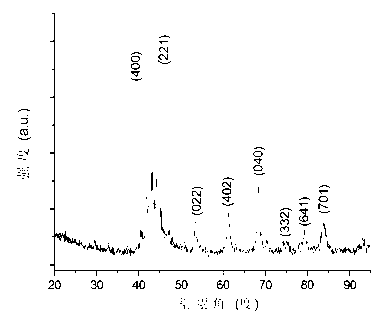

Ni-Mn-Ge magnetic shape memory alloy and preparation method thereof

A memory alloy and magnetic technology, applied in the field of Ni-Mn-Ge magnetic material and its preparation, can solve the problems of limited application, difficulty in obtaining bulk materials, high cost, etc., and achieve the effect of simple and feasible preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation composition is: a single crystal material with magnetic shape memory effect, which is heated by radio frequency with a growth parameter of 245KHz, and argon with a positive pressure of 0.01 to 1MPa is used as a protective gas, and grown in a magnetic levitation copper crucible with a heating power of 20 kilowatts ,

[0034] Its preparation method is carried out according to the following specific steps:

[0035] (1) Weigh Ni, Mn, Ge and Si with a purity of 99.9% respectively according to the molar ratio Ni:Mn:Ge:Si=52:33:12:3 in the above composition, and put the weighed materials in Put it into a copper crucible, put it into a melting furnace, and use a mechanical pump to pre-evacuate to 5×10 -1 Pa; use a molecular pump to evacuate to 5×10 -4 Pa, high-purity argon gas (purity 99.9%) is introduced to make the internal pressure of the melting furnace chamber reach 0.1MPa; Ni is obtained by arc melting 52 mn 33 Ge 12 Si 3 Polycrystalline ingot. Duri...

Embodiment 2

[0043] The preparation composition is Ni 52 mn 33 Ge 12 sn 3 The polycrystalline alloy with magnetic shape memory effect is prepared by arc melting method, with 0.1MPa positive pressure argon as the protective gas, in a water-cooled copper crucible, to prepare polycrystalline ingots, and then to obtain polycrystalline sample. Its preparation method is carried out according to the following specific steps:

[0044] (1) Weigh Ni, Mn, Ge and Sn with a purity of 99.9% respectively according to the molar ratio of each material in the above composition Ni:Mn:Ge:Sn=52:33:12:3, and put the weighed materials in Put it into a copper crucible, put it into a melting furnace, and use a mechanical pump to pre-evacuate to 5×10 -1 Pa; use a molecular pump to evacuate to 1×10 -4 Pa, high-purity argon gas is introduced to make the internal pressure of the melting chamber reach 0.1MPa; an arc is generated, and the arc head is kept at 2-5cm above the sample and swings repeatedly in a small ...

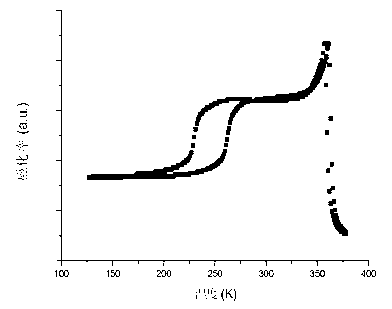

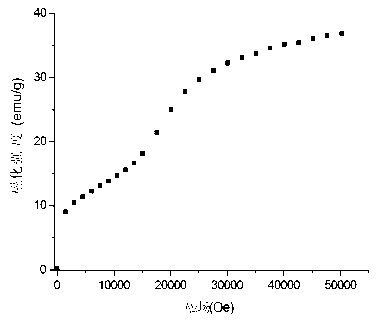

Embodiment 3

[0049] The preparation composition is: Ni 52 mn 32 Ge 15 co 1 A magnetic shape memory alloy polycrystalline with a magnetic field-driven martensitic phase transformation effect; except that the composition becomes Ni:Mn:Ge:Co=52:32:15:1, and the blowing process in step (3) The pressure of argon is 0.05MPa, and the rotational speed of the copper wheel is 25m / s, and the rest of the steps are the same as in Example 2. The above properties were measured, and the obtained magnetization curves are shown in Table 3, from which it can be seen that the phase transition driven by the magnetic field is obvious. The obtained values of the martensitic phase transition temperature and Curie temperature of the sample are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com