Environment-friendly and efficient grading machine

A grading machine and high-efficiency technology, which is applied in the direction of conveyors, conveyor objects, batching and batching instruments, etc., can solve the problems of air pollution, easy dispersion into the air, large floor space, etc., and achieve the effect of preventing dust from overflowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

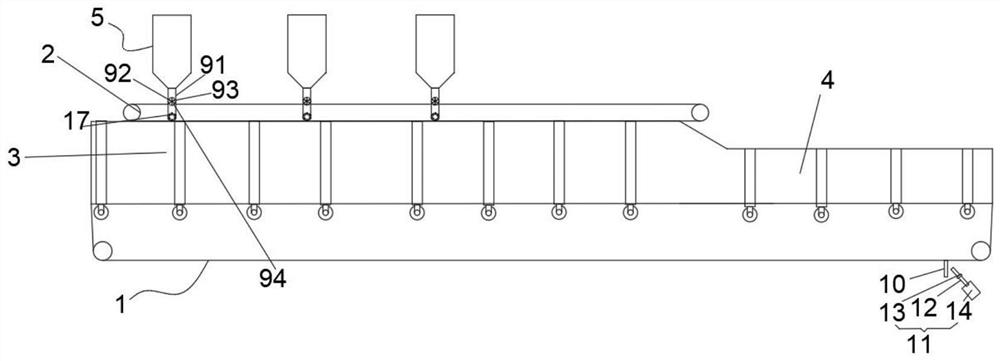

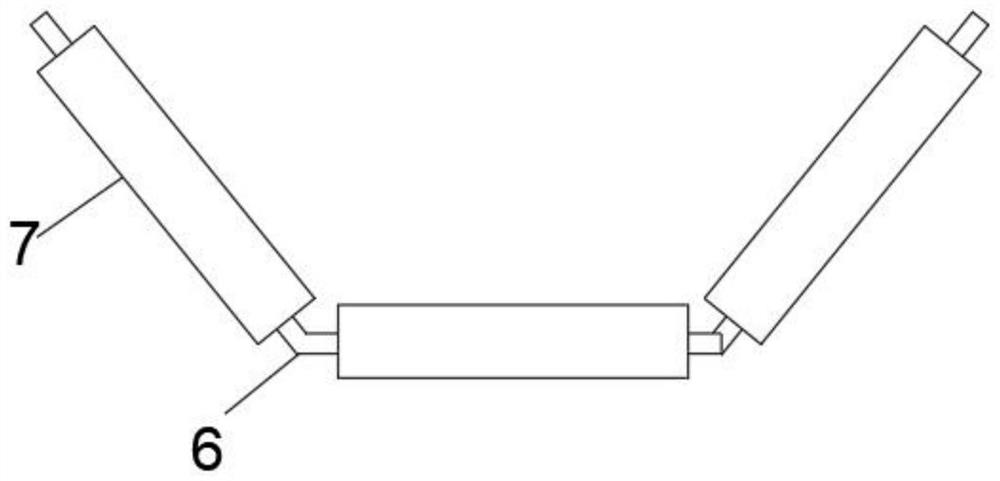

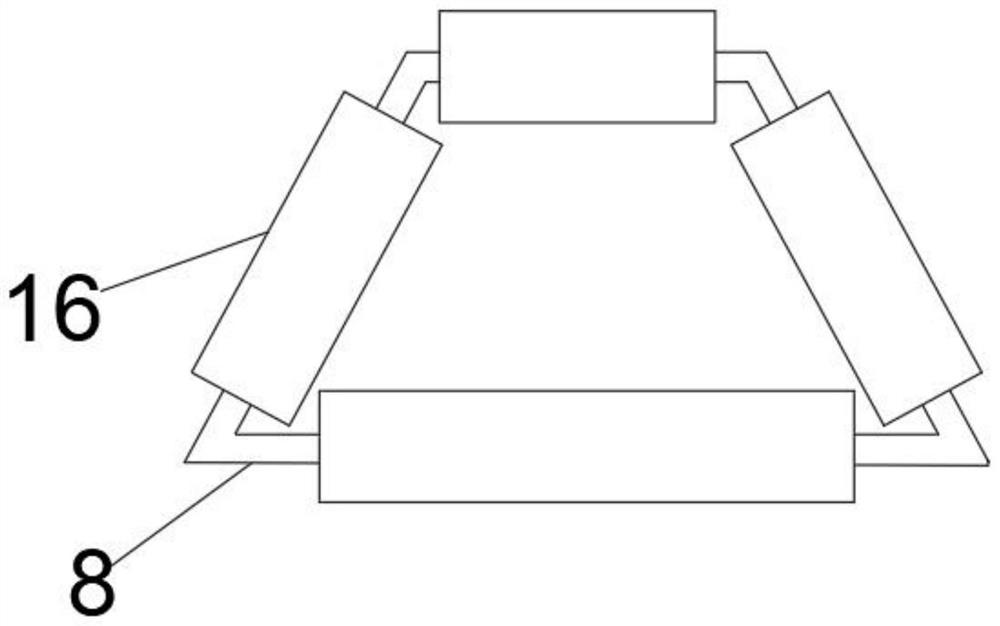

[0024] like Figure 1-Figure 4 An environment-friendly and efficient grading machine shown includes a lower conveyor belt 1, an upper conveyor belt 2, a C-shaped conveyor part 3, an O-shaped conveyor part 4, a quantitative blanking structure 5, a U-shaped conveyor belt rack 6, and a first roller 7 , trapezoidal conveyor belt frame 8, hopper 9, discharge port 91, rotating shaft 92, feeding fan blade 93, quantitative hopper 94, cleaning brush 10, negative pressure dust collection device 11, negative pressure pipe 12, negative pressure pump 13, suction Dust bag 14, bearing 15, second turning roller 16 and material inlet 17.

[0025] The lower conveyer belt 1 comprises a C-shaped conveying part 3 and an O-shaped conveying part 4; the upper conveyer belt 2 is covered above the C-shaped conveying part 3; a number of feeding ports 17 are inserted between the lower conveying belt 1 and the upper conveying belt 2, and the feeding port 17 is connected with several quantitative feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com