Patents

Literature

49results about How to "Realize quantitative cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optical fiber cable cutting device based on light perception control principle

InactiveCN111958667AComplete cutAvoid slipping and offsetting situationsFibre mechanical structuresMetal working apparatusLight perceptionEngineering

The invention relates to the technical field of optical fibers, and discloses an optical fiber cable cutting device based on a light perception control principle. The optical fiber cable cutting device based on the light perception control principle comprises a workbench. A support is fixedly connected with the exterior of the workbench, a cutting assembly is movably connected with the exterior ofthe support, and supporting rods are fixedly connected with the exterior of the support. Limiting blocks are fixedly connected with the exteriors of the supporting rods, and limiting plates are fixedly connected with the interiors of the limiting blocks. Moving frames are movably connected with the exteriors of the limiting plates, teeth are arranged inside the moving frames, and connecting rodsare fixedly connected with the exteriors of the moving frames. By means of the interaction of the limiting blocks, the limiting plates, the moving frames, the teeth, first gears, second gears, gear rings, rotating shafts, rotary rods, the connecting rods and press plates, an optical fiber cable can be tightly pressed and fixed when the optical fiber cable is cut, the situation that the optical fiber cable slips and deviates in the cutting process is avoided, and therefore the optical fiber cable can be fully cut, and the cut surface is relatively flat.

Owner:杭州千耘贸易有限公司

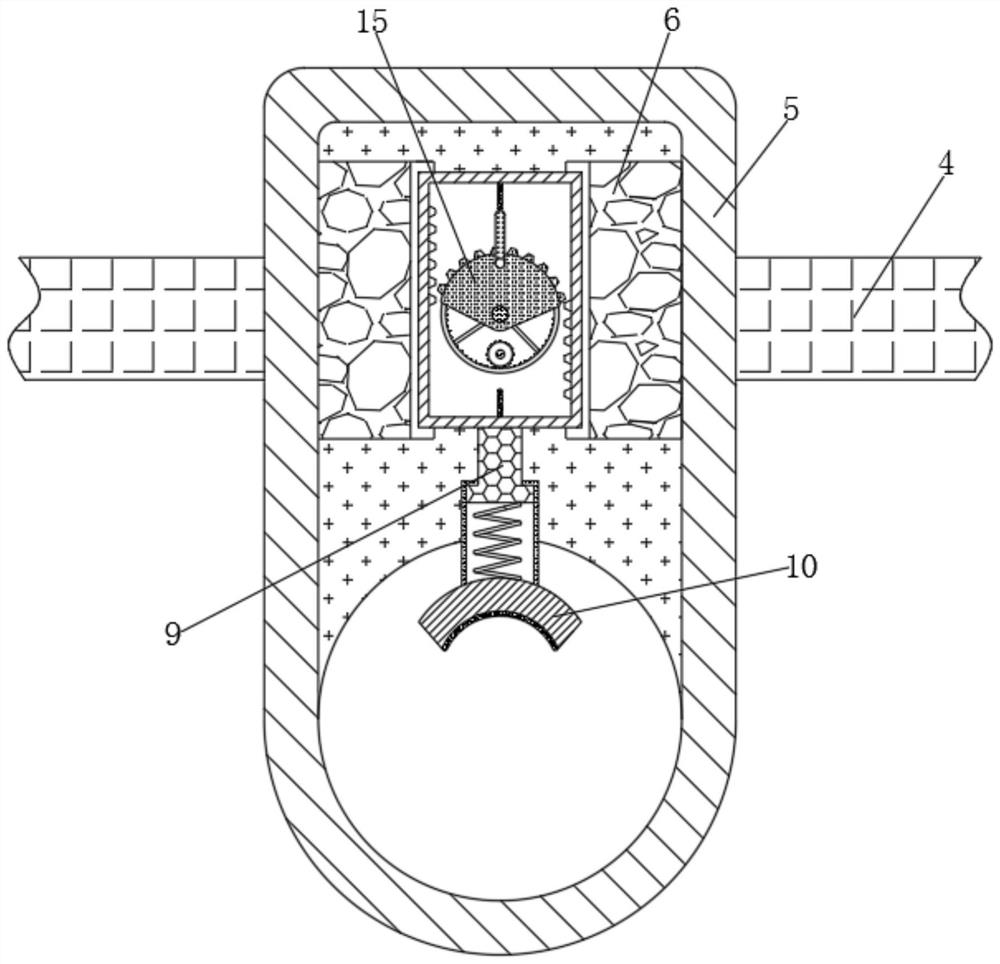

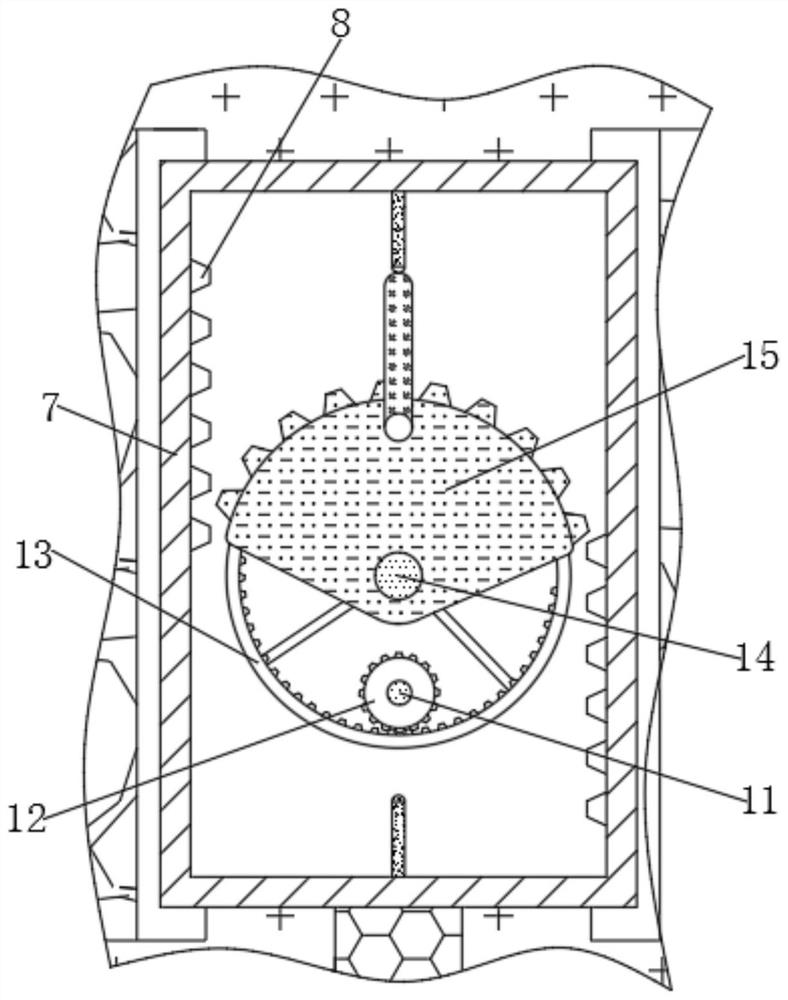

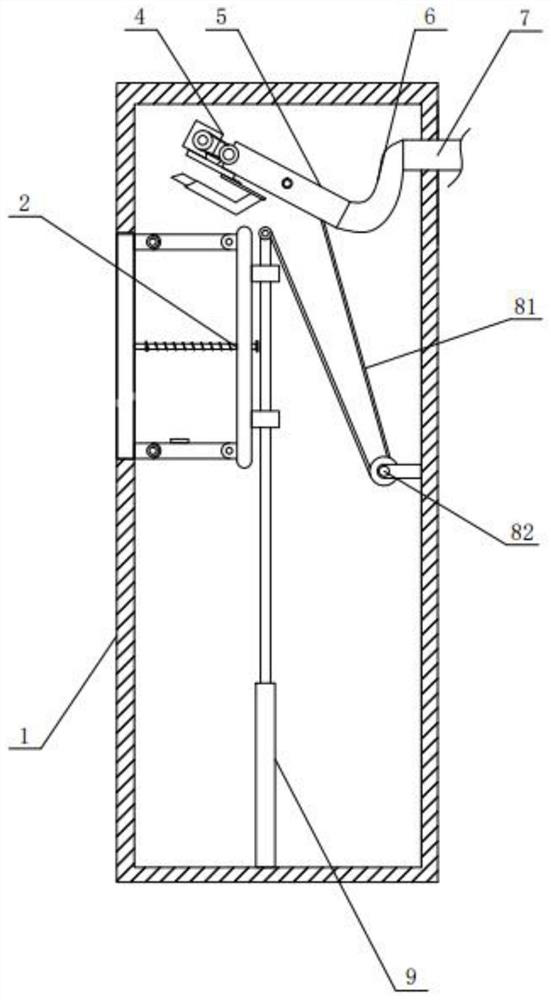

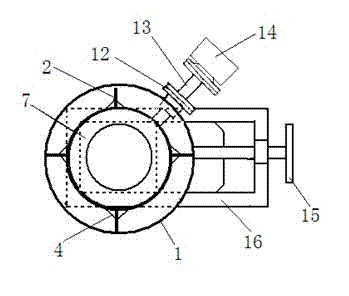

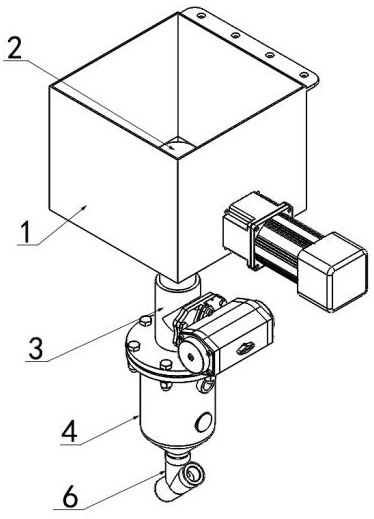

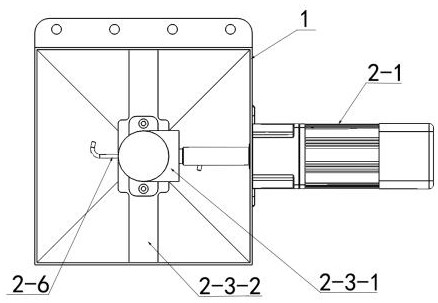

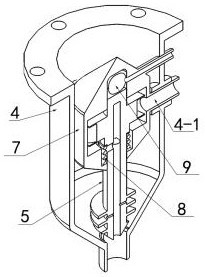

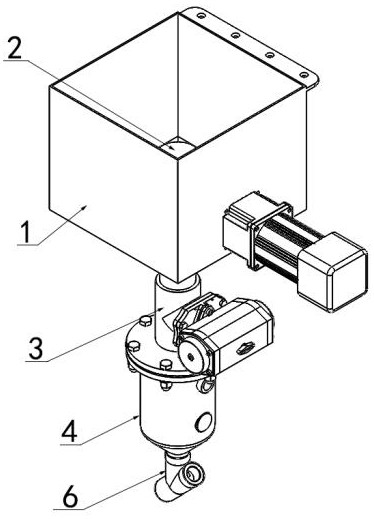

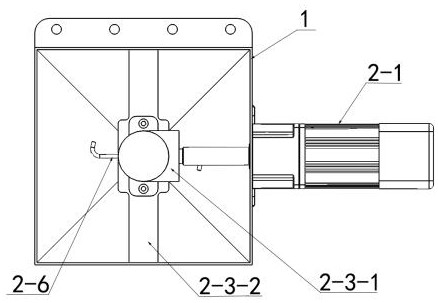

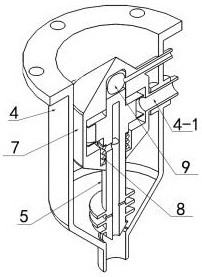

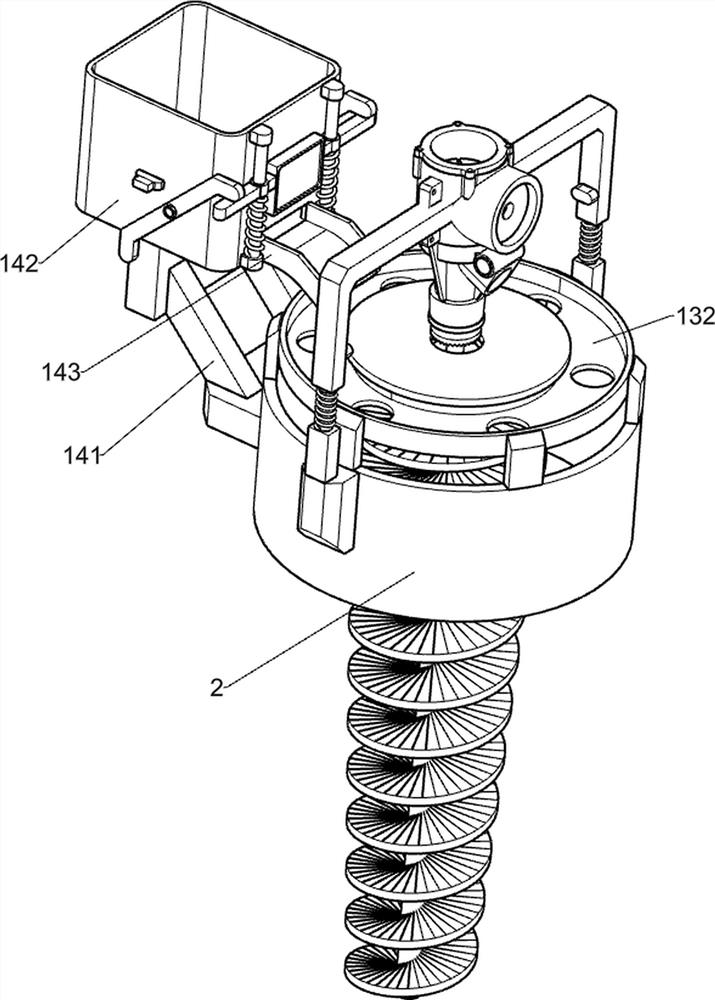

Blanking device for rare-earth electrolysis bath, and rare-earth electrolysis bath

The invention discloses a blanking device for a rare-earth electrolysis bath, and the rare-earth electrolysis bath. The blanking device comprises a hollow stock bin; the stock bin is provided with a blanking opening; the blanking device also comprises a helical discharger and a driving mechanism; the helical discharger comprises a shell comprising a cylindrical cavity; the shell is provided with afeeding opening and a discharging opening, wherein the feeding opening communicates with the blanking opening; the discharging opening is used for a material to flow into an electrolysis bath body; aconveying threaded column used for conveying the material inside the shell to the position of the discharging opening is arranged inside the cavity of the shell; and the conveying threaded column hastransmission connection with the driving mechanism. The blanking device for the rare-earth electrolysis bath, disclosed by the invention, has a quantitative blanking function, can effectively preventprecipitation in the bath due to excess blanking and a lack-of-material state of the electrolysis bath due to insufficient blanking, is hard to block, simple in device and convenient to install and maintain, and lowers the labor intensity of a worker.

Owner:CENT SOUTH UNIV

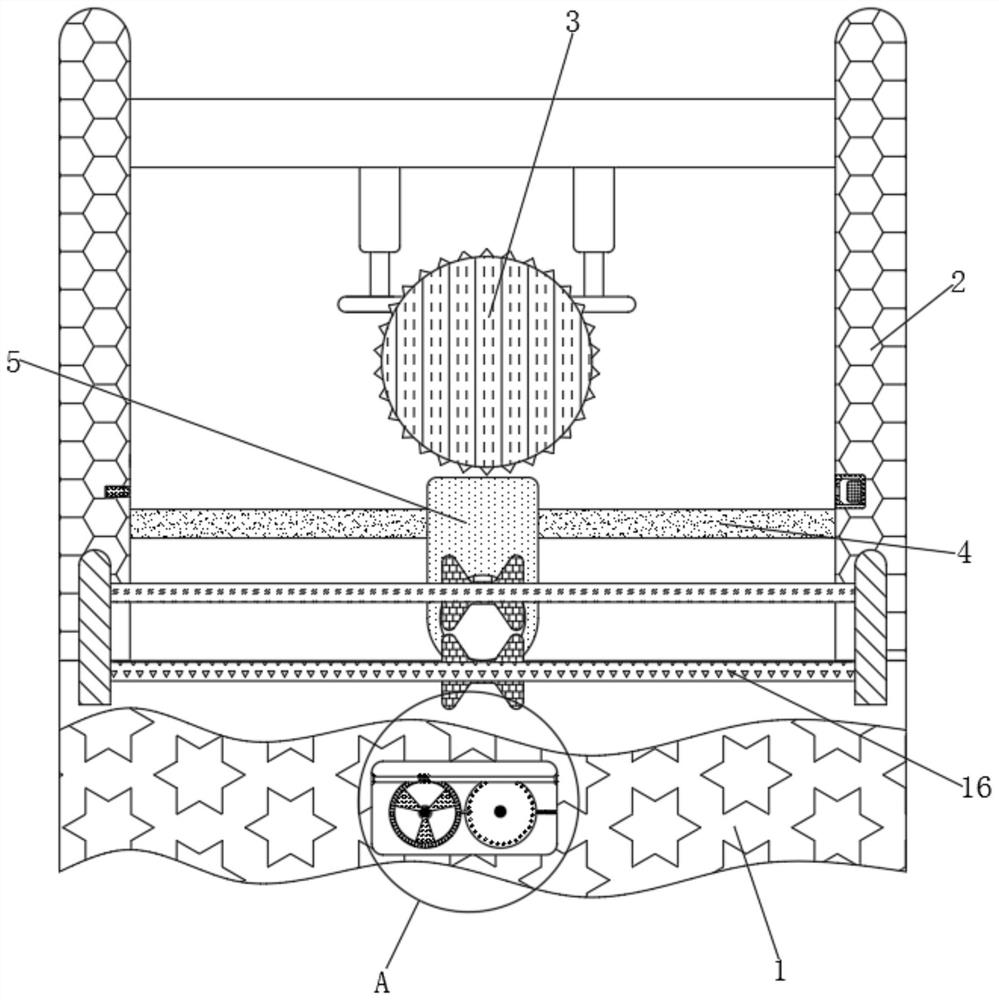

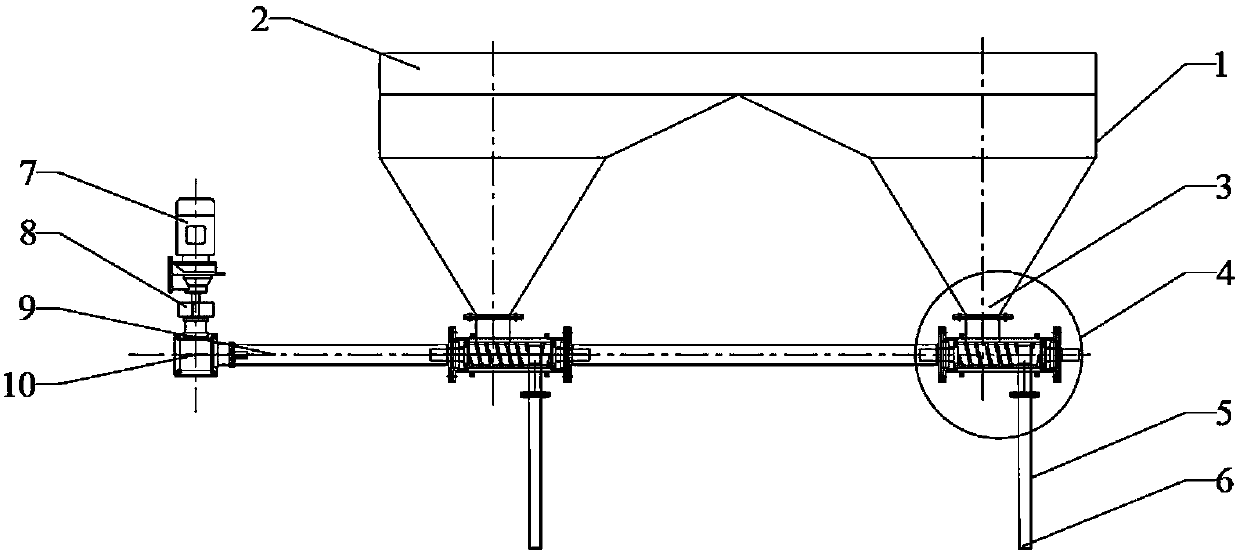

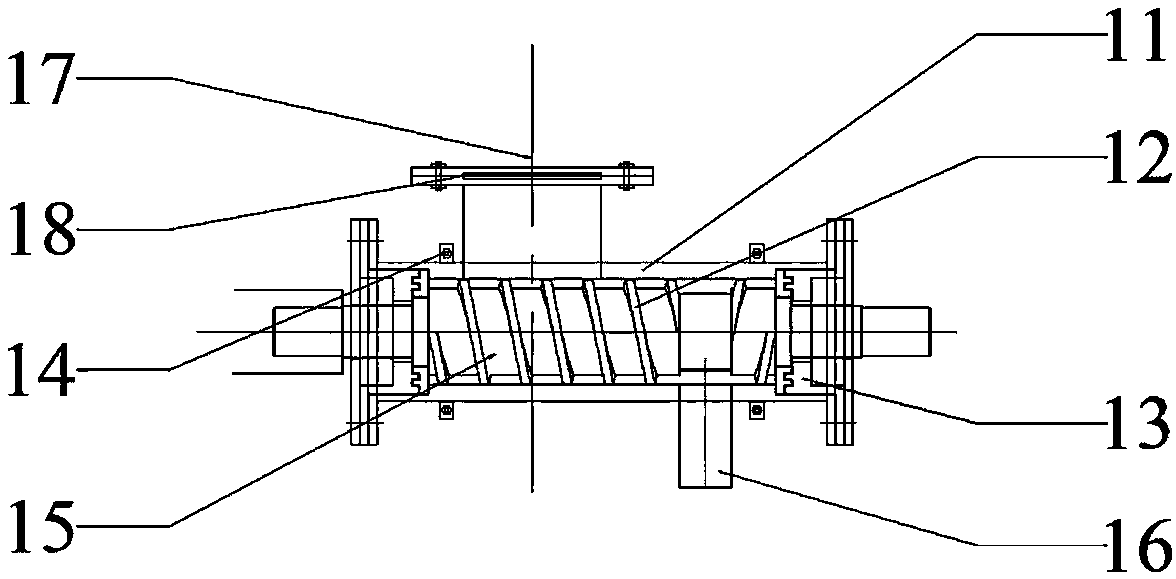

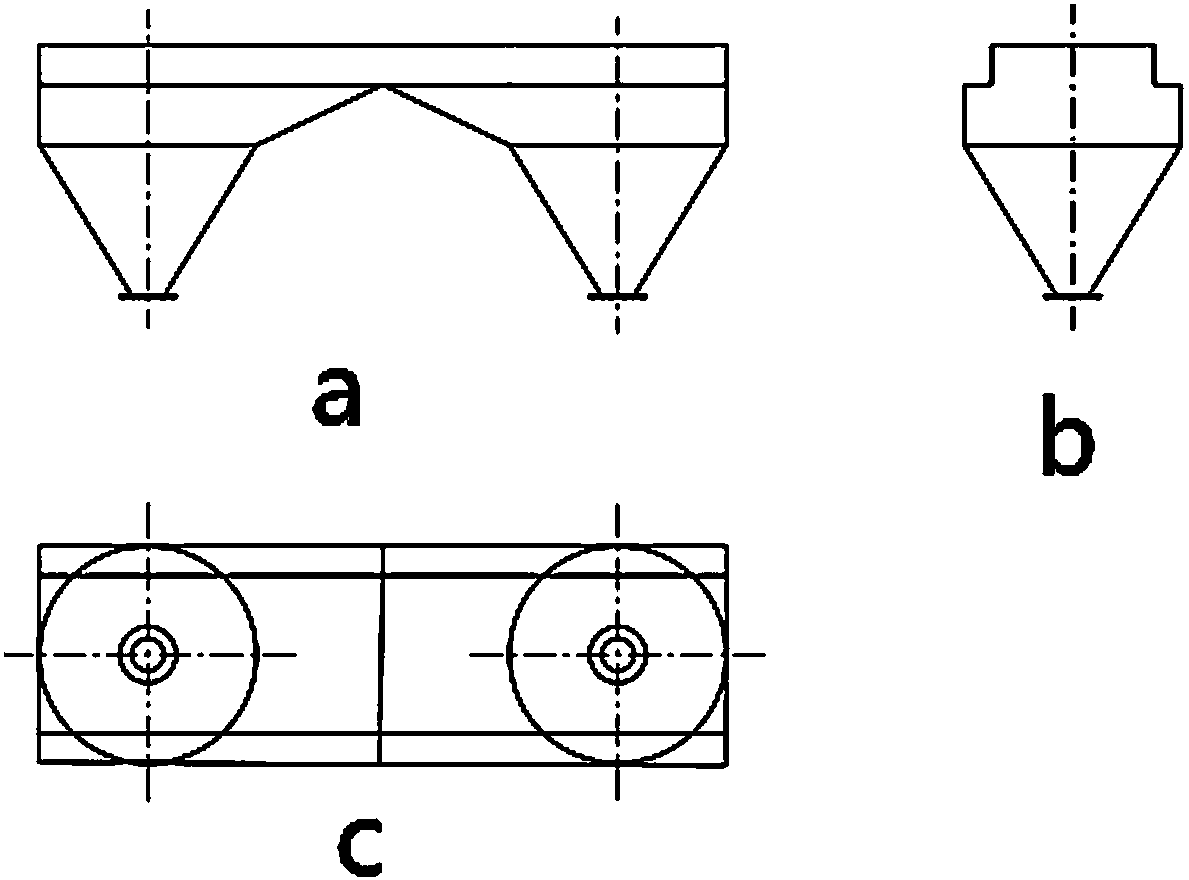

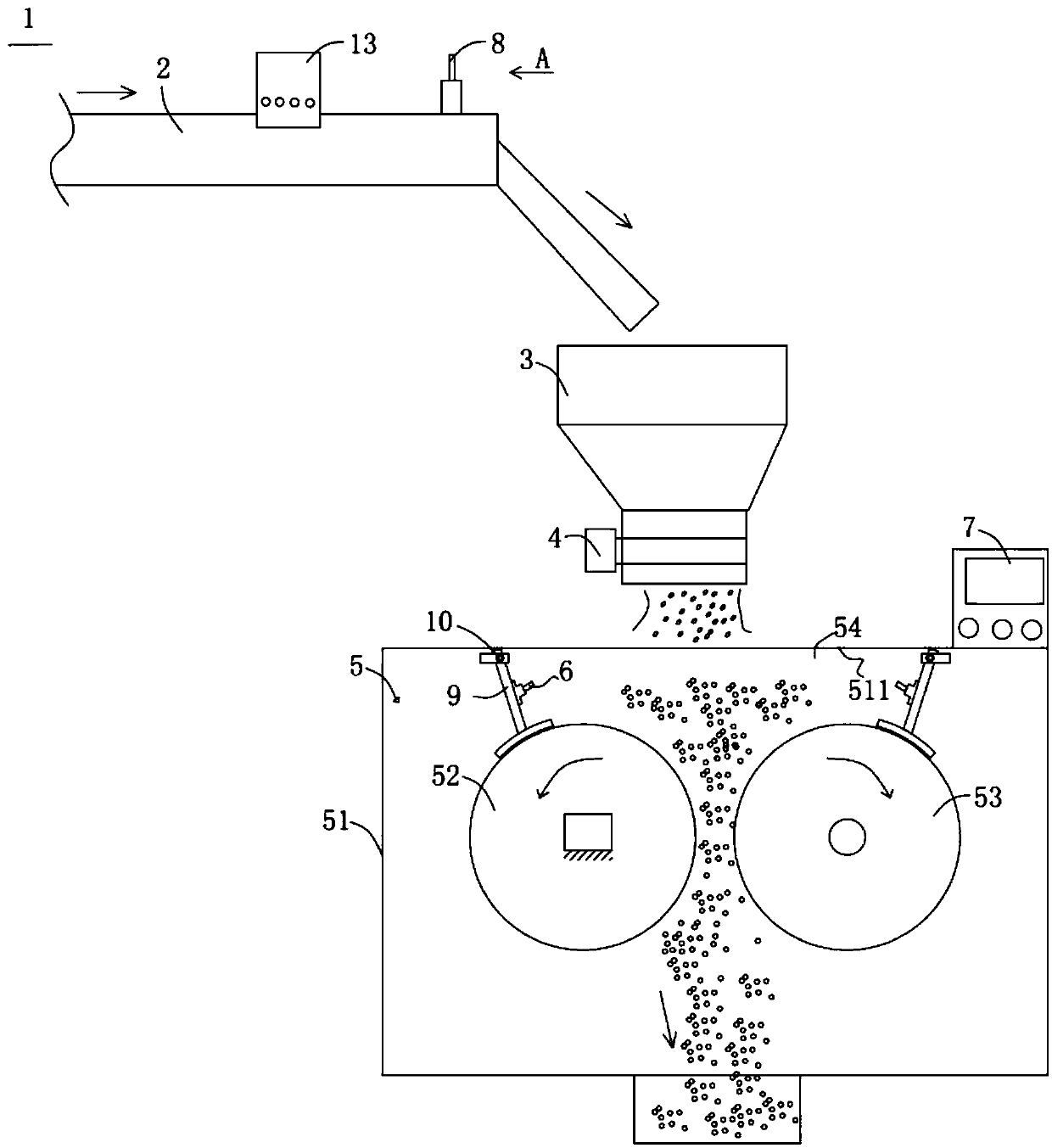

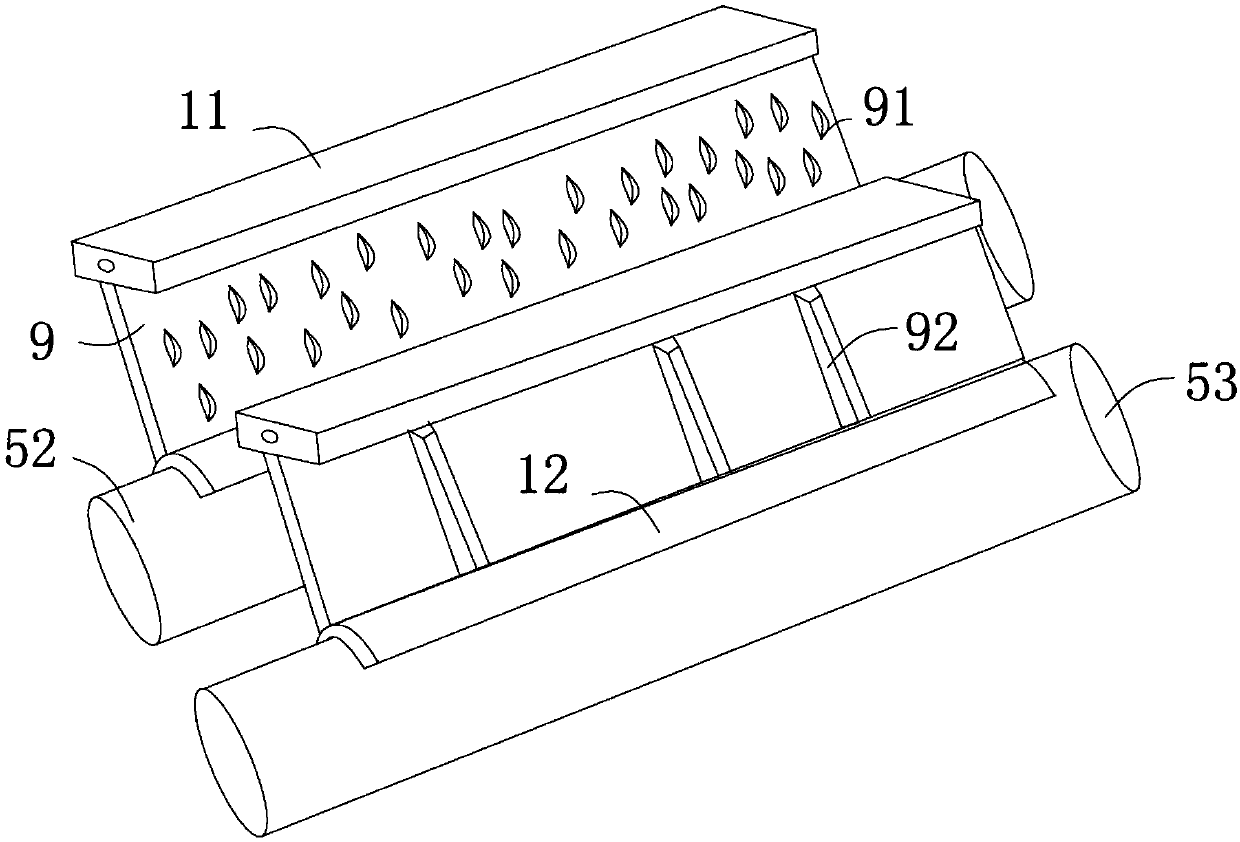

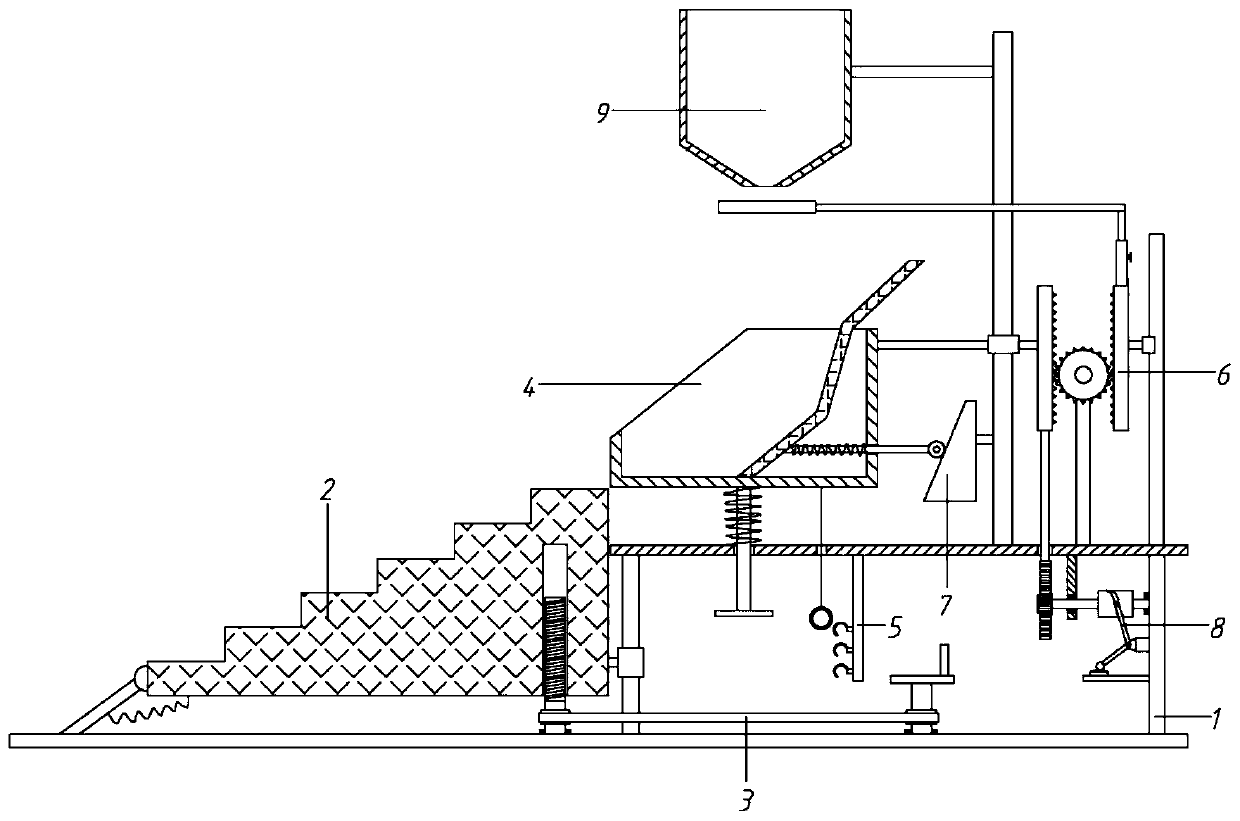

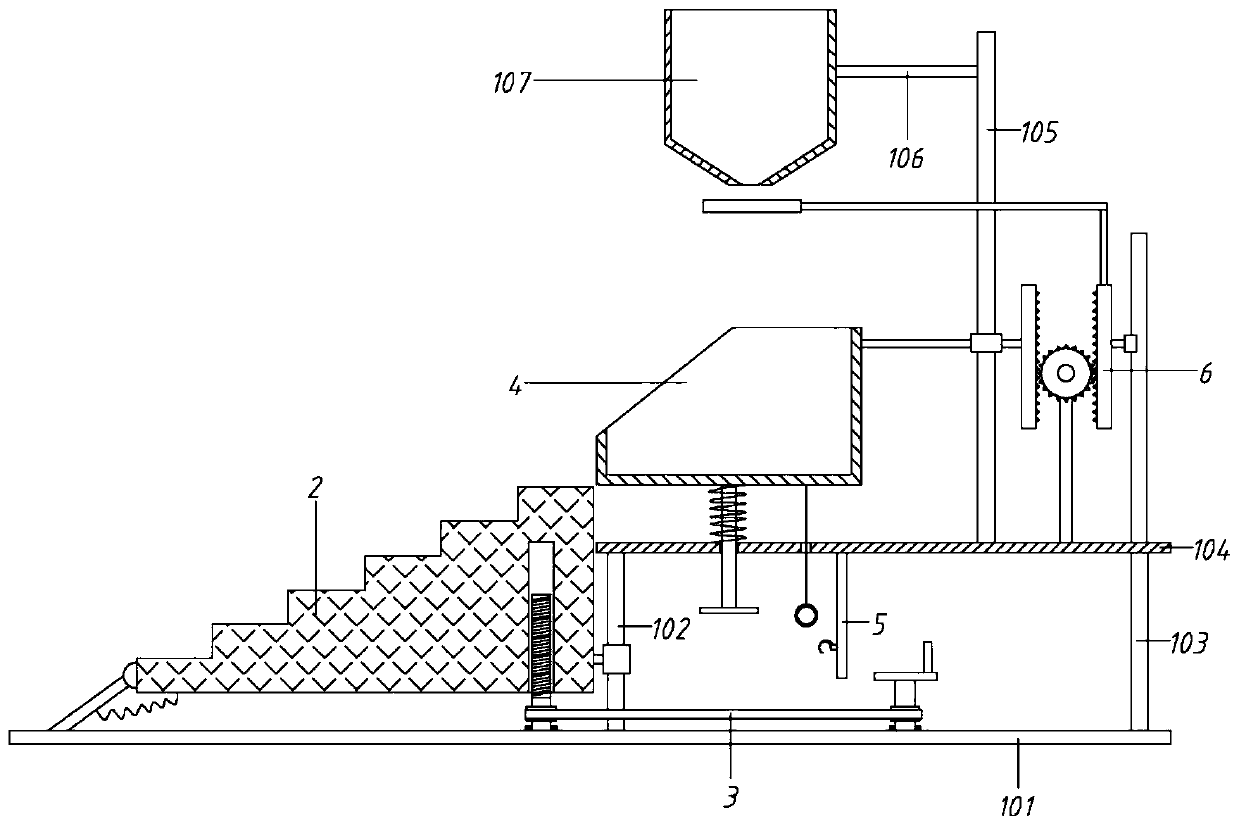

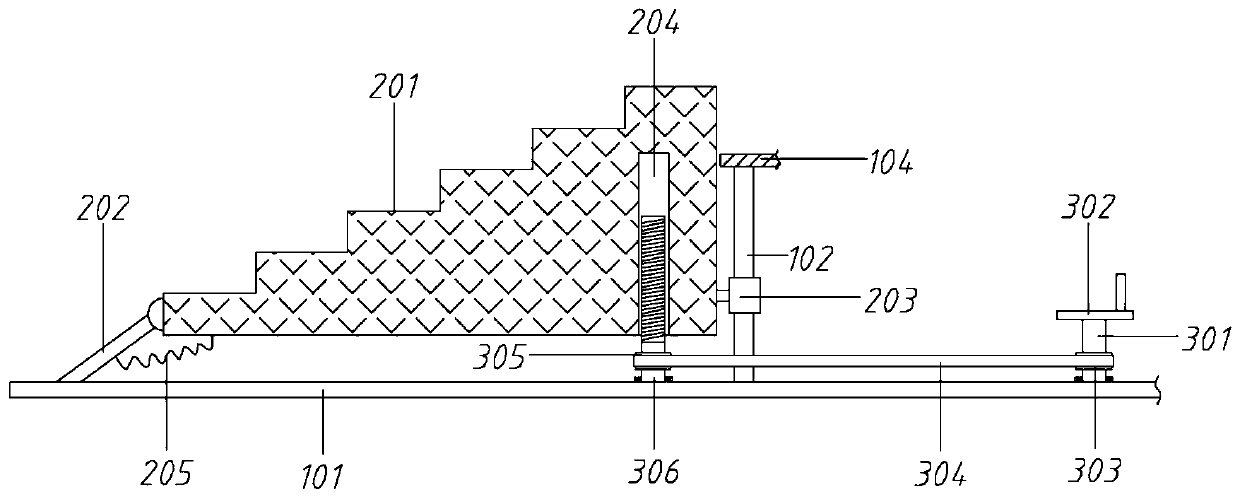

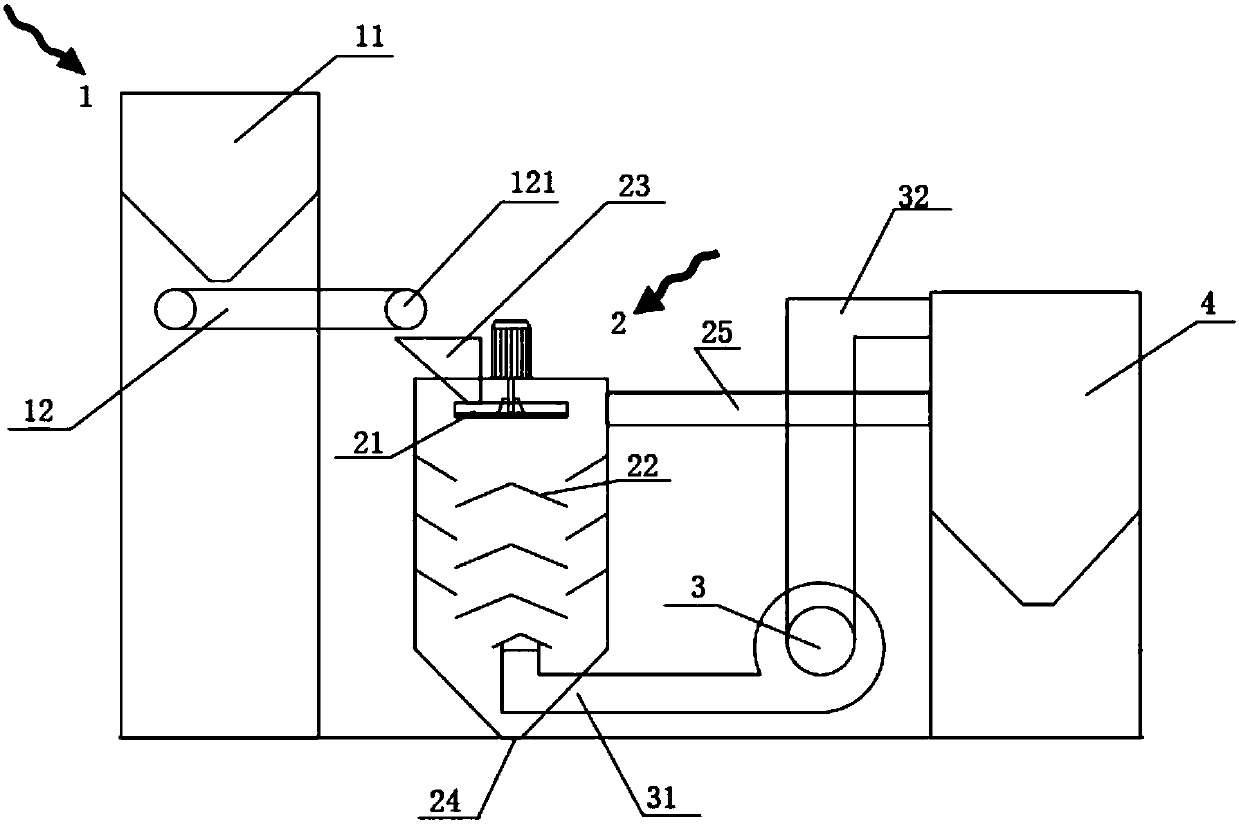

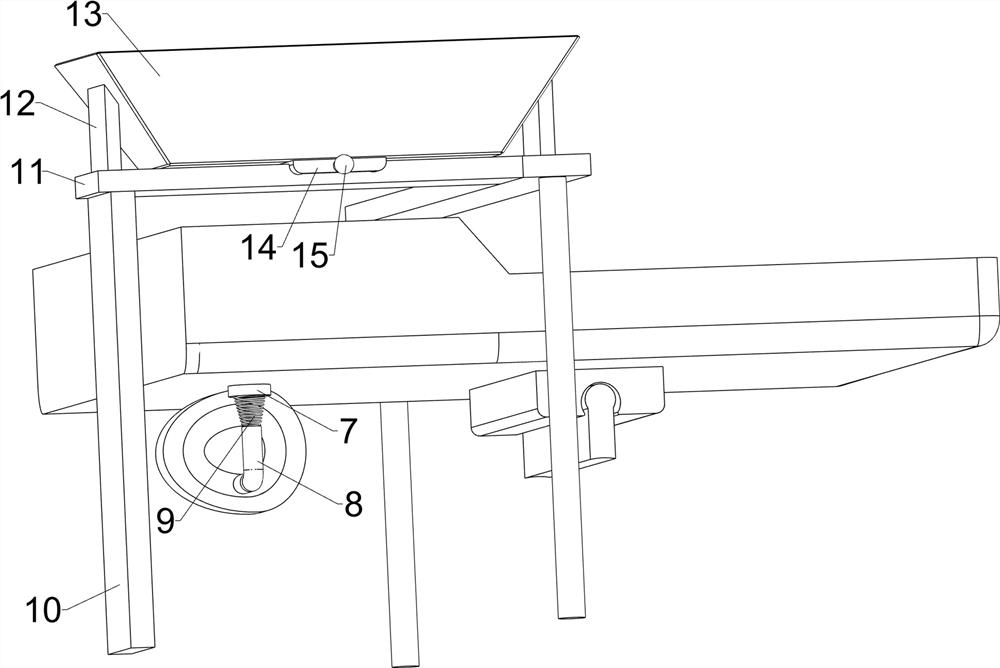

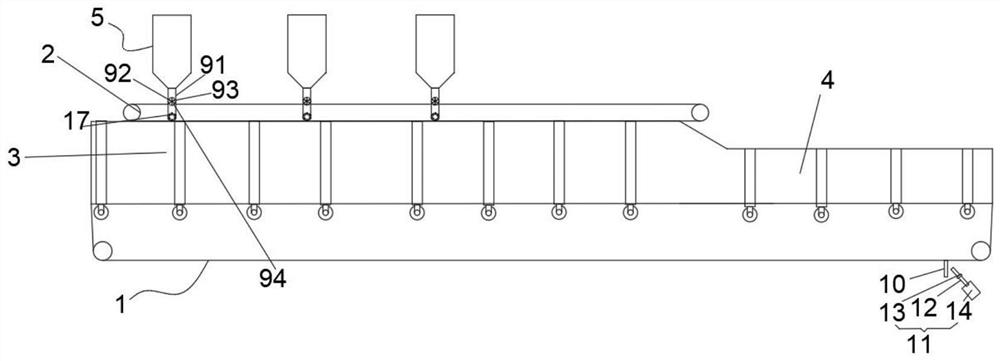

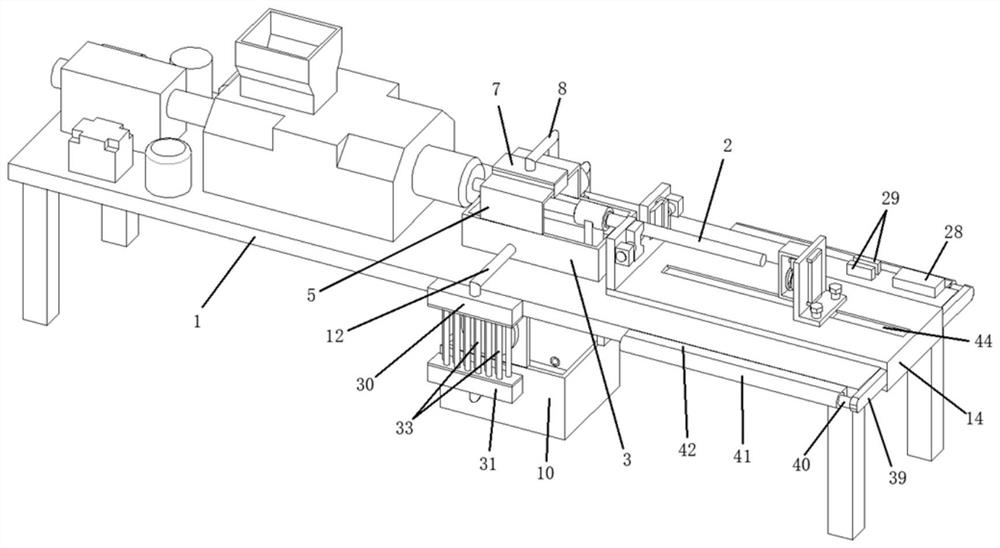

Quantitative feeding cement raw material roller press system

InactiveCN109569782ARealize quantitative cuttingRealize automatic controlCleaning using toolsGrain treatmentsAutomatic controlElectromagnetic valve

The invention relates to a quantitative feeding cement raw material roller press system. The quantitative feeding cement raw material roller press system is used for rolling cement raw materials, andthe quantitative feeding cement raw material roller press system comprises a feeding conveying device for conveying the cement raw materials, a feeding device connected with the feeding conveying device and used for receiving the cement raw materials conveyed by the feeding conveying device and uniformly stirring the cement raw materials, a material locking electromagnetic valve arranged at the discharging end of the feeding device and used for controlling the discharge of the discharging end of the feeding device and a roller press, wherein the roller press comprises a machine body, a fixed extrusion roller and a floating extrusion roller, the fixed extrusion roller and the floating extrusion roller are correspondingly arranged in the machine body, a quantitative feeding accommodating binis formed between the fixed extrusion roller, the floating extrusion roller and the machine body, and the quantitative feeding accommodating bin is connected with the feeding device. The quantitativefeeding cement raw material roller press system uses a control device to perform linkage control over the working states of the roller press, the feeding conveying device and the feeding device, andquantitative feeding and automatic control of the quantitative feeding cement raw material roller press system are realized.

Owner:JIANGSU PENGFEI GROUP

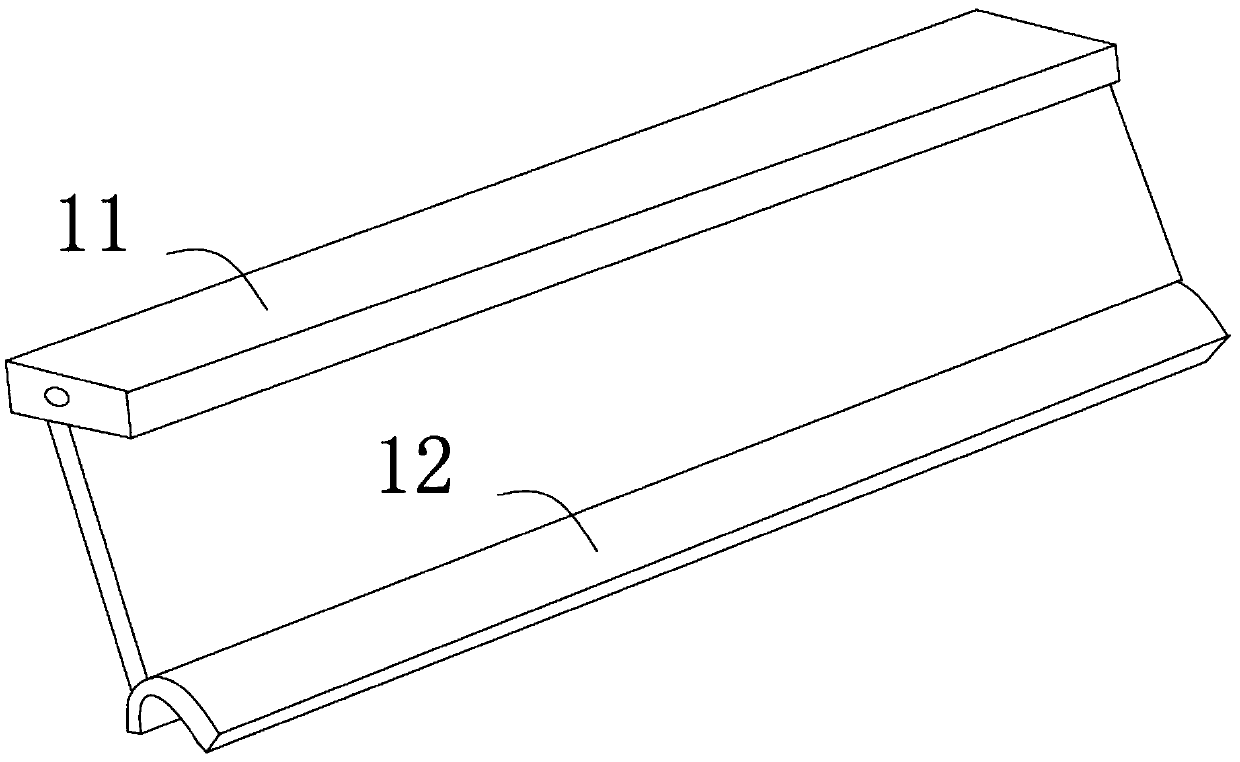

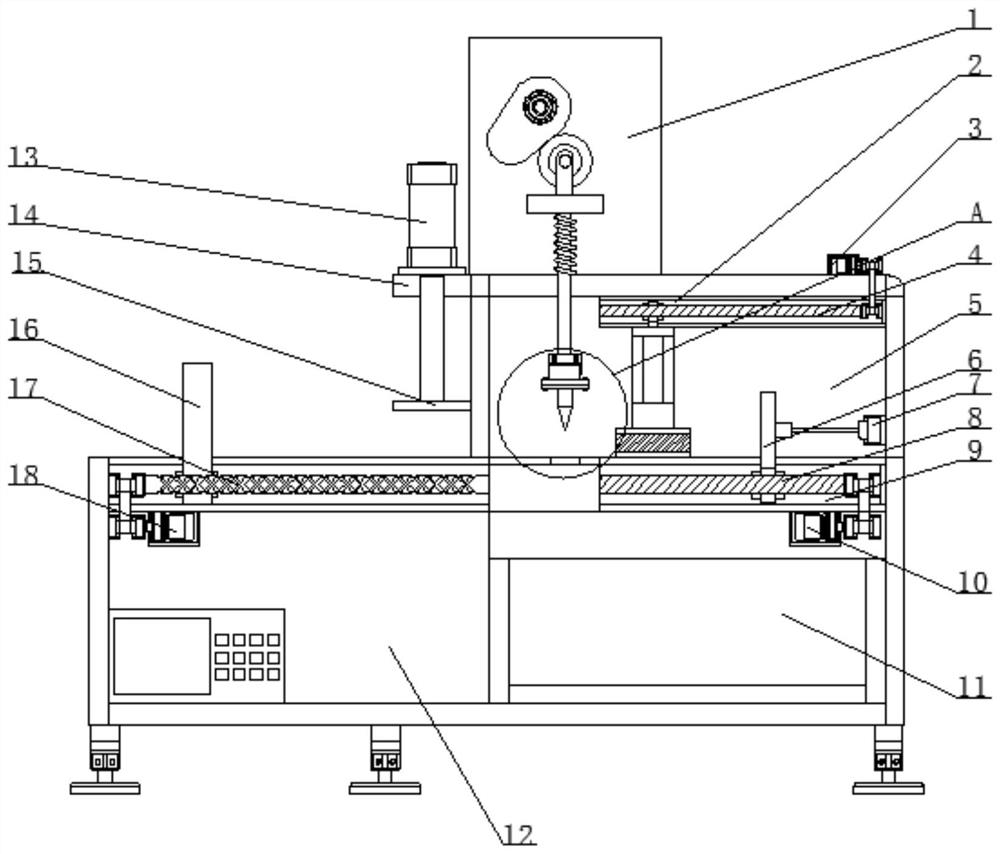

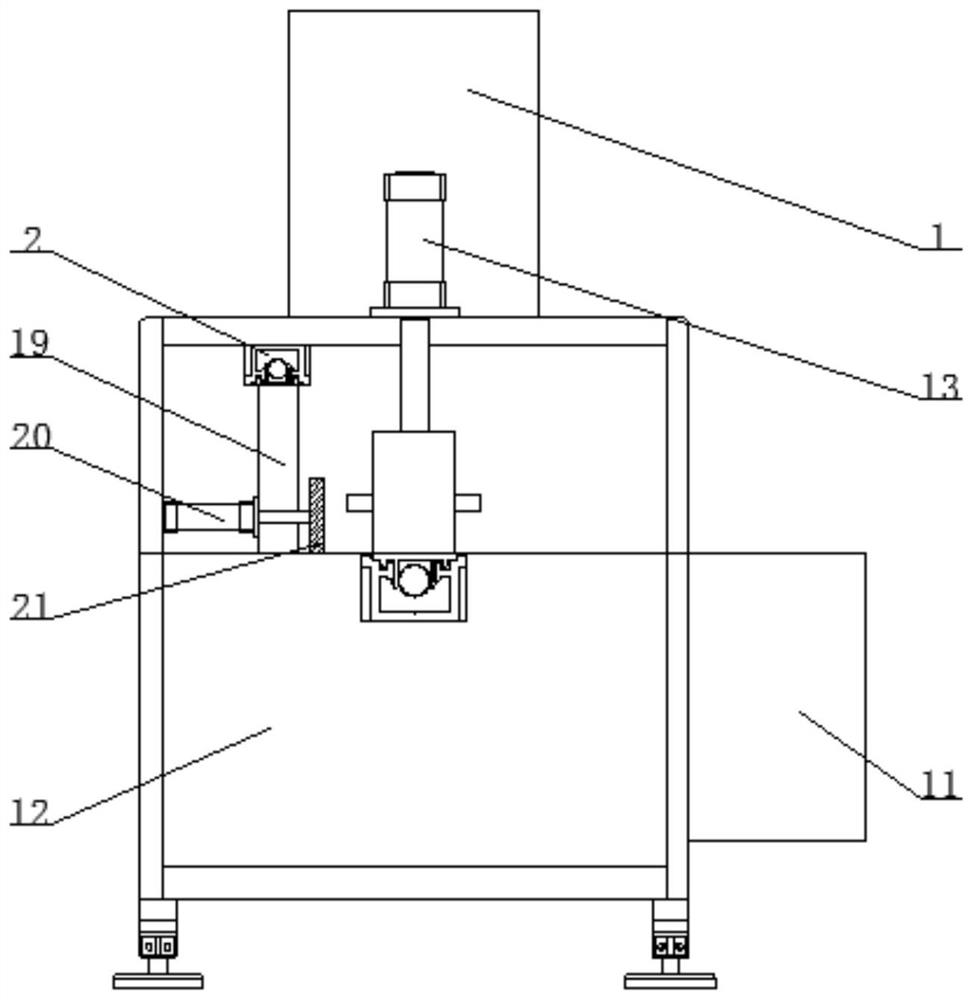

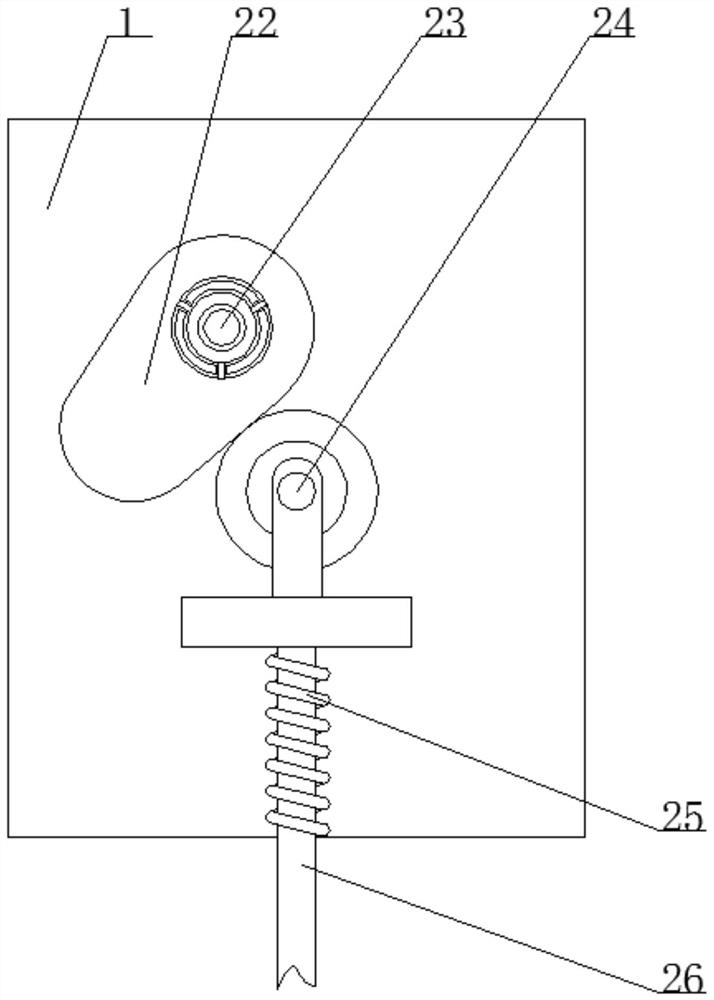

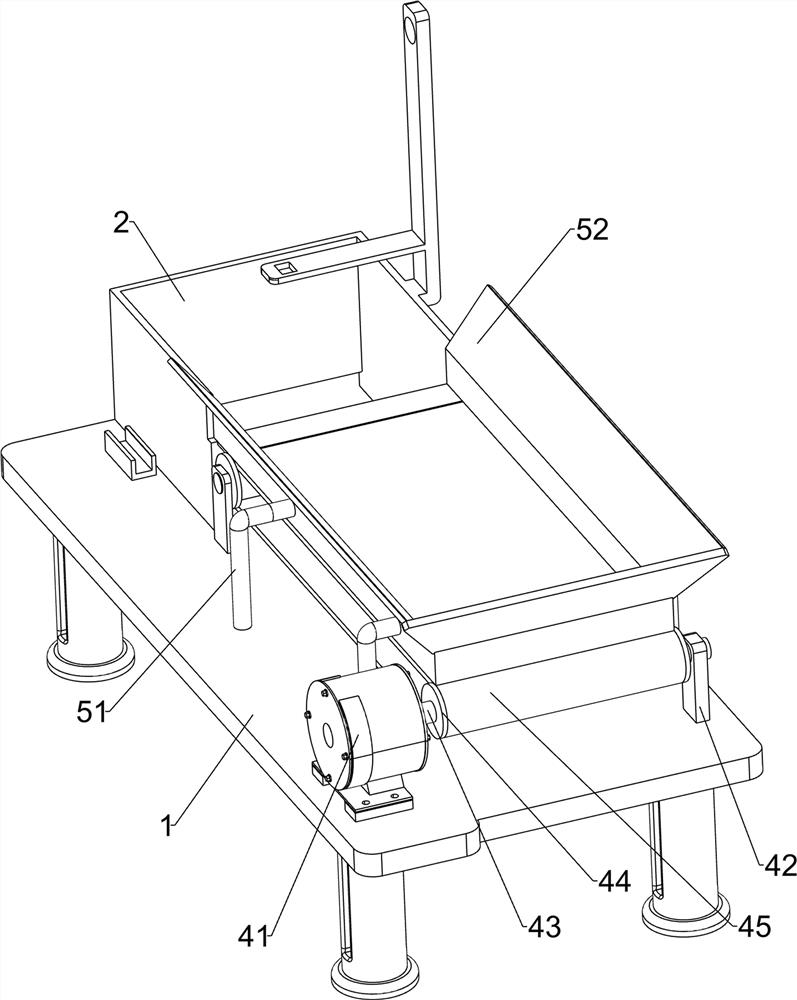

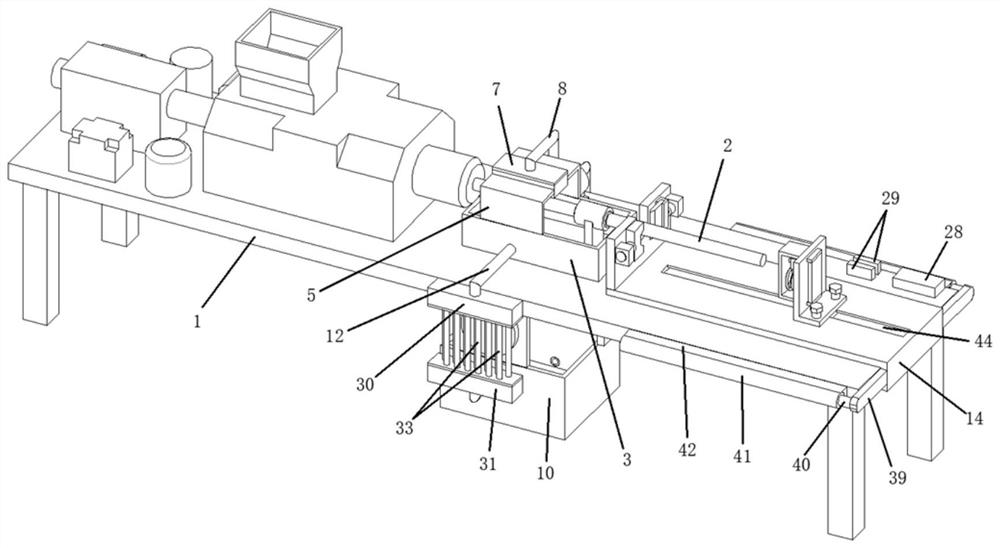

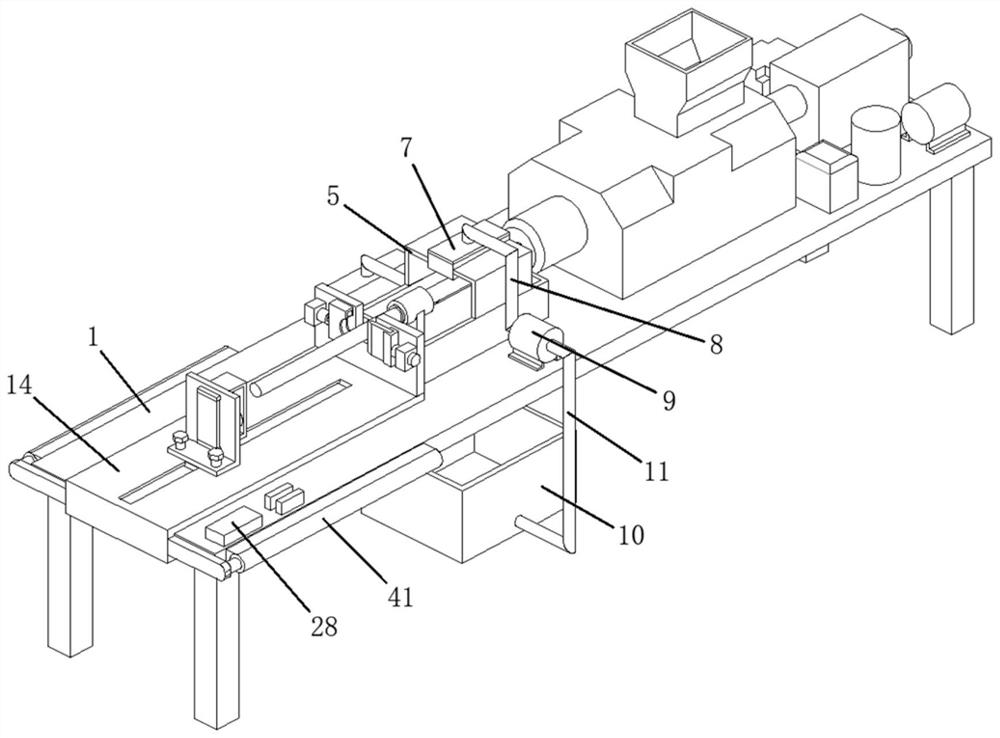

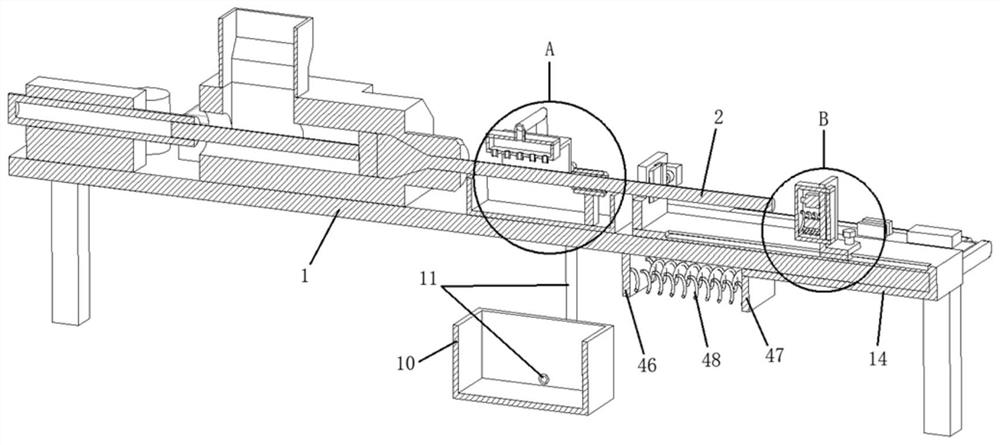

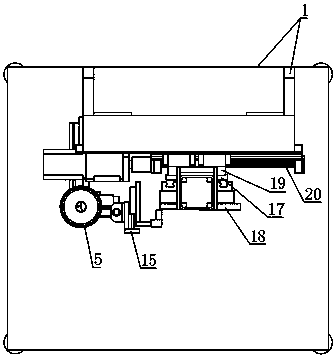

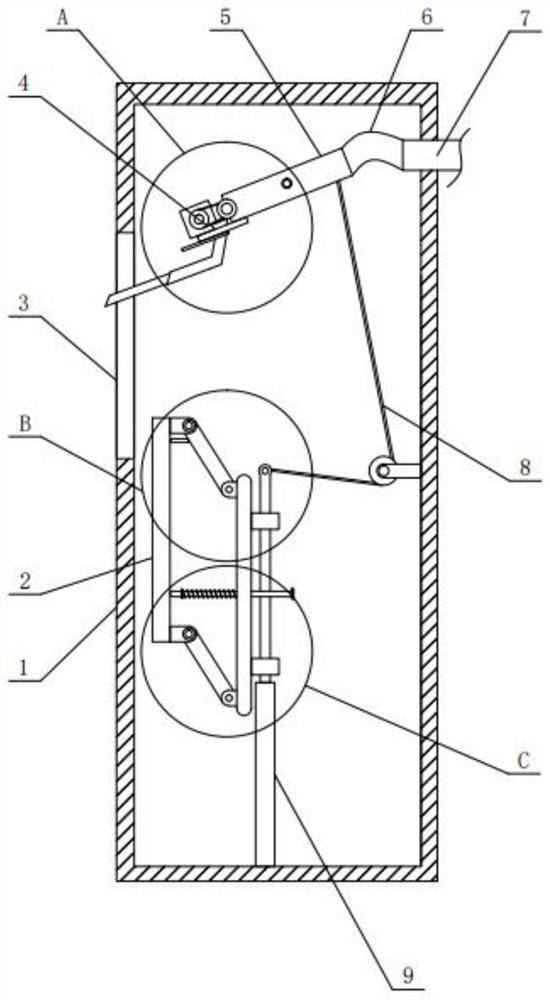

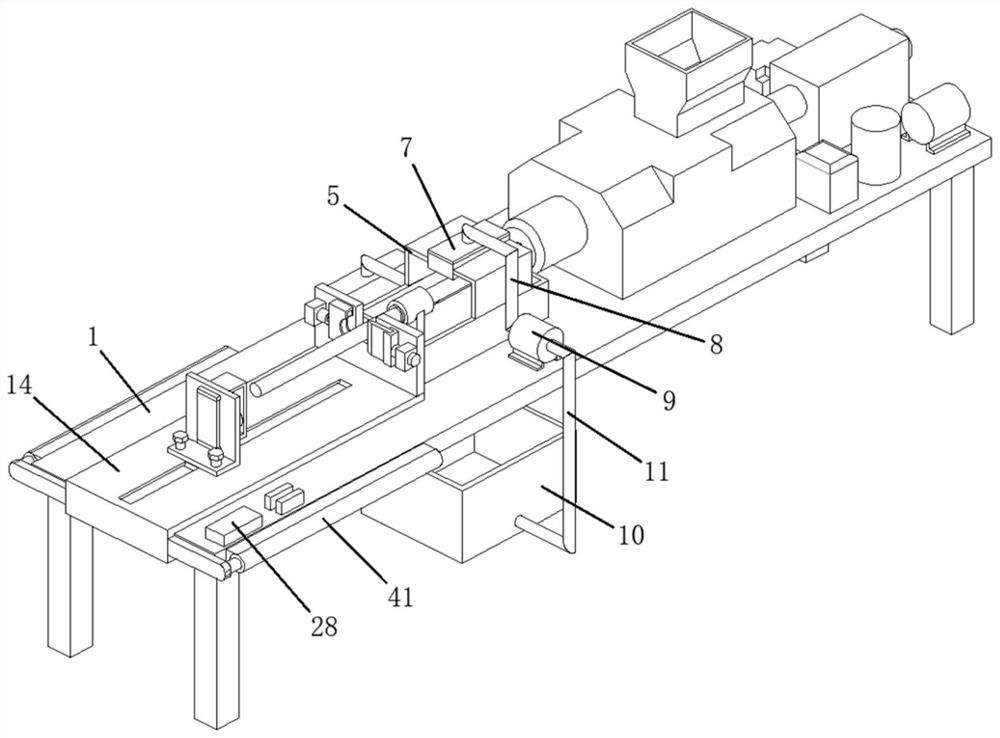

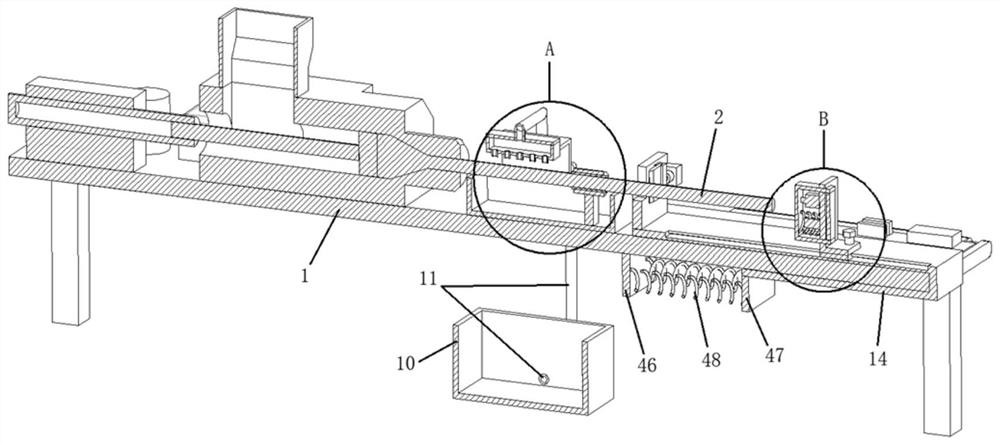

Automatic cutting facility with locking function

InactiveCN111889779AIncrease the level of automationIncrease productivityShearing machinesShearing machine accessoriesElectric machineryStructural engineering

The invention discloses an automatic cutting facility with a locking function. The automatic cutting facility with the locking function comprises a transmission case, a protective cover and a base. Areciprocating lead screw is arranged on the left side of the interior of the base and connected with the base in a rotating mode. A feeding plate is arranged on the top of the base, connected with thebase in a sliding mode and connected with the reciprocating lead screw through a transmission block. The protective cover is arranged on the upper right portion of the base, the transmission case isarranged in the middle of the top of the protective cover. A position control guide rail is arranged in the portion, located below the transmission case, of the base, a position control lead screw isarranged inside the position control guide rail, and the position control lead screw and the position control guide rail are connected in a rotating mode. According to the automatic cutting facility with the locking function, the reciprocating lead screw, a feeding motor, the feeding plate, an adjusting lead screw, a discharging electric cylinder and a discharging plate are arranged, and thereforethe automation level of the device is improved, the device can achieve independent feeding and discharging operation, the production efficiency of the device is improved, and the labor intensity is reduced.

Owner:HUAIYIN TEACHERS COLLEGE

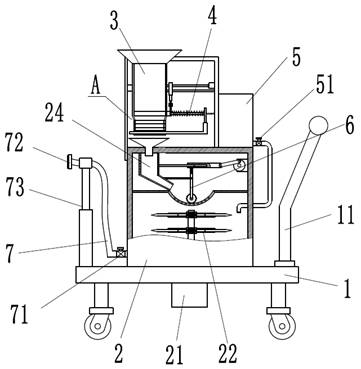

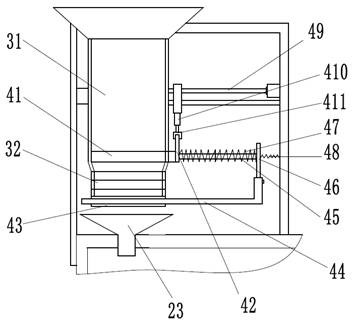

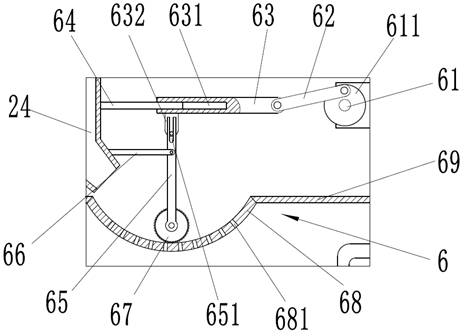

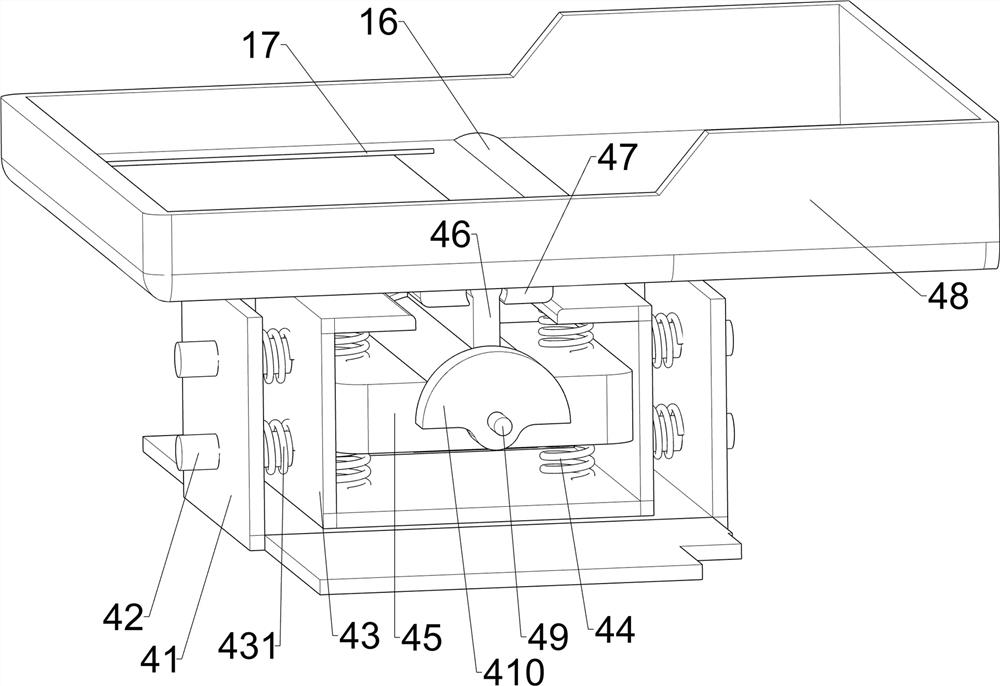

Energy-saving and environment-friendly ring-pull can extruding and recycling device

PendingCN112873971AImprove work efficiencyReduce labor intensityPress ramMechanical engineeringIndustrial engineering

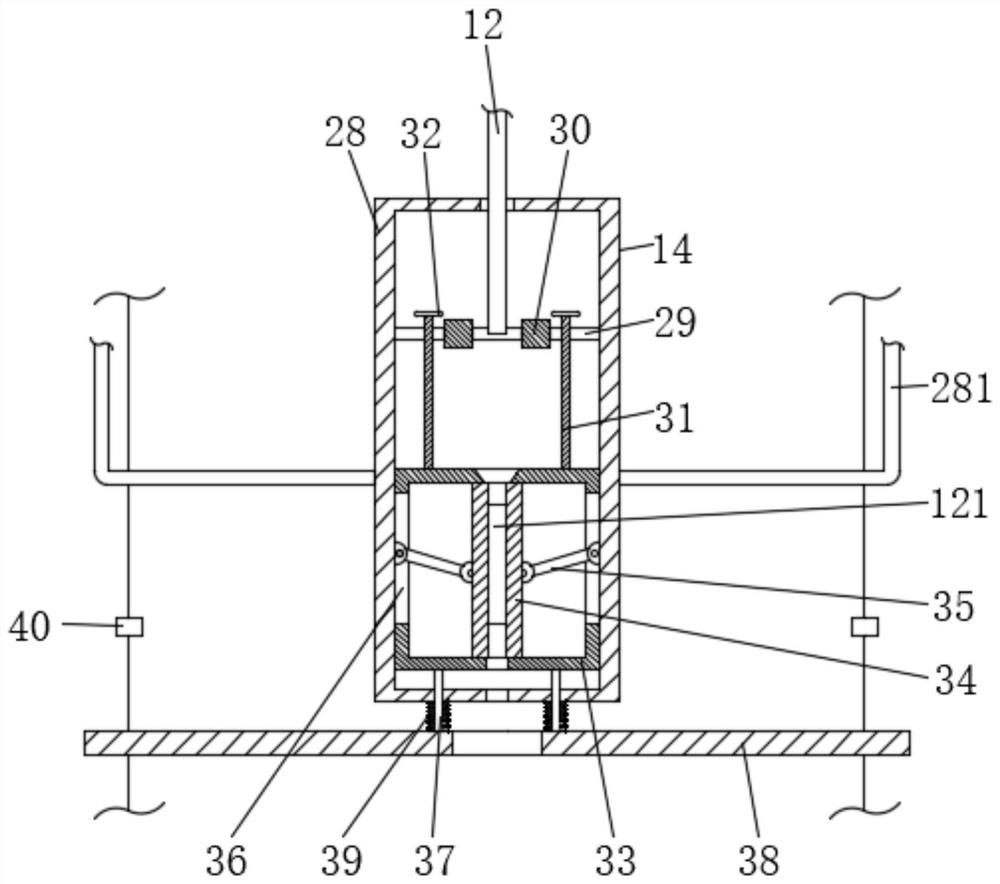

The invention relates to an extruding and recycling device, in particular to an energy-saving and environment-friendly ring-pull can extruding and recycling device. The technical problem to be solved by the invention is to provide the energy-saving and environment-friendly ring-pull can extruding and recycling device which can intermittently discharge ring-pull cans, is not prone to clamping the ring-pull cans in the device after the ring-pull cans are compressed, and can ensure the continuous work of the device. In order to solve the technical problem, the energy-saving and environment-friendly ring-pull can extruding and recycling device comprises a base, a pressing groove, a fixing frame, a driving mechanism, a material blocking assembly and the like; the pressing groove is connected to the left side of the base, the fixing frame is connected to the right side of the top of the base, the driving mechanism and the material blocking assembly are installed on the right side of the base, and the material blocking assembly is located above the driving mechanism. According to the energy-saving and environment-friendly ring-pull can extruding and recycling device, the ring-pull cans can be extruded through a placing assembly and an extruding assembly, the ring-pull cans can be conveyed through the driving mechanism and the material blocking assembly, frequent discharging by people is not needed, and the working efficiency is high.

Owner:南京博杨再生资源回收有限公司

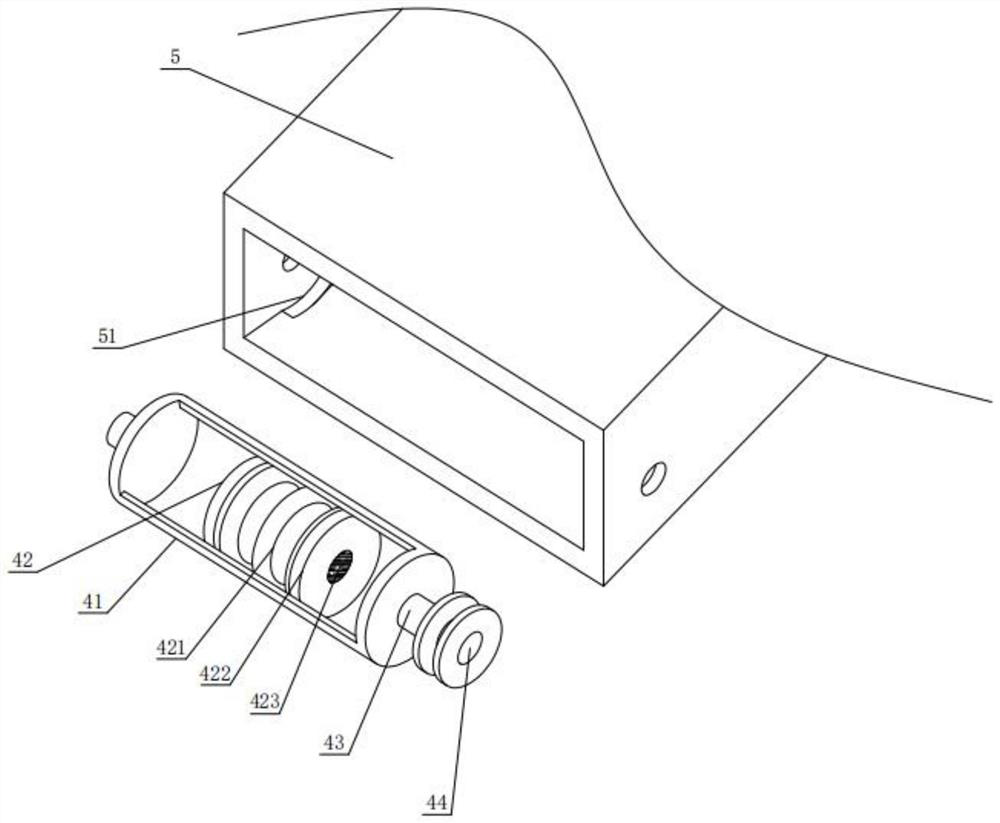

Corrugated board quantitative cutting device

InactiveCN110228089AAchieve fixationAchieve pre-drying treatmentDrying gas arrangementsMetal working apparatusAgricultural engineering

The invention belongs to the field of corrugated board cutting, and particularly relates to a corrugated board quantitative cutting device. According to the corrugated board quantitative cutting device, the problems that an existing corrugated board cutting device is incapable of pre-treating and quantitatively cut a corrugated board are solved. According to the technical scheme, the corrugated board quantitative cutting device comprises a cutting frame, wherein an air cylinder is fixed on the upper end of the cutting frame; an output end of the air cylinder is connected with a lifting rod; the lower end of the lifting rod penetrates through the cutting frame to be fixedly connected with a lifting board; a cutting mechanism is fixedly arranged at the lower end of the lifting board; a cutting platform is fixedly arranged on the cutting frame and positioned below the cutting mechanism; a storing mechanism is fixedly arranged at the rear end of the cutting platform; and a controller is fixedly arranged at one end of the cutting frame. The cutting device is convenient for cutting, fixing and collecting, is capable of drying treatment, and is convenient for counting so as to achieve quantitative cutting.

Owner:CHANGXING QIKAI MECHANICAL EQUIP CO LTD

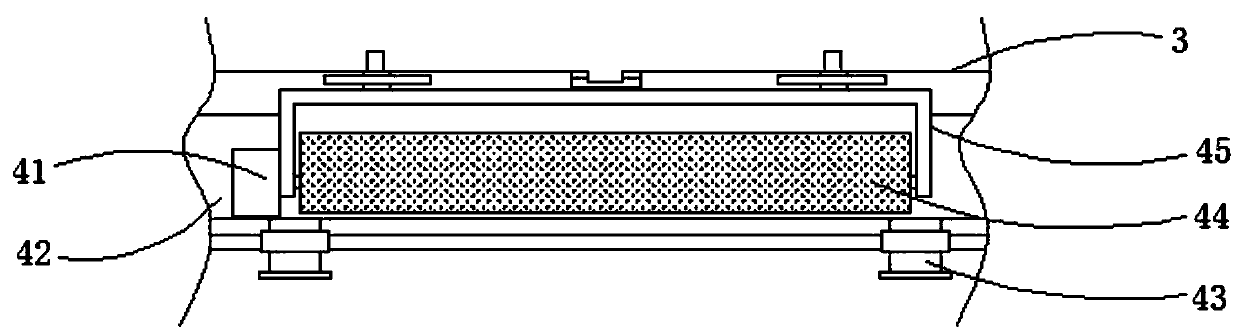

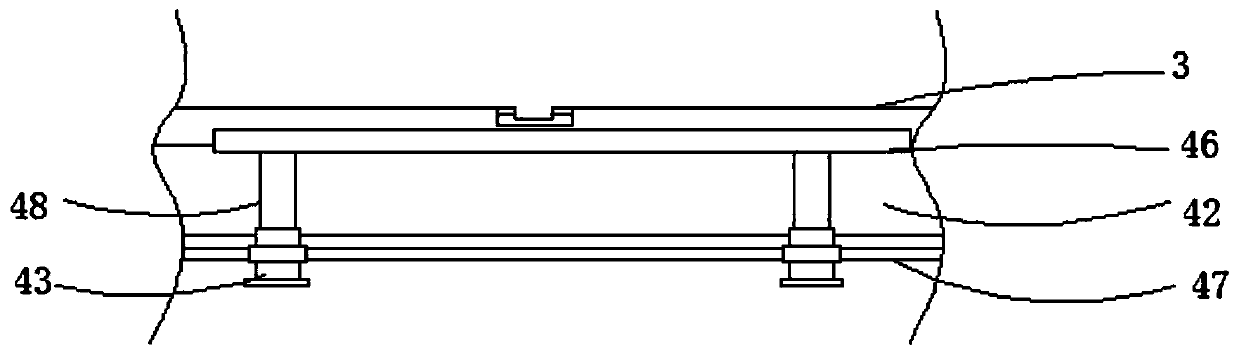

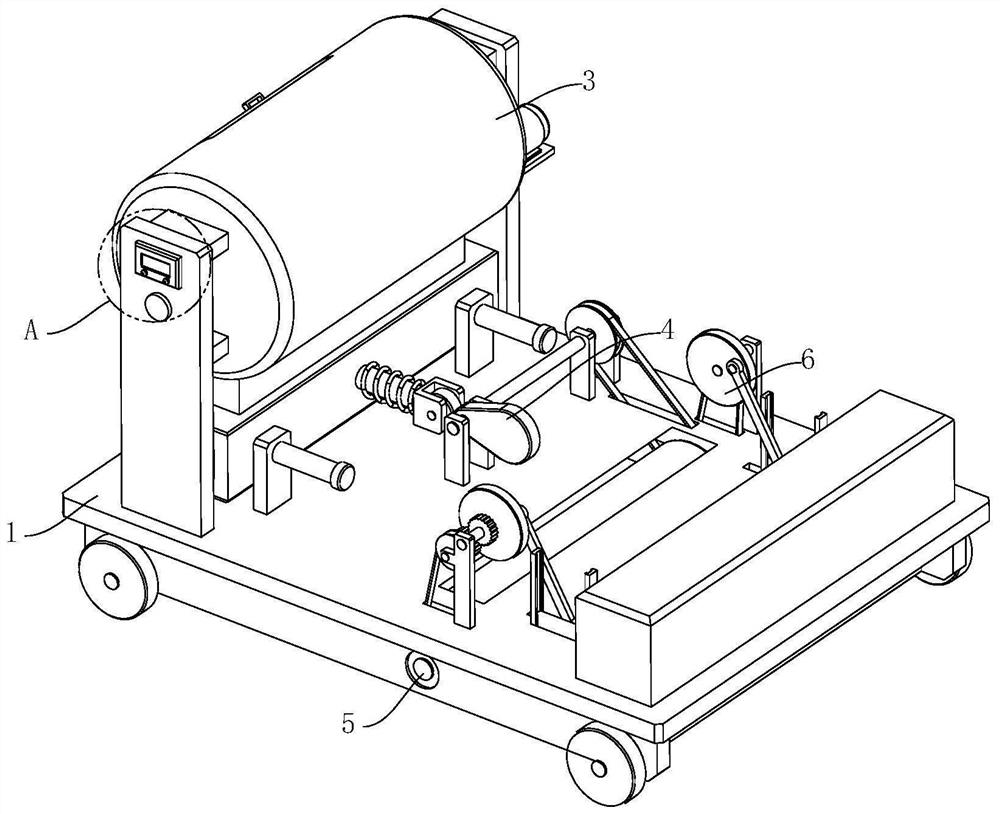

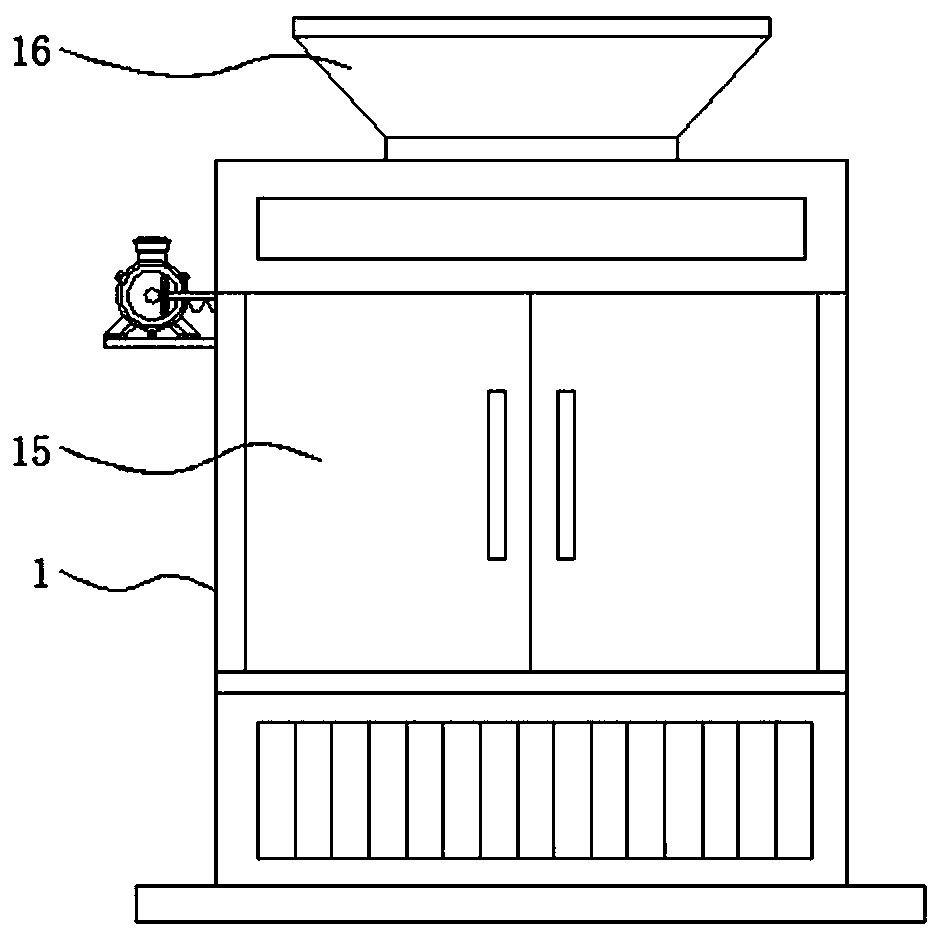

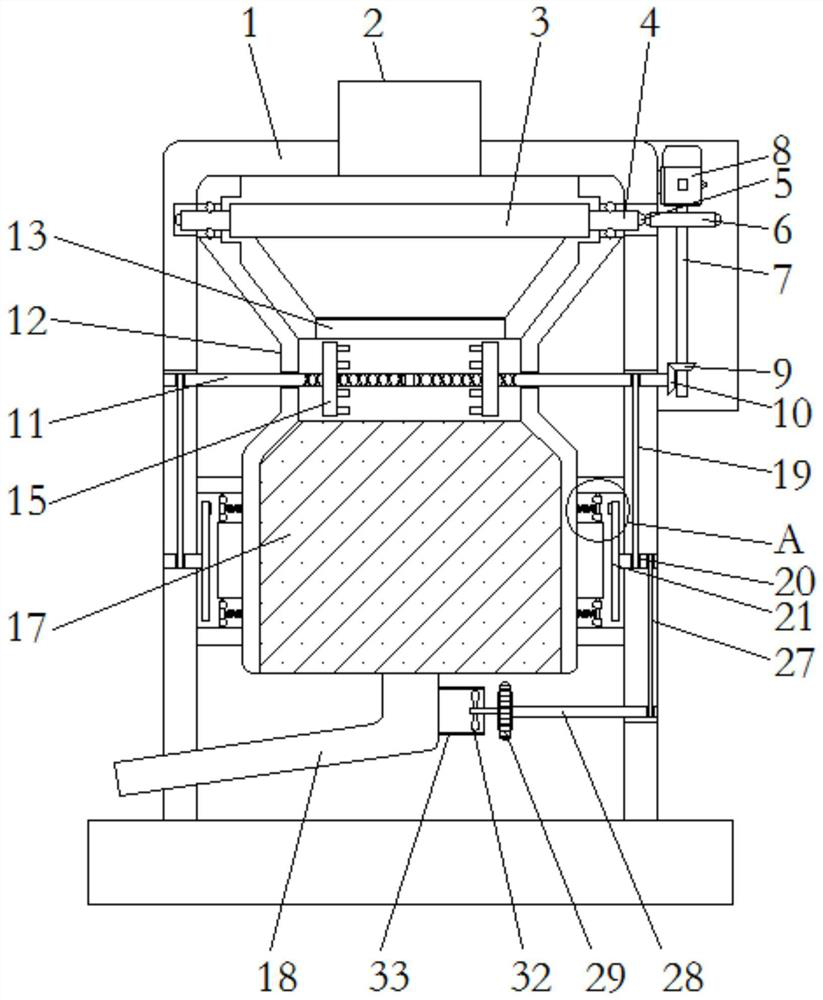

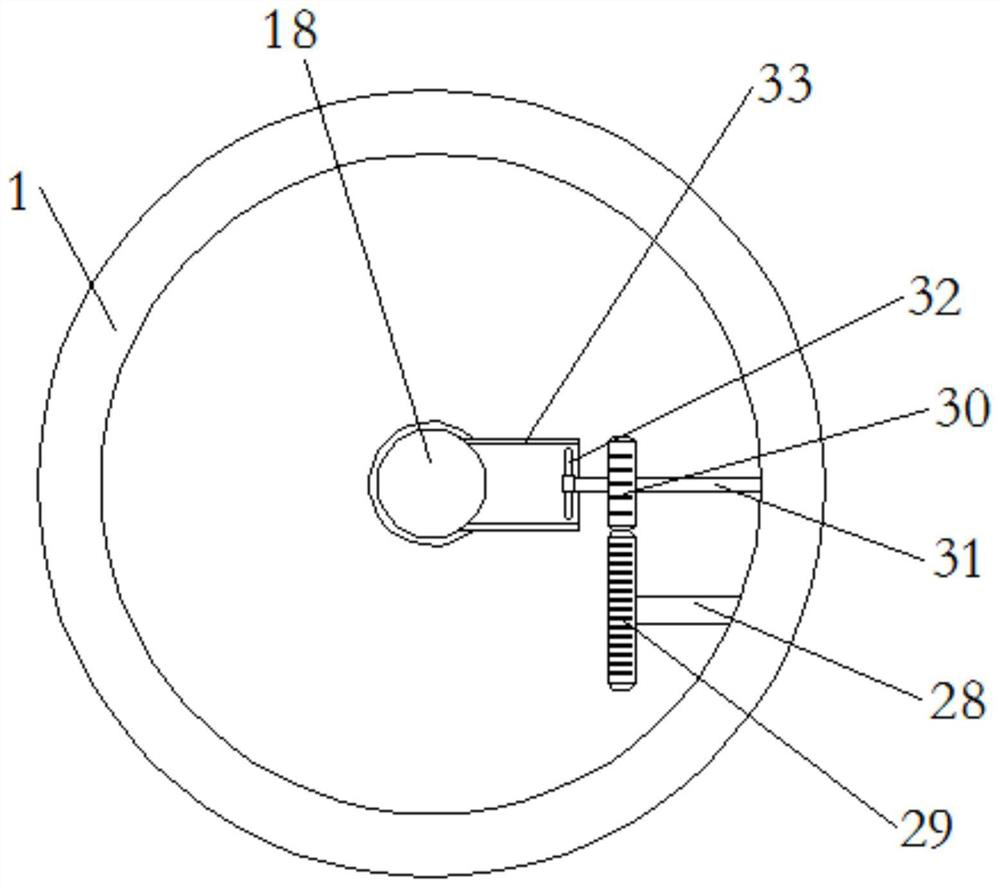

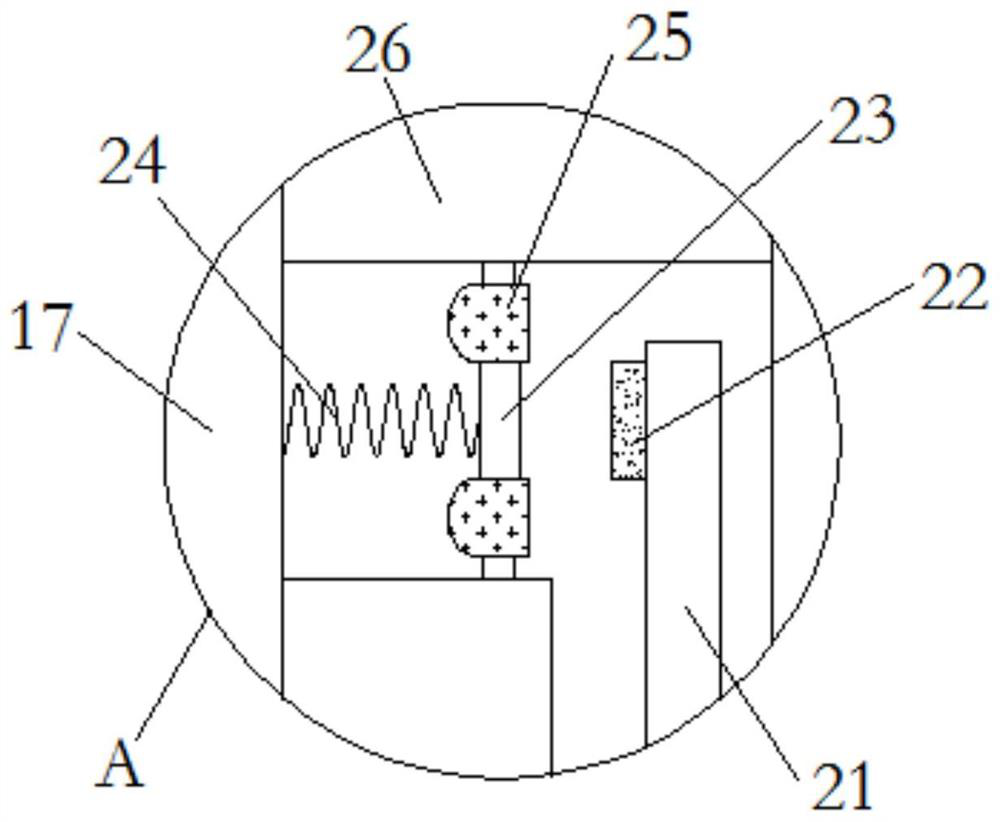

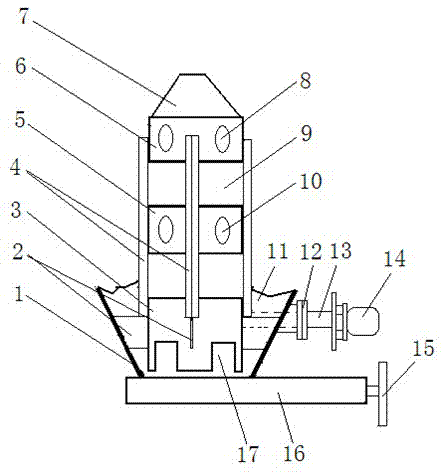

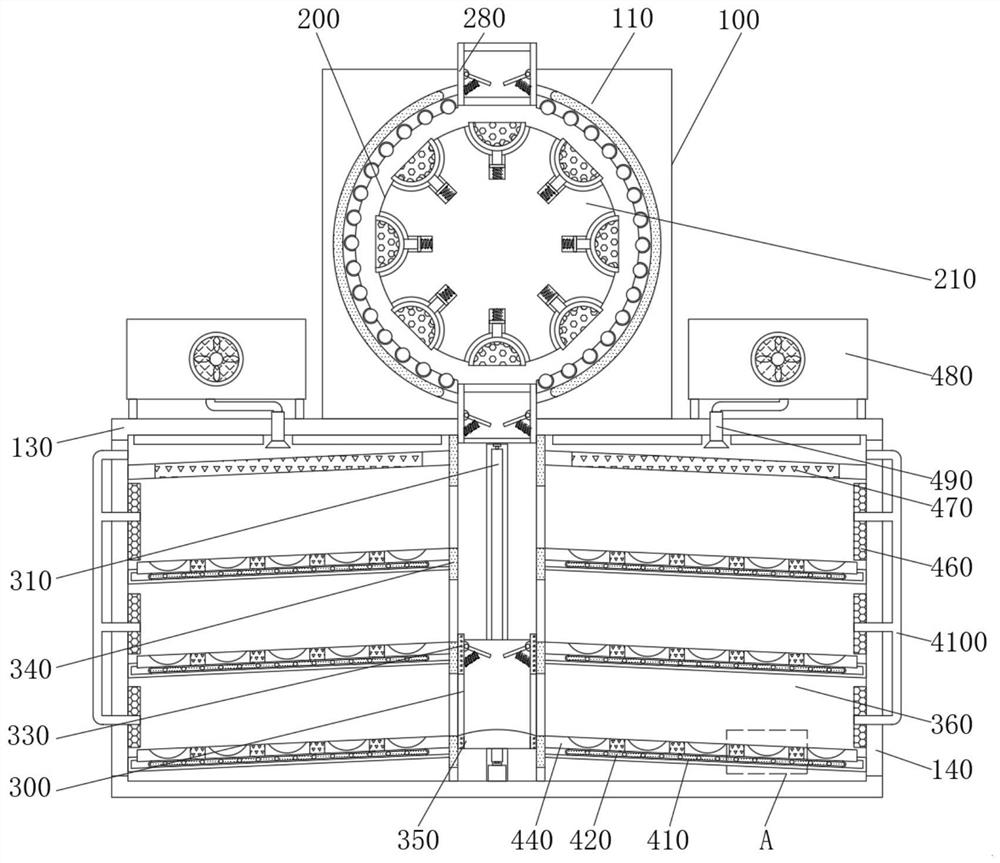

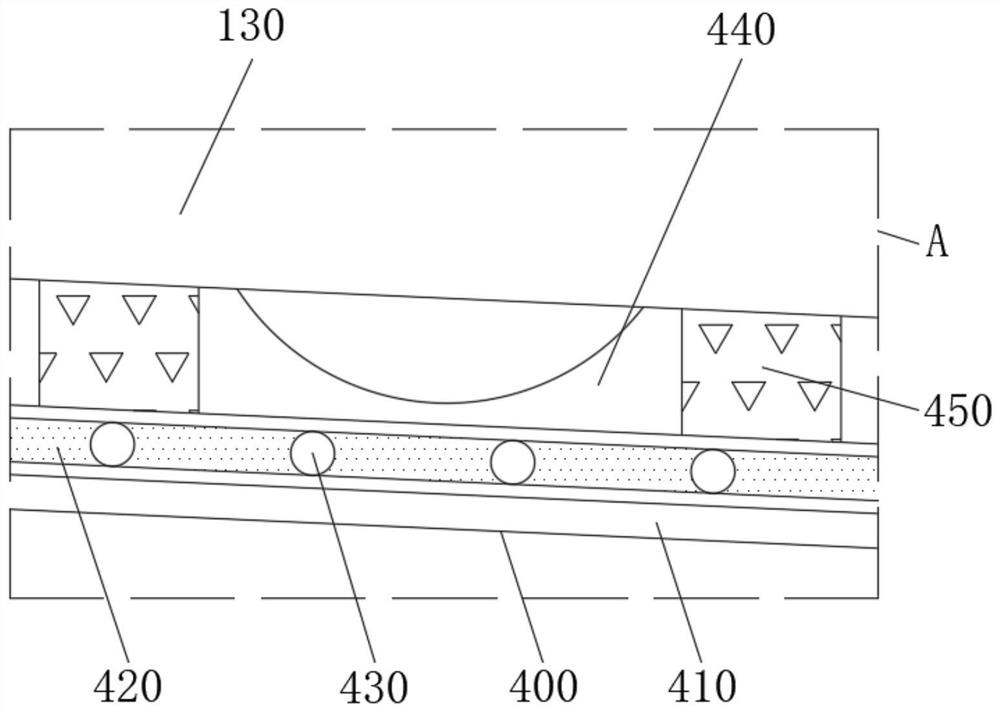

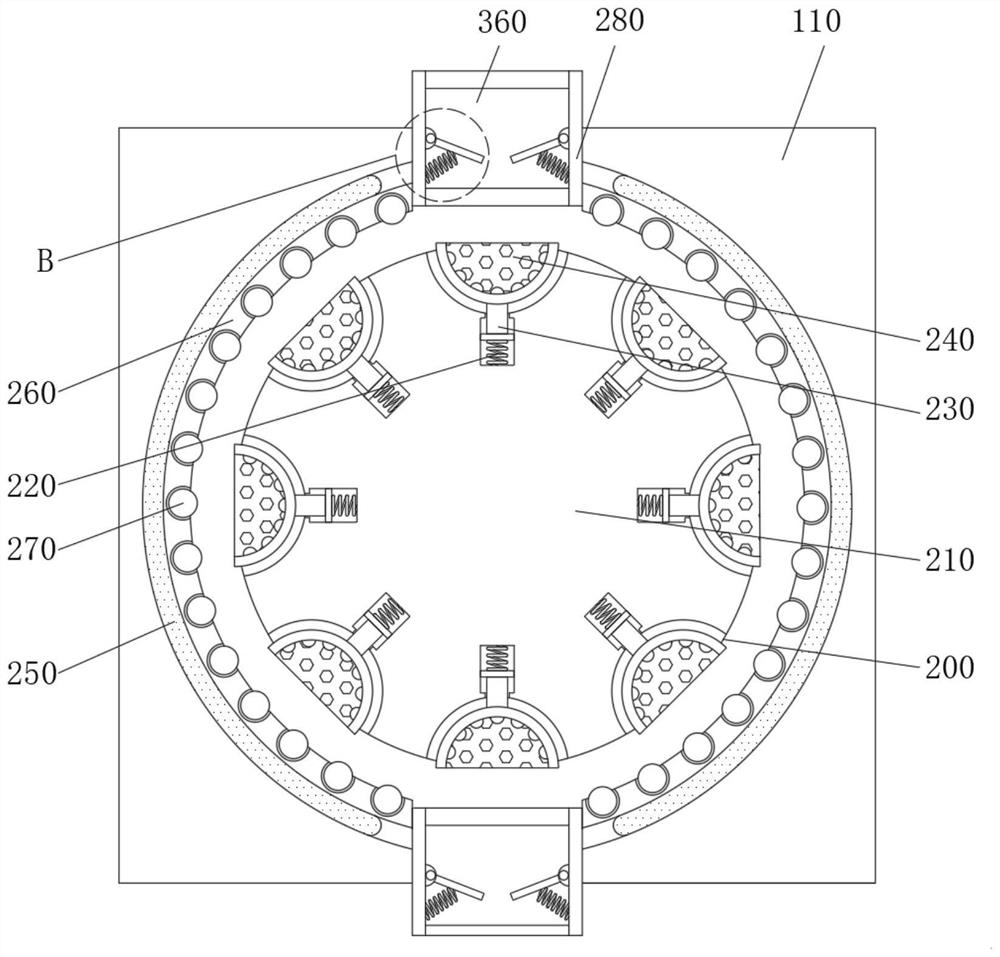

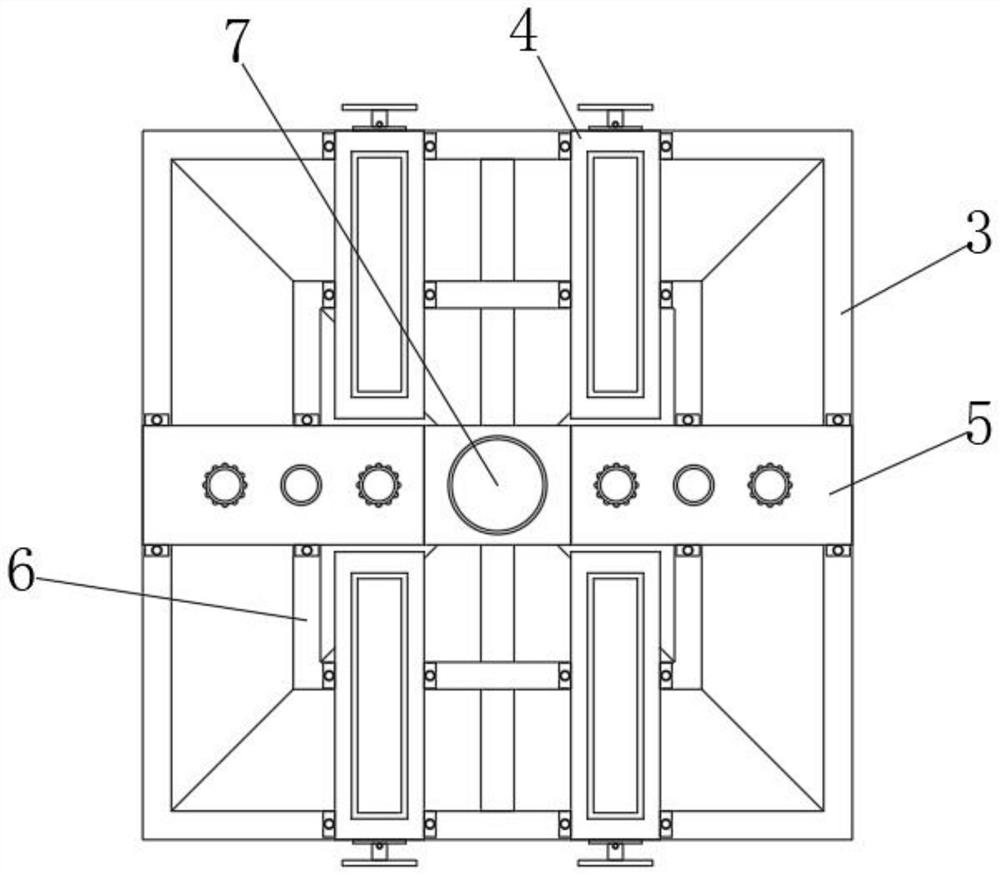

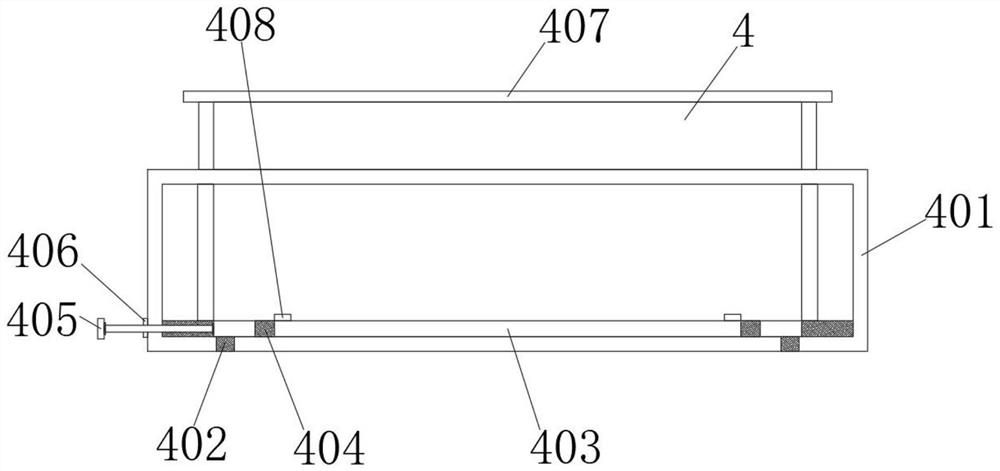

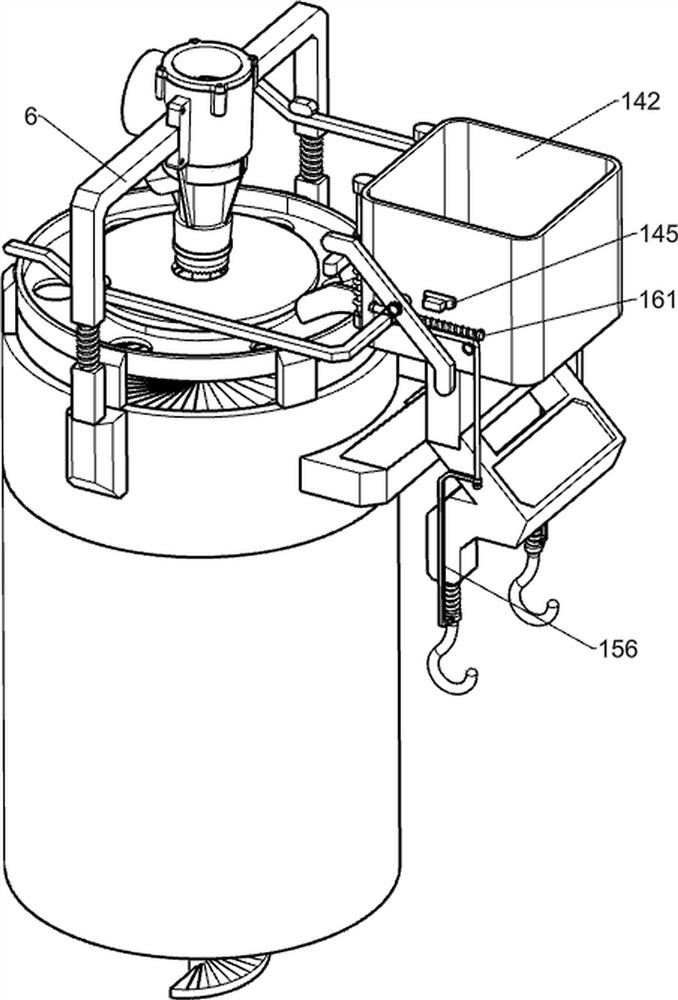

High-fineness ball milling equipment for quartz ceramic processing

ActiveCN114471848AEfficient grindingAvoid accumulationGrain treatmentsElectric machineryManual handling

The invention relates to the technical field of ball-milling equipment, and discloses high-fineness ball-milling equipment for quartz ceramic processing, which comprises a working box provided with a discharge port, and also comprises a working part, the working part comprises a grinding barrel and a motor, the grinding barrel is internally provided with a grinding inner cylinder, and the motor is connected with the grinding inner cylinder; a plurality of discharging holes are formed in the side wall of the grinding barrel and the side wall of the grinding inner barrel, the output end of the motor is connected with a main driving shaft, an annular rack is arranged outside the side wall of the grinding barrel, and a hollow shaft is arranged at one end of the grinding barrel; the grinding barrel is arranged in the working box, the discharging part is arranged on the working box and comprises a storage box, a discharging pipe is arranged on the lower portion of the storage box, a hollow shaft matched with the discharging pipe is arranged at one end of the grinding barrel, and a discharging assembly used for controlling the discharging speed is arranged on the discharging pipe. The device can realize quantitative feeding and timed discharging, manual operation is not needed in the whole process, the automation degree is high, and the grinding effect is good.

Owner:康姆罗拉有限公司

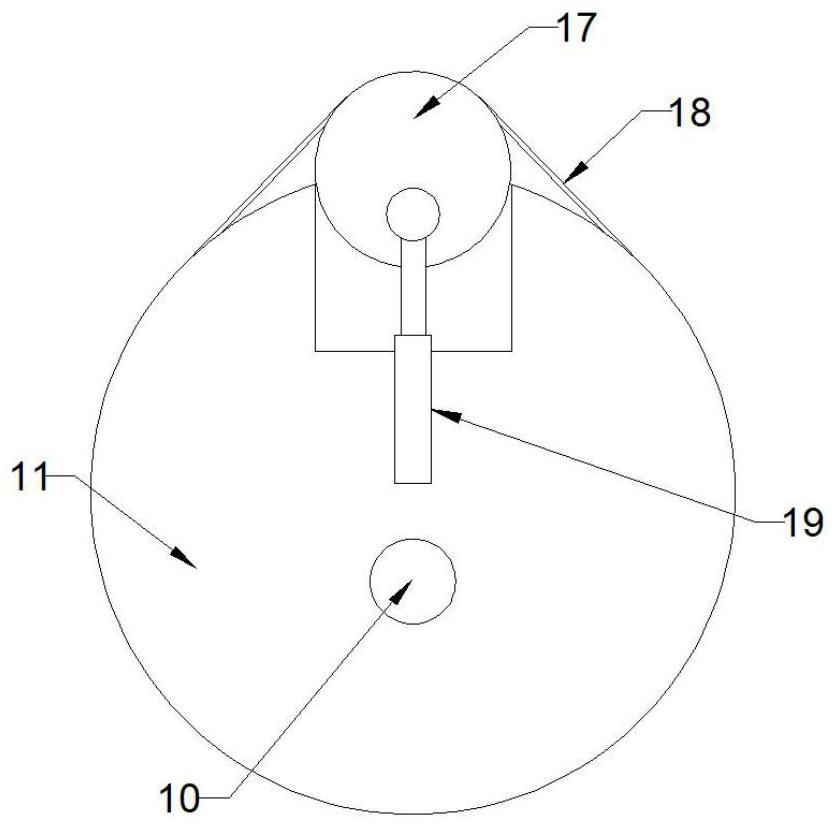

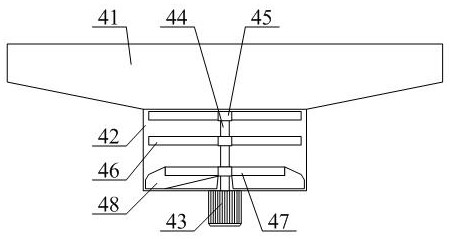

Rice field fertilizer applying device

InactiveCN110089248AAvoid cloggingGuaranteed throwingCentrifugal wheel fertilisersFertilizerFrequency conversion

The invention discloses a rice field fertilizer applying device which comprises a fertilizer box. A scattering disc is arranged below the fertilizer box. The scattering disc is provided with a scattering cavity in a cone frustum shape, and scattering plates are distributed inside the scattering cavity circumferentially. By arranging the scattering plates driven by a frequency conversion motor andthe scattering disc provided with the cone frustum shaped scattering cavity, centrifugal scattering of fertilizer is achieved, the fertilizer scattering efficiency is improved, and meanwhile fertilizer scattering is more uniform; by arranging a discharging pipe and discharging spiral blades, quantified discharging is achieved while blockage of a discharging pipe is avoided, and uniform scatteringis ensured.

Owner:张媛

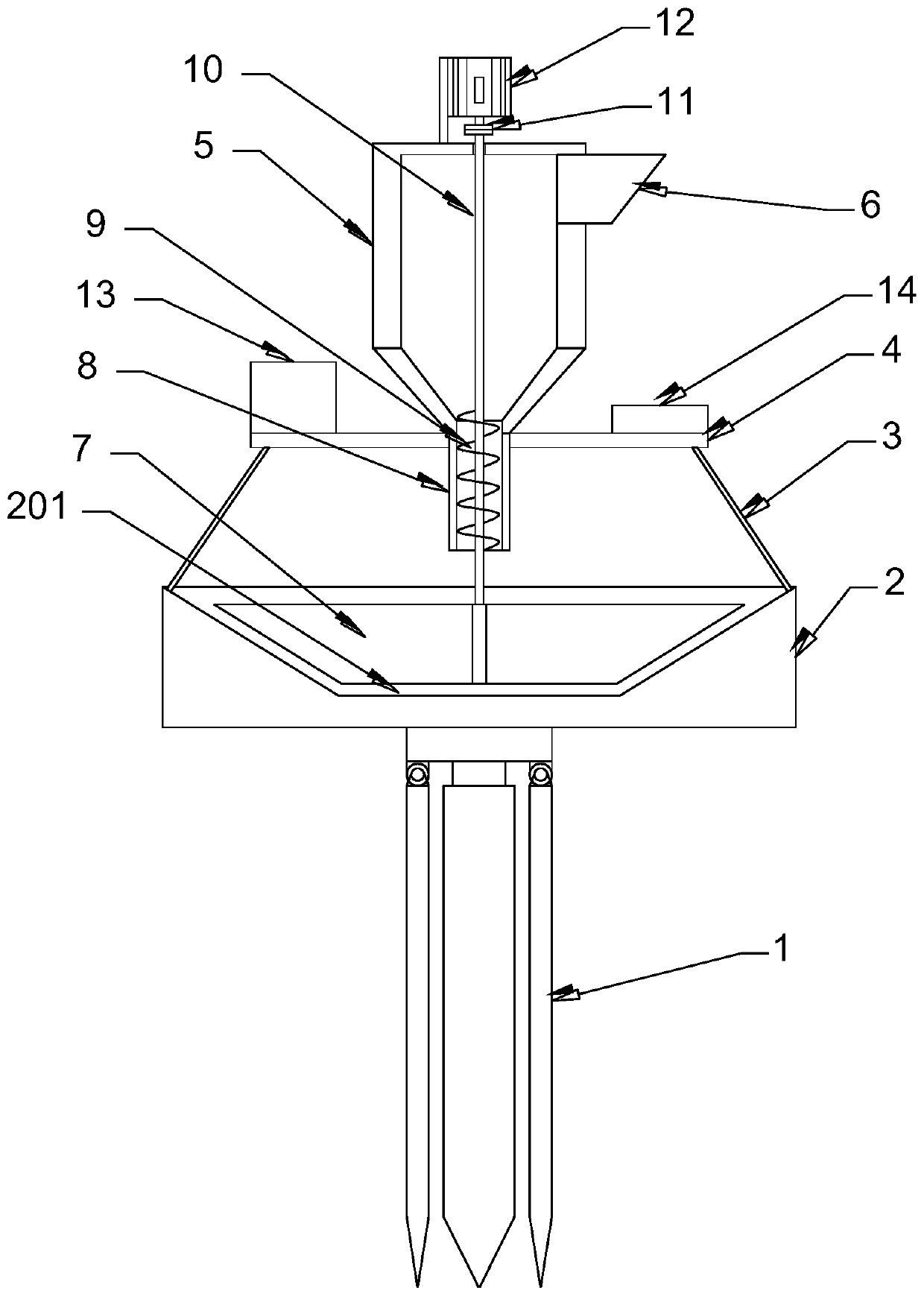

Quantitative fertilization device of vegetable planting water and fertilizer all-in-one machine

InactiveCN114467456ARealize quantitative cuttingGood job continuityRotary stirring mixersTransportation and packagingAgricultural scienceAgricultural engineering

The invention discloses a vegetable planting water and fertilizer all-in-one machine quantitative fertilization device which comprises a frame, a stirring treatment box, a liquid storage box arranged at the top of the stirring treatment box, a material storage barrel and a quantitative discharging control mechanism arranged on the material storage barrel. The quantitative discharging control mechanism comprises a lead screw nut piece located on one side of the storage material barrel, a drawing partition plate and a drawing door plate, the drawing partition plate and the drawing door plate are both arranged on the storage material barrel, the drawing partition plate is located above the drawing door plate in a spaced mode and provided with a driving end plate, a sliding frame penetrates through the driving end plate to be inserted into the drawing partition plate in a sliding mode, and the sliding frame is provided with a limiting end plate. The limiting end plate is connected with the drawing door plate through a connecting frame, a lifting driving mechanism is connected to a nut of the lead screw nut piece, the end of the lifting driving mechanism is connected with a clamping block, the clamping block is connected with the driving end plate or the limiting end plate in a clamped mode, and the drawing partition plate and the drawing door plate alternately act to achieve quantitative discharging. The water and fertilizer mixing ratio is high in precision and easy to adjust, and the mixing process is easy to control.

Owner:WENZHOU VOCATIONAL COLLEGE OF SCI & TECH

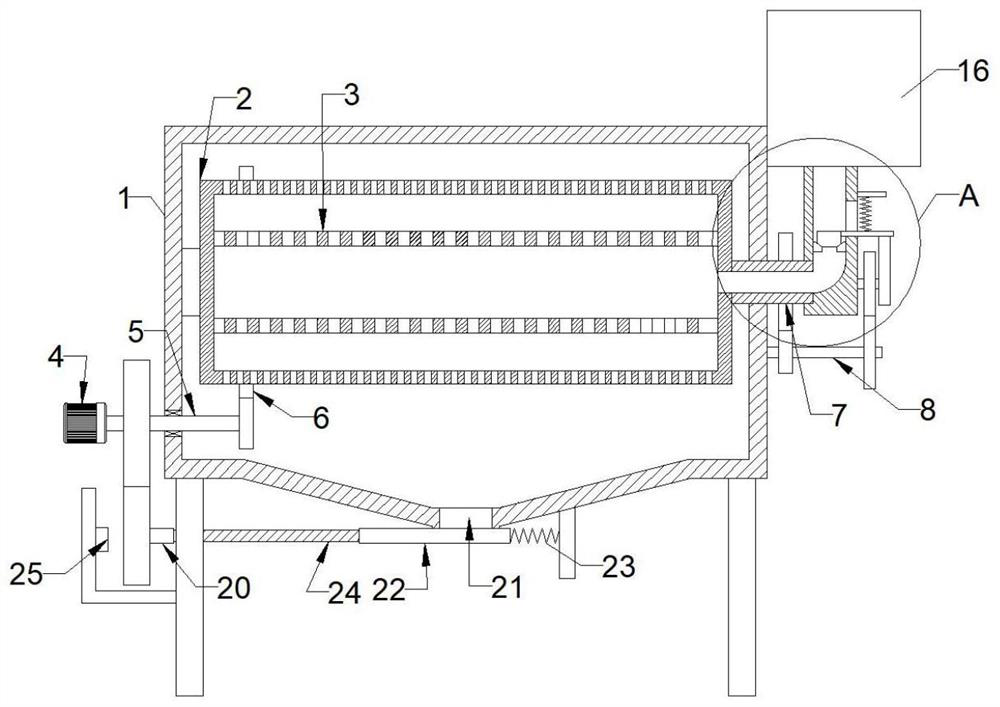

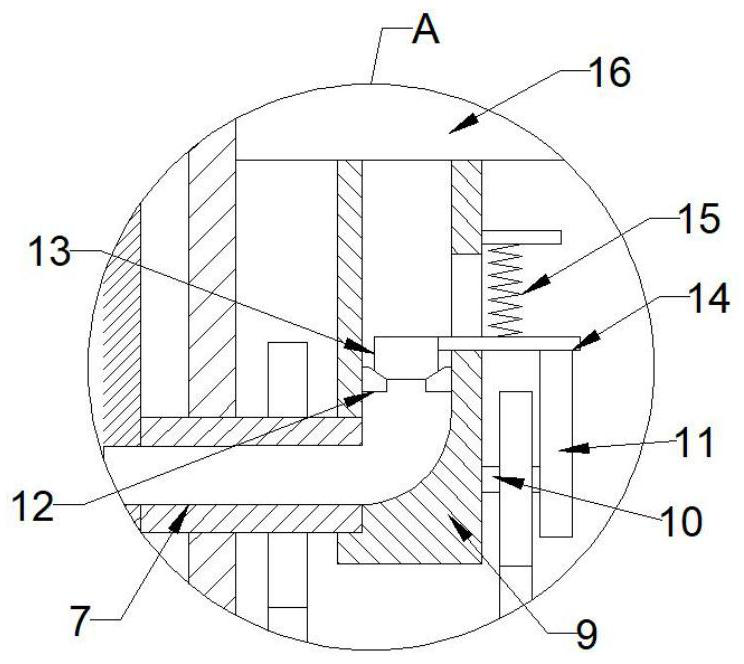

Integrated cooling type tin bar extruding machine

The invention relates to the technical field of extruding machines, in particular to an integrated cooling type tin bar extruding machine. The integrated cooling type tin bar extruding machine comprises an extruding machine body, and the extruding machine body comprises a working table plate, extruded materials, a processor and two electromagnetic valves, wherein a water receiving box is fixedly arranged on one side of the working table plate, a cooling box is arranged on one side of the water receiving box, and L-shaped connecting frames are fixedly arranged on the two sides, away from each other, of the cooling box correspondingly; one side of each L-shaped connecting frame is fixedly connected with one side of the water receiving box, a plurality of cooling holes are formed in one side of the cooling box, and cooling pipes are fixedly arranged on the inner sides of the cooling holes correspondingly. According to the integrated cooling type tin bar extruding machine, through the arrangement of the water receiving box, the cooling box, the cooling pipes, a water pump, a water tank, a cooling device, a cutting base, a tool apron, a hydraulic cylinder, a cutting tool, an L-shaped sliding frame, a touch switch, a spring, a U-shaped frame, a guide damping device, a U-shaped sliding frame and an automatic reset device, the integrated cooling type tin bar extruding machine has the functions of rapid cooling, circulating cooling, automatic slitting, length adjustment, continuous slitting and the like.

Owner:深圳市绿色千田锡业科技有限公司

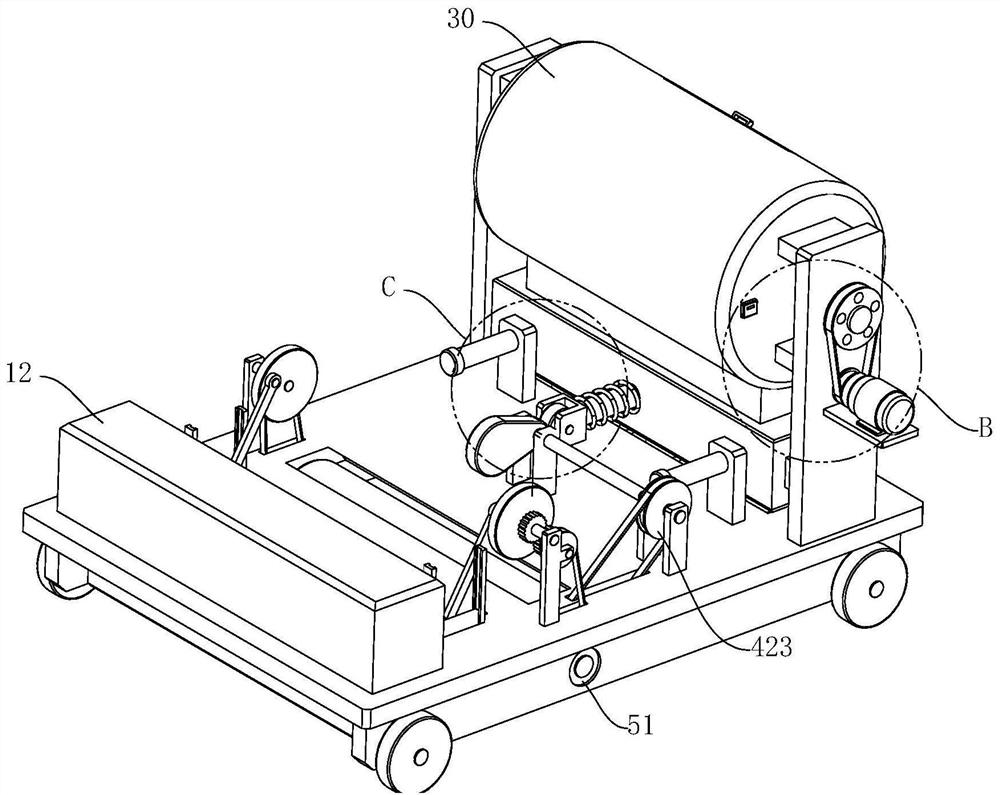

High-performance asphalt self-adaptive laying device and method

ActiveCN112726330AReduce labor intensityImprove laying efficiencyRoads maintainenceElectric machineryDrive motor

The invention relates to the technical field of municipal construction, in particular to a high-performance asphalt self-adaptive laying device and method, the high-performance asphalt self-adaptive laying device comprises an electric trolley, and further comprises a controller, a stirring mechanism, a pushing mechanism, a grinding mechanism and a trimming mechanism, the stirring mechanism comprises a heating kettle, a driving motor and a stirring assembly, and the pushing mechanism comprises a discharging cavity, a pushing plate and an extruding assembly, the grinding mechanism is arranged at the bottom of the electric trolley and used for flattening laid asphalt, the grinding mechanism comprises a flattening assembly and two bearings, the trimming mechanism is arranged at the bottom of the electric trolley and used for cutting off corners of the rolled asphalt, and the trimming mechanism comprises two cutters and two sliding assemblies, the electric trolley and the driving motor are electrically connected with the controller. According to the high-performance asphalt self-adaptive laying device and method, quantitative discharging can be achieved, uniform laying can be guaranteed, meanwhile, the power consumption is small, the construction cost can be reduced, manual assistance is not needed, and laying can be completed in the running process.

Owner:CHINA FIRST HIGHWAY ENG +1

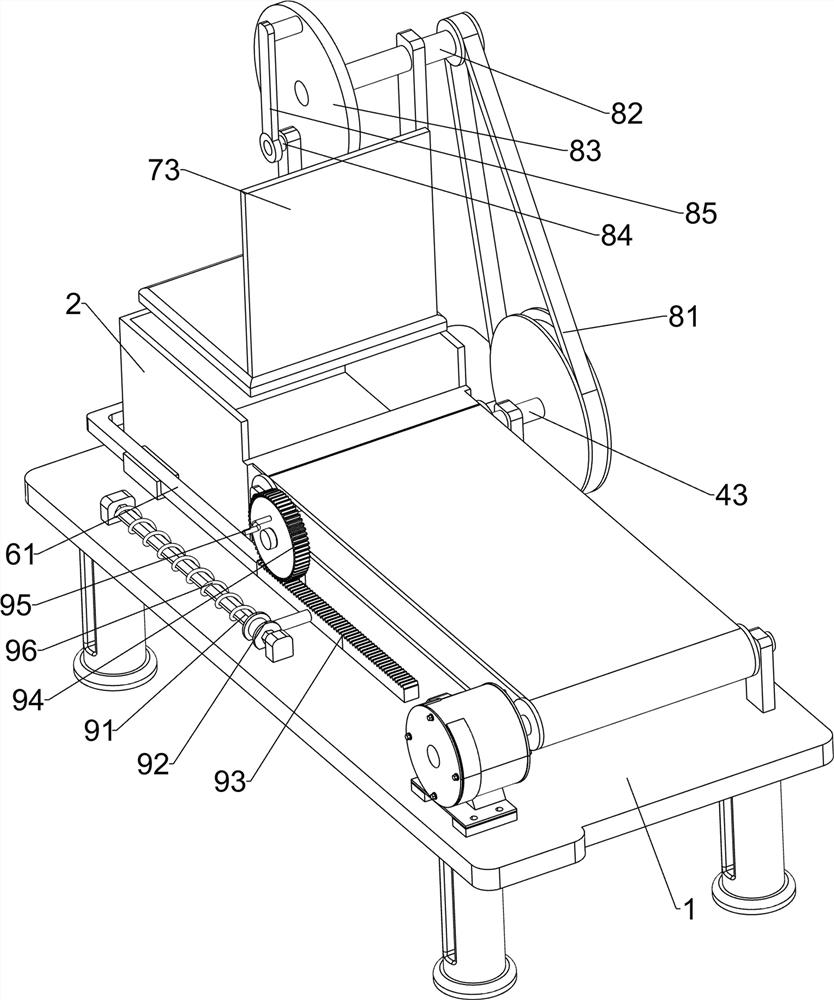

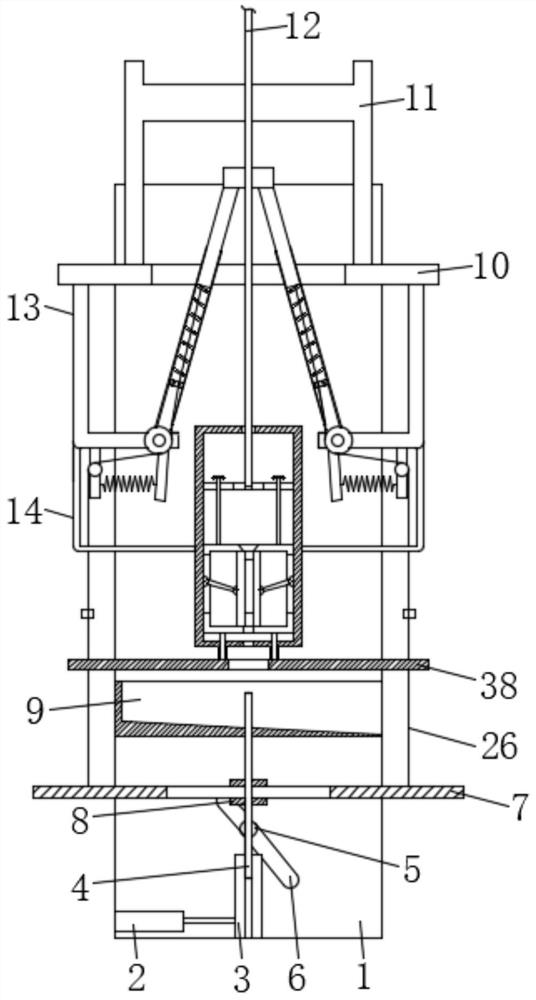

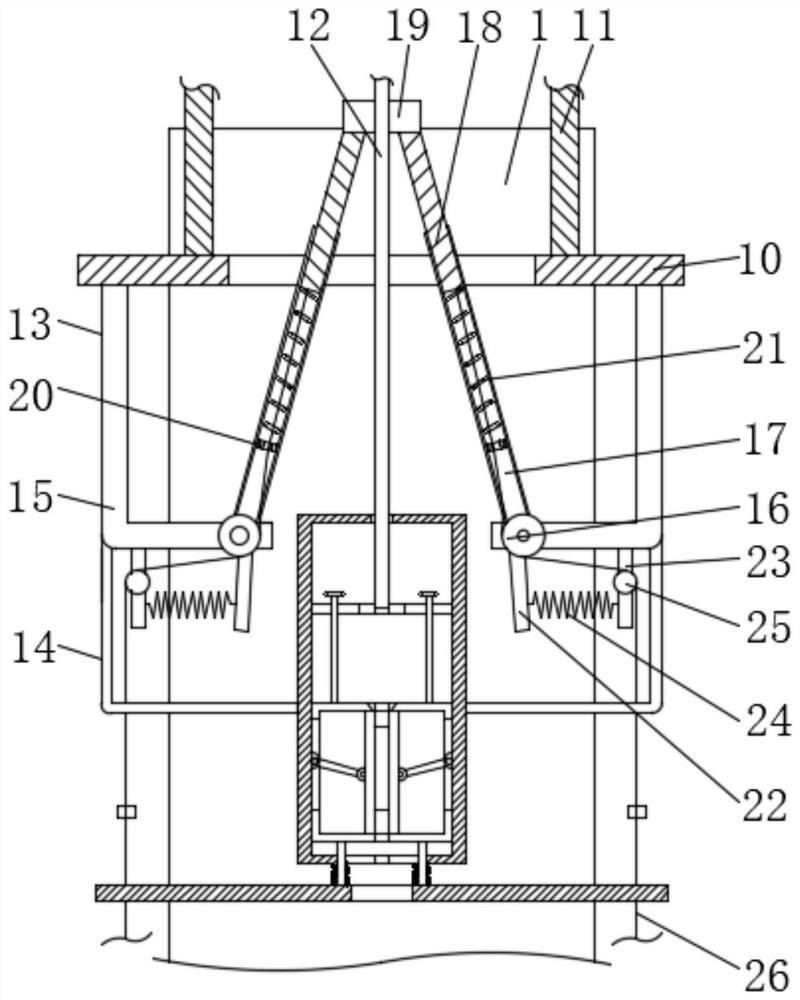

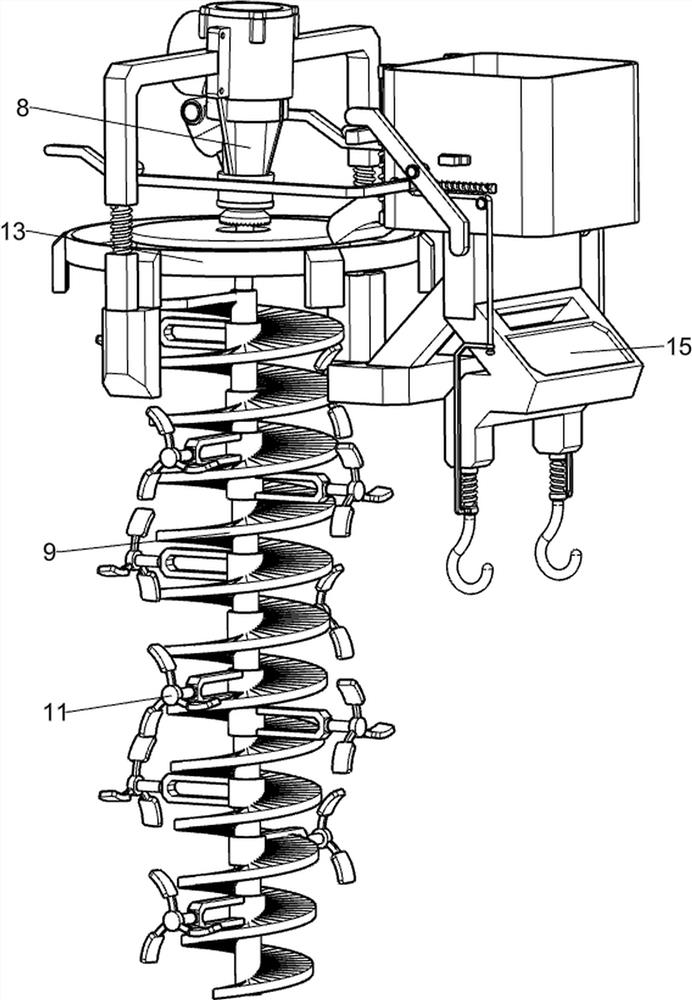

Breeding feeding machine with quantifying function

InactiveCN111066667AWith quantitative functionRealize quantitative cuttingAnimal feeding devicesAvicultureAnimal scienceDraft animals

The invention relates to the technical field of breeding feeding equipment in an agricultural region, in particular to a breeding feeding machine with a quantifying function. By using the self weightincrease and downward movement of a feeding trough during material collection, a No.2 slide sleeve downwards moves along with a slide rod, and a left rack is driven to move. The left rack acts on a right rack through a steering gear, so that the right rack upwards moves; and a blocking plate is driven to continuously move upwards through a No.6 connecting rod and a No.3 connecting rod. After the feeding trough downwards moves for a certain distance, the blocking plate moves to a bottom outlet of a material storage hopper and stops the material discharging after blocking the bottom outlet of the material storage hopper, so that the quantitative discharging is realized; simplicity and convenience are realized; and the manual intervention is not needed. Through the arrangement of a locking assembly, after material discharging is completed, a hanging ring can be hung on a hook by a worker, so that the blocking plate maintains a state of blocking the bottom outlet of the material storage hopper; and automatic continuous material addition is stopped when the livestock eats, so that the problems caused by uninterrupted eating of the livestock are avoided.

Owner:安徽陆明科技有限公司

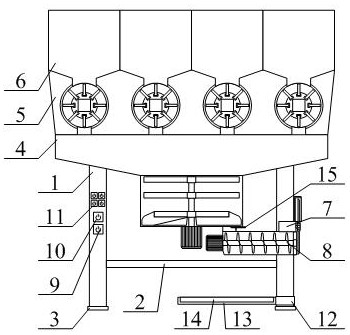

Winnowing device capable of reducing mud content of foundry sand

InactiveCN107716301AReduce descent speedNo emissionsGas current separationDust controlProcess engineering

The invention relates to a winnowing device capable of reducing mud content of foundry sand. The winnowing device includes a discharging device, a winnowing mainframe, a dust collector fan and a bag dust collector. The discharging device includes a discharging hopper and a conveying device. The sand material output end of the conveying device is placed on the upper portion of a feeding port of thewinnowing mainframe. A material-flinging disc and a baffle plate are arranged in the winnowing mainframe. The lower end of the winnowing mainframe is provided with a sand material output port. Meanwhile, one side of the winnowing mainframe is communicated with an air outlet of the dust collector fan, and sand dust in the winnowing mainframe is conveyed into the bag dust collector through a dedusting pipe. According to the winnowing device, quantitative discharging can be achieved, sand is flung into the winnowing mainframe through a centrifugal effect of the material-flinging disc, and the sand descending speed is reduced through the blockage by the baffle plate. Meanwhile, through the action of the dust collector fan, the sand is dedusted, and particles smaller than the standard range are collected into the bag dust collector, to achieve the goal of reducing the mud content.

Owner:阳泉中创陶粒股份有限公司

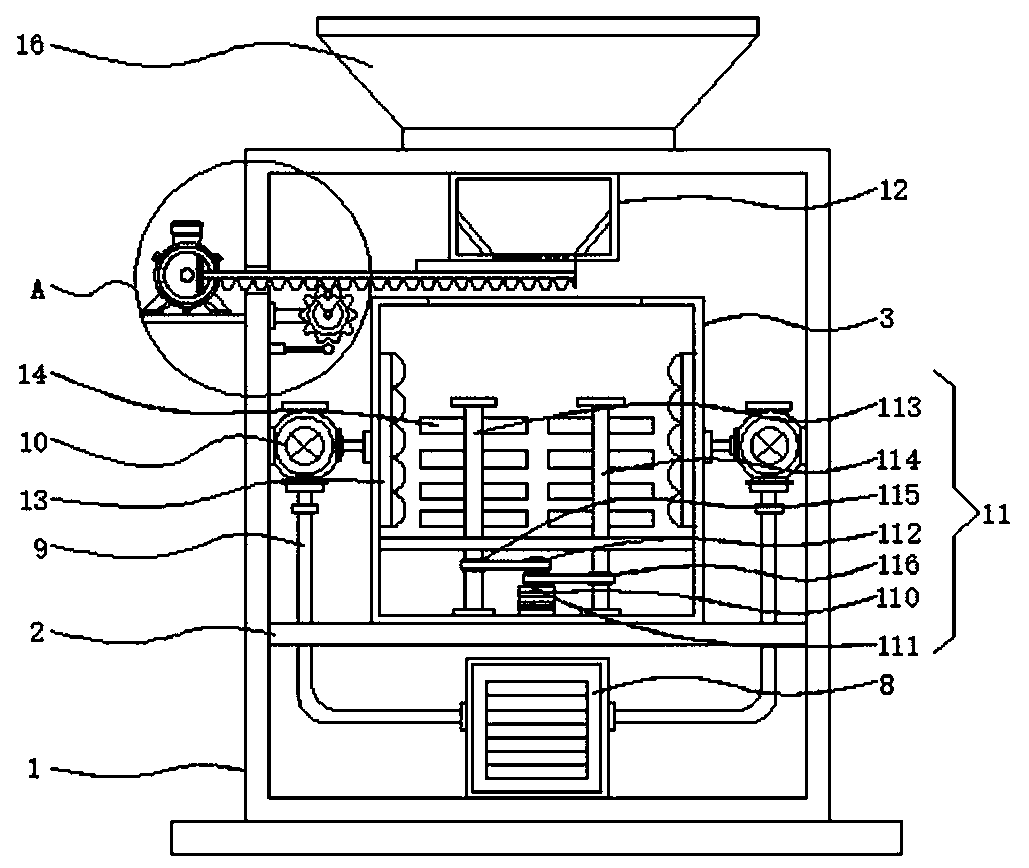

Concentrated feed making equipment

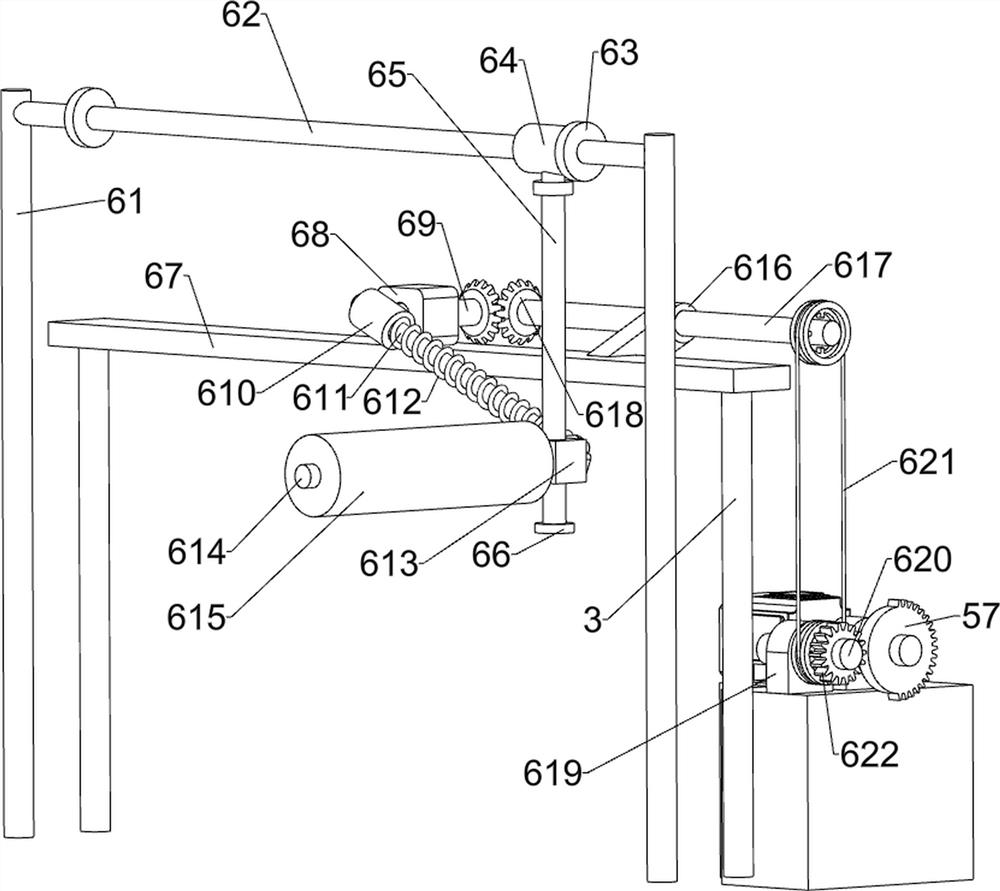

InactiveCN111700296ARealize quantitative cuttingEasy to disassembleFeeding-stuffTransportation and packagingBall bearingElectric machinery

The invention provides concentrated feed making equipment. The concentrated feed making equipment comprises a longitudinal mounting frame, a transverse connecting frame, anti-skid supporting feet, stirring guiding-in frame structures, a connecting cover, classified quantitative guiding-in frame structures, a cutting frame structure, a rotary extruding frame structure, a stirring switch, an extruding switch, a feeding switch, a ball bearing, a transverse plate, an anti-falling hopper and a transverse inserting plate, wherein the transverse connecting frame is mounted on the lower portion of theinner side of the longitudinal mounting frame through bolts; the anti-skid supporting feet are glued to the lower portion of the longitudinal mounting frame; the stirring guiding-in frame structuresare mounted on the upper portion of the longitudinal mounting frame; and the classified quantitative guiding-in frame structures are separately mounted on the upper portion of the connecting cover. According to the concentrated feed making equipment disclosed by the invention, a feeding motor is mounted in the middle of the front side of a circular cover through bolts, and meanwhile, an output shaft is in key connection with the middle of a rotating roller, thus, when the concentrated feed making equipment is used, the feeding motor is convenient to use, the rotating roller drives a T-shaped inserting plate to rotate in the circular cover, and the space of the T-shaped inserting plate is used for realizing quantitative feeding of raw materials.

Owner:利津天普阳光饲料有限公司

Environmentally-friendly sludge treatment device

InactiveCN110746080AQuantitativeControl the feeding speedSludge treatment by de-watering/drying/thickeningWater/sewage treatment apparatusSludgeElectric machine

The invention provides an environmentally-friendly sludge treatment device. The environmentally-friendly sludge treatment device comprises: a box body; a connecting plate, wherein two sides of the connecting plate are fixed to two sides of the inner wall of the box body; a control box, wherein the bottom of the control box is fixed to the top of the connecting plate; and a first motor arranged atone side of the box body through a supporting plate. The environmentally-friendly sludge treatment device can well treat sludge; the first motor is turned on to drive a rotating disc, a straight toothed plate can move left and right, quantification can be well realized, the feeding speed is flexibly controlled, and normal drying of a control box is prevented from being blocked; and a second motoris turned on to make sludge evenly heated in the control box, so the effect of evenly mixing and drying the sludge is achieved, the drying time is greatly shortened, and the drying rate is increased,thereby the practicability of the device is improved.

Owner:榆林市榆阳区水点食品有限公司

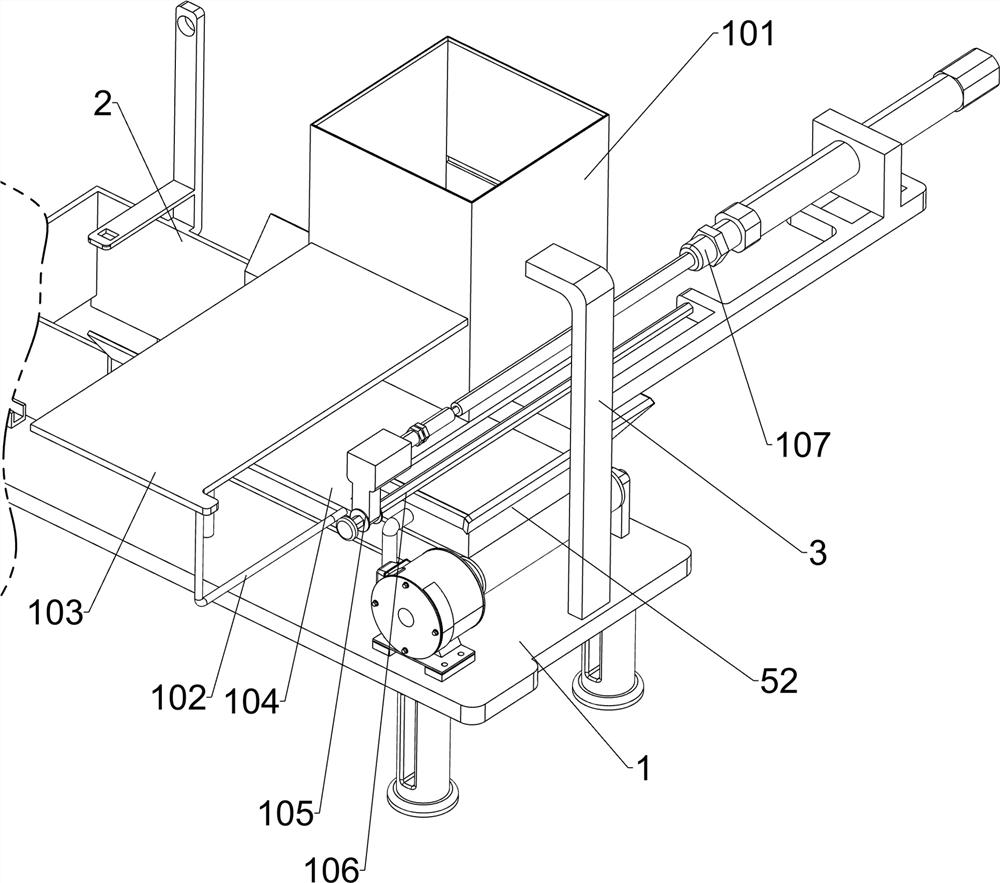

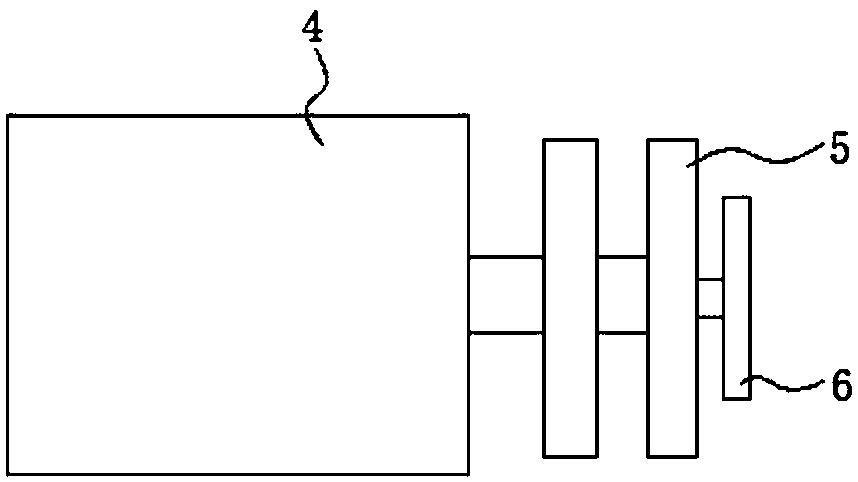

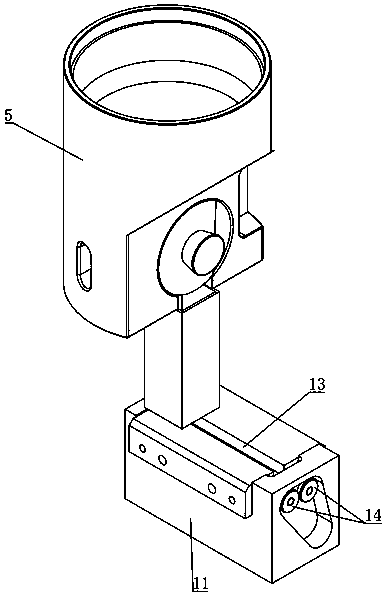

Automatic feeding device of knurling machine

PendingCN109533879ARealize quantitative cuttingHigh degree of automationConveyor partsKnurlingEngineering

The invention discloses an automatic feeding device of a knurling machine. The automatic feeding device comprises a machine frame, a quantitative feeding device and a material conveying device are arranged on the machine frame, the material output end of the quantitative feeding device is connected with the feeding end of the material conveying device, and a workpiece picking and placing device used for transferring a workpiece from the discharging end of the material conveying device to a working position is arranged on the machine frame. The quantitative feeding device, the material conveying device and the workpiece picking and placing device can complete material falling, material conveying and placing of the workpiece into a workpiece clamping device separately, so that automated material feeding is achieved, a manual feeding process is omitted, and thus labor can be further saved and work efficiency can be further improved. The automatic feeding device can be applied to the knurling machine to achieve automatic feeding, and thus the automation degree of the knurling machine can be further improved, work time is shortened and work efficiency is improved.

Owner:SHANDONG VFOOK GOLD IND JEWELRY

Solar heat collection glass tube cutting and collecting integrated device

InactiveCN112142314AQuality assuranceRealize hanging and fixingGlass severing apparatusPhysicsEngineering

The invention discloses a solar heat collection glass tube cutting and collecting integrated device, which comprises a vertical supporting plate, wherein an electric push rod is arranged on the frontside of the vertical supporting plate, a push bushing is fixedly connected to the right end of an output shaft on the electric push rod, a first transmission rod is slidably connected to the inner wall of the push bushing in a limited mode, a sliding block is fixedly connected to the rear side of the first transmission rod, an inclined sliding groove allowing the sliding block to slide is formed in the front side of the vertical supporting plate, and a lifting plate is arranged on the front side of the vertical supporting plate. According to the invention, through cooperative use of the structures, the problems that in the actual use process, due to the fact that when a traditional blanking knife conducts impact cutting on a glass tube, accidental damage of the glass tube is extremely likely to be caused, the cutting effect of the glass tube is uneven, the quality is difficult to standardize and guarantee, and when the cut glass tubes are collected, the glass tubes are easily broken, and inconvenience is brought to use are solved.

Owner:季文婷

3D printing material pretreatment device capable of improving smoothness

InactiveCN112497749AImprove smoothnessAvoid stickinessAdditive manufacturing apparatusManufacturing material handling3d printStructural engineering

The invention discloses a 3D printing material pretreatment device capable of improving smoothness. The 3D printing material pretreatment device comprises an outer box body, a rack, a motor, a first bevel gear, a second bevel gear and a hot melting box. A feeding inlet is formed in the top of the outer box body, and a collecting box is arranged in the outer box body. A fixing piece is mounted on the outer wall of the collecting box, and the rack is arranged on the outer wall of the fixing piece and connected with a first connecting gear in an engaged mode. A discharging pipe is arranged at thetop of a grinding box, and a through groove is formed in the discharging pipe. A pressing plate is connected to the outer wall of a reciprocating lead screw, and a pressing block is arranged on the pressing plate. According to the 3D printing material pretreatment device capable of improving smoothness, the through groove is formed in the discharging pipe, and the size of the through groove is matched with that of a groove in the bottom of the collecting box; and when the groove and the through groove are superposed, materials can fall, and when the groove and the through groove are staggered, the materials cannot fall, and thus, quantitative discharging of the materials can be achieved.

Owner:谭世昌

Feed feeding device for beef cattle breeding

The invention discloses a feed feeding device for beef cattle breeding. The device comprises: a feeding trough, wherein one side of the feeding trough is provided with an opening, the other side of the top of the feeding trough is fixedly connected with a feeding pipe, one end of the feeding pipe is connected with a hose, one end of the hose is connected with a discharging pipe, the middle of the discharging pipe is hinged to the feeding trough. A pull rope is pulled through a piston rod of an electric telescopic rod, the other end of the pull rope pulls the discharging pipe to rotate clockwise, then a telescopic discharging pipe drives a sliding plate to slide inwards on the bottom face of a fixing plate due to the gravity effect, and the telescopic discharging pipe retracts inwards into the feeding trough; in the process that the piston rod drives a lifting plate to move upwards, the connecting rod on the lower side is blocked by a blocking plate, and therefore, the connecting rod rotates anticlockwise, then the sealing baffle moves towards the outer side, the sealing baffle is ejected by a push rod to expand outwards to fill the opening, and then the opening is sealed. Thus, the situation that livestock arbitrarily may destroy a discharging mechanism when feeding is stopped can be prevented.

Owner:湖南振鑫农业科技有限公司

Unpowered natural powder discharging device

ActiveCN103241482ASolve the blockageRealize quantitative cuttingLarge containersStructural engineeringMechanical engineering

The invention provides an unpowered natural powder discharging device. The unpowered natural powder discharging device comprises a discharging cone port arranged at the bottom of a storage bin and provided with a gate and is characterized in that the middle of the discharging cone port is connected with a bottom ring through transverse support wing plates arranged at intervals and then is connected with a middle ring and a top ring at intervals from bottom to top through vertical support rods arranged on an outer wall of the bottom ring at intervals, and a top cover is connected onto the top ring. The unpowered natural powder discharging device does not need any power when normally operates, can completely perform natural discharging by relying on self weight of materials, arch erecting probability is remarkably reduced, and the problem that an arch is blocked due to quick single-point contraction in the prior art is solved thoroughly. The unpowered natural powder discharging device is simple and exquisite in structure and quick and convenient to install and maintain, and achieves quantitative blanking of power materials.

Owner:陈立明

Hot fix device for pattern decoration process

InactiveCN112442910AImprove stabilityRealize quantitative cuttingTextile decorationTextile printerRolling paper

The invention relates to a hot fix device, in particular to a hot fix device for a pattern decoration process. The hot fix device for the pattern decoration process can achieve automatic diamond pasting and prevent fingers of workers from being scratched in the operation process. The hot fix device for the pattern decoration process comprises a base, first supporting rods, an inertia vibration mechanism and a tilting mechanism, wherein a mounting block is arranged on one side of the top of the base; the first supporting rods are symmetrically arranged on the side, close to the mounting block,of the top of the base; the inertia vibration mechanism is arranged on one side of the top of the base; and the tilting mechanism is arranged at the top of the mounting block, and the tilting mechanism is matched with the inertia vibration mechanism. A worker puts a diamond inlaying bottom drawing on the top of a workbench, round diamonds are spread on the surface of the diamond inlaying bottom drawing, a double-shaft motor is started, then the workbench is driven to continuously vibrate to enable the round diamonds to be evenly inlayed on the surface of the bottom drawing, a servo motor is started, and then the effect that printing roll paper covers the surface of the diamond inlaying bottom drawing on the top of the workbench to paste the round diamonds is achieved.

Owner:刘金兰

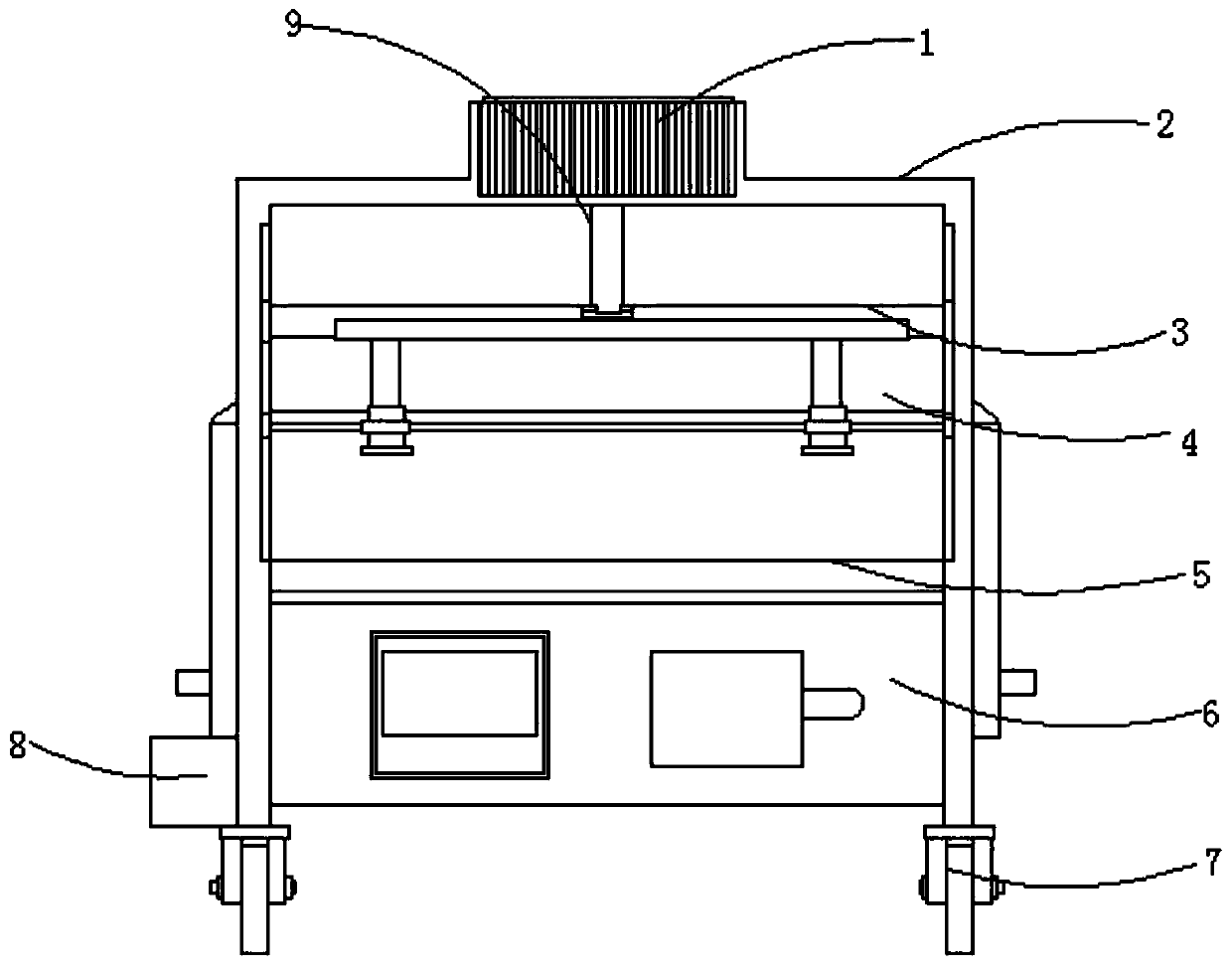

Feeding device for dryer

PendingCN113551515AAvoid wastingHigh degree of automationDrying solid materialsFood treatmentAgricultural engineeringAgricultural science

The invention relates to the technical field of dryers, in particular to a feeding device for a dryer. The feeding device comprises a drying device, the drying device comprises a feeding box, a driving mechanism, a drying box and a box door, the driving mechanism is clamped on the outer surface of the feeding box, and the drying box is fixedly connected to the lower surface of the feeding box. The left and right side faces of the drying box are fixedly connected with box doors through pin shafts, and the face, away from the inner wall of the feeding box, of the driving mechanism is fixedly connected with a quantitative protection device. The device is provided with a rotating roller, a jacking force spring and a protective sleeve, fruits and vegetables poured into the feeding box can be conveyed in a separated manner, a large number of fruits and vegetables are prevented from colliding in the discharging process, meanwhile, quantitative discharging can be achieved, the fruits and vegetables are evenly discharged, and the situation that the fruits and the vegetables extrude one another in the discharging process to cause blockage is prevented; and the discharging effect is guaranteed, and manpower is saved.

Owner:吴明康

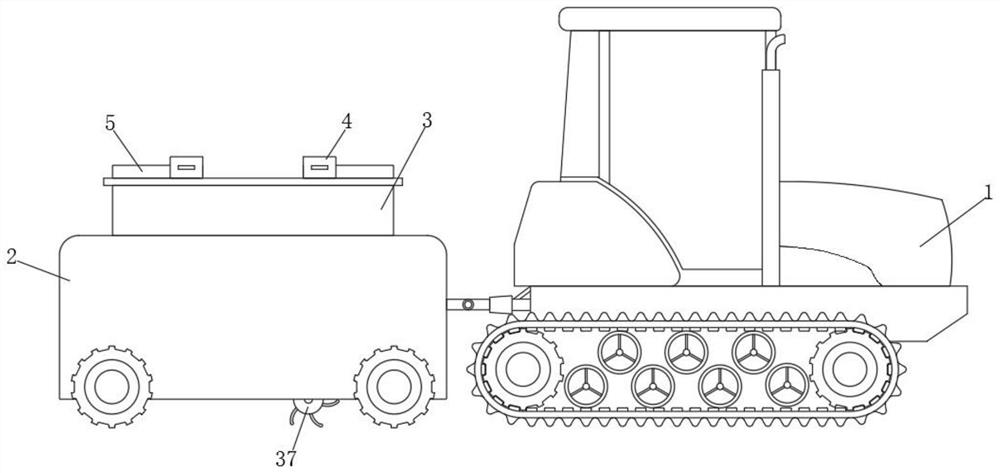

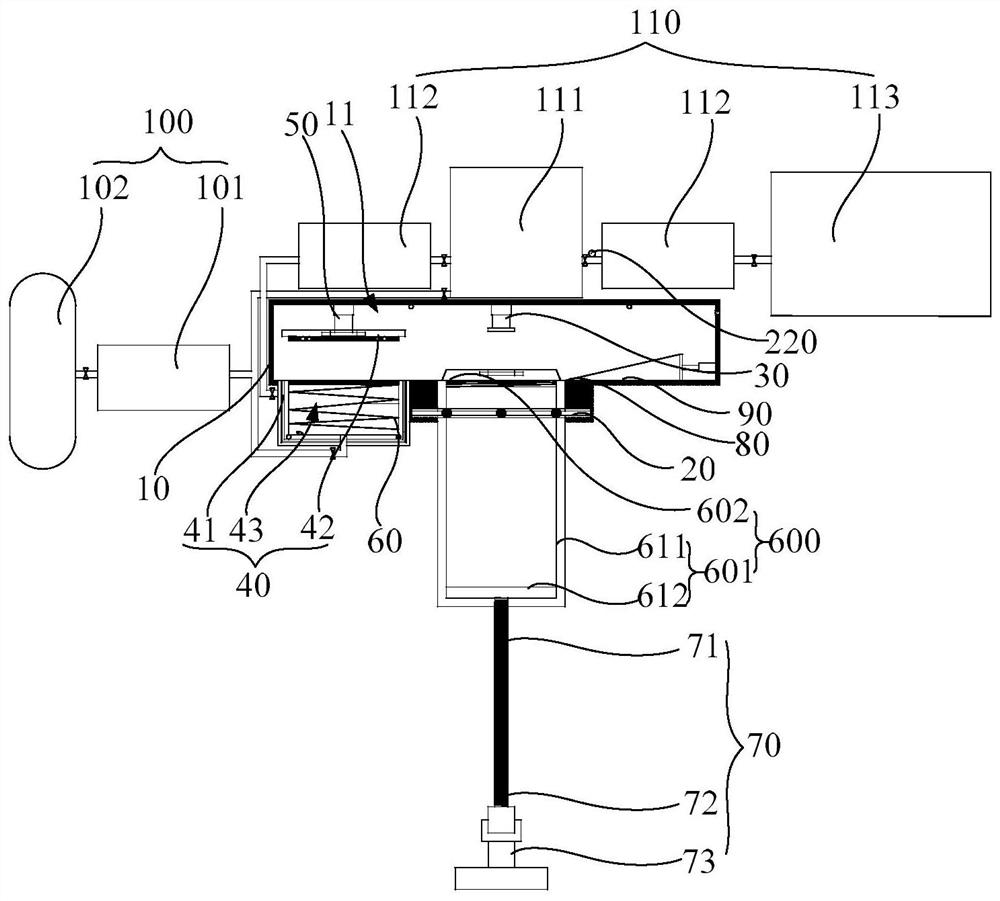

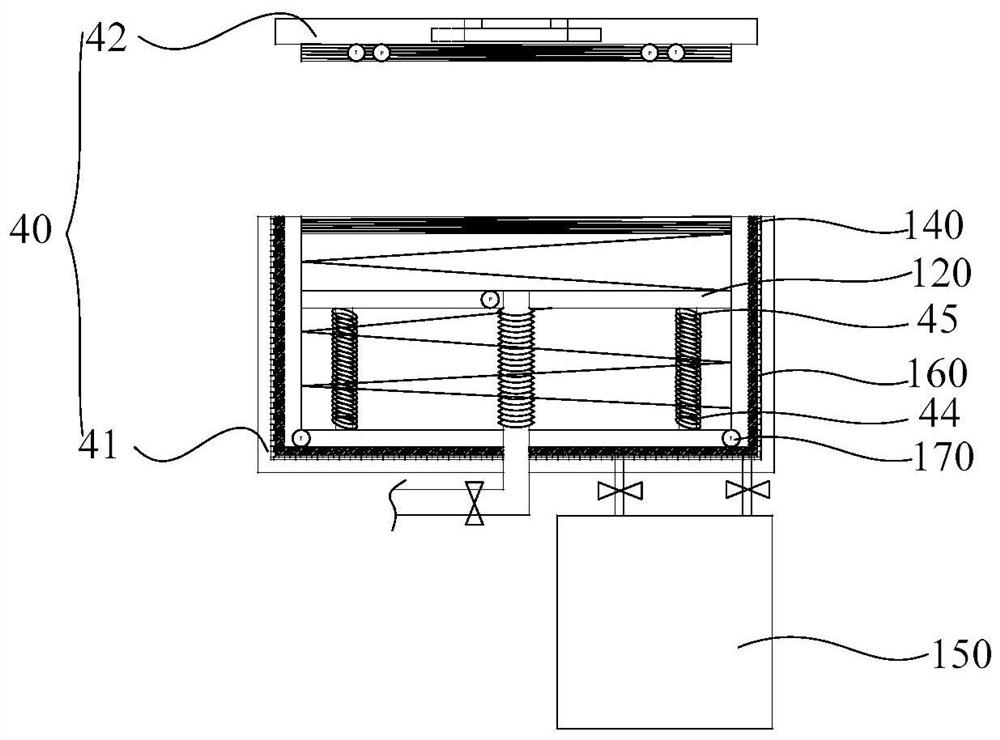

Remediation agent preparation device for soil remediation

ActiveCN114260309AFacilitate mixed reactionsPromote interactionContaminated soil reclamationGrain treatmentsSoil remediationEngineering

The invention discloses a preparation device of a remediation agent for soil remediation, and relates to the technical field of soil remediation, the preparation device comprises a trailer, a box body, a first material separation groove and a second material separation groove, the box body is installed at one end of the trailer, the first material separation groove is installed at the top of the box body, and the second material separation groove is installed in the first material separation groove; the solid quantitative dosing mechanism and the liquid quantitative dosing mechanism are mounted on the first material separation groove and the second material separation groove, so that a worker can conveniently mix and prepare a medicament on to-be-remediated soil in time, the prepared medicament can timely exert the efficacy, meanwhile, the worker can conveniently mix and react a solid medicament and a liquid medicament, and the remediation efficiency is improved. And the first material separation groove and the second material separation groove form two relatively independent reaction grooves, so that mutual reaction between the agents is facilitated, and the situation that part of reactants in the agents influence each other due to the fact that the agents are added into the reaction grooves at a time, and the pesticide effect of the soil remediation agent is reduced is avoided.

Owner:张友超

A vertical intermittent powder material dilute phase injection conveying device

ActiveCN112718299BAvoid cloggingImprove jet release efficiencyFertiliser distributersBulk conveyorsInjection portEngineering

The invention provides a vertical intermittent powder material dilute-phase injection conveying device, which includes a storage hopper, the outlet at the lower end of the storage hopper is connected to the upper end of a sealing valve, the lower end of the sealing valve is connected to a spray tank, and the spray tank is arranged for The air inlet a of the pressurized air source is connected, and the injection conveying device also includes an injection piece arranged in the injection tank, a fan blade is arranged on the upper side wall of the injection piece, and the injection piece part where the fan blade is set rotates and is fixed on the In the injection part casing, the air inlet a is connected to the injection part casing through a conduit, the injection port is provided at the lower end of the injection part, and the channel connecting the inside of the injection part casing and the injection port is arranged in the injection part, and the lower end of the injection part faces the spray tank. The position of the outlet at the lower end forms a Venturi structure, and a stirring member is arranged on the lower side wall of the injection member. The spray conveying device can effectively enhance the anti-blocking, anti-arching and anti-residue capabilities of material injection, reduce manual work, and improve the injection release efficiency of dilute phase materials.

Owner:重庆天本地源科技有限公司

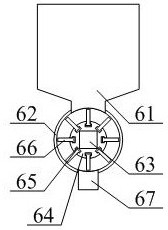

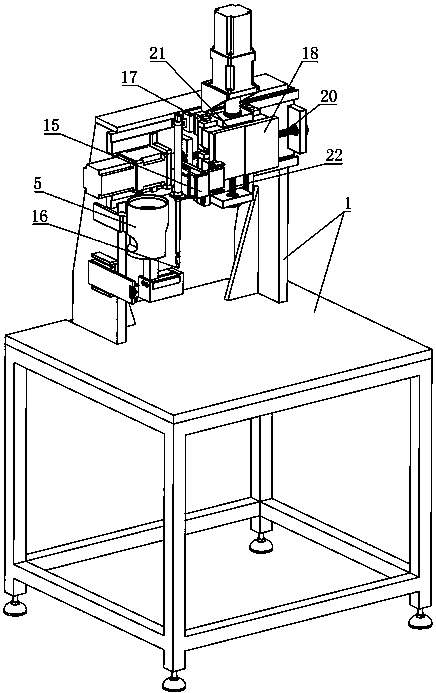

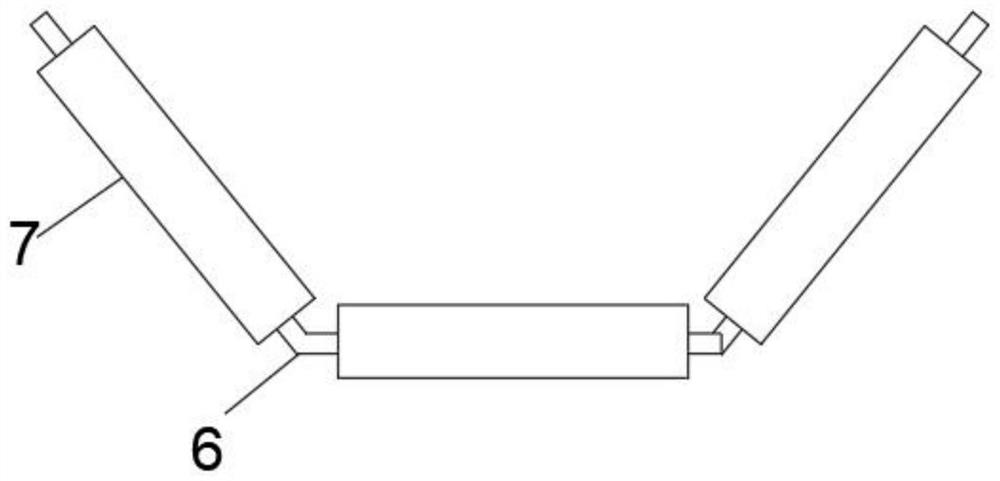

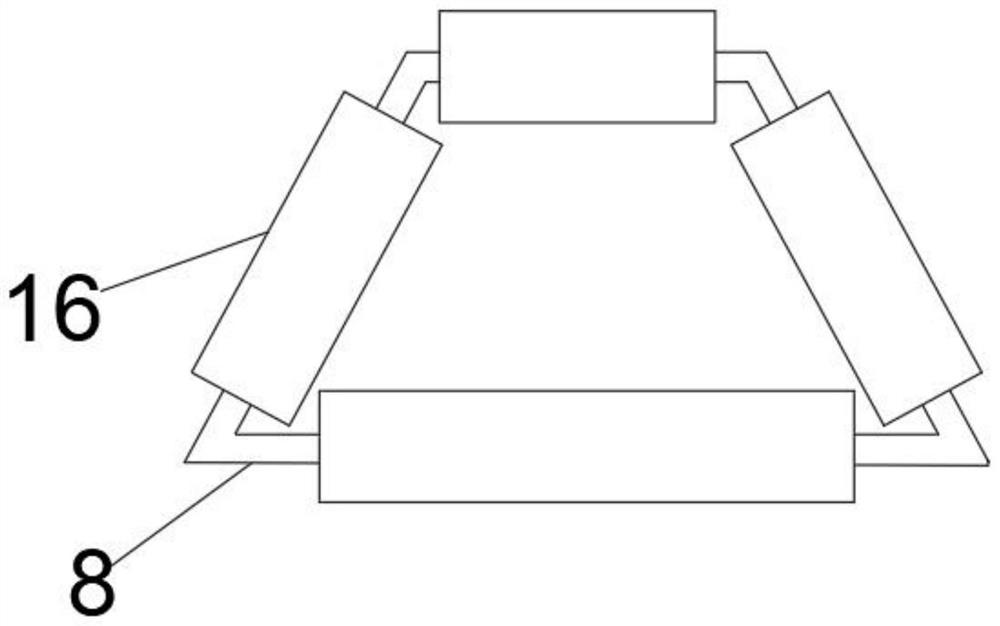

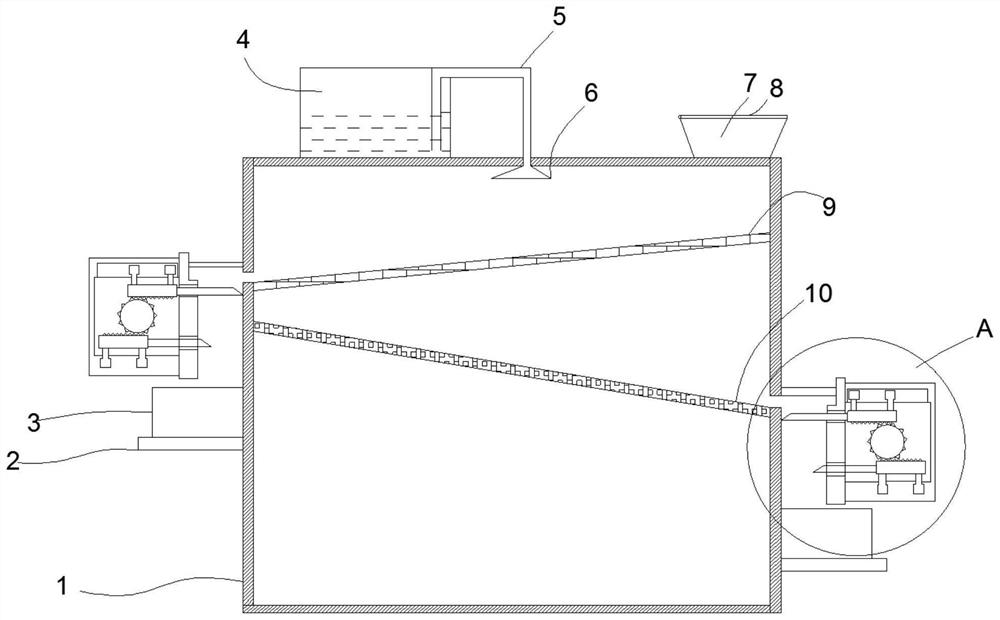

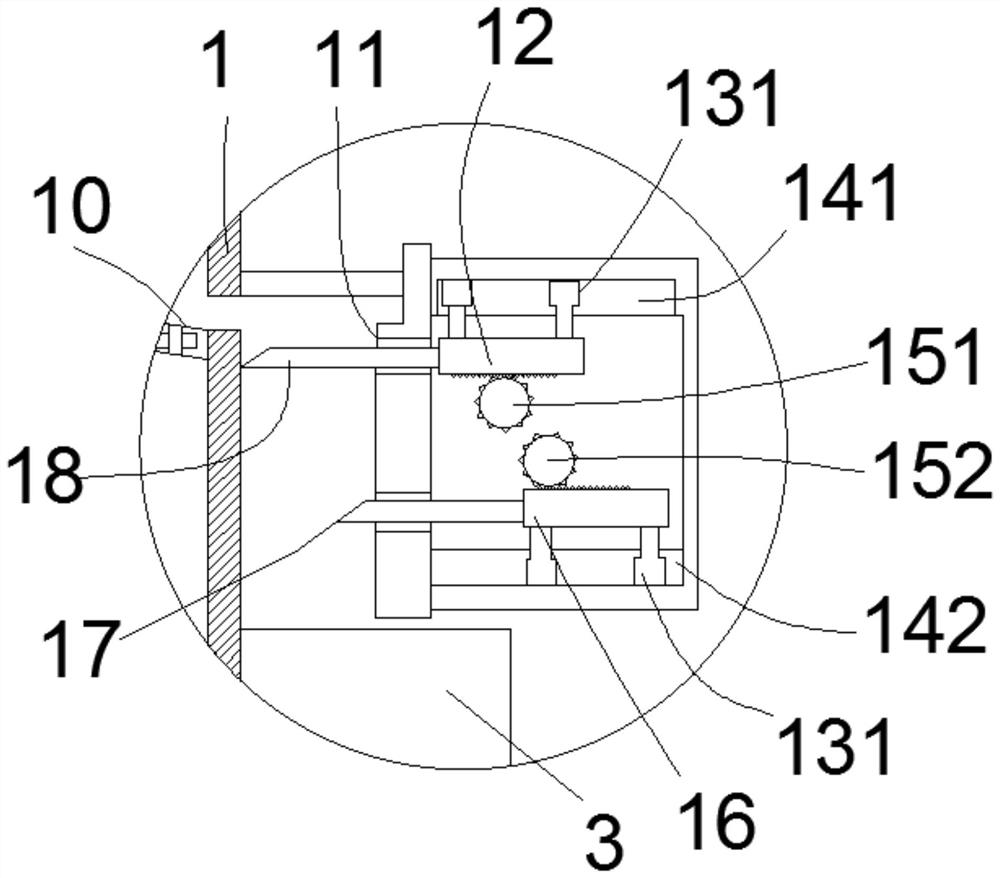

Environment-friendly and efficient grading machine

InactiveCN113954248AEnclosed spaceRealize the effect of blocking rainwaterConveyorsMixing operation control apparatusConveyor beltIndustrial engineering

The invention discloses an environment-friendly and efficient grading machine. The environment-friendly and efficient grading machine comprises a lower conveying belt and an upper conveying belt. The lower conveying belt comprises a C-shaped conveying part and an O-shaped conveying part; the upper conveyor belt covers the upper part of the C-shaped conveying part; a plurality of feeding ports are inserted between the lower conveying belt and the upper conveying belt and communicate with a plurality of quantitative discharging structures correspondingly. The environment-friendly and efficient grading machine has the advantages that the structure is simple; the use is convenient; and materials can be effectively prevented from overflowing or being washed away by water in the grading process, so that the device does not need to be mounted in a plant, the space of the plant is saved, and the environment-friendly requirement is met.

Owner:怀化明达建材有限公司

Vertical intermittent powder and particle material dilute phase jet conveying device

ActiveCN112718299AImprove anti-blockingEnhanced anti-archingFertiliser distributersBulk conveyorsPhysicsEngineering

The invention provides a vertical intermittent powder and particle material dilute phase jet conveying device. The vertical intermittent powder and particle material dilute phase jet conveying device comprises a storage hopper, wherein a discharging port in the lower end of the storage hopper is connected with the upper end of a sealing valve; the lower end of the sealing valve is connected with a jet tank; the jet tank is provided with an air inlet a used for being connected with a pressurization air source; the jet conveying device further comprises a jet piece arranged in the jet tank; fan blades are arranged on the side wall of the upper portion of the jet piece; the portion, provided with the fan blades, of the jet piece is rotationally clamped in a jet piece shell; the air inlet a is connected into the jet piece shell through a guide pipe; a jet opening is formed in the lower end of the jet piece; a channel communicating the interior of the jet piece shell with the jet opening is formed in the jet piece; the lower end of the jet piece faces the discharging port in the lower end of the jet tank and forms a Venturi structure; and a stirring piece is arranged on the side wall of the lower portion of the jet piece. By means of the jet conveying device, the anti-blocking, anti-arching and anti-residue capacity of material jet can be effectively enhanced, manual work is reduced, and the jet release efficiency of dilute phase materials is improved.

Owner:CHENGDU TOBEST DIYUAN TECH CO LTD

An integrated cooling tin bar extruder

ActiveCN112974559BRapid coolingEffective cooling functionDrying solid materials without heatHydraulic cylinderSolenoid valve

The invention relates to the technical field of extruders, in particular to an integrated cooling type tin bar extruder, including an extruder, which includes a worktable, an extruded material, a processor, two solenoid valves, and a workbench One side of the board is fixed with a water box, one side of the water box is equipped with a cooling box, and the two sides away from the cooling box are fixed with an L-shaped connecting frame, and one side of the L-shaped connecting frame is fixed with one side of the water box There are a number of cooling holes on one side of the cooling box, and cooling pipes are fixed inside the cooling holes. In the present invention, by setting a water receiving box, a cooling box, a cooling pipe, a water pump, a water tank, a cooling device, a cutting seat, a knife seat, a hydraulic cylinder, a cutting knife, an L-shaped sliding frame, a touch switch, a spring, a U-shaped frame, Guided damping device, U-shaped sliding frame, and automatic reset device enable it to have functions such as rapid cooling, circulating cooling, automatic cutting, length adjustment, and continuous cutting.

Owner:深圳市绿色千田锡业科技有限公司

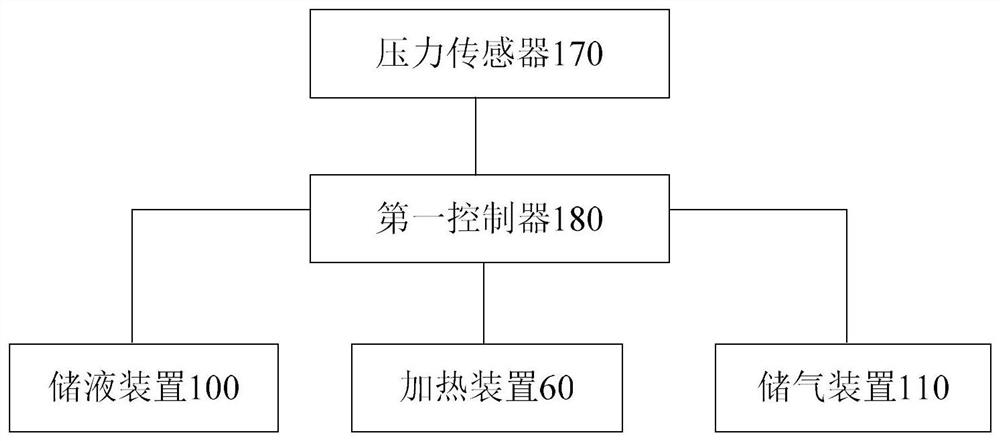

A decomposition device and constant temperature decomposition system for ngh used in gas filling stations

ActiveCN112226258BGuaranteed stabilityEnsure safetyGaseous fuelsMetal working apparatusDecompositionPetroleum engineering

The application provides a decomposition device and constant temperature decomposition system for NGH, wherein the decomposition device includes: a housing, a sealing device, a first opening device, a decomposition kettle, a second opening device, a heating device, a pushing device, a dividing device, a pushing device, liquid storage device and gas storage device. The sealing device is sealed and connected with the storage tank to form a sealed space in the housing; the first opening device opens the storage tank, and the pushing device pushes part of the natural gas hydrate into the housing; the dividing device cuts the natural gas hydrate, and the pushing device hydrates the cut natural gas hydrate Push the material into the decomposition kettle; then the second opening device closes the decomposition kettle to form a closed space in the decomposition kettle, and the heating device heats the decomposition kettle to decompose the natural gas hydrate into liquid and natural gas. In the decomposition device provided by this application, since the division and decomposition of natural gas hydrate are carried out in the casing and decomposition tank, the natural gas hydrate treatment process will not be affected by external environmental factors.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Packaging machine

The invention discloses a packaging machine. The packaging machine comprises a packaging machine main body. A sieve plate and a baffle are arranged in the packaging machine main body. The sieve plateis obliquely arranged. A discharging mechanism is arranged at the tail end of the sieve plate and comprises a toothed disc, an upper toothed plate and a lower toothed plate. The toothed disc is fixedly connected to the output end of a motor. The toothed plates are engaged with the toothed disc. An upper cutter is fixedly connected to one end of the upper toothed plate. A lower cutter is fixedly connected to one end of the lower toothed plate. The motor drives the toothed disc to rotate so as to drive a rack to move, and therefore the feeding of the upper cutter and the lower cutter is achievedunder the driving of the rack, quantitative discharging of materials is achieved, and packaging is more efficient.

Owner:JIANGXI ZHONGSHAN PHARMA IND

Damping type building mortar stirring equipment

PendingCN114030084AAvoid uneven qualityRealize the shock absorption effectCement mixing apparatusVibration suppression adjustmentsStructural engineeringMechanical engineering

The invention relates to stirring equipment, in particular to damping type building mortar stirring equipment. The invention mainly provides damping type building mortar stirring equipment which is suitable for families and can replace manpower to stir gravel and a solution. The damping type building mortar stirring equipment comprises a supporting base, a stirring box, an observation window, a discharging port, lifting tables, lifting frames and first springs. The stirring box is arranged at the top of the supporting base. The observation window is arranged in the middle of the stirring box in an embedded mode. The discharging port is formed in the bottom of the front side of the stirring box. The lifting tables are arranged on the front side and the rear side of the upper portion of the stirring box. The lifting frames are slidably arranged at the tops of the lifting tables, and the first springs are connected between the lifting frames and the tops of the lifting tables. Stirring blades can shake under stress when stirring gravel, a servo motor is driven to move up and down through the elastic force of the first springs, and damping is achieved in cooperation with shaking of the stirring blades.

Owner:徐如涛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com