Manufacturing method of aluminum-cobalt-chromium-iron-nickel high-entropy alloy

A high-entropy alloy, Al-Co-Fe-Cr technology is applied in the field of preparation of Al-Co-Cr-Ni high-entropy alloy, can solve the problems of shortening sintering time, high mold requirements, long ball milling time, etc., and achieves broad application prospects and use value , The effect of reducing uneven melting of materials and accurate and detailed data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063]The present invention will be further described below in conjunction with accompanying drawing:

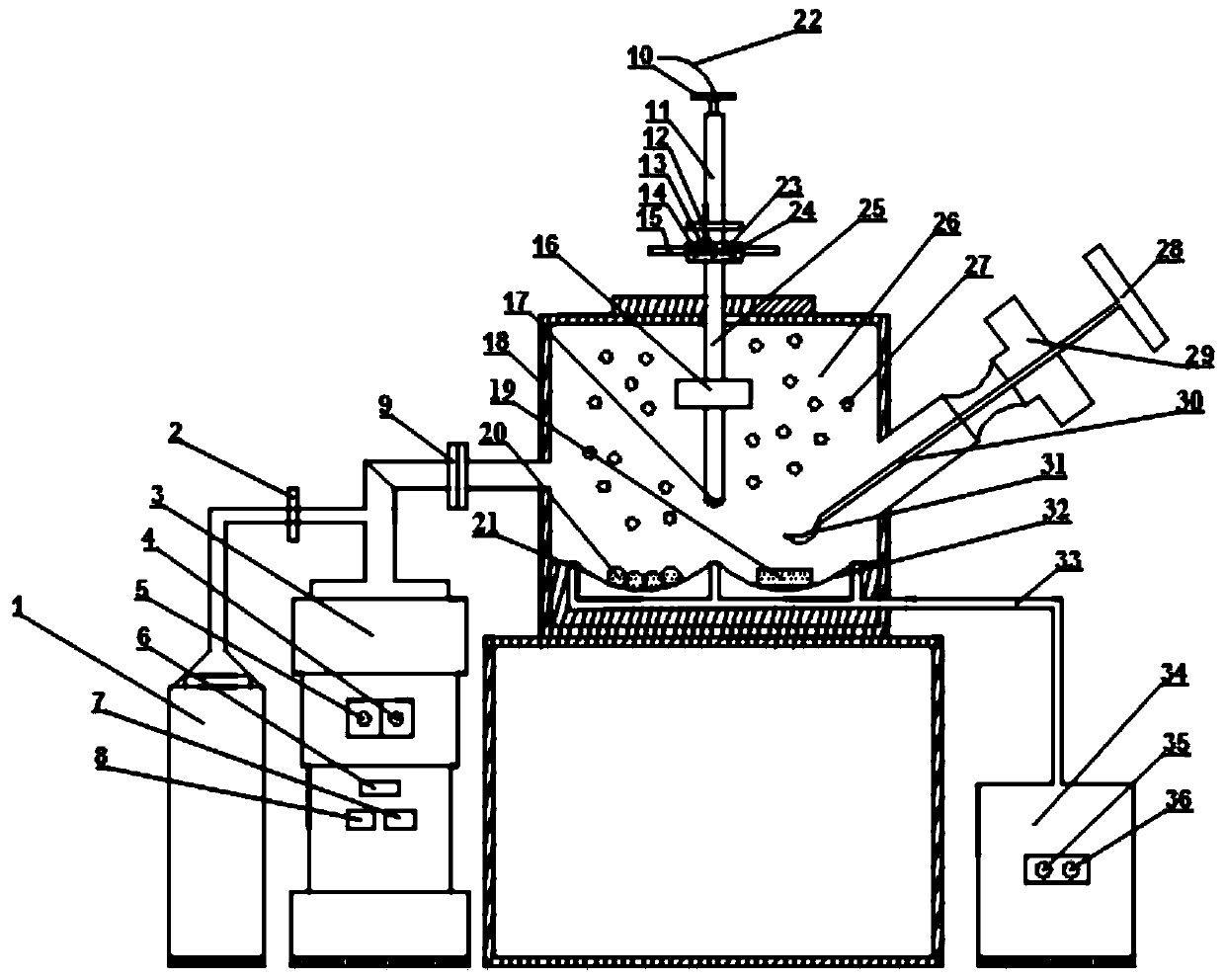

[0064] figure 1 It is the smelting state diagram of the vacuum arc melting furnace, the position of each part, the connection relationship is correct, and the installation is firm.

[0065] Quantities of the chemical substances used in the preparation are determined according to a predetermined range, with grams, milliliters, and cubic centimeters as measurement units.

[0066] The Al-Co-Cr-Fe-Ni high-entropy alloy is prepared by combining three processes: mechanical ball milling, hot pressing sintering, and vacuum arc melting, and is completed by segmental melting;

[0067] Vacuum arc melting furnace 18 is a three-dimensional arc melting furnace with furnace chamber 26 inside and filled with argon gas 27; vacuum arc melting furnace 18 is provided with an elevator device 11 in the middle of the upper part. In the cavity 26, at the lower end of the tungsten pole gun rod 25 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com