Chemical reaction kettle

A chemical reaction kettle and kettle body technology, applied in the field of reaction kettles, can solve problems such as affecting the quality of mixing reaction, insufficient mixing reaction, and reducing performance, so as to facilitate subsequent cleaning, reduce accumulation and adhesion, and reduce stress area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

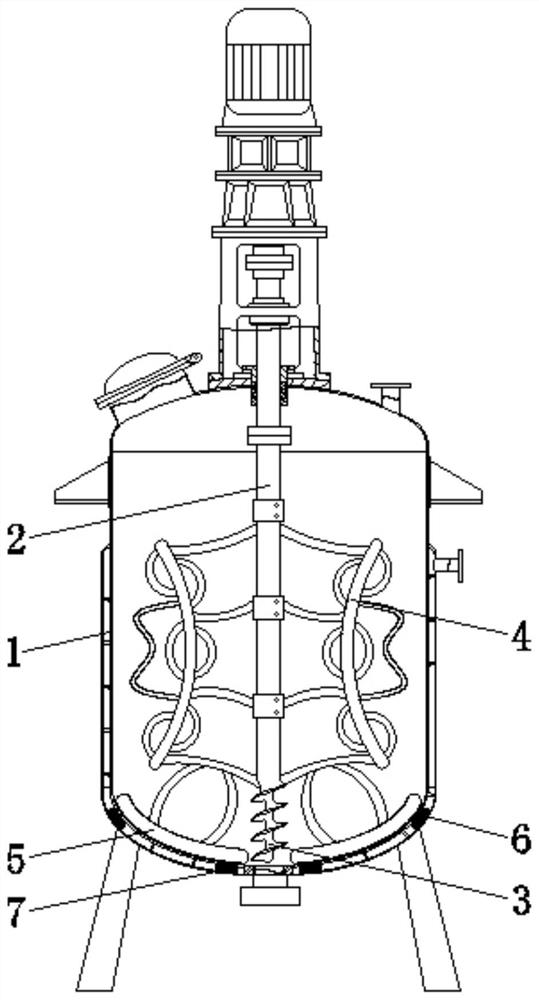

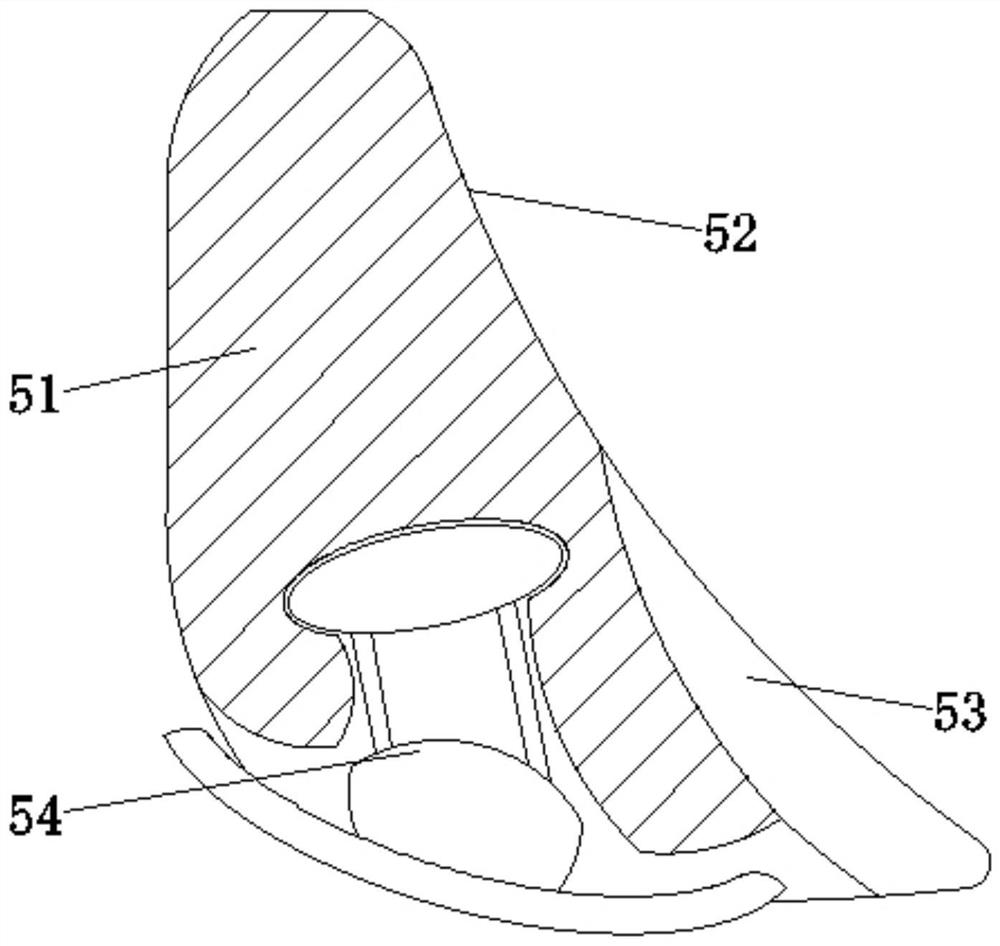

[0034] see Figure 1-7 , the present invention provides a technical solution: a chemical reaction kettle, including a kettle body 1, the interior of the kettle body 1 is provided with a drive shaft 2, a spiral blade 3, an agitator 4, a scraper device 5, a first magnetic block 6, The second magnetic block 7, the driving shaft 2 is connected to the central position of the inner wall top of the kettle body 1, the screw blade 3 is fixed on the bottom end of the driving shaft 2 and near the bottom of the inner wall of the kettle body 1, and the agitator 4 is fixed on the driving shaft 2 The surface of the kettle body 1 is located inside, the scraper device 5 is fixed on the bottom of the stirrer 4 and close to the bottom of the inner wall of the kettle body 1, and the first magnetic block 6 is fixed on the bottom of the inner wall of the kettle body 1 and close to the position of the spiral blade 3 The second magnetic block 7 is fixed on the bottom of the inner wall of the kettle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com