Automatic deviation rectifying device for textile cutting

A deviation correction device and cutting technology, applied in the directions of transportation and packaging, winding strips, sending objects, etc., can solve the problems of skewed cutting of textile materials, inability to meet the accuracy, and the positioning error of the mechanism is large, reaching the level of automation High, improve the cutting effect, good parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

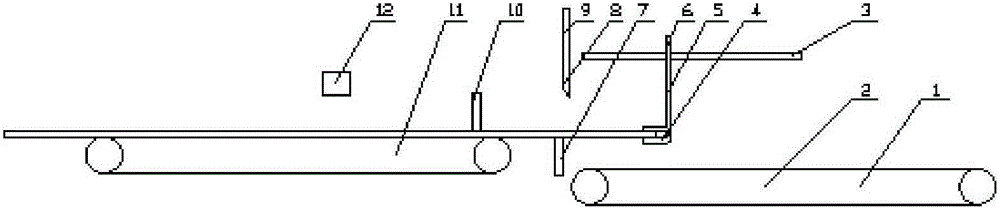

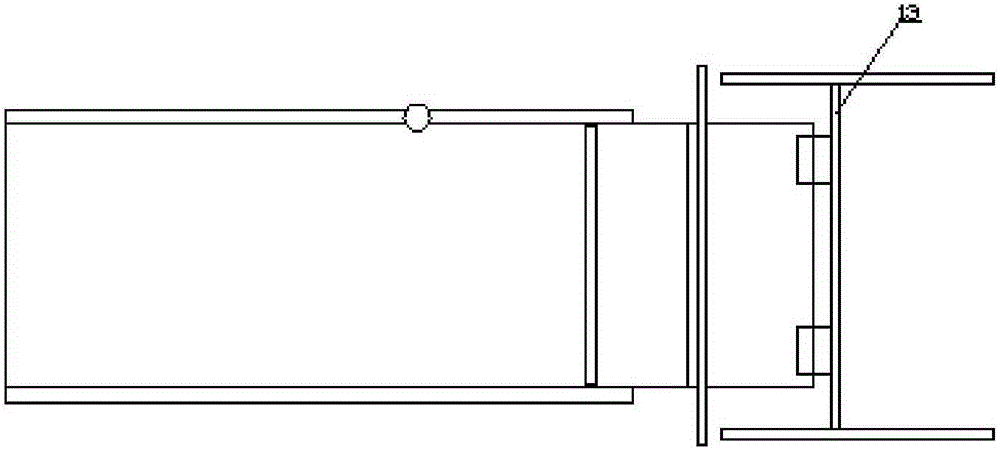

[0014] like figure 1 and figure 2 As shown, an automatic textile cutting deviation correction device includes a conveyor belt 1 , a knife rest 8 , a pressing plate 10 , a clamp 5 , a slide rail 3 , a cross bar 13 , and a camera 12 . The conveyor belt 1 is composed of an upper conveyor belt 11 and a lower conveyor belt 2. The upper conveyor belt 11 is installed horizontally on the left side of the knife rest 8, and is used to drive the textile material to move in the direction of the knife rest 8. The lower conveyor belt 11 is installed on the right side of the knife rest 8 for conveying The cut textile material is placed in the next process; the knife rest 8 is divided into an upper knife rest 9 and a lower knife rest 7, and a blade is installed on the upper knife rest 9; the lower knife rest 7 is installed directly below the upper knife rest 9, It is used to support the textile material during the cutting process; the pressing block 10 is installed on the left side of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com