Preparation method of graphene-reinforced aluminum matrix composite

A technology of composite materials and enhanced aluminum base, which is used in the preparation and application of non-ferrous metal composite materials. It can solve the problems of poor wettability, weak interfacial bonding force, and difficulty in uniform distribution, and achieve pure slurry and good metallographic structure. , No shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

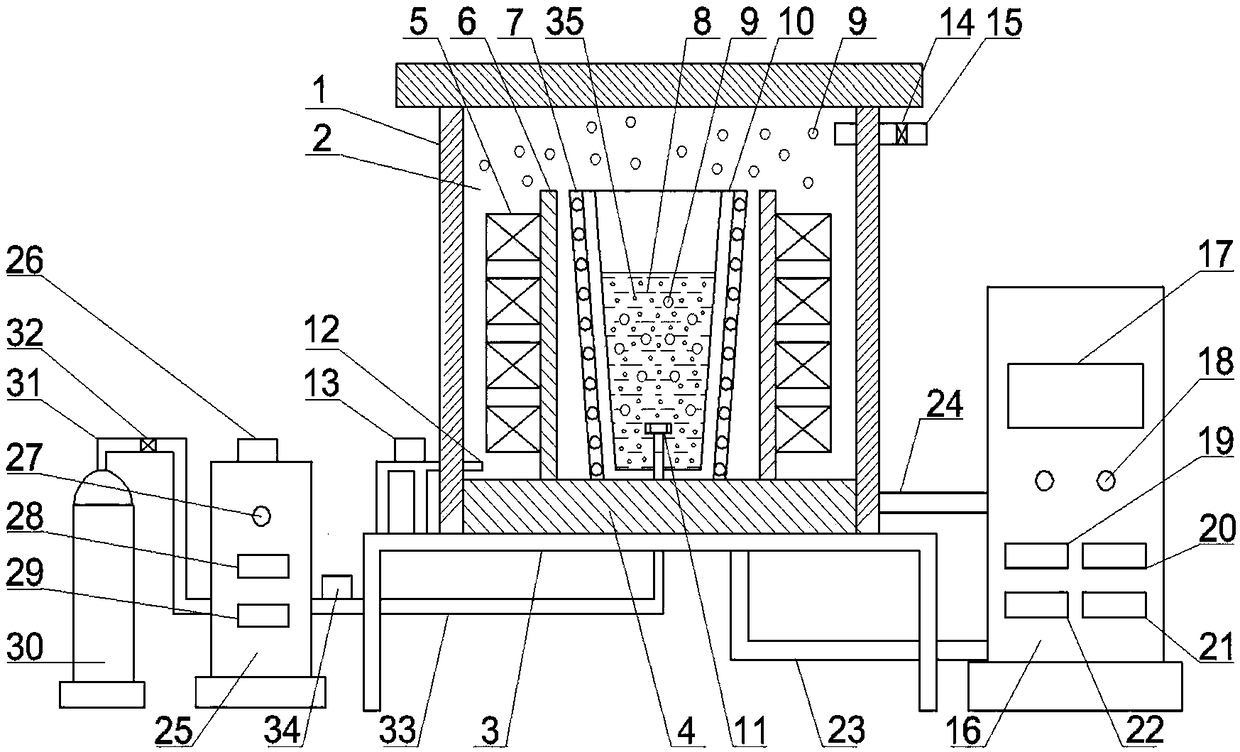

[0055] The present invention will be further described below in conjunction with accompanying drawing:

[0056] figure 1 As shown, it is the smelting state diagram of the graphene aluminum alloy semi-solid slurry, the position and connection relationship of each part must be correct, the ratio should be proportioned, and the operations should be performed in sequence.

[0057] Quantities of chemicals used to prepare smelts are determined in pre-set ranges in grams, milliliters, centimeters3 is the unit of measurement.

[0058] The smelting of graphene aluminum alloy semi-solid slurry is carried out in a smelting and stirring atmosphere furnace, which is completed in the process of heating, smelting, heat preservation and standing, cooling solid liquid, adding graphene aluminum alloy mixed fine powder, and electromagnetic stirring;

[0059] The smelting stirred atmosphere furnace 1 is vertical, the inside of the smelting stirred atmosphere furnace 1 is a furnace chamber 2, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com