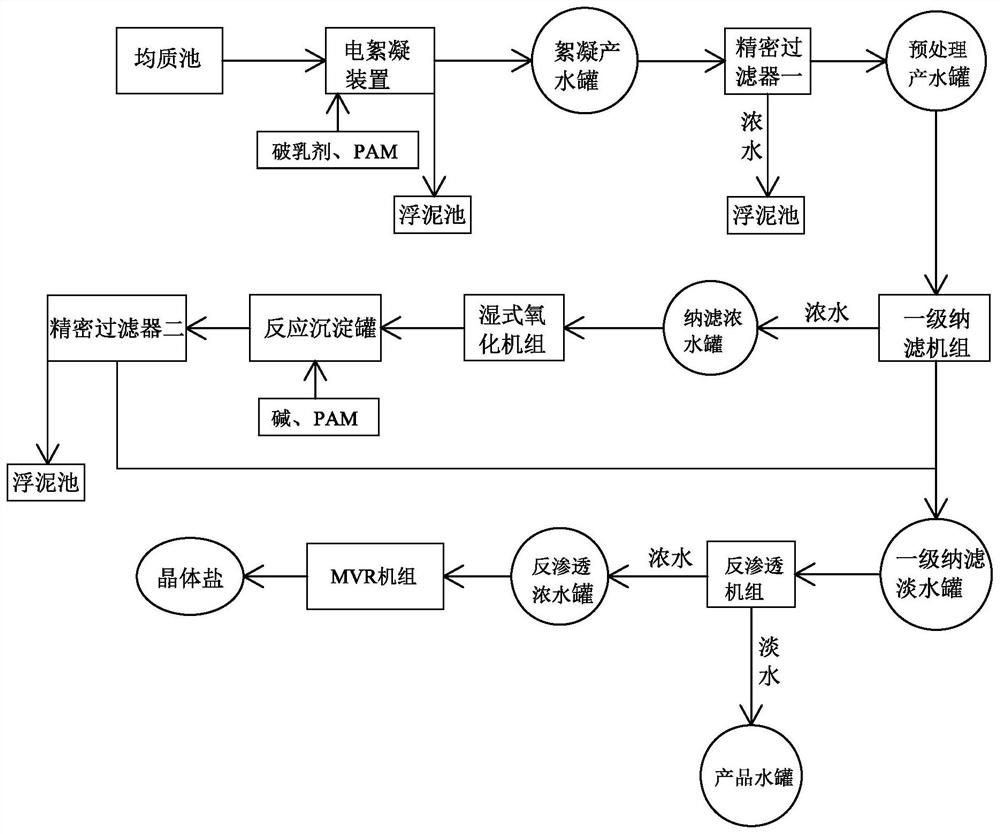

Treatment process of electroplating wastewater

A technology for treating process and electroplating wastewater, applied in metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of long zero-discharge process, difficult biochemical effluent quality, and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment 1 provides a treatment process for electroplating wastewater.

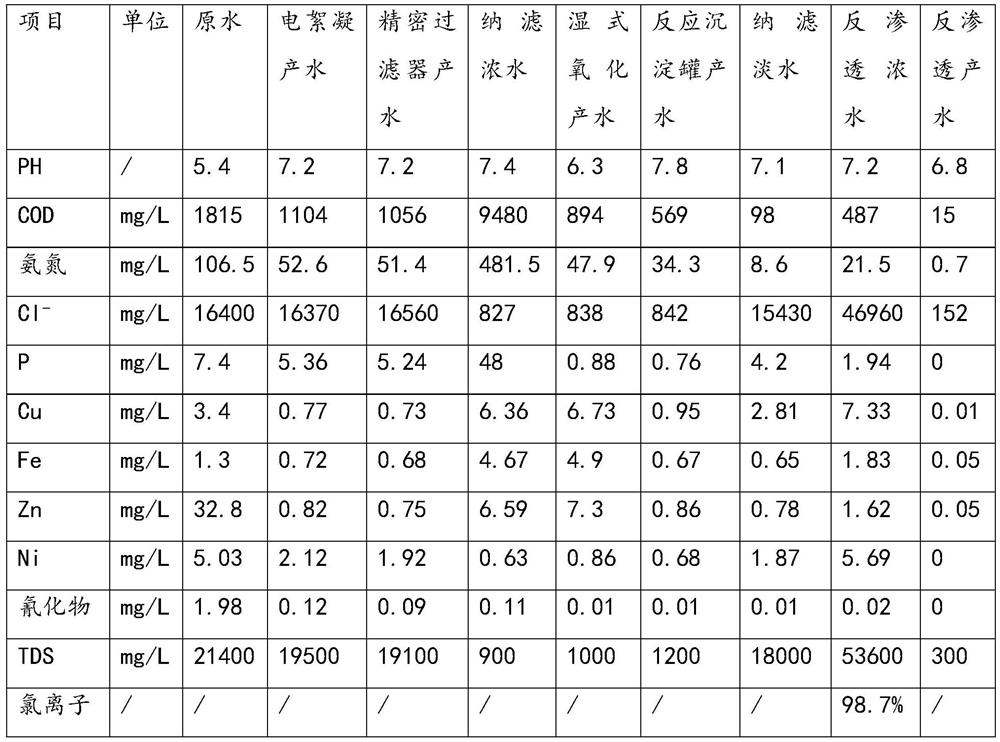

[0037] The electroplating wastewater was tested, and its water quality was: PH: 5-6, COD: 1815mg / L, ammonia nitrogen: 106.5mg / L,

[0038] Cl-: 16400mg / L, P: 7.4mg / L, Cu: 3.4mg / L, Fe: 1.3mg / L, Zn: 32.8mg / L, Ni: 5.03mg / L, Cyanide: 1.98mg / L, TDS: 21400mg / L.

[0039] Prepare and connect related devices: homogeneous tank, electrocoagulation device, flocculation water production tank, precision filter 1, pretreatment water production tank, first-level nanofiltration unit, nanofiltration concentrated water tank, wet oxidation unit, reaction precipitation tank , precision filter two, first-stage nanofiltration fresh water tank, reverse osmosis unit, reverse osmosis concentrated water tank, MVR unit, product water tank; all water tanks are equipped with liquid level gauges, and all water pump outlets are equipped with solenoid valves and pneumatic valve.

[0040] The zero discharge process of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com