Process for synthesizing single-phase sodalite from fly ash

A technology of fly ash and single-phase square, which is applied in the field of production and preparation of inorganic functional materials, to achieve the effect of solving high cost, single component and wide synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Preparation of activated fly ash:

[0026] No. 1 activated fly ash: mix the fly ash and sodium hydroxide according to 1:2 and put it in the muffle furnace, and mix it with 10 o C / min heating rate increased to 600 o C, keep it warm for 4 hours, then cool down to room temperature at the same rate, and get No. 1 activated fly ash after grinding.

[0027] No. 2 activated fly ash: mix the fly ash and sodium hydroxide according to 1:1 and put it in the muffle furnace, and mix it with 5 o C / min heating rate increased to 700 o C, keep warm for 3 hours, then cool down to room temperature at the same rate, and get No. 2 activated fly ash after grinding.

[0028] No. 3 activated fly ash: mix the fly ash and sodium hydroxide according to 3:2 and put them in the muffle furnace, and use 2 o C / min heating rate increased to 800 o C, keep it warm for 2 hours, then cool down to room temperature at the same rate, and get No. 3 activated fly ash after grinding.

Embodiment 1

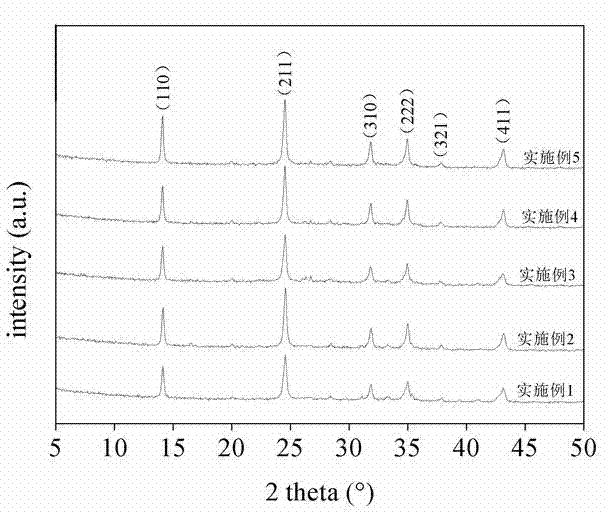

[0030] 4 g of No. 1 activated fly ash, Al(OH) 3 0.4 g and 5 mol / L NaOH 60 mL were sequentially added into the polytetrafluoroethylene liner, mixed evenly, sealed and placed in 100 o C in an electric constant temperature drying oven for 24 h, the crystallized product was repeatedly filtered, washed until neutral, and dried to obtain a single-phase sodalite material. Depend on figure 1 It can be seen that there is only one zeolite phase, sodalite, in the synthesized product, and the crystallinity is relatively high.

Embodiment 2

[0032] 4 g of No. 1 activated fly ash, Al(OH) 3 0.8 g and 5 mol / L NaOH 60 mL were sequentially added into the polytetrafluoroethylene liner, mixed evenly, sealed and placed in 100 o C in an electric constant temperature drying oven for 24 h, the crystallized product was repeatedly filtered, washed until neutral, and dried to obtain a single-phase sodalite material. Depend on figure 1 It can be seen that there is only one zeolite phase, sodalite, in the synthesized product, and the crystallinity is relatively high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com