A kind of supertetrahedral metal-organic framework material, its preparation method and application

A metal-organic framework and supertetrahedron technology, applied in separation methods, chemical instruments and methods, products, etc., to achieve high acid and alkali resistance stability, enhanced interaction, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

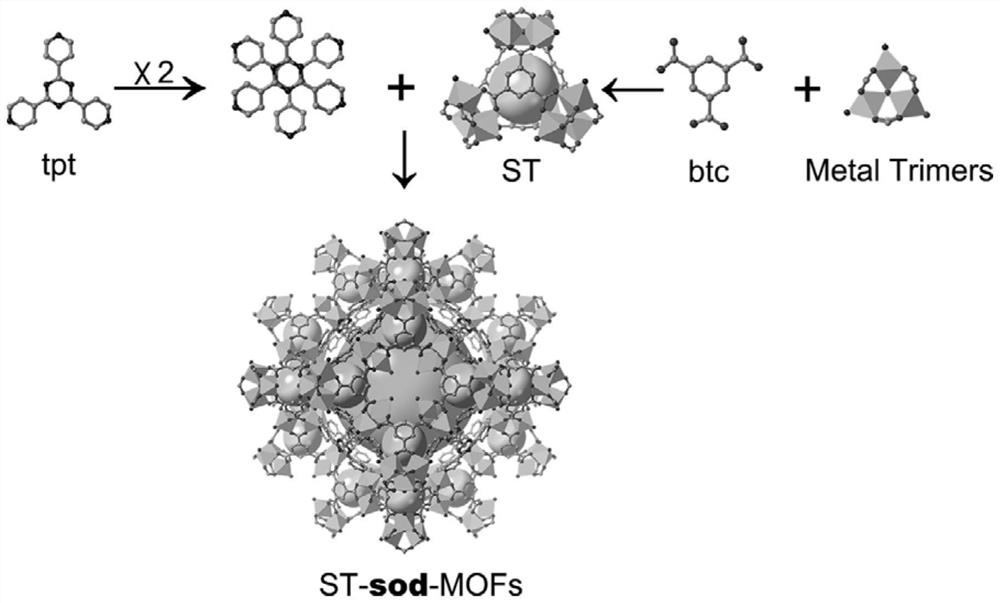

[0047] The preparation method of ST-sod-Co in ST-sod-MOFs comprises the following steps:

[0048] CoSO 4 ·7H 2 O (0.0633g, 0.225mmol), 2,4,6-tris(4-pyridyl)-1,3,5-triazine (0.0162g, 0.052mmol) and 1,3,5-benzenetricarboxylate (0.0324g, 0.154mmol) into a 20ml glass bottle; then drop into N,N-dimethylformamide (4mL) / methanol (1mL) solution; then add 200uL of HBF 4 (tetrafluoroboric acid, 50 wt% aqueous solution), sonicated for 30 min; finally, the mixture was sealed and heated to 110° C. for 10 days. After collection, DMF washing and vacuum drying, the target product red cubic crystal ST-sod-Co was obtained.

[0049] Refer to attached Figure 4 , ST-sod-Co at 77K for N 2 The results of adsorption measurements indicated that ST-sod-Co exhibited a reversible type I adsorption behavior with a stepwise N 2 Adsorption isotherm, which indicates the presence of mesoporous cages in the framework. The saturated adsorption capacity reaches 400cm 3 g -1 , BET surface area is 1310m ...

Embodiment 2

[0053] The preparation method of ST-sod-Ni in ST-sod-MOFs comprises the following steps:

[0054] First Ni(NO 3 ) 2 ·6H 2 O (0.1308g, 0.45mmol), 2,4,6-tris(4-pyridyl)-1,3,5-triazine (0.0310g, 0.10mmol) and 1,3,5-benzenetricarboxylate (0.0632g, 0.30mmol) into a 20ml glass bottle; then drop N,N-dimethylformamide (3mL) / N,N-dimethylacetamide (3mL) / methanol (1mL) solution; Then add 400uL of HSiF 6 (fluorosilicic acid, 25 wt% aqueous solution), sonicated for 30 min; finally, the mixture was sealed and heated to 125° C. for 7 days. After collection, DMA washing and vacuum drying, the target product green cubic crystal ST-sod-Ni was obtained.

[0055] Refer to attached Figure 4 , ST-sod-Ni at 77K for N 2 The results of adsorption measurements indicated that ST-sod-Ni exhibited a reversible type I adsorption behavior with a stepwise N 2 Adsorption isotherm, which indicates the presence of mesoporous cages in the framework. The saturated adsorption capacity reaches 400cm 3 g ...

Embodiment 3

[0059] The preparation method of ST-sod-Co / Ti in ST-sod-MOFs comprises the following steps:

[0060] CoCl 2 ·6H 2 O (0.0734g, 0.31mmol), titanium dichloride (0.0375g, 0.15mmol), 2,4,6-tris(4-pyridyl)-1,3,5-triazine (0.0310g, 0.10mmol) and 1,3,5-benzenetricarboxylate (0.0632g, 0.30mmol) into a 20ml glass bottle; then drop into N,N-dimethylformamide (3mL) / N,N-dimethyl Acetamide (3mL) / methanol (1mL) solution; then add 400uL of HSiF 6 (fluorosilicic acid, 35 wt% aqueous solution), sonicated for 30 min; finally, the mixture was sealed and heated to 140° C. for 3 days. After collection, DMA washing and vacuum drying, the target product red polyhedral crystal ST-sod-Co / Ti was obtained.

[0061] Refer to attached Figure 4 , ST-sod-Co / Ti at 77K for N 2 The results of adsorption measurements indicated that ST-sod-Co / Ti exhibited a reversible type I adsorption behavior with a stepwise N 2 Adsorption isotherm, which indicates the presence of mesoporous cages in the framework. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com