Corrosion-resistant container bag and preparation process thereof

A preparation process and container bag technology, applied in the field of container bags, can solve the problems of corrosion resistance that cannot meet the requirements of the society, corrosion and damage of woven bags, and limited application range, etc., to increase acid and alkali resistance, increase resistance The effect of acidity and alkalinity and increasing the distribution area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

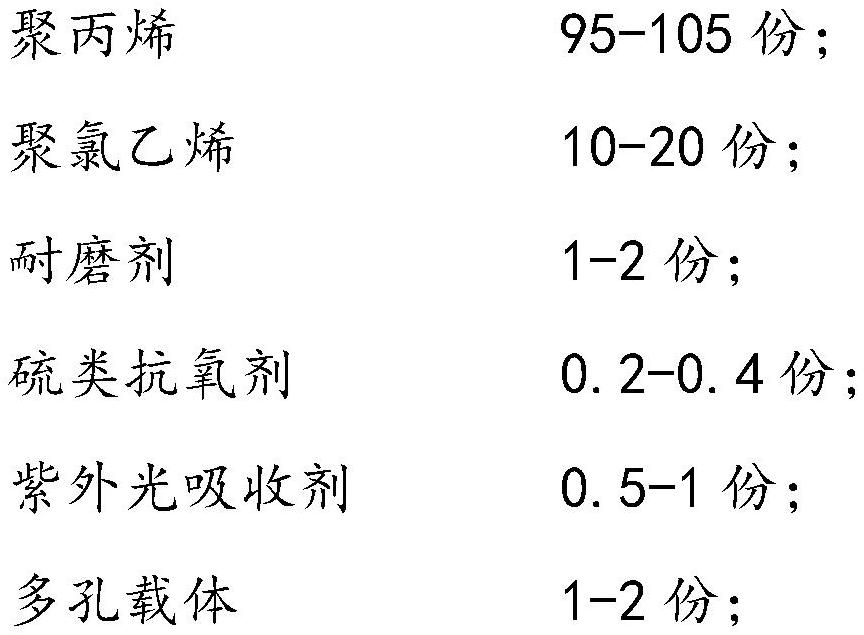

[0032] A corrosion-resistant container bag is made from the following components by weight:

[0033]

[0034] The wear-resistant agent is composed of glass fiber powder and nano carbon black, and the ratio of the glass fiber powder and the nano carbon black is 2:1.

[0035] The preparation process of the above-mentioned container bag comprises the following steps:

[0036] (1) Put polypropylene, polyvinyl chloride, anti-wear agent, sulfur antioxidant, ultraviolet light absorber and porous carrier into a high-speed mixer, and heat, melt and mix at 180°C and 1200 rpm;

[0037] (2) the melt obtained in step (1) is added to the extruder with a feed rate of 120kg / min, the extruder rotational speed is set to 600 rev / min, and the extrusion time is 15 minutes, extruded into a liquid film, and immediately enters the water Cooling and shaping, it becomes a solid film;

[0038] (3) the solid film obtained in step (2) is drawn to the knife holder with a pulling roller, cut into embry...

Embodiment 2

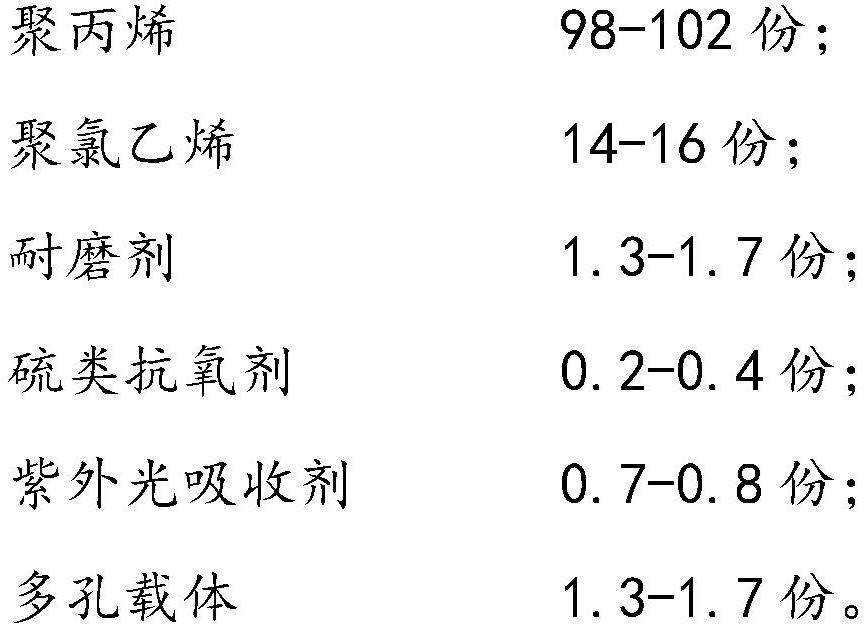

[0041] A corrosion-resistant container bag is made from the following components by weight:

[0042]

[0043] The wear-resistant agent is composed of glass fiber powder and nano carbon black, and the ratio of the glass fiber powder and the nano carbon black is 2:1.

[0044] The preparation process is the same as in Example 1.

Embodiment 3

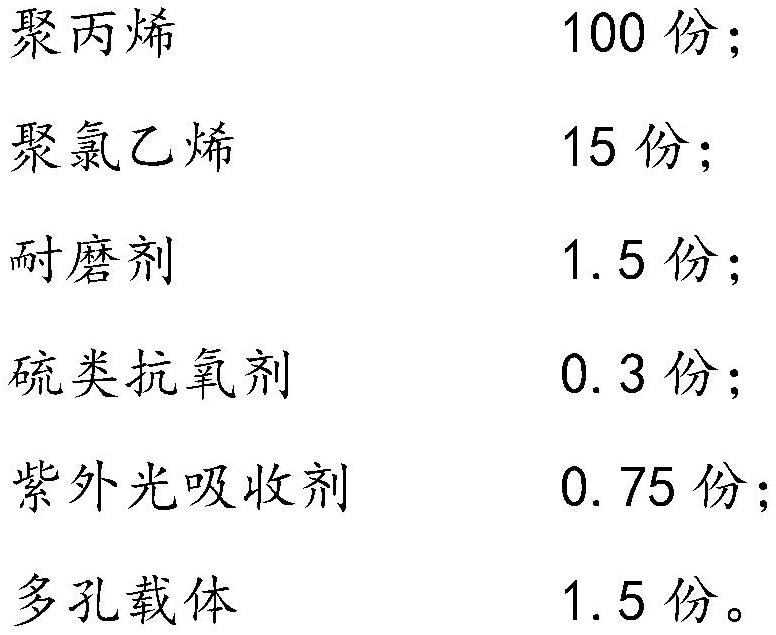

[0046] A corrosion-resistant container bag is made from the following components by weight:

[0047]

[0048] The wear-resistant agent is composed of glass fiber powder and nano carbon black, and the ratio of the glass fiber powder and the nano carbon black is 2:1.

[0049] The preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com