Semi-solid squeezing casting method and system for aluminum alloy

A semi-solid extrusion and aluminum alloy technology, applied in the field of aluminum alloy semi-solid extrusion casting, can solve the problems of reducing the cost of semi-solid slurry preparation, slurry transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The aluminum alloy semi-solid extrusion casting method provided by the present invention is used to prepare aluminum alloy semi-solid extrusion castings. The chemical materials used in this embodiment are: aluminum alloy, zinc oxide, water glass, aluminum foil, acetone, deionized water, and argon; the preparation amount is as follows (in grams, milliliters, centimeters) 3 Is the unit of measurement):

[0050]

[0051] The specific preparation method is as follows:

[0052] (1) Preparation of extrusion die

[0053] The extrusion die is rectangular, the material is stainless steel, the die cavity size is 120mm×30mm×50mm, and the cavity surface roughness is Ra0.08-0.16μm.

[0054] (2) Preparation of coating agent and coating extrusion die

[0055] Weigh 50g±1g of zinc oxide, 10g±1g of water glass, measure 500mL±5mL of deionized water, add it to the mixer for stirring, stirring speed 50r / min, stirring time 80min; after stirring, it becomes a milky white suspension liquid, Namely co...

Embodiment 2

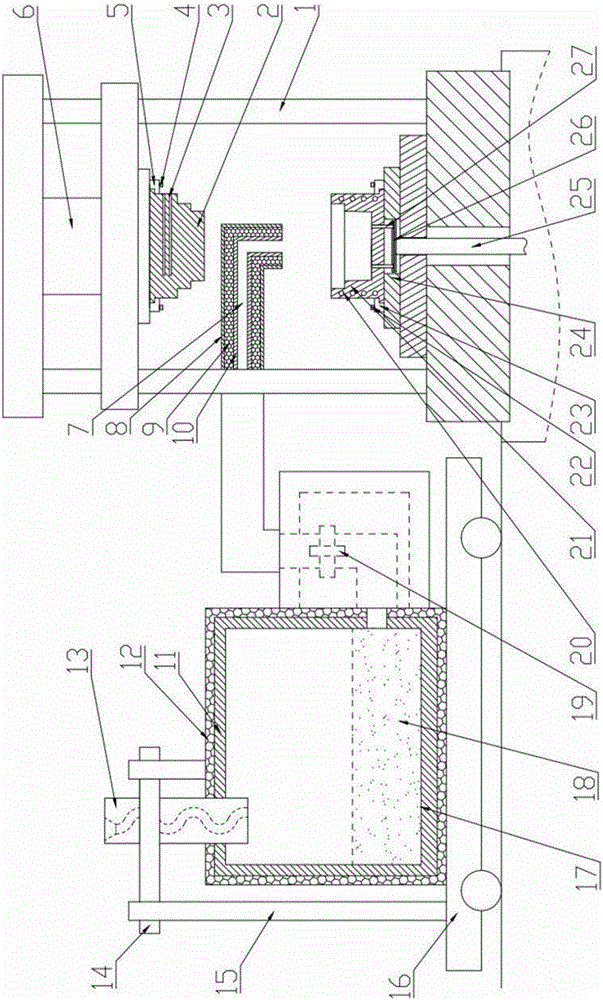

[0079] This embodiment provides a system for semi-solid squeeze casting of aluminum alloy, such as figure 1 As shown, the system can be applied to the above aluminum alloy semi-solid extrusion casting method for preparing aluminum alloy semi-solid extrusion castings, and the system includes:

[0080] The aluminum alloy semi-solid slurry preparation device includes a gate 13 and a heat preservation device 17; wherein: the gate 13 is set at the entrance of the heat preservation device 17 and communicates with the inside of the heat preservation device 17, for receiving the aluminum alloy obtained by smelting and preliminary preparation Aluminum alloy semi-solid slurry; the heat preservation device 17 is used to receive and heat the aluminum alloy semi-solid slurry obtained by preliminary preparation through the gate 13 to form a homogeneous aluminum alloy semi-solid slurry;

[0081] The extrusion molding device includes a heat-preserving extrusion die (2, 21) for extruding the aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com