Preparation method of aluminum, copper and iron quasicrystal

An aluminum-copper-iron and quasicrystal technology is applied in the field of preparation of aluminum-copper-iron quasicrystals, which can solve problems such as process drawbacks and unsuitability for mass production, and achieve the effects of advanced technology, accurate and detailed data, and strict procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with accompanying drawing:

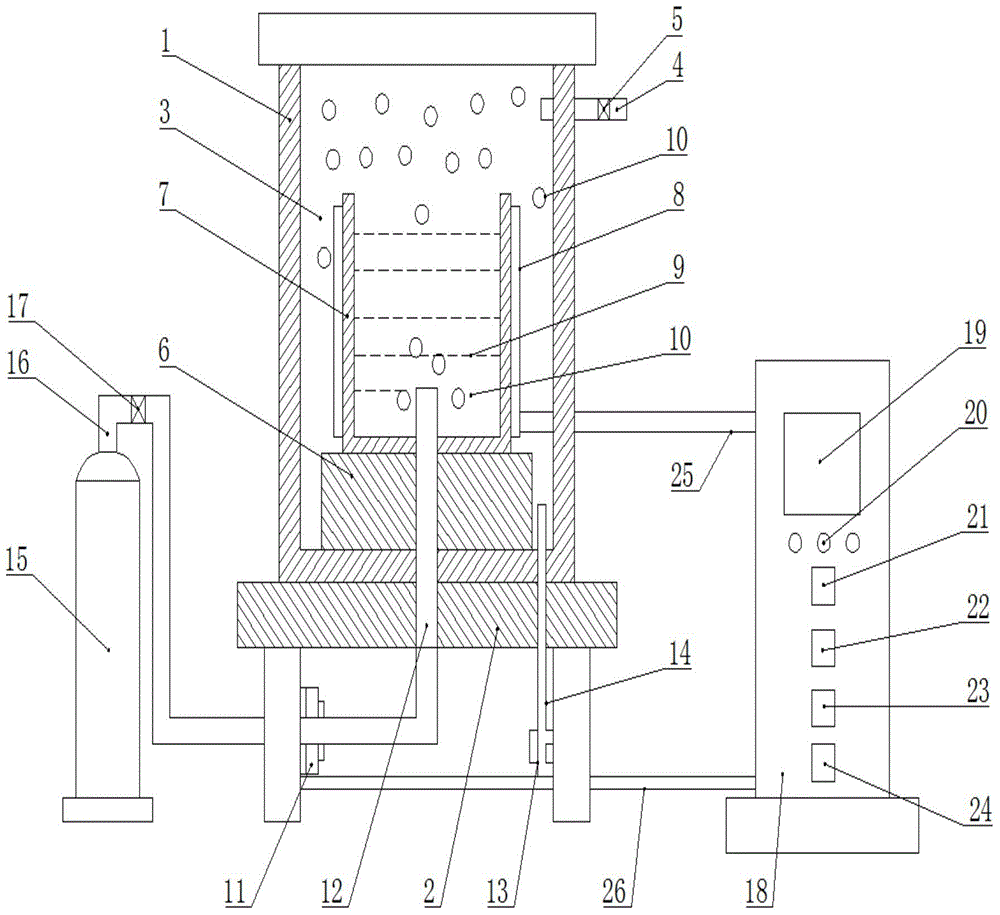

[0062] figure 1 As shown in the figure, in order to prepare the aluminum-copper-iron alloy state diagram for smelting, the position and connection relationship of each part must be correct, the ratio should be proportioned, and the operations should be performed in sequence.

[0063] The amount of chemical substances used in the preparation of smelting is determined according to the preset range, in grams, milliliters, centimeters 3 is the unit of measurement.

[0064] The smelting and preparation of aluminum-copper-iron alloy is carried out in the intermediate frequency induction melting furnace, which is completed in the process of intermediate frequency heating smelting, vacuuming, argon bottom blowing, and casting;

[0065]The intermediate frequency induction melting furnace is vertical, the bottom of the intermediate frequency induction melting furnace 1 is the furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com