Sodalite synthesis method by adopting bentonite through one-step alkali dissolution

A technology of bentonite and sodalite, which is applied in the direction of aluminum silicate and silicate, can solve the problems of complex process and high cost of sodalite preparation, and achieve the effects of simplified process flow, high utilization rate and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

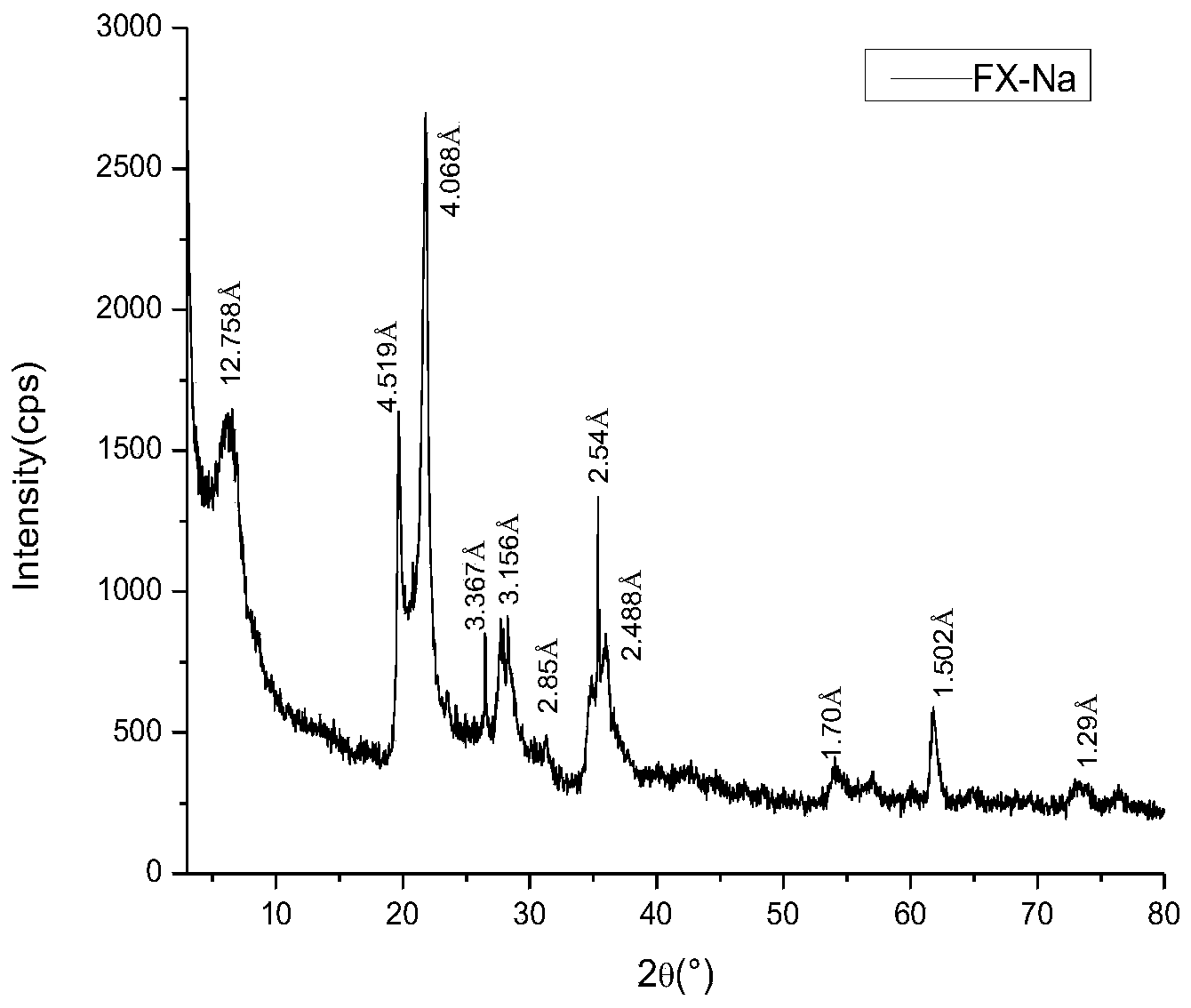

[0040] Embodiment 1: Sodalite is synthesized from sodium bentonite as raw material

[0041] (1) After drying and crushing the sodium-based bentonite raw material, grind it to 100 mesh;

[0042] (2) According to the chemical composition SiO in raw materials and additives after compounding 2 、Al 2 o 3 、Na 2 The molar ratio of O is 1.0:0.33:5.0 Add 10.00Kg sodium bentonite, 61.92Kg sodium hydroxide, 4.54Kg aluminum hydroxide and 350L deionized water, so that the concentration of sodium hydroxide is 3.66mol / L, and put In the reactor of the device, heat from room temperature to 90°C, stir and reflux for 7h, then keep the temperature and age for 17h;

[0043] (3) The product synthesized by the reaction is filtered and washed until the pH is 9, and the desired product is obtained after drying and grinding.

[0044] (4) Mix the filtrate obtained in step (3) with the 1st and 2nd washing water, continue to participate in the reaction, and recycle.

Embodiment 2

[0045] Embodiment 2: Sodalite is synthesized from sodium bentonite as raw material

[0046] Step (1) is identical with embodiment 1;

[0047] (2) According to the chemical composition SiO in raw materials and additives after compounding 2 、Al 2 o 3 、Na 2 The molar ratio of O is 1.0:0.33:10.0 Add 10.00Kg of sodium bentonite, 8.29Kg of sodium metaaluminate and 350L of the filtrate obtained in step (4) of Example 1 or 1 or 2 times of washing water, and add a small amount of sodium hydroxide Make the concentration of sodium hydroxide in the reaction system 7.0mol / L, place it in a reactor with a stirring device, heat it from room temperature to 90°C, stir and reflux for 3h, then keep the temperature and age for 3h;

[0048] Steps (3) and (4) are the same as in Embodiment 1.

Embodiment 3

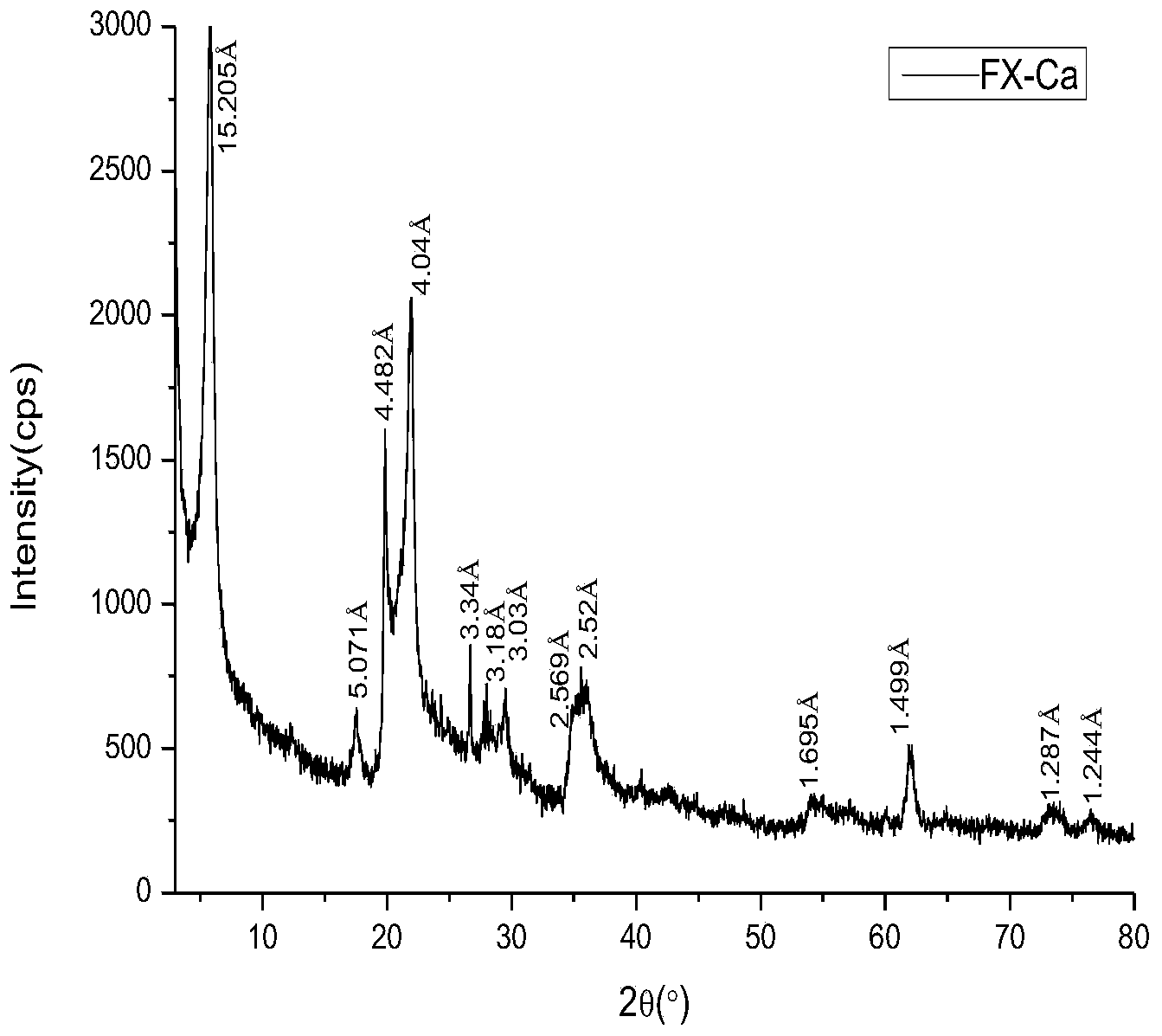

[0049] Embodiment 3: Calcium-based bentonite is a raw material for synthesizing sodalite

[0050] Step (1) is identical with embodiment 1;

[0051] (2) According to the chemical composition SiO in raw materials and additives after compounding 2 、Al 2 o 3 、Na 2 The molar ratio of O is 1.0:0.25:6.0. Add 10.00Kg of calcium-based bentonite, 3.26Kg of aluminum hydroxide and 350L of the filtrate obtained in step (4) of Example 1 or 1 and 2 times of washing water, and add a small amount of sodium hydroxide to make The concentration of sodium hydroxide in the reaction system is 4.45mol / L, and placed in a reactor with a stirring device, heated from room temperature to 95°C, stirred and refluxed for 2 hours, then kept at constant temperature and aged for 9 hours;

[0052] Steps (3) and (4) are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com