Devitrified alpha cordierite microcrystal glass prepared from Bayan Obo tailings and coal ash and preparation method thereof

A technology of glass-ceramics and fly ash, which is applied in the field of glass-ceramics preparation to achieve the effects of solving pollution, improving crystallization ability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

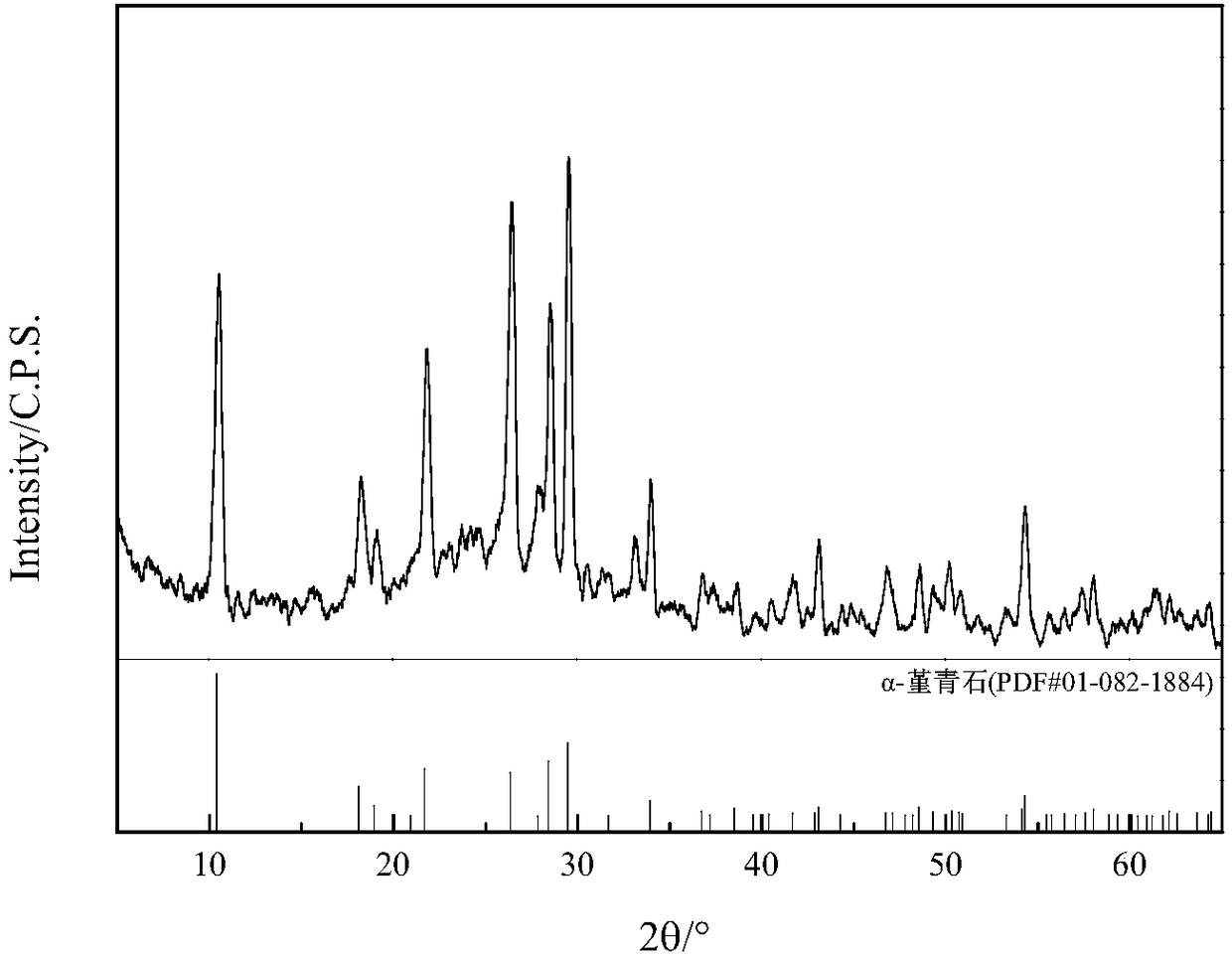

Embodiment 1

[0030] A volume crystallized α-cordierite glass-ceramic prepared by using Baiyan Obo tailings and fly ash, comprising the following raw materials in parts by weight: 13.73 parts of Baiyan Obo tailings, 30.26 parts of fly ash, 25.28 parts of quartz sand, magnesium oxide 9.67 parts, 11.71 parts of alumina, 6.89 parts of borax, 1.63 parts of magnesium fluoride, 0.82 parts of ammonium dihydrogen phosphate.

[0031] The preparation method of volume crystallization α cordierite glass-ceramics comprises the following steps:

[0032] (1) Mixing: each raw material is mixed evenly with a ball mill;

[0033] (2) Melting: heat the mixed raw materials in a corundum crucible to 1550°C for melting, and keep the temperature for 2.5 hours to obtain a glass melt;

[0034] (3) Forming: casting the glass melt into a preheated (600°C) stainless steel mold;

[0035] (4) Annealing: Transfer the formed glass to a heating furnace with an inner temperature of 600°C, anneal for 2.5 hours, and cool to ...

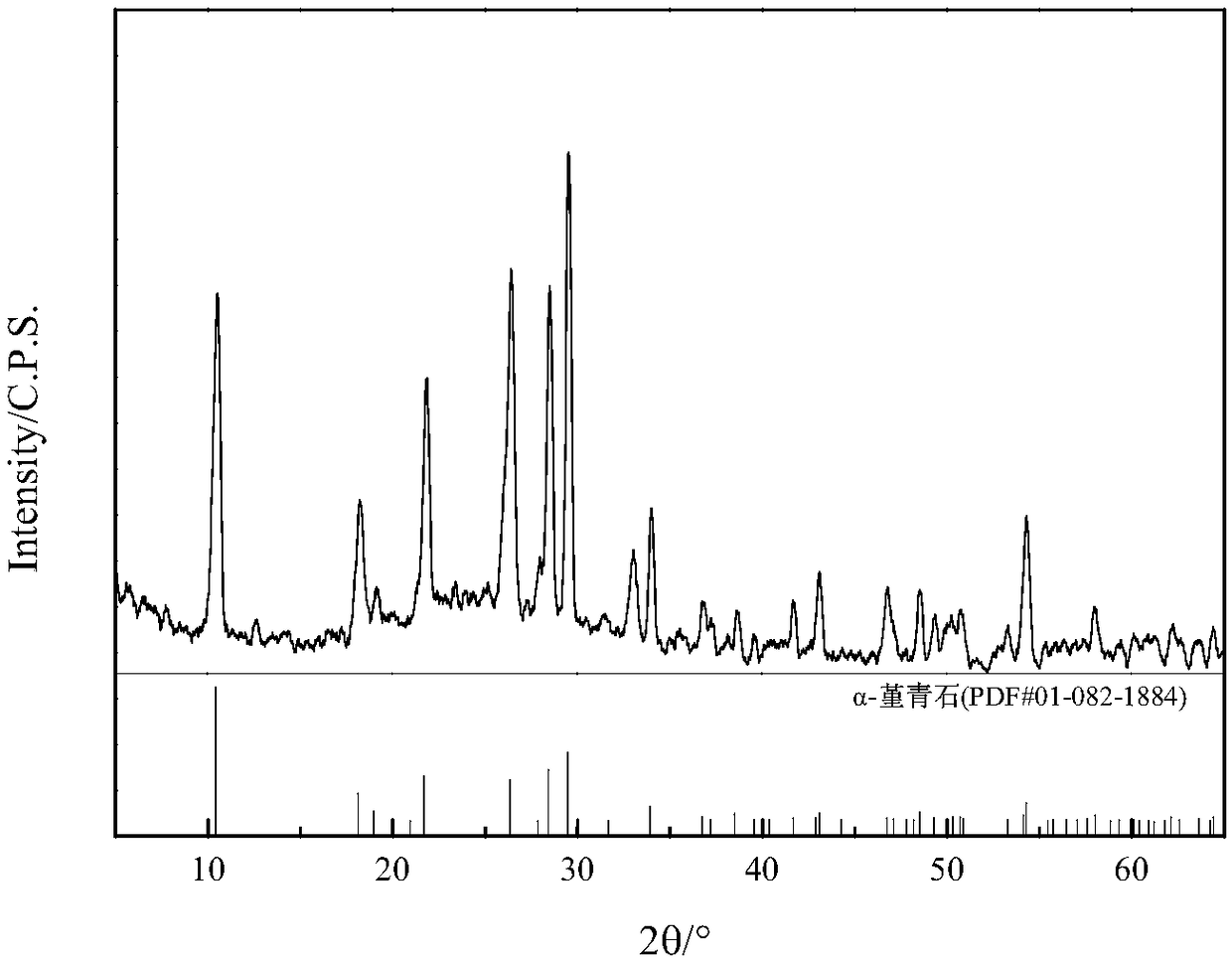

Embodiment 2

[0043] A volume crystallized α-cordierite glass-ceramic prepared by using Baiyan Obo tailings and fly ash, comprising the following raw materials in parts by weight: 13.57 parts of Baiyan Obo tailings, 29.92 parts of fly ash, 25.00 parts of quartz sand, magnesium oxide 7.48 parts, 11.58 parts of alumina, 6.81 parts of borax, 4.84 parts of magnesium fluoride, 0.81 parts of ammonium dihydrogen phosphate.

[0044] The preparation method of volume crystallization α cordierite glass-ceramics comprises the following steps:

[0045] (1) Mixing: each raw material is mixed evenly with a ball mill;

[0046] (2) Melting: heat the mixed raw materials in a corundum crucible to 1550°C for melting, and keep the temperature for 3 hours to obtain a glass melt;

[0047] (3) Forming: casting the glass melt into a preheated (600°C) stainless steel mold;

[0048] (4) Annealing: Transfer the formed glass to a heating furnace with an inner temperature of 600°C, anneal for 3 hours, and cool to room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com