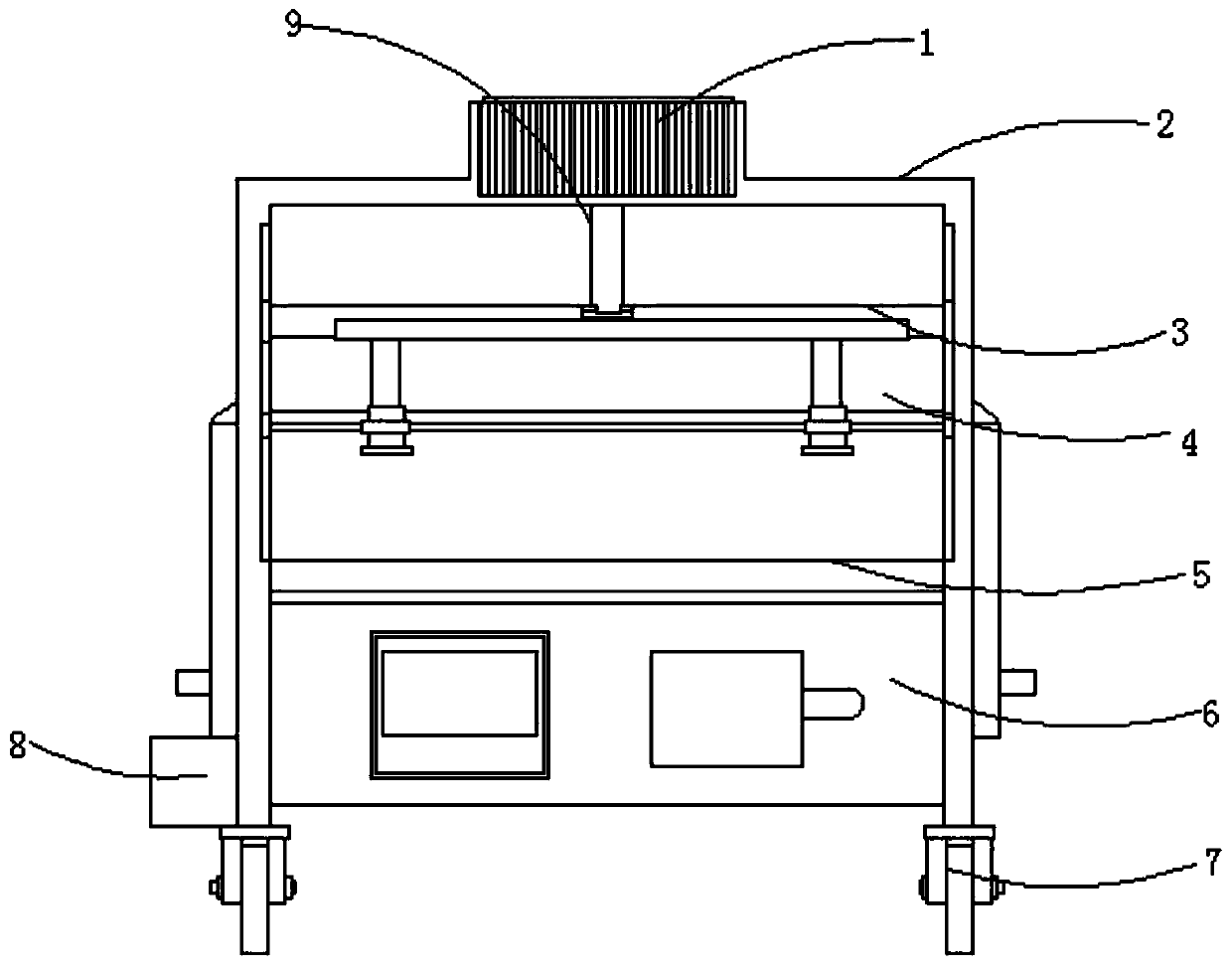

Corrugated board quantitative cutting device

A corrugated cardboard and cutting technology, which is applied in the direction of drying gas arrangement, dryer, metal processing, etc., can solve the problems of inability to achieve quantitative cutting and pretreatment of corrugated boards, and achieve easy cutting and fixing, easy collection, The effect of easy counting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

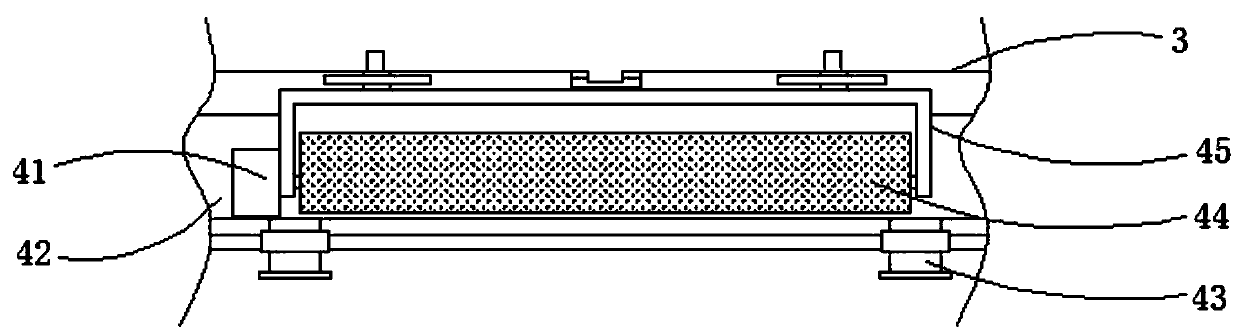

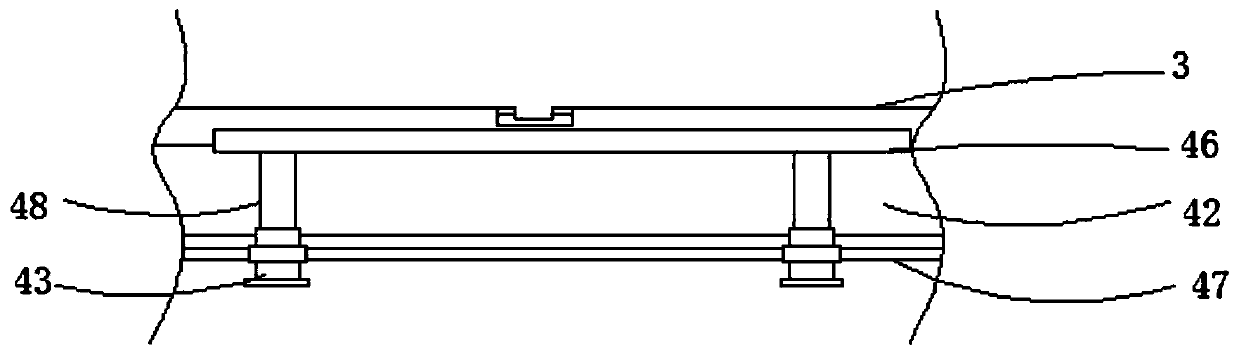

[0027] Example: First, the staff energizes the present invention through the mains, and the staff controls the electric cylinder, the motor 41, the display screen 64, the pressure sensor 61, the blower 651, and the heating wire 652 through the controller 8. The model of the controller 8 is SC200, the pressure sensor 61 model is PT124G-210, the staff first put the corrugated cardboard to be cut on the support plate 62 in the storage box shell 63, the corrugated cardboard presses the pressure sensor 61 through the support plate 62, the pressure sensor 61 receives the pressure information, and transmits the received pressure information to the controller 8, controls the pressure information to be converted into data, and sends instructions to the display screen 64, the display screen 64 can display the corrugated cardboard gravity, and the displayed data is recorded as S1, the staff then starts the blower 651 and energizes the heating wire 652. The heating wire 652 generates high t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com