Remediation agent preparation device for soil remediation

A preparation device and soil remediation technology, applied in the field of soil remediation, can solve problems such as insufficient contact between agents and soil, and achieve the effect of accelerating the reaction time and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

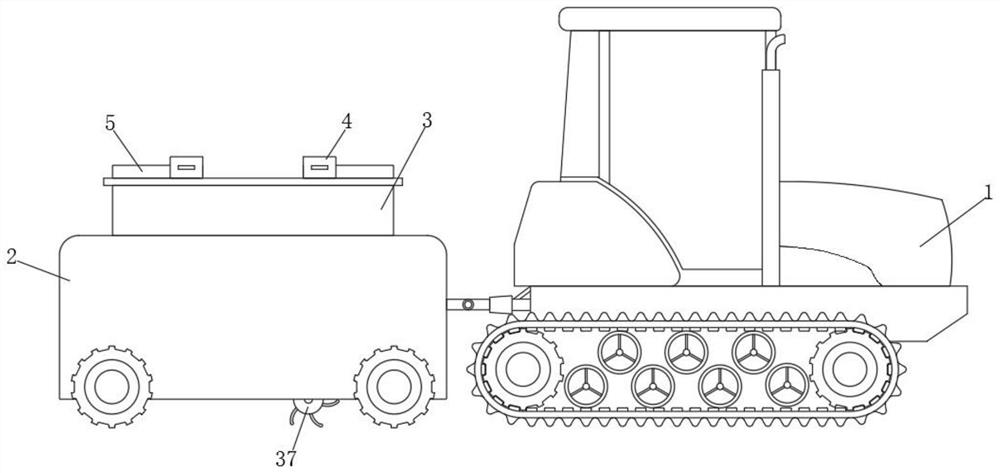

[0044] Such as figure 1 As shown, the entire preparation device for soil remediation is installed at the tail of trailer 1, and trailer 1 uses crawlers to move forward. Similarly, because the entire preparation device for soil remediation lacks traction equipment, the staff can use different types of traction The equipment realizes the movement of the remediation agent preparation device for soil remediation;

[0045] There are several advantages to placing the entire soil remediation agent preparation device on the soil remediation site:

[0046] (1) The staff can sprinkle the prepared soil remediation agent into the soil to be repaired while preparing the soil remediation agent, so as to avoid the inactivation of the biological colonies in the soil remediation agent due to storage, thereby reducing the repair effect of the remediation agent;

[0047] (2) It is convenient for the staff to debug. When some raw materials in the soil remediation agent have a ratio problem, at t...

Embodiment 2

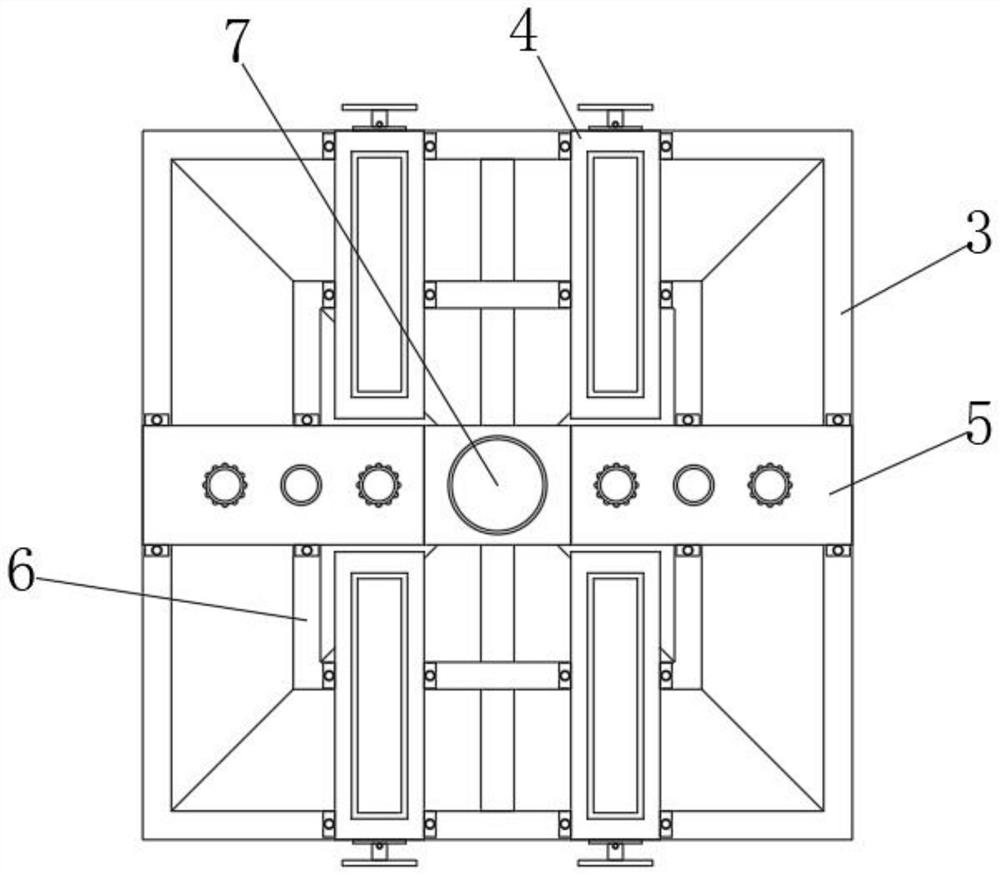

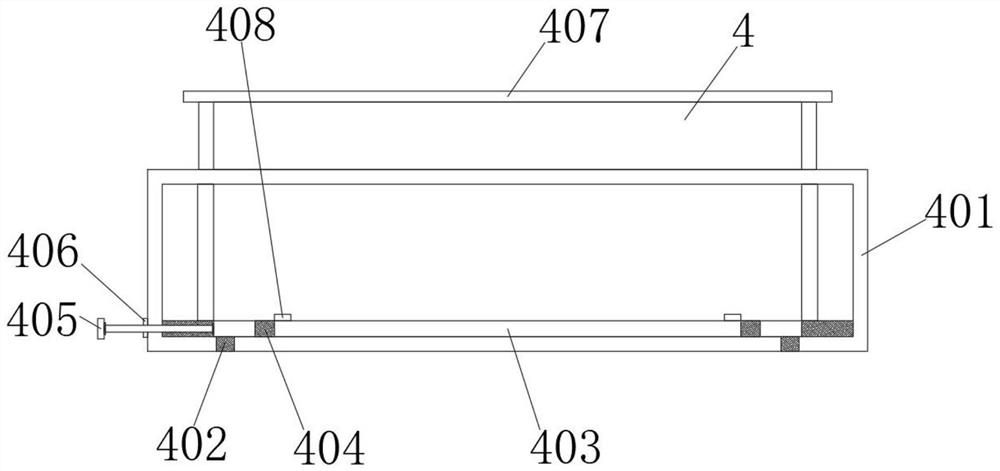

[0054] Such as Figure 7 As shown, the entire raw material enters into the mixing tank 9 along the first material separation tank 3 and the second material separation tank 6, and at this time, the first motor 7 is connected to the first electric push rod 8 and the first electric push rod 8 is connected. The first turntable 10 plays the role of receiving materials, and two groups of stoppers 12 are installed on the side wall of the whole mixing tank 9 simultaneously, as Figure 8 As shown, when the falling raw materials on the first material separation tank 3 and the second material separation tank 6 enter the first turntable 10, the solid and liquid are mixed, and the whole first turntable 10 is equipped with a stirring rod 11, and the first motor 7 Drive the first turntable 10 to rotate, and the stirring rod 11 located on the first turntable 10 starts to stir the solid-liquid raw materials. After the stirring is completed, the first electric push rod 8 at this time is extende...

Embodiment 3

[0058] Such as Figure 10As shown, the rotation of the second motor 20 drives the first rotating shaft 21 to rotate, the first gear 22 and the fifth gear 29 are installed on the entire first rotating shaft 21, and the second gear 23 is installed at the bottom of the entire rotating column 14, and the second gear 23 It is meshed with the first gear 22, and the inner wall of the entire isolation cover 19 is equipped with a third gear 24. The third gear 24 is meshed with the first gear 22, and the third gear 24 is connected with the second turntable 32 outside the box body 2. , a connecting rope 35 is installed on the second turntable 32, and a pulley 34 is also installed on one side of the casing 2. The connecting rope 35 is connected to the ash plate 33 at the bottom of the casing 2 along the pulley 34. When the second turntable 32 rotates , the connecting rope 35 will pull the ash plate 33 to move up and down. When the mixed raw material dropped from the grinding tank 25 falls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com