Patterned glass bottle and manufacturing method thereof

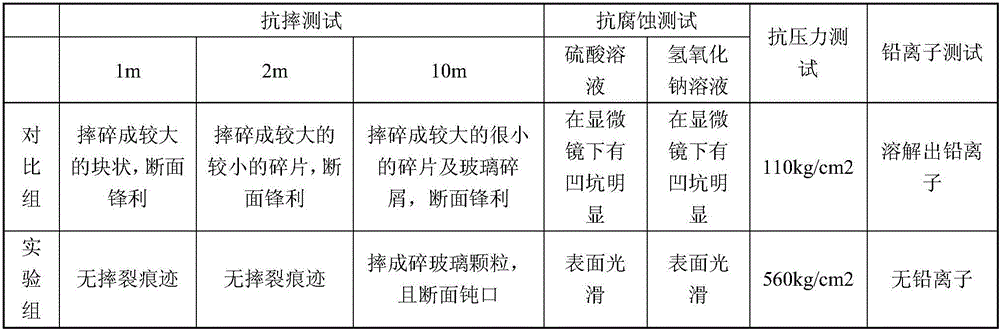

A glass bottle and pattern technology, applied in glass manufacturing equipment, glass blowing, glass molding, etc., can solve problems such as unfavorable production, and achieve the effects of low cost, improved chemical stability, and strong drop resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The invention relates to a patterned glass bottle, which is composed of an inner layer glass and an outer layer glass, a laminated glass is arranged between the inner layer glass and the outer layer glass, and the outer surface of the laminated glass has patterns.

[0024] The inner glass of the present invention is transparent glass, and the components of the inner glass are 200 to 300 parts of lead-free white cullet, 30 parts of real estate quartz sand, 10 parts of soda ash, 10 parts of albite, 5 parts of calcite, and Mingfen 1 part.

[0025] The outer glass of the present invention is transparent glass, and the components of the outer glass are: 200 parts of cullet, 20 parts of soda ash, 1.3 parts of aluminum oxide, 15 parts of borax, 1 part of ferric oxide, 0.5 part of calcium phosphate, 1.5 parts of zirconia and 0.5 parts of titanium oxide.

[0026] The composition of the laminated glass in the present invention is tempered glass having the same composition as tha...

Embodiment 2

[0036] The invention relates to a patterned glass bottle, which is composed of an inner layer glass and an outer layer glass, a laminated glass is arranged between the inner layer glass and the outer layer glass, and the outer surface of the laminated glass has patterns.

[0037] The inner layer glass of the present invention is transparent glass, and the components of the inner layer glass are 300 parts of lead-free white cullet, 40 parts of real estate quartz sand, 15 parts of soda ash, 18 parts of albite, 10 parts of calcite, and sodium sulfate. 2 servings.

[0038] The outer glass of the present invention is transparent glass, and the components of the outer glass are: 300 parts of cullet, 30 parts of soda ash, 2.0 parts of aluminum oxide, 20 parts of borax, 2 parts of ferric oxide, 0.8 part of calcium phosphate, 2.0 parts of zirconia and 1 part of titanium oxide.

[0039] The composition of the laminated glass in the present invention is tempered glass having the same co...

Embodiment 3

[0049] The invention relates to a patterned glass bottle, which is composed of an inner layer glass and an outer layer glass, a laminated glass is arranged between the inner layer glass and the outer layer glass, and the outer surface of the laminated glass has patterns.

[0050] The inner glass of the present invention is transparent glass, and the components of the inner glass are 250 parts of lead-free white cullet, 35 parts of real estate quartz sand, 12 parts of soda ash, 14 parts of albite, 7 parts of calcite, and sodium sulfate. 1.5 servings.

[0051] The outer glass of the present invention is transparent glass, and the components of the outer glass are: 250 parts of cullet, 25 parts of soda ash, 1.8 parts of aluminum oxide, 17 parts of borax, 1.5 parts of ferric oxide, 0.65 part of calcium phosphate, 1.8 parts of zirconia and 0.75 parts of titanium oxide.

[0052] The composition of the laminated glass in the present invention is tempered glass having the same compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com