CaO-Al2O3-MgO-ZrO2-SiO2 series aluminum oxide electronic ceramics

A technology of aluminum oxide and electronic ceramics, applied in the field of electronic ceramics manufacturing, can solve the problems of low viscosity at high temperature, large grain size, unsightly appearance, etc., and achieve the effects of good comprehensive performance, high flexural strength, and not easy to be broken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The CaO-Al described in the embodiment of the present invention 2 o 3 -MgO-ZrO 2 -SiO 2 It is aluminum oxide electronic ceramics, and the electronic ceramics is composed of the following raw materials in weight percentages:

[0036] Al 2 o 3 94% SiO 2 4% ZrO 2 0.3%

[0037] CaO 0.2% MgO 0.8% BaO 0.5%

[0038] Fe 2 o 3 0.02% and the rest are impurities.

[0039] Its manufacturing process is roughly as follows:

[0040] 1. The raw material Al 2 o 3 , SiO 2 , ZrO 2 , CaO, MgO, etc. are ground into powder;

[0041] 2. Add paraffin liquid to make slurry;

[0042] 3. Forming after mixing raw materials;

[0043] 4. Carry out the wax removal process, the temperature required for the wax removal process is about 1100 °C;

[0044] 5. The sintering process is carried out in a double-hole tunnel kiln, and the temperature required for the sintering process is about 1650°C;

[0045] 6. Processing, grinding and modification;

[0046] 7. Finished product pack...

Embodiment 2

[0050] The CaO-Al described in the embodiment of the present invention 2 o 3 -MgO-ZrO 2 -SiO 2 It is aluminum oxide electronic ceramics, and the electronic ceramics is composed of the following raw materials in weight percentages:

[0051] Al 2 o 3 93.6% SiO 2 3.6% ZrO 2 0.2%

[0052] CaO 0.3% MgO 0.9% BaO 0.6%

[0053] Fe 2 o 3 0.05% and the rest are impurities.

[0054] The production process of this embodiment and the production process of Example 1 are both traditional ceramic manufacturing processes, and will not be described in detail here.

[0055] The product of this embodiment has the characteristics of expansion coefficient, crystal phase grain size, etc., which can meet the user's glazing quality requirements, especially in the metallization sealing process, which can eliminate the phenomenon of yellow and gray spots, so that the qualified rate of metal sealing quality is increased from the original 80%. To more than 96%, the product tensile streng...

Embodiment 3

[0057] The CaO-Al described in the embodiment of the present invention 2 o 3 -MgO-ZrO 2 -SiO 2 It is aluminum oxide electronic ceramics, and the electronic ceramics is composed of the following raw materials in weight percentages:

[0058] Al 2 o 3 93% SiO 2 3% ZrO 2 0.6%

[0059] CaO 0.4% MgO 1% BaO 0.2%

[0060] Fe 2 o 3 0.01% and the rest are impurities.

[0061] The production process of this embodiment and the production process of Example 1 are both traditional ceramic manufacturing processes, and will not be described in detail here.

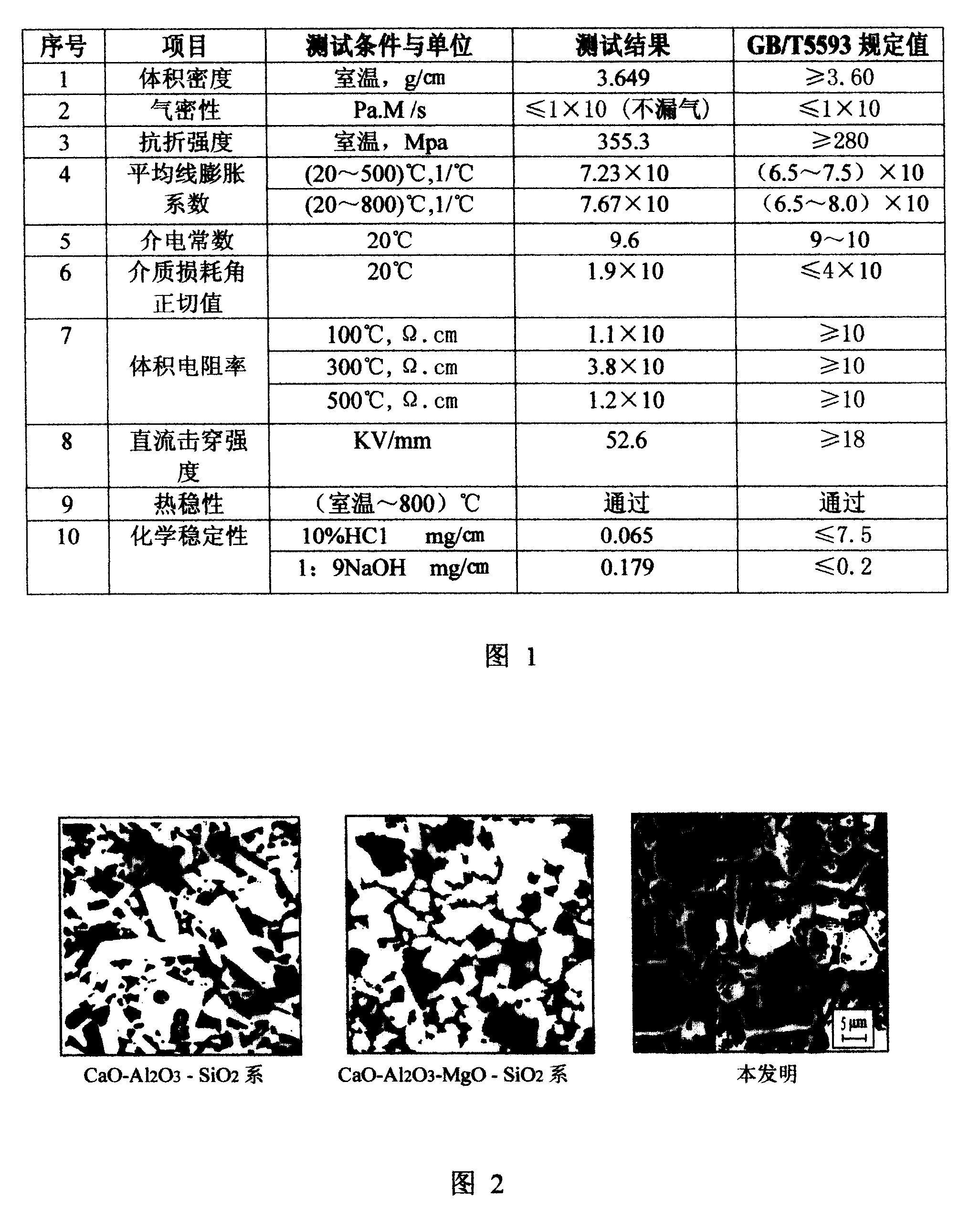

[0062] The product of this embodiment has the advantages of good comprehensive performance, high bulk density, high air tightness, high flexural strength, good thermal stability, not easy to break and no yellow and gray spots, as shown in attached drawings 1 and 2 shown.

[0063] ZrO 2 (Zirconium dioxide) is a new type of toughened ceramic material, which has the characteristics of wear resistance, corrosion resistance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com