Secondary lining integral formworking construction method for tunnel with super-large cross section

A super-large section, secondary lining technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of safe and fast construction of difficult projects, and achieve the effect of saving project cost, reducing investment and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

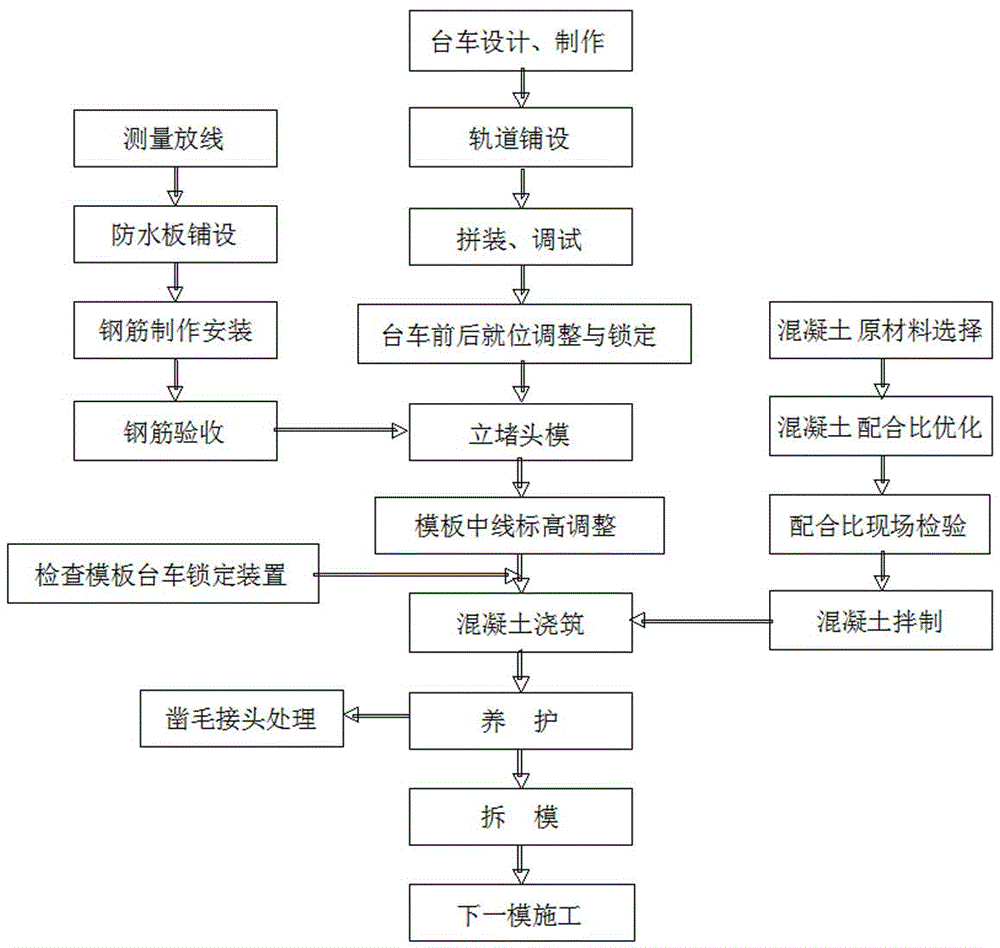

[0077] Below in conjunction with the accompanying drawings, the construction method of the secondary lining of the super large section tunnel of the present invention will be described in detail below.

[0078] As shown in the accompanying drawings, the super-large section tunnel secondary lining integral molding construction method of the present invention includes:

[0079] Main line: trolley design and production → track laying → assembly and commissioning → front and rear adjustment and locking of the trolley → vertical plug mold → adjustment of the center line elevation of the formwork → concrete pouring → maintenance → formwork removal → construction of the next mold;

[0080] In the main line: measuring and setting out → laying waterproof board → making and installing steel bars → checking and accepting steel bars → vertical plugging mold;

[0081] In the main line: selection of concrete raw materials→optimization of concrete mix ratio→site inspection of mix ratio→concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com