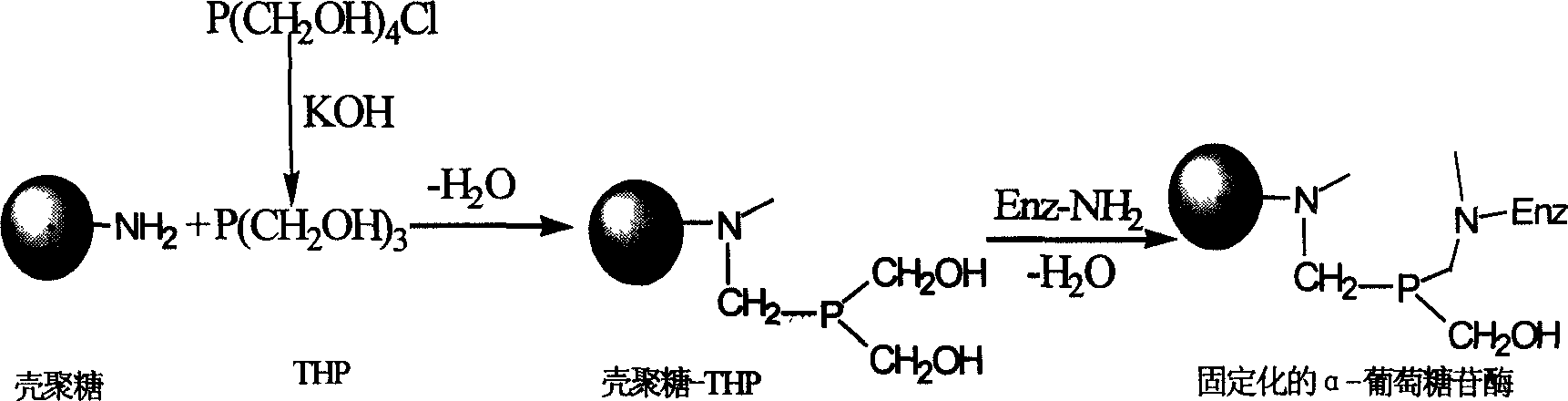

Alpha-glucosidase immobilization method

A technology of glucosidase and chitosan, which is applied in the direction of immobilization on/in the organic carrier, can solve the problems of large loss of enzyme activity, unstable properties, no immobilization of α-glucosidase, etc., and achieve revival High recovery and reduced loss of enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment one: the specific process steps of the present embodiment are as follows:

[0016] a. Pretreatment of chitosan: first prepare chitosan with high degree of deacetylation, get 20g chitosan, add 350mL concentration of 40% NaOH, stir reaction time at 130°C for 5 hours, then wash with water until neutral, Dried at 105°C, pulverized, and passed through a 120-mesh sieve to obtain pretreated chitosan with a deacetylation degree of 93%.

[0017] b. Preparation of trihydroxymethylphosphorus (THP): take equimolar amounts of tetrakishydroxymethylphosphorus chloride (THPC) and KOH, dissolve them in 90mL and 10mL of water respectively, and dissolve the KOH aqueous solution at room temperature under vigorous stirring Add it dropwise to THPC aqueous solution, and the reaction ends when the dropwise addition is completed. The concentration of trihydroxymethylphosphine (THP) obtained in this reaction solution was 2.5 mg / ml.

[0018] c. Cross-linking agent to immobilize α-glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com