Method for preparing porous compound desulfurizer for removing organic sulfide

A desulfurization agent and sulfide technology, applied in chemical instruments and methods, other chemical processes, gas fuels, etc., can solve the problems of natural gas quality decline, high desulfurization cost, difficult regeneration, etc., to achieve accurate and detailed data, good product purity, Effects that are not easy to regenerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with accompanying drawing:

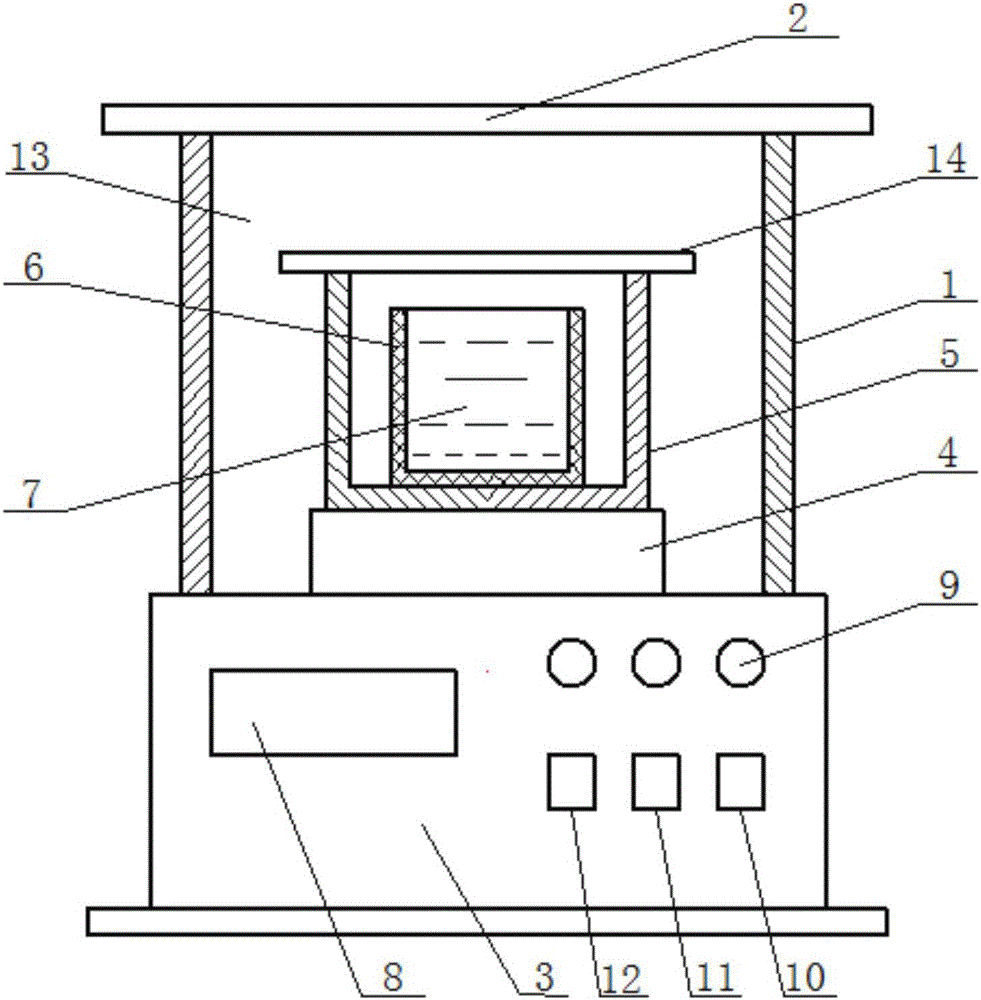

[0067] figure 1 As shown, it is the hydrothermal synthesis state diagram of the activated carbon mixture, and the position and connection relationship of each part must be correct, and the ratio should be adjusted according to the amount, and the operation should be carried out in sequence.

[0068] Quantities of the chemical substances used in the preparation are determined according to a preset range, with grams and milliliters as measurement units.

[0069] The hydrothermal synthesis of the activated carbon mixture is carried out in the reactor, which is heated in a closed state and carried out under the compound reaction;

[0070]The heating furnace 1 is rectangular, and the lower part of the heating furnace 1 is an electric control box 3, the upper part is a furnace cover 2, and the inside is a furnace cavity 13; Reactor 5, a polytetrafluoroethylene container 6 is pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com