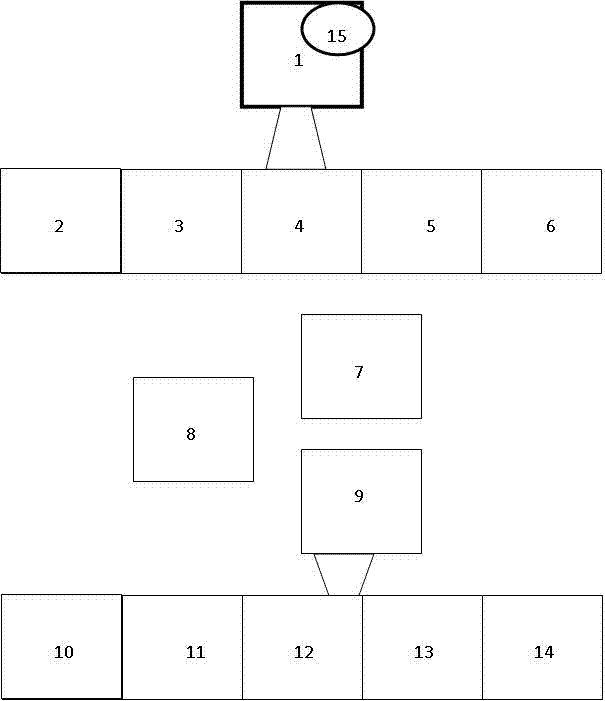

Patents

Literature

45results about How to "Avoid secondary waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

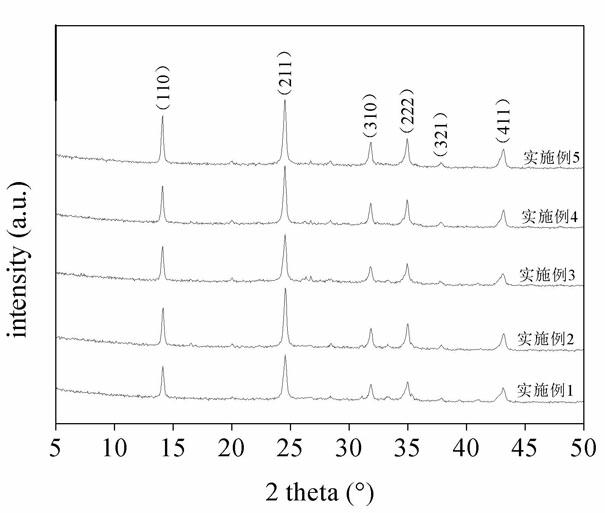

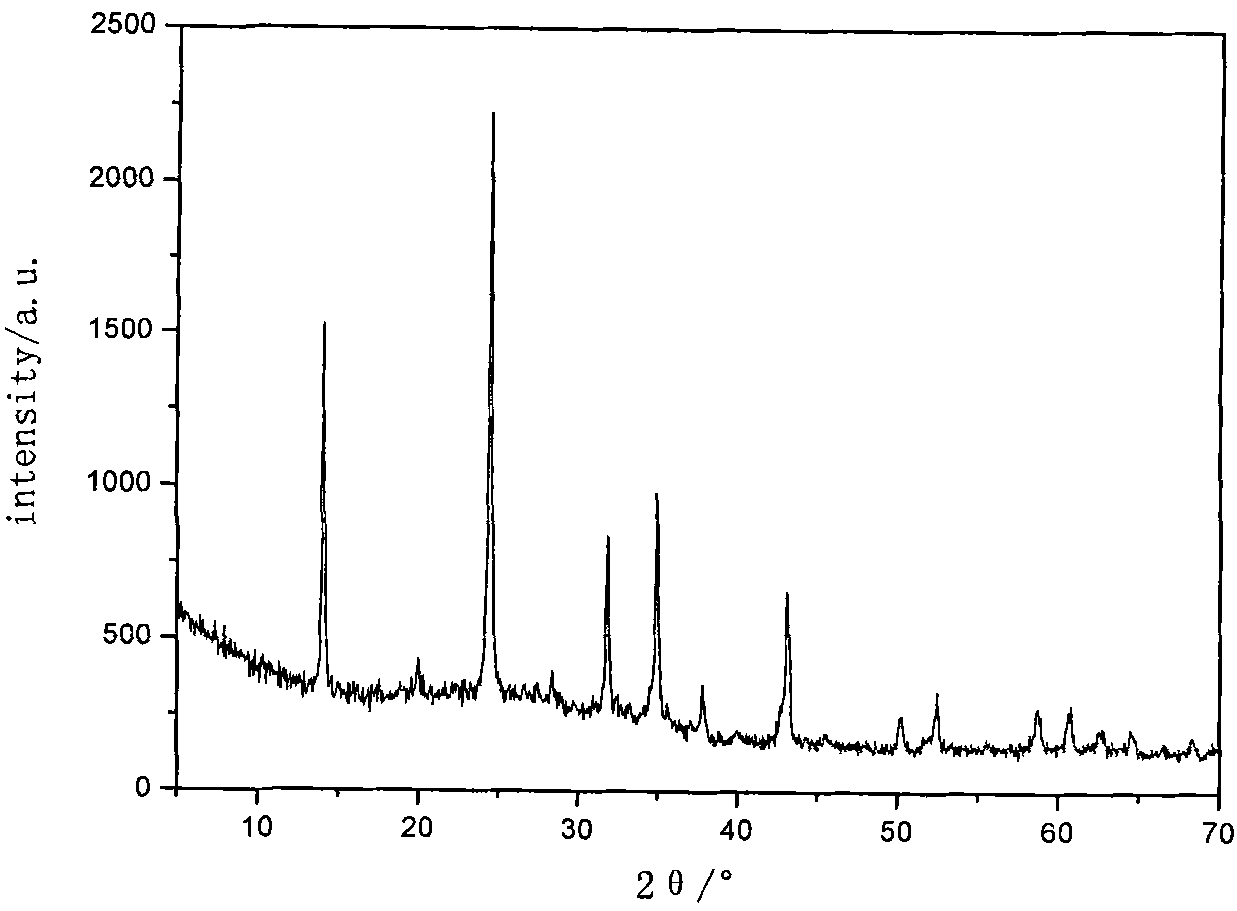

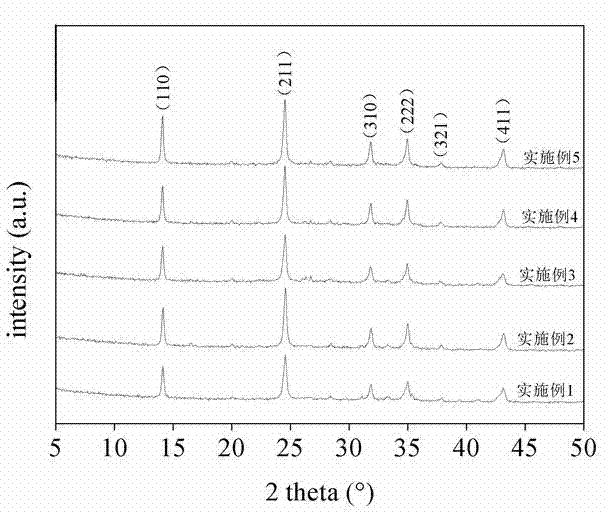

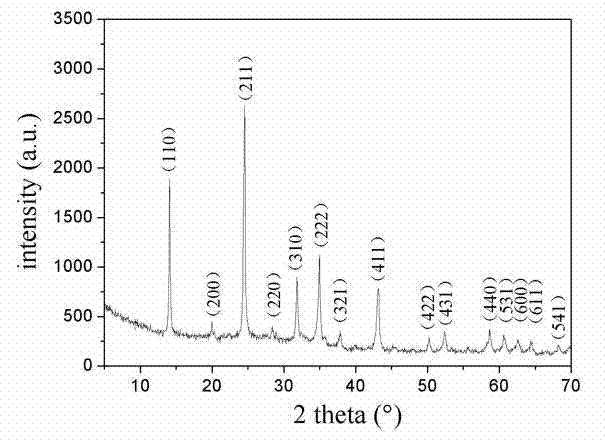

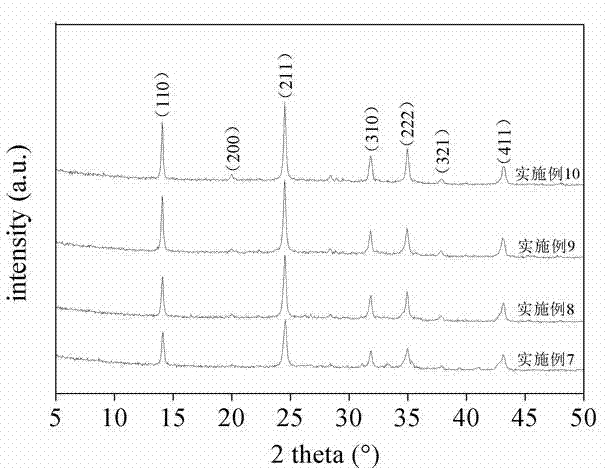

Process for synthesizing single-phase sodalite from fly ash

ActiveCN102173433ASolve the reuse problemExpand sourceSolid waste disposalCrystalline aluminosilicate zeolitesPre treatmentFly ash

The invention belongs to the field of production and preparation of inorganic functional materials, and particularly relates to a process for preparing single-phase sodalite from fly ash, which comprises the following steps: pretreating fly ash by an alkaline fusion method; proportionally adding the activated fly ash, aluminum hydroxide and sodium hydroxide solution into a polytetrafluoroethyleneinner container, evenly mixing, and carrying out hydrothermal crystallization in a sealed constant-temperature drying oven; and finally, filtering the product, washing until the product becomes neutral, and drying to obtain the single-phase sodalite material. The invention successfully synthesizes the low-cost single-phase sodalite zeolitization material by using solid waste-fly ash as the raw material for production. The process has the advantages of low cost, abundant sources of raw material, controllable product performance, no secondary pollution and the like, is simple and easy to operate, and thus, has great industrial application potential.

Owner:NANJING UNIV OF SCI & TECH

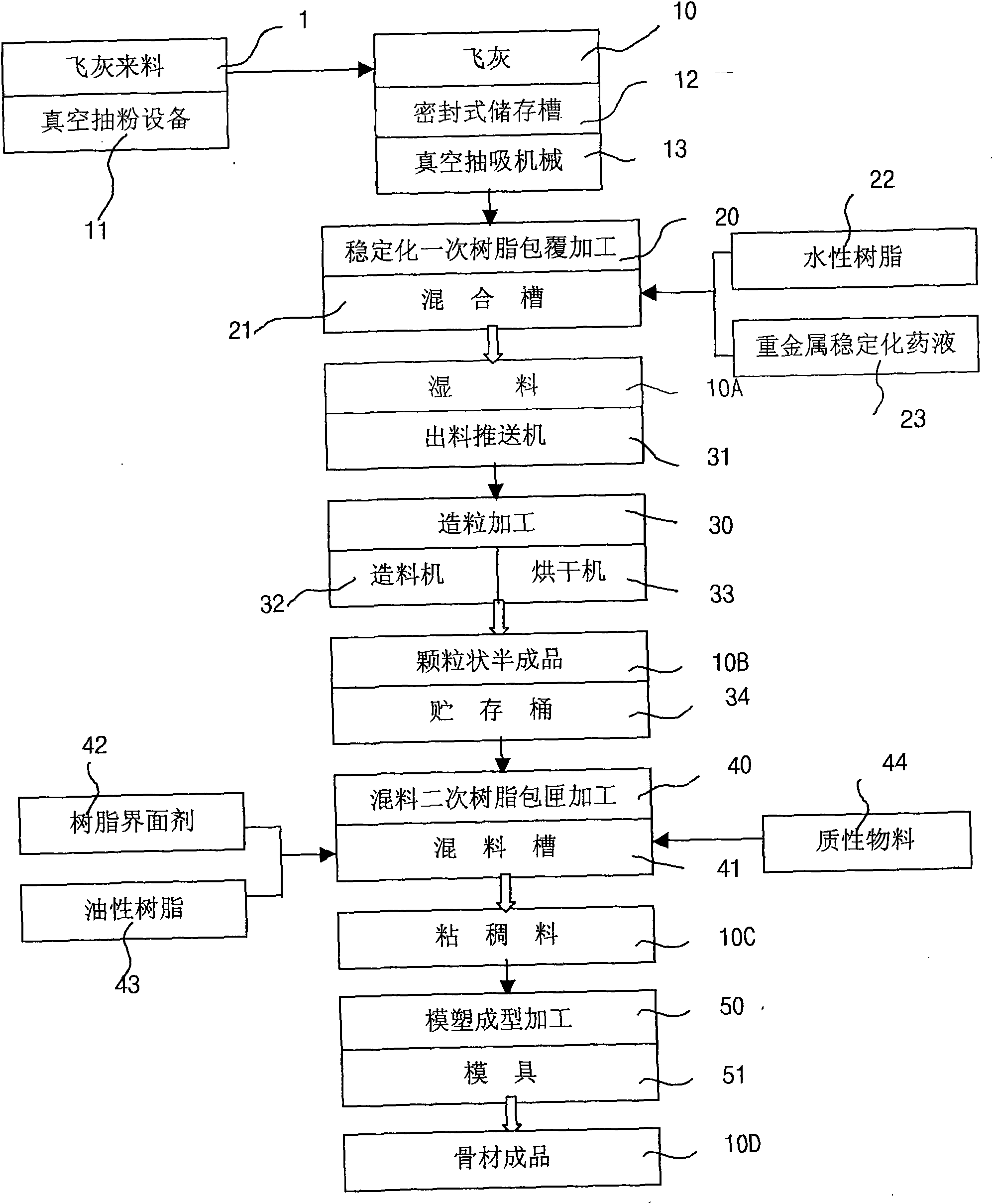

Reuse treating method of flying ash of incinerators

The invention discloses a reuse treating method of flying ash of incinerators, which at least comprises the steps of primary stable resin encapsulating processing, granulation processing, secondary resin packaging processing of mixing material, molding processing and the like for stored flying ash in a factory, and then, a non-dangerous engineering aggregate finished product is completed. In the whole treatment process of the reuse of the flying ash, water-base resin with low price is firstly used for curing and encapsulating the flying ash, therefore, the treatment method reduces the use quantity of oleoresin with high price and obviously reduces the treatment cost of the reuse of the flying ash. The reused finished product has double layers of resin encapsulating and packaging flying ash and exerts better stable property of low water permeability and low heavy metal dissolution.

Owner:陈志光

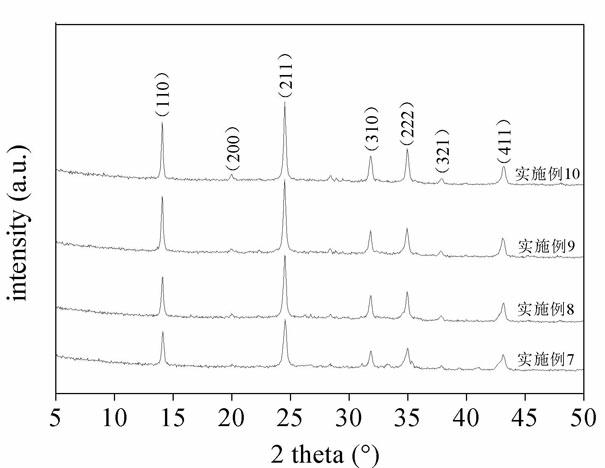

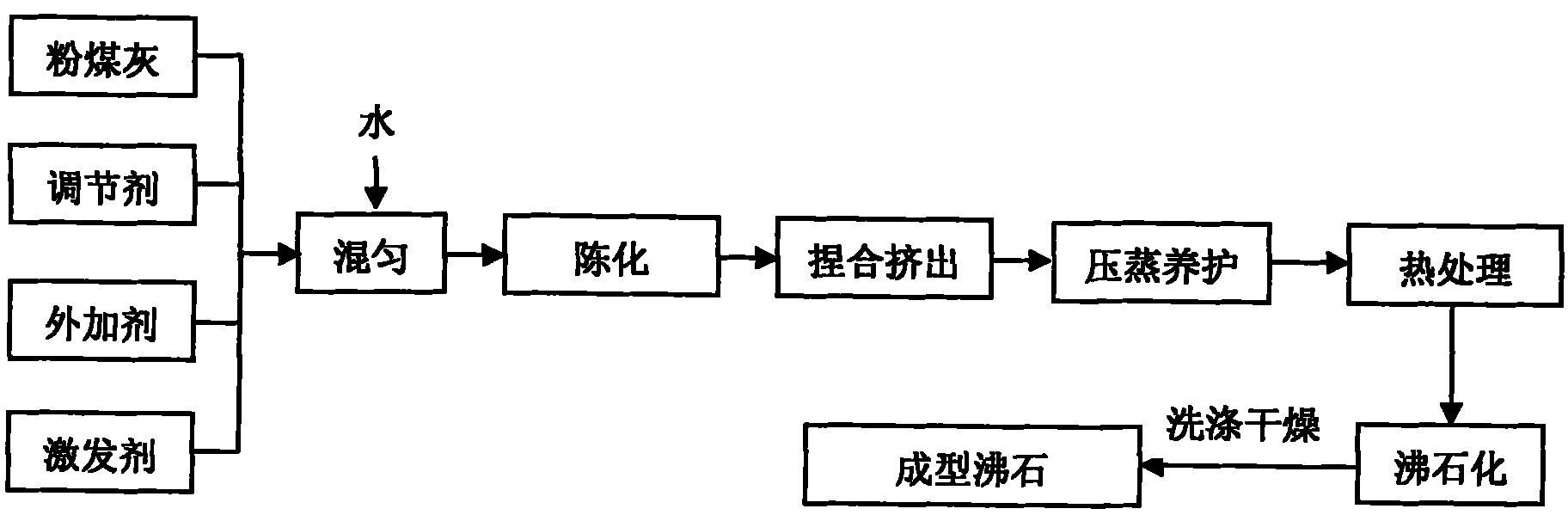

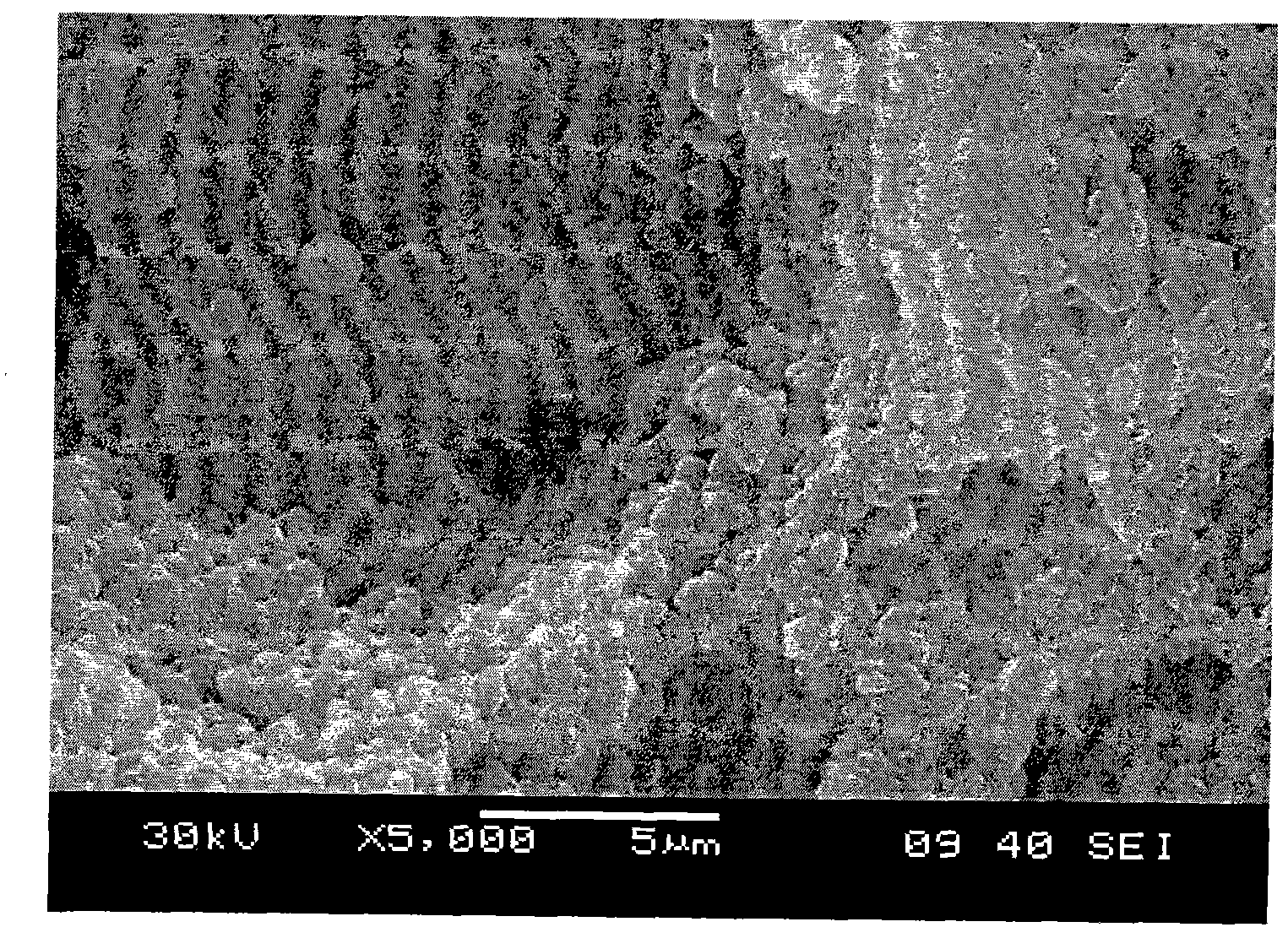

Process for preparing moulded zeolite by utilizing coal ash

InactiveCN101870477ASolve the reuse problemReduce pre-activation processMolecular-sieve and base-exchange compoundsPolymer scienceCoal

The invention discloses a process for preparing moulded zeolite by utilizing coal ash. The concrete method includes: coal ash, regulator, exciting agent, additive and water are fully mixed, ageing is carried out, and extrusion moulding is carried out; moulding material is subject to autoclave maintenance and then is subject to heat treatment in a programmed heating furnace, finally the moulding material is subject to zeolitization in NaOH aqueous solution, and washing and drying are carried out, thus obtaining the moulded zeolite. In the method, coal ash moulding and coal ash zeolitization are combined together, thus not only saving raw material and reducing energy consumption but also shortening process period. The moulded coal ash zeolite prepared by the method has the characteristics of high mechanical strength, simple preparation method, various shapes, low cost, corrosion resistance, light weight and a plurality of three-dimensional through pore canals, thus being capable of being widely applied to the fields of absorbing material, catalyst carrier, wall material and building material.

Owner:NANJING UNIV OF SCI & TECH

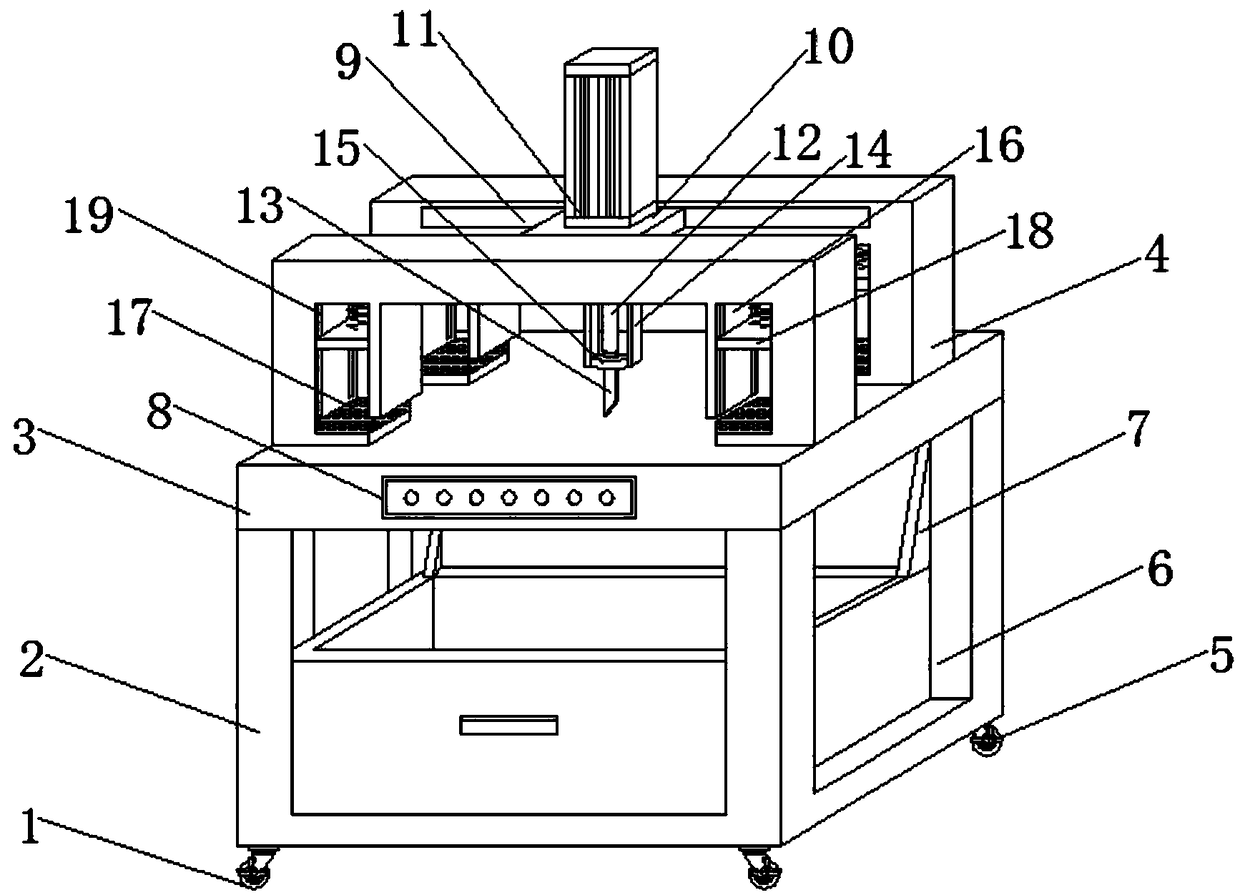

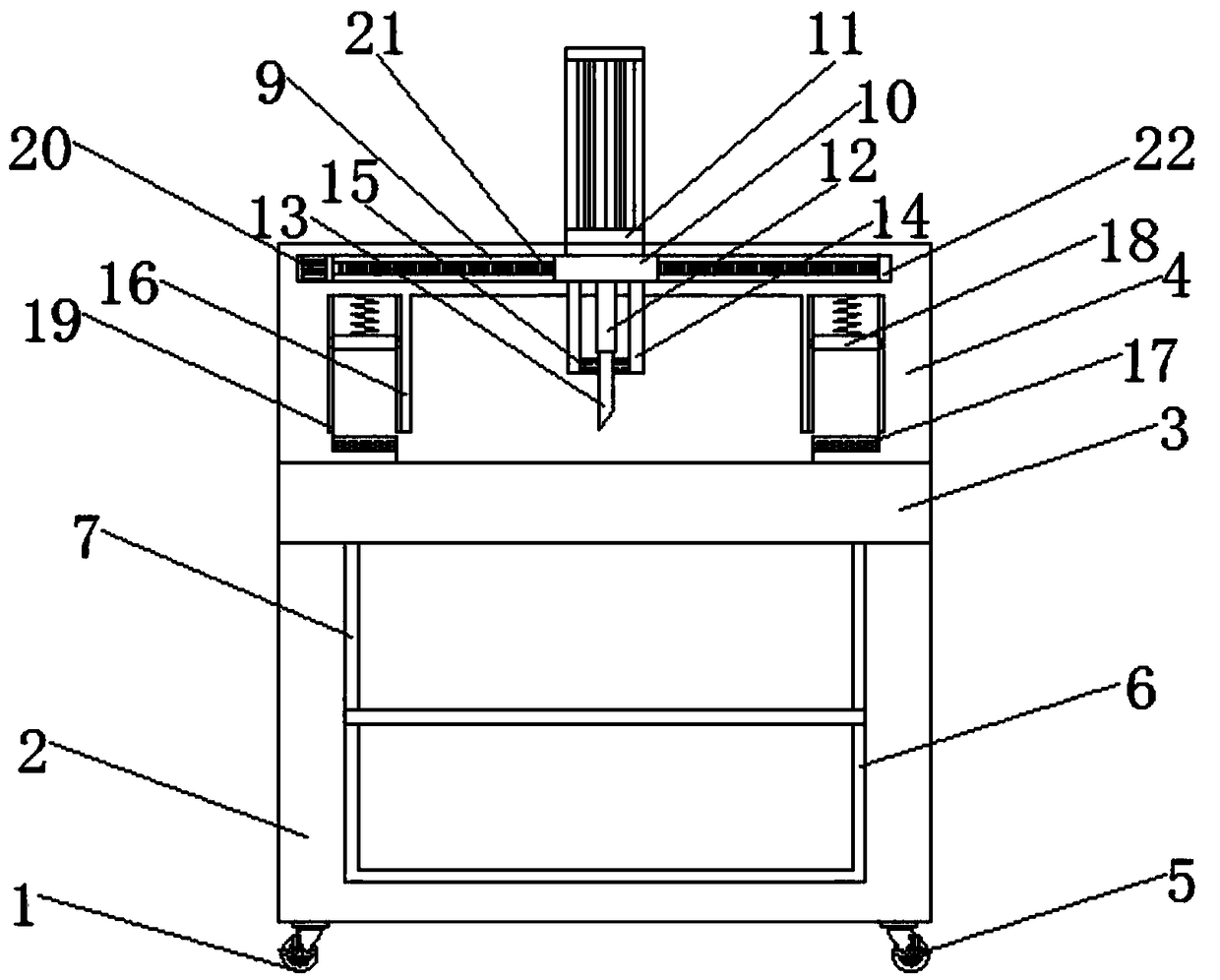

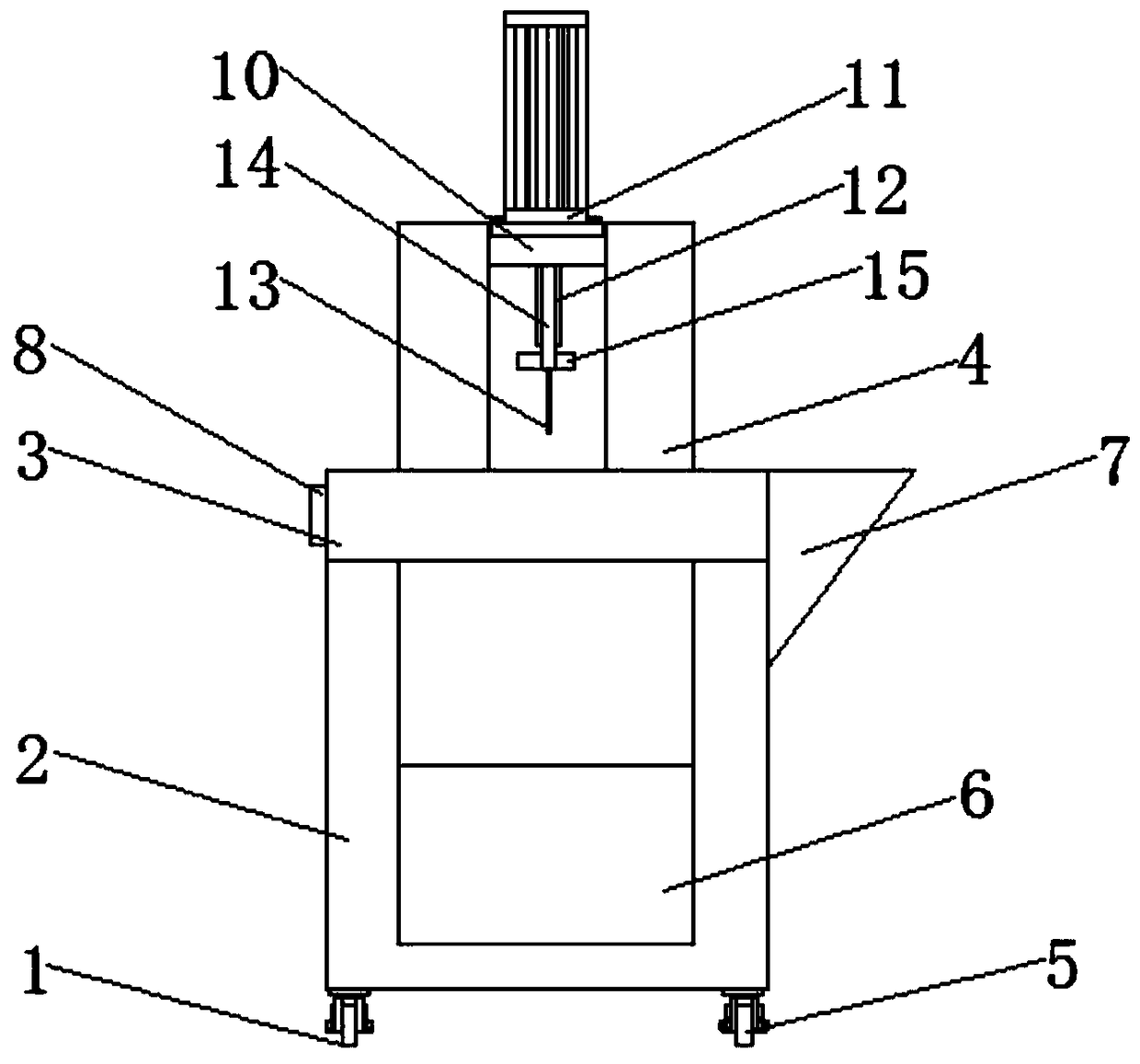

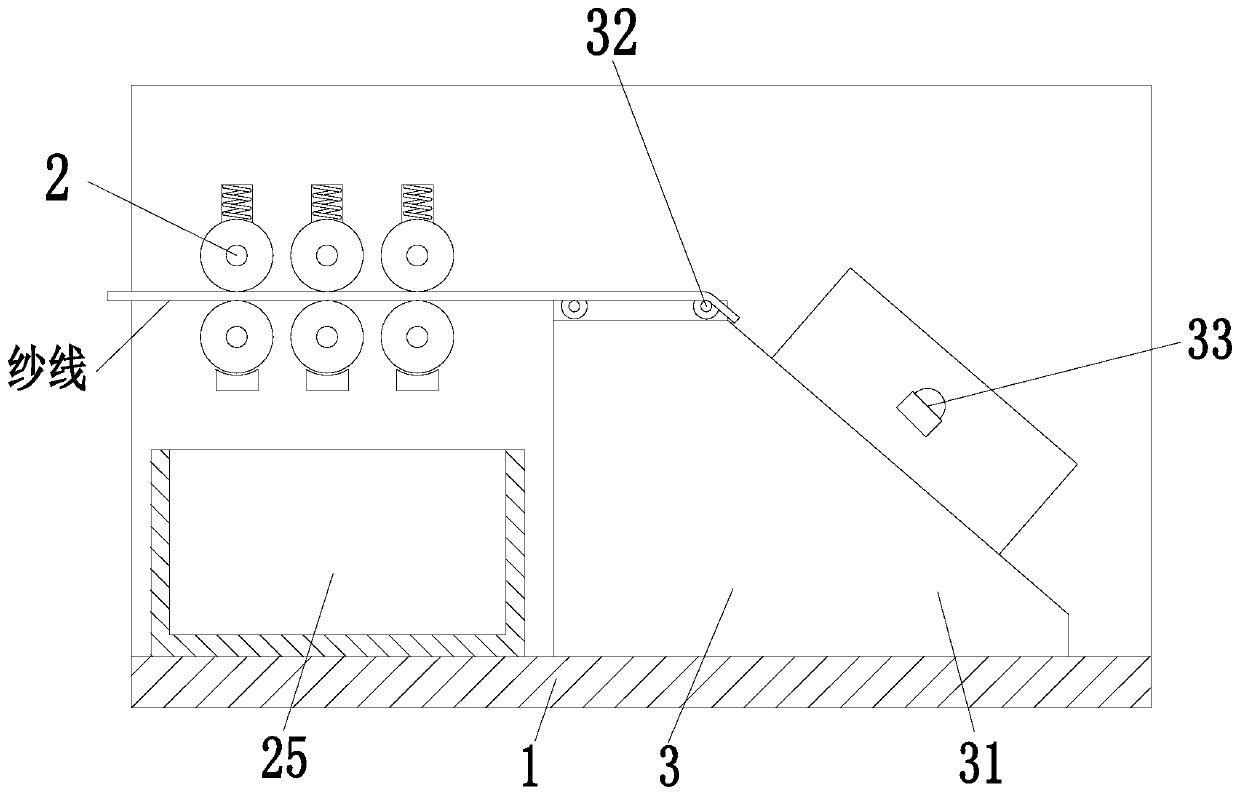

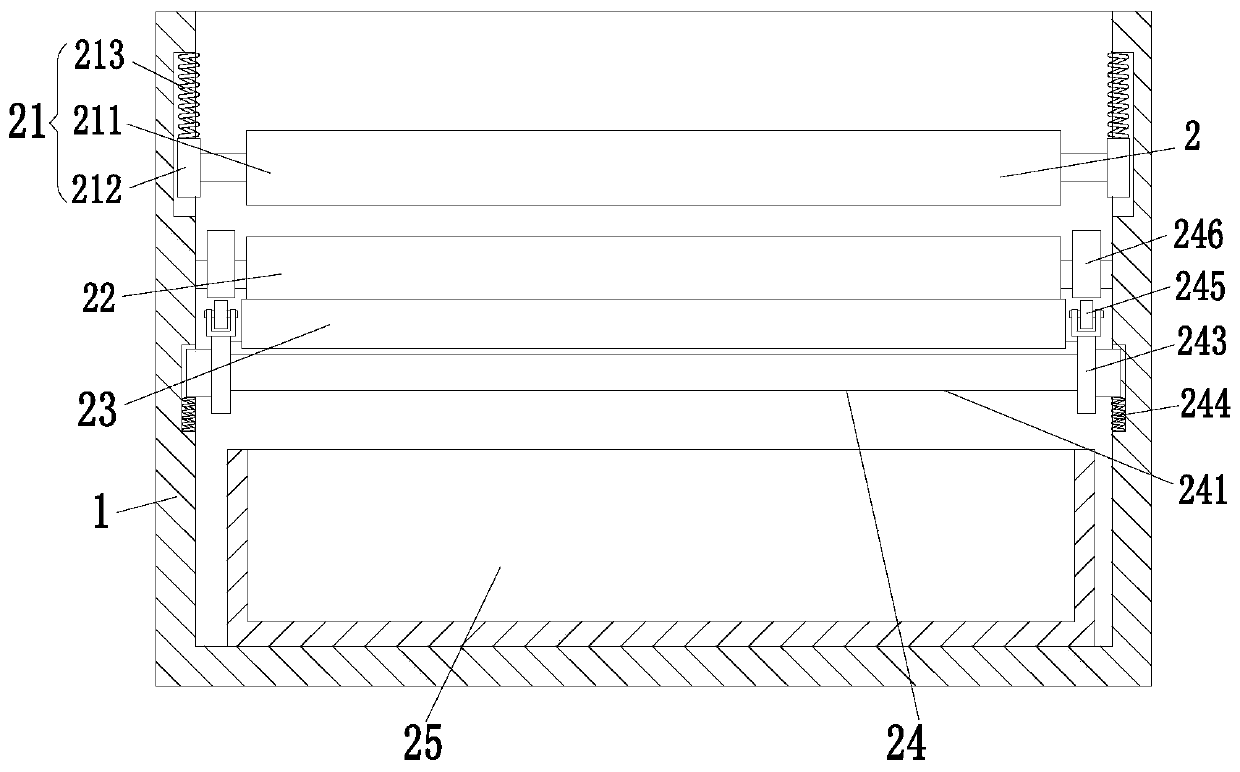

Excess material cutting device specially used for textile equipment

The invention discloses an excess material cutting device specially used for textile equipment. The bottom of a cutting device body is provided with a pedestal. The top of the pedestal is provided with a cutting bench. The two sides of the top of the cutting bench are provided with supports. The top ends of the supports are provided with a chute. One end in the chute is provided with a R280 motor.One end of the R280 motor is fixedly connected to a screw. The outer side of the screw is provided with a slide plate. The top of the slide plate is provided with an electric cylinder. The bottom endof the electric cylinder is fixedly connected to a telescopic rod. The bottom of the telescopic rod is provided with a cutting knife. The two ends of the supports are provided with compaction components. The top ends of the compaction components are provided with springs. The bottom ends of the springs are installed with a pressing plate. The bottom ends of the supports are provided with an electromagnetic plate. The bottom of the pedestal is provided with truckles. In the invention, the electromagnetic plate and the pressing plate are cooperatively used, an excess material can be compacted and is prevented from moving during a cutting process, the device is simple and practical, the cutting effect of the cutting device body is increased, and simultaneously, a secondary waste is avoided,and the utilization rate of resources is increased.

Owner:陈茶仙

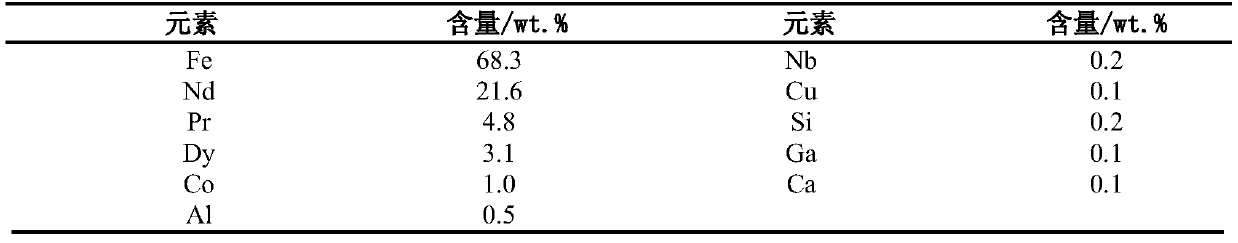

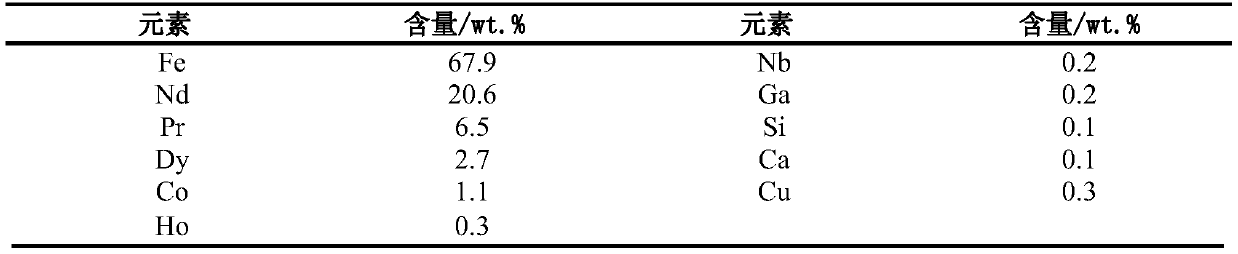

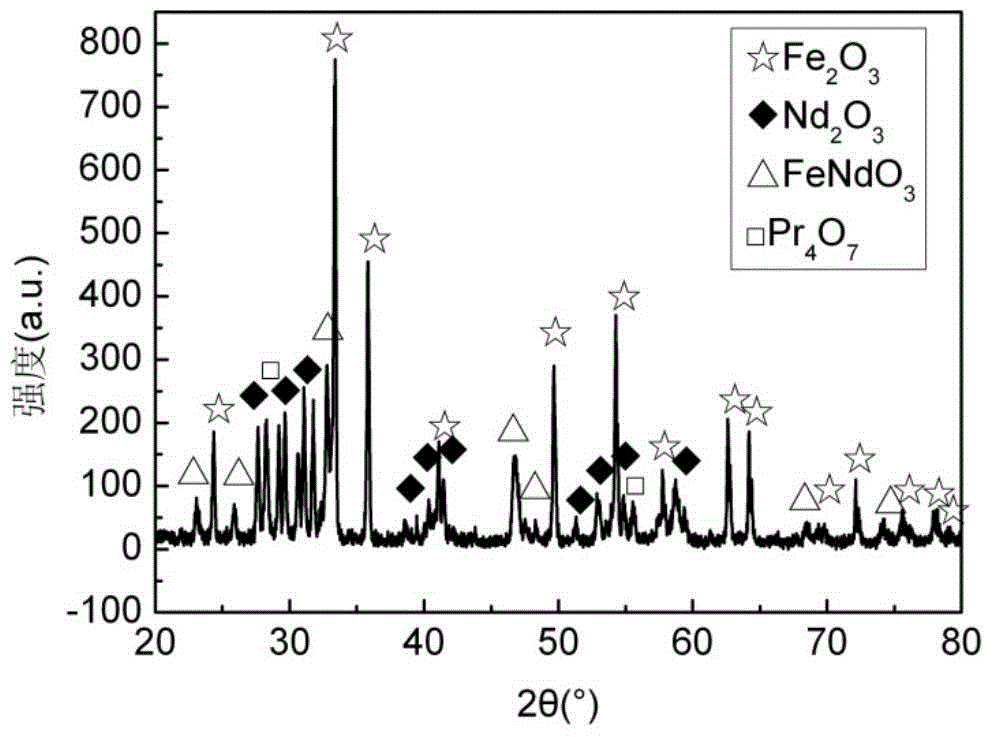

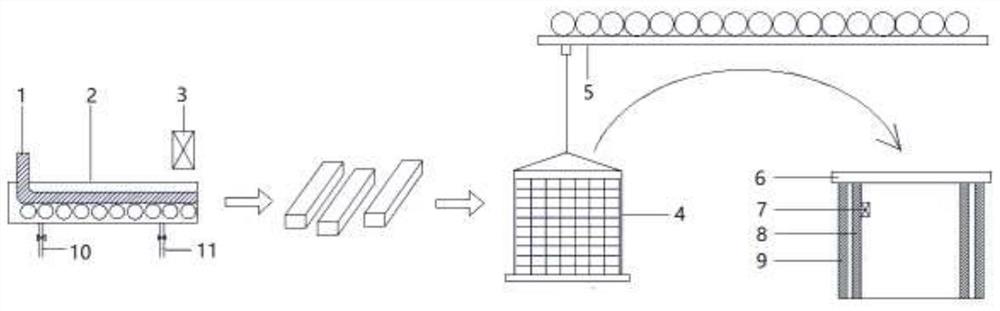

Method for recovering neodymium iron boron alloy powder from neodymium iron boron oil sludge wastes by shot flow and preparation method of regenerated sintered magnet

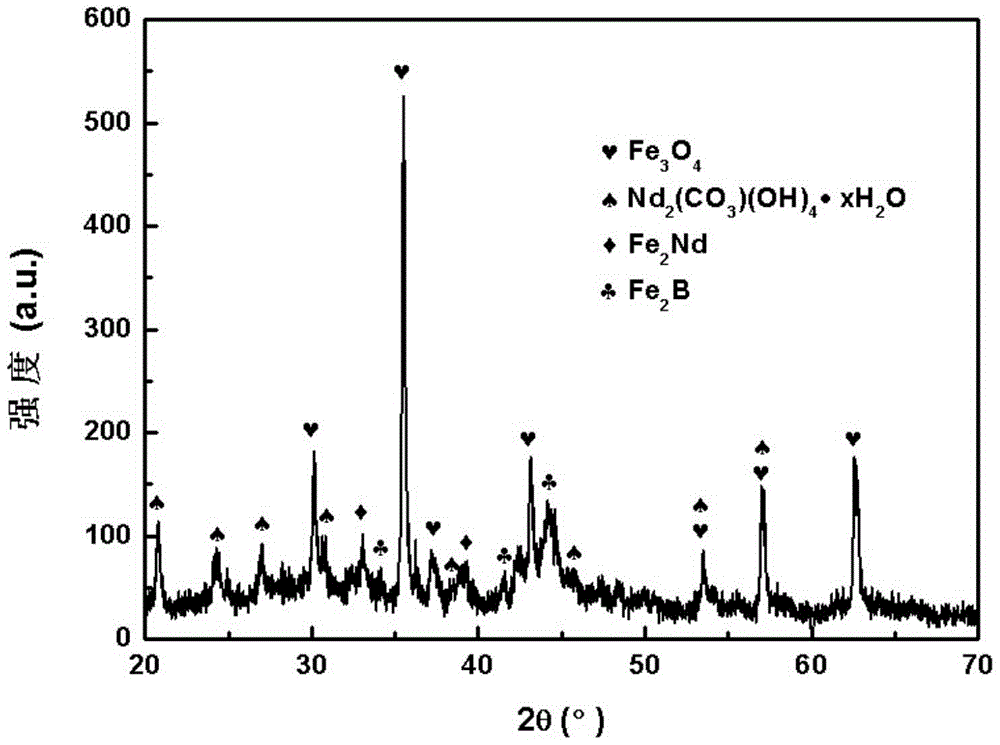

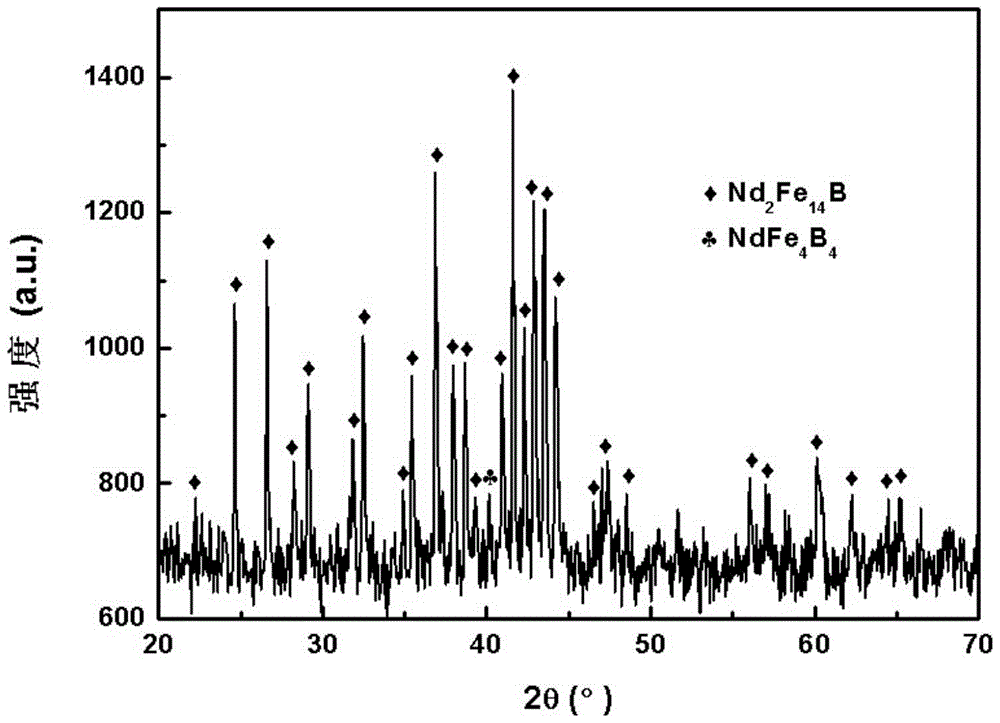

PendingCN109852809AEnable recyclingAvoid distillationProcess efficiency improvementHydrogenAcid dissolution

The invention discloses a method for recovering neodymium iron boron alloy powder from neodymium iron boron oil sludge wastes by a shot flow. The method comprises the following steps: an oil sludge waste drying step: the neodymium iron boron oil sludge wastes are dried to obtain neodymium iron boron oil sludge; and a reduction dispersing step: FeB, neodymium / neodymium-contained compounds and Ca are fed in the neodymium iron boron oil sludge for hydrogen reduction and calcium reduction dispersing reaction to obtain neodymium iron boron alloy powder and calcium oxide mixtures. The invention further discloses a preparation method of a regenerated sintered magnet, a neodymium iron boron sintered magnet and a neodymium iron boron bonded magnet. The method prevents such processes as distillationand acid dissolution through direct drying of the neodymium iron boron oil sludge wastes, shortens the flow, achieves high efficiency and environmental protection, and reduces the production cost. The magnetic energy product of the prepared sintered magnet reaches 33 MGOe.

Owner:JIANGSU JICUI ANTAI CHUANGMING ADVANCED ENERGY MATERIALS RES INST CO LTD

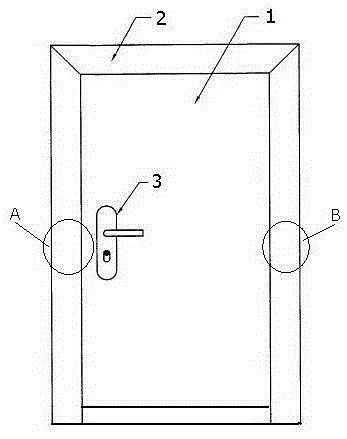

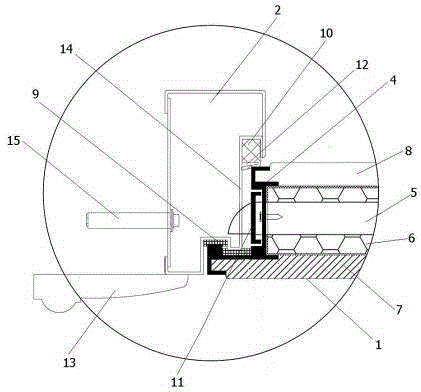

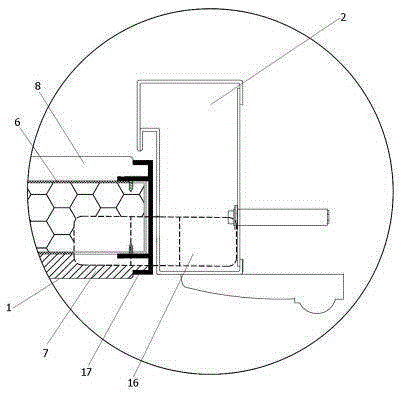

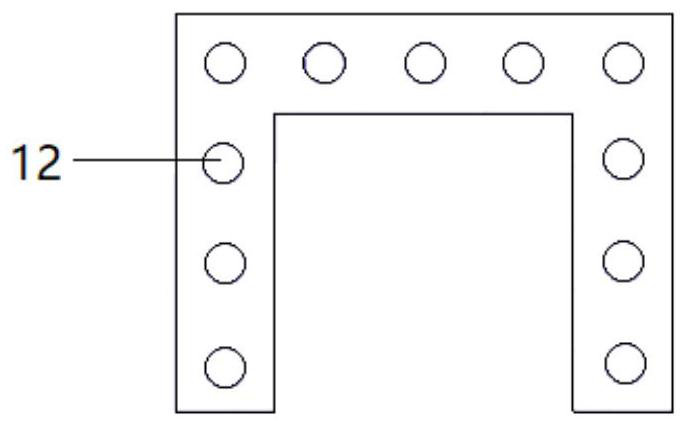

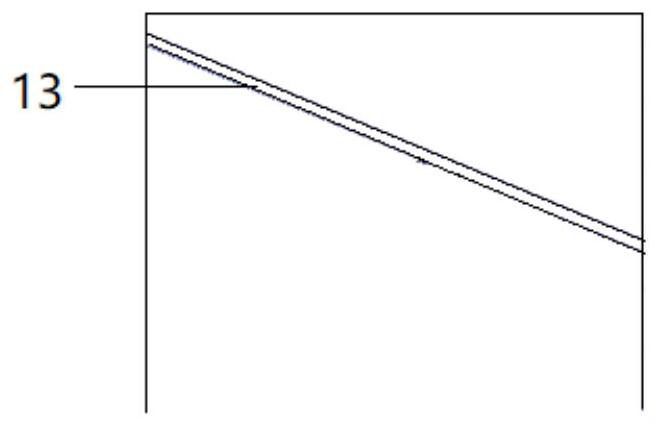

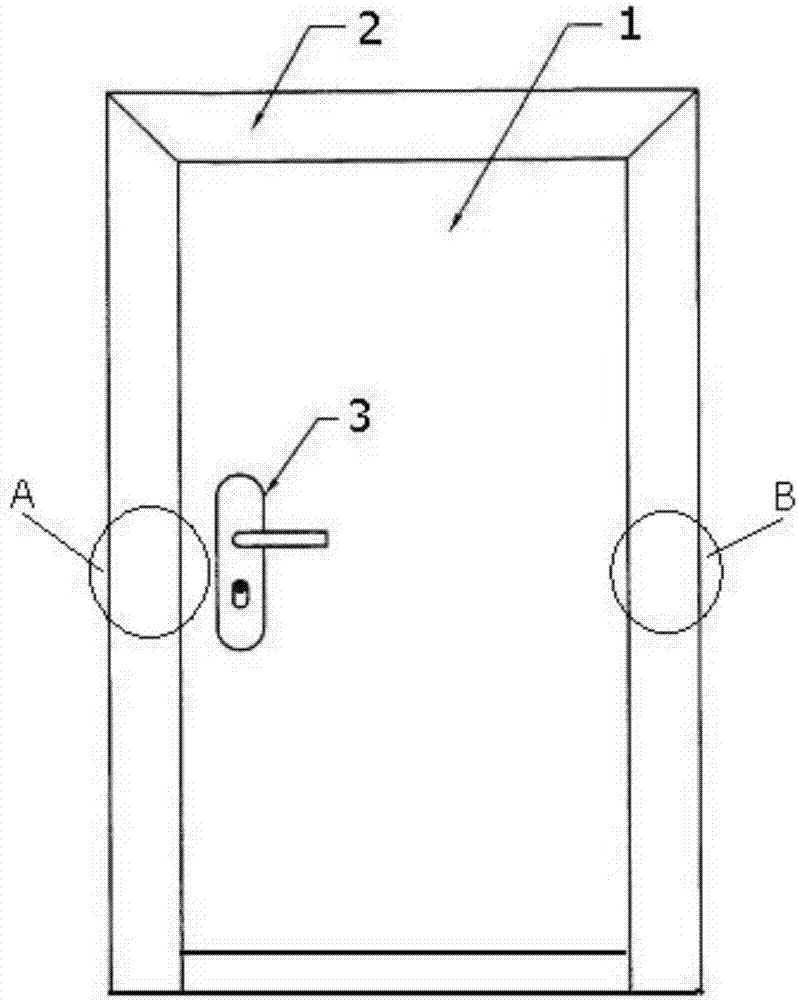

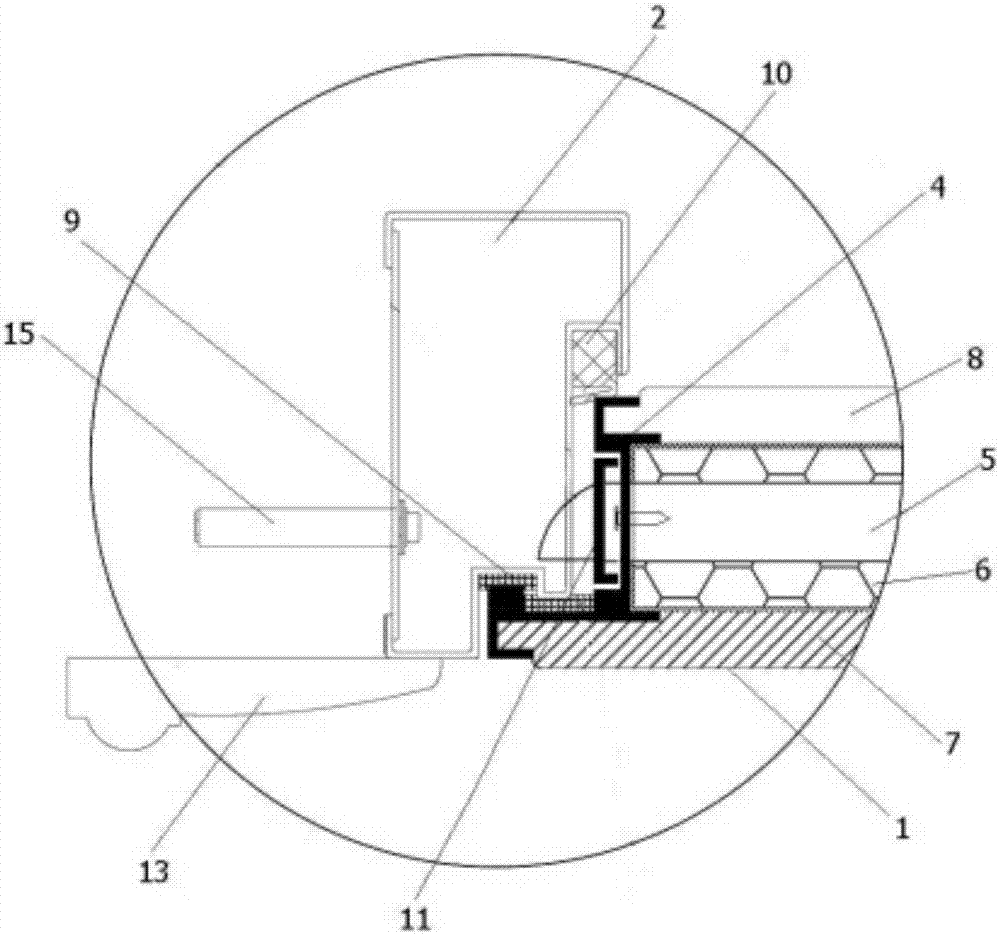

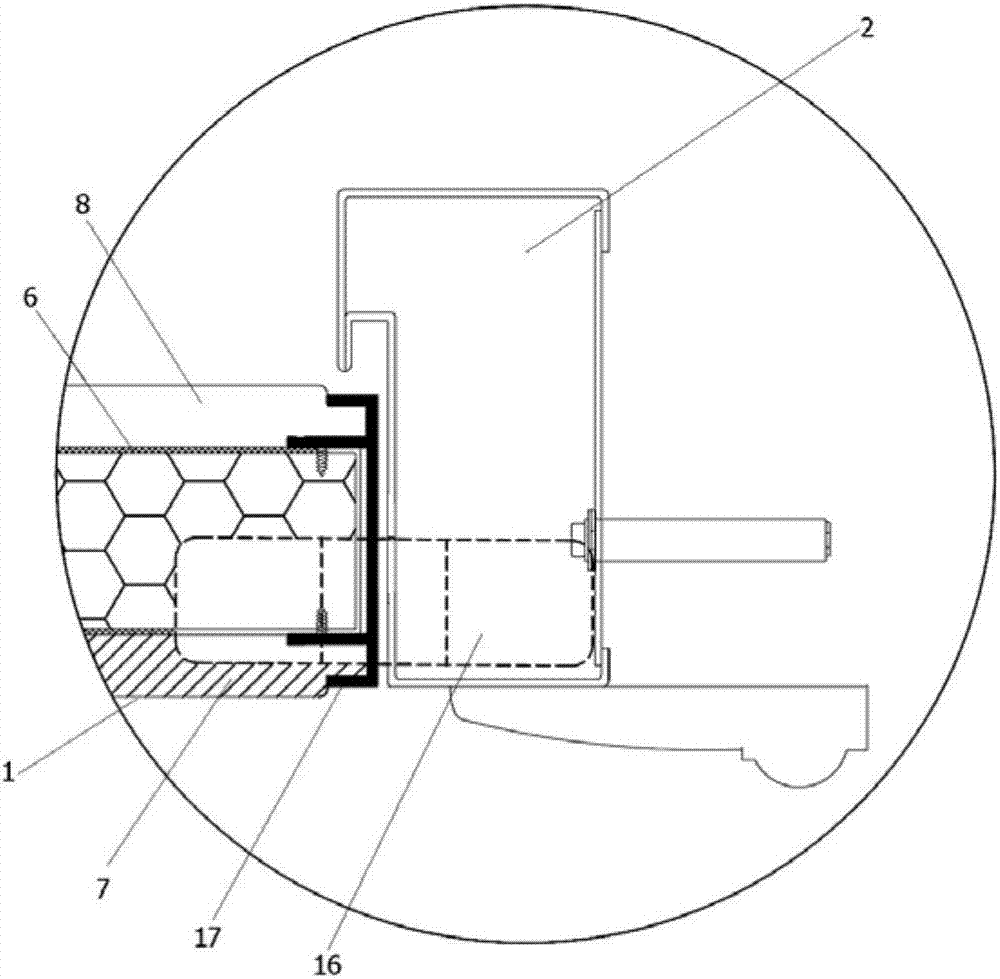

One-piece and two-piece Chinese-style armored door and manufacture and installation process thereof

ActiveCN105298335AAvoid damage phenomenonSolving the Wasted White Space ConundrumFrame fasteningWindow/door framesEngineeringMechanical engineering

The invention discloses a one-piece Chinese-style armored door which is composed of a door frame, a door leaf, a door lock side covering edge, a hinge side covering edge, a door lock, a hinge and a door core. A two-piece Chinese-style armored door which is composed of a door frame, a child door leaf, a mother door leaf, a door lock side covering edge, a hinge side covering edge, a door lock, a hinge, a child door core and a mother door core. A manufacture and installation process of the one-piece Chinese-style armored door comprises the steps of manufacturing the door frame, manufacturing the door core, manufacturing the covering edges and a cover plate, assembling the door frame and the door core, manufacturing a veneer and assembling the veneer. A manufacture and installation process of the two-piece Chinese-style armored door comprises the steps of manufacturing the door frame, manufacturing the child door core and the mother door core, manufacturing the covering edges and a cover plate, assembling the door frame and the door core, manufacturing a child veneer and a mother veneer and assembling the veneers. By the adoption of the one-piece Chinese-style armored door or the two-piece Chinese-style armored door, the problem that door sheets are damaged in the cross construction process is solved; secondary waste caused by replacement and maintenance of a damaged door set is avoided, and environmental protection is facilitated; production and construction procedures are simplified, labor cost is reduced by 40%, and leakproofness, the sound insulation effect and the heat insulation effect are good.

Owner:上海璞玉门业有限公司

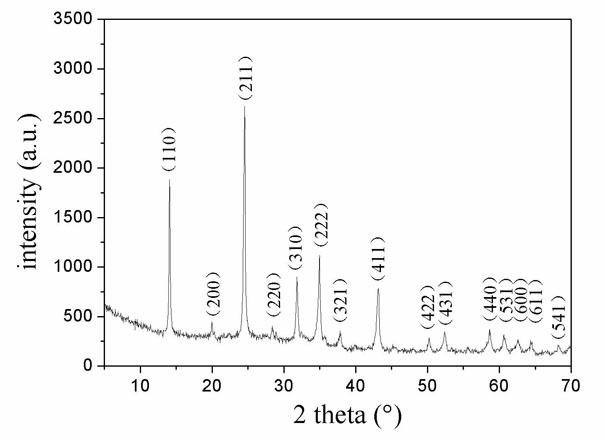

Method for synthesis of 4A molecular sieve with coal ash alkali melting method

InactiveCN101367529BImprove gelationHigh gelation rateAluminosilicate zeolite type-AMolecular sieveMixed materials

The invention discloses a method for synthesizing 4A molecular sieve by adopting the fly ash in alkaline dissolving method; the fly ash with Al2O3 being more than or equal to 36 percent (36 percent to 46 percent), and the mol ratio of the SiO2 / Al2O3 being 1.8 to 2.1 is used to be mixed with alkali according to the mol ratio of Na2O / Al2O3 is 3 to 10, and to be milled and well distributed; the mixed material with the height of each layer being 4 to 8 cm is arranged inside a high-temperature furnace at the temperature of 550 to 800 DEG C to be calcined and activated for 1 to 3 hours. After beingdissolved by the water, the mol ratio of H2O / Na2O is controlled to be 30 to 60, and is mixed at the temperature of 50 to 80 DEG C for 1 to 3 hours, and is colloidized, and then is heated to the temperature of 100 plus or minus 10 DEG C to be held quietly for the crystallization for 4 to 6 hours; after the reaction, the material is filtered, and is washed until the pH value is equal to 9 to 11, and is dried to get the 4A molecular sieve. The molecular sieve is white, the calcium exchanging quantity is more than or equal to 310 mg of CaCo3 / g; and the sieving rate is more than or equal to 90 percent. The invention can integrally use the fly ash of the waste pollutant, and has the advantages of high utilization rate, simple process flow procedures, environmental protection, and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Process for synthesizing single-phase sodalite from fly ash

ActiveCN102173433BSolve the reuse problemExpand sourceSolid waste disposalCrystalline aluminosilicate zeolitesFly ashPollution

The invention belongs to the field of production and preparation of inorganic functional materials, and particularly relates to a process for preparing single-phase sodalite from fly ash, which comprises the following steps: pretreating fly ash by an alkaline fusion method; proportionally adding the activated fly ash, aluminum hydroxide and sodium hydroxide solution into a polytetrafluoroethyleneinner container, evenly mixing, and carrying out hydrothermal crystallization in a sealed constant-temperature drying oven; and finally, filtering the product, washing until the product becomes neutral, and drying to obtain the single-phase sodalite material. The invention successfully synthesizes the low-cost single-phase sodalite zeolitization material by using solid waste-fly ash as the raw material for production. The process has the advantages of low cost, abundant sources of raw material, controllable product performance, no secondary pollution and the like, is simple and easy to operate, and thus, has great industrial application potential.

Owner:NANJING UNIV OF SCI & TECH

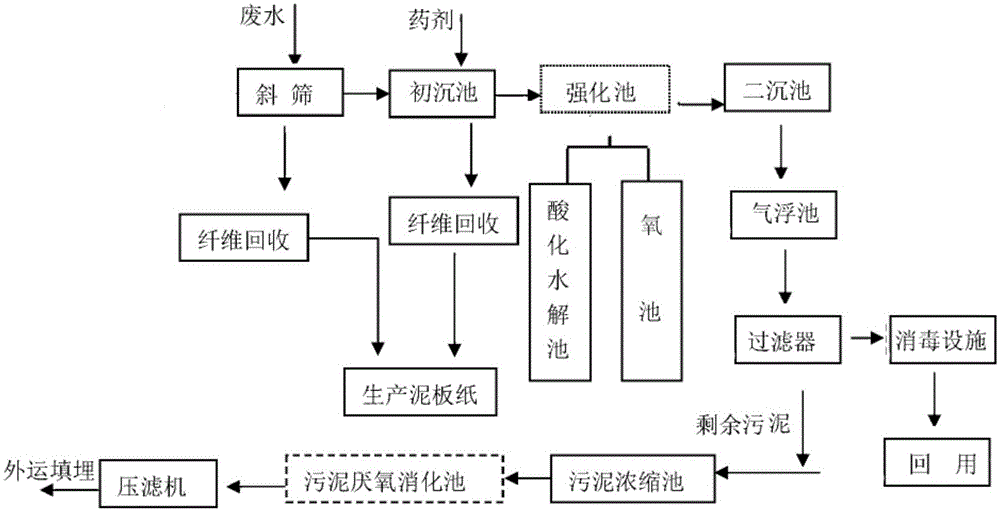

Regenerated papermaking wastewater treatment system

InactiveCN105016585AAvoid secondary wasteReduce manufacturing costMultistage water/sewage treatmentWaste water treatment from plant processingWater treatment systemAcid water

The invention discloses a regenerated papermaking wastewater treatment system. The regenerated papermaking wastewater treatment system comprises an inclined screen, a primary settling tank, a reinforcing tank, a secondary settling tank, an air floatation tank, a filter, a sludge thickener, a sludge anaerobic digester and a filter press. The inclined screen, the primary settling tank, the reinforcing tank, the secondary settling tank and the air floatation tank are sequentially connected through pipelines. The sludge thickener and the sludge anaerobic digester are sequentially connected through a pipeline. The reinforcing tank comprises an acid water dissolution tank and an oxygen tank. The filter is arranged between the air floatation tank and the sludge thickener. The filter press is connected with the sludge anaerobic digester. A large number of clean and impurity-free hot water working media can be recycled, water temperature is high, the hot water working media can be directly fed into a boiler to be recycled without chemical water treatment, therefore, production cost is reduced, and the purposes of saving energy and reducing consumption are achieved.

Owner:怀宁县天元纸业有限公司

Inorganic binding material prepared through classified treatment of building solid waste recycled aggregate and preparation method of inorganic binding material

The invention discloses an inorganic binding material prepared through classified treatment of building solid waste recycled aggregate and a preparation method of the inorganic binding material. The building solid waste recycled aggregate is taken as aggregate for producing inorganic binding material products with different strength. By means of a technology, an inorganic binding material stabilizing material is produced from building solid waste with processes of sorting, pre-wetting, impurity removal, crushing, sieving, secondary prewetting, storage, batching and stirring. By means of the technology for disposing the building solid waste, waste bricks and concrete in the building solid waste are converted into recycled aggregate through a specific processing procedure with sufficiently studied characteristics of the building solid waste, and inorganic binding material stabilized building solid waste recycled aggregate products are formed in cooperation with an inorganic binding material by plant mix, blending and stabilizing; a manual soring platform is fixed on a sieving equipment main body, large light substances are manually picked out, tiny particles and light substances areremoved through an air separation device, and impurity ingredients in the building solid waste are effectively removed.

Owner:北京城建华晟交通建设有限公司 +1

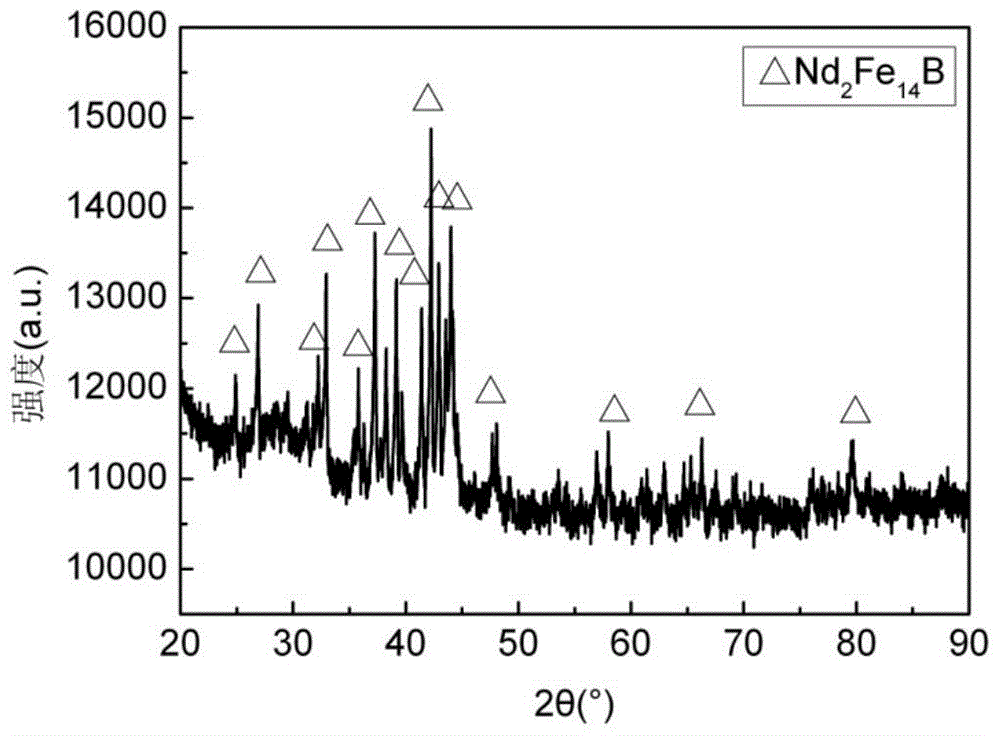

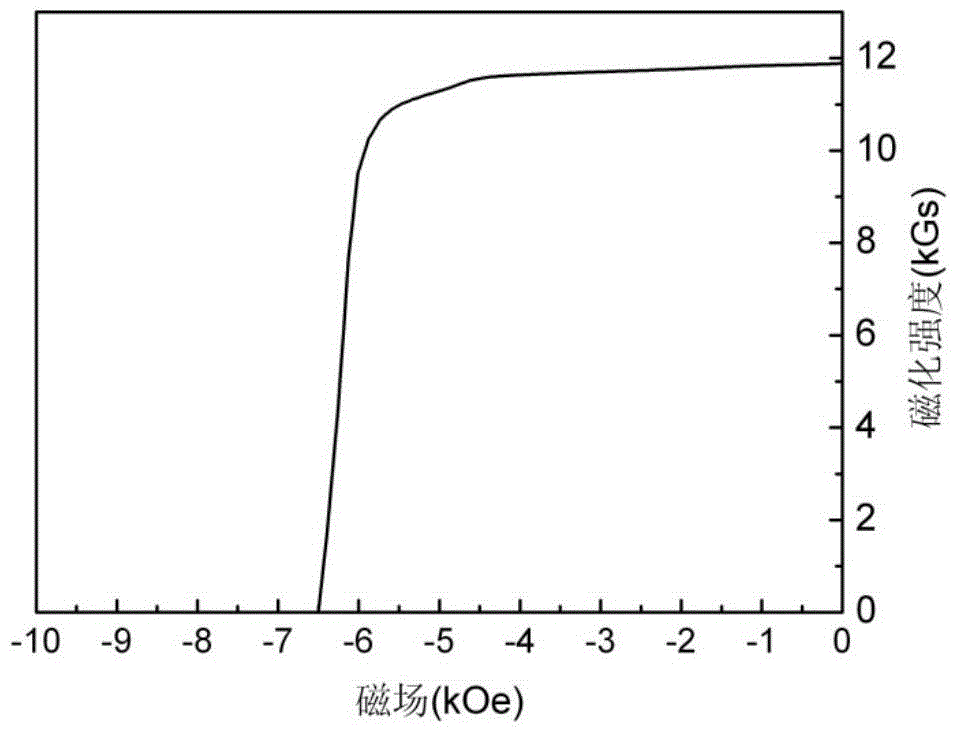

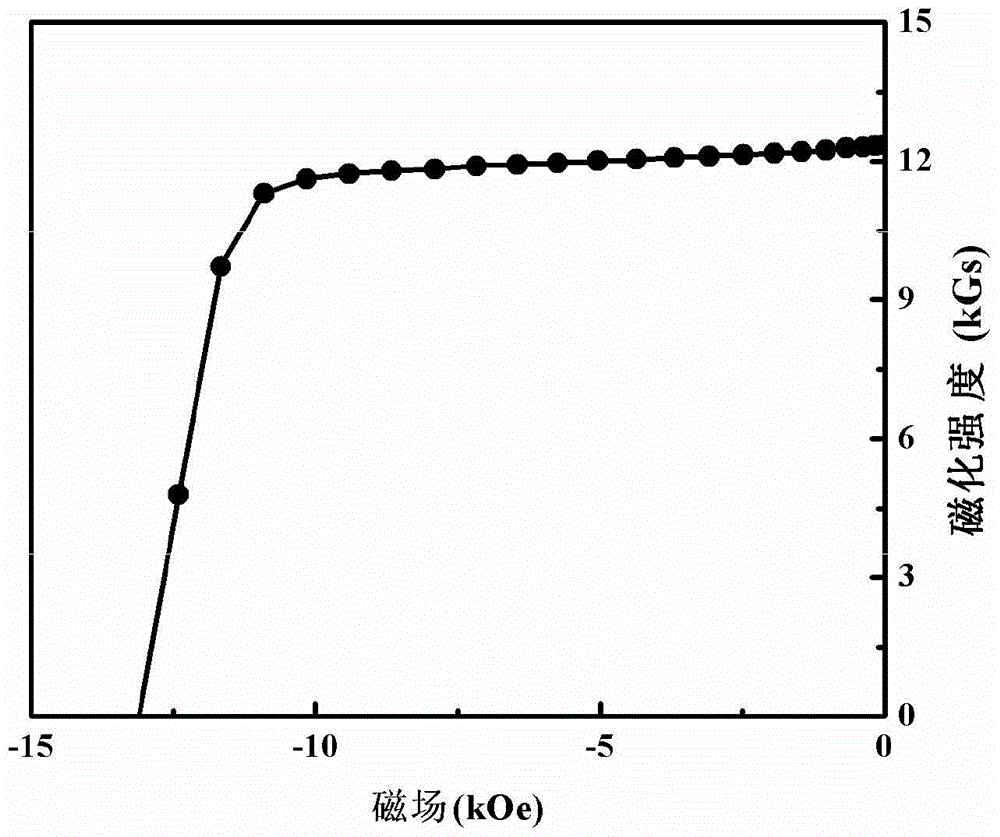

A method of recovering NdFeB oil sludge using reduction diffusion technology

ActiveCN104690277BReduce manufacturing costAvoid secondary wasteRecycling and recovery technologiesDiffusion methodsAcid dissolution

The invention discloses a method for recycling NdFeB oil sludge according to a reduction-diffusion technology, and belongs to the technical field of recycling of NdFeB oil sludge. The method comprises the following steps: (1) oil sludge pretreatment and acid dissolution, (2) co-precipitation and roasting, (3) calcium reduction and diffusion, (4) rinsing and drying, (5) powder mixing and sintering, and the like. The method is efficient and environmentally friendly, and has the advantages that when an NdFeB oil sludge waste material is taken as a raw material, a regenerative NdFeB magnet can be directly obtained; magnetic field ultrasonic treatment is adopted in a rinsing process, so that calcium oxide and other nonmagnetic substances can be effectively removed; through an addition of nanometer powder, the maximum magnetic energy product of the obtained regenerative NdFeB sintered magnet can reach 32 MGOe.

Owner:BEIJING UNIV OF TECH

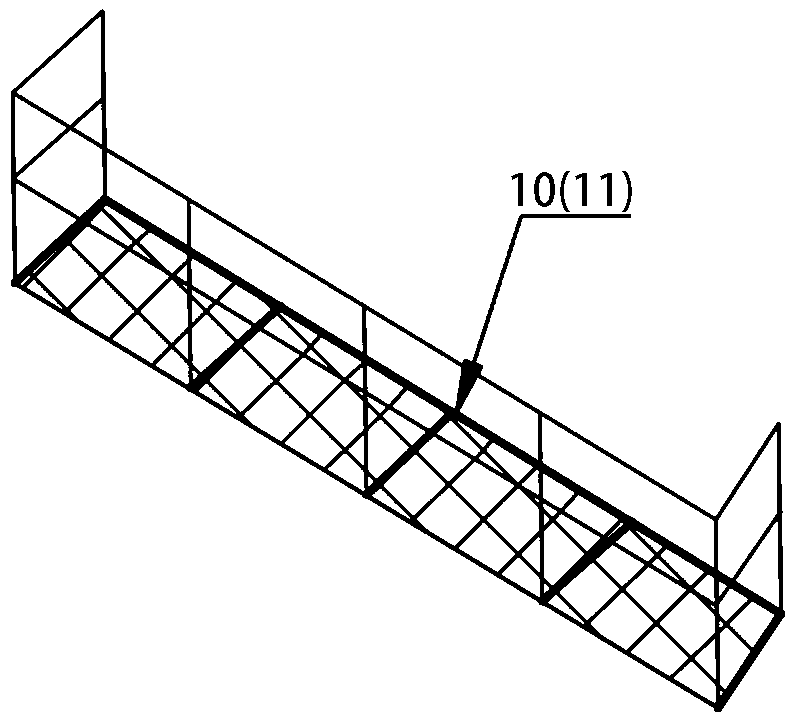

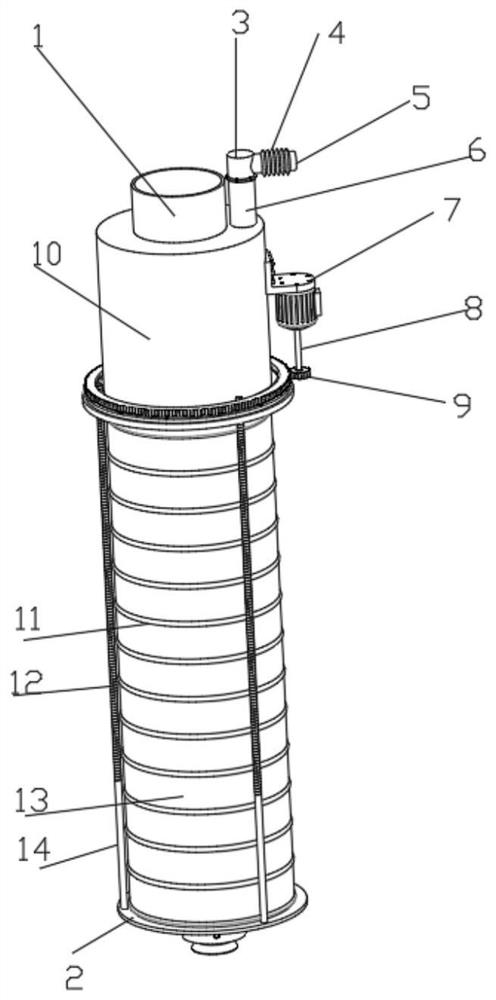

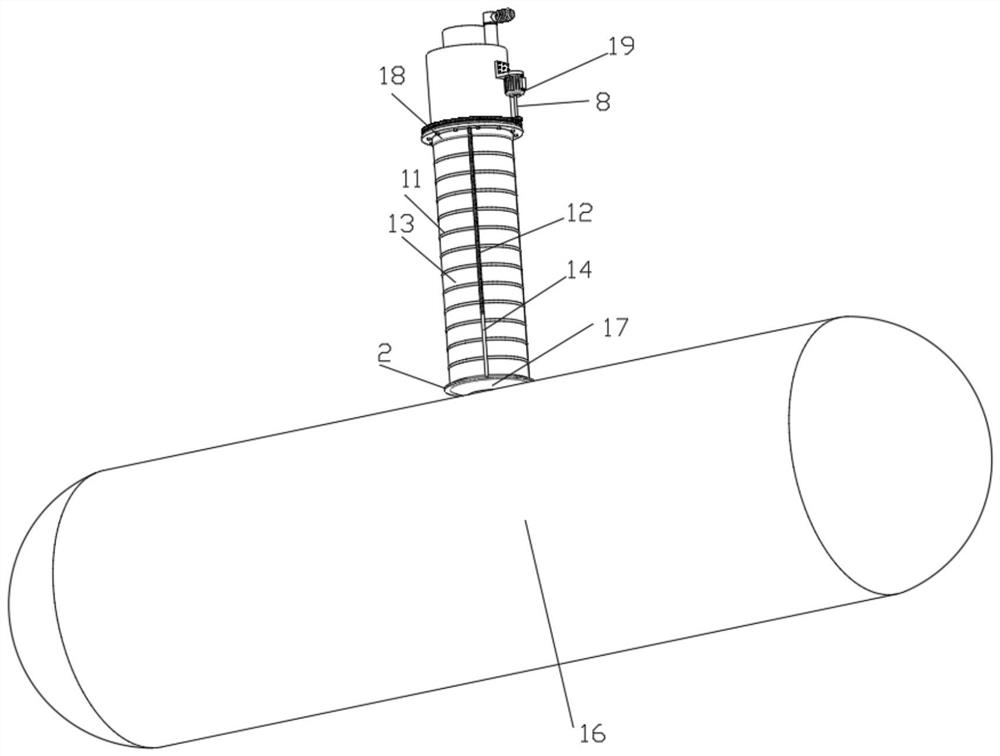

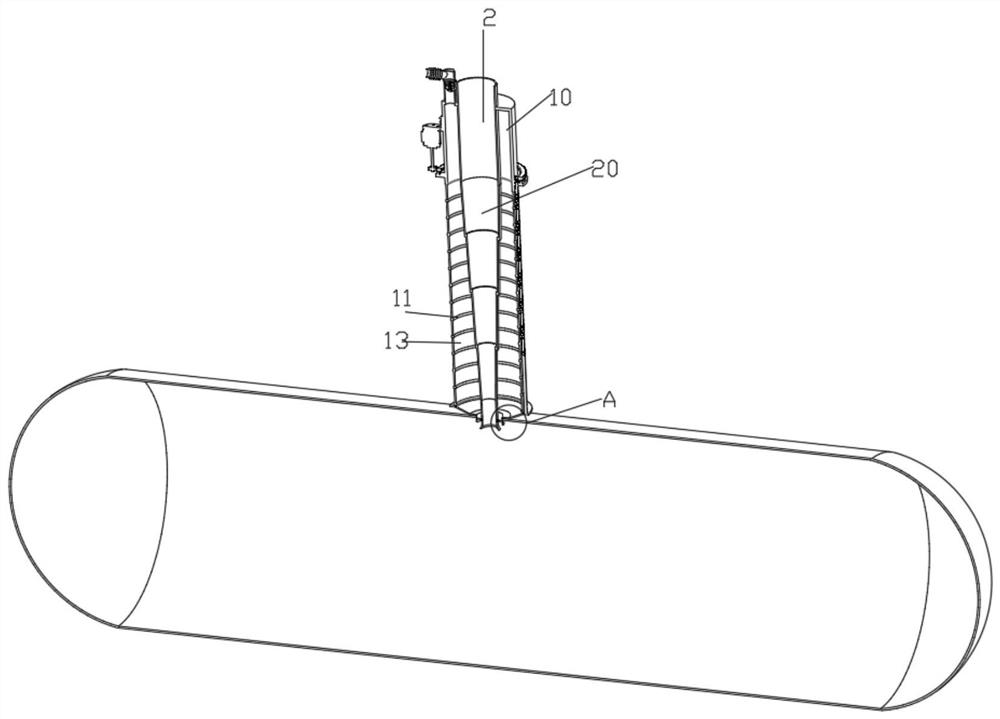

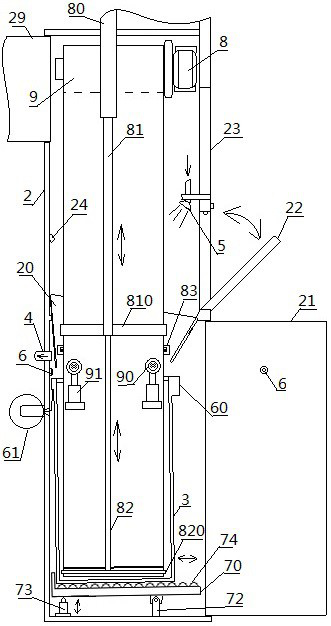

Dry ash sealing and telescopic bulk device

PendingCN113277340AReduce relative spacingImprove stabilityDispersed particle filtrationLoading/unloadingThermodynamicsStraight tube

The invention discloses a dry ash sealing telescopic bulk device, and relates to the technical field of dry ash conveying. The dry ash sealing telescopic bulk device comprises a discharging pipe and a tank car, wherein a feeding hole is formed in the middle end of the top of the tank car, six groups of telescopic sleeves are arranged at the bottom of the discharging pipe, the bottoms of the inner walls of the upper group of telescopic sleeves make contact with the outer walls of the tops of the lower group of telescopic sleeves in an attached mode, the bottom of the telescopic sleeve at the lowest end is fixedly connected to a discharging inner ring, the outer wall of the upper end of the discharging pipe is fixedly connected to a dust collection sleeve, the top of the dust collection sleeve is fixedly connected to a straight pipe, the straight pipe is connected to a filtering structure used for filtering dust, the filtering structure has a blockage clearing function, the top of the straight pipe is in threaded connection with the straight pipe, and the side wall of the straight pipe is fixedly connected to a supporting ring. According to the above solution, no gap exists after each stage of telescopic sleeves is expanded, so that dry ash does not escape due to the existence of pressure difference in the falling process of the discharging pipe.

Owner:中电国瑞供应链管理有限公司淮南分公司

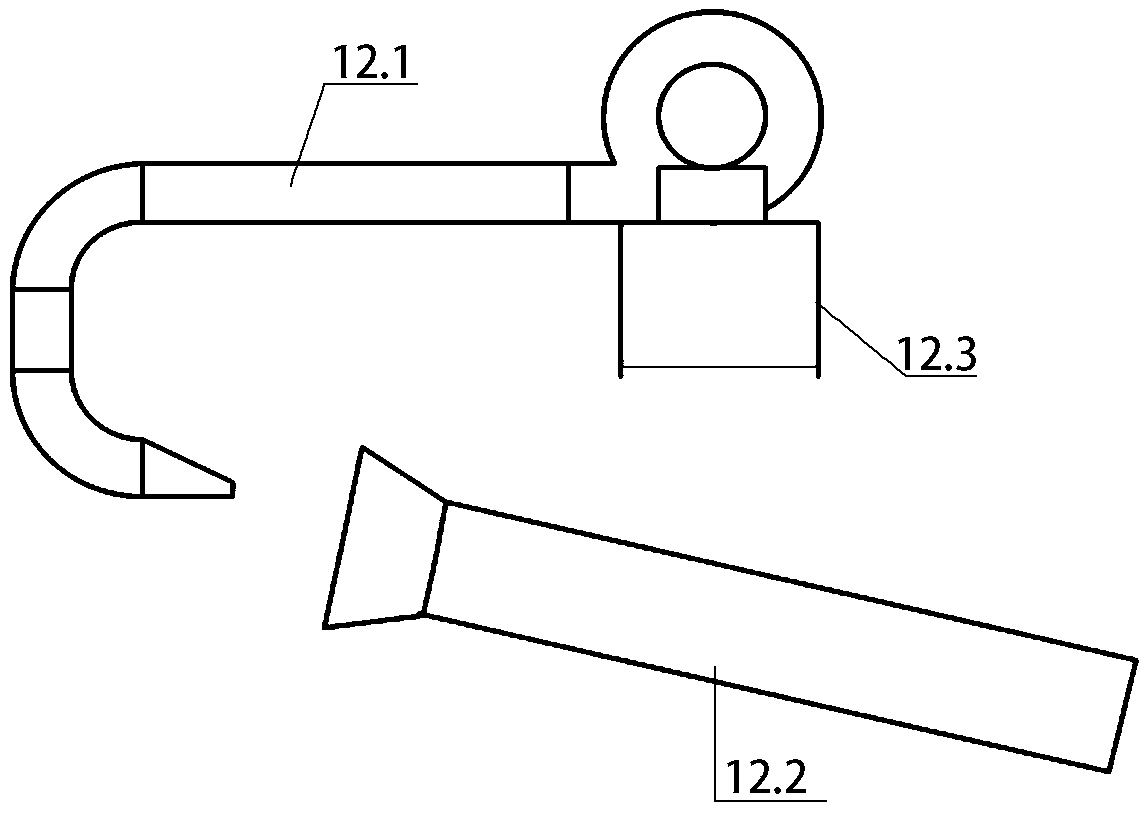

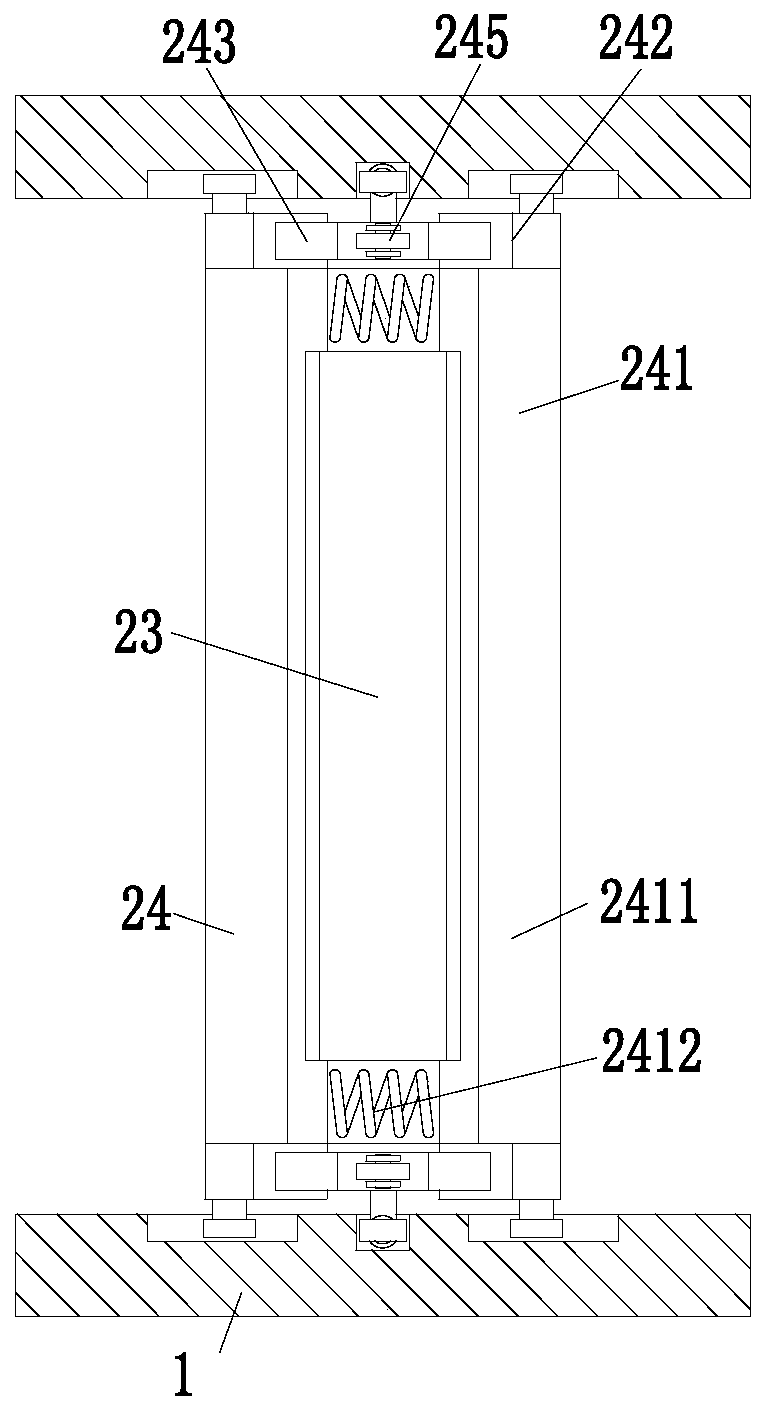

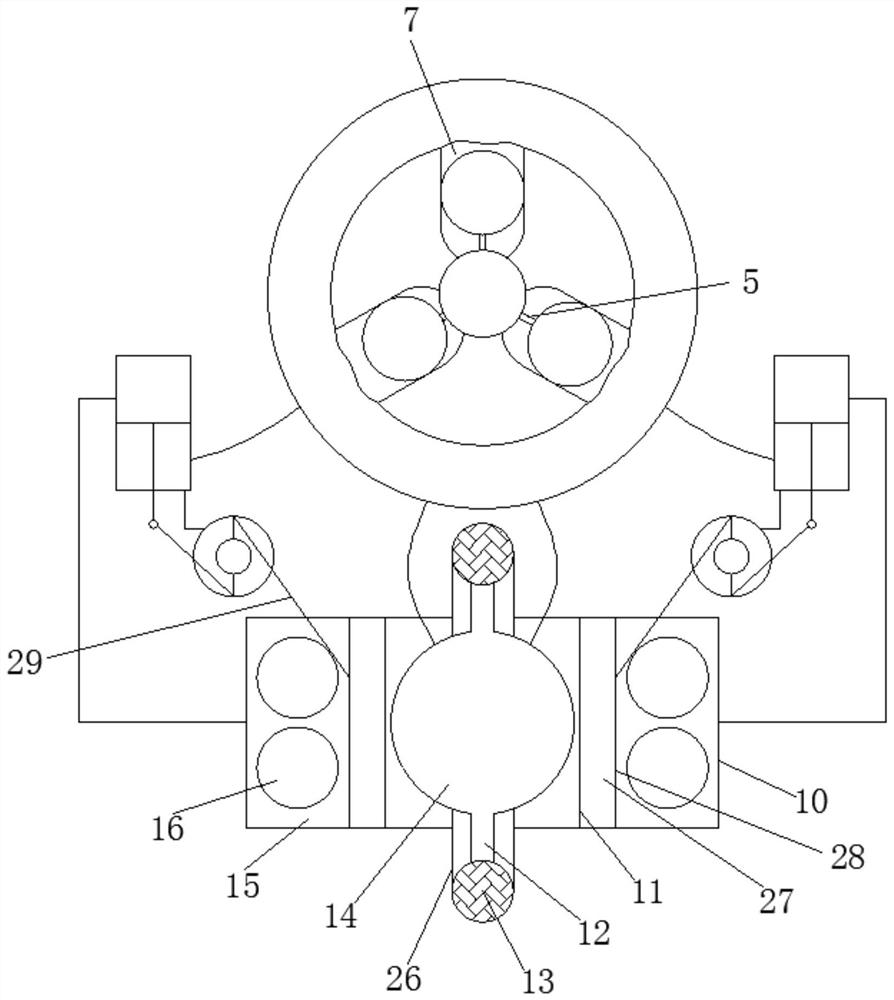

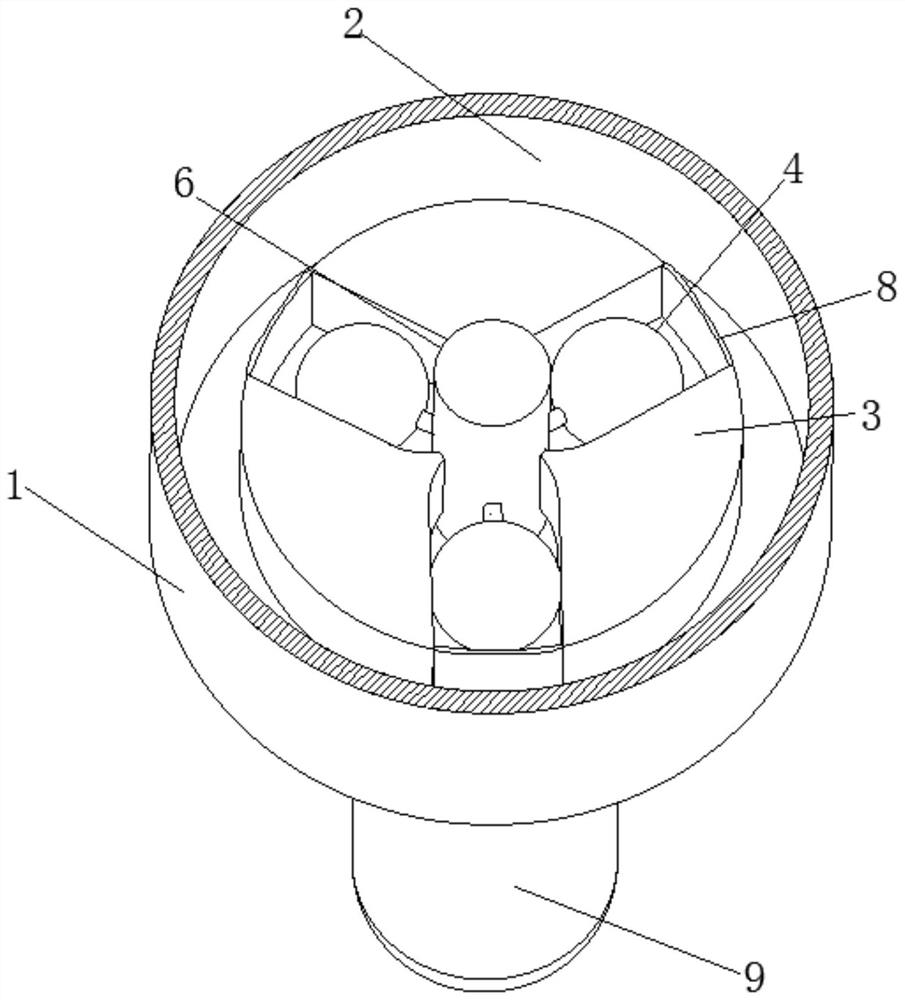

Yarn dip dyeing post-treatment device and method

InactiveCN111020941AGuaranteed Dip Dyeing EffectAvoid secondary wasteTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingYarnPolymer science

The invention relates to a yarn dip dyeing post-treatment device and a yarn dip dyeing post-treatment method. The yarn dip dyeing post-treatment device comprises a fixing frame, a draining device anda washing device, wherein the fixing frame is of a U-shaped structure, the draining device is mounted on the left side in the fixing frame, the washing device is arranged on the right side of the draining device, and the washing device is mounted on the right side in the fixing frame. With the device and the method, the problems that when an existing device is used for processing dip-dyed yarns, alarge amount of dye liquor adheres to the surfaces of the yarns generally, the dye liquor cannot be drained and collected effectively, then waste of the dye liquor is caused easily, meanwhile, the dye liquor has difficulty in immersing into the yarns, so that the dip-dyeing effect of the yarns is poor, moreover, when the existing device is used for washing the yarns, layered washing cannot be carried out on the yarns, so that the washing effect of the yarns is poor and the washing is incomplete, and then the subsequent processing effect of the yarns is influenced are solved.

Owner:卫平山

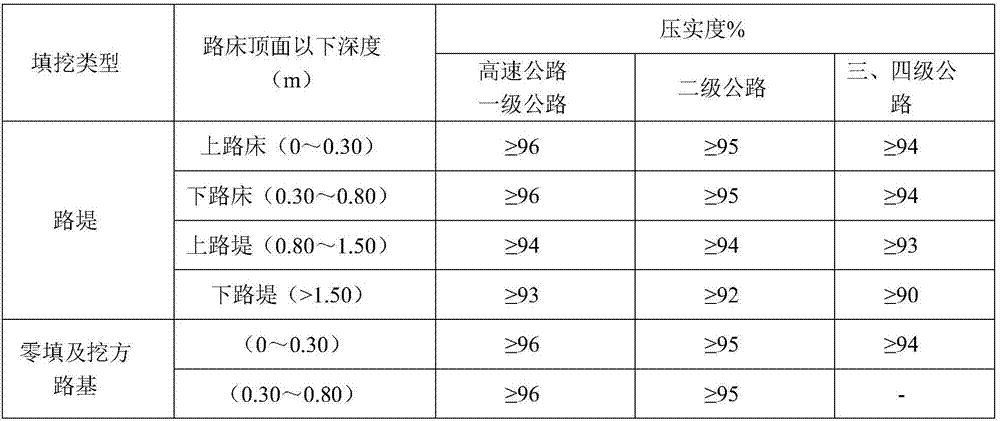

Preparation method and construction method of domestic waste incineration slag comprehensive stabilized soil

The invention discloses a preparation method of domestic waste incineration slag comprehensive stabilized soil. The preparation method comprises the following steps: (1) preparing domestic waste incineration slag; (2) carrying out crushing; (3) respectively selecting 5-20 parts of domestic waste incineration slag with particle size of 2.36mm-4.75mm, 10-20 parts of domestic waste incineration slagwith particle size of 1.18mm-2.36mm, 10-20 parts of domestic waste incineration slag with particle size of 0.600mm-1.18mm, 10-20 parts of domestic waste incineration slag with particle size of 0.300mm-0.600mm, 10-20 parts of domestic waste incineration slag with particle size of 0.150mm-0.300mm and 5-10 parts of domestic waste incineration slag with particle size of 0-0.150mm; (4) doping a curingagent; and (5) adding the mixture obtained in the step (4) into plain soil, adding a proper amount of water, and stirring. After metals are removed from the domestic waste incineration slag, the domestic waste incineration slag is applied to fillings of a pavement, so that the sorting time and the treatment cost are avoided; and the domestic waste incineration slag can be maximally utilized, so that secondary waste is avoided.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD +1

A kind of solid heat storage material and its preparation method and application

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

A short process method for preparing high-performance sintered NdFeB magnets from sintered NdFeB sludge waste

ActiveCN104690270BReduce manufacturing costAvoid secondary wasteInductances/transformers/magnets manufactureMagnetic materialsMetallurgySintered magnets

Owner:BEIJING UNIV OF TECH

Multi-stage phase change recovery and storage device for heat in continuous casting and billet cooling process

InactiveCN112229228ASufficient heat recoveryIncrease profitHeat storage plantsIncreasing energy efficiencyProcess engineeringManufacturing engineering

The invention relates to a multi-stage phase change recovery and storage device for heat in continuous casting and billet cooling processes. A phase change energy storage material is used for recovering and storing a large amount of high-temperature heat generated in continuous casting and high-temperature billet stacking and cooling processes in a metallurgy process. The device comprises a high-temperature continuous casting process phase change recovery energy storage cover, a billet conveying device, a billet stacking cooling chamber and a control system. The high-temperature continuous casting process phase change recovery energy storage cover is used for recovering and storing heat energy in the continuous casting process, and the billet stacking cooling chamber is used for recoveringand storing heat energy in the billet cooling process. The device has the beneficial effects that a large amount of heat released in the high-temperature metal continuous casting process and the billet stacking and cooling process is recovered and stored by using the phase change energy storage material in a multi-stage mode, the recovered and stored heat is used for steam power generation, heatrecovery is sufficient, and meanwhile the energy utilization rate is increased.

Owner:NORTHEASTERN UNIV

A single-opening, double-opening Chinese-style armored door and its manufacturing and installation process

ActiveCN105298335BAvoid damage phenomenonSolving the Wasted White Space ConundrumFrame fasteningWindow/door framesEngineeringBuilding construction

The invention discloses a single-leaf Chinese-style armored door, which is composed of a door frame, a door leaf, a door lock side wrapping, a hinge side wrapping, a door lock, a hinge and a door core. A double-opening Chinese-style armored door is composed of a door frame, a child and a mother door leaf, a door lock side wrapping, a hinge side wrapping, a door lock, a hinge, a child and a mother door core. A single-opening Chinese-style armored door production and installation process includes the following steps: making a door frame; making a door core; making an edge and a cover plate; assembling the door frame and door core; making a decorative panel; assembling a decorative panel. A production and installation process of a double-opening Chinese-style armored door, comprising the following steps: making a door frame; making child and mother door cores; making wrapping and cover plates; assembling the door frame and door core; making child and mother decorative panels; and assembling decorative panels. The invention solves the door panel damage phenomenon in the cross construction process; solves the secondary waste of replacement and maintenance of the whole door after damage, and is beneficial to environmental protection; the production and construction procedures are simplified, the labor cost is reduced by 40%, and the sealing, sound insulation and heat insulation effects are improved it is good.

Owner:上海璞玉门业有限公司

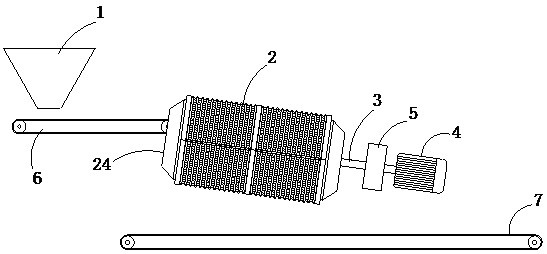

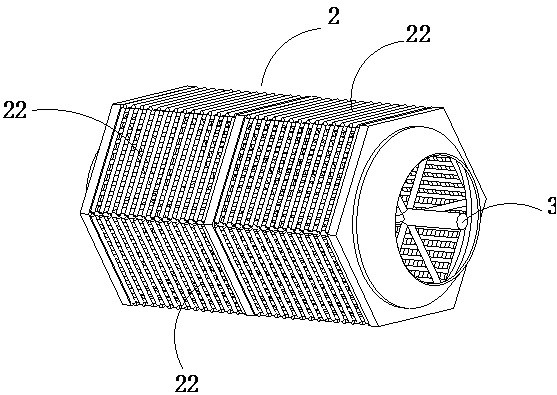

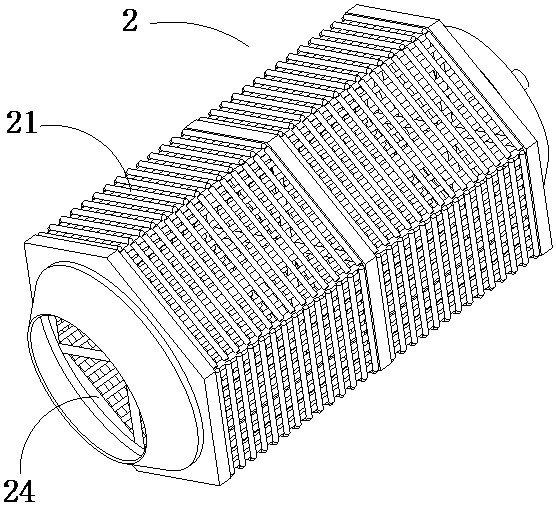

Glass crushing method and crushing device

ActiveCN111841816AEnsure proper recyclingEffective control of particle sizeGlass recyclingGrain treatmentsWaste productEnvironmental engineering

The invention relates to the technical field of solid waste recycling treatment, is used for the garbage environment-friendly recycling industry, and particularly relates to a glass crushing method and a crushing device. According to the glass crushing method and the crushing device, the particle size of crushed glass particles can be effectively controlled in the glass waste crushing process, andthe formation of powdery glass particles can be greatly reduced, so that glass reclaimed material particles can be effectively detected, identified and screened out of high-temperature-resistant glass by a high-temperature-resistant glass detection device, the high quality of the recycled glass material is ensured, a large amount of waste glass regeneration products can be prevented from being scrapped, normal recycling of glass waste products is ensured, secondary waste of resources is avoided, and healthy development of the environmental protection industry is facilitated.

Owner:韶关豪立再生资源利用有限公司

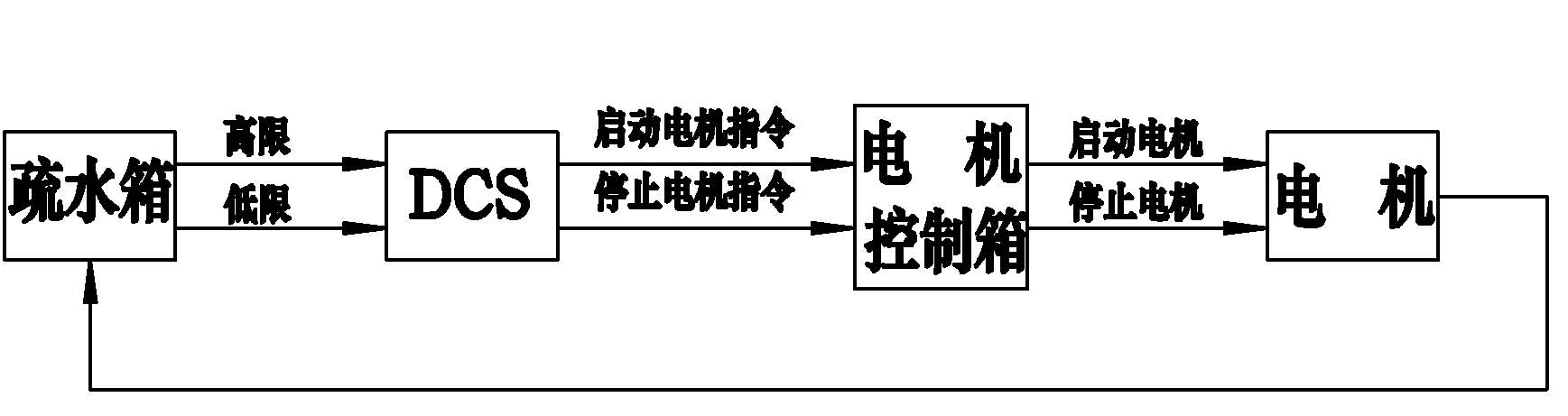

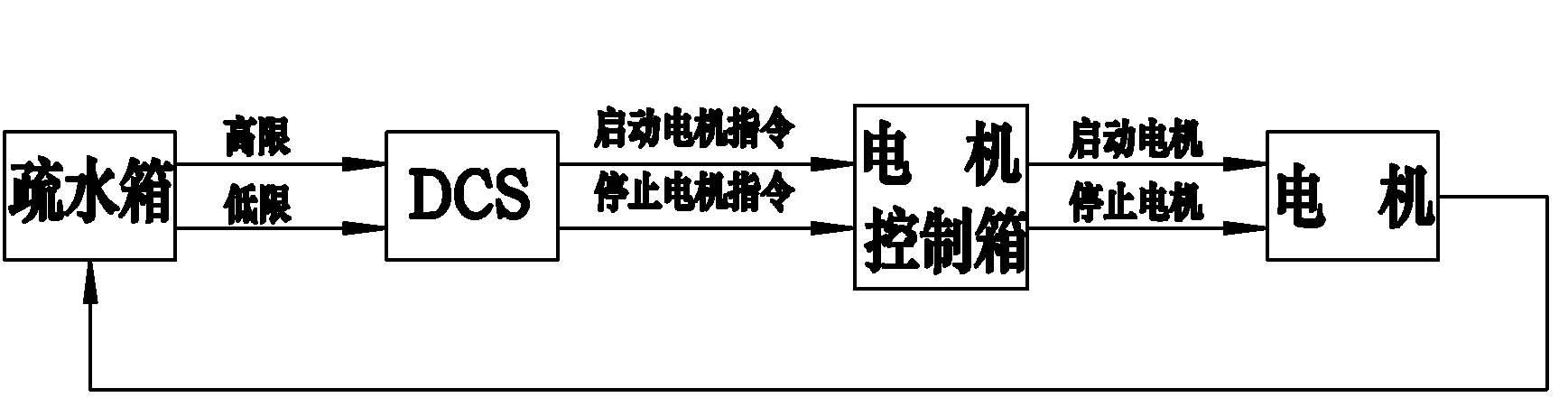

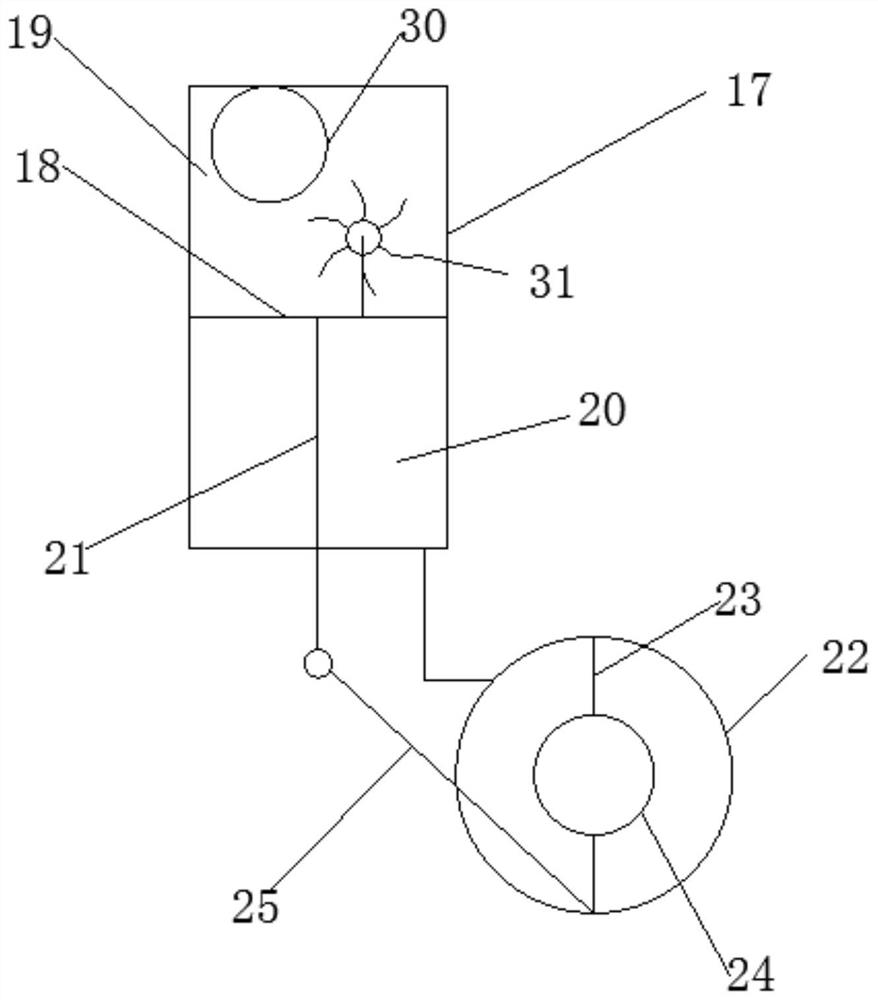

System for monitoring reclamation of condensation water produced by papermaking

InactiveCN102023630AAvoid secondary wasteTotal factory controlProgramme total factory controlElectricityLower limit

The invention discloses a system for monitoring the reclamation of condensation water produced by papermaking, which comprises a water gauge, a DCS system, a motor-controlled cabinet and a motor, wherein the water gauge is arranged in a drainage tank; the water gauge is electrically connected with the DCS system, the DCS system is electrically connected with the motor-controlled cabinet, and the motor-controlled cabinet is electrically connected with the motor; the motor is arranged at a drainage pump; the drainage pump is communicated with the drainage tank; and the water gauge is provided with a warner for providing an alarm when the drainage tank achieves a high limit and a warner for providing an alarm when the drainage tank achieves a low limit. The system provided by the invention has the advantage that a system for automatically controlling and monitoring the water level of the drainage tank is added on the DCS control system, thereby overcoming the secondary waste of the condensation water in a condensation water reclamation system caused by that the capacity of the drainage tank is limited and the back water amount and the steam production amount of a boiler are imbalanced.

Owner:东莞理文造纸厂有限公司

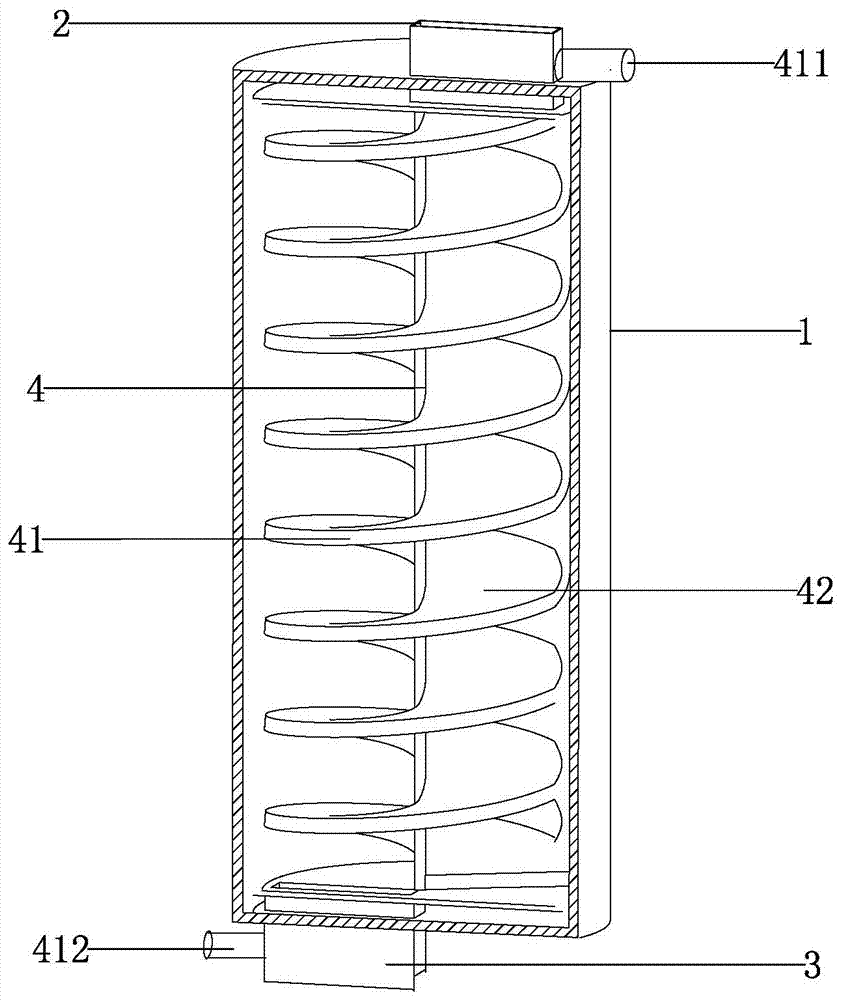

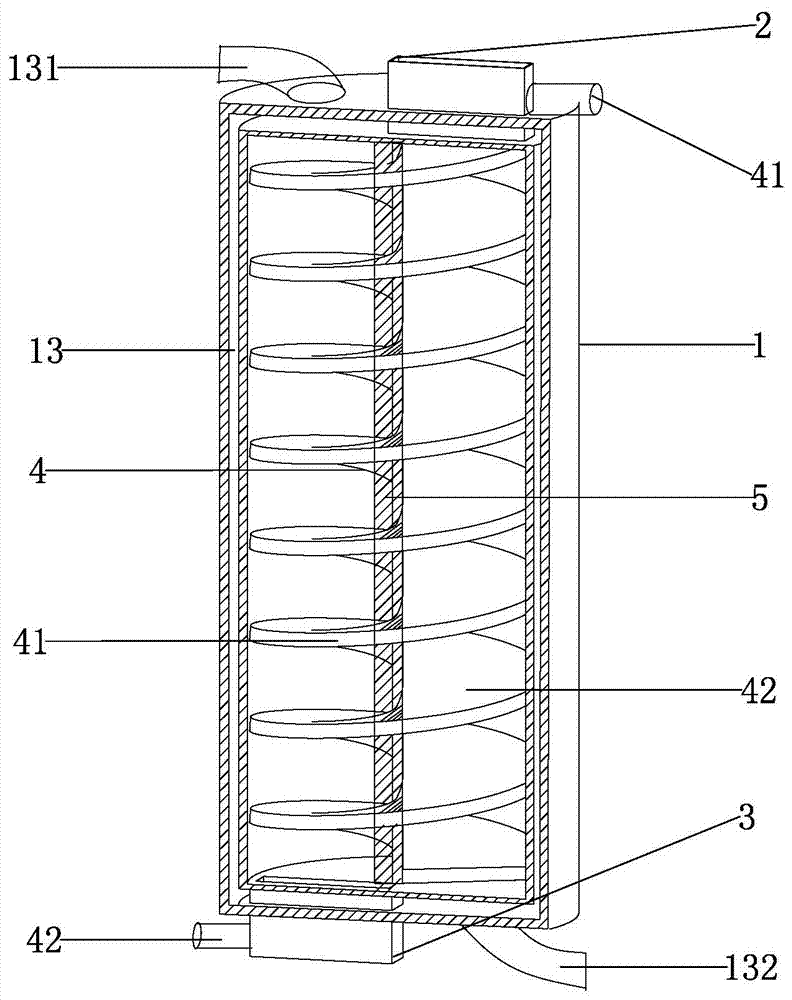

Low-energy-consumption environmentally-friendly magnetized calcination tailing cooling processing system

The invention provides a low-energy-consumption environmentally-friendly magnetized calcination tailing cooling processing system which comprises a closed tailing cooling tank. The cooling processing system is characterized in that the closed tailing cooling tank is vertically arranged, the upper portion of the closed tailing cooling tank is provided with a material inlet, the lower portion of the closed tailing cooling tank is provided with a material outlet, and the tank is internally and vertically provided with a water circulating spiral conveying pipe; the water circulating spiral conveying pipe comprises a water circulating spiral cavity and a material spiral sliding channel, the material spiral sliding channel is located on the upper surface of the water circulating spiral cavity and is spiral downwards together with the water circulating spiral conveying pipe; and the water circulating spiral cavity comprises a water inlet and a water outlet.

Owner:XIAMEN XIN ANDE MINING TECH

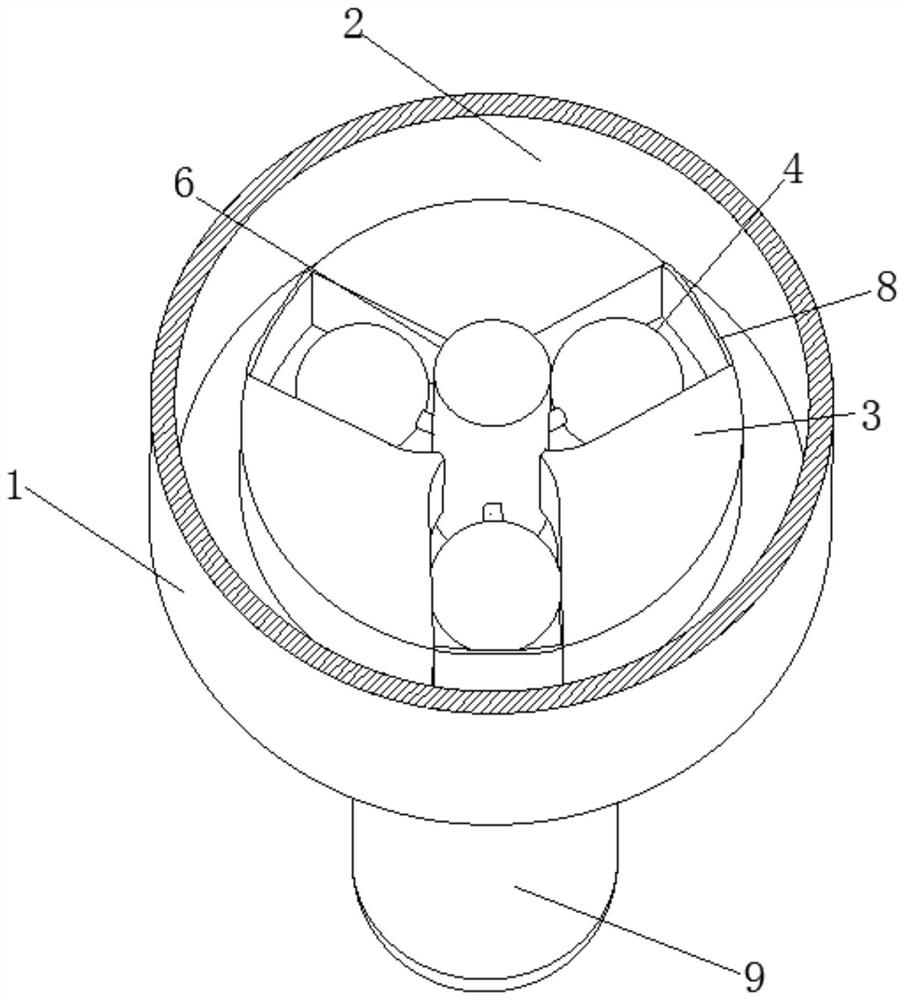

Drilling device for automatically detecting center of needle tail based on machine vision

The invention discloses a drilling device for automatically detecting the center of a needle tail based on machine vision. The drilling device comprises a drilling device body and is characterized in that a drilling cooling mechanism is arranged at the top of the drilling device body, an iron collecting mechanism is arranged below the drilling device body, the iron collecting mechanism is connected with the drilling cooling mechanism through a pipeline, spraying mechanisms are connected to the two sides of the drilling cooling mechanism through pipelines, and are connected with the iron collecting mechanism through pipelines, the drilling cooling mechanism comprises a cooling shell, a rotating shaft is connected to a middle bearing of the cooling shell, a drill bit is fixed to the bottom of the rotating shaft, a rotating disc is fixed to the surface of the rotating shaft, three sets of sliding cavities are formed in the middle of the rotating disc, counterweight balls are slidably connected to the interiors of the three sets of sliding cavities, and elastic films are connected to one sides of the three sets of sliding cavities. The drilling device has the characteristics of being high in practicability, and capable of improving the drilling quality.

Owner:云南特可科技有限公司

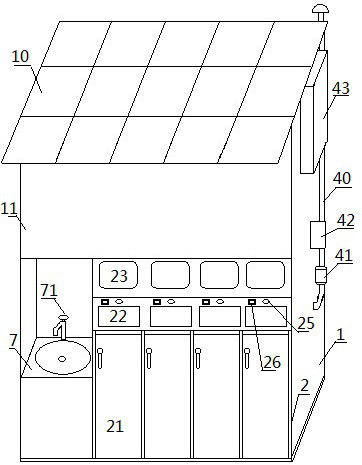

Intelligent odorless garbage storage method and system

PendingCN112938263AHygienic operationAvoid odorRefuse receptaclesRefuse cleaningProcess engineeringIndustrial engineering

The invention discloses an intelligent odorless garbage storage method and system. To solve the problem of peculiar smell of garbage cans, recyclable garbage cans, kitchen garbage cans, harmful garbage cans and other garbage cans are arranged on the front portion of a garbage storage room, each garbage can is internally provided with a garbage can body which can be moved out, and the lower part, the middle part and the upper part of each garbage can body are respectively provided with a garbage can front door, a garbage throwing front door and a display for displaying the garbage throwing condition in the garbage can; a negative pressure exhaust inlet is formed in the inner wall of the garbage can body and is communicated with a filter, a negative pressure pump and a negative pressure discharge pipe of a sterilization and deodorization box; an electronic switch linked with the garbage throwing front door is electrically connected with and controls the negative pressure pump through an intelligent controller; and when garbage is thrown into the front door, the intelligent controller starts the negative-pressure pump to conduct negative pressure discharging of the space in the garbage can, and peculiar smell is prevented from overflowing from the garbage throwing front door by forming the negative pressure condition of the garbage can and the garbage can. The system has the advantages that peculiar smell cannot overflow during garbage throwing, the garbage classification throwing enthusiasm and quality efficiency are remarkably improved, and the surrounding atmospheric environment is protected.

Owner:BEIJING KANGZHIWEI SCI & TECH

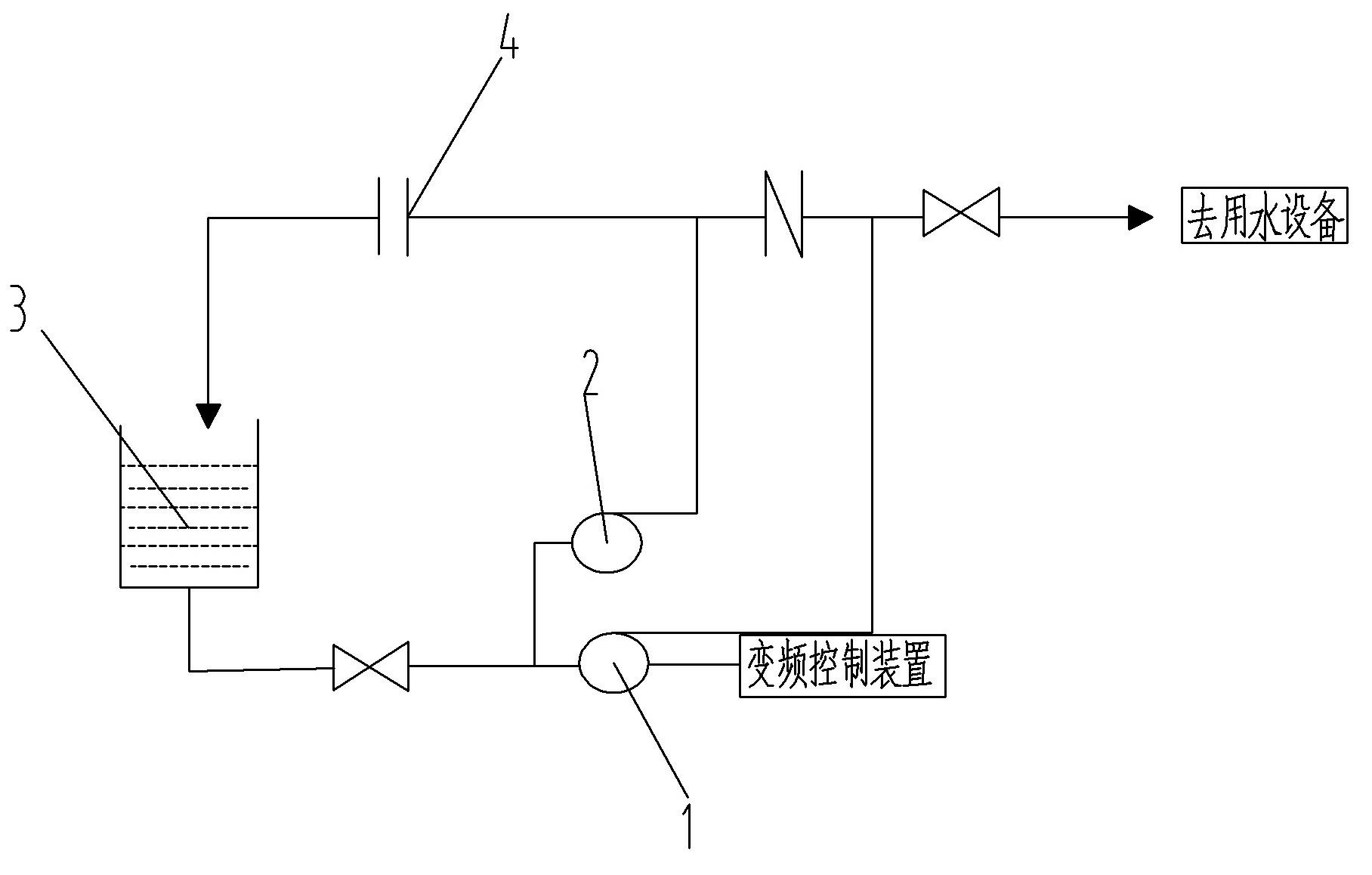

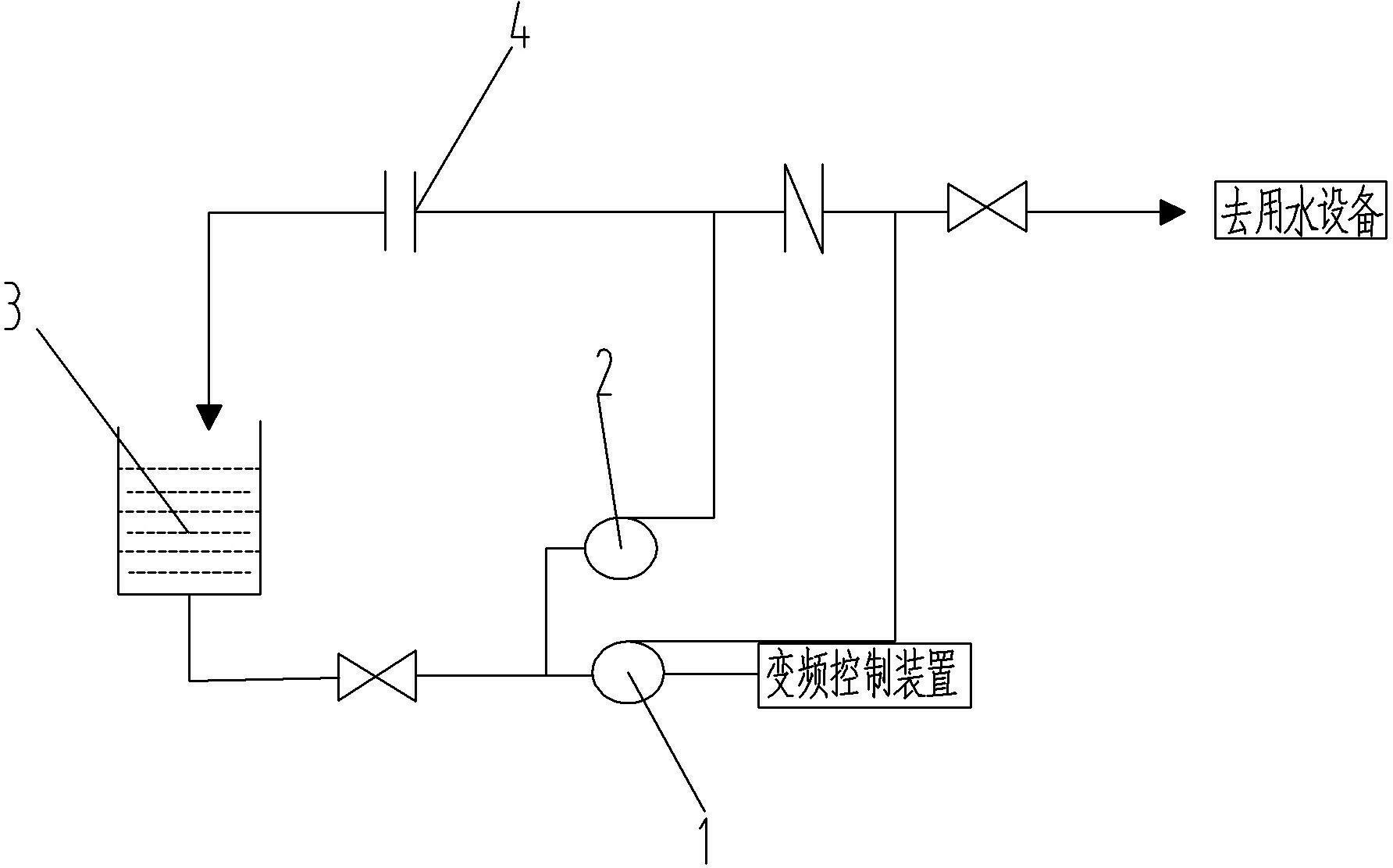

Underground variable-frequency constant-pressure water supply system

The invention discloses an underground variable-frequency constant-pressure water supply system, which comprises a reservoir, a main pump and a pore plate. The main pump is connected with a variable-frequency control device, the variable-frequency control device automatically adjusts the rotation speed of a motor of a water pump in a frequency-variable manner according to change of pressure signals of the system, and the requirement on constant-pressure water supply of the water supply system is met. The underground variable-frequency constant-pressure water supply system directly utilizes underground water resources, the pressure is freely set according to needs of equipment by the aid of variable-frequency constant-pressure water supply technology, and utilization rate of the water resources is improved; secondary waste of energy is avoided, and furthermore, a large quantity of electric energy can be saved by the aid of the frequency-variable technology when flow is changed within a large range; steady precision of the pressure is improved, and the safety running performance and the reliability of production water equipment can be obviously improved; maintenance cost is greatly lowered due to automatic constant-pressure water supply, and unattended operation can be realized; and the underground variable-frequency constant-pressure water supply system guarantees that the pressure is within an allowable range.

Owner:焦作煤业(集团)新乡能源有限公司

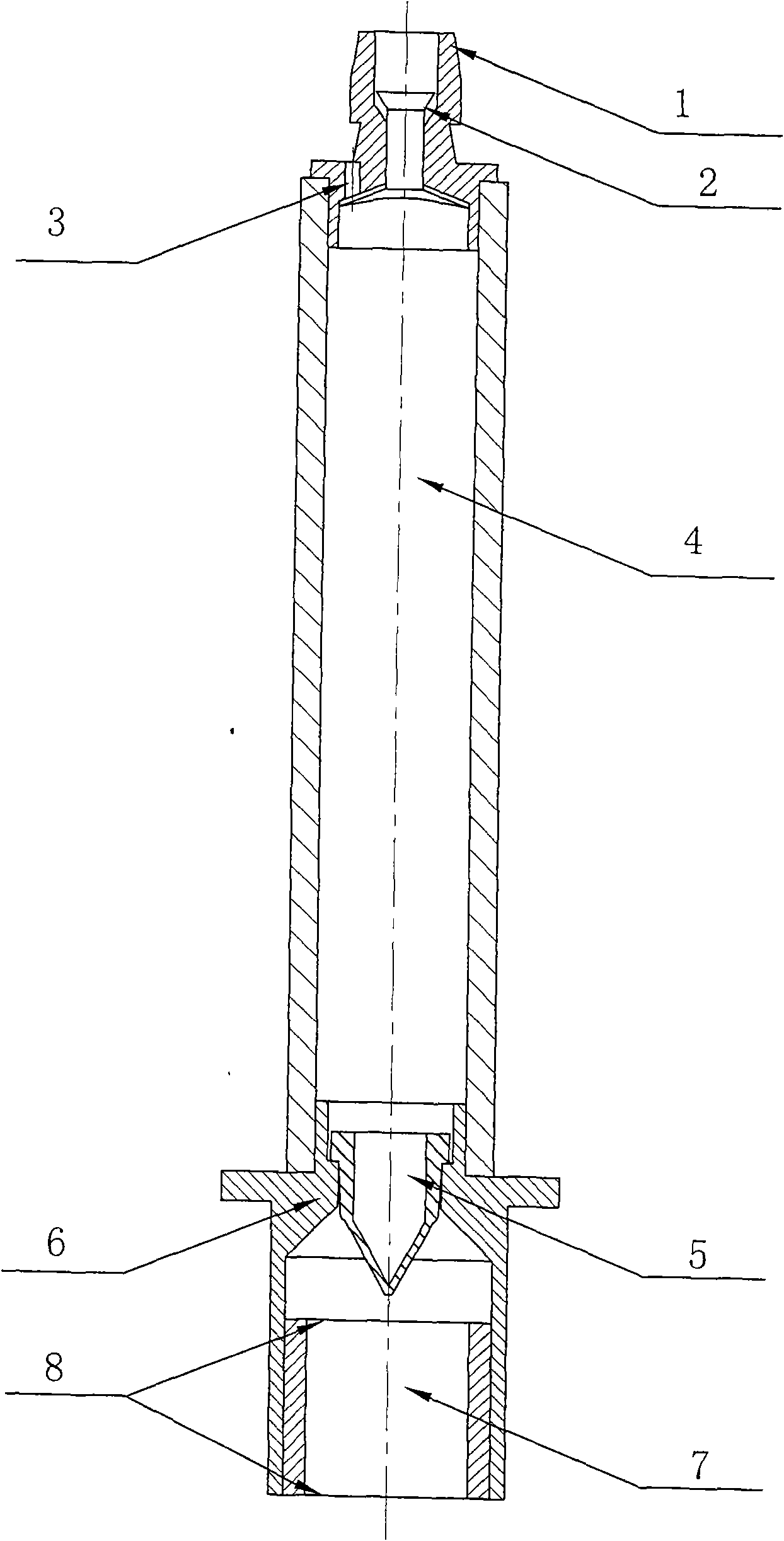

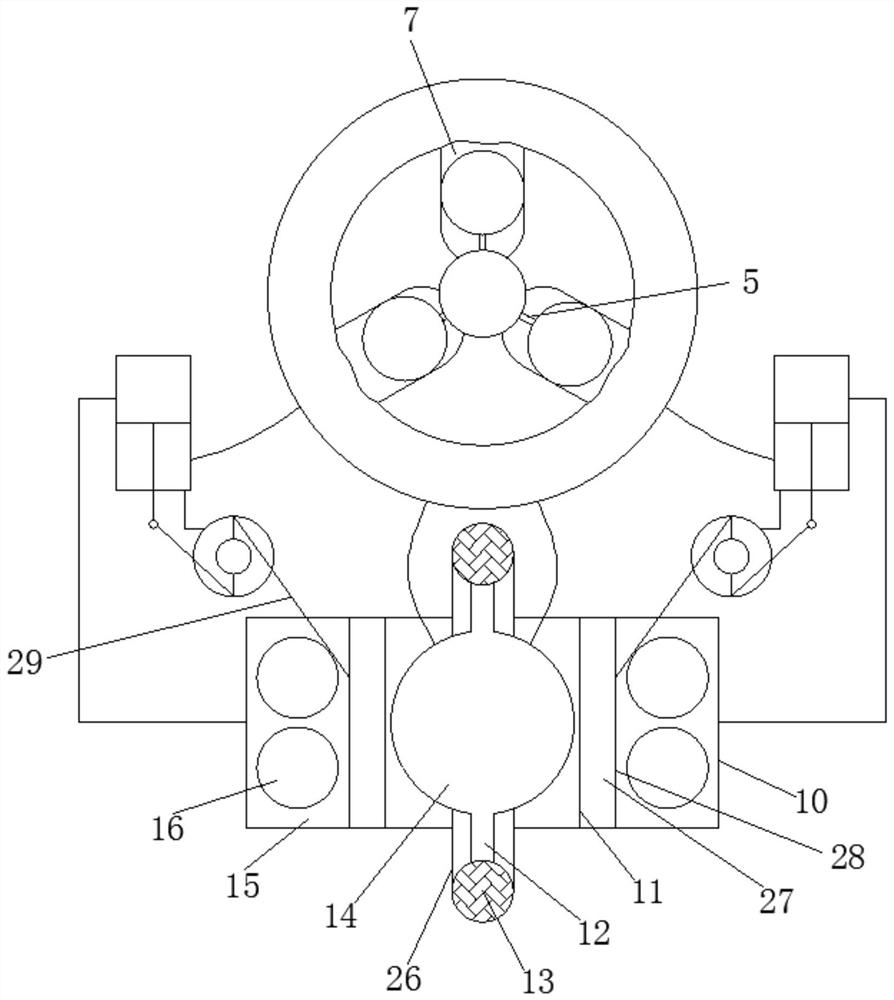

Novel general gas-liquid mixing foaming device

InactiveCN101961217AIncrease the use of functionsEasy functional interchangeHolders and dispensersGeneral purposeEngineering

The invention relates to a novel general gas-liquid mixing foaming device, which comprises a through pipe; a joint is connected above the through pipe; the through pipe is also connected with an air flue connected to the outside; a lower valve is connected below the through pipe; and a foaming device is arranged in the lower valve. The novel general gas-liquid mixing foaming device has the beneficial effects that: by combining the technology, the use function of a soap dispenser can be increased on the basis of no increase, no reduction and no modification of the conventional device to make the conventional soap dispenser device can be used for the soap dispensing function of general use, also can be used for the foaming function of special requirement, and easily realize function exchange; and the soap disperser device can be easily realized without disassembly, so that the use efficiency of a product is improved; and the used foaming function also can fulfill the aim of reasonably using water and saving water, so that the secondary waste is avoided.

Owner:孙文武

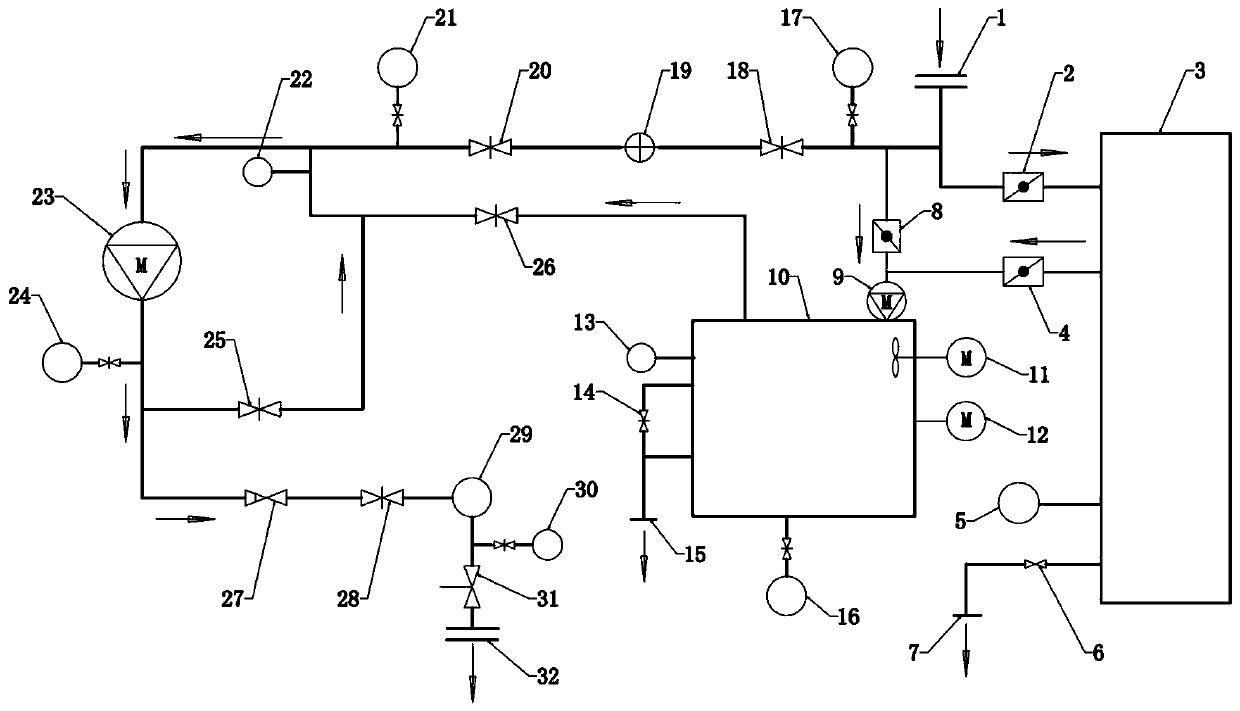

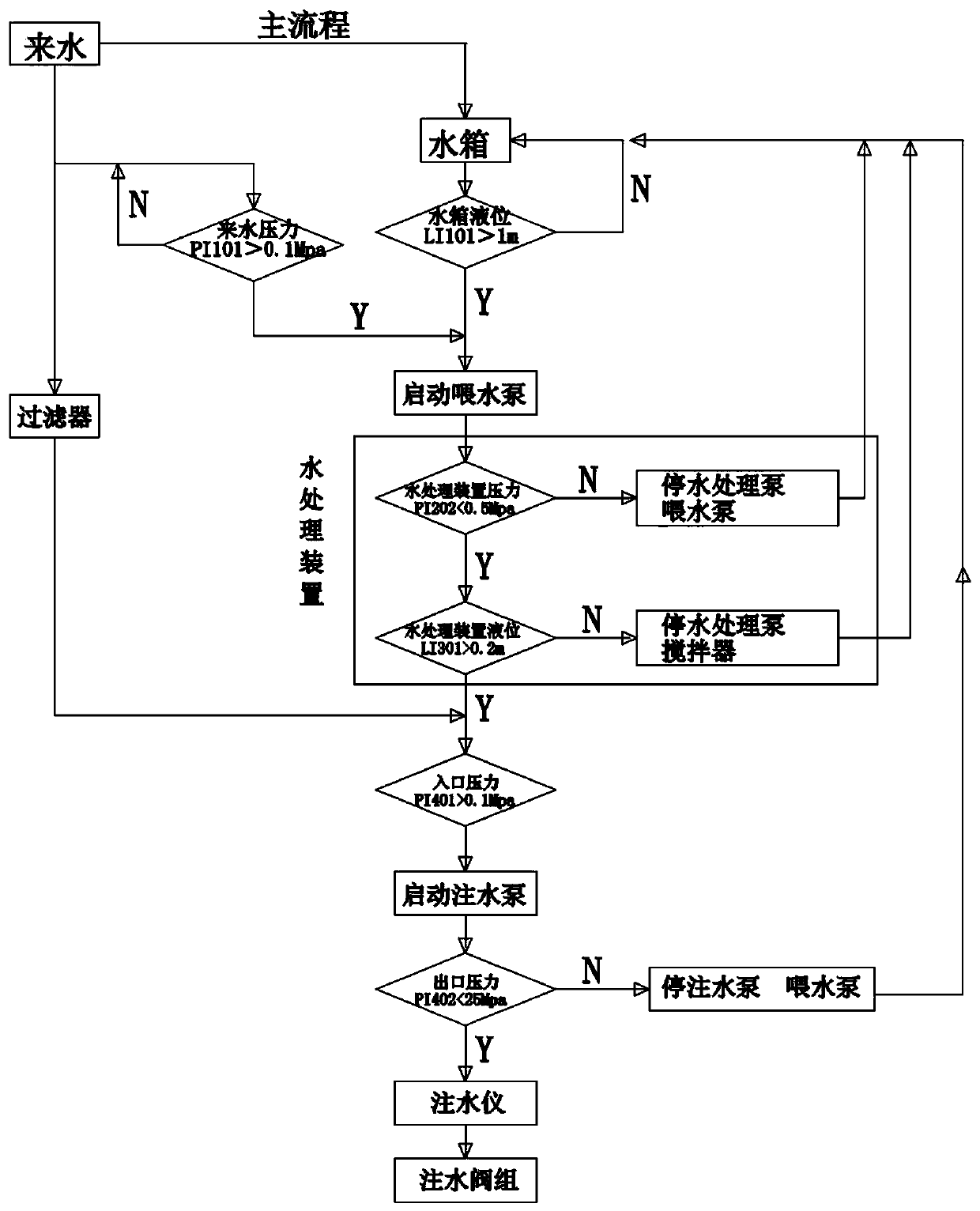

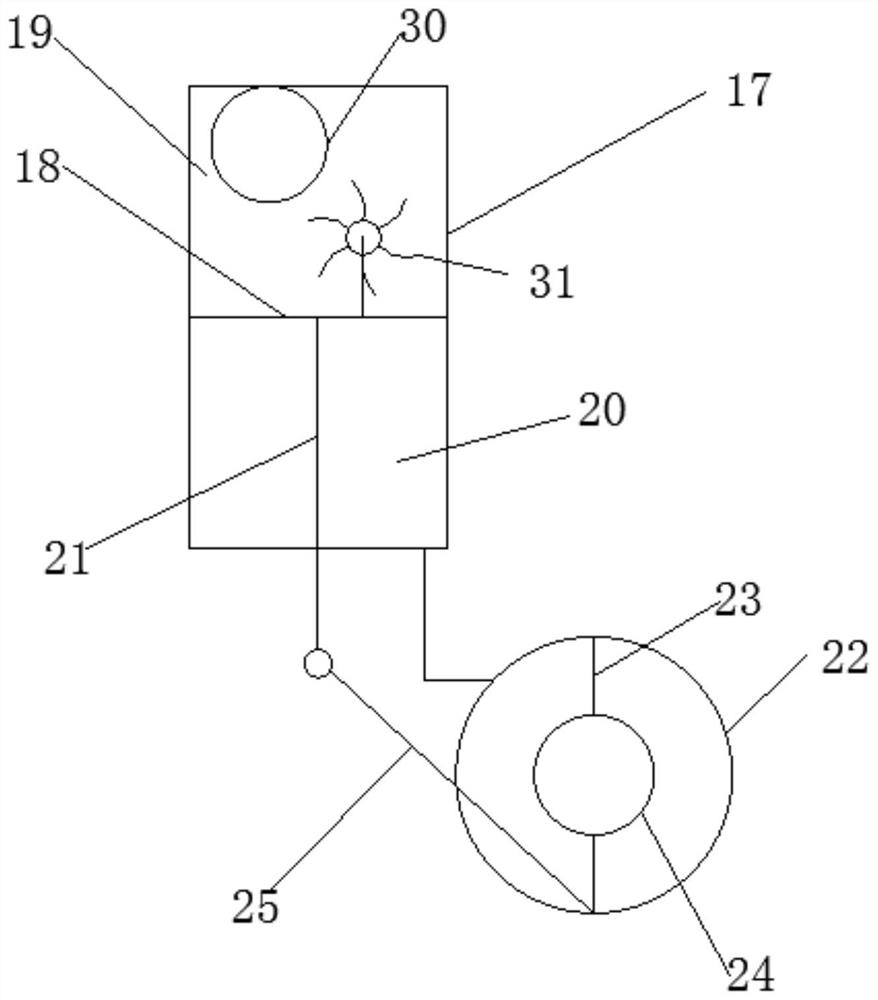

Water injection integrated integrated device and control method

InactiveCN106886236BAvoid secondary wasteSmall footprintSimultaneous control of multiple variablesWater sourceSmall footprint

The invention discloses a water injection integration apparatus and a controlling method thereof. The apparatus comprises a prying base and a water injection system installed at the prying base. The water injection system consists of a water tank, a water feeding pump, a water treatment device and a water injection pump. A water inlet of the water tank is connected with a water source inlet through a pipeline and a water outlet of the water tank is connected with a water inlet of the water feeding pump through a pipeline; a water outlet of the water feeding pump is connected with a water inlet of the water treatment device; a water outlet of the water treatment device is connected with a water inlet of the water injection pump by a pipeline; a water outlet of the water injection pump is connected with a water injection outlet by a pipeline. On the basis of the prying structure, the area occupied by the apparatus is small; assembling becomes convenient; and the apparatus can be allocated and transported repeatedly. With the pressure of the pipe network, water injection is carried out directly or indirectly after boosting, so that secondary energy wasting is avoided and the system efficiency is high; the automation degree is high and the protection functions are completed; and the unattended operation can be realized.

Owner:北京永松菱控技术有限公司

Wheat straw plate for enclosing construction site

InactiveCN106567608AQuality improvementHigh aesthetic valueFencingWood working apparatusBiotechnologySocial benefits

The invention discloses a wheat straw plate for enclosing construction site. The wheat straw plate includes wheat straw, an adhesive and a functional additive. The technical characters of the wheat straw plate are that paving, rolling and trimming is performed on the wheat straw sprayed with the adhesive and the functional additive; and the wheat straw is a naturally-dried raw material. The cheap wheat straw material can be used to provide cheap and fine baffle plates for increasing construction sites, and can provide the cheap and fine baffle plates with reducing five production processes; the conventional mode in which the wheat straw is used for paper making, combustion, fodder and straw mulching (the wheat straw will cause serious water pollution, wheat straw combustion will result in serious air pollution, which are forbidden in our county) is broken through. The wheat straw is used for making plates for enclosing the construction sites, waste materials can be reused, secondary waste can be avoided, the consumption of timber is reduced, and good economic benefits and wide social benefits can be achieved.

Owner:李传集

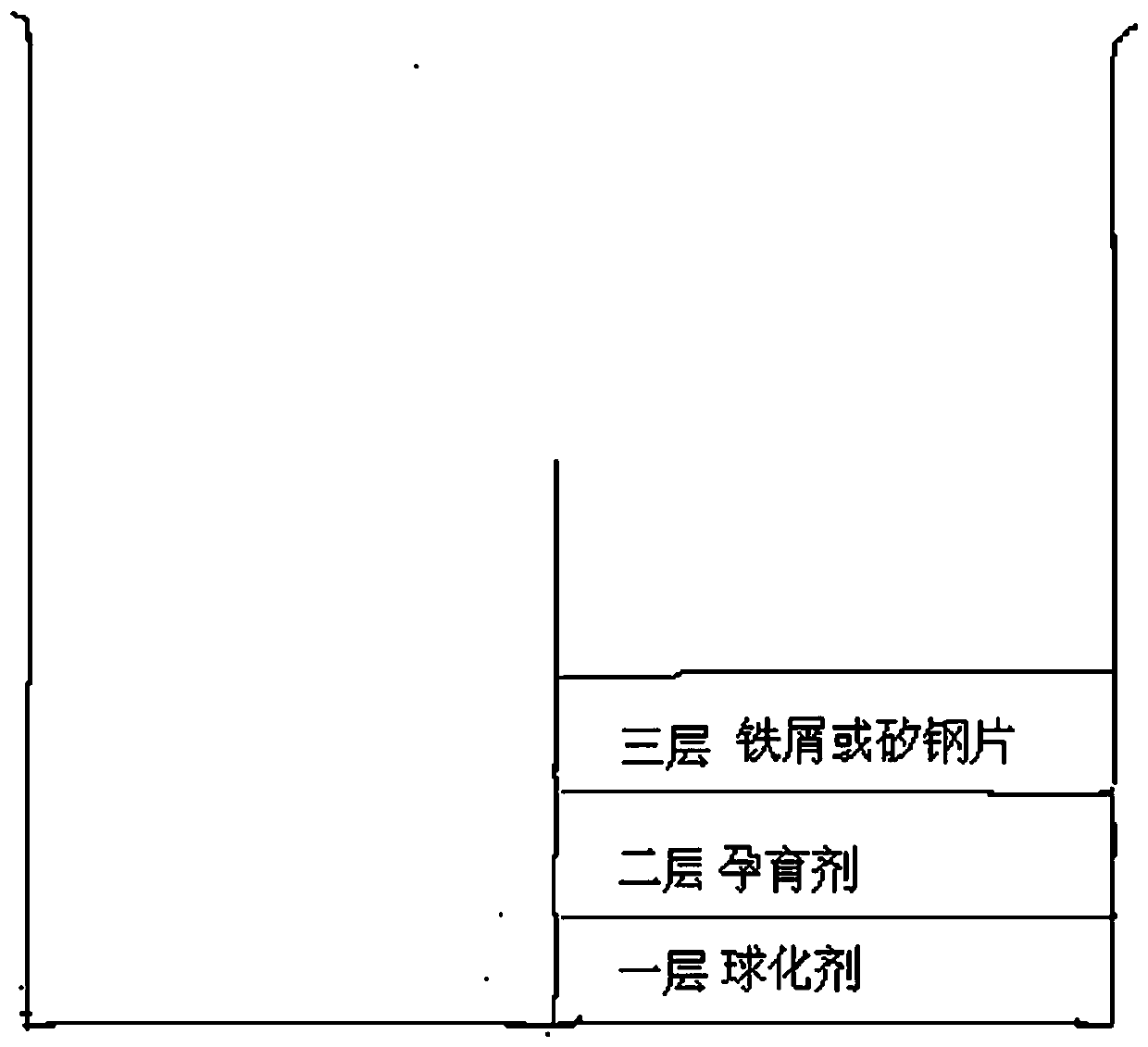

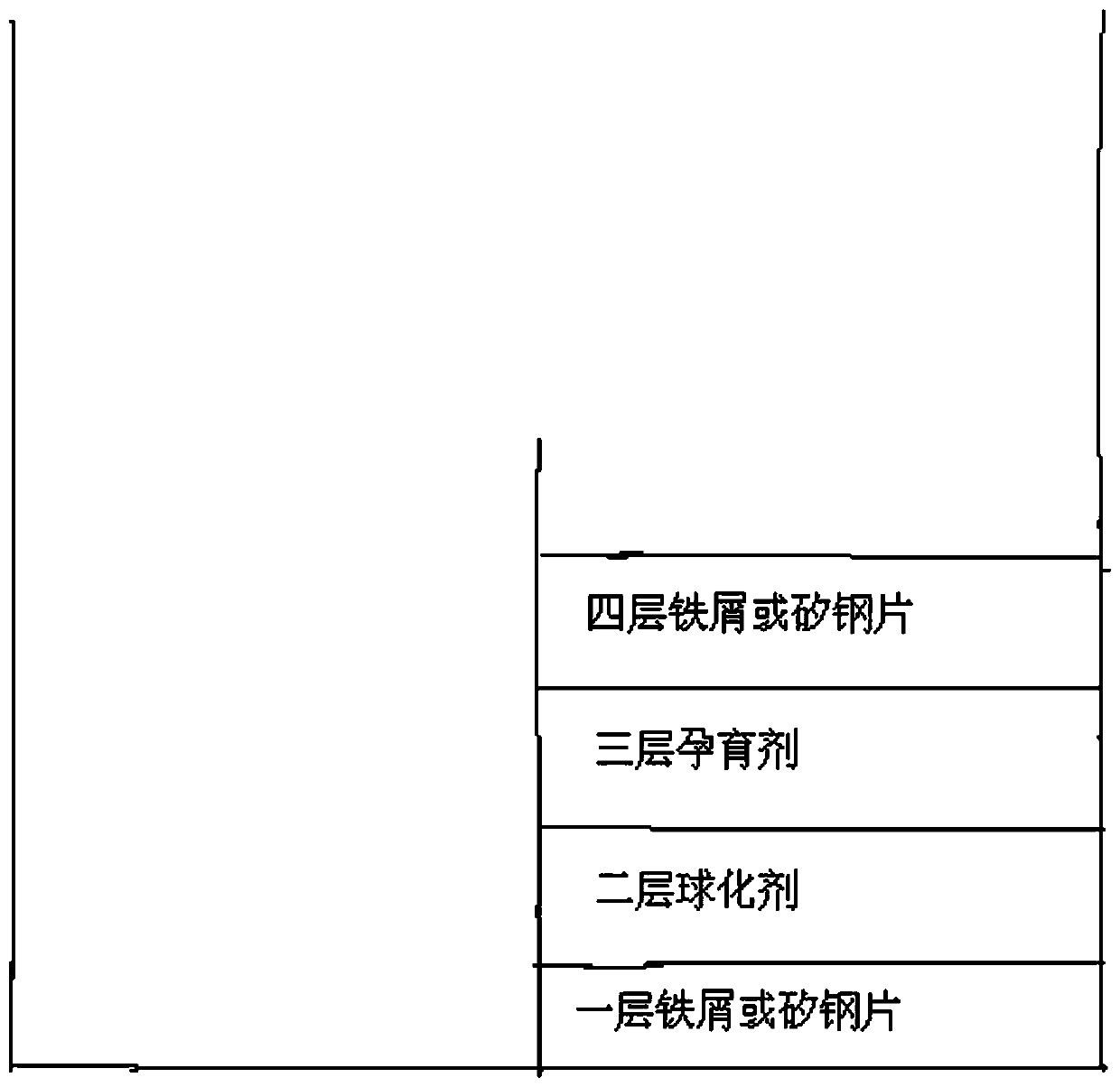

A pressing process for preventing nodularizing agent from sticking to the package

The invention discloses a ladle pressing technology capable of preventing a nodulizing agent from sticking to a ladle. The ladle pressing technology comprises the steps of (1) uniformly laying scrap iron or silicon steel sheets in pits in one side of a dam type pouring ladle dam as a first layer, carrying out leveling, and carrying out compacting through hammering; (2) uniformly laying the nodulizing agent on the first layer as a second layer, carrying out leveling, and carrying out compacting through hammering; (3) uniformly laying a nucleating agent on the second layer as a third layer, carrying out leveling, and carrying out compacting through hammering; and (4) uniformly laying scrap iron or silicon steel sheets on the third layer as a fourth layer, carrying out leveling, and carrying out compacting through hammering, wherein the sum of the first layer thickness, the second layer thickness, the third layer thickness and the fourth layer thickness is not larger than the height of the dam type pouring ladle dam. According to the ladle pressing technology capable of preventing the nodulizing agent from sticking to the ladle provided by the invention, the problem that the nodulizing agent is liable to soften and stick to the bottom of a pouring ladle under high-temperature baking is solved.

Owner:西峡飞龙特种铸造有限公司

A center drilling device for automatic detection of needle tail based on machine vision

ActiveCN113182925BLess quantityControl quantityMaintainance and safety accessoriesRotational axisMachine vision

The invention discloses a drilling device for automatically detecting the center of a needle tail based on machine vision, which includes a drilling device, and is characterized in that a drilling cooling mechanism is arranged on the top of the drilling device, and a Iron collecting mechanism, the iron collecting mechanism is connected to the drilling cooling mechanism by pipes, the spraying mechanism is connected to the pipes on both sides of the drilling cooling mechanism, the spraying mechanism and the iron collecting mechanism are connected by pipelines, and the drilling cooling mechanism The mechanism includes a cooling shell, the middle bearing of the cooling shell is connected with a rotating shaft, the bottom of the rotating shaft is fixed with a drill bit, the surface of the rotating shaft is fixed with a rotating disc, and three groups of sliding cavities are opened in the middle of the rotating disc, The insides of the sliding cavities of the three groups are all slidably connected with counterweight balls, and the sides of the sliding cavities of the three groups are all connected with elastic membranes. The present invention has the characteristics of strong practicability and improved drilling quality.

Owner:云南特可科技有限公司

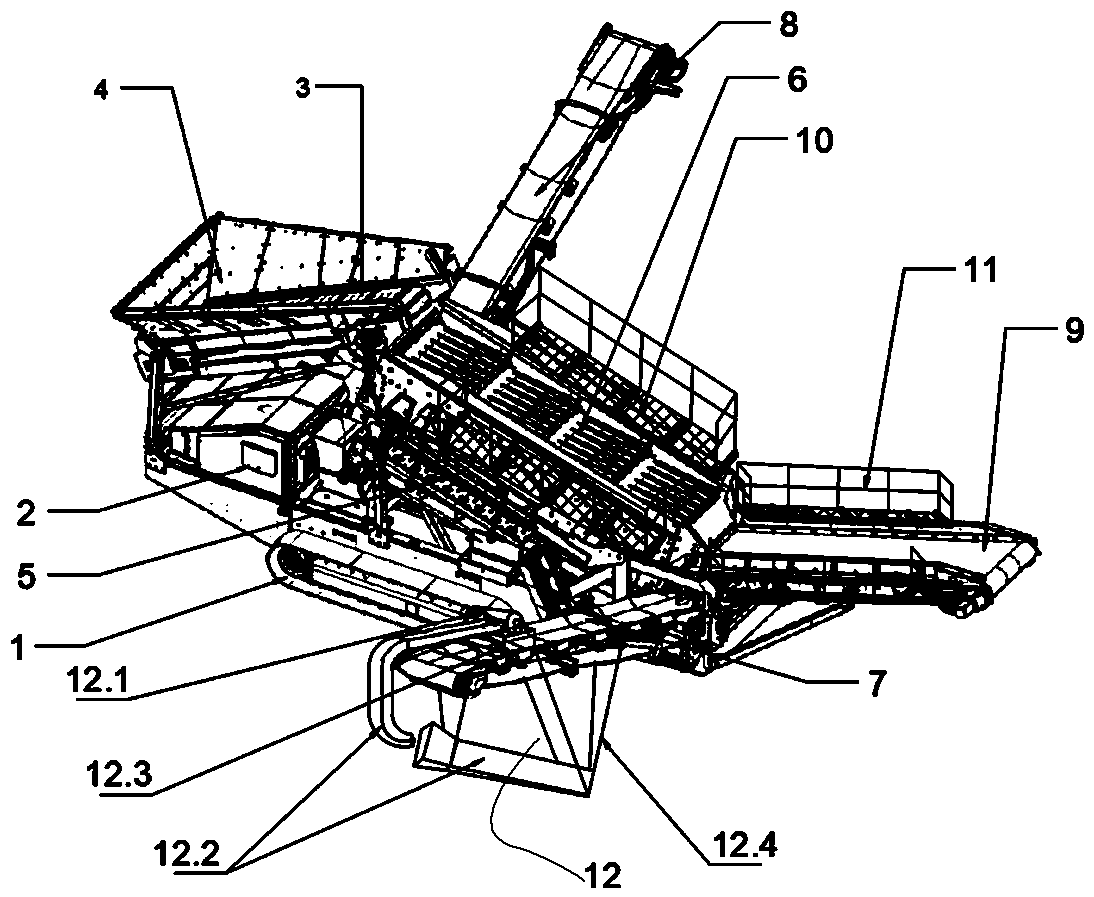

A garbage sorting device

ActiveCN105537242BTo achieve the purpose of classificationReduce usageSolid waste disposalGarbage disposalWaste management

The invention relates to a garbage classification and disposal device, and belongs to the environment protection field, in particular to the garbage disposal field. By arranging the smart garbage classification device, there is no need to arrange garbage cans or other garbage storage facilities at homes or workplaces, and various kinds of garbage can be classified and disposed at any time. The purposes of classifying the garbage and disposing the garbage at any time are realized, and less indoor related facilities are needed.

Owner:HENAN WINNER VIBRATING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com