Patents

Literature

95 results about "Sodalite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

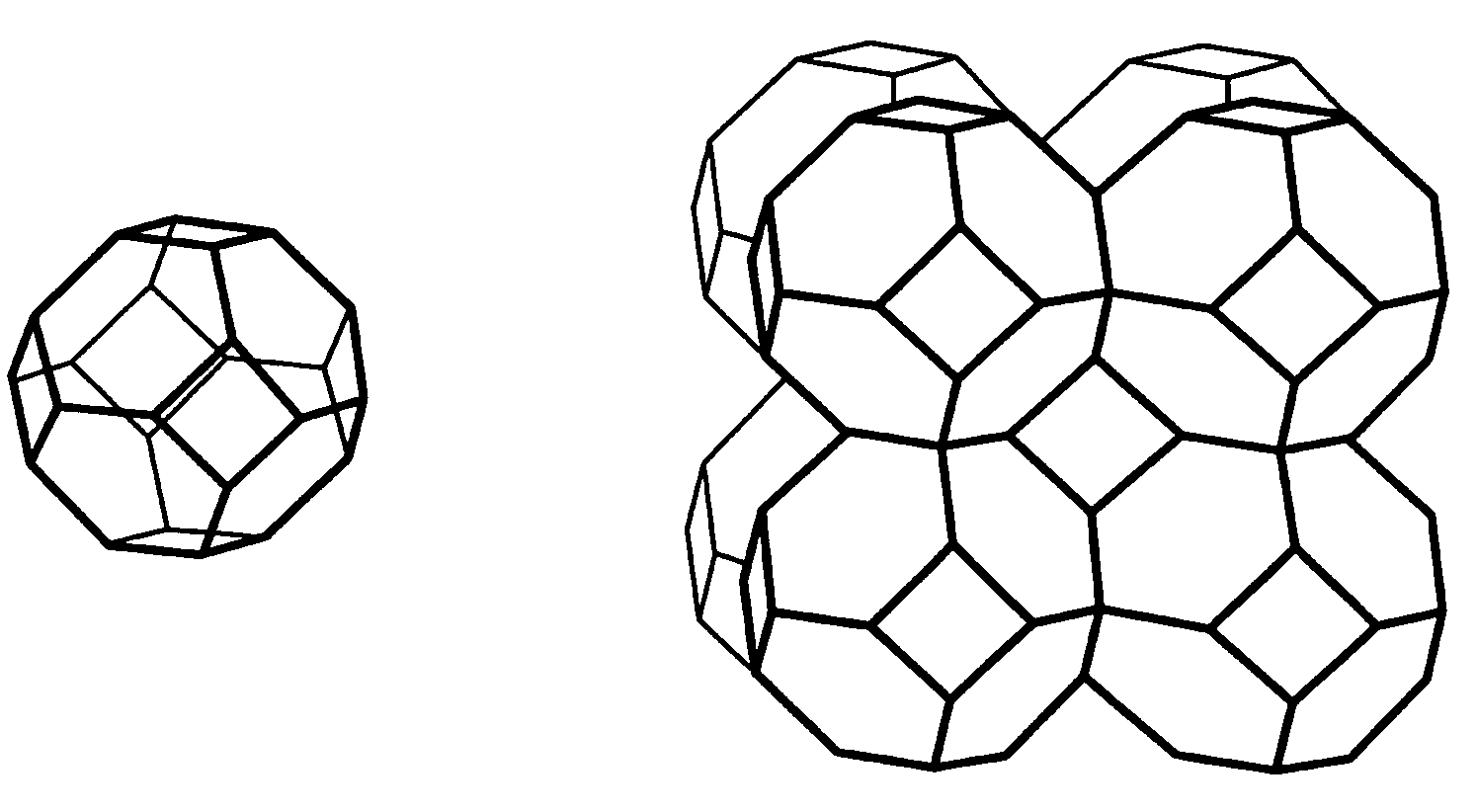

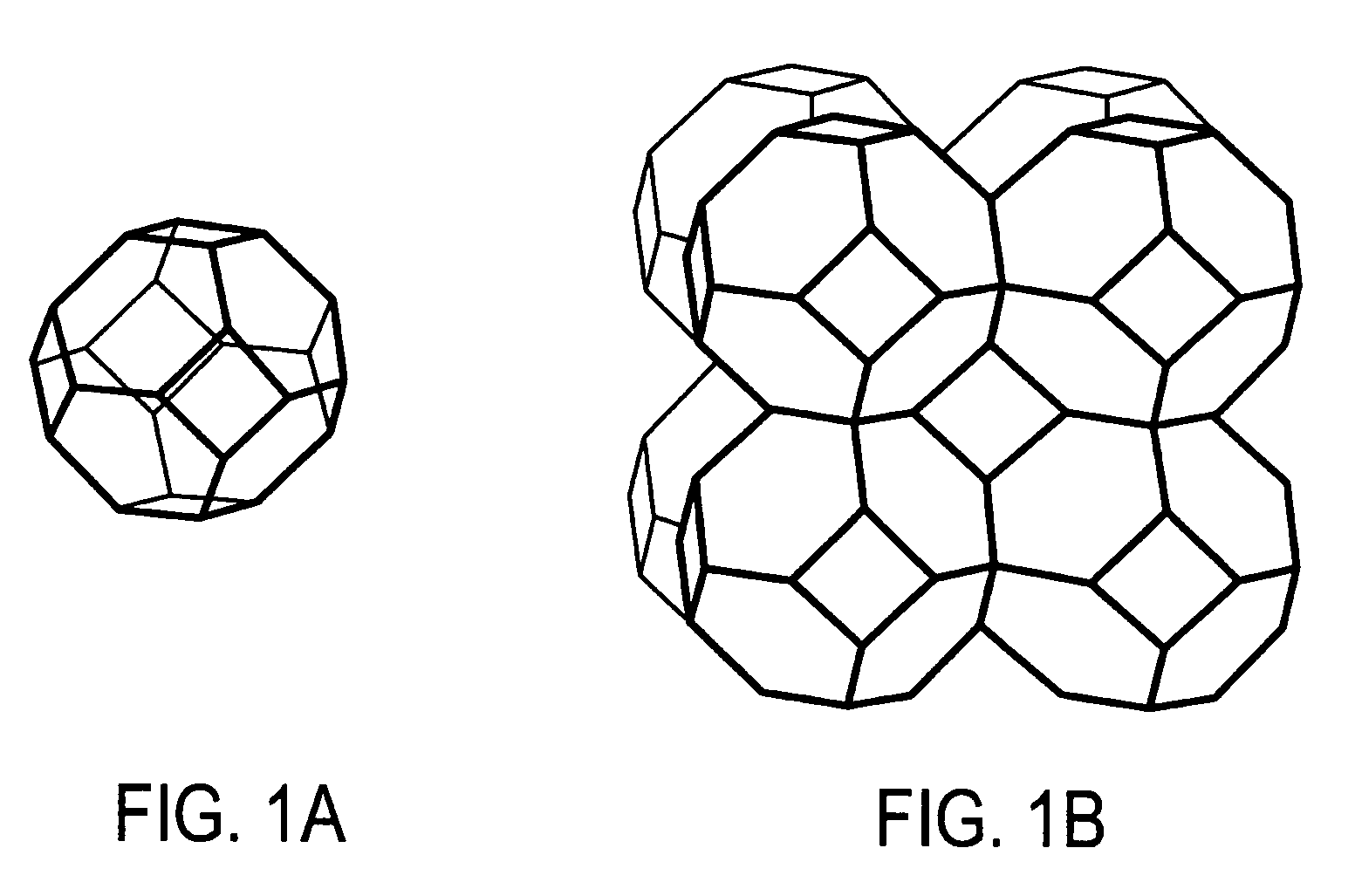

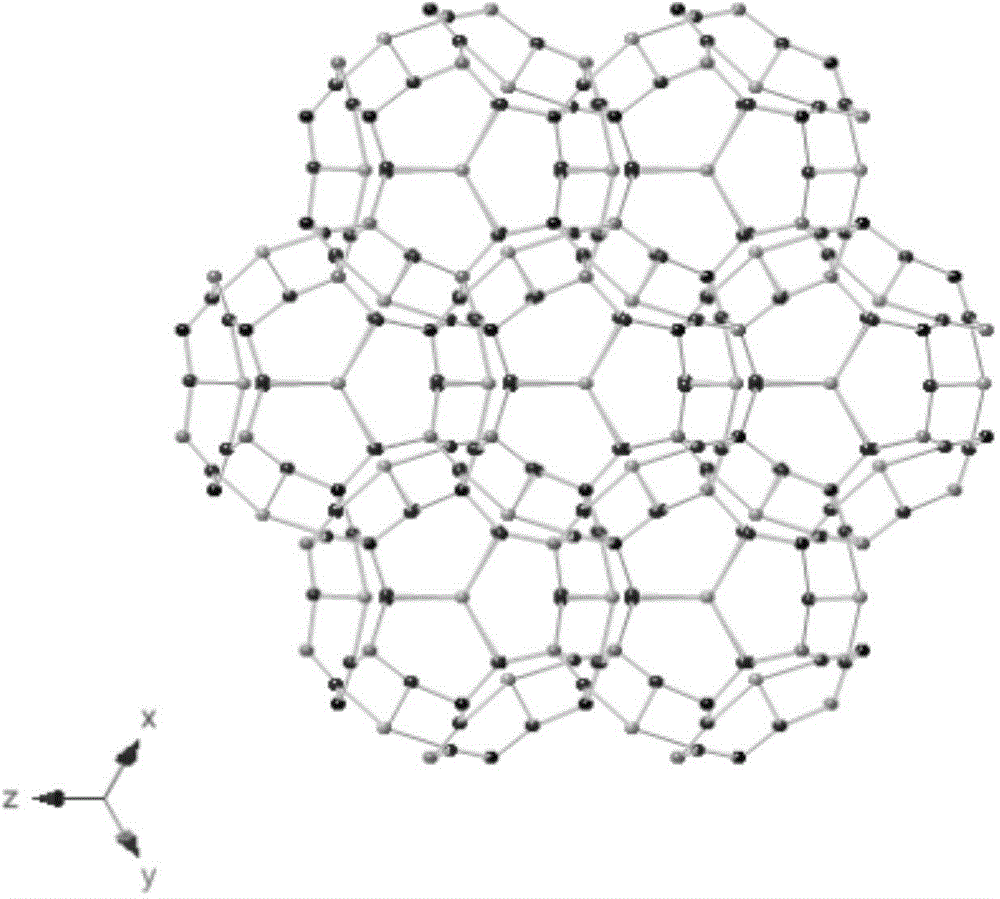

Sodalite is a rich royal blue tectosilicate mineral widely used as an ornamental gemstone. Although massive sodalite samples are opaque, crystals are usually transparent to translucent. Sodalite is a member of the sodalite group with hauyne, nosean, lazurite and tugtupite.

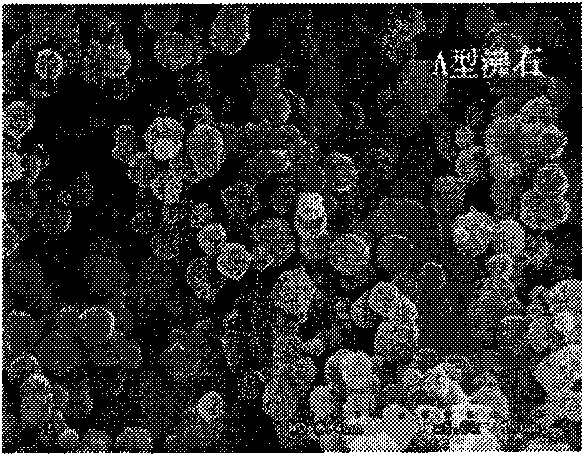

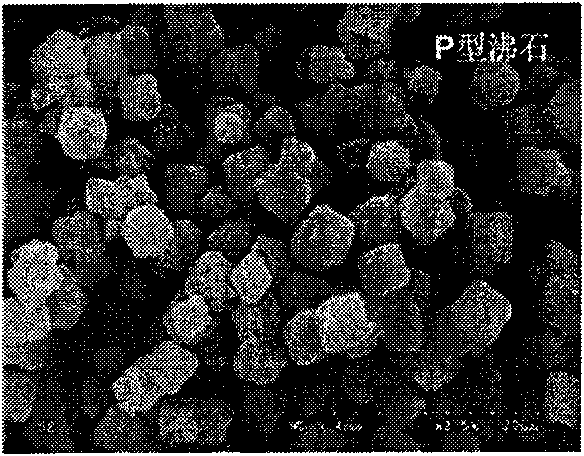

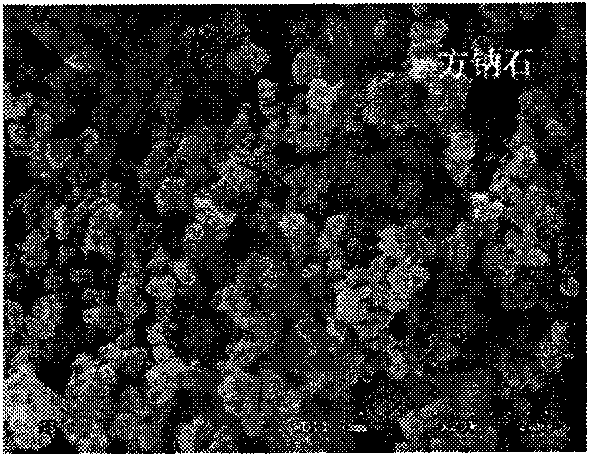

Method for synthesizing pure 4A zeolite, P-shaped zeolite and sodalite with concavo-convex attapulgite clay

InactiveCN101618880AThe synthesis method is simpleRaw materials are easy to getAluminosilicate zeolite type-AFiltrationSynthesis methods

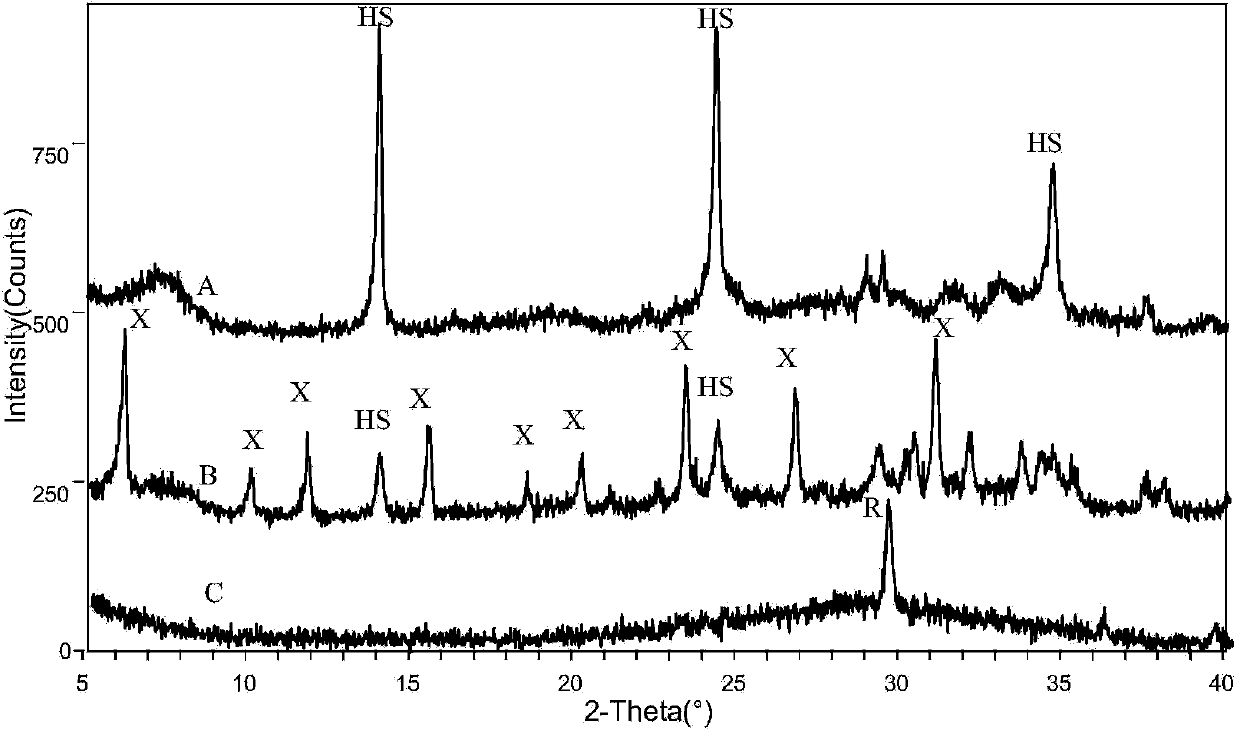

The invention discloses a method for synthesizing pure 4A zeolite, P-shaped zeolite and sodalite with concavo-convex attapulgite clay. The method is characterized by comprising the following steps: firstly, the concavo-convex attapulgite clay is calcined in high temperature; then, the calcined concavo-convex attapulgite clay is soaked by soda liquor to obtain leach liquor containing Na2SiO3; finally, an aluminum source is added into the soda leach liquor to carry out hydrothermal crystallization synthesis, and then, the pure 4A zeolite, the P-shaped zeolite and the sodalite are respectively obtained by filtration, rinsing and drying. In the method, the concavo-convex attapulgite clay is used as raw material, and the genuine 4A zeolite, the P-shaped zeolite and the sodalite are respectively obtained by calcination and soda-leach pretreatment through adjusting synthesis conditions, therefore the invention has the advantages of simple synthesis method, easily obtained raw material and low production cost.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Process for synthesizing single-phase sodalite from fly ash

ActiveCN102173433ASolve the reuse problemExpand sourceSolid waste disposalCrystalline aluminosilicate zeolitesPre treatmentFly ash

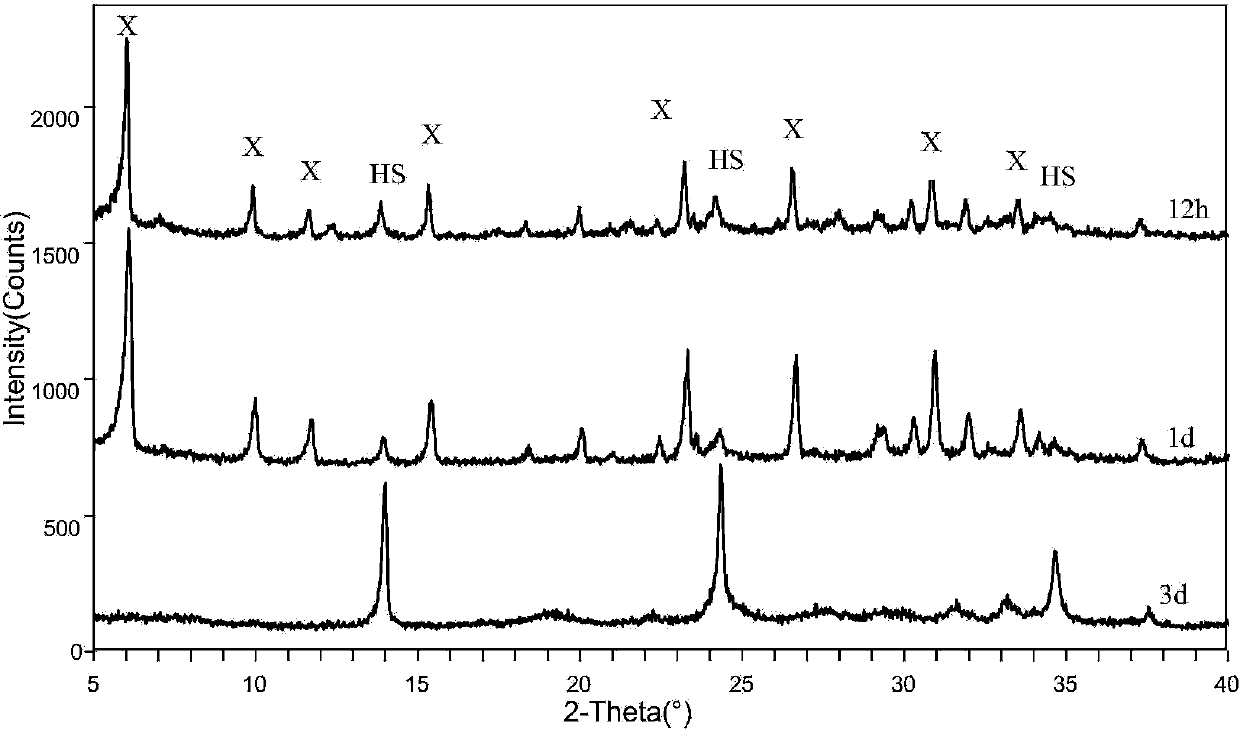

The invention belongs to the field of production and preparation of inorganic functional materials, and particularly relates to a process for preparing single-phase sodalite from fly ash, which comprises the following steps: pretreating fly ash by an alkaline fusion method; proportionally adding the activated fly ash, aluminum hydroxide and sodium hydroxide solution into a polytetrafluoroethyleneinner container, evenly mixing, and carrying out hydrothermal crystallization in a sealed constant-temperature drying oven; and finally, filtering the product, washing until the product becomes neutral, and drying to obtain the single-phase sodalite material. The invention successfully synthesizes the low-cost single-phase sodalite zeolitization material by using solid waste-fly ash as the raw material for production. The process has the advantages of low cost, abundant sources of raw material, controllable product performance, no secondary pollution and the like, is simple and easy to operate, and thus, has great industrial application potential.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of calcium ion exchange type aluminosilicate anticorrosive and anticorrosive paint

The invention provides a non-toxic and anticorrosive paint which is environment-friendly, free of heavy metal, good in anticorrosive effect, and low in cost of raw materials, and has cation exchange property and acid corrosion resistance. The paint comprises calcium exchange aluminosilicate which has anticorrosive effects and belongs to the series of anticorrosive (antirust) paint, wherein the aluminosilicate is an artificially or naturally-synthesized compound which has a certain microcellular structure, absorbability and ion exchange property, the compounds comprise feldspar, kaolin, zeolite, montmorillonite, bentonite, sodalite, mica and the like, and the sodium ion exchange reaction, the ammonium ion exchange reaction and the calcium ion exchange reaction are performed to the compounds so as to prepare calcium exchange aluminosilicate ion exchange type anticorrosive (antirust) paint. The anticorrosive paint which is good in saline water resistance is prepared in cooperation with water-based or solvent-based film-forming materials, addition agent, and the like.

Owner:JIANGSU RONGCHANG NEW MATERIAL TECH +1

Fluorescence standard, and the use thereof

InactiveUS8704158B2Improve homogeneityOptical radiation measurementBioreactor/fermenter combinationsFluorescenceApatite

Owner:QIAGEN LAKE CONSTANCE GMBH

Preparation method of nanometer sodalite powder

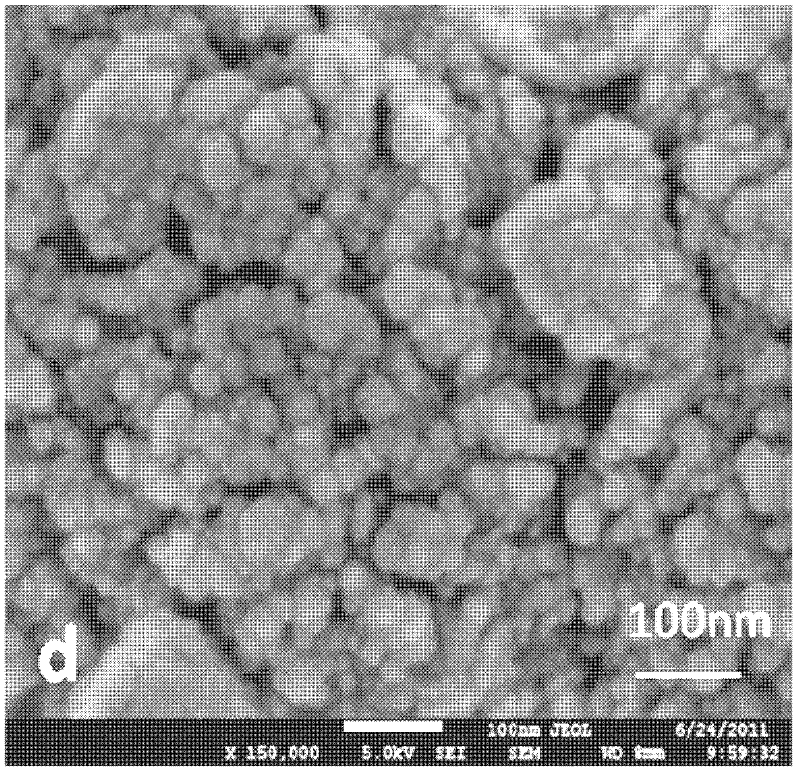

InactiveCN102557056ALarge specific surface areaHigh crystallinityAlkali metal silicatesNanotechnologyCrystallinityIonic liquid

The invention discloses a preparation method of nanometer sodalite powder. A synthetic method is characterized by comprising the following steps of: proportionally mixing NaAlO2, Na2SiO3.9H2O, NaOH, KOH and deionized water into silicon-aluminum sol in a beaker, adding an ionic liquid, i.e., [emim]Bar, stirring uniformly, putting into a microwave reactor, performing magnetic stirring, performing microwave heating, and crystalizing; cooling to the room temperature after crystalizing, taking a crystallization product out, separating and leaching by using a centrifuge, and leaching with deionized water and acetone; and drying a product to obtain sodalite powder. In the synthetic method disclosed by the invention, microwaves are used for heating, so that the crystalizing time is shortened greatly, and a crystal synthesized under the condition that the using amount of the ionic liquid is small has the characteristics of high degree of crystallinity, small particle diameter and narrow particle diameter distribution. According to these characteristics, sodalite has higher application values on the aspects of adsorption and hydrogen storage.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Fluorescence standard, and the use thereof

InactiveUS20110076687A1Improve homogeneityBioreactor/fermenter combinationsPhotometry using reference valueFluorescenceApatite

The invention concerns fluorescence standards, and in particular fluorescence standards for calibrating optical detectors. According to the invention, a fluorescent mineral or mixtures of minerals are employed for use as a fluorescence standard. The fluorescent mineral can be a naturally occurring mineral or a synthetically produced mineral. Preferred fluorescent minerals for use as fluorescence standards are corundum, fluorite, turquoise, amber, zircon, zoisite, iolite or cordierite, spinel, topaz, calcium fluorite, sphalerite or zincblende, calcite or calcspar, apatite, scheelite or calcium tungstate, willemite, feldspars, sodalite, a uranium mineral, a mineral containing Al3+, and in particular ruby and sapphire.

Owner:QIAGEN LAKE CONSTANCE GMBH

Treatment method of radioactive iodine waste

The invention belongs to the technical field of radioactive waste treatment, and relates to a treatment method of radioactive iodine waste. The treating method sequentially comprises the following steps: (1) the radioactive iodine waste reacts with sodium hydroxide, and radioactive iodine waste conversion product powder is obtained; (2) 4A zeolite and the radioactive iodine waste conversion product powder are mixed and then ground, and after drying and weighing, deionized water is added for further grinding, refining and homogenizing treatment, a uniformly wetted mixture is obtained; and (3) the uniformly wetted mixture is hydrolyzed, evaporated to be dry and then subjected to heating sintering, and an iodine sodalite solidified body is obtained. Through the treatment method of the radioactive iodine waste, the radioactive iodine waste can be treated in the modes of simple technological process, energy conservation, environment protection, safety and reliability.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

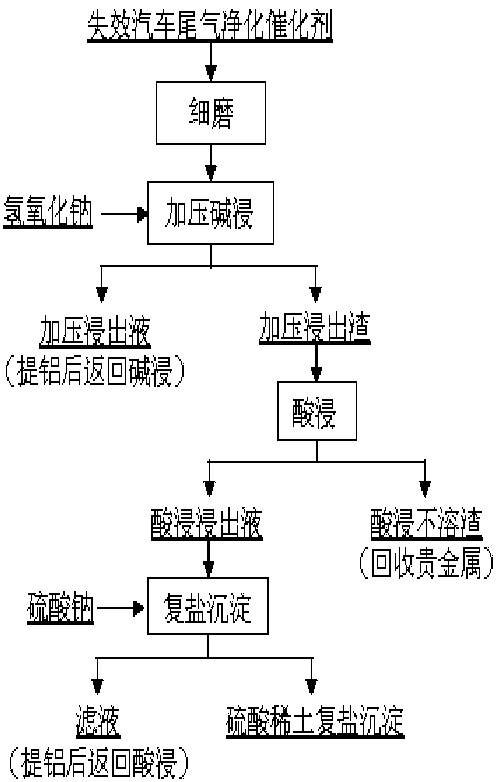

Method for enriching platinum group metal and rare earth in failed automobile exhaust purification catalyst

ActiveCN110055423AFacilitate subsequent extractionComprehensive recycling benefits are goodProcess efficiency improvementRare-earth elementLanthanum

The invention relates to a method for enriching platinum group metal and rare earth in a failed automobile exhaust purification catalyst. The metod comprises the steps that the failed automobile exhaust purification catalyst is finely ground and then is subjected to pressure leaching in a sodium hydroxide solution, gamma-A12O3 in the crystal is partially dissolved, and cordierite carrier in the catalyst is converted into sodalite which is easy to dissolve in an acidic system; acid leaching is carried out on the produced pressure leaching residue, rare earth elements enter the acid leaching solution, and platinum, palladium and rhodium elements are remained in the residue, so that separation of platinum, palladium and rhodium and rare earth is realized; and sodium sulfate is added into theacidic leaching solution to form a rare earth sulfate complex salt precipitate, rare earth elements are recycled, and acidic insoluble residues are further treated to recycle platinum, palladium and rhodium metal. The leaching rate of lanthanum and yttrium reaches 95% or more, platinum, palladium and rhodium in the failed automobile tail gas purification catalyst is enriched by 13 times or more, the subsequent extraction of noble metal is facilitated, and the comprehensive recovery rate of lanthanum and yttrium elements reaches 90% or more.

Owner:CENT SOUTH UNIV

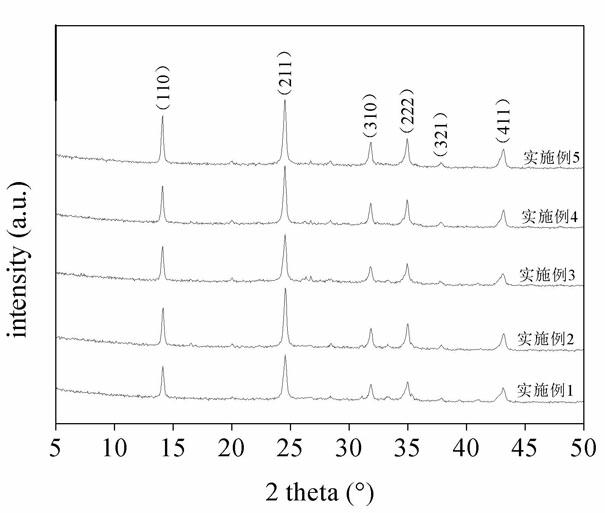

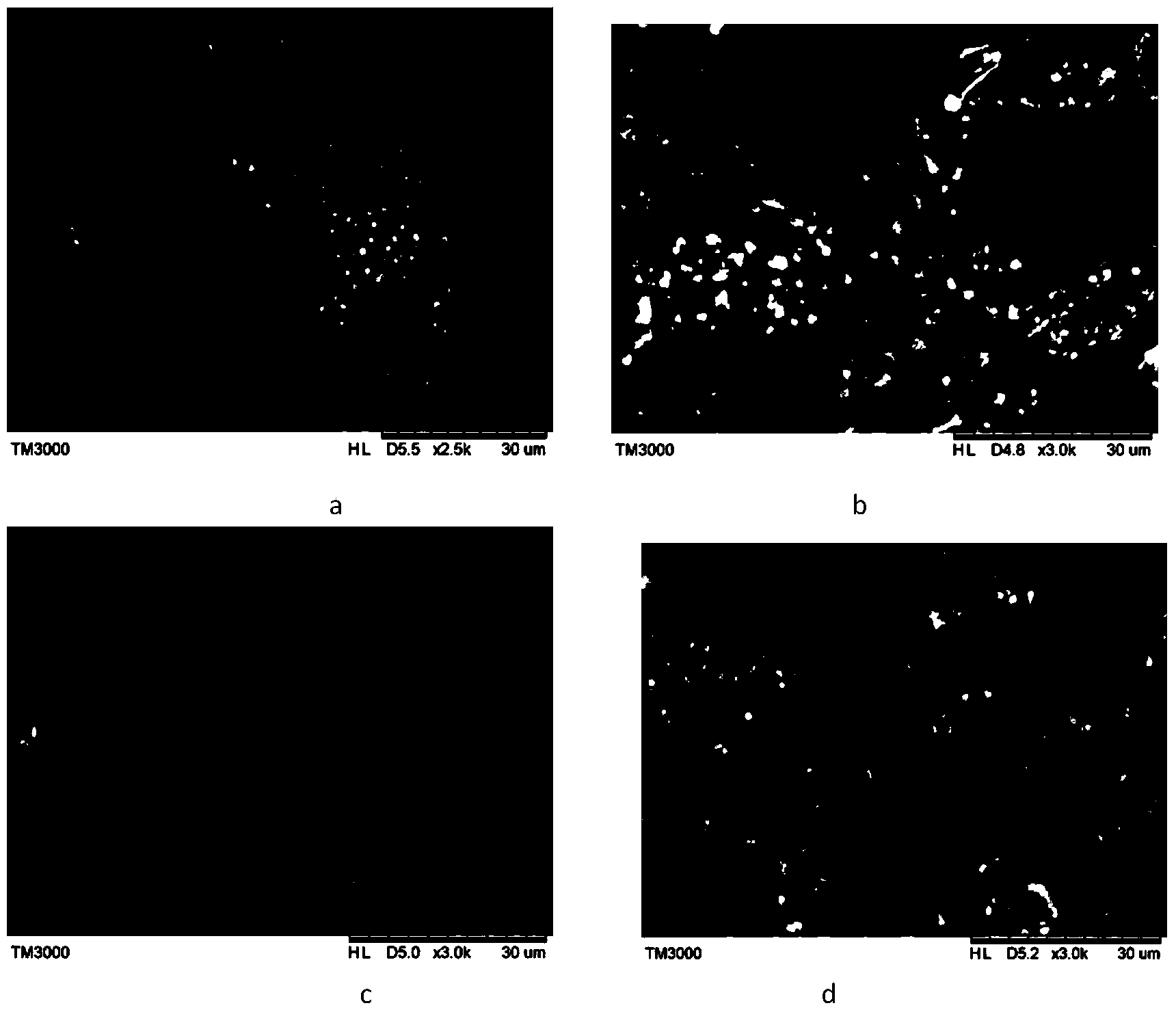

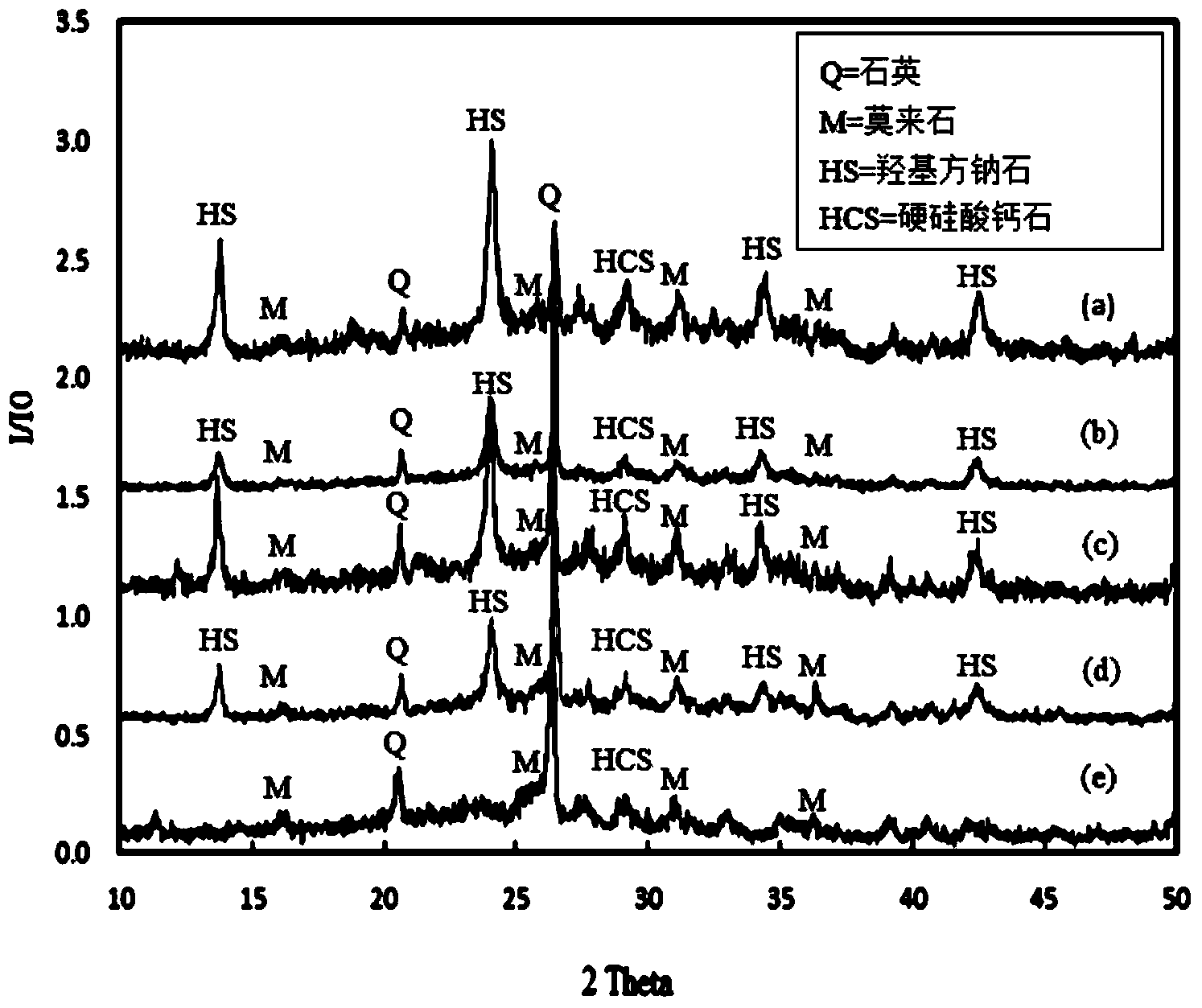

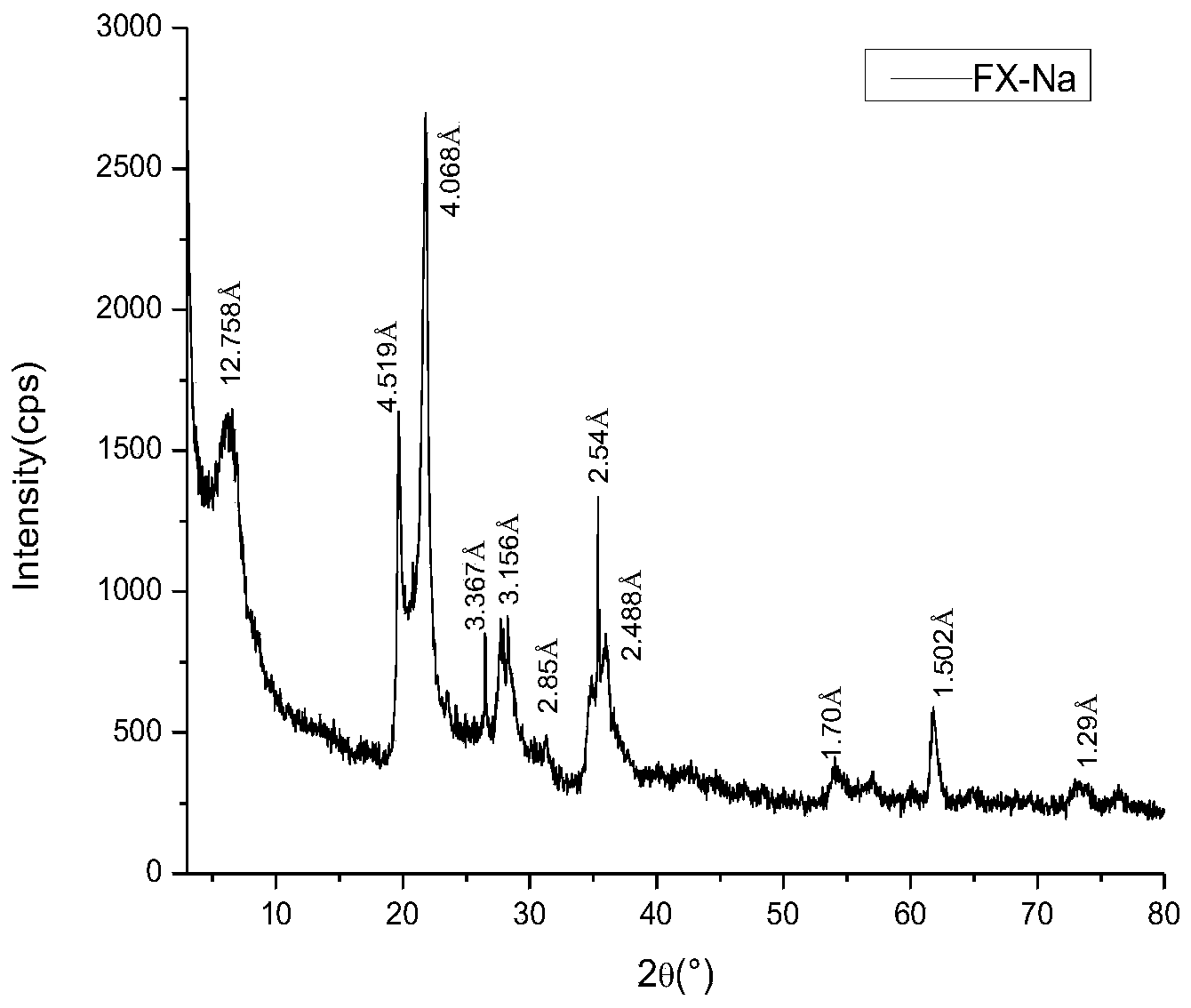

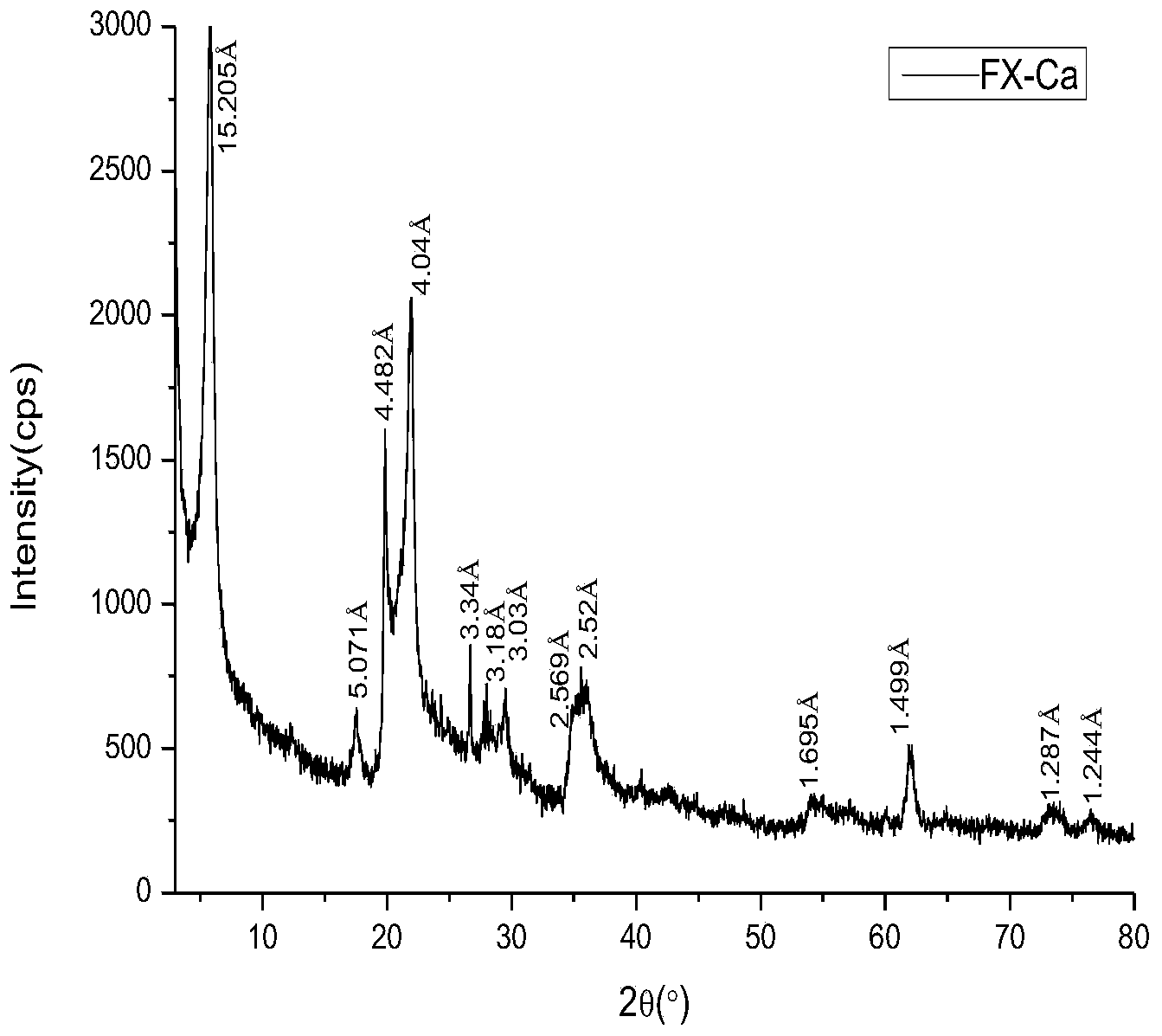

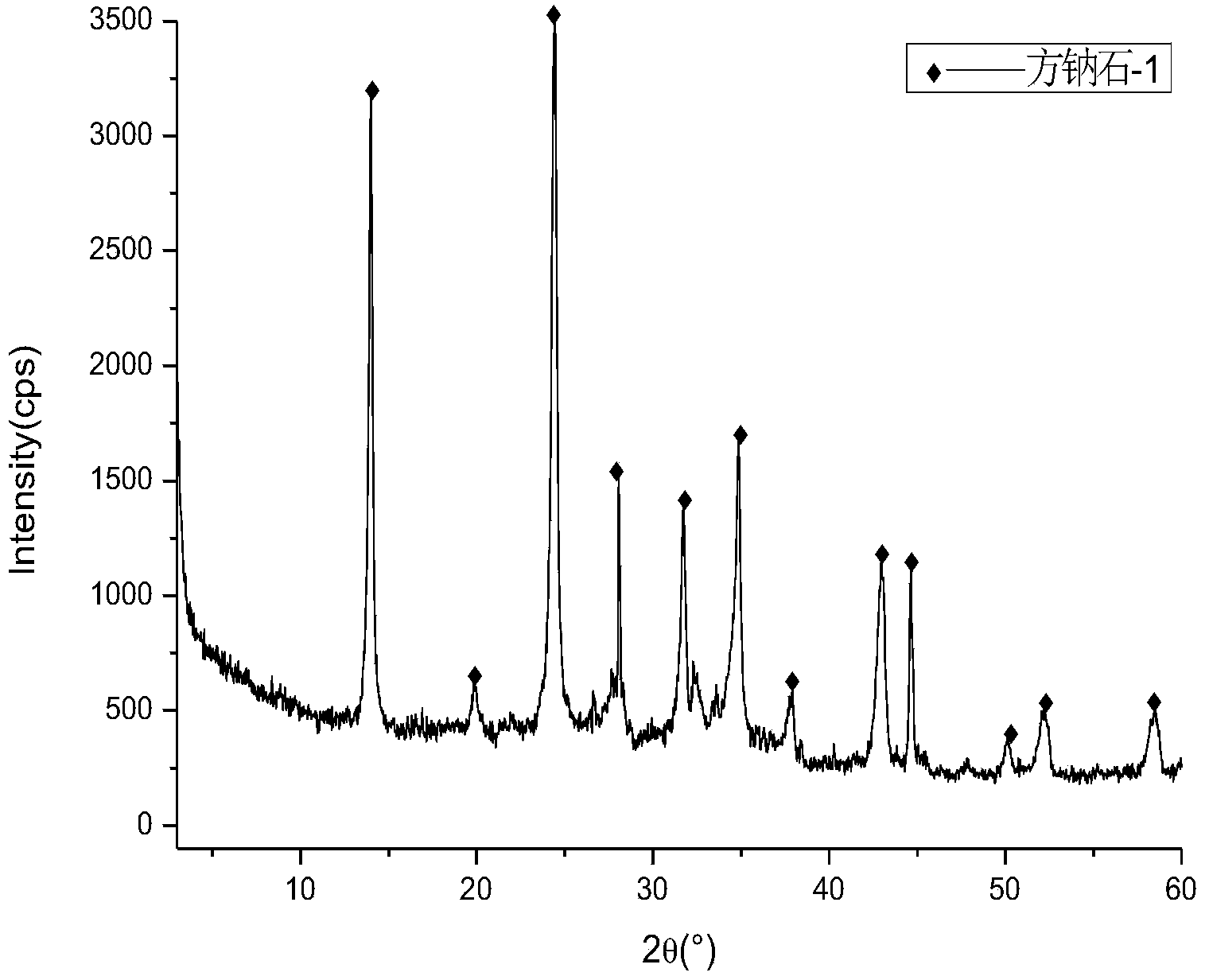

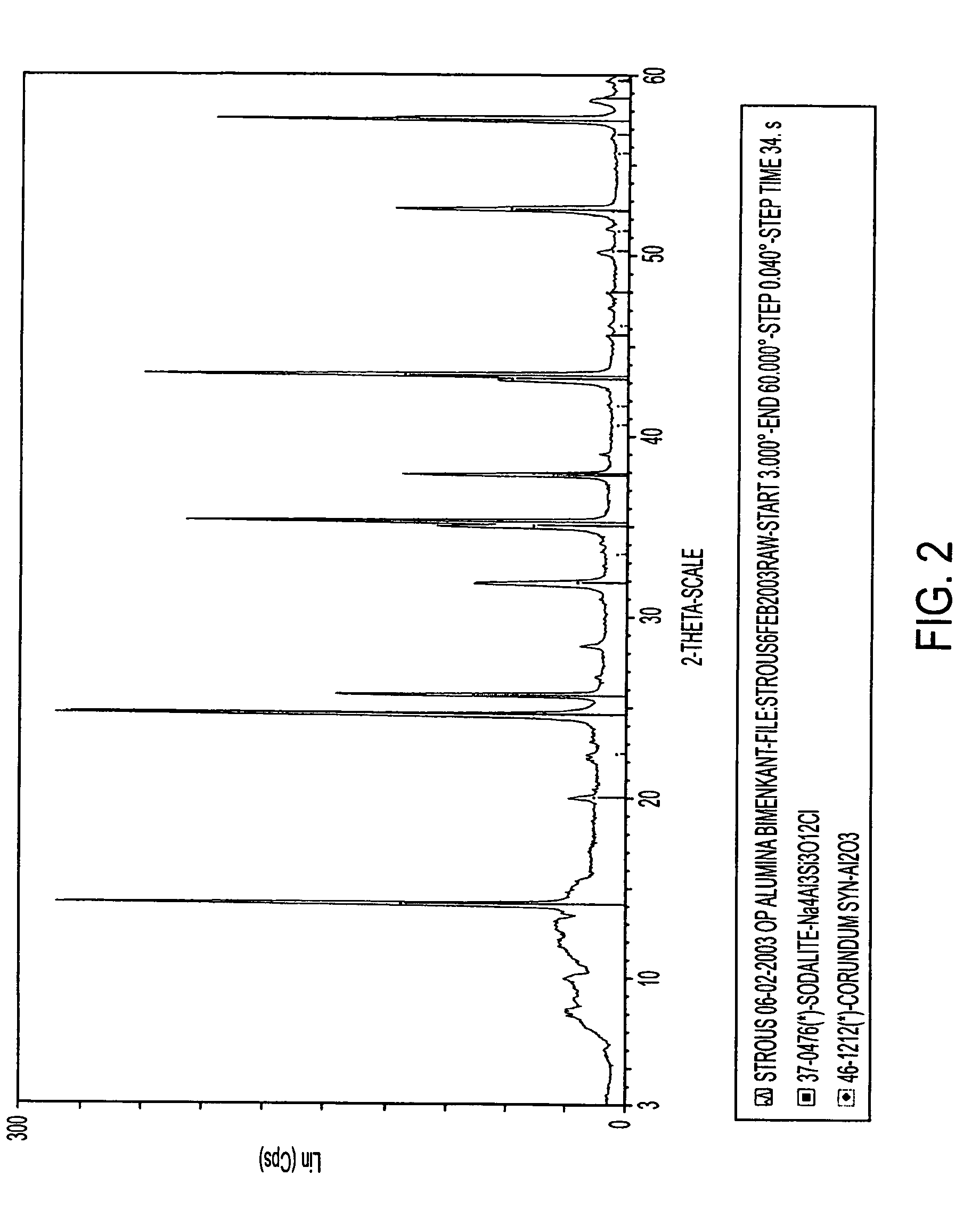

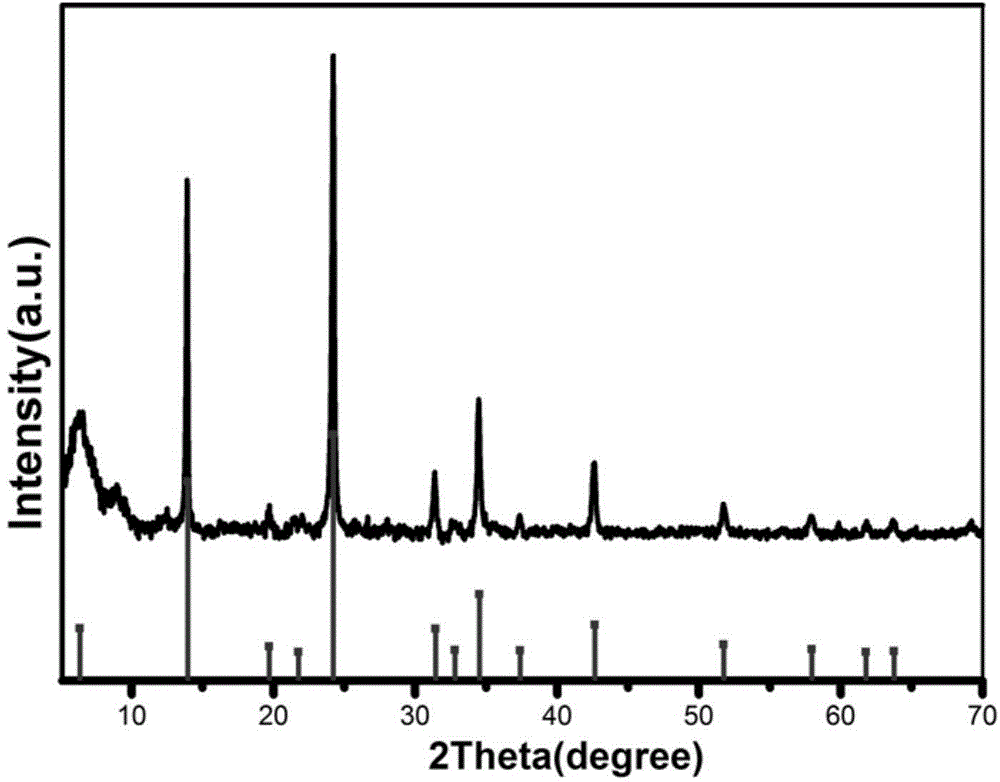

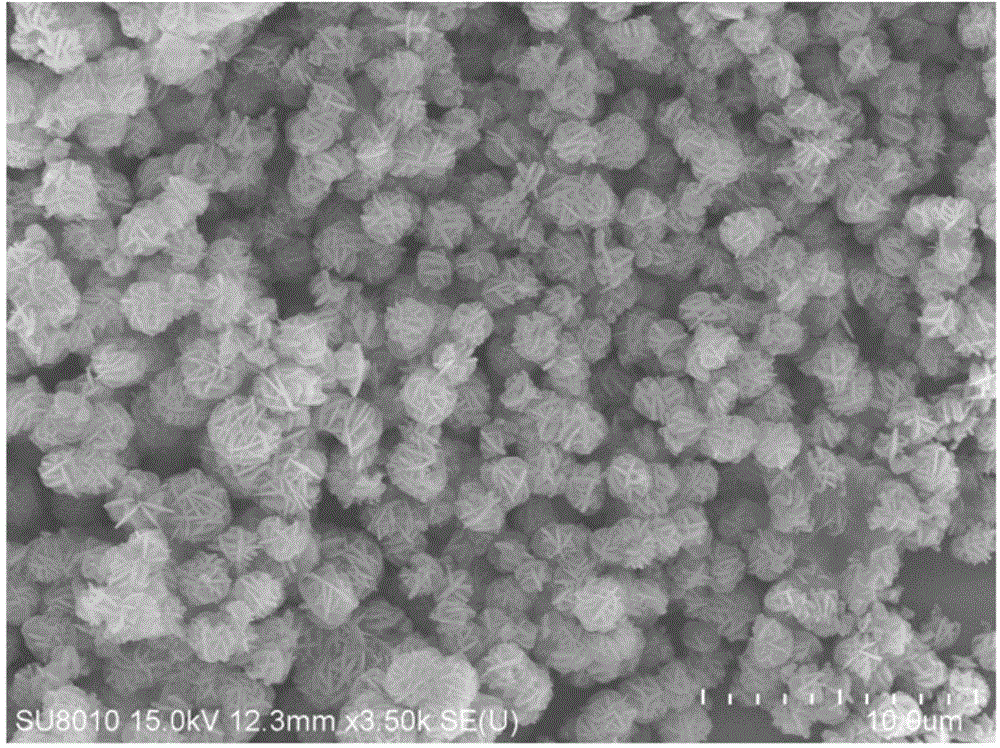

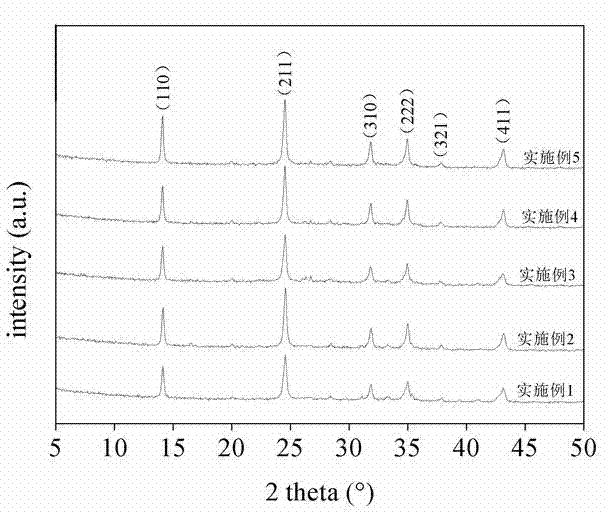

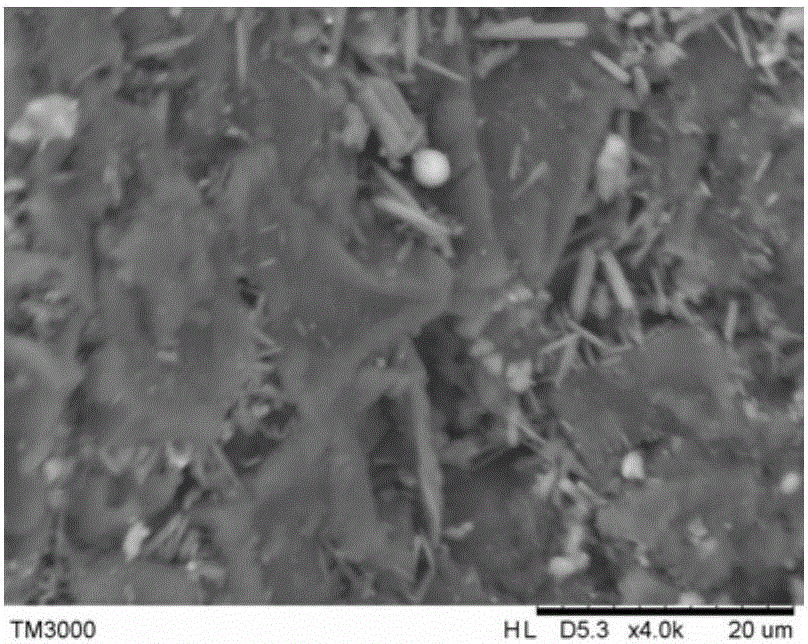

Sodalite zeolite synthesized by fly ash and synthesis method thereof

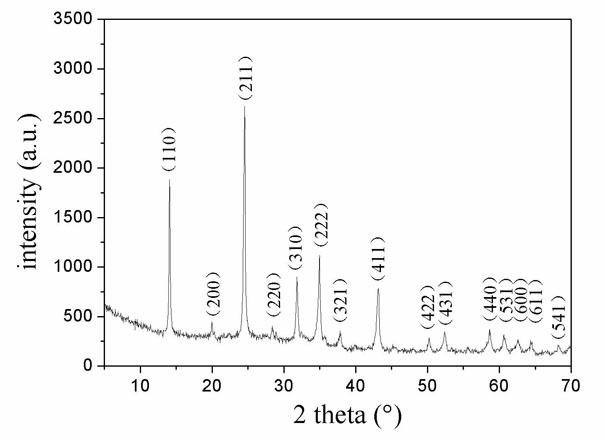

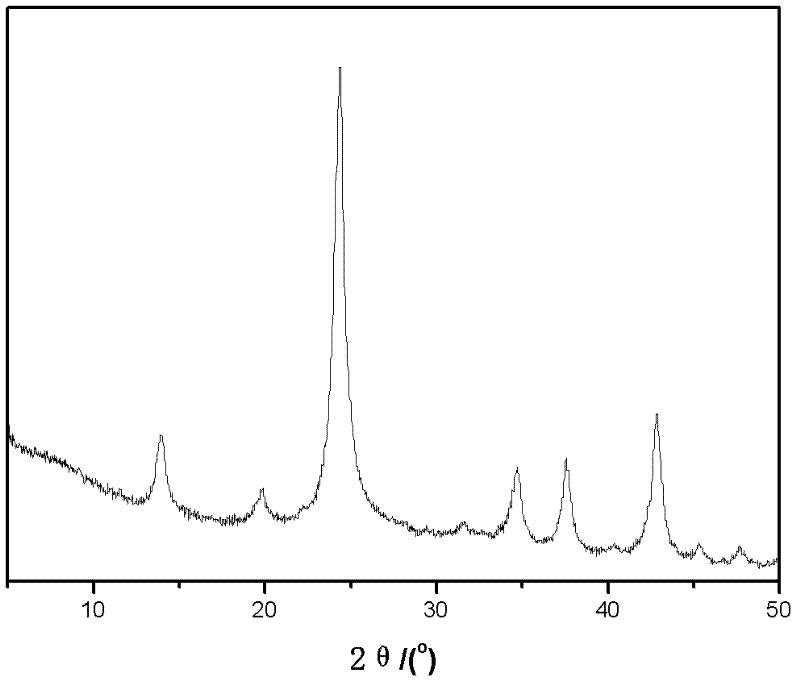

The invention discloses a sodalite zeolite synthesized by fly ash and a synthesis method thereof. The method comprises the following steps: mixing fly ash with clean water, stirring and washing until the upper part of the solution is no longer turbid; then filtering; drying at a temperature of 100 to 105 DEG C until the weight does not change; putting the processed fly ash into high-pressure reaction equipment, adding NaOH solution with a concentration of 4 mol / L according to the mass of the processed fly ash, heating to a default effective temperature of 121 DEG C for carrying out dampness-heat reactions in the high-pressure reaction equipment, wherein the pressure reaches 147 kPa; cooling the reaction product, filtering, and drying so as to obtain sodalite zeolite, wherein the product is ball-shaped particles in glassy state, contains single hydroxyl sodalite zeolite, and the diffraction angles of the powder diffraction characteristic peaks are 14.08 degrees, 24.50 degrees, 31.80 degrees, 34.92 degrees, and 43.14 degrees. The sodalite zeolite is used to eliminate ammonia nitrogen in wastewater; the maximum ammonia absorption amount is 11.0477 mg / g, so that the effect is prominent.

Owner:TIANJIN UNIV

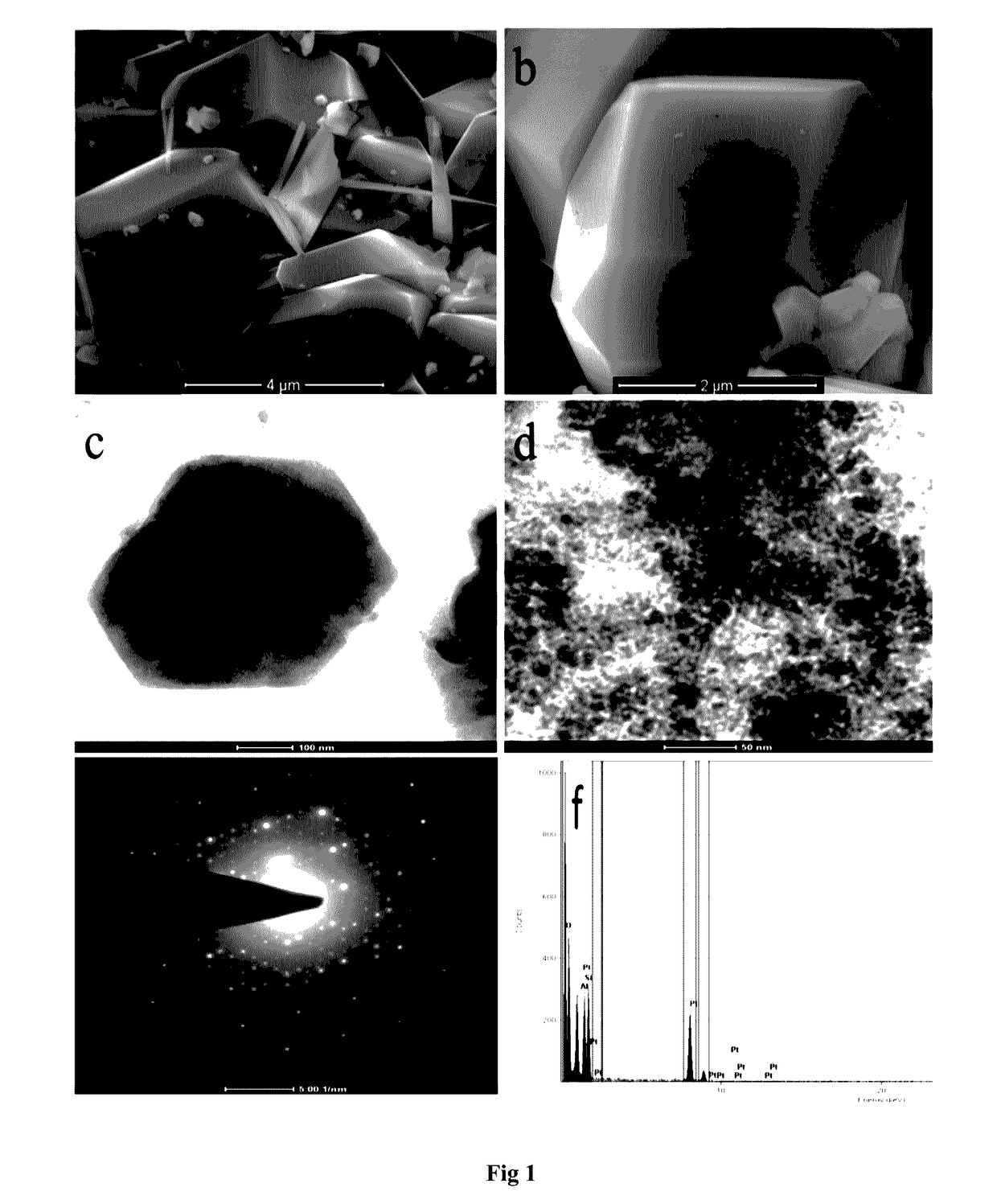

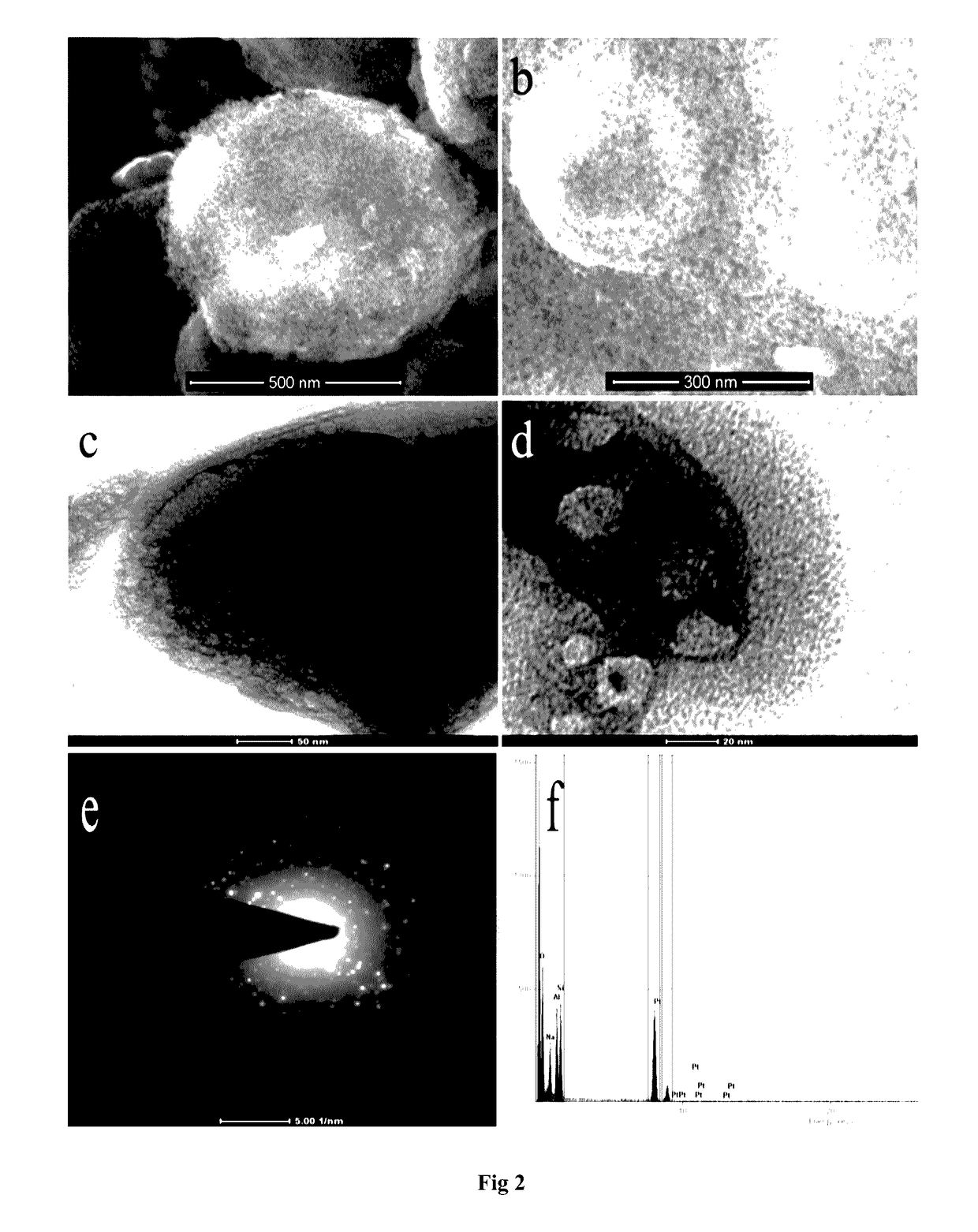

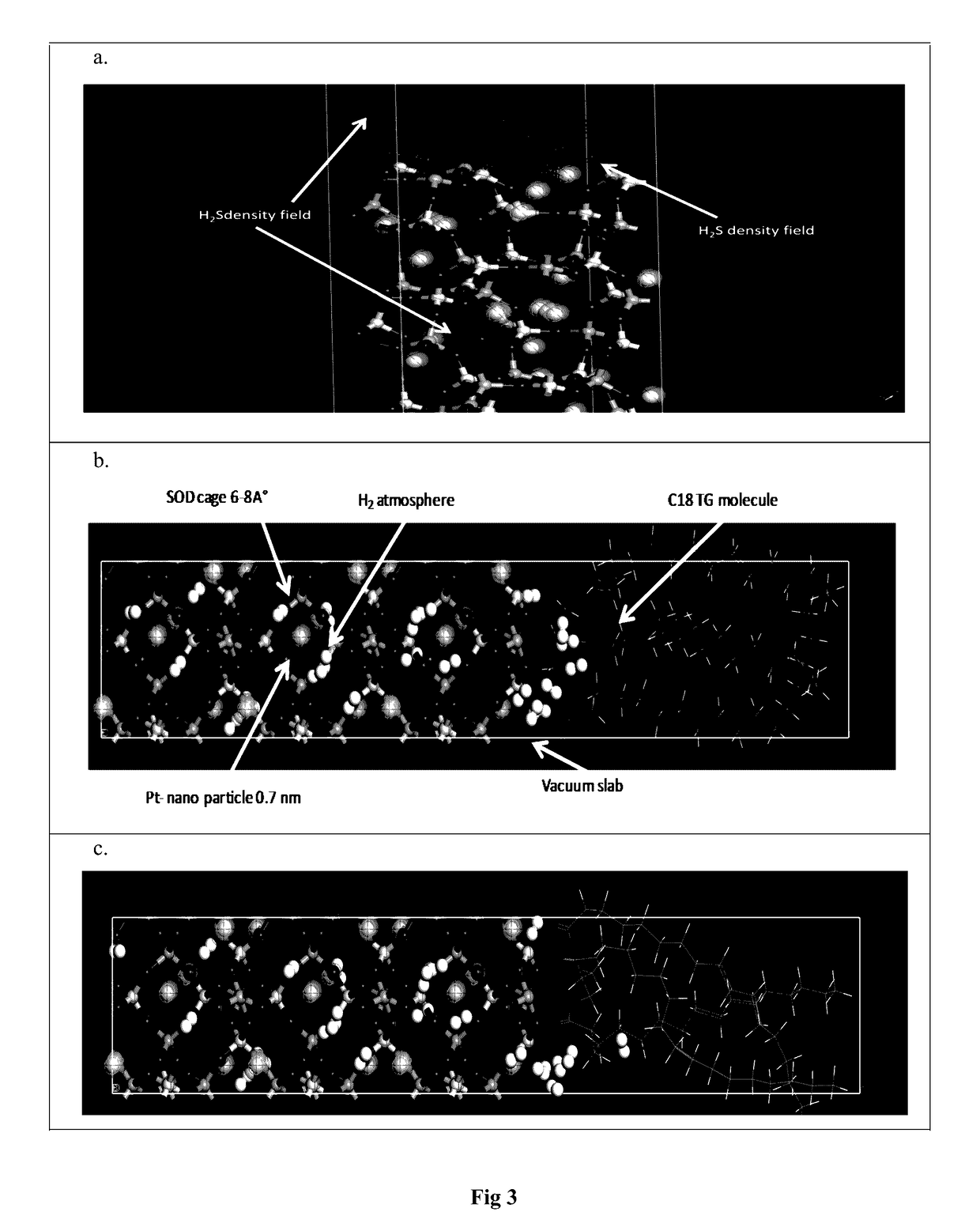

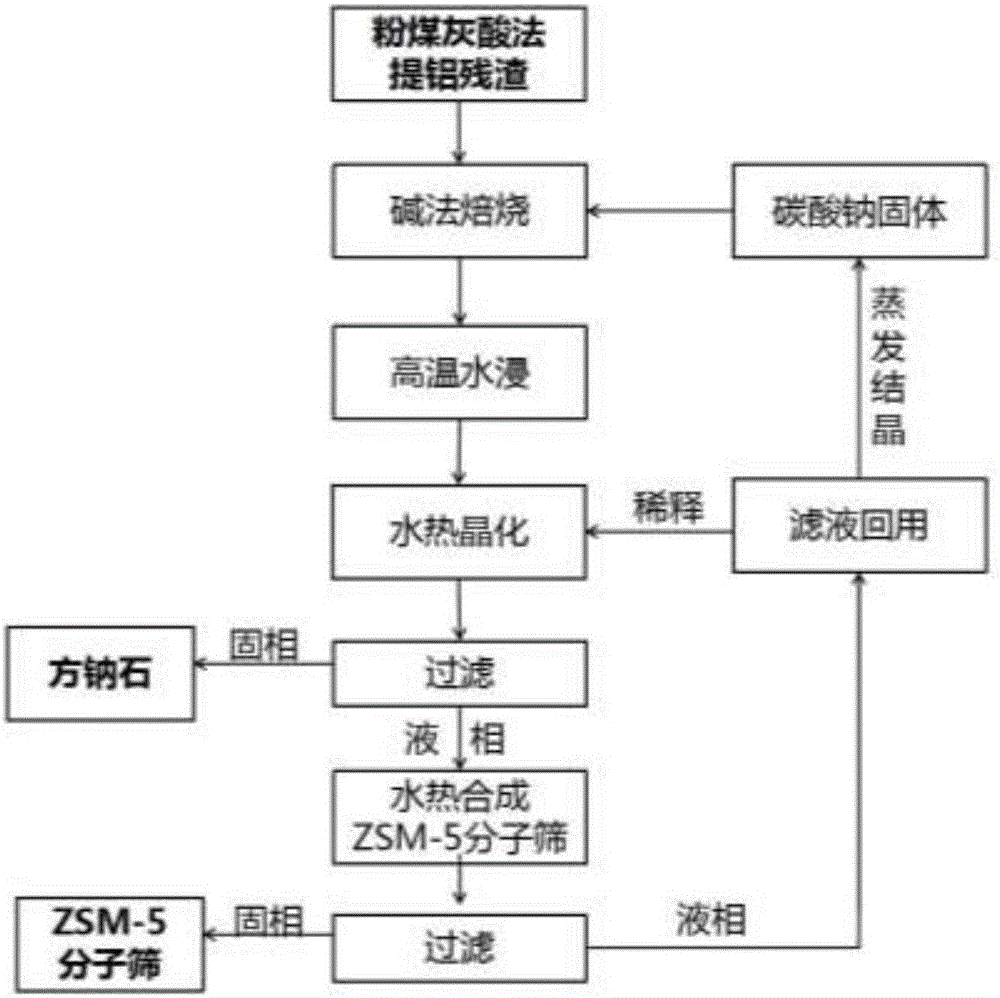

Pt/Pd Sodalite Caged Catalyst Combination with Sulfided Base Metal Catalyst for the Improved Catalytic Hydroprocessing of Feedstock

ActiveUS20170165655A1Avoid poisoningImprove abilitiesMolecular sieve catalystsCatalyst activation/preparationKeroseneSilicon dioxide

A novel pt / pd sodalite caged catalyst combination with sulfided base metal catalyst for improved catalytic hydroprocessing of renewable feedstock. Particularly, the invention relates to a process for preparation of the said catalyst. More particularly, the invention relates to a process for the preparation of hydrocarbon fuel from the feed stock using a said catalyst. Further, the invention discloses a novel catalyst and a process for the preparation of the Pt / Pd encapsulated in sodalite cage with silica-alumina ZSM-5 synthesized around it supported with nickel, molybdenum, cobalt, tungsten or one or more thereof. The invention also provides process to convert vegetable oils, free fatty acids, and microbial lipids, bio-crude and conventional non-renewable crude based feed stocks such as diesel, naphtha, kerosene, gas oil, residue, etc., into gasoline, aviation, diesel, fuel and other hydrocarbons fuel with reduced coke formation and hydrogen generation due to formation of napthenes and aromatics using the novel catalyst.

Owner:COUNCIL OF SCI & IND RES

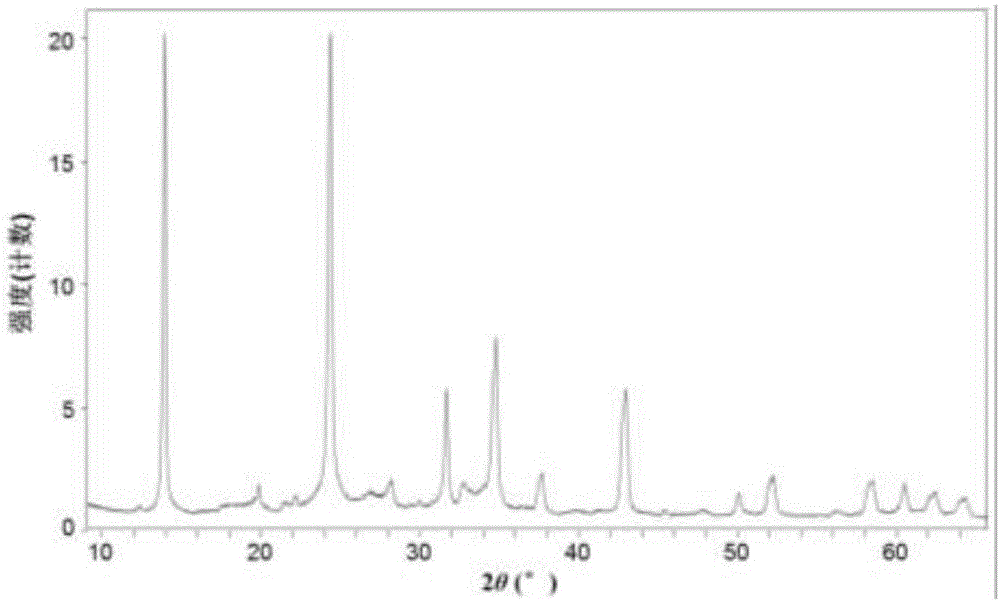

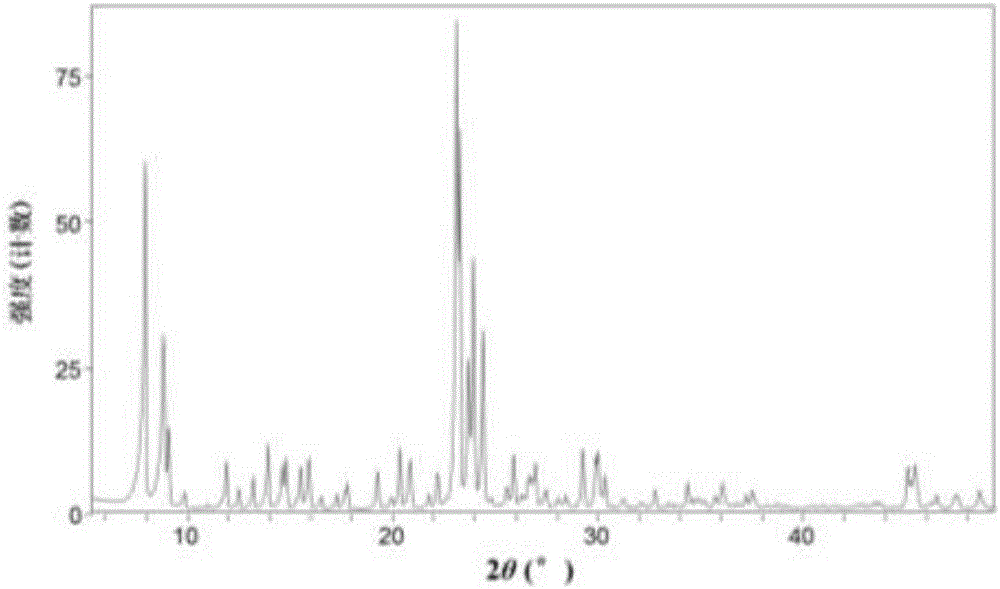

Method for preparing sodalite and ZSM-5 molecular sieve from fly ash acid process aluminum extraction residue and fly ash utilization method

ActiveCN106587099AEffective consumptionPromote resource utilizationPentasil aluminosilicate zeoliteAluminium oxides/hydroxidesDissolution reactionFly ash

The invention relates to the field of fly ash acid process aluminum extraction residue or fly ash utilization, and discloses a method for preparing sodalite and a ZSM-5 molecular sieve from fly ash acid process aluminum extraction residue and a fly ash utilization method. The method comprises the following steps of (1) performing alkaline process roasting on the fly ash acid process aluminum extraction residue to obtain roasting residue materials; (2) performing high-temperature water soaking dissolution reaction on the roasting residue materials to obtain a water soaking product; (3) preparing the water soaking product into sodalite synthesis mother liquid, and performing sodalite hydrothermal crystallization on the sodalite synthesis mother liquid to obtain sodalite powder and first filter liquid; and (4) performing ZSM-5 molecular sieve hydrothermal crystallization on the first filter liquid to obtain the ZSM-5 molecular sieve and second filter liquid. The goals of utilizing the fly ash acid process aluminum extraction residue, improving the utilization rate of the fly ash acid process aluminum extraction residue and utilizing the fly ash are achieved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

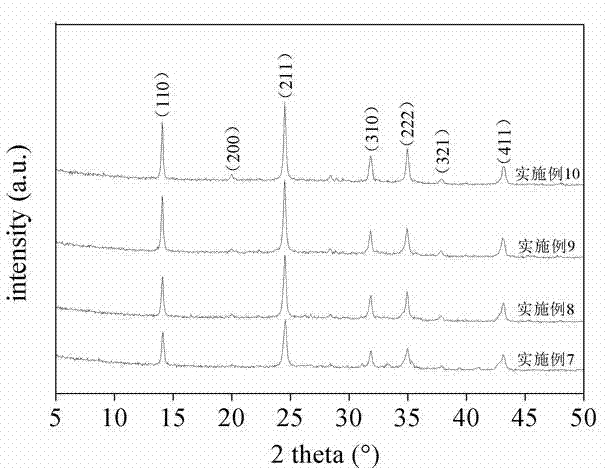

Sodalite synthesis method by adopting bentonite through one-step alkali dissolution

ActiveCN103626194ASimple processReduce energy consumptionAluminium silicatesSodium BentoniteSynthesis methods

The invention discloses a sodalite synthesis method by adopting bentonite through one-step alkali dissolution. The method comprises the following steps: step one: drying, crushing and grinding raw material bentonite; step two, mixing the raw material bentonite with auxiliaries, wherein the molar ratio of chemical components SiO2 to Al2O3 to Na2O in the mixture is 1.0:(0.4-1.0):(4.5-10); putting the mixture in a reactor with a stirring device, stirring while adding water, and performing reaction under a certain condition; step three, filtering, washing, drying and grinding the reaction product obtained through the step two, so as to obtain the sodalite. According to the invention, the whole synthetic process is completed under the condition of normal pressure and low temperature, the technological process is simplified, and the energy consumption is reduced; the sodalite is not required to be calcined and activated, and is directly activated through alkali dissolution, and the sodium hydroxide used as an alkali solvent is used as reaction raw material for continuous reaction, so that the utilization rate is high.

Owner:SOUTHWEAT UNIV OF SCI & TECH

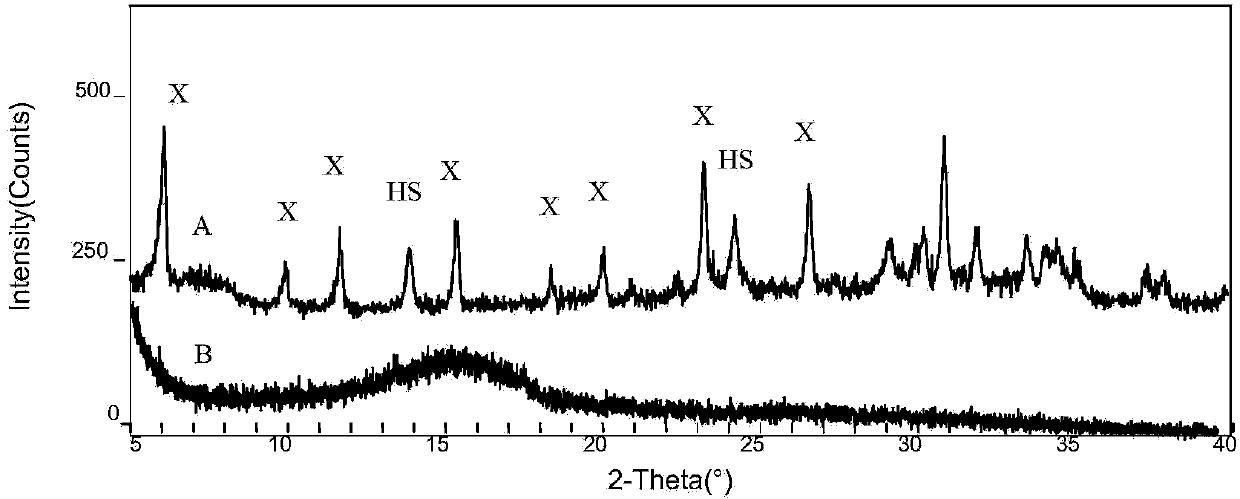

Method for synthesizing Na-X and hydroxysodalite form coal ash filter cake by adopting dry method

InactiveCN103787363AAchieving controllable synthesisHigh purityFaujasite aluminosilicate zeoliteClinker (waste)Process engineering

The invention discloses a method for synthesizing Na-X and hydroxysodalite from a coal ash filter cake by adopting a dry method. The method comprises the steps of preparing a coal ash clinker melt by ash alkaline, then adding water to enable solvends of the coal ash clinker melt by the ash alkaline to be dissolved, adjusting the pH value of the filter cake, and synthesizing zeolite by adopting the dry method. The research shows that different types of zeolite can be prepared by adjusting the pH value of the filter cake and controlling the synthesis time. Two types of zerolite can be synthesized by adopting the method, namely the Na-X and the hydroxysodalite. According to the method, waste coal ash is used, and the zerolite can be synthesized without adding any chemical reagent; the recycling application of the coal ash is realized; the method is a novel method conforming to the green production.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

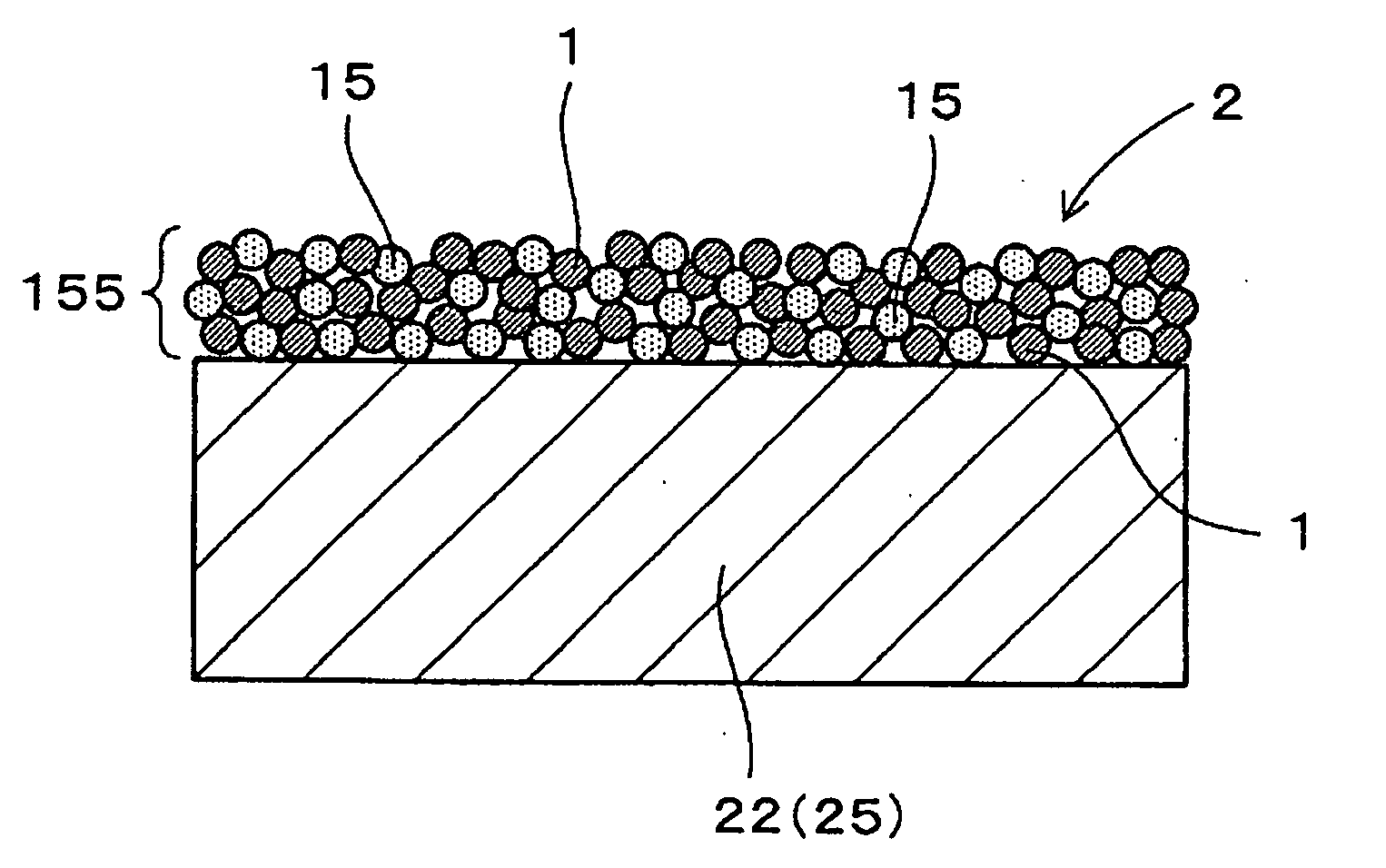

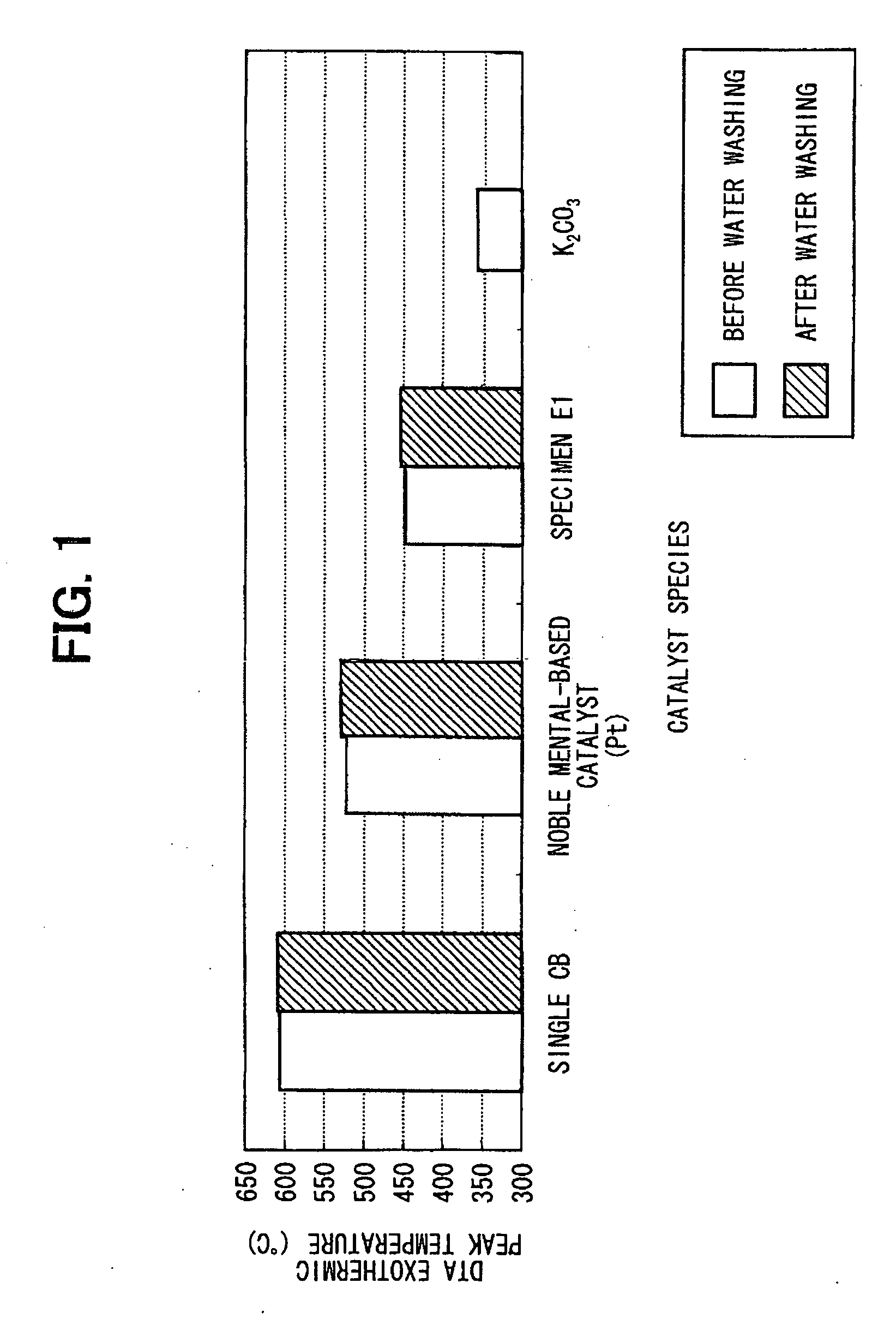

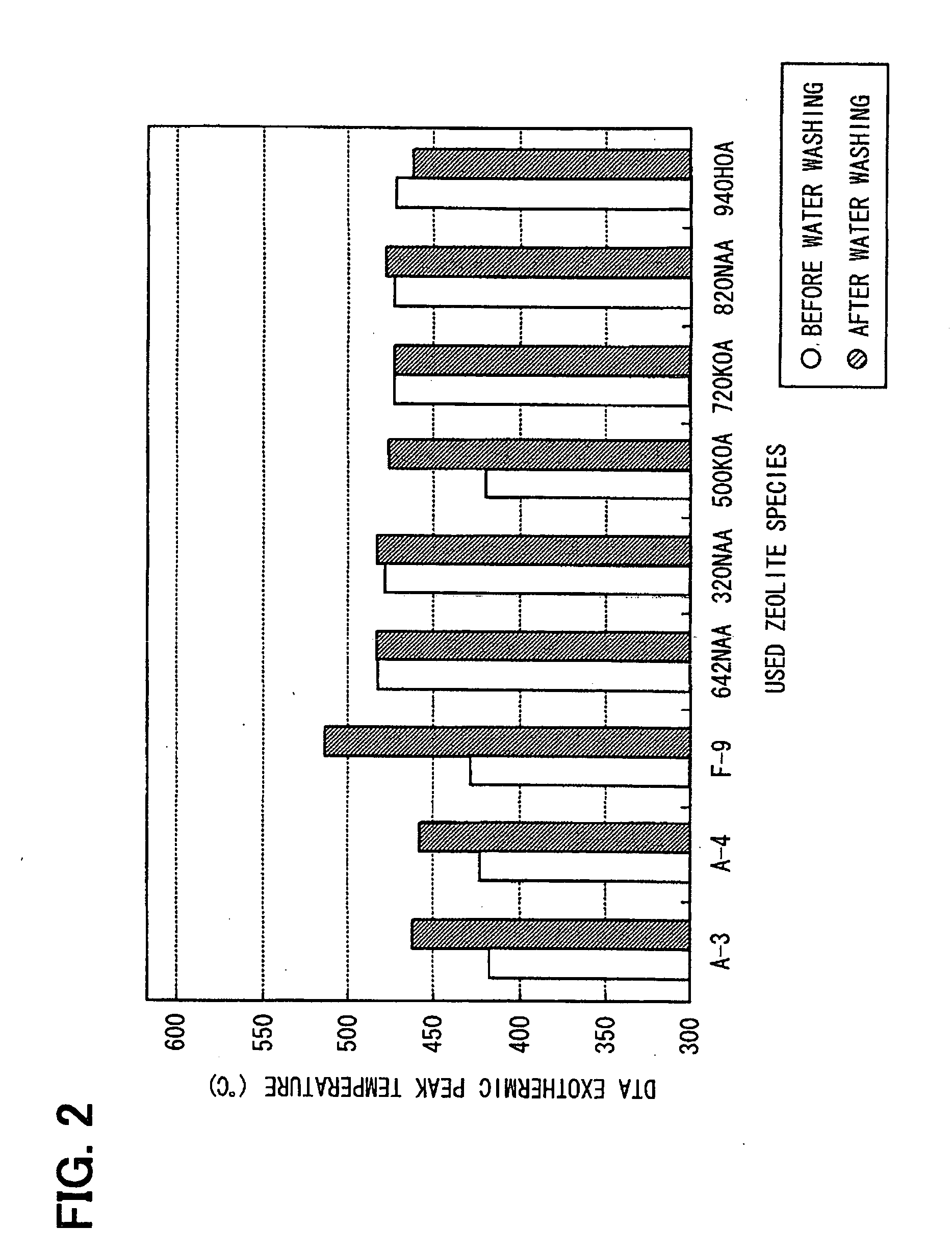

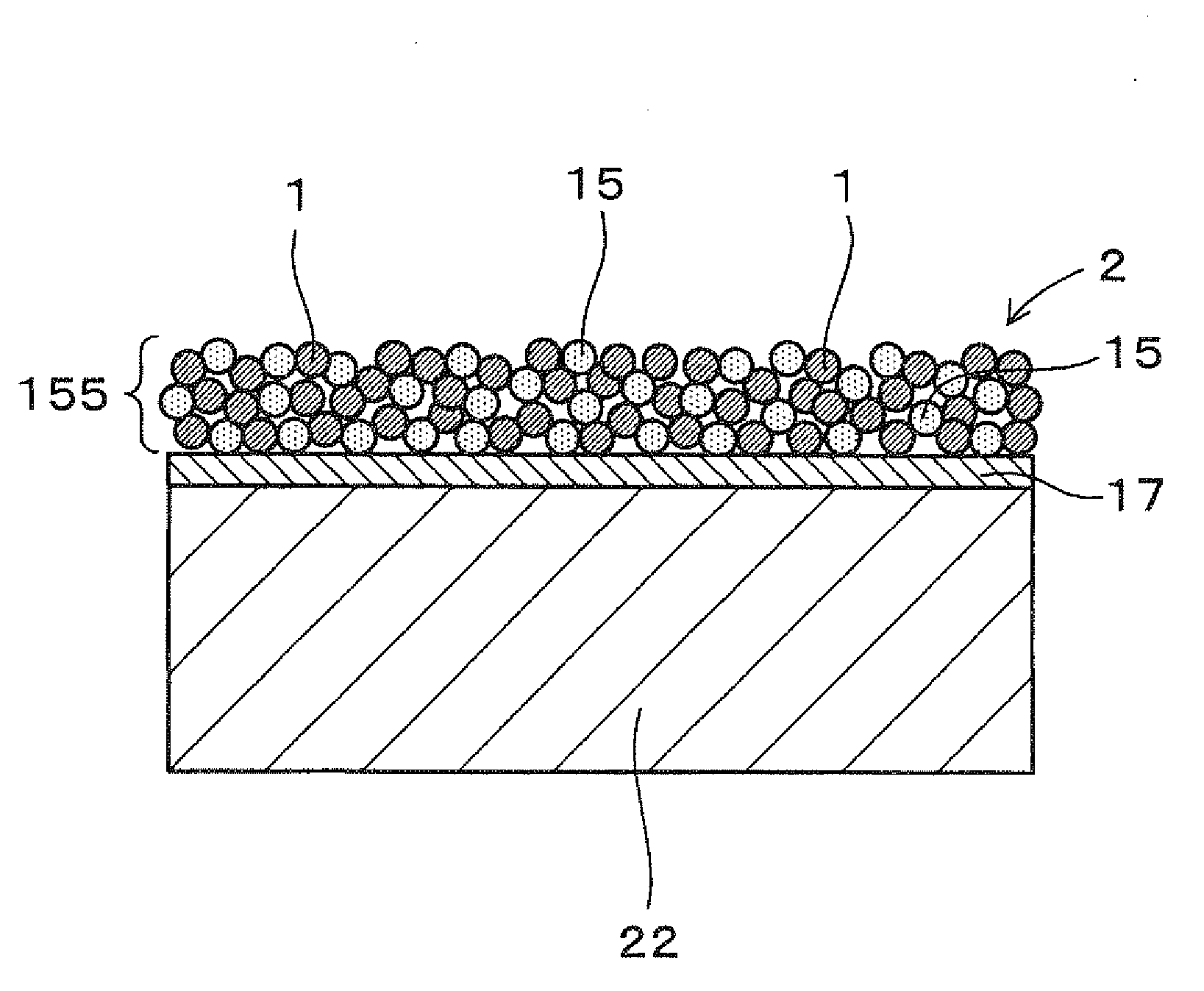

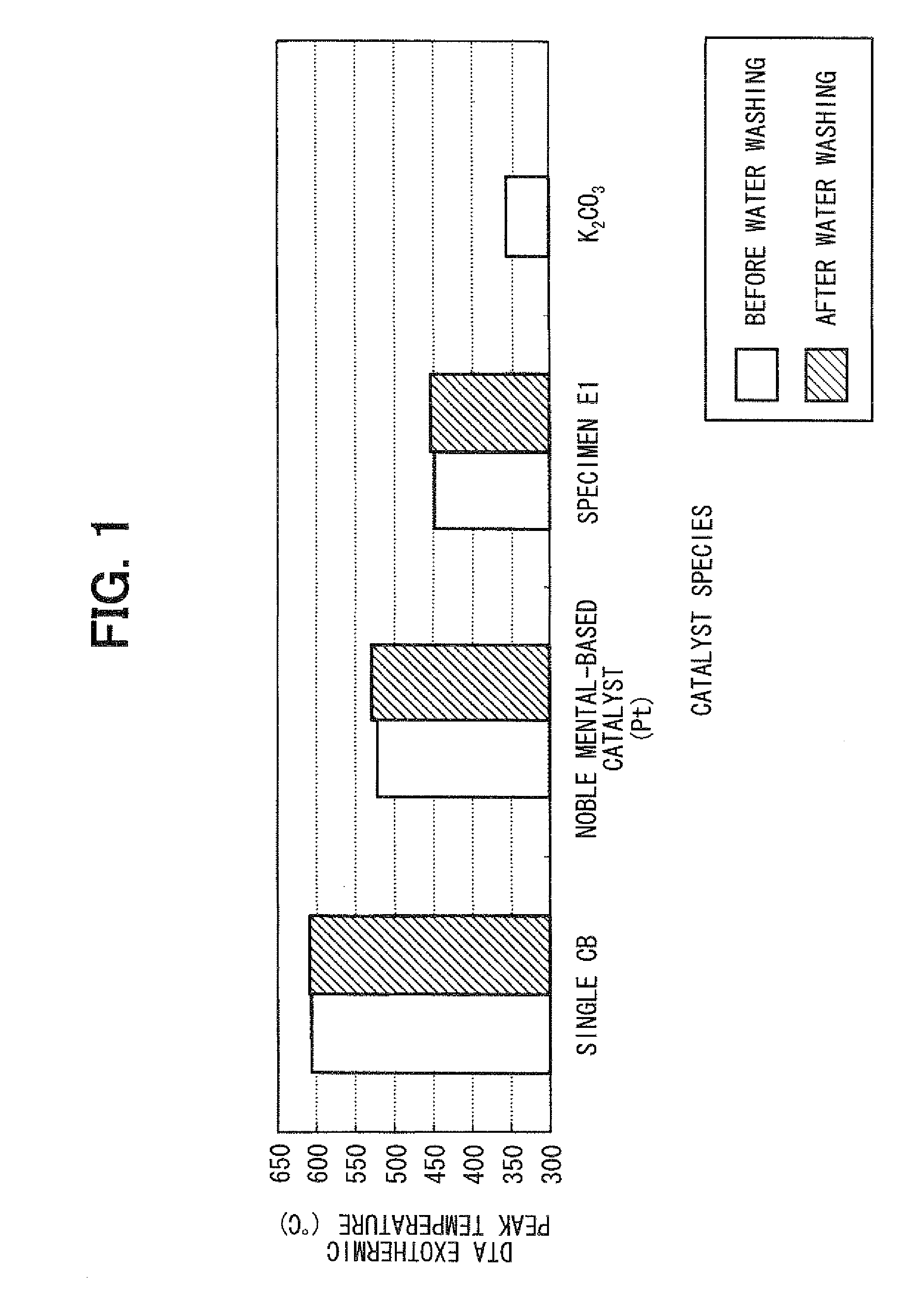

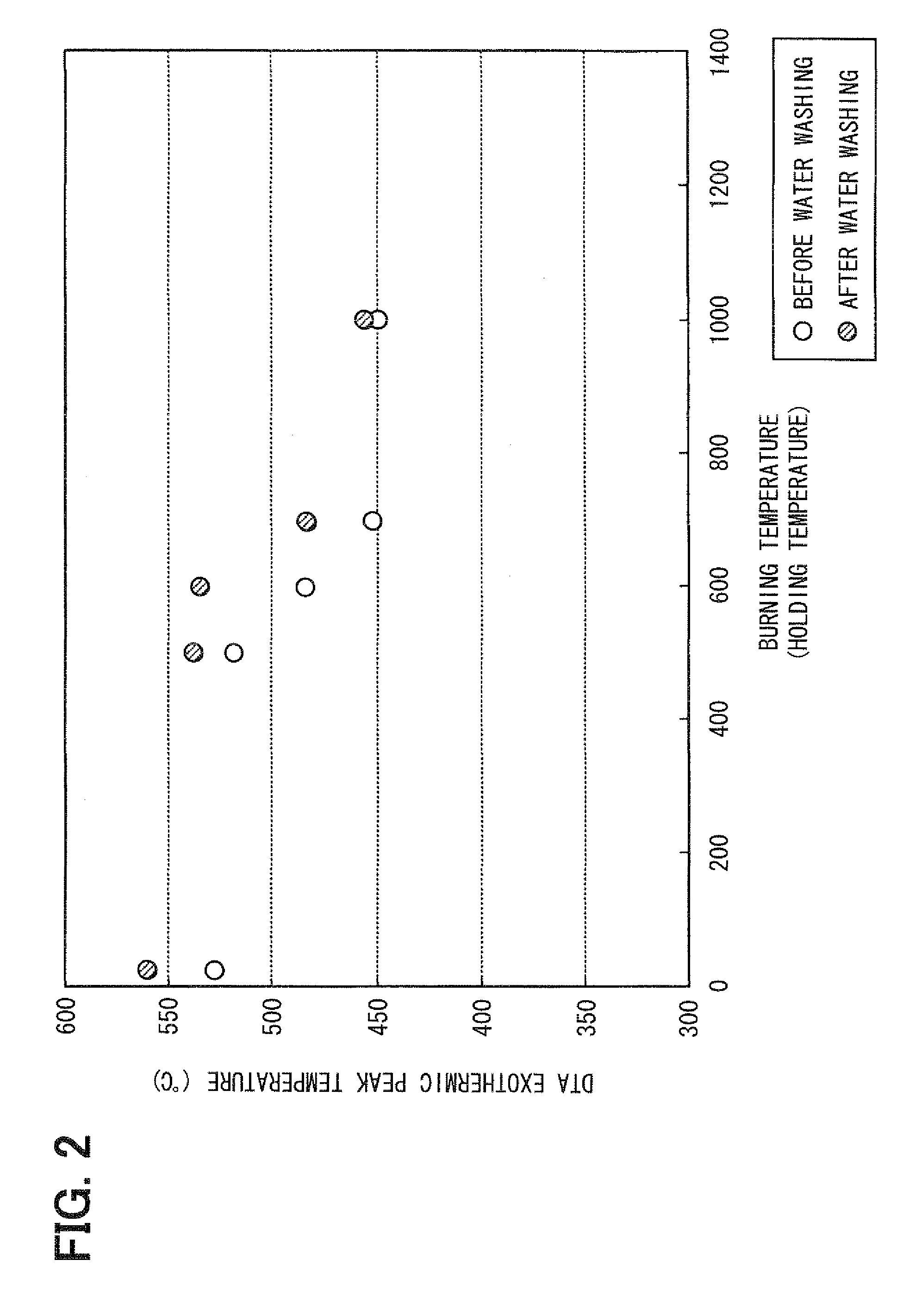

Carbon-based material combustion catalyst, manufacturing method of the same, catalyst carrier, and manufacturing method of the same

InactiveUS20090048093A1Good effectStably burnMolecular sieve catalystsDispersed particle separationAlkaline earth metalCombustion

A carbon-based material combustion catalyst is manufactured by performing a mixing step, a drying step, and a burning step. In the mixing step, zeolite except for sodalite, an alkali metal source, and / or an alkaline earth metal source are mixed in water at a predetermined ratio. In the drying step, a liquid mixture after the mixing step is heated to evaporate the water, thereby obtaining a solid. In the burning step, the solid is burned at a temperature of 600° C. or more. The obtained carbon-based material combustion catalyst causes carbon-based material to be stably burned and removed at a low temperature for a long time.

Owner:NIPPON SOKEN +1

Magnesium modified ultra-stable rare earth y-type molecular sieve and preparation method therefor

ActiveUS20150175432A1Improve activity stabilityReduce coke yieldAluminium compoundsCatalytic crackingMolecular sieveRare earth ions

The present invention provides a magnesium-modified ultra-stable rare earth type Y molecular sieve and the preparation method thereof, which method is carried out by subjecting a NaY molecular sieve as the raw material to a rare earth exchange and a dispersing pre-exchange, then to an ultra-stabilization calcination treatment, and finally to a magnesium modification. The molecular sieve comprises 0.2 to 5% by weight of magnesium oxide, 1 to 20% by weight of rare earth oxide, and not more than 1.2% by weight of sodium oxide, and has a crystallinity of 46 to 63%, and a lattice parameter of 2.454 nm to 2.471 nm. In contrast to the prior art, in the molecular sieve prepared by this method, rare earth ions are located in sodalite cages, which is demonstrated by the fact that no rare earth ion is lost during the reverse exchange process. Moreover, the molecular sieve prepared by such a method has a molecular particle size D(v,0.5) of not more than 3.0 μm and a D(v,0.9) of not more than 20 μm. Such a molecular sieve has both high stability and high selectivity for the target product, while cracking catalysts using the molecular sieve as an active component is characterized by a high heavy-oil-conversion capacity and a high yield of valuable target products.

Owner:PETROCHINA CO LTD

Chemical reaction and separation method

The invention is directed to process for performing a chemical reaction in a reaction mixture, which reaction produces water as by-product, wherein the reaction mixture is in contact with a hydroxy sodalite membrane, through which water produced during the reaction is removed from the reaction mixture, to a process for removing water form mixtures thereof.

Owner:TECH UNIV DELFT

Closestool high in strength and low in weight and preparation method thereof

The invention relates to a closestool high in strength and low in weight and a preparation method thereof. A green body of the closestool comprises 24-29 parts of illite, 12-16 parts of potassium feldspar, 18-23 parts of montmorillonite, 20-28 parts of clay, 13-15 parts of sodalite, 7-11 parts of rutile, 21-27 parts of halloysite, 17-20 parts of allophane, 5-7 parts of barium carbonate, 2-4 parts of johnstonotite, 9-13 parts of calcined kieselguhr, 5-9 parts of glauconite, 6-10 parts of rectorite and 1-3 parts of addition agents; Glaze materials are composed of 6-13 parts of feldspar, 7-12 parts of kaolin, 3-9 parts of germanite, 12-17 parts of vermiculite, 11-15 parts of talcum, 4-8 parts of tourmaline powder and 3-5 parts of nano-silver-powder. The closestool high in strength and low in weight is low in weight, high in strength, low in water absorption and capable of releasing anions and resisting against bacteria.

Owner:广东澳丽泰陶瓷实业有限公司

Preparation method of sodalite zeolite membrane

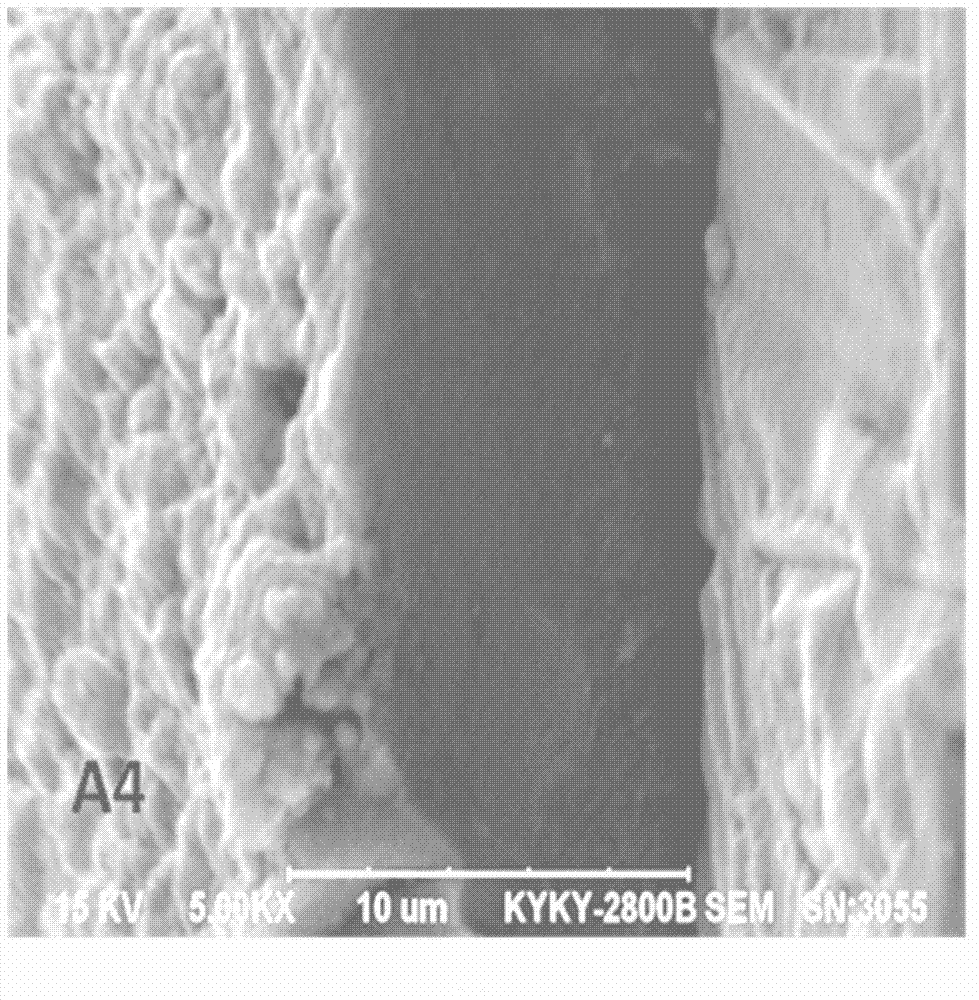

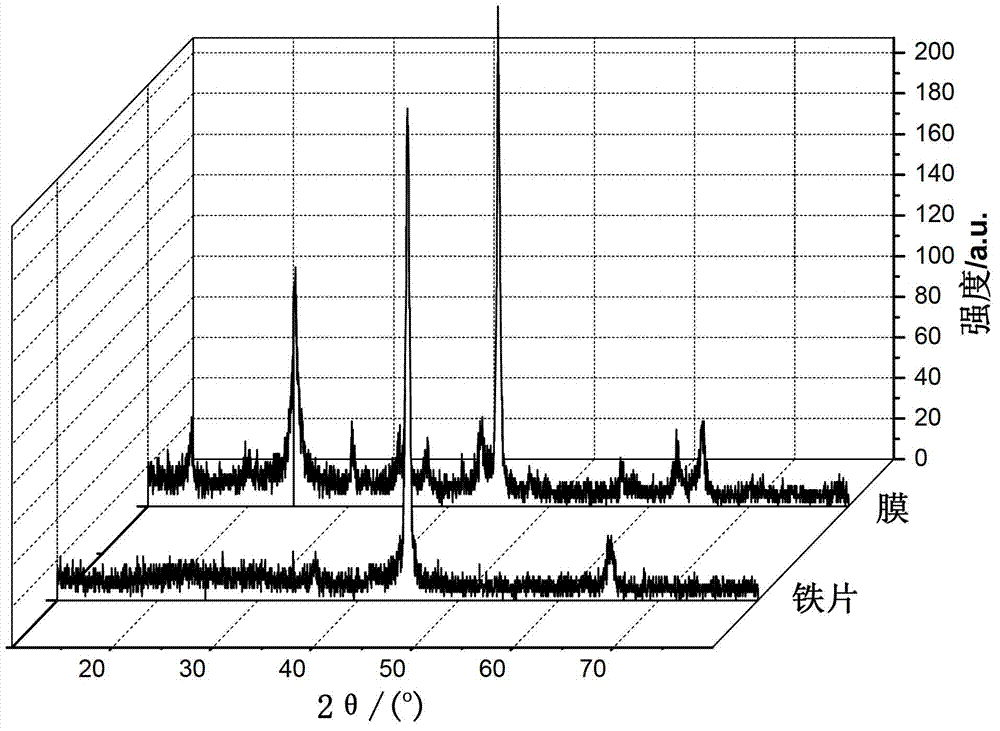

InactiveCN102817031AHigh crystallinityGood microwave absorptionMetallic material coating processesMicrowaveCrystallization temperature

The invention provides a method for preparing a sodalite zeolite membrane, specifically comprising the following steps of: preparing a liquid precursor for membrane formation according to the mol ratio of SiO2: (0.65-1)Al2O3: (0.25-0.5)K2O: (0.02-0.35)Na2O: (42-75)H2O: (5-11)[emim]Br; vertically putting a metal base material which is prepared beforehand into the crystallization liquid precursor; and synthesizing the sodalite zeolite membrane in a microwave reactor at the crystallization temperature of 50-90 DEG C for the crystallization time of 60-150 min. The benefit of the invention is that the continuous compact sodalite zeolite membrane is synthesized under the microwave ionothermal condition. The method is carried out in an open system, and the membrane formation process and the materials are both green and environmentally friendly. The synthetic membrane is resistant to high temperature, acid-base corrosion and bioerosion, and has a good application prospect in the aspect of metal anticorrosion.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Process for making tile with natural jade effect

The invention relates to a process for making tile with natural jade effect which comprises, (1) weighing low-temperature sand, low temperature sodalite, rinsed black clay by a predetermined proportion, ball grinding with water for 11-13 hours, thus obtaining qualified semitransparent clay mortar, (2) drying the semitransparent clay mortar with atomizing tower so as to prepared semitransparent material, loading into work bin for later use. The prepared ceramic brick has the effect of natural jade.

Owner:叶荣崧 +1

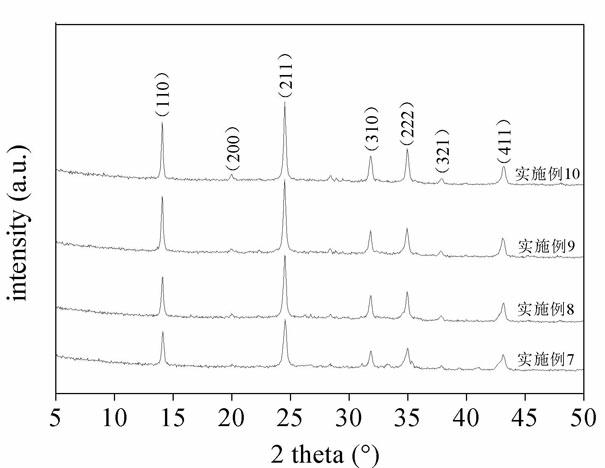

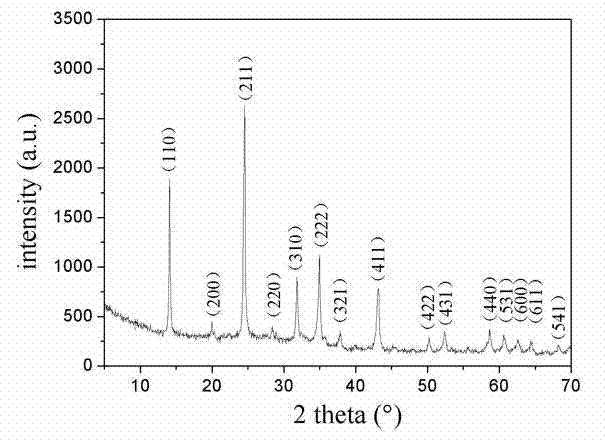

Method for synthesizing SOD type sodalite in low-temperature controllable manner

The invention relates to a method for synthesizing SOD type sodalite in a low-temperature controllable manner. The method comprises the following steps: 1) preparing a mixed solution, namely, dissolving strong alkali into deionized water at normal temperature, adding an aluminum salt and a silicon source, and uniformly stirring, thereby obtaining the mixed solution; and 2) synthesizing the SOD type sodalite, namely, under the stirring condition, adding a clay mineral into the mixed solution, stirring for 0.5-4 hours so as to obtain a mixture, sealing the obtained mixture in a hydrothermal reaction kettle for hydrothermal reaction for 12-26 hours at 60-120 DEG C, or adding the obtained mixture into a backflow reaction device to carry out stirring backflow reaction for 18-36 hours at 80-150 DEG C, and performing aftertreatment, thereby obtaining the SOD type sodalite. The method is free of organic additive, short in synthesis time, convenient in rapid and large-scale production, simple in synthesis step, easily available in raw materials, low in production cost and good in production crystallinity degree.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Ultra-stable rare earth y-type molecular sieve and preparation method therefor

ActiveUS20150151284A1Improve activity stabilityReduce coke yieldAluminium compoundsCatalytic crackingMolecular sieveActive component

The present invention provides an ultra-stable rare earth type Y molecular sieve and the preparation method thereof, which method is carried out by subjecting a NaY molecular sieve as the raw material to a rare earth exchange and a dispersing pre-exchange, then to an ultra-stabilization calcination treatment. The molecular sieve comprises 1 to 20% by weight of rare earth oxide, not more than 1.2% by weight of sodium oxide, has a crystallinity of 51 to 69%, and a lattice parameter of 2.451 nm to 2.469 nm. In contrast to the prior art, in the molecular sieve prepared by this method, rare earth ions are located in sodalite cages, which is demonstrated by the fact that no rare earth ion is lost during the reverse exchange process. Moreover, the molecular sieve prepared by such a method has a molecular particle size D(v,0.5) of not more than 3.0 μm and a D(v,0.9) of not more than 20 μm. Cracking catalysts using the molecular sieve as an active component is characterized by a high heavy-oil-conversion capacity and a high yield of valuable target products.

Owner:PETROCHINA CO LTD

Carbon-based material combustion catalyst, manufacturing method of the same, catalyst carrier, and manufacturing method of the same

InactiveUS20090203517A1Good effectStably burnedCatalyst carriersGas treatmentCombustionAlkaline earth metal

A carbon-based combustion catalyst is obtained by performing a burning step of burning sodalite at a temperature of 600° C. or more. Alternatively, a carbon-based combustion catalyst is obtained by performing the following mixing step, drying step, and burning step. In the mixing step, aluminosilicate (sodalite), and an alkali metal source, and / or an alkaline earth metal source are mixed in water to obtain a liquid mixture. In the drying step, the liquid mixture is heated to evaporate the water thereby obtaining a solid. In the burning step, the solid is burned at a temperature of 600° C. or more. The thus-obtained catalyst can cause carbon-based material to be stably burned and removed at a low temperature for a long time.

Owner:DENSO CORP +1

Red porcelain and method for producing same

A red porcelain consists of the following materials in weight percent: 70-80% of red porcelain, 8-15% of viscose kaolin, 10-20% of big washed-out sand and 2-10% of sodalite. Compared with the prior art, the red porcelain is added with sodalite mineral specially, a porcelain product can naturally form smooth glaze through synthesizing, glaze does not needs to be additional mixed for carrying out a glazing process, thus, production processes are reduced, and moreover, the product is easy to clean and is safe and non-toxic; and a finished product is formed at one time, and the energy consumption is small.

Owner:陈廷重

Process for preparing hydrogen storage sodalite composite material

InactiveCN101503196AHigh degree of industrializationEasy to synthesizeAluminium silicatesAlkali metal silicatesFiltrationIon exchange

The invention discloses a method for preparing hydrogen storage sodalite composite material, belonging to the field of producing and preparing inorganic functional material. The method is characterized in that dried sodalite material is ground, is screened by 100-mesh sieve for separation and then added with transition metal ion water solution; after that, the material which is processed by ion exchange is obtained by ion exchange, suction filtration and drying at the constant temperature is obtained. The obtained material is deacidized under reducing atmosphere, and the sodalite composite material having higher adsorbance for hydrogen under the normal pressure can be obtain after procedure temperature reduction. The method has the advantages that the sodalite composite material having more hydrogen storage quantity under the normal pressure can be prepared; no detrimental impurity and waste emission can be caused in the whole preparation process; the method has remarkable advantages on preparation cost, production performance, process flow, environment-friendly property, economic profit and the like; the raw material is high in industrialization degree, low in cost, simple and convenient in synthesis, low in facility requirement, high in product performance and applicable to commercial process.

Owner:DALIAN UNIV OF TECH

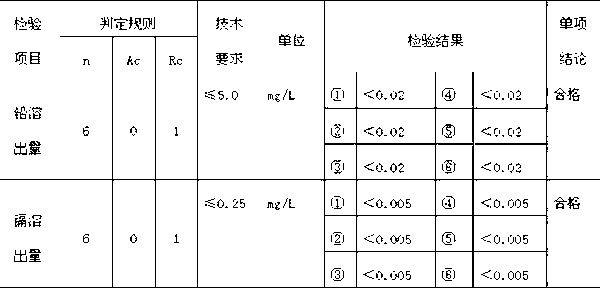

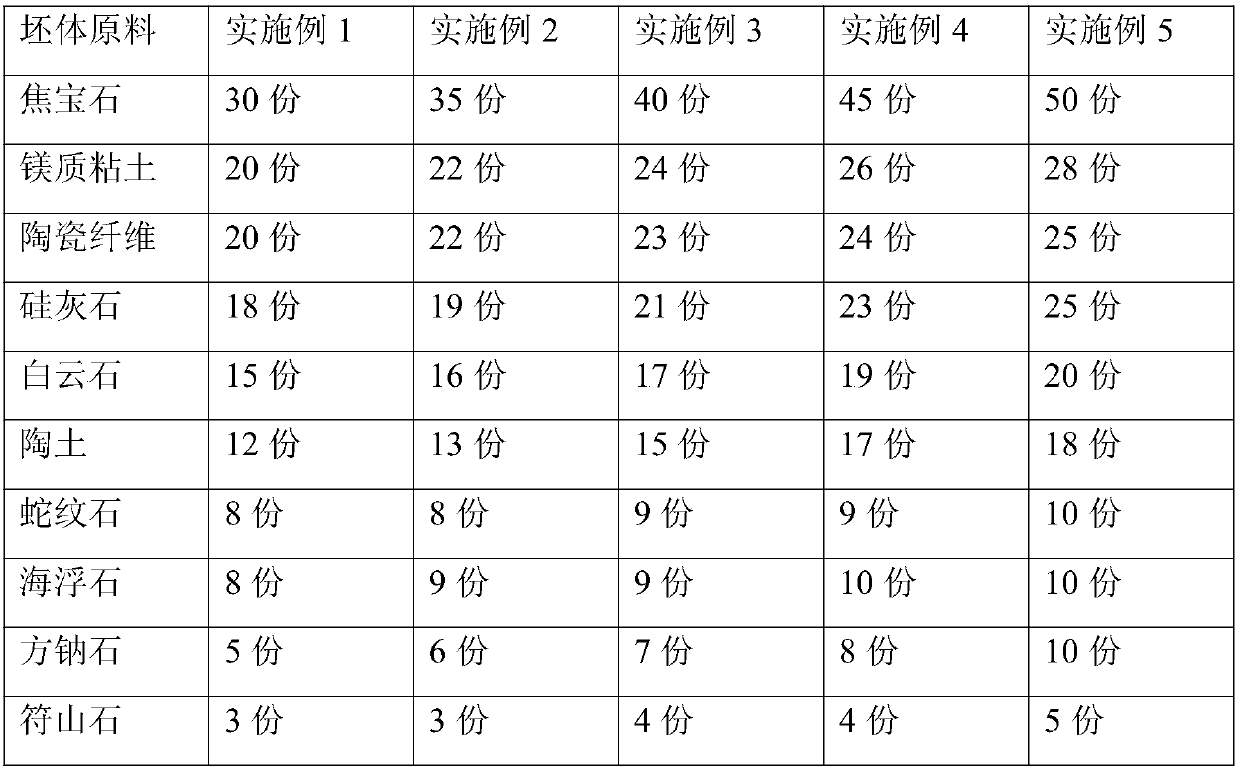

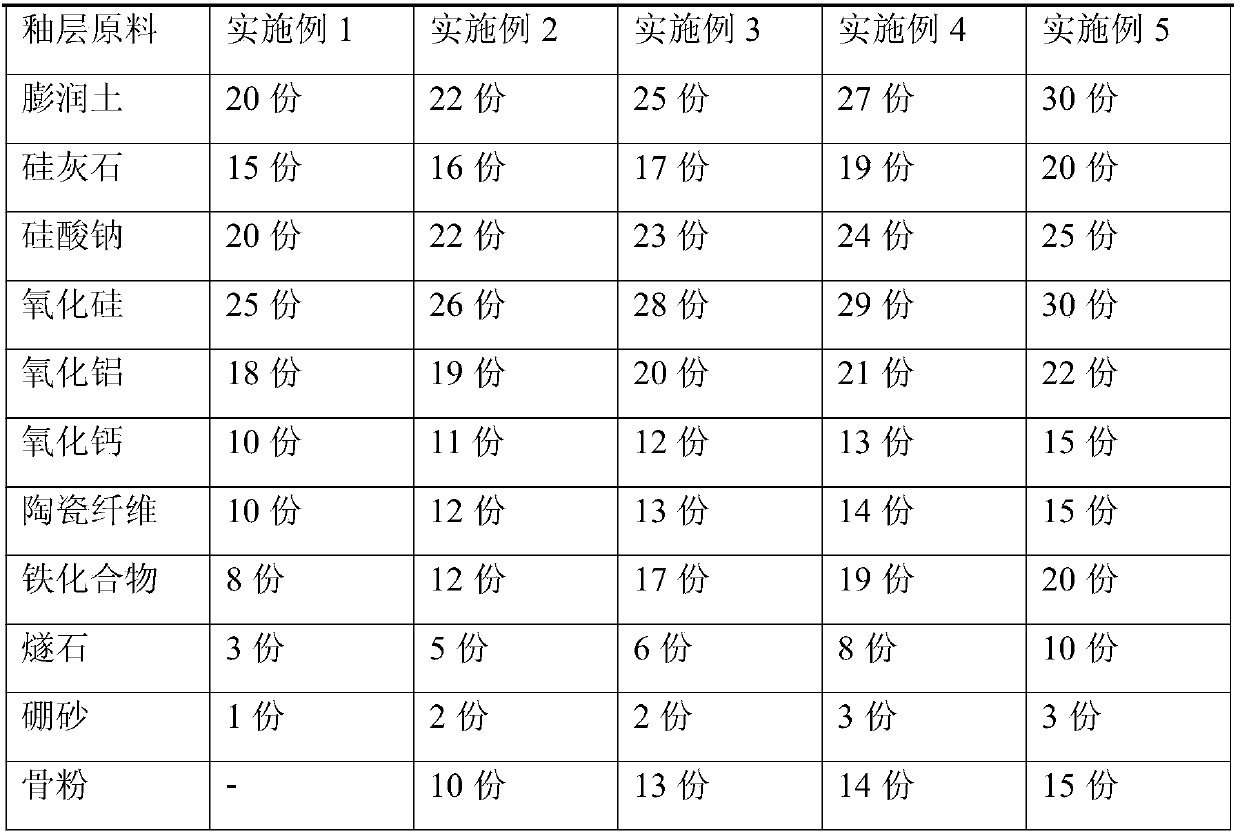

Quick burnt iron series crystal ceramic tableware and preparation technology thereof

The invention provides a quick burnt iron series crystal ceramic tableware which comprises a blank body and an enamel coating applied to the tank body; the blank body is prepared from the following raw materials: flint clay, magnesium clay, ceramic fiber, wollastonite, dolomite, pottery clay, serpentine, bryozoatum, sodalite and idocrase; the enamel coating is prepared from the following raw materials: bentonite, wollastonite, sodium silicate, silicon oxide, aluminum oxide, calcium oxide, ceramic fiber, iron compound, flint and borax. The quick burnt iron series crystal ceramic tableware provided by the invention has the advantages of smooth and bright appearance, mold and smooth hand feel, tough texture, high strength, high water resistance, excellent weather resistance, slow heat conduction and being durable in use.

Owner:FUJIAN DEHUA FIVE CONTINENTS CERAMIC MFG CO LTD

Process for synthesizing single-phase sodalite from fly ash

ActiveCN102173433BSolve the reuse problemExpand sourceSolid waste disposalCrystalline aluminosilicate zeolitesFly ashPollution

The invention belongs to the field of production and preparation of inorganic functional materials, and particularly relates to a process for preparing single-phase sodalite from fly ash, which comprises the following steps: pretreating fly ash by an alkaline fusion method; proportionally adding the activated fly ash, aluminum hydroxide and sodium hydroxide solution into a polytetrafluoroethyleneinner container, evenly mixing, and carrying out hydrothermal crystallization in a sealed constant-temperature drying oven; and finally, filtering the product, washing until the product becomes neutral, and drying to obtain the single-phase sodalite material. The invention successfully synthesizes the low-cost single-phase sodalite zeolitization material by using solid waste-fly ash as the raw material for production. The process has the advantages of low cost, abundant sources of raw material, controllable product performance, no secondary pollution and the like, is simple and easy to operate, and thus, has great industrial application potential.

Owner:NANJING UNIV OF SCI & TECH

Sodalite zeolite synthesized from fly ash and method

The invention discloses a sodalite zeolite synthesized by fly ash and a synthesis method thereof. The method comprises the following steps: mixing fly ash with clean water, stirring and washing until the upper part of the solution is no longer turbid; then filtering; drying at a temperature of 100 to 105 DEG C until the weight does not change; putting the processed fly ash into high-pressure reaction equipment, adding NaOH solution with a concentration of 4 mol / L according to the mass of the processed fly ash, heating to a default effective temperature of 121 DEG C for carrying out dampness-heat reactions in the high-pressure reaction equipment, wherein the pressure reaches 147 kPa; cooling the reaction product, filtering, and drying so as to obtain sodalite zeolite, wherein the product is ball-shaped particles in glassy state, contains single hydroxyl sodalite zeolite, and the diffraction angles of the powder diffraction characteristic peaks are 14.08 degrees, 24.50 degrees, 31.80 degrees, 34.92 degrees, and 43.14 degrees. The sodalite zeolite is used to eliminate ammonia nitrogen in wastewater; the maximum ammonia absorption amount is 11.0477 mg / g, so that the effect is prominent.

Owner:TIANJIN UNIV

Magnesium modified ultra-stable rare earth Y-type molecular sieve and preparation method therefor

ActiveUS9840422B2High selectivityReduce yieldCatalytic crackingMolecular sieve catalystsMolecular sieveRare earth ions

The present invention provides a magnesium-modified ultra-stable rare earth type Y molecular sieve and the preparation method thereof, which method is carried out by subjecting a NaY molecular sieve as the raw material to a rare earth exchange and a dispersing pre-exchange, then to an ultra-stabilization calcination treatment, and finally to a magnesium modification. The molecular sieve comprises 0.2 to 5% by weight of magnesium oxide, 1 to 20% by weight of rare earth oxide, and not more than 1.2% by weight of sodium oxide, and has a crystallinity of 46 to 63%, and a lattice parameter of 2.454 nm to 2.471 nm. In contrast to the prior art, in the molecular sieve prepared by this method, rare earth ions are located in sodalite cages, which is demonstrated by the fact that no rare earth ion is lost during the reverse exchange process. Moreover, the molecular sieve prepared by such a method has a molecular particle size D(v,0.5) of not more than 3.0 μm and a D(v,0.9) of not more than 20 μm. Such a molecular sieve has both high stability and high selectivity for the target product, while cracking catalysts using the molecular sieve as an active component is characterized by a high heavy-oil-conversion capacity and a high yield of valuable target products.

Owner:PETROCHINA CO LTD

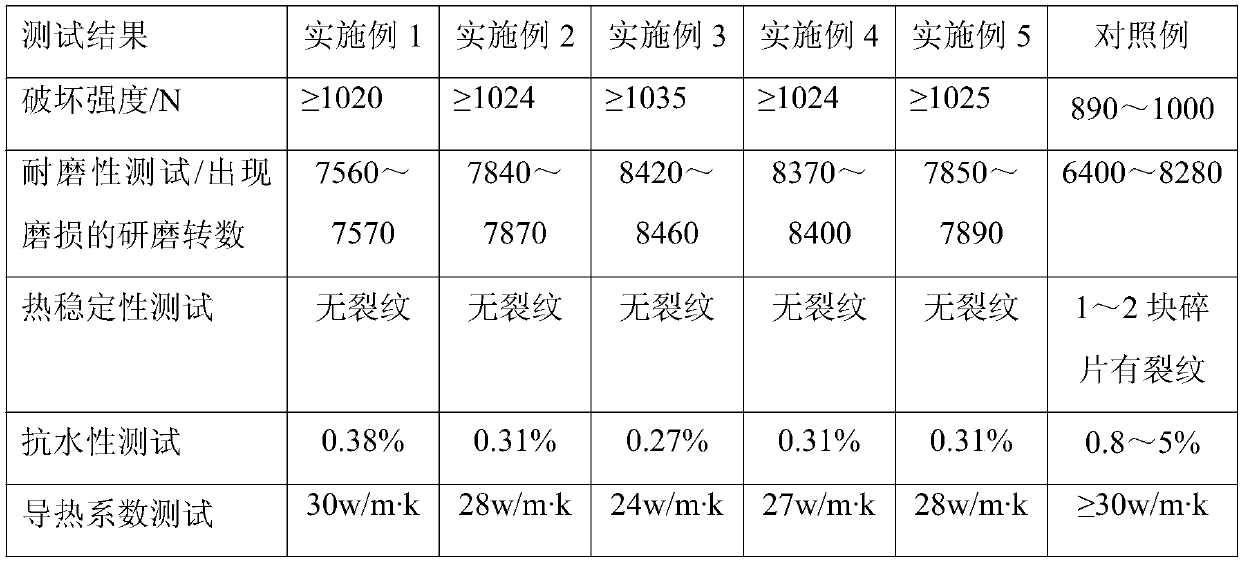

Unbreakable ceramic product and manufacturing method thereof

The invention discloses an unbreakable ceramic product and a manufacturing method thereof. The unbreakable ceramic product is prepared from, by weight, 16-20 parts of sodalite, 10-20 parts of boric acid soil, 50-60 parts of kaolin, 12-18 parts of zirconium dioxide, 8-10 parts of zircon sand, 5-8 parts of fused magnesite, 10-15 parts of aluminum oxide, 15-21 parts of polyimide resin powder, 20-25 parts of nacre powder, 10-15 parts of negative ion powder and 3-5 parts of auxiliaries. The auxiliaries are composed of polyvinyl alcohol, methylcellulose, polyethylene glycol and polyacrylamide. The scientific raw material formula is adopted, the raw materials are gathered into a layered structure in the manufacturing process, cracks are not prone to expanding in the layered material, the ceramic finished product is high in strength and resistant to shock and breaking, cohesiveness among particles is high, and ceramic breakage is reduced.

Owner:DEYI CULTURAL & CREATIVE GRP CO LTD

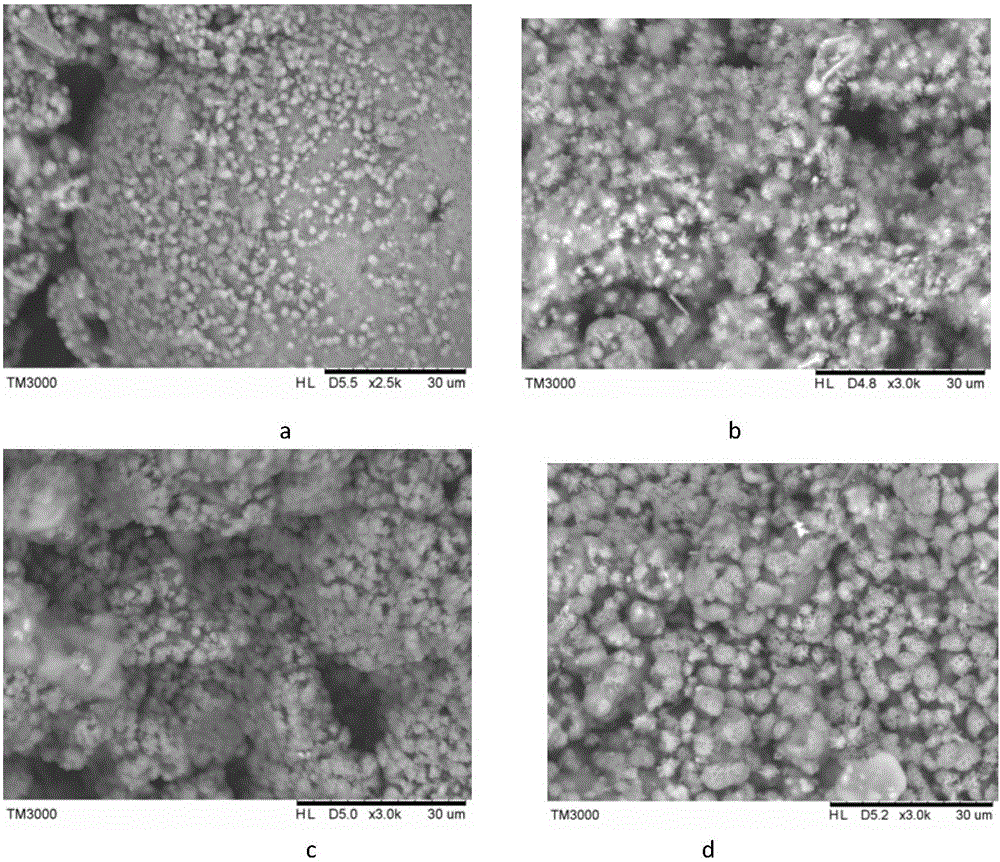

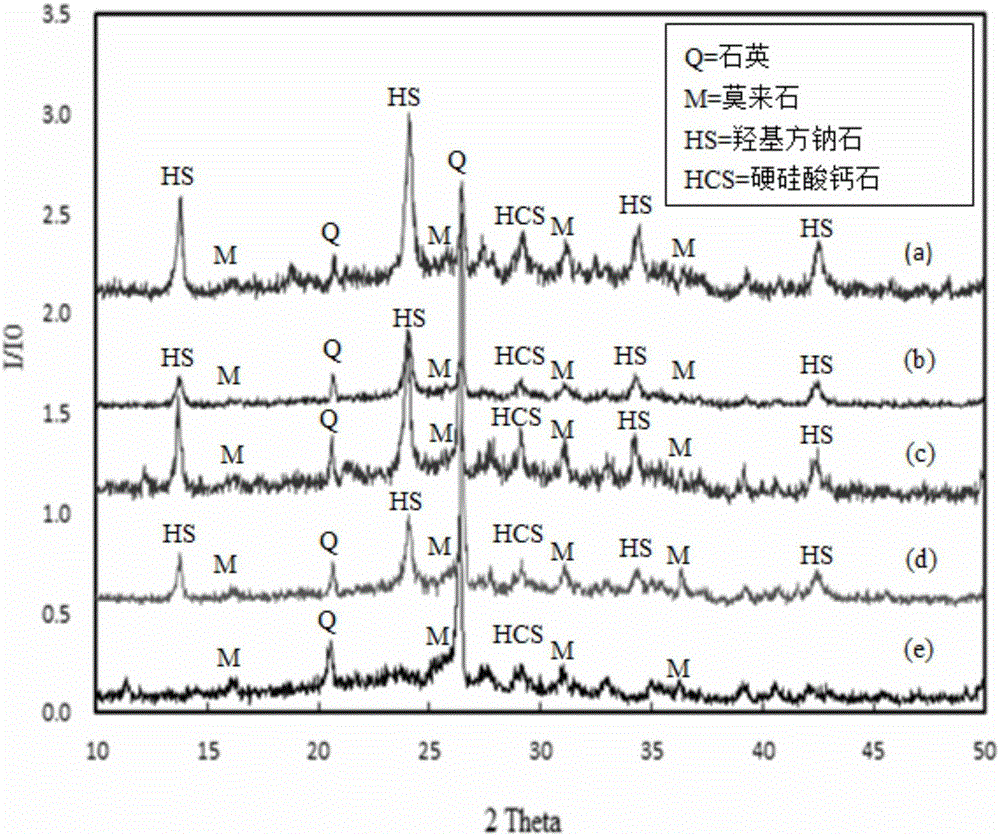

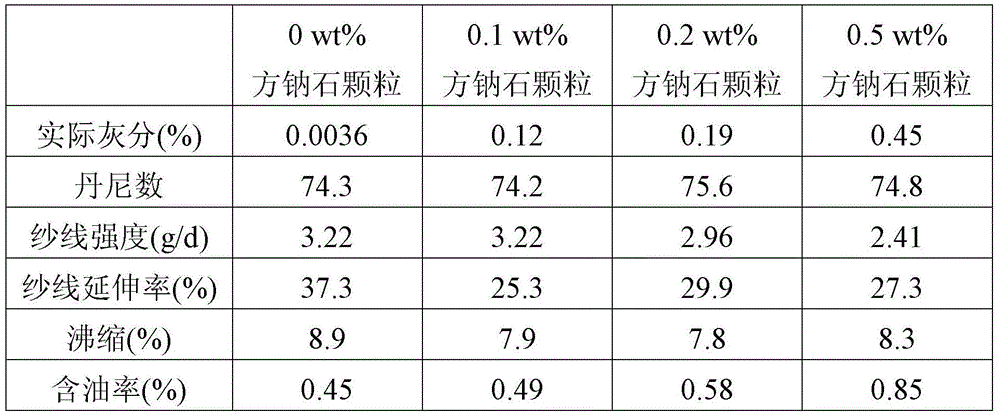

Composition containing sodalite and polyester composite

ActiveCN105273171AEvenly dispersedThe preparation process is simple and controllableAlcoholCarboxylic acid

The invention provides a composition containing sodalite. The composition comprises 55 to 98.5 wt% of dihydric alcohol, polybasic carboxylic acid and 0.5 to 20 wt% of sodalite particles with an average particle size of 10 to 300 nm, wherein a weight ratio of the sodalite particles to polybasic carboxylic acid is in a range of 0.2-3: 1. The invention also provides a polyester composite. A precursor of the polyester composite comprises the composition containing sodalite, precursor dihydric alcohol and precursor dicarboxylic acid, wherein the sum of the mole number of the precursor dihydric alcohol and the mole number of the dihydric alcohol in the composition containing sodalite is a first mole number, the sum of the mole number of the precursor dicarboxylic acid and the mole number of the polybasic carboxylic acid in the composition containing sodalite is a second mole number, a ratio of the first mole number to the second mole number is in a range of 1-1.5: 1, and the sodalite particles accounts for 0.01 to 1 wt% in the polyester composite. The sizes of the sodalite particles are nanometer or almost nanometer, and the sodalite particles can be uniformly dispersed in the dihydric alcohol.

Owner:FENGYANG PRODION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com