Patents

Literature

147results about How to "Improve cropping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid agent multielement fertilizer and its production method

InactiveCN1410395AChange physiologyPromote absorptionOrganic fertilisersFertilizer mixturesManganesePlant cell

A multi-element liquid fertilizer contains active components, additive and water. Its active components includes 13 components, such as potassium sulfate, borax, copper sulfate, manganese sulfate, zinc sulfate, etc.. The additives include 9 components, such as disodium hydrogen phosphate, nitric acid, useful bacteria, useful enzyme, etc.. It can improve the activity of plant cells, change physiological mechanism of plant, increase yield, and make plant robust.

Owner:孙国庆 +1

Multi-functional biological organic bacterial fertilizer and production method therefor

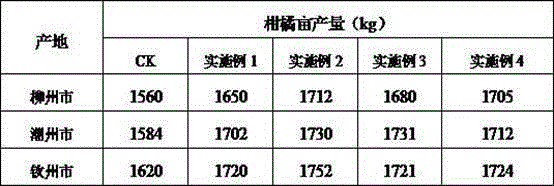

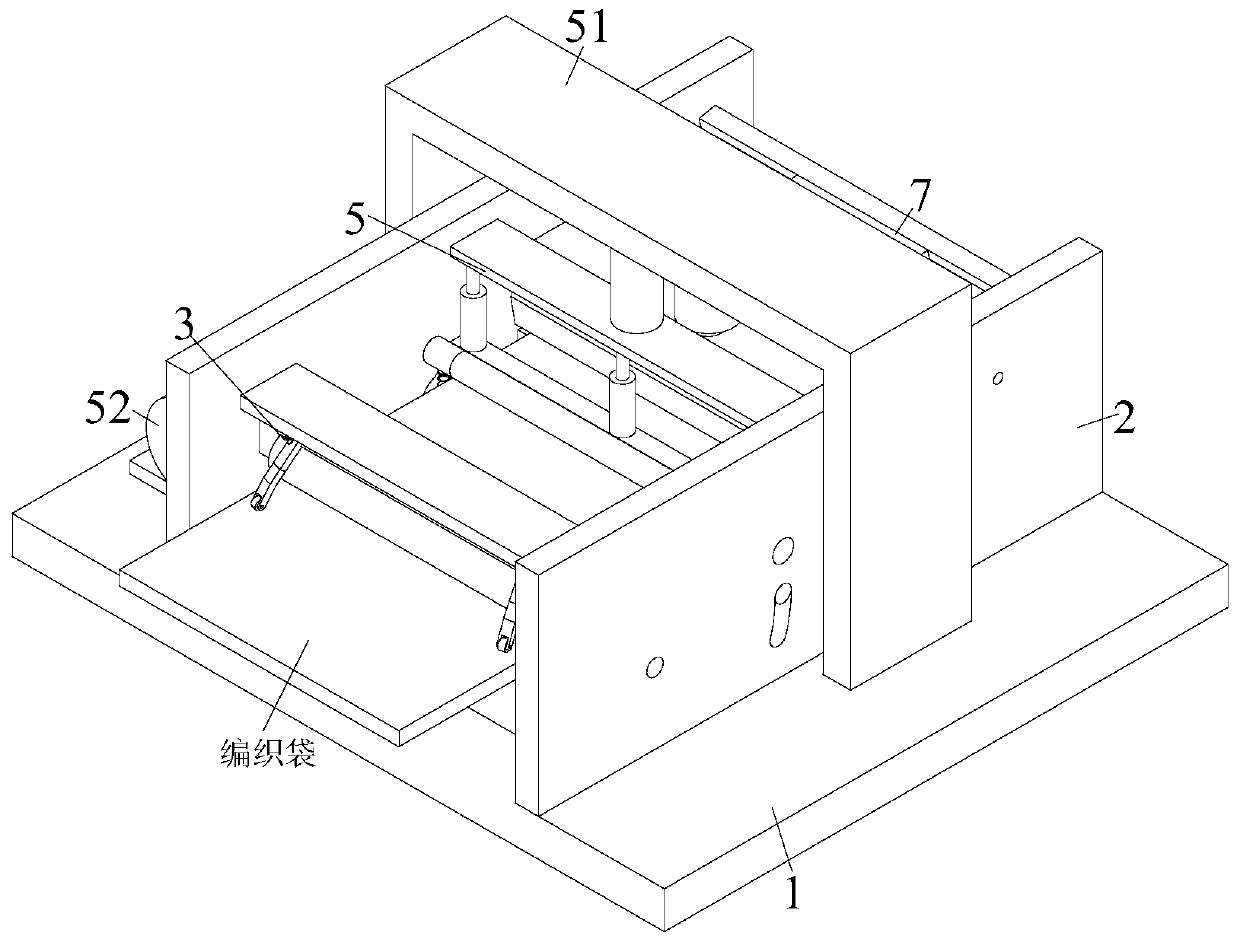

The invention discloses a multi-functional biological organic bacterial fertilizer and a production method therefor. The fertilizer is characterized by being prepared from the following raw materials in parts by weight: 30-60 parts of organic matters, 15-20 parts of crop straws, 15-20 parts of pineapple waste residues, 5-10 parts of human excrement, 5-10 parts of traditional Chinese medicine waste residues, 5-10 parts of compound amino acids, 5-10 parts of humic acid, 0.5-1.0 part of medium elements, 0.1-0.5 part of beneficial bacteria, 0.1-0.5 part of a vegetable insecticide and 0-0.1 part of somatomedin. The multi-functional biological organic bacterial fertilizer can be used for quickly supplementing nutrients in a fruit growing process, avoids various insect pests while the fertilizer is applied, and is obvious in yield-increasing effect compared to that of a conventional inorganic fertilizer. By improving the formula, the biological organic fertilizer has good functions in fertilizing soil, improving the soil structure, loosening and not hardening the soil, providing nutrients required by plant growth and saving the fertilizer, and is remarkable in economical benefit.

Owner:陈宝娟

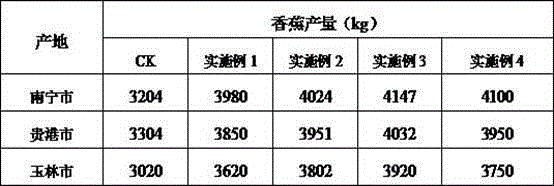

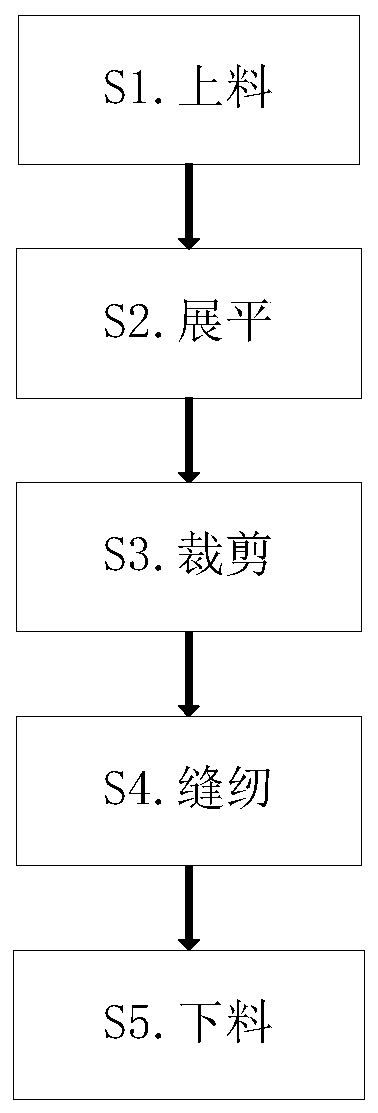

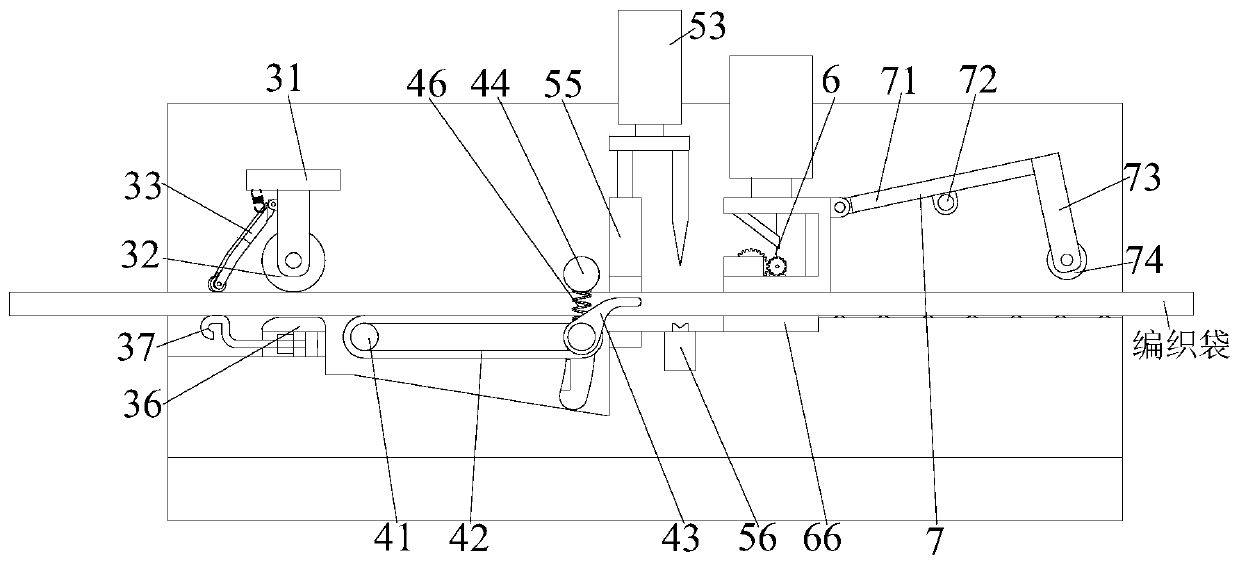

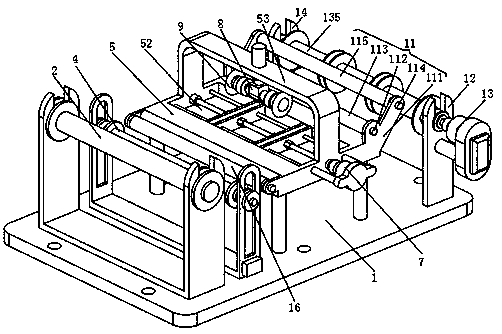

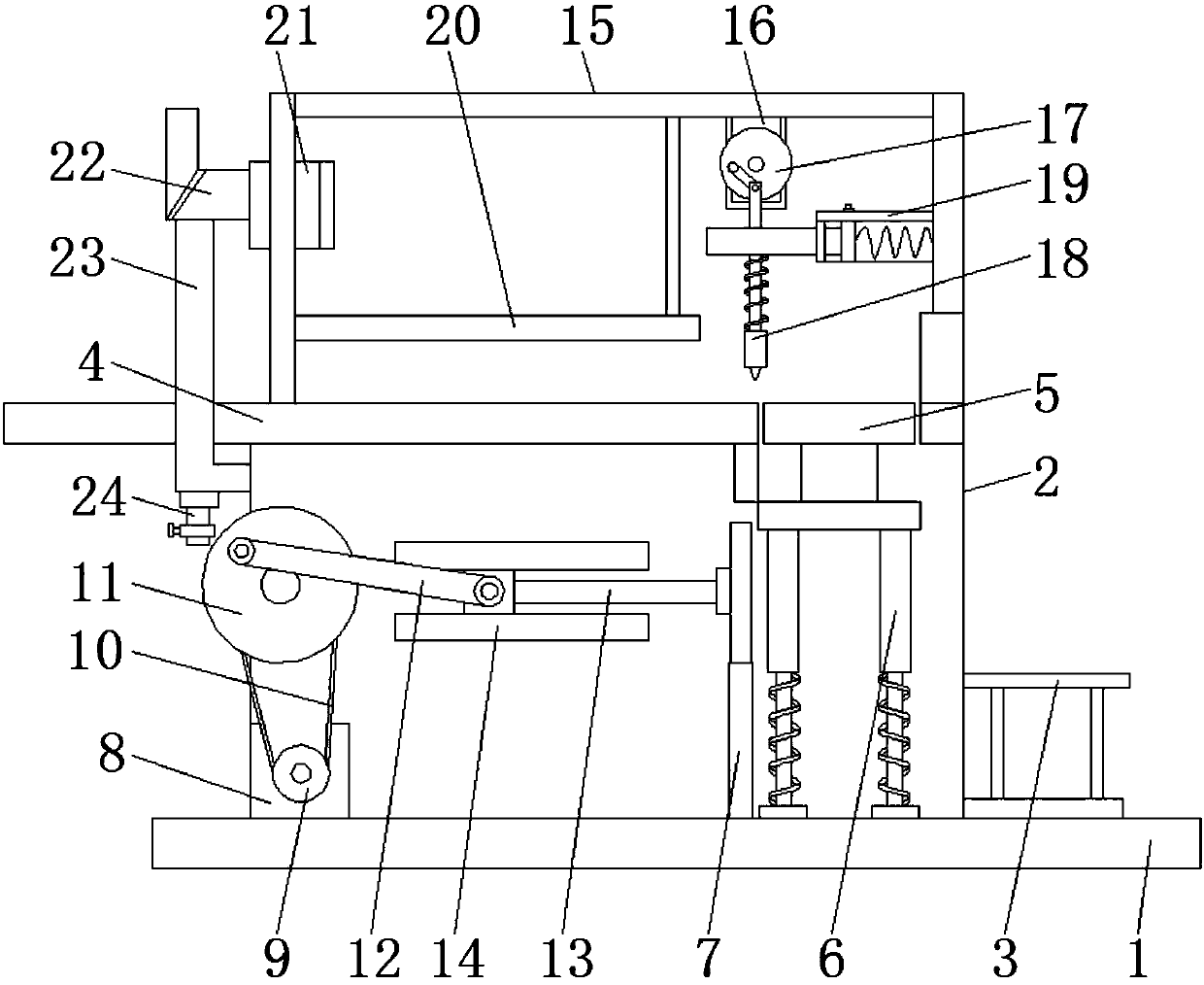

Manufacturing and processing method for plastic woven bags

ActiveCN111361211AReduce production failuresImprove production efficiencyBag making operationsPaper-makingMechanical engineeringIndustrial engineering

The invention relates to a manufacturing and processing method for plastic woven bags. A workbench, two side plates, a flattening device, a conveying device, a cutting device, a sewing device and a discharging device are included; the side plates are forwards and backwards symmetrically mounted at the upper end of the workbench; the flattening device is mounted at the left ends of the inner sidesof the side plate; the conveying device is arranged on the right side of the flattening device; the cutting device is arranged on the right side of the conveying device; the sewing device is arrangedon the right side of the cutting device; and the discharging device is mounted at the right end of the sewing device. According to the manufacturing and processing method for the plastic woven bags, the problems that during manufacturing of traditional plastic woven bags, the plastic woven bags are manufactured in the processing manners of cutting or sewing with manpower cooperated with machines,the manual cutting or sewing accuracy and efficiency are relatively low, during manufacturing by existing plastic woven bag manufacturing equipment, the plastic woven bags are cut and sewn directly, the condition that the plastic woven bags are unqualified due to folding and dislocation of the plastic woven bags occurs very easily and the like can be solved.

Owner:盐城市亿德塑料包装有限公司

Corrugated paper cutting device

InactiveCN105922315ASimple structureFast croppingMetal working apparatusArticle deliveryEngineeringKnife blades

The invention discloses a corrugated paper cutting device. The corrugated paper cutting device comprises a support, a conveying plate, a driving mechanism, a controller, a cutting mechanism, a first pressing and holding mechanism and a second pressing and holding mechanism. Guide rails are arranged on the support. The conveying plate is movably mounted on the guide rails. A plurality of grooves are formed in the conveying plate at intervals and are sequentially arranged in the length direction of the guide rails. The length direction of the grooves is perpendicular to or obliquely crosses with the length direction of the guide rails. The driving mechanism is used for driving the conveying plate to move in the length direction of the guide rails. The driving mechanism is in communication connection with the controller. The cutting mechanism is used for cutting corrugated paper and comprises a driving unit and a blade. The driving unit drives the blade to move close to the grooves or far from the grooves. The corrugated paper cutting device is simple in structure and good in corrugated paper cutting effect.

Owner:BENGBU ZHENHUA PACKING MACHINERY

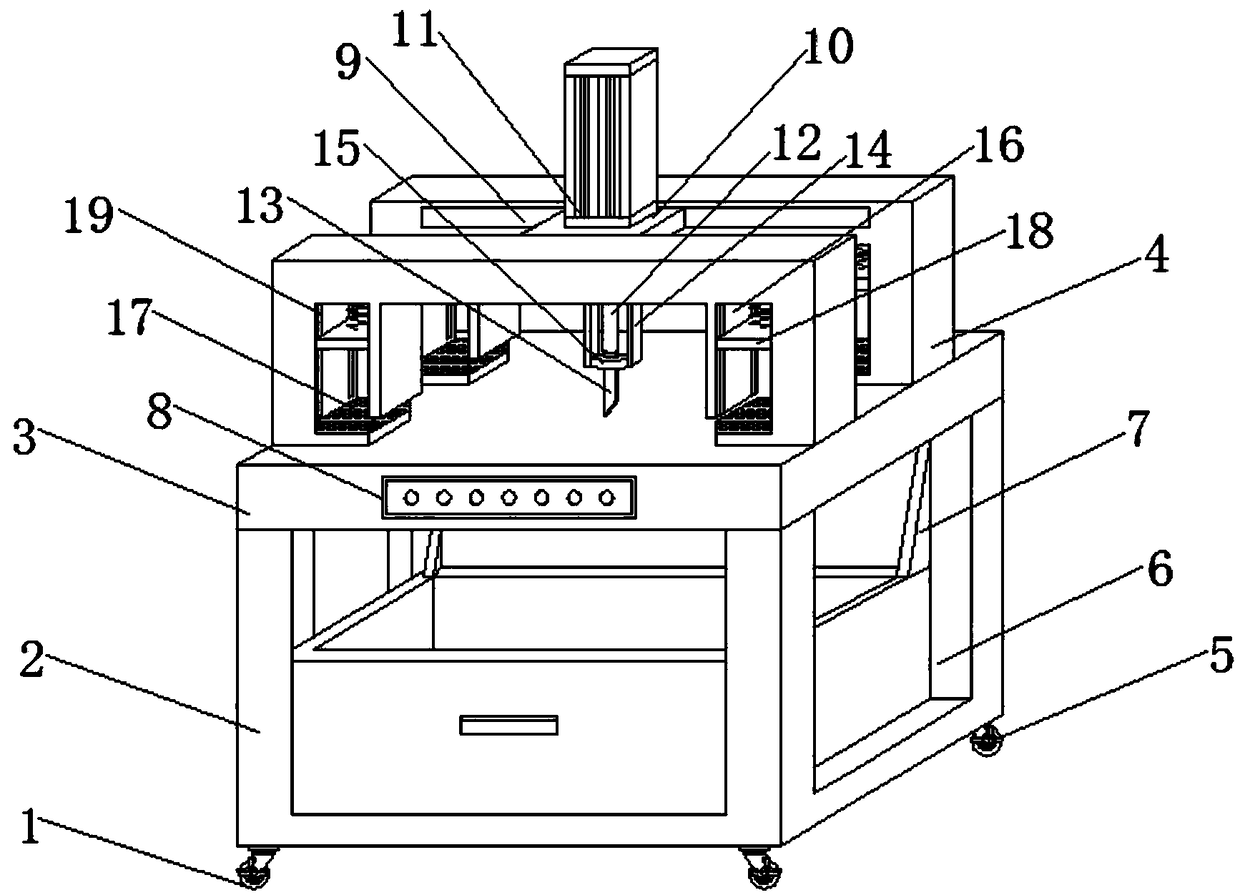

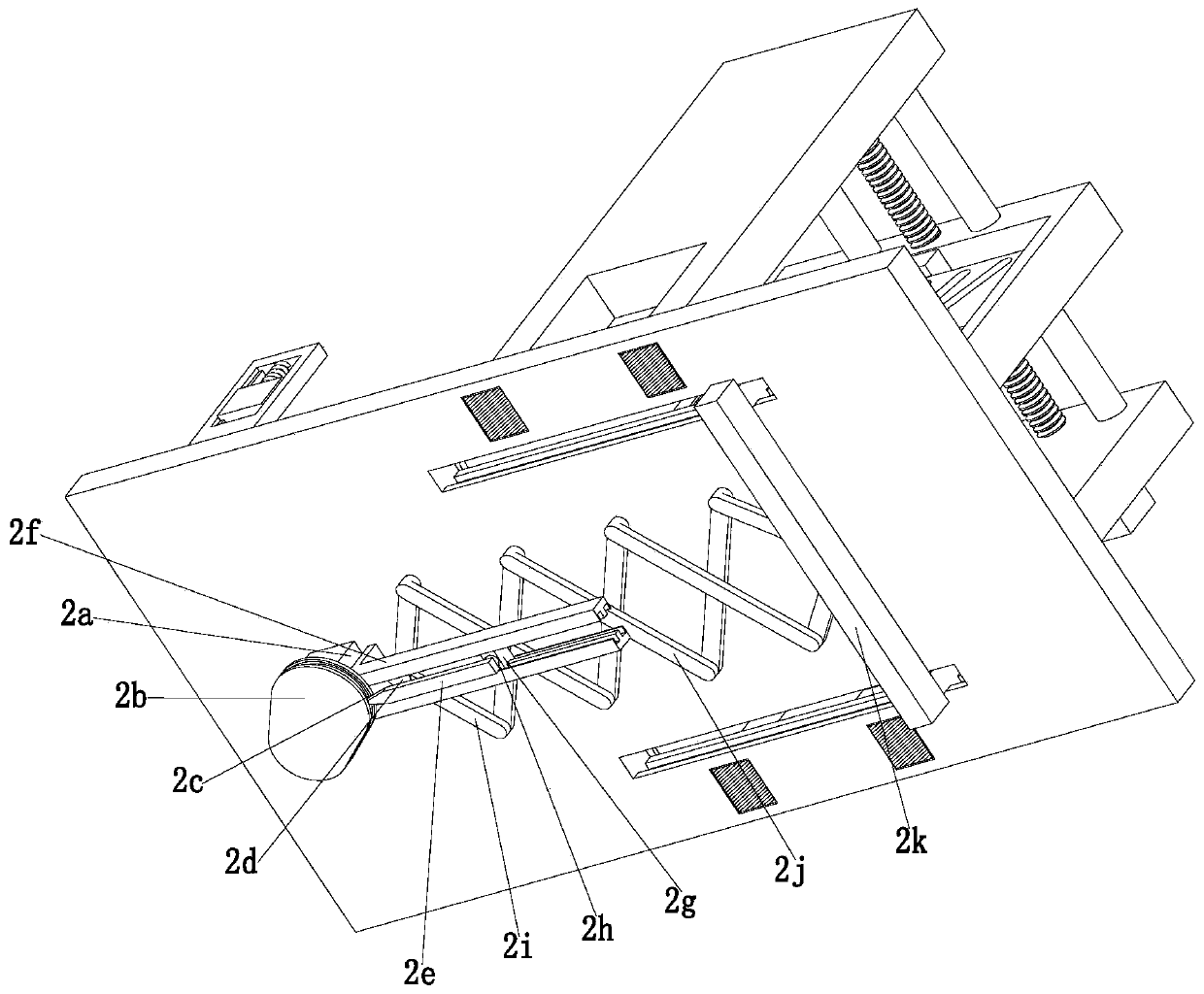

Garment processing fabric cutting device

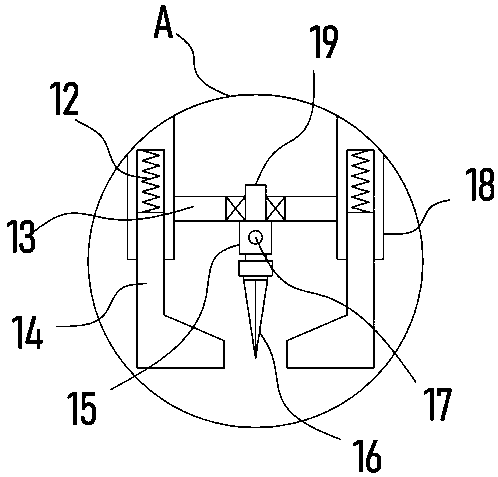

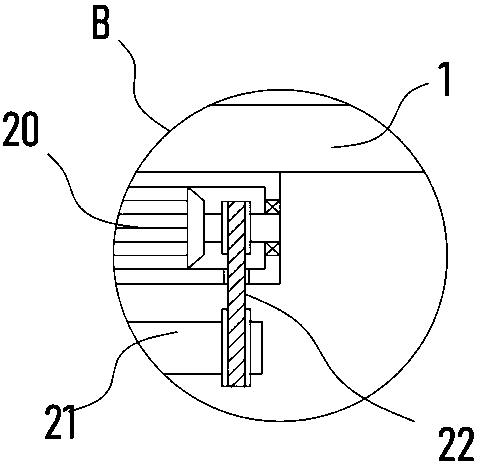

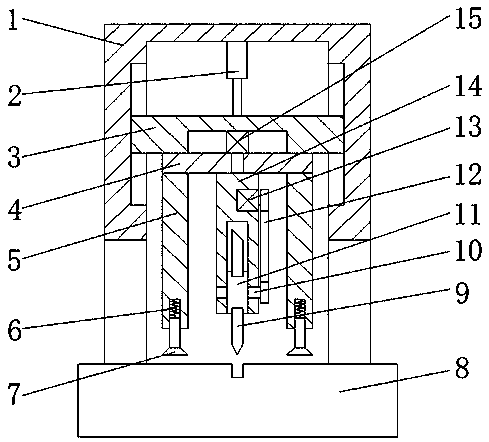

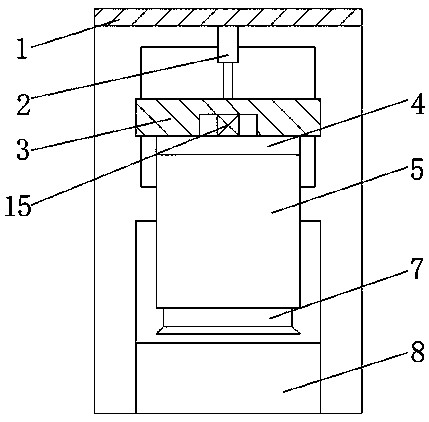

InactiveCN109940684AKeep the position fixedAvoid wrinklesSevering textilesMetal working apparatusDrive shaftEngineering

The invention discloses a garment processing fabric cutting device and relates to the technical field of garment processing. The garment processing fabric cutting device comprises a supporting frame;a cutter used for cutting a fabric is arranged above a supporting table; a gearbox is fixed to the top in the supporting frame; a driven shaft is in drive connection to the interior of the gearbox through a drive mechanism; a horizontal plate is horizontally fixed in inner threaded sleeve blocks; the cutter is fixedly installed at the bottom of the horizontal plate through a steering mechanism; and a limiting spring is fixedly connected between a pressing block and each inner threaded sleeve block. By adopting the garment processing fabric cutting device, the fabric is pressed by the pressingblocks from the two sides of the cutter before being cut with the cutter, so that the position of the fabric during cutting of the cutter is fixed, and the quality of cutting due to movement of the fabric is effectively avoided; and arranged pressing rollers can be used for smoothening the fabric before the fabric is cut and are driven by arranged compression springs respectively to compress thesmoothened fabric, so that wrinkles generated when the fabric is cut can be effectively prevented, and the cutting effect of the fabric is greatly improved.

Owner:温州崇奥礼品有限公司

Garment cutting device wide in application range

PendingCN107761350AImprove croppingImprove cutting efficiencySevering textilesElectric machineryEngineering

The invention discloses a garment cutting device wide in application range. The garment cutting device comprises a rack, sliding grooves are formed in the inner walls of the two sides of the rack, andthe inner walls of the two sliding grooves are connected with the same sliding table in a sliding mode; a hydraulic cylinder is fixed to the inner wall of the top of the rack through screws, and oneend of a piston rod of the hydraulic cylinder is fixed to the outer wall of the top of the sliding table through a screw; the outer wall of the bottom of the sliding table is fixedly provided with a fixing plate through screws, a rotating shaft hole is formed in the outer wall of the top of the fixing plate, and a rotating shaft is connected with the inner wall of the rotating shaft hole through abearing; the outer wall of the bottom of the rotating shaft is fixedly provided with a mounting frame through screws. By means of the cooperation of a transmission chain and the rotating shaft, cutters can be quickly replaced; the proper cutters are selected according to different cloth textures, and the cutting effect and the cutting efficiency can be improved; a second motor is arranged so thatthe cutters can rotate according to processing needs to be suitable for cutting at different angles.

Owner:盐城融凡纺织制衣有限公司

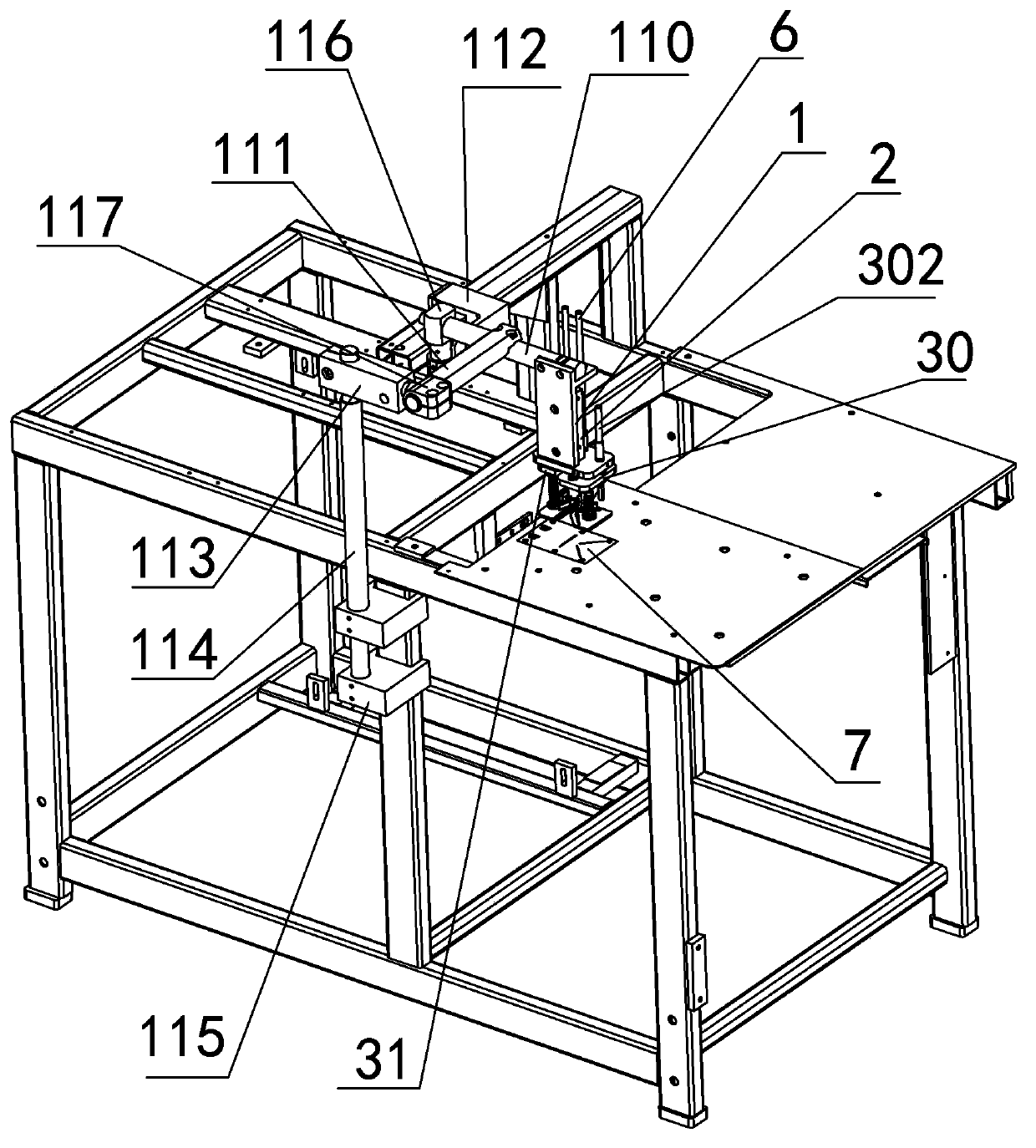

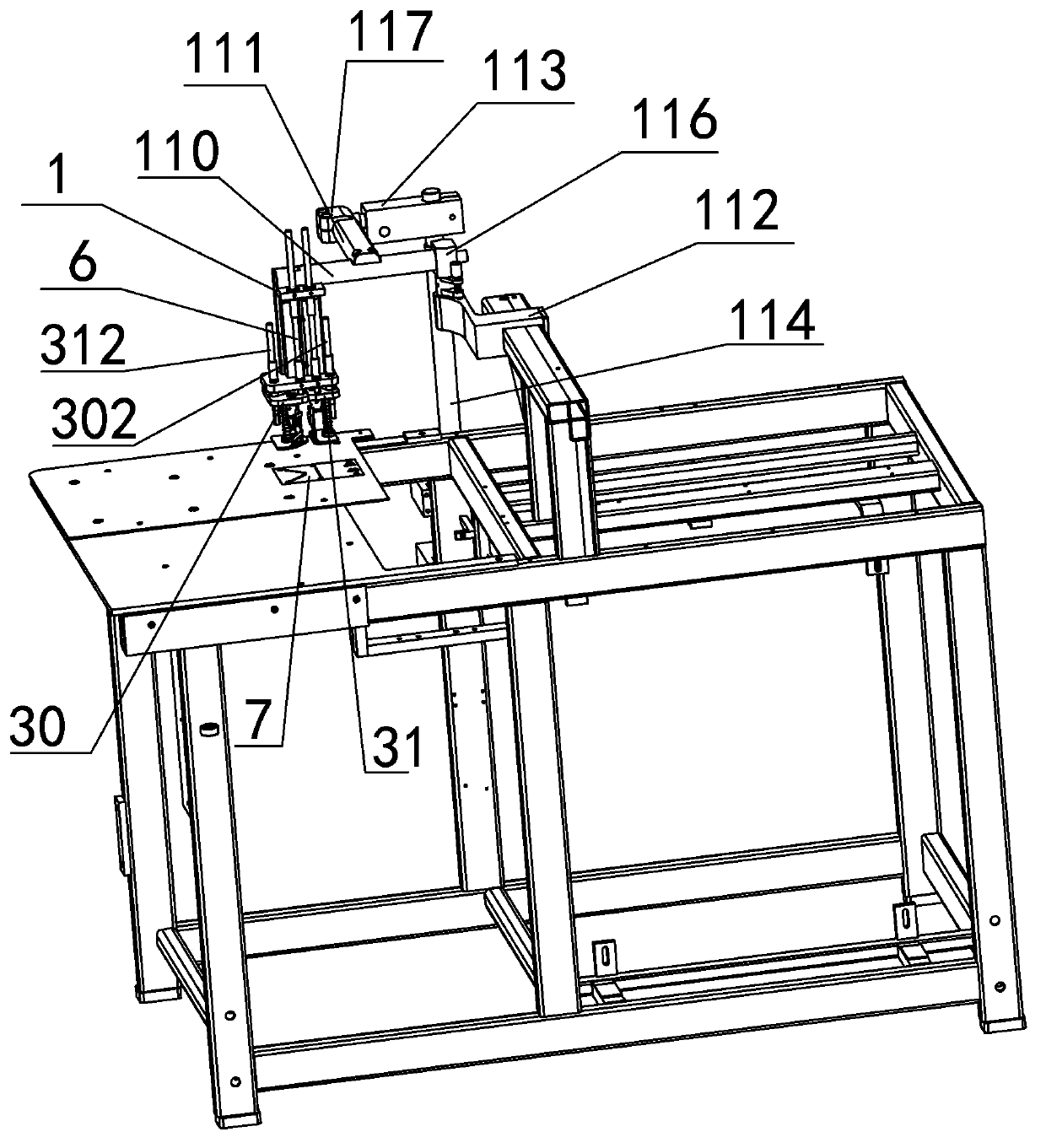

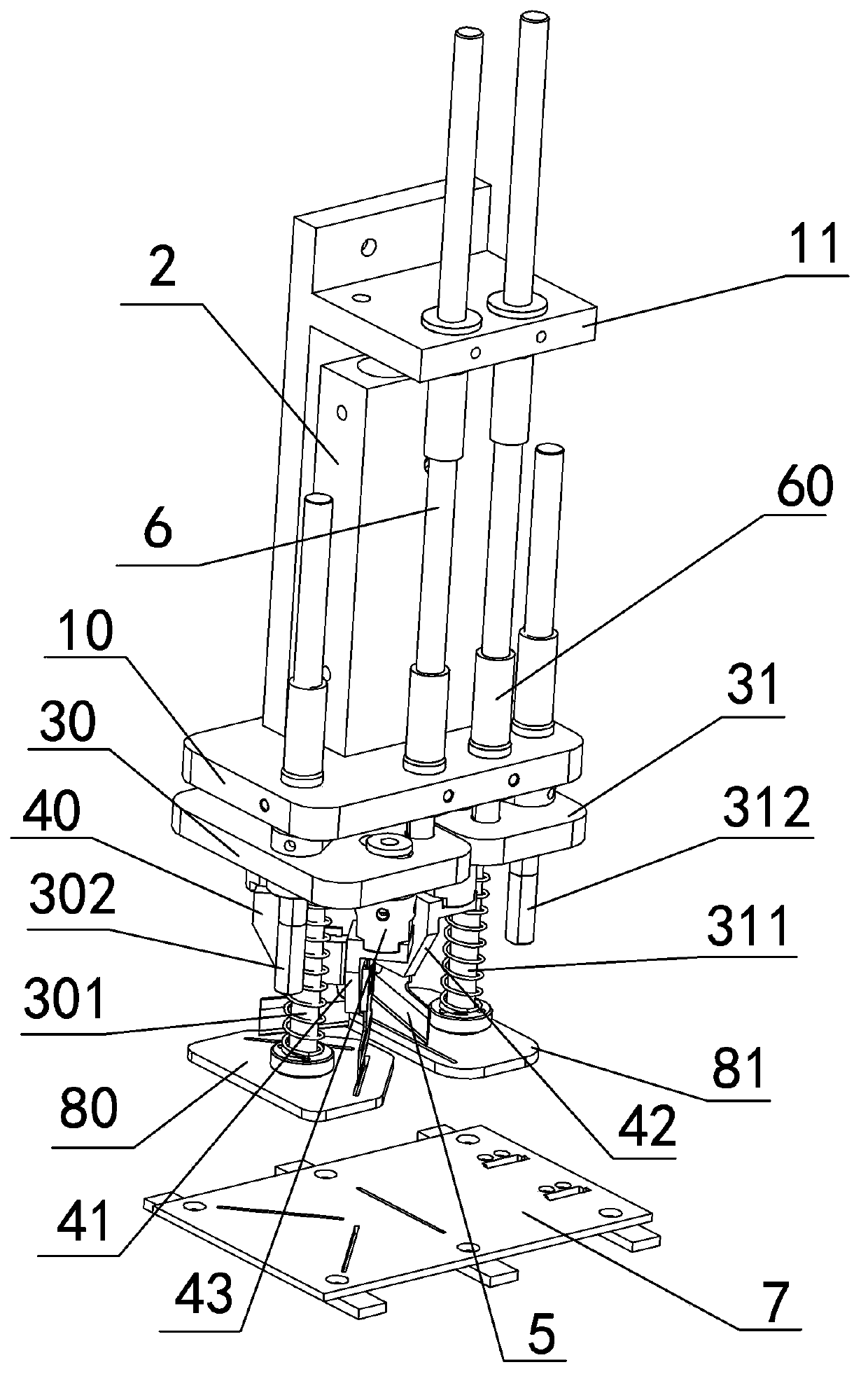

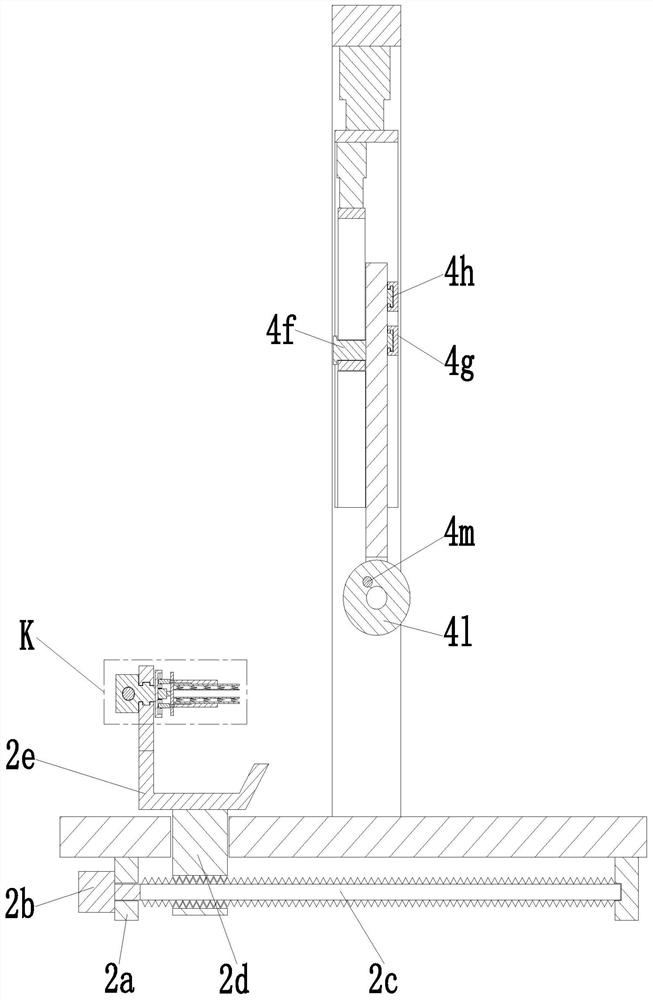

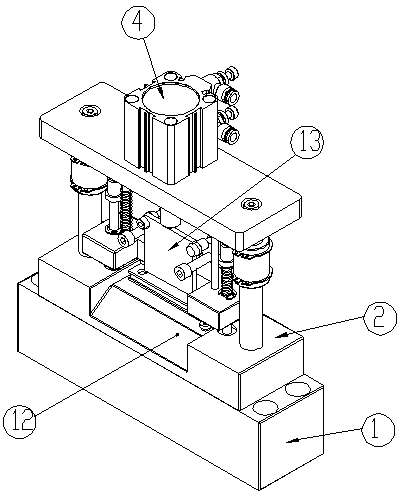

Sewing machine cutter device

ActiveCN103388244AThere will be no rotational offsetStable travelWorkpiece carriersEngineeringPiston rod

The invention relates to a sewing machine cutter device. Two cylinders or a cylinder with two piston rods is mounted on a cylinder mounting seat, a horizontal cutter mounting plate and a left-and-right cutter mounting plate are respectively fixed onto the end parts, downwards extending out of the cylinder respectively, of the two piston rods; and the left-and-right cutter mounting plate and the horizontal cutter mounting plate are provided with a cutter blade with adjustable mounting height and mounting angle respectively. The sewing machine has the advantages of being simple in structure, timesaving, laborsaving, high in mounting efficiency, manpower-saving, high in automation degree and simple and convenient to operate.

Owner:BULLMER ELECTROMECHANICAL TECH

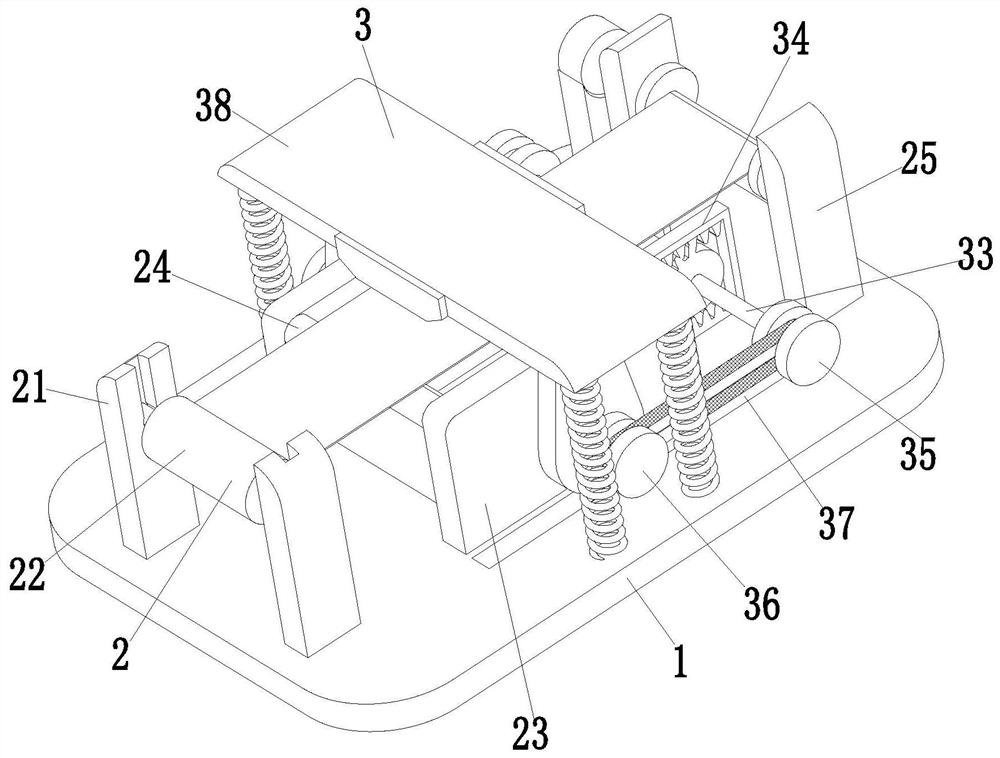

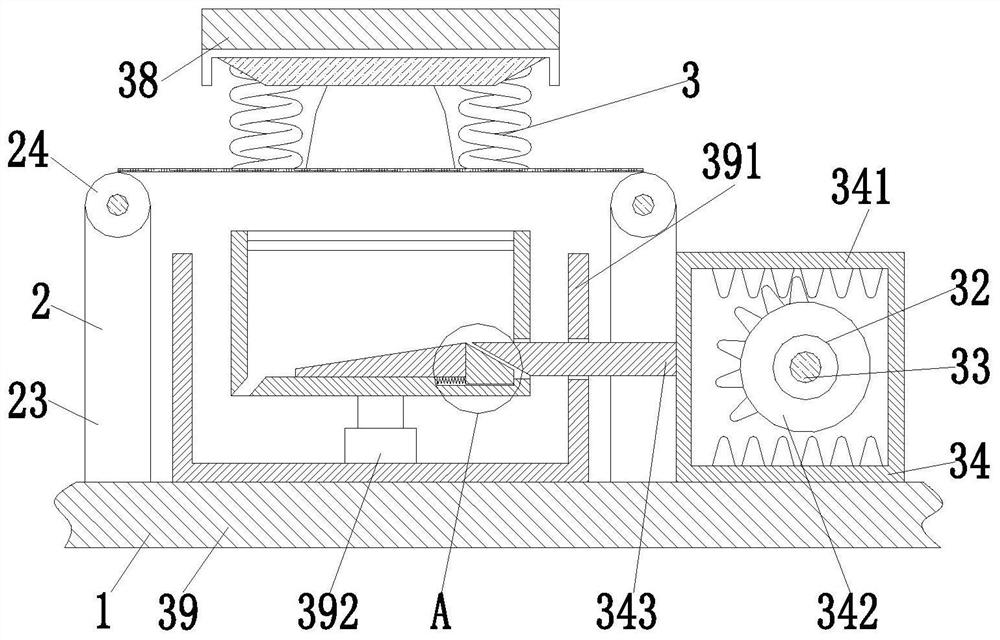

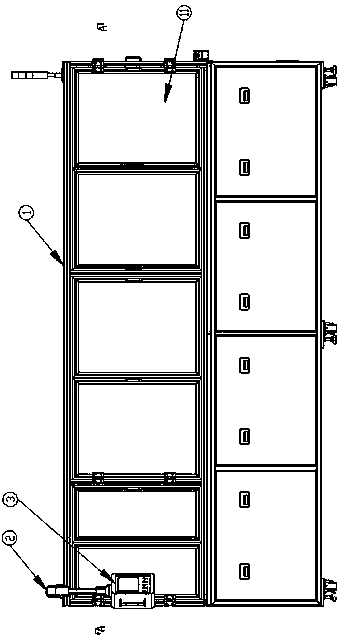

Novel textile fabric cutting and collecting machine

InactiveCN110055738AEasy to tightenImprove croppingSevering textilesWebs handlingTextileRaw material

The invention discloses a novel textile fabric cutting and collecting machine. The novel textile fabric cutting and collecting machine comprises a bottom plate, wherein six uniformly distributed mounting holes are formed in the upper surface of the bottom plate, a fixing device is arranged at the left end of the upper surface of the bottom plate, the left side of the upper surface of the bottom plate is provided with a fixing plate, the fixing plate is positioned on the right side of the fixing device, a limiting hole is formed in a side surface of the fixing plate, a tightening device is arranged in the limiting hole, and four braces which are distributed in a rectangular manner are arranged in the middle of the upper surface of the bottom plate. According to the novel textile fabric cutting and collecting machine, the fixing device and a winding roller can be detached, quick replacement of an external cloth releasing roller and the winding roller is facilitated, the position of a circular cutter can be adjusted, and cloth is convenient to cut into standby raw materials with different widths, the time is saved, the cut cloth can be wound and collected while being cut, the workingefficiency can be effectively provided, and the novel textile fabric cutting and collecting machine is simple to operate and convenient to use.

Owner:高峰

Paperboard cutting and processing equipment

ActiveCN105922331APrevent deviationGuarantee subsequent processing accuracyMetal working apparatusPaperboardEngineering

The invention discloses paperboard cutting and processing equipment. The equipment comprises a mounting frame, a conveyor belt, a rotary shaft, a first driving unit, a cutting part and a pressing and holding part. The conveyor belt is mounted on the mounting frame. The upper surface of the conveyor belt is provided with a plurality of accommodating grooves which are evenly distributed in the length direction of the conveyor belt. The length direction of the accommodating grooves is perpendicular to the length direction of the conveyor belt. The lower surface of the conveyor belt is provided with first gears which are distributed in the length direction of the conveyor belt. The rotary shaft is rotatably mounted on the mounting frame. One end of the rotary shaft is arranged in a space defined by the conveyor belt. The local peripheral surface of the rotary shaft is provided with second gears which are distributed in the circumferential direction of the rotary shaft. The second gears are engaged with the first gears. The first driving unit is used for driving the rotary shaft to rotate. The cutting part is used for cutting paperboards and comprises a second driving unit and a blade. The second driving unit is used for driving the blade to move close to the accommodating grooves or far from the accommodating grooves. The paperboard cutting and processing equipment is good in paperboard cutting effect.

Owner:BENGBU ZHENHUA PACKING MACHINERY

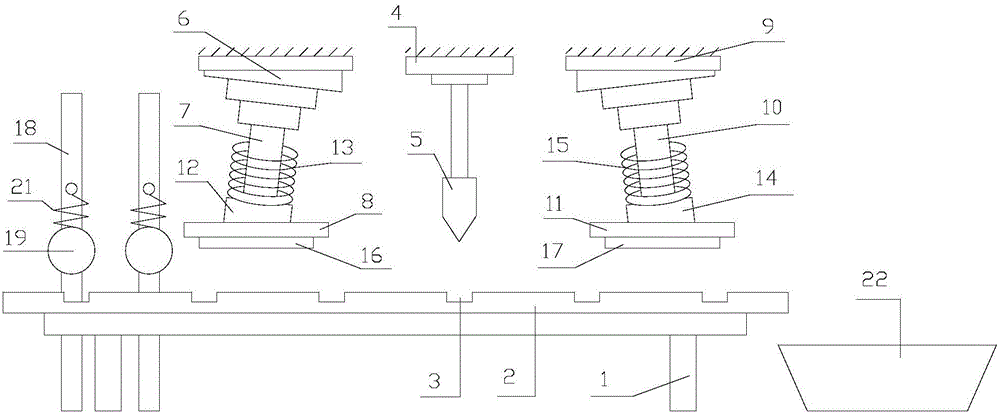

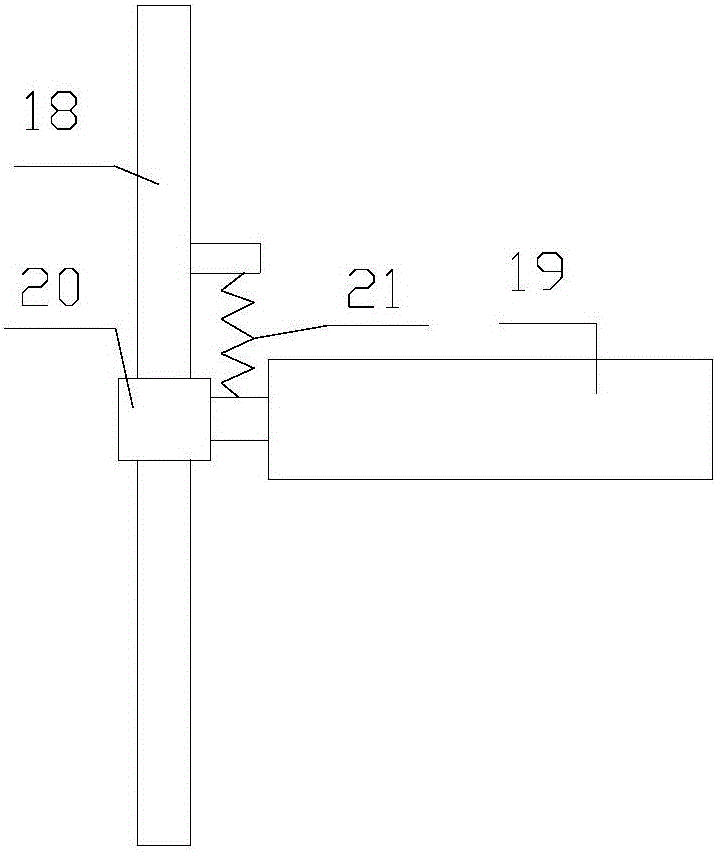

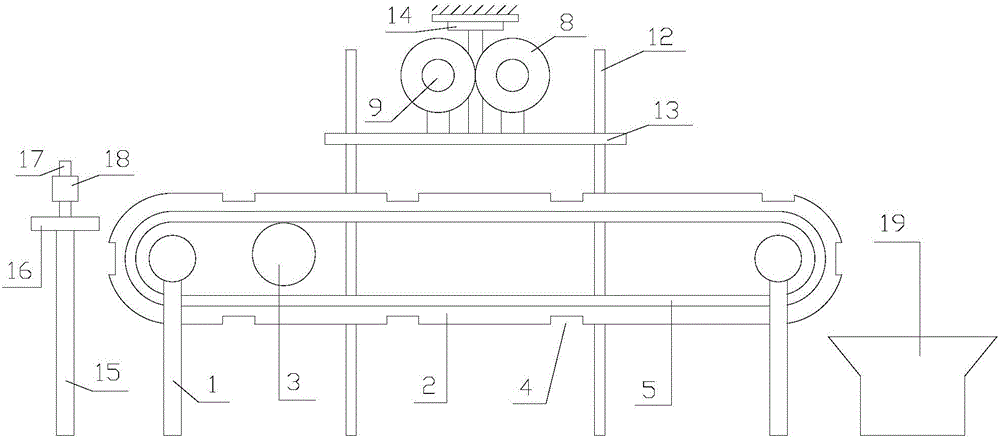

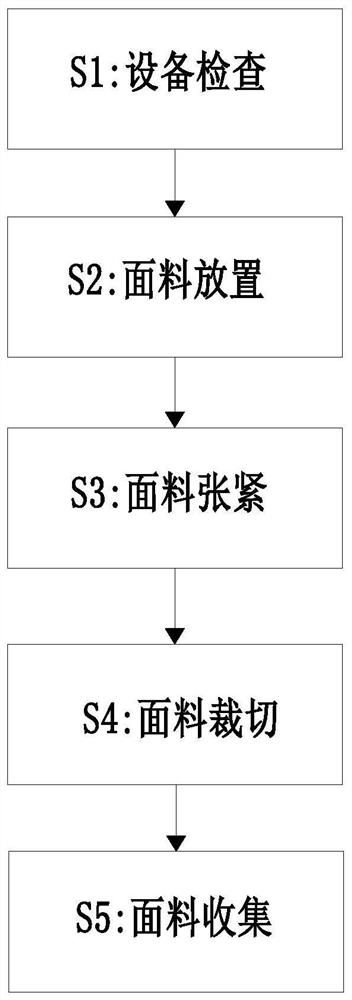

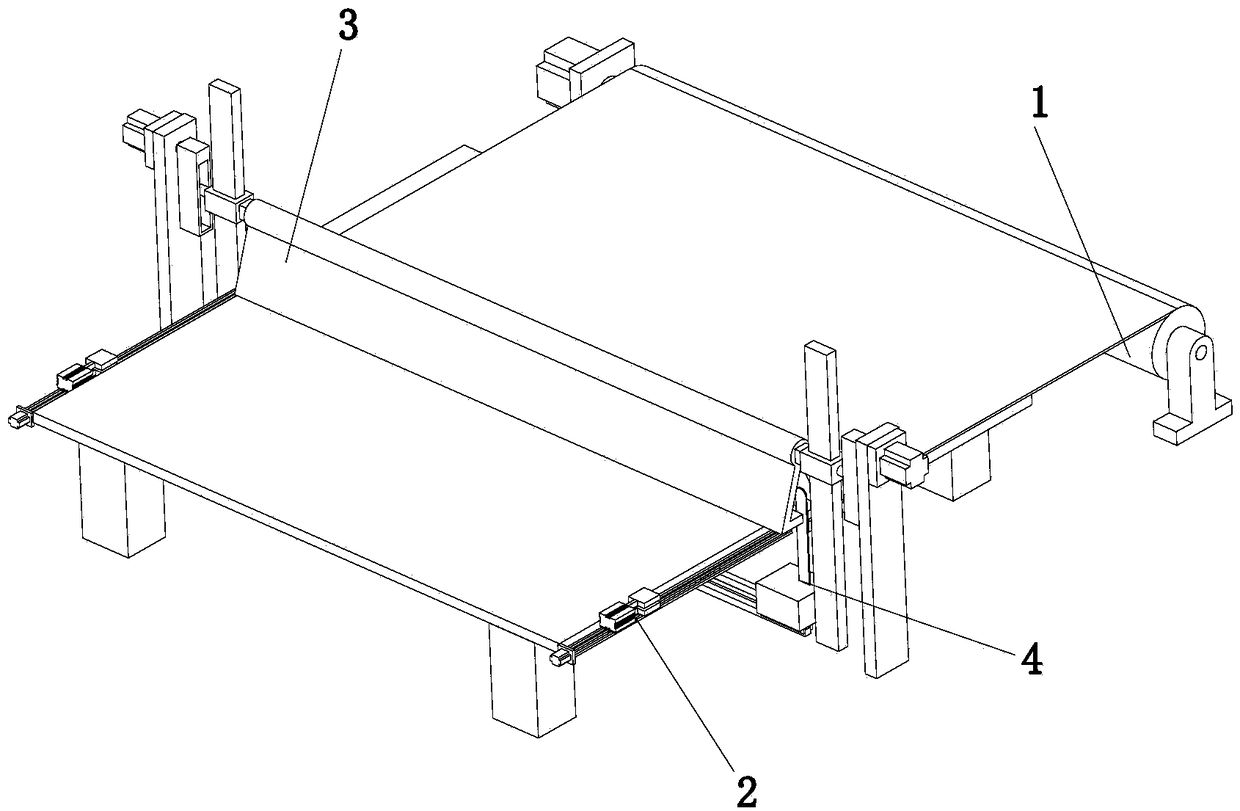

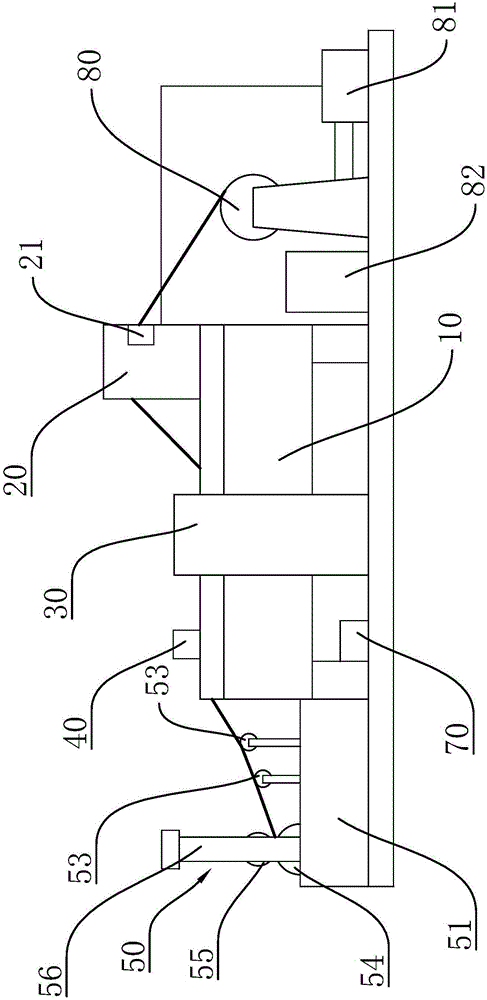

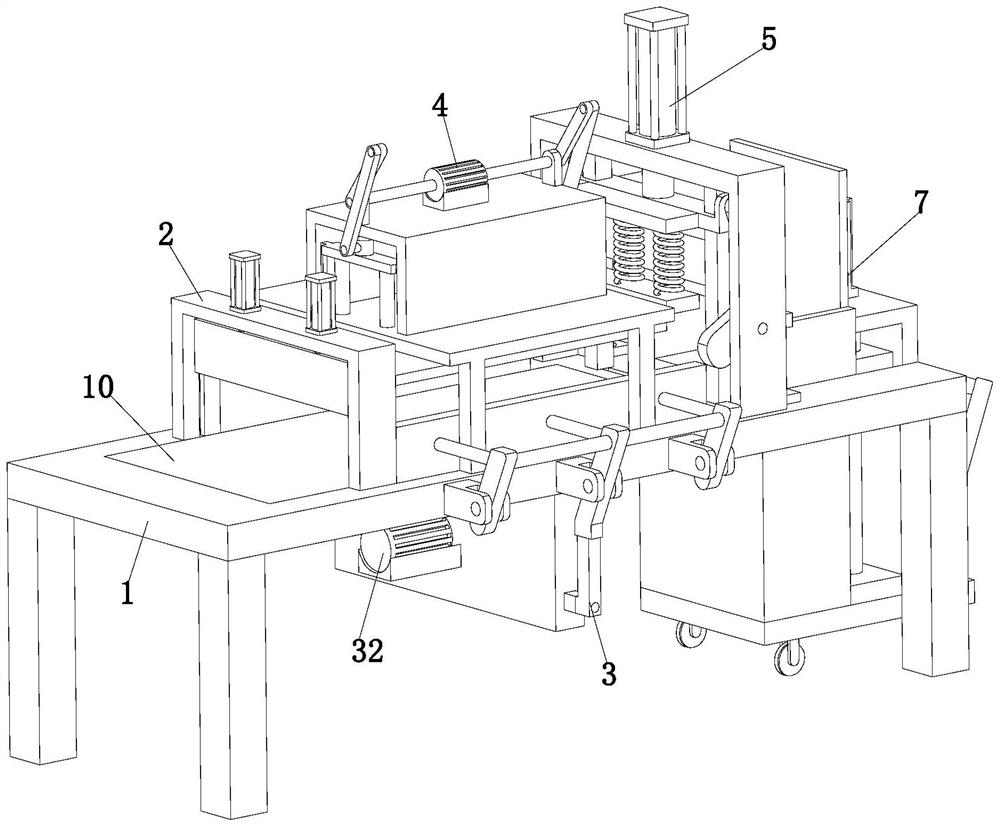

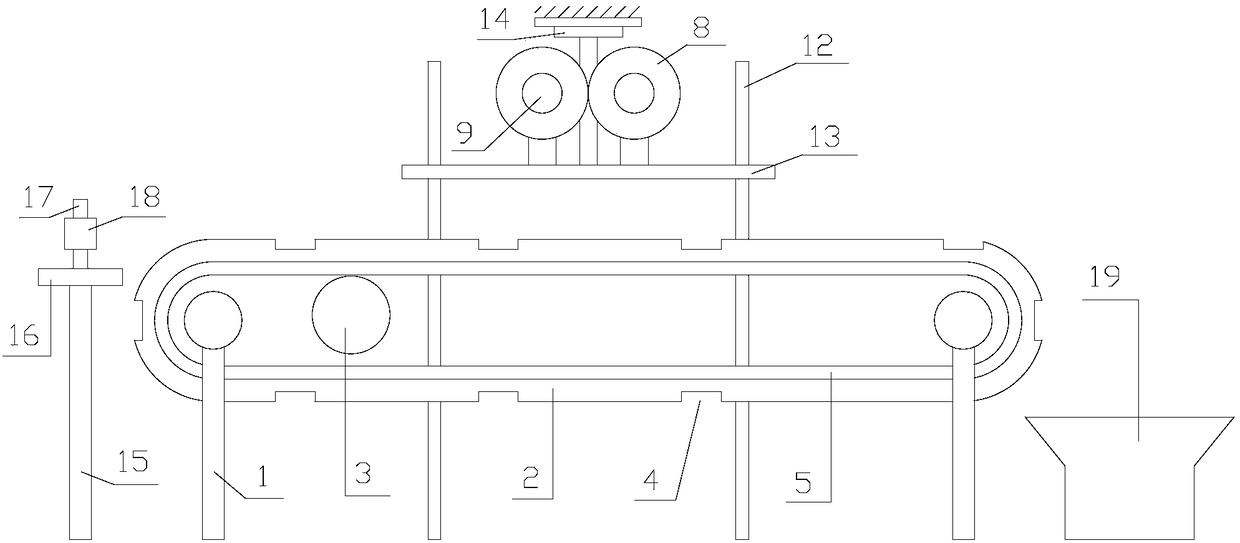

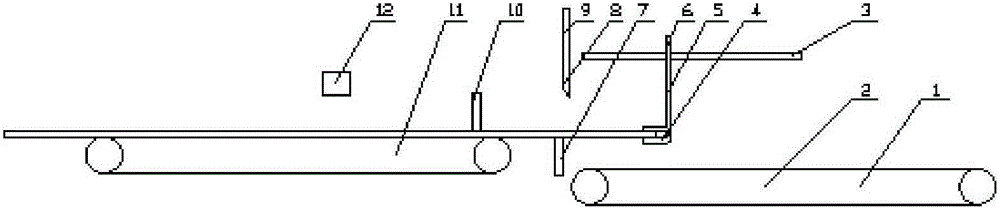

Non-woven fabric clothing fabric cutting processing method

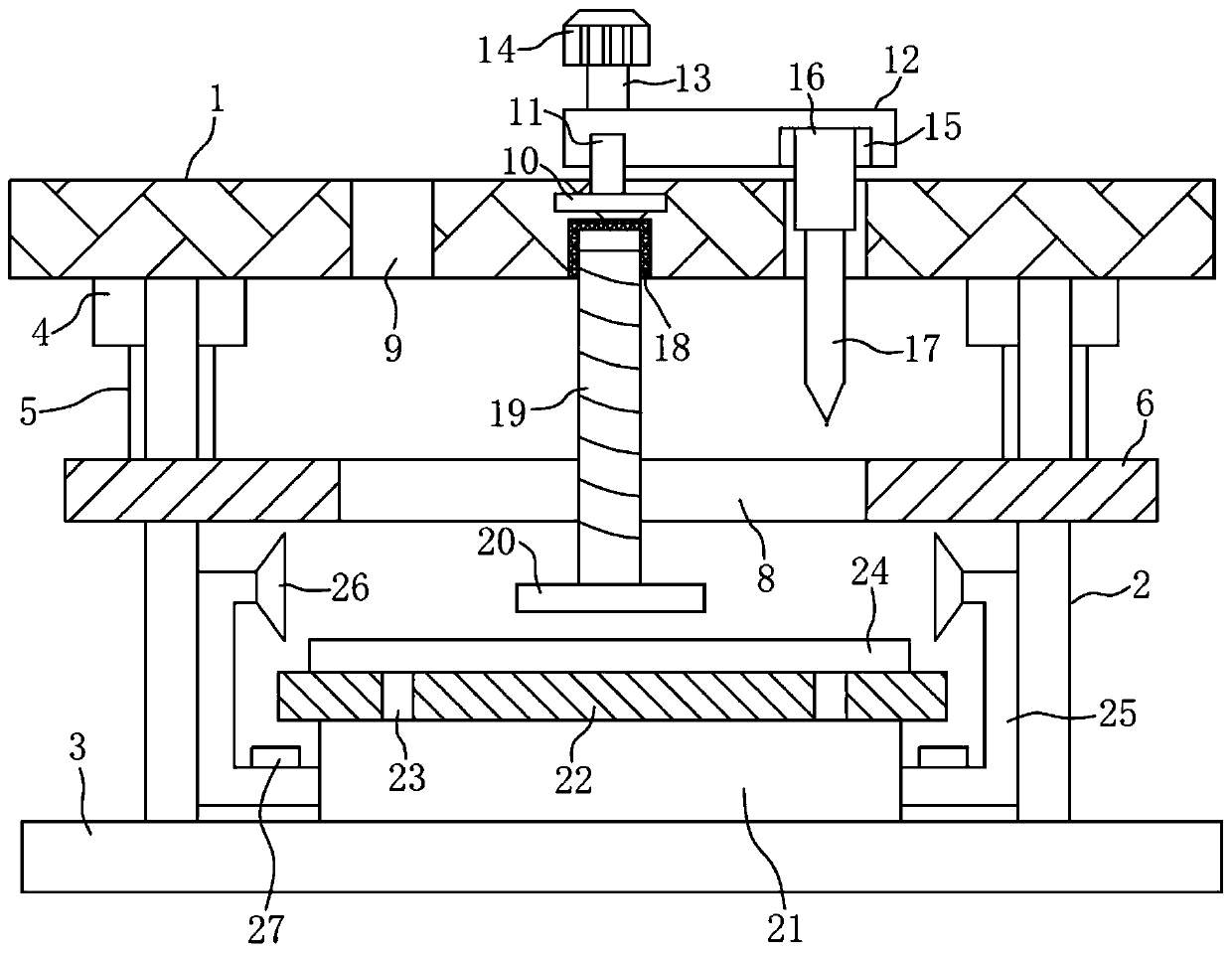

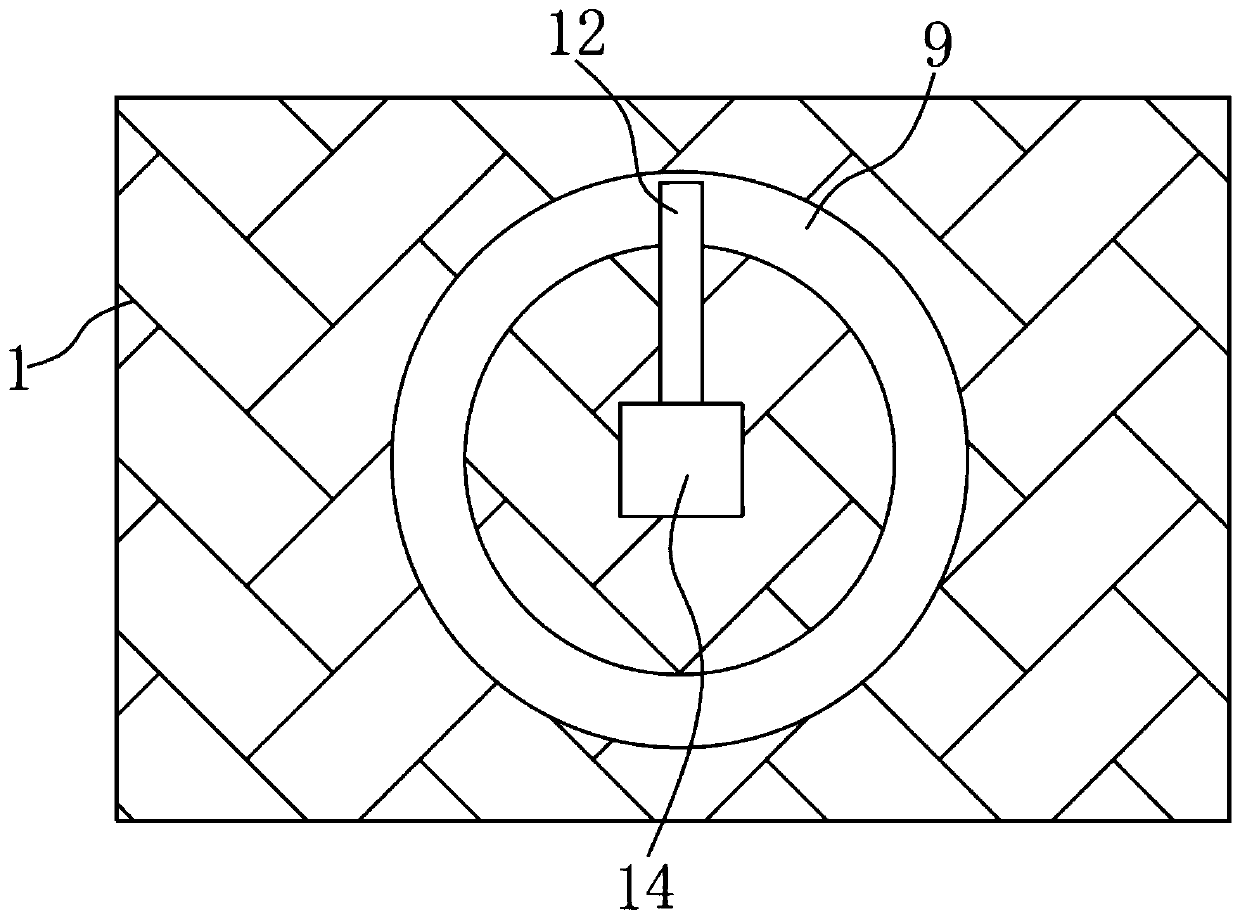

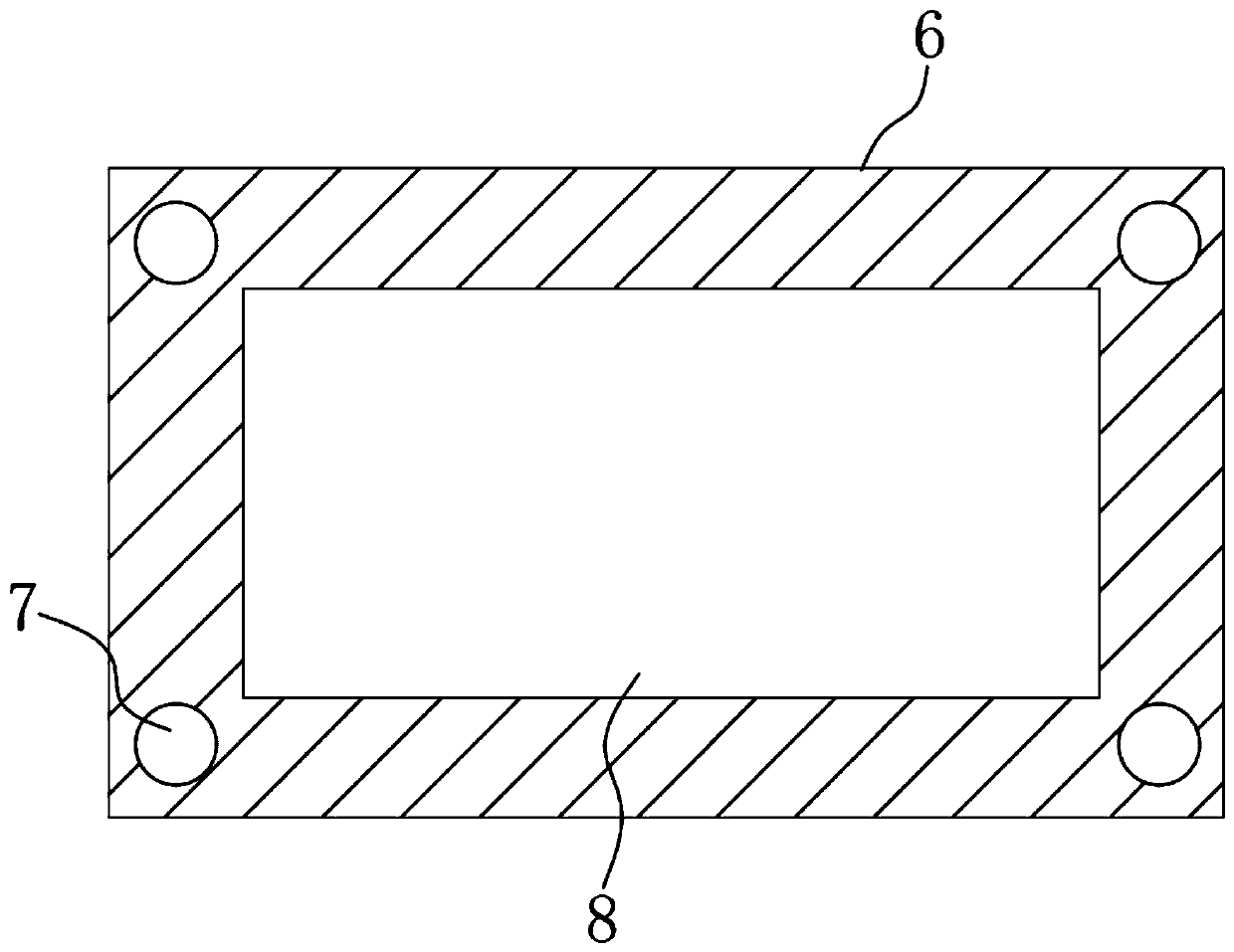

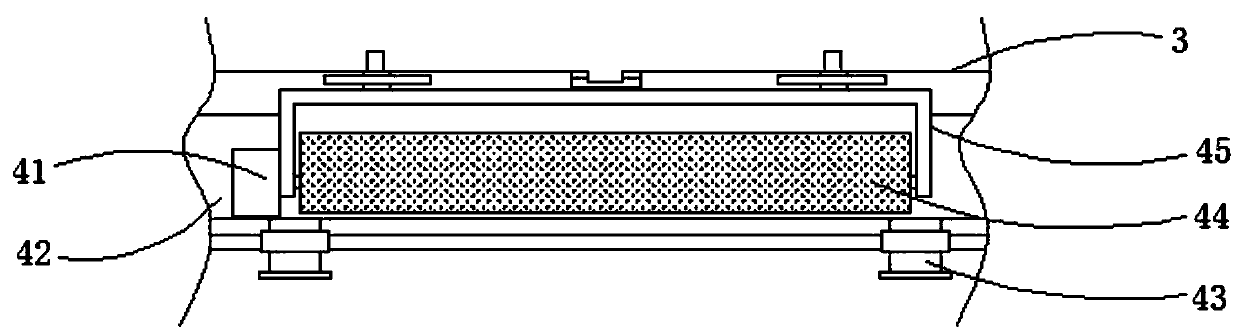

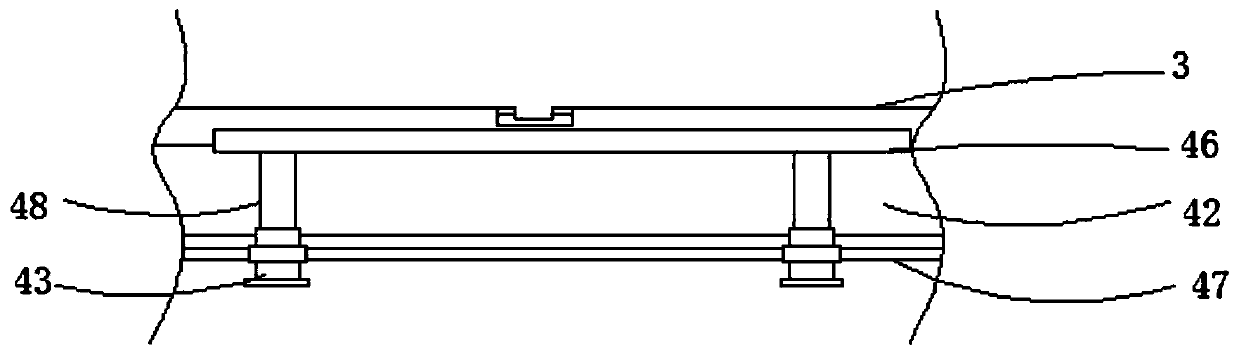

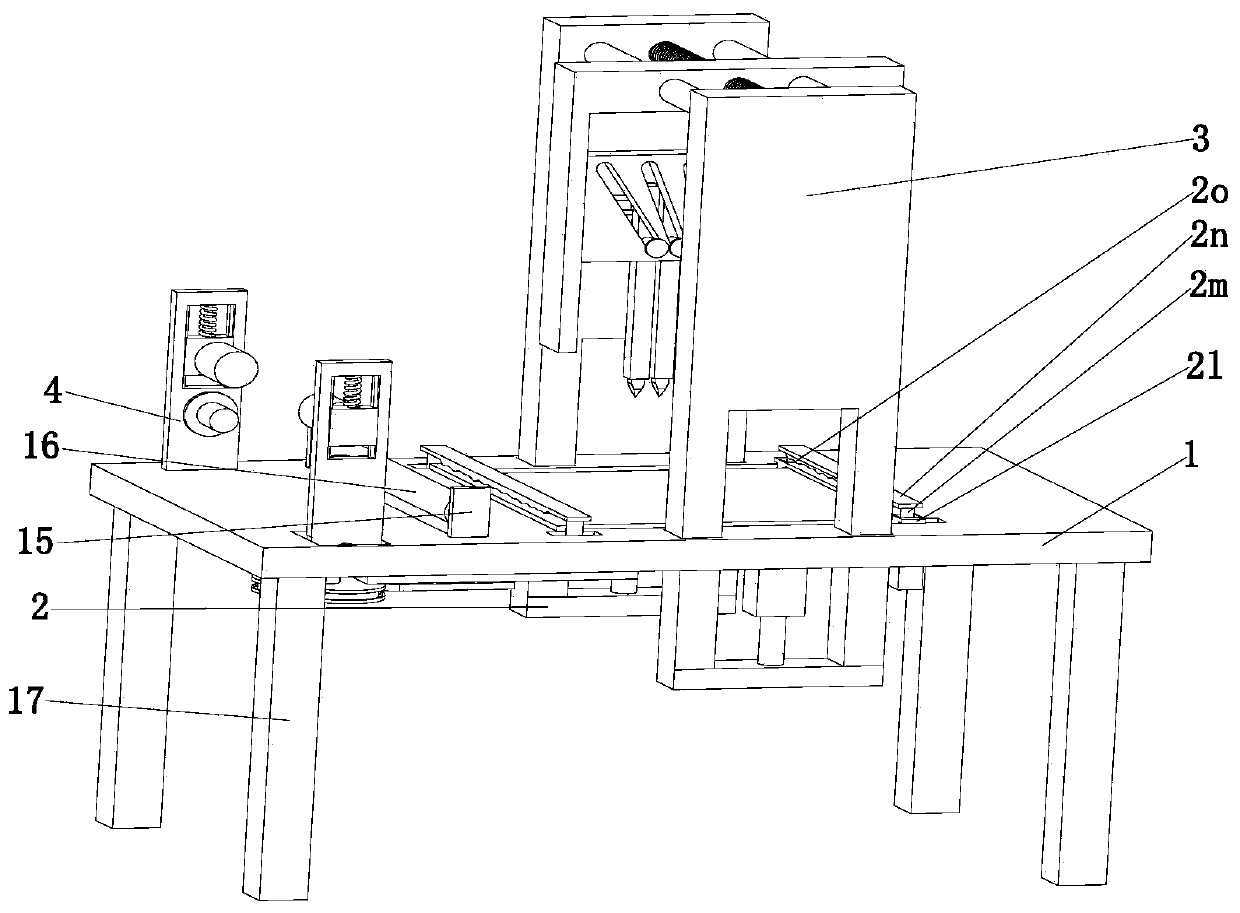

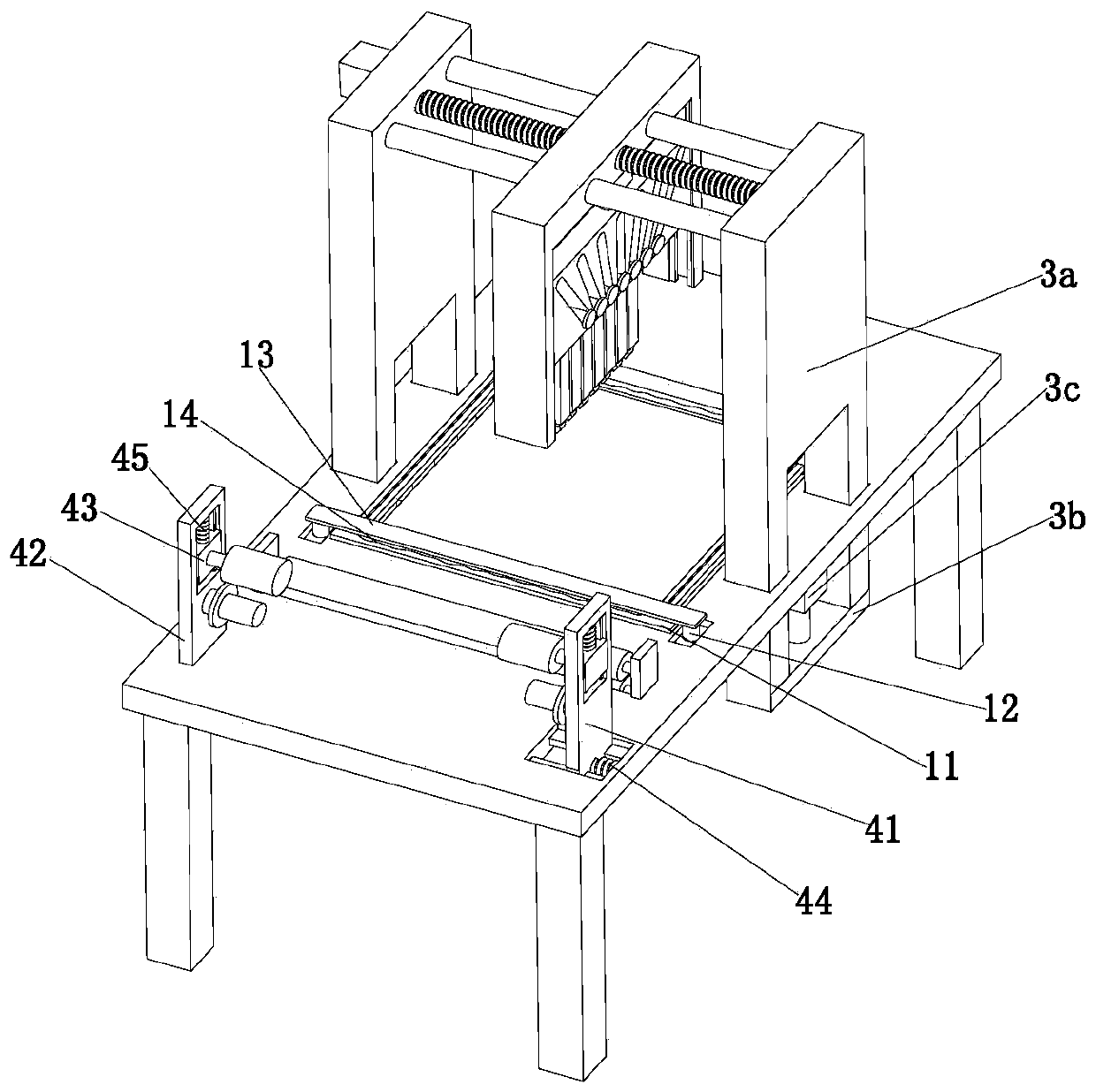

ActiveCN112160146AImprove croppingImprove flatnessSevering textilesArticle deliveryStructural engineeringNonwoven fabric

The invention relates to a non-woven fabric clothing fabric cutting processing method. The method uses auxiliary non-woven fabric clothing fabric cutting processing equipment. The auxiliary non-wovenfabric clothing fabric cutting processing equipment comprises a bottom plate, a tensioning device and a cutting device, the middle part of the upper end surface of the bottom plate is provided with the tensioning device, and the cutting device is arranged above the tensioning device and installed on the bottom plate. According to the non-woven fabric clothing fabric cutting processing equipment, the problems that existing non-woven fabric clothing fabric cutting processing equipment cannot tension non-woven fabric before cutting the non-woven fabric, wrinkles appear on the surface of the non-woven fabric, and consequently a notch is uneven during cutting, and the cutting effect and the cutting precision are affected can be solved; and the problems that the existing non-woven fabric clothing fabric cutting processing equipment cannot cut the non-woven fabric into a specific shape, cannot meet the requirement for making clothing through the non-woven fabric, cannot collect the non-wovenfabric while cutting the non-woven fabric, consumes time and labor and is low in cutting processing efficiency can be solved.

Owner:九江太信科技有限公司

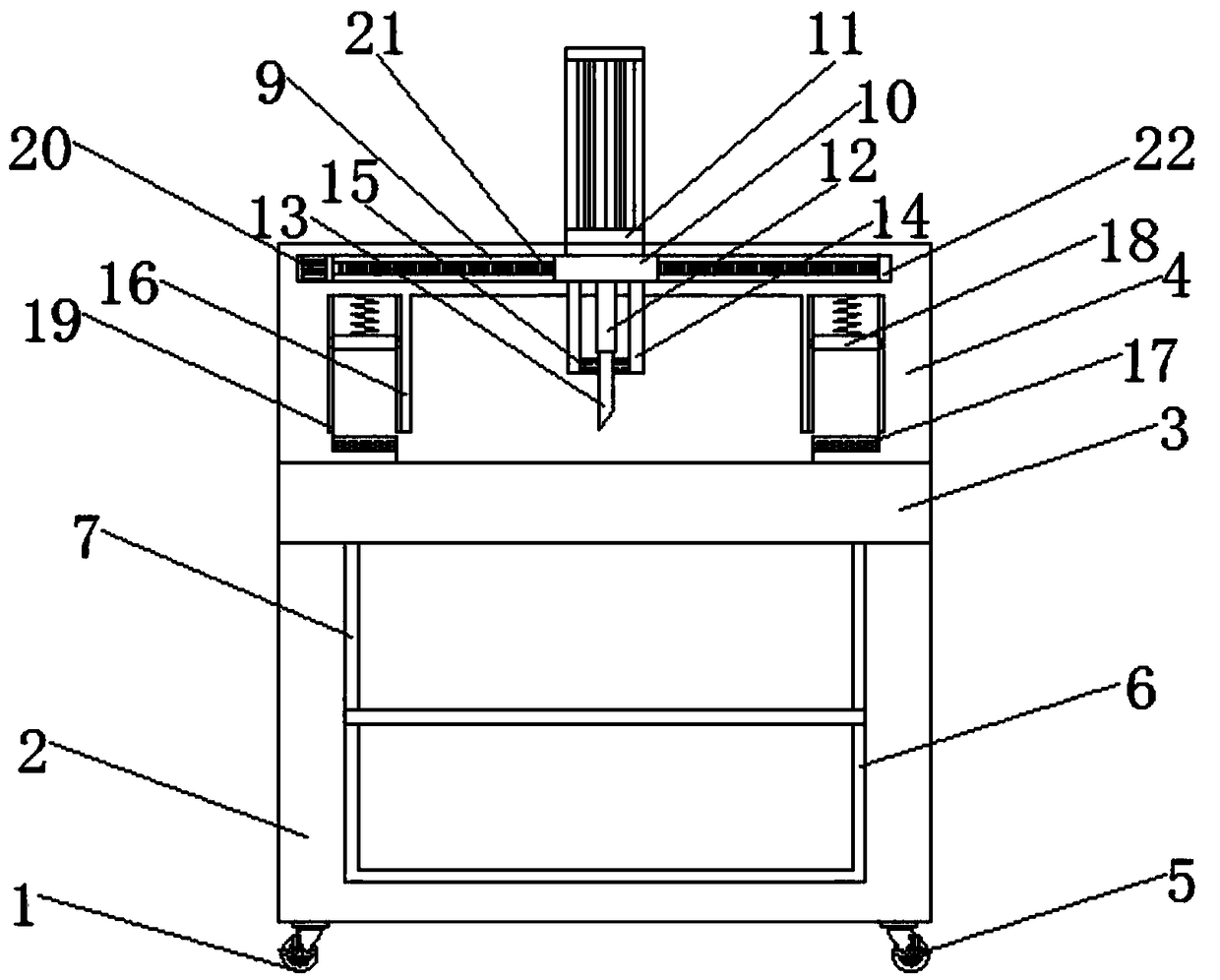

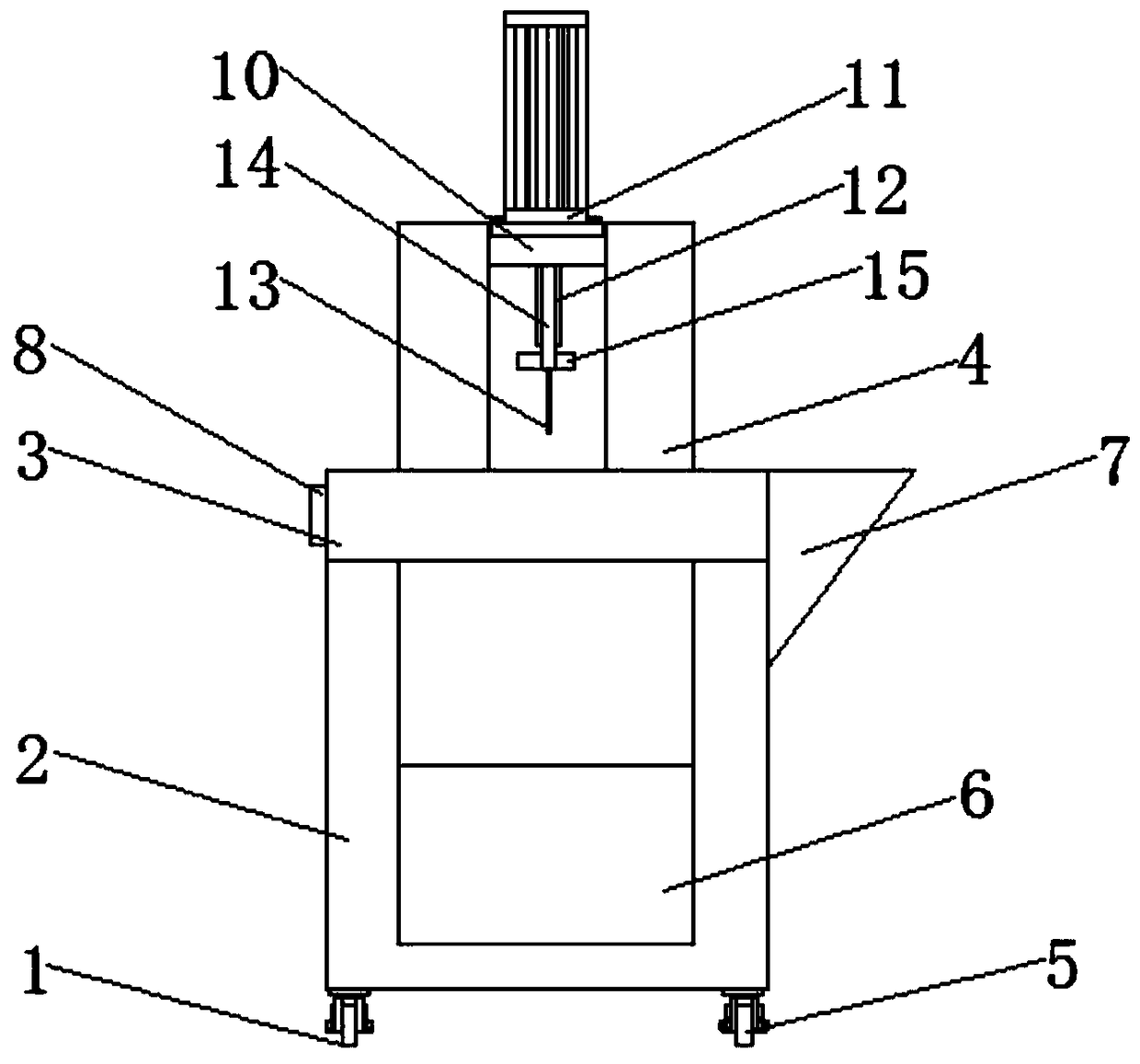

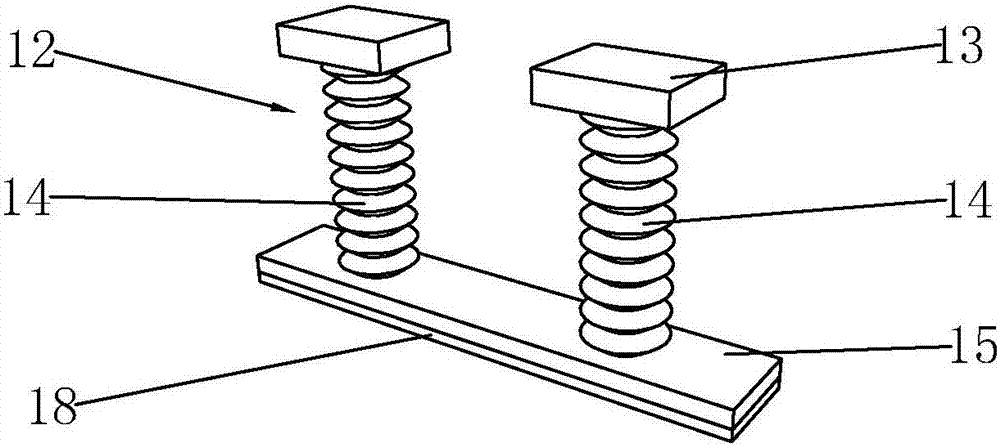

Excess material cutting device specially used for textile equipment

The invention discloses an excess material cutting device specially used for textile equipment. The bottom of a cutting device body is provided with a pedestal. The top of the pedestal is provided with a cutting bench. The two sides of the top of the cutting bench are provided with supports. The top ends of the supports are provided with a chute. One end in the chute is provided with a R280 motor.One end of the R280 motor is fixedly connected to a screw. The outer side of the screw is provided with a slide plate. The top of the slide plate is provided with an electric cylinder. The bottom endof the electric cylinder is fixedly connected to a telescopic rod. The bottom of the telescopic rod is provided with a cutting knife. The two ends of the supports are provided with compaction components. The top ends of the compaction components are provided with springs. The bottom ends of the springs are installed with a pressing plate. The bottom ends of the supports are provided with an electromagnetic plate. The bottom of the pedestal is provided with truckles. In the invention, the electromagnetic plate and the pressing plate are cooperatively used, an excess material can be compacted and is prevented from moving during a cutting process, the device is simple and practical, the cutting effect of the cutting device body is increased, and simultaneously, a secondary waste is avoided,and the utilization rate of resources is increased.

Owner:陈茶仙

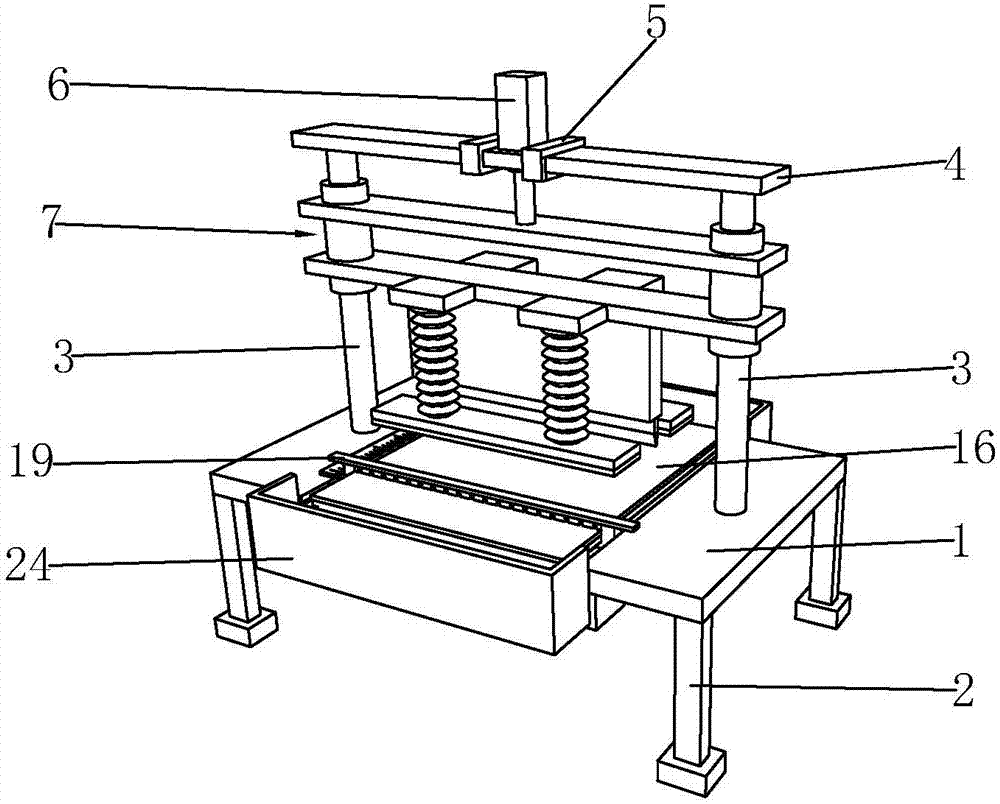

Trimming cutter for textile fabric

The invention discloses an edge cutting machine for textile fabrics, which comprises a working platform and supporting feet, the supporting feet are arranged on four corners of the bottom surface of the working platform, support rods are symmetrically distributed on the working platform, and the top of the supporting rods is provided with a fixed Clamps, there is a drive cylinder between the fixed clamps, a platen assembly is provided between the support rods, the drive cylinder is connected to the platen assembly, elastic pressure seats are provided on both sides of the platen assembly, blades are provided at the bottom of the platen assembly, and the working platform There is a backing plate on the top, the backing plate is located below the blade, a wiper is slidably connected to the working platform, and a strip brush is arranged on the bottom surface of the wiper, and the strip brush is in contact with the backing plate, and U-shaped frames are symmetrically distributed on the bottom surface of the working platform , A collection frame is arranged on the U-shaped frame, and the collection frame is in the shape of an upper opening. The invention has the advantages of compact structure, flexible connection, high working efficiency, good cutting effect, convenient cleaning of waste materials, and effectively keeping the working environment clean.

Owner:嵊州市靖洁纺织机械有限公司

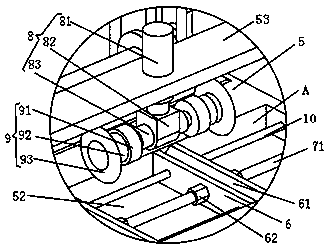

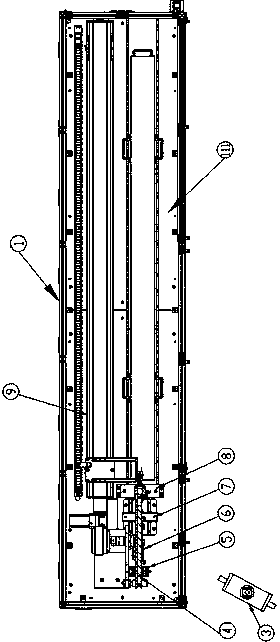

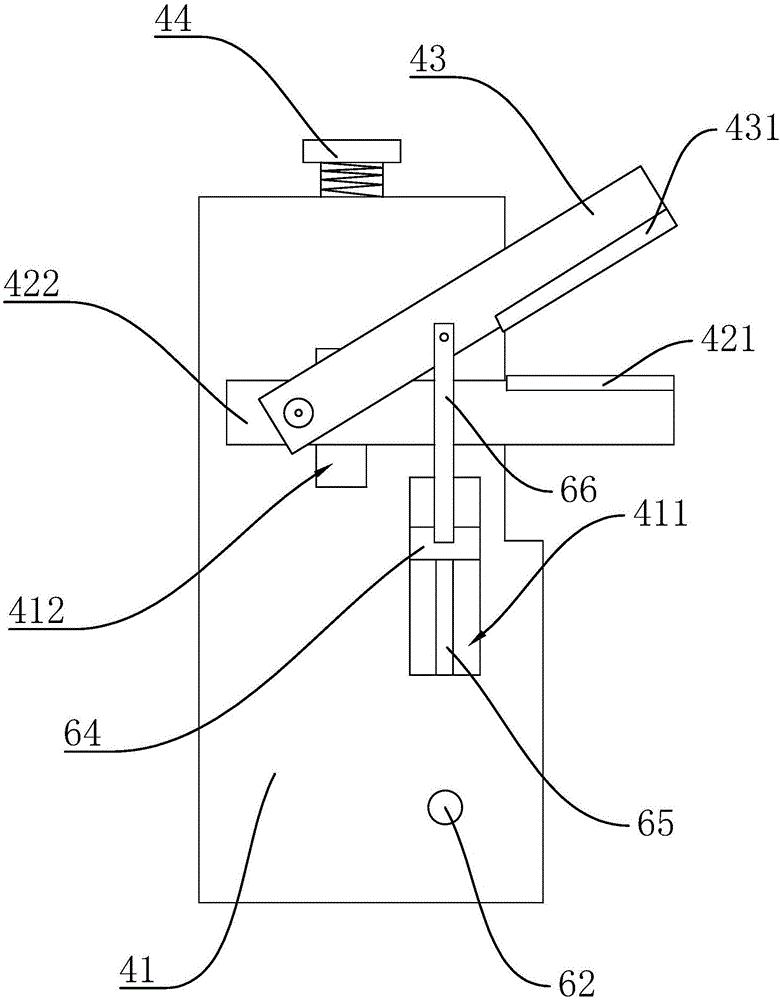

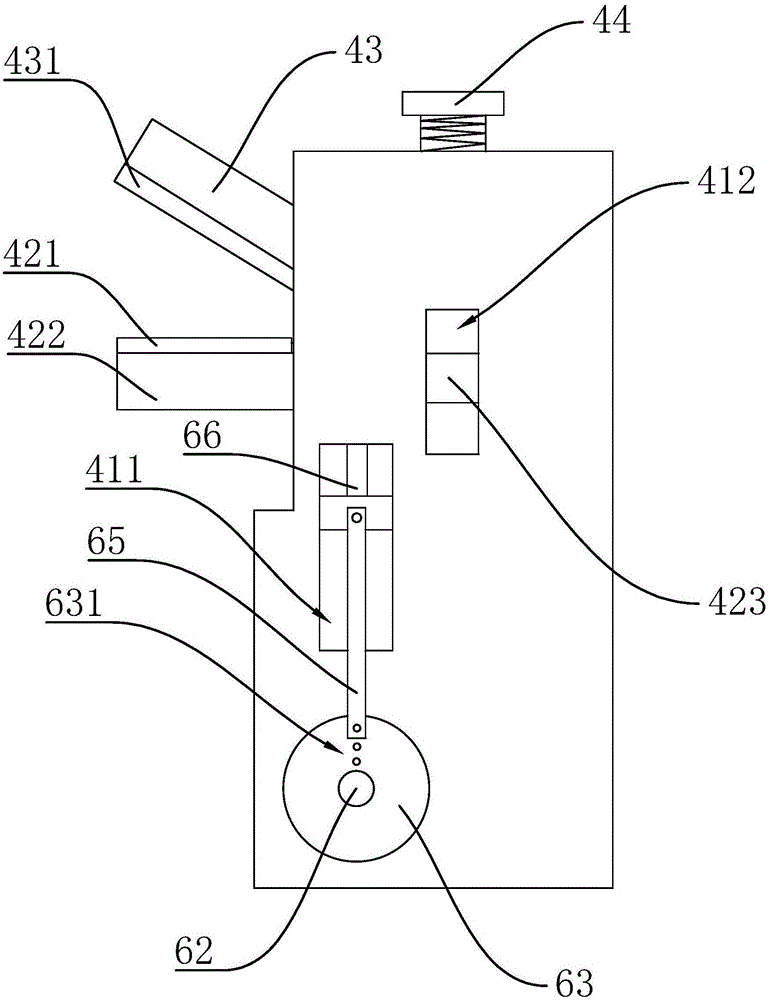

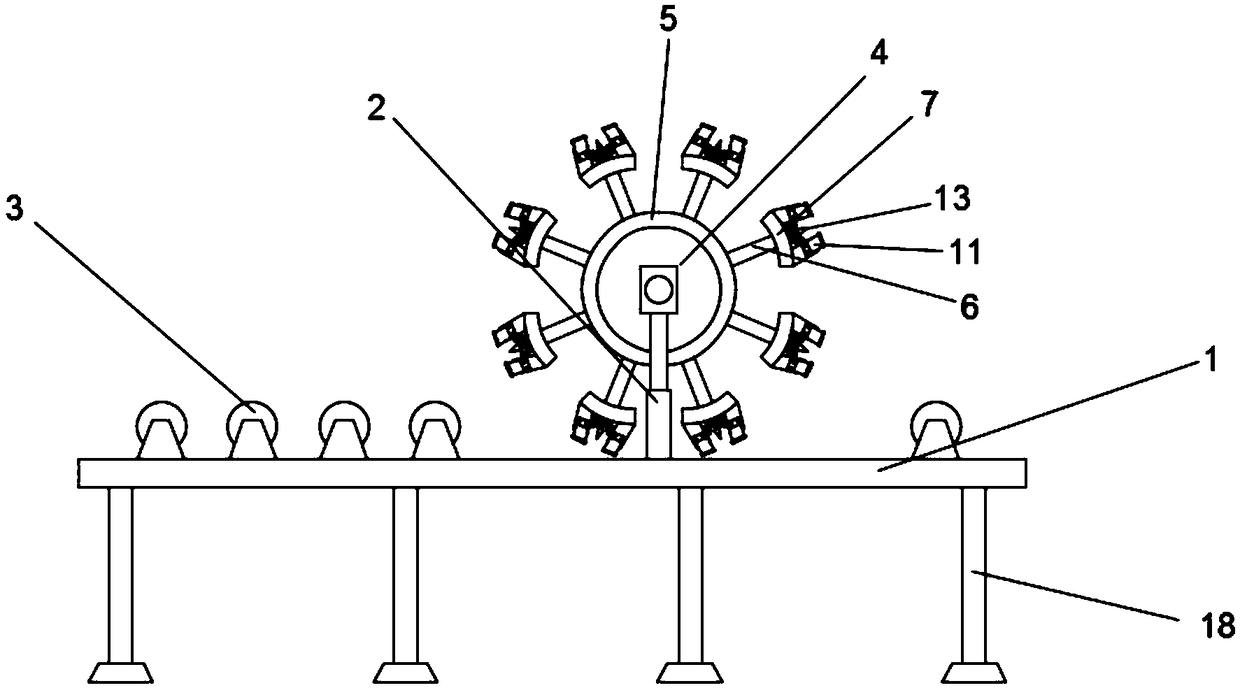

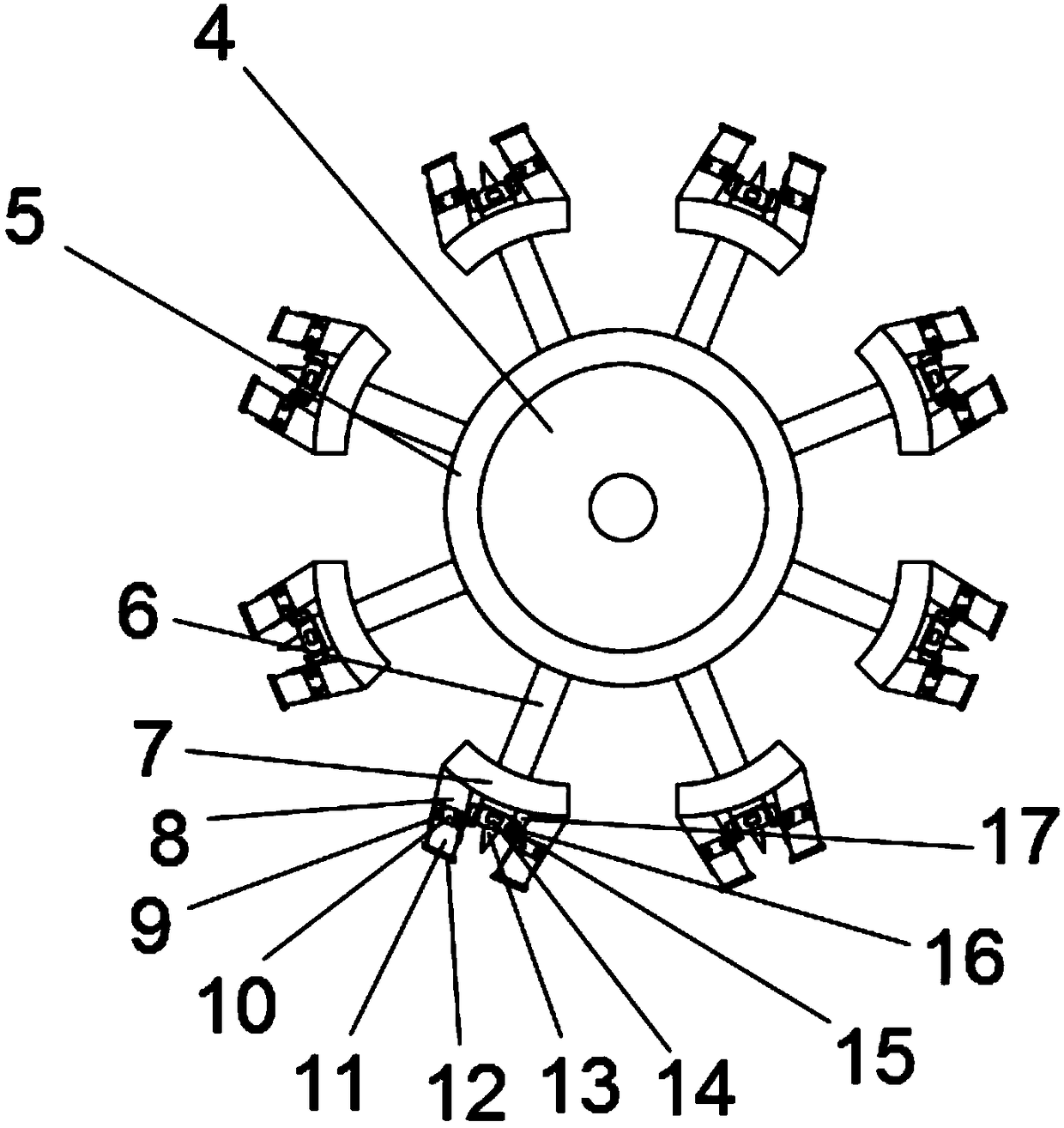

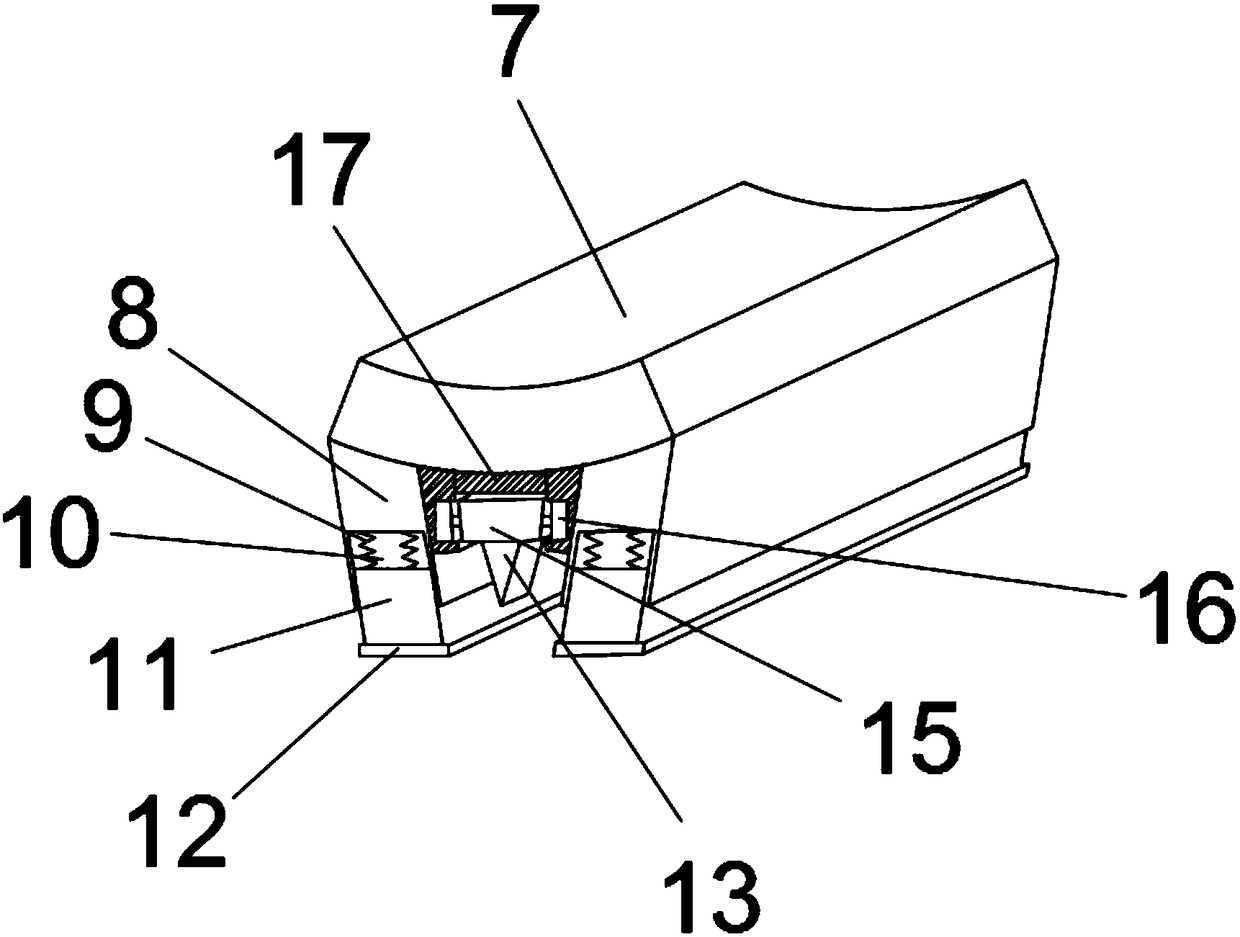

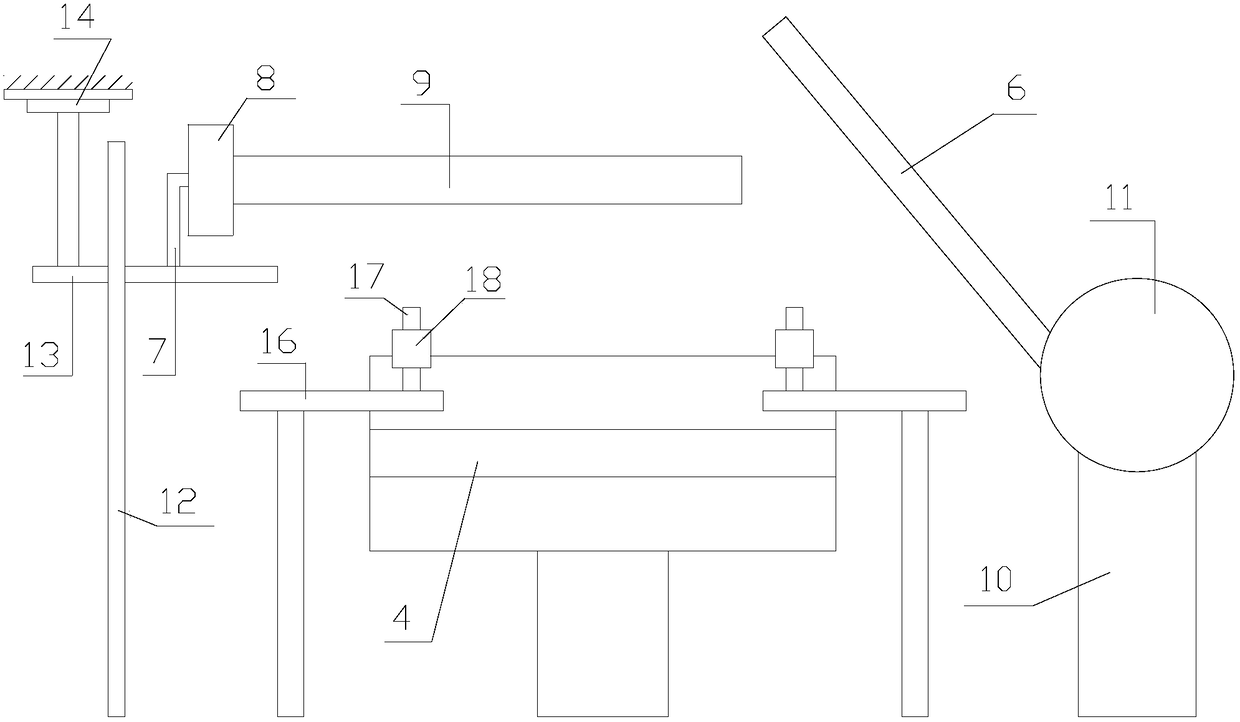

Rotating pulling and tailoring device for nonwoven fabric

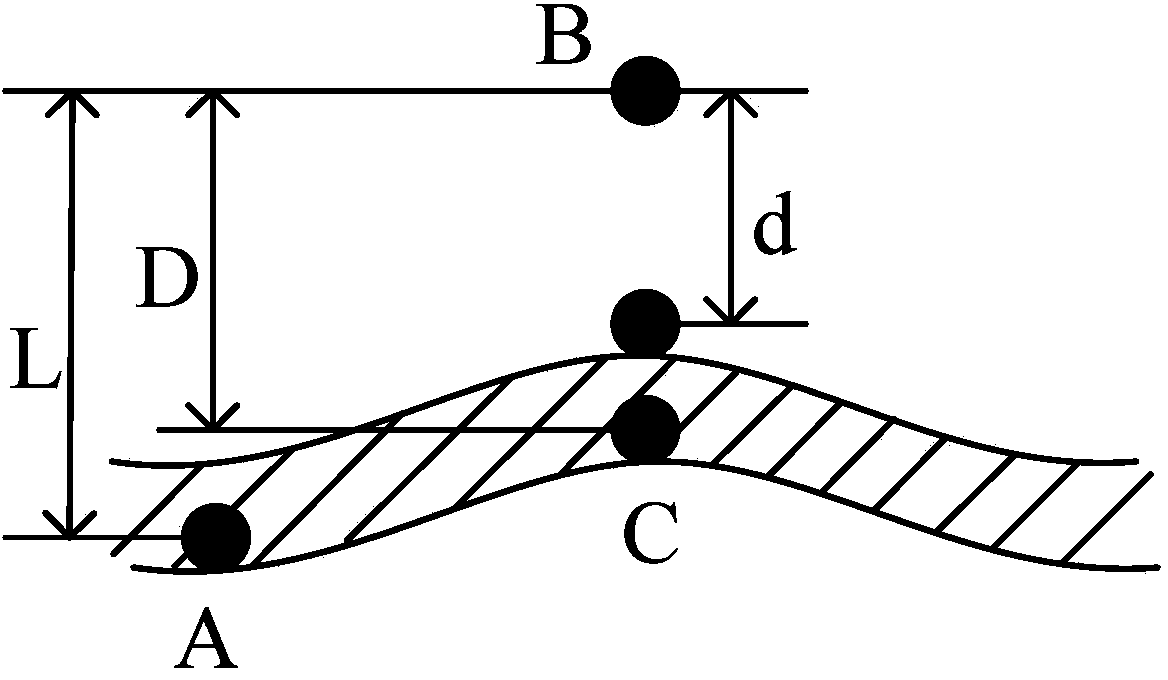

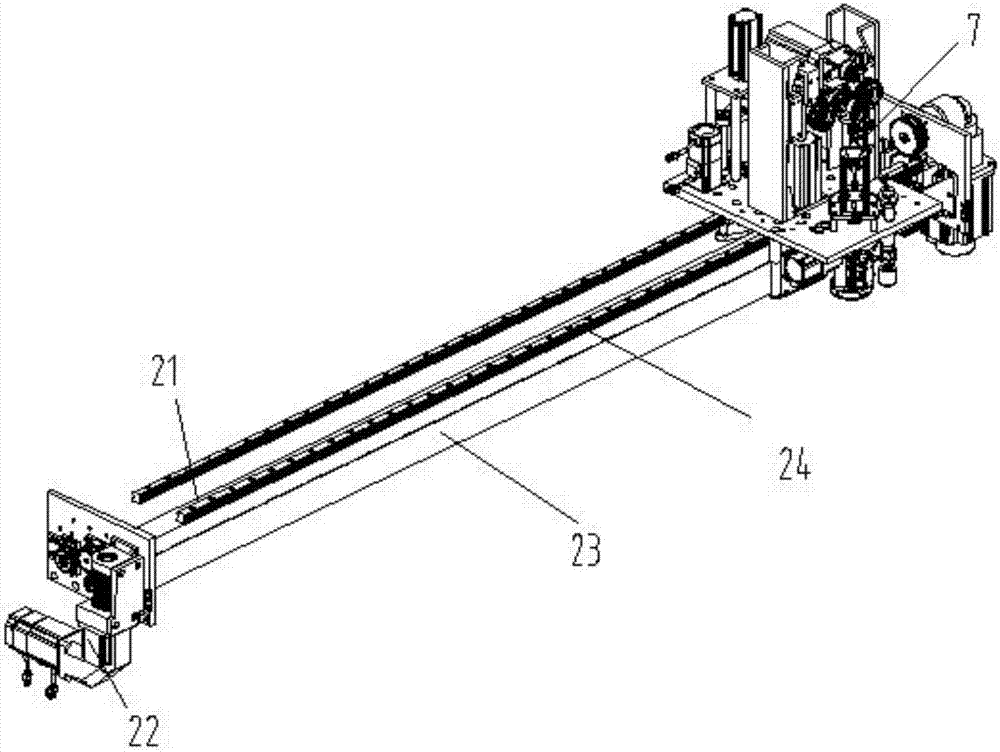

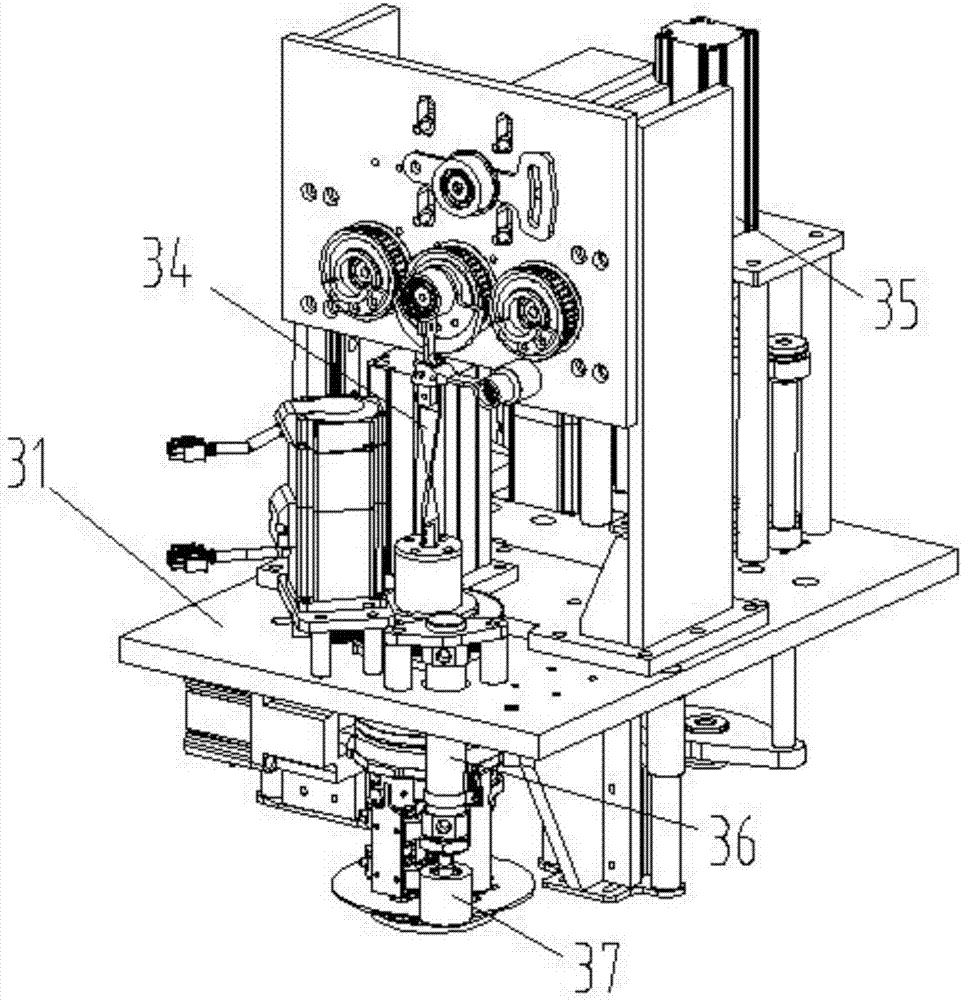

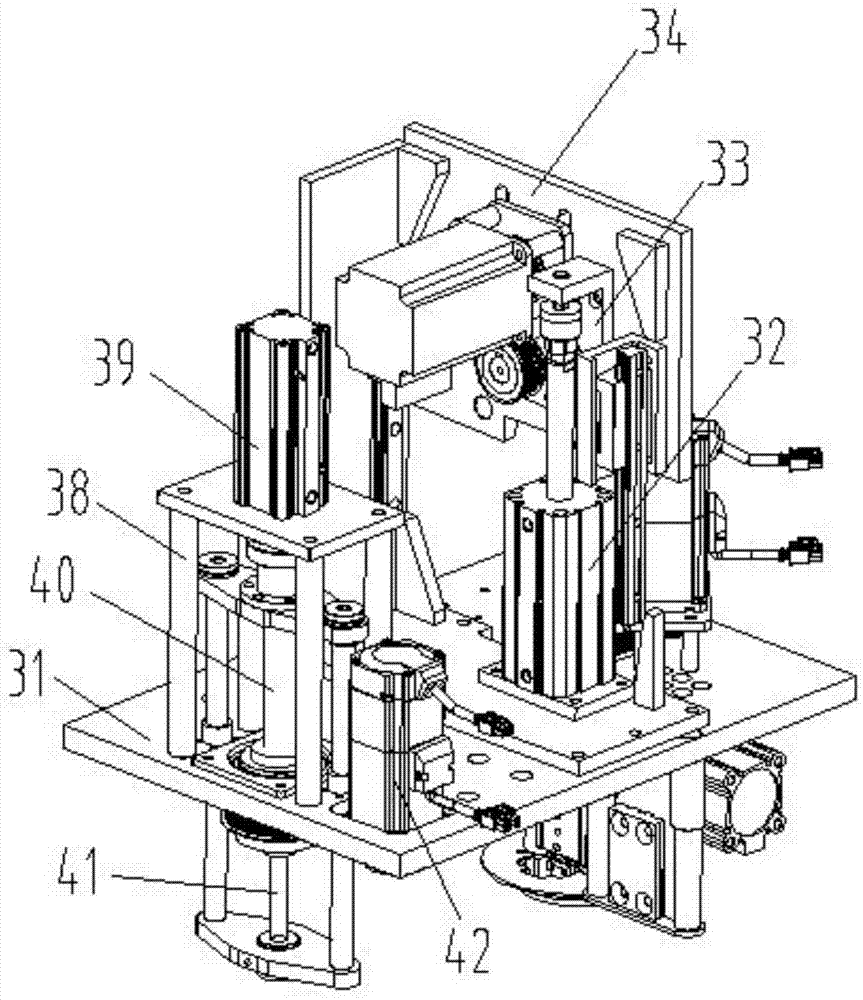

InactiveCN109335790AEasy to holdImprove croppingSevering textilesWebs handlingProduction lineManufacturing technology

The invention belongs to the technical field of manufacturing of automatic production line equipment, and specifically relates to a rotating pulling and tailoring device for a nonwoven fabric. The device comprises a coiling device, a pulling device, a pressing device, a tailoring device and a control device, wherein the coiling device comprises a rotating motor, and a rotating shaft which is sleeved with a nonwoven fabric roller; the pulling device comprises a plurality of pulling assemblies; the pressing device comprises a pressing assembly, and a driving mechanism for driving the assembly tolift; the tailoring device is arranged under the pressing assembly and comprises a cutting saw and a moving electric cylinder, and a cutting roller is driven by the moving electric cylinder to move in the axis direction of the rotating shaft; and the control device comprises a controller, and a sensor assembly which is electrically connected to the controller. With the adoption of the device, thetailoring effect is improved; and the end part of the tailored nonwoven fabric can be conveniently clamped, so that the tailoring efficiency can be improved.

Owner:安徽柏昂新材料有限公司

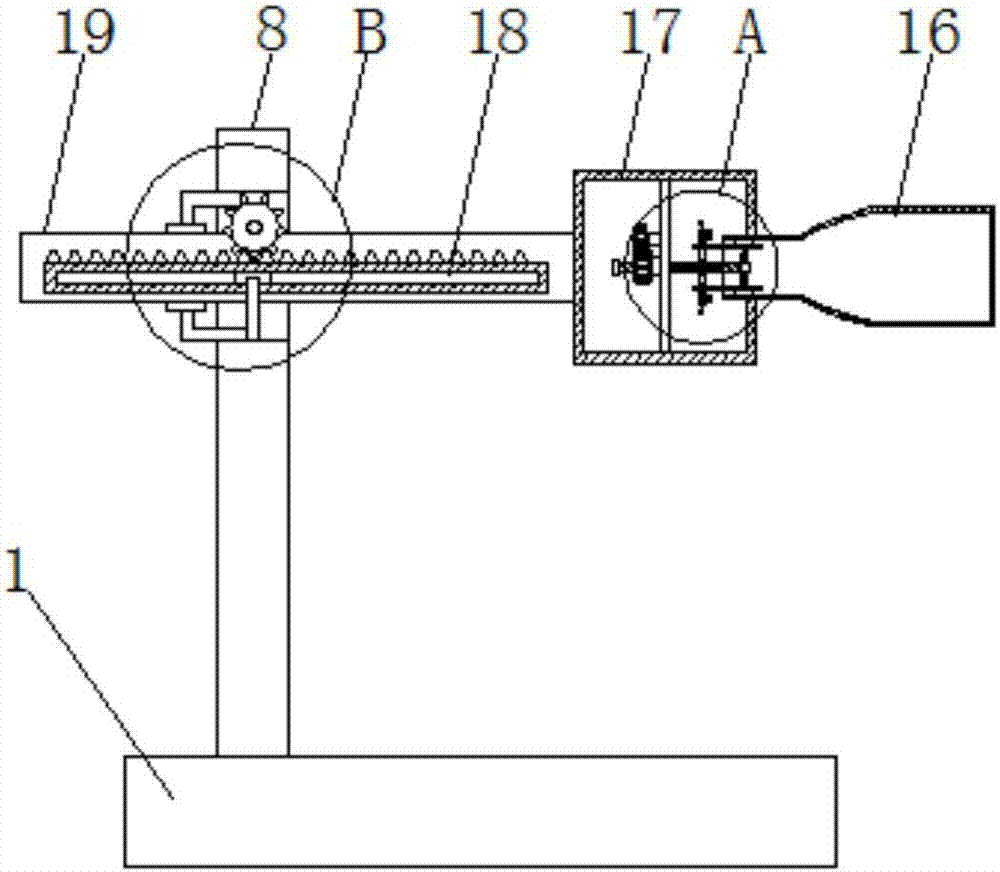

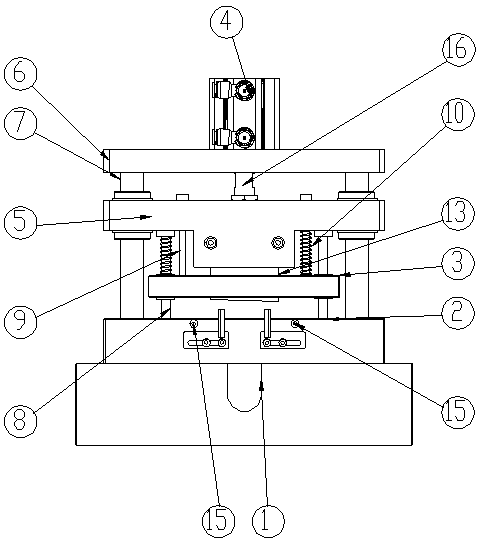

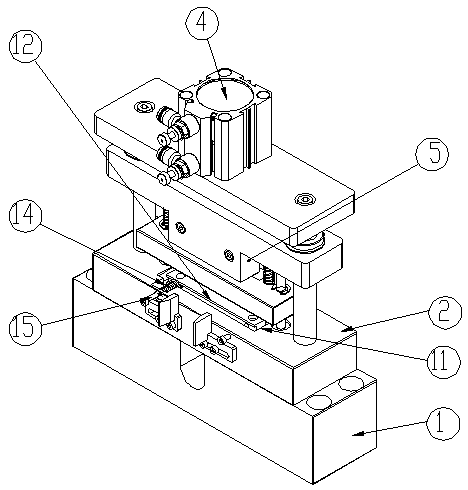

Full-automatic efficient cutting machine for bus bar

PendingCN108274241APrevent slippingAvoid offsetOther manufacturing equipments/toolsEngineeringMechanical engineering

A full-automatic efficient cutting machine for a bus bar is characterized in that the full-automatic efficient cutting machine comprises a square cutting machine shell; a controller support is arranged on the top of the cutting machine shell; one end of the controller support is fixed to the top of the cutting machine shell, and a controller is fixed to the bottom of the other end of the controller support and is a PLC; and an operation room is arranged on the upper portion of the cutting machine shell, and a discharging assembly, a deburring mechanism, a straightening mechanism, a compressionfeeding mechanism, a cutting mechanism and a traction mechanism are sequentially arranged on a bottom plate of the operation room from left to right. Using of manual work is avoided, labor force is liberated, the time and labor are saved in operation, and the requirement of enterprises for large-scale mechanical production is met conveniently.

Owner:苏州市中辰昊科技有限公司

Adjustable plastic bottle clamping device

InactiveCN107972207APlay a limiting effectEasy to adjustPlastic recyclingMechanical engineeringPlastic bottle

The invention discloses an adjustable plastic bottle clamping device. The adjustable plastic bottle clamping device comprises a base. The upper end of the base is symmetrically provided with first supporting rods. A communicating groove is formed in the side wall of each first supporting rod in a penetrating mode. A moving plate is arranged in each first communicating groove. First sliding groovesare formed in the side walls of the upper end and the lower end of each moving plate. The opposite inner side walls of each first communicating groove are fixedly connected with L-shaped rods. Opposite one ends of the two L-shaped rods are fixedly connected with first sliding blocks. The side walls of the opposite one ends of the two first sliding blocks are slidably connected with the first sliding grooves correspondingly. The side walls of the two ends of the moving plates penetrate through the communicating grooves correspondingly. The side walls of the moving plates are fixedly connectedwith rack plates. The adjustable plastic bottle clamping device is reasonable in structural design and simple in operation, a user can self-adjust conveniently, and the cutting effect can be improvedunder the condition that high stability is achieved.

Owner:马鞍山远大塑料制品实业有限公司

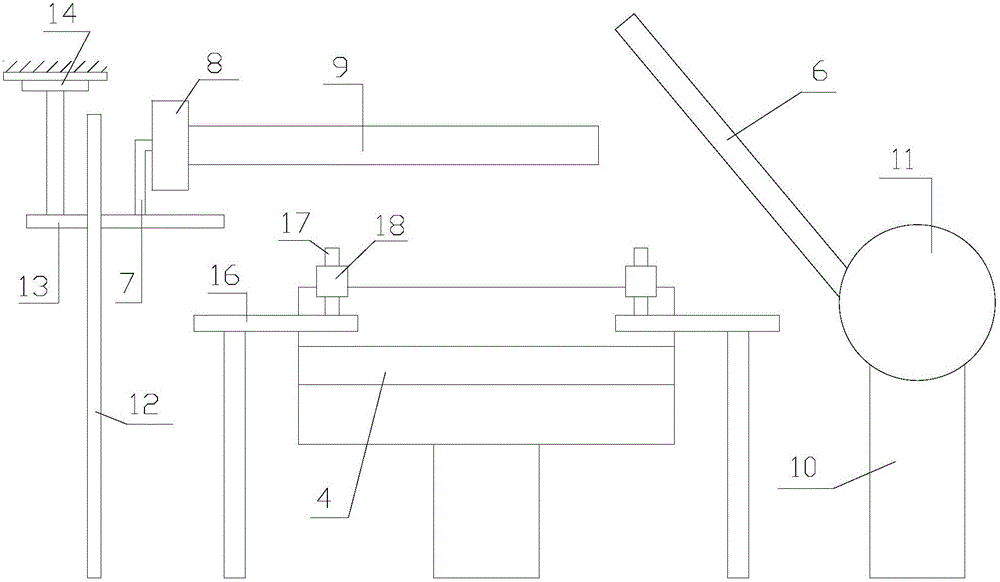

Rubber raw material pre-treatment method

InactiveCN111702833AImprove cutting efficiencyImprove cutting effectMetal working apparatusMechanical engineeringManual handling

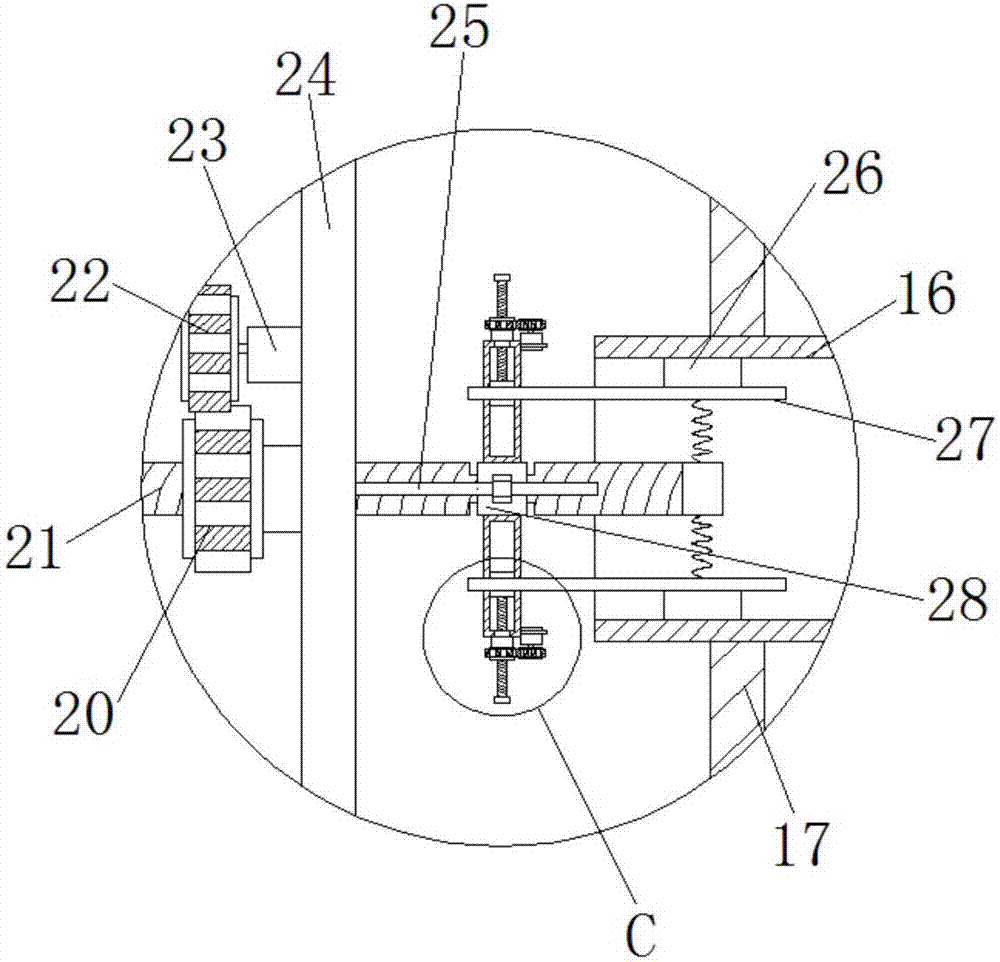

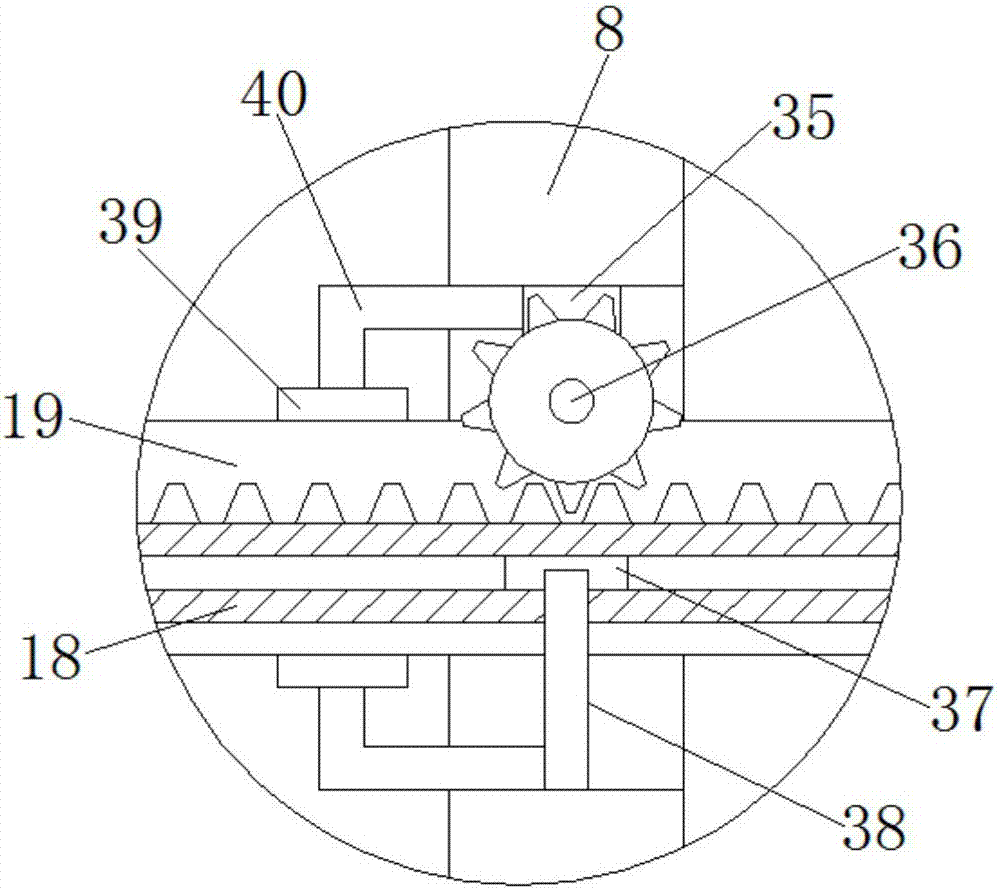

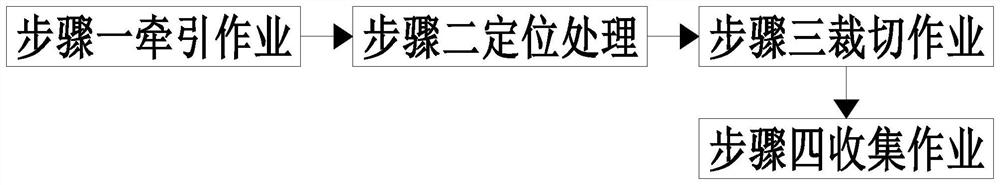

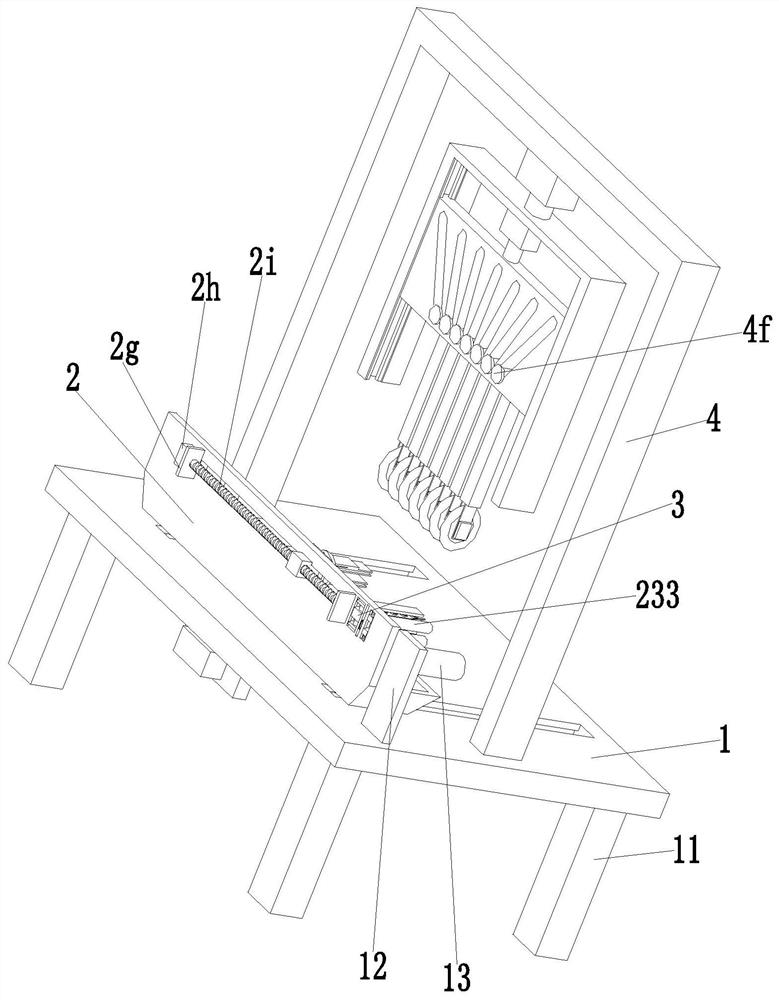

The invention relates to a rubber raw material pre-treatment method. The method mainly comprises the following steps of traction work, positioning treatment, cutting work, collection work and other procedures. Used rubber raw material treatment equipment comprises a bottom plate, a traction device, a positioning device and a cutting device, and the problems existing in existing rubber strip cutting that cutting after manual measuring is adopted in traditional rubber strip cutting, when a worker uses a tool for cutting a rubber strip, due to manual operation errors, the worker is frequently hurt by the tool due to cutting, the efficiency of manual cutting of the rubber strip is low, the cutting quality cannot be ensured, the raw material is wasted, when existing rubber strip cutting equipment cuts the rubber strip, only one segment of rubber strip can be cut at one time, the cutting speed is low, the rubber strip cutting length is not even, a cut opening is not flat, and the rubber strip cutting efficiency and effect can be improved.

Owner:胡帆

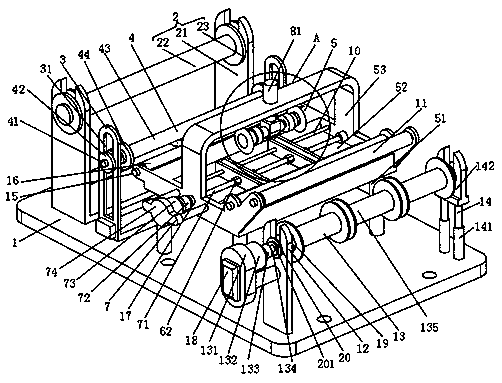

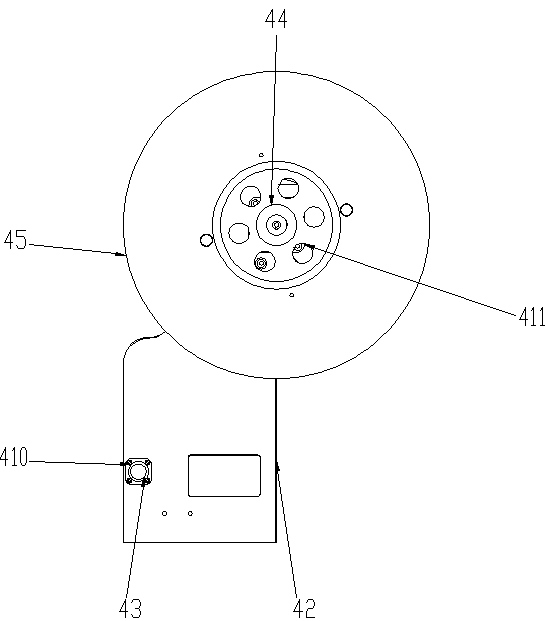

Rapier loom

ActiveCN106048864AImprove surface qualityAccurate and fast resetLoomsAuxillary apparatusPush and pullMotor drive

The invention provides a rapier loom which comprises a workbench, a warp let-off mechanism, a weft let-off mechanism, a slitter edge cutting mechanism and a rolling mechanism. The slitter edge cutting mechanism comprises a cutter rest, a fixed cutter body and a movable cutter body, the fixed cutter body is provided with a first blade, the movable cutter body is provided with a second blade, the fixed cutter body is fixed to the cutter rest in a height-adjustable mode, the movable cutter body is hinged to the fixed cutter body, and the first blade and the second blade abut against each other to form a cutting opening; the slitter edge cutting mechanism further comprises a motor driving the movable cutter body to rotate, a transmission shaft and a rotating disc, and the transmission shaft is controlled by the motor and fixedly connected to the center of the rotating disc; the cutter rest is provided with a longitudinal sliding groove, a sliding block is arranged in the sliding groove, a first connecting rod used for driving the sliding block to rise and fall is arranged between the sliding block and the rotating disc, a second connecting rod used for pushing and pulling the movable cutter body is arranged between the sliding block and the movable cutter body, one side of the sliding block is fixedly connected with the second connecting rod, and the second connecting rod is hinged to the movable cutter body; the other side of the sliding block is hinged to the first connecting rod, and the first connecting rod is hinged to the eccentric position of the rotating disc.

Owner:LANGXI YUANHUA TEXTILE

Filter cloth positioning and cutting device

The invention discloses a filter cloth positioning and cutting device. The filter cloth positioning and cutting device comprises a top plate, wherein guide columns are symmetrically and fixedly arranged on the top plate, and symmetrical hydraulic cylinders are fixedly connected to a positioning plate; an annular groove is formed in the top plate, a rotating shaft is fixedly arranged on the side, far away from the top plate, of a rotating rod, a lifting air cylinder is fixedly arranged in an installing groove, and a cutting knife is arranged on the lifting air cylinder; and a threaded hole is formed in the side, opposite to a limiting plate, of the center of the top plate, a threaded rod is movably arranged in the threaded hole, and a central pressing plate is fixedly arranged at the end, far away from the threaded hole, of the threaded rod. According to the filter cloth positioning and cutting device, the structure for double fixing and pressing an outer layer and the center of a filter cloth raw material is arranged in the device, so that the side edge of to-be-cut filter cloth is always in the straining state, the condition that the filter cloth subject to partial side edge cutting is inclined, so that cutting of the residual side edge is influenced is avoided, meanwhile, a dust collection device and a dust suction device are arranged in a built-in mode, and the dust prevention effect is good.

Owner:淮北雷德机电科技有限公司

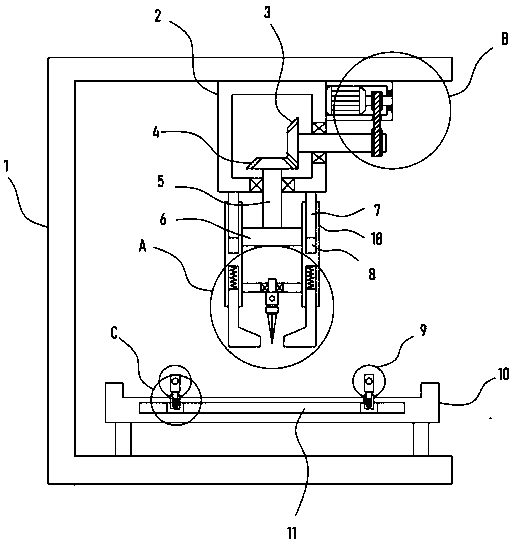

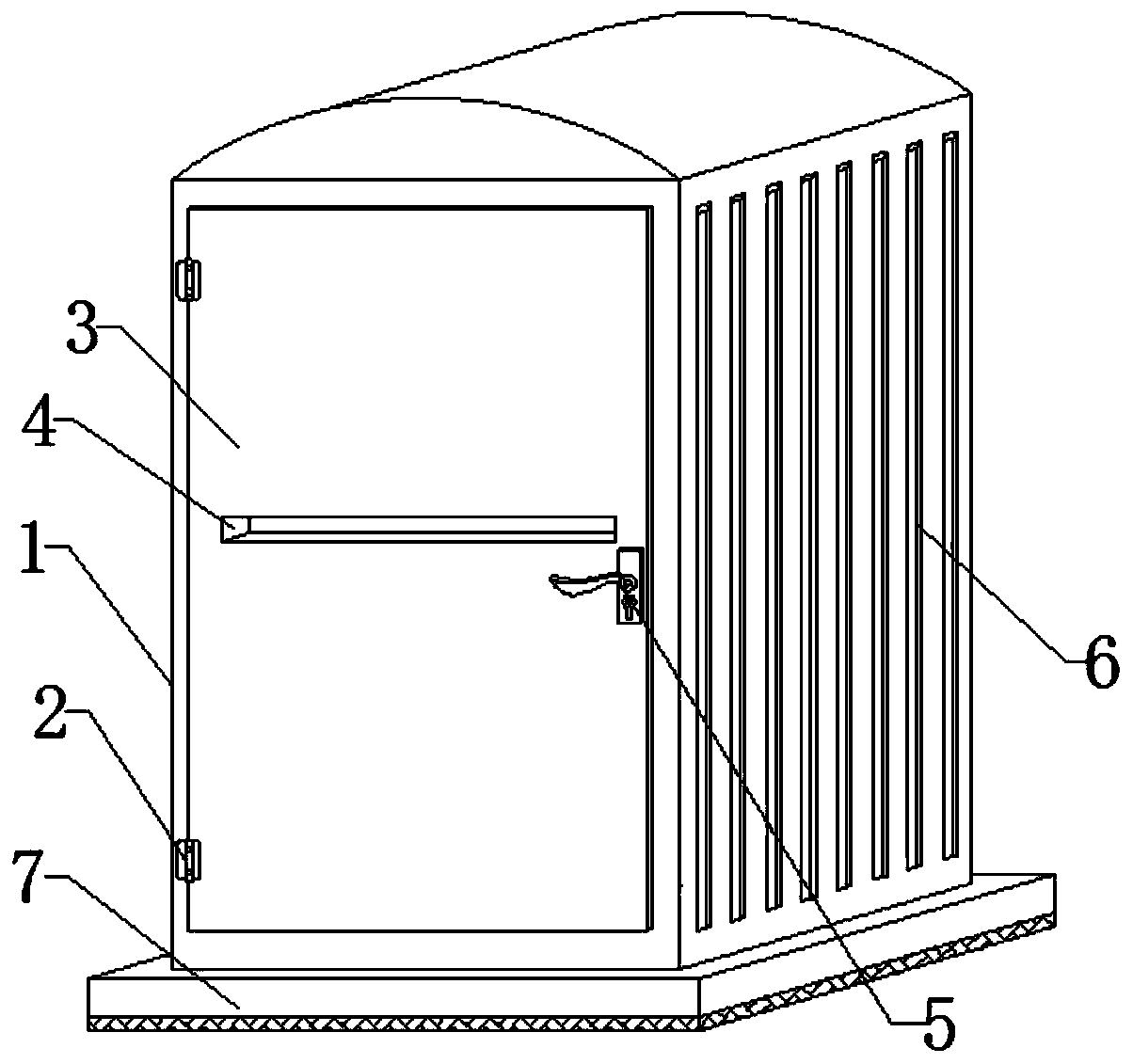

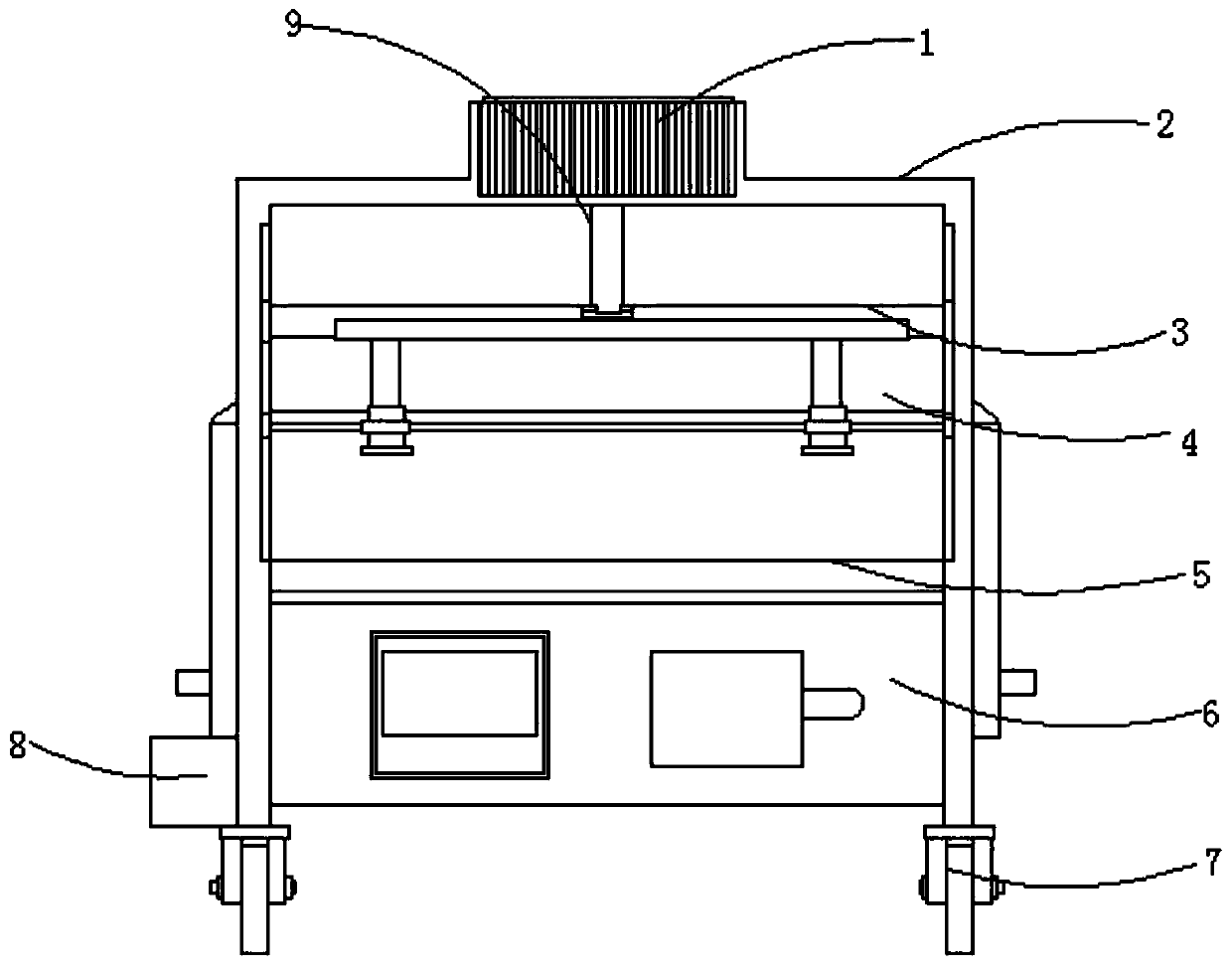

Automatic film cutting mechanism for circuit board film laminating machine

InactiveCN110996544AEasy to cutAvoid wear and tearNon-metallic protective coating applicationEngineeringMechanical engineering

The invention discloses an automatic film cutting mechanism for a circuit board film laminating machine, and relates to the antenna installation field. The automatic film cutting mechanism comprises alaminating machine body, the outer surface of the laminating machine body is connected with a maintenance door through a hinge, and a through hole penetrates through the outer surface of the maintenance door. A heat dissipation groove is formed at one side of the laminating machine body, and a bottom plate is fixed at the bottom of the laminating machine body. During mounting, a worker also pullsa pull ring to enable a limiting rod to overcome the resistance of a second spring to contract, then, the worker aligns one end of a mounting piece at a mounting groove, then, pushes the mounting piece into the mounting groove, and when the mounting piece is pushed to a certain extent and can not move continuously, the worker loosens the pull ring, so that one end of the limiting rod is driven tobe inserted into a limiting groove under the reset capacity of the second spring, the mounting piece is limited, and the mounting piece and a cutter are prevented from automatically sliding out of the mounting groove during working to influence the cutting. The automatic film cutting mechanism is easy to mount and dismount, is convenient to replace and maintain the cutter, and is practical and convenient.

Owner:湖南东神自动化设备有限公司

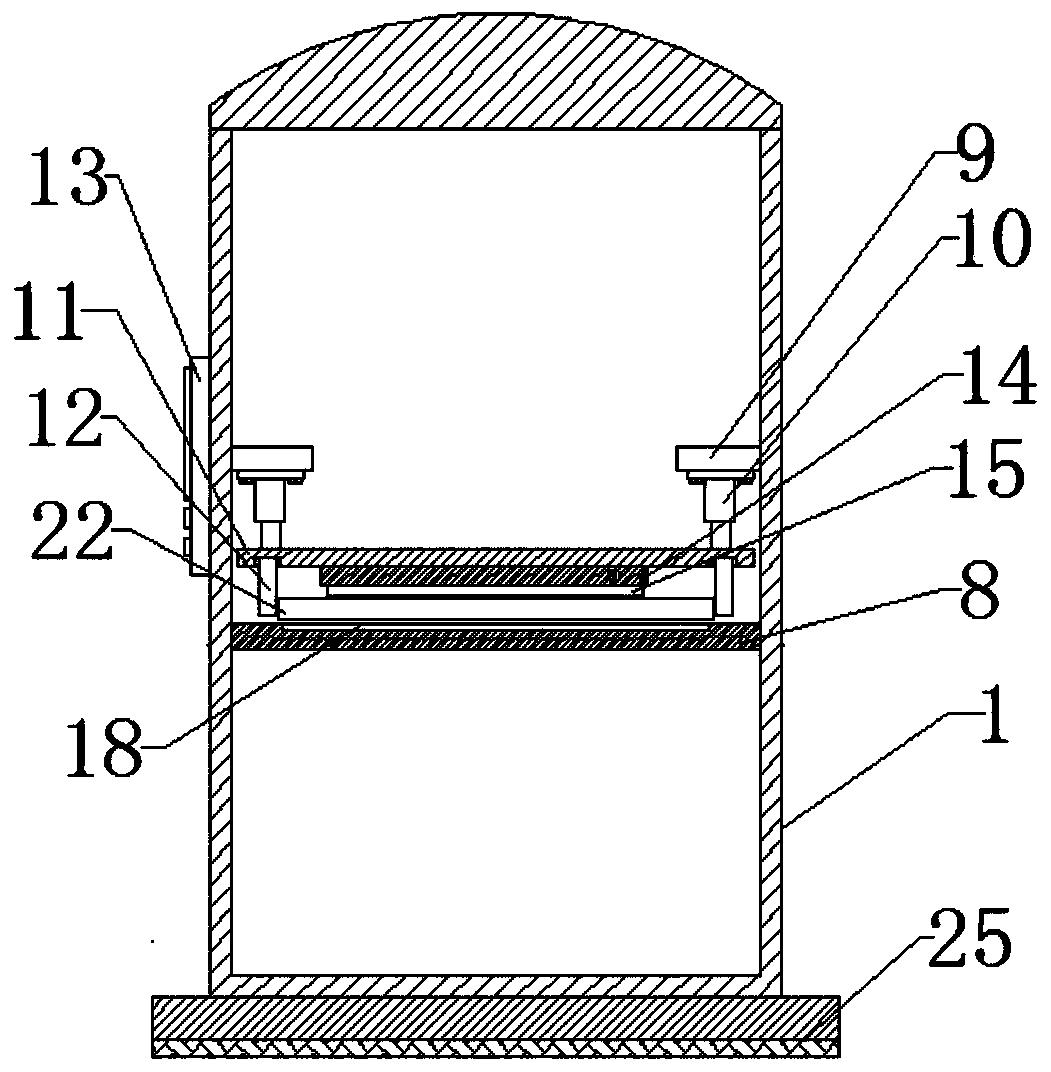

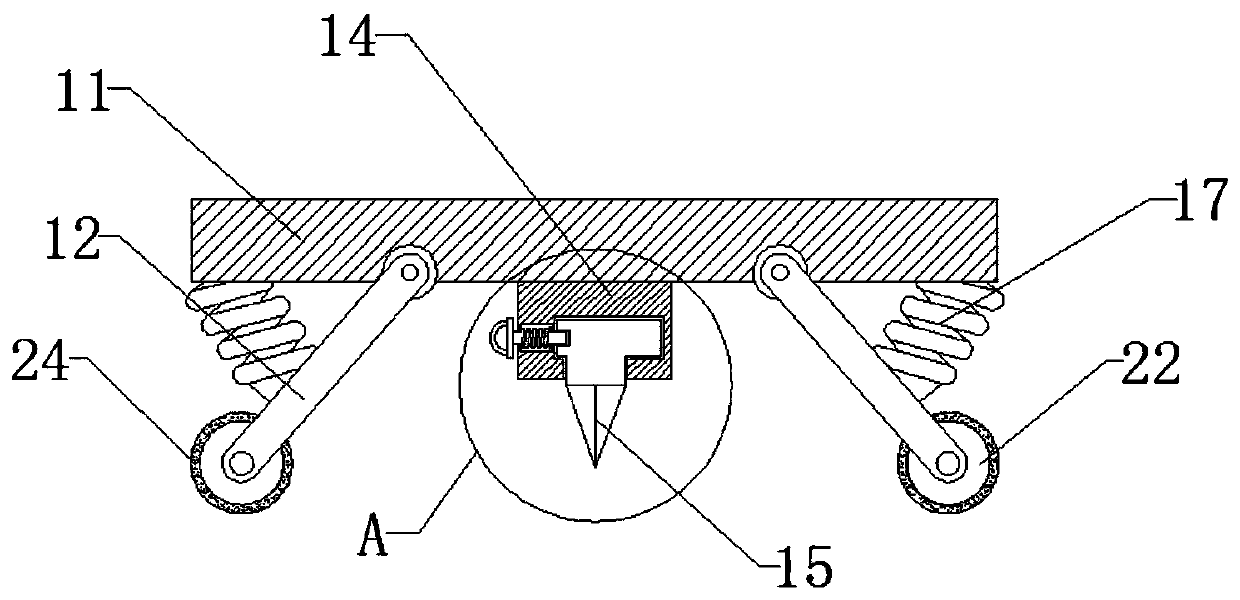

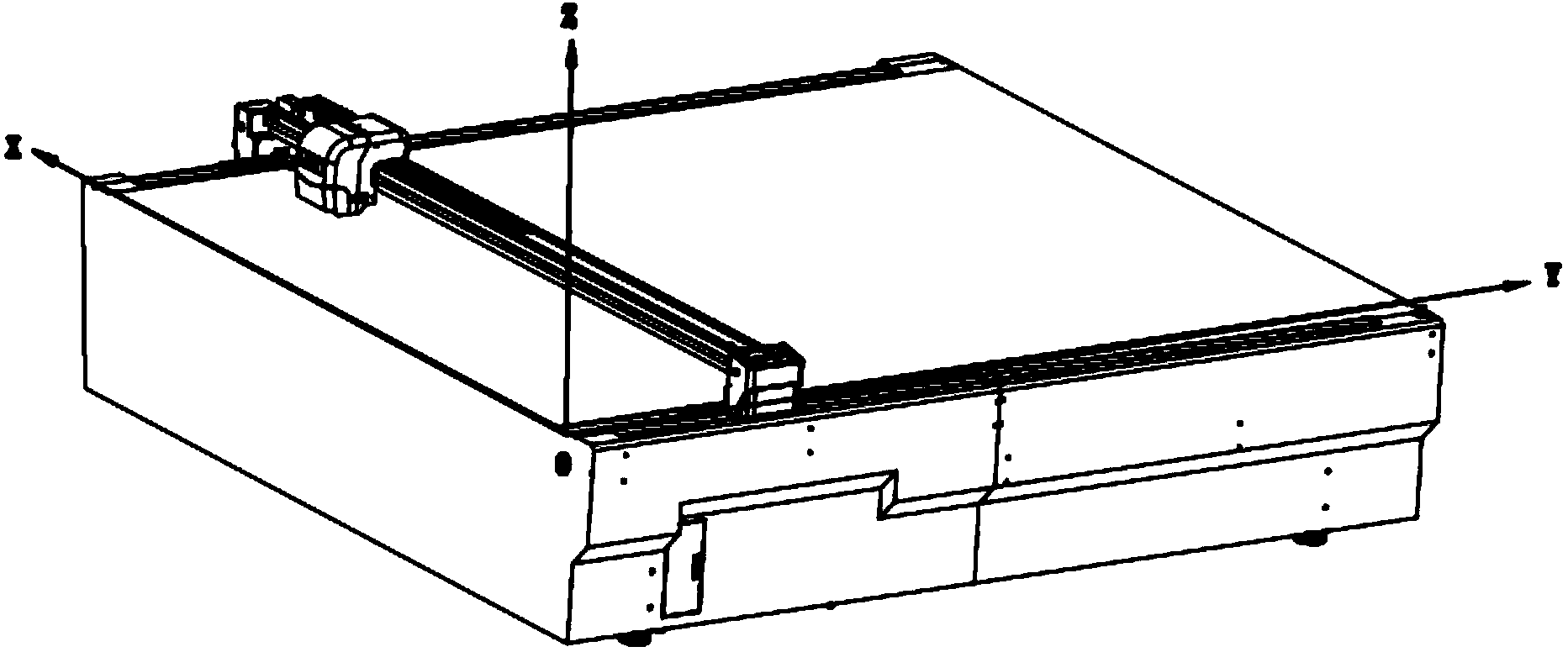

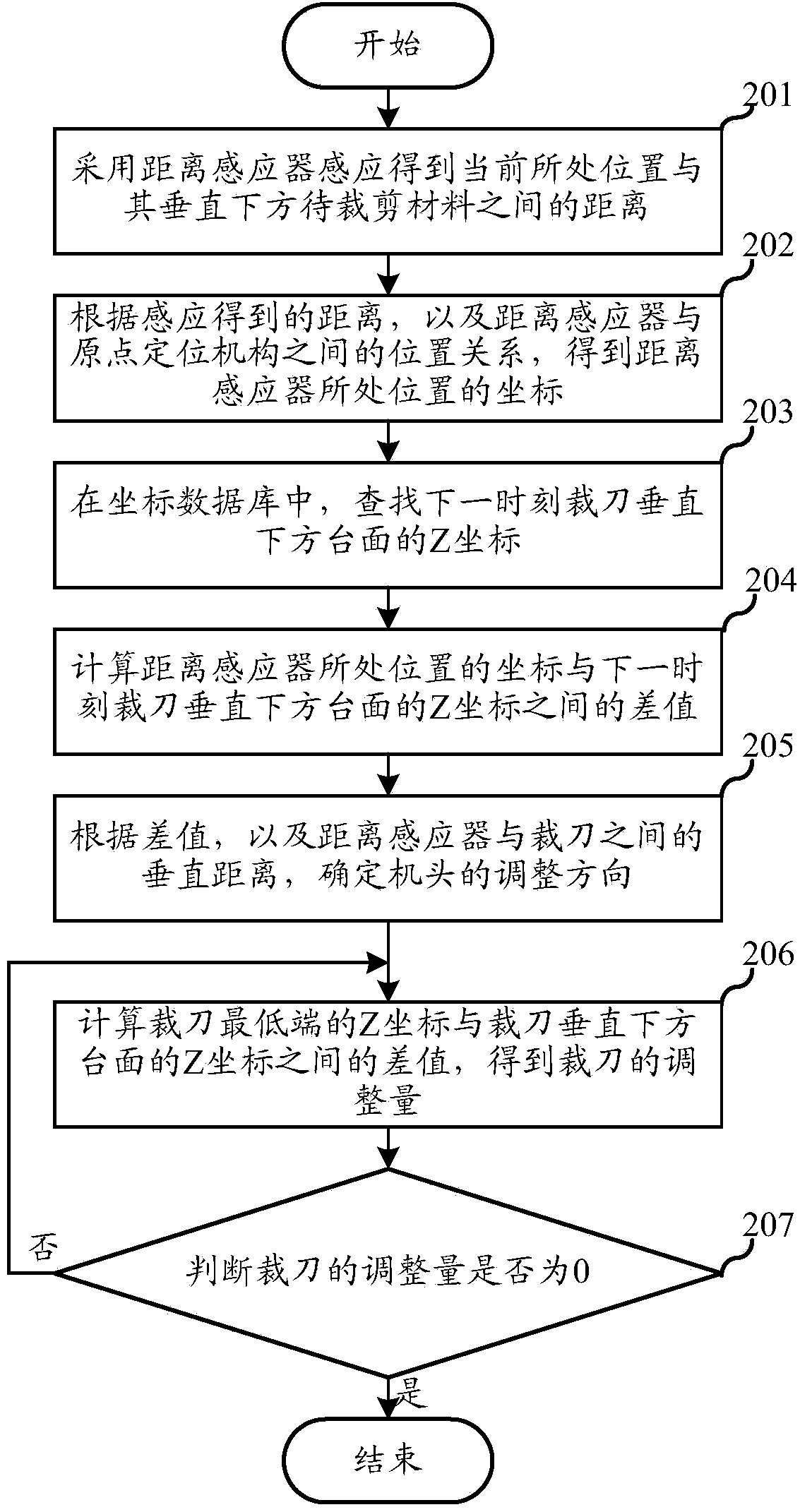

Automatic cutting machine and cutting method thereof

The invention relates to the technical field of automatic cutting, and discloses an automatic cutting machine and a cutting method thereof. The adjustment amount of a cutting knife is obtained according to the position relation between the lowest end of the cutting knife and a table surface; the adjustment amount is the vertical distance between the lowest end of the cutting knife and the table surface; if the adjustment amount of the cutting amount is not 0, up and down position of the cutting knife is adjusted until the adjustment amount of the cutting knife is 0. When the automatic cutting machine adopts the method to conduct cutting, the position of the cutting knife can be adjusted in real time; the distance between the cutting knife and the table surface can be maintained; the lowest end of the cutting knife is enabled to be arranged above the surface of the table surface, so as to promote the cutting effect; not only is cutting ensured to be complete, but also contact and damage of the cutting knife and the cutting table surface can be avoided.

Owner:长园和鹰科技(河南)有限公司

Fabric cutting device capable of adapting to belt conveying

ActiveCN106854830AReduce lifting speedAvoid situations that damage the conveyor beltSevering textilesMetal working apparatusEngineeringMechanical engineering

The invention relates to a fabric cutting device capable of adapting to belt conveying. The fabric cutting device comprises a feeding device, the feeding device is provided with a fabric cutting frame, the fabric cutting frame is provided with a cutting device, the cutting device comprises a cutter sleeve on the fabric cutting frame, the lower portion of the cutter sleeve is provided with a cutter groove, the cutter groove is communicated with the cutter sleeve, and a cutter lifting pull rod matched with a cutter in the cutter groove is arranged in the cutter groove, the upper portion of the cutter lifting pull rod is hinged to a cutting rotating base, a cutting rotating rod is further hinged to the cutting rotating base, the other end of the cutting rotating base sleeves a sleeving shaft on a cutting mounting plate on the fabric cutting frame, the other end of the cutting rotating rod is connected to a cutting rotating sleeve, and the cutting rotating sleeve is matched with a cutting lifting motor on the cutting mounting plate. The cutter lifts or descends through the hinged cutter lifting pull rod, the cutting rotating rod and the cutting rotating base, a maximum lifting and descending range is limited, the lifting or descending speed can be slowed down through regulation, and damage to a conveying belt by the cutter is avoided greatly.

Owner:华清(扬州)织物有限公司

Rapid paving method for PVC (polyvinyl chloride) plastic floor

ActiveCN112609920ANeat pavementImprove work efficiencyFlooringPolyvinyl chlorideWater resource management

The invention discloses a rapid paving method for PVC (polyvinyl chloride) plastic floor. The rapid paving method comprises the following steps of (S1) cleaning the ground: cleaning up ground sundries, and removing dust and grit which are attached to the surface of the ground, so that the ground is in a sand-free state; (S2) constructing self-leveling mortar: pouring self-leveling mortar on the cleaned ground, and scraping the self-leveling mortar to be flat by using a paving device, wherein the thickness of the self-leveling mortar is 3 to 5 mm, ventilation is kept, and the self-leveling mortar is naturally dried to be smooth and flat; (S3) pre-paving the floor: performing small-range trial paving on the self-leveling mortar so as to guarantee the pattern and color ratio of floor paving, determining the floor paving trend, and performing paving marking on the floor; (S4) performing overall floor paving: paving according to the floor marking sequence, and cutting the floor in the connecting position of the wall body and the ground; and (S5) compacting the floor: do not clean the paved floor again or remove sundries and dust from the surface, and compacting the floor by using the paving device. According to the rapid paving method, a gap between the floor and the ground is eliminated, and air is exhausted, so that the floor is orderly paved, and the working efficiency is high.

Owner:安徽飞镖知识产权服务股份有限公司

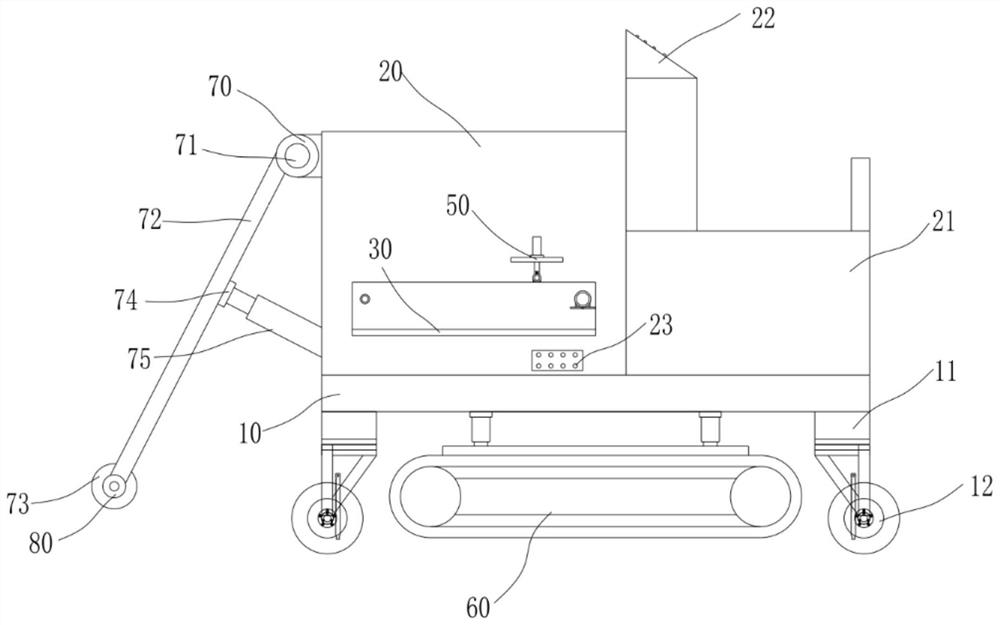

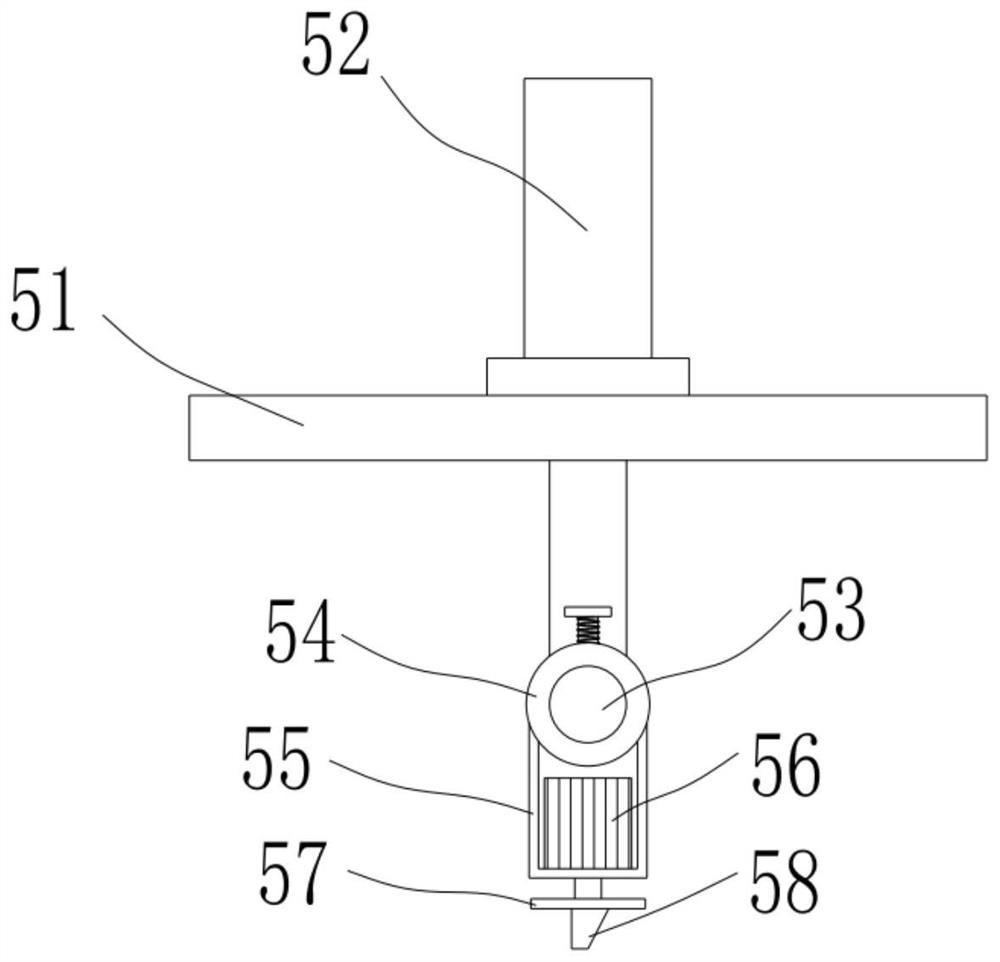

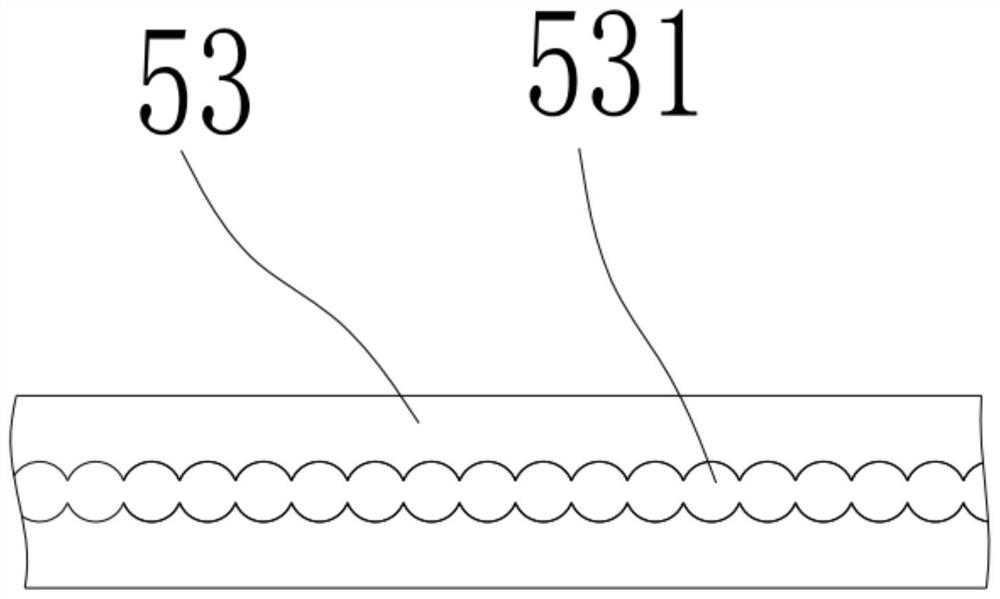

Tailoring and settling intelligent robot for paper production

InactiveCN107696097AEffective extractionGuaranteed accuracyDirt cleaningMetal working apparatusPaper productionElectric machinery

The invention discloses an intelligent robot for cutting and arranging paper production, which comprises a machine table, a machine case is fixedly installed on the top of the machine table, a material storage rack on the machine table is movably connected to the side of the machine table, and a The material transfer table, the movable set on the material transfer table is equipped with a collection table, the top of the collection table is fixedly connected with the top of the transmission device, the transmission device is fixedly installed at the bottom of the inner cavity of the chassis, and the side of the transmission device is fixedly installed with a positioning plate Ⅰ , the bottom end of the inner chamber of the case is fixedly installed with a servo motor on the side away from the transmission device. The cutting and finishing device used for paper production draws the wound paper to the material transfer table in the chassis through the traction device, and uses the limit net cover to limit, and uses the external connection pipe and the air duct to cooperate with the fan to isolate the chassis and The dust in the cover is effectively extracted to ensure the internal environment, reduce the error of cutting paper, and ensure the accuracy and efficiency of paper traction and cutting.

Owner:傅恺

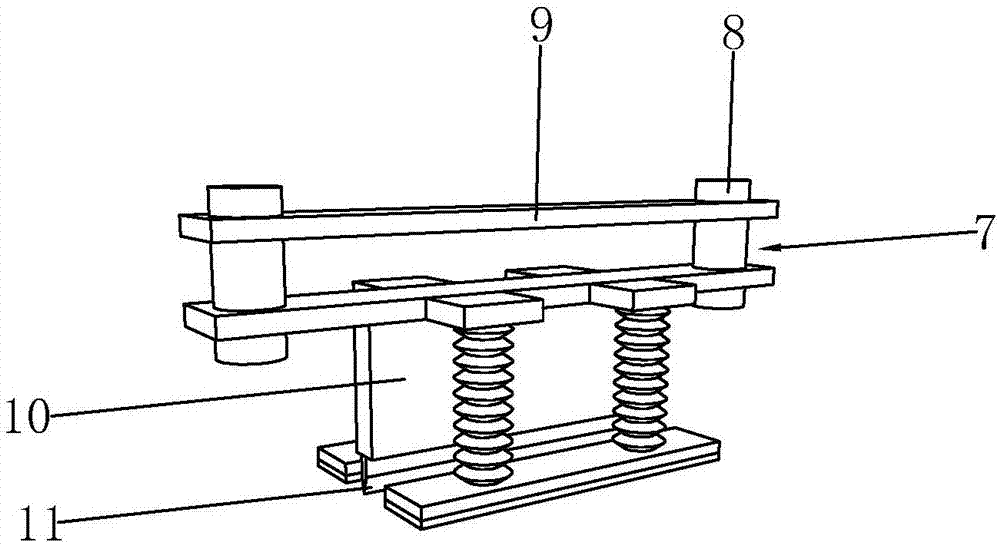

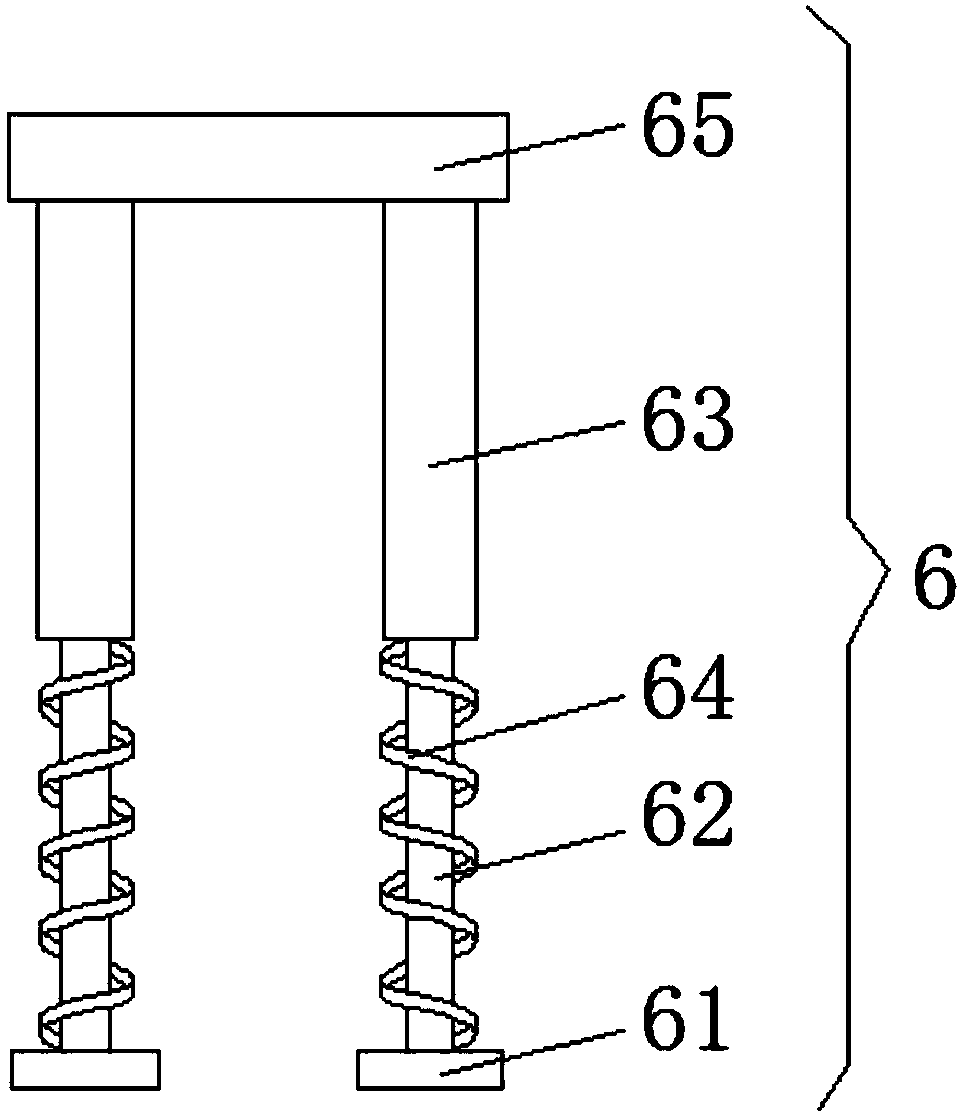

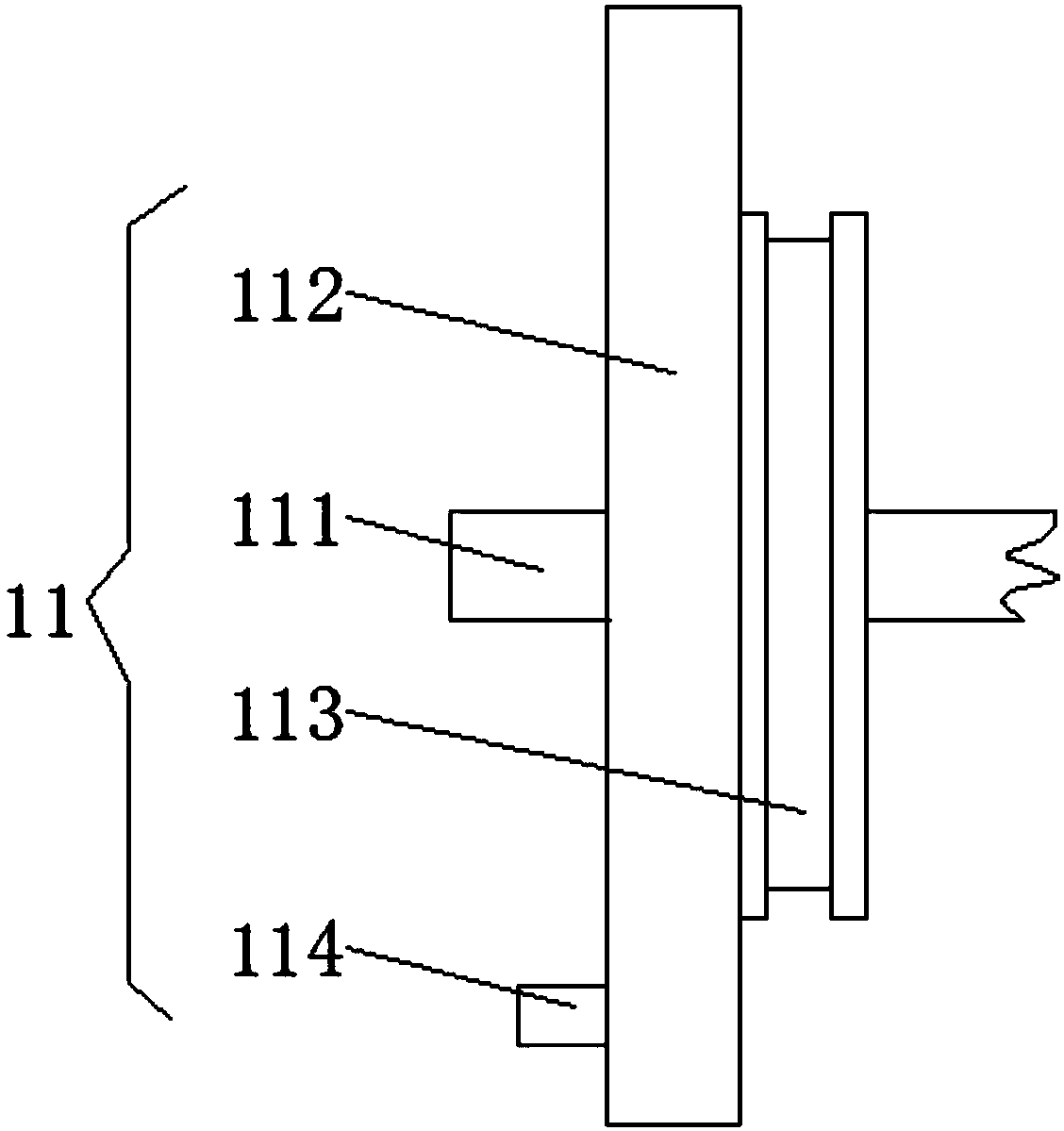

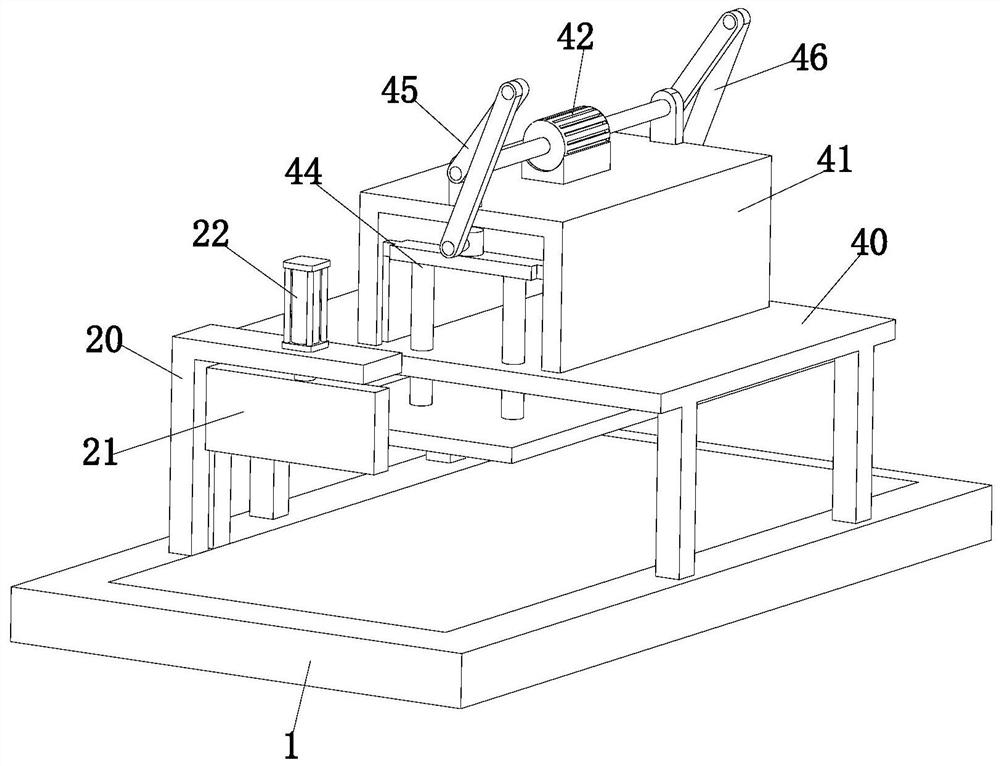

Cutting mechanism of efficient cutting machine for bus bars

PendingCN108274058AAdapt to large-scale standardized productionGuaranteed Cut SpecificationsShearing machinesShearing machine accessoriesEngineeringCutting guide

The invention discloses a cutting mechanism of an efficient cutting machine for bus bars. The cutting mechanism is characterized by comprising a cutting base, a lower cutter mounting base, a lower cutter, cutting guide shafts, a cutting air cylinder mounting block, a cutting air cylinder, an upper cutter mounting block, a cutting air cylinder connecting shaft, pre-pressing guide shafts, a pre-pressing block, lifting columns, pre-pressing springs and an upper cutter. According to the cutting mechanism, the pre-pressing block is adopted for pre-pressing, so that in the formal cutting process, the bus bars cannot deviate, and therefore the cutting specification can be guaranteed, and the cutting effect can be improved; and the upper cutter and the lower cutter are matched, the lower cutter with a bevel blade is adopted, the lower cutter which is specially arranged is matched with a lower cutter spring, so that the lower cutter has the resilience force in the cutting process, a blade of the upper cutter and the blade of the lower cutter do not collide with each other when the upper cutter and the lower cutter perform the cutting action, and therefore the situation that the cutters aredamaged can be avoided. The cutting mechanism has the advantages that mechanical production is adopted, the cutting efficiency is high, the cutting specification is unified, and the cutting mechanismis suitable for large-scale standardized production of enterprises.

Owner:中辰昊智能装备(江苏)有限公司

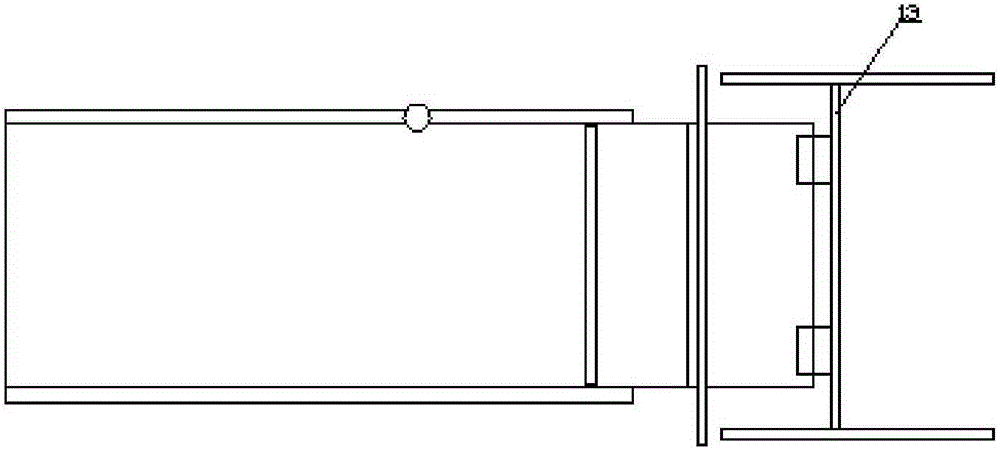

Batch cutting device for medical non-woven fabric masks

InactiveCN112941884AImprove croppingAchieve levelingSevering textilesWoven fabricStructural engineering

The invention discloses a batch cutting device for medical non-woven fabric masks, and belongs to the technical field of non-woven fabric mask processing. The batch cutting device comprises a processing table, a tidying device, clamping devices, a limiting device, a cutting device and a discharging device, wherein the processing table is arranged on the horizontal plane; a conveying mechanism is arranged on the processing table; a cutting hole is further formed in the processing table; the tidying device is installed on the processing table and directly faces the conveying mechanism; the clamping devices are installed on the two outer side walls of the processing table; the limiting device is arranged on the processing table and directly faces the conveying mechanism; the cutting device is arranged on the side of the limiting device; and the discharging device is arranged on the side of the cutting device. By means of mutual operation of the arranged devices, multiple layers of non-woven fabrics can be automatically tidied, and the non-woven fabrics can be positioned before cutting, so that the cutting effect is better; and the cut non-woven fabrics can be automatically discharged and stacked, so that carrying is convenient, and the whole processing efficiency is improved.

Owner:刘广伟

Aluminum-plastic film cutting device for lithium ion battery

ActiveCN109079910AProtectiveSimple structureMetal working apparatusWebs handlingEngineeringPlastic film

The invention discloses an aluminum-plastic film cutting device for a lithium ion battery. The aluminum-plastic film cutting device for the lithium ion battery comprises a platform. Two groups of lifting rods are fixedly installed at the top of the platform. A rotating roller is rotatably connected between the lifting rods. An electric push-pull rod is fixedly installed on the side wall of the rotating roller. One end of the electric push-pull rod is fixedly connected with an adjusting frame. Two groups of brackets are fixedly connected to the outer wall of the adjusting frame. Telescopic cavities are formed in the bottoms of the brackets; and buffer supporting legs are movably connected in the telescopic cavities. Springs arranged between the buffer supporting legs and the bottoms of thetelescopic cavities, tooth rails are fixedly installed between the brackets, movable tool rests are movably connected between the tooth rails, cutting knives are fixedly connected to the bottoms of the movable tool rests, motors are fixedly arranged in the movable tool rests, gears are rotatably connected to both sides of the movable tool rests, and the gears mesh with and the tooth rails. The aluminum-plastic film cutting device for the lithium ion battery greatly improves cutting efficiency and cutting effect, is convenient to adjust, and is easy to popularize and apply.

Owner:于浩淼

A kind of cardboard cutting and processing equipment

ActiveCN105922331BPrevent deviationGuarantee subsequent processing accuracyMetal working apparatusCardboardConveyor belt

The invention discloses paperboard cutting and processing equipment. The equipment comprises a mounting frame, a conveyor belt, a rotary shaft, a first driving unit, a cutting part and a pressing and holding part. The conveyor belt is mounted on the mounting frame. The upper surface of the conveyor belt is provided with a plurality of accommodating grooves which are evenly distributed in the length direction of the conveyor belt. The length direction of the accommodating grooves is perpendicular to the length direction of the conveyor belt. The lower surface of the conveyor belt is provided with first gears which are distributed in the length direction of the conveyor belt. The rotary shaft is rotatably mounted on the mounting frame. One end of the rotary shaft is arranged in a space defined by the conveyor belt. The local peripheral surface of the rotary shaft is provided with second gears which are distributed in the circumferential direction of the rotary shaft. The second gears are engaged with the first gears. The first driving unit is used for driving the rotary shaft to rotate. The cutting part is used for cutting paperboards and comprises a second driving unit and a blade. The second driving unit is used for driving the blade to move close to the accommodating grooves or far from the accommodating grooves. The paperboard cutting and processing equipment is good in paperboard cutting effect.

Owner:BENGBU ZHENHUA PACKING MACHINERY

Automatic deviation rectifying device for textile cutting

InactiveCN105151878AStable positionImprove parallelismArticle deliveryWebs handlingMechanical engineeringTextile

The invention discloses an automatic deviation rectifying device for textile cutting and relates to the field of textile cutting. By the adoption of the automatic deviation rectifying device for textile cutting, the problem that in the prior art, poor cutting is caused by cutting deflection is solved. The automatic deviation rectifying device for textile cutting comprises a conveying belt, a knife rest, a pressing plate, clamps, sliding rails, a cross rod and a camera. The conveying belt is composed of an upper conveying belt body and a lower conveying belt body. The upper conveying belt body is horizontally mounted on the left edge of the knife rest. The lower conveying belt body is mounted on the right edge of the knife rest. Two pairs of clamps are mounted on the right edge of the knife rest. Each pair of clamps includes upper clamp pliers and lower clamp pliers. The upper clamps and the lower clamps are hinged together and can be used for clamping and placing textile materials freely. The clamps move front and back on the cross rod. The two ends of the cross rod are fixedly connected with the sliding rails. The clamps move leftwards and rightwards on the sliding rails through the cross rod. The camera is mounted on one side of the conveying belt bodies and used for recognizing whether the edges of the textile materials are perpendicular to the knife rest or not.

Owner:SUZHOU CHAOSHENG PRINTING & PLATEMAKING IND

Corrugated board quantitative cutting device

InactiveCN110228089AAchieve fixationAchieve pre-drying treatmentDrying gas arrangementsMetal working apparatusAgricultural engineering

The invention belongs to the field of corrugated board cutting, and particularly relates to a corrugated board quantitative cutting device. According to the corrugated board quantitative cutting device, the problems that an existing corrugated board cutting device is incapable of pre-treating and quantitatively cut a corrugated board are solved. According to the technical scheme, the corrugated board quantitative cutting device comprises a cutting frame, wherein an air cylinder is fixed on the upper end of the cutting frame; an output end of the air cylinder is connected with a lifting rod; the lower end of the lifting rod penetrates through the cutting frame to be fixedly connected with a lifting board; a cutting mechanism is fixedly arranged at the lower end of the lifting board; a cutting platform is fixedly arranged on the cutting frame and positioned below the cutting mechanism; a storing mechanism is fixedly arranged at the rear end of the cutting platform; and a controller is fixedly arranged at one end of the cutting frame. The cutting device is convenient for cutting, fixing and collecting, is capable of drying treatment, and is convenient for counting so as to achieve quantitative cutting.

Owner:CHANGXING QIKAI MECHANICAL EQUIP CO LTD

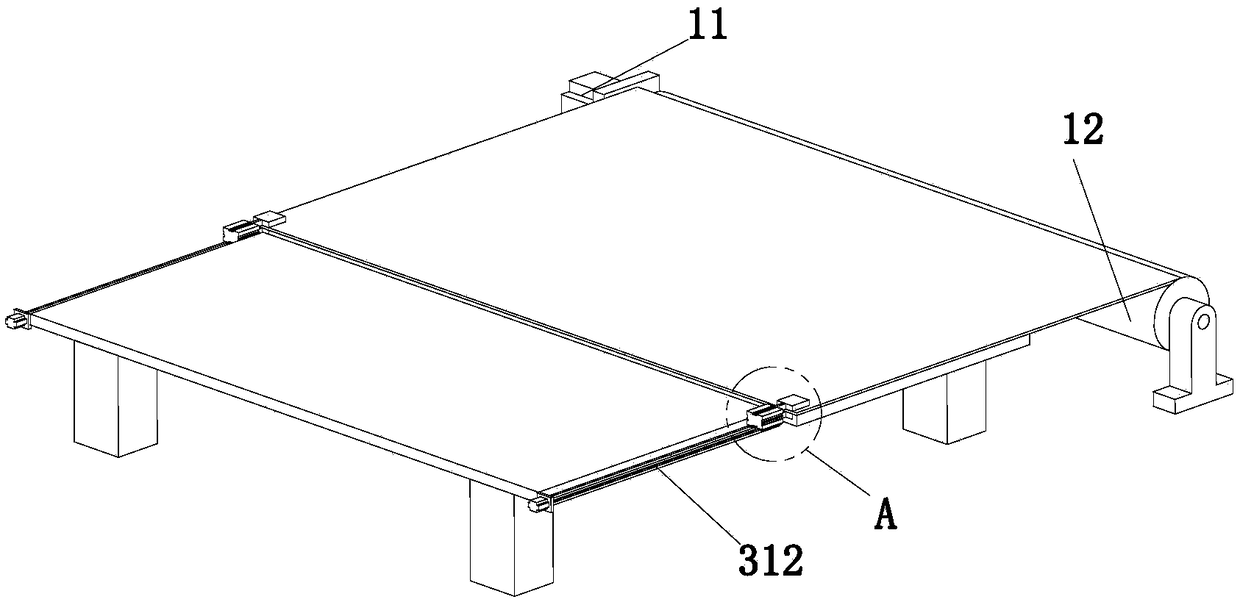

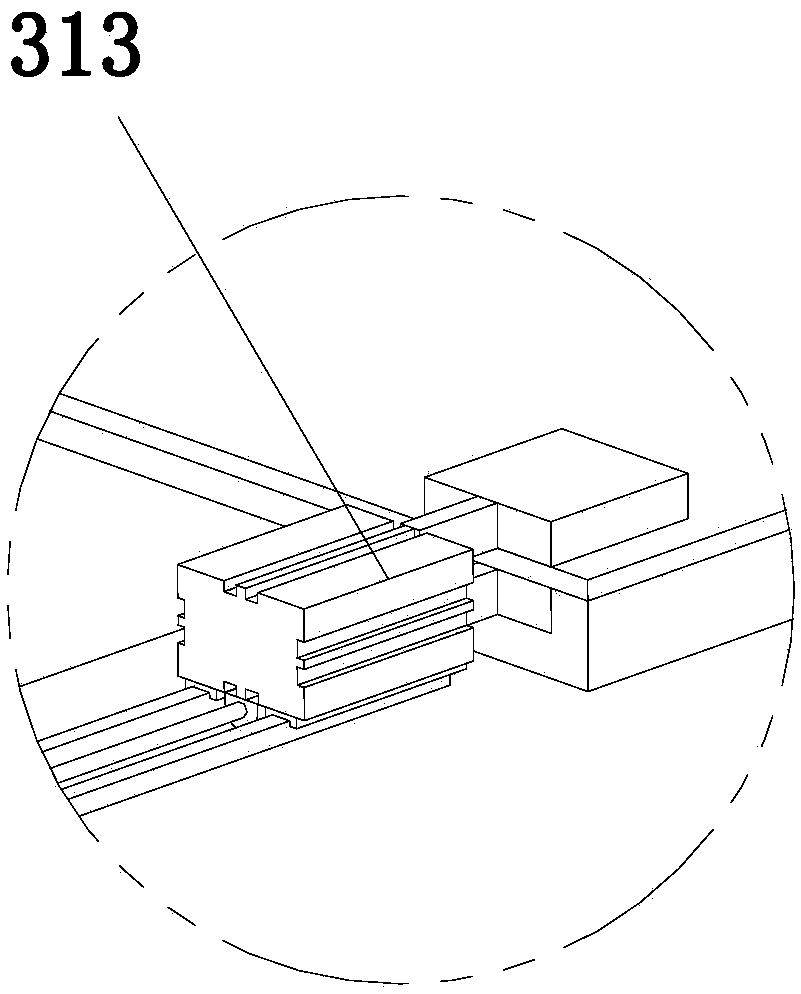

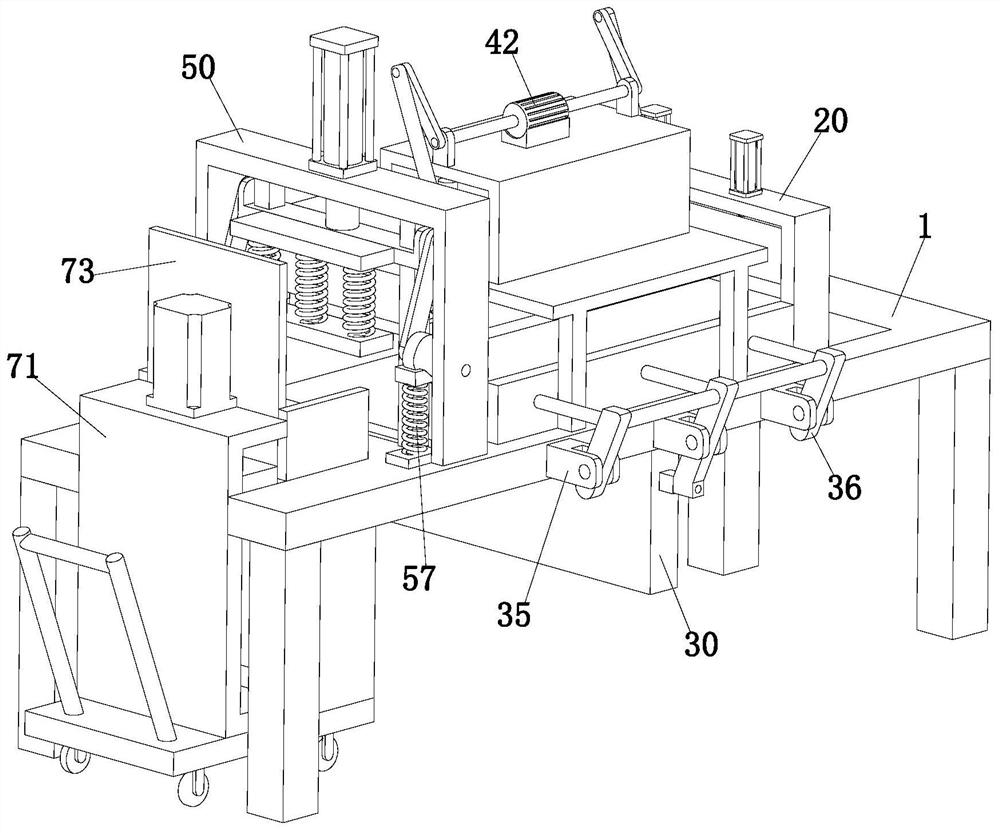

Precise cloth cutting device and method

ActiveCN111394981AImprove cutting efficiencyImprove croppingSevering textilesWebs handlingEngineeringMechanical engineering

The invention relates to a precise cloth cutting device. The precise cloth cutting device comprises a bottom plate, a stretching device, a cutting device and an unwinding device, wherein the stretching device is mounted at the lower end of the bottom plate; the cutting device is mounted at the middle end of the bottom plate; and the unwinding device is mounted at the left end of the bottom plate.The precise cloth cutting device can solve the following problems in an existing cloth cutting process: 1, when cloth is cut by manually holding scissors, the cutting precision is low, burrs are easily generated, the labor intensity is high, the cutting efficiency is low, and the cut cloth is difficult to reach the required size due to the fact that the factor of human errors is large, and the cutting precision is low; and 2, in the manual cutting process, the cloth is soft, so that the cloth is easily stressed and contracted during cutting, cutter relieving is caused, the cutting quality cannot be guaranteed, the cloth is cut in a manual tensioning mode, large-batch processing is not facilitated, sometimes, the width of the cloth is too large, the cloth is often cut to be uneven, the appearance is influenced, the cloth is wasted, and the cloth cutting efficiency and the cutting effect are greatly improved.

Owner:北京东方蓝地服装股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com