Auxiliary supporting structure capable of inhibiting thin-wall structure from deformation

A technology of auxiliary support and thin-walled structure, which is applied in the direction of additive manufacturing, improvement of process efficiency, energy efficiency, etc., can solve the problem of difficult control of the deformation of the open structure, difficulty of support removal, heavy workload, and inaccurate surface accuracy. Guarantee and other issues, to achieve the effect of reducing the difficulty and workload of support removal, suppressing surface deformation, and suppressing warping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

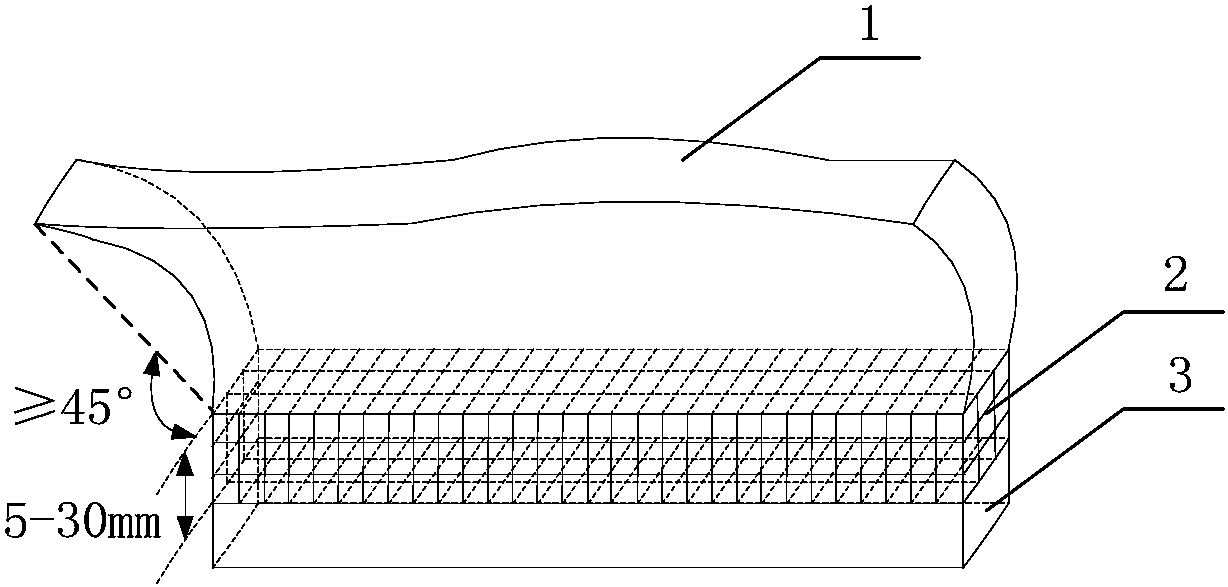

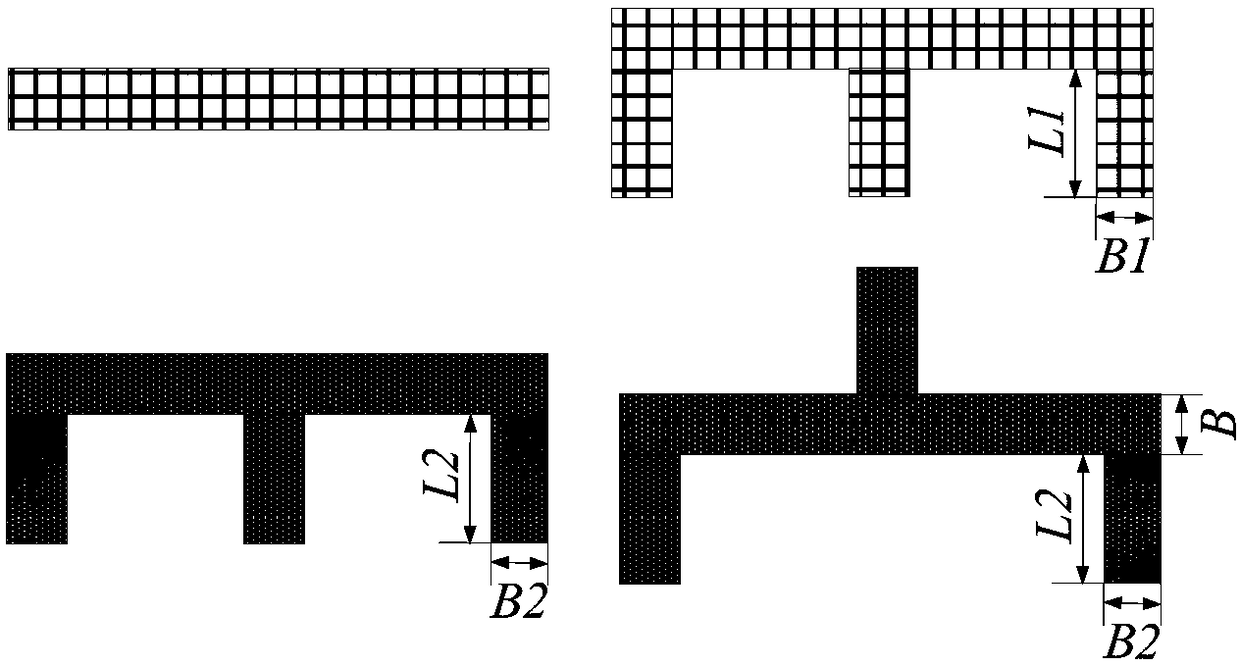

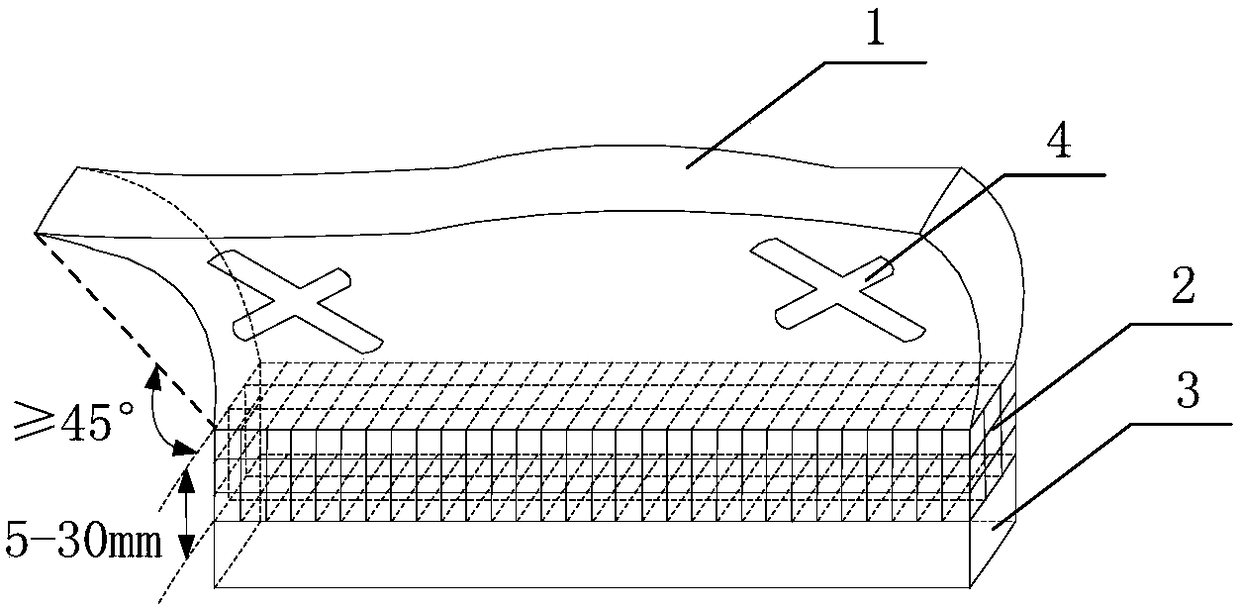

[0023] Such as figure 1 As shown, an auxiliary support structure for suppressing deformation of a thin-walled structure according to the present invention is provided between the thin-walled structure 1 and the formed substrate to form a support, which includes a fixedly connected grid support part 2 and a solid support part 3, That is, the auxiliary support structure adopts an integral auxiliary support in which the section in the growth direction is in the form of "grid + solid", and the solid part and the grid part are firmly connected.

[0024] The lower end of the grid support part 2 is supported on the solid support part 3, and a support is formed between the suspended end of the thin-walled structure 1 and the solid support part 3; the grid support part 2 adopts a sheet type or "mountain" font structure; the upper end of the solid support part 3 is supported on the lower end surface of the grid support part 2, and the lower end is supported on the shaped substrate; the ...

Embodiment 2

[0032] Such as figure 1 As shown, an auxiliary support structure for suppressing deformation of a thin-walled structure according to the present invention is provided between the thin-walled structure 1 and the formed substrate to form a support, which includes a fixedly connected grid support part 2 and a solid support part 3, That is, the auxiliary support structure adopts an integral auxiliary support in which the section in the growth direction is in the form of "grid + solid", and the solid part and the grid part are firmly connected.

[0033] The lower end of the grid support part 2 is supported on the solid support part 3, and a support is formed between the suspended end of the thin-walled structure 1 and the solid support part 3; the grid support part 2 adopts a sheet type or "mountain" font structure; the upper end of the solid support part 3 is supported on the lower end surface of the grid support part 2, and the lower end is supported on the shaped substrate; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com