Patents

Literature

240results about How to "Accurate and informative data" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

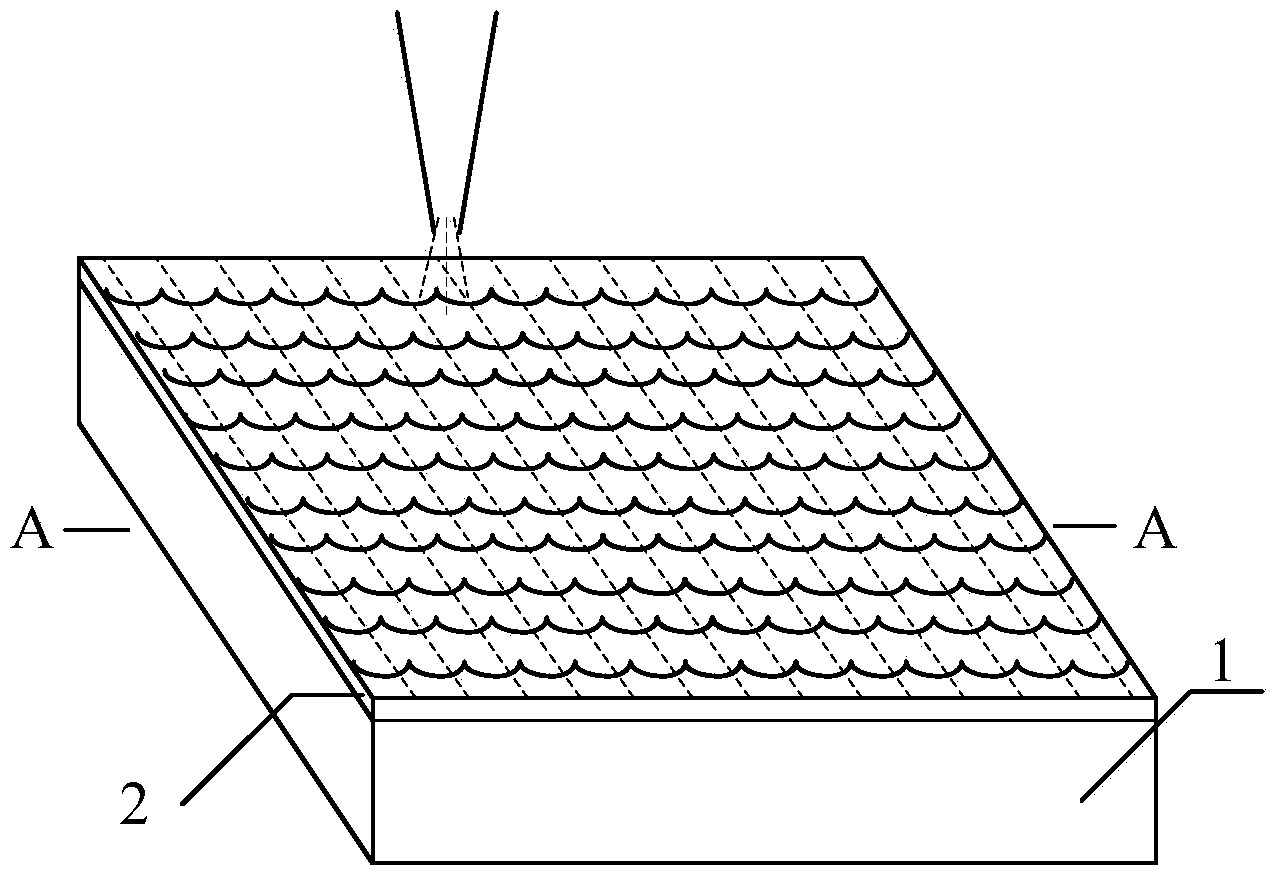

Preparation method of shielding aluminum-based aluminum plate

InactiveCN103911610AImprove corrosion resistanceAdvancedPressure inorganic powder coatingMolding machineRolling mill

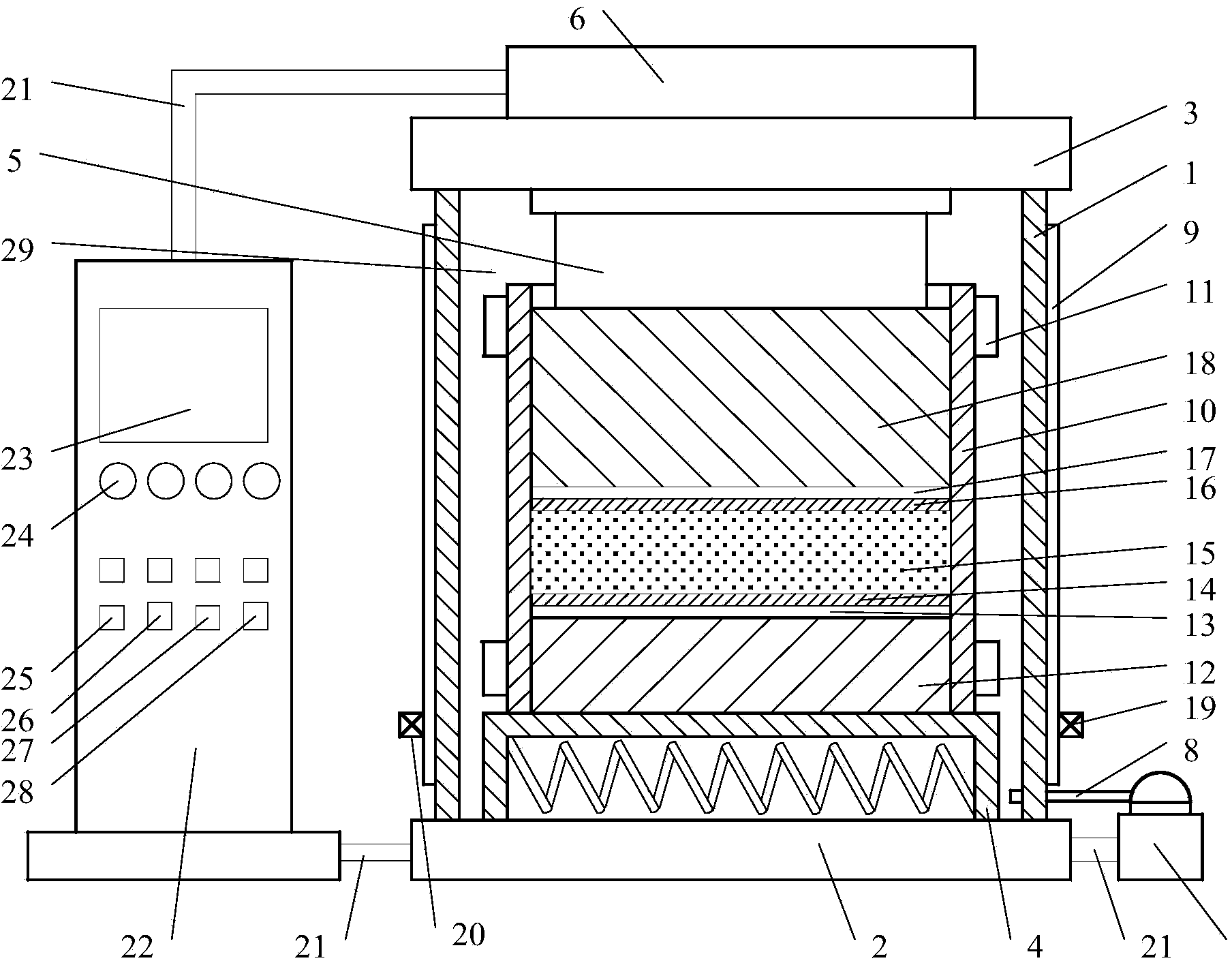

The invention relates to a preparation method of a shielding aluminum-based aluminum plate. Aiming at the defect that aluminum has poor mechanical properties, an enhancing and toughening neutron absorbing material is adopted and mixed with an aluminum alloy powder, and then the mixture is pressed by virtue of a hot-press molding machine and rolled by virtue of a rolling mill, and thus formed into the shielding aluminum-based aluminum plate. The preparation method is advanced in process, and complete and accurate in data; the tensile strength of the prepared shielding aluminum-based aluminum plate reaches up to 270MPa, the corrosion resistance of the shielding aluminum-based aluminum plate can be improved by 50%, and the nuclear protective shielding neutron absorbability of the shielding aluminum-based aluminum plate is greater than or equal to 92%, and therefore, the shielding aluminum-based aluminum plate can be used as a nuclear protective neutron absorbing material, and the method is perfectly ideal for preparing the shielding aluminum-based aluminum plate.

Owner:TAIYUAN UNIV OF TECH +1

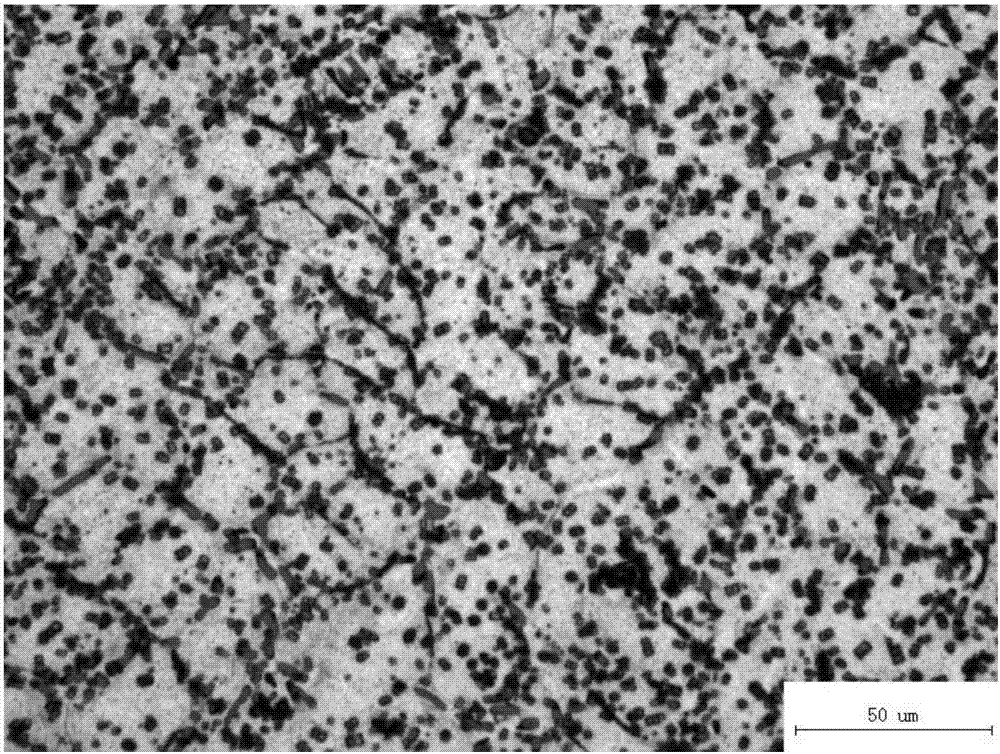

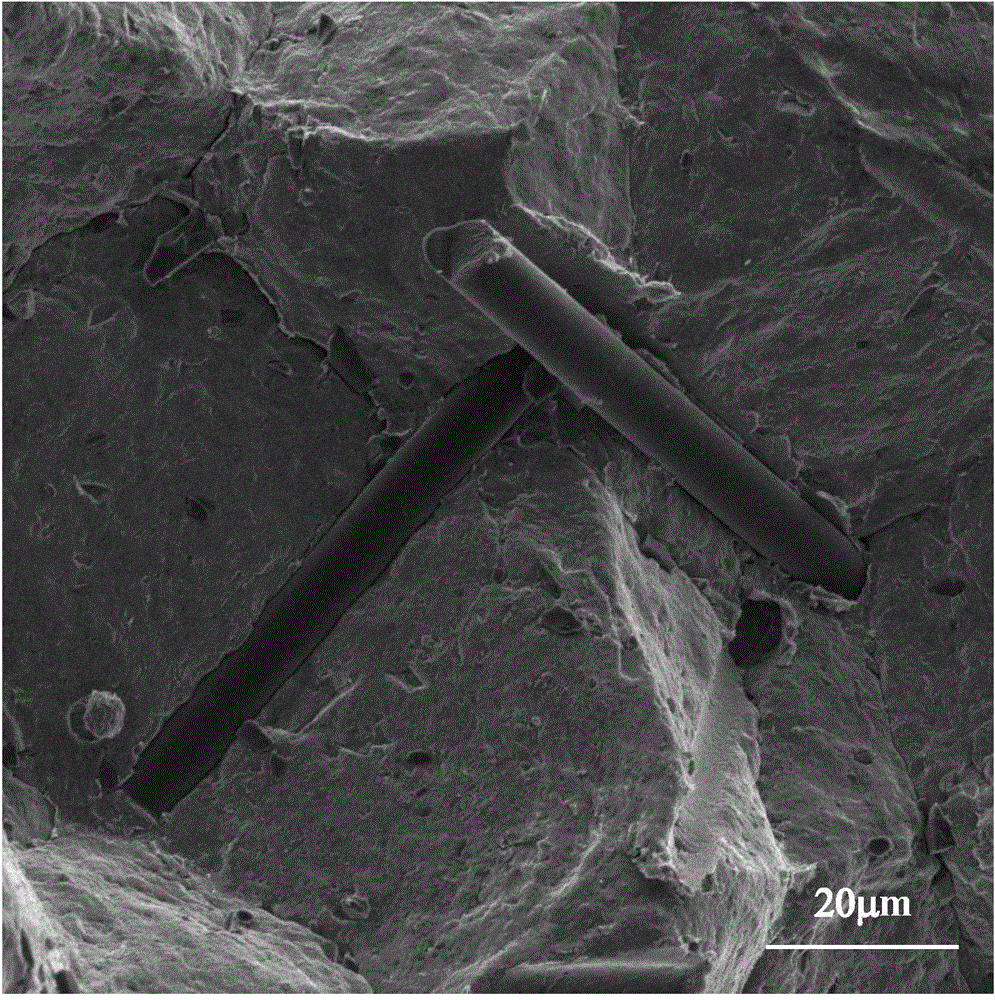

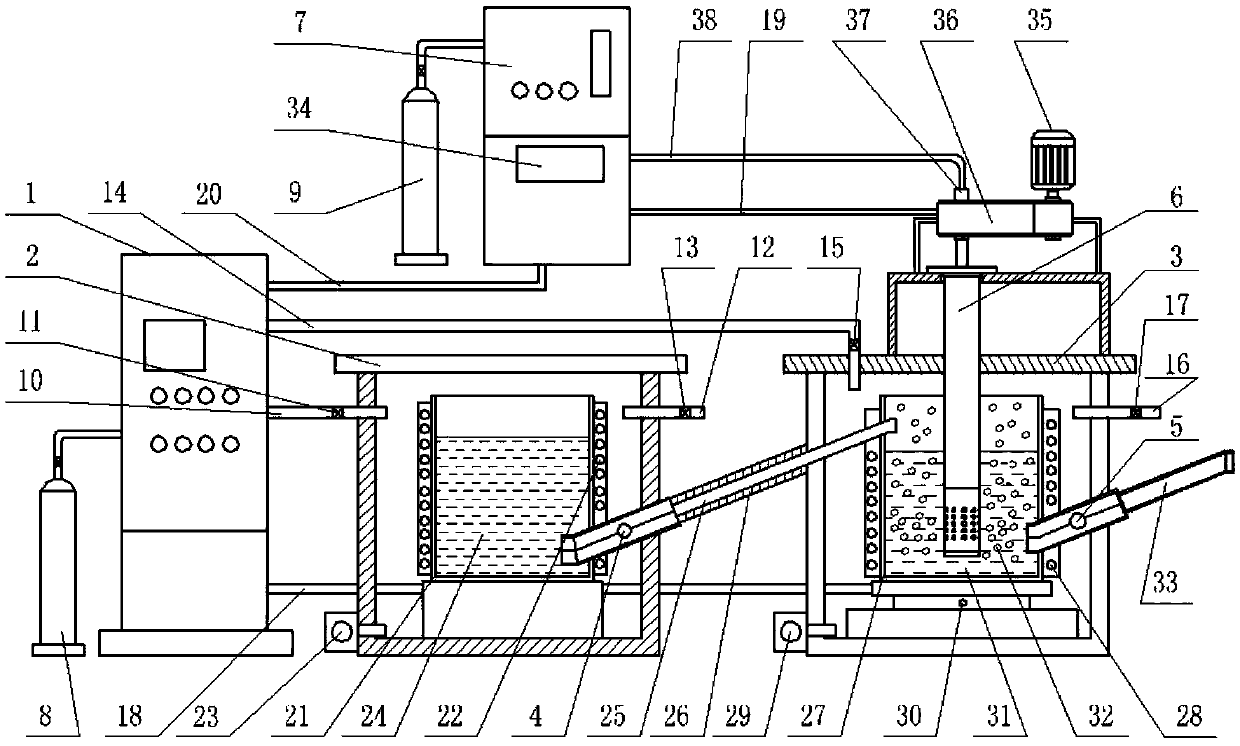

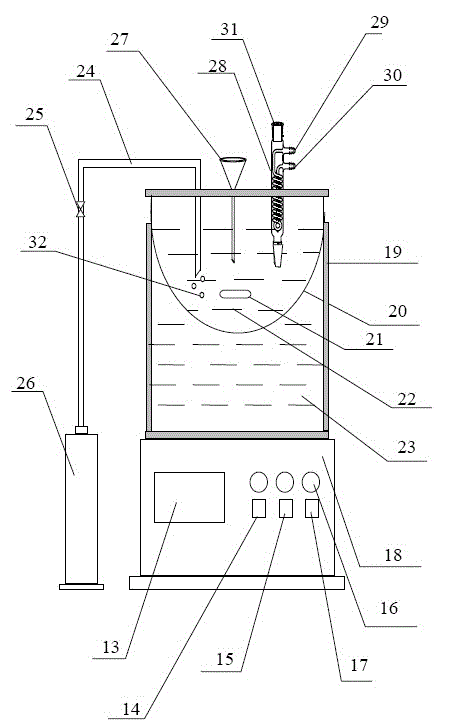

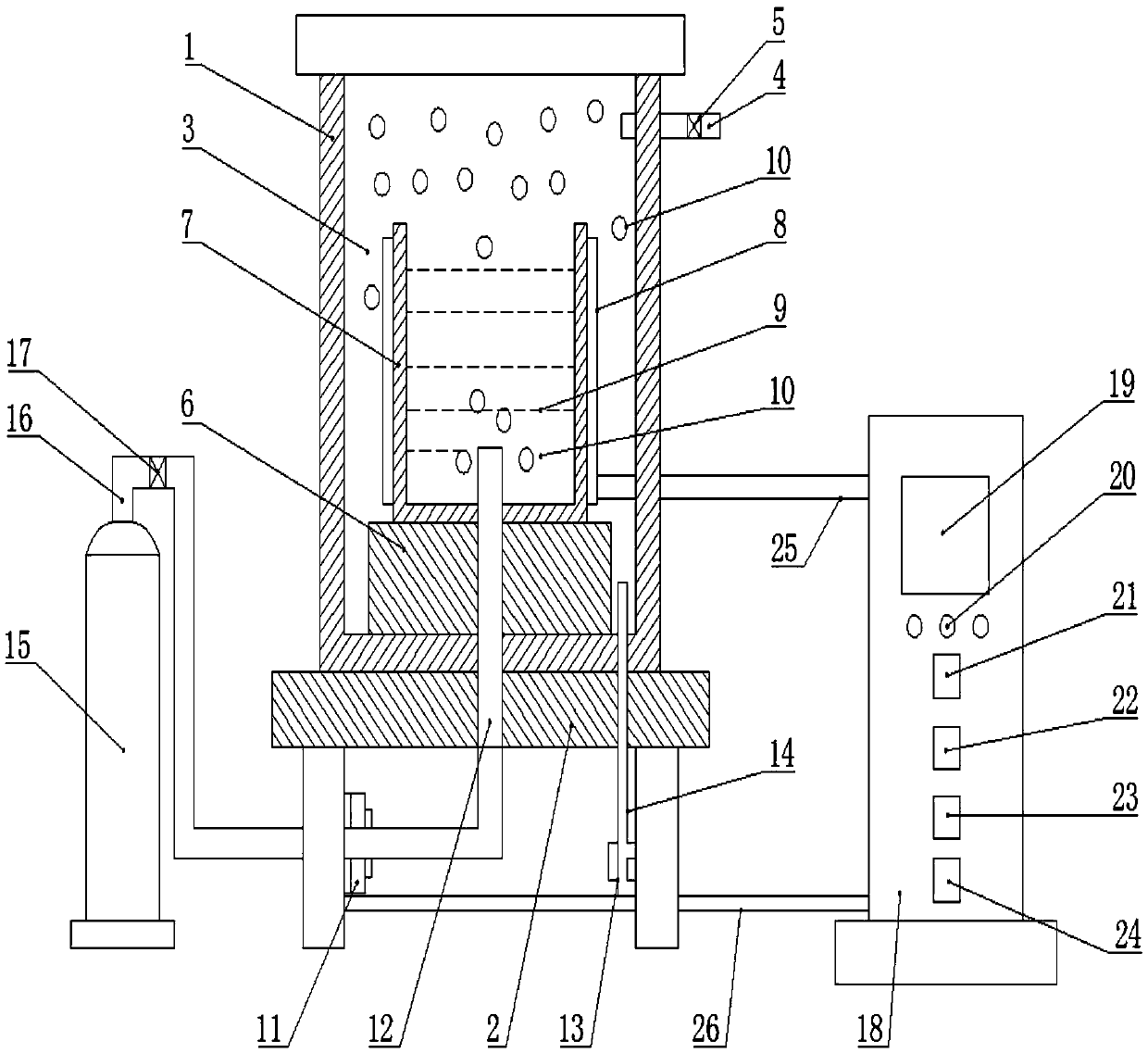

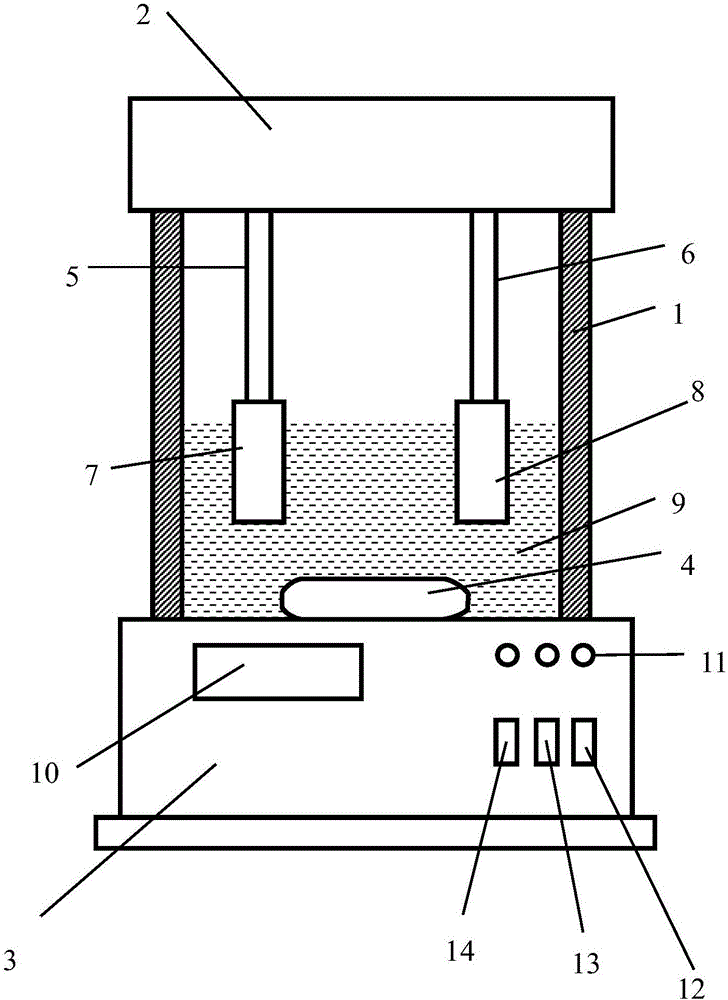

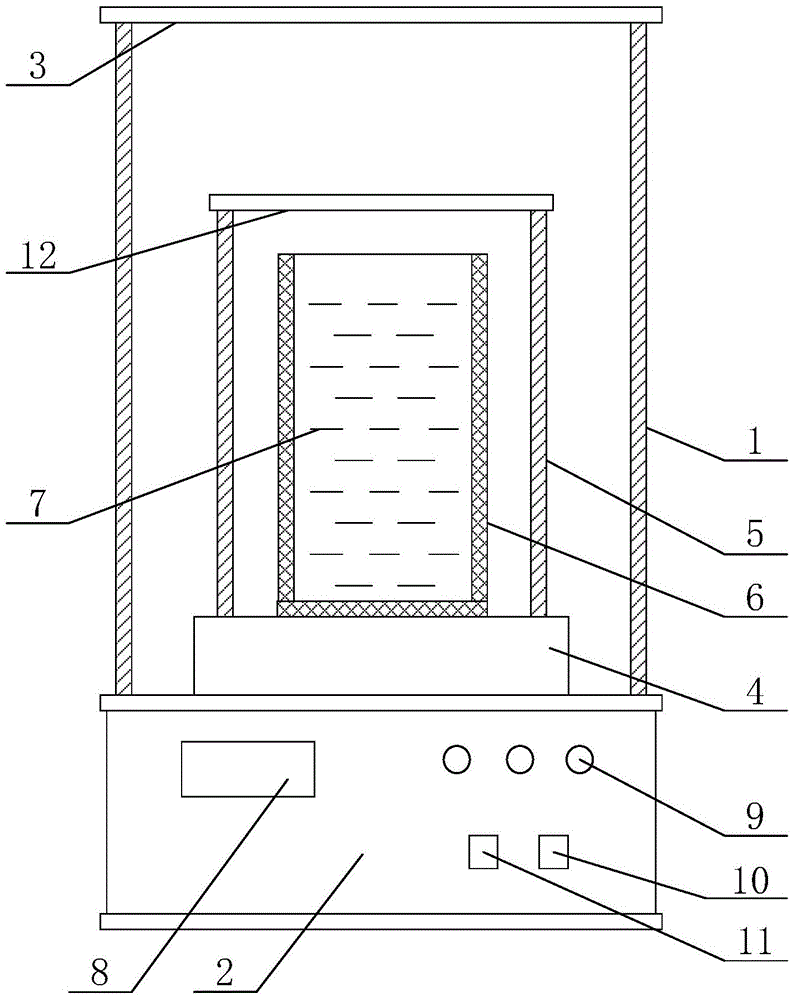

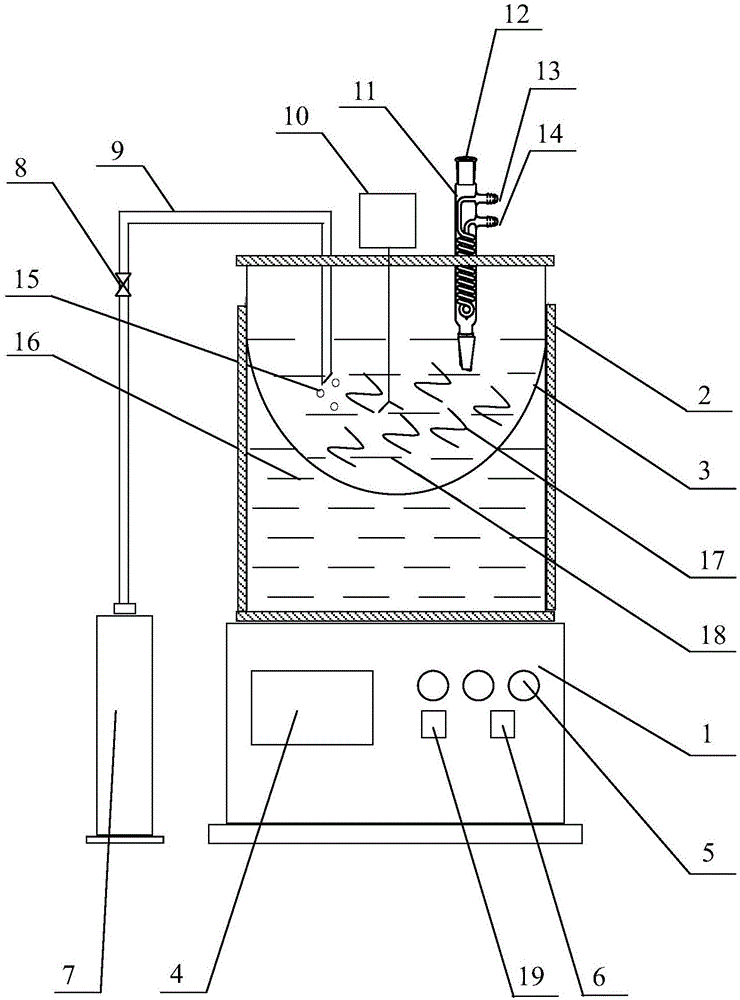

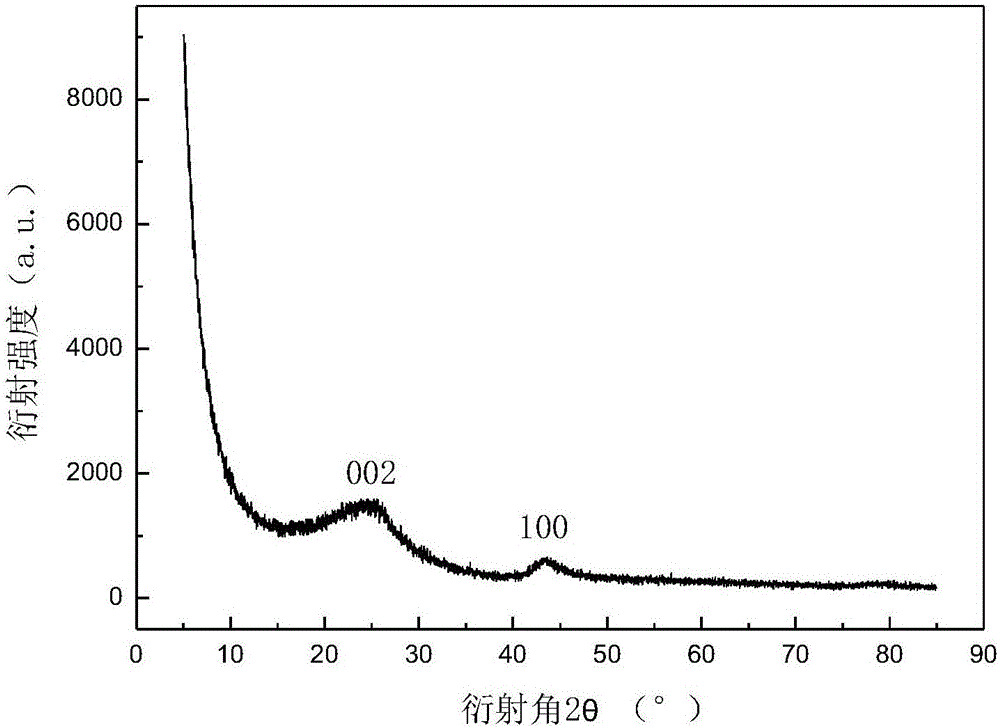

Preparation method of graphene-reinforced aluminum matrix composite

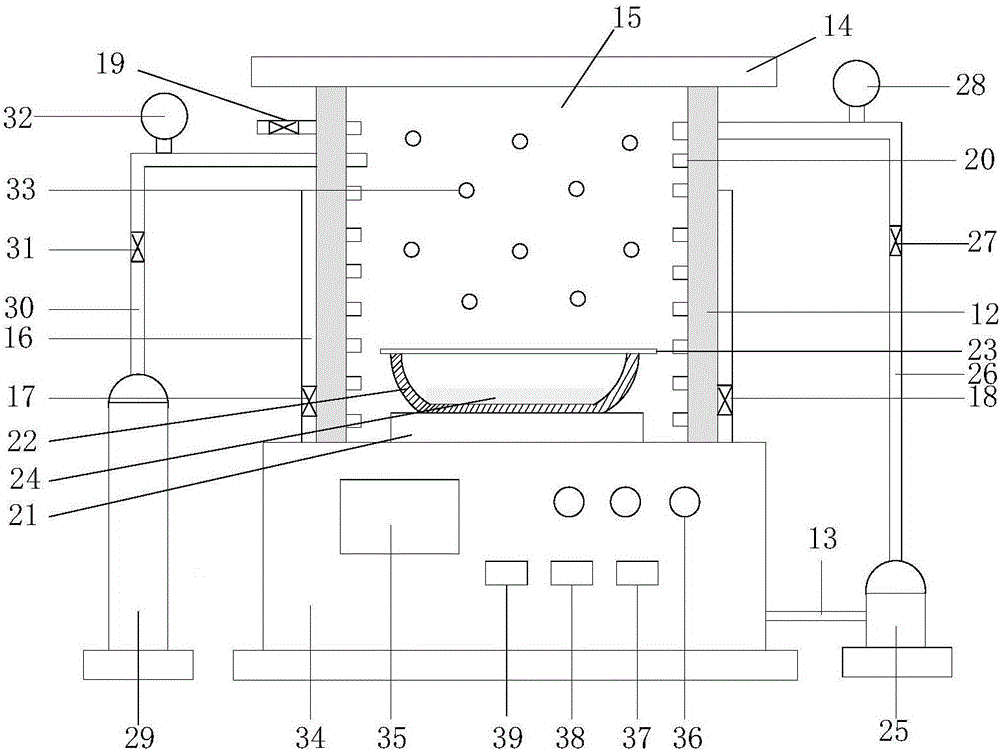

The invention relates to a preparation method of a graphene-reinforced aluminum matrix composite. Aiming at the conditions that graphene is nonuniformly dispersed in an aluminum alloy matrix and is difficult to combine with the matrix, the preparation method adopts a semi-solid squeeze casting method, and comprises the steps of smelting in a smelting and stirring atmosphere oven, electromagnetically stirring, pouring, and conducting squeeze casting to obtain the graphene-reinforced aluminum matrix composite. The preparation method is advanced in process, accurate and detailed in data, and precise in process; a slurry is pure; a metallographic structure is good in compactness without the phenomenon of shrinkage porosity; the prepared graphene-reinforced aluminum matrix composite has the hardness reaching to 87 HB, the tensile strength reaching to 255 MPa, the elongation reaching to 8%, and the compactness reaching to 99.6%; and the preparation method is the advanced preparation method of the graphene-reinforced aluminum matrix composite.

Owner:ZHONGBEI UNIV

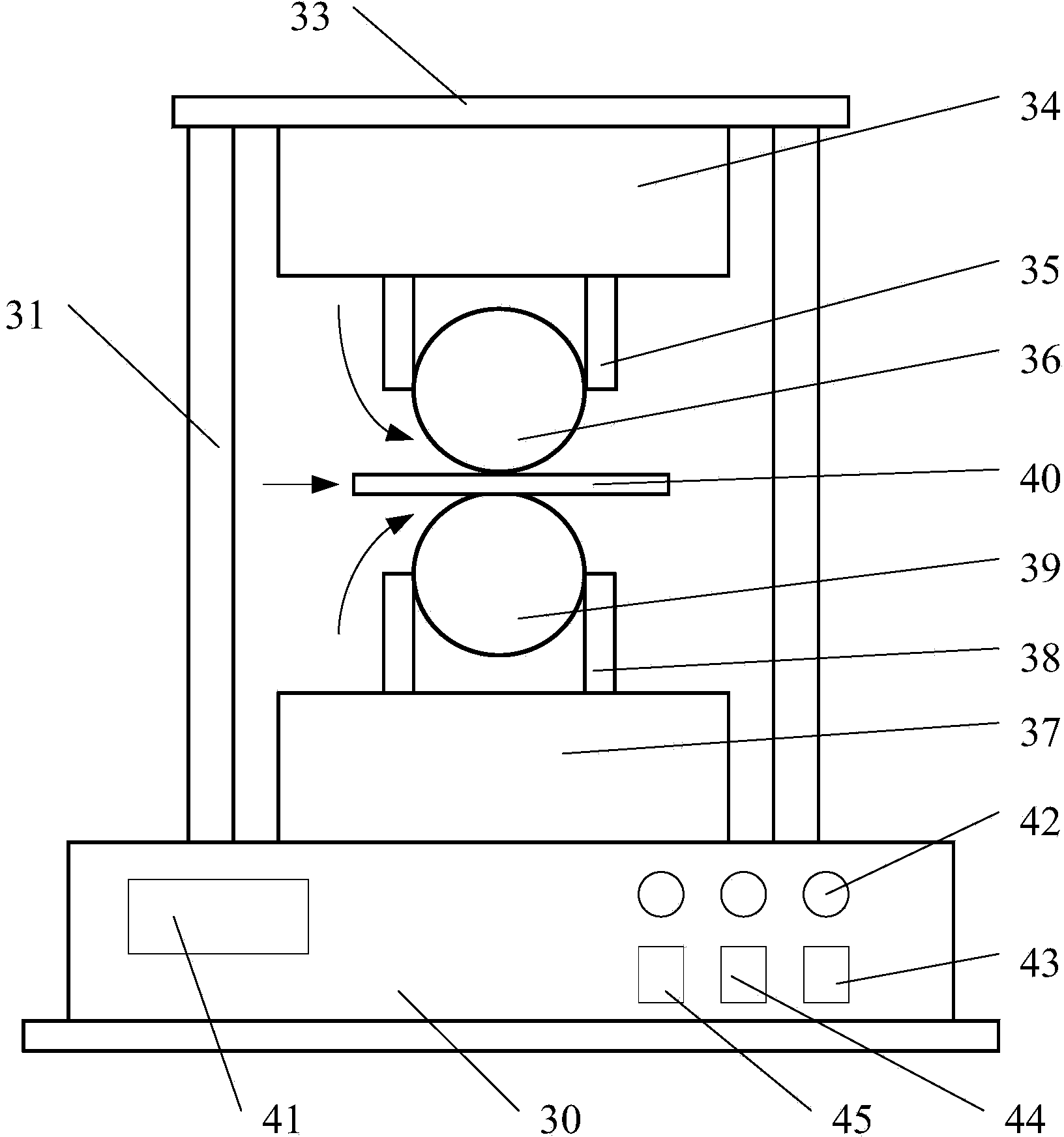

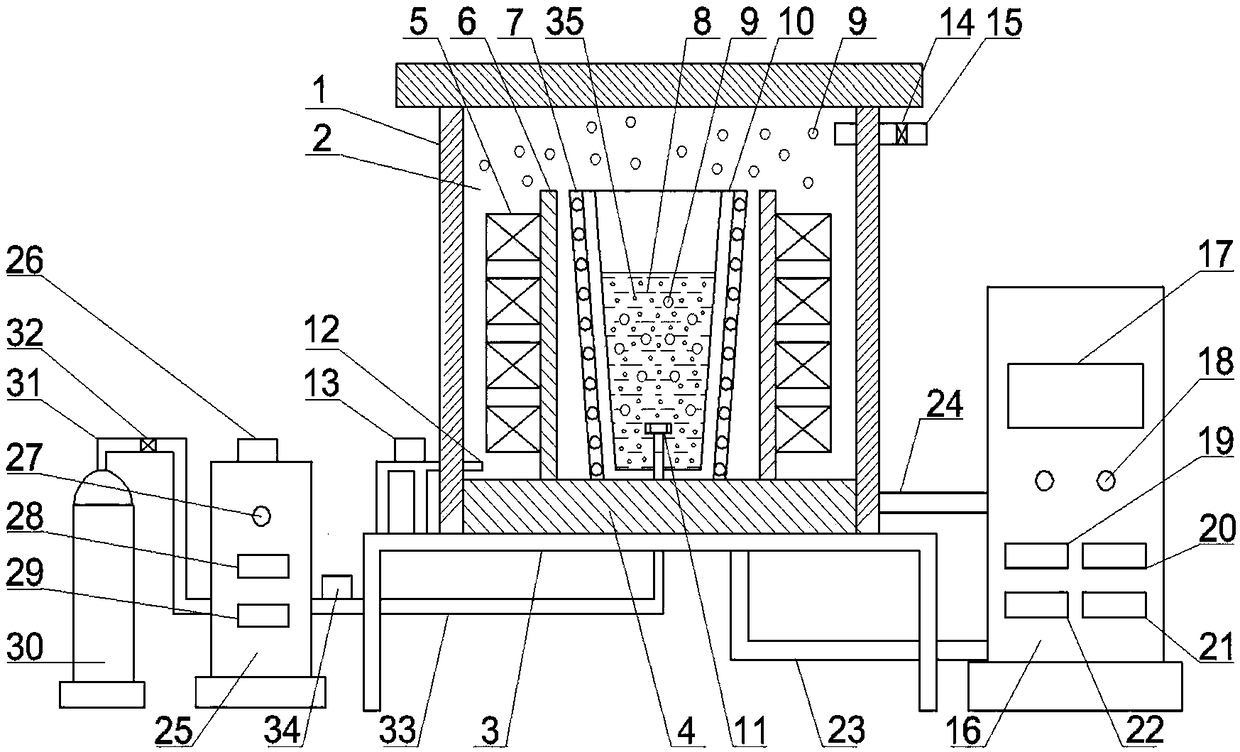

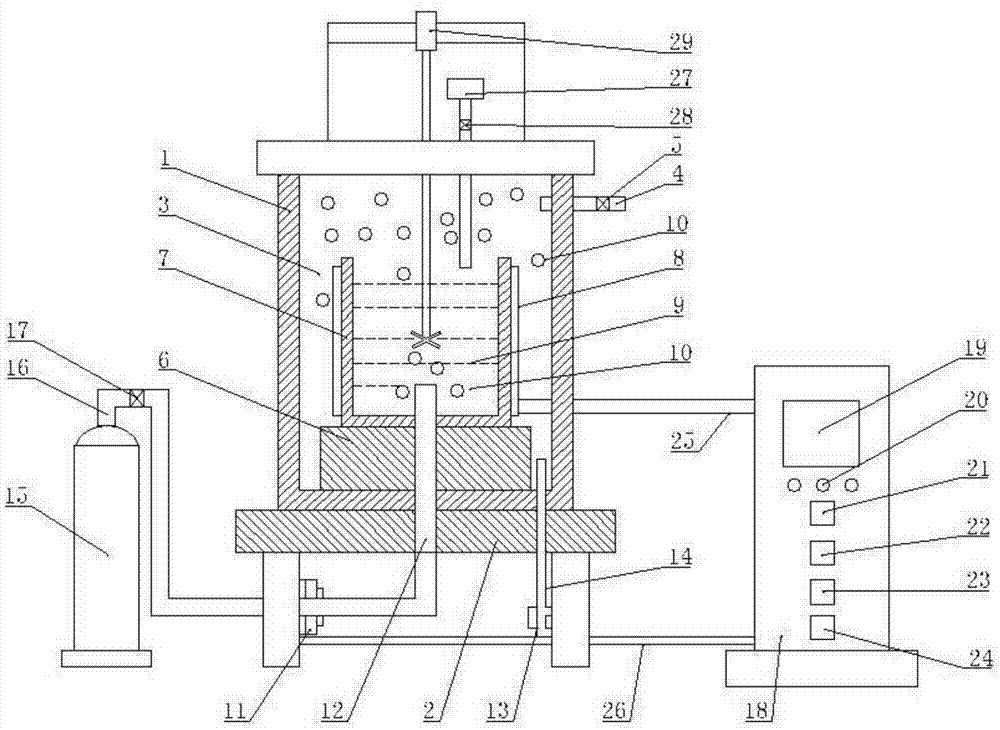

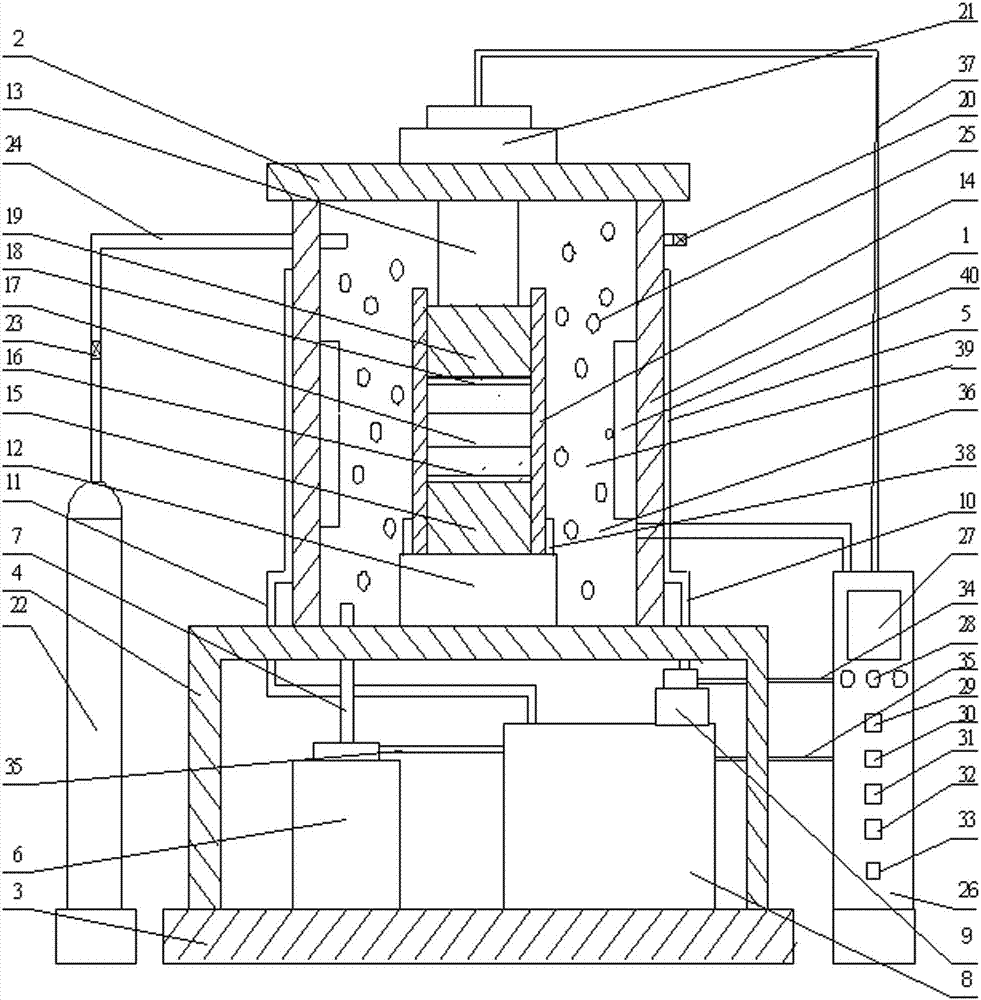

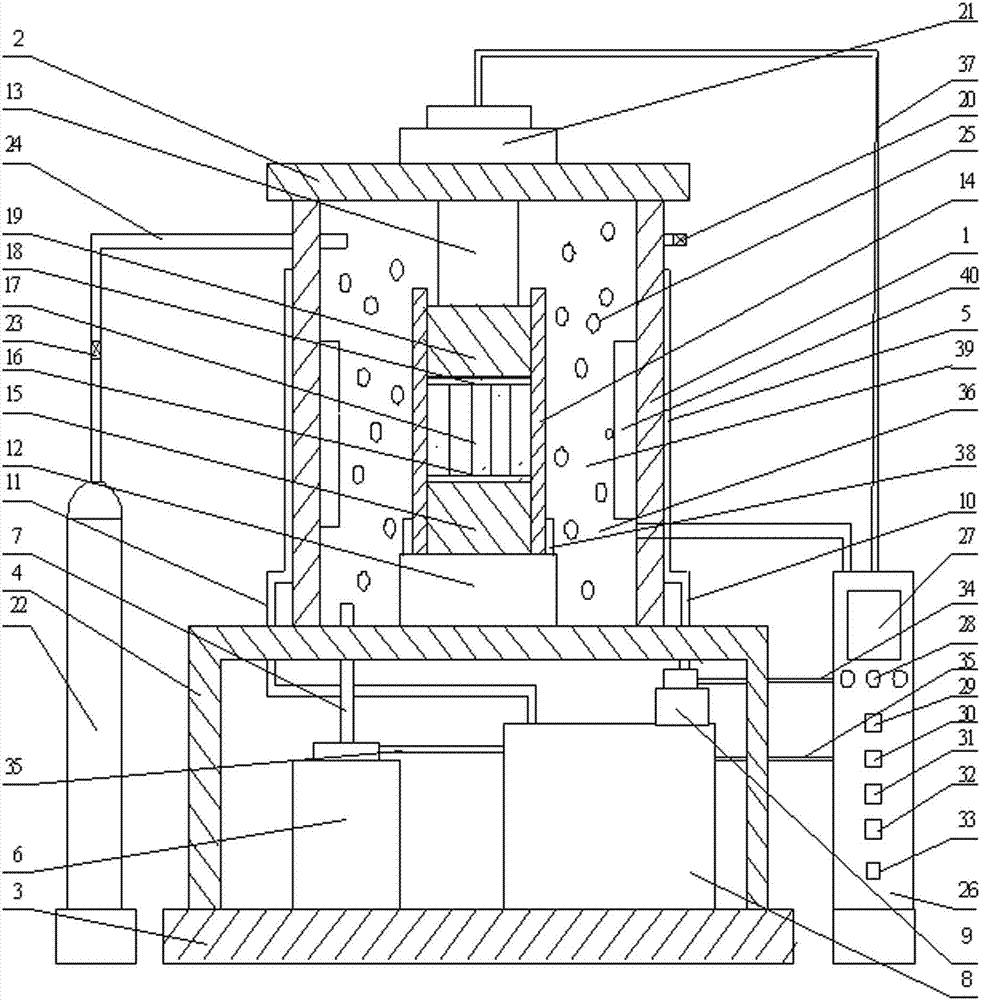

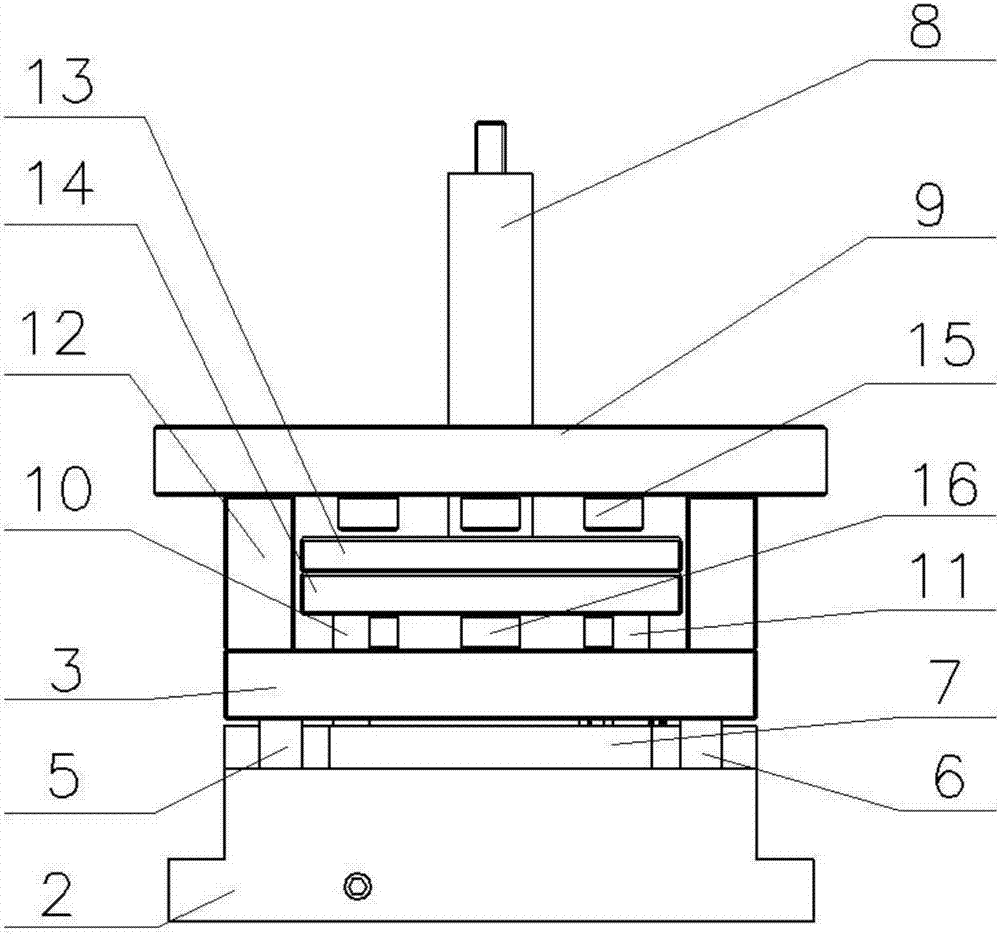

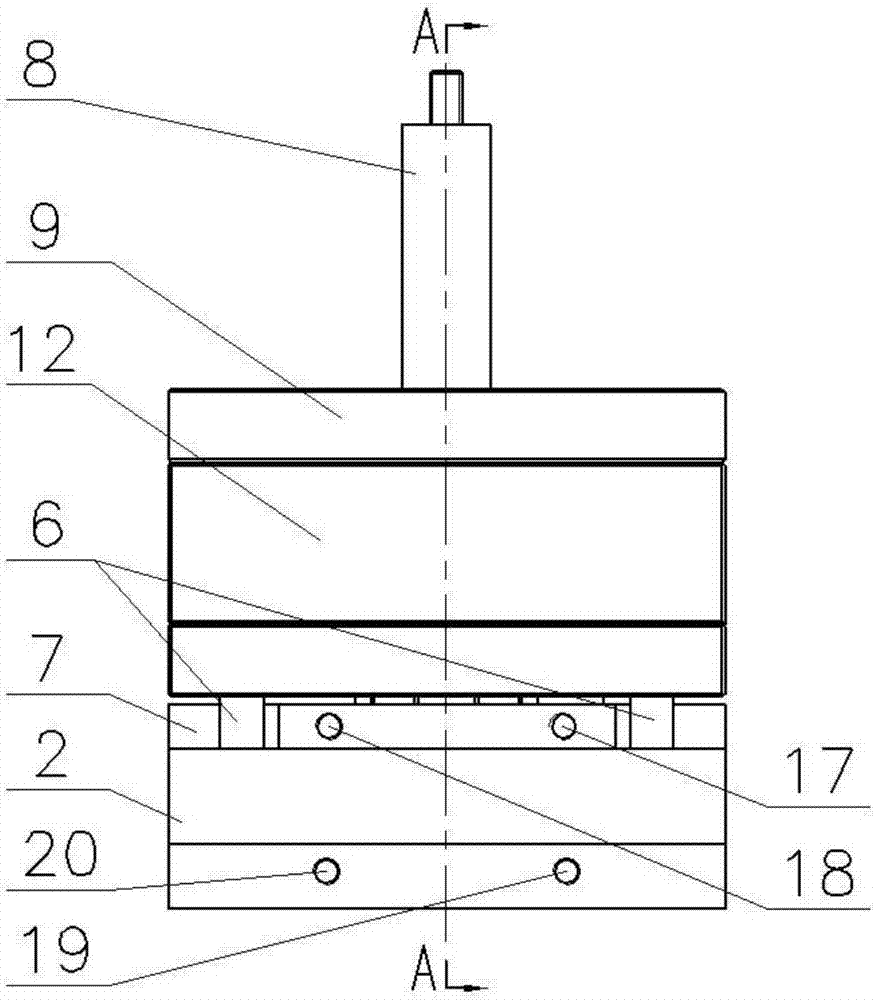

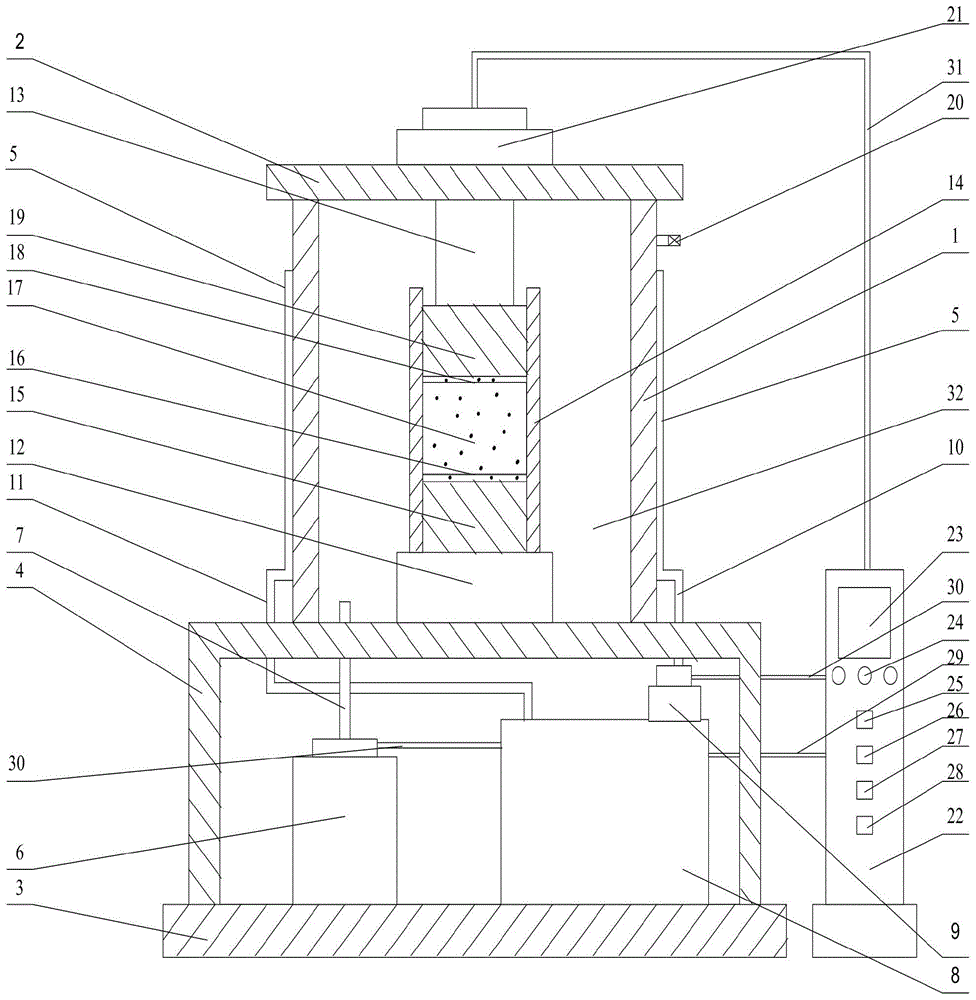

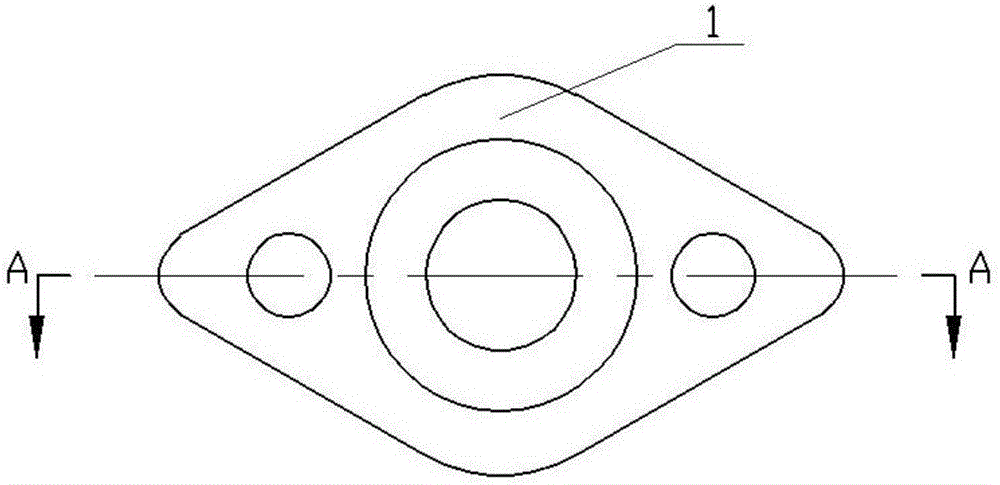

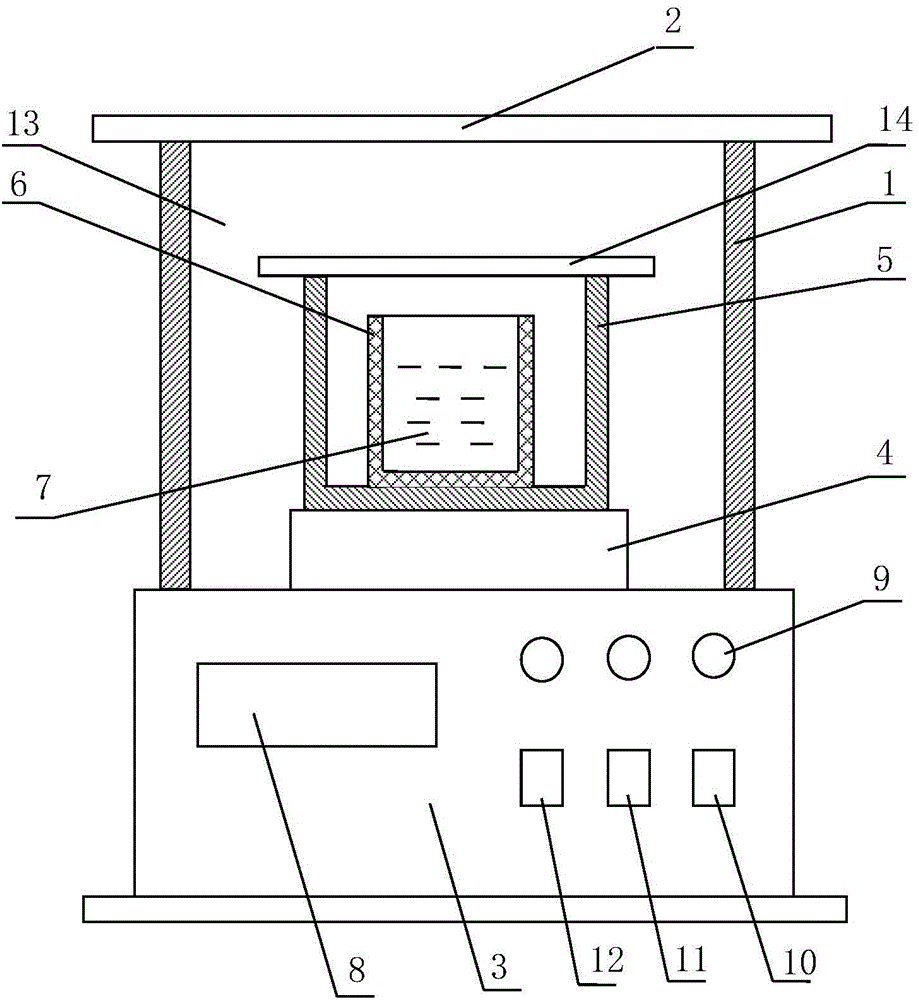

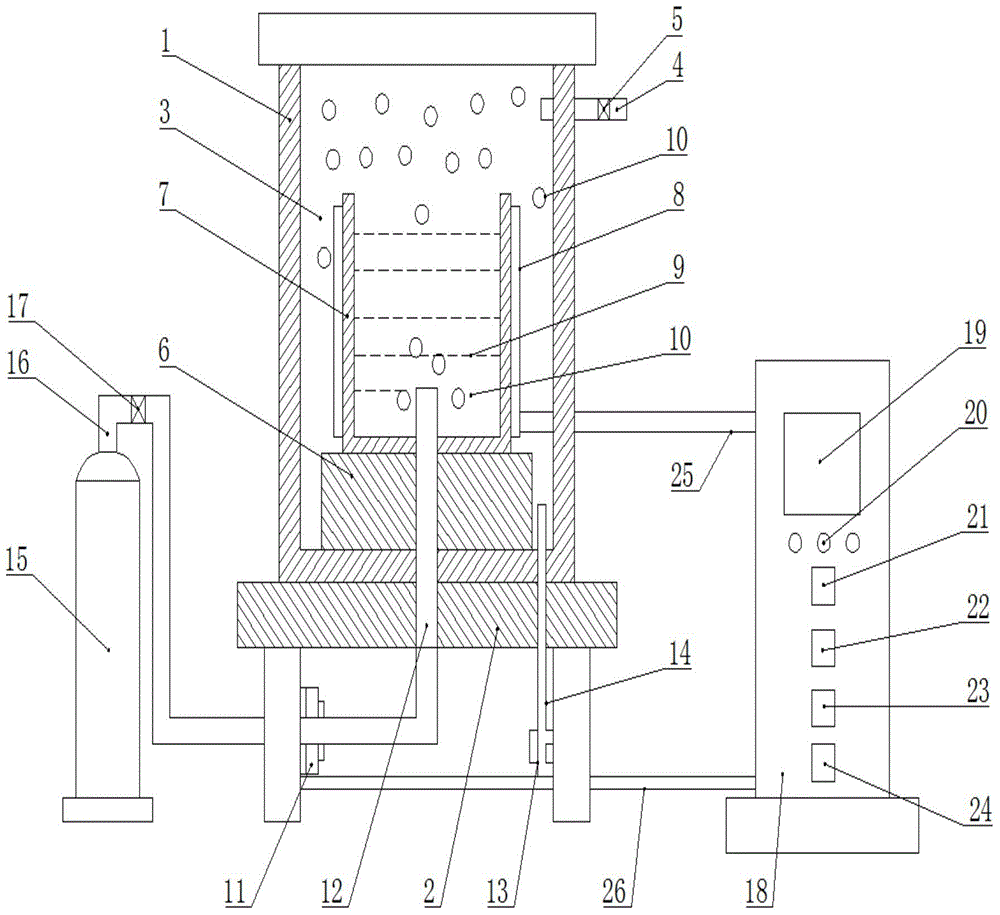

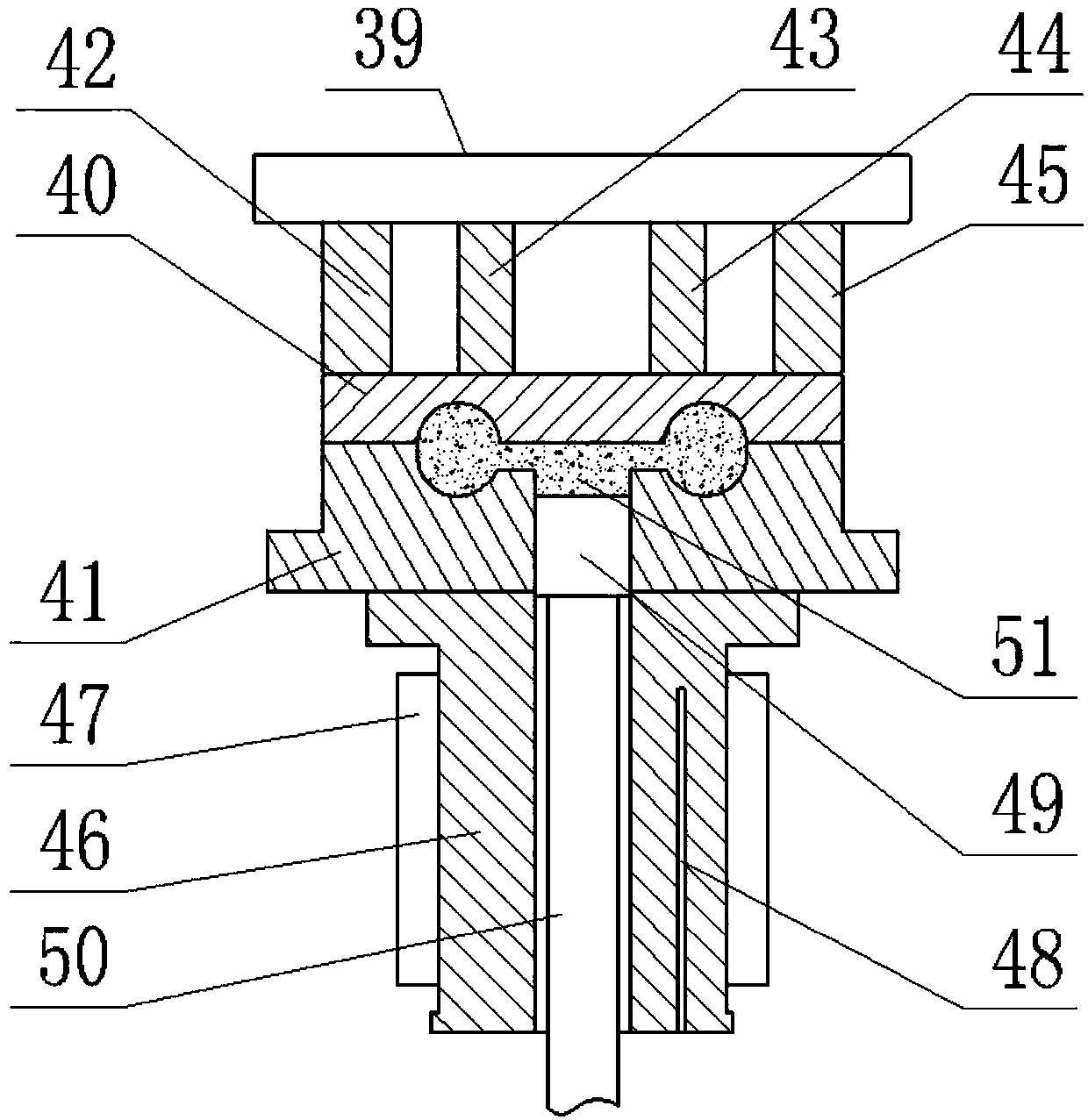

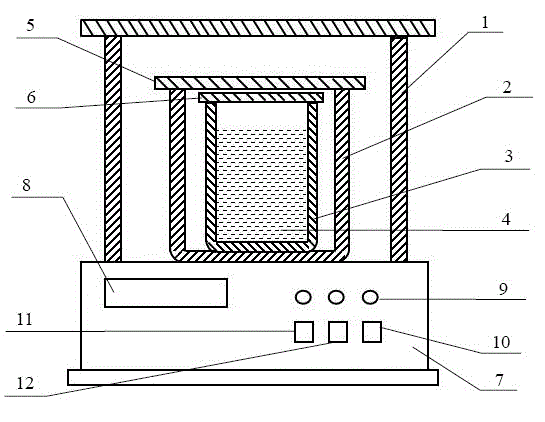

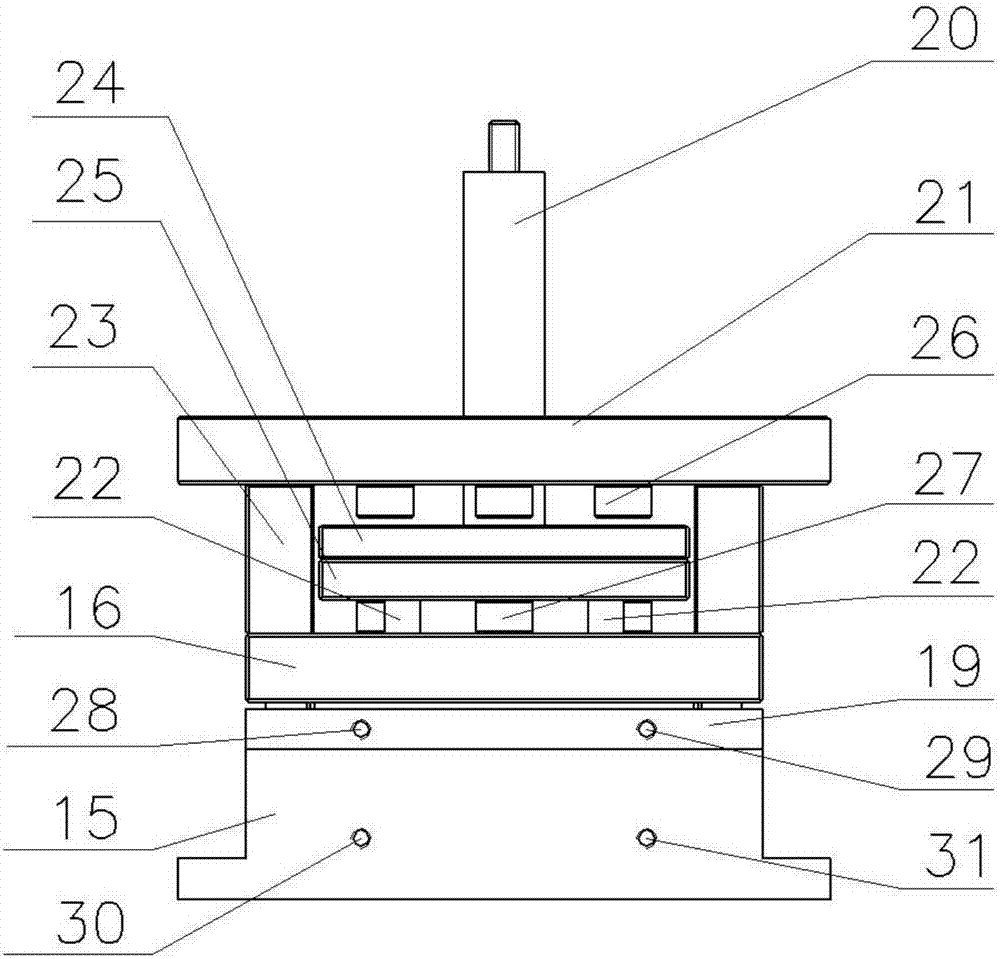

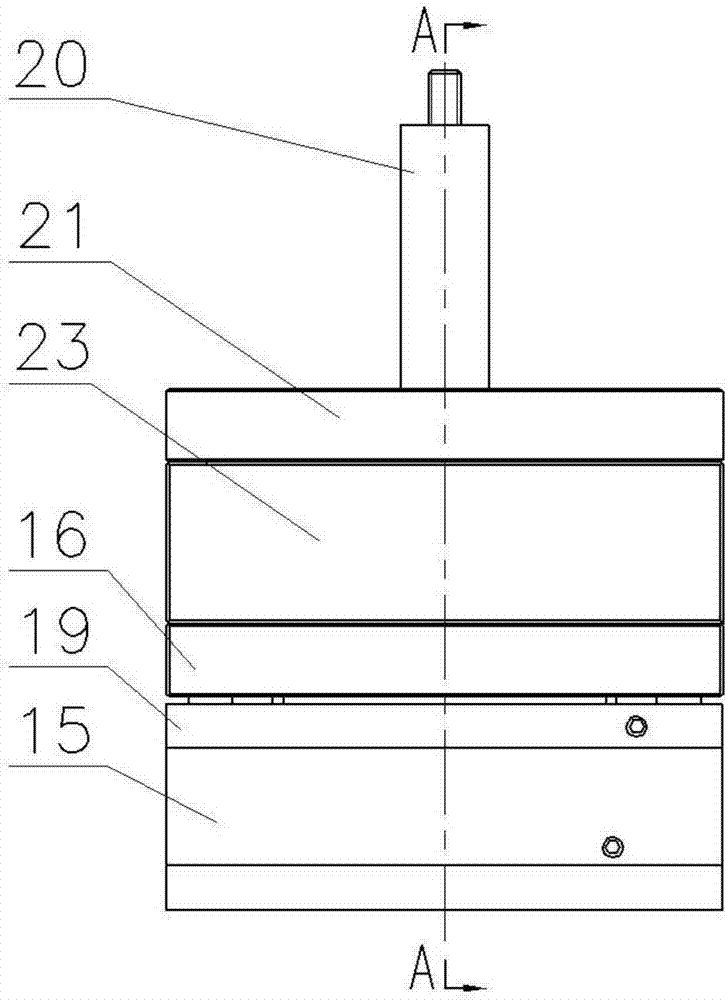

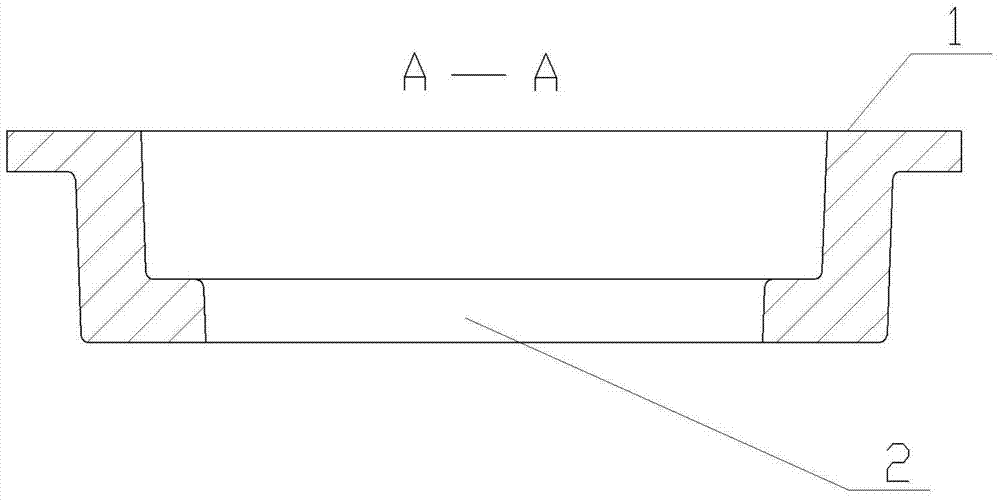

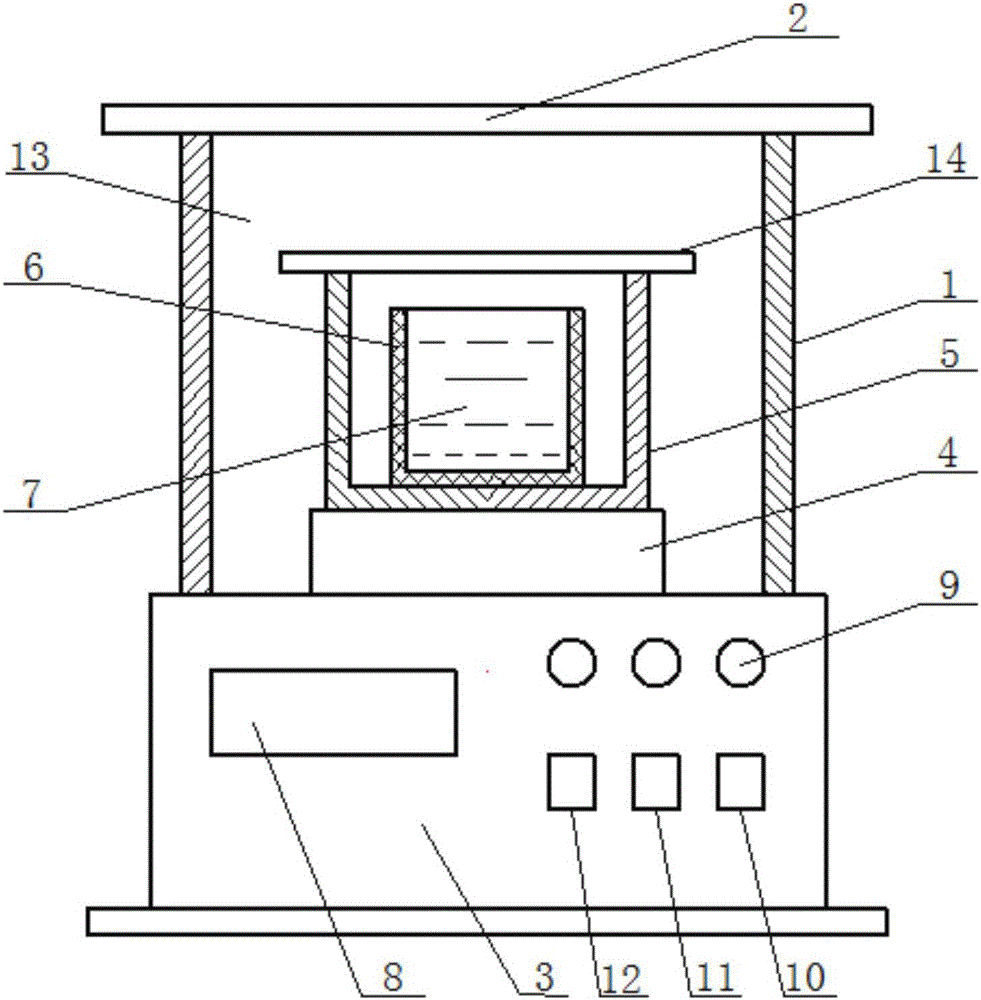

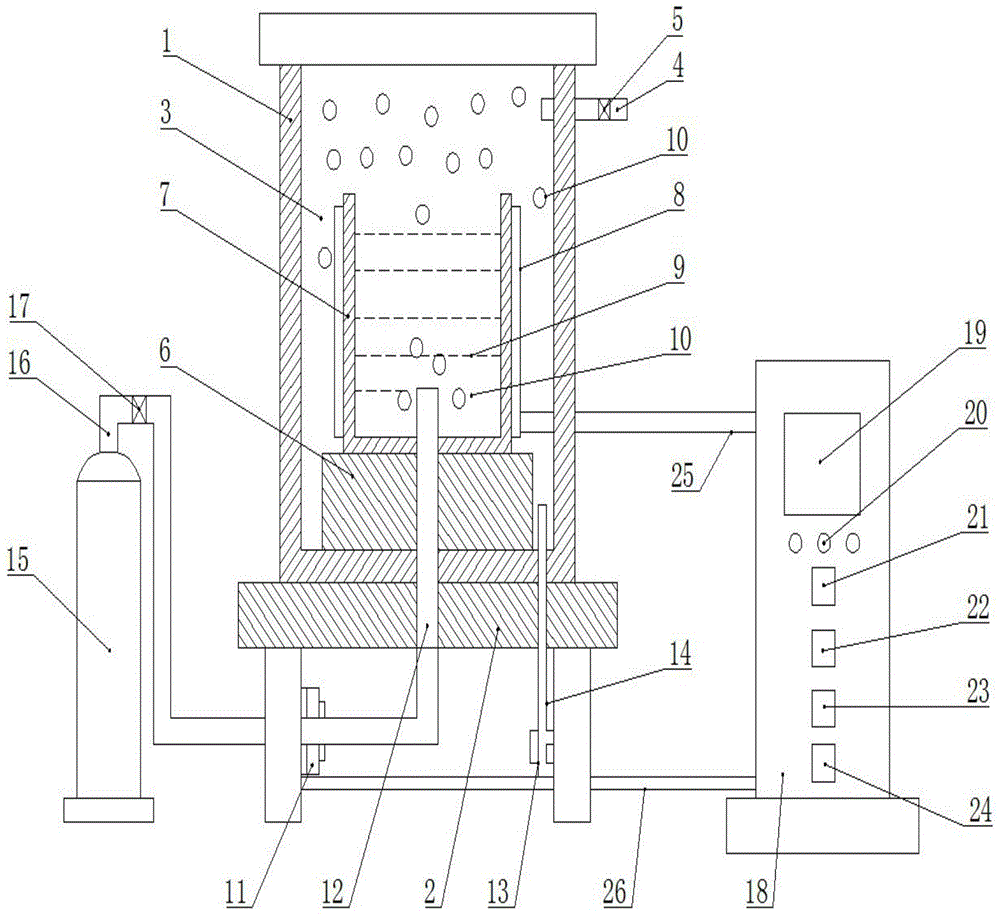

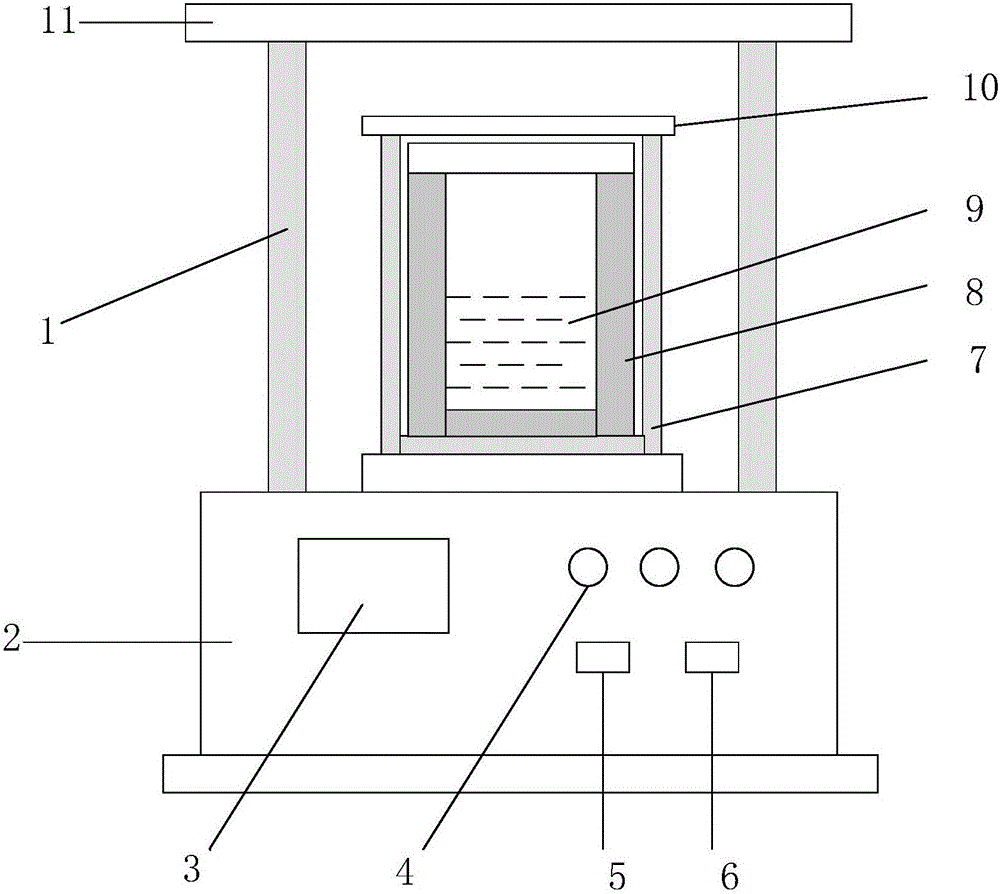

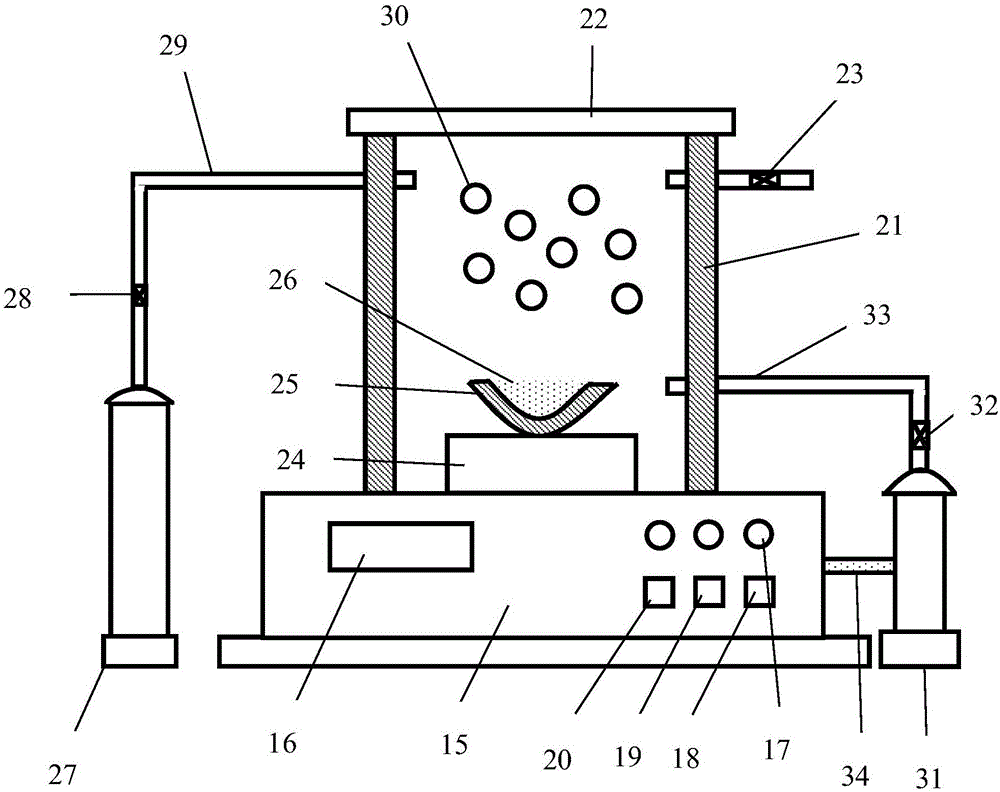

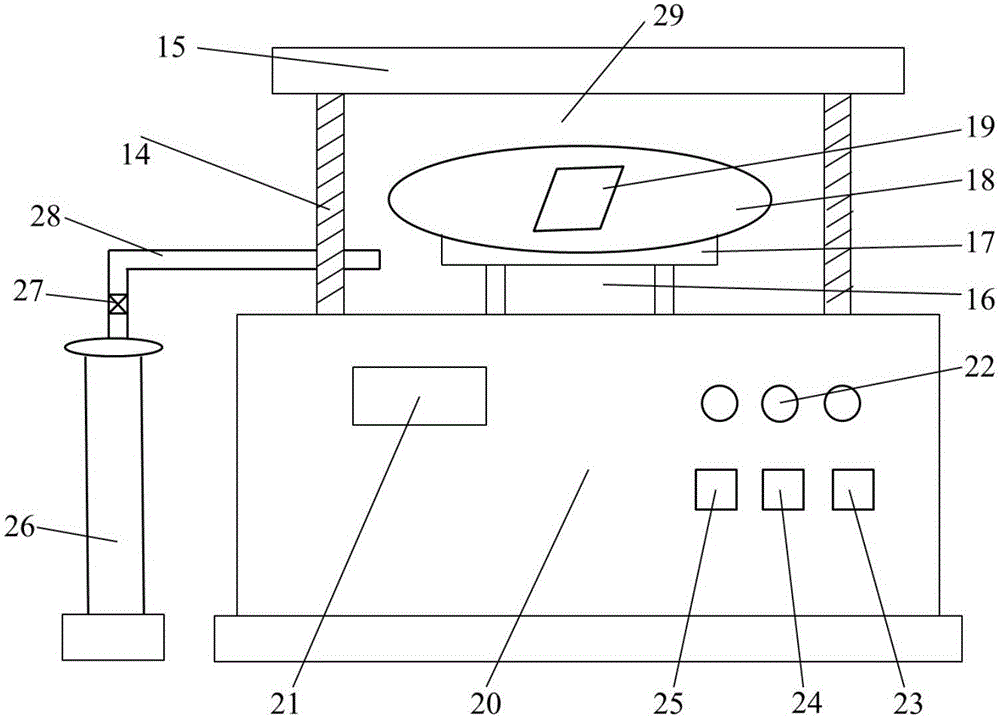

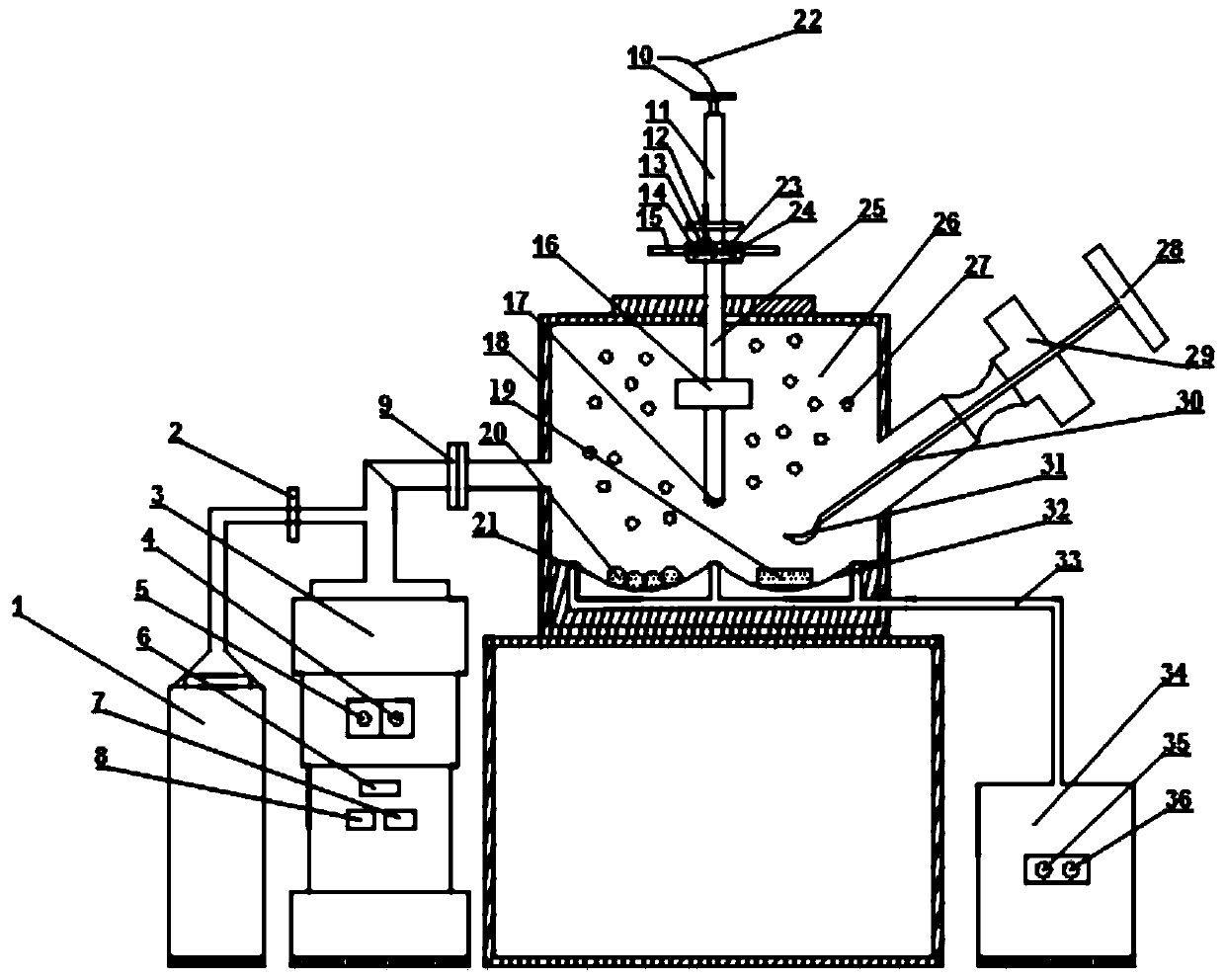

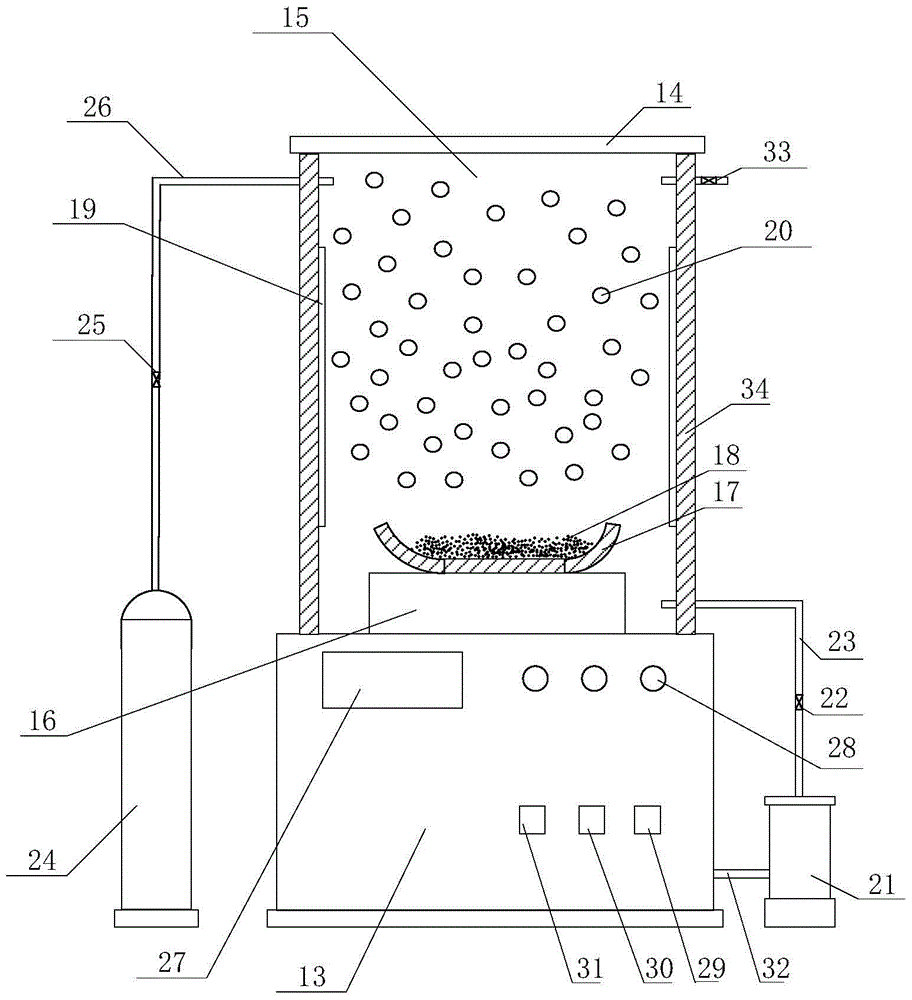

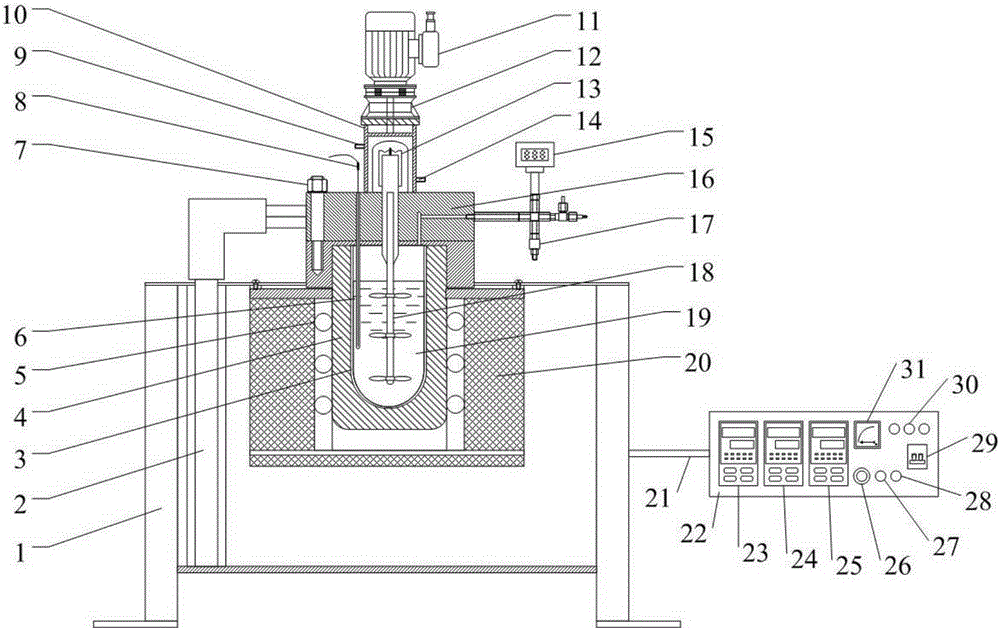

Semi-solid squeezing casting method and system for aluminum alloy

The invention relates to a semi-solid squeezing casting method and system for aluminum alloy and belongs to the technical field of preparation and application of nonferrous materials. The method comprises the following steps that firstly, an aluminum alloy block is cut into aluminum alloy pieces, the aluminum alloy pieces are wrapped with aluminum foil correspondingly, and then the wrapped aluminum alloy pieces are preheated; the preheated aluminum alloy pieces are smelted, so that molten aluminum alloy is obtained; the molten aluminum alloy is poured into a heat preservation device for heat preservation via a sprue with a bent channel or an inverted conical channel, and semi-solid aluminum alloy slurry is obtained; the semi-solid aluminum alloy slurry is poured into a heat preservation squeezing mold to be subjected to squeezing molding treatment; and finally, pressure application continues after the squeezing molding treatment is completed, then a casting is jacked out and subjected to air cooling, and an semi-solid aluminum alloy squeezed casting is obtained. According to the preparation method, the advanced process is achieved, procedures are precise, data are accurate and full, and after heat treatment of the prepared semi-solid aluminum alloy squeezed casting, the hardness of the casting can be up to 82.9 HB and the tensile strength of the casting can be up to 279 Mpa.

Owner:ZHONGBEI UNIV

Squeeze casting method for mixed-particle-reinforced type aluminum matrix composite

The invention relates to a squeeze casting method for a mixed-particle-reinforced type aluminum matrix composite. The squeeze casting method for the mixed-particle-reinforced type aluminum matrix composite aims at the problem that the tension strength and the hardness of an aluminum matrix composite are low. According to the squeeze casting method, an aluminum alloy serves as a matrix material, aluminum-copper-iron-beryllium quasicrystal and zirconium carbonate serve as reinforcing agents, an al-sc master alloy serves as a modificator, the aluminum alloy, aluminum-copper-iron-beryllium quasicrystal, the zirconium carbonate and the al-sc master alloy are subjected to melting in a vacuum melting furnace, mechanical stirring, argon bottom blowing protecting, squeezing and heat treatment, and then the mixed-particle-reinforced type aluminum matrix composite is prepared. According to the squeeze casting method, the technology is advanced, the processes are rigorous, and data are precise, full and accurate; the mechanical performance of the aluminum matrix composite is enhanced greatly, the tension strength reaches to 409 MPa, the hardness reaches to 150.2 HV, and the elongation reaches to 4.7%; and the squeeze casting method for the mixed-particle-reinforced type aluminum matrix composite is an advanced method.

Owner:WENXI COUNTY REGAL MAGNESIUM

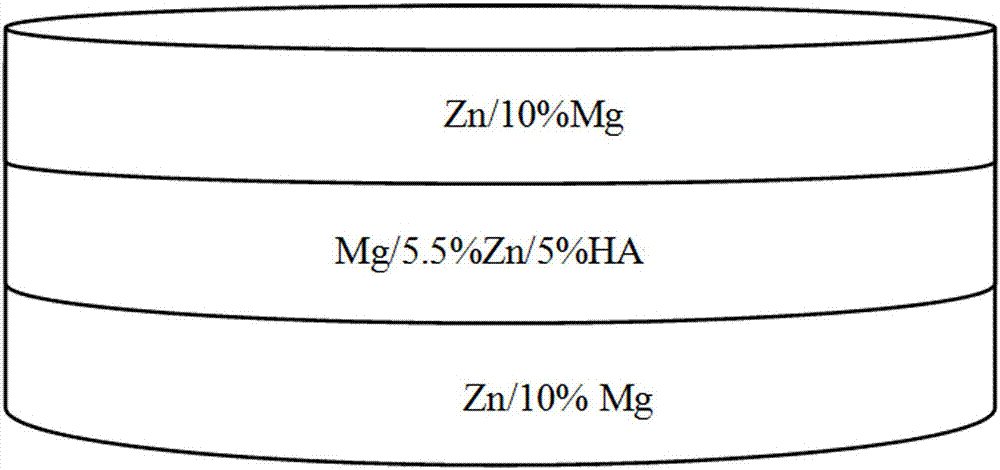

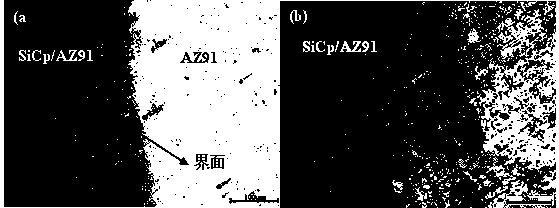

Preparing method of zinc magnesium function gradient biological composite

ActiveCN107385251AImprove the bonding strength of the interfaceNo debondingGradient materialStress shielding

The invention relates to a preparing method of a zinc magnesium function gradient biological composite. Magnesium powder, zinc powder and HA powder are adopted to serve as raw materials, ball milling powder mixing, die filling and vacuum discharge plasma sintering are carried out, and a zinc magnesium composite of two gradient structures is prepared. The preparing method is advanced in technology, data are full and accurate, a prepared zinc magnesium gradient material is high in combination strength on the interface, the debinding phenomenon is avoided, wear resistance and mechanical properties(the crush resistance strength is 293.66MPa, the elasticity modulus is 8.0 GPa, and breaking tenacity is 9.327 MPa.mm<1 / 2>) of all gradient layers are matched with the natural bone, the stress shielding effect is effectively avoided, and the preparing method is an ideal preparing method for a degradable biomedical metal gradient material.

Owner:TAIYUAN UNIV OF TECH

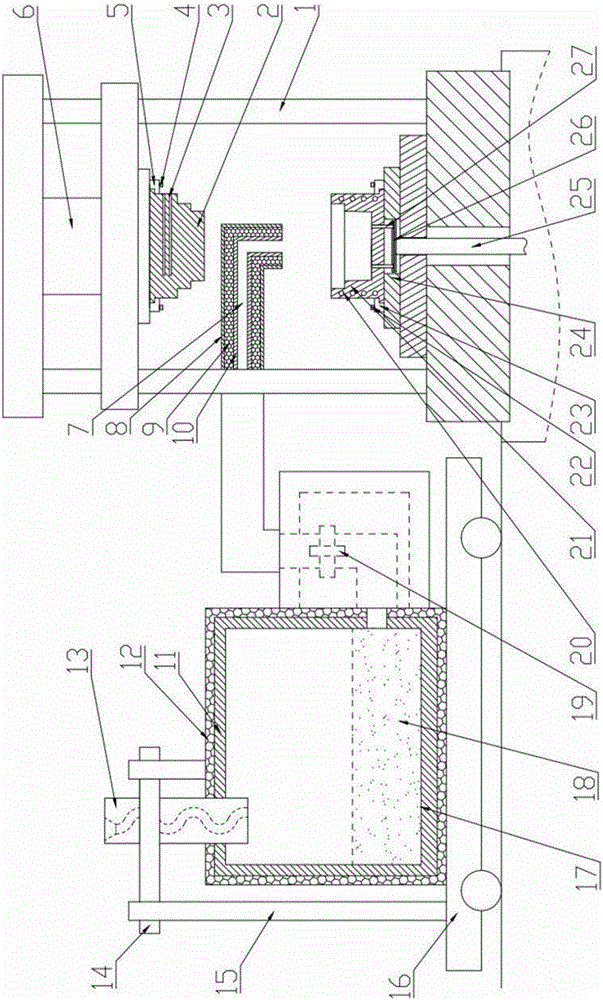

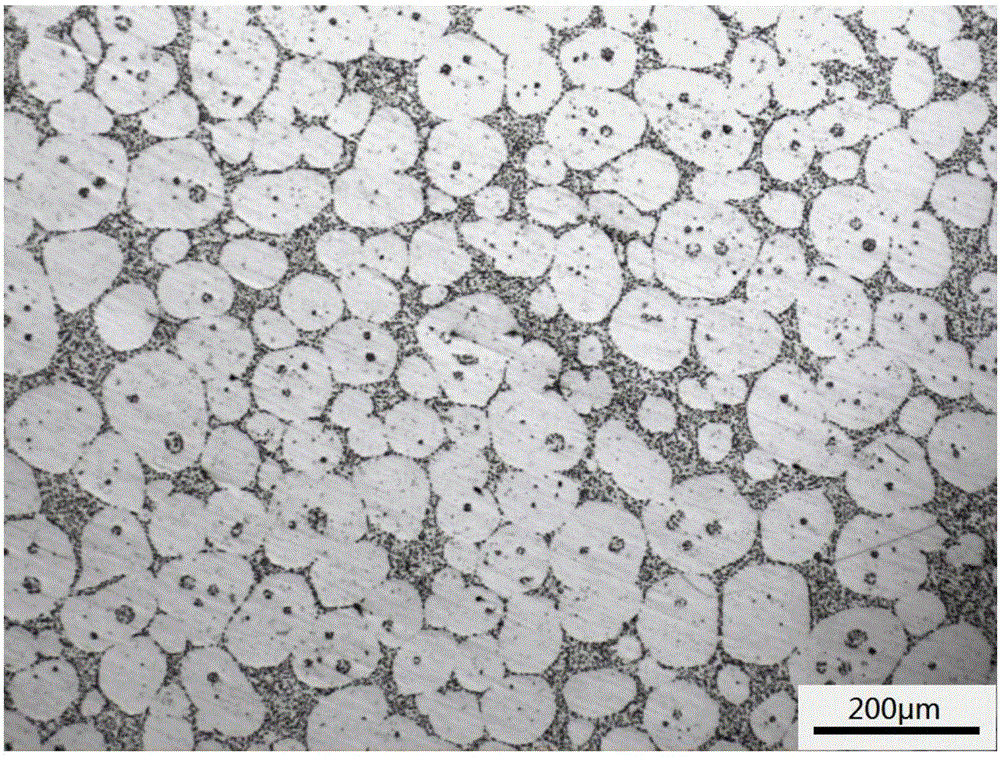

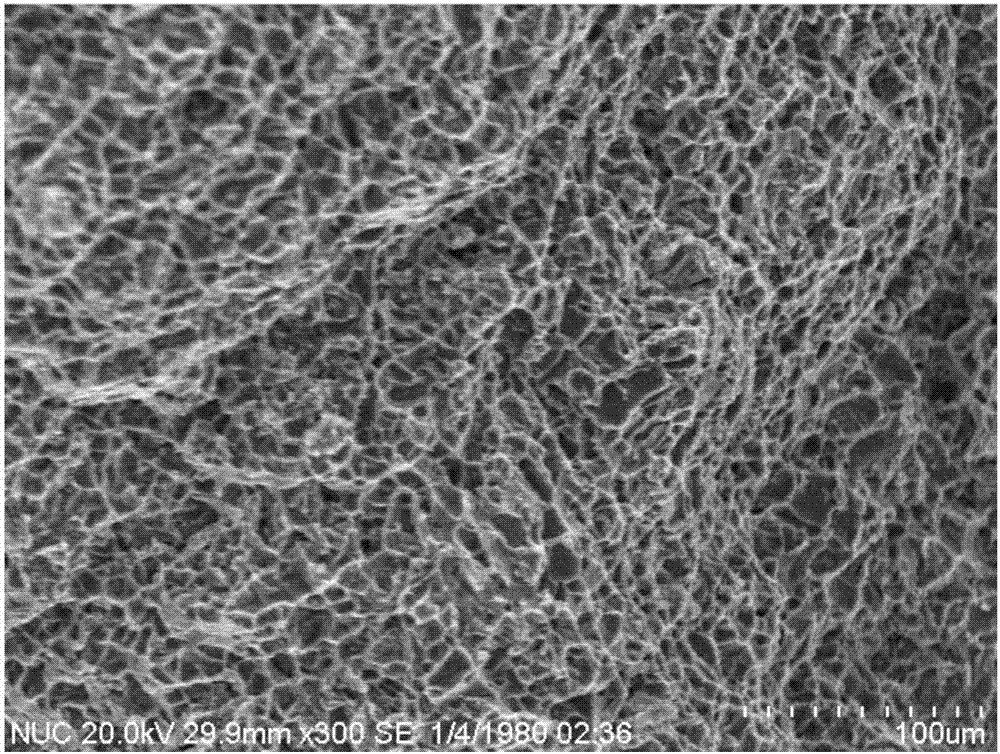

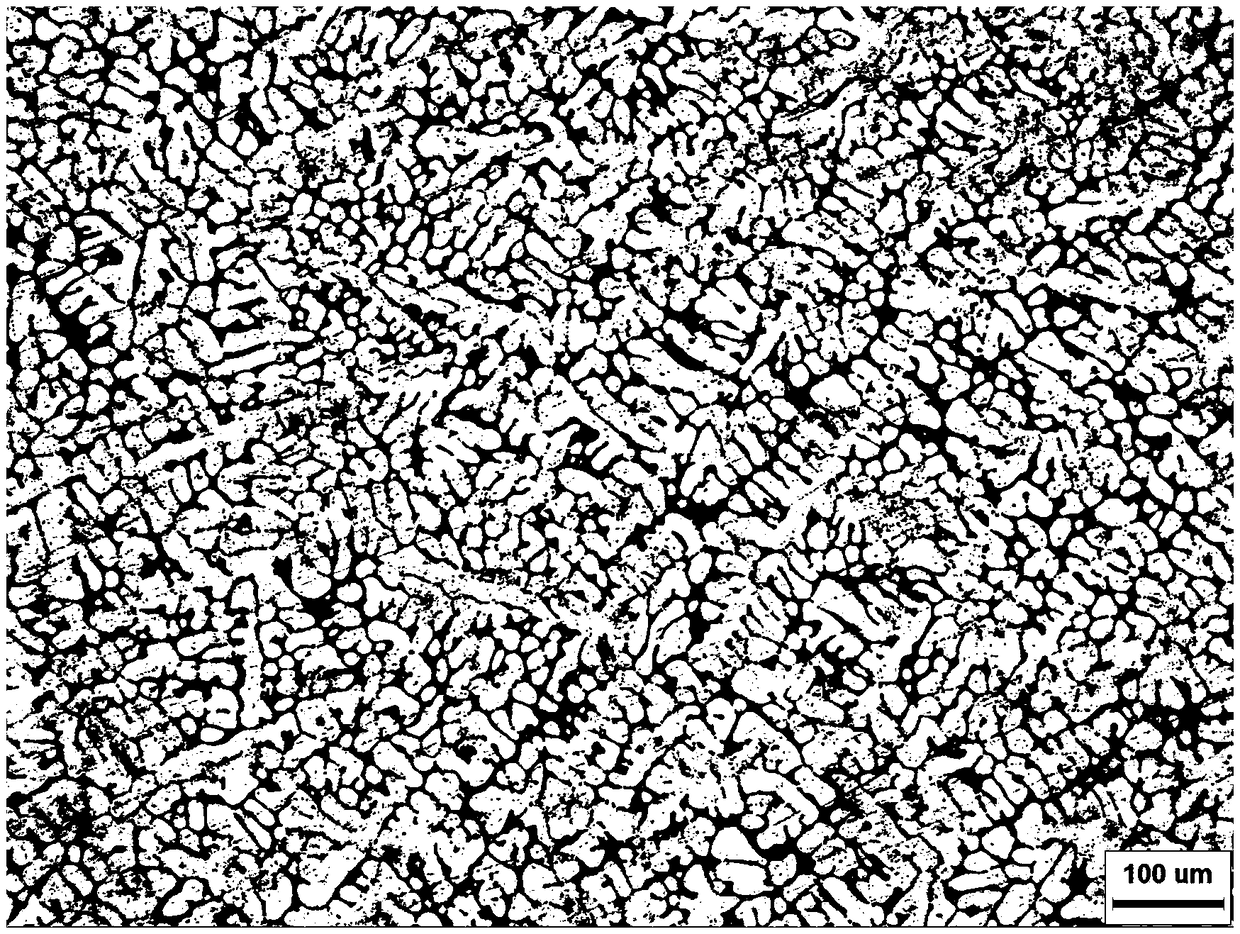

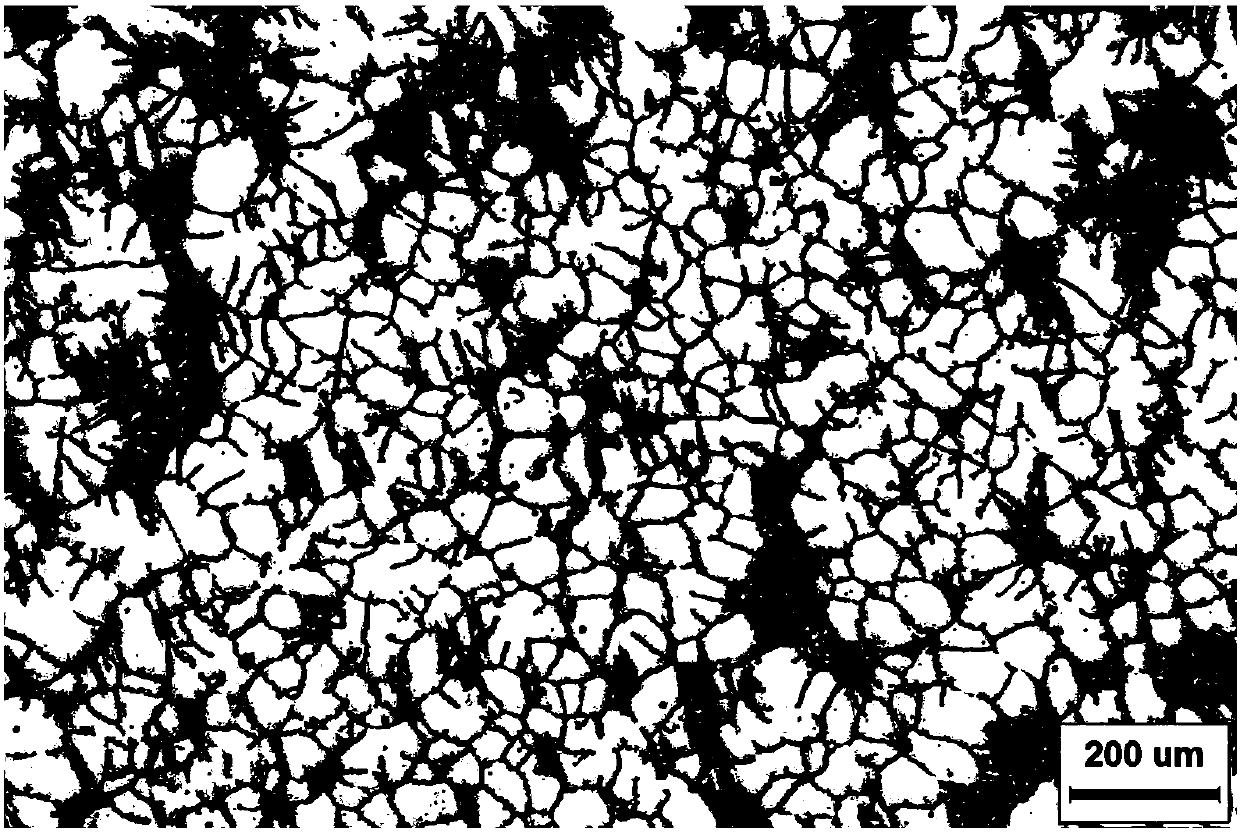

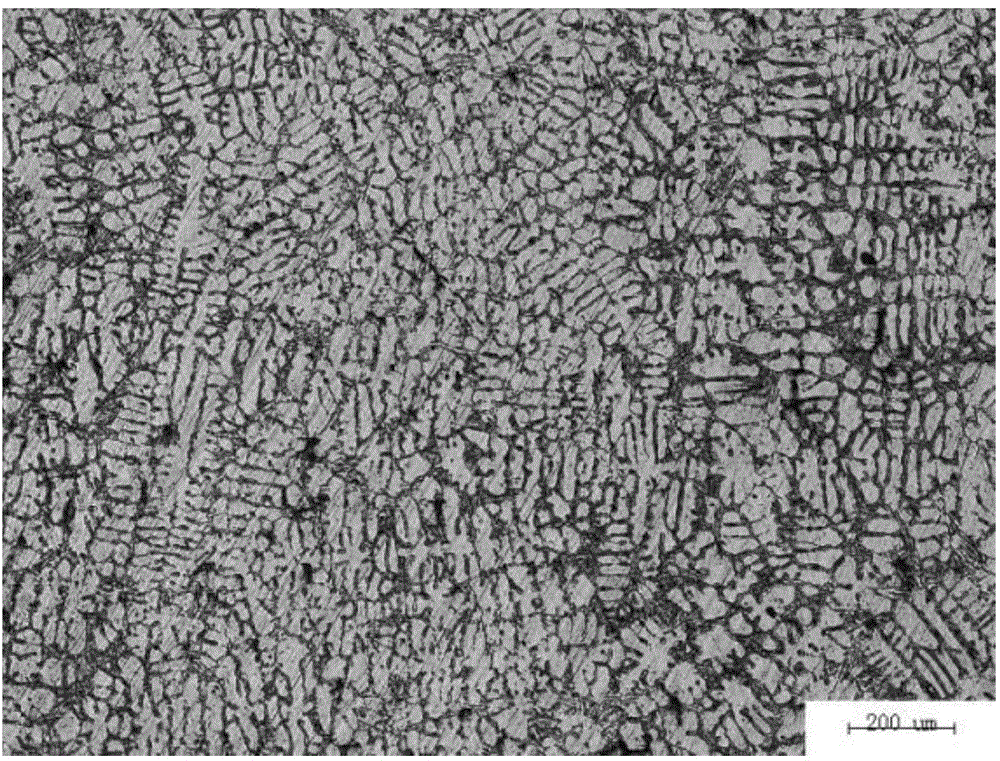

Aluminum alloy semisolid secondary combined extrusion casting method

The invention relates to an aluminum alloy semisolid secondary combined extrusion casting method to overcome the defects that in the current aluminum alloy semisolid extrusion casting technology, the quality of a sizing agent is extremely hard to control, meanwhile, close connection between sizing agent preparing and forming is very difficult to achieve, and the stability is poor. By adopting the aluminum alloy semisolid secondary combined extrusion casting method, semisolid sizing agent preparing and extrusion casting forming integration is achieved through the secondary combined extrusion casting technology. The preparation method is advanced, data is accurate and detailed, formed parts cast in a secondary combined extrusion manner are precise in shape, the metallographic structure compactness is good, primary alpha-Al is composed of spherical grains and nearly-spherical grains, the number of rose grains is small, the grain size is obviously reduced, the extension strength reaches 235 Mpa, the ductility reaches 8.5 %, and the aluminum alloy semisolid secondary combined extrusion casting method is advanced.

Owner:ZHONGBEI UNIV

Preparation method of carbon fiber reinforced magnesium matrix composite

The invention relates to a preparation method of a carbon fiber reinforced magnesium matrix composite, which is implemented by taking magnesium and carbon fibers as raw materials through carrying out surface galvanization, ball-milled powder mixing, die-filling, vacuum discharge and plasma sintering, and rolling on carbon fibers so as to obtain the carbon fiber reinforced magnesium matrix composite. The preparation method is advanced in process and detailed and accurate in data, a galvanization layer on the surface of the carbon fiber can effectively improve the wettability of the carbon fiber and a magnesium matrix, the interface bonding is good, the micro-hardness of the prepared carbon fiber reinforced magnesium matrix composite is 58 HV, the bending strength is 206 MPa, and the tensile strength is 172 MPa, therefore, the method is an extremely ideal preparation method of carbon fiber reinforced magnesium matrix composites.

Owner:TAIYUAN UNIV OF TECH

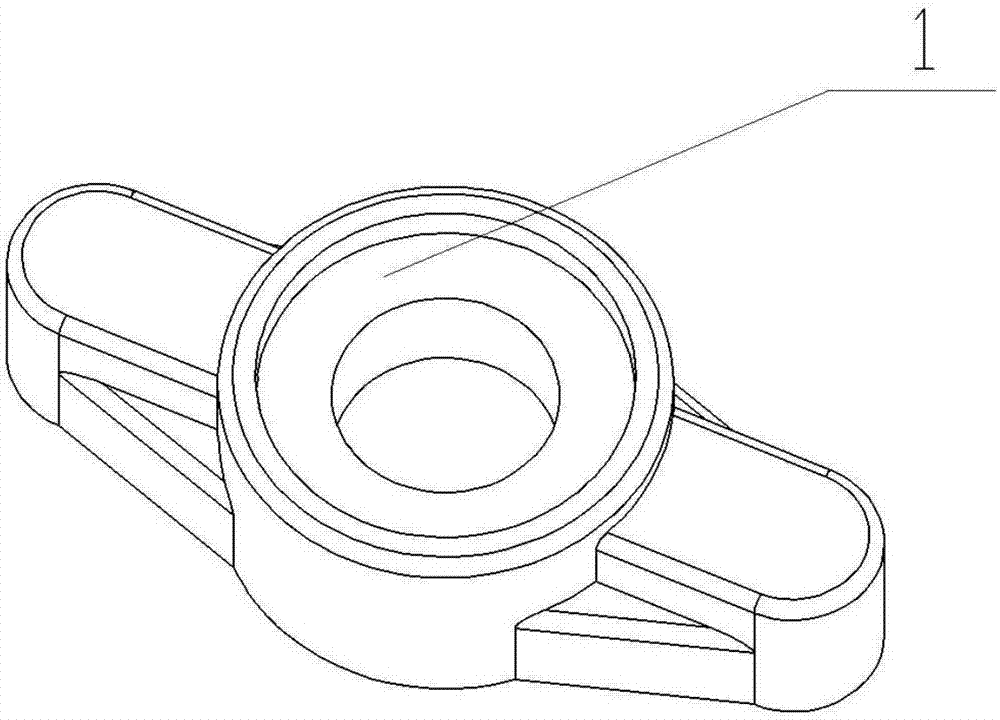

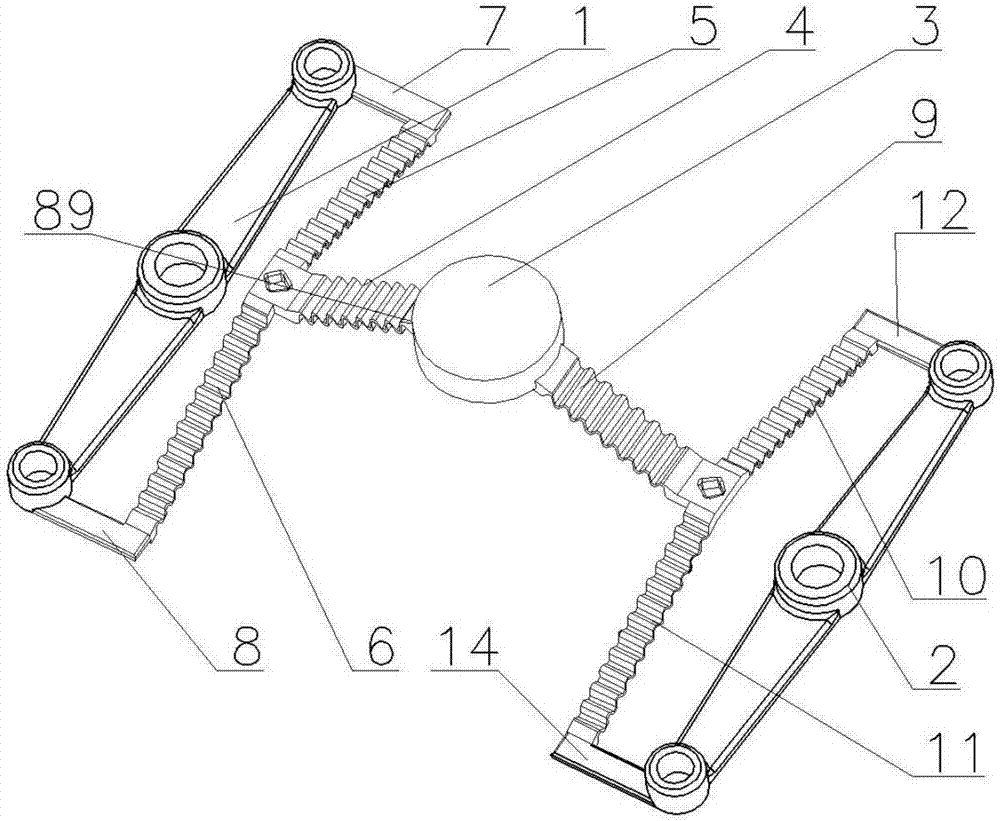

Composite squeeze casting method for magnesium alloy special-shaped parts

The invention relates to a composite squeeze casting method for magnesium alloy special-shaped parts in order to avoid the situations that in the casting process of the magnesium alloy special-shaped parts, the hole shrinkage phenomenon and the shrinkage loosening phenomenon are serious, and the structural compactness of a metallographic structure is poor. According to the composite squeeze casting method, firstly, a composite squeeze casting mold is prepared; gas protection is performed in the whole process of magnesium alloy liquid; the magnesium alloy liquid is smelted through a vacuum furnace, cast and subjected to composite squeeze casting; and the magnesium alloy special-shaped parts are manufactured. The technology of the preparation method is advanced; data are accurate and detailed; the magnesium alloy special-shaped parts manufactured through composite squeeze casting are accurate in shape, good in metallographic structure compactness and free of the hole shrinkage phenomenon and the shrinkage loosening phenomenon, and the tensile strength can be 180 MPa; and the composite squeeze casting method for the magnesium alloy special-shaped parts is advanced.

Owner:KANG MEI TECH DEV

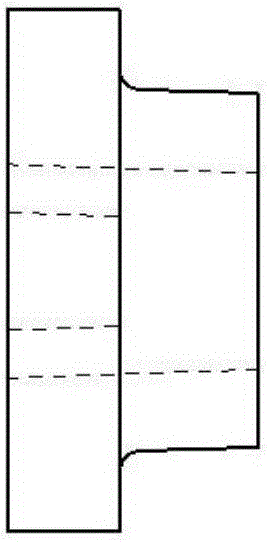

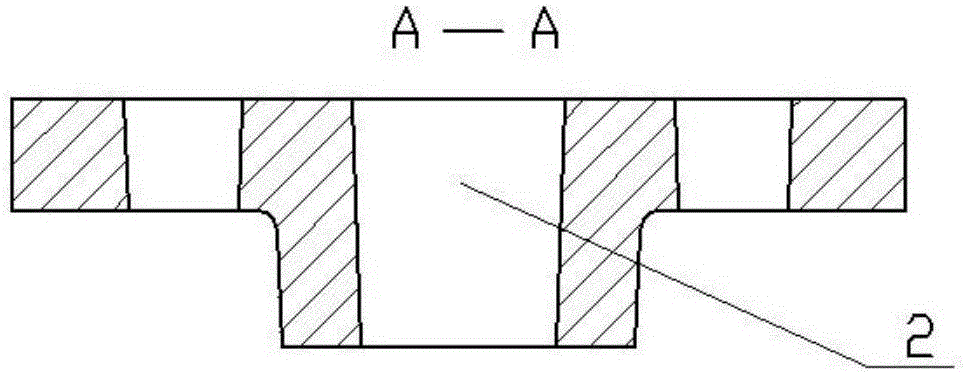

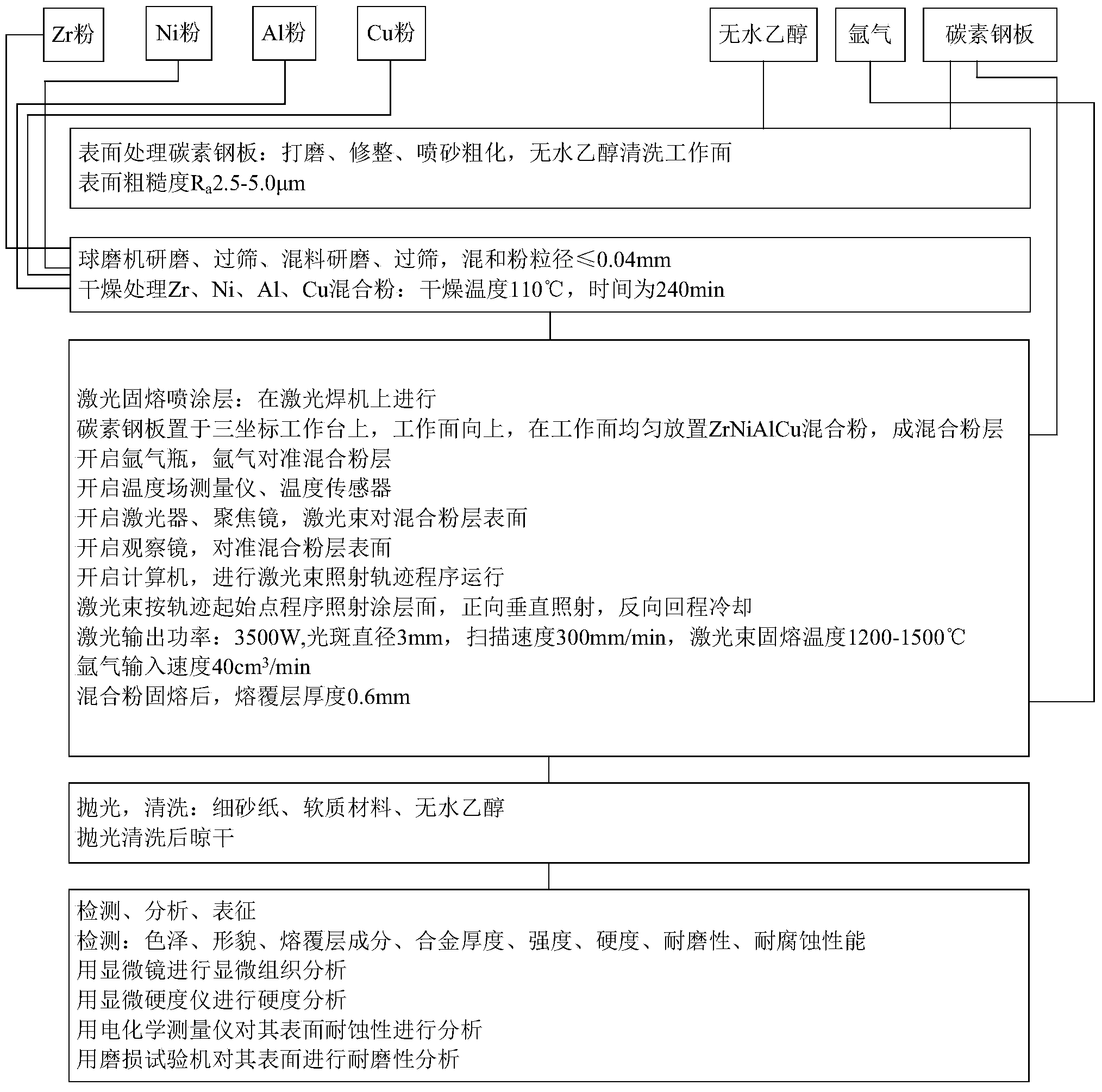

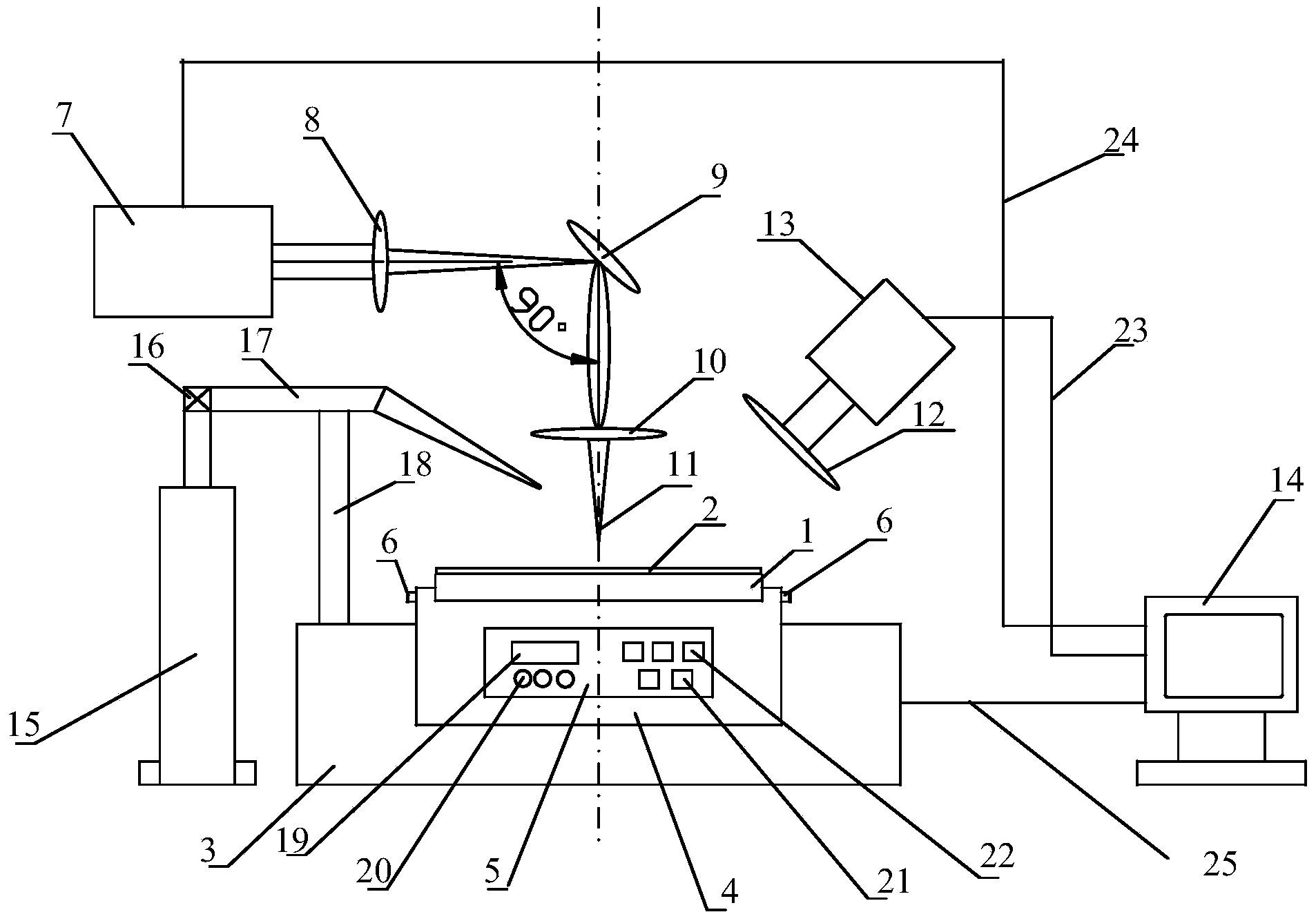

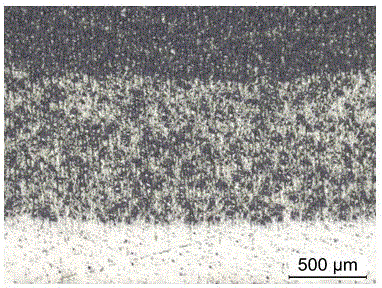

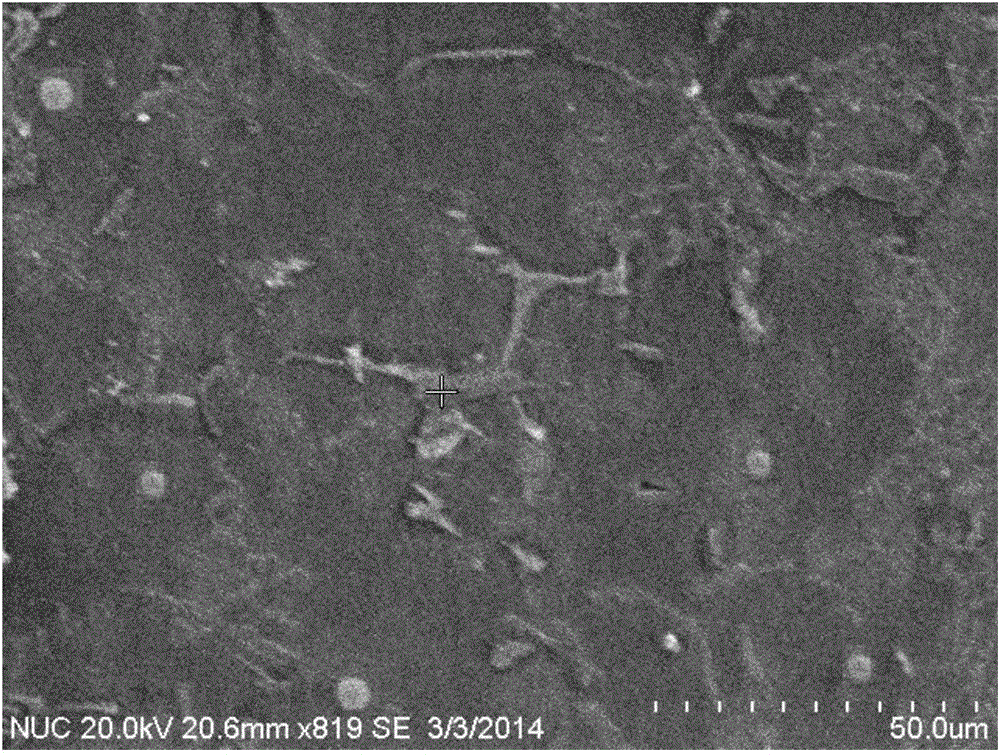

Method adopting laser cladding to form amorphous alloy coating on surface of carbon steel

ActiveCN103668177AEnhanced Amorphous Formation AbilityShort processMetallic material coating processesAlloy coatingLaser beams

The invention relates to a method adopting laser cladding to form an amorphous alloy coating on the surface of carbon steel, and as the laser cladding method is adopted on a laser welder, the carbon steel plate is intensified. The technical scheme comprises the following steps: sand blasting the surface of the carbon steel; preparing mixed powder of zirconium, nickel, aluminum and copper; cladding the surface of the carbon steel by utilizing a laser beam, and enabling the laser beam to perform all-directional irradiation along a locus curve set by a computer program; forming the amorphous alloy coating after amorphous alloy powder is fused and cured on the surface of the carbon steel. By the adoption of the method, the surface hardness, abrasion resistance and corrosion resistance of the carbon steel are greatly improved; compared with the performances before treatment, the surface hardness of the carbon steel is increased by four times, the abrasion resistance is increased by four times, and the corrosion resistance is increased by 1000%; the intensifying method has the advantages of advanced process, detailed and accurate data, short technological process and simplicity in realization, and is safe, stable and reliable; the cladding coating is solid and not easy to drop off; the method is ideal in intensifying the surface of the carbon steel.

Owner:大同市森源激光再制造技术有限公司

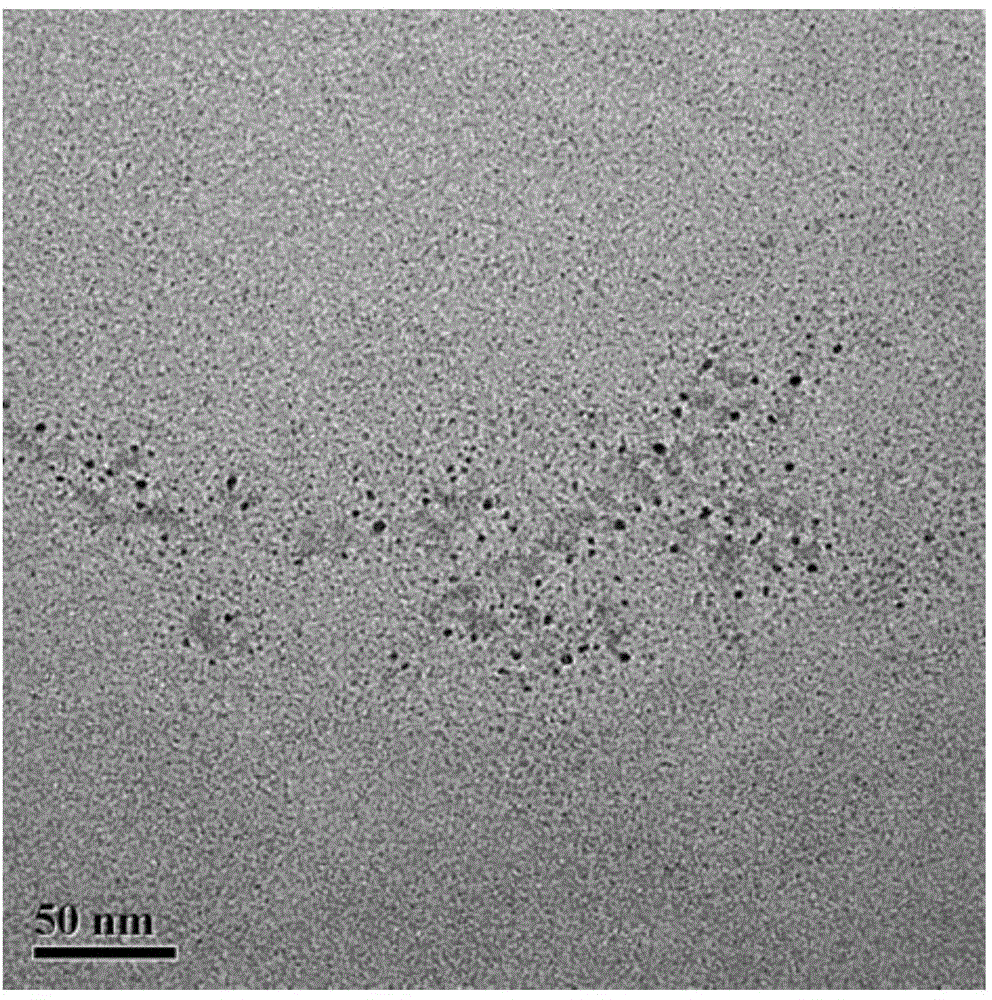

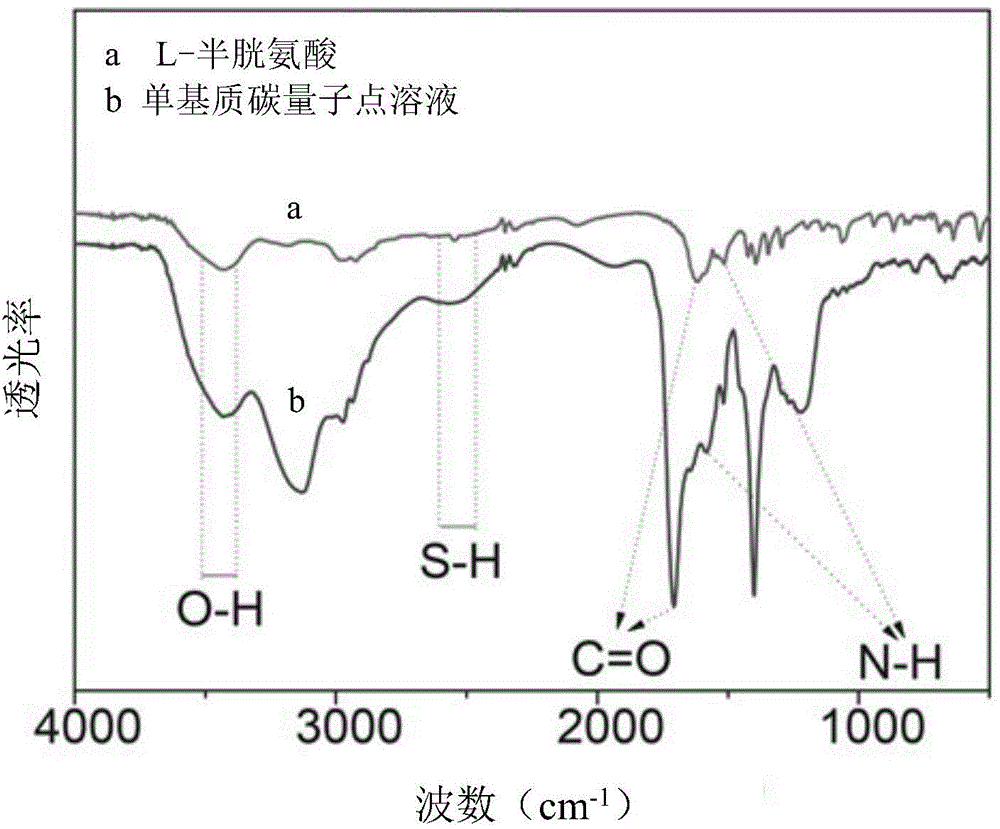

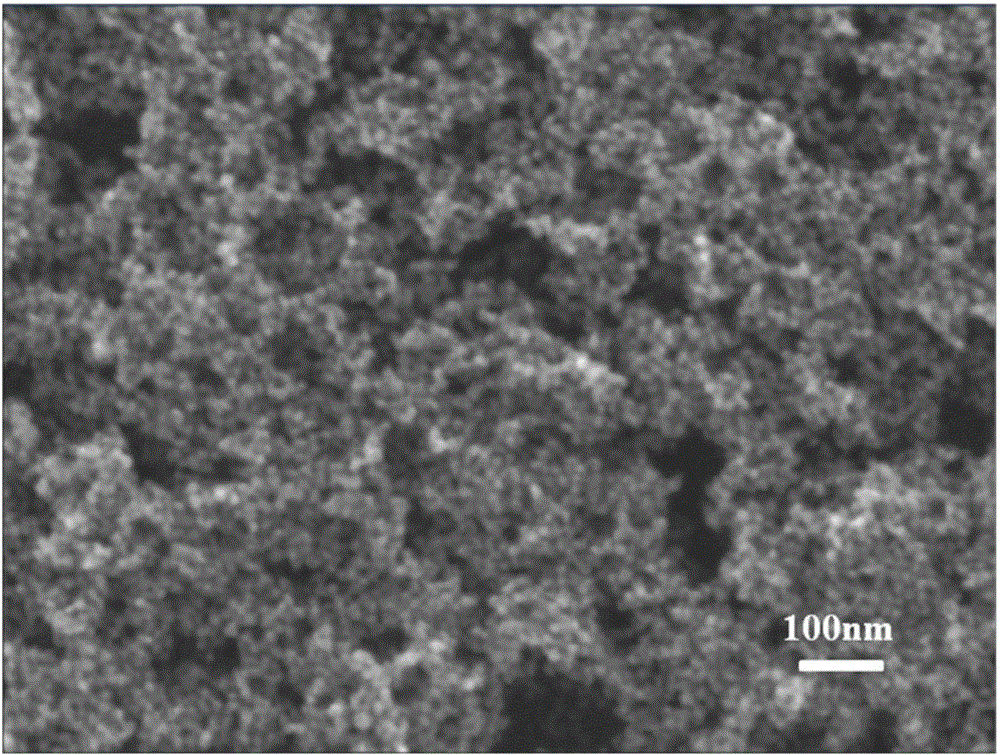

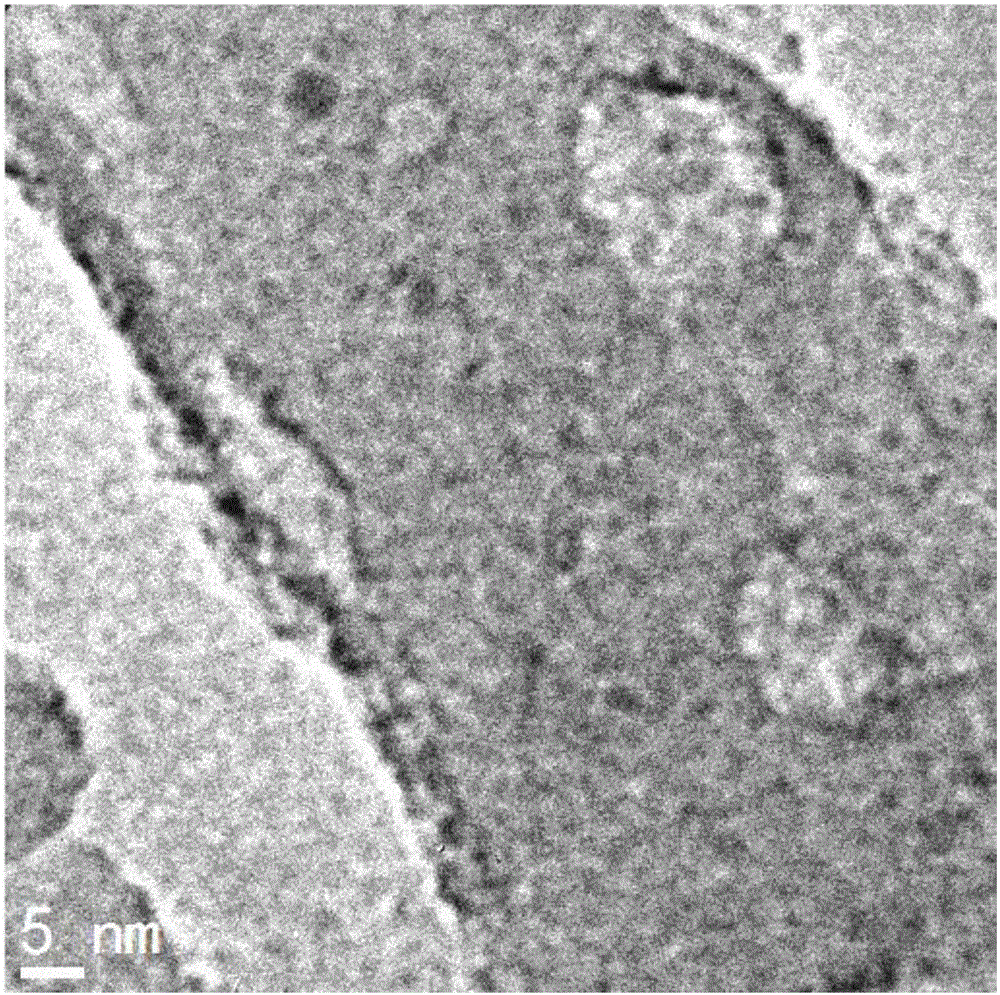

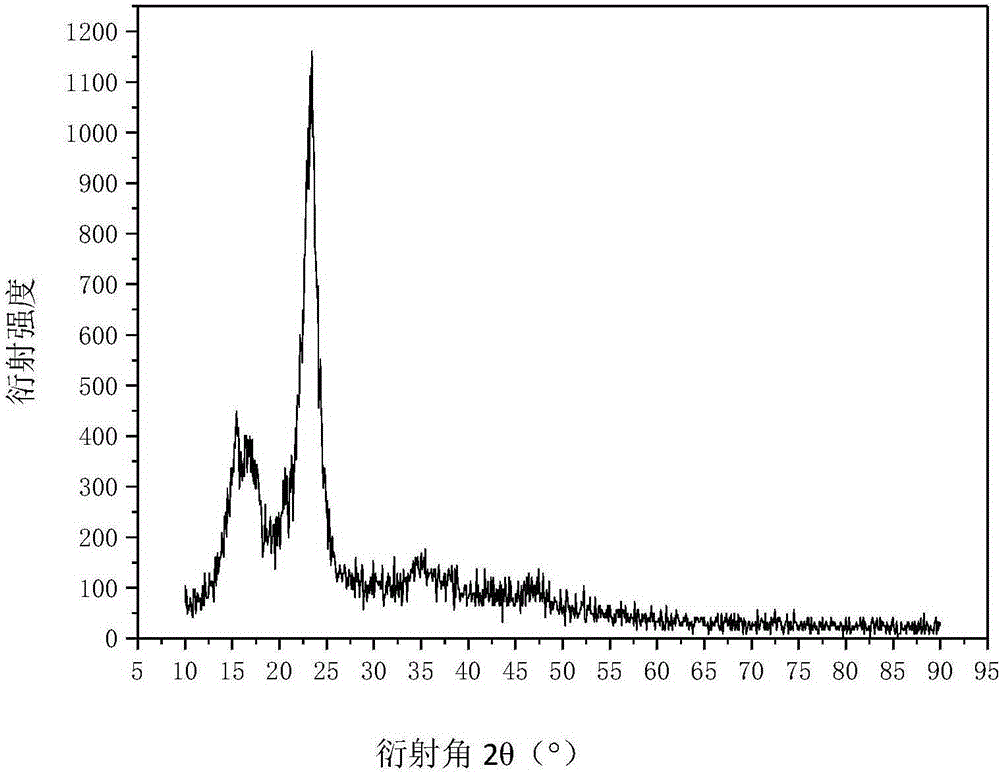

Preparation method of single-matrix carbon quantum dot white light fluorescent powder

ActiveCN104830328AHigh purityAdvancedEnergy efficient lightingLuminescent compositionsFiltrationSolvent

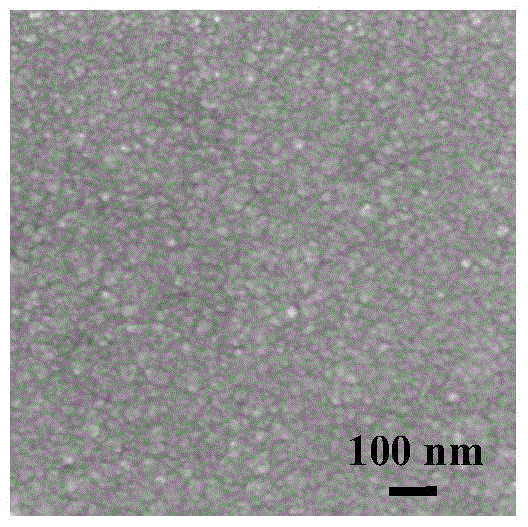

The invention discloses a preparation method of single-matrix carbon quantum dot white light fluorescent powder to solve the problems that the single-matrix carbon quantum dot white light fluorescent powder is big in preparation difficulty, low in purity and easy to cause fluorescence quenching due to agglomeration. The single-matrix carbon quantum dot white light fluorescent powder is prepared by taking citric acid as a carbons source, L-cysteine as an additive and deionized water as a solvent, adopting a hydrothermal synthesis method to prepare a single-matrix carbon quantum dot aqueous solution, and performing closed reaction, injection filtration, dialysis, gelatinization and vacuum drying. The preparation method is advanced in process and accurate and informative in data, the prepared product is dark-brown powder, the particle diameter of the powder is less than or equal to 8nm, the color coordinates comprise x=0.325 and y=0.356, the prepared product emits white light and is good in purity reaching 98.5%, and the fluorescence quenching caused by agglomeration is avoided, so that the prepared method can be used for preparing white light light-emitting diodes and is a very ideal method for preparing the single-matrix carbon quantum dot white light fluorescent powder.

Owner:TAIYUAN UNIV OF TECH

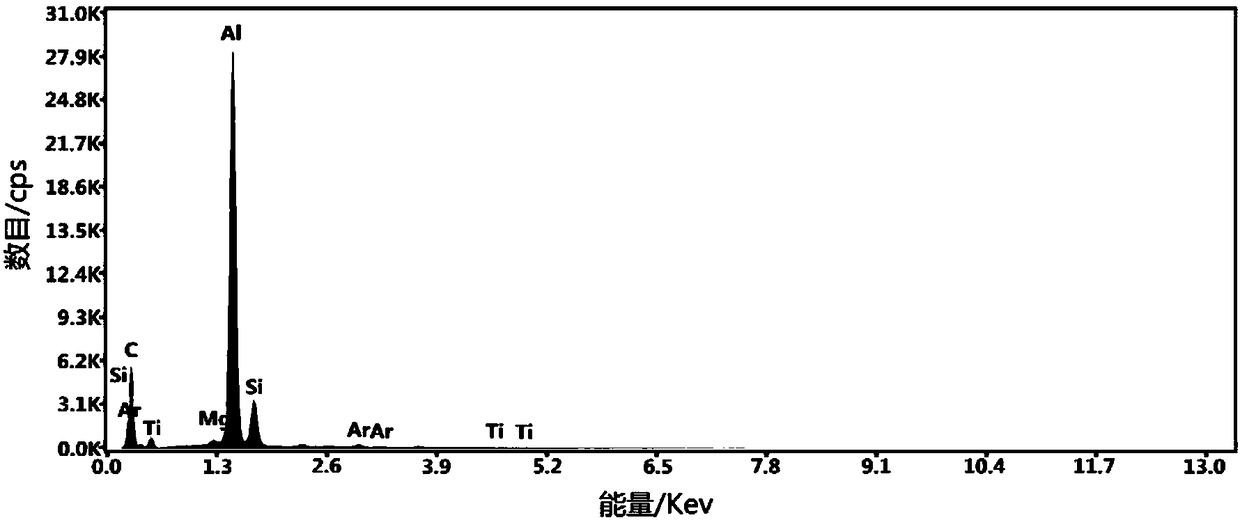

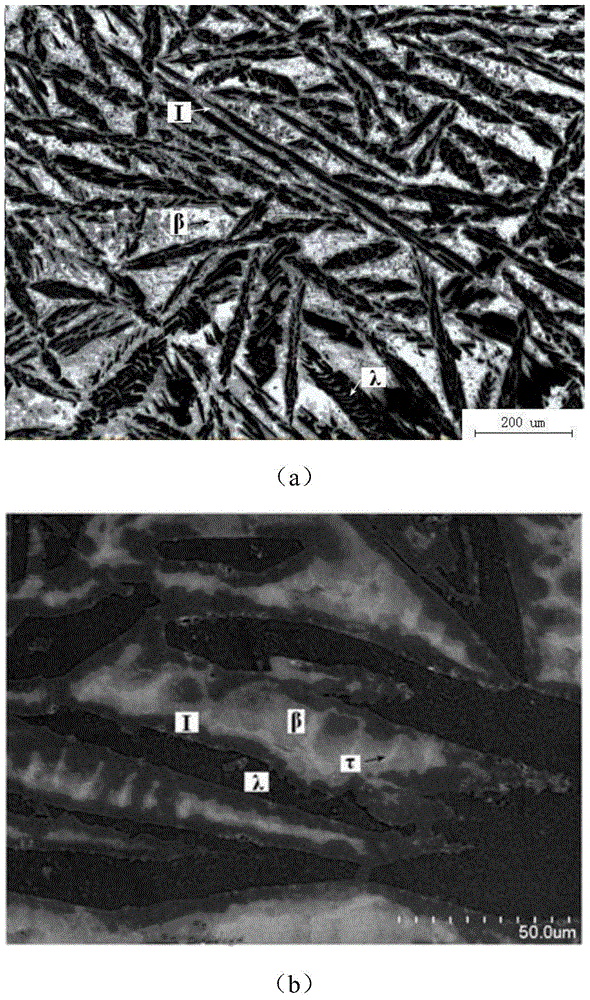

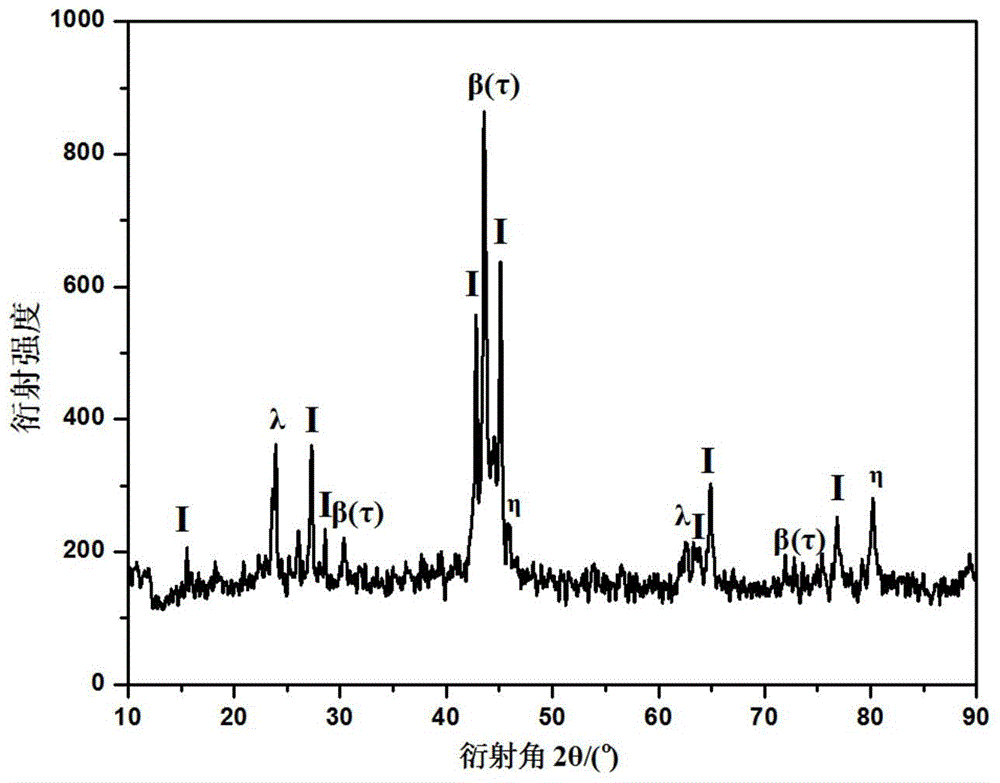

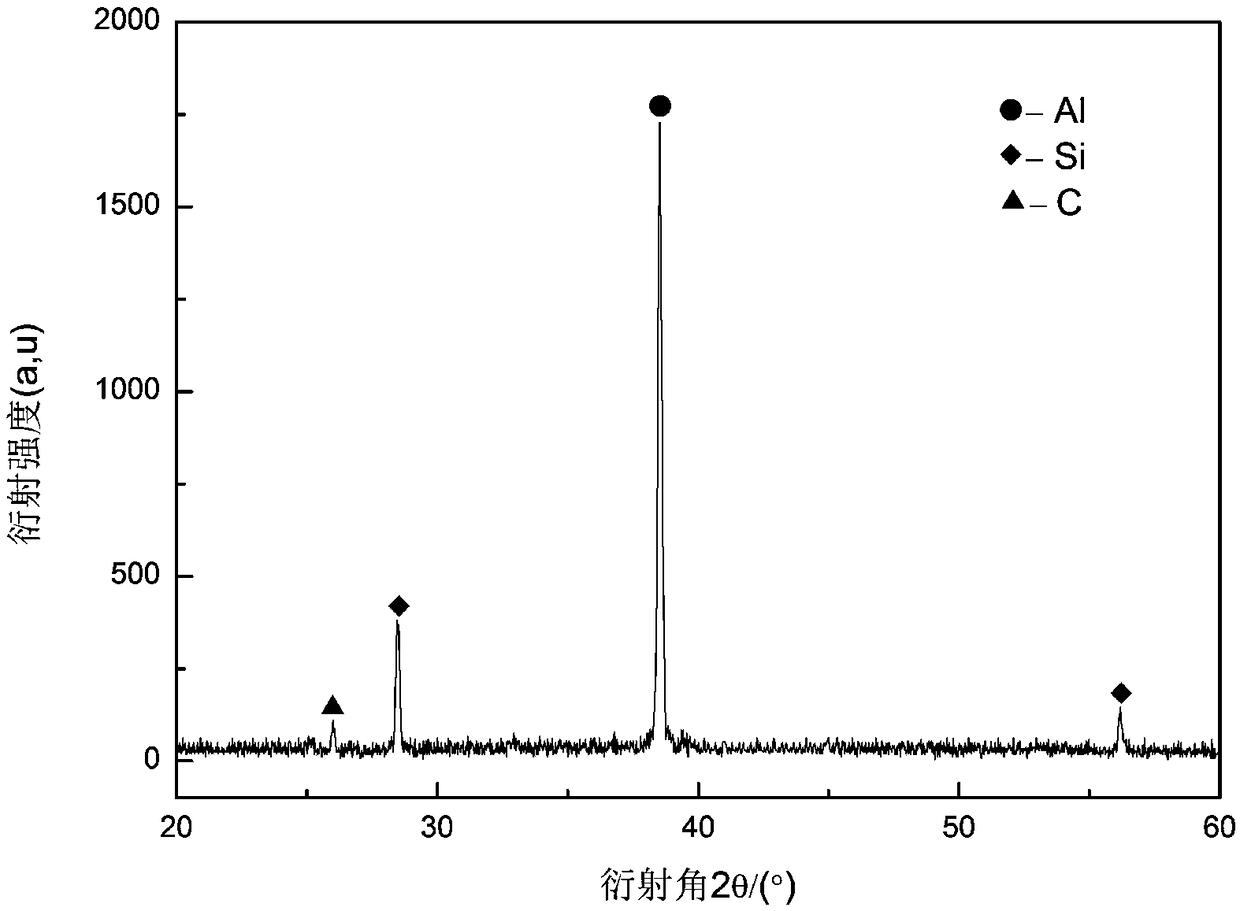

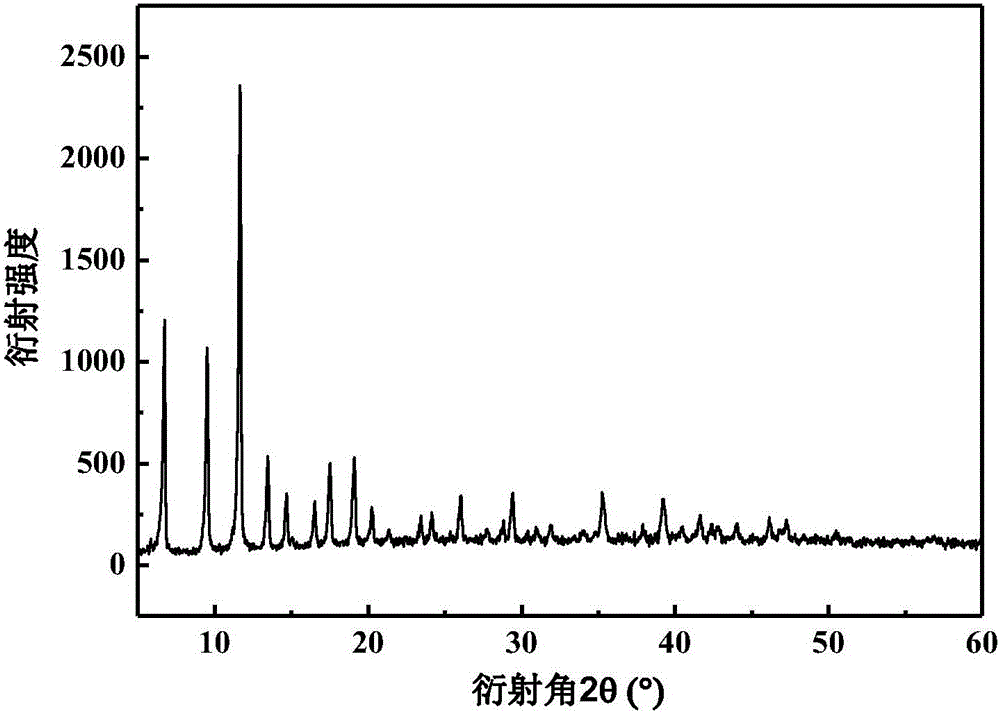

Preparation method of aluminum, copper and iron quasicrystal

The invention relates to a preparation method of an aluminum, copper and iron quasicrystal. In order to solve the problem that process defects exist as the preparation method of the aluminum, copper and iron quasicrystal is difficult, the preparation method comprises the following steps: smelting and casting, quickly cooling, thermally treating and annealing and quenching to prepare an aluminum, copper and iron quasicrystal block material by adopting a medium-frequency induction smelting furnace casting method. The preparation method of the aluminum, copper and iron quasicrystal disclosed by the invention is advanced in process, accurate and full in data; the I phase of the quasicrystal is Al61.92Cu26.21Fe11.87, the product purity is high, the I phase content of the quasicrystal is 98%, the mechanical performances are stable, the hardness is 796HV, and therefore, the preparation method can be applied to various industrial fields and is a very ideal preparation method of the aluminum, copper and iron quasicrystal.

Owner:ZHONGBEI UNIV

Die-casting method of graphene enhanced aluminum based composite material

The invention relates to a die-casting method of a graphene enhanced aluminum based composite material, and aims at solving the problems of nonuniform dispersion and difficult combining with a substrate of graphene in an aluminum alloy substrate. A semi-solid die-casting method is adopted, the graphene enhanced aluminum based composite material is prepared through melting, heat preserving, electromagnetic stirring, tamping and die-casting. The method has the advantages that the technology is advanced, data is accurate and real, procedures are strict, slurry is purified, metallographical structure compactness is good, hole shrinkage and loosening are prevented, the hardness of the prepared graphene enhanced aluminum based composite material reaches up to 85 HB, the hardness is improved by 66% compared with the substrate, the tensile strength reaches up to 8%m the tensile strength is improved by 5% compared with the substrate, the compact degree reaches up to 99.6%, and the preparation method of the graphene enhanced aluminum based composite material is advanced.

Owner:ZHONGBEI UNIV

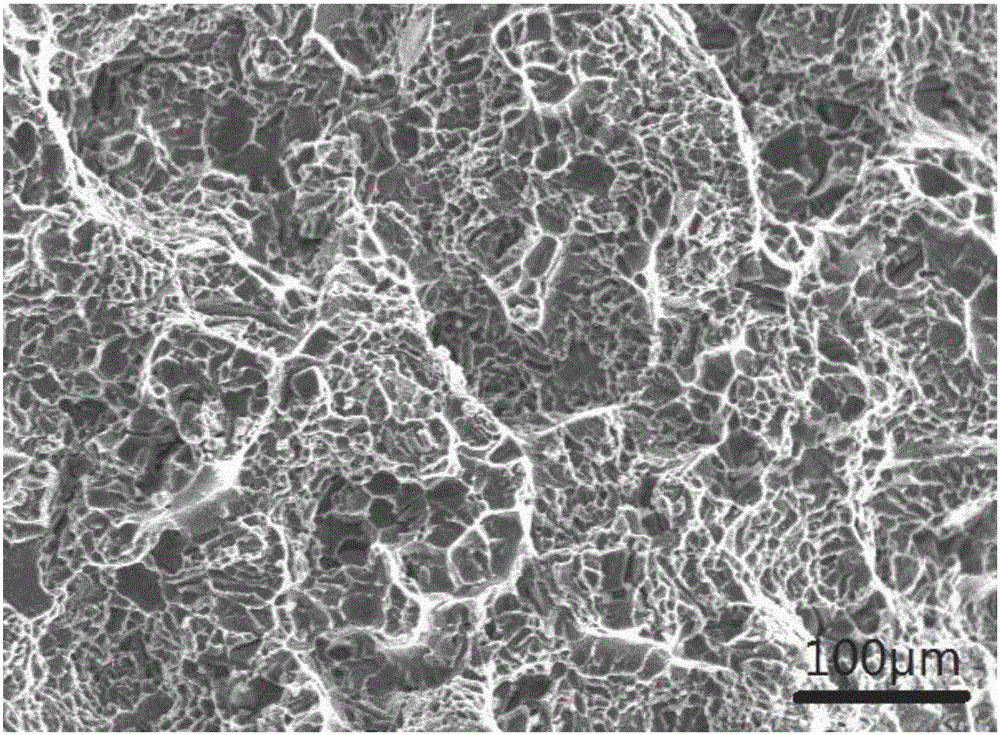

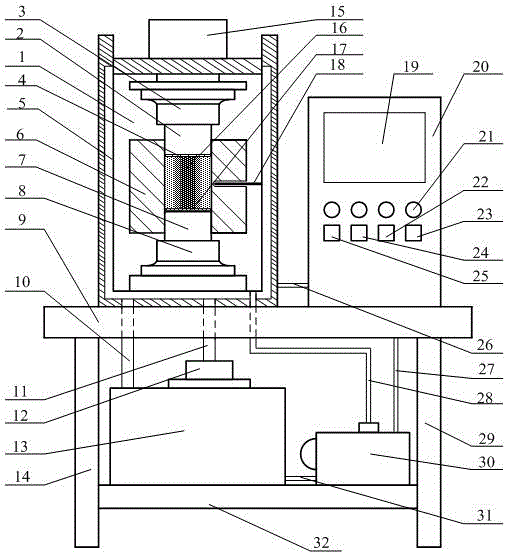

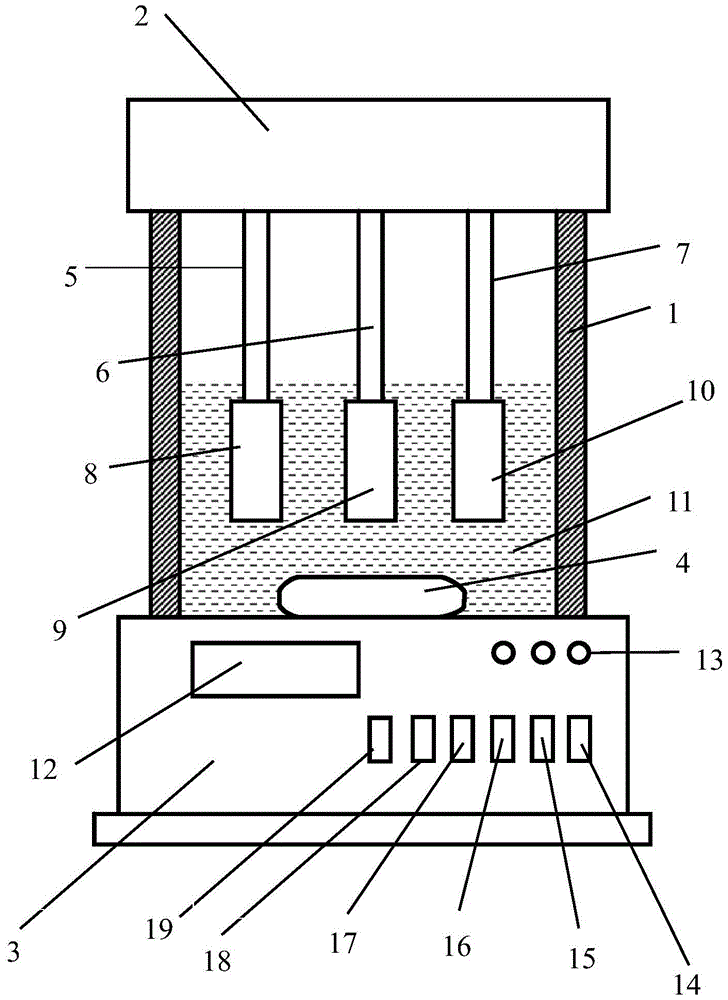

Magnesium-based composite material semi-solid indirect extrusion casting forming method

The invention relates to a magnesium-based composite material semi-solid indirect extrusion casting forming method. According to the magnesium-based composite material semi-solid indirect extrusion casting forming method, in order to solve the problems that wettability is poor between reinforcing body particles and matrix material, agglomerate is prone to be generated, distribution is uneven, anda prepared casting is low in performance, magnesium-zinc-yttrium quasi-crystals with high hardness, high elasticity and good binding property with a matrix are added to a magnesium alloy matrix and used as a reinforcing body, the casting is obtained through smelting in a vacuum atmosphere smelting furnace, ultrasonic-assisted vibration stirring in a composite stirring furnace and indirect extrusion casting, and therefore the mechanical property of the casting is improved; the machining method is advanced in process, data are accurate and detailed, the metallographic structure of the casting isgood in compactness, and defects of shrinkage cavity and shrinkage porosity do not exist; and the initial phase in the metallographic structure is composed of spherical and near-spherical grains, dendritic grains basically disappear, the grain size is obviously refined, tensile strength reaches 225 Mpa, the elongation rate is 6.5%, and hardness reaches 86 HV, so that the method is advanced.

Owner:KANG MEI TECH DEV

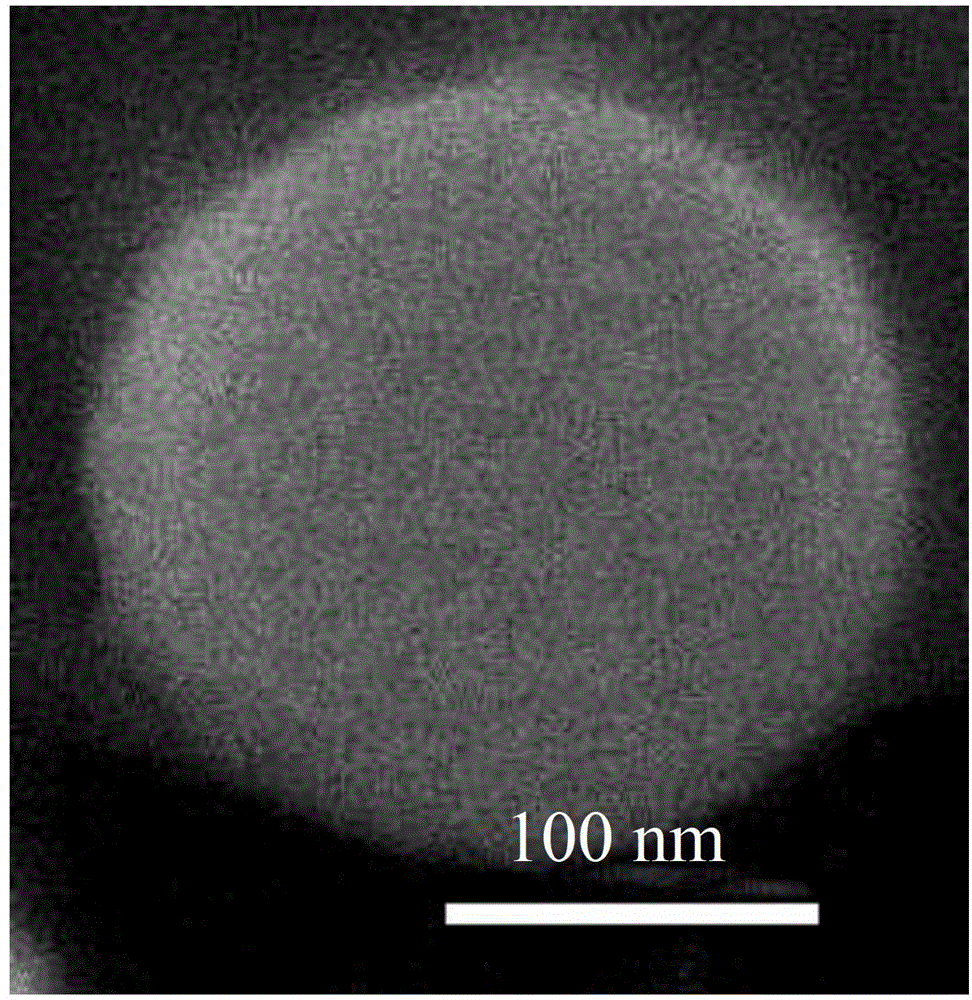

Porous imprinting carbon nano-sphere preparation method

The present invention relates to a porous imprinting carbon nano-sphere preparation method, which comprises adopting a glucose solution to carry out hydrothermal synthesis of carbon nano-spheres, and carrying out surface modification, sintering carbonization, and grafting modification on the porous carbon nano-spheres to finally prepare the porous imprinting carbon nano-spheres. The preparation method has characteristics of rigorous process, advancement, reasonability, and accurate and detailed data. The product has the following characteristics that: a morphology is good, the product is black round particles, a particle diameter is less than or equal to 180 nm, a porous imprinting effect is significant, the product can be matched with a plurality of chemical substances, product purity is good and achieves 99%, and a yield is high and achieves 91%. In addition, the preparation method is an ideal porous imprinting carbon nano-sphere preparation method.

Owner:TAIYUAN UNIV OF TECH

Semisolid combined extrusion casting forming method of magnesium alloy casting

The invention relates to a semisolid combined extrusion casting forming method of a magnesium alloy casting. With respect to the situation that the slurry quality is difficult to control in magnesium alloy semisolid extrusion casting and the disadvantages that the slurry preparation and forming connection is poor and the stability is poor, by adopting the semisolid combined extrusion casting forming method of the magnesium alloy casting, integration of semisolid slurry preparation and extrusion casting forming is realized through a combined extrusion casting technique. The semisolid combined extrusion casting forming method is advanced in technology, data is precise and full and accurate, the prepared casting is precise in shape, a primary phase consists of spheroidal and near-spheroidal grains, dendritic grains are few, the grain size is reduced, the metallurgical structure compactness is good, the strength of extension reaches 205Mpa, the elongation percentage reaches 6.2%, and the semisolid combined extrusion casting forming method of the magnesium alloy casting is advanced.

Owner:SHANXI BADA MAGNESIUM

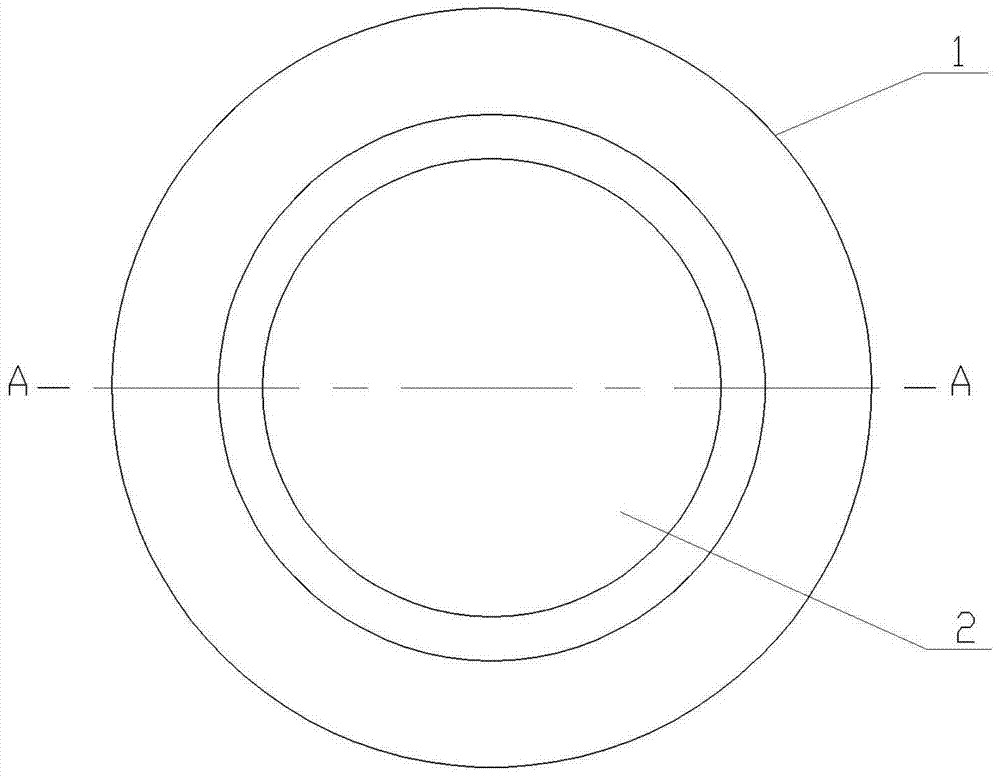

Compound extrusion casting method of aluminum alloy ring

The invention relates to a compound extrusion casting method of an aluminum alloy ring and aims to overcome the defects that severe hole-shrinkage and collapsing occurs in casting of aluminum alloy ring parts and the metallographic structure is poor in compactness. The method includes: manufacturing a compound extrusion casting mold and manufacturing the aluminum alloy ring by means of smelting of aluminum alloy melt, pouring, and compound extrusion casting. The method has the advantages that the method is technically advanced, data are accurate and full, the aluminum alloy ring made by compound extrusion casting has precise shape, the metallographic structure is good in compactness, no shrinking or collapsing occurs, tensile strength is up to 230MPa, hardness is up to 75HB, pinhole degree is first-class, and the method is ideal and is suitable for manufacturing other aluminum alloy parts.

Owner:SHANXI SHENZHOU AEROSPACE SCI & TECH CO LTD

Preparation method of laminated gradient neutron absorbing material

The invention relates to a preparation method of a laminated gradient neutron absorbing material. To overcome the defect that plastic deformation of high-content boron carbide and rare earth oxide aluminum alloy-based composite materials is difficult, aluminum alloy is adopted as an outer layer material, the contents of boron carbide and rare earth oxide are gradually increased from the outer layer to the inner layer, a neutron absorbing material blank is prepared through the plasma discharge sintering technology, hot extrusion is carried out through a hydraulic press machine, and the laminated gradient neutron absorbing material is prepared in a hot rolling mode through a rolling mill. According to the preparation method, the process is advanced, data are accurate and detailed, the tensile strength of the prepared neutron absorbing material reaches 240 MPa, the elongation percentage of the prepared neutron absorbing material reaches 6.3%, the corrosion resistance of the prepared neutron absorbing material can be improved by 70%, the prepared neutron absorbing material can be used for nuclear protection, and the preparation method is an advanced method for preparing laminated gradient metal-based composite materials.

Owner:TAIYUAN UNIV OF TECH

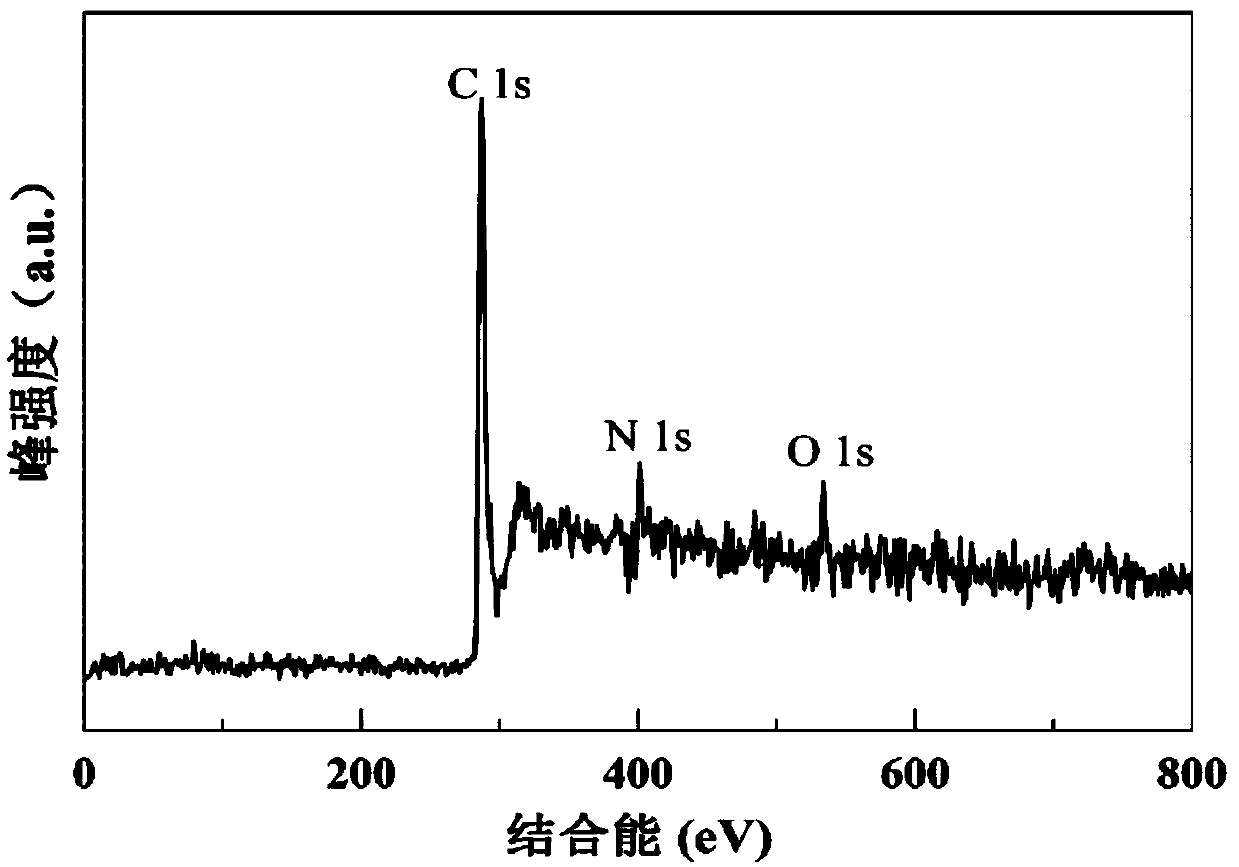

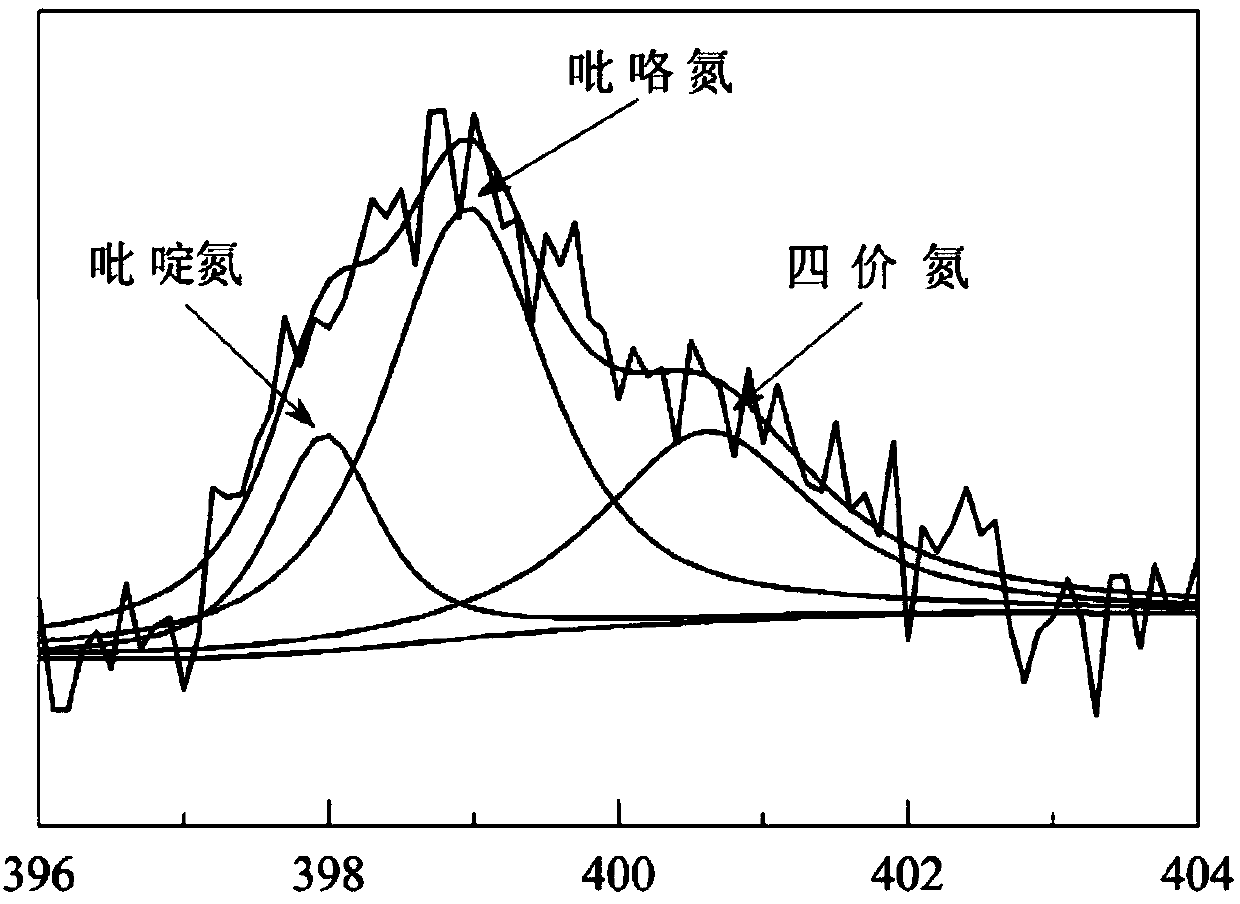

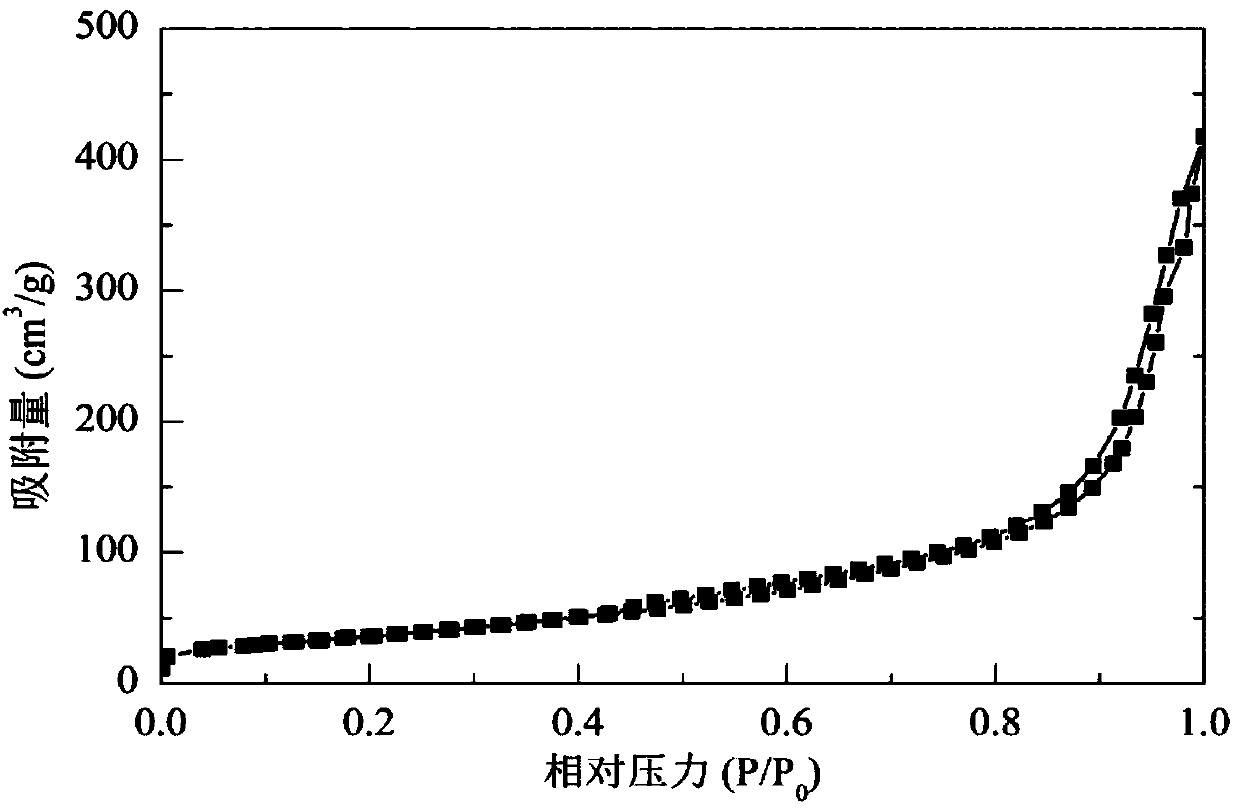

Preparation method and application of high-efficiency nitrogen-doped carbon nanotube

ActiveCN107686105ASmall particle sizeEvenly dispersedOrganic compound preparationCarbon compoundsMultiwalled carbonFiltration

The invention discloses a preparation method of a high-efficiency nitrogen-doped carbon nanotube. The preparation method comprises the following steps: adding a multiwalled carbon nanotube into a nitric acid solution; closing the solution in an autoclave; pressurizing to 0.4 to 1.0 MPa, and stirring; then heating to 120 to 200 DEG C and keeping for 1 to 4 hours; finally, cooling to room temperature by the autoclave; washing to neutral and carrying out suction filtration and drying; mixing the carbon nanotube with a melamine solid according to the mass ratio being 1 to (1 to 4), and uniformly grinding by using mortar; and carrying out high-temperature sintering in nitrogen, washing to neutral and then drying to obtain the nitrogen-doped carbon nanotube. The nitrogen doping amount of the high-efficiency nitrogen-doped carbon nanotube disclosed by the invention is 4.6 to 10.3 weight percent.

Owner:TAIYUAN UNIV OF TECH

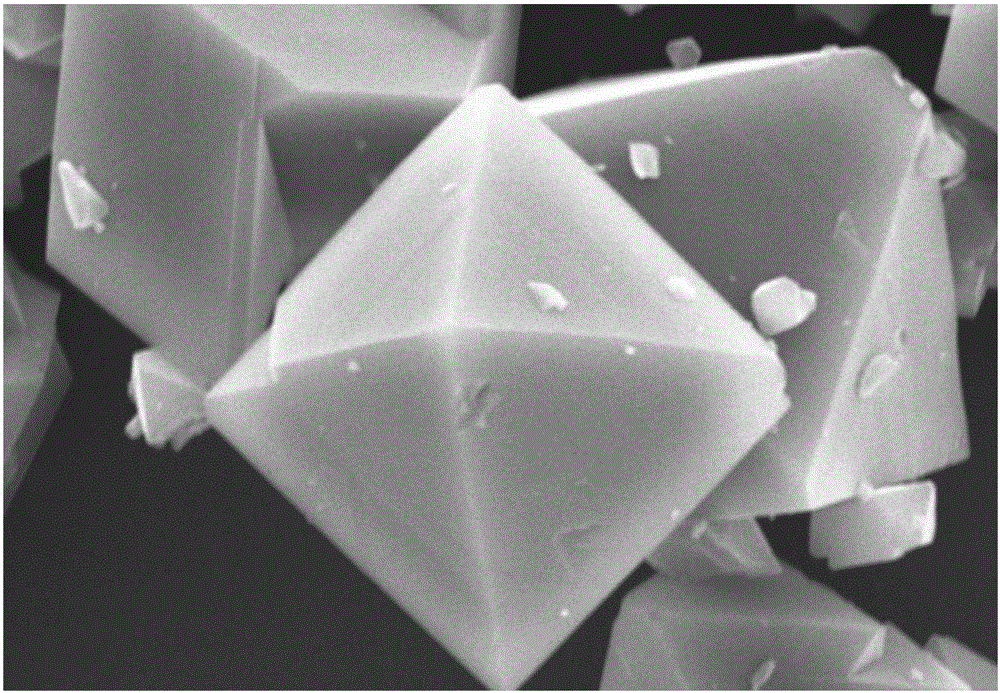

Method for preparing porous compound desulfurizer for removing organic sulfide

InactiveCN106334530APromote regenerationIncrease costOther chemical processesGaseous fuelsOrganic sulfide compoundActivated carbon

The invention relates to a method for preparing a porous compound desulfurizer for removing an organic sulfide. Against the conditions that organic sulfur in natural gas and particularly sulfur ether are difficult to remove and the desulfurizer is difficult to regenerate after being used, a metal organic frame compound is compounded with activated carbon; through preparation of activated carbon mixed liquid, reaction kettle hydro-thermal synthesis, soaking, suction filtration, washing and vacuum freezing drying, the porous compound desulfurizer is prepared, the porous compound desulfurizer is black blue crystal, the crystal is in an octahedron shape, the crystal particle size is smaller than or equal to 17 [mu]m, the crystal particle is in a porous shape, the pore diameter size is smaller than or equal to 0.7 nm, the product purity is 99.6%, the product can be used for removing the organic sulfide in natural gas and have a very good sulfur ether removing effect, the desulfurizer is reproducible after adsorbing sulfur ether, and the use cost is reduced. The preparation method is advanced in process, data is precise, detailed and accurate, the product is good in purity and high in precision, and the method is an advanced method for preparing the porous compound desulfurizer for removing the organic sulfur and particularly sulfur ether.

Owner:TAIYUAN UNIV OF TECH

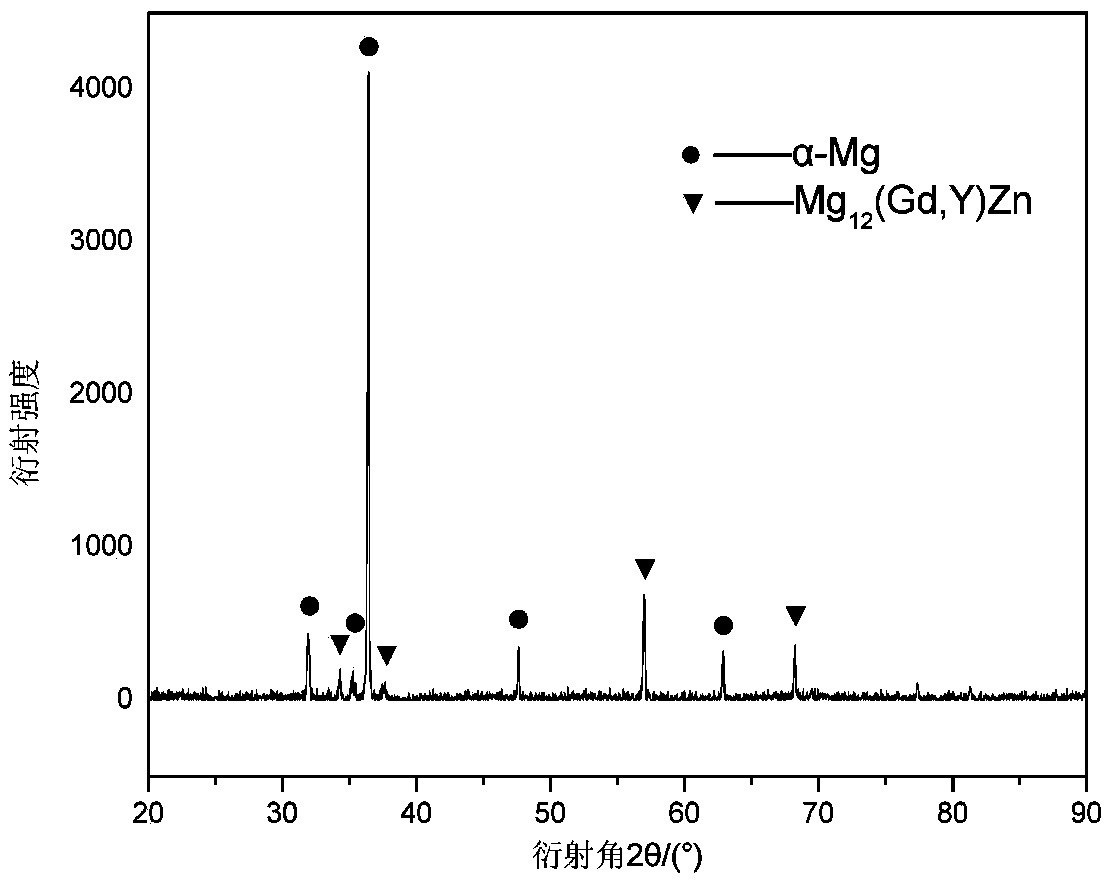

Preparation method of long-period-structure-reinforced magnesium-zirconium alloy ingot

The invention relates to a preparation method of a long-period-structure-reinforced magnesium-zirconium alloy ingot, which comprises the following steps: by using magnesium, zinc, a magnesium-yttrium interalloy, a magnesium-gadolinium interalloy and a magnesium-zirconium interalloy as raw materials, melting in a vacuum melting furnace, protecting in argon, carrying out cast forming, and carrying out heat treatment to obtain the long-period-structure-reinforced magnesium-zirconium alloy ingot. The tensile strength is up to 312 MPa, the elongation percentage is up to 8%, and the product purity is up to 99.5%. The preparation method has the advantages of advanced technique and full and accurate data, and is an advanced method for preparing the long-period-structure-reinforced magnesium-zirconium alloy ingot.

Owner:WENXI COUNTY REGAL MAGNESIUM

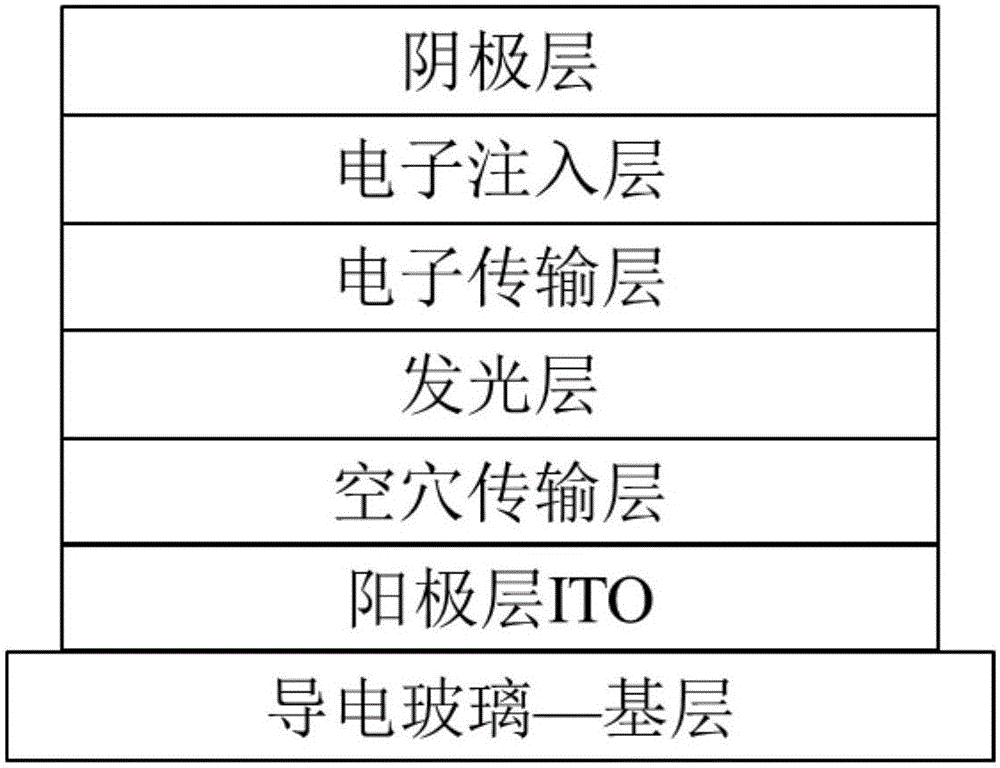

Rapid preparation method for cuprous oxide nano-film

InactiveCN105696047APromote absorptionAdvancedElectrolytic inorganic material coatingNanotechnologyPulsed DCUltraviolet lights

The invention relates to a rapid preparation method for a cuprous oxide nano-film. According to the structural features of cuprous oxide, copper acetate and lactic acid are adopted as raw materials, lauryl sodium sulfate is used as a surface dressing agent, deionized water is used as a solvent, sodium hydroxide is adopted as a pH alkaline modifier, and the cuprous oxide nano-film is prepared through an electrochemical pulse direct-current electrolytic method. According to the rapid preparation method, the process is advanced, data are accurate and full, the nano-film is a yellow film, the section of the nano-film is rectangular, and the film thickness is smaller than or equal to 30 nm; the cuprous oxide nano-film is composed of particles which are in the shape of nano-balls, the diameter of the particles is smaller than or equal to 30 nm, and product purity reaches 99.6%; combination between the nano-film and conductive glass is firm, the nano-film can obviously absorb ultraviolet light and visible light, currents of 240 [mu]A / cm2 can be generated under irradiation of a 100W xenon lamp, and the nano-film can be used for solar power generation and photovoltaic products; the rapid preparation method for the cuprous oxide nano-film is advanced.

Owner:TAIYUAN UNIV OF TECH

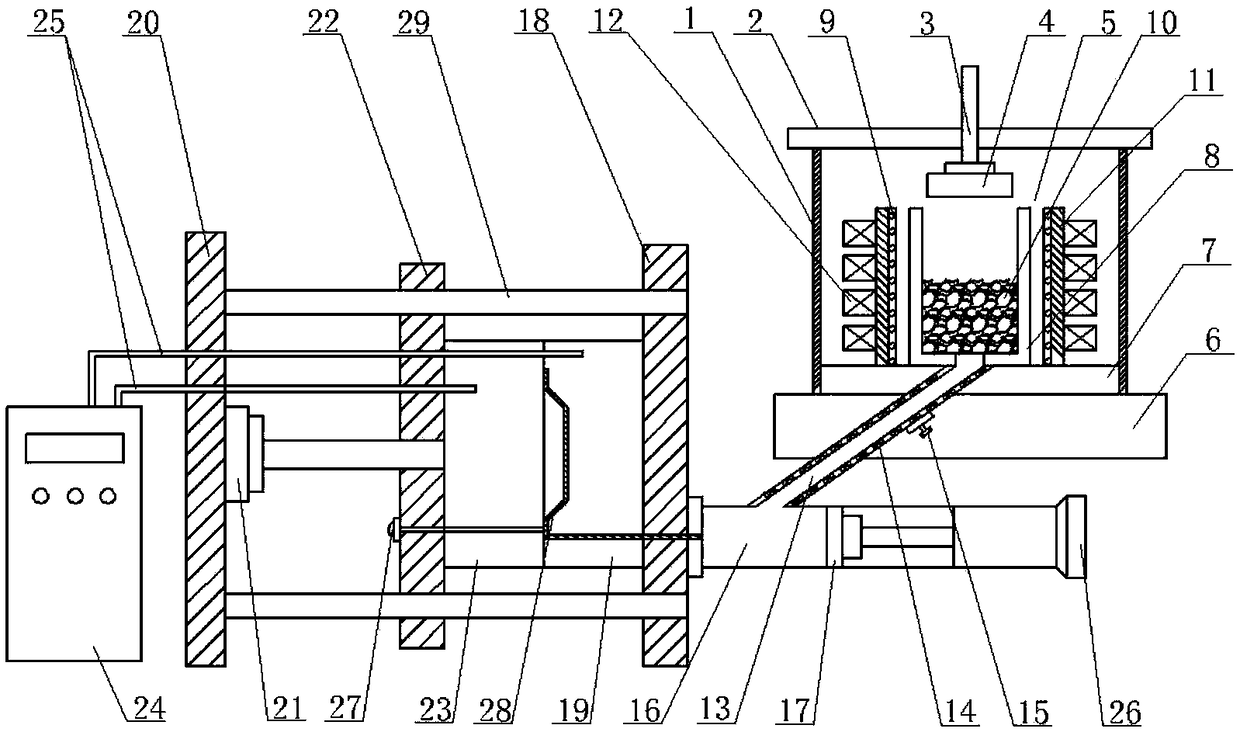

Preparation method of quasi-crystal reinforced type aluminum-based composite material

The invention relates to a preparation method of a quasi-crystal reinforced type aluminum-based composite material. Aiming at a condition that the aluminum-base material has low hardness, low tensile strength and bad corrosion resistance, the preparation method comprises the following steps: smelting in a vacuum smelting furnace, performing argon gas bottom-blowing protection, casting and extruding by using the aluminum alloy as a matrix and taking aluminum copper iron quasi-crystal as an enhancer. The preparation method is advanced in process, strict in procedure and precise and accurate in data. The prepared quasi-crystal enhanced aluminum matrix composite material has hardness up to 82.6 HB which is increased by 61.33%, tensile strength up to 283Mpa which is increased by 74.75%, and corrosion resistance is increased by 30%. The preparation method is an ideal preparation method of the quasi-crystal reinforced type aluminum-based composite material.

Owner:ZHONGBEI UNIV

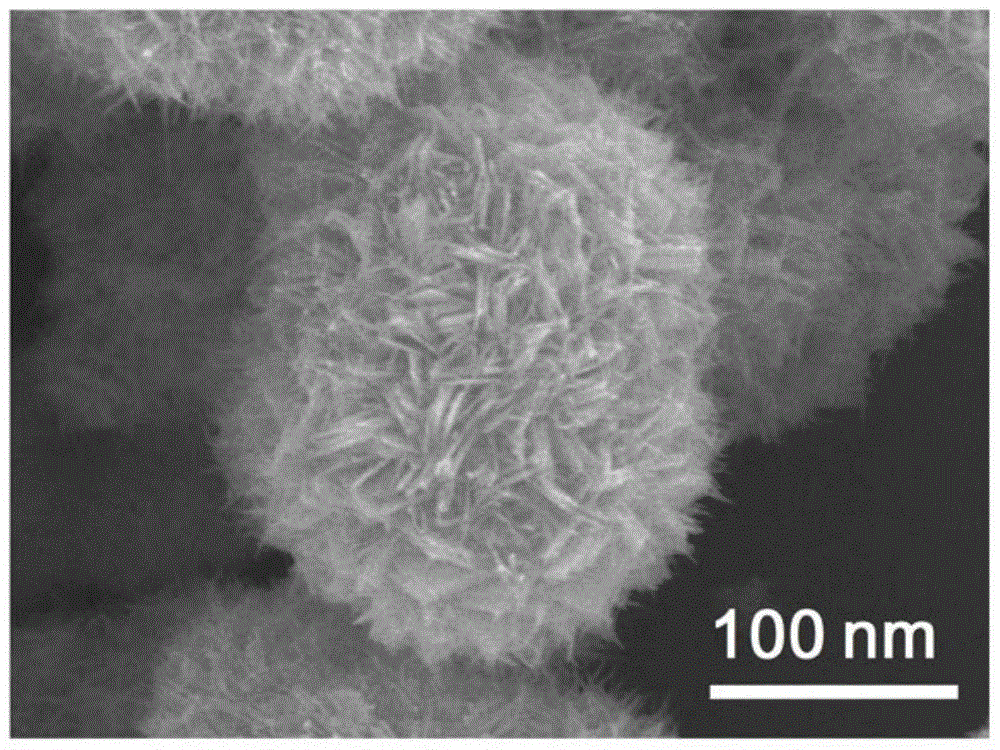

Preparation method for gold-loaded tin oxide nanometer material for detecting hydrogen

ActiveCN105665734AHigh purityAdvancedTransportation and packagingMetal-working apparatusHydrogenPotassium

The invention relates to a preparation method for a gold-loaded tin oxide nanometer material for detecting hydrogen. In order to deal with the conditions that hydrogen detecting gas sensitive materials are low in sensitivity, low in response speed and poor in stability, the gold-loaded tin oxide nanometer material is made from potassium stannate, chloroauric acid and glucose and prepared through the steps of hydro-thermal synthesis through a reaction still, vacuum heat treatment and grinding and sieving. According to the preparation method, the process is advanced, and data are full and accurate; products are atropurpureus crystals, the crystal particle diameter is smaller than or equal to 80 nm, and the product purity is high and reaches 99.6%; the gas sensitivity of the material on 100 ppm hydrogen reaches 25, response time is 1 s, and recovery time is 3 s; the sensitivity is high, response and recovery are fast, and the material can be applied to a gas sensor for detecting hydrogen. The preparation method for the gold-loaded tin oxide nanometer material is quite advanced.

Owner:TAIYUAN UNIV OF TECH

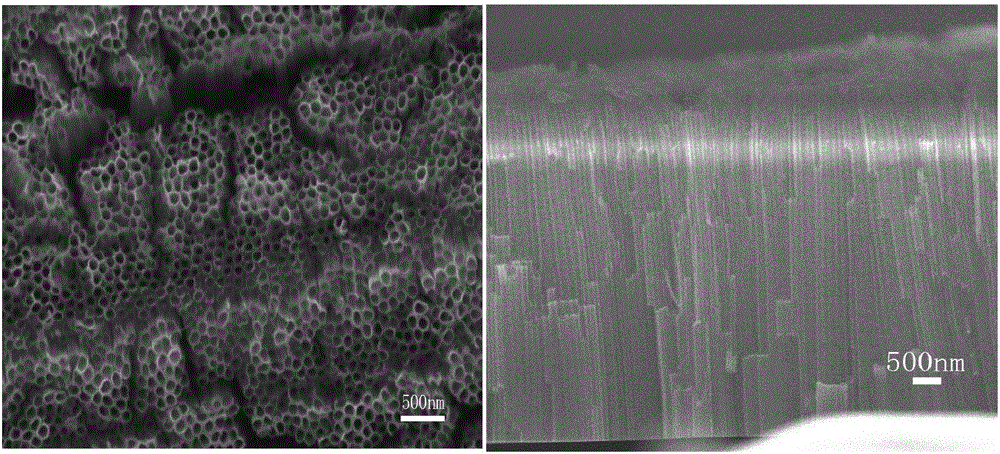

Rapid preparing method of black titanium dioxide nanotube array

ActiveCN106245092APromote absorptionEvenly arrangedSurface reaction electrolytic coatingNanotechnologyTio2 nanotubeUltraviolet lights

The invention relates to a rapid preparing method of a black titanium dioxide nanotube array. A titanium dioxide nanotube array is prepared through an anodic oxidation method according to the structural characteristics of titanium dioxide with ethylene glycol and ammonium fluoride as the raw materials and deionized water as the solvent, the titanium dioxide nanotube array is wrapped by aluminum powder and subjected to heat treatment, and then the black titanium dioxide nanotube array is prepared. The preparing method is advanced in process, data is precise, full and accurate, the product is in a black film shape, and the section of the film is rectangular; the black titanium dioxide nanotube array is neat and uniform in arrangement, is firmly combined with a titanium substrate, has a remarkable absorption effect on ultraviolet light and visible light and can be used in solar power generation and photovoltaic products; the rapid preparing method is advanced.

Owner:TAIYUAN UNIV OF TECH

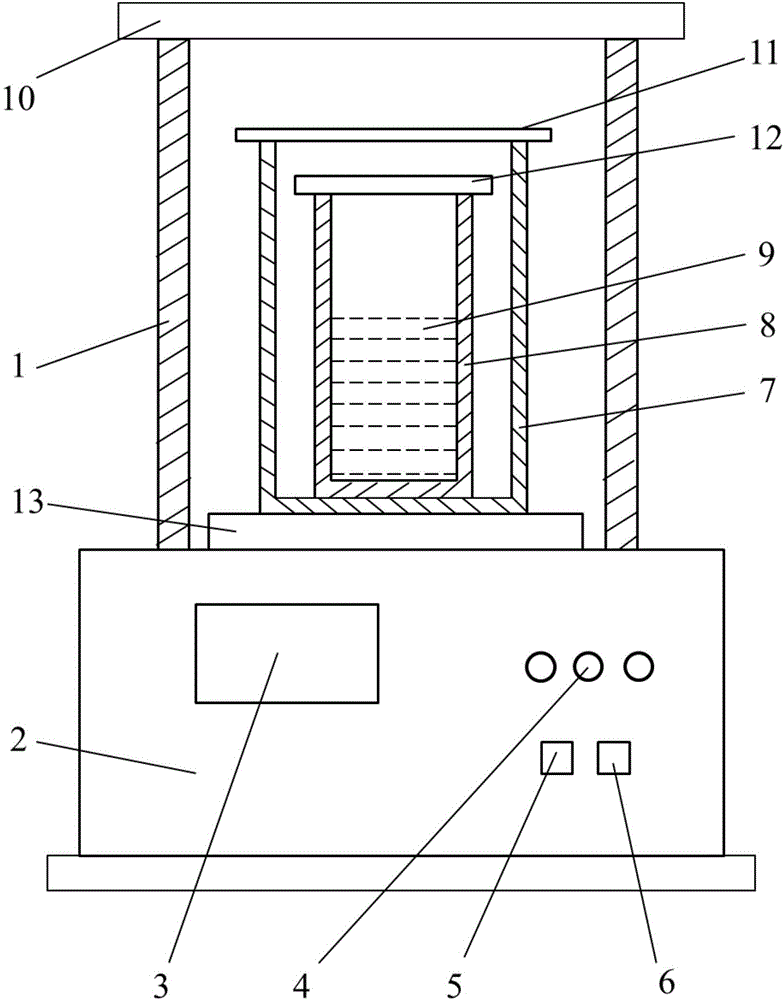

Preparation method for light emitting diode by taking carbon quantum dots as light emitting layer

InactiveCN106229387AImprove luminosityAdvancedSemiconductor devicesElectron transferLight-emitting diode

The invention relates to a preparation method for a light emitting diode by taking carbon quantum dots as a light emitting layer. For overcoming the shortcomings of the used material, structural characteristics and light emitting property of the light emitting diode, the carbon quantum dots are prepared firstly; then the carbon quantum dots are used as the light emitting layer and conductive glass is used as a base layer; next, a hole transport layer and the light emitting layer are spin coated; and an electron transfer layer, an electron injection layer and a negative electrode layer are evaporated to prepare the light emitting diode; the prepared light emitting diode adopts a seven-layer structure; the carbon quantum dot light emitting layer is excellent in the light emitting property, and the luminance can achieve 70cd / m<2>; the preparation method is advanced in technology and accurate and detailed in data; a continuous technological process can be formed from the preparation of the light emitting material to the preparation of the light emitting diode; and therefore, the preparation method is an advanced preparation method for the light emitting diode by taking the carbon quantum dots as the light emitting layer.

Owner:TAIYUAN UNIV OF TECH

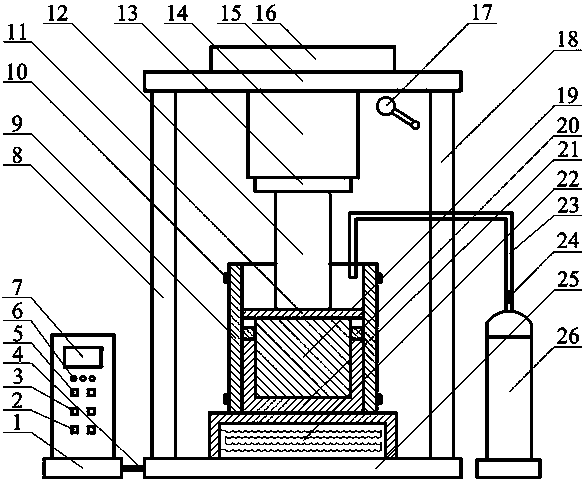

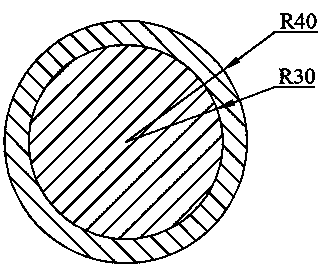

Method for preparing reinforced magnesium alloy block-coated magnesium alloy bar

ActiveCN103464727AStable mechanical propertiesHigh strengthUltimate tensile strengthMechanical property

The invention relates to a method for preparing a reinforced magnesium alloy block-coated magnesium alloy bar. Due to the disadvantages of the mechanical property of magnesium alloy, the cylindrical material of the reinforced magnesium alloy block-coated magnesium alloy bar is prepared through casting, doping, coating and hot pressing; the internal part of the material is the cylindrical magnesium alloy bar, and the external part is in a circular ring shape; the cylinder is firmly combined with the circular ring, so that the compactness is excellent. The preparation method is advanced and compact in process, detailed and accurate in data, and is an ideal method for preparing the reinforced magnesium alloy block-coated magnesium alloy bar; the prepared coated composite material is high in strength and stable in mechanical property.

Owner:山西银光华盛镁业股份有限公司

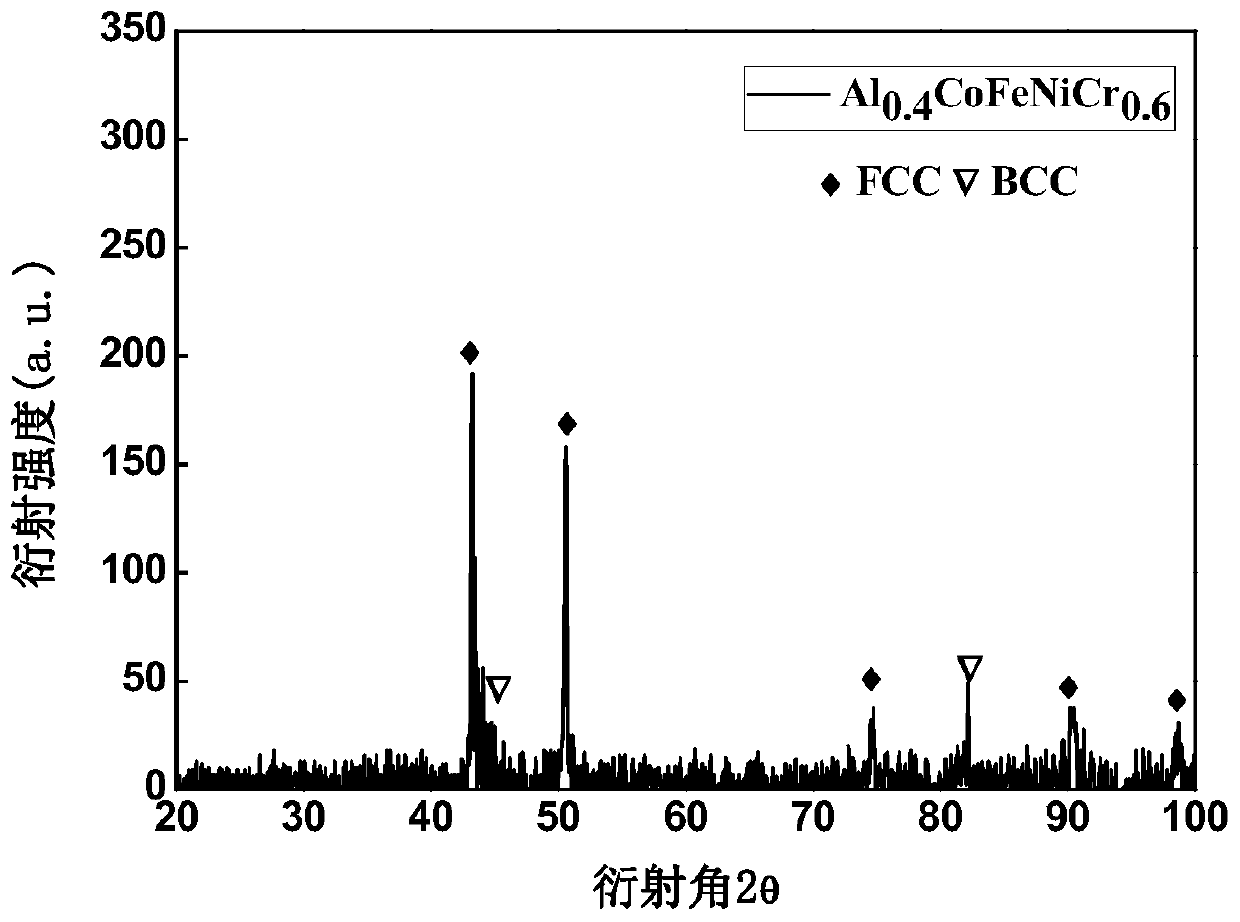

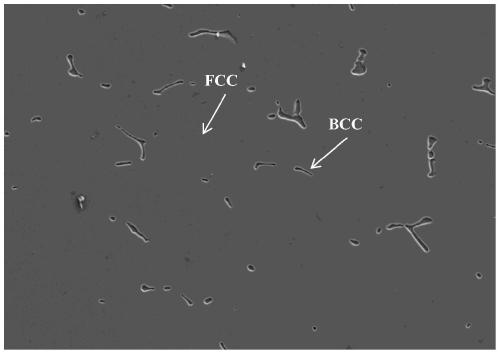

Manufacturing method of aluminum-cobalt-chromium-iron-nickel high-entropy alloy

The invention relates to a manufacturing method of aluminum-cobalt-chromium-iron-nickel high-entropy alloy. By means of the combination of mechanical ball milling, low-temperature hot pressed sintering and vacuum melting, the aluminum-cobalt-chromium-iron-nickel high-entropy alloy is manufactured and comprises an FCC+BCC bi-phase structure, the BCC phase serves as the precipitated phase and is distributed in the substrate FCC phase, the vickers hardness is 232HV, and the yield strength is 432 MPa. The manufacturing method is advanced in technology and accurate and detailed in technical parameter. The manufactured aluminum-cobalt-chromium-iron-nickel high-entropy alloy is excellent in performance and has the high application value and the broad application range, and the manufacturing method is an advanced manufacturing method.

Owner:ZHONGBEI UNIV

Preparation method of molybdenum-doped tungsten oxide gas-sensitive material

ActiveCN105712405AHigh purityAdvancedMaterial nanotechnologyTungsten oxides/hydroxidesHydrothermal synthesisChloride

The invention relates to a preparation method of molybdenum-doped tungsten oxide gas-sensitive material and aims to overcome the defect that a single-component tungsten oxide gas-sensitive material is low in sensitivity, low in response speed and poor in selectivity. The nano-scale molybdenum-doped tungsten oxide gas-sensitive material is prepared by doping molybdenum to tungsten oxide and subjecting tungsten chloride and ammonium molybdate to hydrothermal synthesis, vacuum calcining and grinding and screening. The preparation method employs advanced process, data are precise and elaborate, the product is light yellow powder, the particle diameter of the powder is < / =200 nm, the product has high purity up to 99.5% and has good gas sensitivity up to 26.5 for 10 ppm hydrogen sulfide, the product is useful in various gas sensors, and the preparation method is an advanced method for preparing molybdenum-doped tungsten oxide gas-sensitive materials.

Owner:TAIYUAN UNIV OF TECH

Preparation method of porous carbon nanotube

The invention relates to a preparation method of a porous carbon nanotube, and aims to solve the problems of easiness in agglomeration, poor dispersity and small specific surface area of a carbon nanotube. The porous carbon nanotube is prepared from a carbon nanotube serving as a raw material through solution preparation, ultrasonic dispersion treatment, acid oxidation, freeze drying, vacuum sintering, acid soaking, washing-suction filtration and drying in vacuum. The preparation method has the advantages of advanced and rapid process, and accurate and abundant data; a product is black powder with the particle diameter of less than or equal to 60nm; pores are uniformly distributed in the surface of the carbon nanotube, and the pore diameters are less than or equal to 10nm; the product purity is up to 99.5 percent, and the specific surface area is increased by 520 percent; the method is an advanced method for preparing the porous nanotube tube.

Owner:TAIYUAN UNIV OF TECH

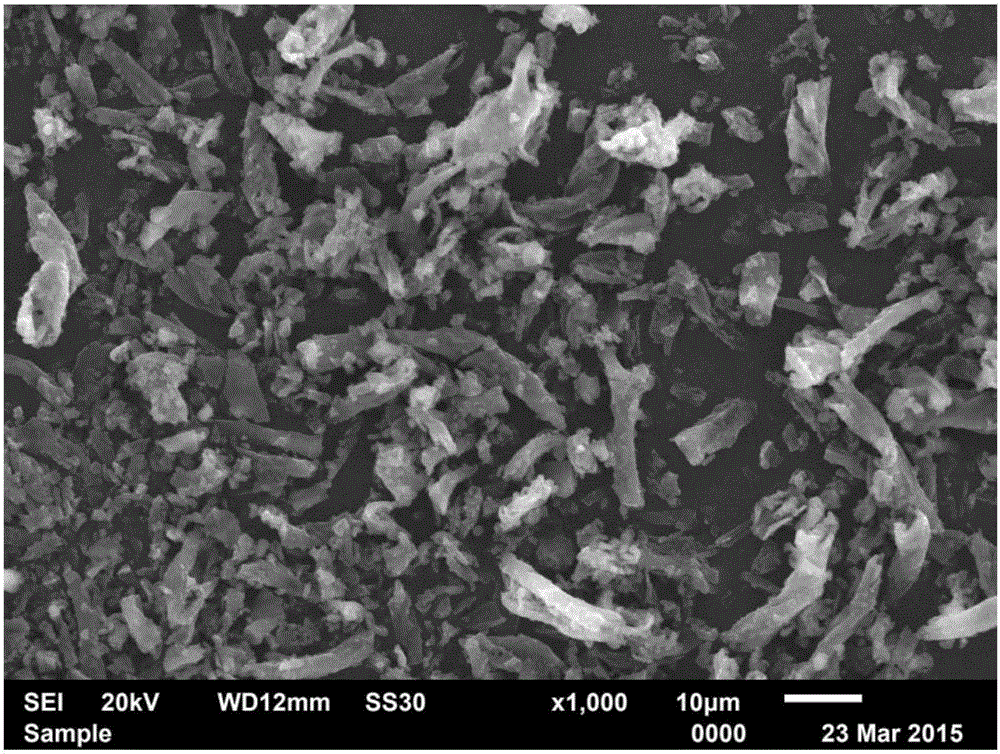

Method for rapidly preparing carbon material from waste polyester-cotton fabric

The invention relates to a method for rapidly preparing a carbon material from waste polyester-cotton fabric. Aiming at the condition that the waste polyester-cotton fabric is high in stock, serious in pollution and difficult to recover, the waste polyester-cotton fabric is washed, sterilized, degraded, separated and stripped at high pressure, and is frozen, dried and ground to prepare the carbon material. Meanwhile, byproducts such as terephthalic acid and ethylene glycol are also separated out. The preparation method is advanced in technology, and accurate and detailed in data; the prepared and separated carbon material is powder; the diameters of powder particles are less than or equal to 130nm; the product purity reaches 99.8%; the byproduct terephthalic acid is powder; the diameters of the powder particles are less than or equal to 2 microns; the product purity reaches 99.6%; the byproduct ethylene glycol is a colorless transparent liquid; the product purity reaches 99.3%; the products can be reutilized as chemical raw materials; and the method is a very advanced method for preparing the carbon material and the byproducts employing the waste polyester-cotton fabric.

Owner:SHANXI RUISAIGE TEXTILE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com