BiFeO3 target and film production method

A target and thin film technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problem of unpublished BiFeO3 material preparation process, and achieve favorable target phase formation and dense target material. , The effect of dense and uniform surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

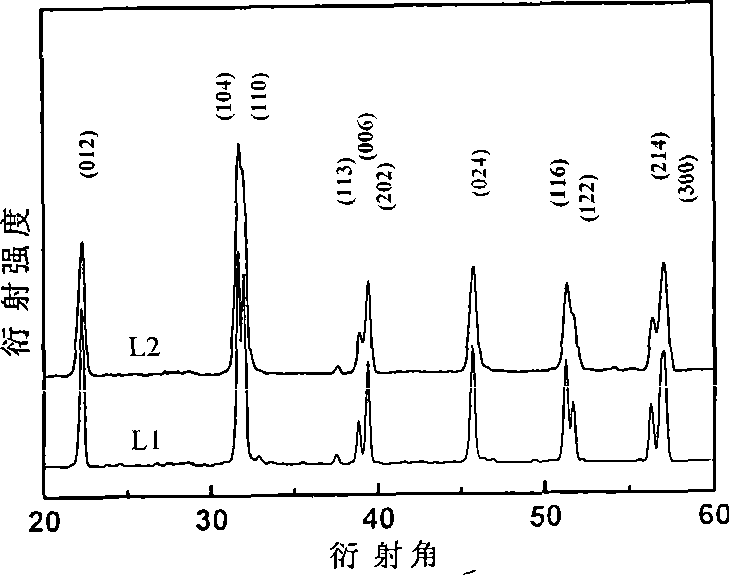

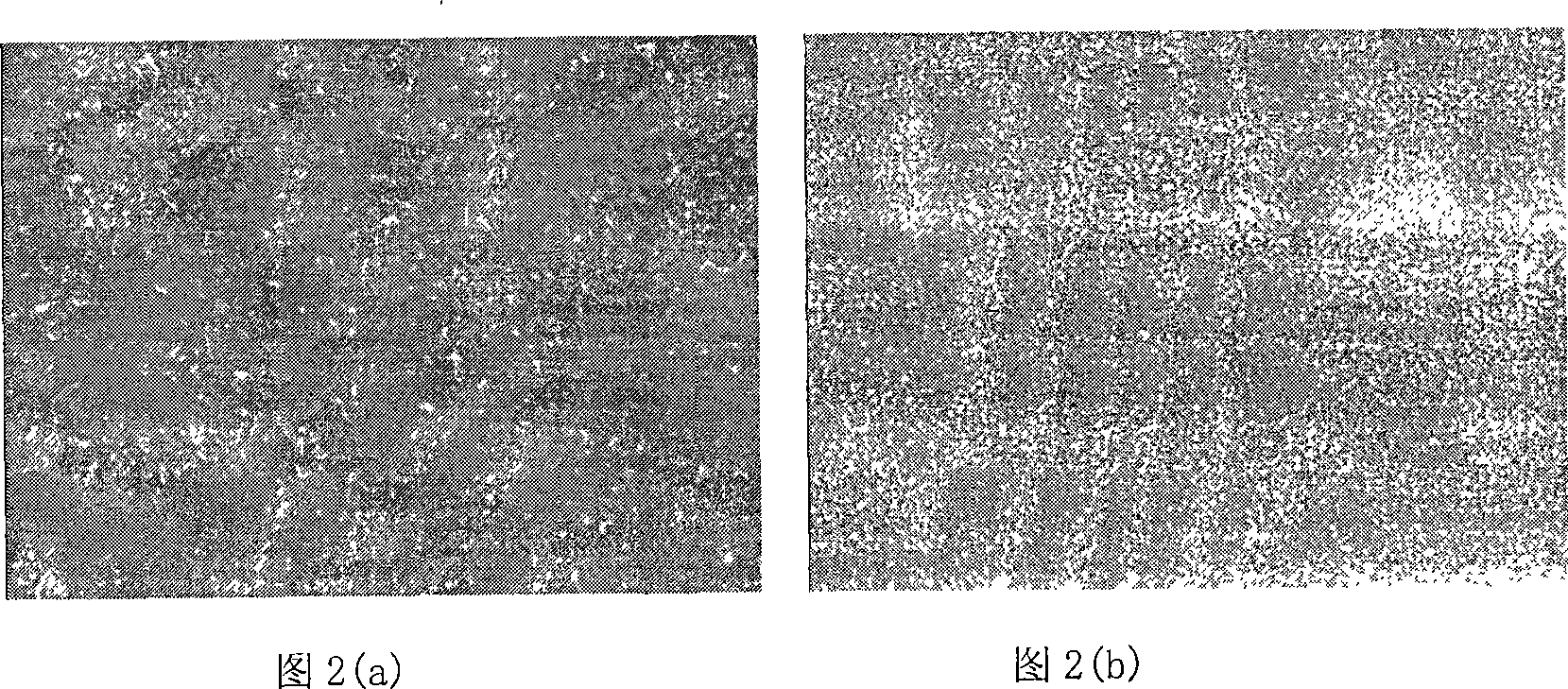

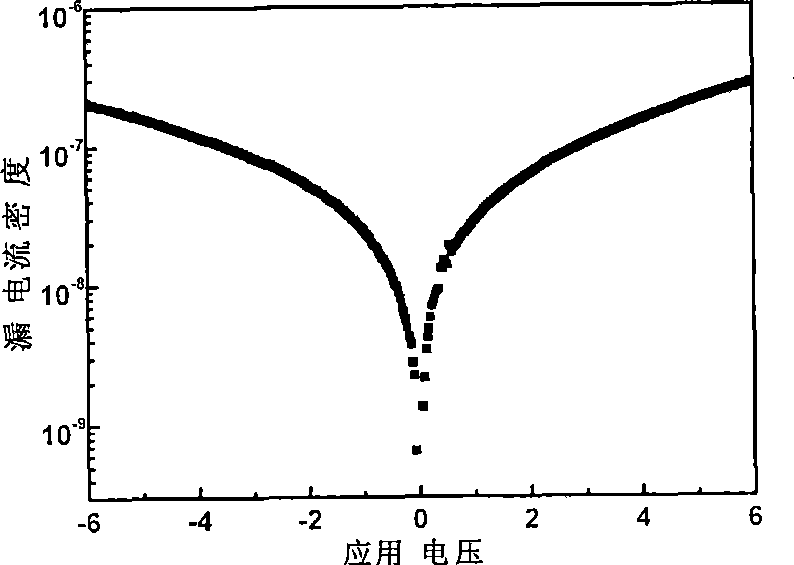

[0040] Example 1 Preparation of pure BiFeO 3 Target and film

[0041] (1) Using the following raw materials (all of which are analytically pure, with a purity of over 99.9%), using an improved solid-phase reaction method to prepare pure BiFeO for RF magnetron sputtering 3 Target

[0042] Considering that Bi is volatile under high temperature conditions, in BiFeO 3 Based on the ideal chemical composition ratio, a composition formula with an excess of 6% of Bi is used to make up for the loss of Bi volatilization.

[0043] Bismuth trioxide Bi 2 O 3 89.803g

[0044] Iron trioxide Fe 2 O 3 29.035g

[0045] The specific method is:

[0046] 1.1) Put the weighed Fe 2 O 3 And Bi 2 O 3 Mix the powder evenly, put it into an agate mortar, and grind it until the powder is uniformly dark red. Preliminary mixing and grinding can effectively prevent the delamination of the mixture during ball milling, thereby inhibiting the segregation of components in the preparation of the target.

[0047] 1.2)...

Embodiment 2

[0070] Example 2 Preparation of A-site Dy-doped Bi 0.95 Dy 0.05 FeO 3 Target and film

[0071] 1) Using the following raw materials (all of which are analytically pure, with a purity of 99.9% or more), a solid-phase reaction method is used to prepare a target material for RF magnetron sputtering with a Dy doping content of 10%;

[0072] Considering that Bi is volatile under high temperature conditions, in Bi 0.95 Dy 0.05 FeO 3 Based on the ideal chemical composition ratio, a composition formula with an excess of 1% Bi is used to make up for the loss of Bi volatilization.

[0073] Bismuth trioxide Bi 2 O 3 90.368g

[0074] Iron trioxide Fe 2 O 3 32.261g

[0075] Dysprosium trioxide Dy 2 O 3 3.768g

[0076] The specific method is:

[0077] 1.1) Put the weighed Fe 2 O 3 , Dy 2 O 3 And Bi 2 O 3 After the powder is mixed evenly, put it in an agate mortar and grind it initially until the powder is uniformly dark red;

[0078] 1.2) Add 40ml of absolute ethanol, use a planetary ball mill ...

Embodiment 3

[0095] Example 3 Preparation of B-site Ti-doped BiFe 0.9 Ti 0.1 O 3 Target and film methods, including

[0096] 1) Using the following raw materials (all of which are analytically pure, with a purity of 99.9% or more), a solid phase reaction method is used to prepare a target material for RF magnetron sputtering with a Ti doping content of 10%;

[0097] Considering that Bi is volatile under high temperature conditions, BiFe 0.9 Ti 0.1 O 3 On the basis of the ideal chemical composition ratio, a formula with an excess of 5% of Bi is used to make up for the loss of Bi volatilization.

[0098] Bismuth trioxide Bi 2 O 3 88.956g

[0099] Iron trioxide Fe 2 O 3 26.131g

[0100] Titanium dioxide TiO2 2.905g

[0101] The specific method is:

[0102] 1.1) The weighed Fe 2 O 3 , TiO 2 And Bi 2 O 3 After the powder is evenly mixed, put it into an agate mortar and grind it initially until the powder is uniformly dark red;

[0103] 1.2) Add 42ml of acetone, use a planetary ball mill for 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com