Preparation method of long-period-structure-reinforced magnesium-zirconium alloy ingot

A long-period structure, magnesium-zirconium alloy technology, which is applied in the preparation and application of non-ferrous metal materials, can solve the problems that the technology needs to be improved, and achieve the effect of advanced technology and accurate and detailed data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with accompanying drawing:

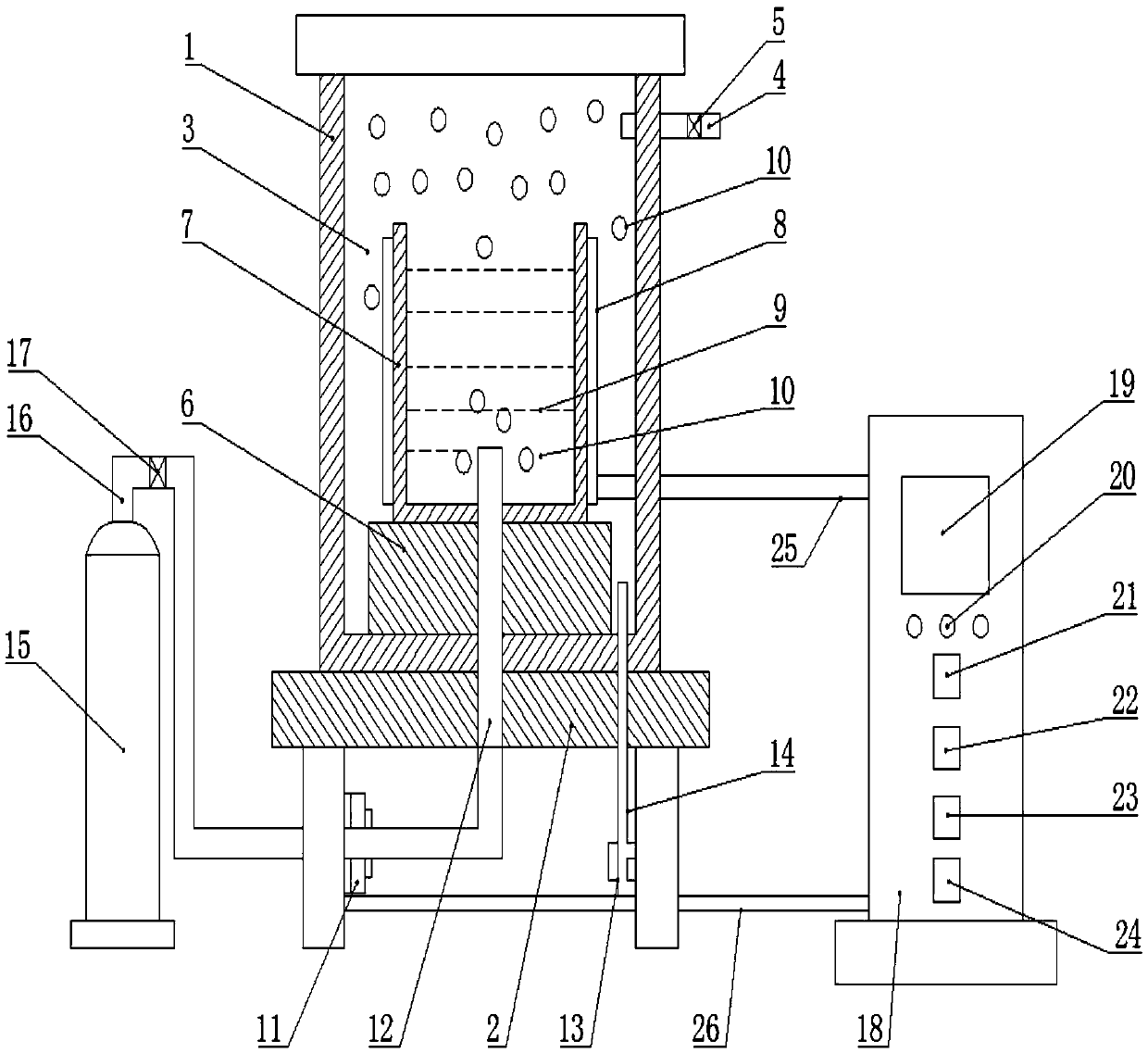

[0070] figure 1 As shown, it is the smelting state diagram of the magnesium-zirconium alloy ingot with long-period structural reinforcement. The position of each part must be correct, and the operation should be carried out in sequence.

[0071] Quantities of chemicals used in preparation are determined in pre-set ranges in grams, milliliters, centimeters 3 is the unit of measurement.

[0072] The melting of magnesium-zirconium alloy with long-period structural reinforcement is carried out in a vacuum melting furnace, which is completed in the process of medium-frequency induction heating, vacuuming, argon bottom blowing, and casting;

[0073] The vacuum melting furnace is vertical, the bottom of the vacuum melting furnace 1 is the furnace seat 2, and the interior is the furnace chamber 3. A workbench 6 is arranged at the bottom of the furnace chamber 3, and a melting cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com