Patents

Literature

56 results about "Magnetic order" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic order is a common phenomenon in three-dimensional materials, such as ferromagnetic order in iron bar magnets, where the magnetic moments on all iron atoms point in the same direction. In one or two dimensions, long-range magnetic order at temperatures higher than zero is not possible, however, according to the Mermin-Wagner theorem.

Nanoparticle coated material and production method of same

The invention provides a method of producing a nanoparticle coated material, comprising a support and a nanoparticle layer formed on the support, wherein the nanoparticle layer contains nanoparticles comprising a CuAu type or Cu3Au type hard magnetic ordered alloy, and wherein the method satisfies at least one of the following conditions (i) and (ii): (i) the method comprises the steps of forming a shielding layer on the support before forming the nanoparticle layer; and (ii) a step of forming the nanoparticle layer comprises: the steps of applying a coating liquid containing nanoparticles capable of forming a CuAu type or Cu3Au type hard magnetic ordered alloy phase on the support to form a coating film; and irradiating laser light on the coating film.

Owner:FUJIFILM CORP +1

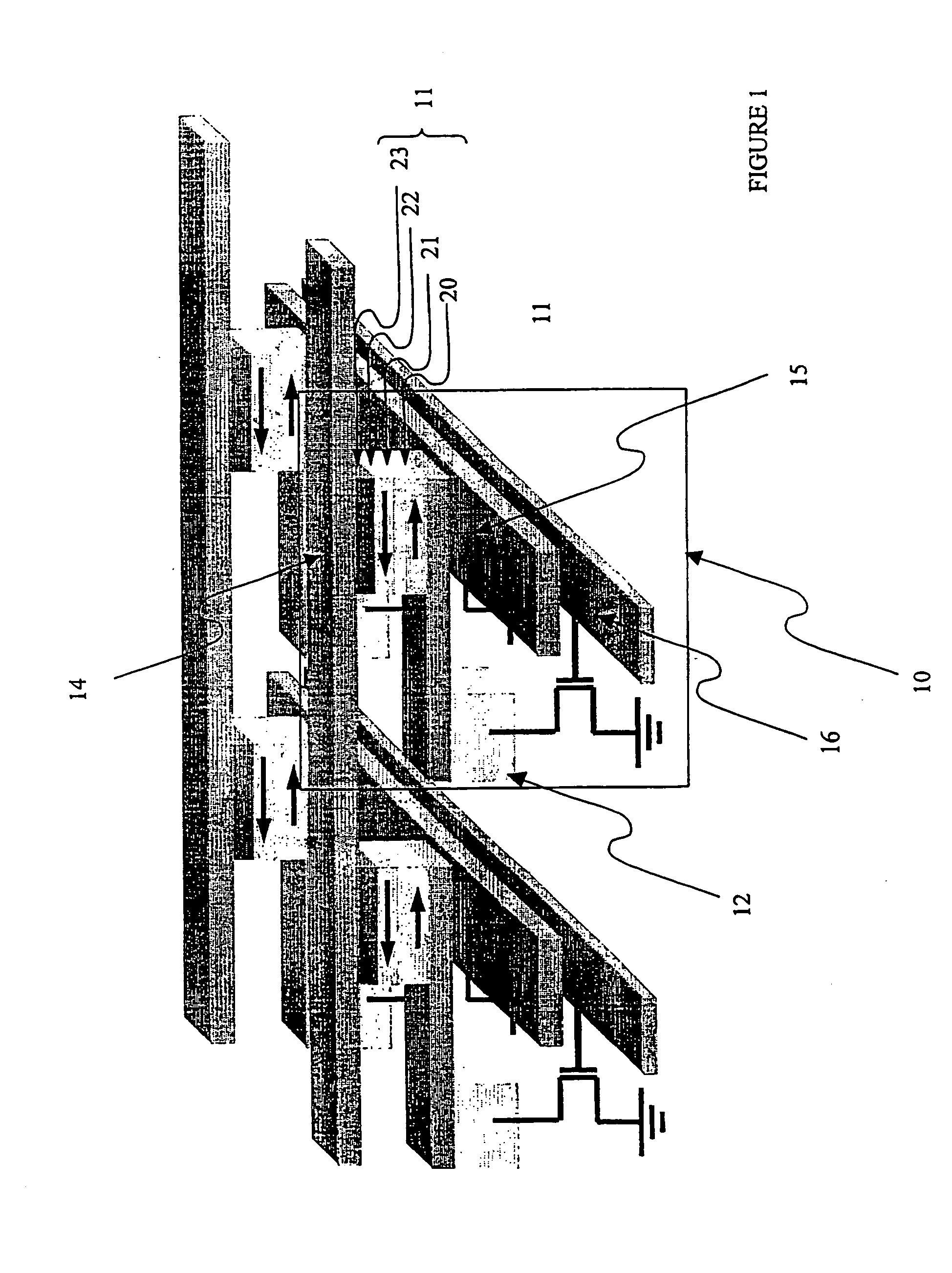

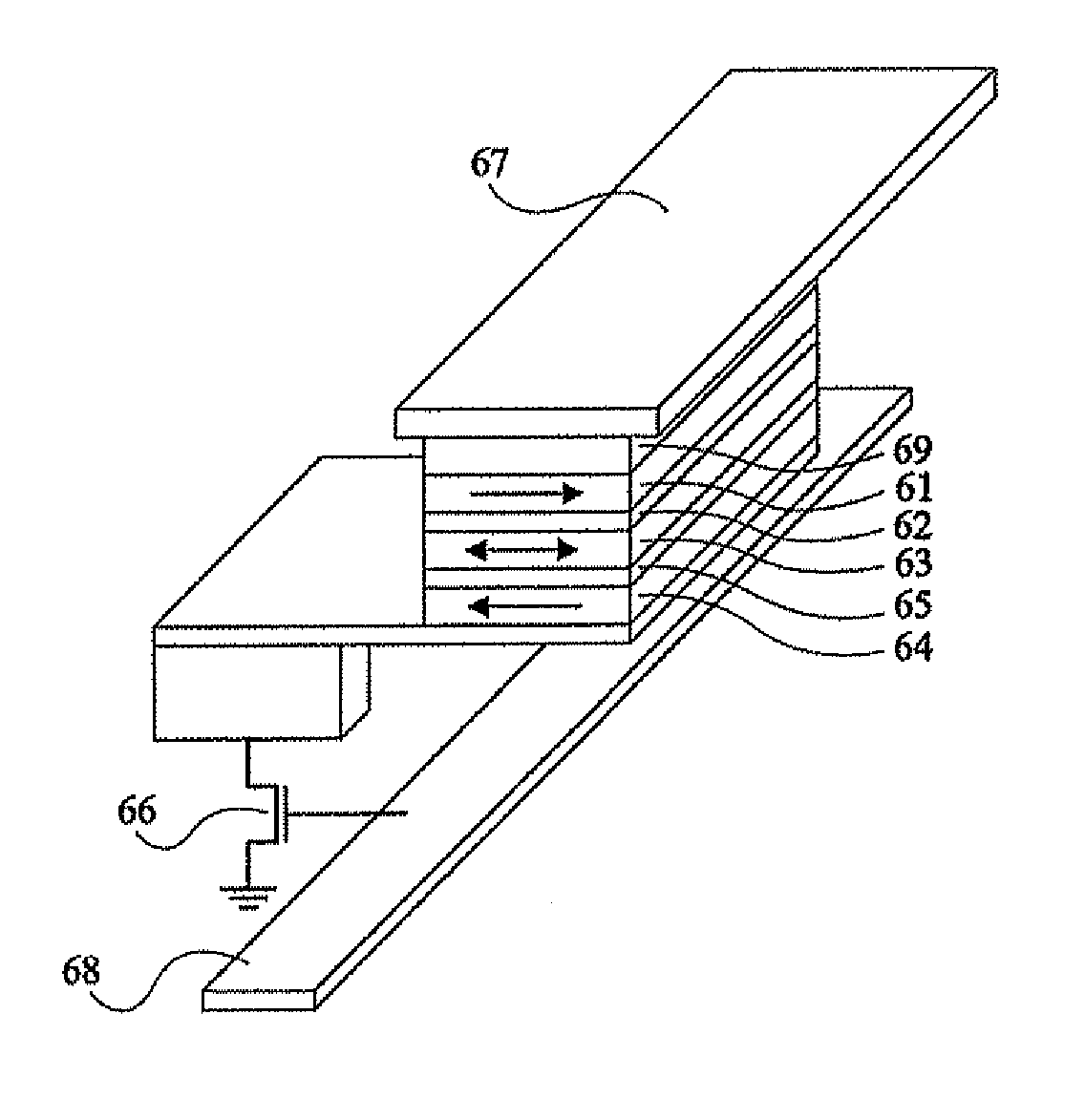

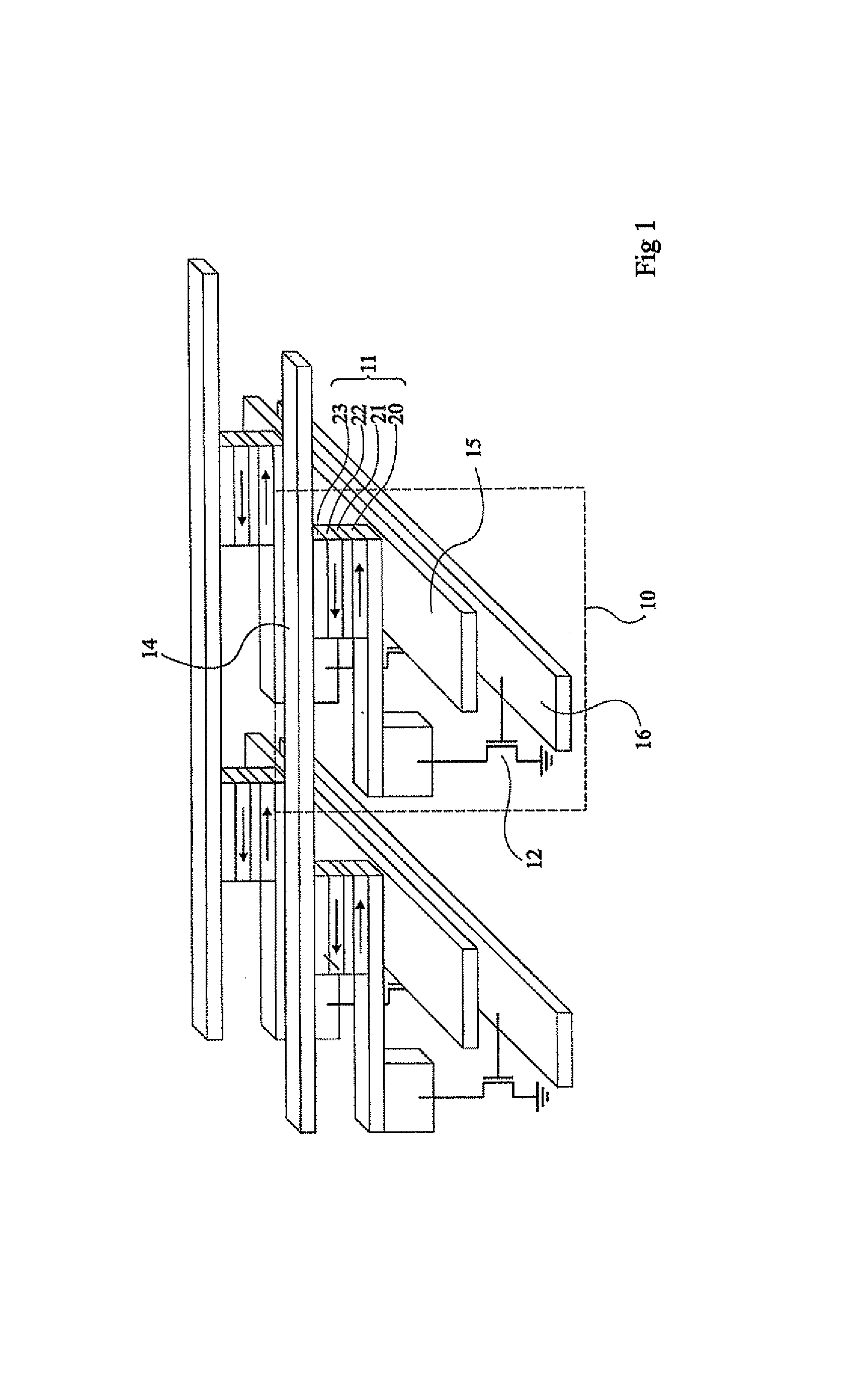

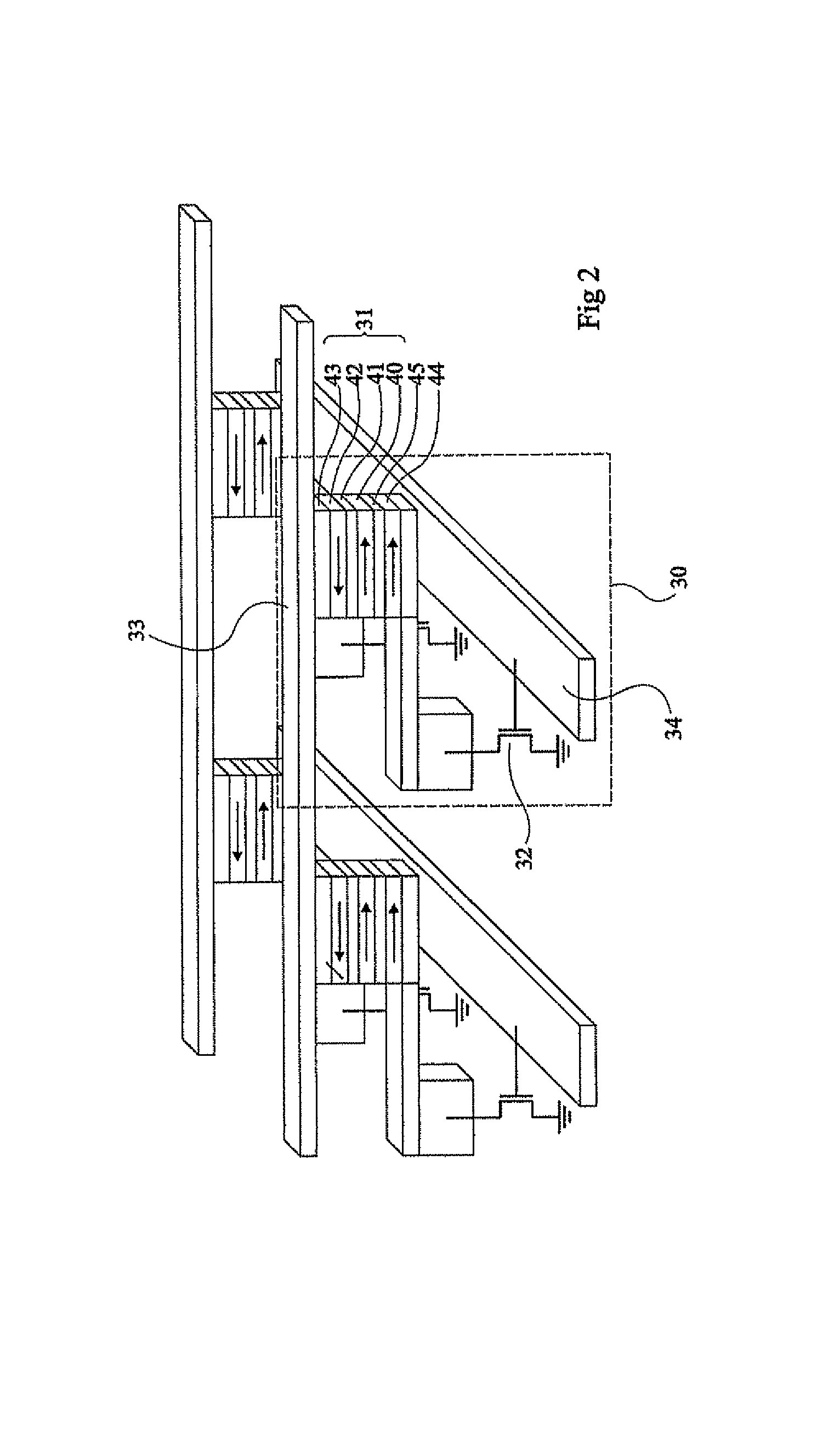

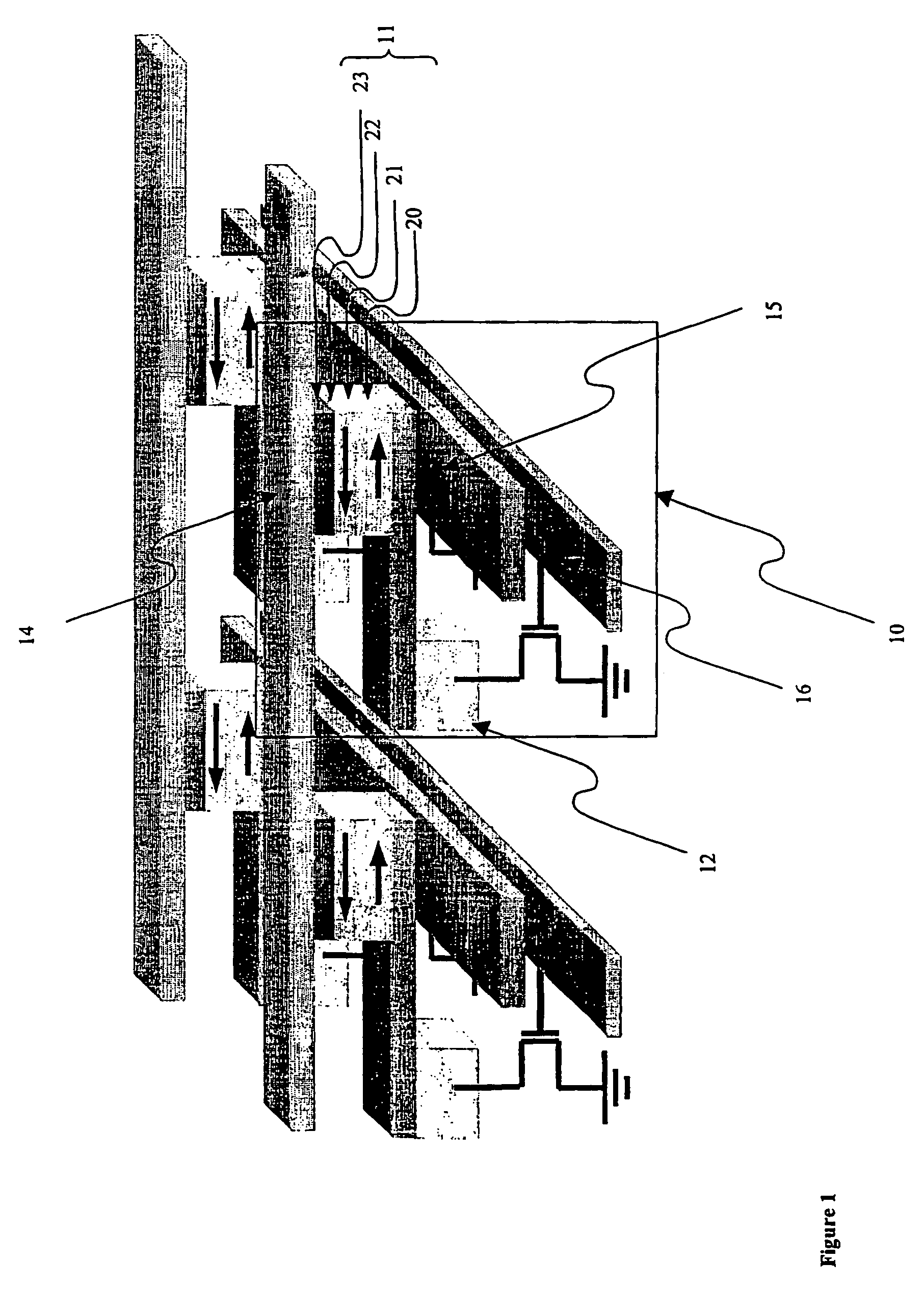

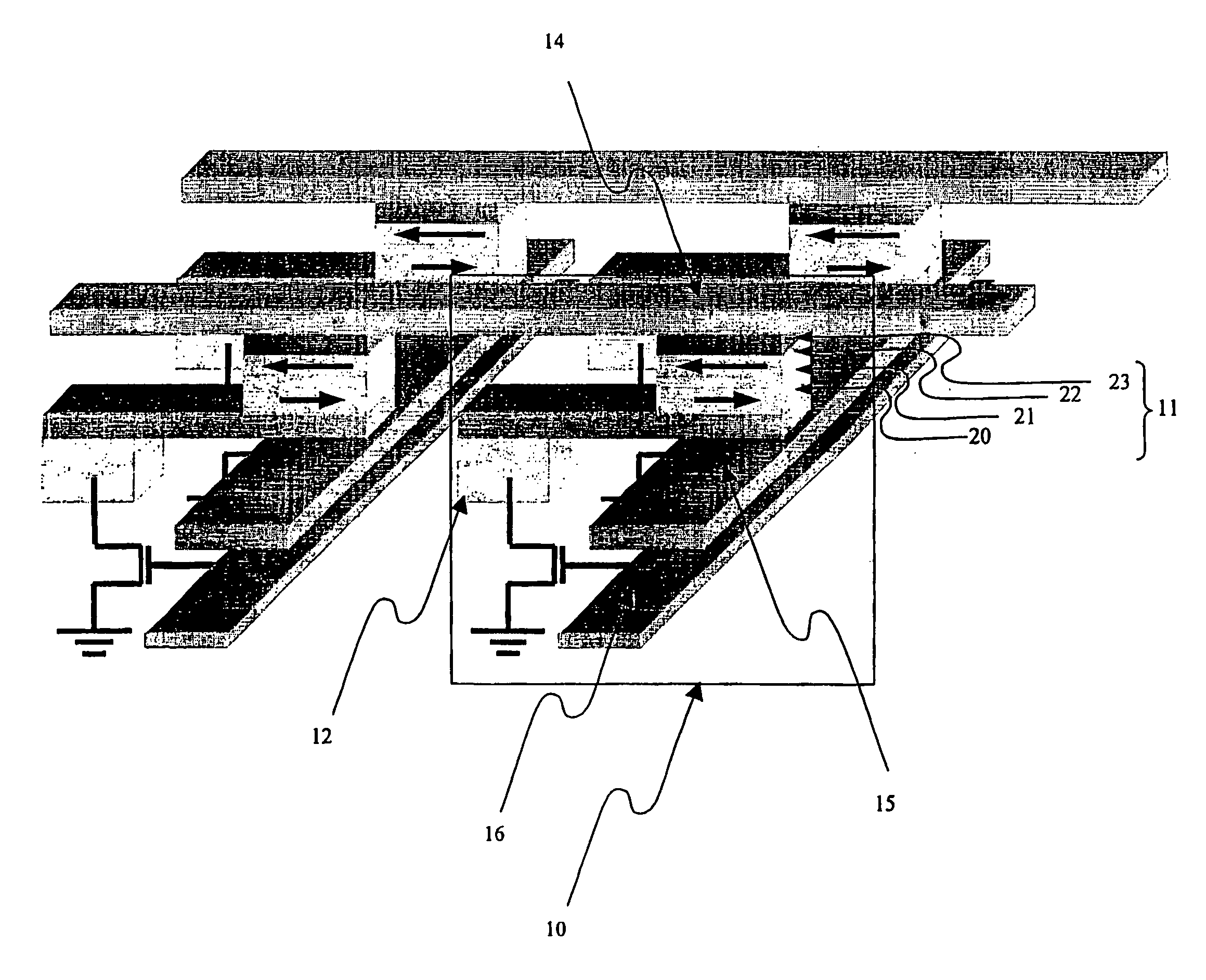

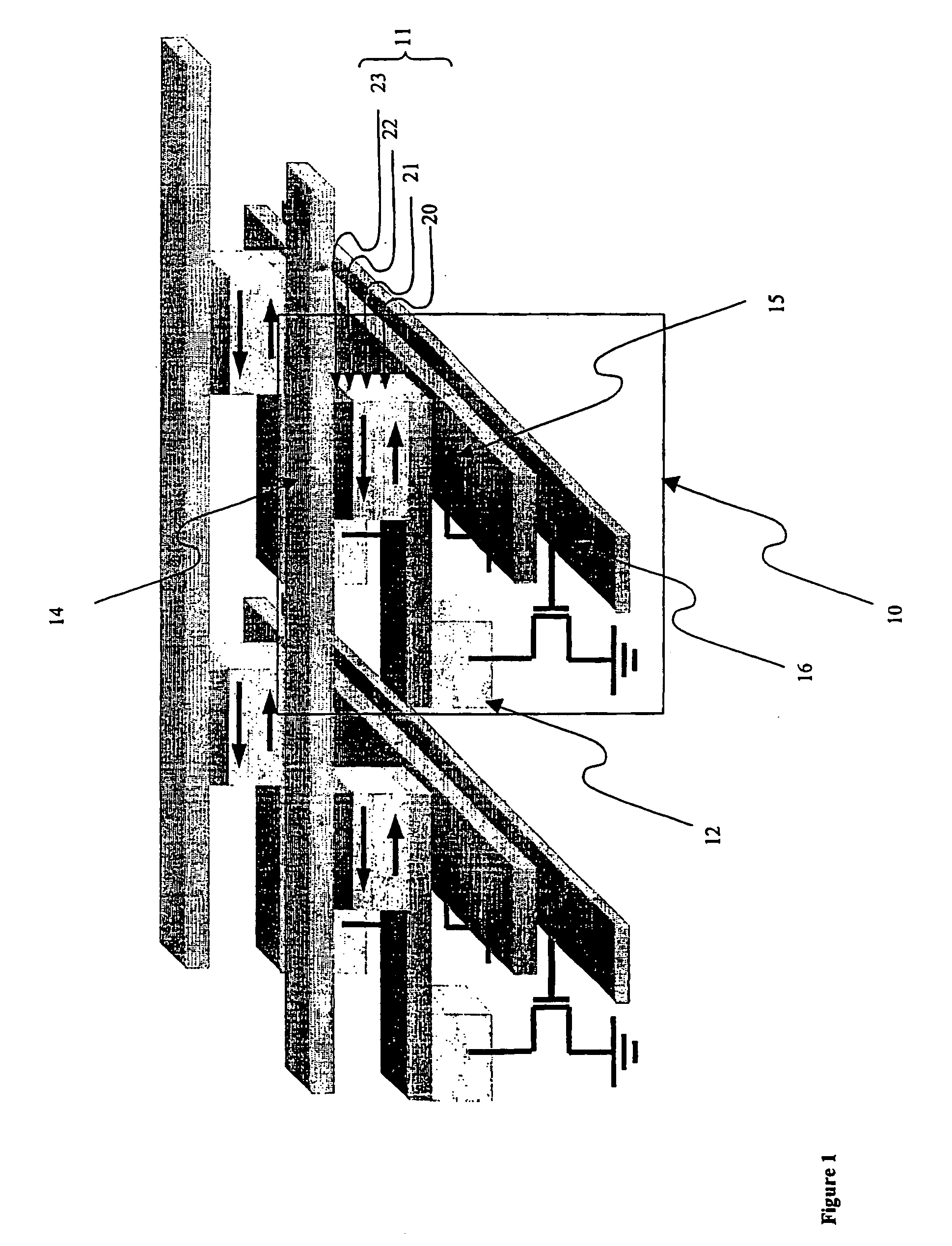

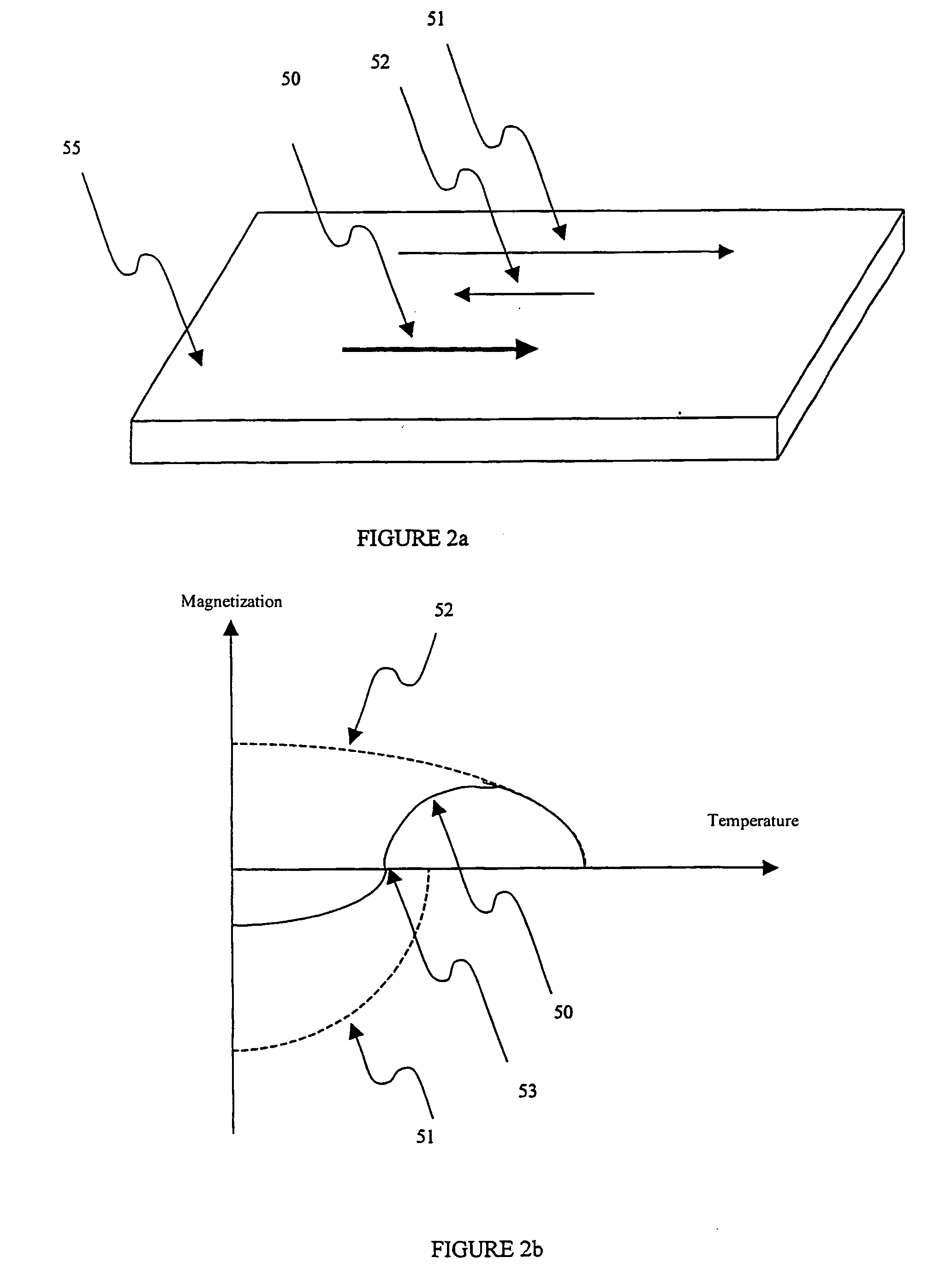

Magnetic memory with spin-polarized current writing, using amorphous ferromagnetic alloys, writing method for same

InactiveUS20050040433A1Reduce current densityElectric shock preventionNanomagnetismMagnetic-field-controlled resistorsMagnetizationMagnetic memory

The invention concerns a magnetic memory, whereof each memory point consists of a magnetic tunnel junction (60), comprising: a magnetic layer, called trapped layer (61), whereof the magnetization is rigid; a magnetic layer, called free layer (63), whereof the magnetization may be inverse; and insulating layer (62), interposed between the free layer (73) and the trapped layer (71) and respectively in contact with said two layers. The free layer (63) is made with an amorphous or nanocrytallized alloy based on rare earth or a transition metal, the magnetic order of said alloy being of the ferromagnetic type, said free layer having a substantially planar magnetization.

Owner:CENT NAT DE LA RECHERCHE SCI

Magnetic memory with spin-polarized current writing, using amorphous ferromagnetic alloys, writing method for same

Owner:CENT NAT DE LA RECHERCHE SCI

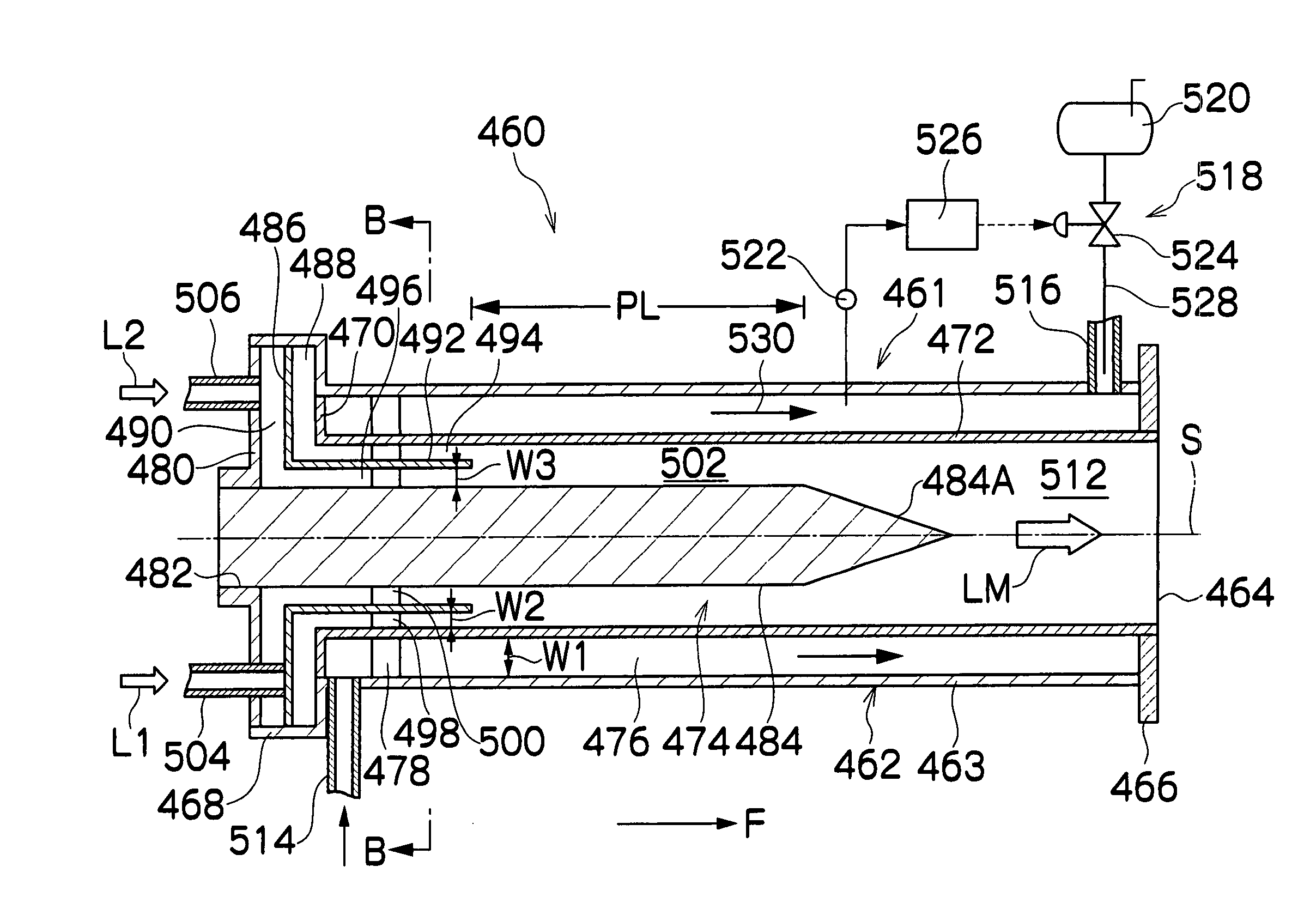

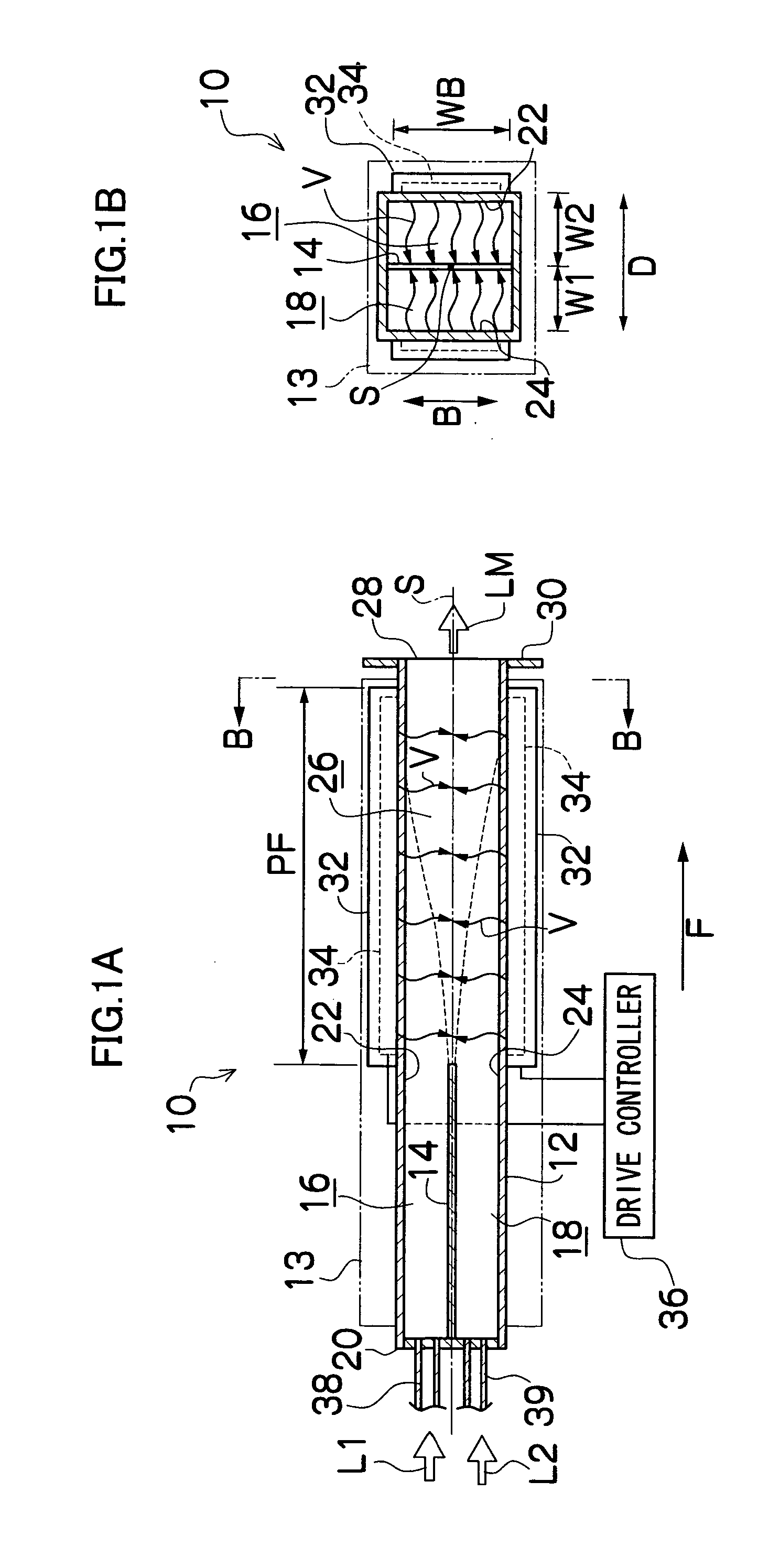

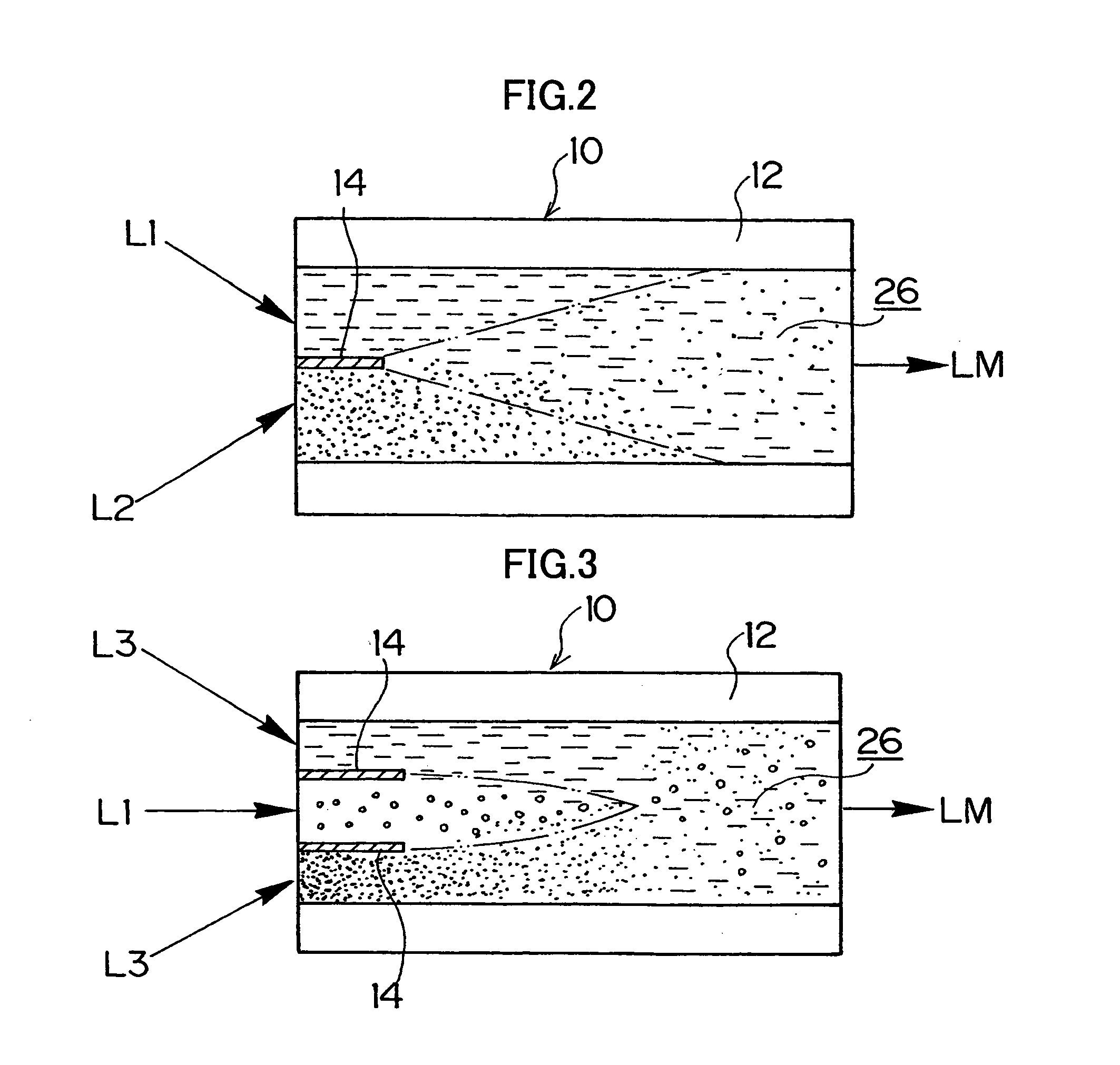

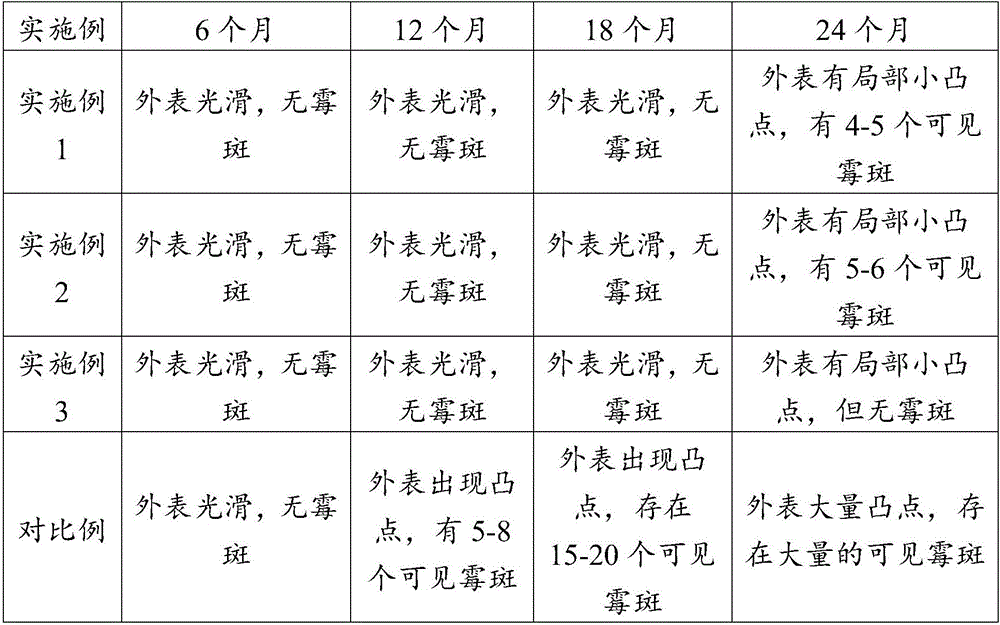

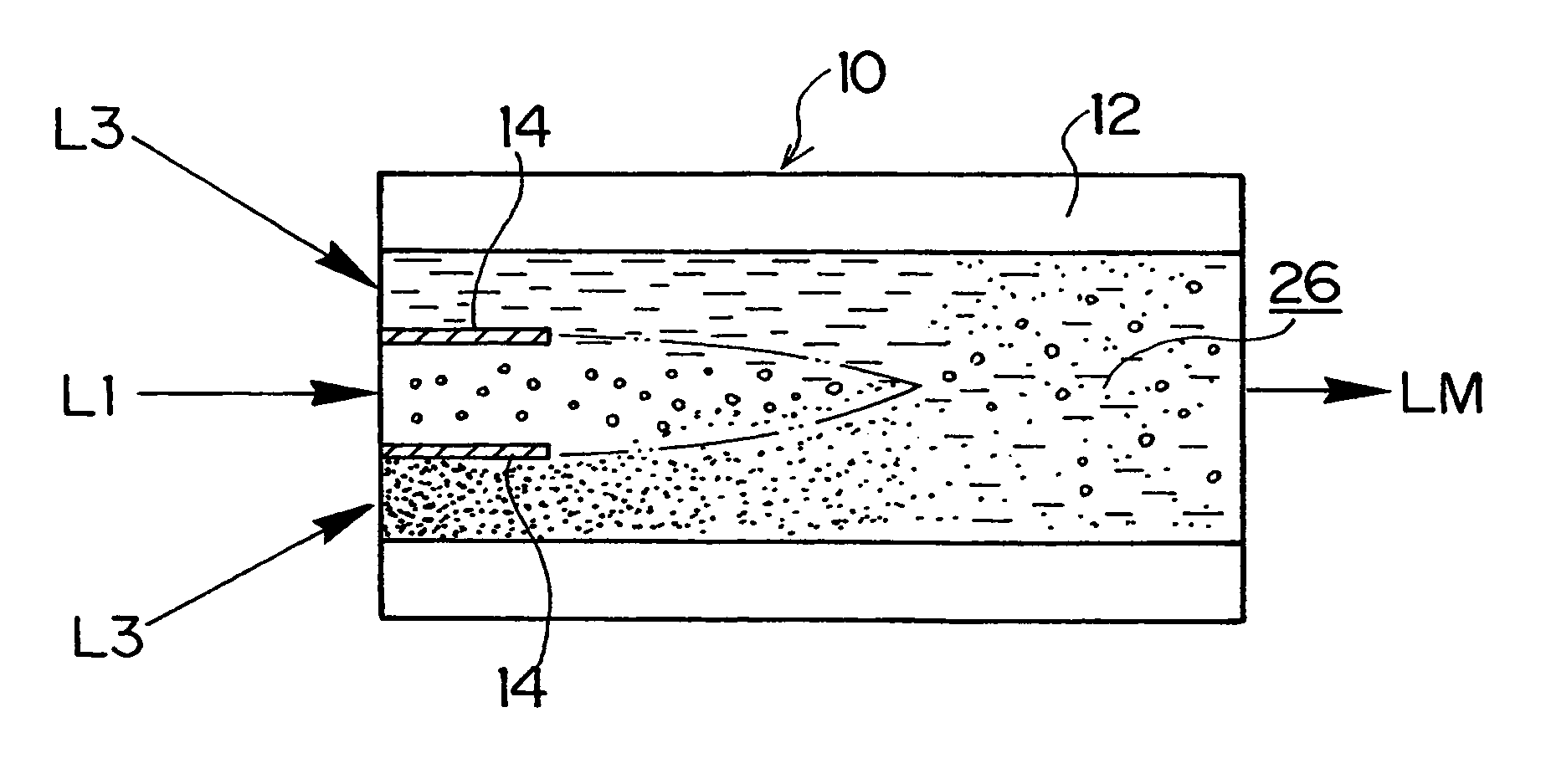

Method of producing magnetic particles and reaction method using microreactor and microreactor

ActiveUS20050223847A1Good monodispersityReduce noiseAdditive manufacturing apparatusTransportation and packagingMicroreactorAlloy

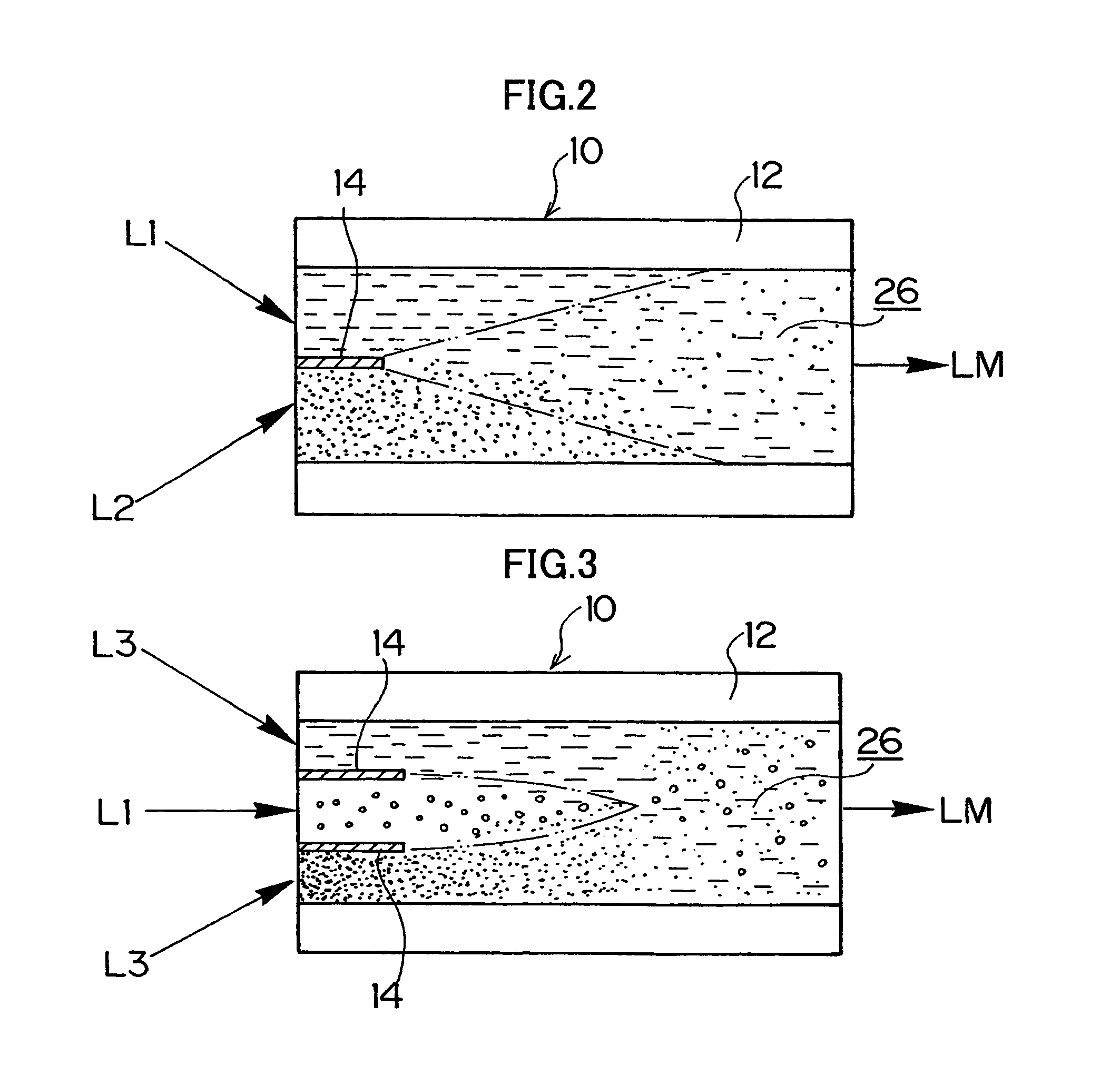

In a method of producing magnetic particles which includes the steps of preparing alloy particles capable of forming a CuAu or Cu3Au hard magnetic ordered alloy phase and of forming magnetic particles for forming CuAu or Cu3Au magnetic particles, a plurality of solutions L1 and L2 for preparing the alloy particles are passed in a thin-plate laminar flow and diffused in the direction perpendicular to the flow direction at the contact interface of the solutions L1 and L2 in a mixing channel by using a microreactor, whereby a uniform mixing reaction is conducted in a short time.

Owner:FUJIFILM CORP +1

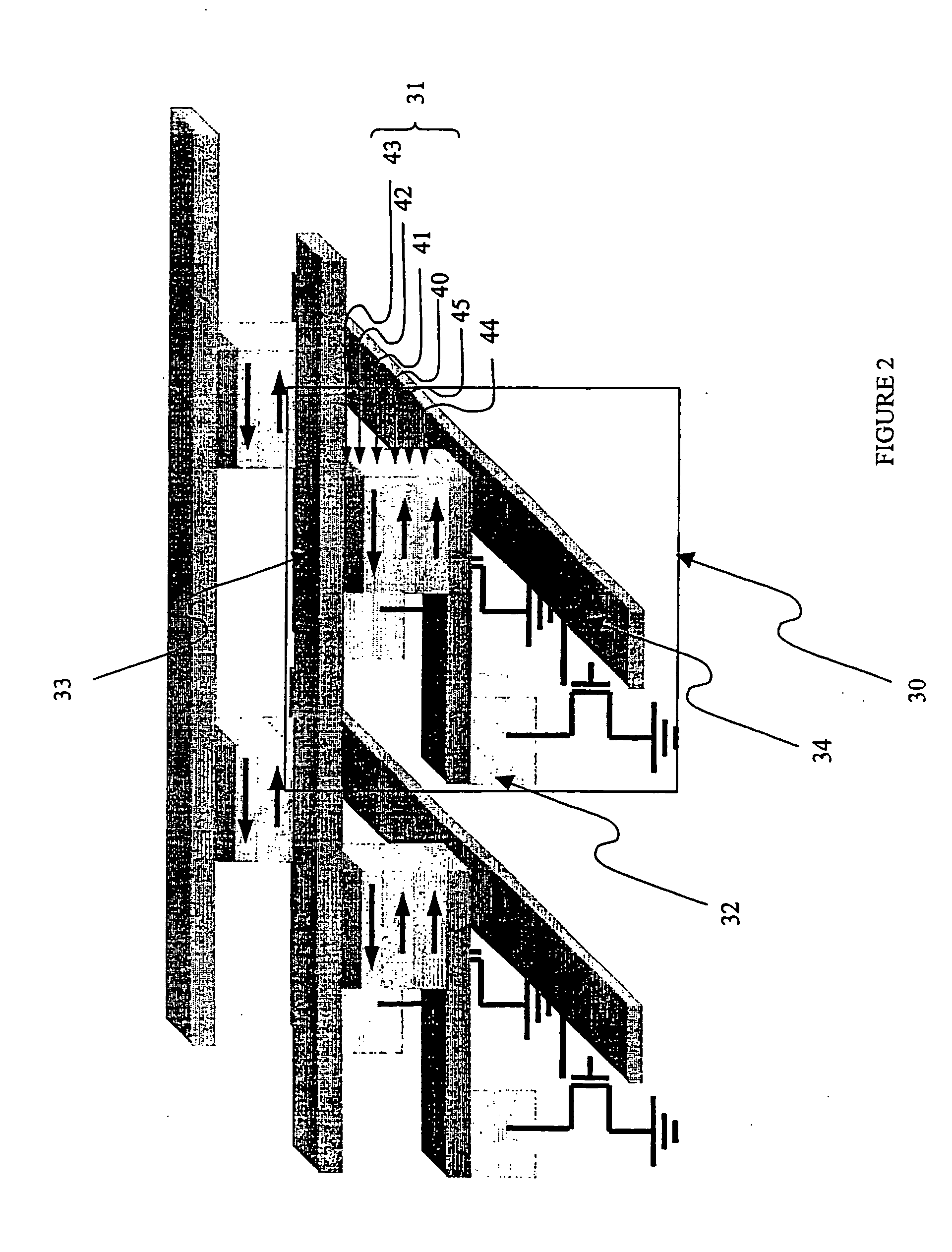

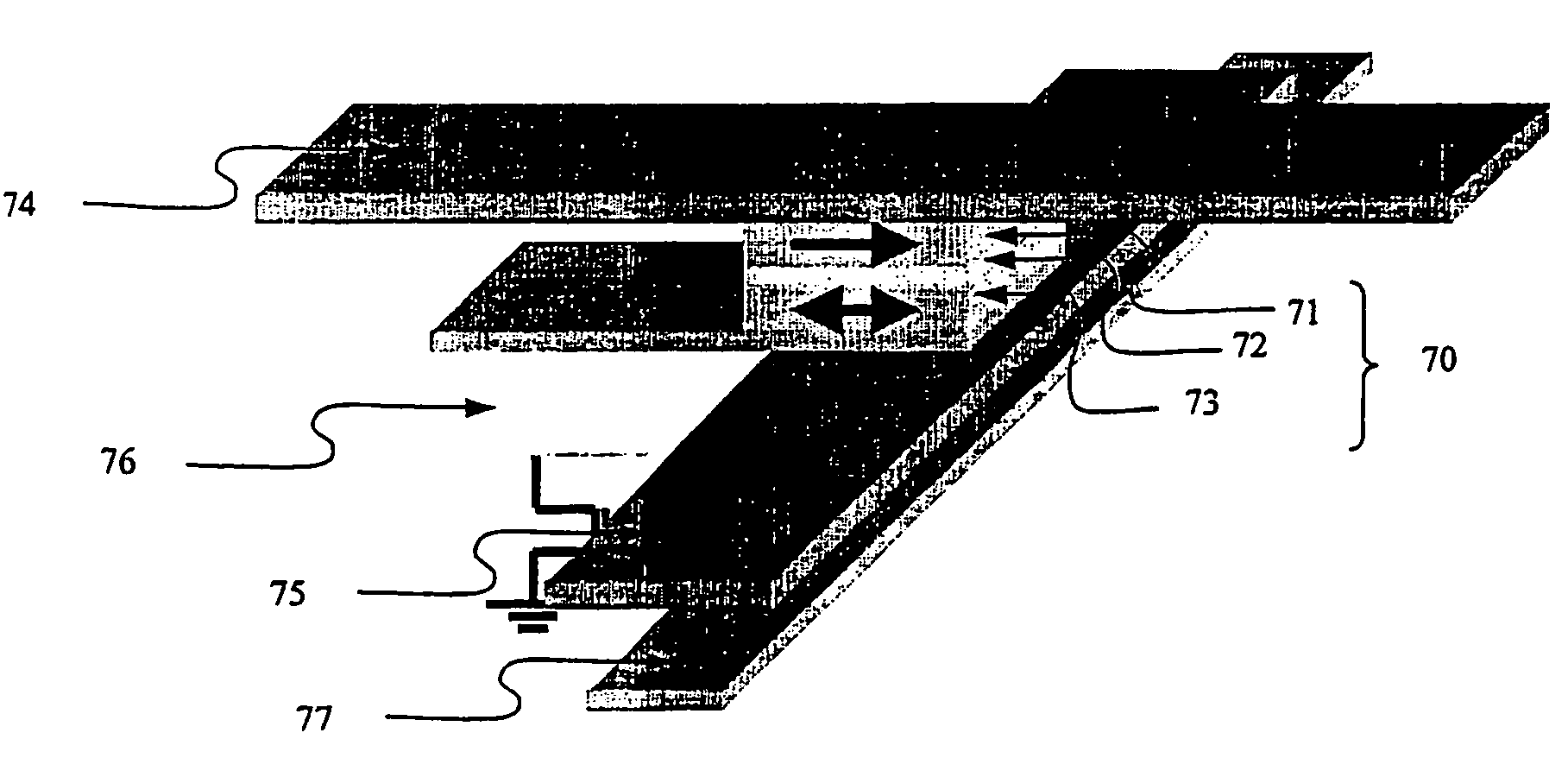

Magnetic memory with write inhibit selection and the writing method for same

InactiveUS7129555B2Error minimizationNanomagnetismMagnetic-field-controlled resistorsRare earthMagnetization

The invention relates to a magnetic memory with write inhibit selection and the writing method for same. Each memory element of the invention comprises a magnetic tunnel junction (70) consisting of: a magnetic layer, known as the trapped layer (71), having hard magnetisation; a magnetic layer, known as the free layer (73), the magnetisation of which may be reversed; and an insulating layer (72) which is disposed between the free layer (73) and the trapped layer (71) and which is in contact with both of said layers. The free layer (73) is made from an amorphous or nanocrystalline alloy based on rare earth and a transition metal, the magnetic order of said alloy being of the ferrimagnetic type. The selected operating temperature of the inventive memory is close to the compensation temperature of the alloy.

Owner:CENT NAT DE LA RECHERCHE SCI

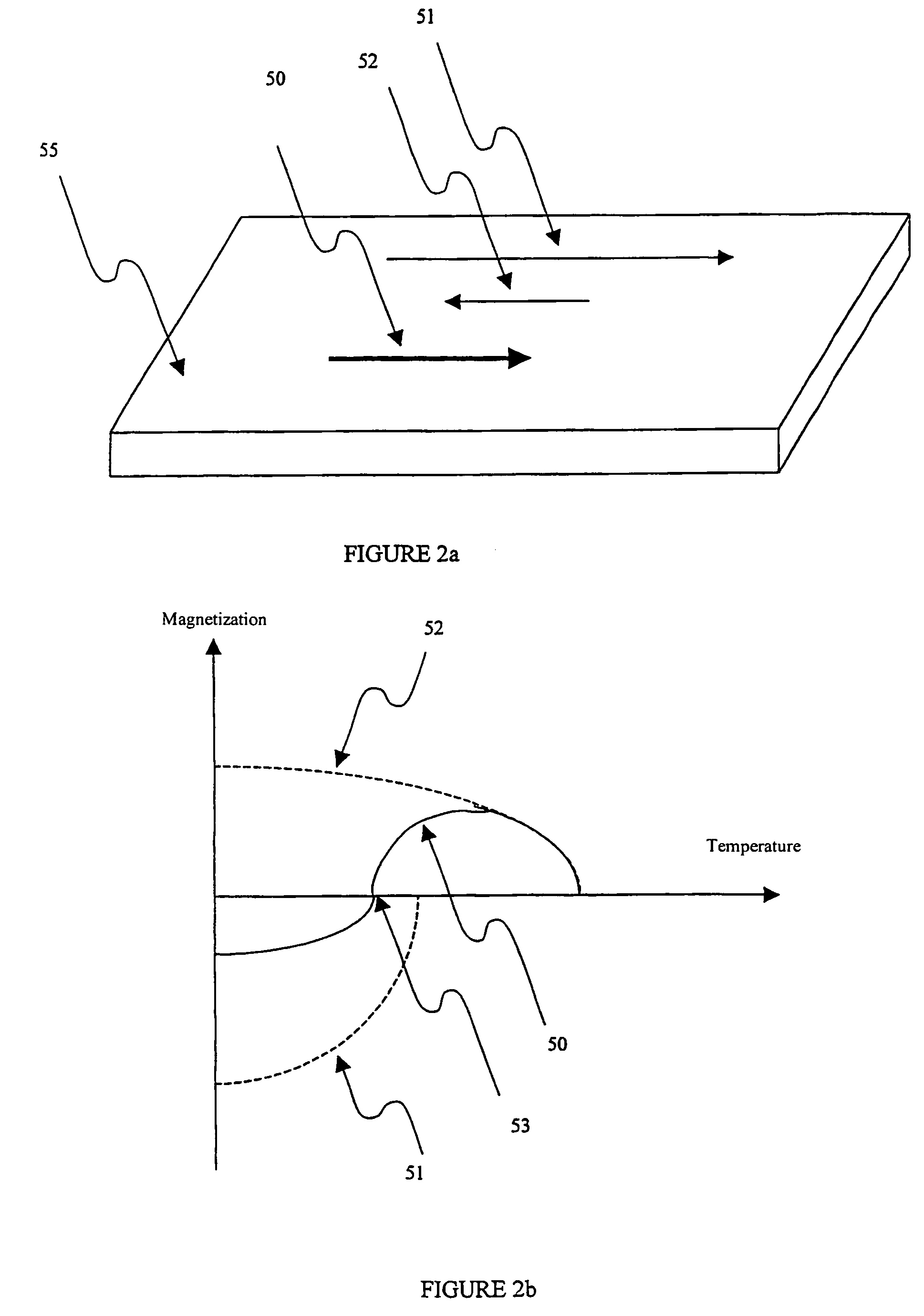

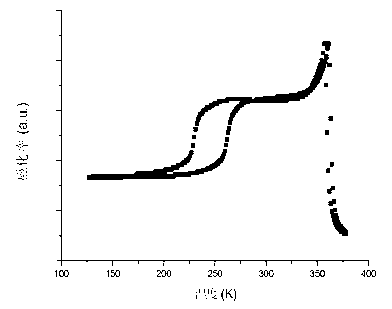

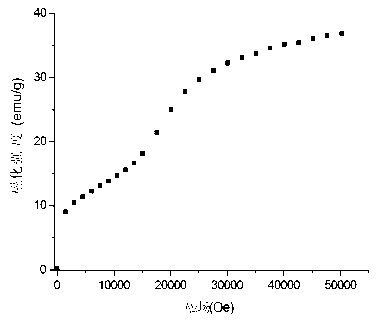

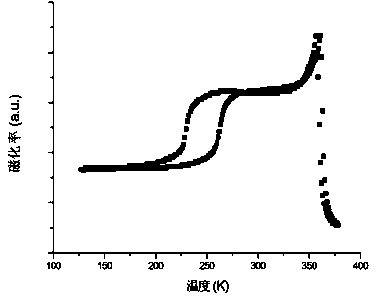

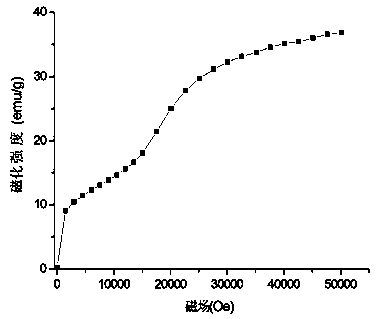

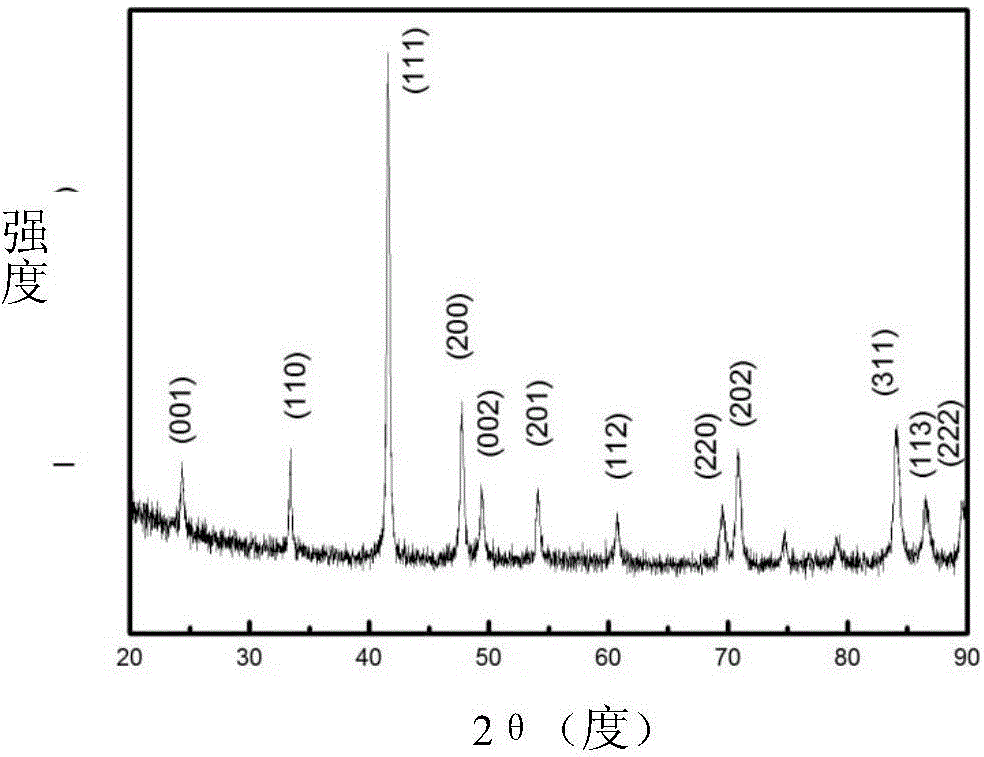

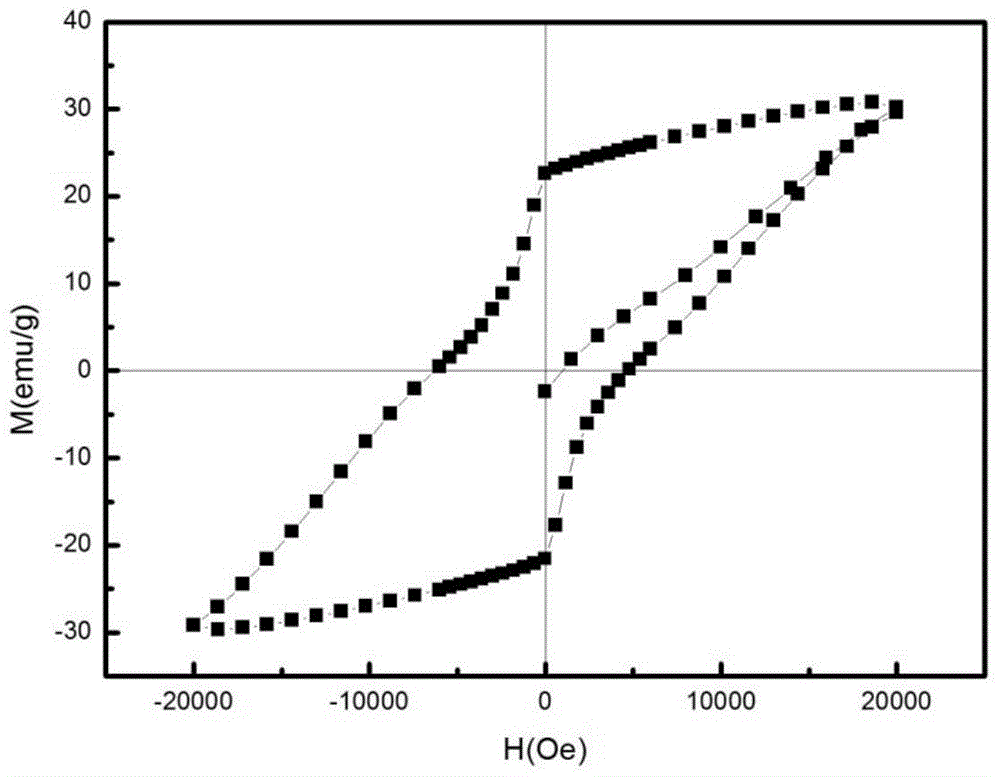

Ni-Mn-Ge magnetic shape memory alloy and preparation method thereof

ActiveCN102851545AEasy to prepareWide range of usesPolycrystalline material growthBy pulling from meltMain group elementSingle crystal

The invention relates to a Ni-Mn-Ge magnetic shape memory alloy of which the chemical formula is NixMnyGezMa, wherein M is a main group element or transition group element; and 51<x<55, 31<y<40, 5<z<20, a<5, x+y+z+a=100, and x, y, z and a represent atomic percents. The alloy is a monocrystalline material or polycrystalline material. The main group element is In, Sn, Sb, As or Si; and the transition group element is Ti, Fe or Co. The magnetic material with magnetic shape memory effect has shape memory effect and ferromagnetic property, and appears the property of entropic change (magnetic card effect) caused by magnetic-field-driven phase change and magnetic order degree change, wherein the change value is up to S=8J / Kkg.

Owner:HEBEI UNIV OF TECH

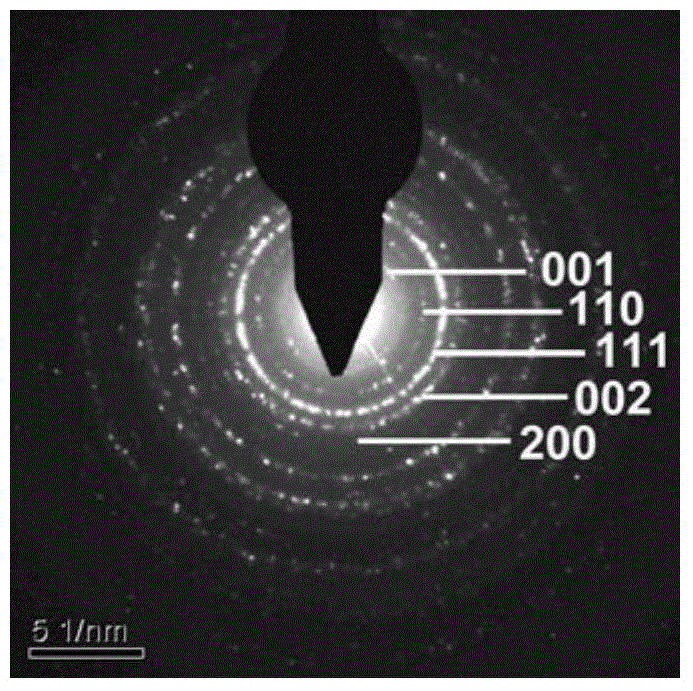

Magnetic particle of CuAu(1) or CuAu(III) type its production method, magnetic recording medium and its production method

The present invention relates to a method of producing a magnetic particle including forming a layer containing an alloy particle that can form a CuAu-type or Cu3Au-type hard magnetic ordered alloy phase on a support, oxidizing the layer, and annealing the layer in a non-oxidizing atmosphere. The invention also relates to a method of producing a magnetic particle including producing an alloy particle that can form a hard magnetic ordered alloy phase, oxidizing the alloy particle, and annealing the particle in a non-oxidizing atmosphere, and a magnetic particle produced by the foregoing production method. Further, the invention relates to a magnetic recording medium comprising a magnetic layer containing a magnetic particle and a method of producing a magnetic recording medium including forming a layer containing an alloy that can form the foregoing hard magnetic ordered alloy phase, oxidizing the layer, and annealing the layer in a non-oxidizing atmosphere.

Owner:FUJIFILM CORP

Magnetic memory with write inhibit selection and the writing method for same

InactiveUS20050047206A1Minimizes addressing errorError minimizationNanomagnetismMagnetic-field-controlled resistorsMagnetic memoryRare earth

The invention relates to a magnetic memory with write inhibit selection and the writing method for same. Each memory element of the invention comprises a magnetic tunnel junction (70) consisting of: a magnetic layer, known as the trapped layer (71), having hard magnetisation; a magnetic layer, known as the free layer (73), the magnetisation of which may be reversed; and an insulating layer (72) which is disposed between the free layer (73) and the trapped layer (71) and which is in contact with both of said layers. The free layer (73) is made from an amorphous or nanocrystalline alloy based on rare earth and a transition metal, the magnetic order of said alloy being of the ferrimagnetic type. The selected operating temperature of the inventive memory is close to the compensation temperature of the alloy.

Owner:CENT NAT DE LA RECHERCHE SCI

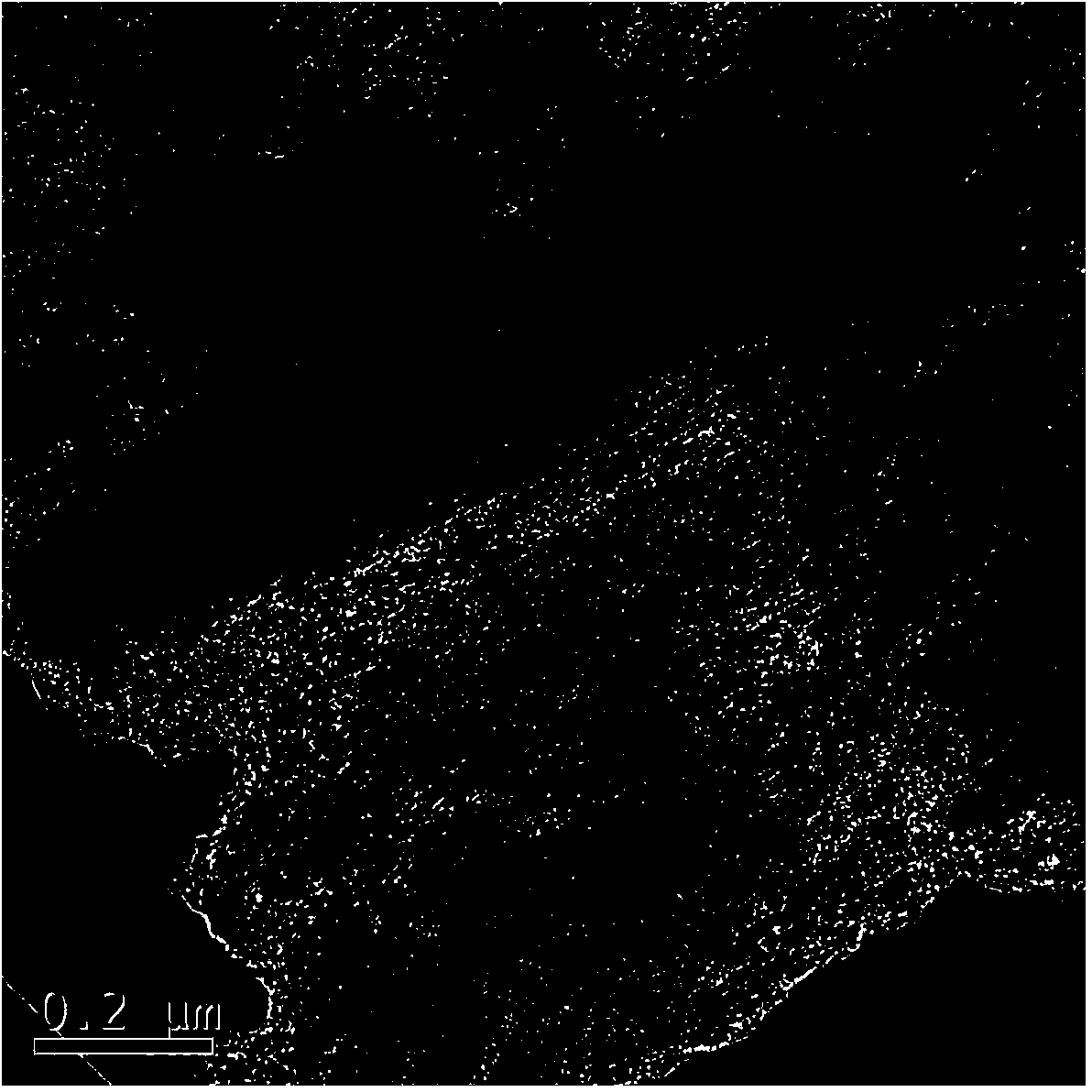

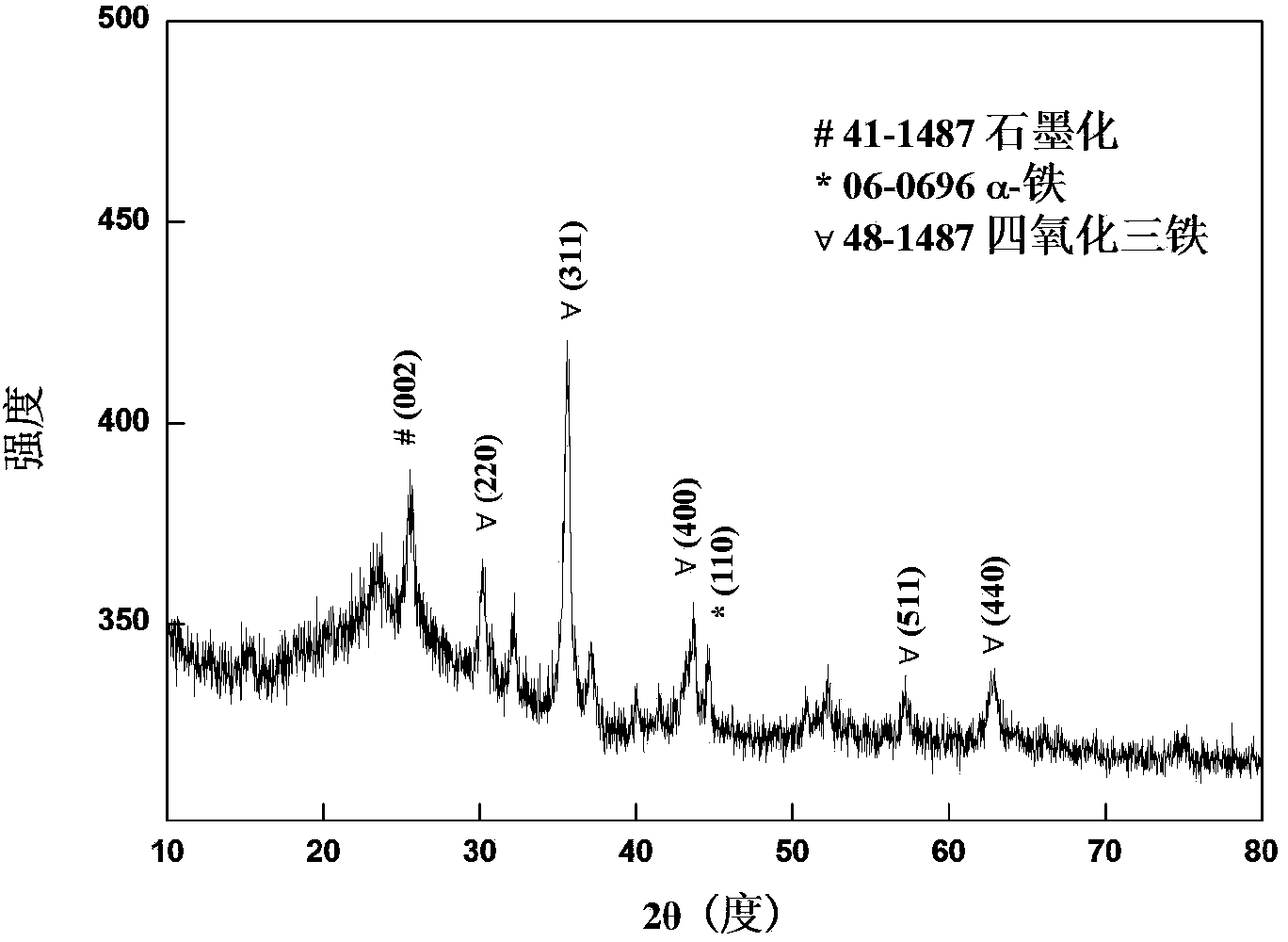

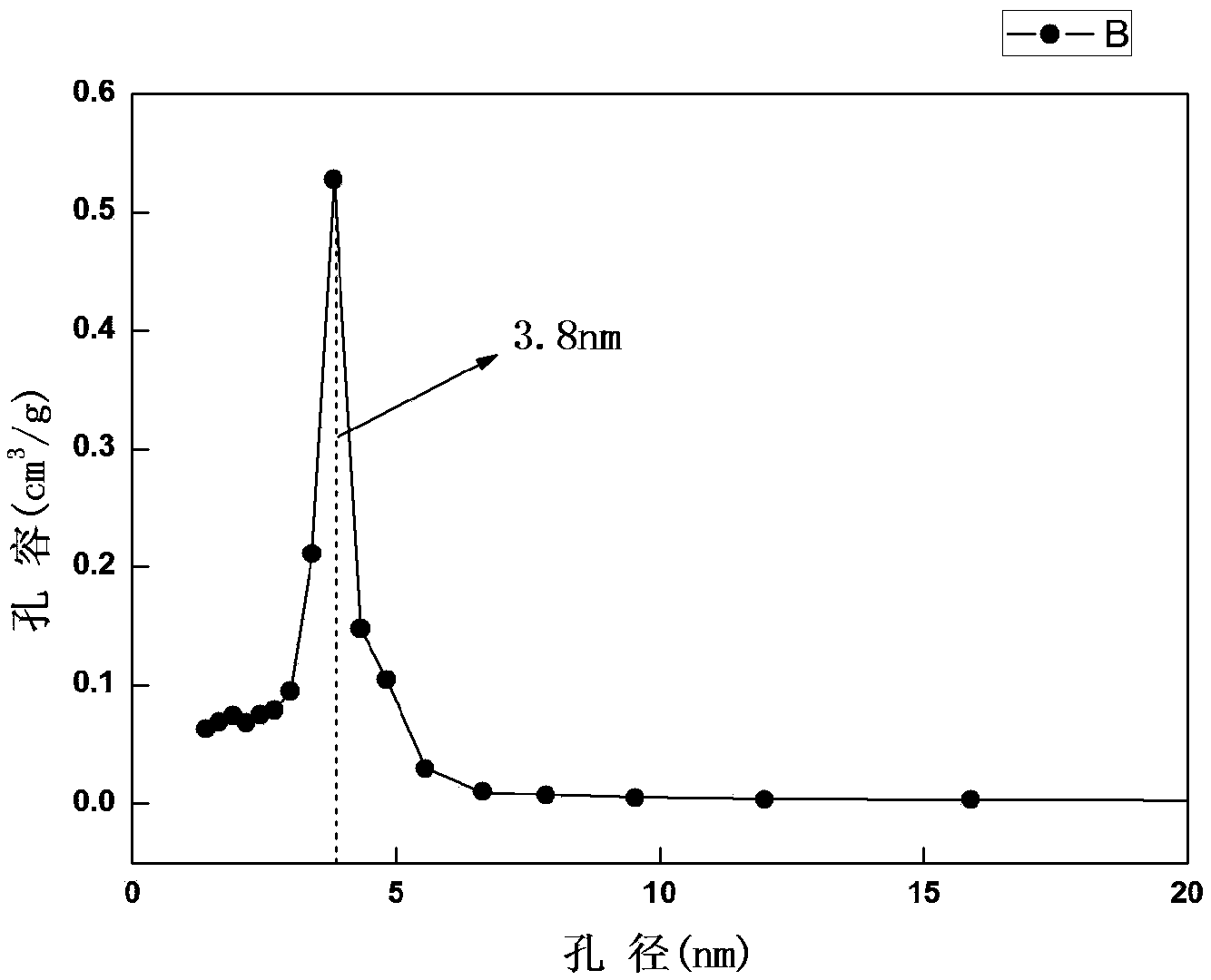

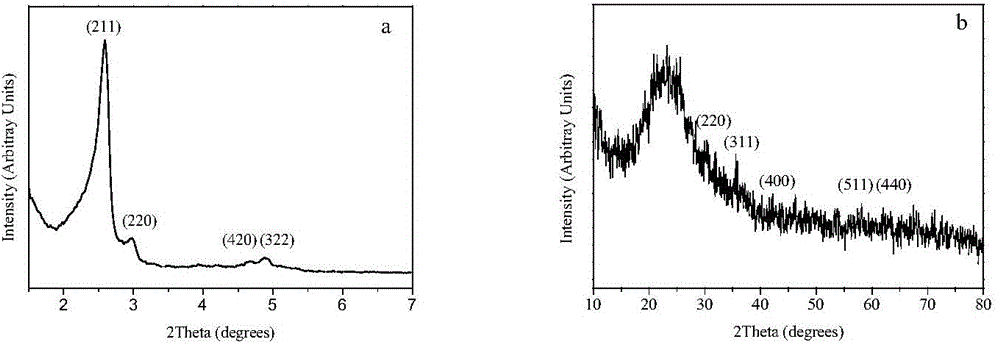

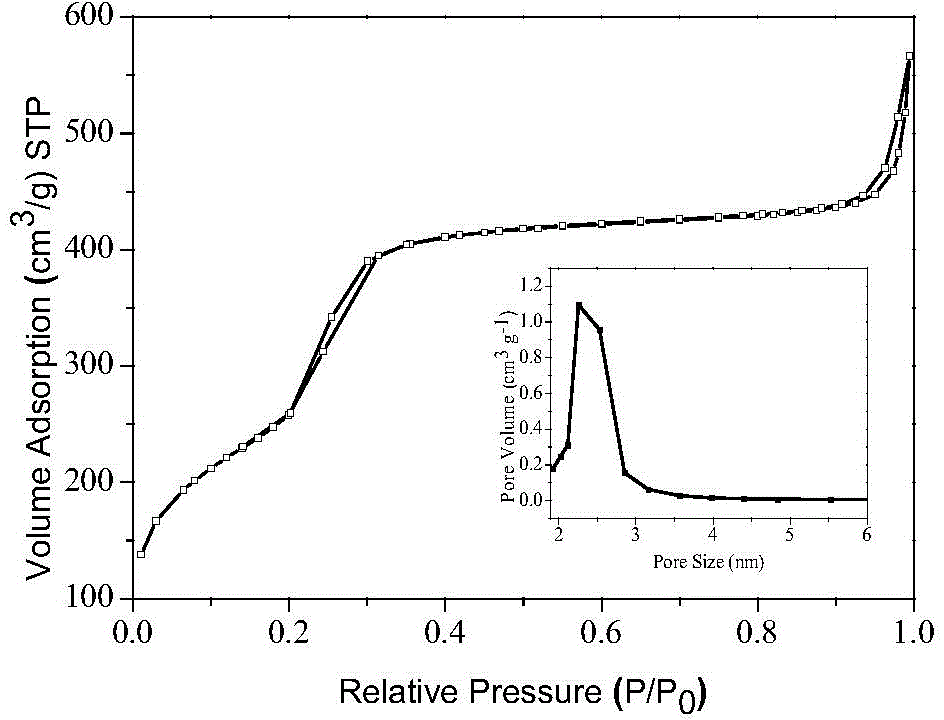

Nitrogen hybridized magnetic ordered mesoporous carbon adsorbent, and preparation method and application thereof

InactiveCN103706328AReduce difficultyLow costOther chemical processesWater contaminantsPorous carbonSorbent

The invention relates to a nitrogen hybridized magnetic ordered meso-porous carbon adsorbent. The aperture of the adsorbent is within 3.8nm, the surface part of the adsorbent is graphitized, and the adsorbent comprises magnetic nano particles; the magnetic nano particles are iron oxide nano particles and iron nano particles. A preparation method of the adsorbent comprises the following steps: adding a meso-porous silicon SBA-15 template into an organic solution which contains furfuryl alcohol and ferric nitrate and is easy to volatilize, sufficiently mixing, performing thermal polymerization, subsequently carbonizing on the presence of an inert gas, finally removing silicon by using a strong alkali solution, and separating, washing and drying so as to obtain magnetic ordered meso-porous carbon; and dissolving the magnetic ordered meso-porous carbon into a strong acid solution, controlling the temperature to be less than 5 DEG C, adding aniline and ammonium persulfate, sufficiently mixing, washing and drying the complex after polymerization, and carbonizing on the presence of the inert gas so as to obtain the nitrogen hybridized magnetic ordered meso-porous carbon adsorbent. The adsorbent is high in adsorption efficiency, large in adsorption volume and short in adsorption balance time.

Owner:HUNAN UNIV

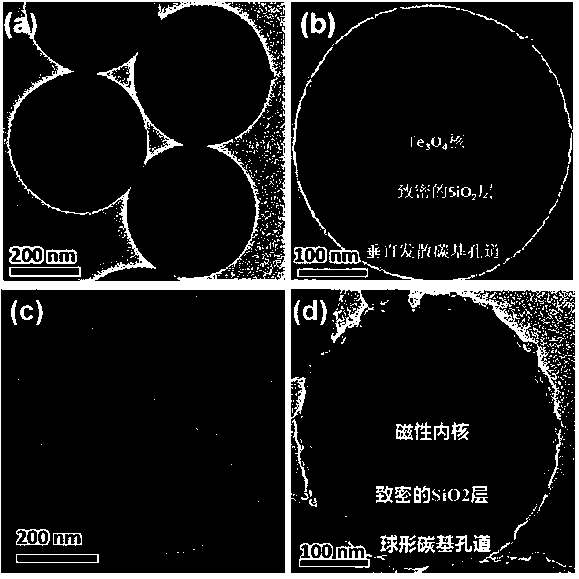

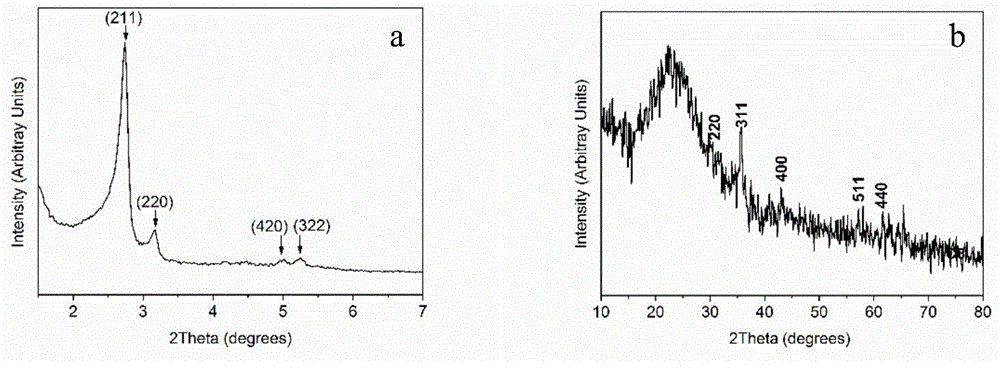

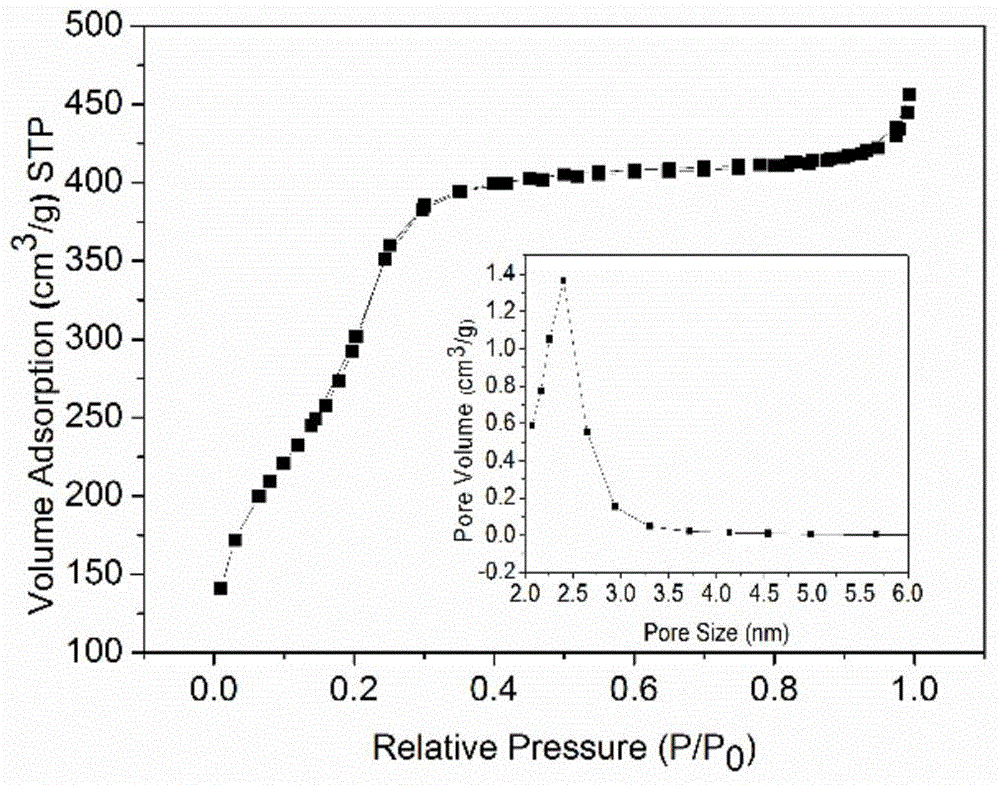

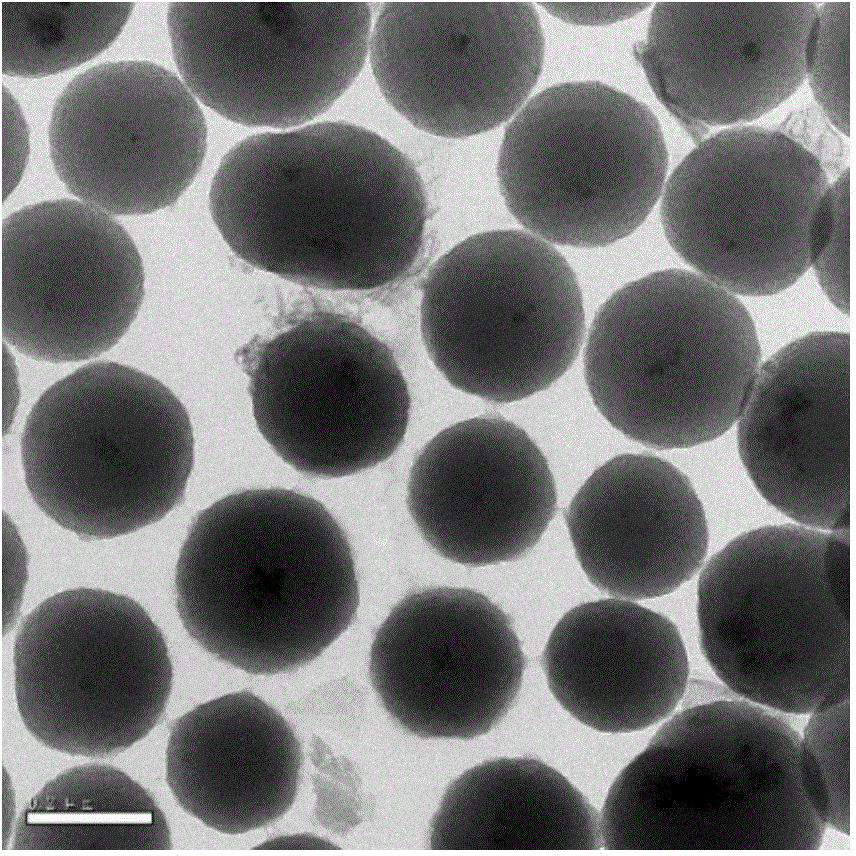

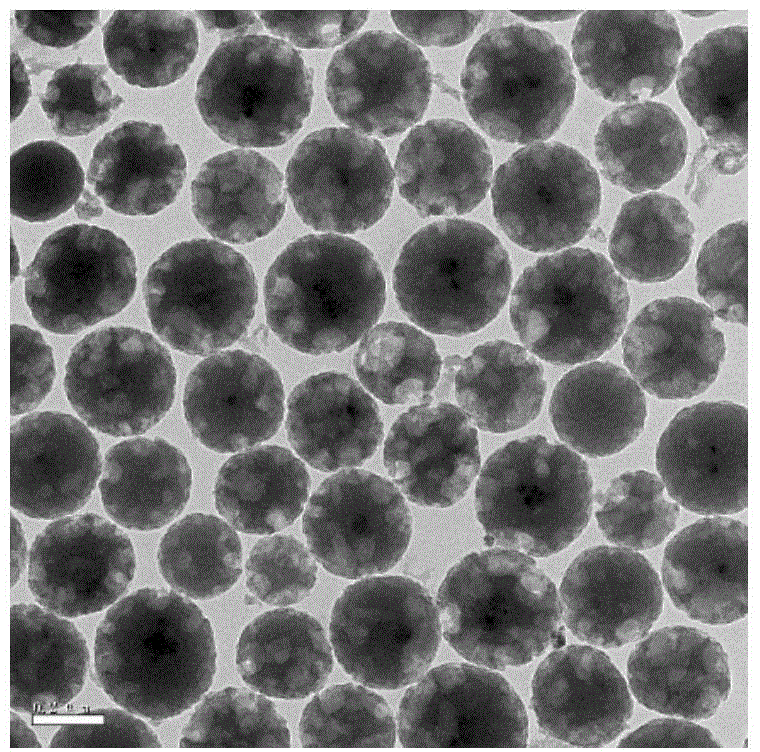

Magnetic ordered mesoporous carbon-based or polymer-based core-shell structural microsphere and preparation method thereof

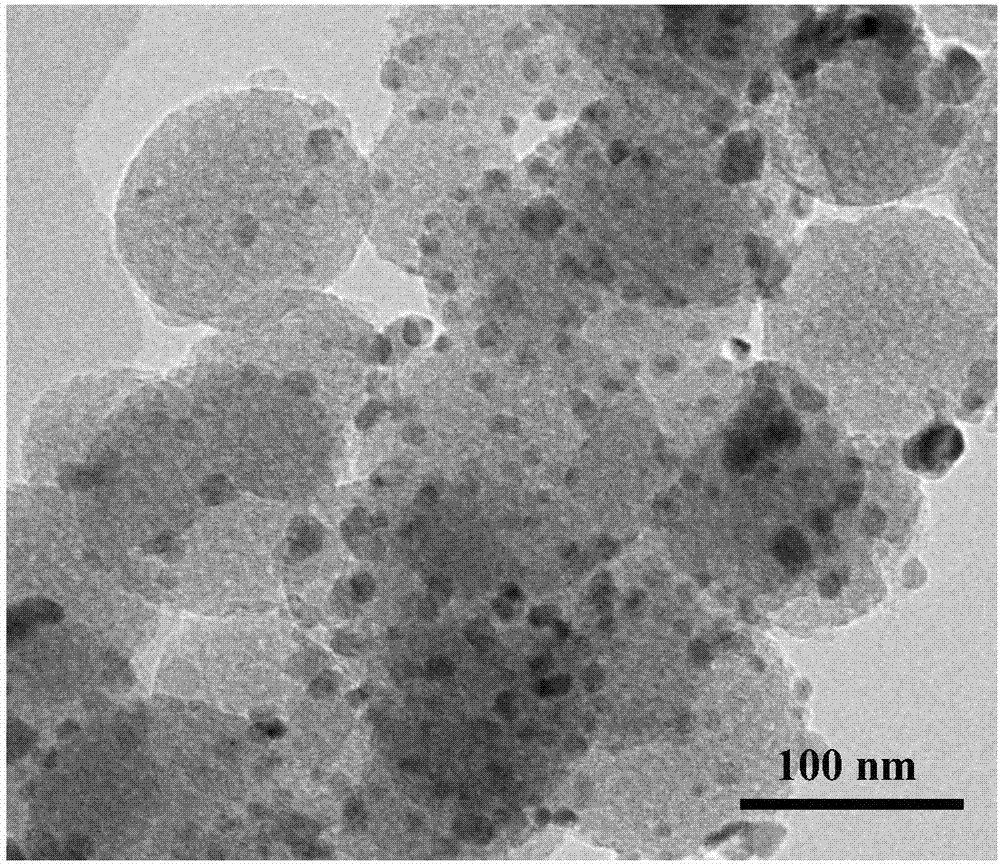

ActiveCN110075770AHigh purityFacilitated DiffusionOther chemical processesAlkali metal oxides/hydroxidesMicrosphereMagnetite Nanoparticles

The invention belongs to the technical field of advanced nano materials, and specifically relates to a magnetic ordered mesoporous carbon-based or polymer-based core-shell structural composite microsphere and a preparation method thereof. According to the preparation method, magnetic nanoparticles are adopted as seeds, and the surface of the magnetic nanoparticles is coated with a dense silica protective layer with a sol-gel method; a macromolecular surfactant / polymer layer composite material of an ordered mesostructure is deposited on the surface of silicon dioxide by adopting an interface co-assembly technique and using a large molecular weight block copolymer as a templating agent; and finally, a magnetic mesoporous carbon-based composite microsphere having a strong surface hydrophobicity is obtained by calcination and carbonization in nitrogen, or a surface functionalized magnetic mesoporous polymer-based composite microsphere is obtained by removing the templating agent on the surface of the macromolecular with a solvent extraction method. The composite microsphere provided by the invention has the characteristics of strong magnetic responsiveness, relatively large ordered mesoporous passages, regular and ordered shell core structure, controllable hydrophilia and hydrophobicity and easy material transport and diffusion, and has important application prospects in the fieldof adsorption and separation.

Owner:FUDAN UNIV

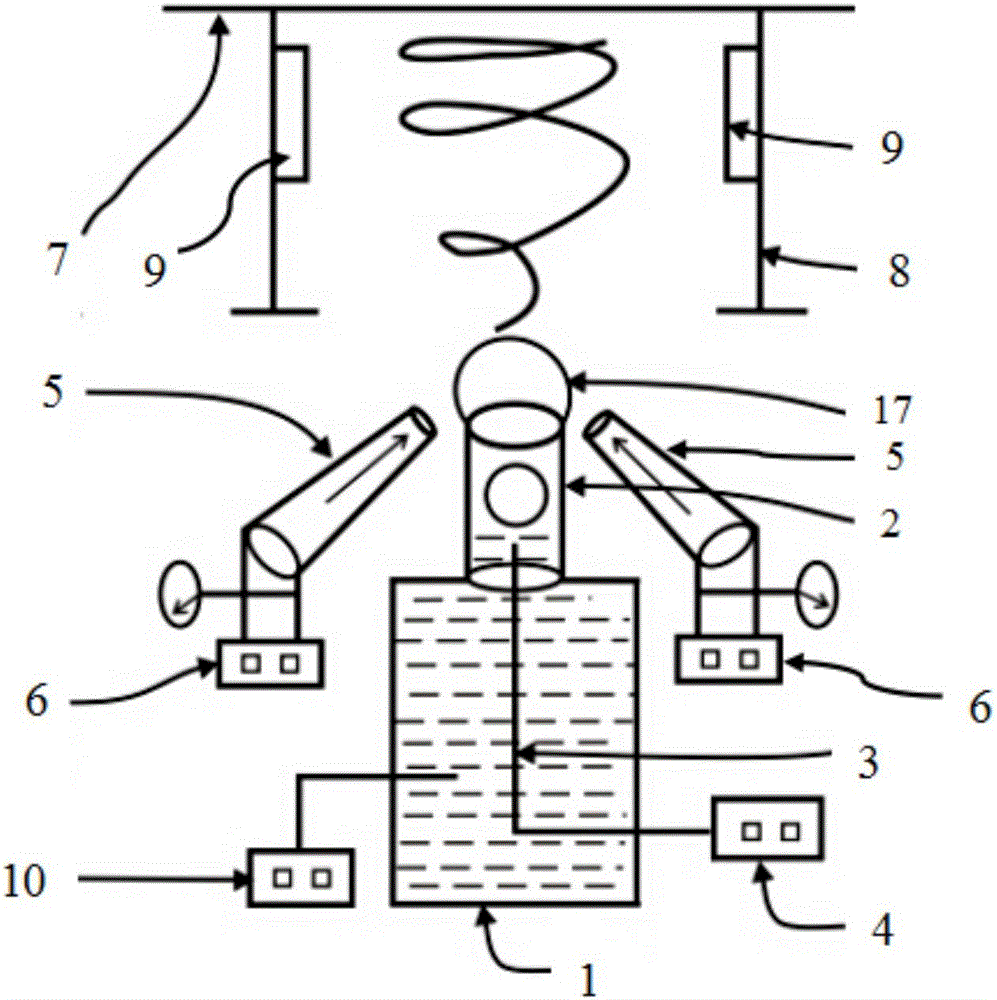

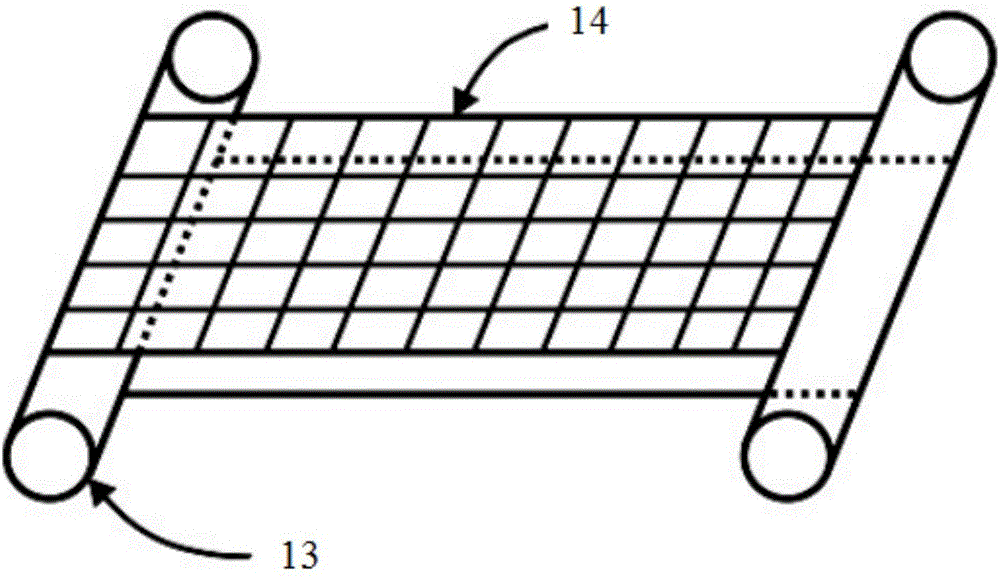

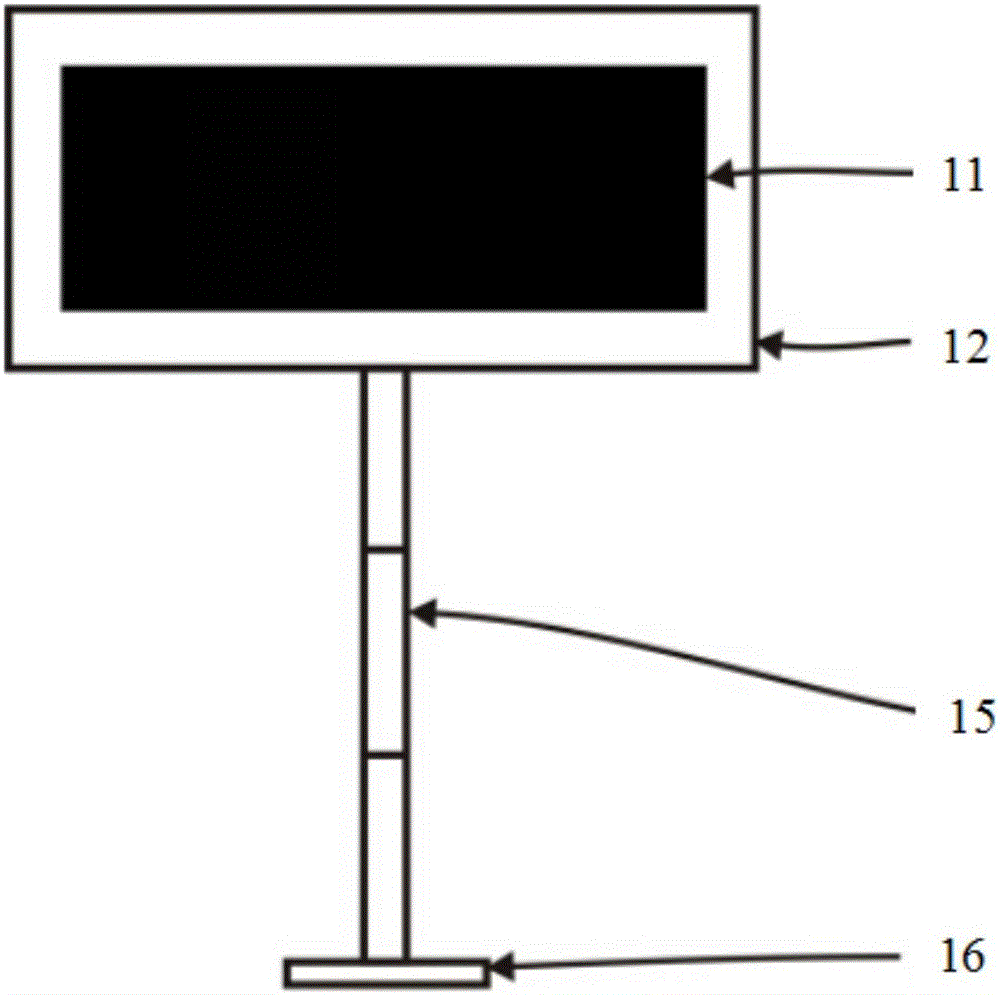

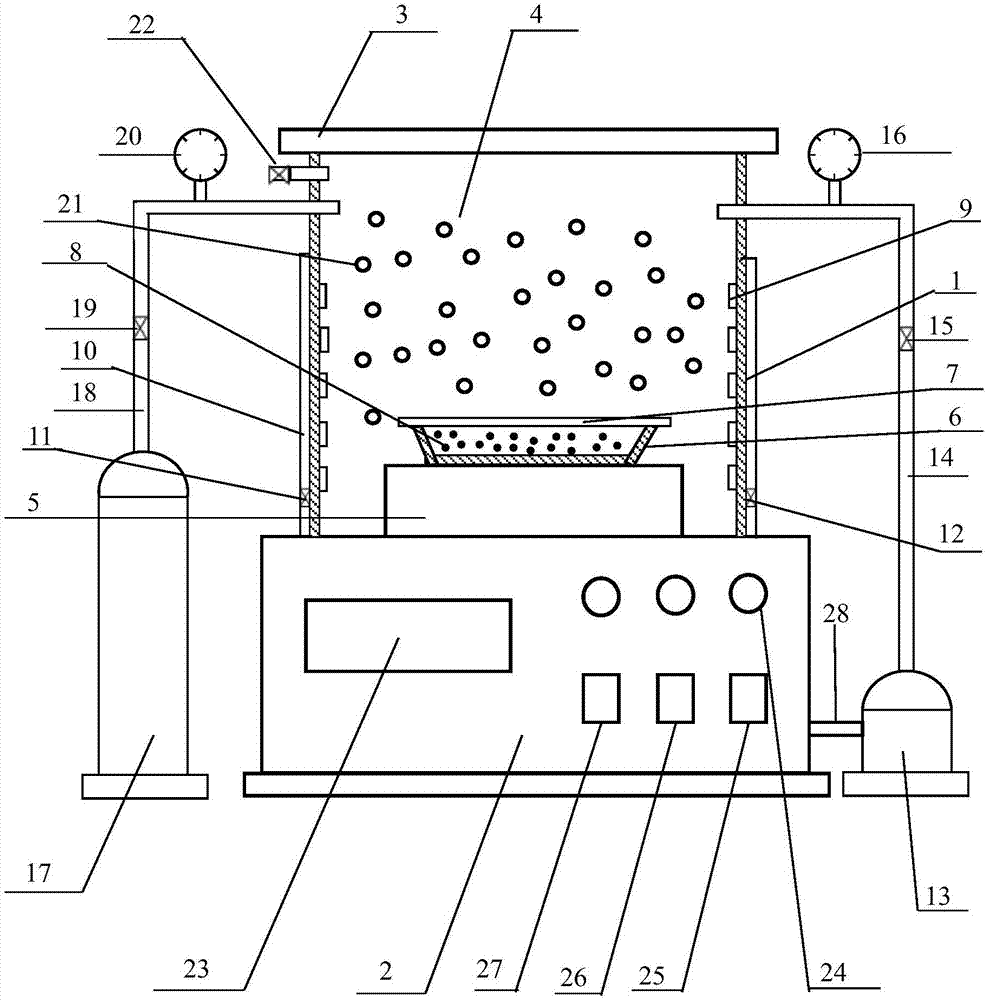

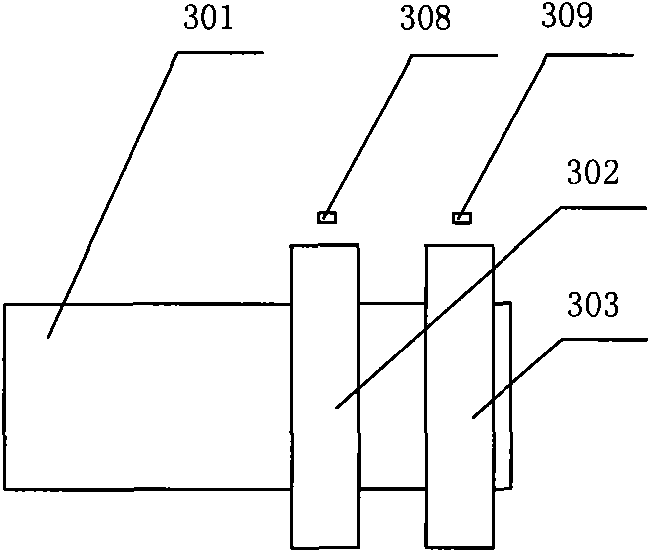

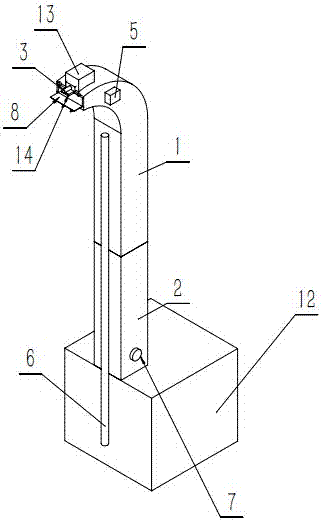

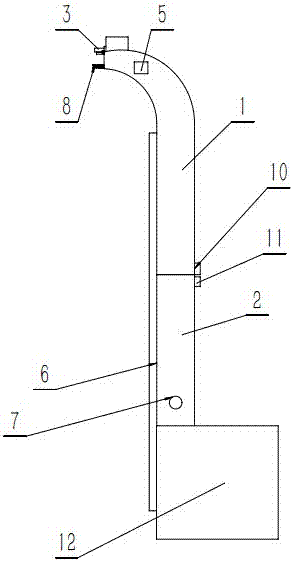

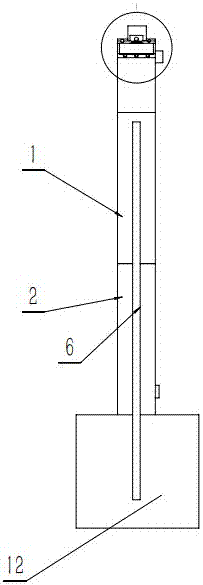

Airflow and air bubble spinning device for preparing magnetic ordered nano composite material and method thereof

InactiveCN105821496AIncrease productionThe spinning process is simple and easy to controlSpinning solutions preparationStretch-spinning methodsFiberNanofiber

The invention discloses an airflow and air bubble spinning device for preparing a magnetic ordered nano composite material and a method for spinning by utilizing the device. The airflow and air bubble spinning device comprises a liquid storage groove, an air bubble spraying pipe, a glass pipe, an air bubble generator, an air spraying pipe, an airflow generator, a receiving device arranged above the air bubble spraying pipe, a bracket platform which is fixedly connected with the receiving device, a magnetic control device mounted on the bracket platform and a liquid feeding device, wherein one end of the glass pipe is communicated with the air bubble generator and the other end of the glass pipe is communicated with the interior of the air bubble spraying pipe; the air spraying pipe is arranged on the side face of the air bubble spraying pipe and is connected with the airflow generator. In a spinning process, air bubbles are formed on the surface of a polymer solution containing magnetic nano-particles; after rising and breaking, the air bubbles are further subjected to stretching and thinning with airflow as power to form a lot of disordered magnetic nano fibers; and the disordered magnetic nano fibers do regular movement in a magnetic field control region generated by the magnetic control device to form a lot of ordered magnetic nano fibers and the ordered magnetic nano fibers are collected on the receiving device.

Owner:SUZHOU UNIV

Magnetic ordered mesopore composite material, as well as preparation and application thereof

InactiveCN104353416AUniform sizeEasy to introduceOther chemical processesWater contaminantsMagnetite NanoparticlesMicroscopic scale

The invention discloses a magnetic ordered mesopore composite material, as well as a preparation and application thereof. The preparation method of the material comprises the following steps: modifying the surfaces of cobalt ferrite nano particles with a cationic surfactant, namely hexadecyl trimethyl ammonium bromide (CTAB), uniformly mixing the product with a segmented copolymer, namely EO130PO70EO130 (F108) and CTAB in an alcohol water system, and adding tetraethyl orthosilicate. The composite material is of a spherical microstructure with uniform size under the observation of a transmission electron microscope, and the magnetic nano particles are coated with the inside of MCM-48 silicon dioxide balls; the magnetic ordered mesopore composite material which is synthesized by the method has excellent magnetic property, maintains large specific surface area and pore volume, and can be applied to the field of adsorption, separation, catalysis, information storage, biological medicine, and the like.

Owner:NANJING UNIV OF SCI & TECH

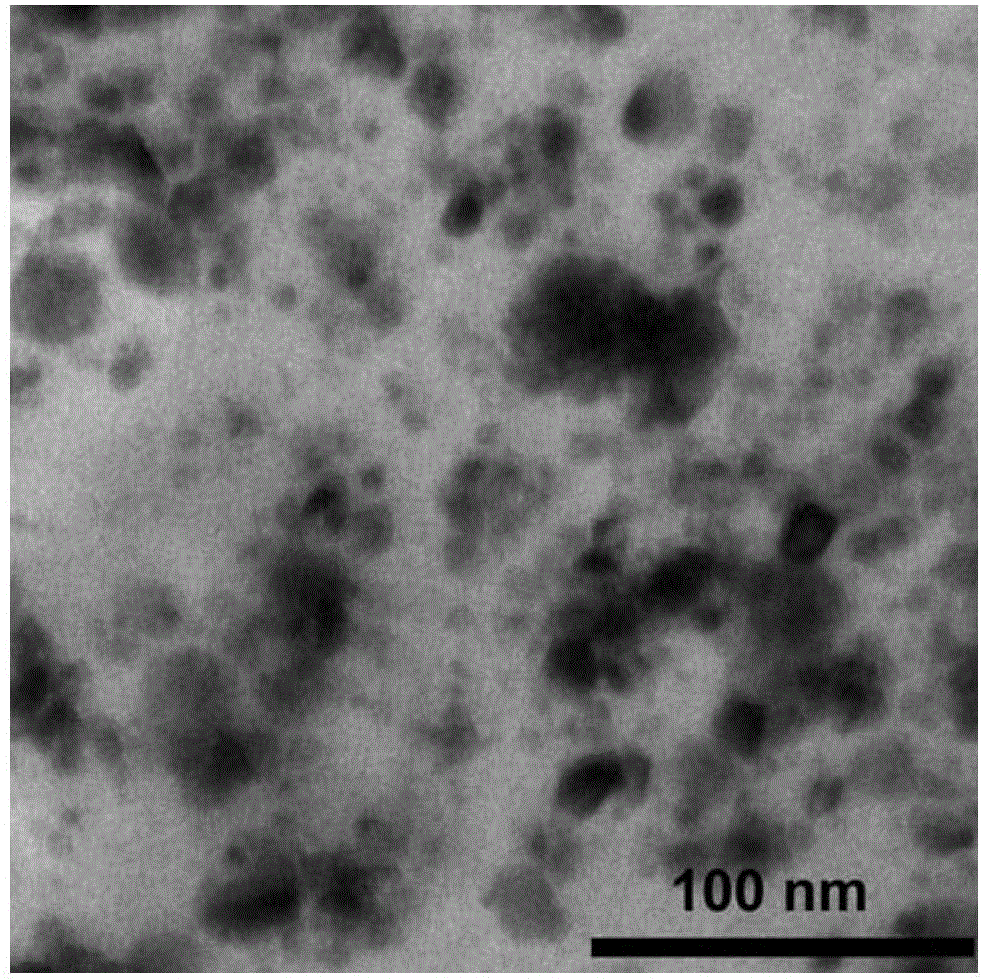

Preparation method of magnetic ordered mesoporous carbon nanospheres for magnetic targeted drug delivery

ActiveCN107032324AAdvancedAccurate and informative dataOrganic active ingredientsPowder deliveryPhenolMaterials science

The invention relates to a preparation method of magnetic ordered mesoporous carbon nanospheres for magnetic targeted drug delivery. Aiming at the defects of non-specificity and high toxicity of antitumor drugs, with phenol, formaldehyde, sodium hydroxide and alpha-type iron oxide as raw materials and iron nitrate as a magnetic agent, after hydrothermal synthesis and vacuum sintering at high temperature are conducted, the magnetic ordered mesoporous carbon nanospheres are prepared as a controlled release formulation of a cancer targeted drug. According to the preparation method, the process is advanced, and data is complete and accurate; the product is black powder particles, the particle size is <= 100 nm, the specific surface area of the nanospheres reaches 344.9 m<2> / g, the particles have magnetic ordered mesoporous structures with the pore diameter of the mesoporous <= 3 nm, and the purity of the product reaches 99.8%; the preparation method of the magnetic ordered mesoporous carbon nanospheres is advanced.

Owner:TAIYUAN UNIV OF TECH

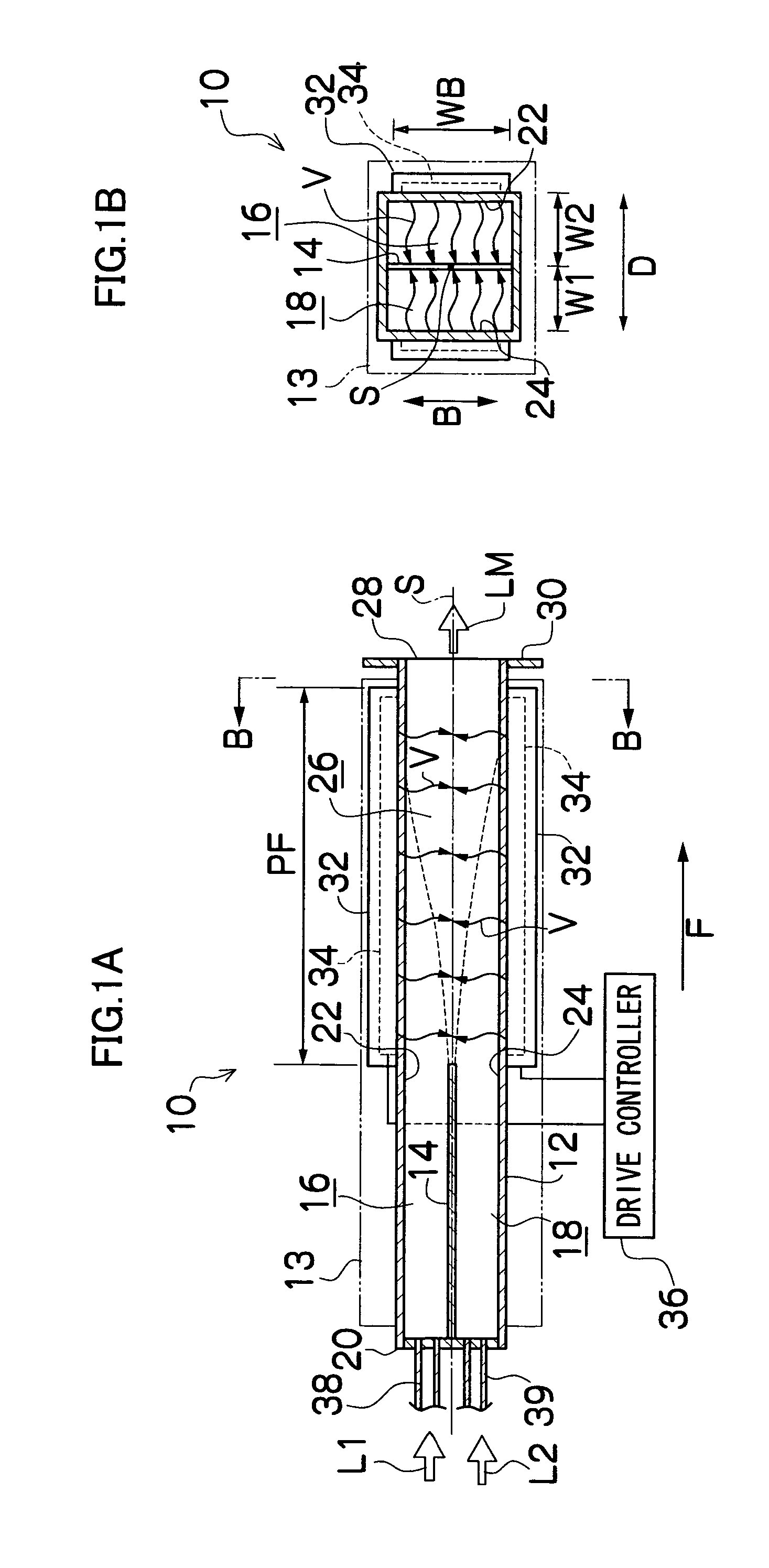

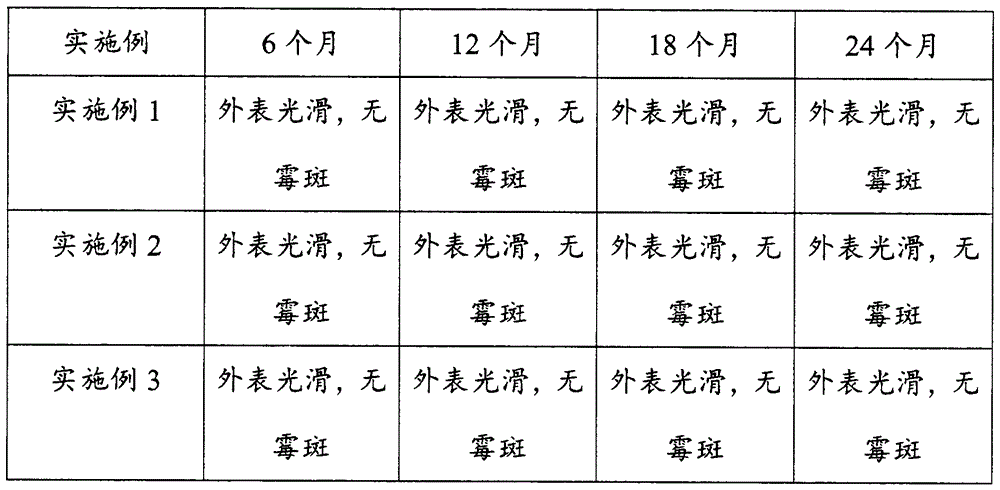

Environmentally-friendly dry powder emulsion paint for inner wall and preparation method thereof

The invention relates to an environmentally-friendly dry powder emulsion paint for an inner wall and a preparation method thereof. The environmentally-friendly dry powder emulsion paint for the inner wall is prepared through the following raw materials in parts by weight: 20-35 parts of white cement, 20-35 parts of calcium carbonate powder, 8-18 parts of ash calcium powder, 30-40 parts of modified degreased soybean powder pulp, 5-10 parts of titanium dioxide, 10-20 parts of propolis powder, 6-8 parts of water soluble glucan, 4-6 parts of flatting agent, 2-3 parts of organobentonite, 1-3 parts of nanometer magnetic ordered mesoporous medium, 2-3 parts of antioxidant, and 1-3 parts of additive, wherein the additive is at least one of flame-retardant powder, nanometer negative ion powder and an antistatic agent; the flatting agent is a liquid acrylic flatting agent. The environmentally-friendly dry powder emulsion paint for the inner wall is reasonable in raw material selection, and proper in matching; compared with an existing emulsion paint, the prepared dry powder emulsion paint has the advantages of being outstanding in water resistance, outstanding in bonding performance, high in consistency in the drying process, and high in flatness; in addition, the emulsion paint is high in stability during the drying process, is influenced slightly by the outside condition, and is hard to discolor; in addition, the emulsion paint is outstanding in antibacterial capacity, high in static resistance and high in fire retardance.

Owner:陈浩谦

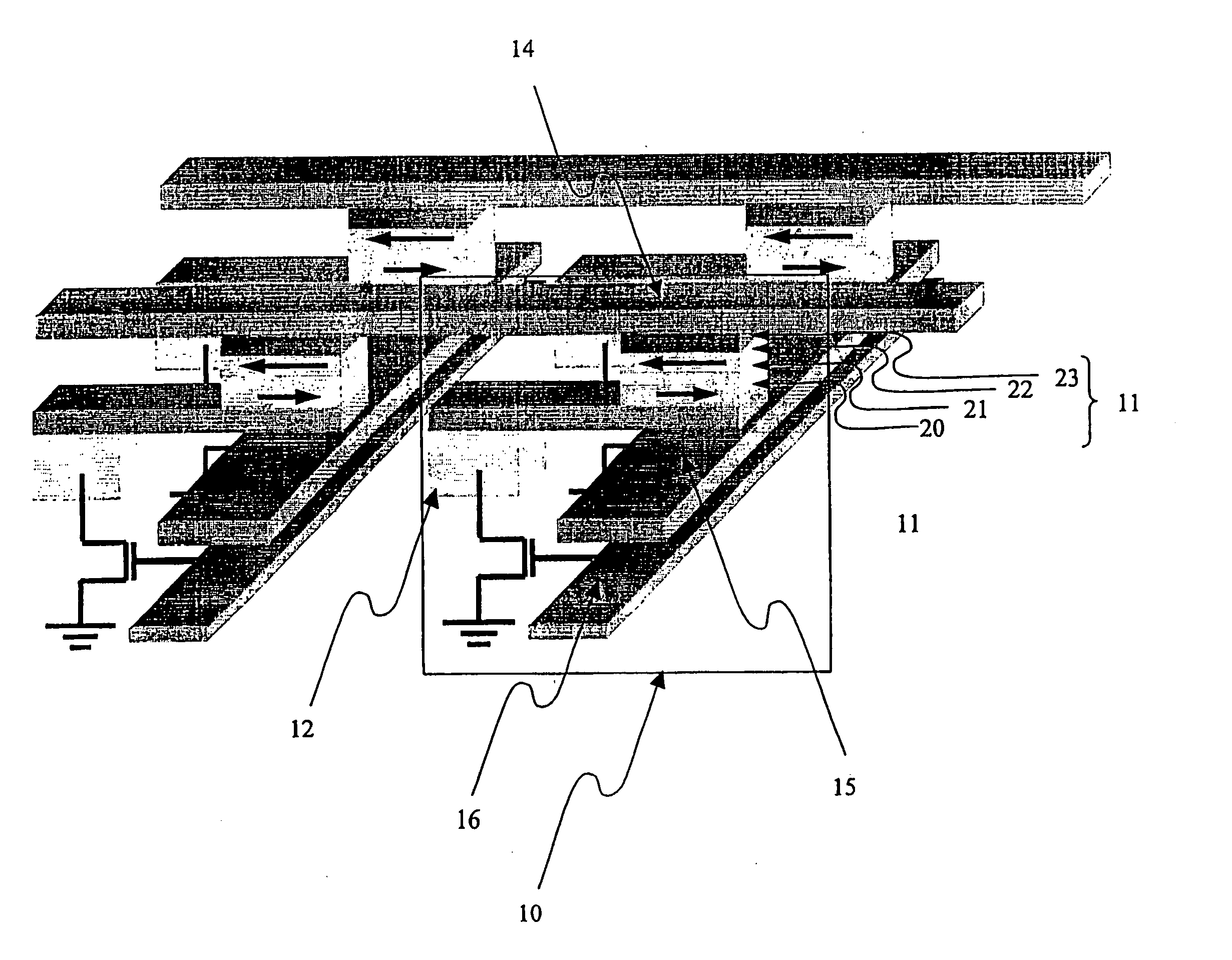

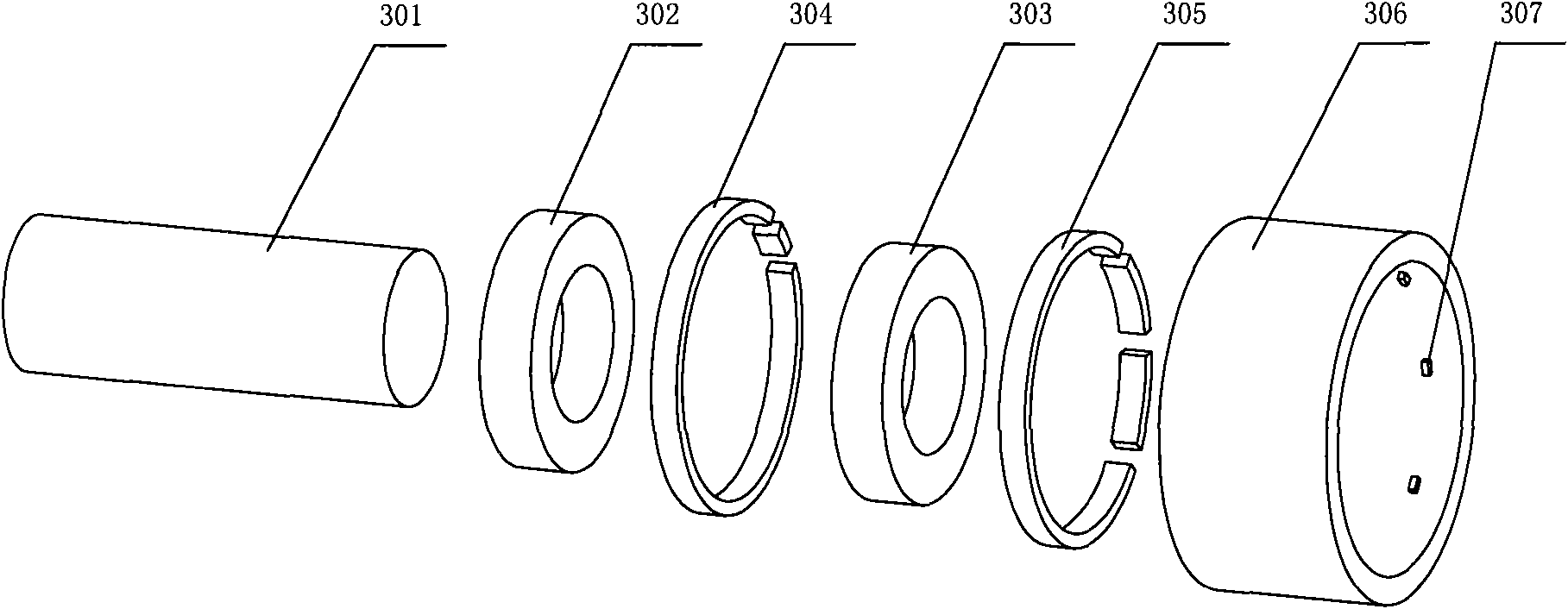

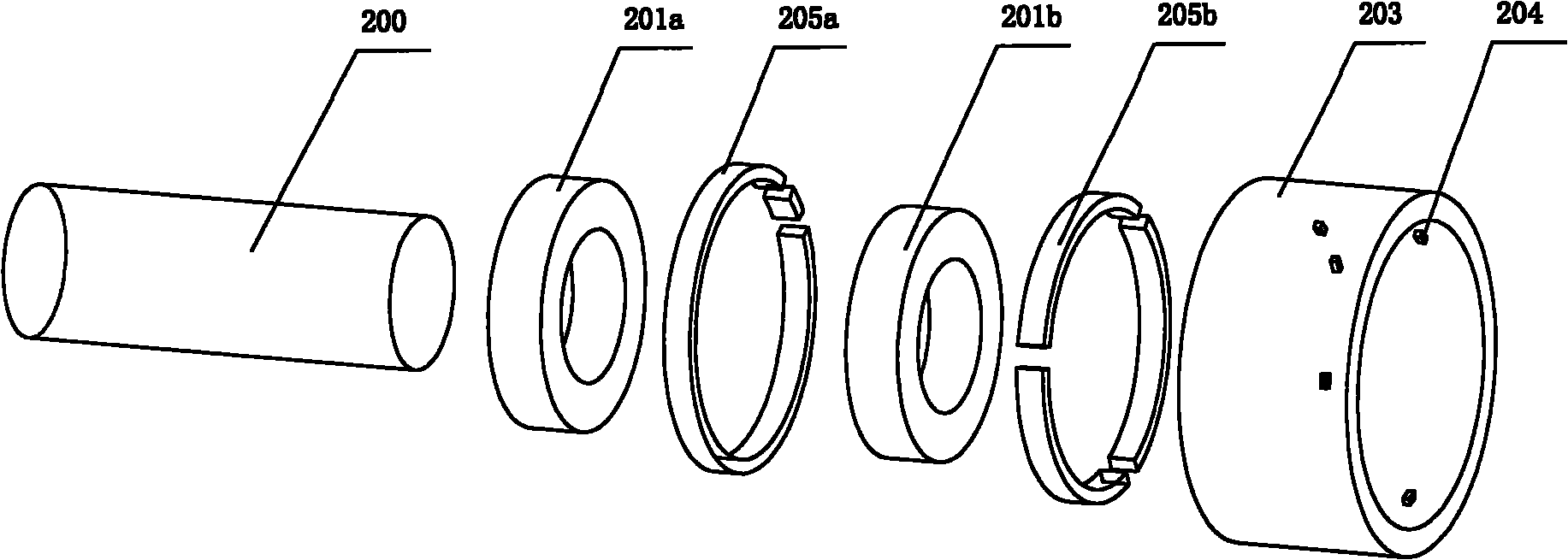

Position detecting device and signal processing device and method thereof

InactiveCN101876559AUniform magnetic field distributionReduce leakageConverting sensor output electrically/magneticallyLocation detectionMagnetic poles

The invention discloses a position detecting device and a signal processing device and method thereof. The position detecting device comprises a rotor and a stator covering the rotor inside, wherein the rotor comprises a first magnetic steel ring and a second magnetic steel ring which are fixed on a rotation axis; the first magnetic steel ring is uniformly magnetized into N (<=2n) pairs of magnetic poles and the adjacent two poles have opposite polarity; the total number of the magnetic poles of the second magnetic steel ring is N and the magnetic order is determined according to the specificmagnetic order algorithm; and m-numbered magnetic induction elements which are distributed at a certain angle and correspond to the first magnetic steel ring are arranged on the same circumference with the center of the first magnetic steel ring as the circle center on the stator, and n-numbered magnetic induction elements which are distributed at a certain angle and correspond to the second magnetic steel ring are arranged on the same circumference with the center of the second magnetic steel ring as the circle center on the stator. The device and the method of the invention can simplify theproduction process, improve the measuring precision, lower the production cost and improve the cost performance.

Owner:HANGZHOU SES MACHINERY

Fiber material with health function and preparation method thereof

The invention relates to a fiber material with a health function and a preparation method thereof. The fiber material with the health function is a composite layer structure composed of an inner layer and an outer layer, wherein the inner layer is compounded by a trace transfer layer, an element transformation layer and a physical activation layer; the outer layer is a latex function layer; the trace transfer layer adopts polyester concentrated screen cloth; the element transformation layer adopts an interwoven non-woven fabric; the physical activation layer is coarse negative ion cloth; and the latex function layer is composed of the following components in parts by weight: 50-65 parts of latex, 10-20 parts of a synthetic resin, 5-10 parts of negative ion powder, 20-40 parts of safflower wormwood slurry flour, 5-10 parts of far infrared mineral substance, 20-40 parts of bamboo charcoal fiber powder, 5-20 parts of diatom ooze and 3-5 parts of magnetic ordered mesoporous media. The healthy fiber board comprising traditional Chinese medicine components, negative ions and far infrared emission components is scented, dry and comfortable and capable of improving energy, is used for prompting breathing and adsorption of insole materials of shoes, promoting blood circulation, dredging the channels, invigorating the circulation of blood, defying age and resisting allergy, and can effectively inhibit bacteria and prevent foot odor.

Owner:HANGZHOU KAIYUE NEW MATERIAL CO LTD

Anti-mold paper packing box and producing process thereof

ActiveCN106149466AImprove spraying effectImprove uniformityFlexible coversCoatings with pigmentsEmulsionPolyvinyl alcohol

The invention relates to an anti-mold paper packing box and a producing process thereof. The anti-mold paper packing box comprises a packing box body, wherein at least one anti-mold coating layer is arranged on the outer surface of the packing box body; the anti-mold coating layer is prepared from the following raw materials in parts by weight: 50-60 parts of an acrylic emulsion, 30-40 parts of a PU resin copolymer emulsion, 4-6 parts of polyvinyl alcohol, 0.5-0.7 part of a defoaming agent, 0.1-0.3 part of an inorganic sterilization agent, 1-3 parts of organic bentonite and 1-3 parts of magnetic ordered mesopore carbon. The anti-mold paper packing box has the beneficial effects that the production efficiency is high, a product is high in anti-mold efficiency and convenient to coat, the service life of the anti-mold paper packing box can be greatly prolonged, and the quality of a packed article can be guaranteed.

Owner:陈煊皓

Diaper with good absorbing, water-locking and antibacterial properties and processing technique thereof

ActiveCN110123528AGood drainage and absorption performanceIncrease the areaAbsorbent padsBaby linensHigh absorptionResin microsphere

The invention relates to a processing technique of a diaper. A diaper body is included and is provided with a surface layer, a flow guide layer, an absorbing core layer and a bottom membrane layer sequentially from top to bottom; the absorbing core layer comprises a dust-free paper layer and a high-absorption material layer sequentially from bottom to top; the high-absorption material layer is made by mixing antibacterial high-absorption resin microspheres and fluff pulp in a mass ratio of (3-4):(7-6). A synthetic method of the antibacterial high-molecular water-absorbing resin microspheres applied in the diaper acts as a modification to a method of synthesizing high-molecular water-absorbing resin via a solution process; magnetic ordered mesoporous carbon nanospheres with multiple ducts,regular pore size and large specific surface area are used as a carrier; therefore, polymerization efficiency is improved, the finished high-molecular water-absorbing resin microspheres have uniform character, and the post-treatment procedures are simple.

Owner:HANGZHOU COCO HEALTHCARE PRODS +2

Synthesis method and application of superabsorbent resin microspheres with antibacterial properties

ActiveCN110272517AIncrease the areaImprove liquid storage capacityAbsorbent padsBandagesResin microsphereSynthesis methods

The invention relates to a synthesis method and application of superabsorbent resin microspheres with antibacterial properties. The synthesis method comprises the following steps: (1) adding a certain amount of magnetic ordered mesoporous carbon nanospheres and a polymer dispersing agent to a certain amount of water, performing full and even stirring, then performing vacuum and / or ultrasonic-assisted degassing treatment for 1-2 h, adding a certain amount of acrylic acid, performing even stirring, and controlling the temperature at 35-45 DEG C; (2) adding a certain amount of sodium hydroxide to the system obtained in the step (1) while stirring, and controlling the temperature at 65-75 DEG C in the reaction process; (3) adding a certain amount of a composite crosslinking agent and an initiator, and controlling the temperature at 80-90 DEG C for a reaction for 2-3 hours so as to form a semi-finished product superabsorbent resin colloid, wherein the composite crosslinking agent is a mixture of NMBA and PEGDA; and (4) putting the superabsorbent resin colloid obtained in the step (3) in a certain amount of a solvent, performing rinsing for 1-3 times, adding a certain amount of a nano-silver antibacterial agent, performing drying until the moisture content at less than 3%, performing pulverization to a certain particle size, and performing magnetic separation so as to obtain the superabsorbent resin finished product.

Owner:HANGZHOU COCO HEALTHCARE PRODS +2

Method of producing magnetic particles and reaction method using microreactor and microreactor

ActiveUS7470308B2Good monodispersityImprove deformationAdditive manufacturing apparatusTransportation and packagingMicroreactorAlloy

Owner:FUJIFILM CORP +1

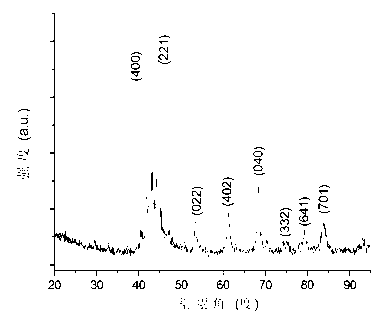

Method for growing nanometer particles on substrate

InactiveCN105081352AGood dispersionEvenly dispersedNanotechnologyRoom temperatureMagnetite Nanoparticles

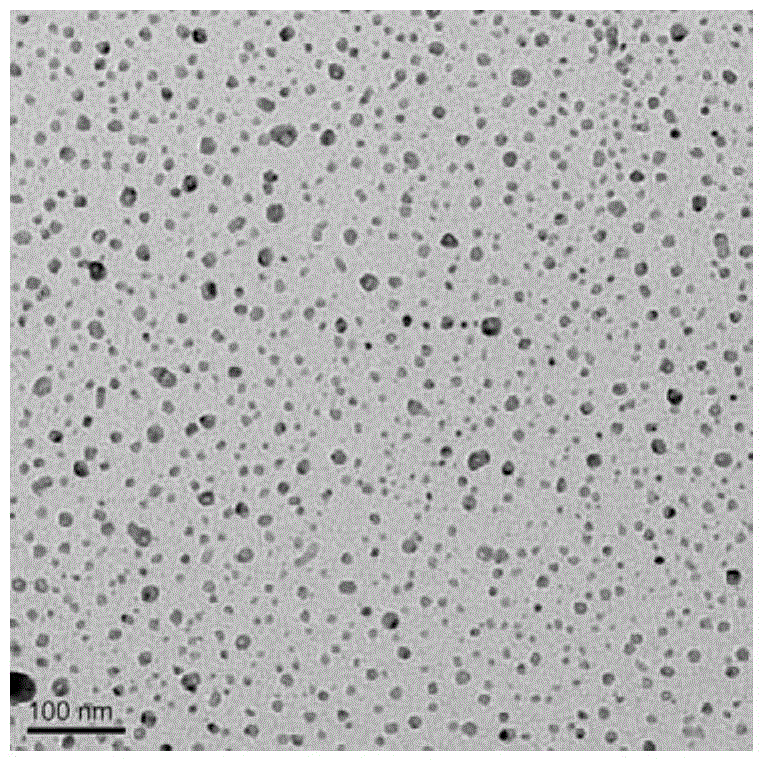

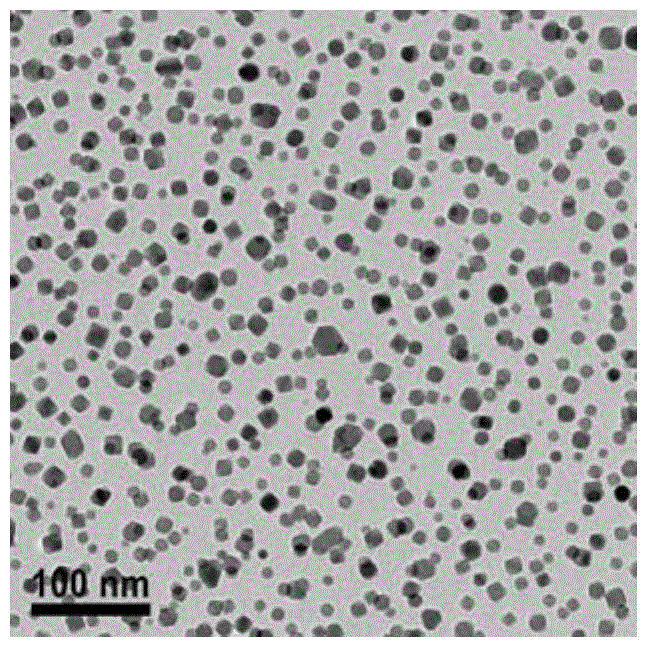

The invention provides a method for growing nanometer particles on a substrate. According to the method, a metal pecursor solution is carried on the surface of the substrate; after solvents are evaporated, the substrate carrying metal precursor particles is obtained; then, the substrate is subjected to direct high-temperature calcinations, so that the metal precursor particles are subject to thermolysis reaction to remove other elements except metal elements; finally, the substrate is cooled to the room temperature to obtain magnetic nanometer particles. Compared with the prior art, the method has the advantages that the agglomeration between the particles is effectively avoided; the uniformly scattered nanometer particles with uniform particle diameter are obtained; particularly, when the optimum calcination temperature is higher than the phase forming temperature during nanometer alloy particle preparation, the uniformly scattered metal nanometer particles with chemical and magnetic ordered phases can be obtained through one-step synthesis; the preparation process is greatly simplified; meanwhile, the particle agglomeration phenomenon in the annealing process is avoided.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

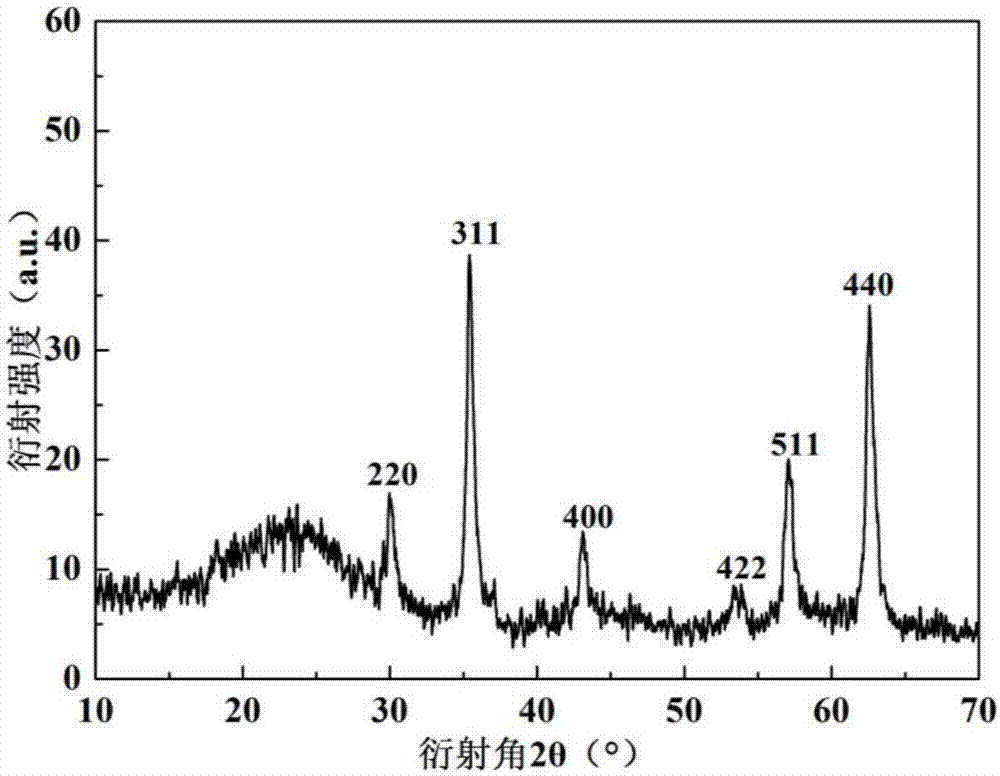

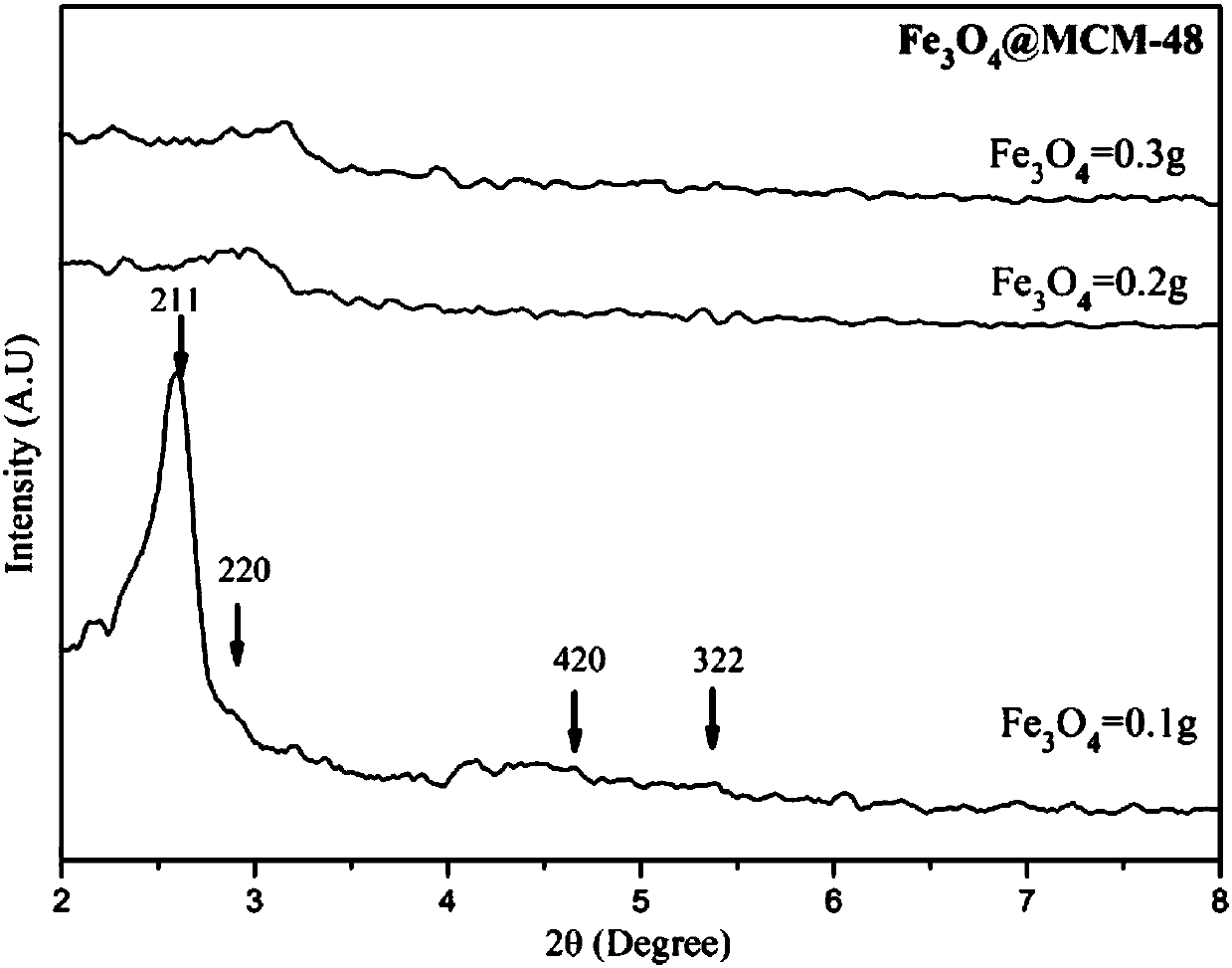

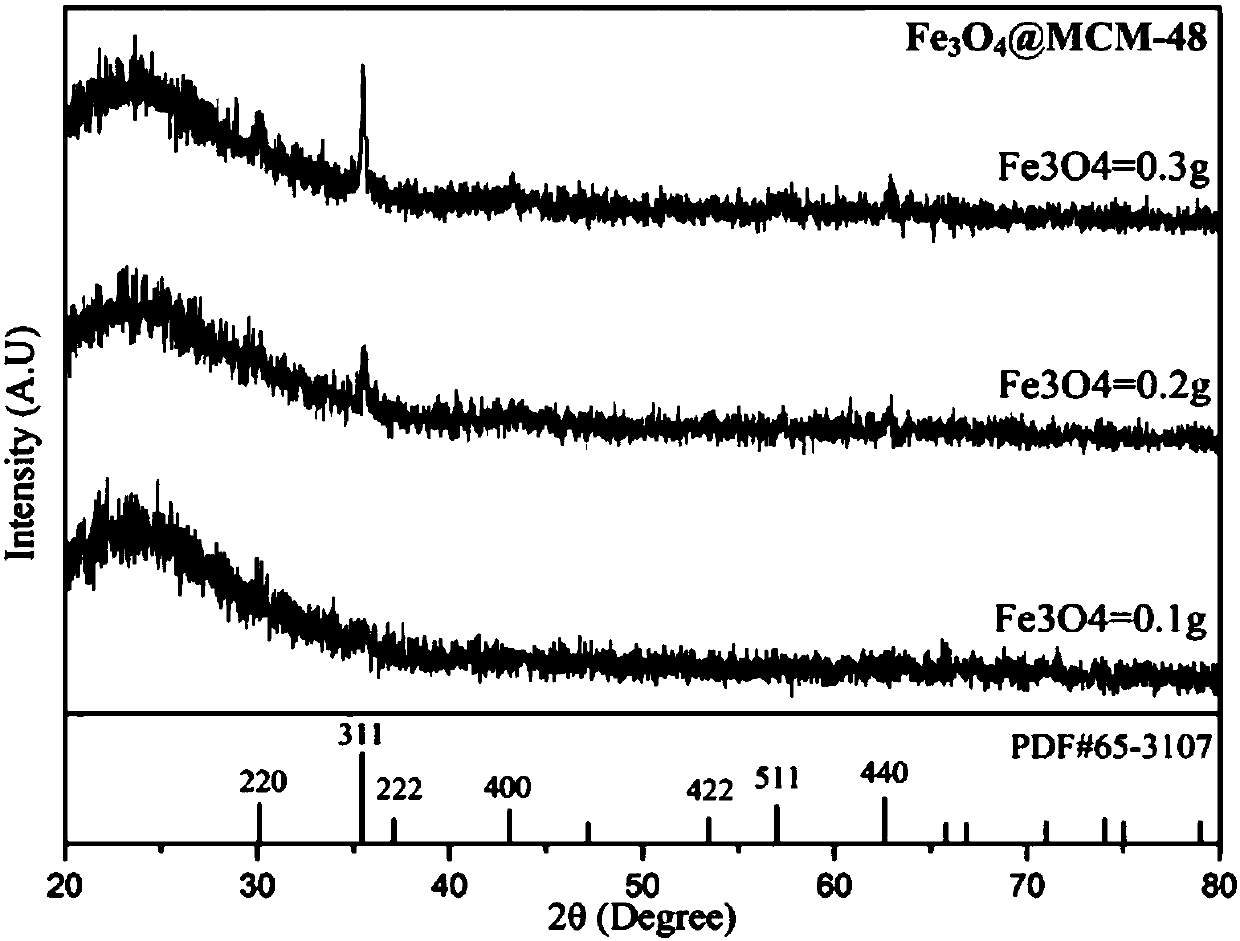

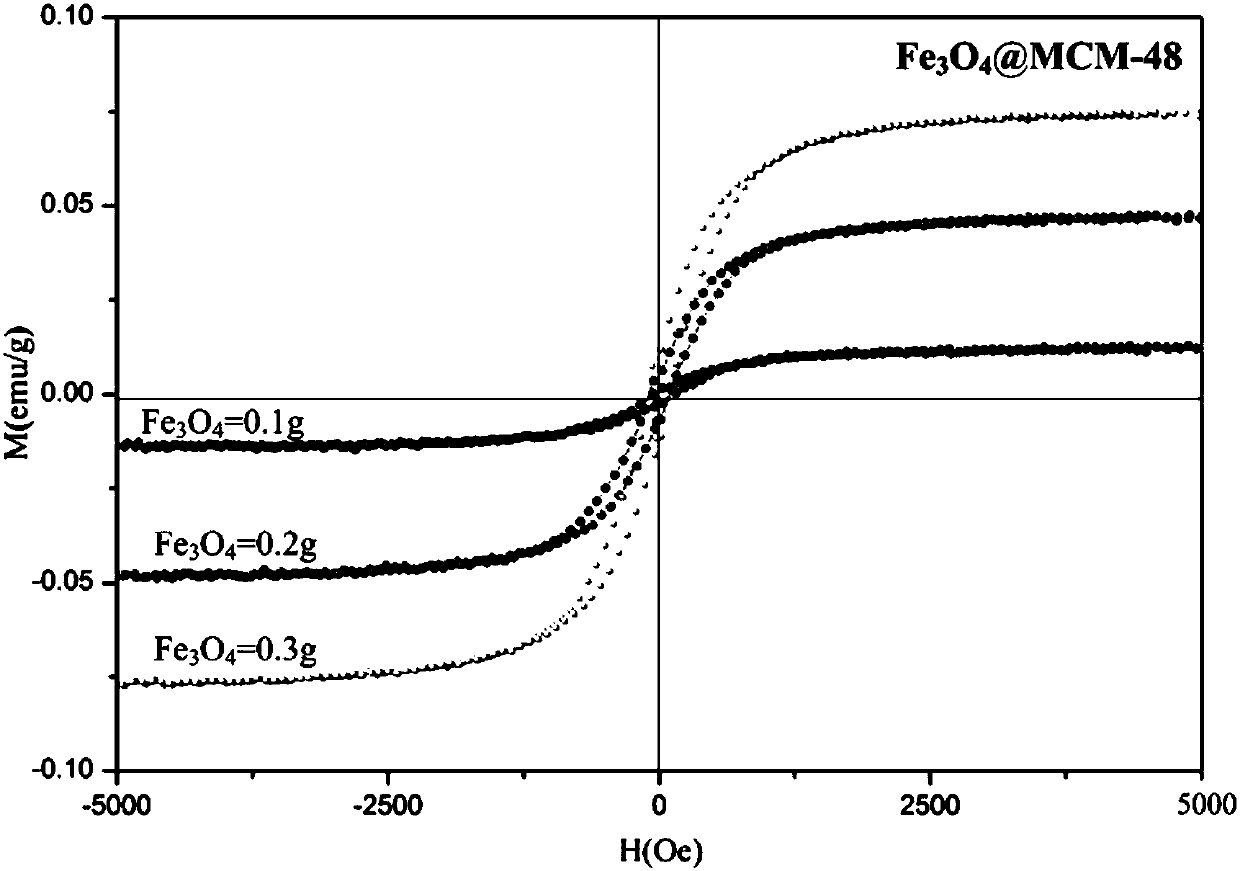

Preparation method of magnetic ordered mesopore Fe3O4@MCM-48 composite adsorbing material

ActiveCN107803180AStrong guidanceLow toxicityOther chemical processesAlkali metal oxides/hydroxidesMolecular sieveMaterial synthesis

The invention belongs to thel field of magnetic composite material synthesis technology, and particularly discloses a preparation method of a magnetic ordered mesopore Fe3O4@MCM-48 composite adsorbingmaterial. The preparation method includes steps of combining a ferrite Fe3O4 grain and a mesoporous molecular sieve MCM-48; roasting in a muffle furnace at 450-650 DEG C, so as to obtain the Fe3O4@MCM-48 magnetic mesopore composite adsorbing material with a core-shell structure. The method is low in cost, low in toxicity, simple in operation, gentle in condition, and short in consumed time; the prepared material has magnetism and the mesoporous duct of the molecular sieve; the preparation method has huge prospect in absorption and separation, and drug carrier.

Owner:BIOBASE BIODUSTRY (SHANDONG) CO LTD

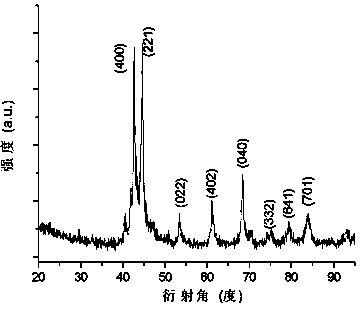

Ni-Mn-Ge magnetic shape memory alloy and preparation method thereof

ActiveCN102851545BEasy to prepareWide range of usesPolycrystalline material growthBy pulling from meltAlloySingle crystal

The invention relates to a Ni-Mn-Ge magnetic shape memory alloy of which the chemical formula is NixMnyGezMa, wherein M is a main group element or transition group element; and 51<x<55, 31<y<40, 5<z<20, a<5, x+y+z+a=100, and x, y, z and a represent atomic percents. The alloy is a monocrystalline material or polycrystalline material. The main group element is In, Sn, Sb, As or Si; and the transition group element is Ti, Fe or Co. The magnetic material with magnetic shape memory effect has shape memory effect and ferromagnetic property, and appears the property of entropic change (magnetic card effect) caused by magnetic-field-driven phase change and magnetic order degree change, wherein the change value is up to S=8J / Kkg.

Owner:HEBEI UNIV OF TECH

Celadon olive green glaze, preparation method thereof and olive green glazed porcelain

ActiveCN107382065AReasonable choiceCooking temperature controllablePotassium carbonateMaterials science

The invention relates to the technical field of ceramics, in particular to a celadon olive green glaze, a preparation method thereof and olive green glazed porcelain. The celadon olive green glaze is prepared from a main ingredient and auxiliary materials in a mass ratio of (8-9):1, wherein the main ingredient is formed by processing the following raw materials in parts by weight: 20-30 parts of Xiaomei glaze soil, 20-30 parts of Xikou glaze soil, 15-25 parts of Zhoucun glaze soil and 5-10 parts of kaolin, and the auxiliary materials are formed by processing the following raw materials in parts by weight: 20-40 parts of silica powder, 6-12 parts of soda ash, 10-18 parts of feldspar powder, 10-15 parts of aluminum hydroxide, 5-8 parts of zinc oxide, 8-12 parts of calcium carbonate, 6-8 parts of borax, 2-6 parts of potassium carbonate, 6-10 parts of barium sulfate and 8-15 parts of magnetic ordered mesoporous nickel ferrite. The celadon olive green glaze provided by the invention has the beneficial effects that the novel celadon olive green glaze is reasonable in raw material selection, cooking temperature is controllable, rate of finished products is high, product uniformity is good, and processing controllability is good.

Owner:大唐(龙泉)青瓷有限公司

Magnetic ordered mesopore composite material with cavity structure, synthesis and application

InactiveCN104353410AIncrease the areaLarge hole volumeOther chemical processesAlkali metal oxides/hydroxidesSurface-active agentsSilicon dioxide

The invention discloses a magnetic ordered mesopore composite material with a cavity structure, synthesis and application. The magnetic ordered mesopore composite material is prepared by the following steps: uniformly mixing a cationic surface active agent named cetyl trimethyl ammonium bromide (CTAB) which is modified on surfaces of cobalt ferrite nano particles, and a segmented copolymer EO130PO70EO130(F108) and CTAB in an alcohol-water system at room temperature, adding tetraethoxysilane, stirring to be uniform, adjusting the pH value of a stock solution so as to enable the stock solution to be subjected to hydro-thermal reaction for 24 hours under different pH value conditions, filtering, drying, and roasting so as to prepare the composite material. The microstructure of the composite material is a spherical particle with a cavity structure via observation by a transmission electron microscope; the position of the cavity in a silicon dioxide sphere can be controlled well by adjusting the pH value. The composite material synthesized by the method not only has favorable magnetic property, but also can maintain high specific surface area and pore volume; macro molecules such as proteins can be accommodated in the cavity structure, so that the magnetic ordered mesopore composite material has extremely high application value in the fields of adsorption, separation, catalysis, information storage, biological medicine and the like.

Owner:NANJING UNIV OF SCI & TECH

Method for preparing chemical and magnetic ordered-phase nanoparticles

InactiveCN105436510AAvoid reunionLow costInductances/transformers/magnets manufactureCalcinationMaterials science

The invention provides a method for preparing chemical and magnetic ordered-phase nanoparticles through a one-step solid-phase high-temperature sintering process. The method comprises the steps that a large amount of solid dispersing agent powder, such as NaCl and KCl, which can be dissolved in water easily and metal precursor powder are evenly mixed; high-temperature calcination is directly conducted on the mixed powder for the thermal decomposition reaction, so that other elements, except metal elements, in a precursor are removed; and the calcination temperature is controlled to be higher than the magnetic ordered-phase forming temperature, so that crystal-phase growth of prepared nanoparticles is promoted by using dispersing agents as carriers, and thus the chemical and magnetic ordered-phase nanoparticles are obtained. Compared with an existing preparation technique that chemical and magnetic ordered-phase nanoparticles can be obtained only after annealing of chemical disorder nanoparticles synthetized in liquid-phase mode, by the adoption of the method, the chemical and magnetic ordered-phase nanoparticles can be obtained through one-step synthesis without the annealing process, phenomena of agglomeration and growth of the nanoparticles in the high-temperature calcinations are avoided, and the method has good application prospects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

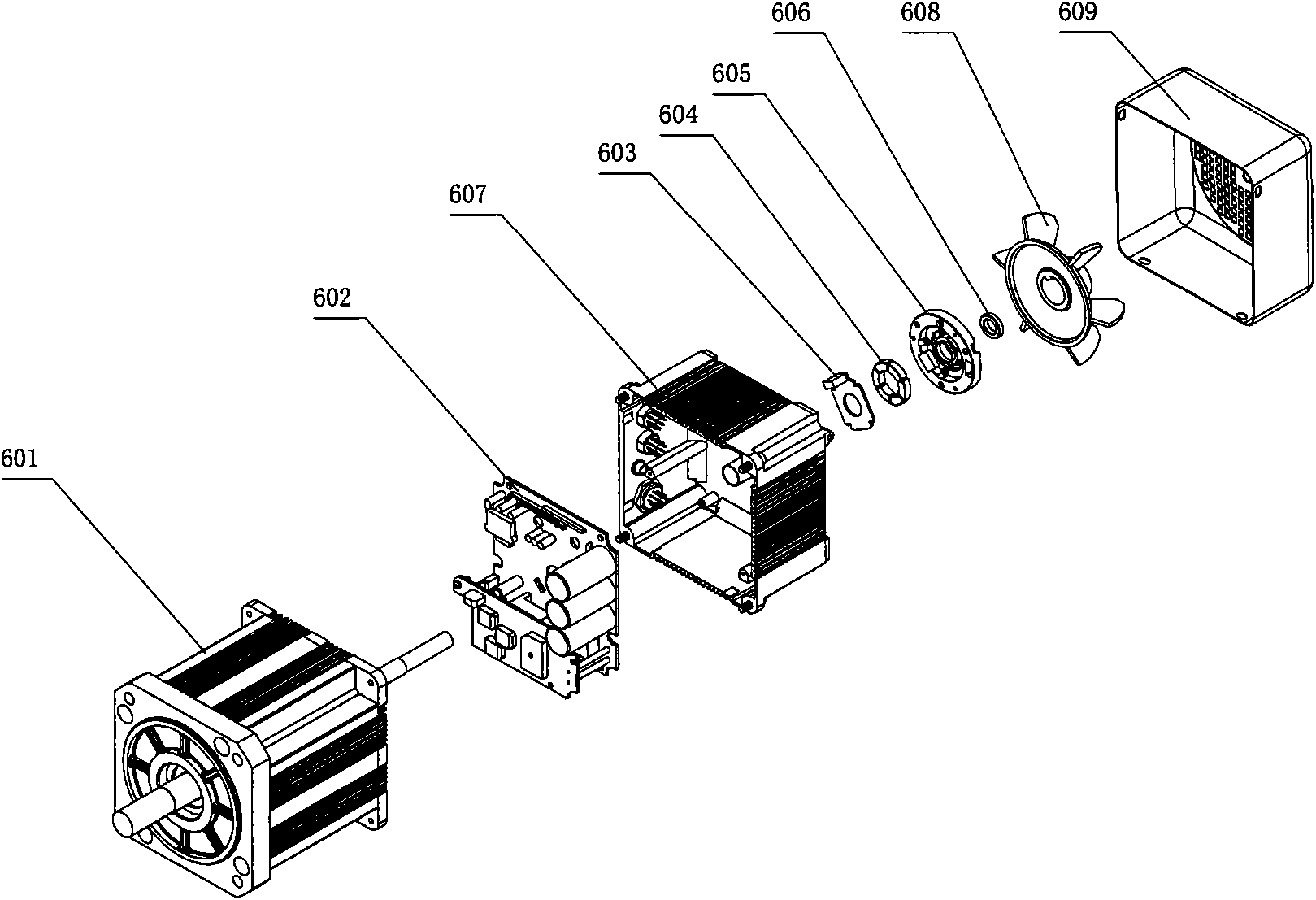

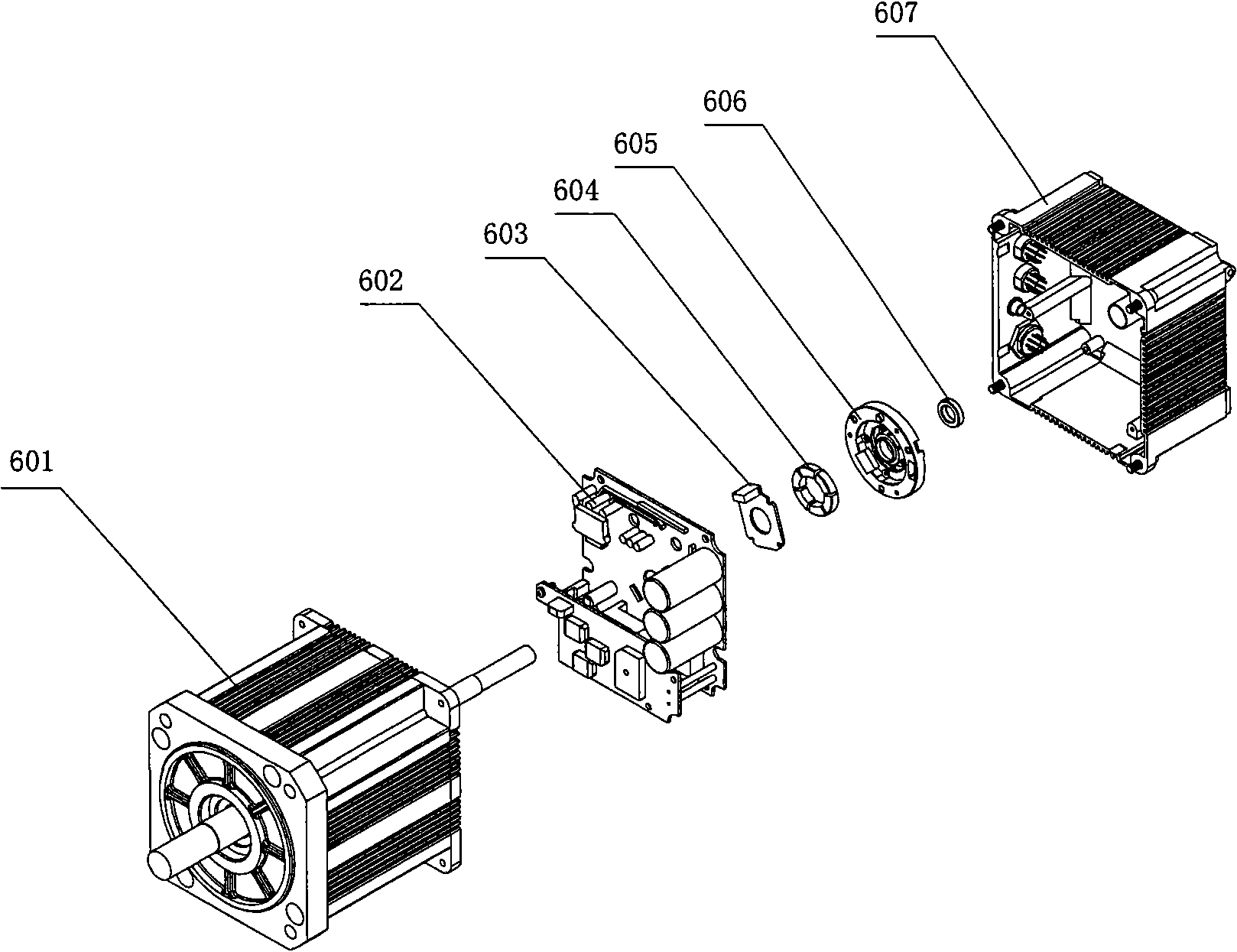

Electric motor

ActiveCN101877527ACost-effectiveFlexible matchingMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMagnetic poles

The invention discloses a motor, comprising a body, a controller and a magnetoelectric sensor. The motor is characterized in that the magnetoelectric sensor is used for sensing rotation of a motor shaft, transmitting the sensed voltage signal to the controller, obtaining the rotation angle or position of the motor shaft through processing of the controller and further realizing precise control of the motor; the magnetoelectric sensor comprises a rotor and a stator covering the rotor inside; the rotor comprises a first magnetic steel ring and a second magnetic steel ring which are respectively fixed on the shaft of the same motor; n-numbered magnetic induction elements which are uniformly distributed and correspond to the second magnetic steel ring are arranged on the stator; the magnetic order of the magnetic poles of the second magnetic steel ring ensures the n-numbered magnetic induction elements to be output in the Gray code format; the two adjacent magnetic induction elements are output with difference of one-bit change; and m-numbered magnetic induction elements which are distributed at a certain angle are arranged corresponding to the first magnetic steel ring. The motor has low cost, high system reliability and high system response speed.

Owner:BEIJING JINGYI JINGYE ELECTRIC TECH

Antibacterial and antistatic wallpaper and preparation method thereof

InactiveCN107503230AEffective anti-mold and anti-staticExtended service lifeDefoamers additionSpecial paperAntistatic agentEmulsion

The invention discloses antibacterial and antistatic wallpaper which comprises a wallpaper body, wherein at least one antibacterial and antistatic coating layer is arranged on each of the inner and outer surfaces of the wallpaper body; the antibacterial and antistatic coating layer is prepared from the following raw materials in parts by weight: 30 to 40 parts of PU resin copolymer emulsion, 6 to 8 parts of polyvinyl alcohol, 0.2 to 0.3 part of a defoaming agent, 0.2 to 0.4 part of a nano antibacterial agent, 0.2 to 0.4 part of an antistatic agent, 1 to 2 parts of organic bentonite and 1 to 3 parts of magnetic ordered mesoporous carbon.

Owner:陈雪珍

Tree rot repair device and repair method based on same

The invention relates to a tree rot repair device and a repair method based on the same. The repair device comprises an upper rod, a lower rod and a pull cable. The top of a bending part is provided with a scraping mechanism for removing old bark and rot parts, a baffle is arranged at the corresponding position of the scraping mechanism on the lower portion of the bending part, and the middle of the bending part is provided with an air suction device. The bottom of the lower rod is provided with switches for controlling the scraping mechanism and the air suction device. The scraping mechanism is further provided with an automatic coating mechanism for coating of a repair agent. The repair agent is formed by processing, by weight parts, 60-80 parts of crystal soda, 15-25 parts of propolis powder, 5-12 parts of organic bentonite, 10-20 parts of water soluble glucan, 6-10 parts of nanoscale magnetic ordered mesoporous media and 80-120 parts of water. The repair agent used in a coating method can quickly repair arbor trunk rot and is high in repair efficiency and good in safety and environmental friendliness.

Owner:杭州爱立特生态环境科技股份有限公司

Wood or paper-based packing box integrated spraying manufacture method

InactiveCN105925094AGuaranteed qualityIncrease productivityCoatings with pigmentsAntifouling/underwater paintsCardboardPolyvinyl alcohol

The invention relates to a wood or paper-based packing box integrated spraying manufacture method. The method comprises 1, processing a packing box semi-finished product plate, 2, pretreating the packing box semi-finished product, 3, putting the packing box semi-finished product wood plate or paperboard into an inlet of a transmission belt of an integrated spraying device, and uniformly spraying a waterproof and moldproof coating to the outer surface of the packing box semi-finished product wood plate or paperboard by the spraying device, wherein the waterproof and moldproof coating is prepared from 80-85 parts by weight of a polyacrylic acid emulsion, 4-5 parts by weight of polyvinyl alcohol, 0.5-0.6 parts by weight of an antifoaming agent, 0.1-0.2 parts by weight of a dispersant, 0.1-0.2 parts by weight of an inorganic bactericide and 4-5 parts by weight of an auxiliary agent and the auxiliary agent is magnetic ordered mesoporous carbon or magnetic ordered mesoporous nickel ferrite, 4, drying the sprayed packing box and discharging the packing box through an outlet of the transmission belt, and 5, carrying out molding through a packing box molding machine to obtain a finished product. The method has high production efficiency. The product has high waterproof and mildew-resistant efficiency, is convenient for coating, has a long service life and guarantees content quality.

Owner:LONGQUAN CITY JIAWEN WOOD IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com