Patents

Literature

43results about How to "Improve acid and alkali resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer emulsion architectural waterproof coating modified by emulsified asphalt and preparation method of coating

InactiveCN105419517AImprove mechanical propertiesGood high and low temperature resistanceBituminous coatingsWeather resistanceAsphalt

The invention provides polymer emulsion architectural waterproof coating modified by emulsified asphalt. The polymer emulsion architectural waterproof coating is characterized by being prepared from the following raw materials in parts by weight: 20 to 45 parts of polymer emulsion, 0.2 to 0.5 part of dispersing agent, 0.2 to 0.5 part of emulsifying agent, 0.3 to 0.6 part of defoaming agent, 0.2 to 0.4 part of sterilizing agent, 10 to 35 parts of the emulsified asphalt, 30 to 52 parts of powdery fillers and 7 to 15 parts of water. The polymer emulsion architectural waterproof coating disclosed by the invention has the advantages of good mechanical performance, good weather resistance, strong waterproof ability and acid-base corrosion resistance.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

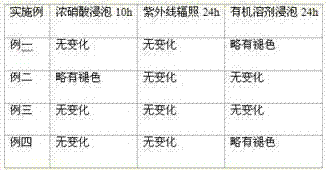

Preparation method of wet-process Maya-blue-like dye

ActiveCN103044970AUniform responseImprove acid and alkali resistanceOrganic dyesEngineeringOrganic solvent

The invention discloses a preparation method of wet-process Maya-blue-like dye, which comprises following steps: firstly, dissolving the dye macromolecules in water or organic solvent, then adding attapulgite clay and performing adsorption for 2 hours at room temperature; in the next place, adding silicon compound and catalyst, rising the temperature to 60-100 DEG C and reacting for 4-48 hours, cooling to room temperature, and filtrating and washing; and finally, drying at 100 DEG C for 4-10 hours and obtaining Maya-blue-like dye. Compared with the dry method, the Maya-blue-like dye prepared by the method provided by the invention is provided with the properties of uniform tinct, acid and alkali resistance, resolvent resistance, ultraviolet ray resistance and the like, and is provided with extensive application prospect in the fields of paint and cultural relic reparation and the like.

Owner:中国科学院兰州化学物理研究所盱眙凹土应用技术研发中心

Method for preparing tungsten-nickel hard alloy

InactiveCN101857926AImprove acid and alkali resistanceGood acid and alkali resistanceCemented carbideVacuum furnace

The invention discloses a method for preparing a tungsten-nickel hard alloy. The method comprises the following steps of: preparing the following raw materials in percentage by weight: 90 percent of WC powder, 9.6 percent of Ni powder and 0.4 percent of Cr3C2 powder; after performing ball-milling on the raw materials for 36 hours, cutting and precipitating for 24 hours; drying for 100 + / -5 minutes; controlling the temperature to be 85+ / -5 DEG C; blending glue by adding 10ml of the glue into per kilogram of mixed raw materials; doping a forming agent SBS by adding 0.1Kg of the forming agent SBS into per kilogram of the mixed raw materials; pressing and forming; sintering the mixed materials by using a vacuum furnace; controlling the temperature to be raised to 1,450 DEG C from 300 DEG C; cooling to normal temperature; and discharging a product out of the furnace. Due to the adoption of the method, a material has improved acid and alkali resistance but no magnetism and is suitable to be used for producing a movement axis of an acid-alkali flow instrument and the movement axis of an instrument and a meter needing avoiding magnetic interference.

Owner:厦门百克精密钨钢刀模有限公司

Acid-alkali-resistant compressive thermal insulation material and preparation method thereof

ActiveCN103980659AImprove acid and alkali resistanceHigh compressive strengthThermal insulationCorrosion

The invention discloses an acid-alkali-resistant compressive thermal insulation material and a preparation method thereof. The acid-alkali-resistant compressive thermal insulation material consists of the following components in parts by weight: 67-72 parts of phenolic resin, 9-12 parts of glass beads, 25-30 parts of polystyrene, 19-23 parts of aluminum silicate, 33-42 parts of polyurethane, 8-14 parts of calcium sulfate, 14-18 parts of aluminum chloride and 26-34 parts of water. The method for preparing the acid-alkali-resistant compressive thermal insulation material comprises the following steps: grinding and crushing, mechanically stirring, cooling and the like. The prepared thermal insulation material has high acid and alkali resistance and compressive property, can tolerate corrosion of acid and alkali and has the compressive strength of 14.6-15.7MPa and heat conductivity coefficient of 0.015-0.019W / (m.K).

Owner:WUJIANG YINGLIDA PLASTIC PACKAGING

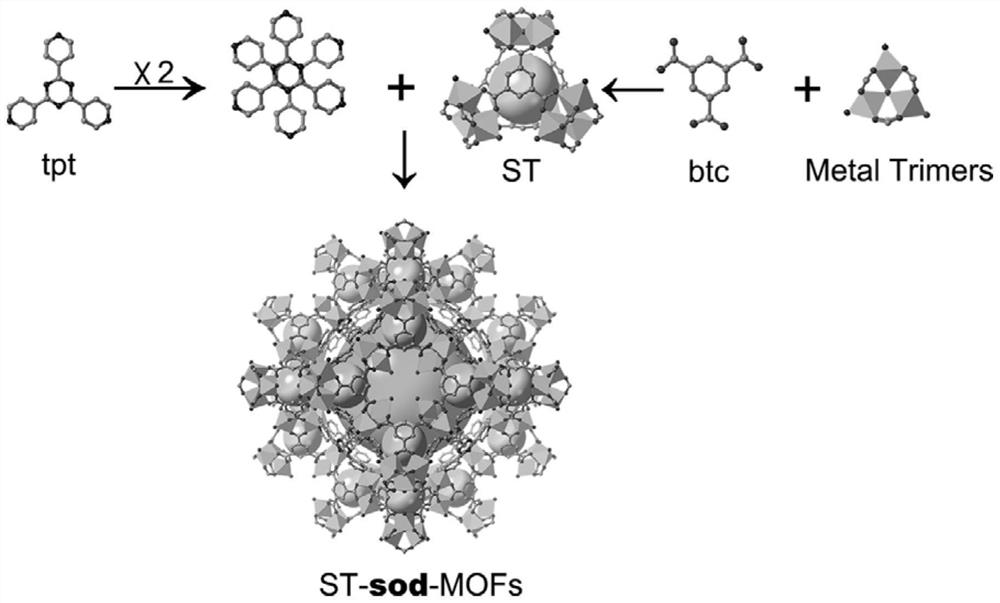

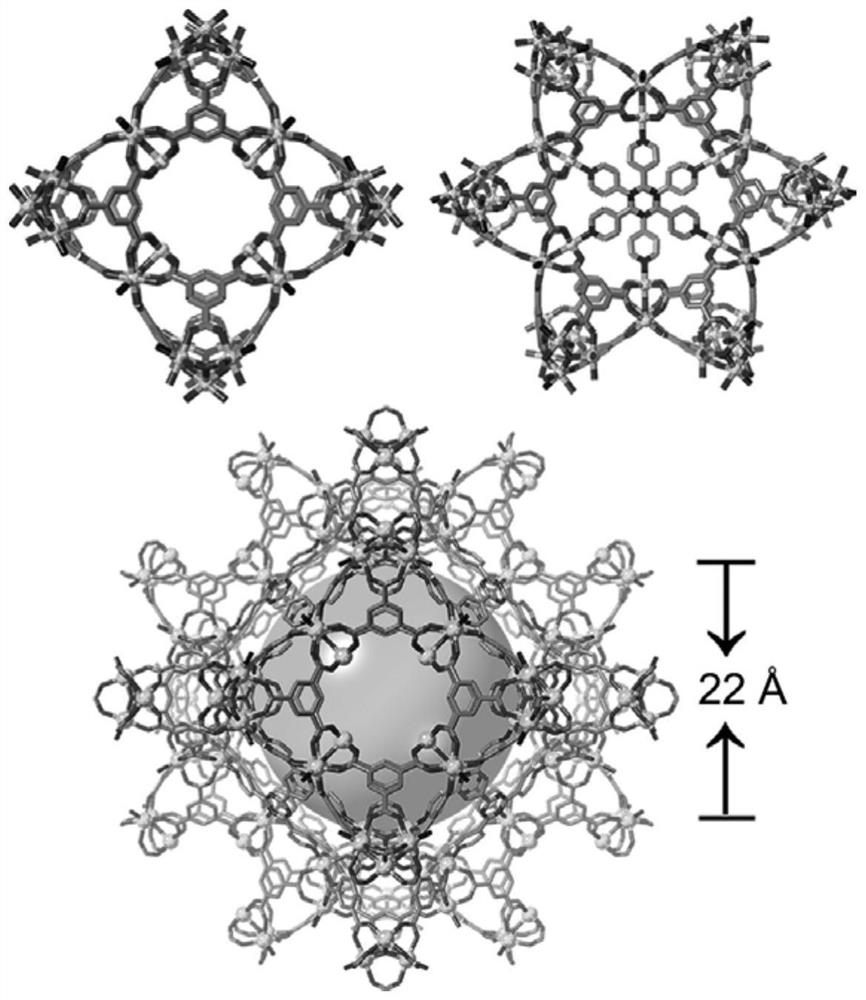

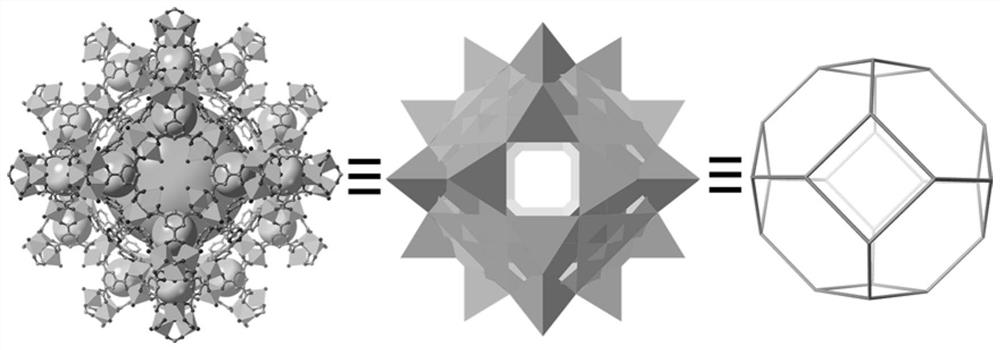

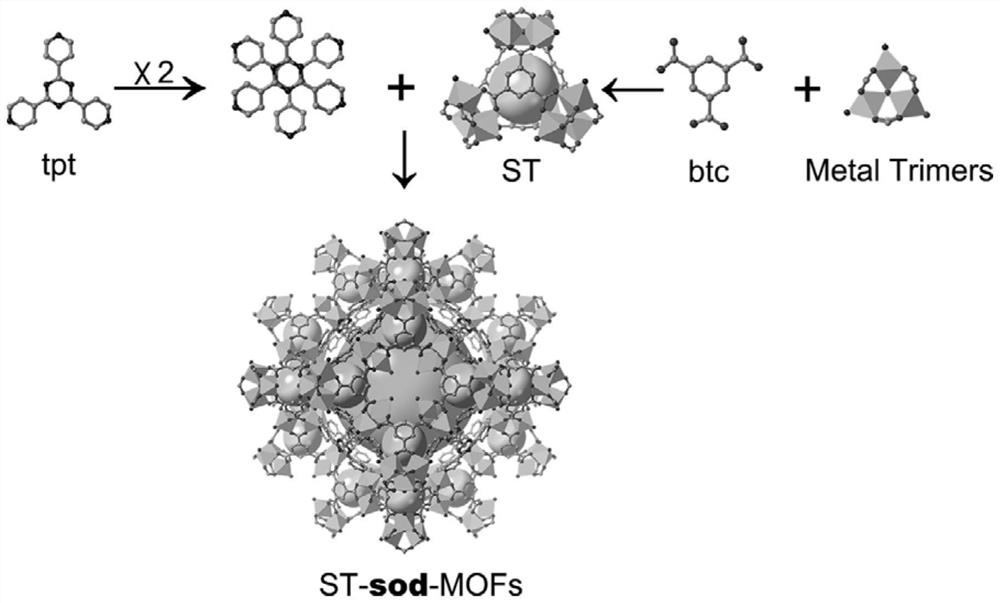

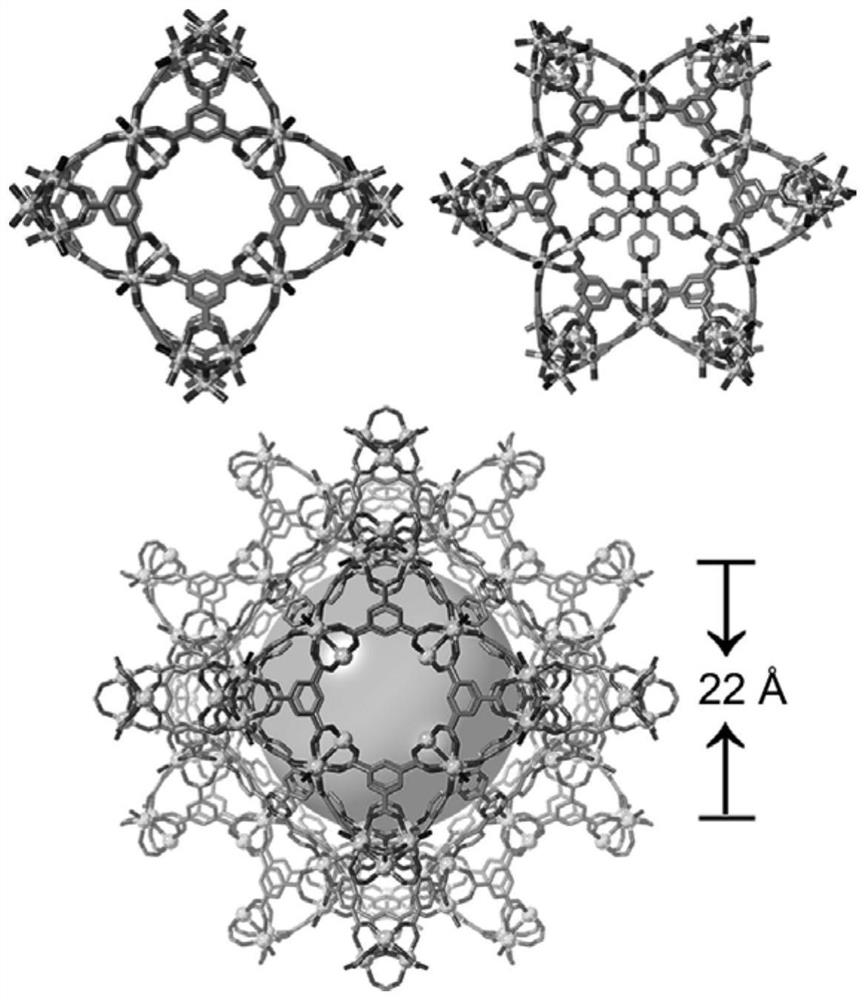

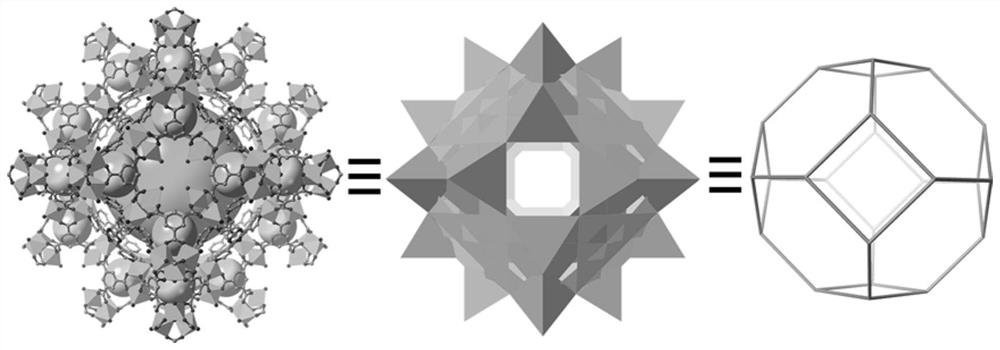

Supertetrahedron metal organic framework material as well as preparation method and application thereof

ActiveCN112126072AEnhanced interactionImprove acid and alkali resistanceProductsReagentsIon clustersIndium

The invention discloses a supertetrahedron metal organic framework constructed based on a window-space-directed assembly strategy as well as a preparation method and application thereof. The novel window-space-directed assembly strategy is provided, a series of building units based on hypertetrahedron are designed and synthesized to construct a metal organic framework material ST-sod-MOFs with ultra-microporous quadrilateral windows and mesoporous sod cages in an angle sharing mode, and the structural general formula of the metal organic framework material is [M3(OH / O)(H2O / F)(btc)2(tpt)2 / 3], wherein M is a metal ion or a combination of two dissimilar metal ions, and is a single metal ion of magnesium, manganese, iron, cobalt, nickel, zinc, aluminum, scandium, gallium, indium and the like or a binary combination of titanium, vanadium, scandium, gallium and indium with one of iron, cobalt, nickel and magnesium. The metal organic framework material is a three-dimensional sod type networkframework formed by trinuclear metal ion cluster nodes and organic ligands through coordination bonds. ST-sod-Co / Ti not only has good thermal stability and relatively high acid and alkali resistance stability, but also shows good performance in the aspect of C2H2 / CO2 separation.

Owner:FUJIAN UNIV OF TECH

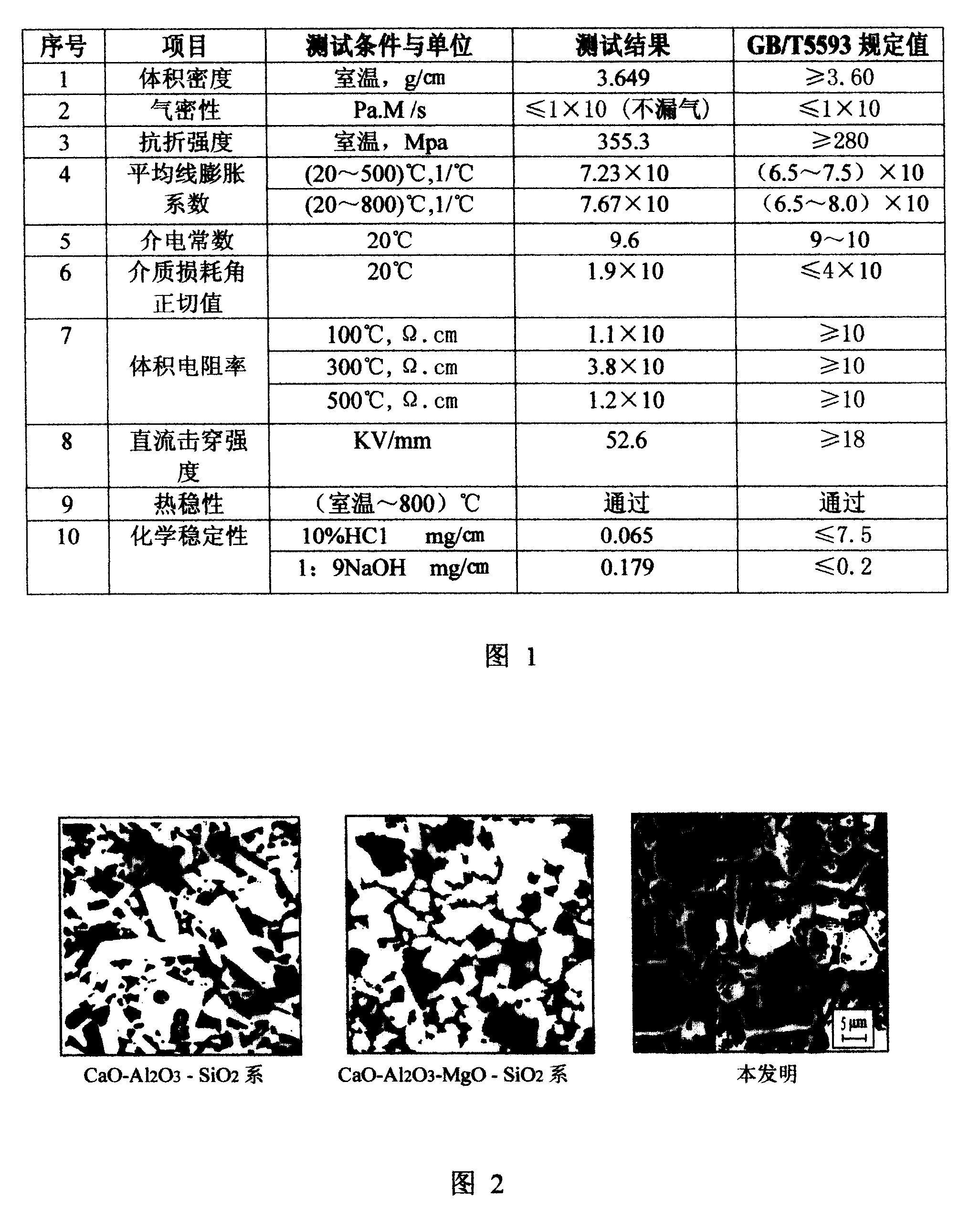

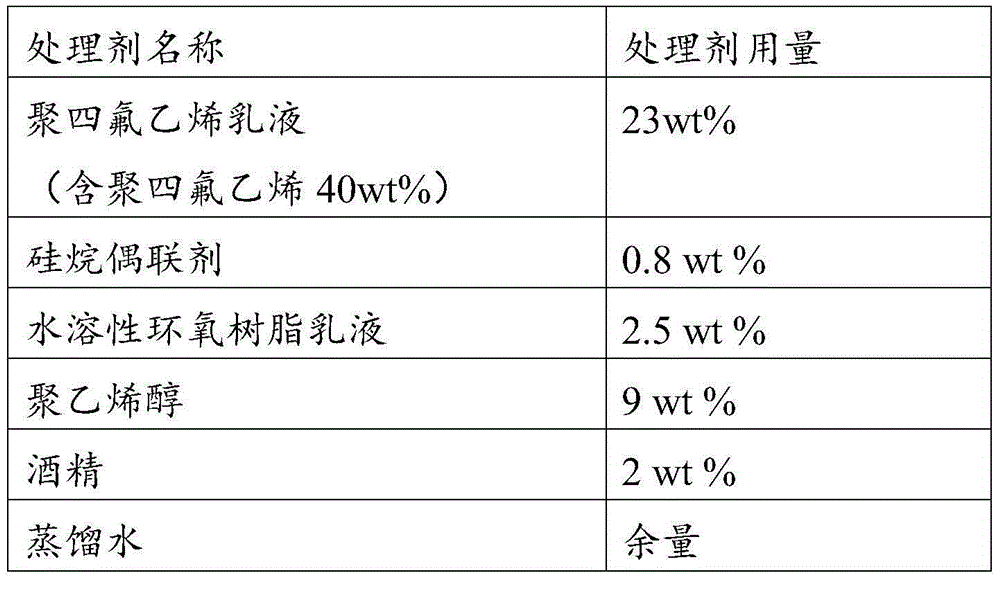

CaO-Al2O3-MgO-ZrO2-SiO2 series aluminum oxide electronic ceramics

InactiveCN101250057AEliminate yellow and gray spotsHigh tensile strengthFlexural strengthAir tightness

The invention discloses an aluminum oxide electronic ceramic of CaO-AI<2>O<3>-MgO-ZrO<2>-SiO<2> system, which is composed of 93-94 wt% of AI<2>O<3>, 3-4 wt% of SiO<2>, 0.2-0.6 wt% of ZrO<2>, 0.2-0.4 wt% of CaO, 0.8-1 wt% of MgO, 0.2-0.6 wt% of BaO and 0.01-0.05 wt% of Fe<2>O<3>, while the left is foreign material. The invention adds zirconium material into the prior ceramic materials to satisfy the glazing demand of user at expansion factor, grain phase and granularity and eliminate yellow brown spot at metallization sealing process, to improve the pass percentage of metal sealing quality of at least 96%, improve tensile strength and acid and alkali resistant degrees, and improve all quality indexes. The inventive product has better compressive performance, high air tightness, high flexural strength, high acid and alkali resistance, high direct current breakdown strength and non yellow brown spot, which is not easy to break.

Owner:大埔县特陶科技有限公司

Preparation method of organic silicon defoamer

ActiveCN107469411AImprove acid and alkali resistanceSoothing Strong Hydrophobic and OleophobicFoam dispersion/preventionDefoamerMaleic anhydride

The invention belongs to the technical field of chemical engineering and particularly relates to a preparation method of an organic silicon defoamer. The preparation method comprises the following steps: by taking silicone oil as a base material, modifying the silicone oil by using a methyl vinyl dichlorosilane monomer to increase silicon oxygen bonds in the silicone oil; then performing protection by using maleic anhydride to increase the acid and alkali resistance; and then performing a grafting reaction with allyl polyoxyethylene ether to form the polyether modified organic silicon defoamer. Under the action of ammonium glycyrrhetate, the hydrophobic and lipophobic properties of the defoamer are alleviated, the stability is enhanced, and a layering phenomenon of the defoamer is prevented.

Owner:GUANGDONG REBON ADVANCED MATERIALS CO LTD

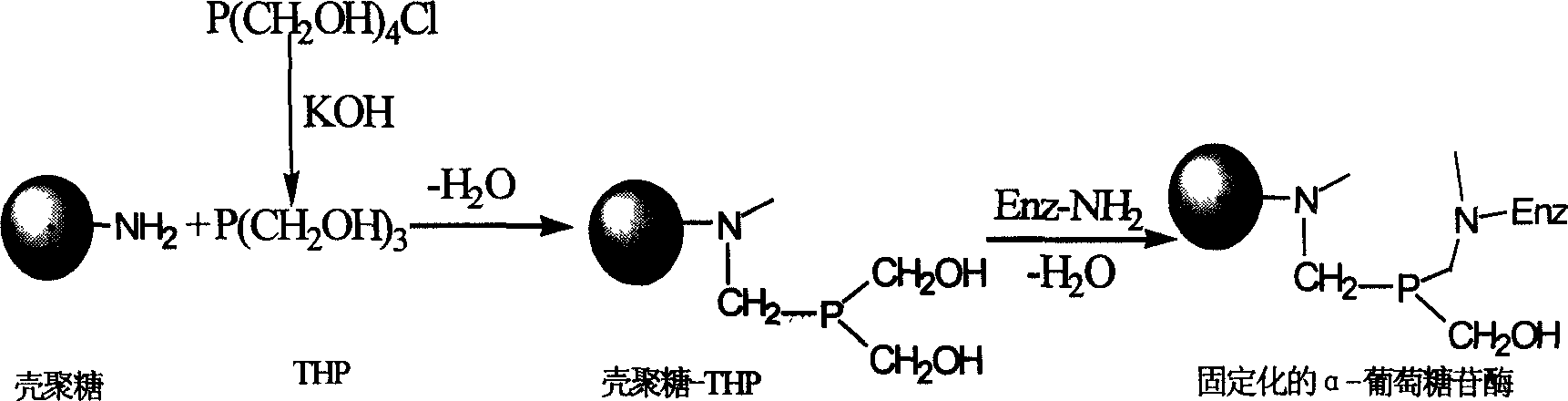

Alpha-glucosidase immobilization method

InactiveCN1618959AImprove thermal stabilityImproved resistance to organic solventsOn/in organic carrierAlgluceraseChloride

A process for immobilizing alpha-glucosidase by using chitosan as carrier and using trihydroxymethyl phosphorus for cross-linking includes removing acetyl from chitosan, reacting between phoshporus tetrahydroxymethyl chloride and KOH to obtain trihydroxymethyl phosphorus, adding the deacetylated chitosan, reacting, filtering, water wasing, washing by potassium phosphate solution as buffering liquid, adding alpha-glucosidase, immobilizing, washing by water and then said buffering liquid, and storing at 4 deg.C.

Owner:SHANGHAI UNIV

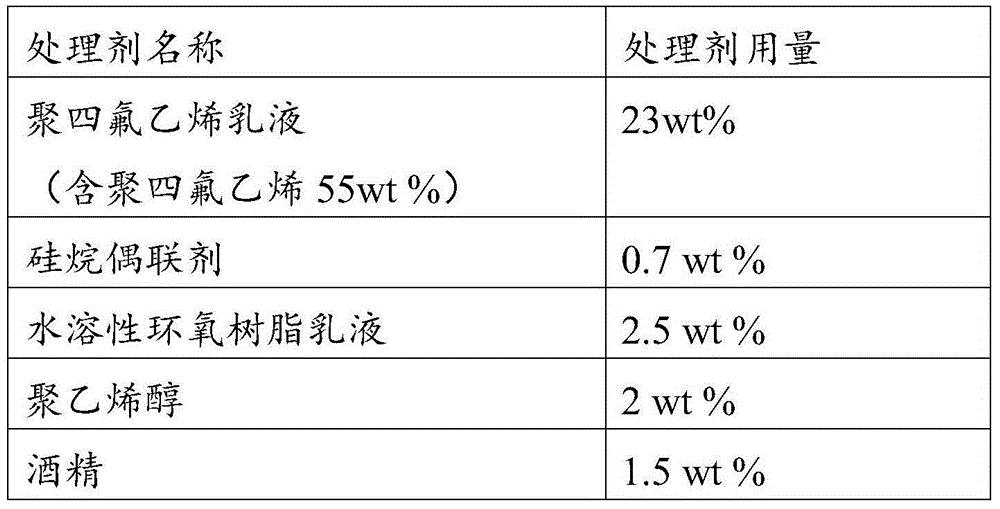

Preparation method of high-precision coating filter material

ActiveCN104436861AImprove acid and alkali resistanceExtended service lifeSynthetic resin layered productsGlass/slag layered productsPolytetrafluoroethyleneFilter material

The invention provides a preparation method of a high-precision coating filter material. According to the preparation method, the filter material can be well combined with PTFE (Polytetrafluoroethylene), and the performances of the filter material can be improved. The method comprises the following steps: (1) carrying out heat cleaning treatment, namely, performing the heat cleaning treatment on the filter material and removing various assistants on the surface of the filter material at high temperature; (2) performing immersion treatment, that is, performing PTFE immersion treatment on the filter material after heat cleaning treatment; (3) baking, drying, and carrying out heat setting on the filter material after immersion treatment sequentially; (4) coating the filter material after heat setting; and (5) performing volatilization, drying, sintering and heat setting on the filter material after coating treatment sequentially. According to the preparation method of the high-precision coating filter material, the filter material is subjected to heat cleaning treatment before immersion treatment, thus, wiredrawing impregnating compound remained on the surface of the fiber can be effectively removed, and the fabric strength can be ensured not to be lost; the acidic and alkali resistances, the water resistance, the oxidation resistance and the abrasion and folding resistances of the filter material can be effectively improved, and the service life of the filter material can be prolonged.

Owner:辽宁新洪源环保材料有限公司

Acid and alkali resistant heat dissipating coating and preparation method thereof

ActiveCN103351772AImprove acid and alkali resistanceImprove durabilityAnti-corrosive paintsWaxCarbon black

The invention discloses an acid and alkali resistant heat dissipating coating and a preparation method thereof. The coating is characterized in that raw materials composing the coating comprise, by weight, 48-55 parts of a furan resin, 2.8-3.2 parts of tetramethyl ethylenediamine, 60-70 parts of ethyl acetate, 2.8-3.5 parts of graphite powder, 2.5-3.5 parts of white carbon black, 1-2 parts of a silane coupling agent KH570, 3.0-4.0 parts of ultramicro wax powder, 3.8-4.5 parts of methyltris(methylethylketoximino)silane, 0.7-0.9 parts of an antioxidant 1010, 1.5-2.0 parts of polyvinyl alcohol, 1.4-1.6 parts of tripropyleneglycoln-butylether, 0.8-1.2 parts of fatty alcohol polyoxyethylene ether and 20-30 parts of aluminum nitride. The hybrid reaction of the graphite powder with aluminum nitride and the like under the action of the silane coupling agent increases the acid and alkali resistance of aluminum nitride, and the film of the coating has the advantages of good durability, good water resistance, good moisture resistance, good corrosion resistance and good adhesiveness.

Owner:贺州钟山县双文碳酸钙新材料有限公司

Electronic device adopting magnetron sputtering to plate film, and manufacturing method thereof

InactiveCN103266303AReduce pollutionEmission reductionVacuum evaporation coatingSputtering coatingHigh energyAlloy

The invention discloses an electronic device adopting magnetron sputtering to plate a film, and a manufacturing method thereof. The manufacturing method comprises: placing a clean substrate in a vacuum container, carrying out vacuum pumping to achieve 10<-4> Pa, introducing high-purity argon gas to achieve 0.5 Pa, carrying out high energy argon ion cleaning, sputtering metal cooper to achieve a desired thickness, sputtering metal silver to achieve a desired thickness, and sputtering a 4:1 CuMo alloy to achieve a thickness of 50 nm. With the method, the manufactured filters, the manufactured duplexers and other electronic devices have advantages of high bonding strength of the film layer and the substrate, good electrical conductivity, acid resistance, alkali resistance, high production rate, high yield, strong manufacturing environment protection, and the like.

Owner:SUZHOU YIGUANG FILM TECH

Vinyl anticorrosion coating material and manufacturing method thereof

InactiveCN104177990AImprove compactnessImprove acid and alkali resistanceAnti-corrosive paintsEpoxy resin coatingsKetoneSolution composition

The invention relates to a vinyl anticorrosion coating material and a manufacturing method thereof. The method includes: adding bisphenol A type epoxy vinyl ester resin into styrene, a co-polymerization solution containing an acid group, silicone oil, a polyacrylate solution and aminopropyltriethoxysilane, dispersing, dissolving, stirring at a high speed, adding fumed silica, titanium dioxide, barite, silica powder and carbon black under stirring, grinding by a sand mill to prepare a liquid mixture, adding glass flakes into the liquid mixture, dispersing at a high speed, and adding a modified urea solution during the dispersion step. A B solution comprises cobalt naphthenate and a styrene mixed solution. A C solution comprises methyl ethyl ketone peroxide, methyl ethyl ketone and a phthalate mixed solution. When the coating material is to be used, an A solution, the B solution and the C solution are mixed. A coating of the coating material has excellent adhesive force, impact resistance, wear resistance, resistance to heat and humidity, resistance to sea water and salt fog resistance and long working lifetime, and is suitable for splashing-zone and underwater corrosion resistance of ocean platforms, marine work steel structures, and the like.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

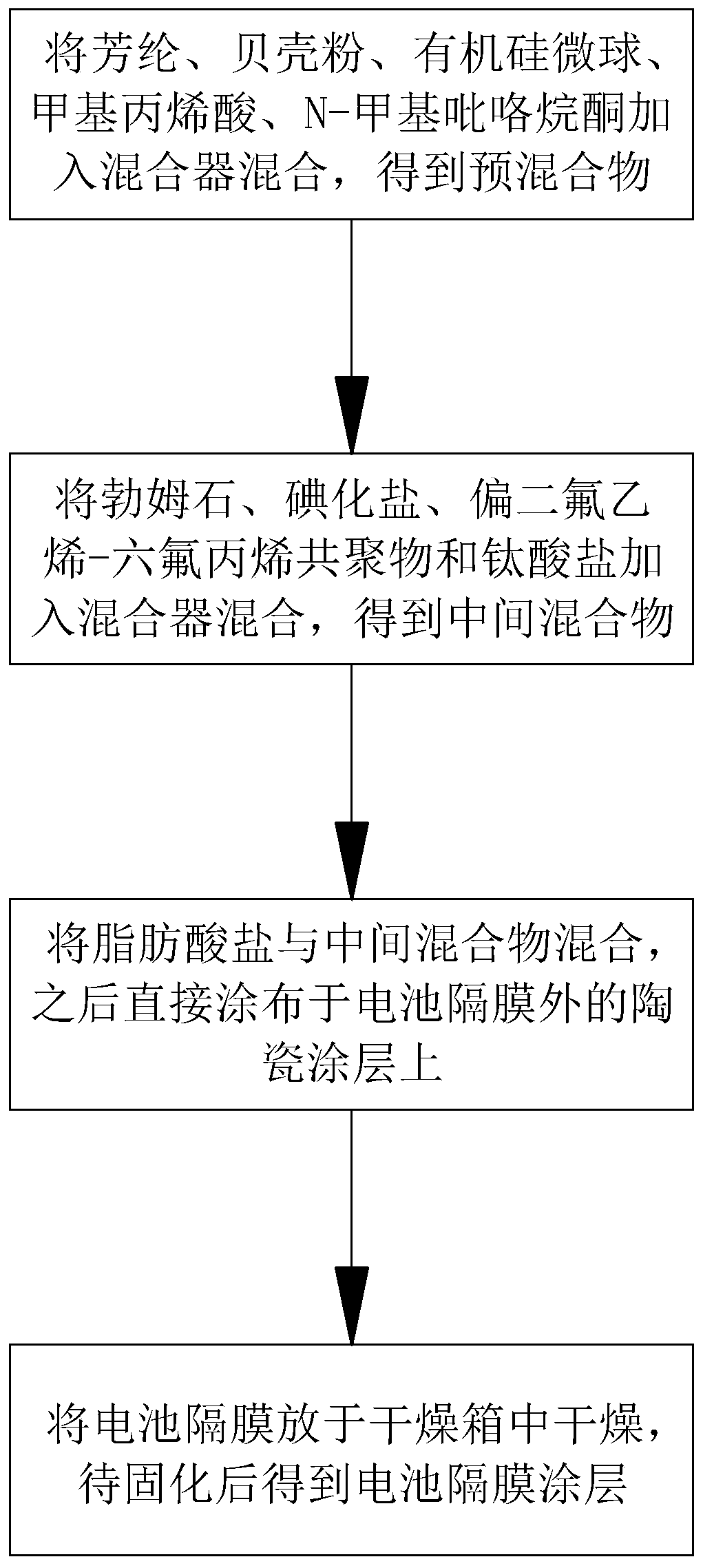

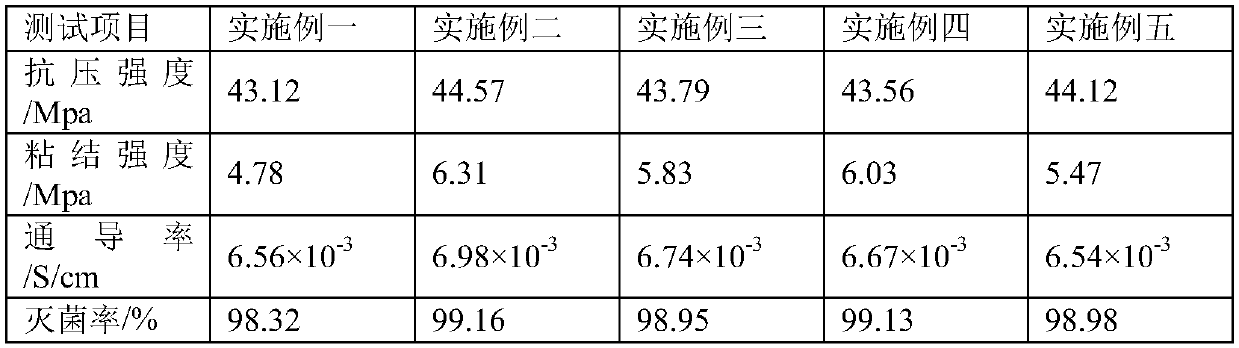

Lithium battery separator coating and preparation method thereof

InactiveCN110148700AHigh mechanical strengthImprove acid and alkali resistanceSecondary cellsCell component detailsElectrical resistivity and conductivityMicrosphere

The invention discloses a lithium battery separator coating, relating to the field of lithium batteries. The lithium battery separator coating comprises, by weight, 23 to 31 parts of aramid, 15 to 19parts of silicone microspheres, 8 to 12 parts of shell powder, 4 to 6 parts of boehmite, 3 to 5 parts of iodized salt, 12 to 16 parts of fluorinated polymers, 15 to 17 parts of methacrylic acid, 6 to12 parts of titanate, 15 to 19 parts of N-methylpyrrolidone, and 8 to 12 parts of fatty acid salts. The coating prepared by the above formula has strong adhesive properties, a battery separator and positive and negative electrode sheets are bonded well, at the same time, the electrical conductivity is high, and so the coating is suitable for most lithium batteries. Moreover, the preparation methodis simple and is suitable for large-scale popularization and use.

Owner:深圳市宝聚合新材料技术应用有限公司

Alkali-acid resistant building glue

InactiveCN108913073AImprove acid and alkali resistanceEvenly dispersedNon-macromolecular adhesive additivesMacromolecular adhesive additivesIsocyanate compoundAcid resistance

Owner:FOSHAN LINGXIE ENVIRONMENTAL PROTECTION TECH CO LTD

Modified CPP thin film used for lithium battery flexible packaging film

ActiveCN110697249AImprove acid and alkali resistanceStrong chemical resistanceFlexible coversWrappersPolypropyleneCorrosion resistant

The invention discloses a modified CPP thin film used for a lithium battery flexible packaging film. The thin film is made through three-layer co-extrusion, flow coating roller cooling shaping, automatic thickness measuring adjusting, corona processing, side cutting winding and slitting operation. Ternary polymerization polypropylene, homo-polypropylene and mixed polypropylene serve as base materials, a crosslinking monomer and an initiating agent are added into all layers of polypropylene, an extruding machine is used for enabling the polypropylene to have a mico-crosslinking reaction with the crosslinking monomer and the initiating agent, through the method, the thin film can effectively improve corrosion resistance, composite tightness between film layers can be improved, through addingof novolac epoxy vinyl ester resin, corrosion resistance can reach the degree of lithium battery electrolyte resisting, graphene is added, reduction of composite system strength due to adding of thecrosslinking monomer and the novolac epoxy vinyl ester resin can be relieved, and the requirements of the CPP film for a lithium battery to puncture resistance and impact resistance can be effectivelyachieved.

Owner:JIESHOU CITY TIANHONG PACKAGING MATERIAL

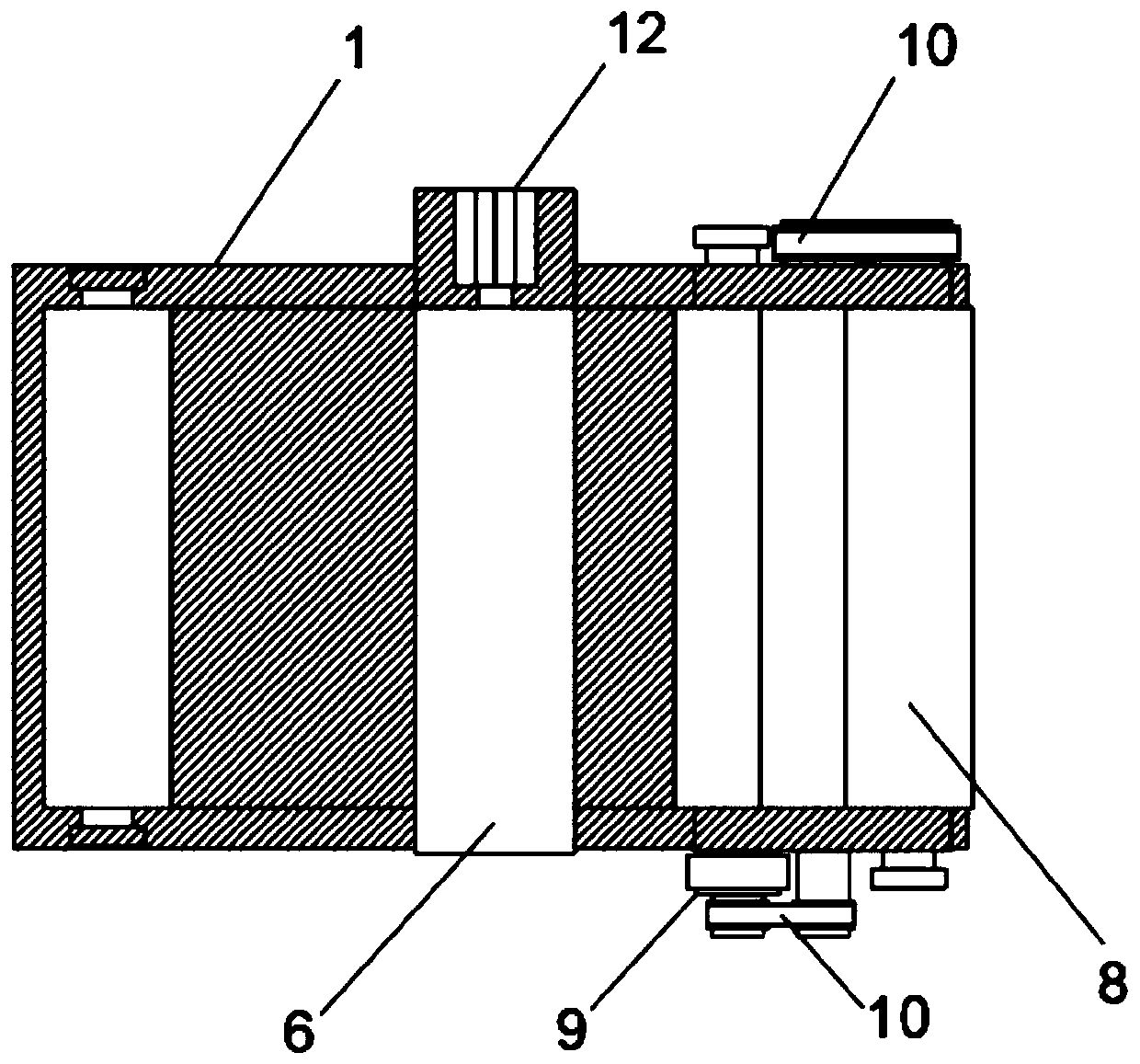

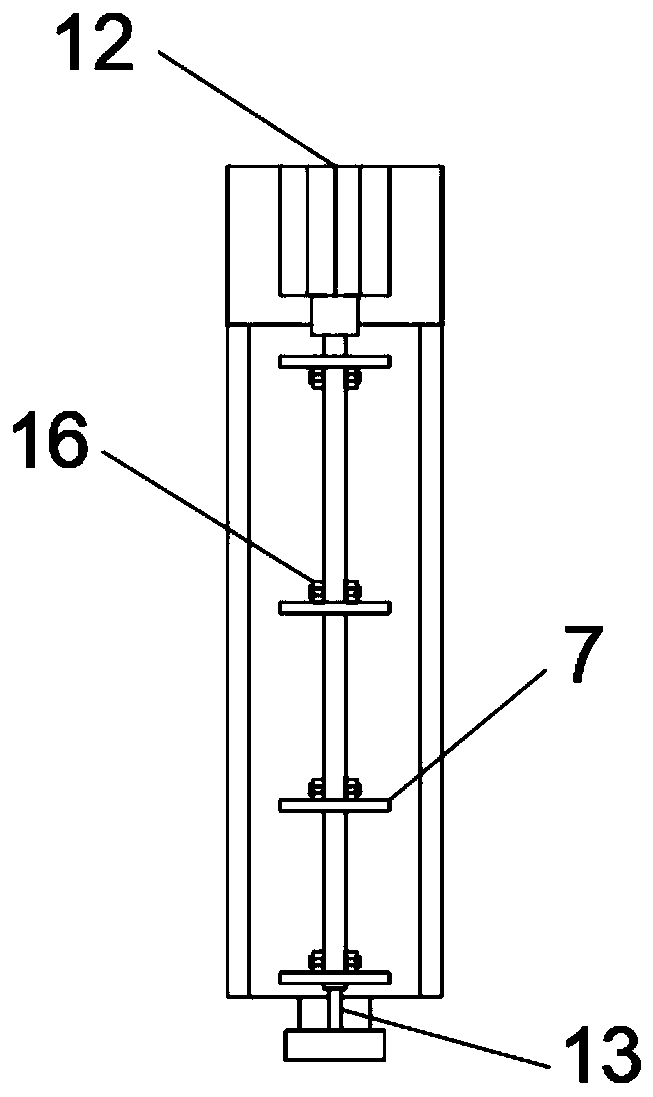

Antiflaming acid-alkali resistant conveyer belt covering glue and preparation method thereof

InactiveCN104927138ADelay corrosion aging crackingImprove acid and alkali resistanceCorrosion resistantCarbon black

The invention provides antiflaming acid-alkali resistant conveyer belt covering glue which is prepared from the following components in parts by weight: 70 parts of neoprene CR 322, 20 parts of natural rubber, 10 parts of butadiene rubber 9000, 1-2 parts of an antiager RD, 1-3 parts of an antiager 4010 NA, 4-8 parts of zinc oxide, 2-8 parts of magnesium oxide, 1-3 parts of stearic acid, 1-3 parts of mold cleaner 985 P, 5-20 parts of chlorinated polyethylene CPE 135, 15-50 parts of N 220 carbon black, 10-30 parts of N 330 carbon black, 1-4 parts of sulphur, 10-30 parts of superfine barium sulfate, 4-8 parts of antimonous oxide, 10-30 parts of chlorinated paraffin 70, 5-20 parts of zinc borate and 1-3 parts of an accelerant DM. The invention further provides a preparation method of the antiflaming acid-alkali resistant conveyer belt covering glue. The antiflaming acid-alkali resistant conveyer belt covering glue has the advantages of being corrosion resistant and unlikely to age and chap during the transportation process, excellent in abrasion resistance and tearing property, and long in service life.

Owner:江苏凯嘉橡胶科技股份有限公司

Bird repelling composition used for power network lines

InactiveCN105368313AGood wear resistanceImprove acid and alkali resistanceCoatingsAluminium silicateParaffin oils

The invention discloses a bird repelling composition used for power network lines. The bird repelling composition is prepared by taking nano silicon dioxide, nano titanium dioxide, asbestos powder, epoxy modified silicon resin, emulsified silicone oil, multiwalled carbon nanotube, aluminium silicate fibre, FeCuMnO3.5, ammonium hydrogen carbonate, acrylic acid, 2,4,6-tris(dimethylaminomethyl)phenol, dibutyltin dilaurate, styrene-acrylic emulsion, ammonium polyphosphate, chlorinated paraffin, isopropyl phenyl diphenyl phosphate, ethyecellulose, xylene, folium artemisiae argyi, scirpoides holoschoenus, musk, and eucalyptus oil as raw materials, via distribution mixing. The bird repelling composition possesses corrosion resistance and wear resistance, and is capable of realizing self cleaning.

Owner:国网山东莒南县供电公司 +1

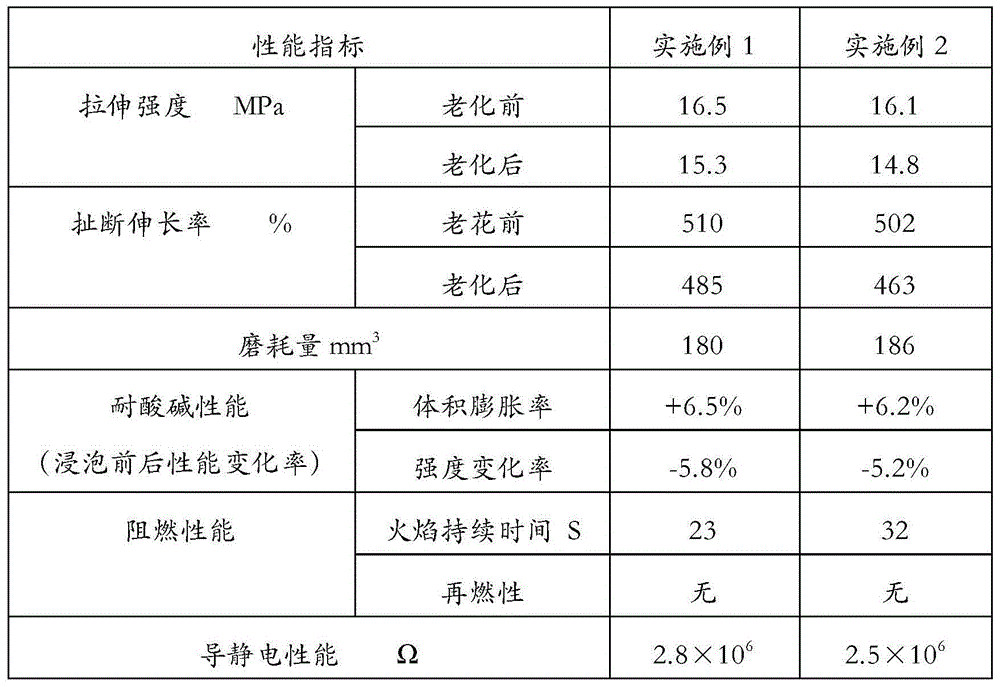

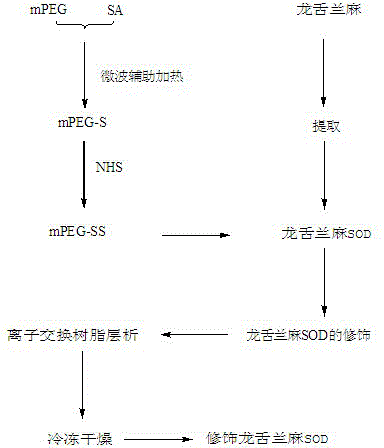

Preparation method of freeze-dried powder for modifying ixtle SOD

ActiveCN104357410AShorten activation timeImprove activation efficiencyOxidoreductasesProteolysisOrganic synthesis

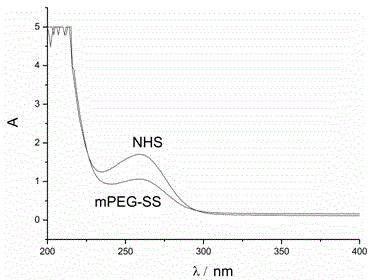

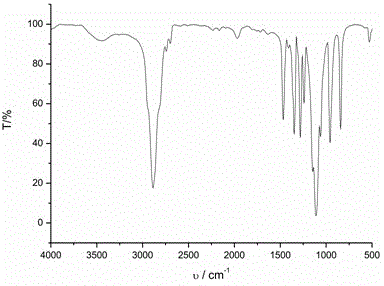

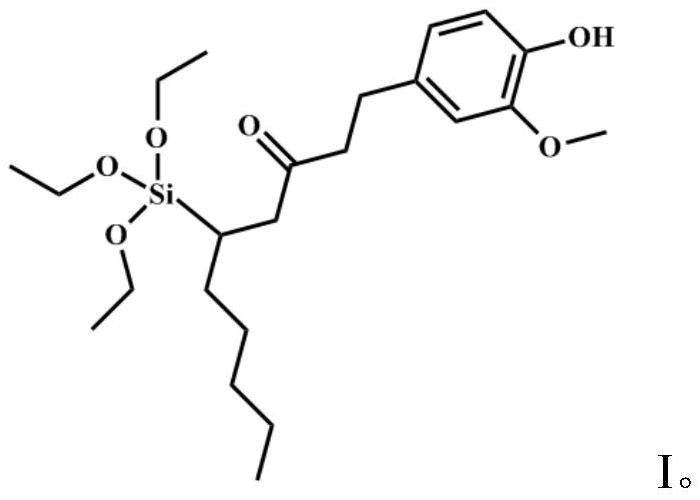

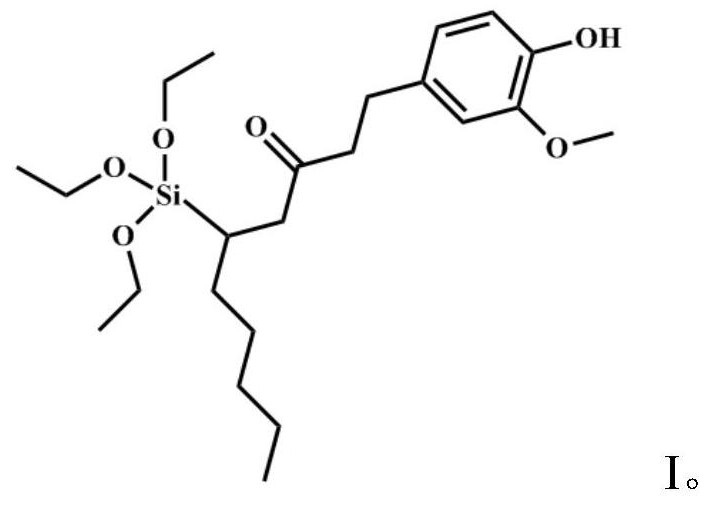

The invention relates to a preparation method of freeze-dried powder for modifying ixtle SOD and belongs to the technical field of organic synthesis and application. The preparation method is characterized in that microwave-assisted succinic anhydride (SA) and N-hydroxyl succinimide (NHS) activated monomethoxypolyethylene glycol (Mpeg) are used as a activation modifying agent and ixtle superoxide dismutase (SOD) is used as a modifying object to prepare a modifier for modifying ixtle SOD. According to the preparation method of the activation modifying agent, microwave-assisted heating is utilized, so that the activation time is shortened greatly, and the activation efficiency is improved; the ixtle SOD is modified by the activation modifying agent, and the modifier for modifying SOD is prepared; the obtained modifier has higher capability of heat resistance, acid-base resistance and proteolysis resistance compared with natural ixtle superoxide dismutase, and the immunogenicity is lowered or eliminated.

Owner:LINGNAN NORMAL UNIV

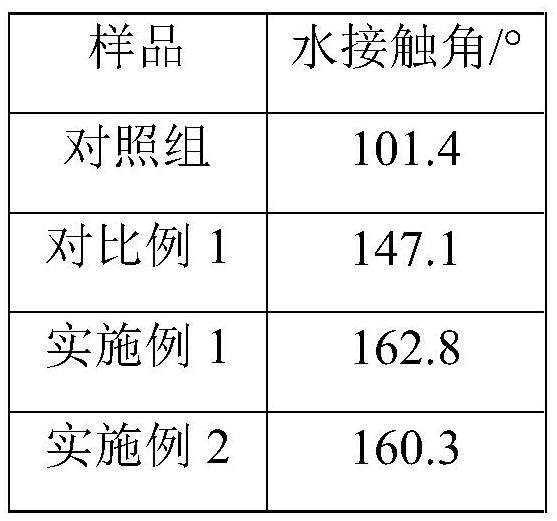

Low-adsorption antibacterial centrifuge tube and application thereof

InactiveCN112973821AImprove hydrophobicityImprove wear resistancePlastic recyclingLaboratory glasswaresOrganic foreign materialHydrophobe

The invention discloses a low-adsorption antibacterial centrifugal tube and application thereof, and relates to the technical field of centrifugal tubes. The preparation method of the low-adsorption antibacterial centrifuge tube comprises the following steps: pretreatment of the surface of the centrifuge tube: firstly, sequentially removing oil and cleaning organic impurities from the commercially available centrifuge tube, and then carrying out hydroxylation treatment on the surface of the centrifuge tube; and surface coating treatment of the centrifugal tube: dissolving the modified silane coupling agent in methanol, coating the surface of the centrifugal tube subjected to hydroxylation treatment with a film, airing, and carrying out heat treatment to obtain the coated centrifugal tube. The centrifugal tube prepared by the invention has excellent biological adhesion resistance, good stability, low adsorption performance and good antibacterial performance; and the hydrophobic property is still excellent at high temperature, and the wall hanging phenomenon of liquid is improved.

Owner:HANGZHOU ANYU TECH CO LTD

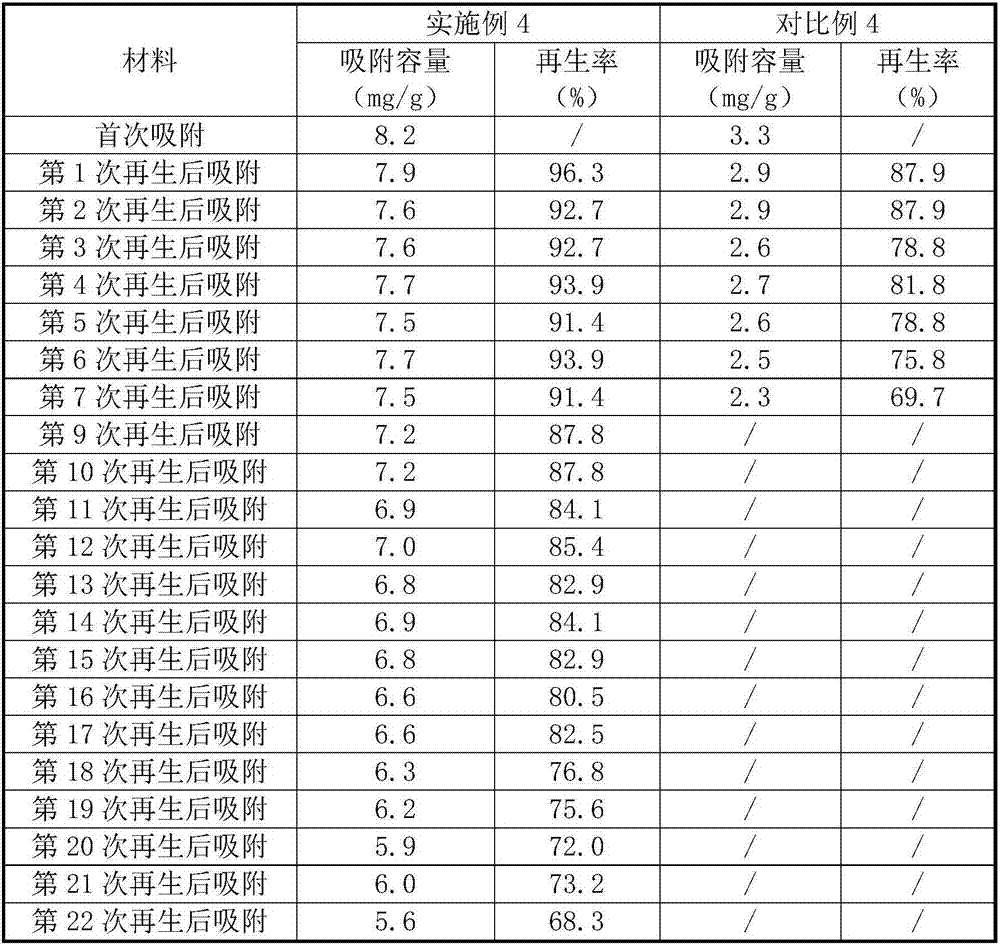

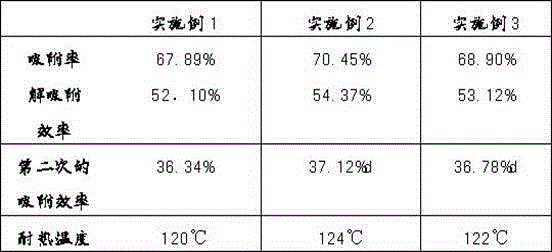

Renewable adsorption material for deep phosphorus removal of water, preparation method and application of renewable adsorption material

ActiveCN107051371AHigh specific surface areaImprove acid and alkali resistanceOther chemical processesWater contaminantsTotal phosphorusChemistry

The invention provides a renewable adsorption material for deep phosphorus removal of water, a preparation method and application of the renewable adsorption material. A carbonization step is added in the preparation process of the material; after calcination and carbonization are carried out with the surface of the material wrapped with a carbon source material, on one hand, the roughness of the surface can be improved to increase the specific area, and on the other hand, the acid and alkali resistance of the material can be improved to some extent to prolong the service life of the material, which is beneficial to multiple times of regeneration and use. The prepared phosphorus adsorption material is excellent in adsorption property and especially suitable for deep treatment of wastewater with a low total phosphorus concentration. Compared with the prior art, the prepared material is high in phosphorus removal efficiency and long in service life, the regeneration method of the material is simple, the regeneration effect is excellent, and the regeneration rate is still kept at 70% or above after 20 times of regeneration of the material.

Owner:芜湖格丰环保科技研究院有限公司

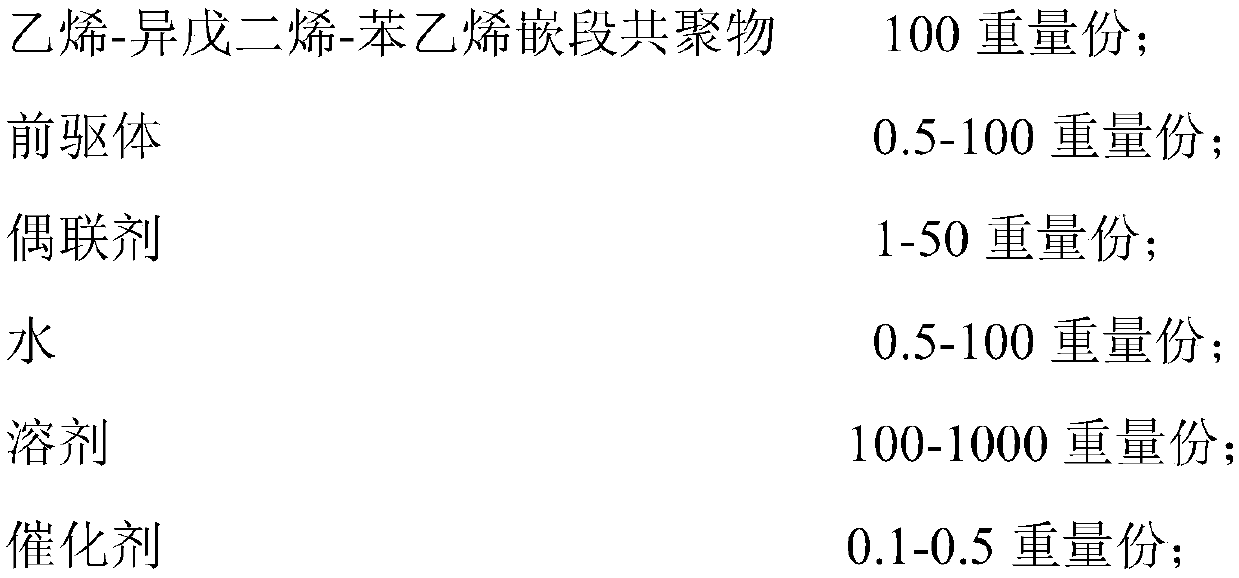

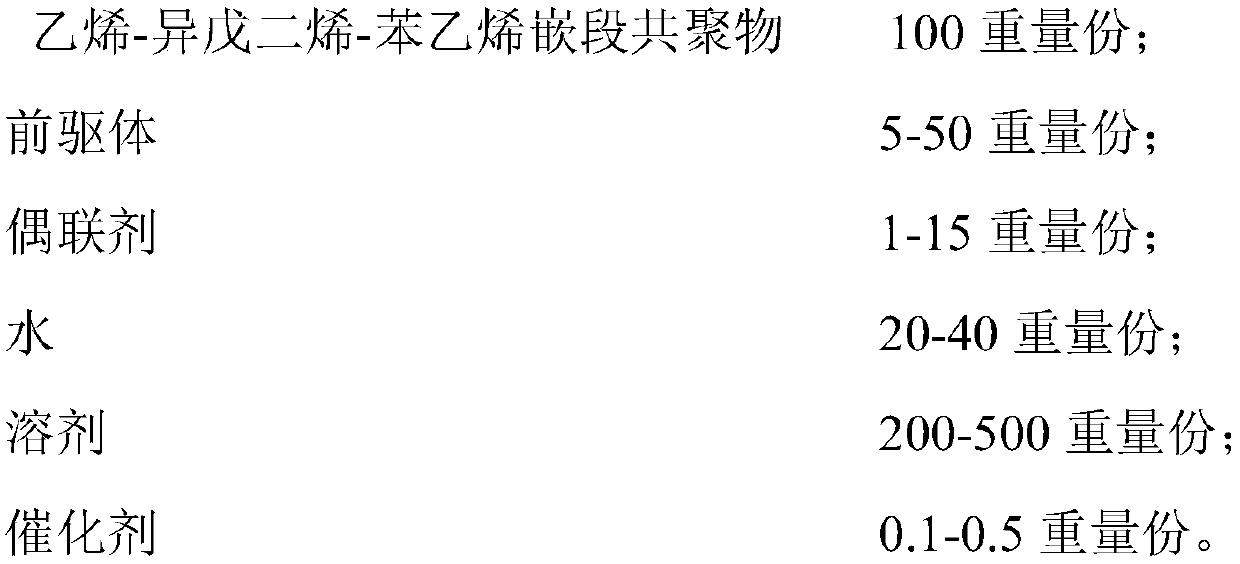

Self-repairing material for oil-gas well cementation and preparation method

PendingCN111039591AImprove temperature resistanceImprove acid and alkali resistanceDrilling compositionResilient modulusIsoprene

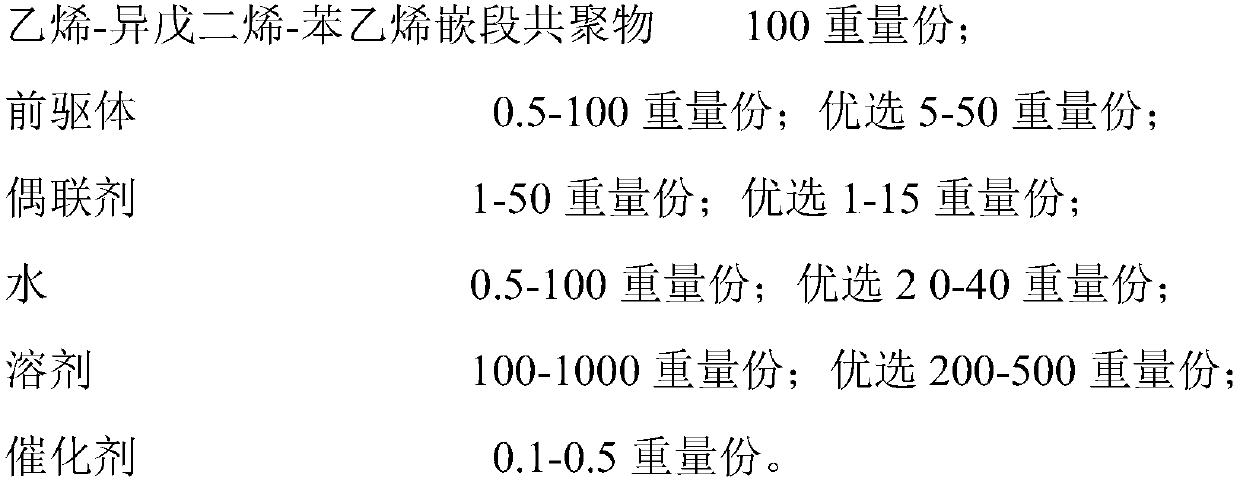

The invention discloses a self-repairing material for oil and gas well cementation and a preparation method. The self-repairing material is prepared from the following raw materials in parts by weight: 100 parts of an ethylene-isoprene-styrene segmented copolymer, 0.5-100 parts of a precursor, 1-50 parts of a coupling agent, 0.5 to 100 parts of water, 100-1000 parts of a solvent and 0.1-0.5 part of a catalyst. According to the invention, the ethylene-isoprene-styrene segmented copolymer is subjected to physical modification; powder is physically coated with nano silicon dioxide so that non-porous coating is realized, the cementation characteristic between rubber particles and CSH gel is improved, the temperature resistance and stability of self-repairing particles are improved, the mechanical property of set cement is improved, the elastic modulus of the set cement is effectively reduced, and the strain rate of the set cement is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment process of electroplating wastewater

PendingCN113336378AImprove water qualityStable than biochemical processWater treatment parameter controlTreatment involving filtrationReverse osmosisElectro flocculation

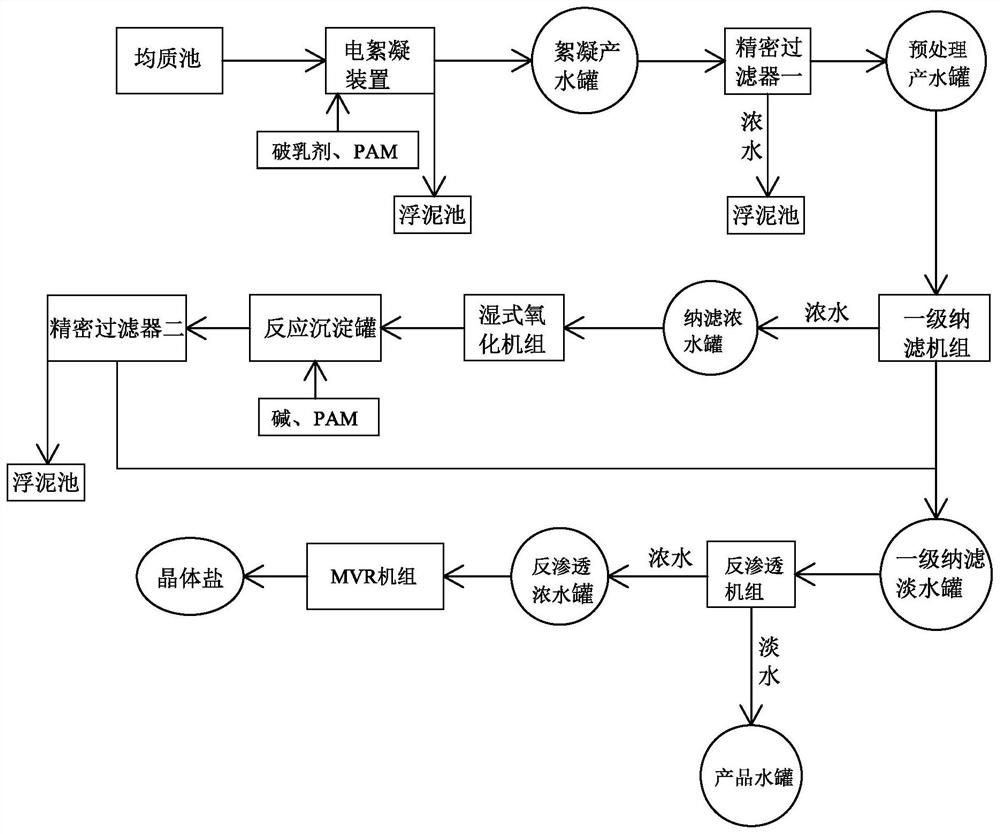

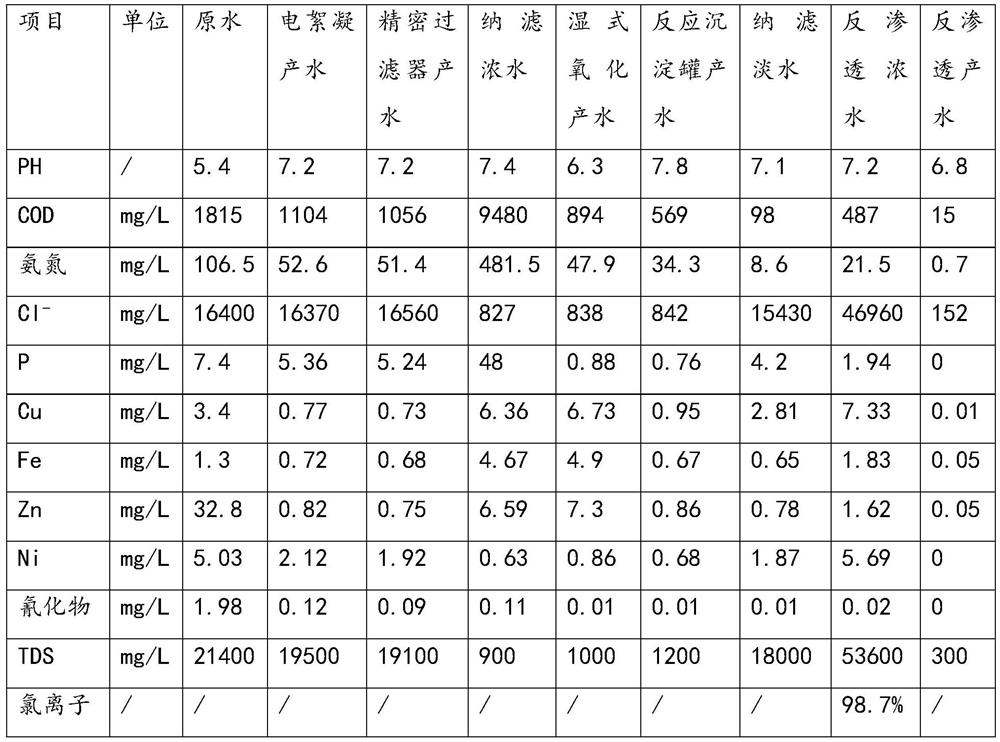

The invention provides a treatment process of electroplating wastewater. The treatment process comprises the steps of (1) setting equipment; (2) connecting equipment; (3) enabling the wastewater to enter a homogenizing tank and then be pumped into an electric flocculation device, and enabling produced water to enter a flocculation water production tank; (4) filtering electric flocculation produced water by a precision filter I; (5) separating produced water in the pretreatment produced water tank by a primary nanofiltration unit, enabling fresh water to enter a primary nanofiltration fresh water tank, and enabling concentrated water to enter a nanofiltration concentrated water tank; (6) conveying the nanofiltration concentrated water to a wet oxidation unit, adding alkali and PAM into the produced water subjected to wet oxidation for precipitation, and then enabling the produced water to enter a primary nanofiltration fresh water tank; (7) separating the primary nanofiltration fresh water by using a reverse osmosis unit, enabling concentrated water to enter a reverse osmosis concentrated water tank, and enabling the fresh water to enter a product water tank; and (8) conveying the reverse osmosis concentrated water to an MVR unit for crystallization, and evaporating sodium chloride salt. The treatment process of the electroplating wastewater is low in investment, reliable in operation, low in energy consumption and capable of really realizing zero discharge of electroplating wastewater.

Owner:SHANGHAI YUKE ENVIRONMENTAL ENG CO LTD

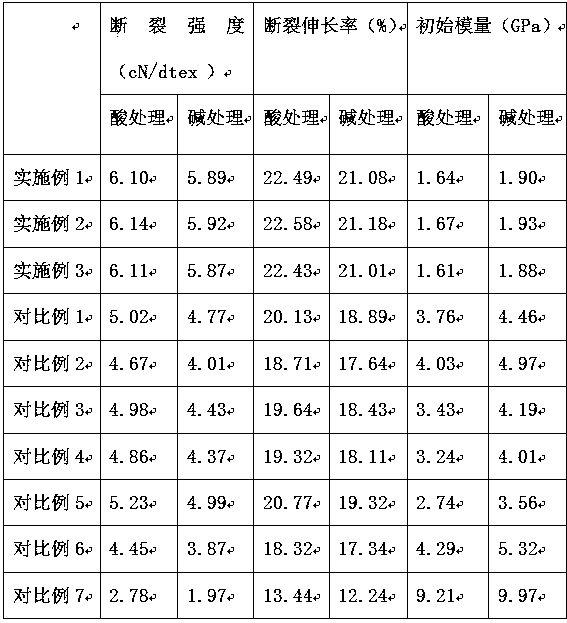

Treatment method of improving acid-base resistance of mulberry silk

InactiveCN109235020AImprove acid and alkali resistanceEnhanced van der Waals forcesPhysical treatmentVibration treatmentSodium benzoateAqueous solution

The invention belongs to the technical field of silk processing, and particularly relates to a treatment method of improving acid-base resistance of mulberry silk. The method comprises the following steps of: (1) putting the mulberry silk in a erythritol aqueous solution for heat preservation soaking, draining off the solution, fishing out the mulberry silk, performing magnetization treatment andvacuum treatment when no water drips, and (2) soaking the mulberry silk in treatment liquid, performing ultrasonic treatment, draining off the liquid, fishing out the mulberry silk, and performing freezing treatment, steam treatment and microwave drying when no water drip, wherein the treatment liquid is prepared from the following raw materials: taurine, sodium benzoate, gallic acid, chlorogenicacid, fructus momordicae polysaccharide and water. The flexibility and elasticity of a silk fiber structure are effectively improved; the surface of the silk fiber structure is covered with a compactprotection film, so that the mulberry silk can have the better acid-base resistance; the tensile property and flexibility of the mulberry silk are effectively improved under an acid-base condition; the quality of the mulberry silk is greatly improved under the acid-base condition; and the usability of the mulberry silk is improved.

Owner:ANHUI SANLI SILK GRP

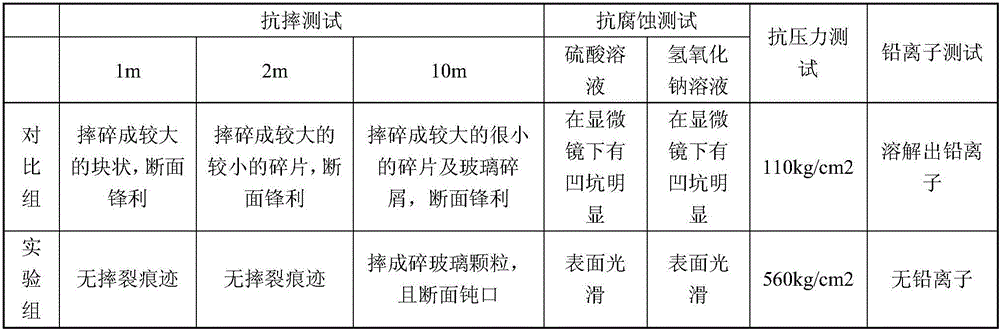

Patterned glass bottle and manufacturing method thereof

InactiveCN106587611AImprove acid and alkali resistanceHigh chemical stabilityGlass blowing apparatusGlass tempering apparatusMolten glassLaminated glass

The invention provides a patterned glass bottle and a manufacturing method thereof, belonging to the technical field of glass bottle manufacturing. The patterned glass bottle is composed of inner-layer glass and outer-layer glass, wherein laminated glass is arranged between the inner-layer glass and the outer-layer glass, and the laminated glass has patterns. The manufacturing method comprises the following steps: (1) melting the raw material of the laminated glass, then putting a laminated glass blank into a mold, and blowing the laminated glass blank with the mouth to enable the laminated glass to be molded into a laminated glass bottle; (2) putting an inner-layer glass blank into the laminated glass bottle to obtain a glass bottle combining inner-layer glass and laminated glass; (3) hanging the glass bottle obtained in the step (2) in the mold, pouring the outer-layer molten glass into gaps, and cooling the molten glass for molding; and (4) sealing the glass bottle to obtain the required glass bottle. The glass bottle and the manufacturing method thereof have the advantages that the process is simple, the cost is low, built-in patterns are formed so as to increase the aesthetic feeling of the glass bottle and improve the grade of wine, and the anti-breaking effect is good.

Owner:柳州市昌泉贸易有限公司

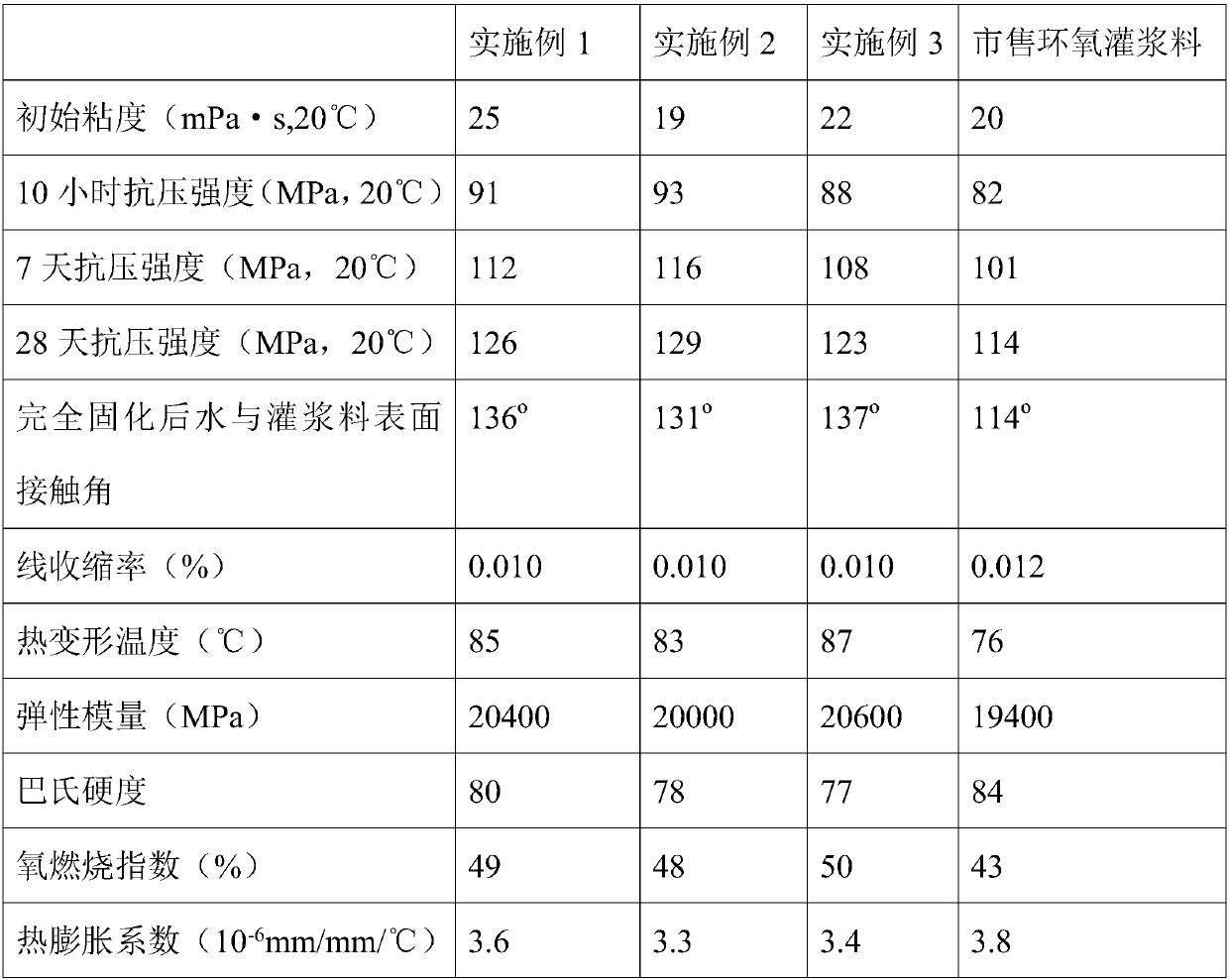

Fluorine-modified hydrophobic epoxy grouting material and preparation method thereof

InactiveCN107868410AImprove acid and alkali resistanceHigh hardnessEpoxy resin coatingsChemistryBENZYL ALCOHOL/WATER

The invention relates to a fluorine-modified hydrophobic epoxy grouting material and a preparation method thereof. The fluorine-modified hydrophobic epoxy grouting material is prepared from the following components in parts by weight: a component A: 80 to 100 parts of epoxy resin, 10 to 20 parts of a fluorine-containing coupling agent, 25 to 35 parts of a reactive diluent; a component B: 15 to 20parts of an organic fluorine curing agent, 12 to 18 parts of Kevlar fiber, 6 to 10 parts of a curing accelerator, 12 to 18 parts of benzyl alcohol and 3 to 6 parts of a catalyst. The fluorine-modifiedhydrophobic epoxy grouting material disclosed by the invention has the advantages of high hydrophobicity, high acid and alkali resistance, higher hardness and higher impact resistance.

Owner:HUNAN CHENLI NEW MATERIAL CO LTD

Greystone fiber modified porous light active calcium silicate highly radioactive wastewater treatment agent and preparation method

ActiveCN105413653AImprove acid and alkali resistanceImprove the adsorption effectOther chemical processesRadioactive decontaminationIonTetraethyl orthosilicate

The invention discloses a greystone fiber modified porous light active calcium silicate highly radioactive wastewater stabilization treatment agent and a preparation method. The composition is prepared from, by weight, 12-14 parts of greystone fiber, 40-42 parts of porous light active calcium silicate, 20-21 parts of silicon-magnesium rubber, 10-12 parts of epoxy group magnetic polymer microspheres, 20-22 parts of modified attapulgite, 3-4 parts of cetyl trimethyl ammonium bromide, 5-6 parts of sodium hydroxide, 2.5-3.5 parts of tetraethyl orthosilicate, 20-21 parts of modified iron oxide zeolite, 6-7 parts of cationic surfactant cetyl trimethyl ammonium bromide ionic liquid, 30-40 parts of polypropylene ester fiber, an adequate amount of deionized water, an adequate amount of ethyl alcohol and an adequate amount of water. The greystone fiber is adopted to modify the porous light active calcium silicate, the modified attapulgite is adopted to carry the greystone fiber, fusion is promoted, and acid and alkali resistance of adsorbent is improved; meanwhile, by means of the modified iron oxide zeolite and a silicon-magnesium rubber alkali solution, the adsorbing effect of a product is improved, and by means of the thermal reversibility of the silicon-magnesium rubber, the heat-resisting stability of the product is improved.

Owner:胡倾成

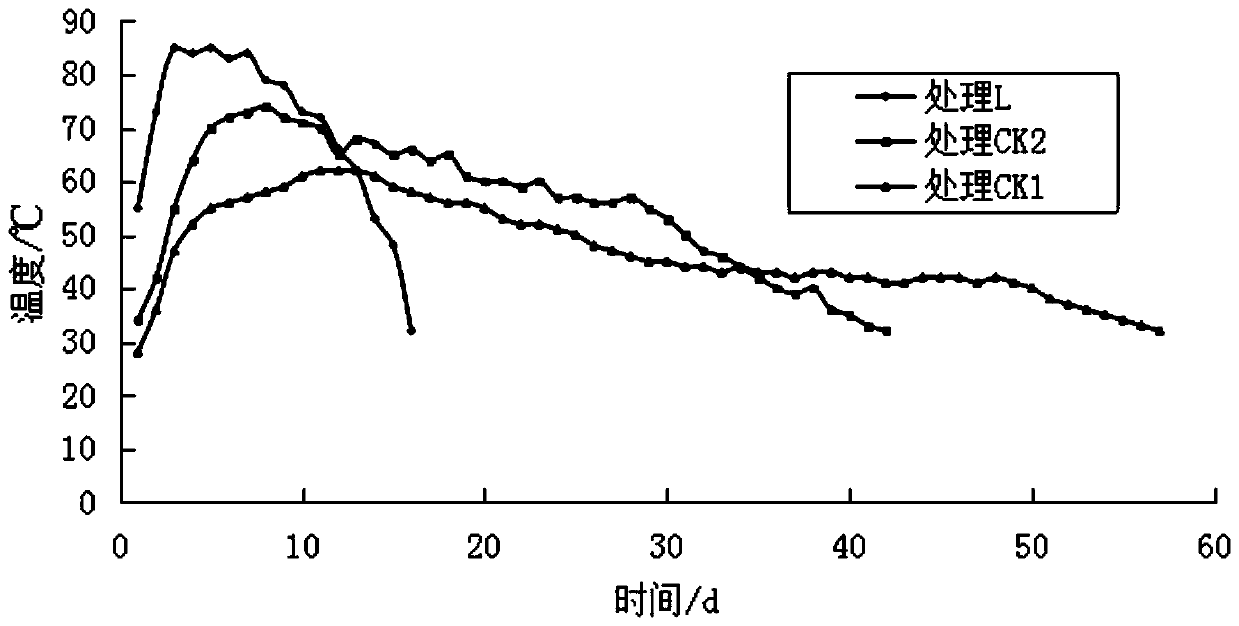

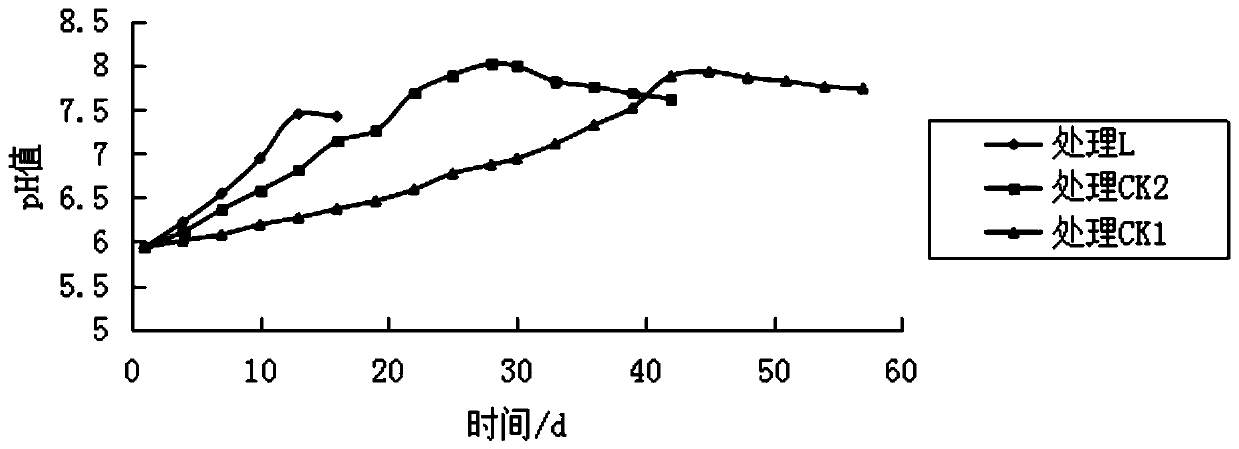

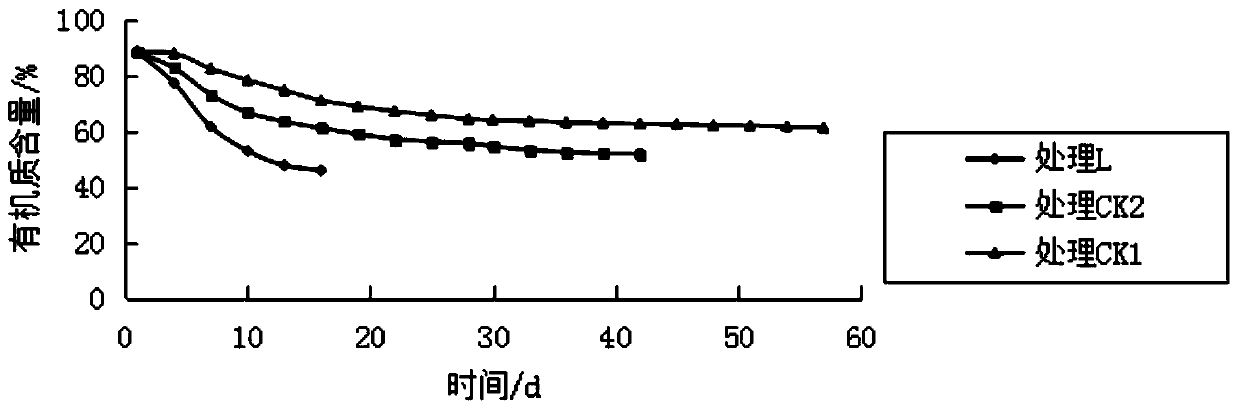

A kind of liquor lees decomposer and its preparation method and application

ActiveCN106906168BPrevent secondary pollution and corruptionHigh temperature resistantBio-organic fraction processingBacteriaCelluloseAlcohol

The invention discloses a liqueur vinasse decomposition agent. The preparation method comprises the steps that thermoactinomyces sacchari CP with characteristics of high temperature resistance, alcohol resistance and acid and alkali resistance is scientifically compounded with existing rotten funguses, and meanwhile cellulose, xylogen, starch, protein, fat and the like in the vinasse are sufficiently degraded though the synergistic effect among different rotten funguses. Processing of alcoholic strength dropping, acidity dropping and the like of the vinasse is avoided, composting fermentation of the fresh liqueur vinasse can be directly conducted, component process is reduced, and manpower, material resources, financial resources and time are saved; the period of entering the high temperature period is short (reaching 55 DEG C in one day, reaching 85 DEG C in three days), the period of maintaining high temperature fermentation time is long (maintaining 83-85 DEG C for three days), and the fermentation period is shortened (only 15-16 days) and 26-27 days shorter than that of existing liqueur vinasse decomposition agent; the yield and the quality (putrescibility) of organic fertilizer are effectively improved, secondary pollution decomposition and soil alkalinization of the vinasse are avoided, the environment and the soil are protected, and a new shortcut for making high quality organic fertilizer through direct high temperature compost maturity of the liqueur vinasse is opened up.

Owner:陕西枫丹百丽生物科技有限公司

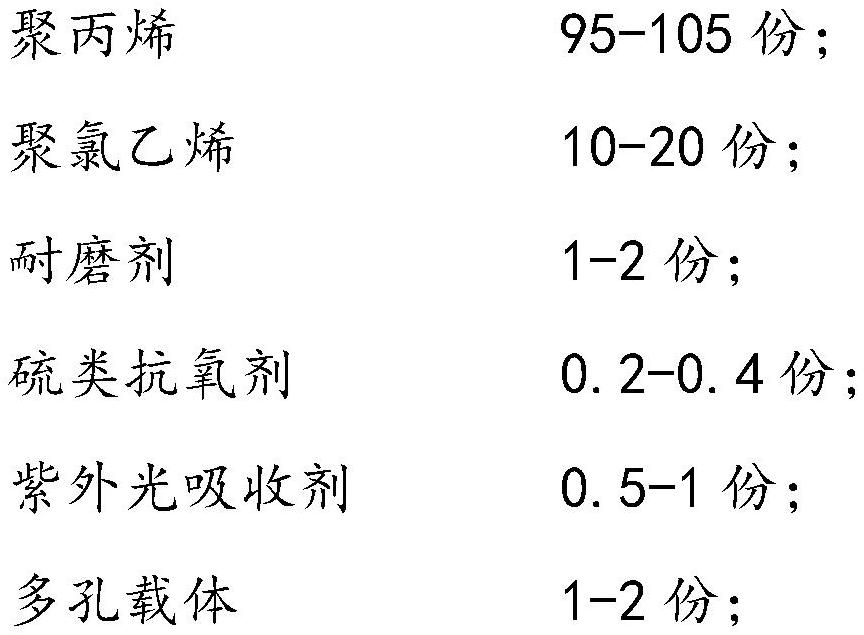

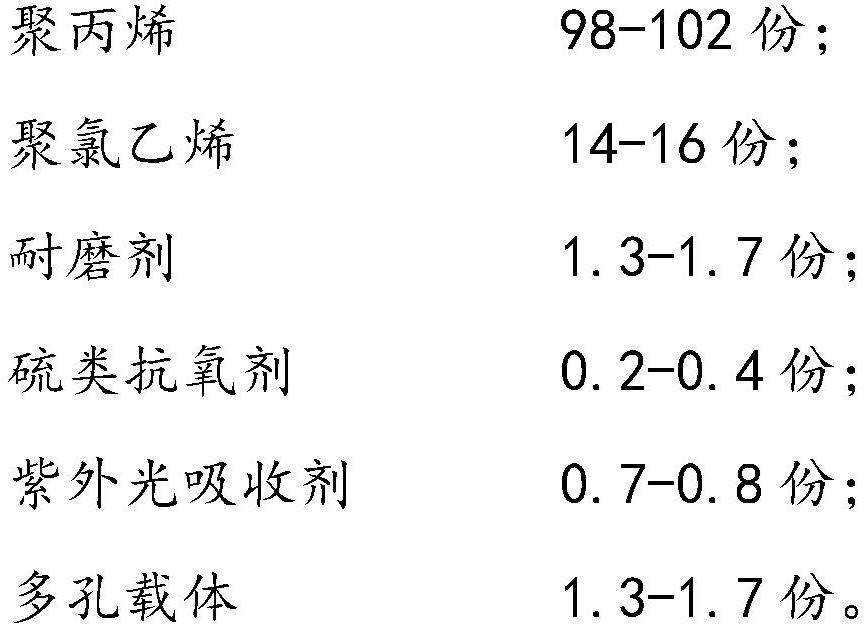

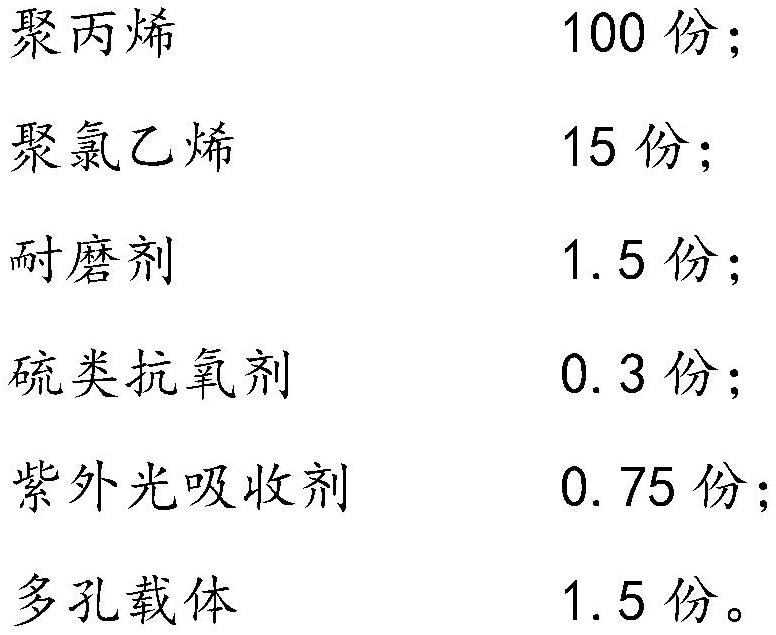

Corrosion-resistant container bag and preparation process thereof

PendingCN114854126AHigh tensile strengthImprove acid and alkali resistanceBio-packagingConjugated synthetic polymer artificial filamentsPolypropyleneCorrosion resistant

The invention discloses a corrosion-resistant container bag and a preparation process thereof. Relates to the technical field of container bags. The problem that a container bag in the prior art is insufficient in acid and alkali resistance is solved. The container bag is prepared from the following components in parts by weight: 95-105 parts of polypropylene; 10 to 20 parts of polyvinyl chloride; 1-2 parts of a wear-resistant agent; 0.2 to 0.4 part of a sulfur antioxidant; 0.5-1 part of an ultraviolet light absorber; 1-2 parts of a porous carrier; the wear-resistant agent is composed of glass fiber powder and nano carbon black; the flexible freight bag has excellent acid and alkali resistance, the service life of the flexible freight bag is prolonged, and the application range is widened.

Owner:河南步锐实业有限公司

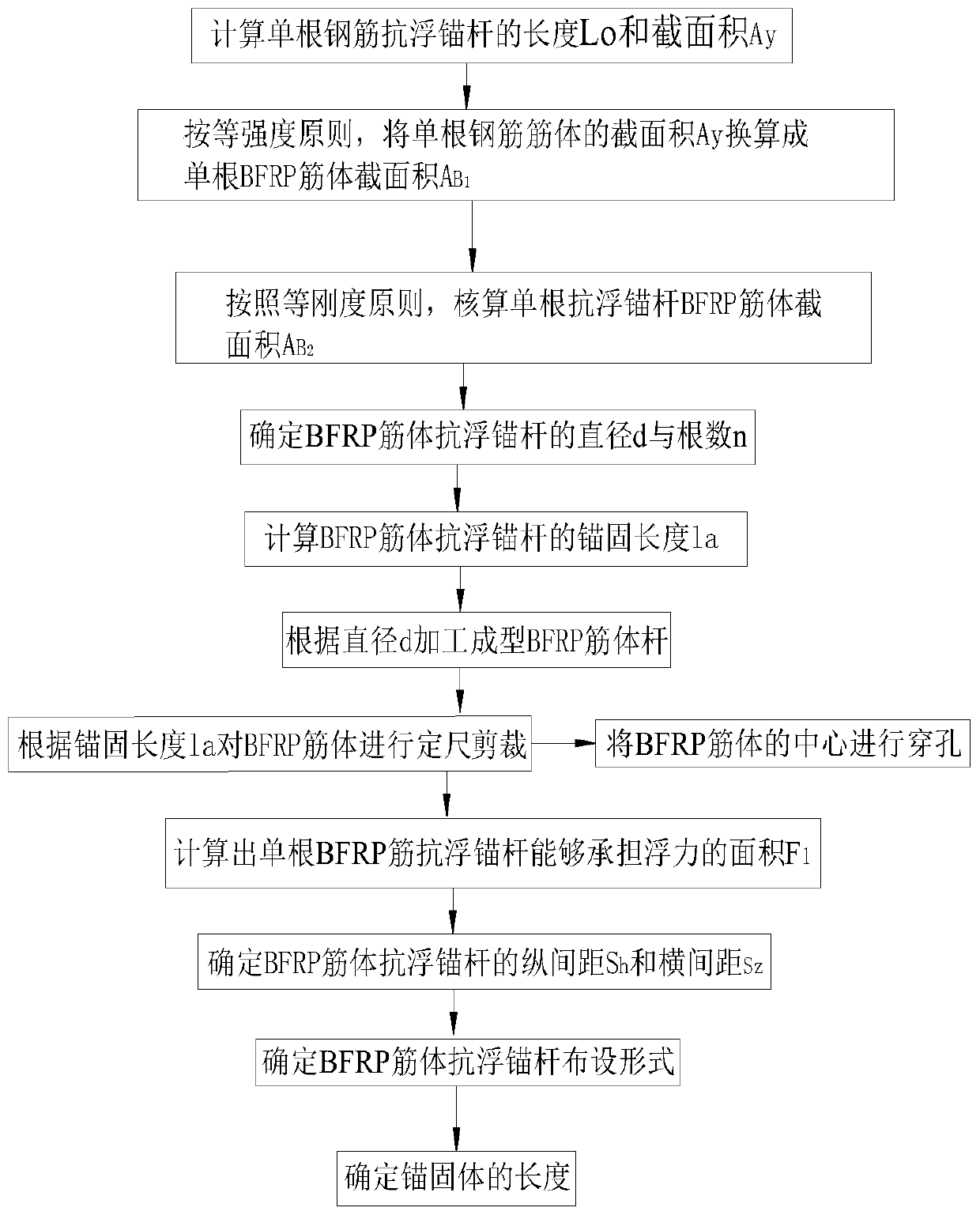

Design method of BFRP bar anti-floating anchor rod

ActiveCN110130333AImprove compactnessImprove acid and alkali resistanceProtective foundationBulkheads/pilesRebarCorrosion resistant

The invention discloses a design method of a BFRP bar anti-floating anchor rod, and relates to the field of construction engineering. The problems that a rebar serving as a bar of an anti-floating anchor rod is tedious in manufacturing and cannot be used in the corrosion-resistant environment, or the construction procedure and the engineering construction cost are increased due to the addition ofanti-corrosion measures are solved. According to the key points of the technical scheme, the design method comprises the following steps that firstly, the length and the sectional area of a rebar rodof the rebar anti-floating anchor rod are calculated; then, according to the equal strength and equal stiffness conversion principle, the sectional area of a rebar body of the rebar is converted intothe sectional area of BFRP bar bodies; then the diameter and the number of the BFRP bar bodies are calculated; then, the BFRP bar bodies are subjected to fixed-size clipping through a bar cutting machine, and then BFRP composite materials are machined to form the BFRP bar bodies. The design method has the effects that the anti-floating anchor rod has extremely high acid resistance and extremely high alkali resistance, thus corrosion of rebar rod materials used in the harsh environment can be prevented, and the anti-floating durability of a building and the construction efficiency are improved.

Owner:SOUTHWESTERN ARCHITECTURAL DESIGN INST

A kind of supertetrahedral metal-organic framework material, its preparation method and application

ActiveCN112126072BEnhanced interactionImprove acid and alkali resistanceProductsReagentsIon clustersIndium

The invention discloses a hypertetrahedral metal-organic framework constructed based on a window-space oriented assembly strategy and its preparation method and application; a novel window-space oriented assembly strategy is proposed, and a series of supertetrahedral building unit structures based on angles are designed and synthesized. Metal organic framework materials ST‑sod‑MOFs with ultramicroporous quadrilateral windows and mesoporous sodalite cages are built in a shared way. The general structure formula of this type of metal organic framework materials is: [M 3 (OH / O)(H 2 O / F)(btc) 2 (tpt) 2 / 3 ], where M is a metal ion or a combination of two different metal ions, such as magnesium, manganese, iron, cobalt, nickel, zinc, aluminum, scandium, gallium, indium and other single metal ions or titanium, vanadium, scandium, A binary combination of gallium, indium, and one of iron, cobalt, nickel, and magnesium, respectively. This type of metal organic framework material is a three-dimensional sodalite network skeleton formed by trinuclear metal ion cluster nodes and organic ligands through coordination bonds. Among them, ST‑sod‑Co / Ti not only has good thermal stability and high acid and alkali resistance stability, but also 2 h 2 / CO 2 Good performance in separation.

Owner:FUJIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com