Method for rapidly preparing carbon material from waste polyester-cotton fabric

A technology of polyester-cotton fabrics and carbon materials, which is applied in the field of rapid preparation of carbon materials from waste polyester-cotton fabrics, can solve the problems of waste of resources, environment, less than 10%, pollution, etc., and achieve the effect of advanced technology and accurate and detailed data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

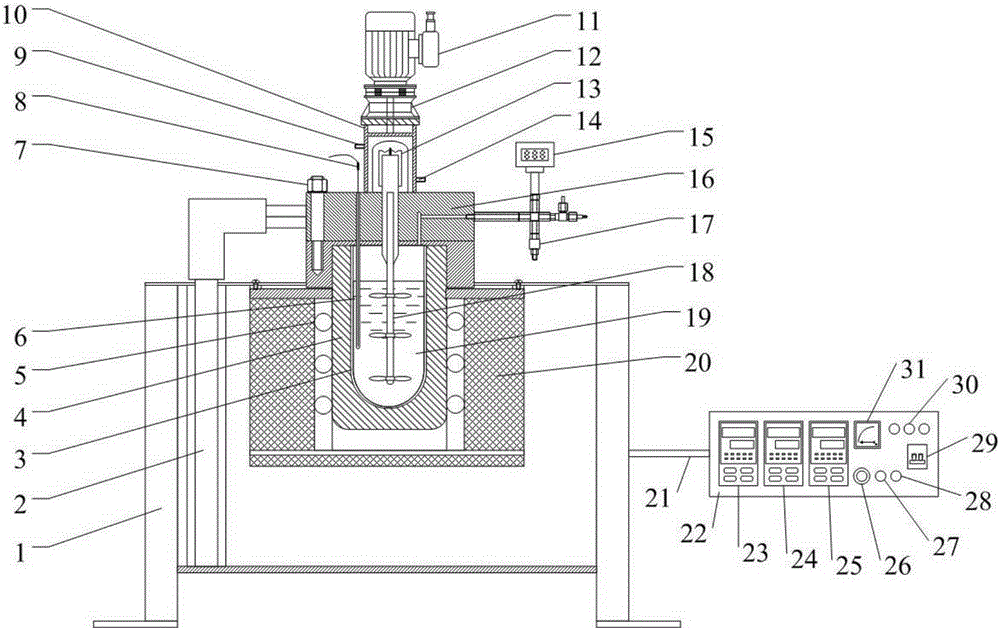

[0071] The present invention will be further described below in conjunction with accompanying drawing:

[0072] figure 1 As shown, it is a diagram of the degradation state of waste polyester-cotton fabrics, and the positions of each part must be correct, proportioned according to quantity, and operated in sequence.

[0073] Quantities of the chemical substances used in the preparation are first determined according to a preset range, with grams, milliliters, and millimeters as measurement units.

[0074] The degradation of waste polyester-cotton fabrics is carried out in a high-pressure reactor, which is completed in the process of heating and stirring;

[0075] The autoclave is vertical, the kettle body 4 is a cylinder, and is mounted on the autoclave support 1, and the upper part is the kettle cover 16, and the kettle body 4 and the kettle cover 16 are fixed by the bolt nut 7; The lifting device 2, the upper part of the lifting device 2 is connected with the kettle cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com