Patents

Literature

52results about How to "Good crystallization performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

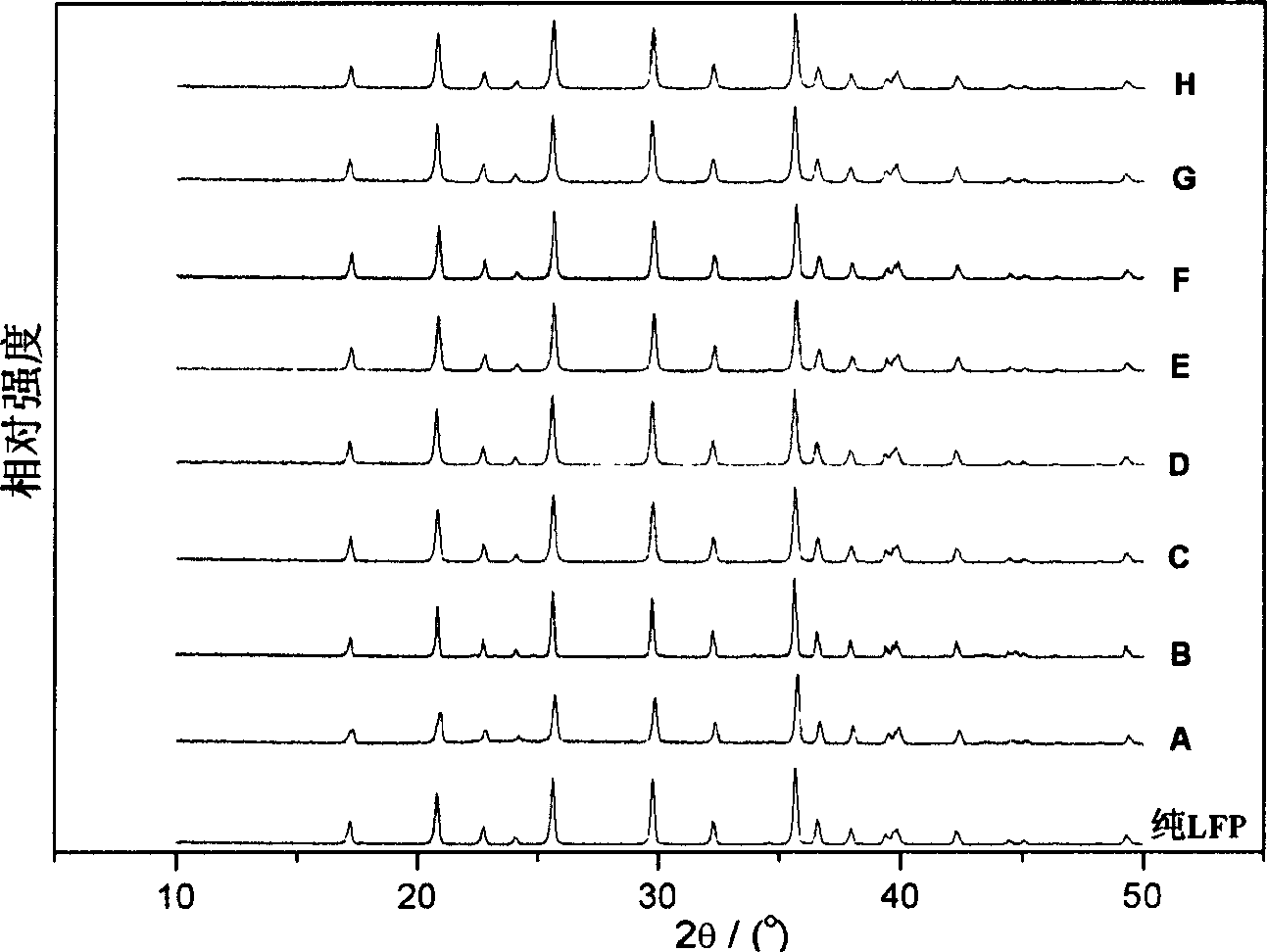

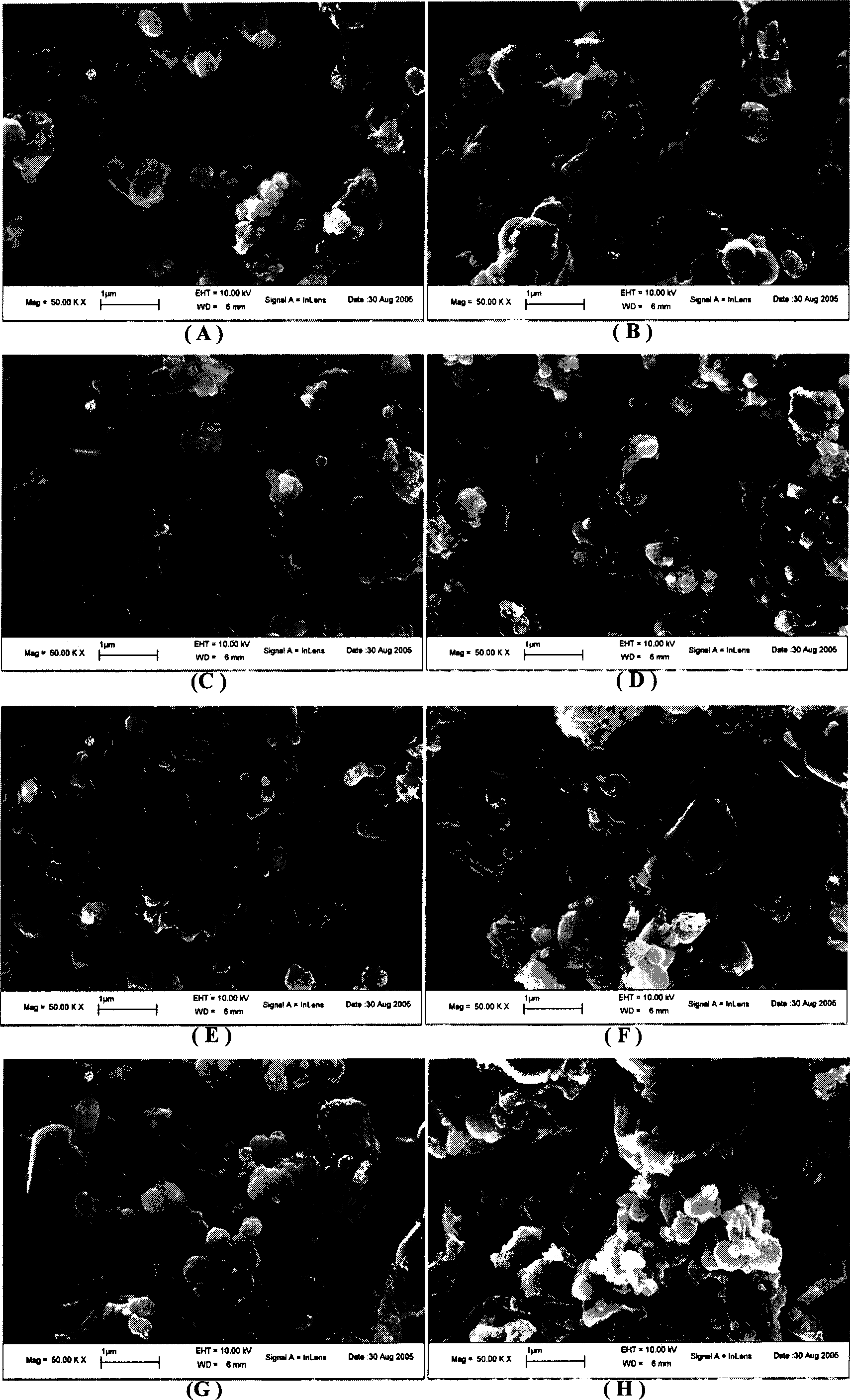

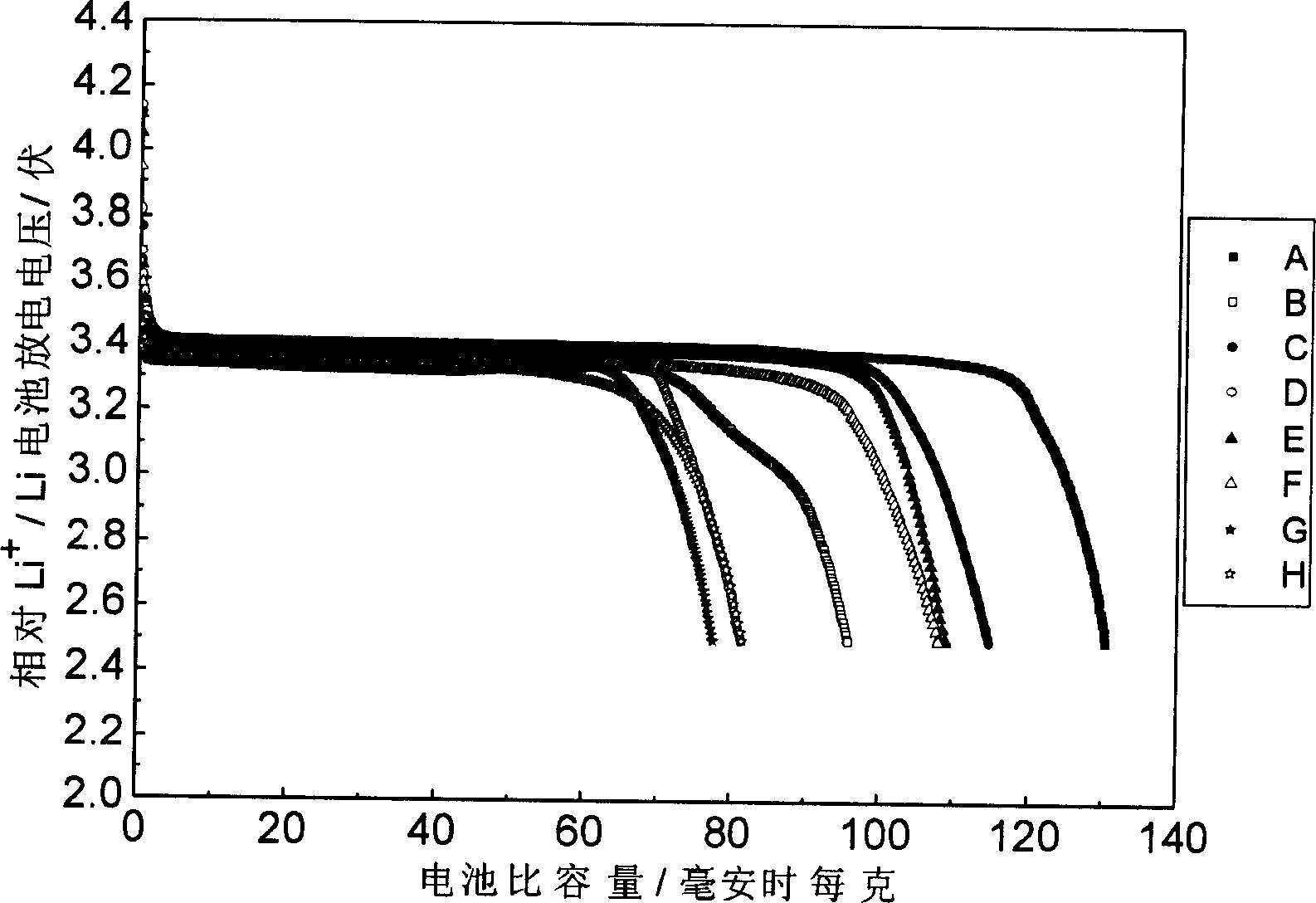

Preparation method of phosphorus position partly substituted iron lithium phosphate powder

InactiveCN1785823AGood crystallization performanceUniform compositionSulfur compoundsLithium compoundsTungstenPhosphate

The present invention discloses a preparation method of phosphorus position partial substituted type iron lithium phosphate powder body, belonging to the field of electrochemical power supply material preparation technology. The molecular formula of said positive electrode iron lithium phosphate of lithium ion cell is LiFeP1-yDyO4. Its preparation method includes the following steps: mixing lithium salt, ferrous salt, phosphate and substitution compound according to a certain mole ratio, drying, low-temperature prefiring and high-temperature secondary calcining so as to obtain the phosphorus position partial substituted type iron lithium phosphate powder body. Said invention uses the compound of boron, tungsten, sulfur and silicon or elementary substance as substitution compound.

Owner:TSINGHUA UNIV

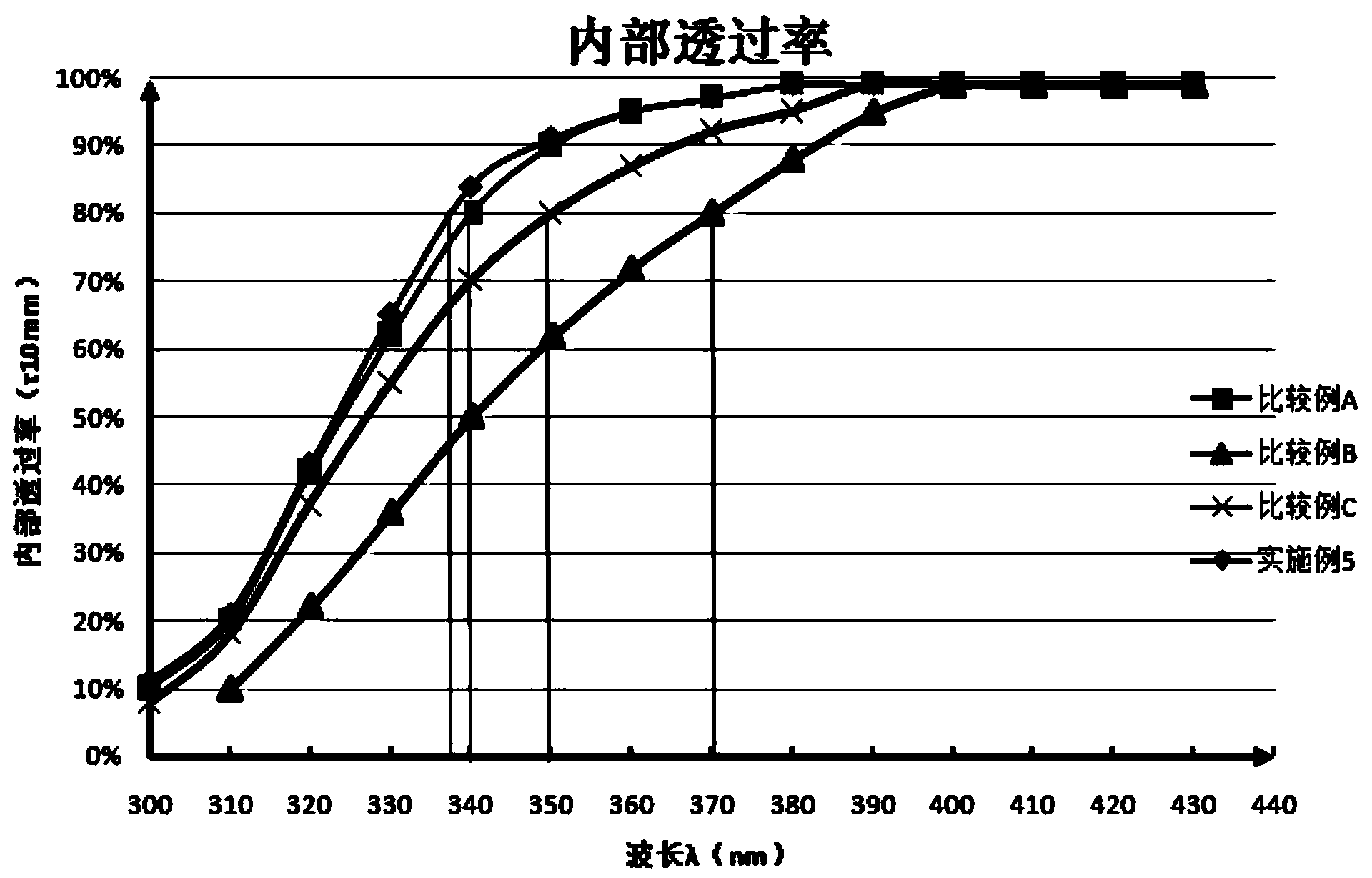

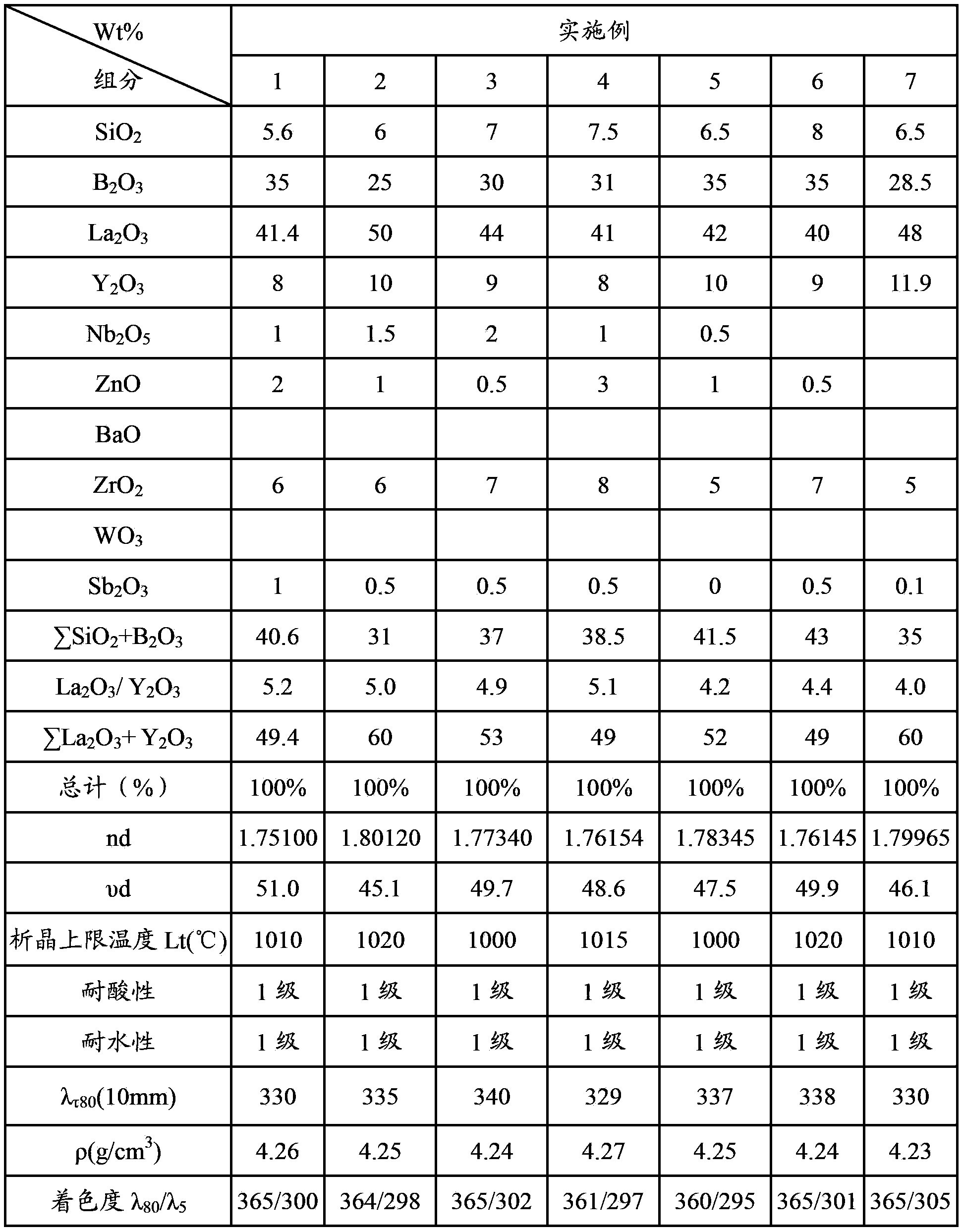

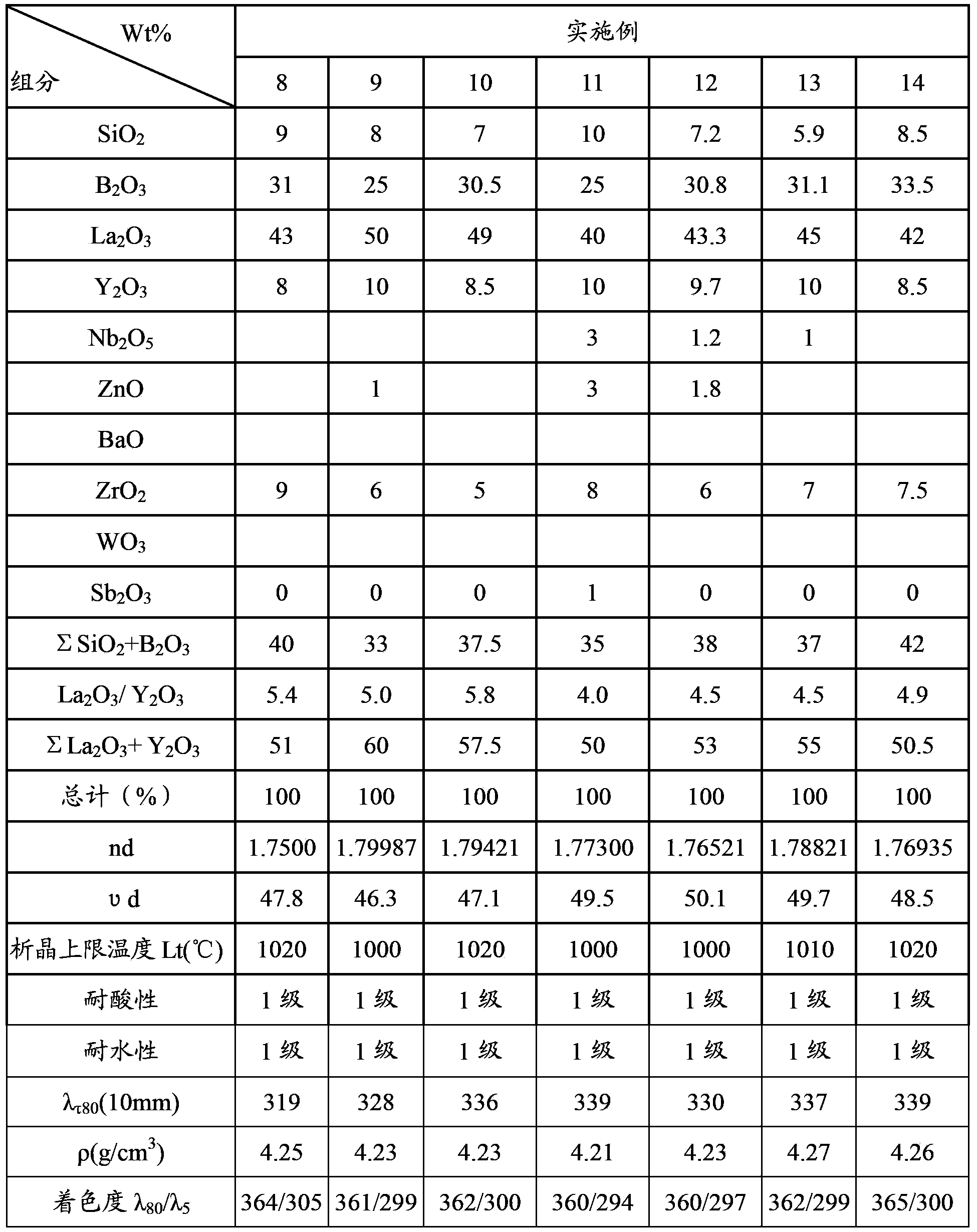

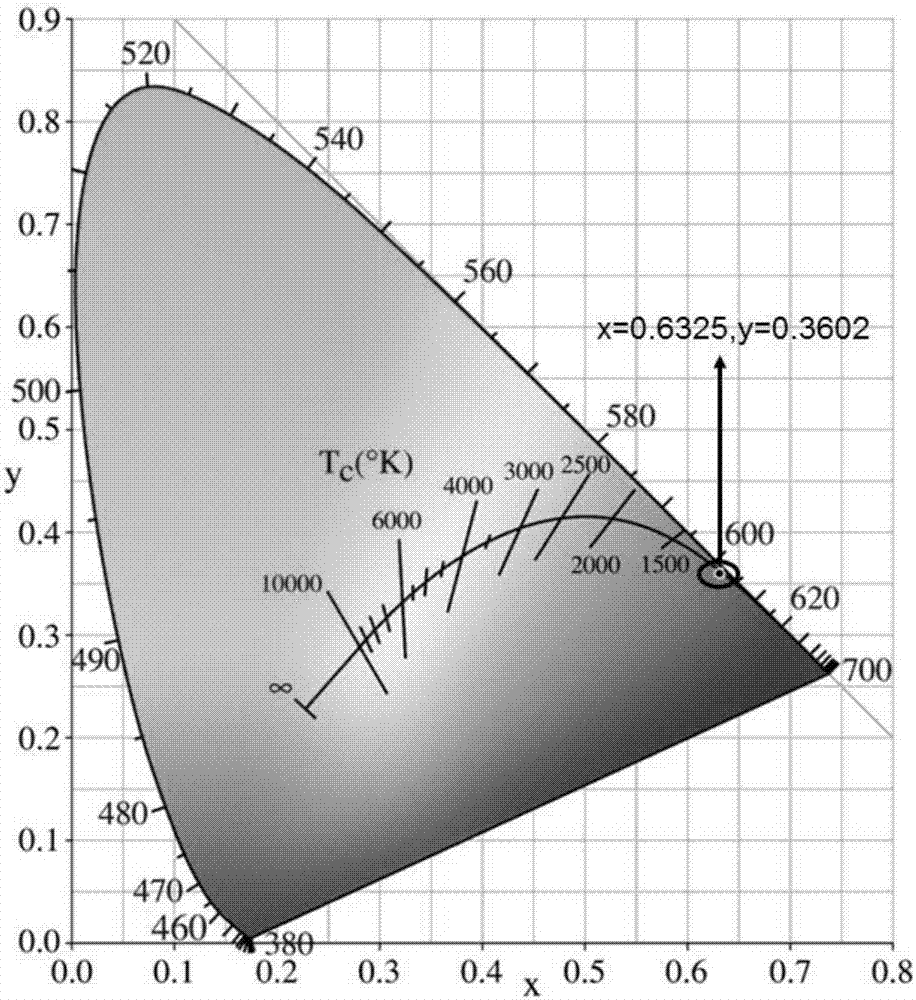

Lanthanum flint optical glass and preparation method thereof

The invention provides lanthanum flint optical glass which takes Si2O, B2O3 and La2O3 as main components and a preparation method thereof. The lanthanum flint optical glass is free of thorium, cadmium and arsenic. The refractivity of the optical glass is 1.75-1.80, the Abbe number is 45-51, and the optical glass has excellent chemical stability. The optical glass comprises the following compounds in percentage by mass: 5.6-10% of SiO2, 25-35% of B2O3, 40-50% of La2O3, more than 8% and less than 12% of Y2O3, 5-10% of ZrO2, 0-3% of ZnO, 0-3% of Nb2O5, 0-1% of Sb2O3, 30-44% of Sigma(SiO2+B2O3) and 45-60% of Sigma(La2O3+Y2O3). The optical glass is free of Ta2O5, Gd2O3, Yb2O3, TiO2, Li2O, PbO, WO3 and BaO. The optical glass has low cost, low specific gravity and high internal transmittance, thus having great market competition advantages.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

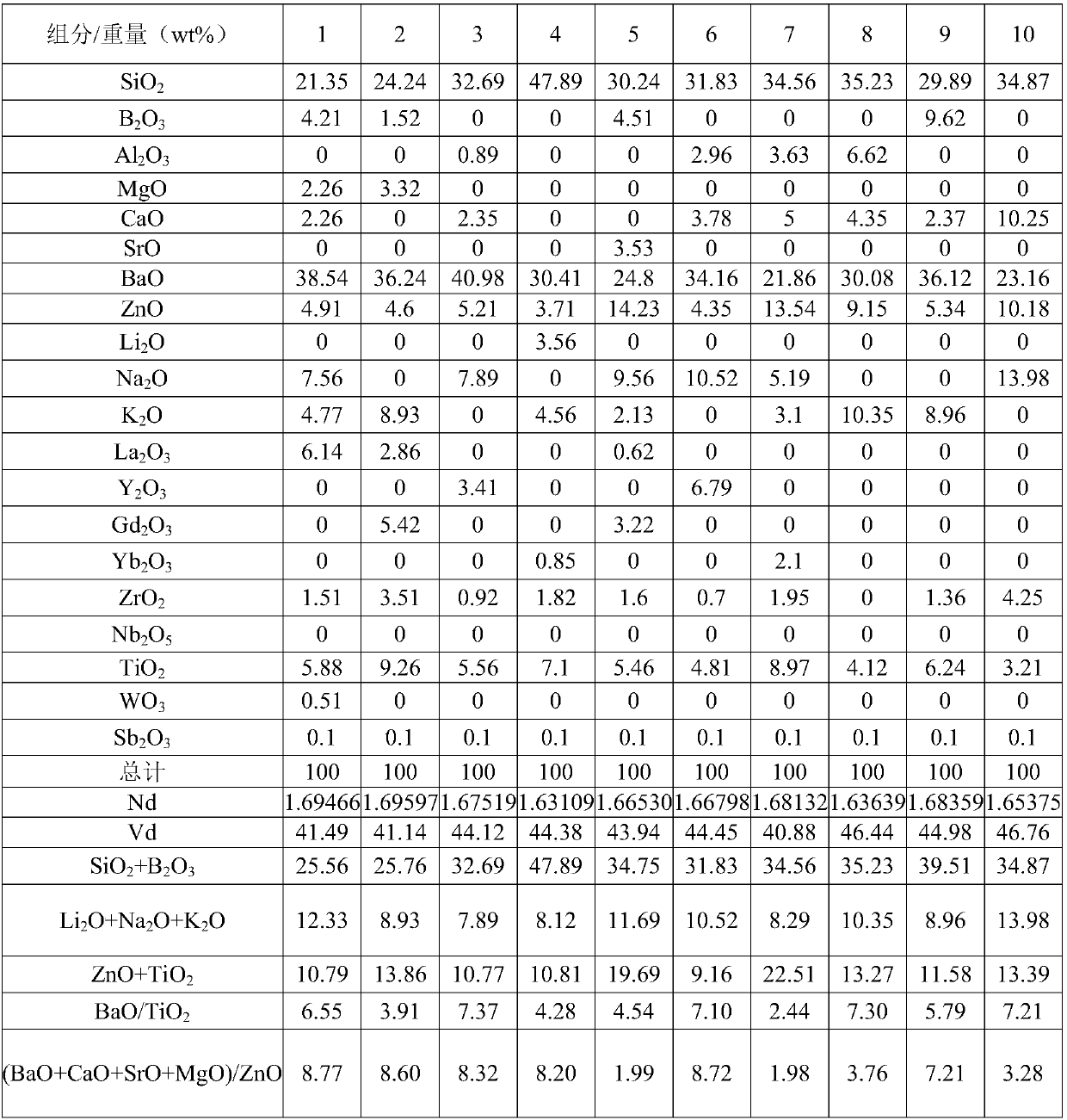

Optical glass

ActiveCN107663011ALow costGood chemical stabilityOptical elementsLaser technologyAlkaline earth metal

The invention provides environment-friendly optical glass with relatively low cost, good chemical stability, the refractive index of 1.60-1.70 and the abbe number of 40-50. The optical glass containsthe following components in percentage by weight: 20-50% of SiO2, 0-15% of B2O3, 1-15% of TiO2, 2-20% of ZnO and 15-50% of BaO. According to the optical glass, under the premise that Nb2O5 is reducedand even is not contained, contents of alkali metals, alkaline earth metals, ZnO and TiO2 are optimized, glass with low cost, good chemical stability and excellent crystallization property is obtained, the glass can be widely applied to the fields of imaging, projection, telecommunication, optical communication engineering and laser technology application, and requirements of the modern novel photoelectric product can be met.

Owner:CDGM OPTICAL GLASS

Optical glass

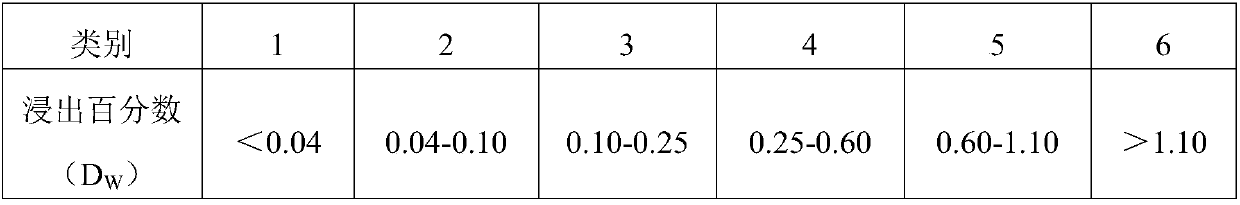

ActiveCN102674686AGood crystallization performanceGood chemical stabilityRefractive indexAcid resistance

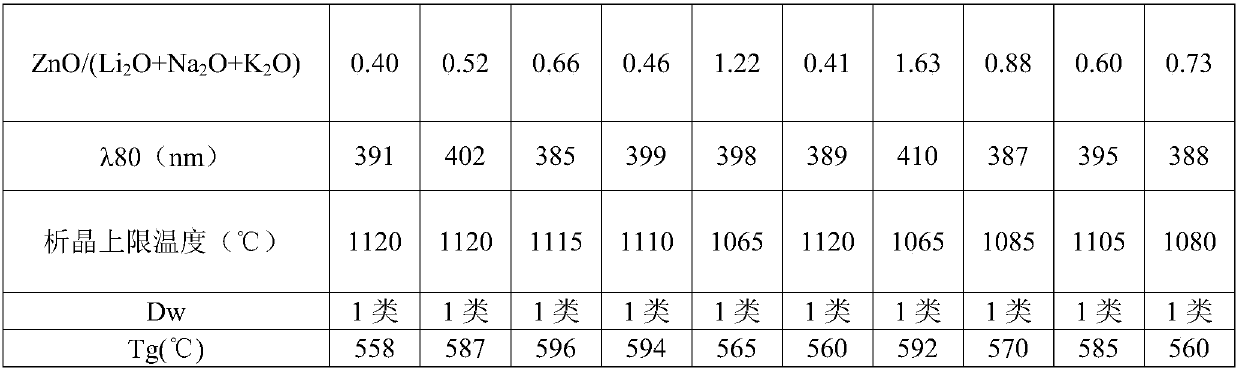

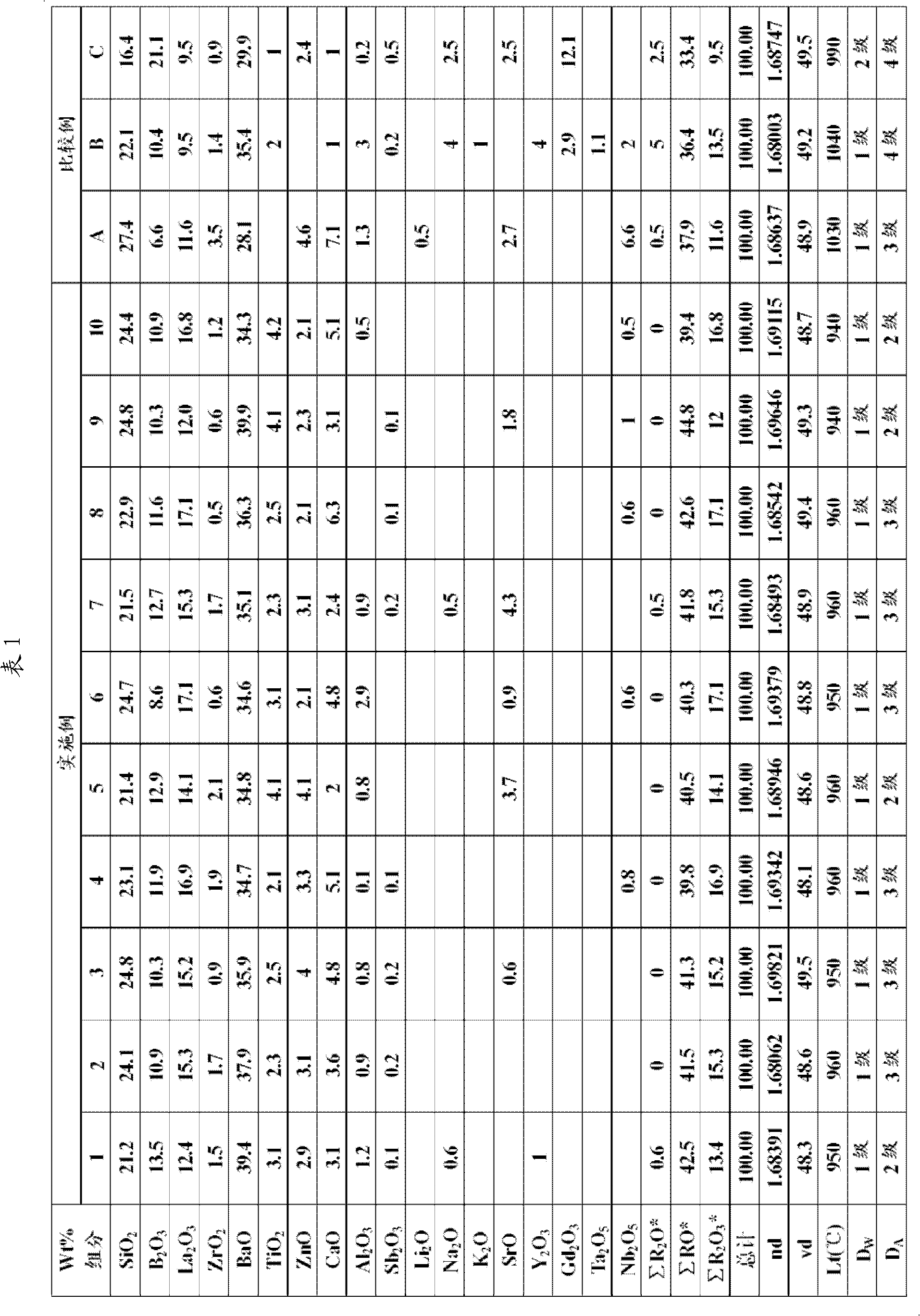

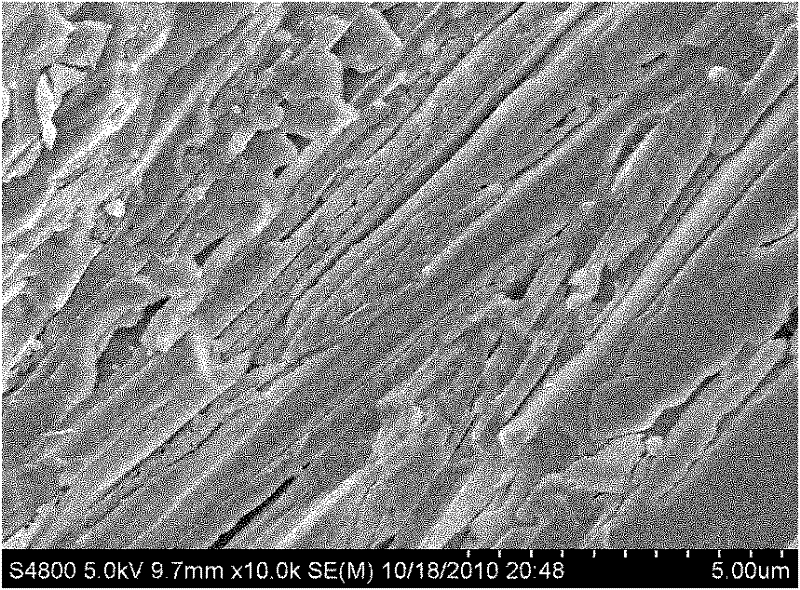

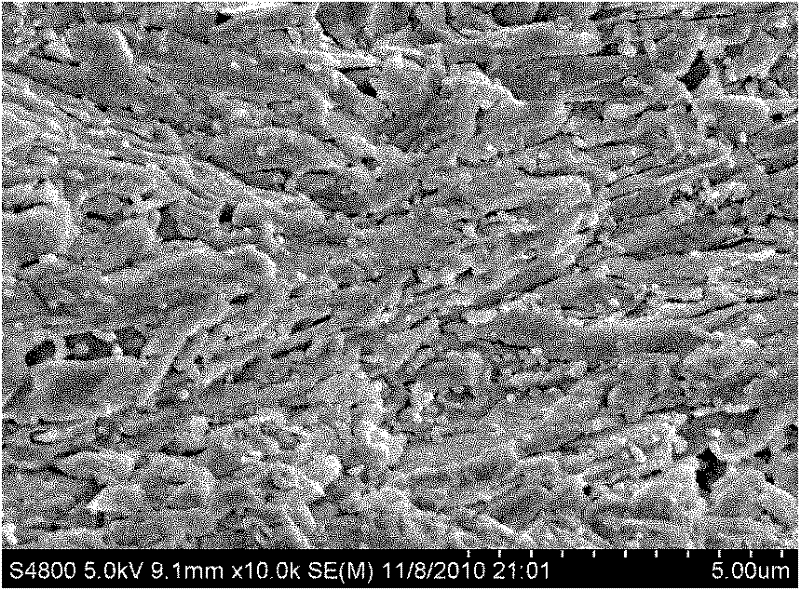

The invention provides optical glass which takes SiO2, B2O3, BaO and La2O3 as main components and contains no lead, thorium, cadmium, arsenic and fluorine. The refractive index (nd) of the optical glass is between 1.68-1.70, and the abbe number (vd) of the optical glass is 48-50. The optical glass has the characteristic of good crystallization property and is suitable for production. Through test according to a GB / T 17129 method, the water resistance (DW) of the optical glass is grade 1, and the acid resistance of the optical glass (DA) is grade 3 or above. The optical glass comprises the following components in percentage by weight: 21-25 percent of SiO2, 8-14 percent of B2O3, 12-18 percent of La2O3, 0.5-3 percent of ZrO2, 34-40 percent of BaO, 2-5 percent of TiO2, 2-5 percent of ZnO, 2-7 percent of CaO, 0-3 percent of Al2O3 and 0-1 percent of Sb2O3, and the total content of the components is above 95 percent, and the total content of glass components is 100 percent.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

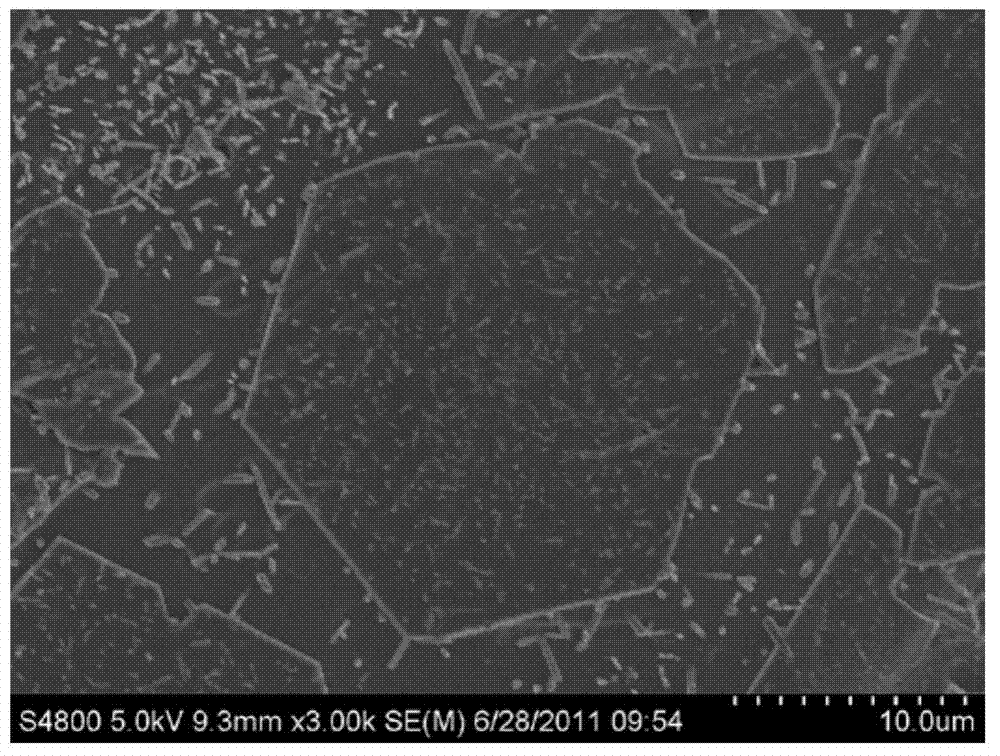

CaO-MgO-Al2O3-SiO2 microcrystalline glass and preparation method thereof

InactiveCN102173592ALower crystallization activation energyImprove growth indexDevitrificationActivation energy

The invention discloses a CaO-MgO-Al2O3-SiO2 microcrystalline glass which is composed of glass aggregate and oxide nucleating agent accounting for 3wt% of glass aggregate, wherein the glass aggregate is composed of the following components in percentage by weight: 50-55wt% of SiO2, 6-10wt% of MgO, 15-18wt% of CaO, 10-12wt% of Al2O3, 3-6wt% of Na2O and / or K2O, 8wt% of CaF2 and 1wt% of Sb2O3. The invention simultaneously provides a preparation method of the CaO-MgO-Al2O3-SiO2 microcrystalline glass. In the CaO-MgO-Al2O3-SiO2 microcrystalline glass, nucleating agent of oxide and fluoride is adopted, so that the devitrification activation energy of a system is lowered, a crystal growth index is improved, and the devitrification capability of the microcrystalline glass is greatly enhanced, thereby bringing convenience for preparing the microcrystalline glass with a whole method.

Owner:ZHEJIANG UNIV

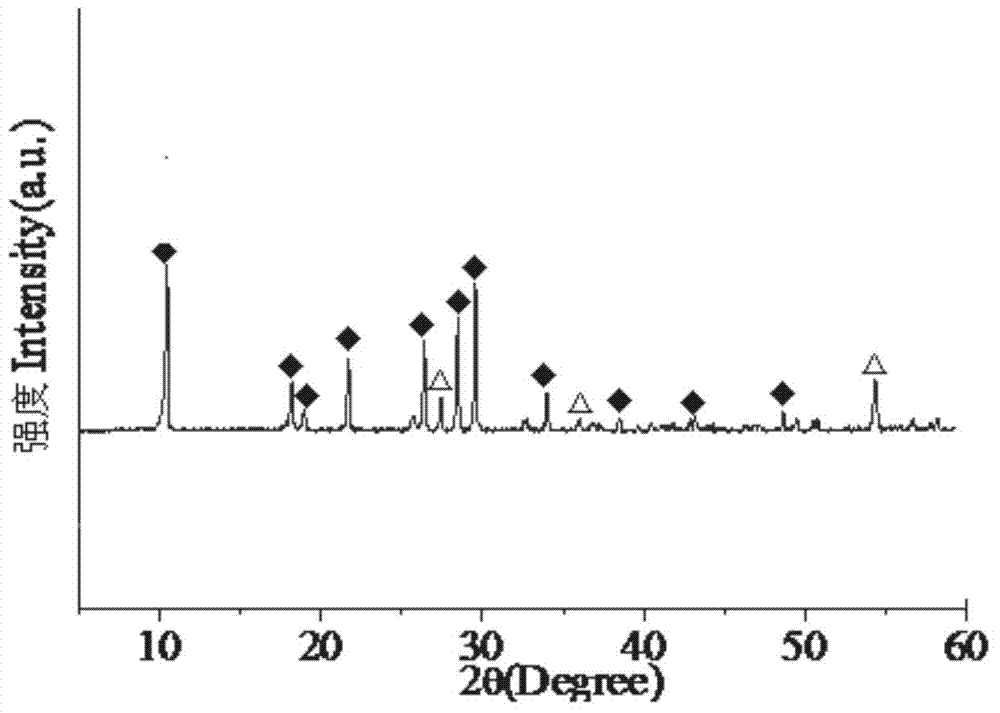

Manganic niobium doping type lithium manganate cathode material for lithium-ion secondary battery and preparation method thereof

InactiveCN101540399AGood crystallization performanceUniform compositionElectrode manufacturing processesManganese compoundsSolid phasesElectrical battery

The invention relates to a manganic niobium doping type lithium manganate cathode material for a lithium-ion secondary battery and a preparation method thereof. The invention adopts a solid-phase method which is easy for industrialization and prepares cathode material lithium manganate powder for the manganic niobium doping type lithium-ion secondary battery with good crystallization performance and uniform ingredients through a simple ball milling and sintering process by controlling the ball milling time and the sintering temperature and time. The chemical general formula of the lithium battery cathode material is LiMn<2-x>NbxO4, wherein, x is larger than 0 but smaller than 0.2. Compared with common lithium manganate, the lithium battery cathode material has the characteristics of higher capacity, better circulation and more superior magnification performance and is easier for industrialized production.

Owner:济宁市无界科技有限公司

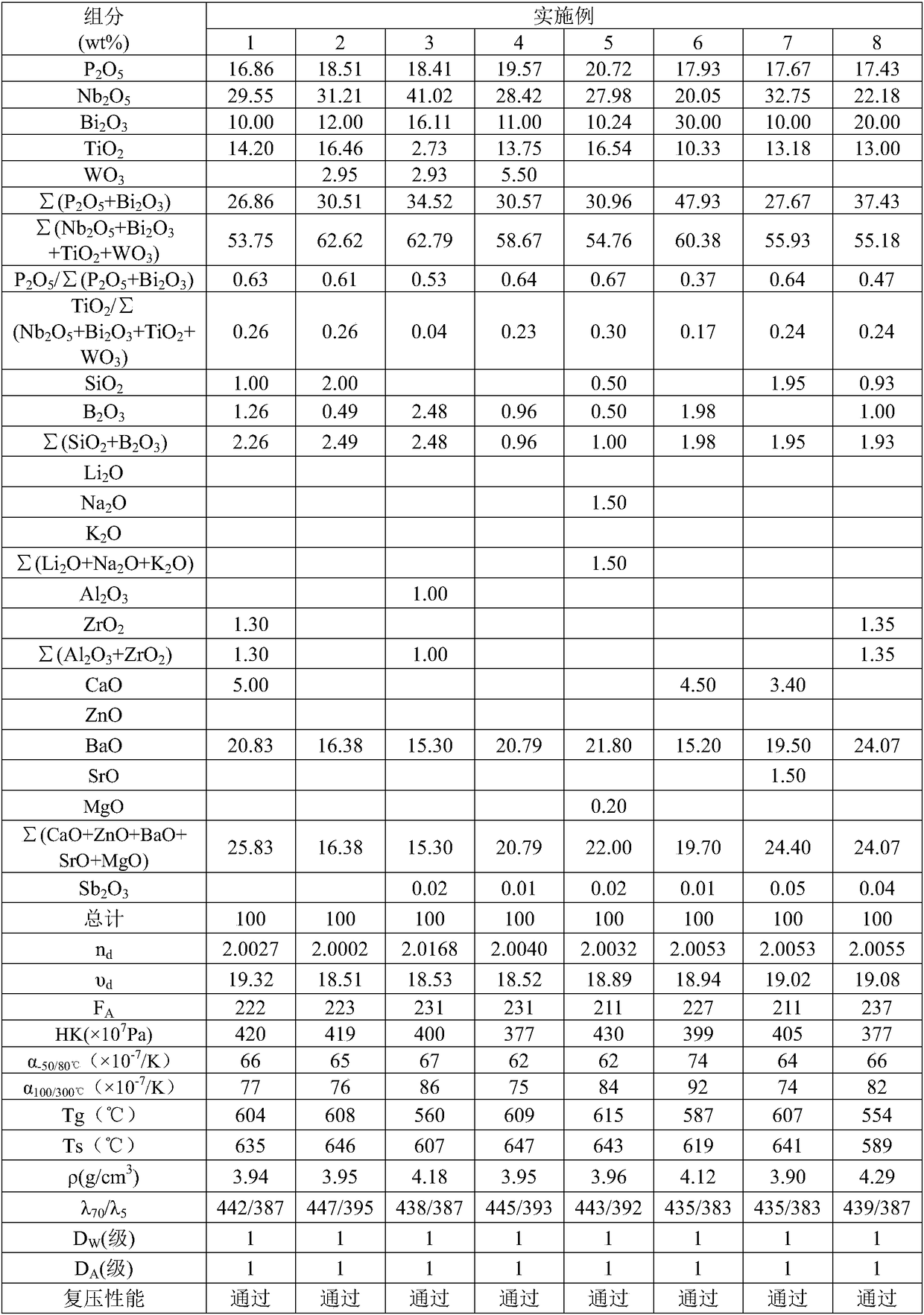

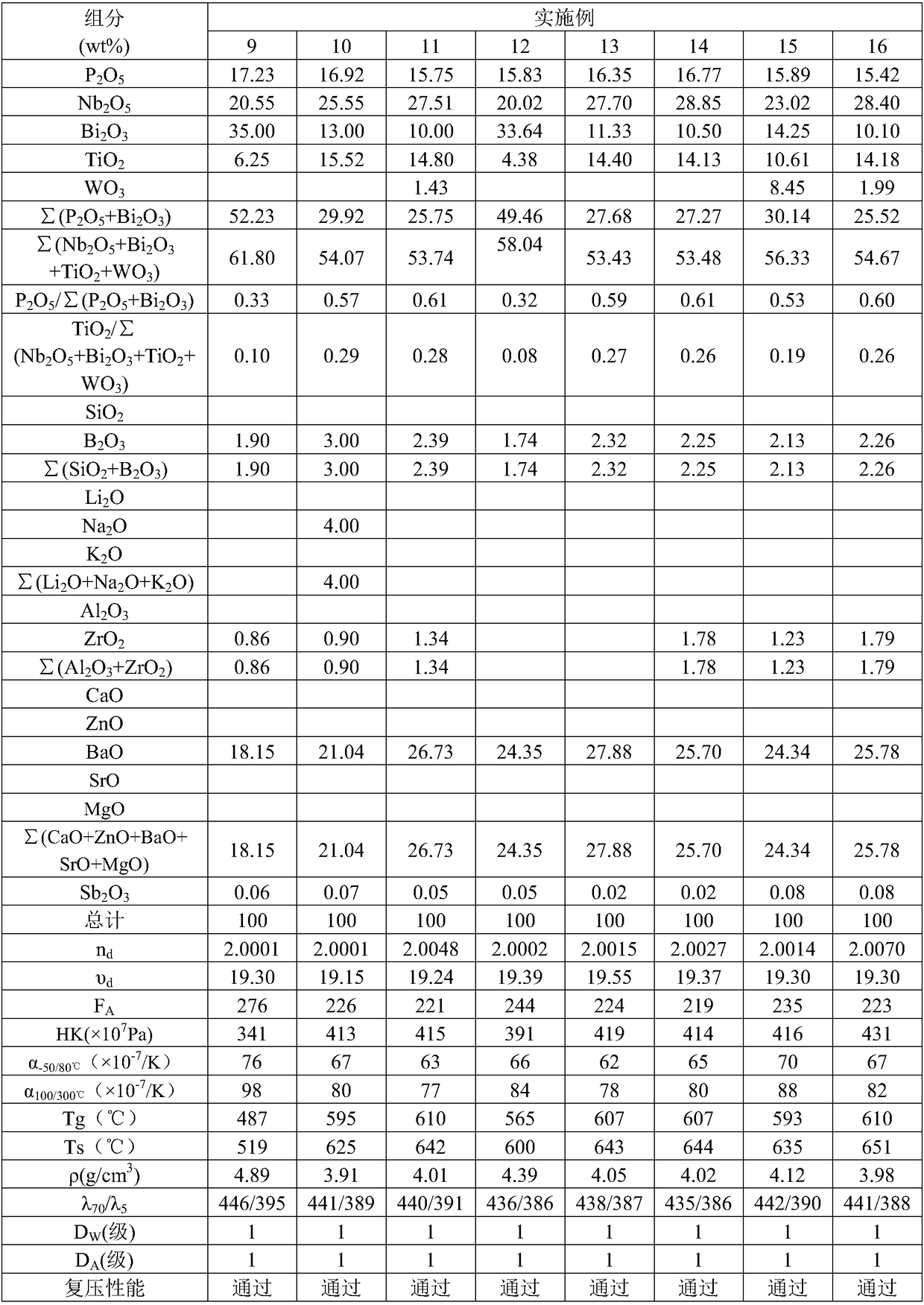

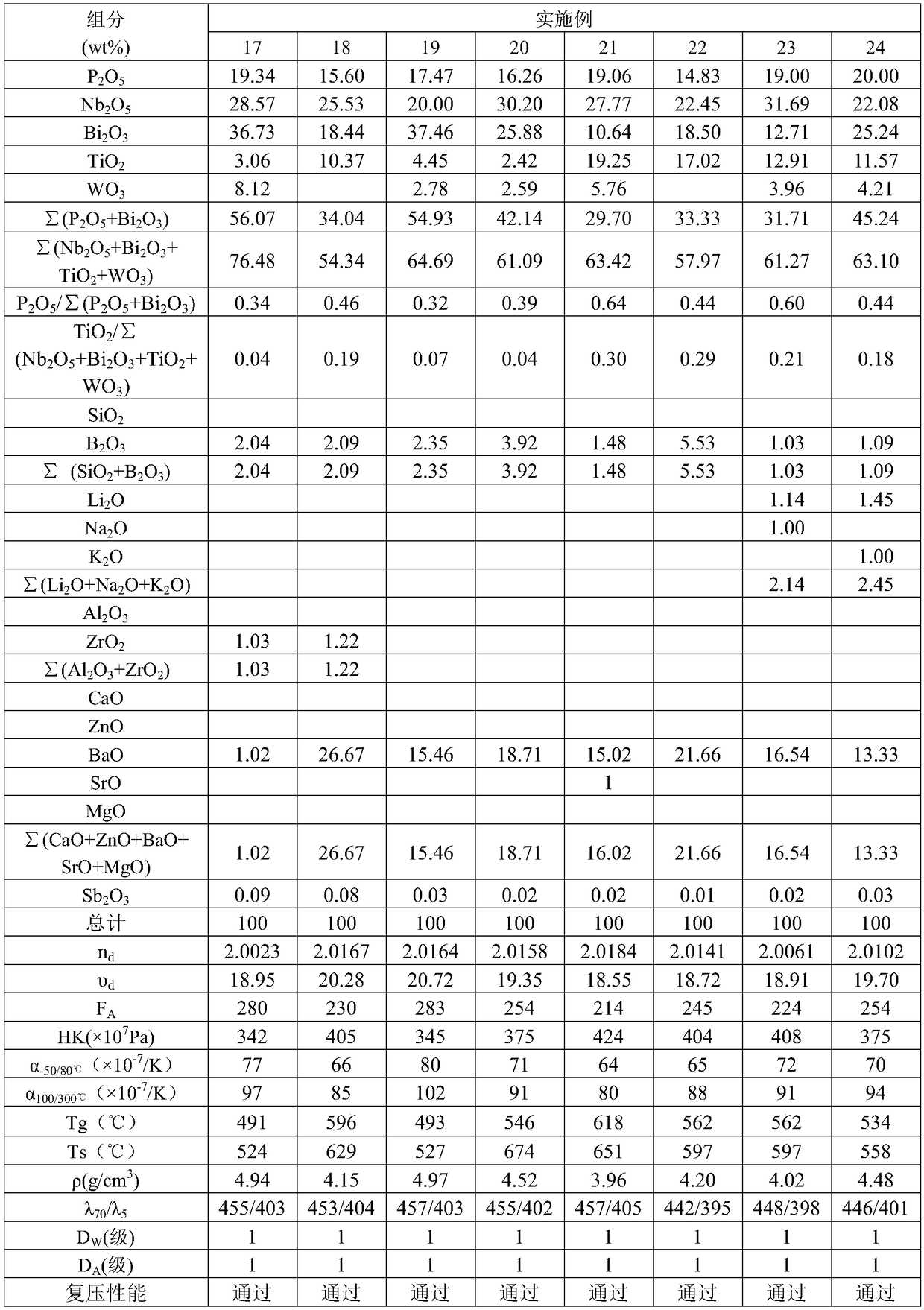

Optical glass and preparation method thereof

ActiveCN108975682AImprove performanceHigh refractive indexGlass pressing apparatusRefractive indexMiniaturization

The invention relates to optical glass and a preparation method thereof. The optical glass is prepared from the following components in percentage by weight: 10-21% of P2O5, 10-50% of Bi2O3, 0-50% ofNb2O5, 0-20% of TiO2, 0-12% of WO3, 0-6% of SiO2, 0-6% of B2O3, 0 -6% of Li2O, 0-4% of Na2O, 0-6% of K2O, 0-4% of Al2O3, 0-3% of ZrO2, 0-5% of CaO, 0-5% of ZnO, 0-30% of Ba0, 0-2% of MgO, 0-3% of SrOand 0-0.1% of Sb2O3. The optical glass has the advantages of being excellent in performance, high in refractive index, high in dispersion and capable of decreasing the number of lens, prisms and otheroptical elements used in an optical system, and therefore the requirements of light weight and miniaturization of the overall optical system are met.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

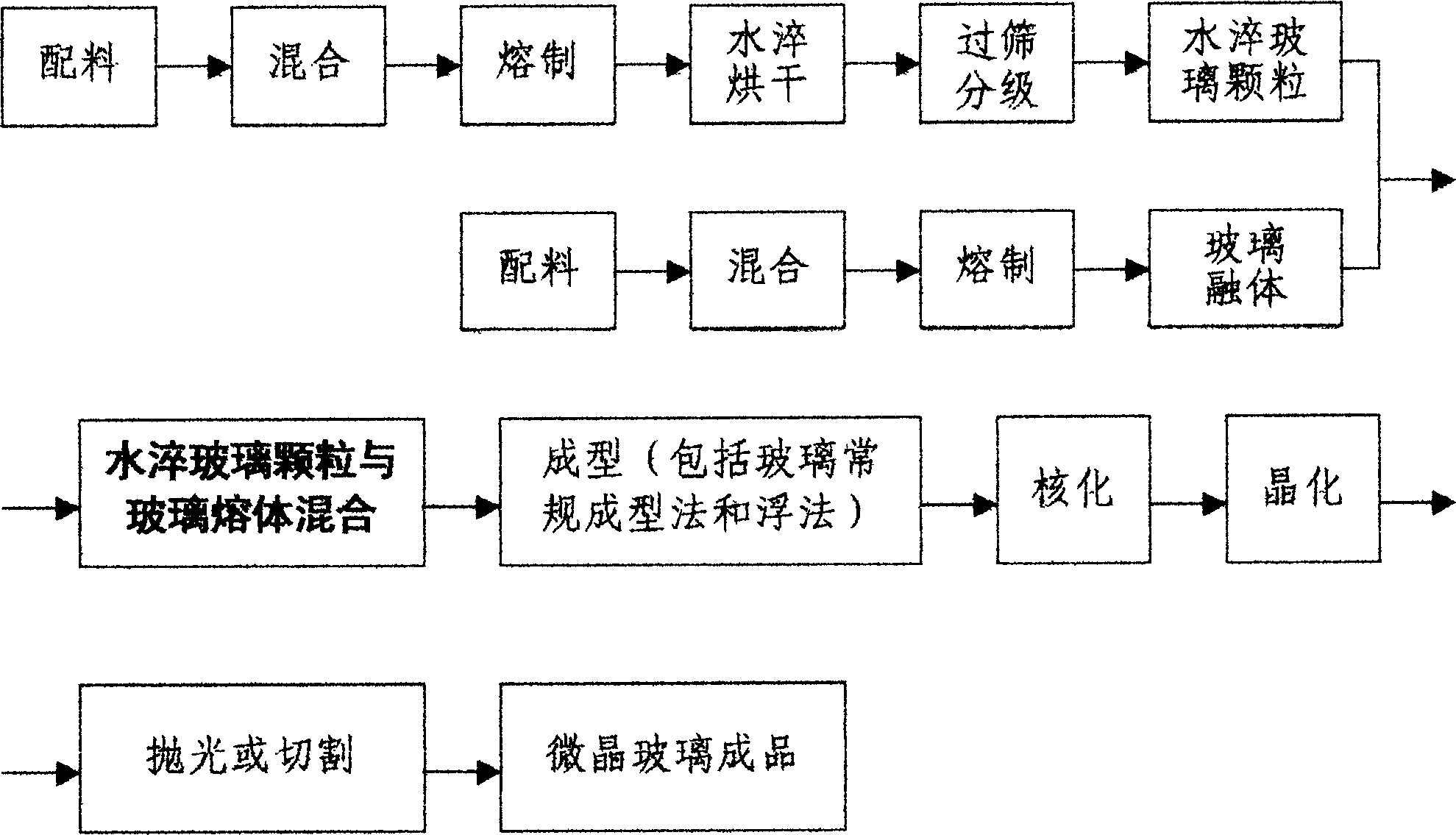

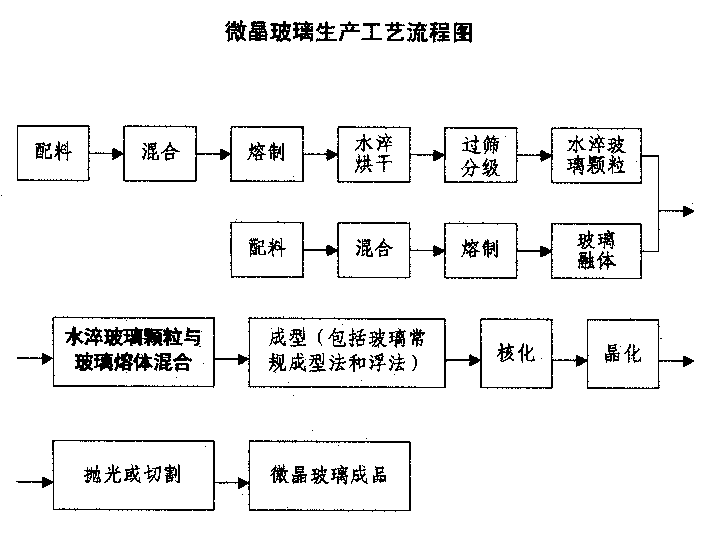

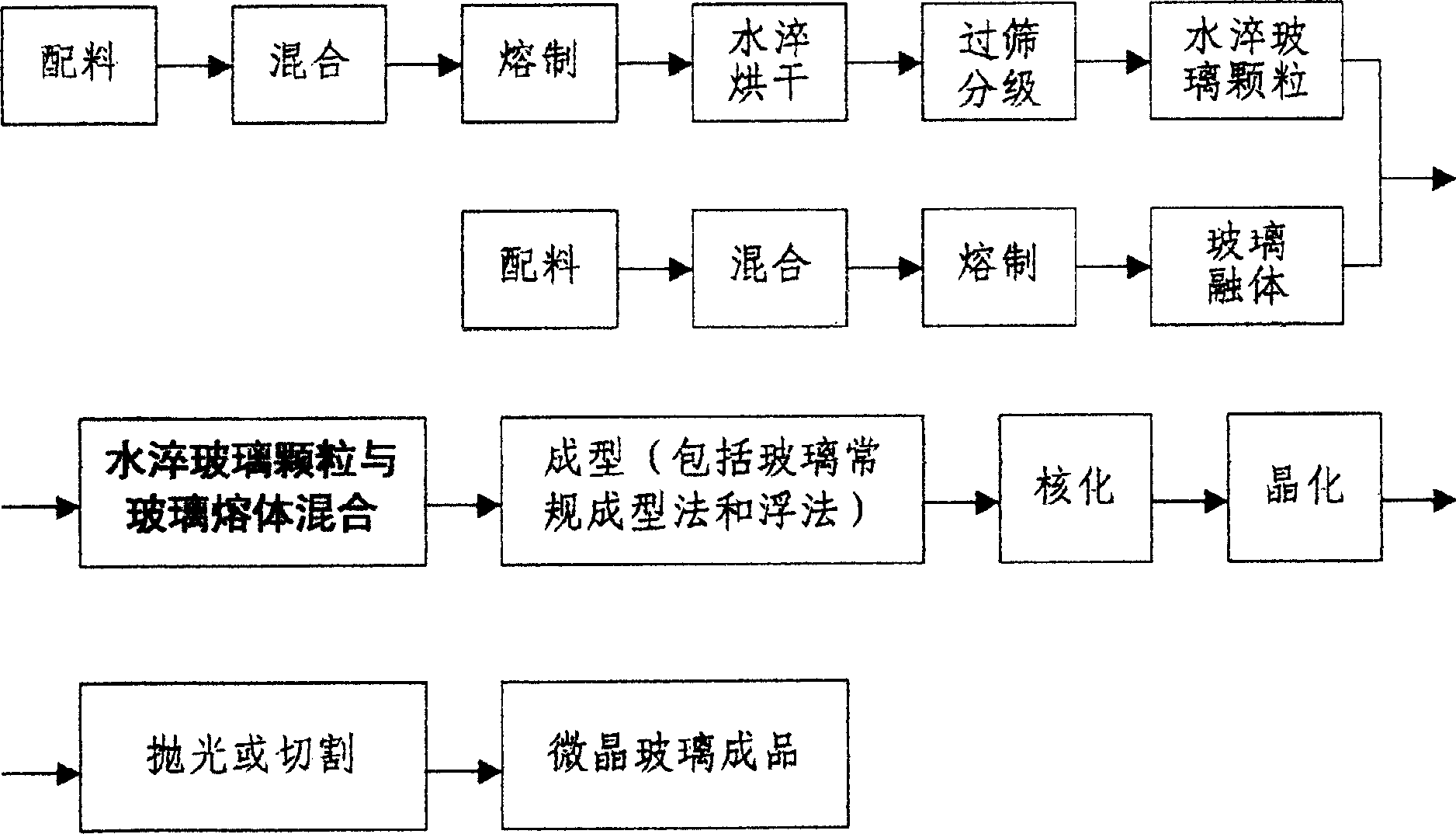

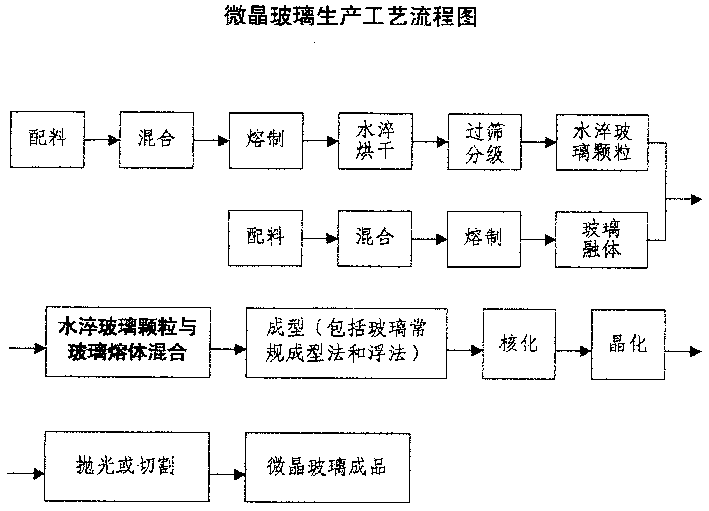

Method for producing micro crystal glass

InactiveCN1458098AAvoid it happening againImprove densification performanceGlass productionNucleationProduced water

The production process of devitrified glass includes a sintering process comprising compounding material, smelting, water quenching and sieving to grade, to produce water quenched glass grains; a melting process comprising compounding material, mixing and smelting to produce glass melt; mixing the water quenched glass grains with the glass melt; and subsequent conventional steps of forming, nucleation, crystallizing, polishing and cutting. Compared with available sintering process and melting process, the present invention has the advantages of raised overall re-crystallization capacity, shortened crystallization period, less pores in the product, etc. and is suitable for various glass production methods.

Owner:匡敬忠

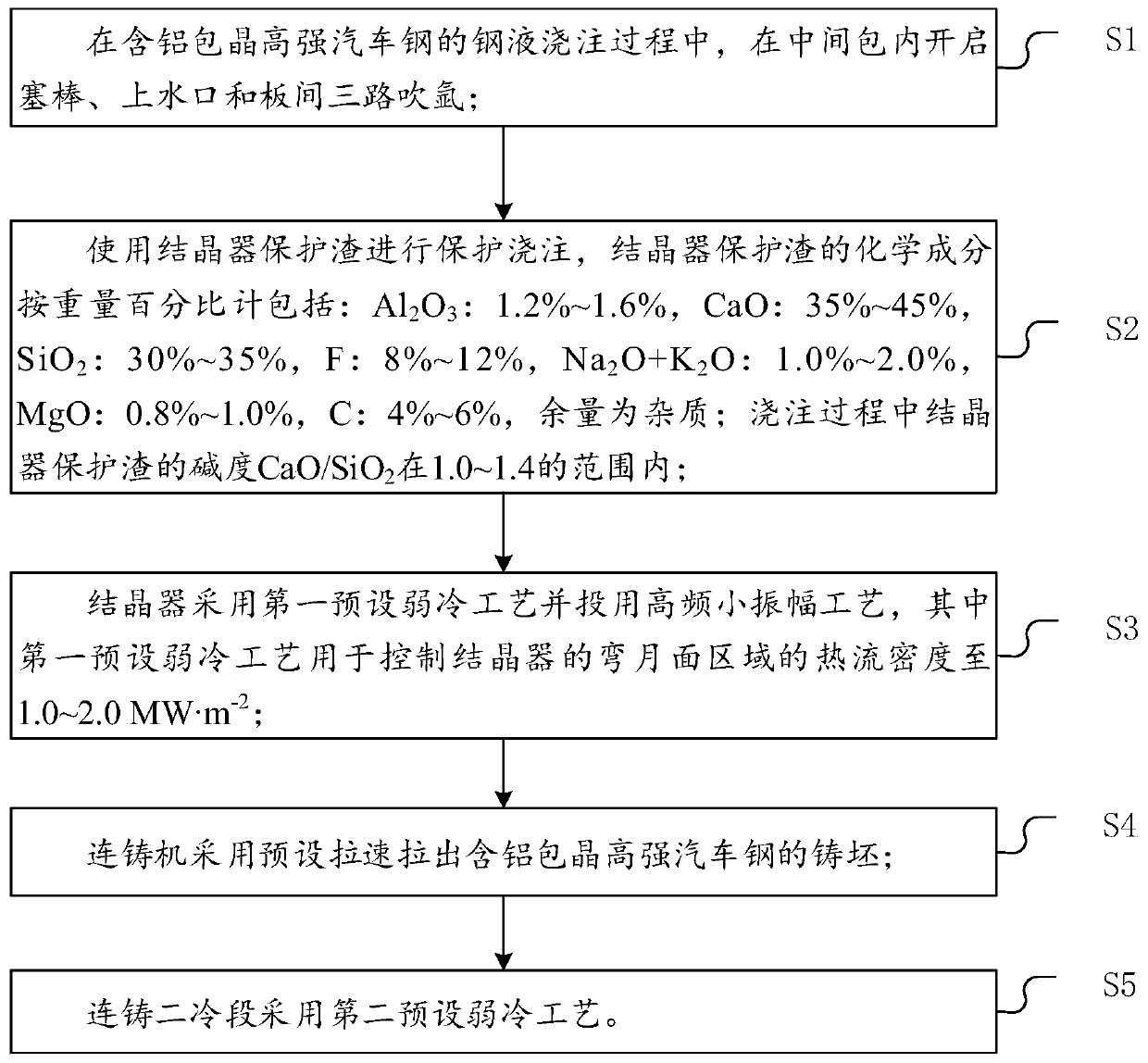

Continuous casting method of aluminum-containing peritectic high-strength automobile steel

The invention discloses a continuous casting method of aluminum-containing peritectic high-strength automobile steel. The method comprises the following steps that in the molten steel pouring processof the aluminum-containing peritectic high-strength automobile steel, a stopper rod, an upper nozzle and an inter-sheet device are opened in a tundish for three-way argon blowing; crystallizer covering slag is used for casting protection, and the crystallizer covering slag comprises the chemical components of, in percentage by weight, 1.2 %-1.6 % of Al2O3, 35 %-45 % of CaO, 30 %-35 % of SiO2, 8 %-12 % of F, 1.0 %-2.0 % of (Na2O + K2O), 0.8 %-1.0 % of MgO and 4 %-6 % of C; a crystallizer adopts a first preset weak cooling process and a high-frequency small-amplitude process is put into use, wherein the first preset weak cooling process is used for controlling the heat flux density of a meniscus area of the crystallizer to be 1.0-2.0 MW.m <-2>; a casting blank of the aluminum-containing peritectic high-strength automobile steel is cast by a continuous casting machine at a preset casting speed; and a continuous casting secondary cooling section adopts a second preset weak cooling process.According to the scheme, surface cracks and bonding defects of the casting blank are remarkably reduced.

Owner:SHOUGANG CORPORATION

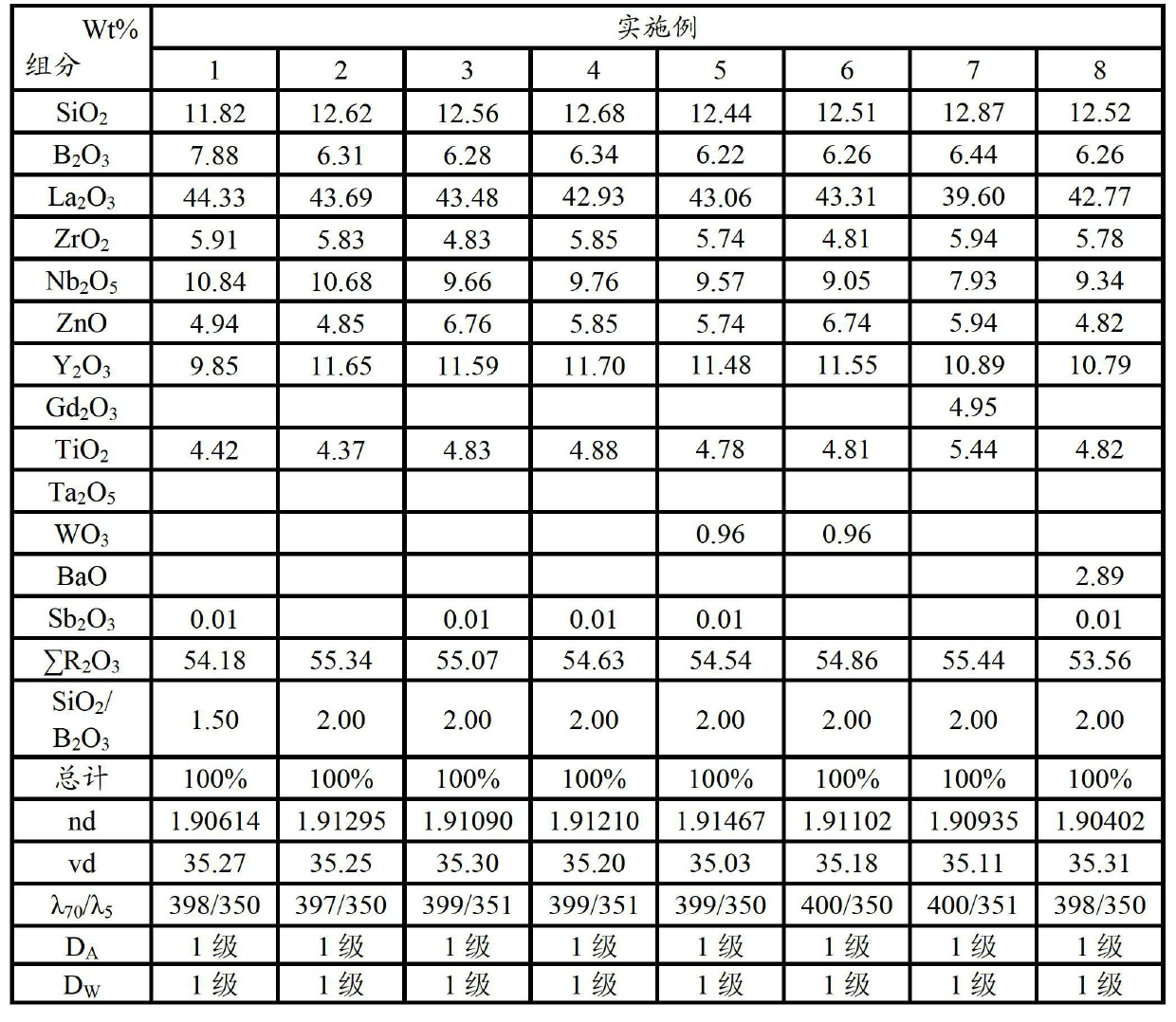

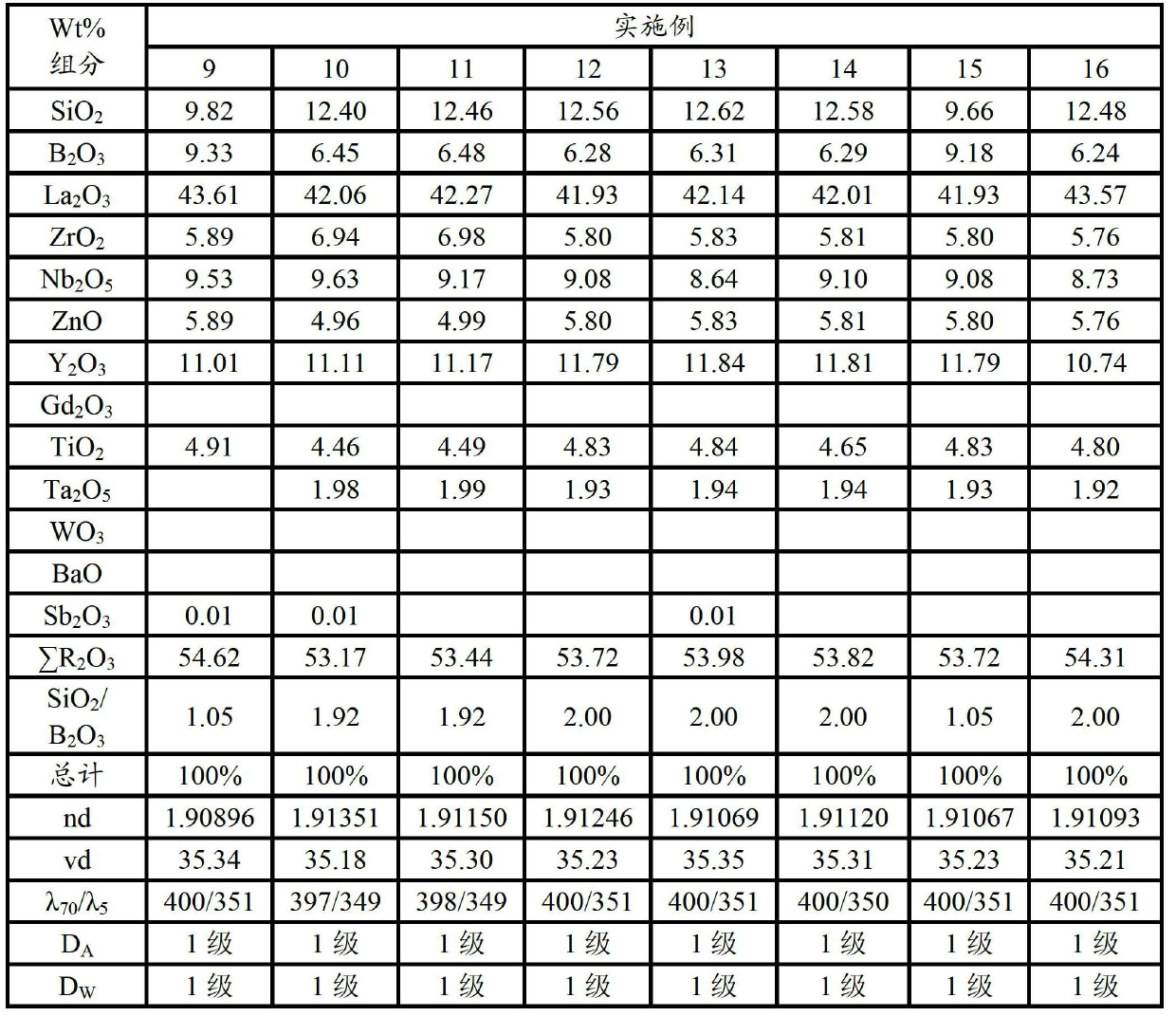

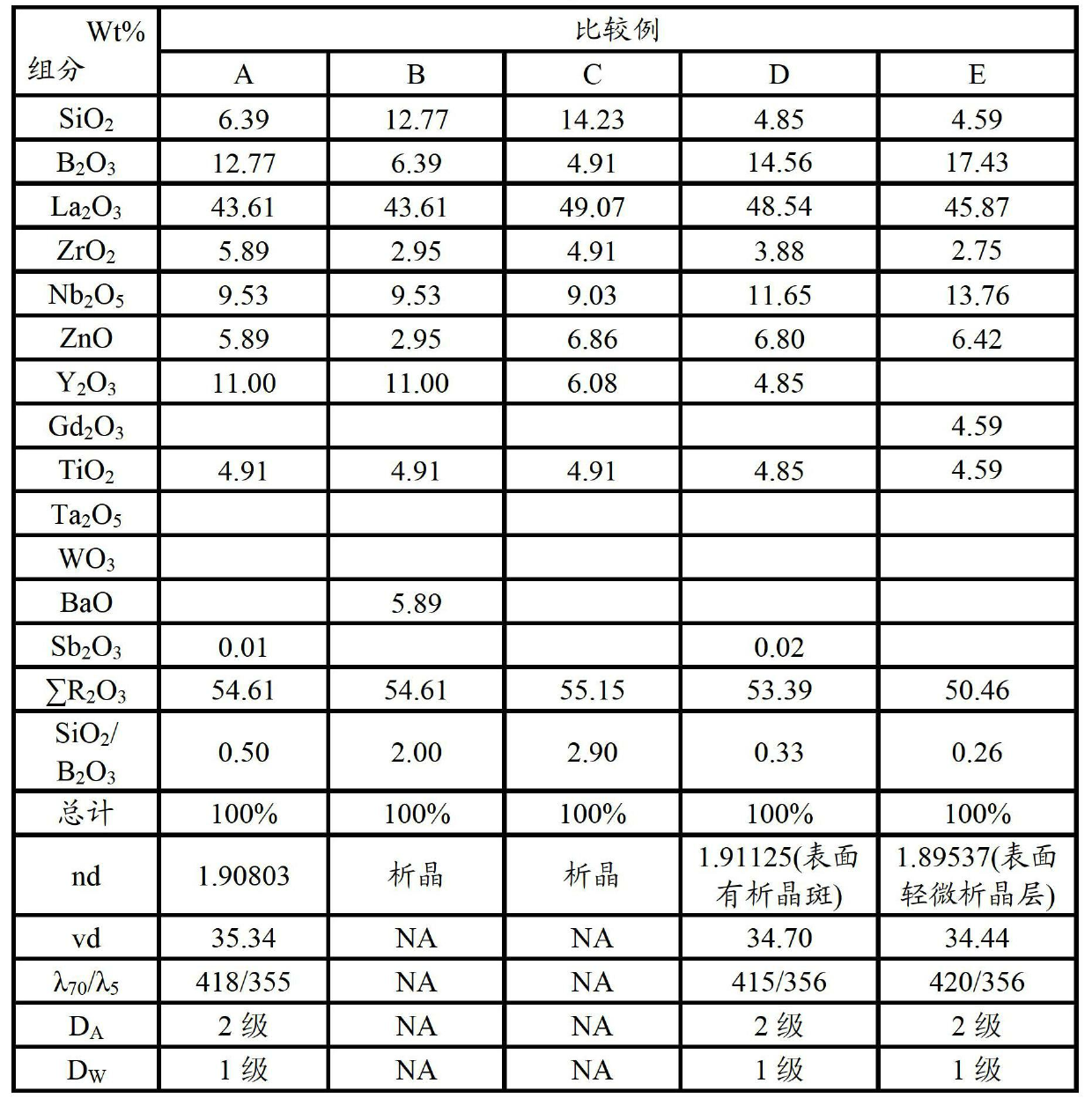

Optical glass

The invention provides high refractive index and low dispersion lanthanide-series optical glass which is suitable for production and secondary compression. The high refractive index and low dispersion lanthanide-series optical glass comprises SiO2, B2O3, La2O3, ZrO2, Nb2O5, ZnO, Y2O3 and TiO2 which are taken as necessary components, and 0-1wt% of Sb2O3 taken as optional component; the optical glass does not contain Th, Cd or As; the content of SiO2 is more than that of B2O3; the refractive index (nd) is between 1.90 and 1.92; and the Abbe number (vd) is between 33 and 36.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

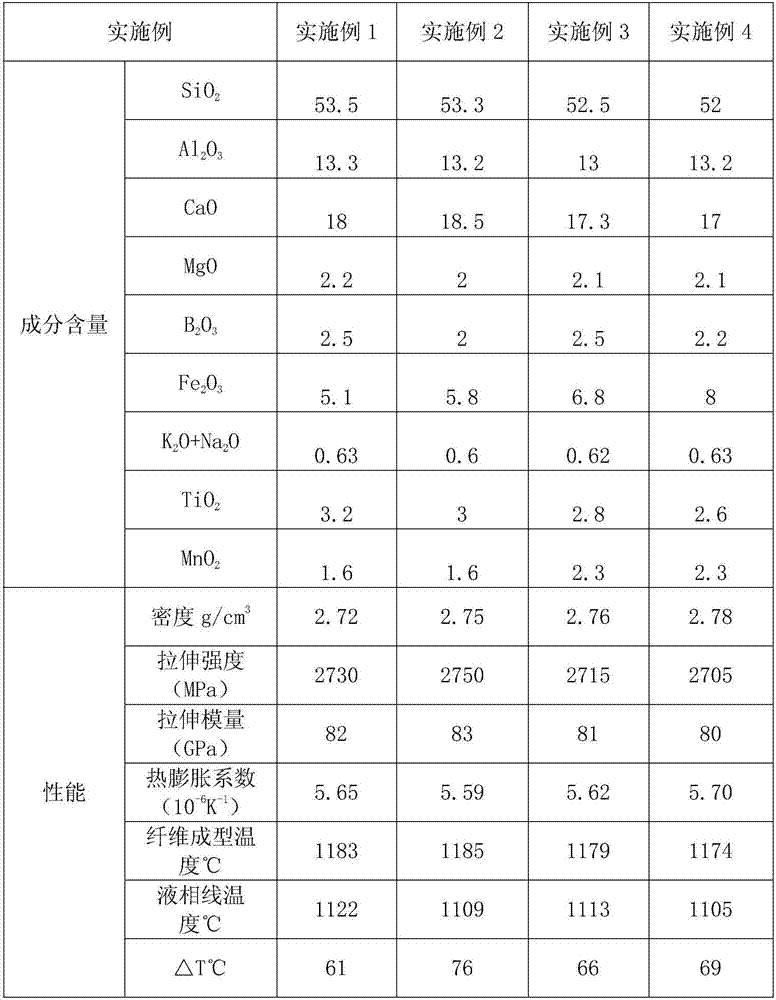

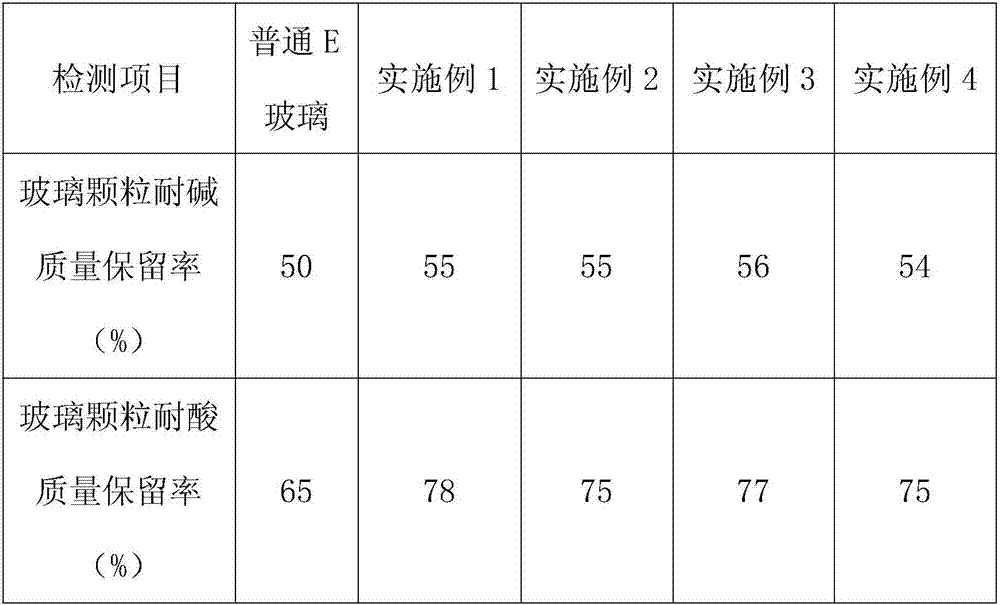

Black glass fiber and preparation method thereof

InactiveCN106927672AImprove coloring abilityGood crystallization performanceGlass making apparatusFiberGlass fiber

The invention provides black glass fiber and a preparation method thereof. The black glass fiber prepared by virtue of the preparation method contains SiO2, Al2O3, CaO, MgO, B2O3, Fe2O3, TiO2, MnO2 and K2O+Na2O. The black glass fiber is prepared through direct wiredrawing in a preparation process, and secondary dip dyeing is omitted, so that the problems in the prior art that the dyeing is not uniform, the dyeing adhesive force is poor and the fiber is easy to fall in a secondary dip dyeing process are solved. The preparation method provided by the invention has the beneficial effects that the prepared black glass fiber is low in melting temperature and high in acid-base resistance, and the main raw material is basalt which is widely distributed, high in reserve and low in cost, so that the production cost is greatly lowered.

Owner:TAISHAN FIBERGLASS INC

Lanthanides optical glass TZLaF5 with high refraction index, low dispersion and environmental protection

The invention discloses a formula of lanthanides optical glass TZLaF5 with high refraction index, low dispersion and environmental protection, and a production technology thereof. The lanthanides optical glass comprises the following components in percentage by weight: 5 to 10% of SiO2, 15 to 20% of B2O3, 25 to 36% of La2O3, 28 to 40% of Gd2O3, 4 to 10% of ZrO2, 5 to 10% of Ta2O5, 1 to 5% of ZnO, 1 to 5% of BaF2, and 1 to 5% of Al2O3. The lanthanides optical glass is produced by the steps of mixing the components, founding at the temperature of 1430 to 1480 DEG C, molding at 1200 DEG C, and performing fine annealing on the molded mixture for about 7 days at the temperature of 650 to 700 DEG C. The TZLaF5 is the lanthanides optical glass with high refraction index and low dispersion for producing digital camera, digital video, high-grade mobile phone and the like.

Owner:NANTONG JINGXIN OPTICAL GLASS

Arsenic-free and leadless lanthanum crown optical glass NLaK40 and method for manufacturing same

The invention discloses an arsenic-free and lead-free lanthanide optical glass NLaK40 and a manufacturing method, wherein, based on weight percentage, the glass comprises 25-30 percent of SiO2, 13-18 percent of B2O3, 13-20 percent of La2O3, 0-0.5 percent of Gd2O3, 1-3 percent of TiO2, 0.5-1.5 percent of ZrO2, 0.5-1.5 percent of CaO, 30-35 percent of BaO, 0-0.2 percent of Nb2O5, 0.5-2.0 percent of K2O, 0-0.5 percent of WO3, and 0.5-1.5 percent of Na2O. The invention uses TiO2, a small amount of Nb2O5, Gd2O3 and WO3 to replace PbO; meanwhile, the invention adds a small amount of CaO, Na2O, K2O and ZrO2 into the glass to adjust the melting performance and the required optical constant requirements; the invention also adds clarifying agent to the glass. The invention meets the required optical performance requirements and has good melting and operating performances, which can produce quality products at a low cost.

Owner:上海新沪玻璃有限公司

Method of preparing high-strength wear-resisting glass ceramics by utilizing iron tailings

The invention discloses a method of preparing high-strength wear-resisting glass ceramics by utilizing iron tailings. The method comprises the following steps of preparing raw materials comprising the following components in parts by weight: 35-40 parts of iron tailings, 20-25 parts of quartz, 10-12 parts of magnesium carbonate, 13-15 parts of aluminum oxide, 3-4 parts of calcium oxide, 6-7 parts of titanium oxide, 3-5 parts of boron oxide and 1 part of antimony oxide; mixing the materials, fusing the materials at 1450 DEG C-1500 DEG C, preserving the heat, carrying out compression molding or calendaring molding on the obtained molten glass, annealing plate-shaped glass and then preserving the heat for 3-5 hours at 950 DEG C-1000 DEG C, and cooling to the room temperature to obtain the high-strength wear-resisting glass ceramics. The method is a preparation method of CMAS glass ceramics, which takes iron tailings as main materials and realizes integral crystallization.

Owner:ZHEJIANG UNIV

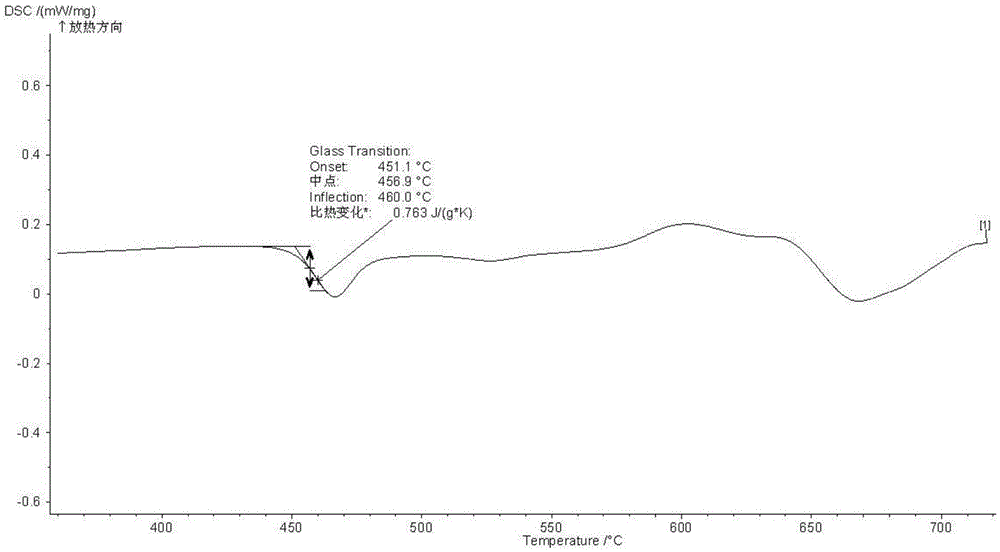

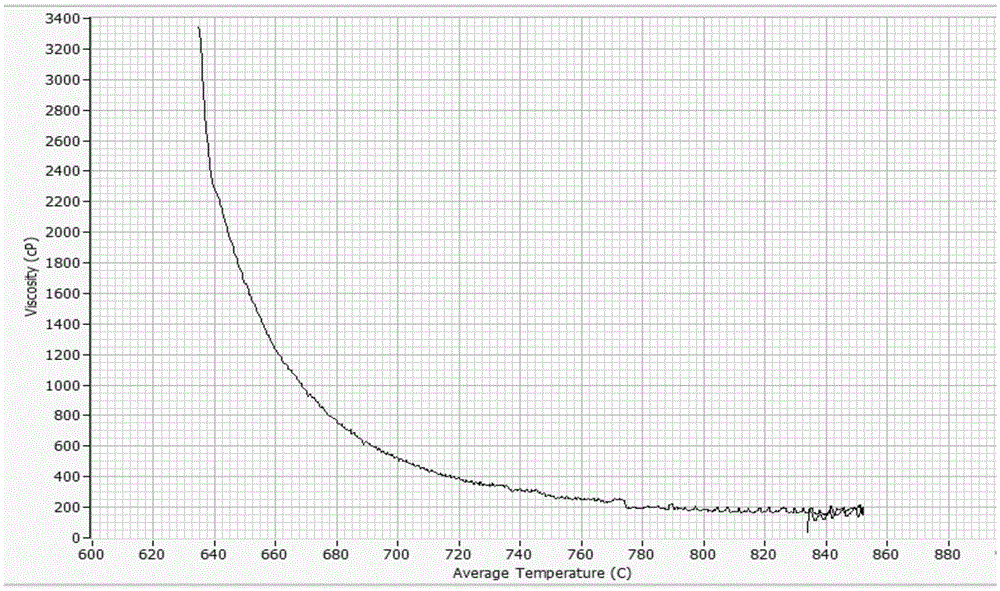

Neodymium-doped fluorophosphate glass and preparation method thereof

ActiveCN105601106AGood crystallization performanceImproved viscosity propertiesGlass furnace apparatusGlass shaping apparatusFluorescencePhosphate glass

The invention relates to neodymium-doped fluorophosphate laser glass and a preparation method thereof. The glass mainly comprises low-content phosphate and high-content divalent and trivalent metal fluoride. The positive ions of the glass include, by mole percentage, 12.0-12.1% of P<5+>, 28.2-28.6% of Al<3+>, 7.7-7.8% of Mg<2+>, 18.8-19.1% of Ca<2+>, 18.8-19.1% of Sr<2+>, 9.4-9.5% of Ba<2+>, 3.4-3.5% of Y<3+>, 0.2-1.6% of Nd<3+> and 82.49-82.59% of F<-> / (F<->+O<2->). Compared with existing neodymium-doped fluorophosphate laser glass, the neodymium-doped fluorophosphate glass is excellent in glass forming performance, long in fluorescence lifetime, low in nonlinear coefficient, free of alkali and applicable to solid-state laser amplification.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Polyester polyol and preparation method thereof

ActiveCN112250845AReduce energy consumptionGood crystallization performancePreparation by ester-hydroxy reactionPolycarbonateEther

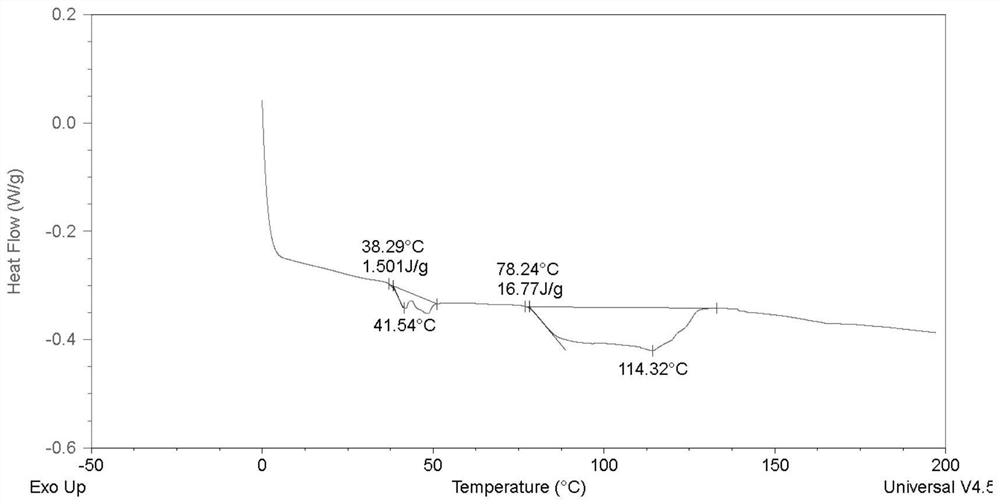

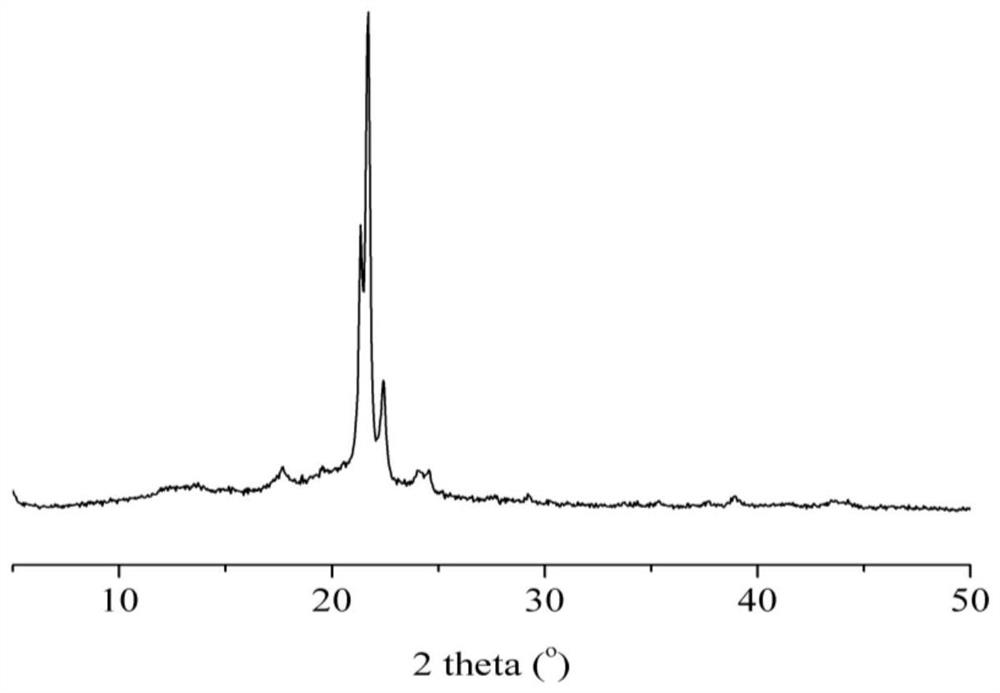

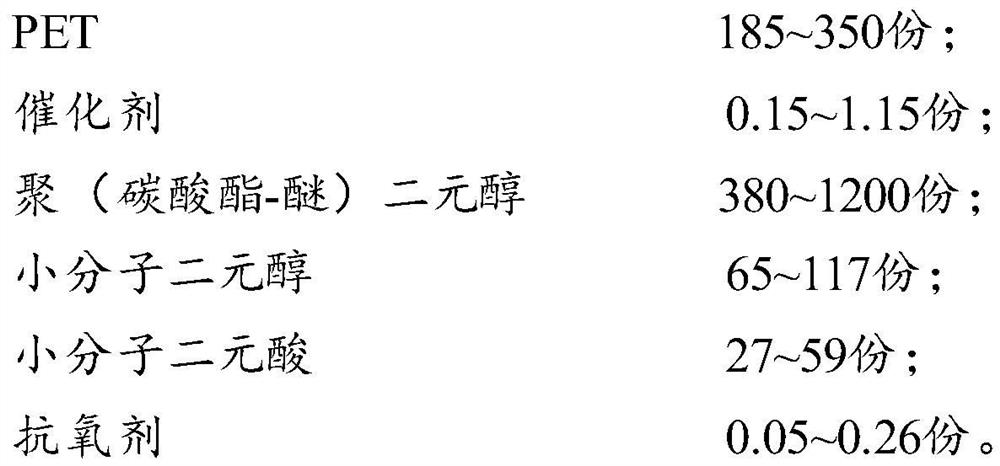

The invention provides polyester polyol, which is prepared from the following raw materials in parts by weight: 185-350 parts of PET (Polyethylene Terephthalate); 0.15 to 1.15 parts of a catalyst; 380to 1200 parts of poly (carbonic ester ether) dihydric alcohol; 65 to 117 parts of small molecular diol; 27 to 59 parts of small molecular binary acid; 0.05 to 0.26 part of an antioxidant. The preparation method of the polyester polyol provided by the invention does not need a complex post-treatment process, so that the energy consumption is greatly reduced, and the problem that a large amount ofthree wastes are generated is solved; the polyester polyol prepared by the invention has three groups of sharp spectral peaks in a range of 19-24 DEG C, which indicates that the polyol has excellent crystallinity and can become a substitute of the traditional polyester polyol. The invention also provides a preparation method of the polyester polyol.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

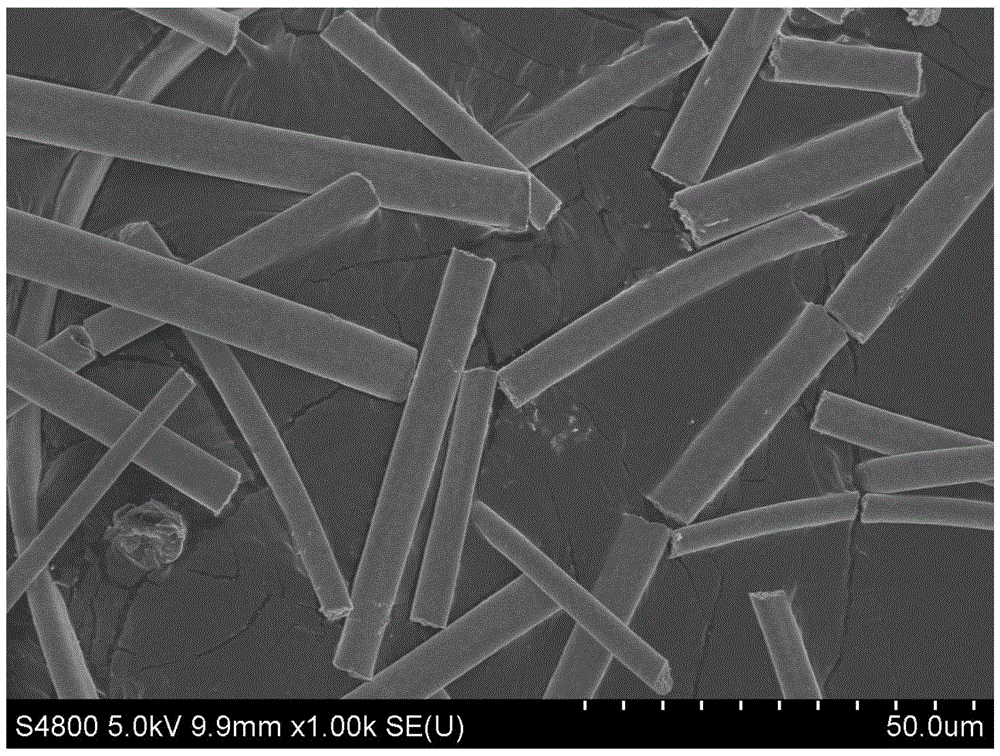

Barium zirconate fiber and method for preparing same

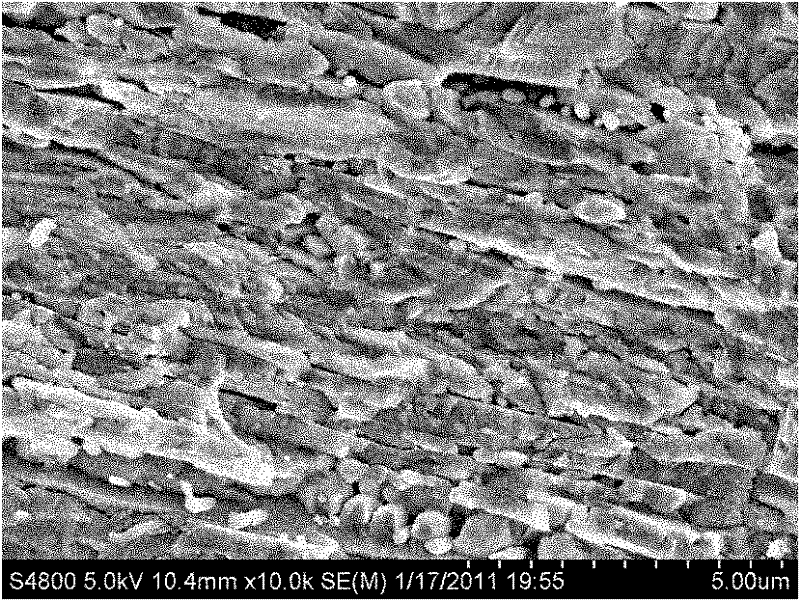

ActiveCN105624834AGood crystallization performanceUniform diameterInorganic material artificial filamentsSolventChemistry

The invention relates to a barium zirconate fiber and a method for preparing the same. The diameter of the barium zirconate fiber is 1-20 micrometers, and crystalline phases of the barium zirconate fiber are cubic phases and can keep stable under the condition of high temperatures of 1500 DEG C. The method includes proportionally sufficiently stirring basic zirconium carbonate, barium sources, acid sources and solvents under the condition of temperatures of 10-90 DEG C until solution is clear and transparent, and concentrating the solution under vacuum conditions to obtain barium zirconate precursor spinning solution; carrying out high-speed centrifugal thread throwing on the precursor spinning solution to obtain a diameter precursor fiber and carrying out high-temperature heat treatment on the diameter precursor fiber to obtain the barium zirconate fiber. The barium zirconate fiber and the method have the advantages of simple processes, low cost, high yield, environmental friendliness and the like. Besides, the barium zirconate fiber is reliable in quality, has the uniform diameter and has a broad application prospect in the field of high-temperature heat-insulation materials, high-temperature proton conductors, fuel batteries and the like.

Owner:SHANDONG UNIV

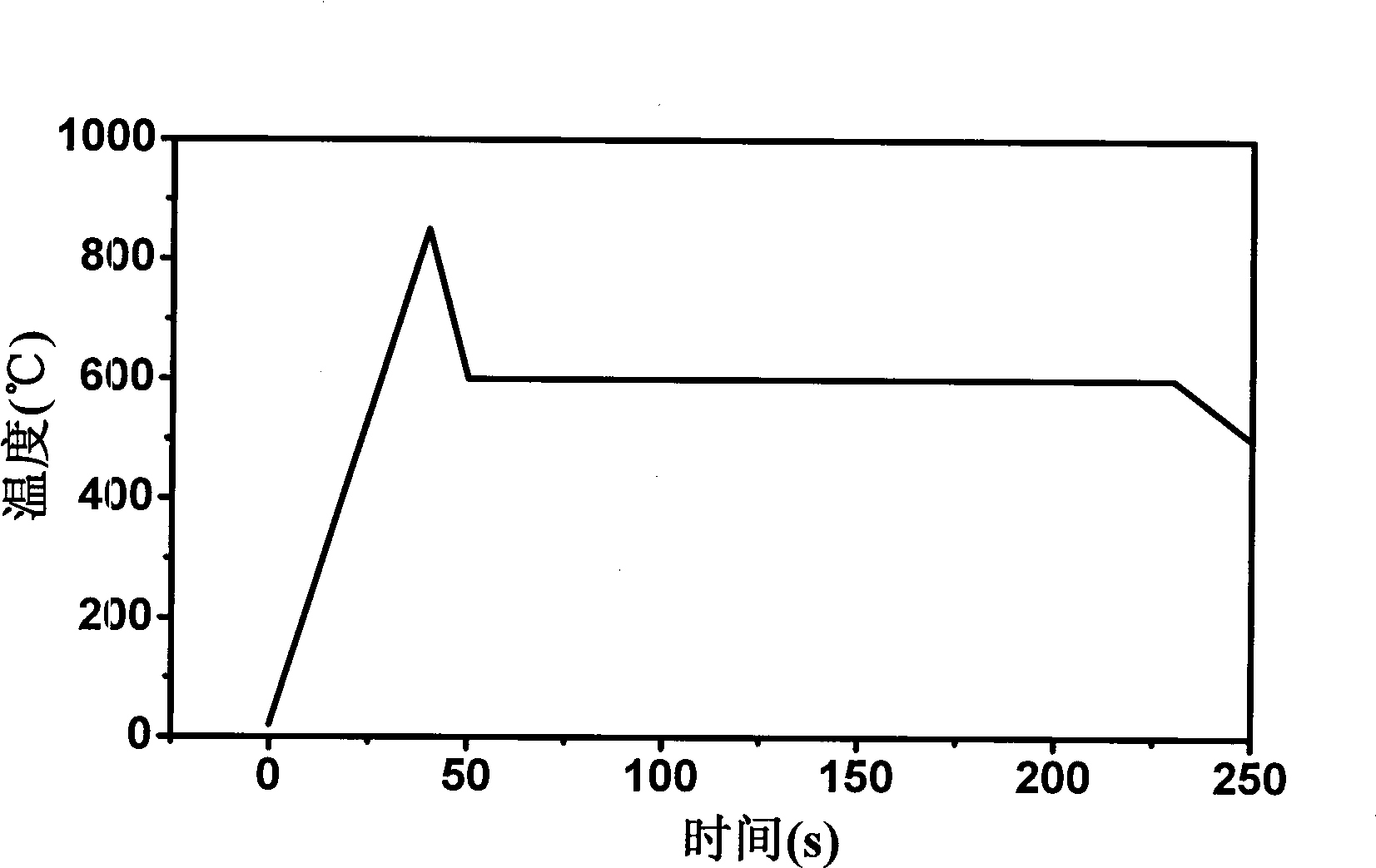

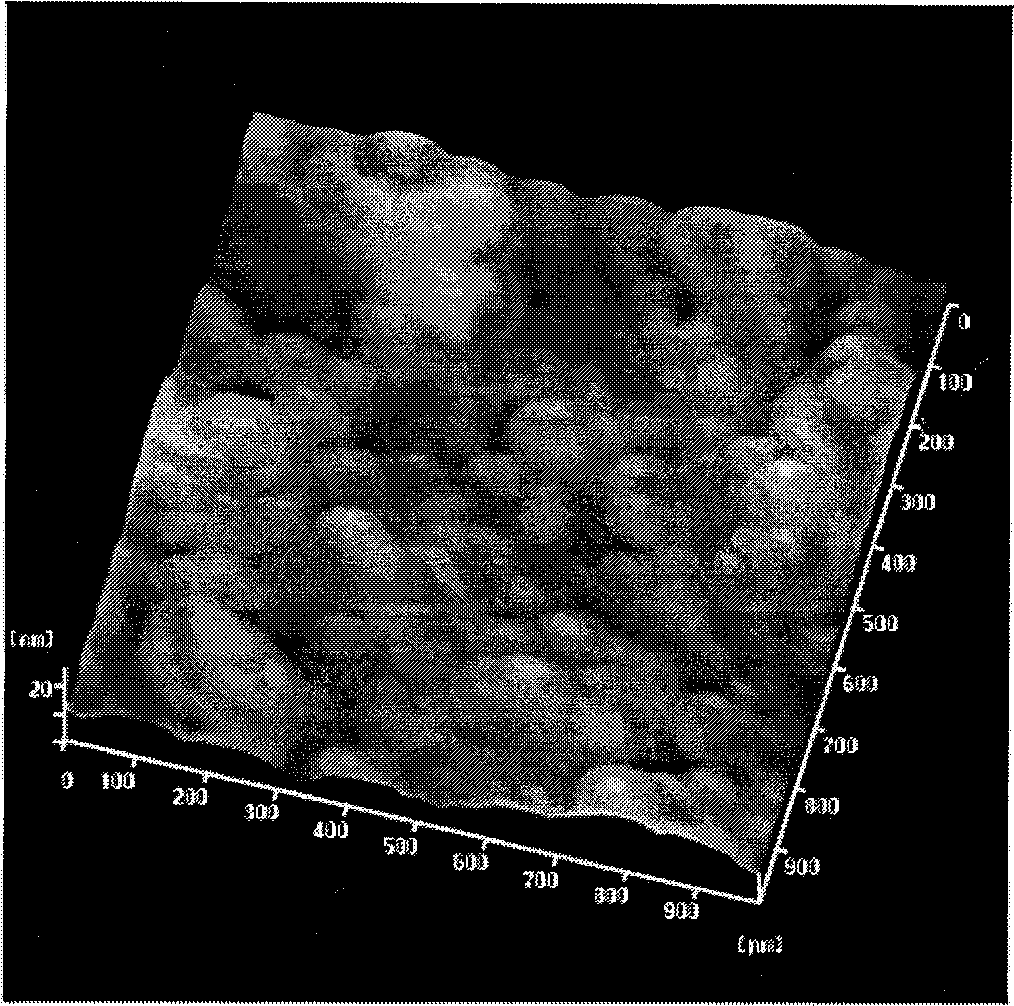

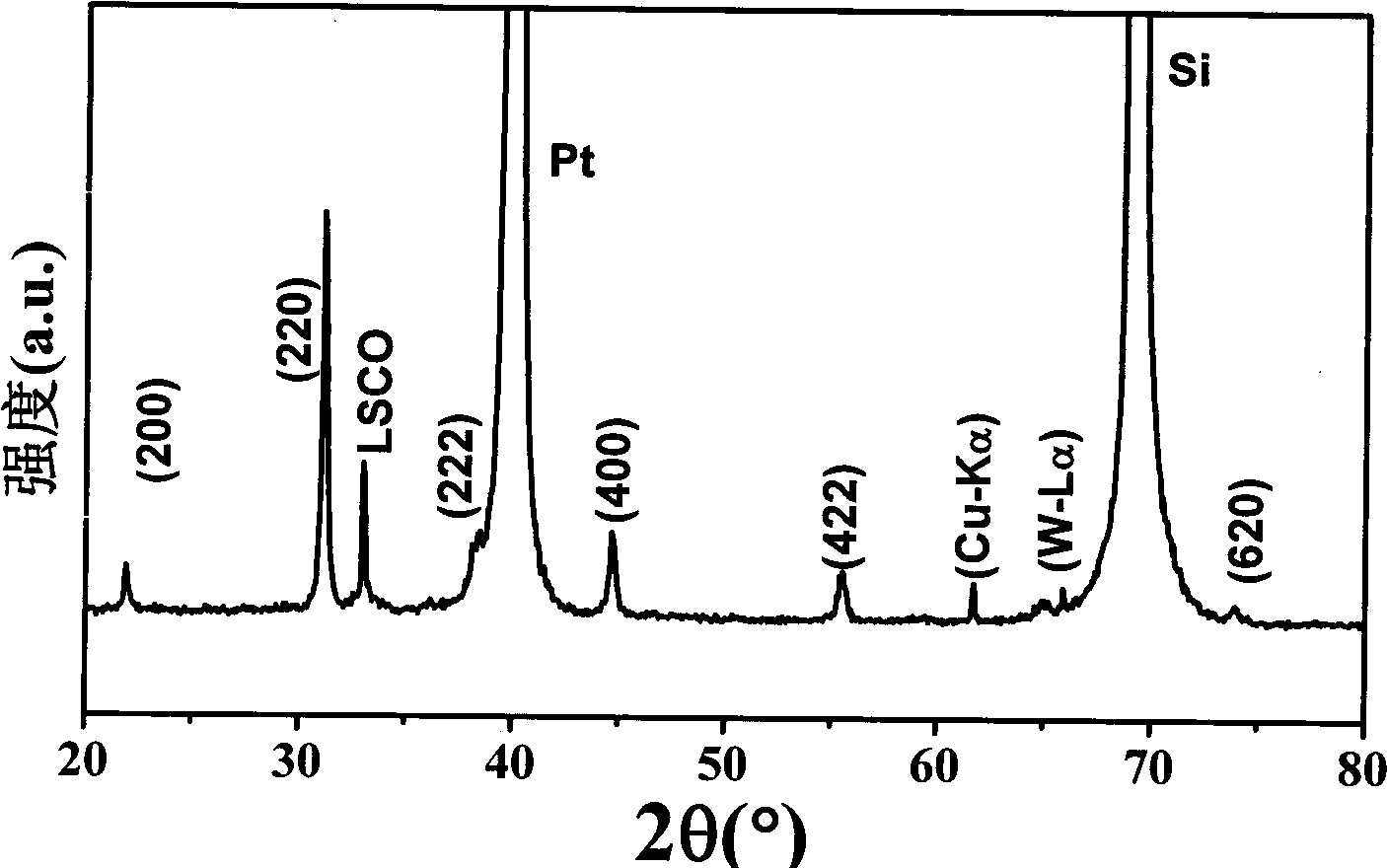

Method for the annealing preparation of tantalum scandium acid plumbum-based ferroelectric film by two step method

InactiveCN101532175AHigh purity perovskite phaseGood crystallization performancePiezoelectric/electrostrictive device manufacture/assemblyPolycrystalline material growthScandiumRms roughness

A method for the annealing preparation of a tantalum scandium acid plumbum-based ferroelectric film by a two step method is disclosed, comprising the technological steps of preparing a transition layer, preparing the tantalum scandium acid plumbum-based ferroelectric film and annealing the tantalum scandium acid plumbum-based ferroelectric film; annealing the tantalum scandium acid plumbum-based ferroelectric film comprises the steps of: putting the tantalum scandium acid plumbum-based ferroelectric film in an annealing furnace, heating up to 800-850 DEG C at a heating rate of 40 DEG C / s in an oxygen flow and then stopping heating up at once so that the tantalum scandium acid plumbum-based ferroelectric film is naturally cooled to 500-600 DEG C along with the furnace, preserving the heat for 3-5 minutes, and afterwards naturally cooling the ferroelectric film to room temperature along with the furnace. The tantalum scandium acid plumbum-based ferroelectric film prepared by the method has a perovskite phase purity capable of reaching 100%, good crystallization performance and low RMS roughness on the surface as well as also has the characteristic of high polarization intensity and high preferred orientation.

Owner:SICHUAN UNIV

Optical compound glass

The invention relates to an optical compound glass, which is characterized in that the optical compound glass is prepared from the following ingredients in parts by weight: 20-50% of SiO2, 0-15% of B2O3, 1-15% of TiO2, 2-20% of ZnO, 15-50% of BaO, 0-10% of Al2O3, 0-10% of Fe3O4, 0-10% of ZrO2, 0-15% of Nb2O5, 0-10% of La2O3, 0-10% of Gd2O3, 0-10% of Y2O3, 0-10% of Yb2O3, 0-10% of MgO, 0-15% of CaO, 0-10% of SrO, 0-10% of Li2O, 0-15% of Na2O, 0-15% of K2O and 0-1% of Sb2O3. According to the optical compound glass, on a premise that Nb2O5 is lowered or is in the absence, the contents of alkali metal, alkaline earth, ZnO and TiO2 are optimized to obtain the glass with low cost, good chemical stability and excellent devitrification performance, and the optical glass has a refractive index of 1.60-1.70 and an Abbe number of 40-50 and can meet the requirements of modern novel photoelectric products.

Owner:南通振鹏激光科技有限公司

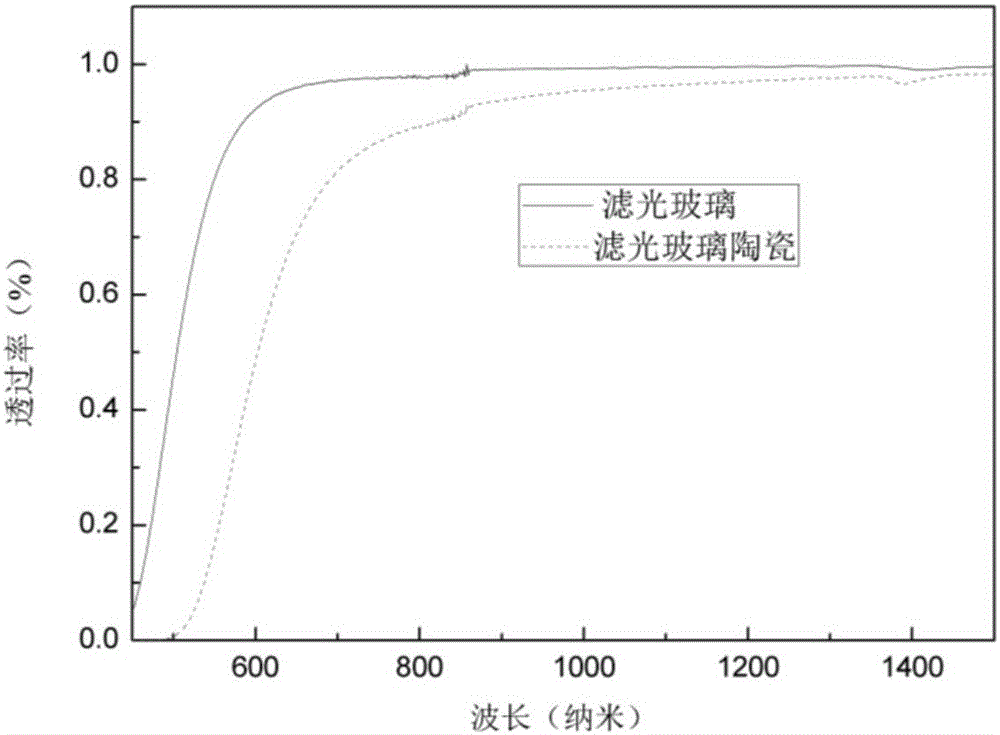

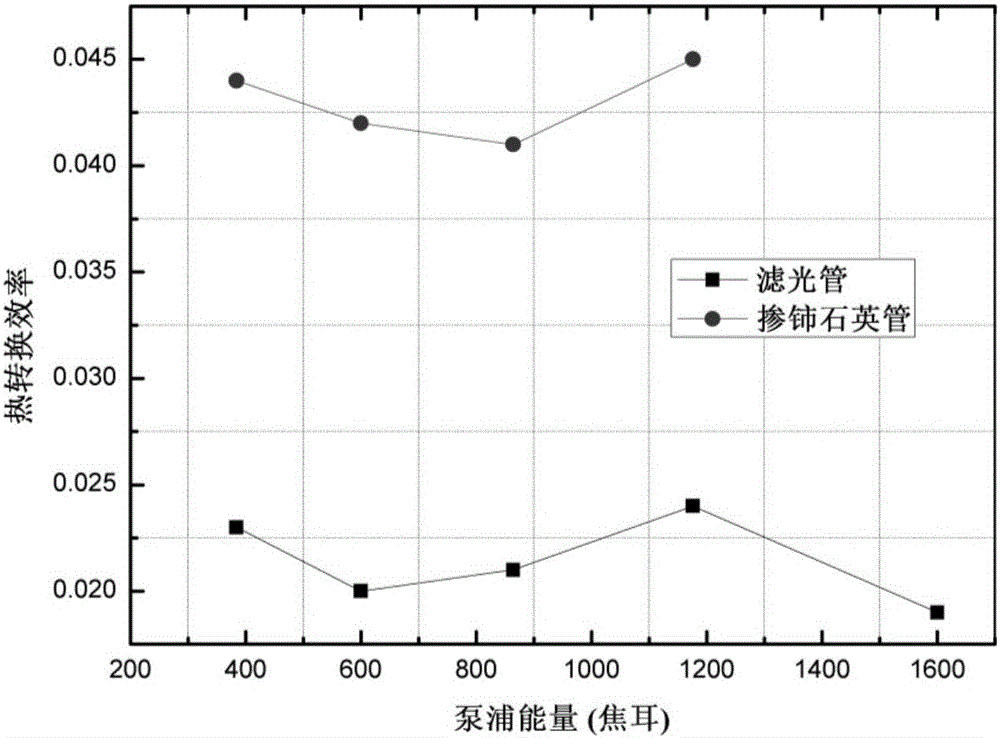

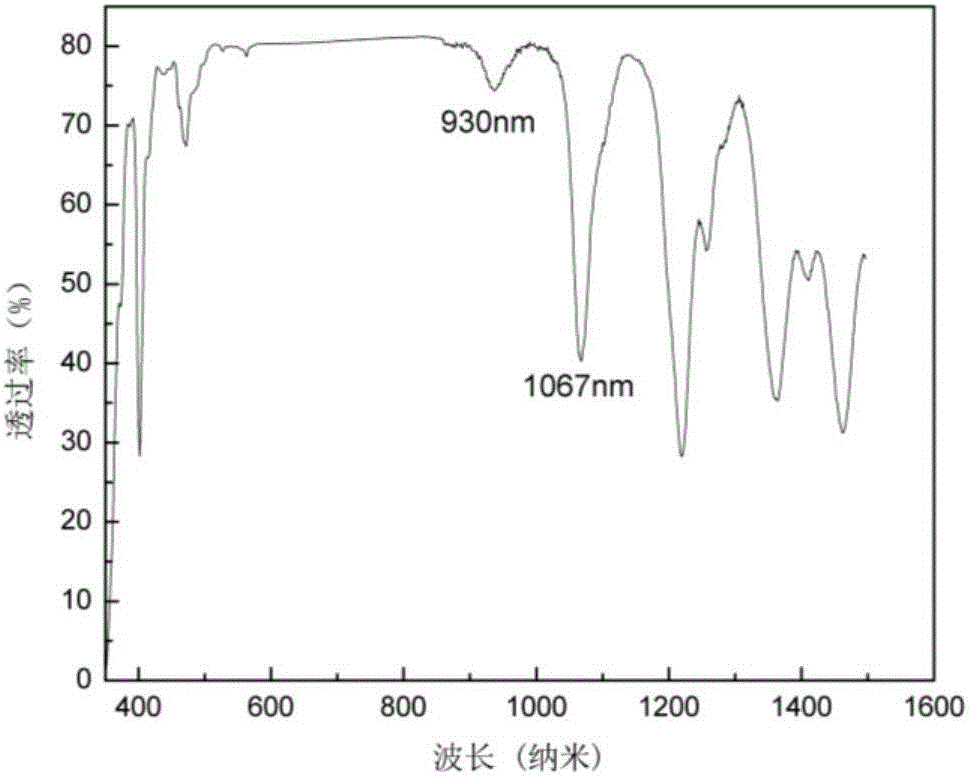

Ultraviolet cut high aluminosilicate crystallized glass doped with cerium and titanium and production method of ultraviolet cut high aluminosilicate crystallized glass

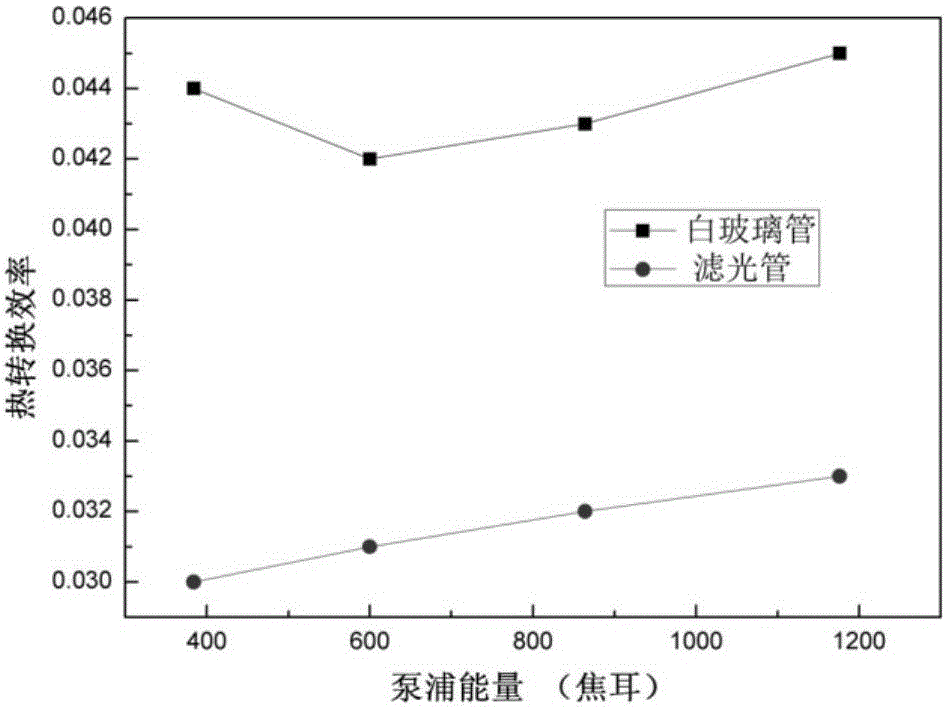

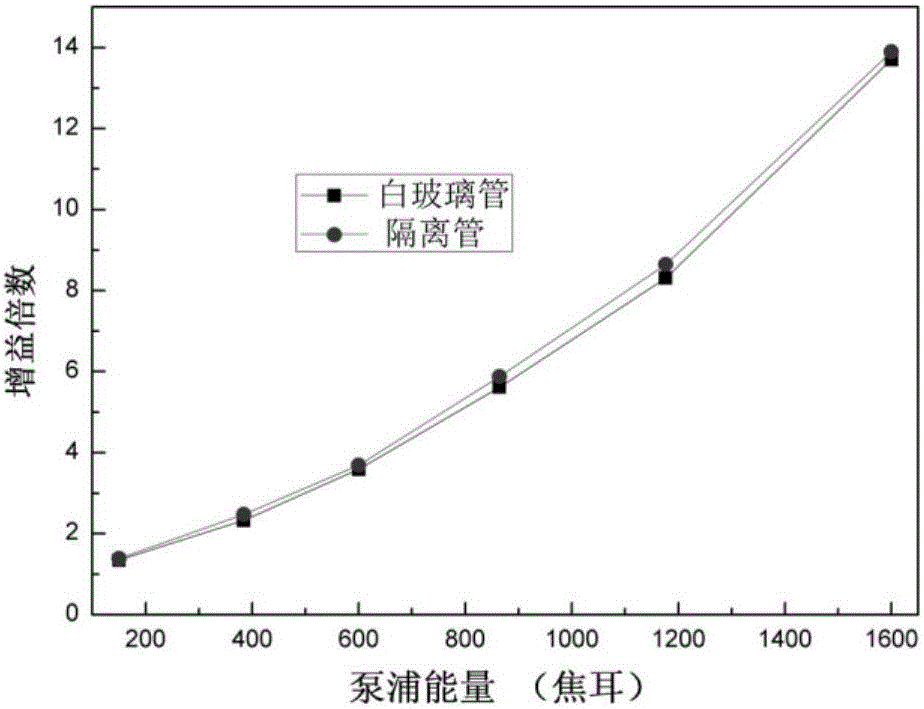

The invention relates to ultraviolet cut high aluminosilicate crystallized glass doped with cerium and titanium. Filter pipe glass is produced from the compositions in percentage of 40-50mol% of SiO2, 25-35mol% of Al2O3, 5-10mol% of MgO, 0-5mol% of ZnO, 0-5mol% of Li2O, 5-10mol% of TiO2, 0-5mol% of ZrO2, and 3-8mol% of CeO2. The heat conductivity of the produced glass is 1.0-1.2W / MK, and the thermal expansion is between 50*10<-7> / K to 60*10<-7> / K. The produced glass can realize tunable cut for xenon lamp spectra in the range of 200-600nm after being subjected to grinding, polishing and microlite heat treatment. According to the ultraviolet cut high aluminosilicate crystallized glass disclosed by the invention, the heat exchange efficiency of xenon lamps can be reduced to 50% or above, and the heat distortion of neodymium glass under the condition of pumping for the xenon lamps can be reduced by 60% or above, so that the repetition work frequency of neodymium glass lasers is further improved, and the ultraviolet cut high aluminosilicate crystallized glass is hopeful for being used in hectowatt high-frequency neodymium laser systems.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Samarium and ytterbium doped infrared absorption high aluminum silicate microcrystalline glass

ActiveCN106082676AHas absorbing propertiesGood crystallization performanceHigh energyThermal expansion

The invention provides a samarium and ytterbium doped infrared absorption high aluminum silicate microcrystalline glass. The filter tube glass comprises the following components by molar percentage: 40-50mol% of SiO2, 25-35mol% of Al2O3, 5-15mol%of MgO, 0-15mol% of ZnO, 0-5mol% of Li2O, 0-10mol% of TiO2, 0.5-2mol% of ZrO2, 0-5mol% of CeO2, 0.5-3mol% of Sm2O3, and 0-0.5mol% of Yb2O3. The glass has thermal conductivity of 1-1.2W / MK, and thermal expansion of the 50-60*10<-7> / K, and can realize absorption in the spectral range of 900-1600 nm through grinding, polishing, and microcrystalline heat treatment. The invention is expected to be used in neodymium glass and YAG laser system to obtain laser output with high frequency and high energy.

Owner:杭州光学精密机械研究所

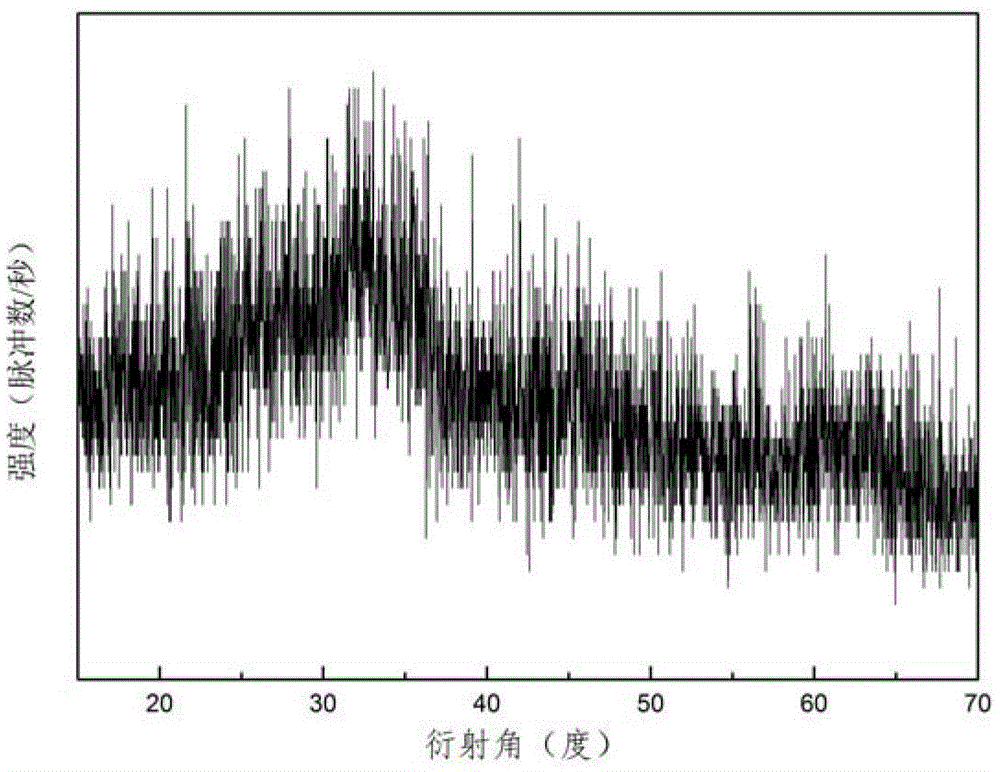

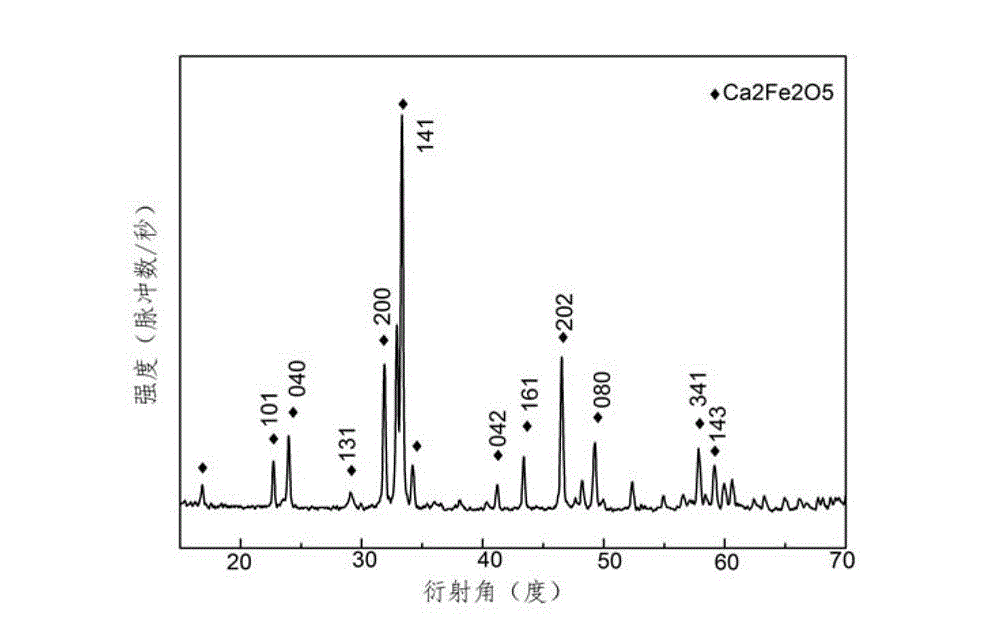

Method for preparing Ca2Fe2O5 nano powder

InactiveCN103145190ASmall granularityGood crystallization performanceMaterial nanotechnologyChemical industryMuffle furnaceChemistry

The invention provides a method for preparing Ca2Fe2O5 nano powder, which comprises the following steps: evenly mixing an iron nitrate solution and a calcium nitrate solution to obtain a mixed solution A; and adding glycine into the mixed solution A according to the propellant chemistry theory, sending into a muffle furnace, heating to 100-300 DEG C to carry out self-propagating reaction to obtain deep-brown fluffy primary powder, and roasting at 100-300 DEG C to obtain the Ca2Fe2O5 nano powder. The invention has the advantages of cheaper raw materials and simple technological operation; the roasting temperature is obviously lowered, thereby being beneficial to energy saving and environmental protection; and the glycine used as a combustion improver is non-toxic and harmless, thereby ensuring the health and safety of operating personnel. The Ca2Fe2O5 nano powder prepared by the method provided by the invention has the advantages of high purity, small and uniform particle size and favorable crystallinity, and can be used as a photocatalyst for degrading organic pollutants or as a cathode material for solid fuel cells.

Owner:SHAANXI UNIV OF SCI & TECH

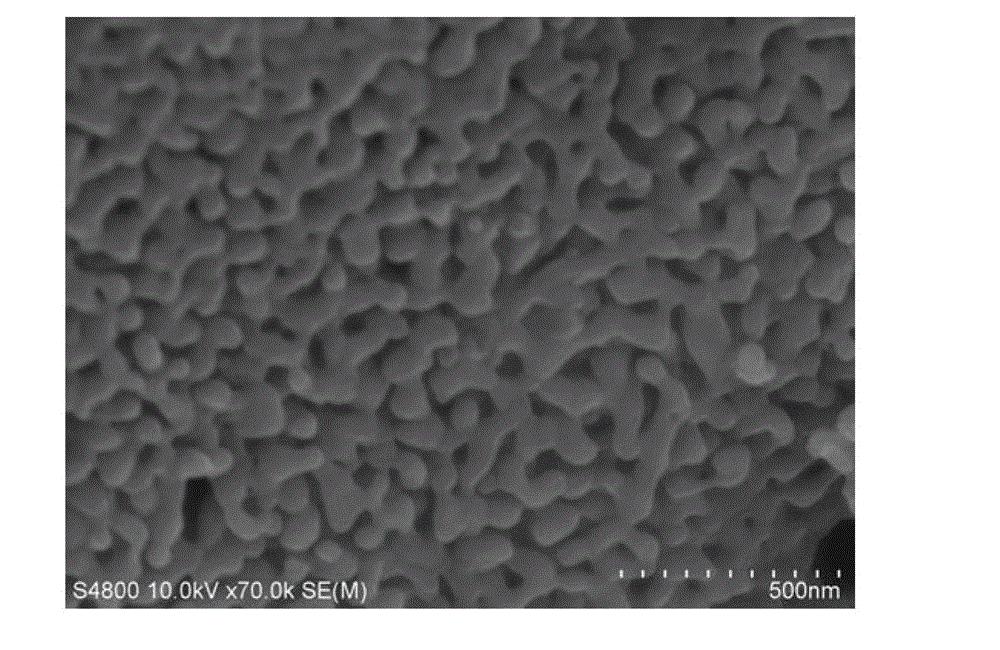

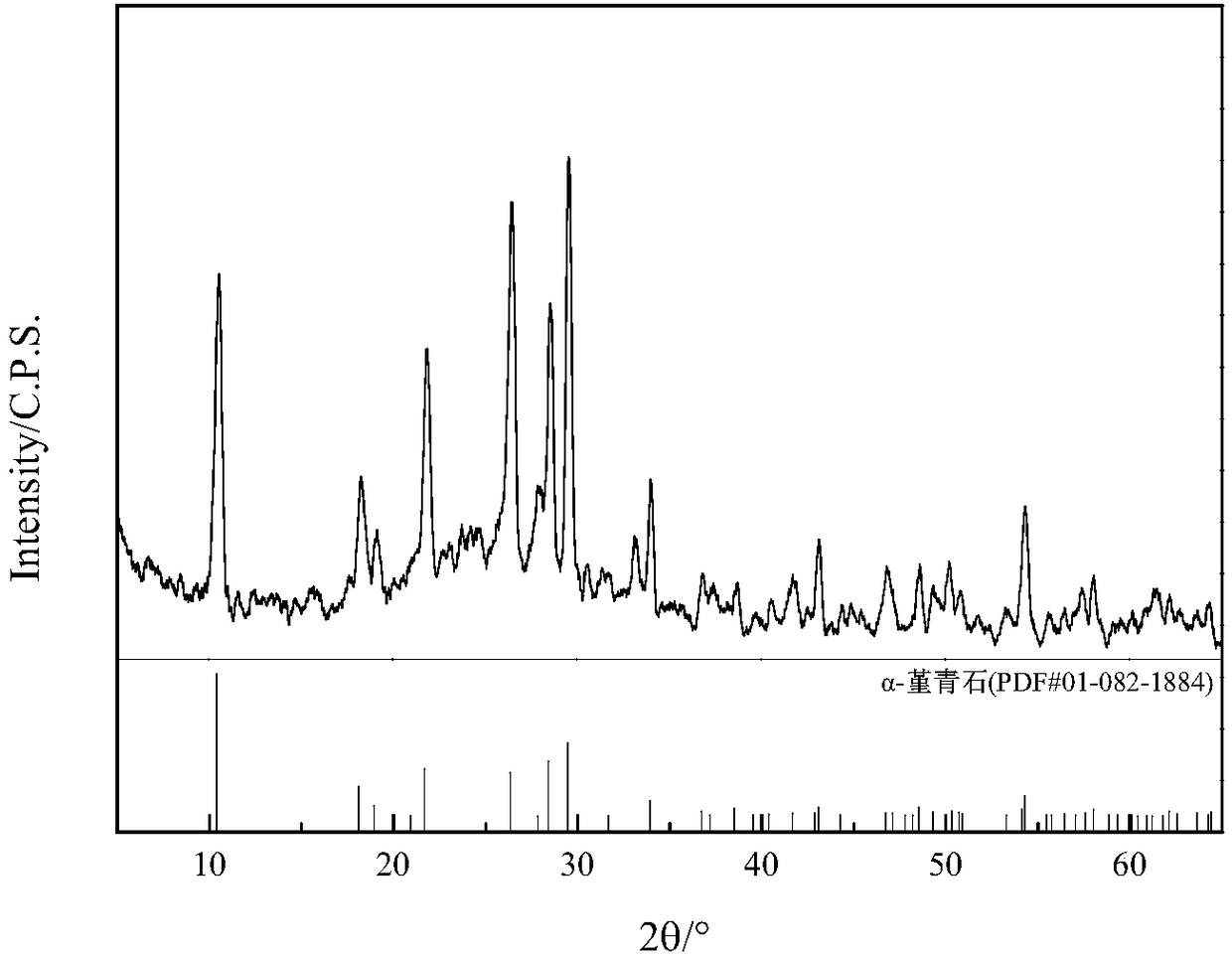

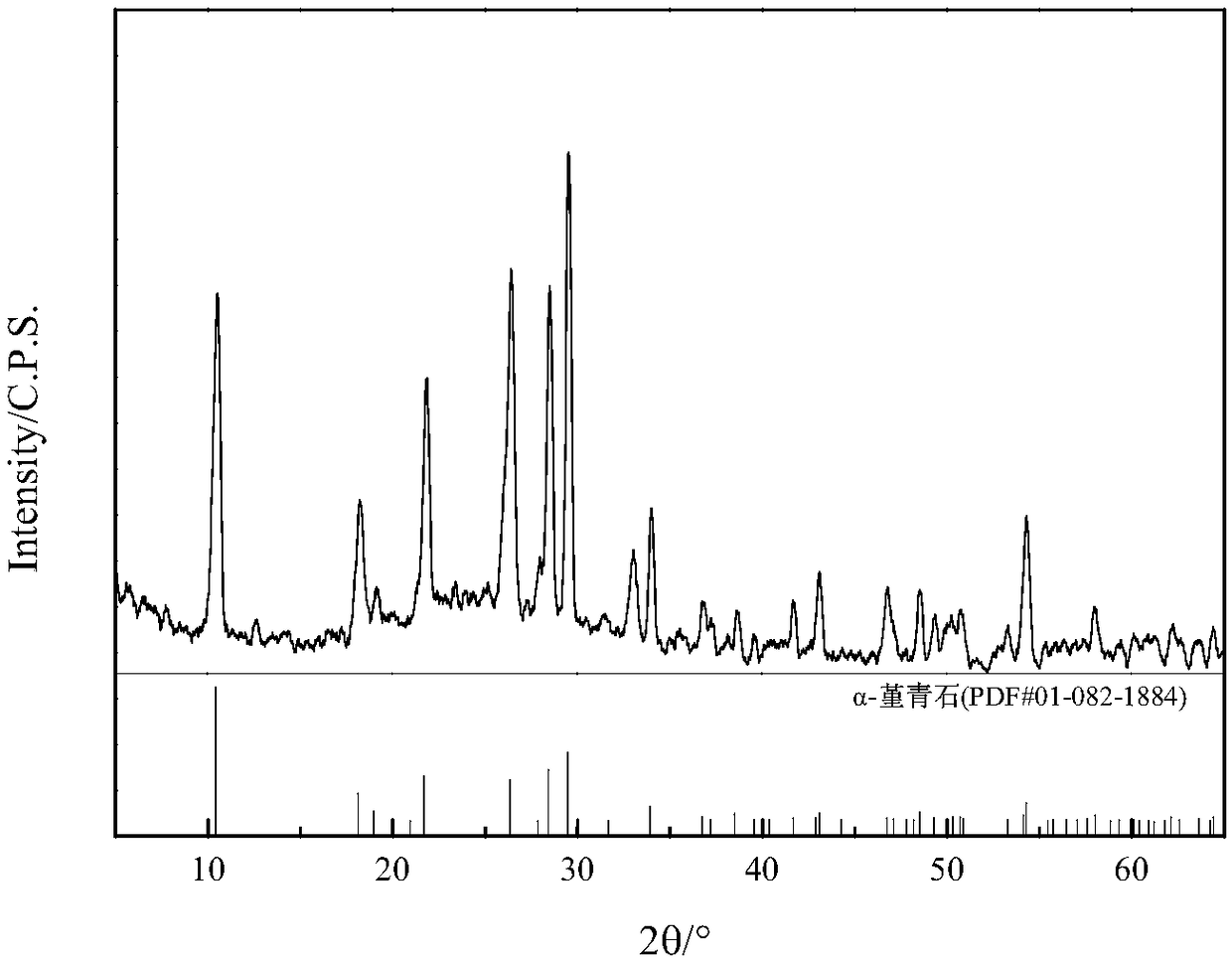

Devitrified alpha cordierite microcrystal glass prepared from Bayan Obo tailings and coal ash and preparation method thereof

The invention relates to devitrified alpha cordierite microcrystal glass prepared from Bayan Obo tailings and coal ash and a preparation method thereof. The devitrified alpha cordierite microcrystal glass is mainly characterized in that adding amount of Bayan Obo tailings, coal ash and other necessary raw materials is controlled, so that requirements of the cordierite chemical component are met; ammonium dihydrogen phosphate is further added, and magnesium fluoride is used to replace the original part of magnesium oxide in the raw material, so that devitrification ability of alpha cordierite is improved; a fusion preparation process is adopted to perform nucleating heat treatment for 1-5 hours within a temperature range being 700-800 DEG C, and crystallization thermal treatment for 1-5 hours within a temperature being 1000-1100 DEG C, so that an alpha cordierite microcrystal glass material with high strength and a low thermal expansion coefficient, which is basically free of gas holesand separates out alpha cordierite in the devitrification form, is produced; and a method is provided for realizing high-additional-value utilization of solid waste such as cordierite tailings and coal ash while land occupation is reduced, and the polluted environment problem is solved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Method for producing micro crystal glass

InactiveCN1217873CAvoid it happening againImprove densification performanceGlass productionNucleationProduced water

The production process of devitrified glass includes a sintering process comprising compounding material, smelting, water quenching and sieving to grade, to produce water quenched glass grains; a melting process comprising compounding material, mixing and smelting to produce glass melt; mixing the water quenched glass grains with the glass melt; and subsequent conventional steps of forming, nucleation, crystallizing, polishing and cutting. Compared with available sintering process and melting process, the present invention has the advantages of raised overall re-crystallization capacity, shortened crystallization period, less pores in the product, etc. and is suitable for various glass production methods.

Owner:匡敬忠

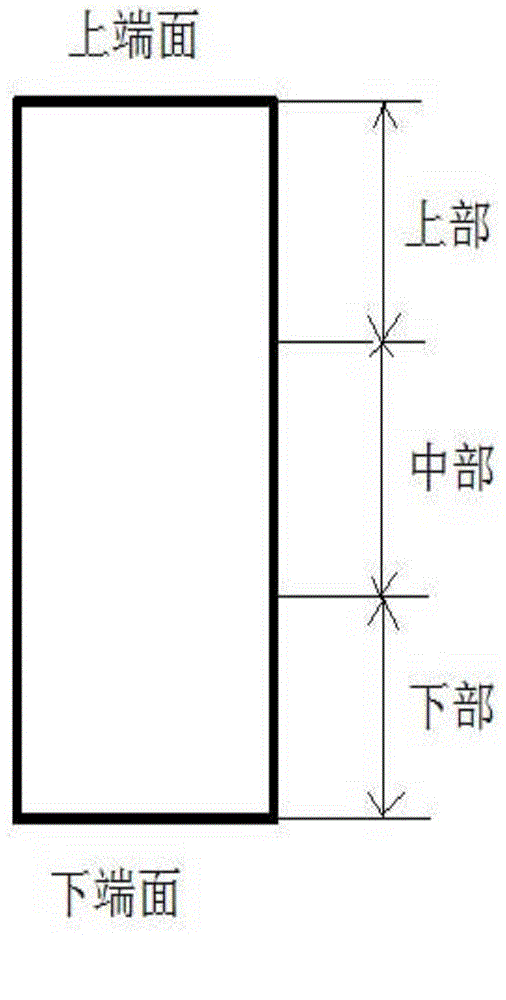

Rare earth magnetostriction material and preparation method thereof

ActiveCN105986310AGood crystallization performanceShort processPolycrystalline material growthAfter-treatment detailsDirectional solidificationCrucible

The invention provides a preparation method of a rare earth magnetostriction material. The method comprises three processes of smelting, directional solidification and heat treatment. The directional solidification process comprises the following steps that 1, a magnetostriction alloy smelted solution obtained in a smelting crucible is poured into a quartz tube of a heat insulation device; 2, a pull-down process is started, and the quartz tube arranged on a base of a pull-down rod perpendicularly moves downwards along with the pull-down rod, wherein the downward moving process has three time periods, and different pull-down progresses are set in the different time periods; 3, in the downward moving process of the quartz tube, the alloy smelted solution in the quartz tube is gradually solidified, the pull-down process is finished after the quartz tube is completely moved out of the heat insulation device, and finally the alloy smelted solution forms a rare earth magnetostriction bar of a certain structure. In addition, the invention further provides the rare earth magnetostriction bar prepared through the method. The rare earth magnetostriction bar is good in crystallization property; meanwhile, the fluctuation range of magnetostriction coefficient of materials on upper, middle and lower different portions is small, and is 18ppm to the minimum.

Owner:GRIREM ADVANCED MATERIALS CO LTD

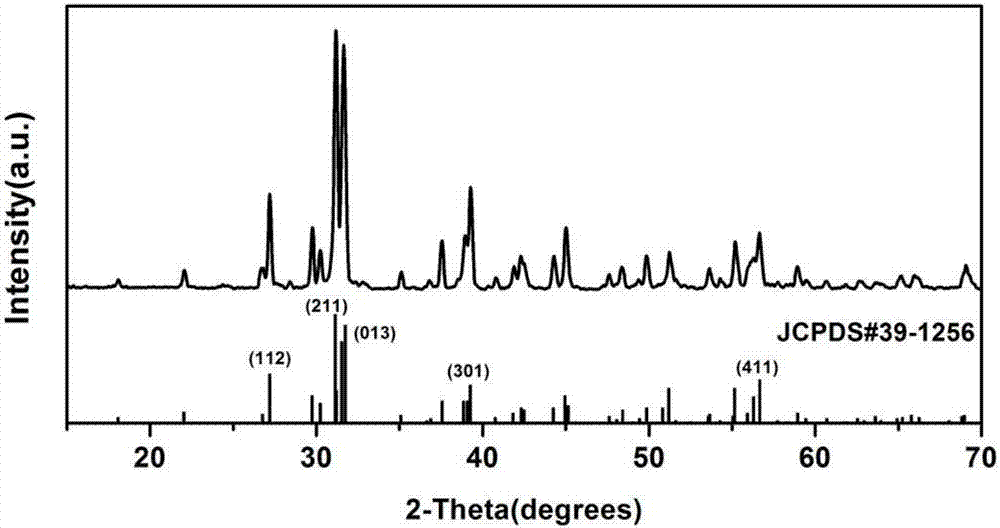

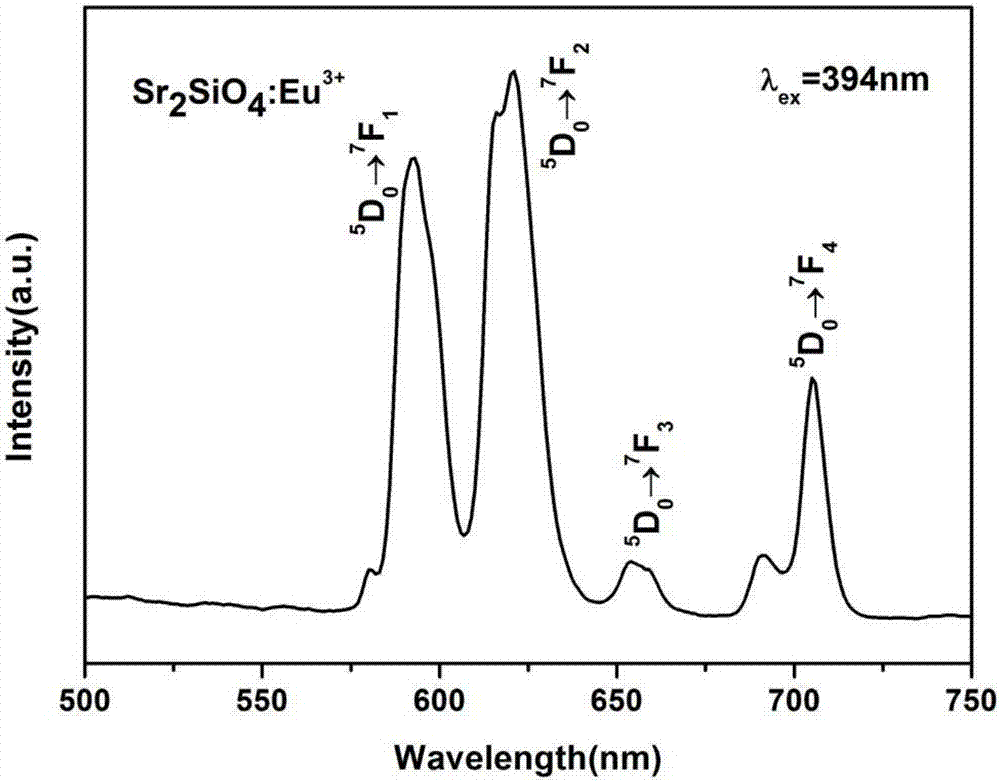

Europium-doped strontium silicate red and orange fluorescent powder and preparation method thereof

InactiveCN107043622AReduce energy consumptionGood crystallization performanceLuminescent compositionsSolid phasesTemperature resistance

The invention discloses europium-doped strontium silicate red and orange fluorescent powder and a preparation method thereof. The method comprises the following steps of weighing SrCO3, SiO2 and Eu2O3 as raw materials at the molar ratio of (2-2.2):1:(0.005-0.070) separately, and fully grinding and mixing the weighed raw materials at a room temperature evenly; and putting the mixture obtained in the previous step into a crucible, putting the crucible into a high-temperature resistance furnace, raising the temperature to 950-1050 DEG C at the rate of 1-2 DEG C / min from a room temperature, carrying out heat preservation for 2-3h, cooling to the room temperature and taking out the product to obtain calcined powder. Through reducing the sintering temperature and carrying out calcination for multiple times, compared with a traditional solid-phase method, the reaction conditions are relatively mild, the energy consumption is greatly reduced, the prepared fluorescent powder is higher in purity, and excellent luminous performance of the fluorescent powder is obtained.

Owner:SHAANXI UNIV OF SCI & TECH

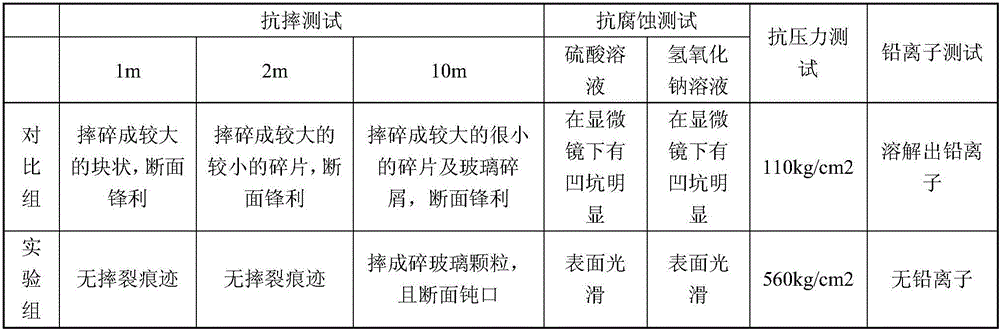

Patterned glass bottle and manufacturing method thereof

InactiveCN106587611AImprove acid and alkali resistanceHigh chemical stabilityGlass blowing apparatusGlass tempering apparatusMolten glassLaminated glass

The invention provides a patterned glass bottle and a manufacturing method thereof, belonging to the technical field of glass bottle manufacturing. The patterned glass bottle is composed of inner-layer glass and outer-layer glass, wherein laminated glass is arranged between the inner-layer glass and the outer-layer glass, and the laminated glass has patterns. The manufacturing method comprises the following steps: (1) melting the raw material of the laminated glass, then putting a laminated glass blank into a mold, and blowing the laminated glass blank with the mouth to enable the laminated glass to be molded into a laminated glass bottle; (2) putting an inner-layer glass blank into the laminated glass bottle to obtain a glass bottle combining inner-layer glass and laminated glass; (3) hanging the glass bottle obtained in the step (2) in the mold, pouring the outer-layer molten glass into gaps, and cooling the molten glass for molding; and (4) sealing the glass bottle to obtain the required glass bottle. The glass bottle and the manufacturing method thereof have the advantages that the process is simple, the cost is low, built-in patterns are formed so as to increase the aesthetic feeling of the glass bottle and improve the grade of wine, and the anti-breaking effect is good.

Owner:柳州市昌泉贸易有限公司

Glass beer bottle and preparation method thereof

InactiveCN111925119AGood chemical stabilityIncrease surface tensionGlass shaping apparatusCalcium biphosphateCrack resistance

The invention relates to the technical field of glass bottle beer packaging, is used for improving the anti-cracking performance of glass beer bottles, and in particular relates to a glass beer bottleand a preparation method thereof. The formula of the glass beer bottle comprises the following components in parts by weight: 30-40 parts of glass slag, 30-35 parts of quartz sand, 10-15 parts of sodium carbonate, 5-15 parts of calcite, 5-15 parts of feldspar, 1-3 parts of calcium phosphate and 1-3 parts of manganese dioxide. The preparation method comprises the following steps: mixing the raw materials, grinding into powder, feeding into a smelting furnace to prepare a stock solution, pouring the stock solution into a mold for molding, sequentially carrying out cooling, demolding and annealing procedures, and feeding into a tempering box for heating and quick cooling treatment. The problem that an existing glass bottle is poor in crack resistance is solved. The sodium carbonate, the calcium phosphate and the manganese dioxide are added into the raw materials of the glass beer bottle, so that the raw materials fully react with the glass slag and the quartz sand when being molten in the smelting furnace, and the obtained product improves the chemical stability, surface tension and crystallization capacity of the glass beer bottle, so that the prepared glass beer bottle has higher anti-cracking performance.

Owner:郑州市华源玻璃制品有限公司

Manufacturing method of glass wine bottle

InactiveCN107572782AImprove chemical temperatureIncrease surface tensionGlass shaping apparatusCalcium biphosphateCombustion

The invention discloses a manufacturing method of a glass wine bottle. The method comprises a raw material formula of the glass wine bottle, wherein the raw material formula comprises the following raw materials: broken glass, third-class sand, sodium carbonate, limestone, alumina, calcium phosphate, titanium oxide, a clarifying agent and a combustion improver. The manufacturing method comprises the following steps: (1) breaking the glass into granular glass and performing freeze drying; (2) mixing the granular glass and other raw materials and performing ball-milling on the mixture into powder; (3) drying the powder and pouring the dried powder into a smelting furnace for melting, so as to obtain solution; (4) feeding the solution into a forming machine for forming, and cooling to room temperature, so as to obtain a finished product. The manufacturing method is reasonable in design and convenient in operation, the manufactured glass wine bottle is strong in breaking resistance, high temperature resistance and low temperature resistance and good in quality.

Owner:安徽九亿包装科技有限公司

High-uniformity optical glass and preparation method thereof

PendingCN114538775ANot easy to change chemicallyImprove heat resistanceGlass pressing apparatusGlass productionRefractive indexOptical glass

The invention discloses high-uniformity optical glass and a preparation method, and relates to the technical field of optical glass, the optical glass has the characteristics of optimal opaqueness, optimal whiteness, optimal brightness and the like, has strong adhesive force, is not easy to generate chemical change, has a very high melting point, also has a relatively good ultraviolet shielding effect, and can be used for preparing optical glass. The boric acid can improve the heat resistance and transparency of the optical glass, improve the mechanical strength and shorten the melting time, and the optical glass is excellent in performance, has the characteristics of high refractive index and high dispersion, has stable optical properties and high optical uniformity, and has the advantages of high temperature resistance, low expansion coefficient, high mechanical strength, good chemical performance and the like; the optical glass is excellent in devitrification performance, devitrification resistance, chemical stability and mechanical performance and high in transmittance, the chromatic aberration of an optical system is improved, the preparation method of the optical glass is simple and easy to implement, and batch production is easy to achieve.

Owner:湖北省椿丰光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com