Composite squeeze casting method for magnesium alloy special-shaped parts

A technology of composite extrusion and extrusion casting machine, which is applied in the field of composite extrusion casting of magnesium alloy special-shaped parts, and can solve the problems of low production efficiency, incapable of heat treatment of die castings, and shrinkage porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described below in conjunction with accompanying drawing:

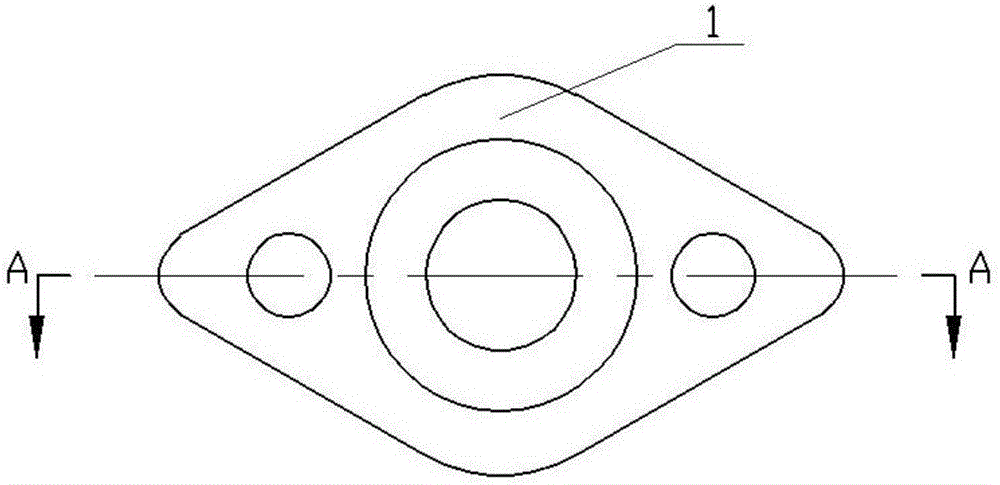

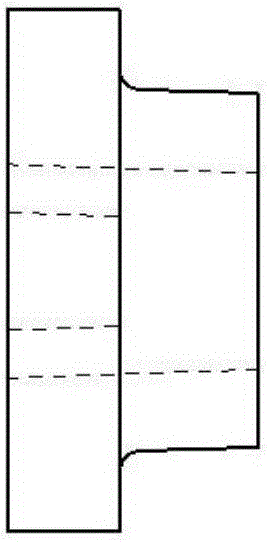

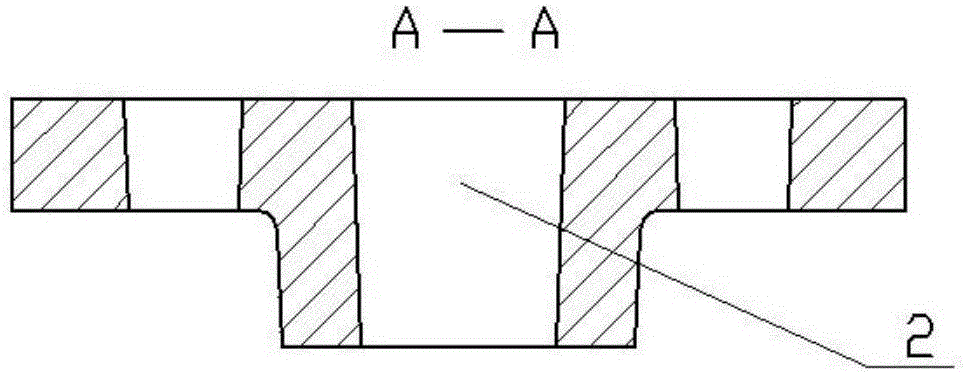

[0075] figure 1 , 2 , Shown in 3, is the structure drawing of magnesium alloy special-shaped parts, and part 1 has circular hole 2 in the middle part, and both sides also have circular hole.

[0076] Figure 4 , 5 , Shown in 6, 7, 8, and 9 are structural diagrams of a compound extrusion casting mold, and the mold is composed of a die 4, a punch 3 and a compound extrusion device;

[0077] Die 4 is connected with punch frame 17 by left guide post 15, right guide post 16;

[0078] The punch 3 is fixedly connected with the punch frame 17, the mold frame 9, and the punch plate 6, the punch 3 is fixed on the punch frame 17, the punch frame 17, the mold frame 9, and the punch plate 6 are fixed by bolts 19 and pin shafts 20 ;

[0079] The composite extrusion device is composed of a push plate 10, a left connecting guide post 13, a right connecting guide post 14, an upper ejec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com