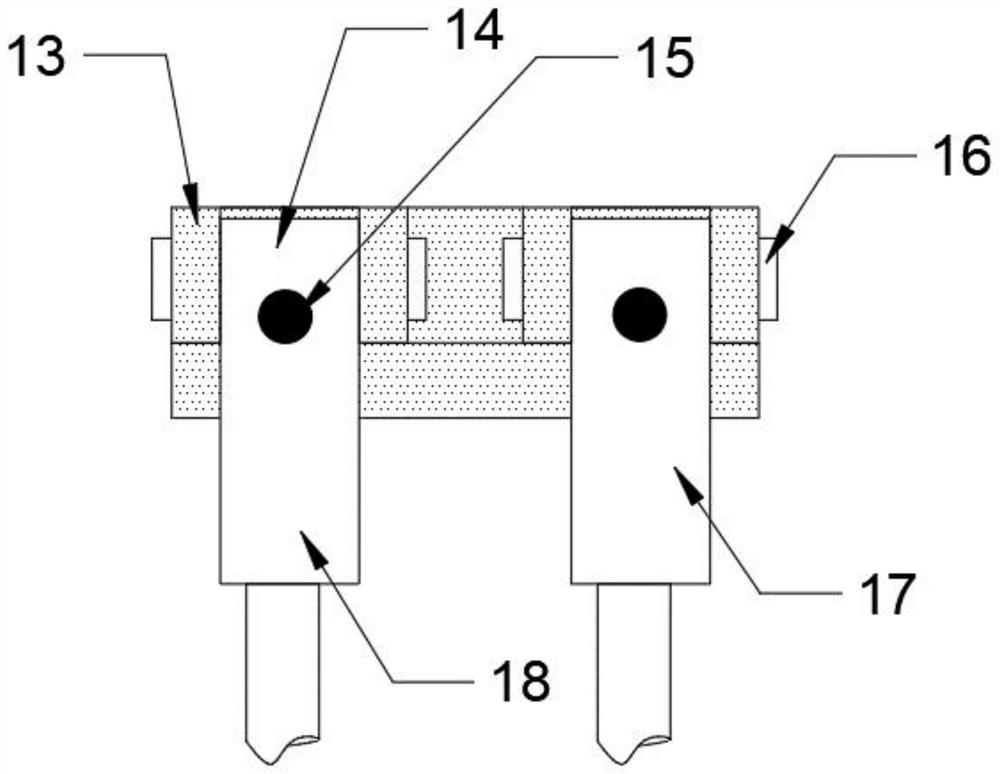

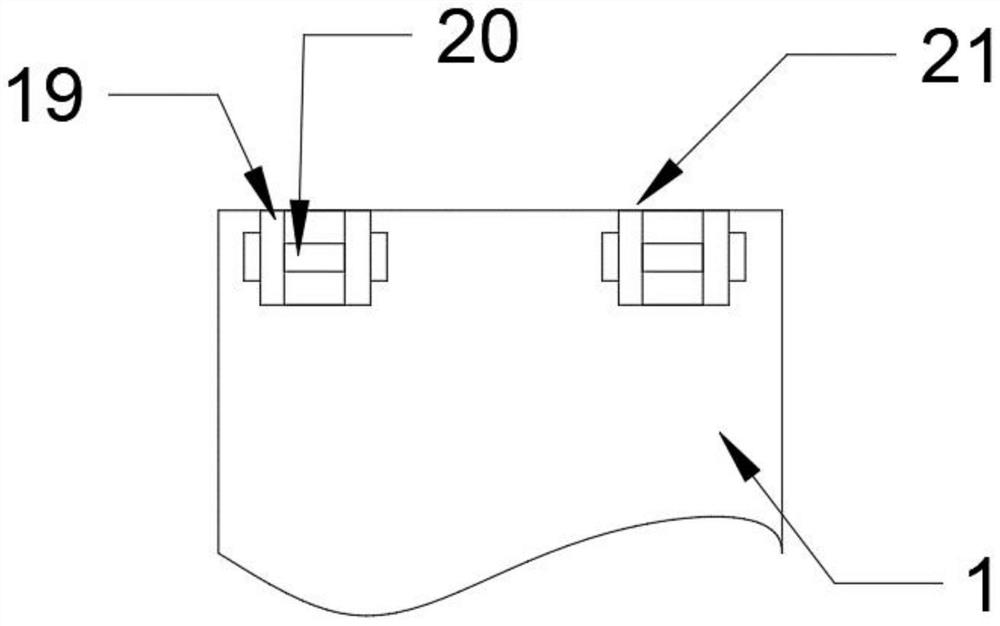

Petroleum pipeline traction and transfer device with anti-extrusion function

ActiveCN113697667AEasy dockingAvoid the effect of direct collision contactRunwaysTrolleysButt jointTransportation technology

The invention relates to the technical field of petroleum pipeline transportation, in particular to a petroleum pipeline traction and transfer device with an anti-extrusion function. In order to solve the problem that in the traction process of a petroleum pipeline, the butt joint end tilts, and consequently the petroleum pipeline is extruded and deformed in the butt joint process, the petroleum pipeline traction and transfer device with the anti-extrusion function is provided and comprises supporting frames, a traction system and the like; and the traction system used for pulling the petroleum pipeline is connected among the bottoms of the three supporting frames. The petroleum pipeline traction and transfer device achieves the effects that in the petroleum pipeline traction process, the petroleum pipeline traction and transfer device adapts to the butt joint ends with different tilting angles, the tilted butt joint ends are straightened to be in the horizontal state, and the follow-up pipeline butt joint is facilitated.

Owner:东营辰鑫应用技术开发有限公司

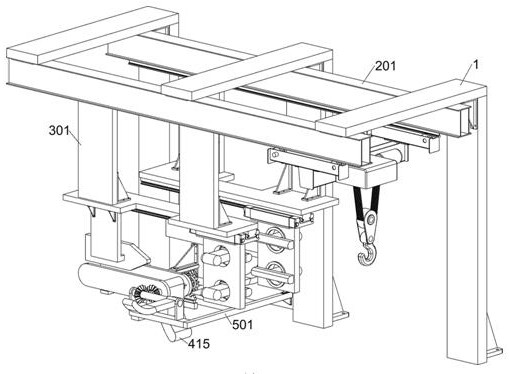

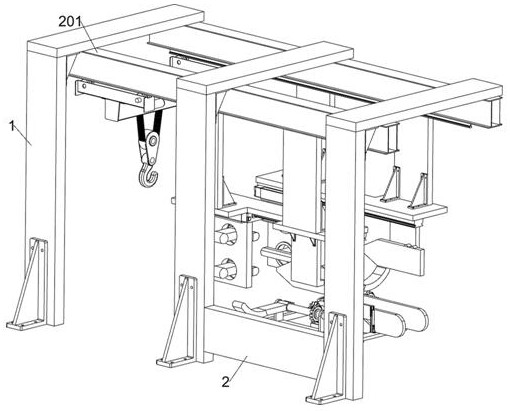

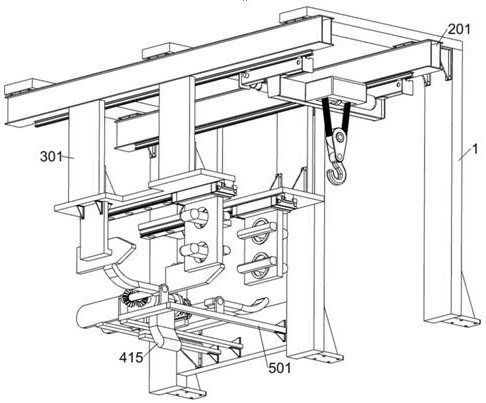

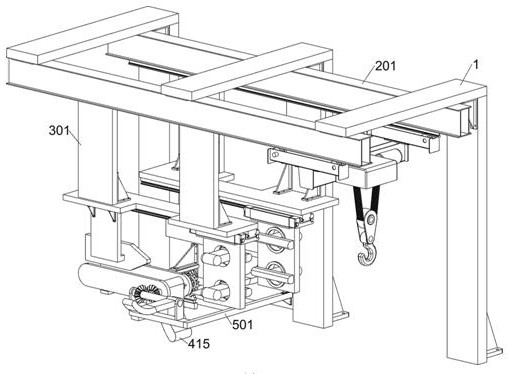

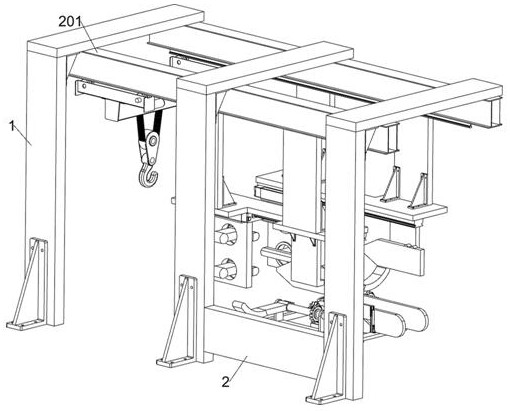

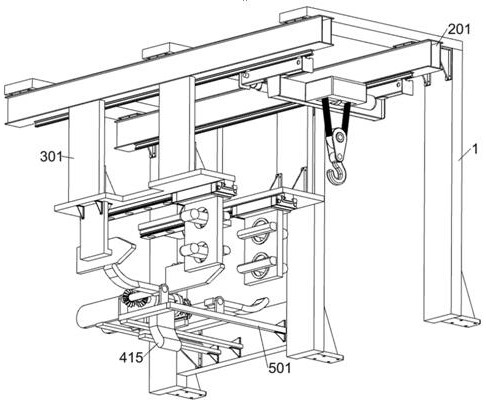

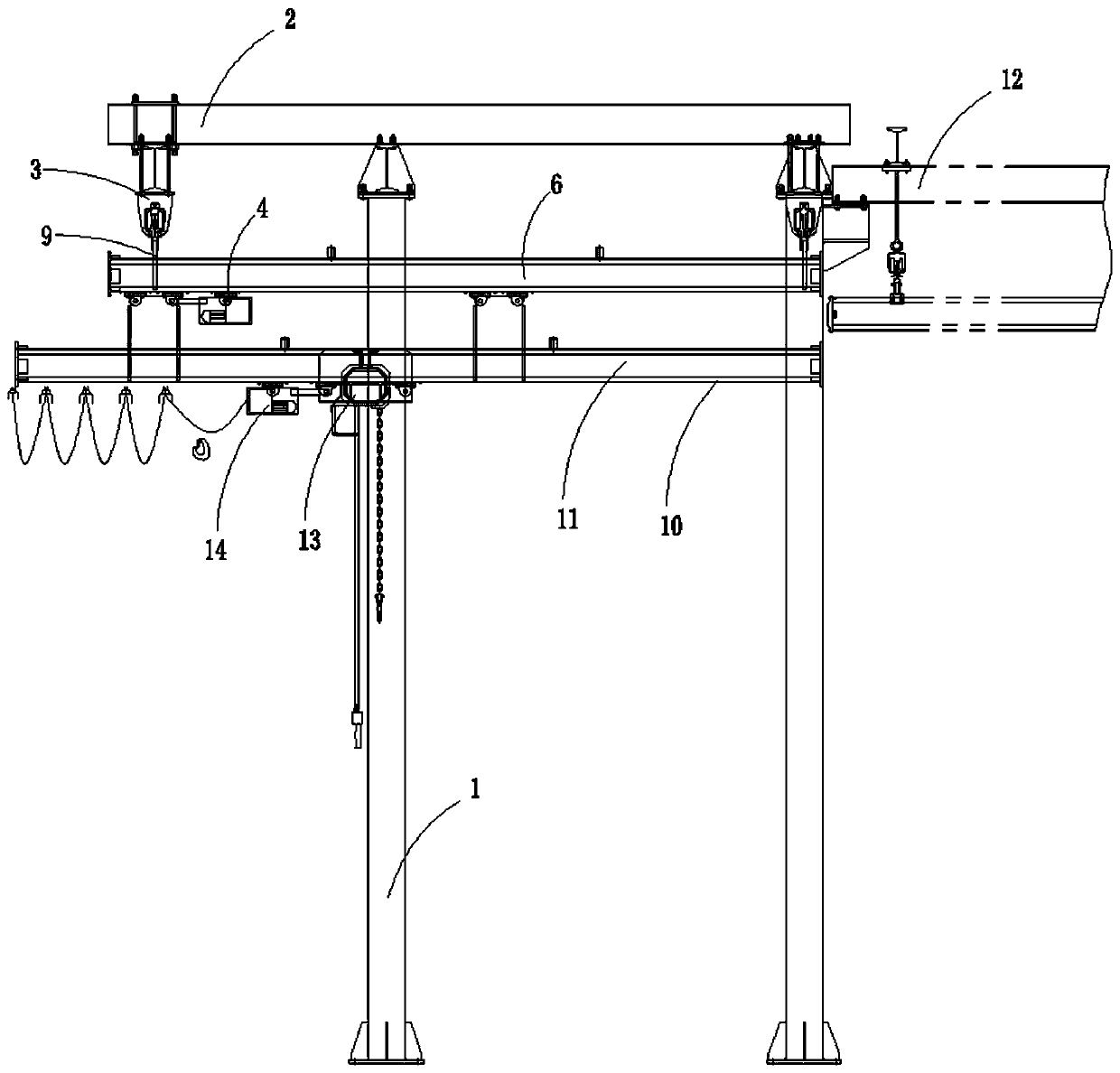

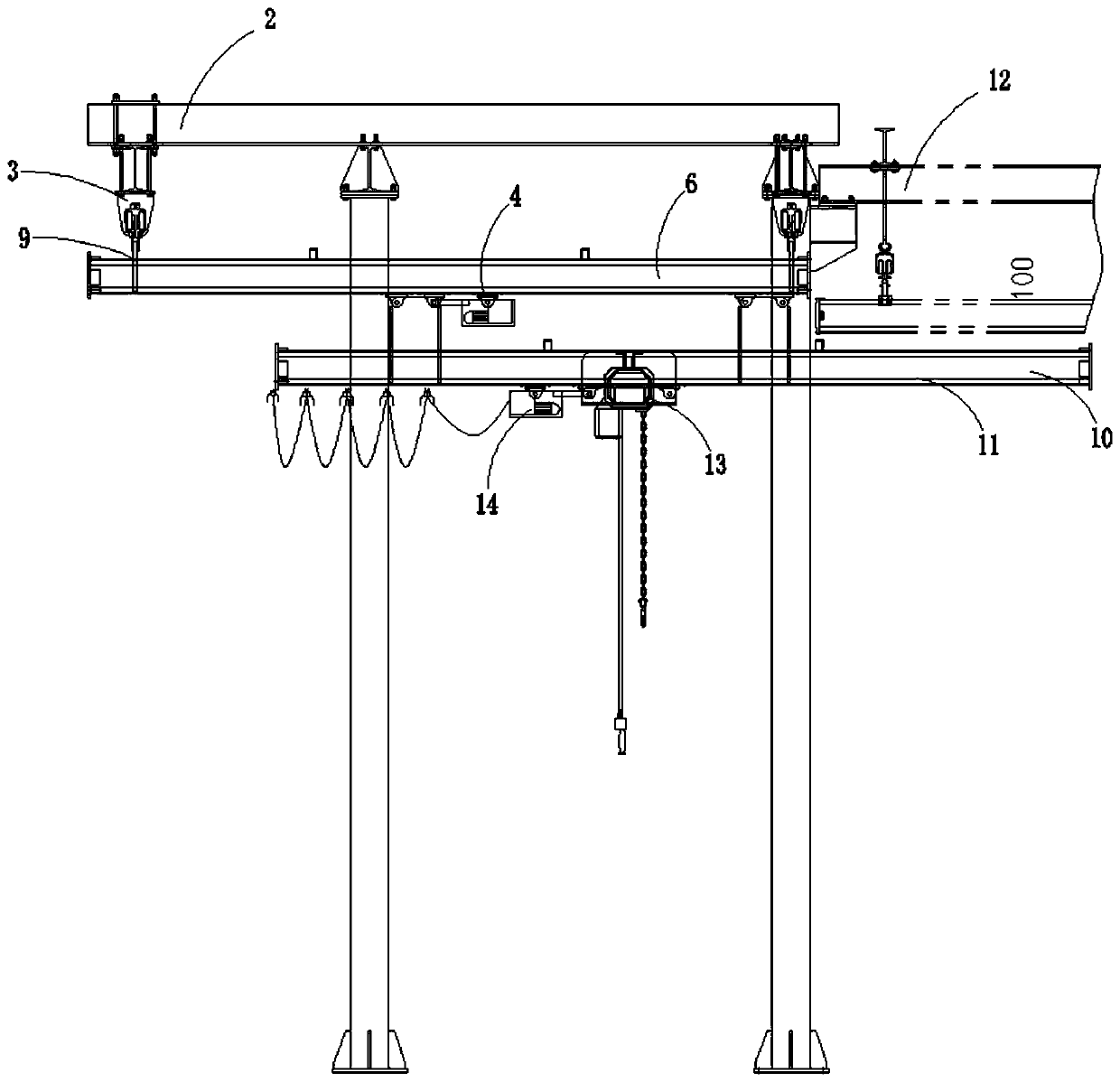

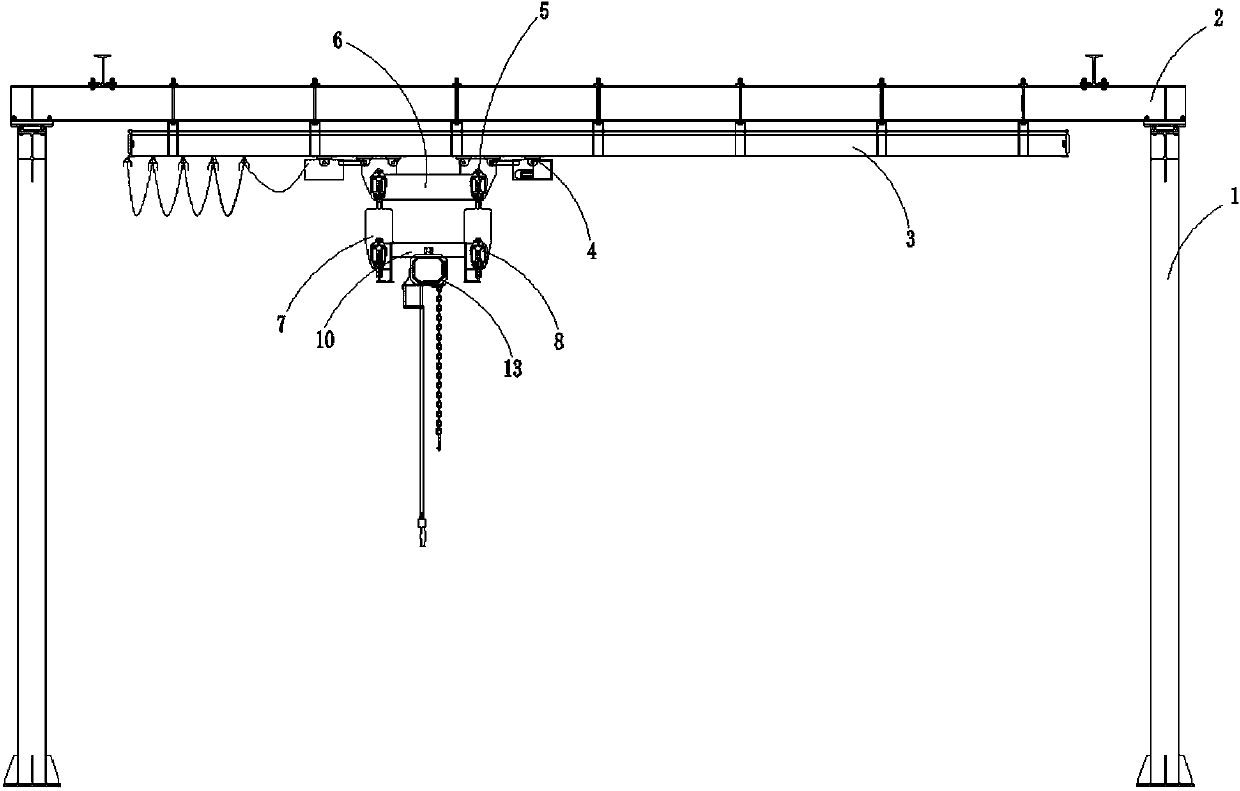

Telescopic structure of crane

PendingCN110386556ASuppression of warpingAvoid the problem of empty wheel pressureTravelling cranesRunwaysLoad carryingWheel and axle

The invention discloses a telescopic structure of a crane. The structure comprises a stand column, a steel beam connected to the top end of the stand column, first guide rails symmetrically arranged at the bottom of the steel beam, a first driving wheel arranged on the first guide rails, a balance beam arranged under the steel beam and connected with the first driving wheel through a first connecting frame, a second guide rail arranged at the lower end of the balance beam, a second driving wheel arranged on the second guide rail, a telescopic beam arranged below the balance beam and connectedwith the second driving wheel through a second connecting frame, and a third guide rail arranged at the lower end of the telescopic beam. According to the telescopic structure of the crane, a traditional flexible KBK rail is transformed into a telescopic type so that the telescopic structure can be conveniently applied to occasions limited by places. When one side of the telescopic beam is extended for hoisting, the other side of the telescopic beam abuts against the first driving wheel and a second driving wheel axle by an assembled rolling shaft, so that the problem of empty wheel pressure caused by warping of the first driving wheel and the second driving wheel is solved, and the stability of load carrying adjustment is improved.

Owner:江阴帕沃特起重机械有限公司

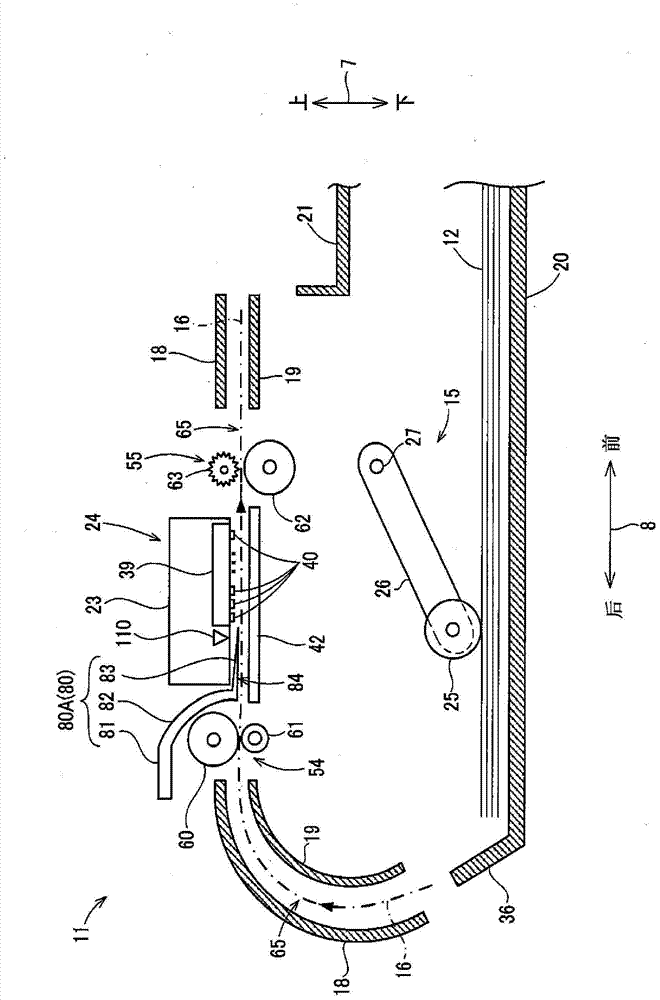

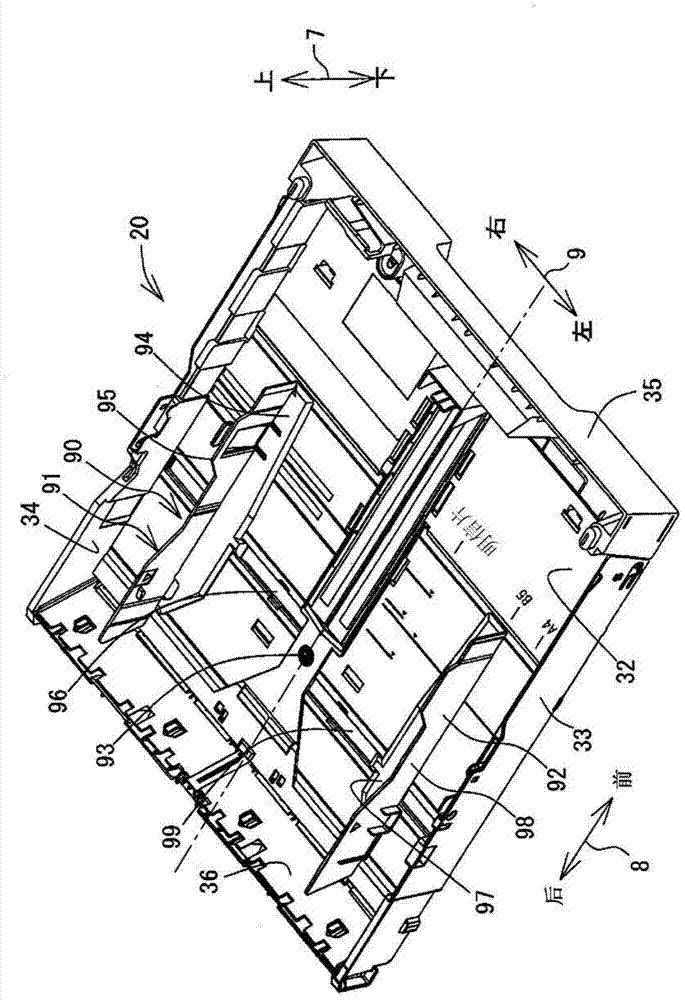

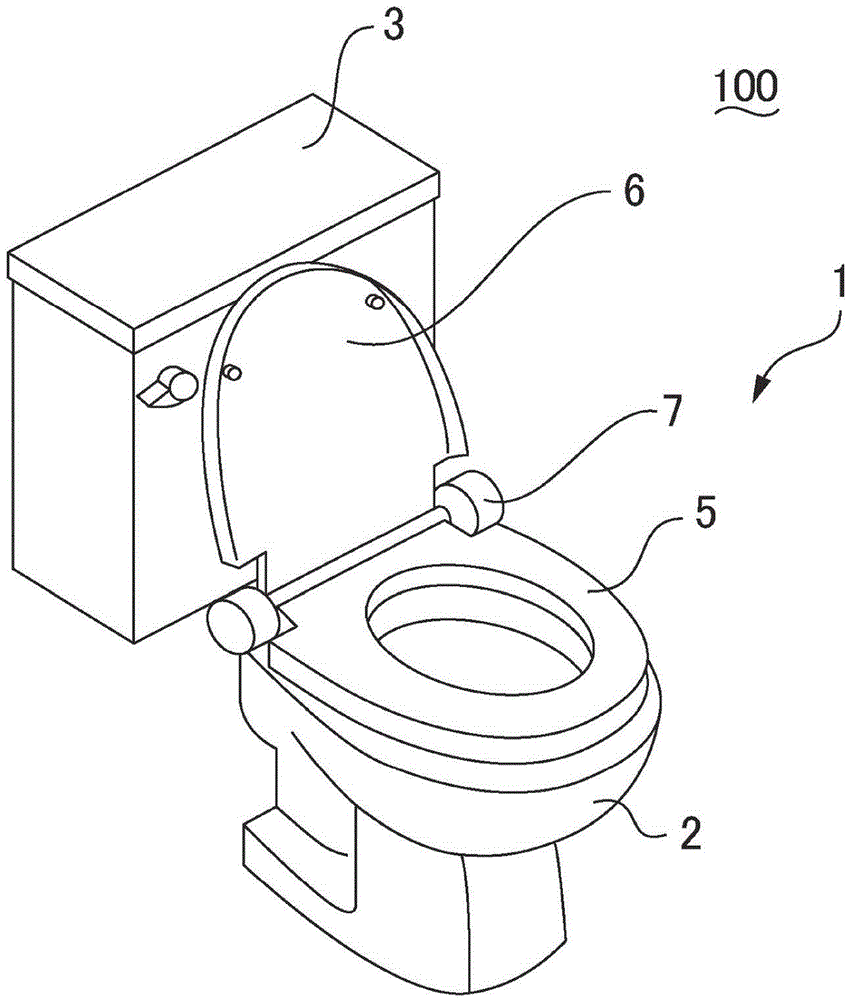

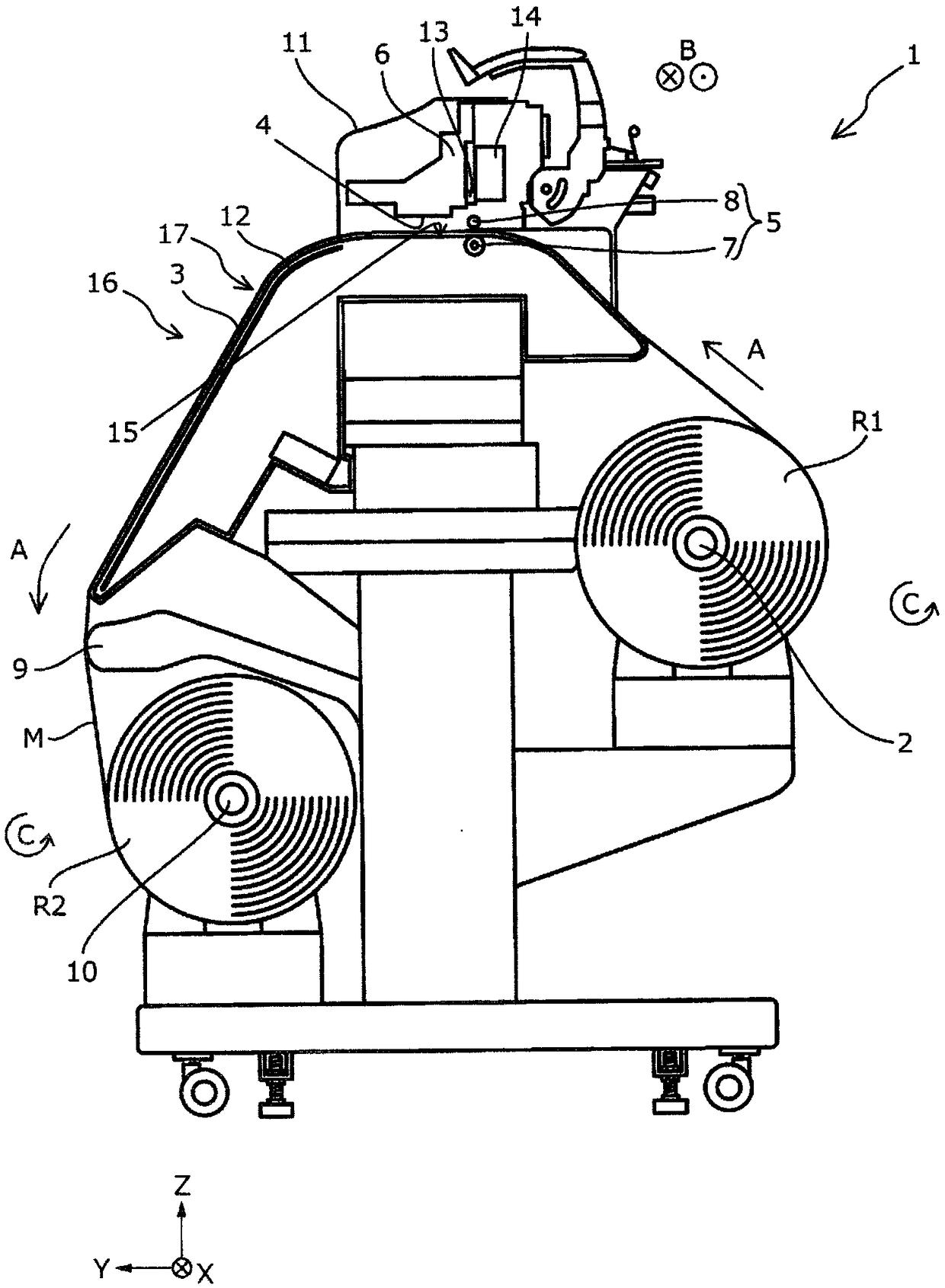

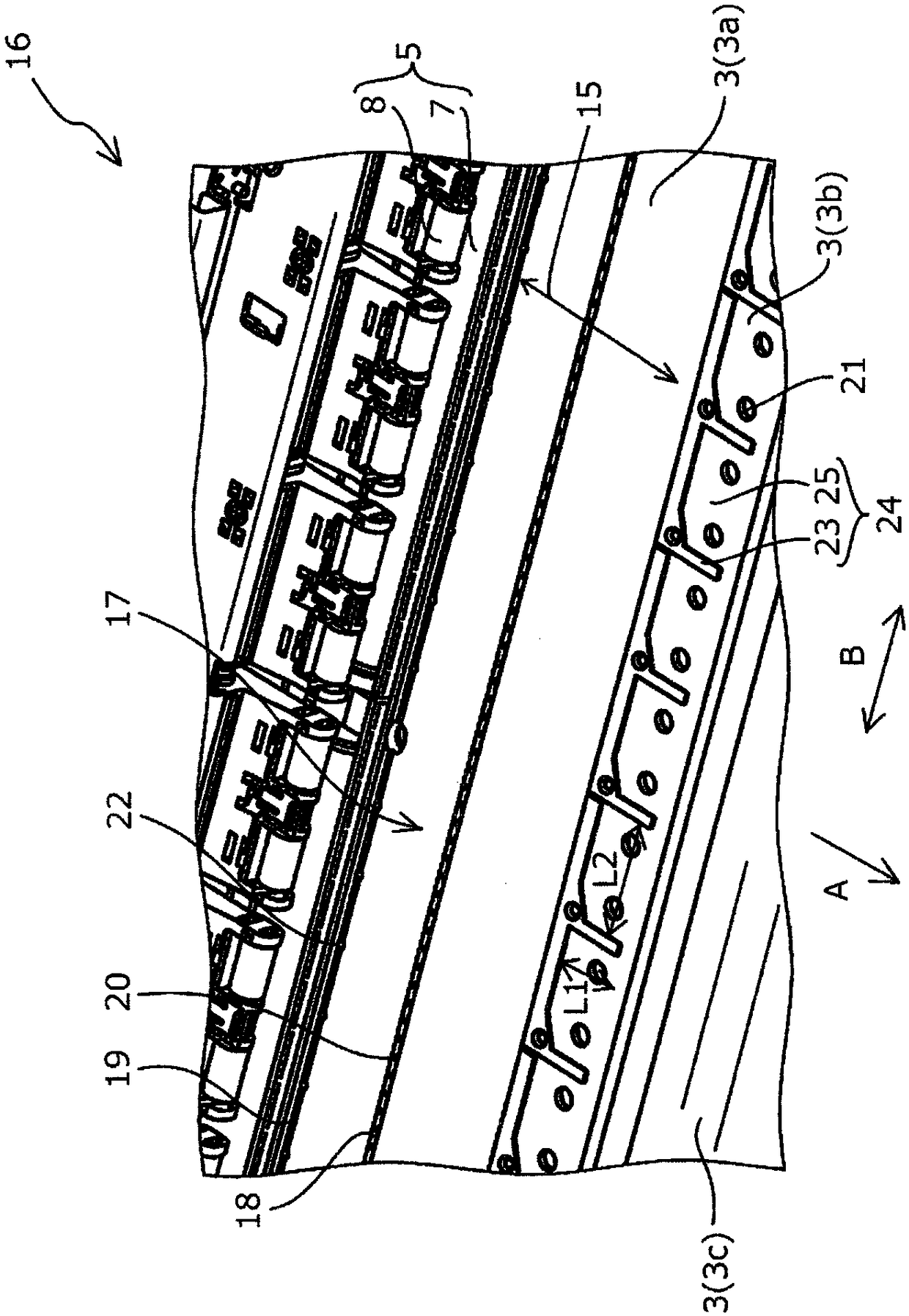

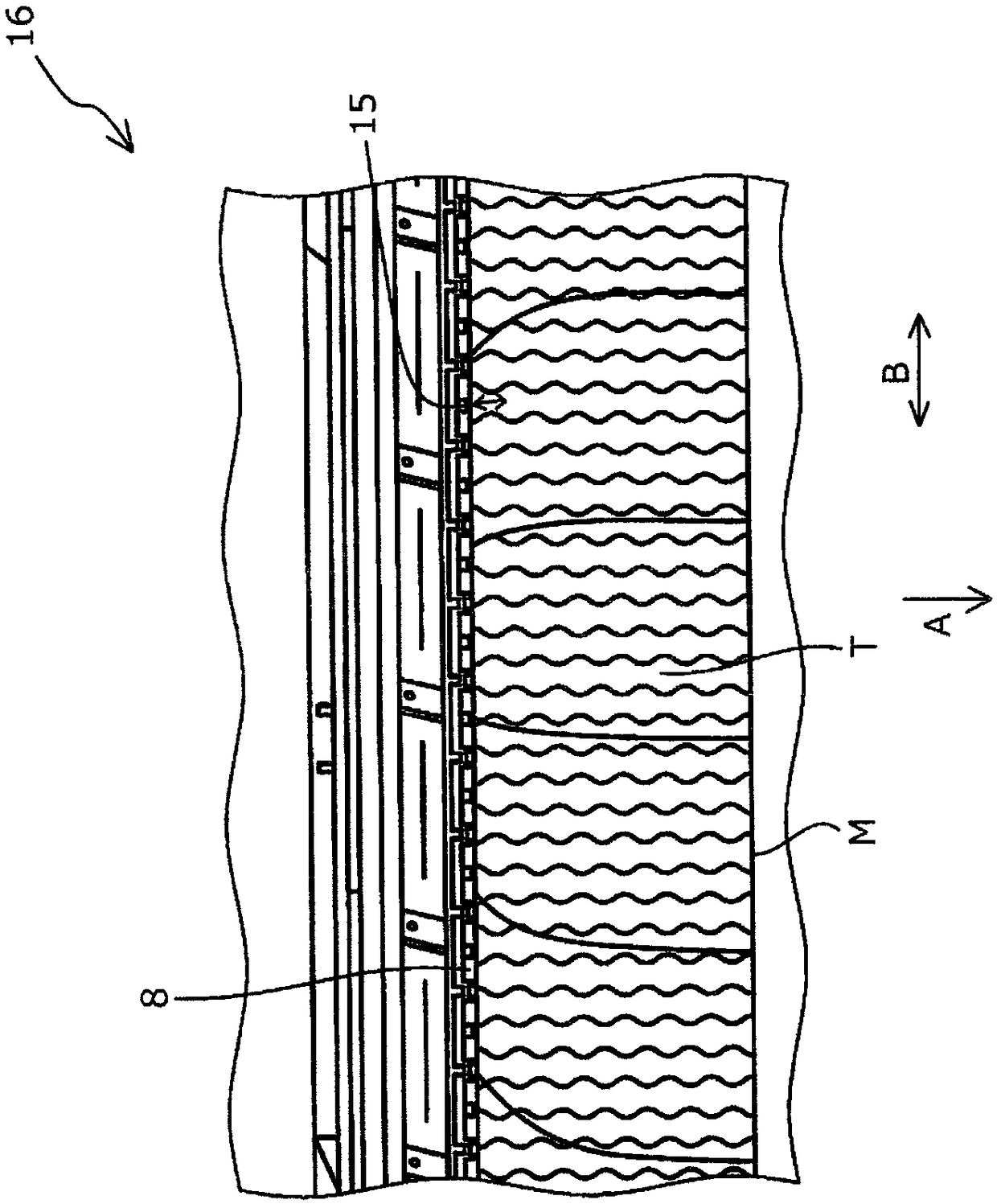

Liquid discharge apparatus

ActiveCN108688348ASuppression of warpingOther printing apparatusWebs handlingImaging qualityTransport medium

There is provided a liquid discharge apparatus (1), which can inhibit the reduction of image quality due to transported medium wrapping from a supporting surface and medium deformation. The liquid discharge apparatus (1) includes: a transporting unit (5) that transports a medium (M) in a transporting direction (A), a discharge portion (4) that discharges a liquid to the medium (M) positioned in adischarge range (15), and a supporting portion (17) that has a first supporting surface (3a) and a second supporting surface (3b), as a supporting surface (3) supporting the medium (M) to be transported by the transporting unit (5), in which the first supporting surface (3a) supports the medium (M) in the discharge range (15) and does not have unevenness in a width direction (B) intersecting the transporting direction, the second supporting surface (3b) supports the medium (M) on a downstream side of the discharge range (15) in the transporting direction and includes uneven portions in which afirst portion (23) and an uneven portion (24) of a second portion (25), which is further recessed than the first portion, are formed alternately in the width direction.

Owner:SEIKO EPSON CORP

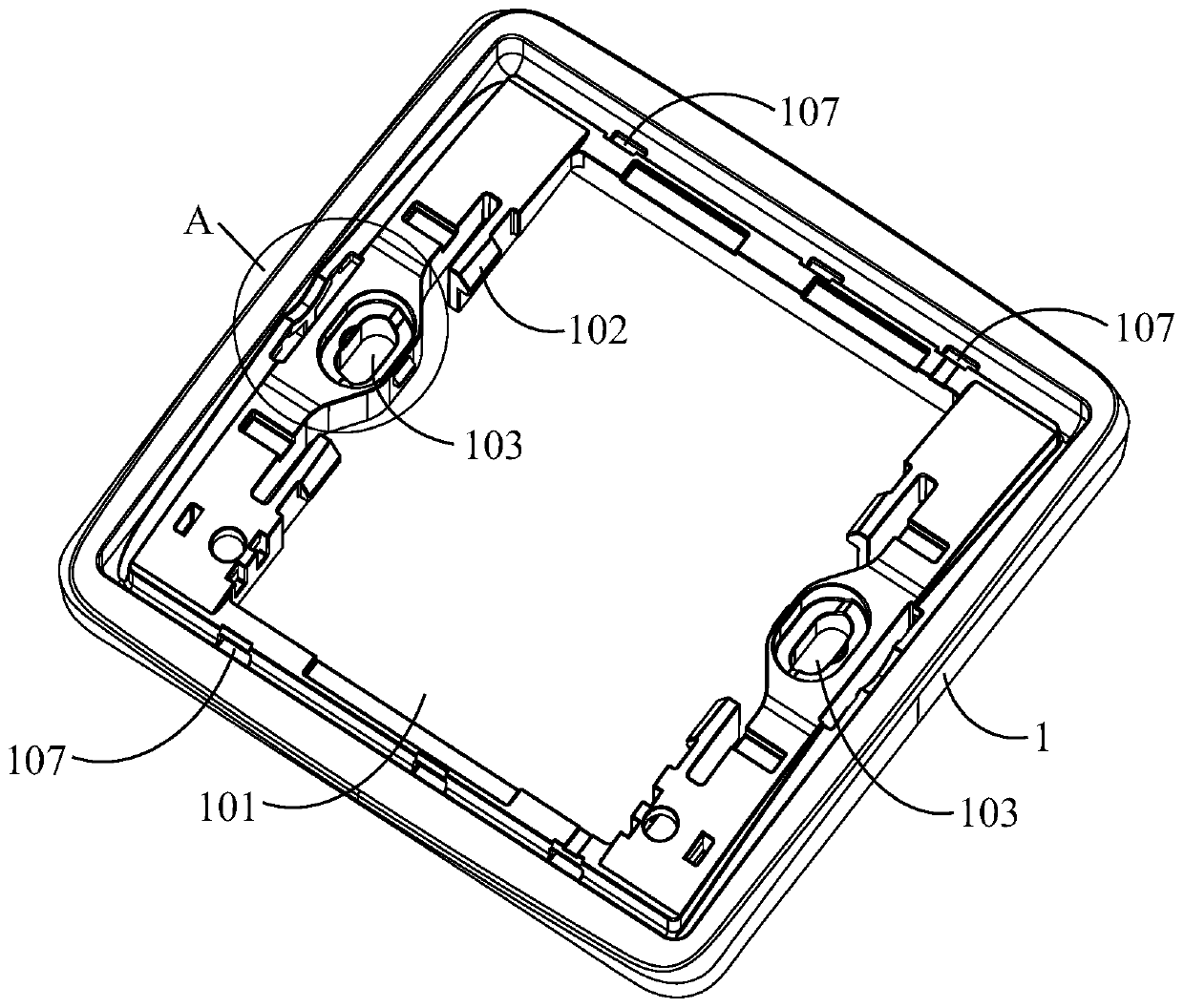

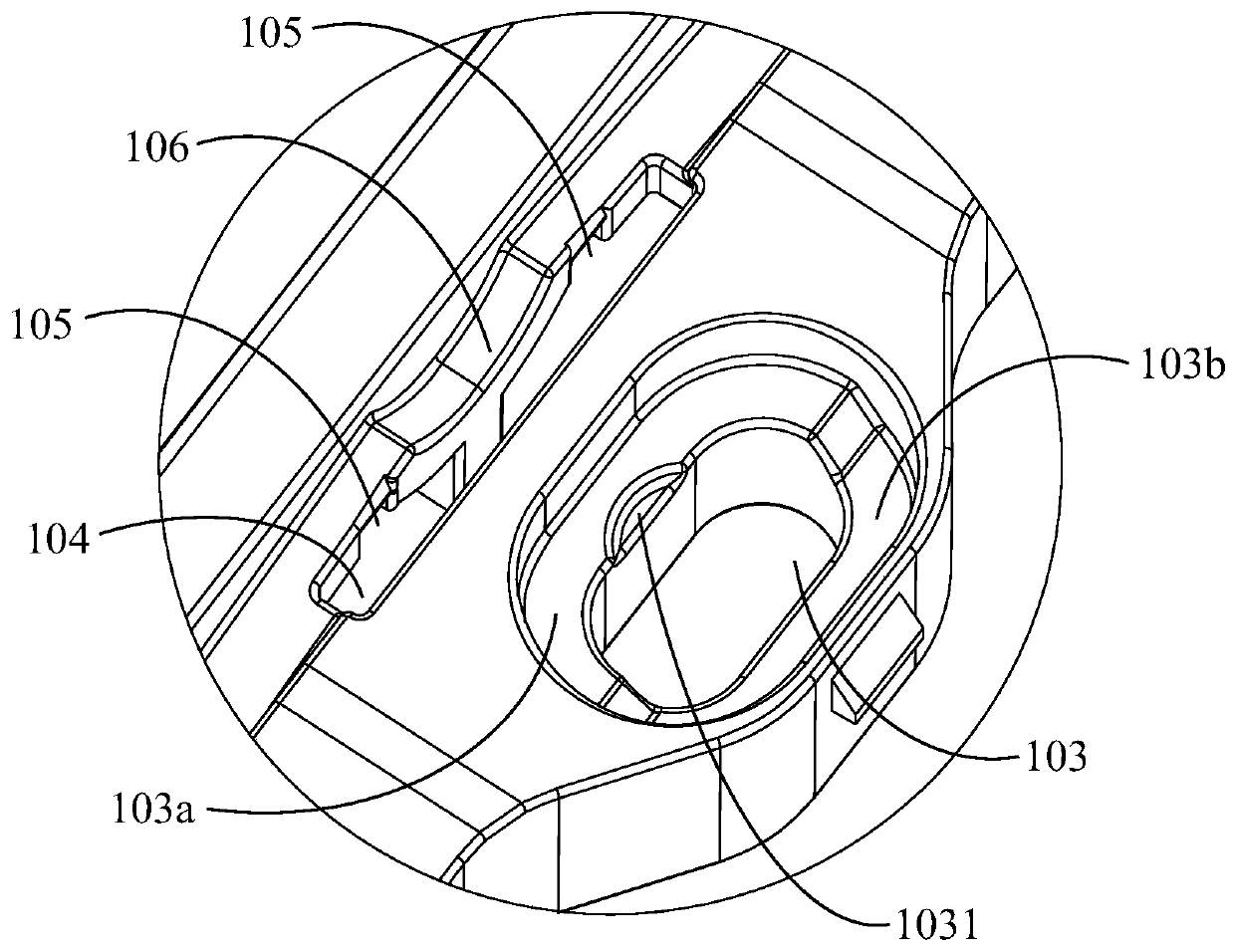

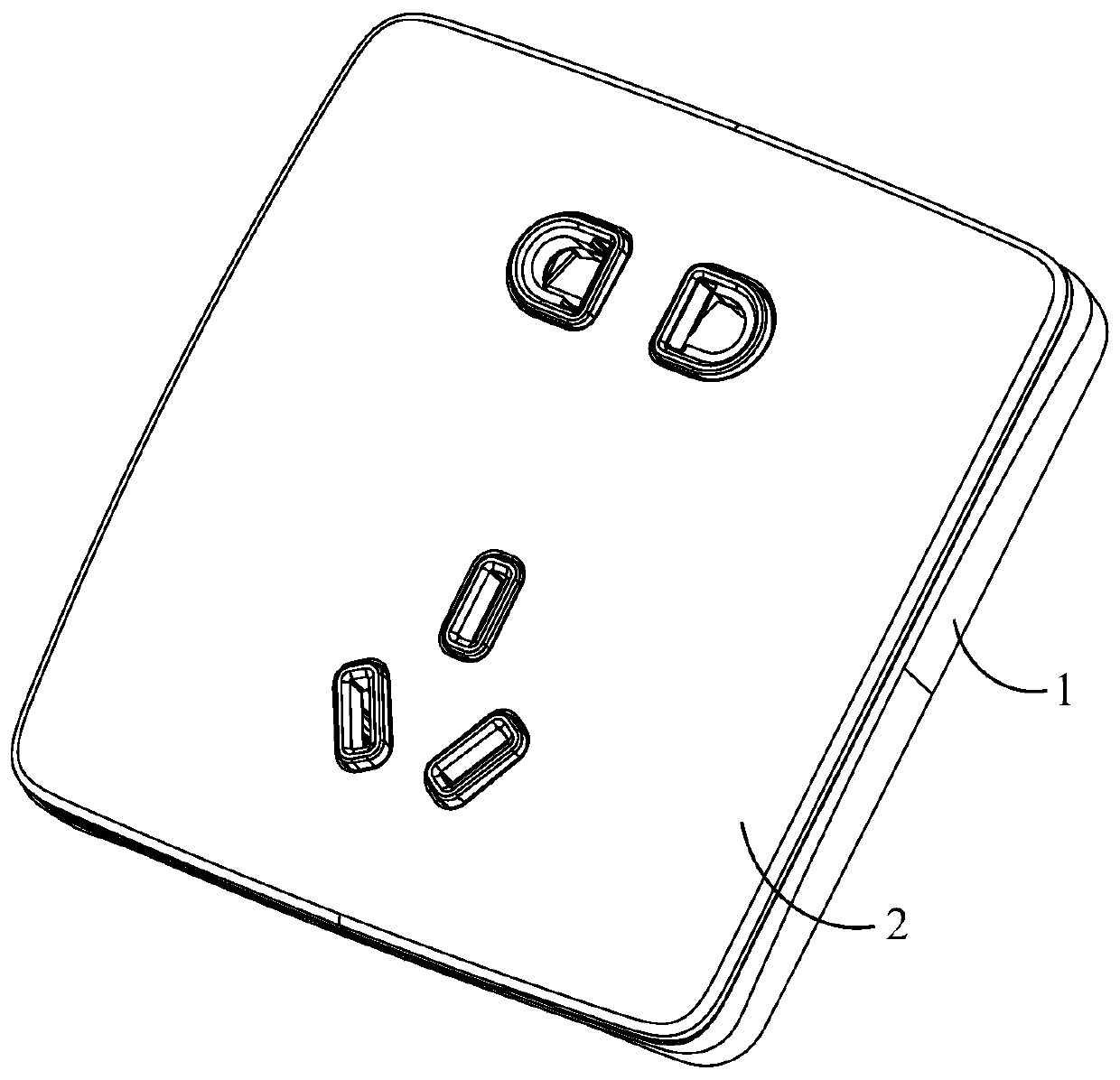

Borderless Wiring Appliances

ActiveCN109088219BSuppression of warpingAvoid liftingCoupling device detailsMechanical engineeringElectrical and Electronics engineering

Owner:PANASONIC INFORMATION INSTR SHANGHAI

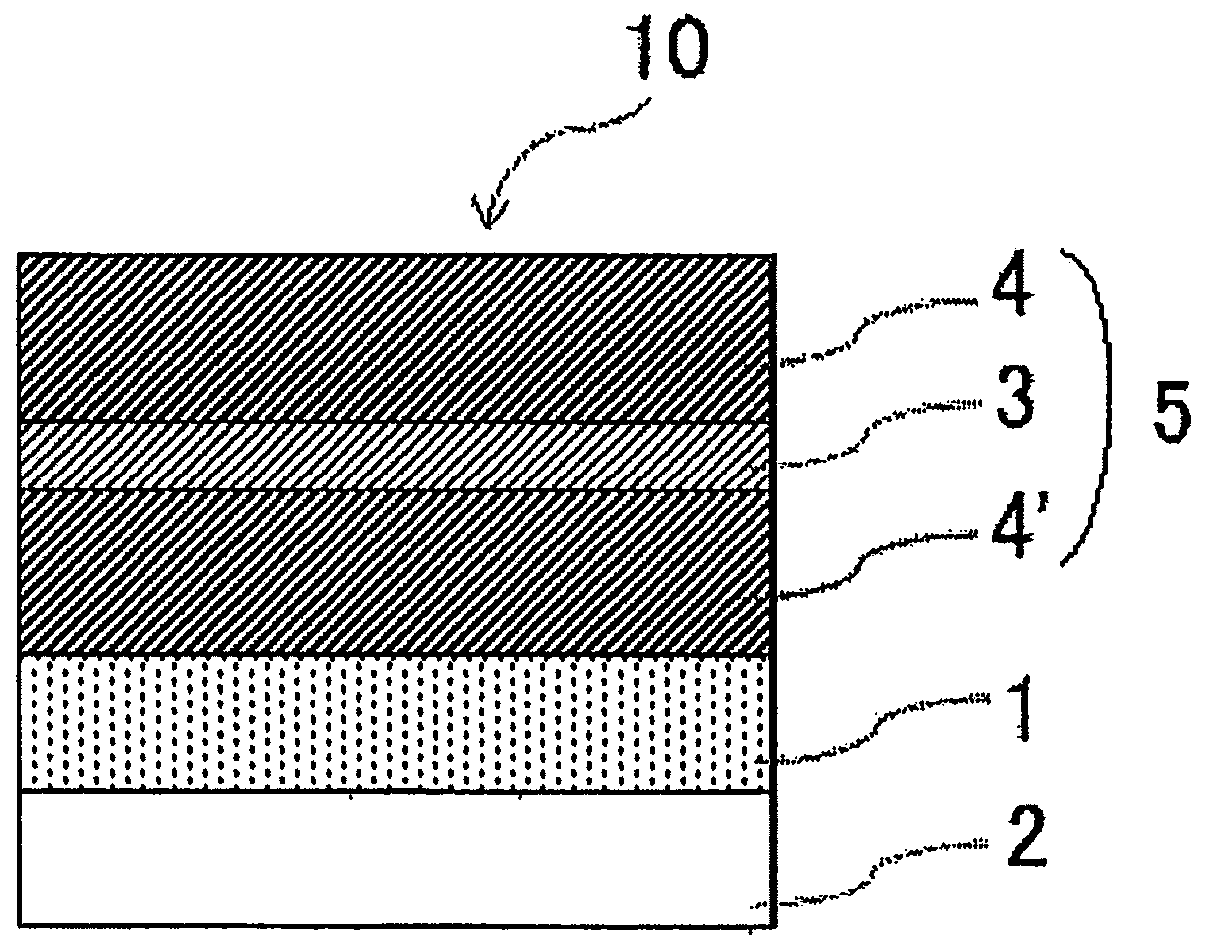

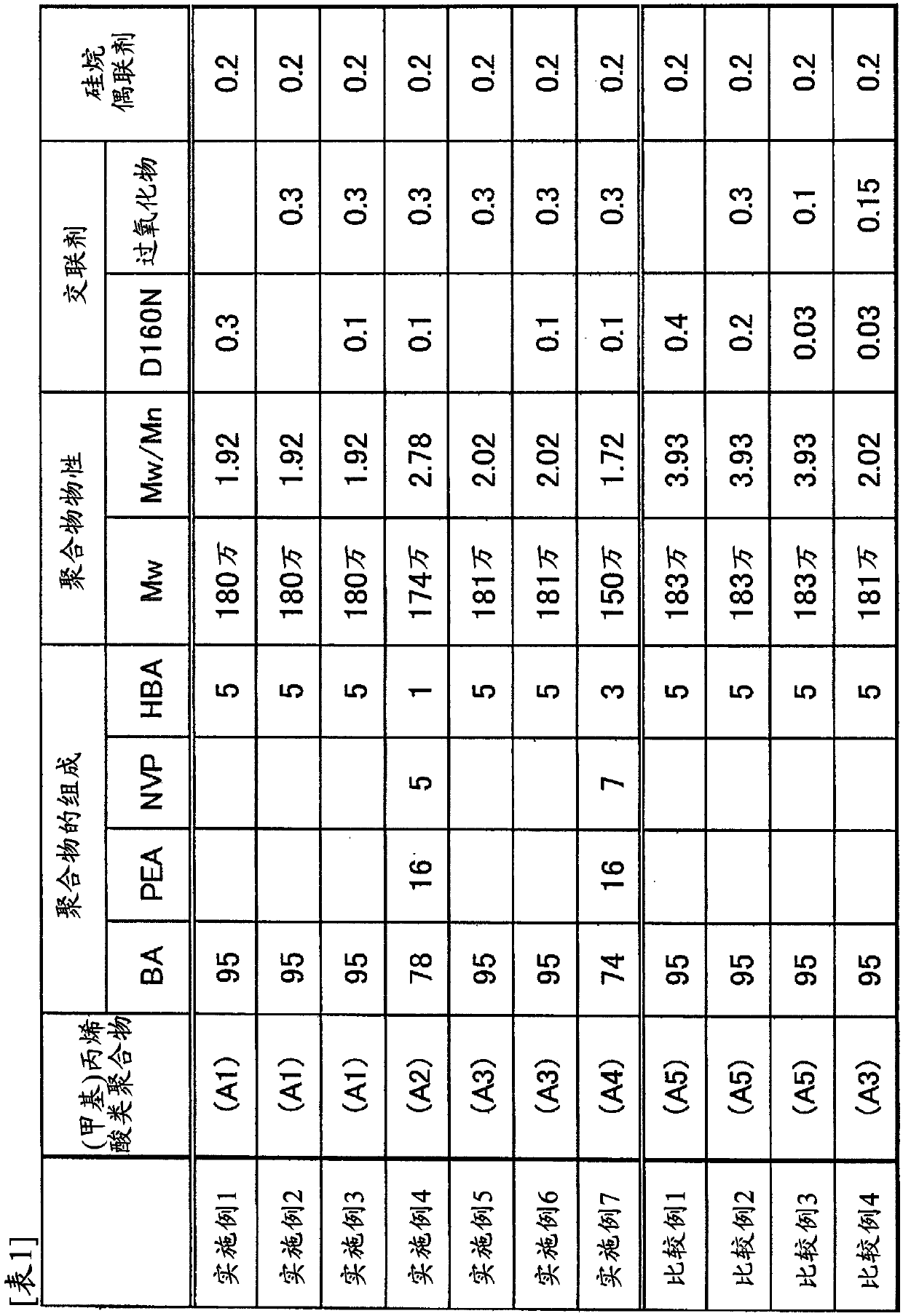

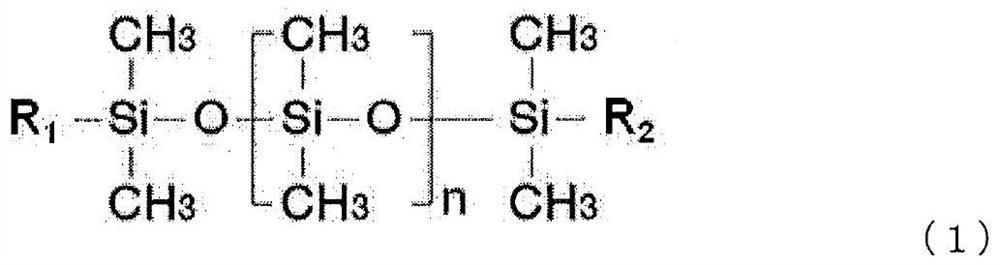

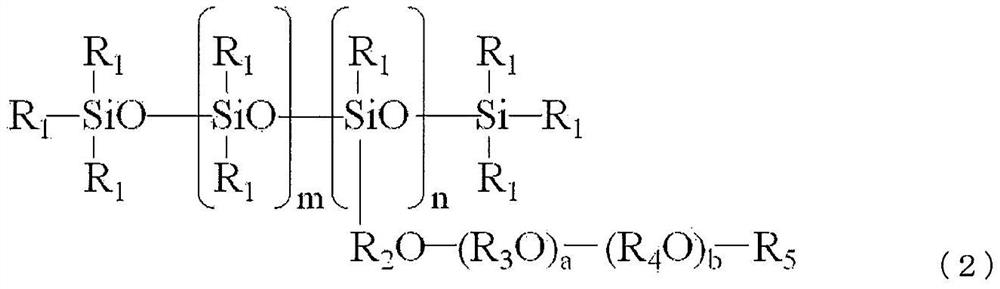

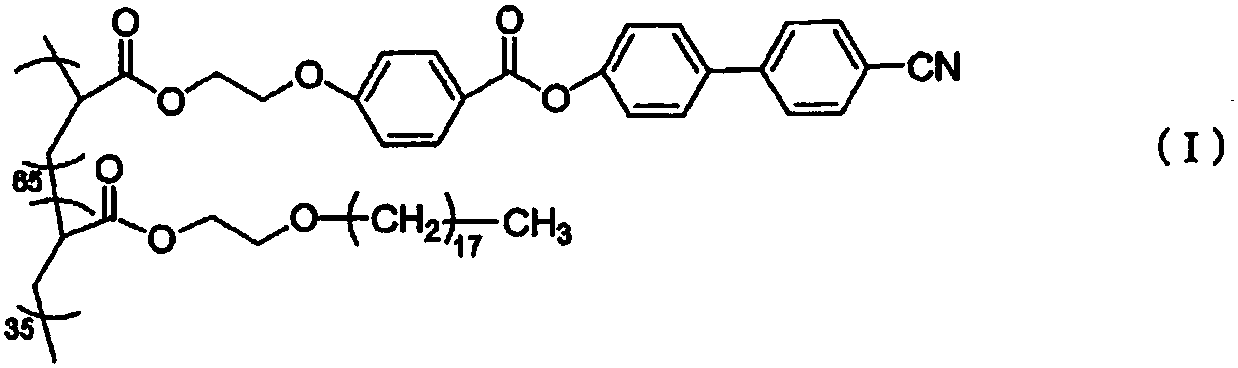

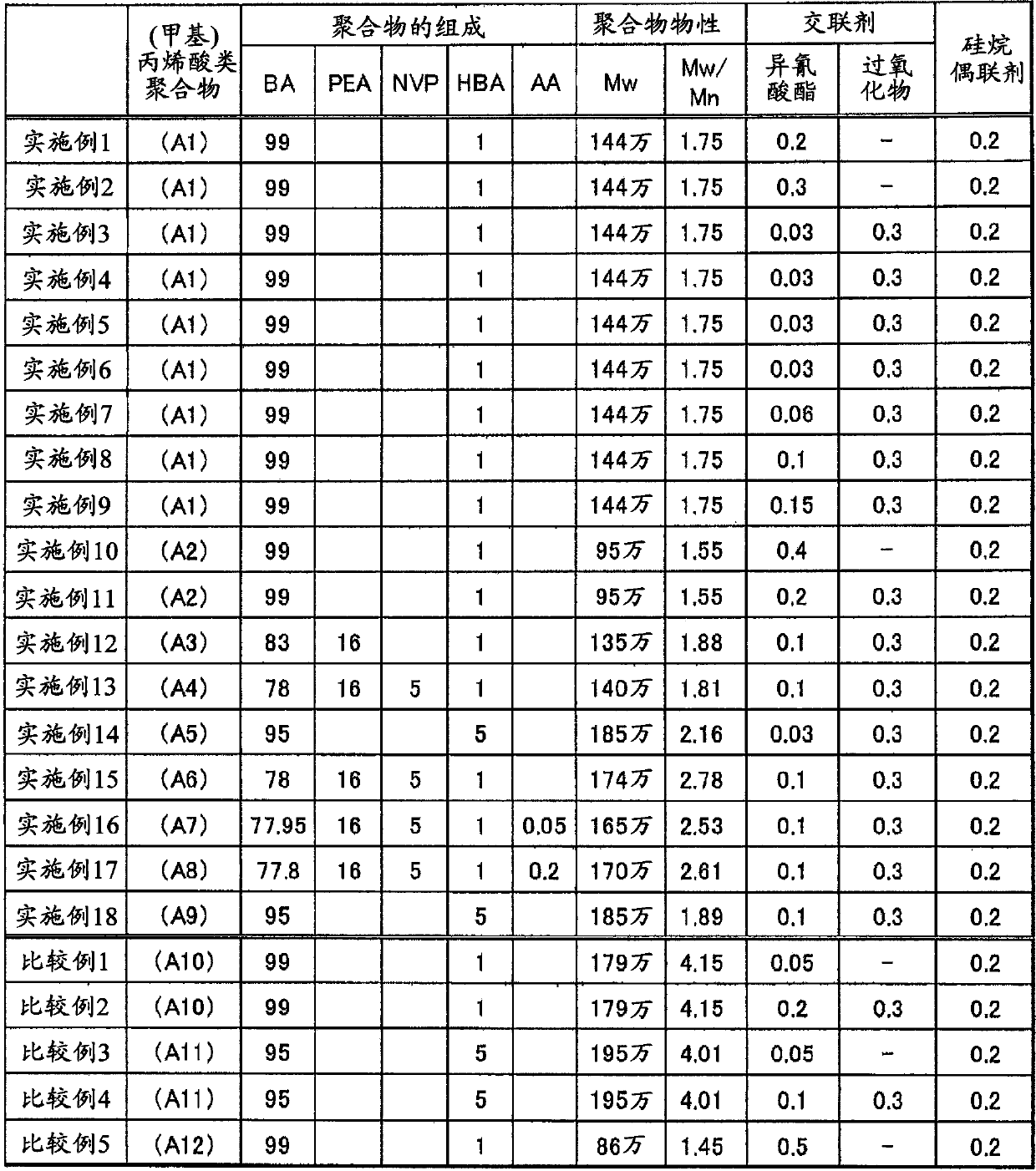

Optical adhesive layer, manufacturing method of optical adhesive layer, optical film with adhesive layer, and image display device

ActiveCN109790423ANo light leakAvoid foamingNon-macromolecular adhesive additivesPolarising elementsMeth-Liquid-crystal display

The purpose of the present invention is to provide: an optical adhesive layer which has excellent durability such that foaming, peeling, etc., do not occur on an adherend under heating and humidification conditions, and which does not cause optical leakage even on a narrow frame panel; an optical film with adhesive layer, having the aforementioned optical adhesive layer on at least one surface ofthe optical film; and a liquid crystal display device which uses the aforementioned optical film with adhesive layer. This optical adhesive layer, formed from an adhesive composition containing a (meth)acrylic polymer, is characterized by having a gel fraction exceeding 90%, and a 350,000 or higher weight average molecular weight of the sol content.

Owner:NITTO DENKO CORP

Machine head auxiliary pushing device of scraper conveyor

The invention provides a machine head auxiliary pushing device of a scraper conveyor. The device comprises a first telescopic mechanism, a second telescopic mechanism, a power integration mechanism, apushing telescopic rod, an auxiliary pushing mechanism and a hinge seat set. Compared with the prior art, the device has the following beneficial effects that hydraulic oil pipes are arranged, a hydraulic jack I and a hydraulic jack II of the auxiliary pushing mechanism can work normally and are connected with a control valve group through the hydraulic oil pipes, and the auxiliary pushing mechanism can be hinged to the upper surface of the right end of a supporting base through the hinge seat set due to the design of the auxiliary pushing mechanism and the hinge seat set. When the hydraulicjack I and the hydraulic jack II on the hinge seat set stretch and retract to work, supporting force is provided, the hydraulic jack I and the hydraulic jack II synchronously stretch when the pushingtelescopic rod pushes a machine head, the situation that the machine head frequently floats upwards in the pushing direction of a working face during use in the machine head operation process is avoided, the machine head is restrained from tilting, and normal pushing of the machine head is ensured.

Owner:HUNAN COAL MINE MACHINERY CO LTD

Adhesive composition, adhesive sheet and optical member

ActiveCN108342163BPrevent slidingSuppression of warpingNon-macromolecular adhesive additivesFilm/foil adhesive primer layersPolymer scienceOligomer

The present invention relates to an adhesive composition, an adhesive sheet, and an optical member. The present invention provides an adhesive composition that is less prone to slipping (shifting), warping, and peeling on optical members such as polarizing plates, and is excellent in curl adjustment, adhesiveness, and light peelability (repeelability). A pressure-sensitive adhesive sheet formed of an agent composition, and an optical member bonded with the pressure-sensitive adhesive sheet. The adhesive composition of the present invention is characterized in that it contains an adhesive polymer and a fluorine-containing oligomer having a weight average molecular weight of 3,500 or more.

Owner:NITTO DENKO CORP

Rubber-based pressure-sensitive adhesive composition, rubber-based pressure-sensitive adhesive layer, pressure-sensitive adhesive film, optical film with rubber-based pressure-sensitive adhesive layer, optical member, and image display device

ActiveCN109689821AGood durabilityExcellent low moisture permeabilityNon-macromolecular adhesive additivesFilm/foil adhesivesPressure sensitiveChemistry

The present invention provides a rubber-based pressure-sensitive adhesive composition which contains a rubber-based base polymer, the rubber-based base polymer comprising an isobutylene-based polymerhaving a polydispersity coefficient, (weight-average molecular weight) / (number-average molecular weight), of 4 or less. A 50 mum-thick rubber-based pressure-sensitive adhesive layer formed from the rubber-based pressure-sensitive adhesive composition has a moisture permeability at 40 DEG C and 92% RH of 50 g / (m2*day) or less. The rubber-based pressure-sensitive adhesive composition of the presentinvention can form a rubber-based pressure-sensitive adhesive layer which has low moisture permeability and has so high durability that the adhesive layer can be inhibited from suffering troubles including lifting and peeling even in high-temperature environments.

Owner:NITTO DENKO CORP

Optical adhesive layer, manufacturing method of optical adhesive layer, optical film with adhesive layer, and image display device

PendingCN109790420AAvoid foamingPrevent peelingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMeth-Liquid-crystal display

The purpose of the present invention is to provide: an optical adhesive layer which can suppress the occurrence of foaming, peeling, lifting, etc., on an adherend (an optical film) under heating and humidification conditions, and which has high adhesion reliability and excellent durability at high temperatures; an optical film with adhesive layer, having the aforementioned optical adhesive layer on at least one surface of the optical film; and a liquid crystal display device which uses the aforementioned optical film with adhesive layer. The optical adhesive layer, formed from an adhesive composition containing a (meth)acrylic polymer, is characterized by having a 70% or higher gel fraction, and a 55 [mu]m or higher creep value when applying a load of 500g for one hour in a 115 degrees centigrade environment.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com