Preparation method of quasi-crystal reinforced type aluminum-based composite material

An aluminum-based composite material and enhanced technology, which is applied in the field of preparation and application of non-ferrous metal materials, can solve the problems that the process technology needs to be improved, and achieve the effect of advanced technology, strict process and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with accompanying drawing:

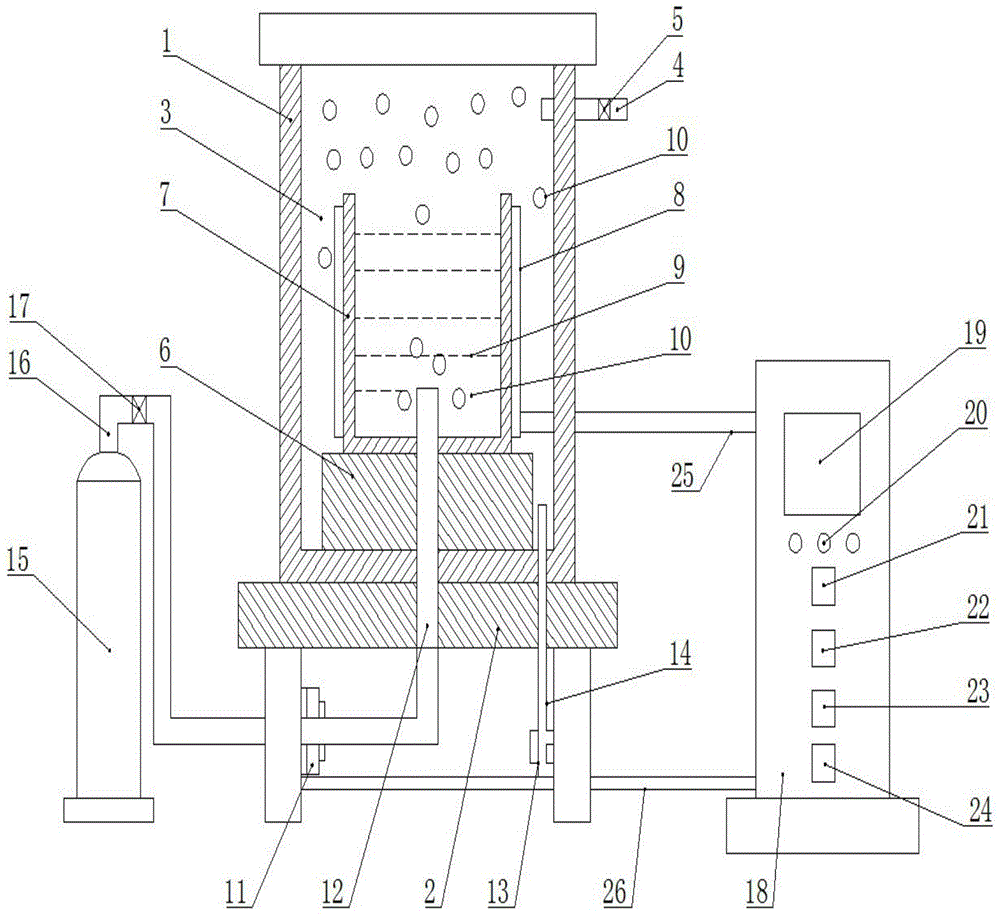

[0064] figure 1 As shown in the figure, it is the smelting state diagram of the quasi-crystal reinforced aluminum matrix composite material. The position of each part must be correct, and the operation should be carried out in sequence.

[0065] The amount of chemical substances used in the preparation is determined according to the pre-set range, in grams, milliliters, centimeters 3 is the unit of measurement.

[0066]The smelting of quasi-crystal enhanced aluminum matrix composites is carried out in the intermediate frequency induction melting furnace, which is completed in the process of intermediate frequency induction heating, vacuuming, argon bottom blowing, and casting; the intermediate frequency induction melting furnace is vertical, and the intermediate frequency The bottom of the induction melting furnace 1 is the furnace seat 2, and the inside is the furnace ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com