Patents

Literature

304results about How to "Prevent stacking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

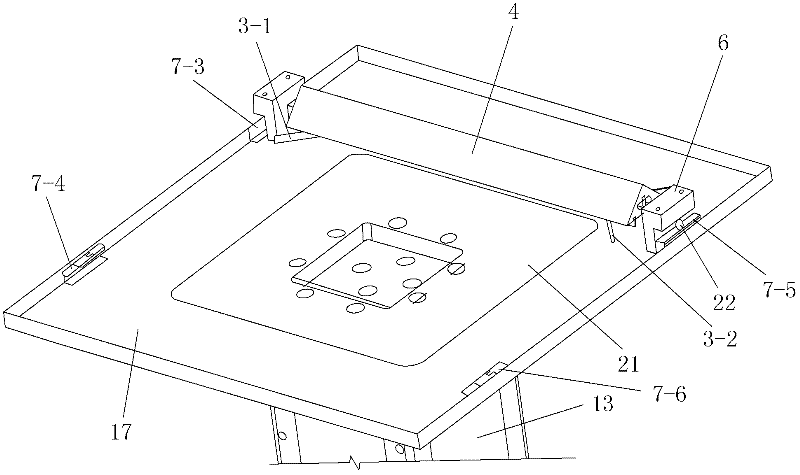

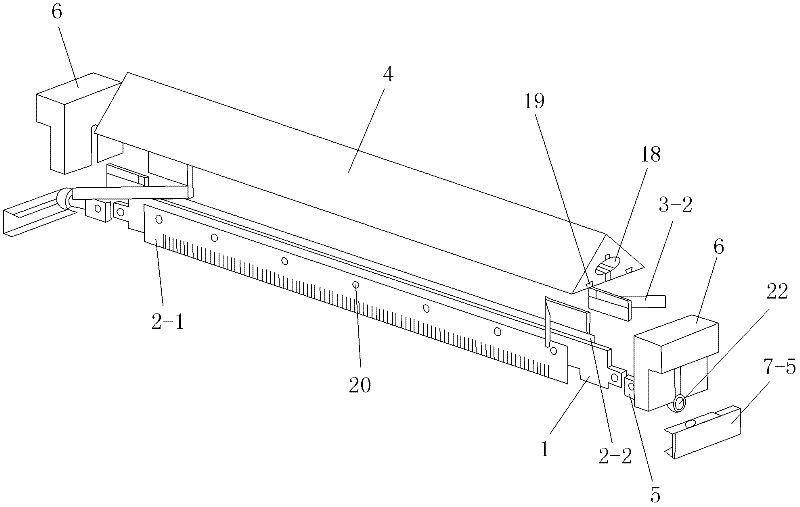

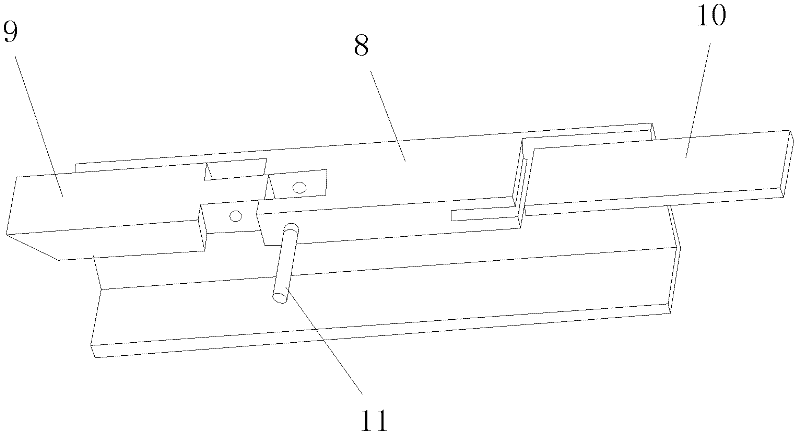

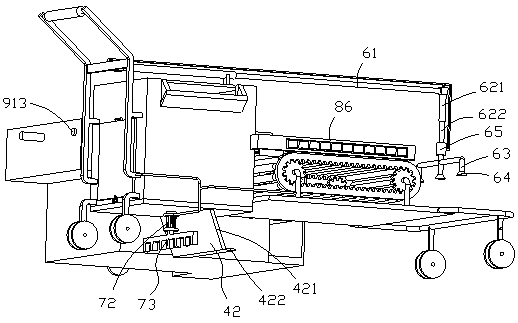

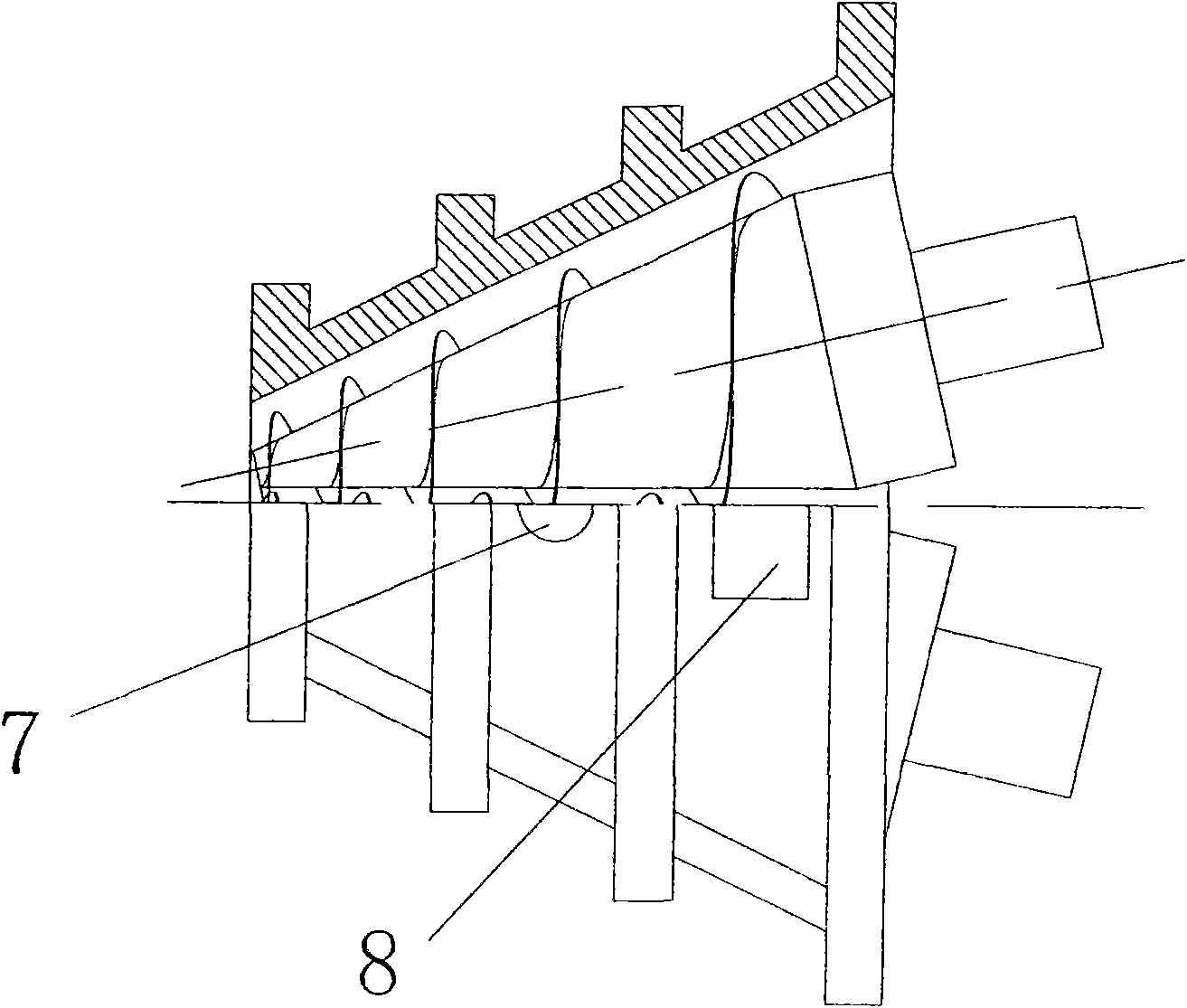

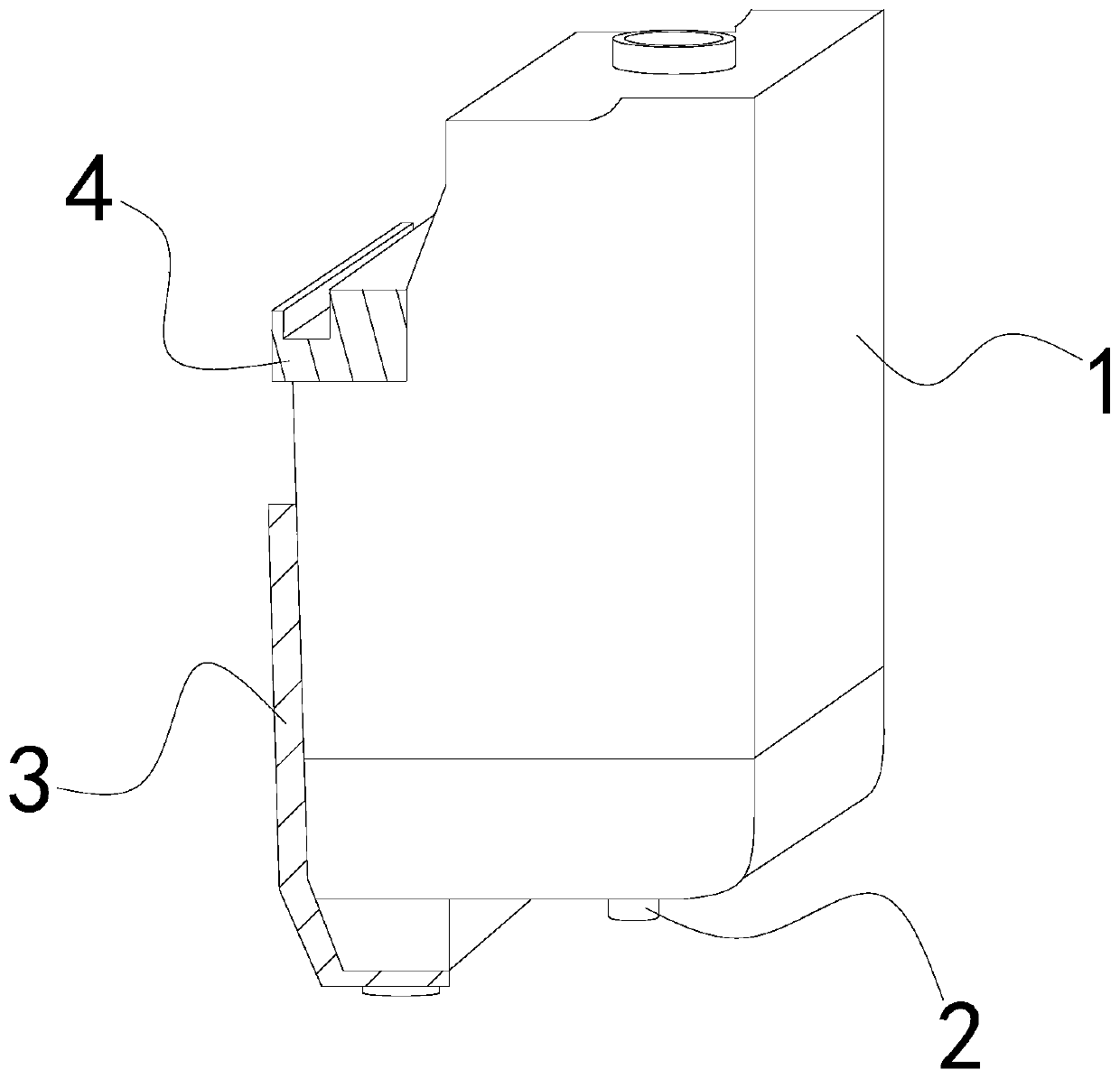

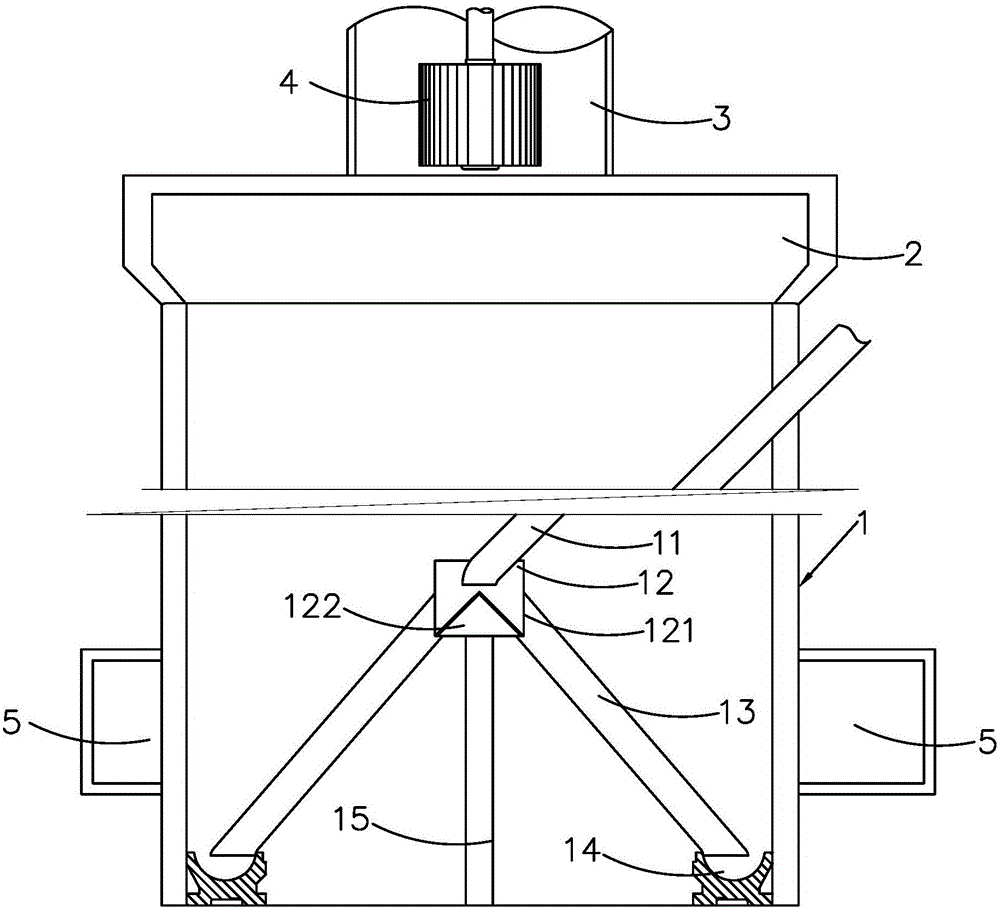

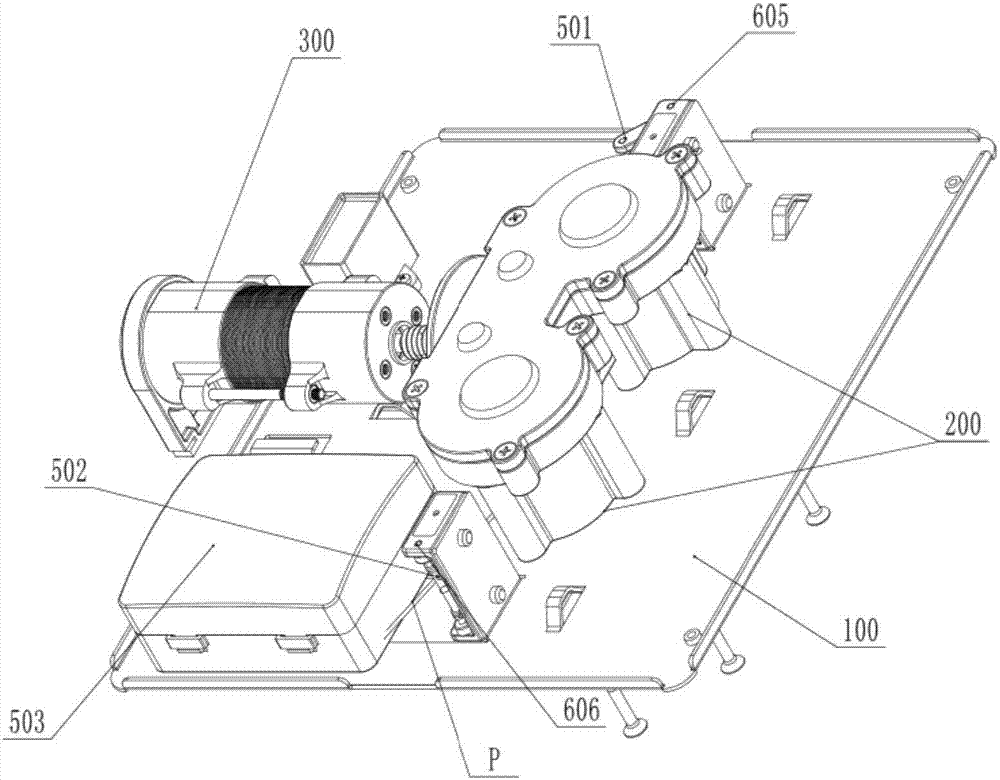

Powder spreading device for rapid forming equipment

The invention discloses a powder spreading device for rapid forming equipment, comprising a moving mechanism, a scraping plate mechanism, a left-side wing and a right-side wing, wherein the moving mechanism does horizontal-linear reciprocating movement back and forth on a forming working platform; the scraping plate mechanism is fixedly arranged at the bottom part of the moving mechanism; the left-side wing and the right-side wing are movably arranged at the left side and the right side of the bottom part of the moving mechanism; the moving mechanism comprises a pushing block, a connecting rod, a left traveling mechanism and a right traveling mechanism, wherein the connecting rod is arranged at the bottom part of the pushing block; the left traveling mechanism and the right traveling mechanism are respectively and symmetrically arranged at the left end part and the right end part; the scraping plate mechanism comprises a front scraping plate and a rear scraping plate which are symmetrically arranged; and both the left-side wing and the right-side wing are splayed side wings II which are consists of two inclined side plates III and can move horizontally towards left and right alongthe scraping plate mechanism. In the powder spreading device, the structure is simple, the assembly and disassembly of all the parts are simple and convenient, the adjustment and control of all the parts are simple and easy, the independent modular working can be realized, the powder spreading is fast, the reliability is high, and the defects of difficult powder confinement, complex structure and difficult adjustment of powder-spreading areas and the like in the existing powder-spreading device can be solved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

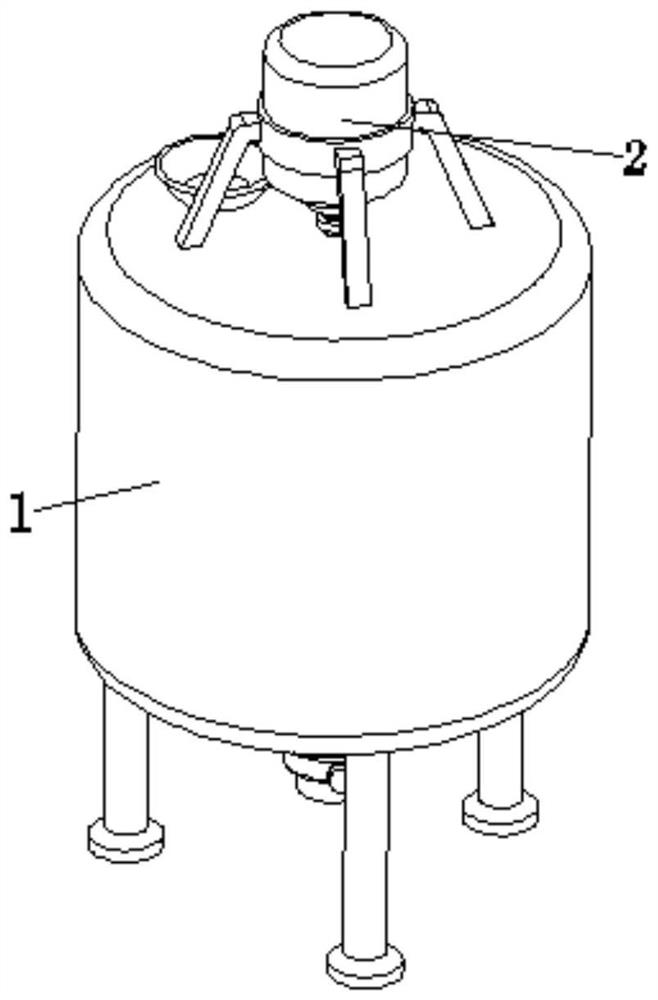

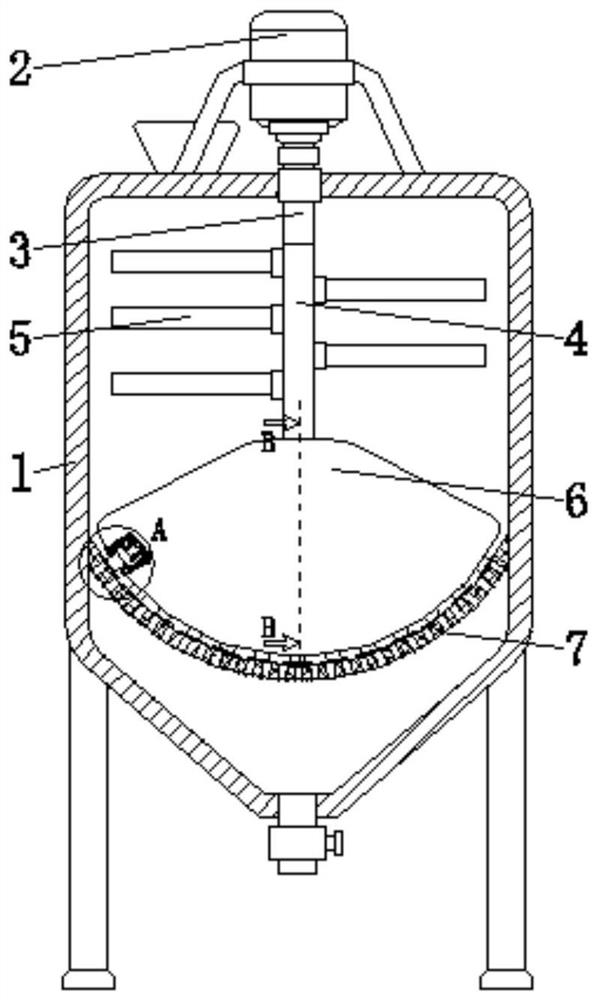

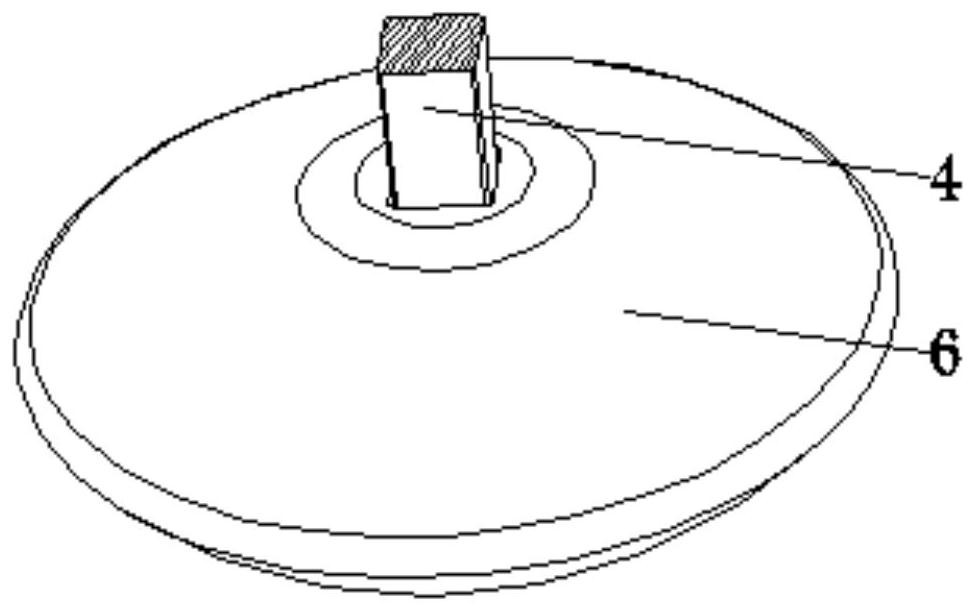

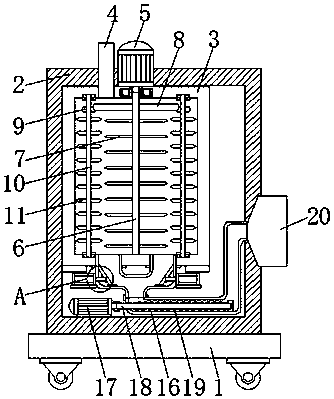

Feed processing equipment

The invention discloses feed processing equipment. The feed processing equipment comprises a grinding tank and a driving motor, wherein a rotating shaft is rotatably connected to the center of the topof the grinding tank; the top end of the rotating shaft is fixedly connected with an output shaft of the driving motor through a coupling; a square connecting rod is fixed to the bottom end of the rotating shaft and located in the center of the interior of the rotating shaft; deflector rods are fixed to the surface of the square connecting rod; a grinding device is arranged at the bottom end of the square connecting rod, the grinding device is in sliding connection with the square connecting rod; and a sieve plate is fixed to the position, close to the bottom of the grinding device, in the grinding tank. The invention relates to the technical field of feed processing. According to the feed processing equipment, the effects of uniform grinding and adhesion prevention are achieved; elasticpressing can be carried out, and the grinding space is automatically and moderately increased, so that large and small granular materials uniformly leak, and grinding is rapid and uniform; and meanwhile, sticky materials on the inner wall can be automatically scraped off, so that the working efficiency and the use performance are improved.

Owner:莱阳和美华饲料有限公司

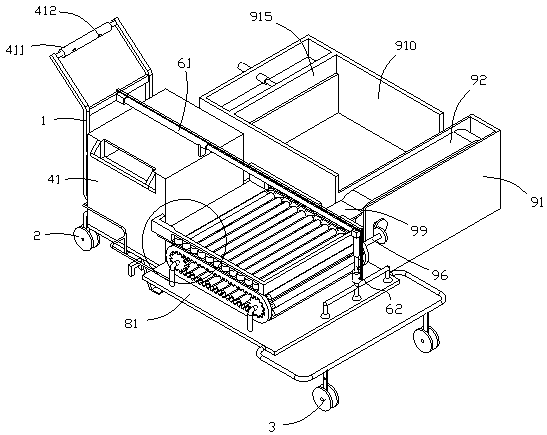

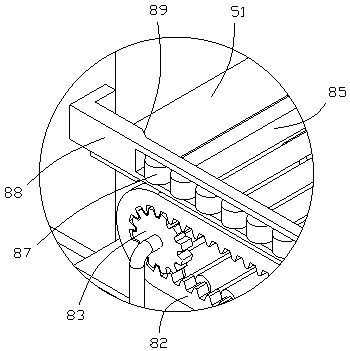

Automatic brick paving equipment for road for highway engineering

InactiveCN110670447AConsistent service lifeImprove flatnessRoads maintainenceVehicle frameArchitectural engineering

The invention discloses automatic brick paving equipment for a road for highway engineering. The automatic brick paving equipment comprises a frame, front wheels, rear wheels, a cement spreading device and a road brick paving device, wherein the horizontal height of each rear wheel is greater than the horizontal height of each front wheel; the cement spreading device is used for flatly spreading cement to the road to form a cement layer on the road, and comprises a cement mixing box, a discharging component arranged on the lower part of the cement mixing box, and a material paving plate arranged on the rear side position of the discharging component; and the road brick paving device comprises a leveling component, a feeding device cooperated with the leveling component, and a paving component cooperated with the leveling component, wherein the leveling component comprises a leveling table arranged on the side wall of the cement mixing box, a conveying component used for conveying roadbricks on the feeding device to the leveling table, and a guidance component arranged on the top position of the conveying component. Road brick pavement in the equipment disclosed by the invention isrealized through automated cooperation among all devices, brick pavement time consumption is short, and working efficiency is high.

Owner:陈楚旋

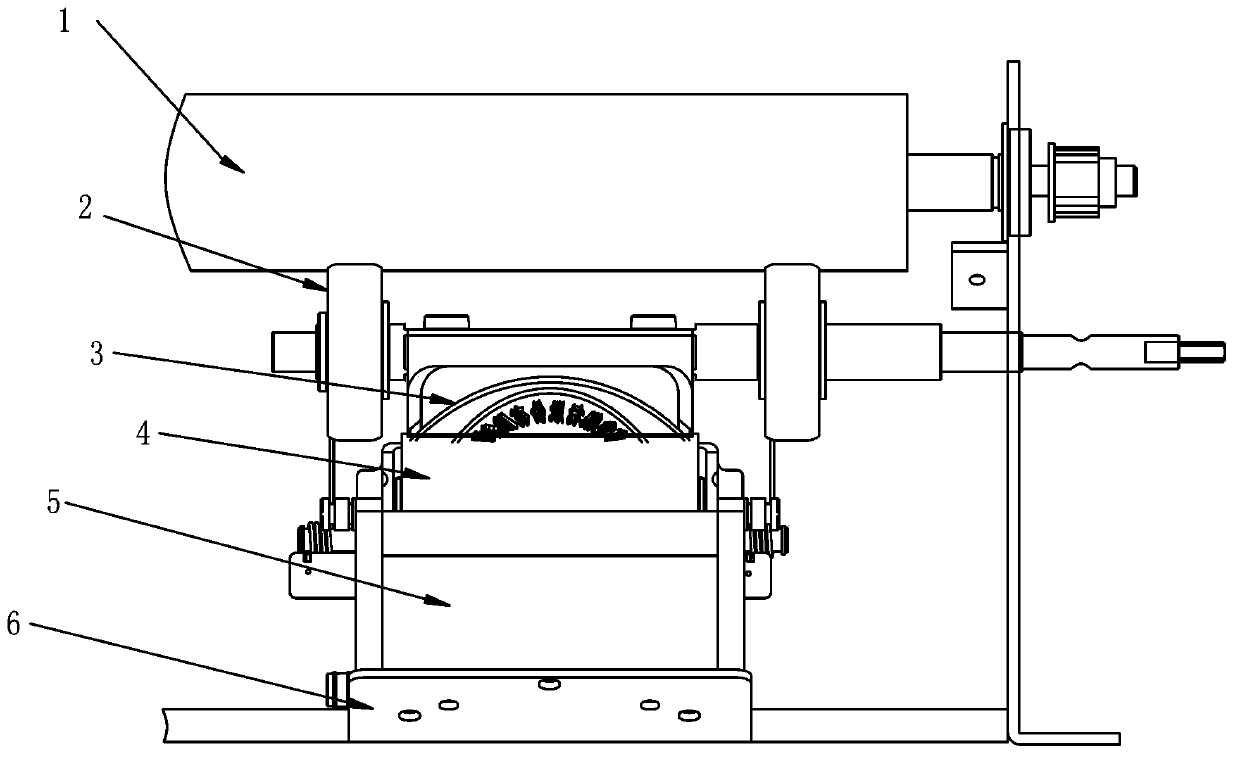

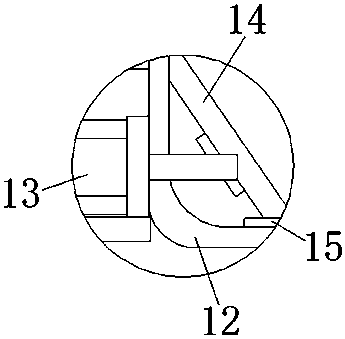

Mechanism for controlling ink of roller stamping machine

ActiveCN103465655AControllable oil contentConditions that do not cause accumulationStampingEngineeringPaper sheet

The invention relates to a mechanism for controlling ink of a roller stamping machine. An ink box mechanism comprises an ink box base; a sponge wheel, a printing pad, sponge oil adsorption pillars and a printing pad spring are arranged in the ink box base; the printing pad is supported in the ink box base by the printing pad spring; at least one sponge oil adsorption pillar is arranged between the printing pad and the bottom of the ink box base; the upper part of the ink box base is provided with an opening; the sponge wheel is arranged on the opening by a rebounding device, so that the sponge wheel is in contact with the printing pad under the action of the pressure and is rebounded and returned after the pressure is relieved; the position on a paper pickup roller shaft of a paper pickup roller mechanism, which is above the sponge wheel, is fixedly provided with a stamp wheel; the stamp wheel comprises a convex surface and a concave surface; a stamp of the stamp wheel is arranged on the convex surface; and when the paper pickup roller shaft drives the stamp wheel to rotate, the convex surface of the stamp wheel presses down the sponge wheel, so that the sponge wheel is pressed down to be in contact with the printing pad and is pressed up to be in contact with a paper feeding rubber wheel. The mechanism has a simple structure; when the mechanism continuously feeds ink and continuously works for a long time, ink is uniform; and the stamp is integrated and is not deformed.

Owner:CHINA ELECTRONICS GREAT WALL CHANGSHA INFORMATION TECH

Food processing device capable of improving raw material crushing quality

ActiveCN110801919AGuaranteed stabilityEasy to disassembleGrain treatmentsProcess engineeringManufacturing engineering

The invention discloses a food processing device capable of improving the raw material crushing quality. The food processing device capable of improving the raw material crushing quality comprises a base. A fixing plate and a control panel are separately fixed to the two sides of the base. A groove is formed in one side of the control panel, and an adjustment mechanism is arranged in the groove. Arotary disc, an installation block and an ejection plate are arranged on the adjustment mechanism. A power mechanism is arranged on the ejection plate and corresponds to the installation block. A crushing barrel is detachably connected to the ejection plate. The food processing device is convenient to move and fix, and the stability of the food processing device is well guaranteed; the positionsof crushing knives can be rapidly adjusted to prevent raw material from adhering to the inner wall of the crushing barrel, and the angle of the crushing barrel can be adjusted to enable the crushing knives to rise or fall during rotation, so that the crushing quality and efficiency are improved; accumulation of the raw materials can be effectively avoided, so that all the raw materials are effectively crushed; and the food processing device can be sealed effectively and is convenient to clean, and the service life of the food processing device is prolonged.

Owner:江西省绿滋肴实业有限公司

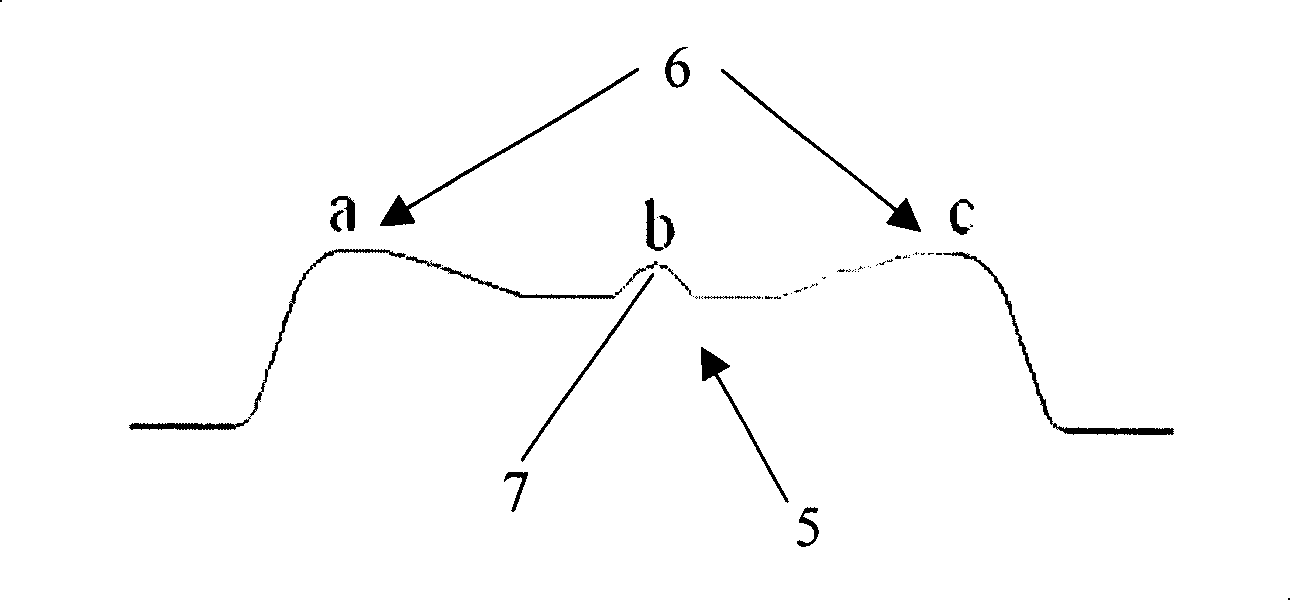

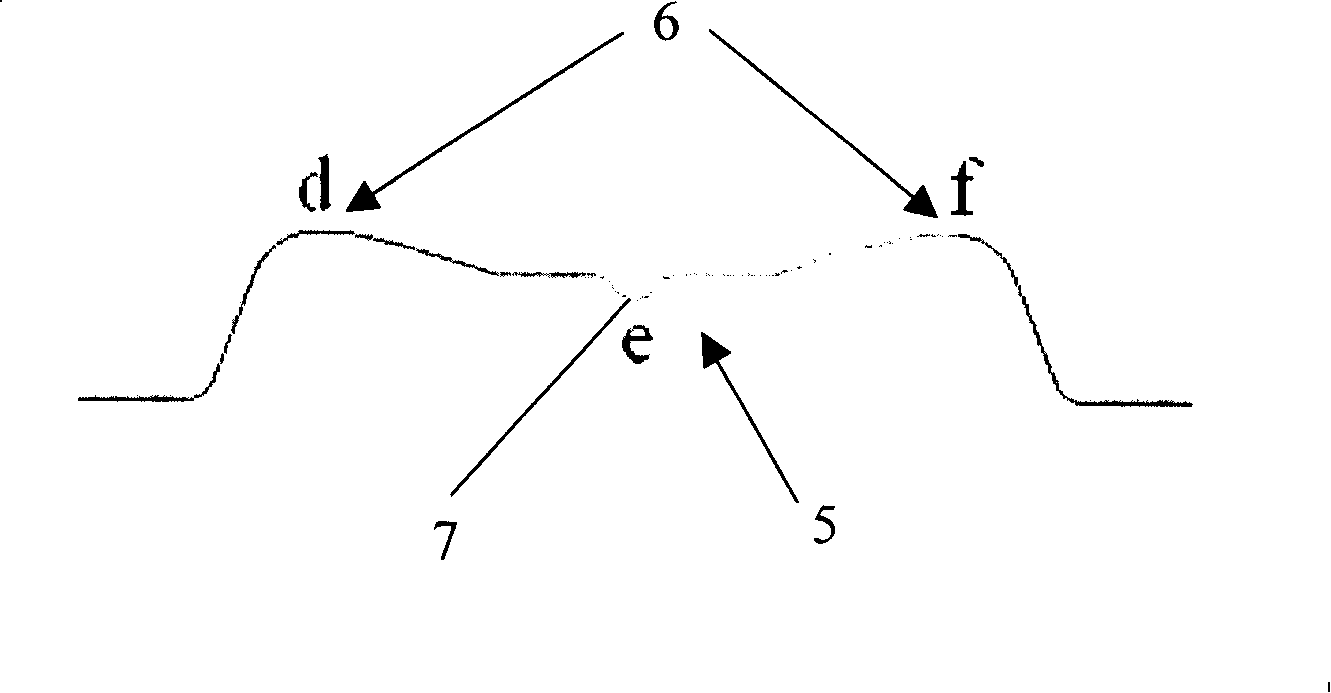

Method for forming part drawing modeling with dent structure

The invention relates to a molding method for drawing and molding a part with depressed structure. The molding method comprises the steps that: a panel is draw and molded, the draw and molded part comprises a depressed area (5) and a protruding area (6) located around the depressed area (5), and a material gathering bar (7) is formed in the depressed area (5); then the draw and molded part is die cut so as to die cut the material gathering bar (7). During the drawing and molding process of the molding method for drawing and molding the part with the depressed structure, as the gathering bar is formed in the depressed area of the part, so the flow of the material can be well controlled during the drawing process; therefore, material accumulation is hard to occur in the transitional part from the protruding area to the depressed area, thus avoiding the wrinkle and laminated material on the surface of the part after drawing molding, enhancing the molding quality of the parts and reducing the defective rate.

Owner:BYD CO LTD

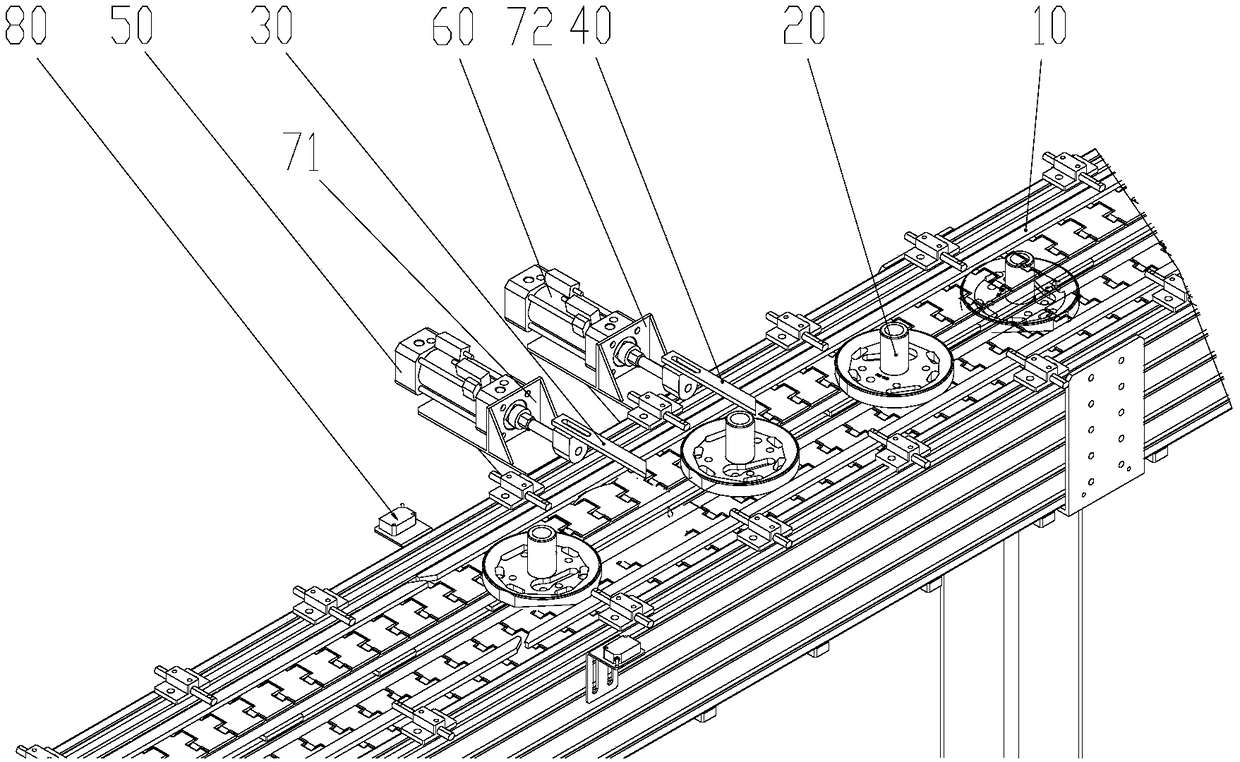

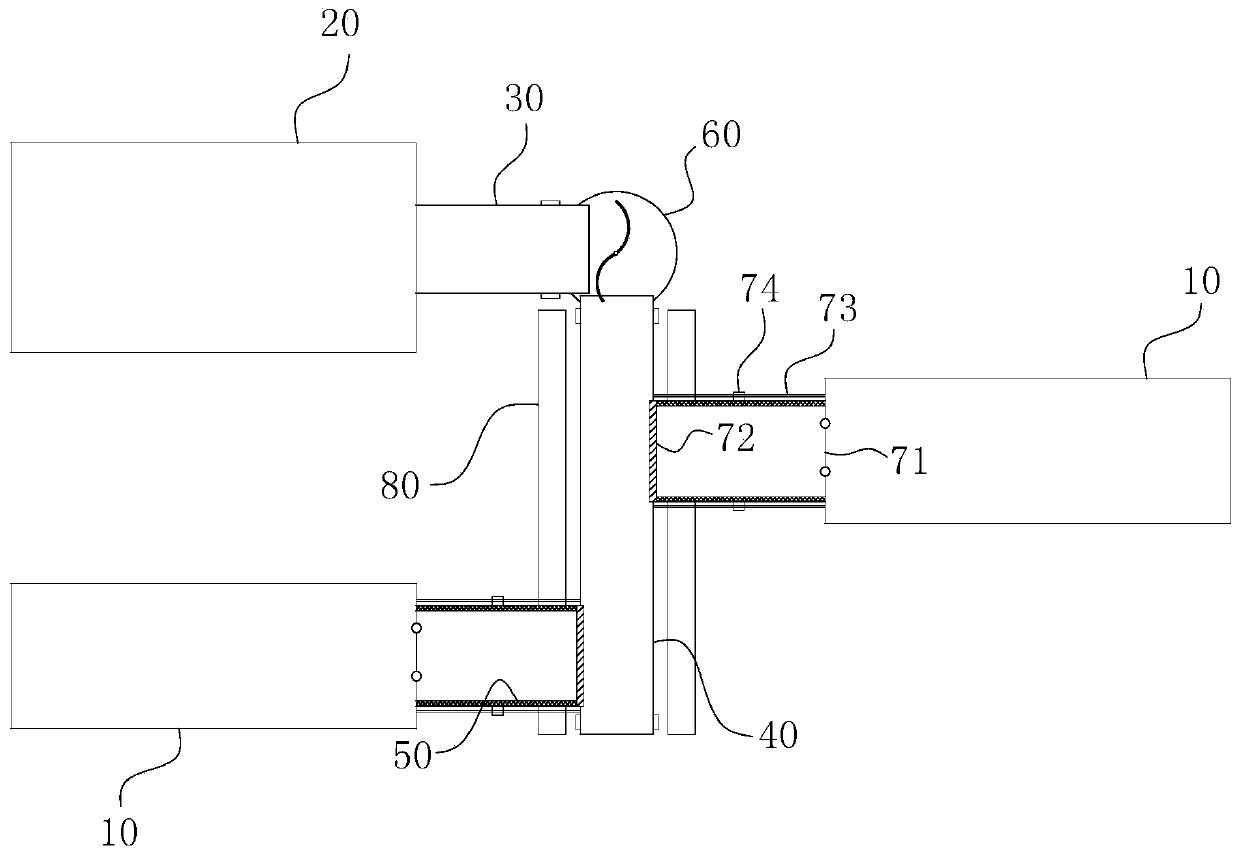

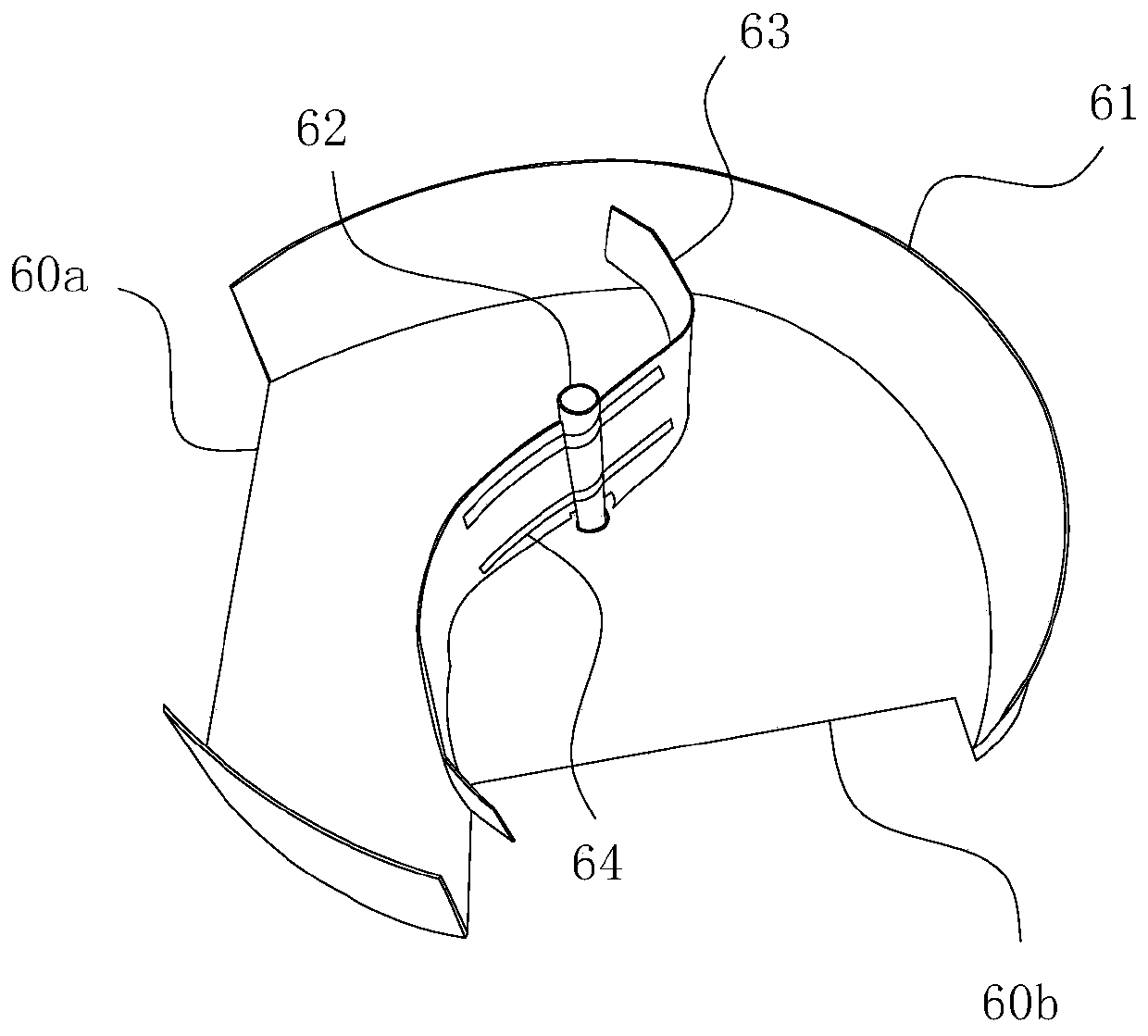

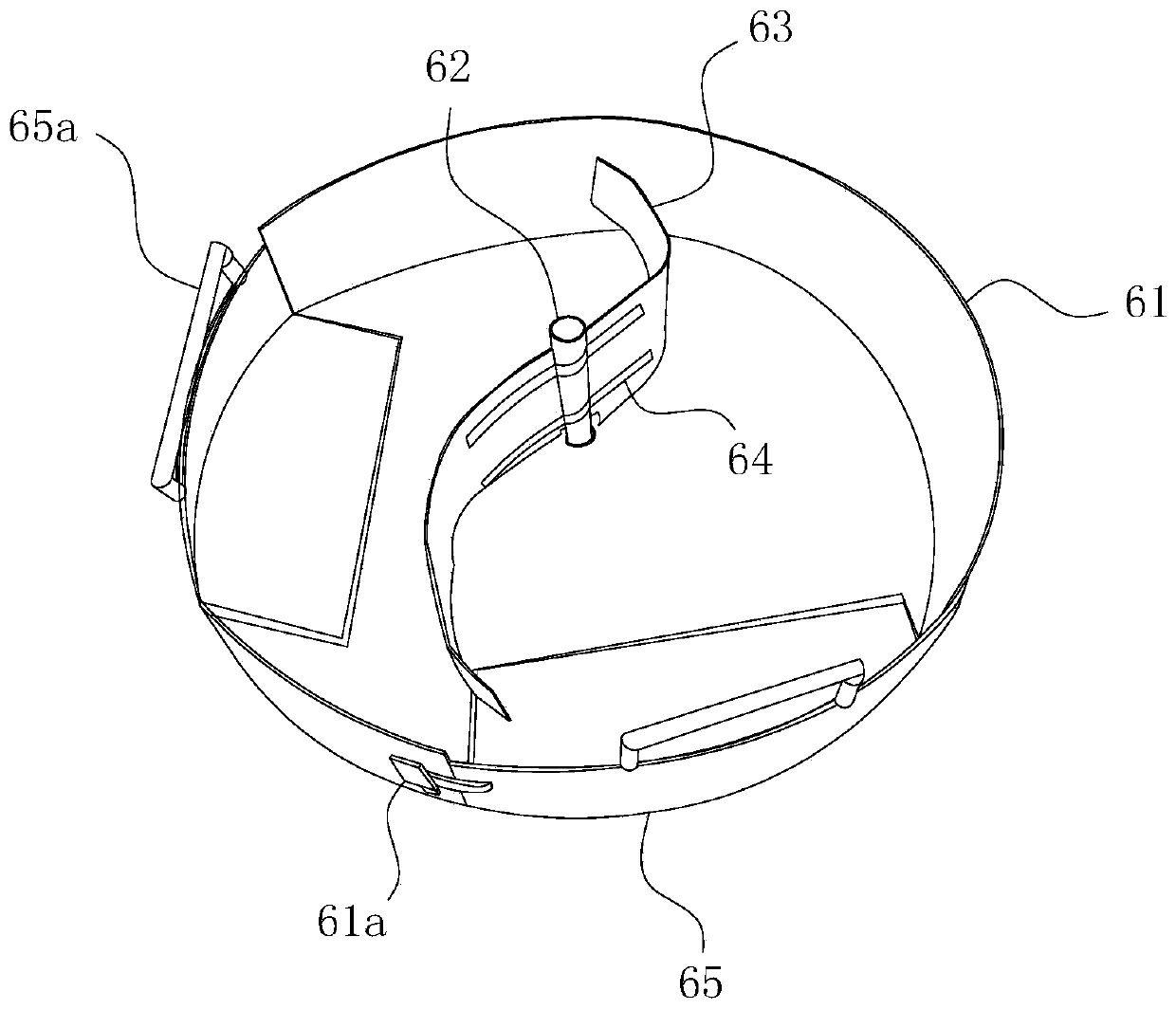

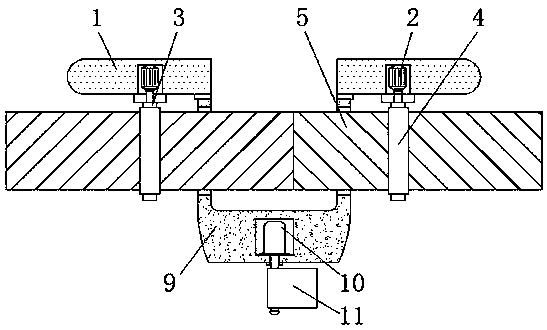

Flange separation mechanism and flange machining line with same

InactiveCN108438866AAvoid accumulation of flange partsEasy to grabConveyor partsStart signalEngineering

The invention provides a flange separation mechanism and a flange machining line with the same. The flange separation mechanism is used for separating flange parts positioned on a flange conveying line; the flange separation mechanism comprises a first separation part and an induction device, wherein the first separation part is arranged above the flange conveying line in the horizontal directionin an extension manner; the extension direction of the first separation part is perpendicular to the conveying direction of the flange conveying line to stop or avoid from the flange parts on the first separation part; the induction device is arranged on the flange conveying line; a detecting head of the induction device is arranged towards a preset taking area of the flange conveying line for detecting if the flange parts are in the preset taking area; and when the flange parts are not in the preset taking area, a starting signal for shrinking the first separation part is sent to the first separation part, so that the flange parts positioned at the upstream of the first separation part reach a preset taking position by the first separation part. The flange separation mechanism solves theproblem of easy accumulation of the flange parts on the flange conveying line in the prior art.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

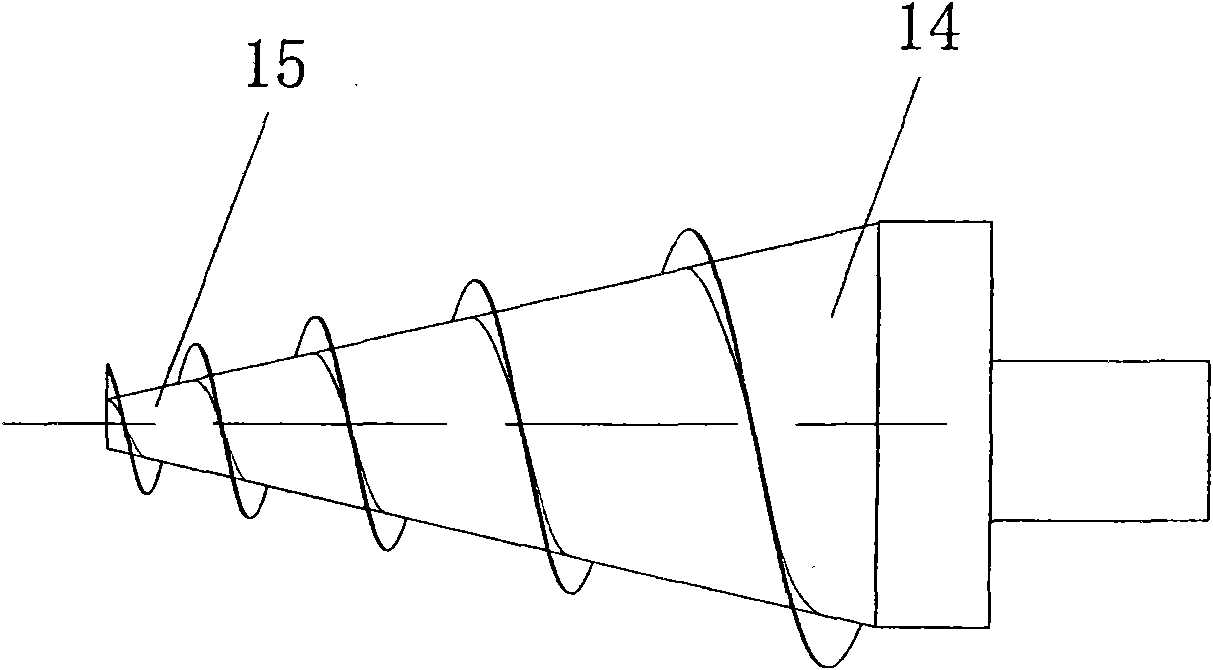

Side feed conveying system for conveying filler with low bulk density

InactiveCN101590690APrevent stackingImprove delivery capacityVolumetric Mass DensityMechanical engineering

The invention discloses a side feed conveying system for conveying a filler with low bulk density, which comprises a hopper, a screw barrel connected with an extruding machine and a screw rod module, wherein the hopper is arranged above a feed opening of the screw barrel, the screw rod module is arranged inside the screw barrel, the hopper wall of the hopper is a sandwich structure comprising an outer layer and an inner layer, a gap between the outer layer and the inner layer is provided with a plurality of baffles, the bottom of the inner layer of the hopper wall is provided with an exhaust opening, and a hopper cover above the hopper wall is provided with a suction opening of an externally connected exhausting system. The side feed conveying system realizes good exhaust, increases the conveying capacity of the screw rod module, and avoids the situation of the accumulation of the filler in the hopper at the same time, thereby improving the accuracy of the feeding.

Owner:合诚技术股份有限公司

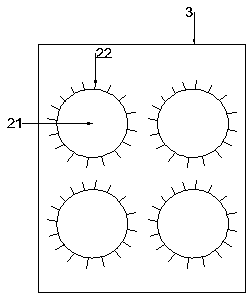

Plant protection powder spraying machine with anti-blocking function

InactiveCN108293970AWith anti-clogging functionEffective stirringRotary stirring mixersTransportation and packagingEngineeringPowder Spray

The invention discloses a plant protection powder spraying machine with an anti-blocking function, and relates to the technical field of plant protection machines. The plant protection powder sprayingmachine with the anti-blocking function comprises a bottom plate, the top of the bottom plate is fixedly connected with the bottom of a box body, and a material collecting box is arranged in the boxbody; the front side and the rear side of the material collecting box are fixedly connected with the front side and the rear side of the inner wall of the box body respectively, and the bottom of a feeding pipe is inserted into one side of the top of the material collecting box; the feeding pipe is communicated with an inner cavity of the material collecting box, and the end, back on to the material collecting box, of the feeding pipe penetrates through the top of the box body and extends to the upper part of the box body; a first motor is arranged in the middle of the top of the material collecting box. The plant protection powder spraying machine with the anti-blocking function is provided with the first motor, a rotating rod and a stirring rod so that pesticide powder in the material collecting box can be effectively stirred; air cylinders are arranged on the two sides of a material guide pipe, and push plates are arranged at the output ends of the air cylinders in a matched mode sothat the situation that the pesticide powder blocks the material guide pipe can be effectively avoided.

Owner:江苏智改数转智能制造科技有限公司

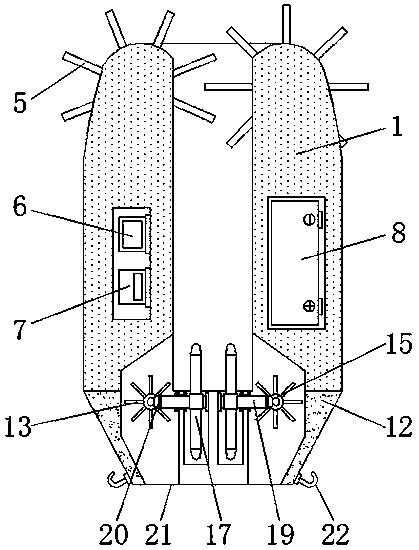

Breeding production system for sheep

ActiveCN109874682ASolve the problem of easy aggregationEasy to handleGeneral water supply conservationAnimal feeding devicesEngineeringFodder

The invention belongs to the technical field of sheep feeding, and particularly relates to a breeding production system for sheep. Specifically, feed is uniformly stirred by a feed mixer, and a discharge port, a sending conveyer belt and a feeding conveyer belt are started through a controller; the feed passes through the sending conveyer belt and is guided and conveyed to the feeding conveyer belt through a feed diverter; when the feed is conveyed to the tail end of the feeding conveyer belt, the controller is turned off, and feed conveying is completed. A door fence of a sheep house is lifted through the action of a crowbar, at the time, a fence at a feeding walkway descends and is closed under the action of the crowbar, and animals reach the front portion of the feeding conveyer belt through the feeding walkway; then, the crowbar is controlled to close the door fence and lift the fence, at the time, the door fence at the sheep house descends and is closed, and the animals stretch heads into the surface of the feeding conveyer belt to eat feed. The problem that the feed is easy to gather when a feed path is turned, and the feed efficient transportation function and the efficientventilation effect of the environment in the sheep house are achieved on the premise that the transportation face is the same plane.

Owner:ANHUI AGRICULTURAL UNIVERSITY

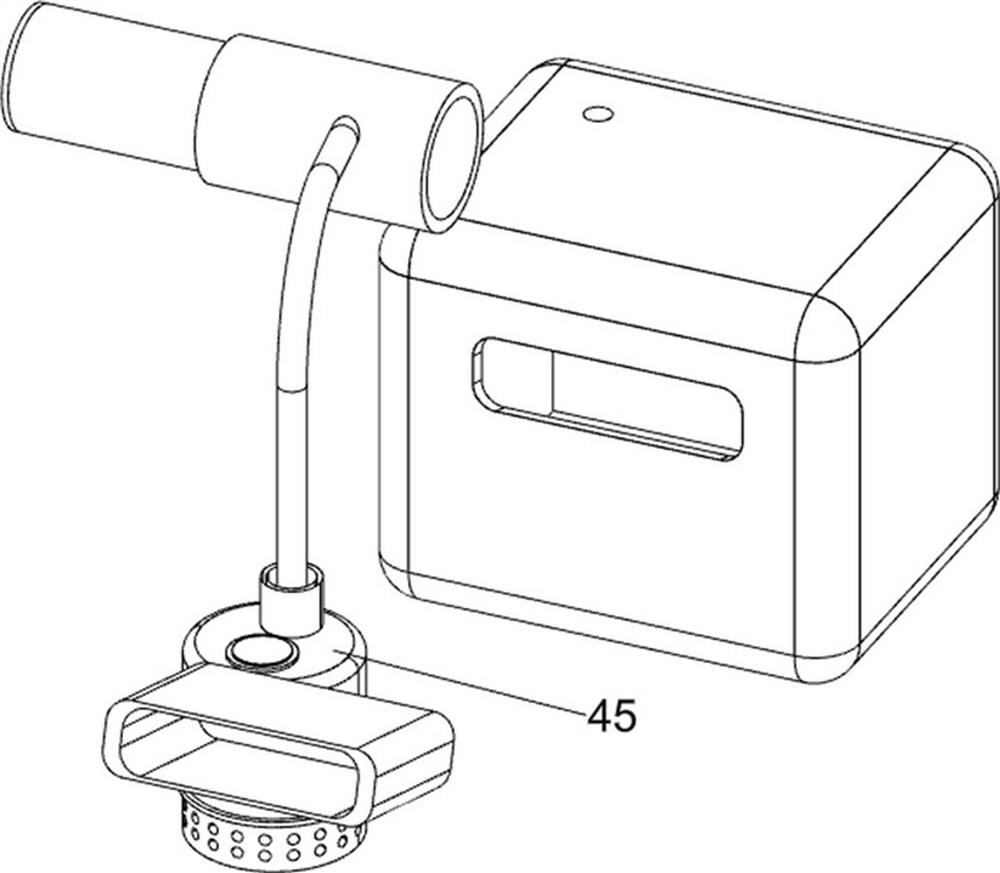

VOC online monitor for organic acid environment

InactiveCN111610293AConvenient sampling and testingPlay a thrustWithdrawing sample devicesGas analyser construction detailsOrganic acidProcess engineering

The invention relates to a VOC online monitor for an organic acid environment. The monitor comprises a monitor body, and a monitoring cavity is formed in the inner side of the monitor body; a cleaningopening is formed in the top of the monitor body; the cleaning opening is communicated with the monitoring cavity; a sealing cover is arranged at the top of the monitor body; the sealing cover is provided with an air inlet hole and an air outlet hole; a vacuum pump is mounted on the upper surface of the sealing cover; an extraction opening of the vacuum pump is communicated with the air outlet hole; an air pressure monitor is installed on the side face of the monitor body, the upper portion of the air inlet hole is communicated with a communicating pipe, one end of the communicating pipe is communicated with an electromagnetic valve, the communicating pipe is communicated with an air outlet of an air inlet non-return mechanism through the electromagnetic valve, and an air inlet of the airinlet non-return mechanism is communicated with an air inlet unit. The movable range of the air inlet unit can be greatly enlarged through a lifting mechanism, so that sampling detection work is conducted on air of different heights.

Owner:合肥汇酷谷生物技术有限公司

Paint spraying equipment for new energy automobile parts

PendingCN112934536APrevent stackingAvoid stickingSpraying apparatusMotor vehicle partAutomotive engineering

The invention relates to paint spraying equipment, in particular to paint spraying equipment for new energy automobile parts. According to the technical aims, the paint spraying equipment for the new energy automobile parts is capable of automatically spraying paint, saving time and labor and improving the working efficiency. According to the technical scheme, the paint spraying equipment for new energy automobile parts comprises a bottom plate, a containing assembly, a servo motor and a paint spraying mechanism, wherein the containing assembly is arranged on one side of the bottom plate; the servo motor is arranged on the right side of the containing assembly; and the paint spraying mechanism is arranged on one side of the bottom plate. Through cooperation of the paint spraying mechanism and a rotating mechanism, people do not need to manually rotate parts, the rotating mechanism drives the parts to rotate, and the situation that paint is accumulated due to non-uniform spraying of the parts is prevented.

Owner:廖军

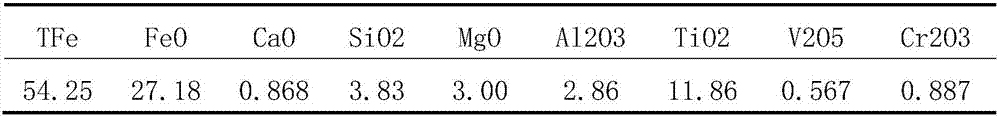

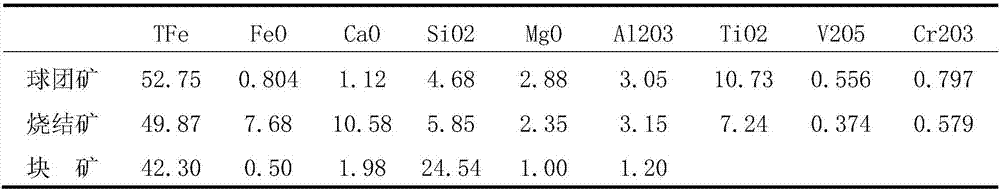

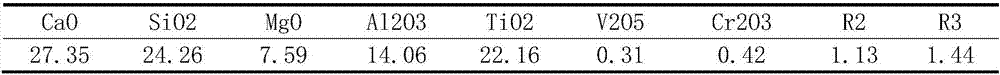

Method for preventing slag from being accumulated at center of high-chromium vanadium-bearing titanomagnetite hearth

The invention relates to the field of blast furnace ironmaking methods, in particular to a method used for preventing slag from being accumulated at the center of a high-chromium vanadium-bearing titanomagnetite hearth and capable of effectively eliminating the slag accumulation at the center of the high-chromium vanadium-bearing titanomagnetite hearth. The slag mainly comprises, by mass, 0.35-0.50% of Cr2O3, 25-28% of CaO, 23.5-26% of SiO2, 7-11% of MgO, 13-15% of Al2O3 and 20-23% of TiO2. According to the method, by precisely adjusting the proportion of the main components in the slag, the thermal stability, the chemical stability and flowability of the slag are optimized effectively, and the slag is made to have the suitable melting temperature and the sufficient desulfurization capacity, so that the situation of the slag accumulation at the center of the high-chromium vanadium-bearing titanomagnetite hearth is prevented. According to the method, the modification of an original scheme is small, the slag accumulation state is improved greatly on the premise of guaranteeing the production efficiency, and the method is especially suitable for the production performed in the high-chromium vanadium-bearing titanomagnetite hearth.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

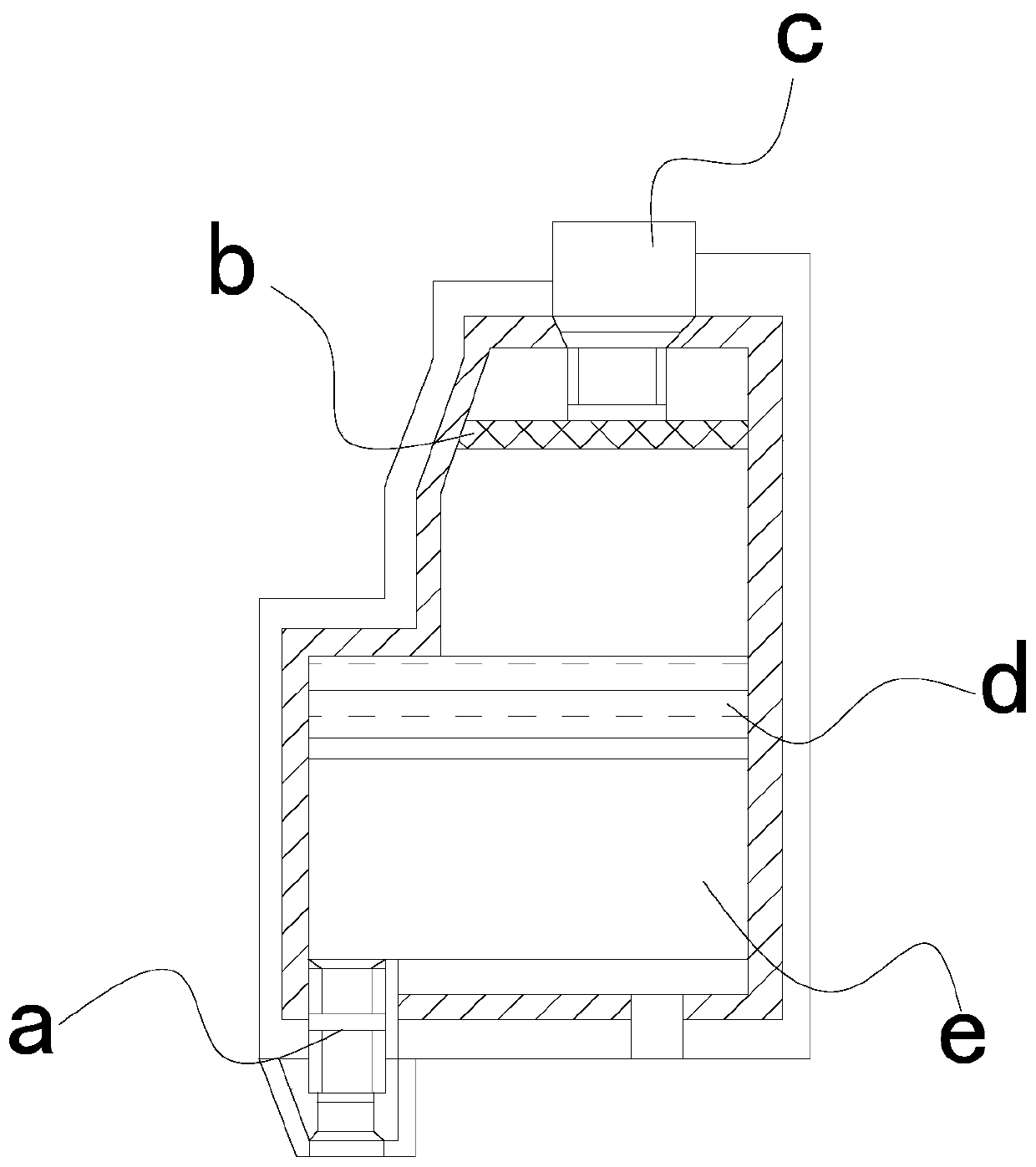

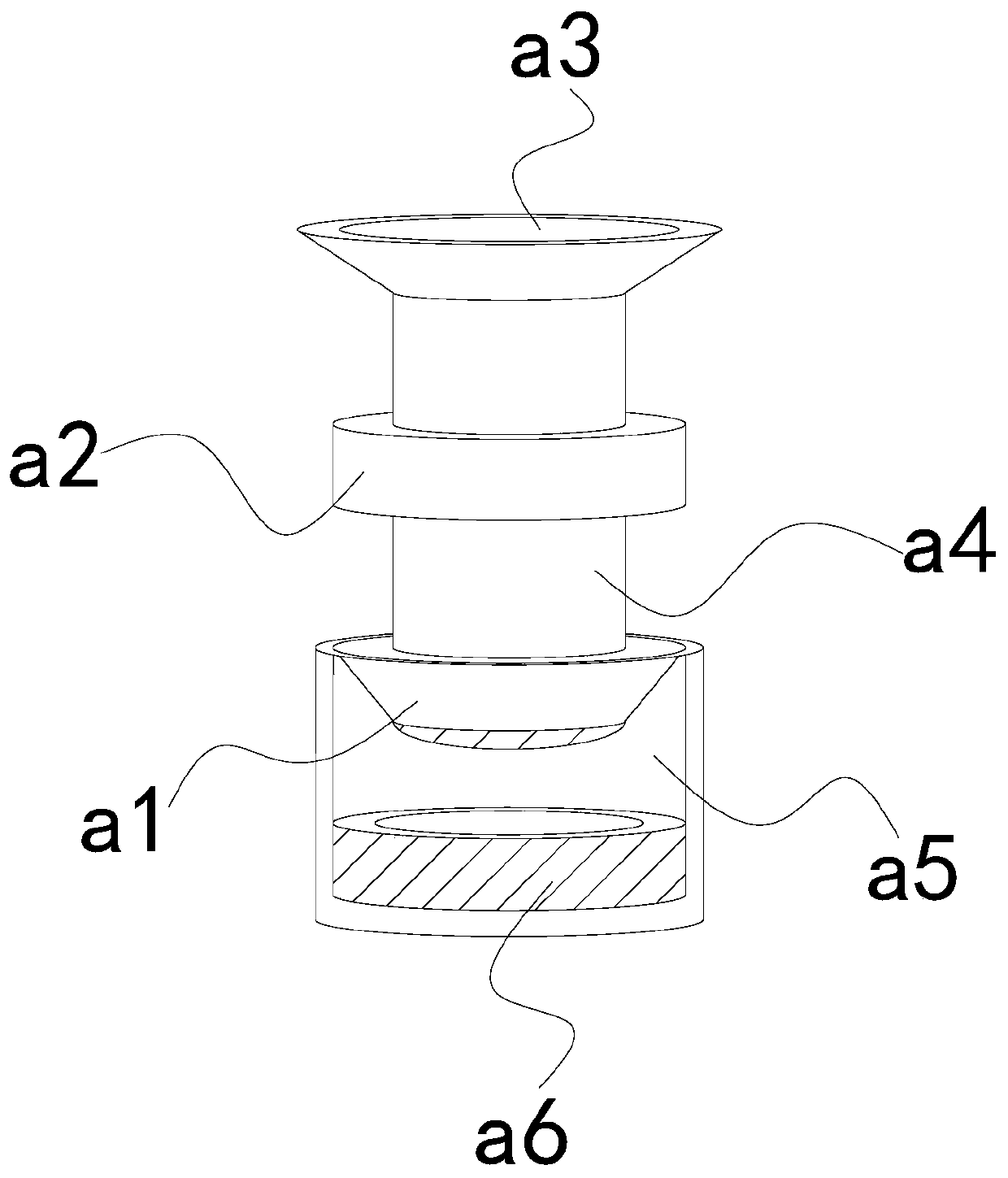

Anti-clogging type ink cartridge for inkjet printer

The invention discloses an anti-clogging type ink cartridge for an inkjet printer. The anti-clogging type ink cartridge for the inkjet printer structurally comprises an ink cartridge main body, an air-return air channel, a circuit board and an installing buckle block, wherein the installing buckle block is installed on the upper left part of the ink cartridge main body and is connected with the ink cartridge main body in a buckled mode, the air-return air channel is arranged on the lower right part of the ink cartridge main body, the air-return air channel is in clearance fit with the ink cartridge main body, and the circuit board is arranged on the left side of the ink cartridge main body and is connected with the ink cartridge main body in a buckled mode; when equipment is used, throughan arranged composite inkjet tube mechanism, the anti-clogging type ink cartridge for the inkjet printer can avoid the conditions that the inkjet printer should start to carry out printing operation in a short period generally, otherwise, ink staying in an inkjet nozzle and paper and dust in air can generate a solidification phenomenon, and then the service life of the nozzle is affected, so thatthe problems that the printed imaging effect is not good and graphite particles are prone to being stacked at the bottom are caused; and the ink in an inkjet tube is enabled not to be prone to solidification, and meanwhile, the stacking of the graphite particles is reduced.

Owner:潘瑶麟

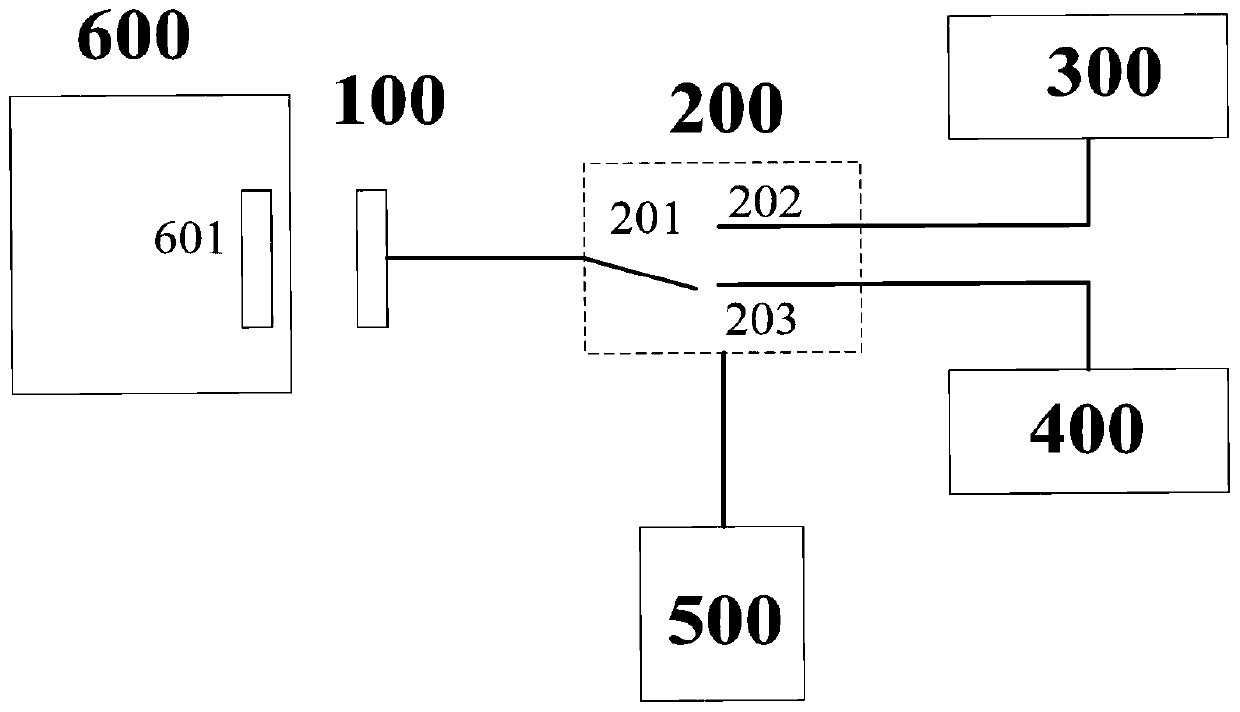

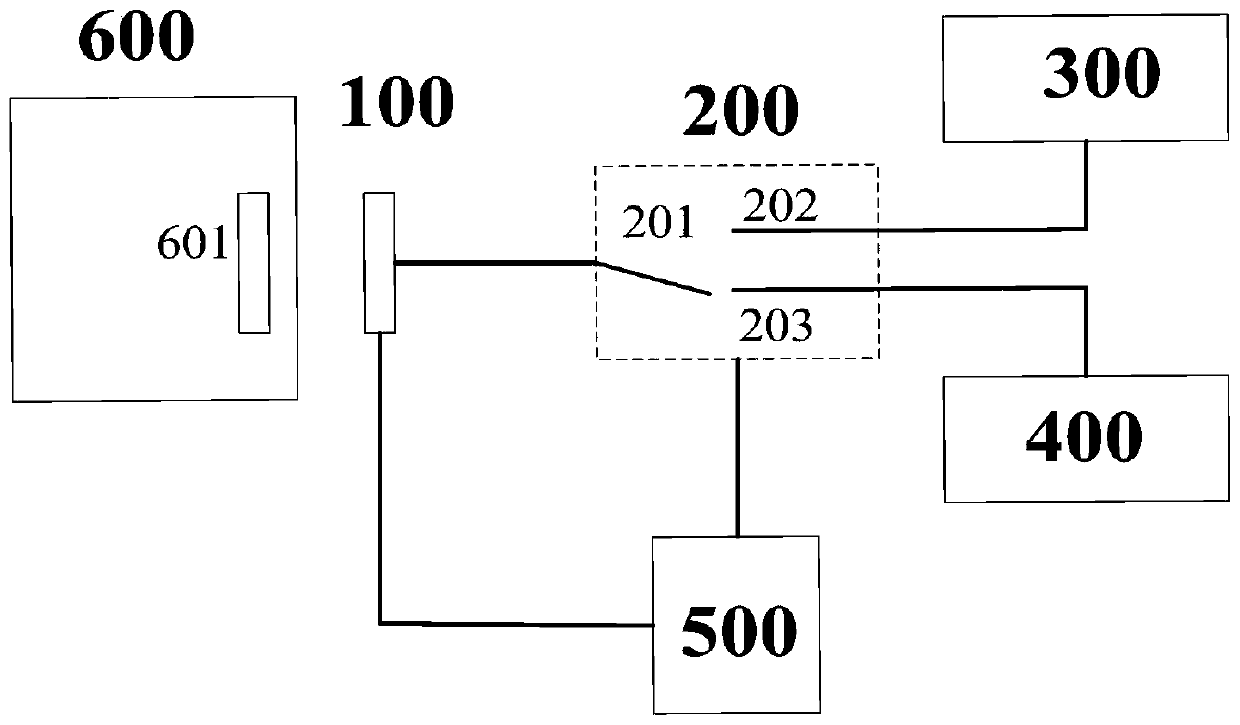

Circuit control device and method

ActiveCN111245055AImprove securityPrevent stackingBatteries circuit arrangementsCapacitance measurementsControl engineeringCharge control

The embodiment of the invention discloses a circuit control device and method. The circuit control device is applied to electronic equipment. The device comprises a charging control module, a circuitswitching module, a capacitance detection module, a first change-over switch and a first polar plate, the first change-over switch comprises a first common end, a second end and a third end. The firstpolar plate is electrically connected with the first common end; the charging control module is electrically connected with the second end; the capacitance detection module is electrically connectedwith the third end; the circuit switching module is used for controlling the electric conduction state of the first change-over switch; when the first common end is electrically connected with the second end, the second common end is electrically connected with the second end; the charging control module carries out charging through the first polar plate and a second polar plate of the charging equipment, and the capacitance detection module obtains a first capacitance value through the first polar plate under the condition that the first common end and the third end are electrically conducted, so that the stacking of devices can be avoided and the safety is improved through the device.

Owner:VIVO MOBILE COMM CO LTD

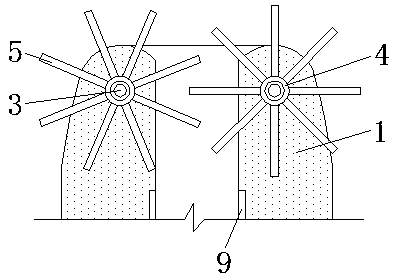

Cleaning device convenient for collecting water surface waste

The invention discloses a cleaning device convenient for collecting water surface waste, including floating plates, a water tank, tailboards and poking strips, the floating plates are internally provided with brushless motors, vertical shafts are arranged under the brushless motors, first leaf plates are installed on each sleeve rod, the first leaf plates are connected with the vertical shafts through the sleeve rods separately, first bevel gears are positioned inside the tailboards, mounting grooves inside which the poking strips are positioned are formed in the tailboards, the poking stripsare positioned outside sleeves, openings are formed in the tailboards, and the tailboards are externally provided with hooks. According to the cleaning device convenient for collecting water surface waste, driving devices composed of the brushless motors, the vertical shafts, the sleeve rods and the first leaf plates separately can not only drive the cleaning device to move, but also poke the water from the outside of the cleaning device into the water tank, thereby facilitating the water to be discharged to the rear of the cleaning device to form pushing force, and simultaneously facilitatingthe collection and poking of the water surface waste.

Owner:江苏源泉泵业股份有限公司

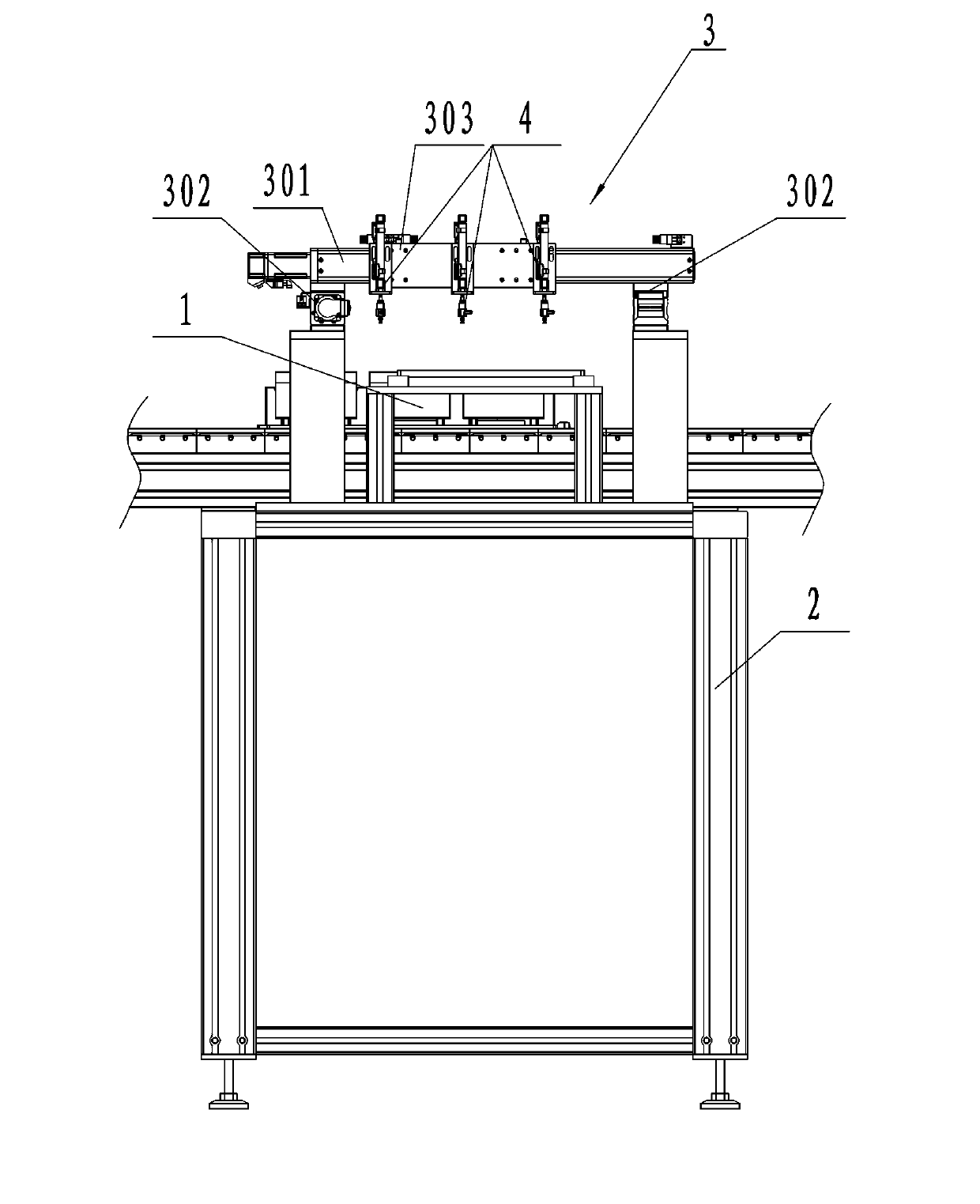

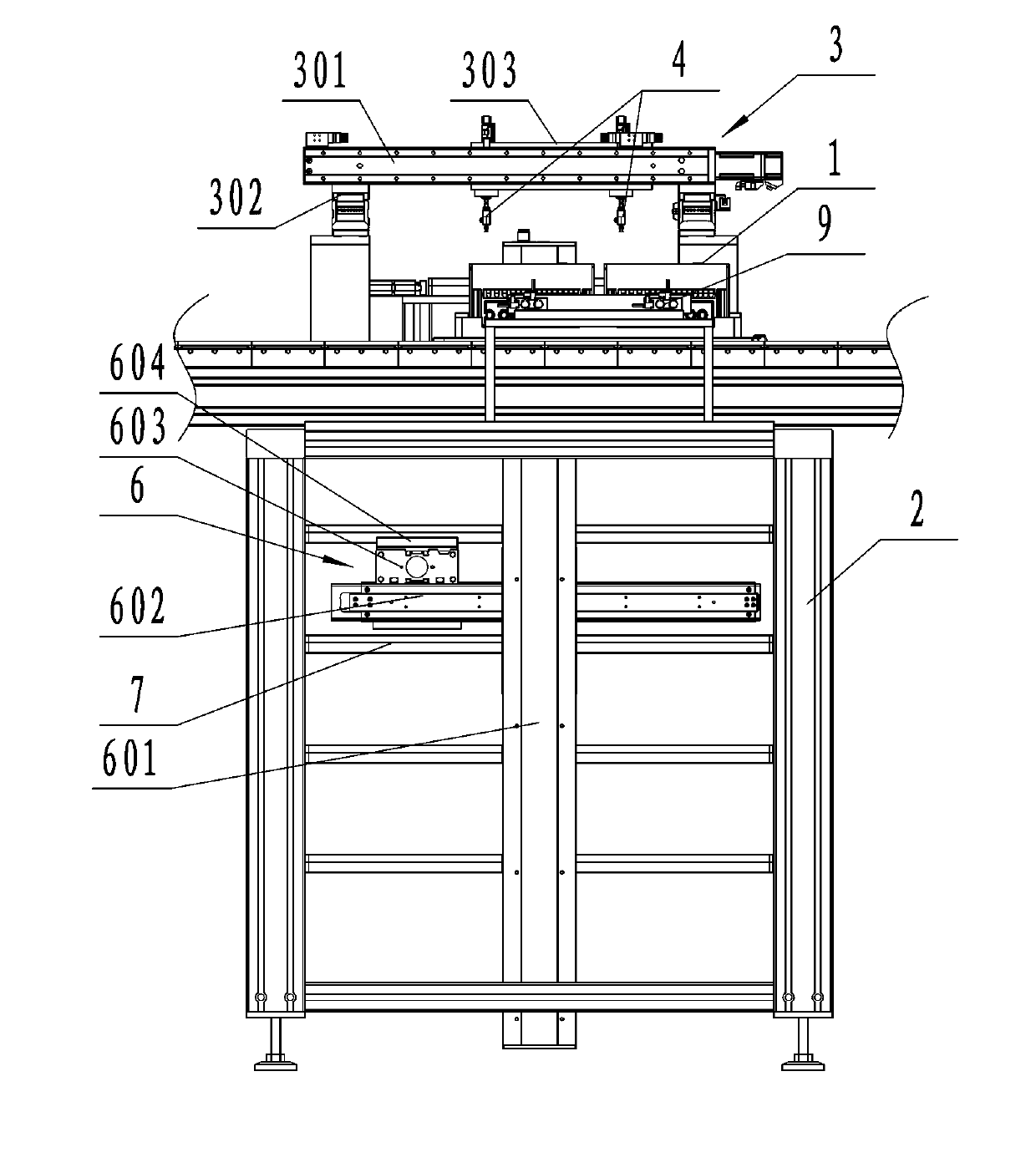

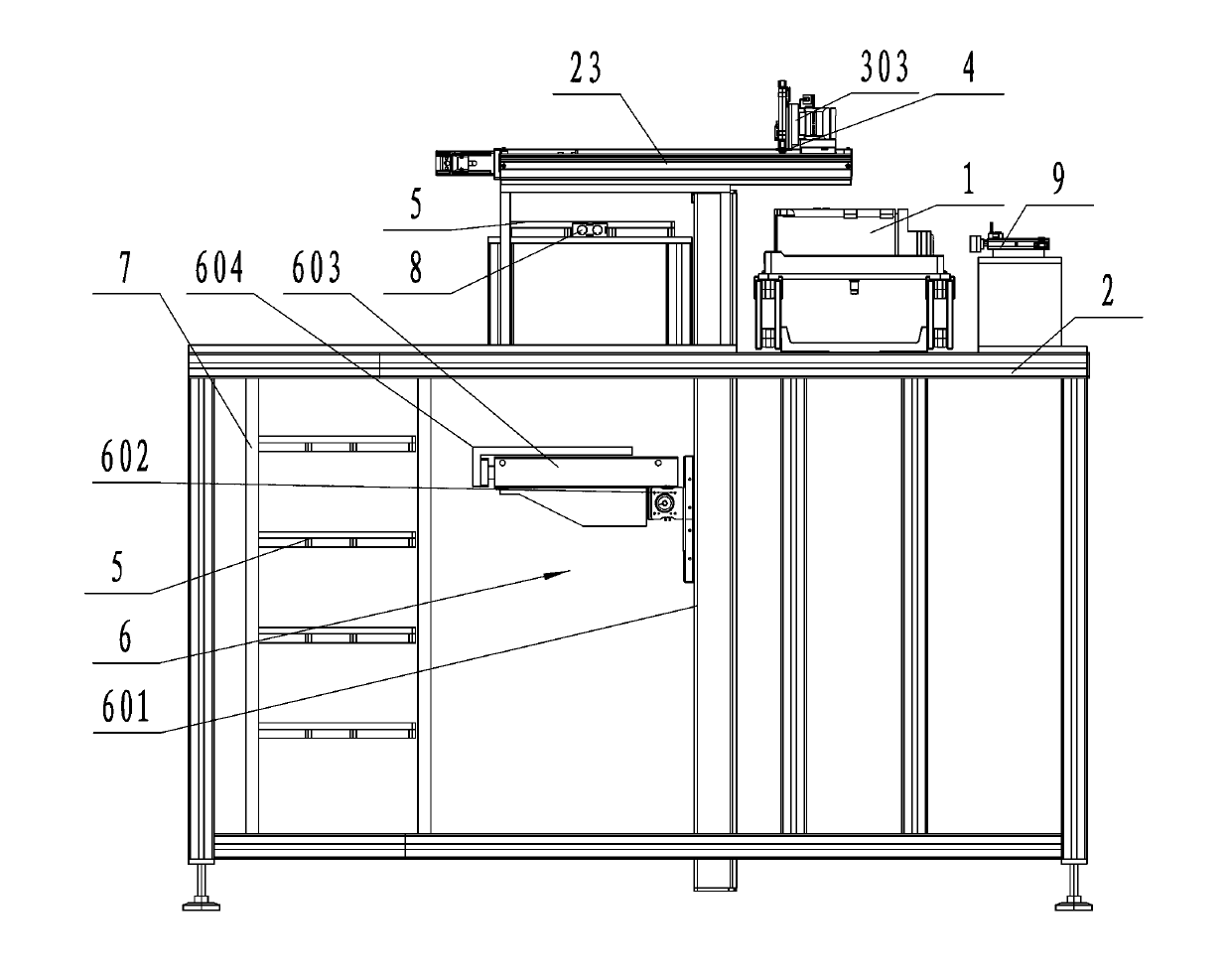

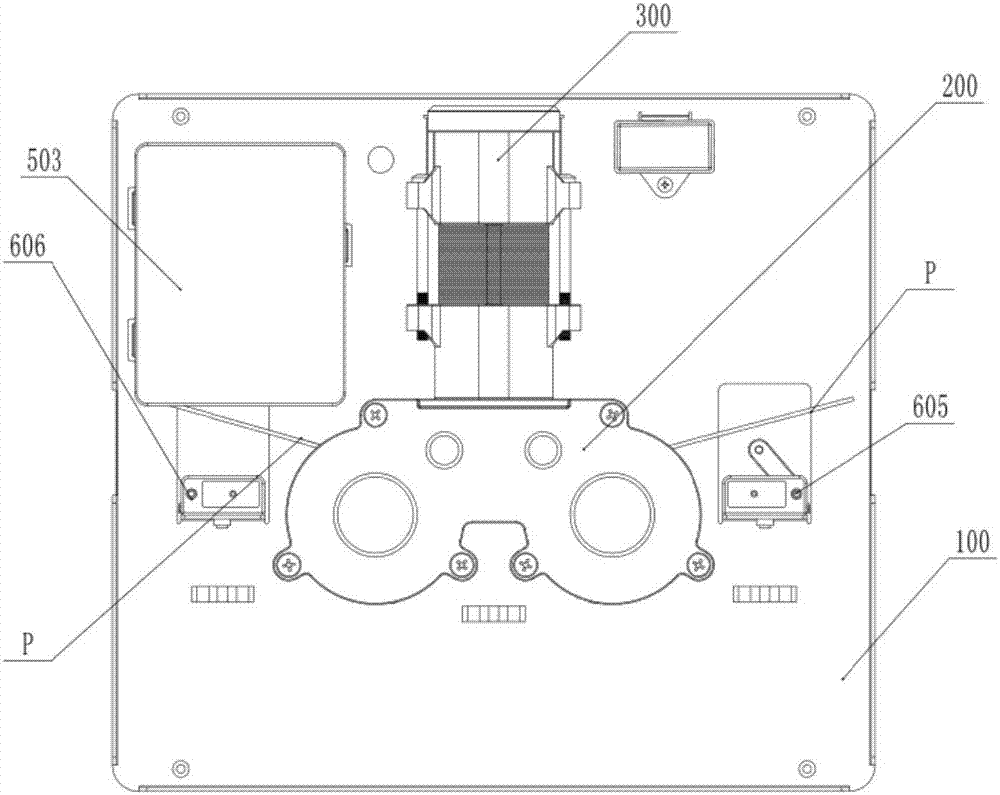

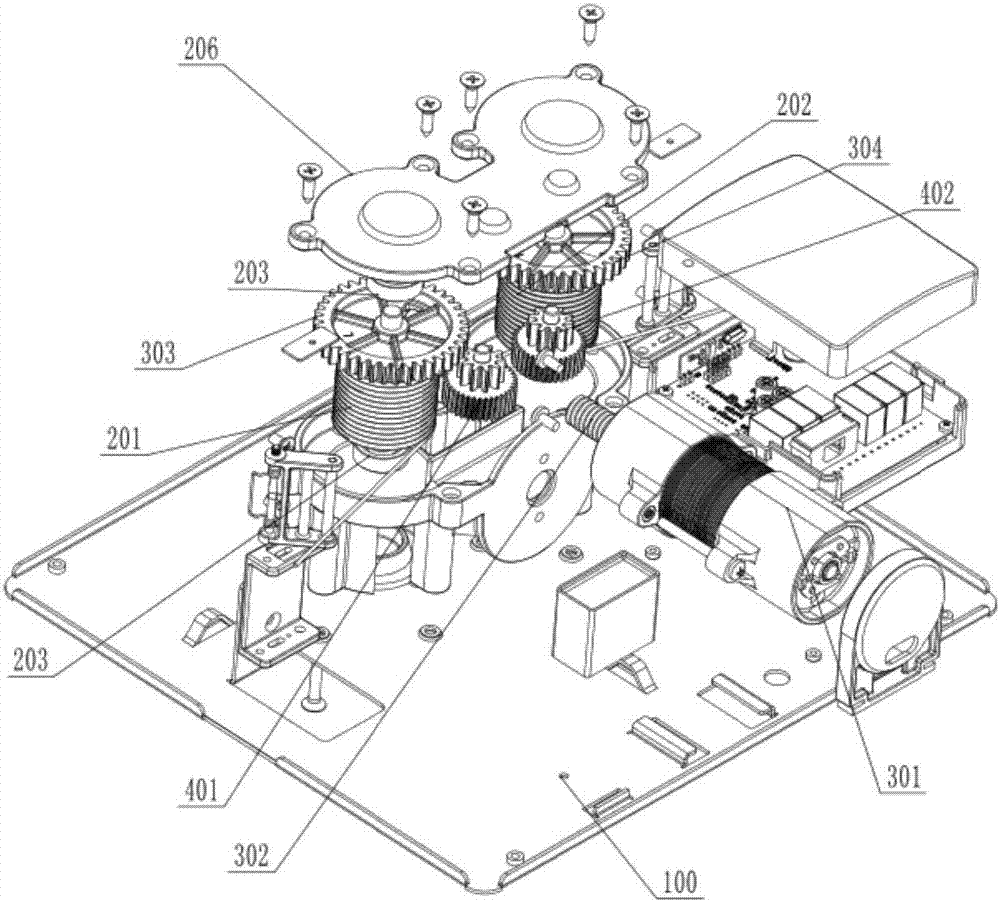

Electric energy meter automatic sealing device and method

ActiveCN103000081ARealize automatic sealingAvoid influenceStampsTime integral measurementManipulatorElectricity meter

The invention discloses an electric energy meter automatic sealing device and method, relating to automatic sealing of an electric energy meter. Most of the existing sealing modes are a manual threading lead sealing mode which causes low labor efficiency and high labor intensity; and the lead material brings potential harm to human bodies. The device disclosed by the invention is characterized in that a frame body is provided with a three-axis right-angle manipulator, an electric energy meter positioning mechanism, a seal taking and placing mechanism and a seal material disc, wherein the three-axis right-angle manipulator is provided with an X axis, a Y axis and a Z axis; the X axis and the Y axis are driven by a servo motor; the Z axis is driven by a servo motor or a cylinder; the frame body is provided with a Y-direction manipulator guide rail, an X-direction manipulator guide rail and a seal material disc positioning frame; the X-direction manipulator guide rail is provided with a Z-axis mounting frame; the Z-axis mounting frame is provided with multiple Z axes; the seal taking and placing mechanism is arranged at the lower end of the Z axis; the seal taking and placing mechanism comprises a flexible vacuum chuck; and the electric energy meter positioning mechanism is provided with an electric energy meter positioning cylinder. Through the technical scheme, the working efficiency is improved, and the heavy metal pollution is avoided.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +1

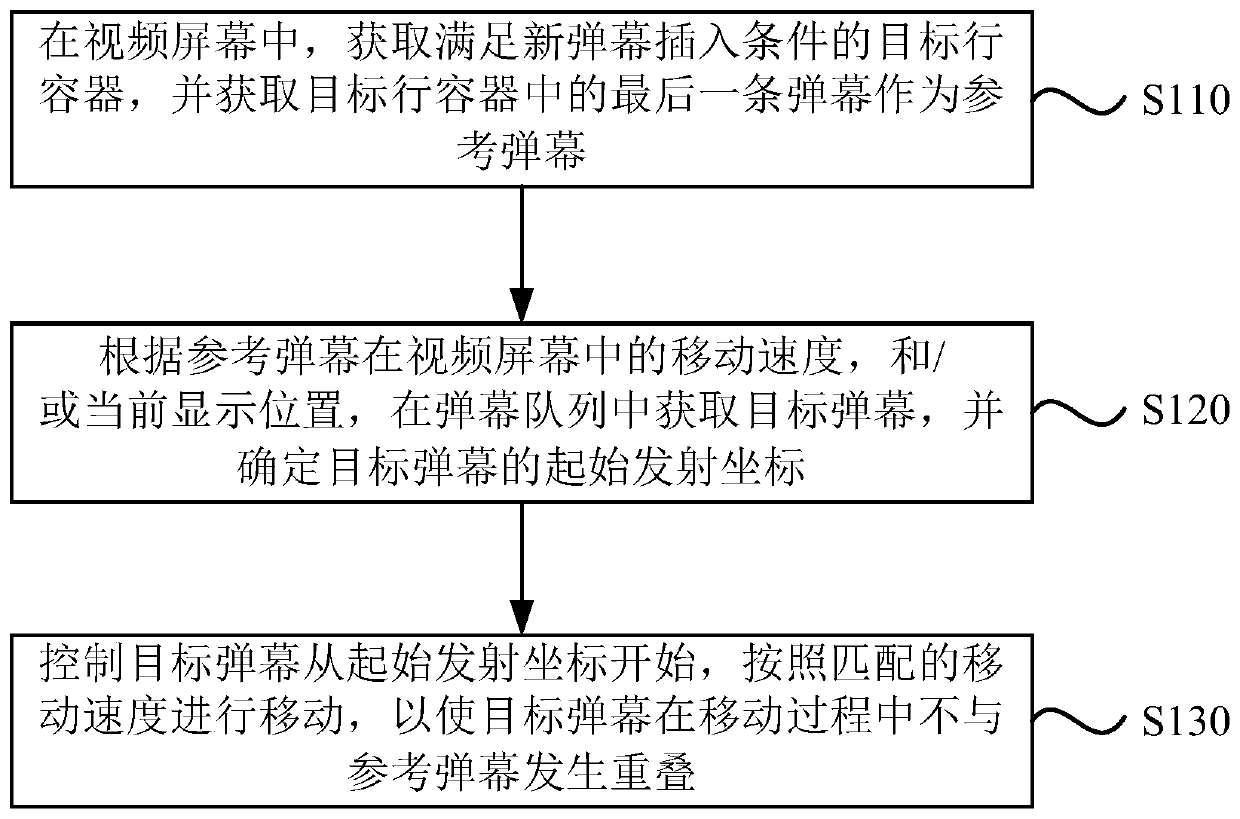

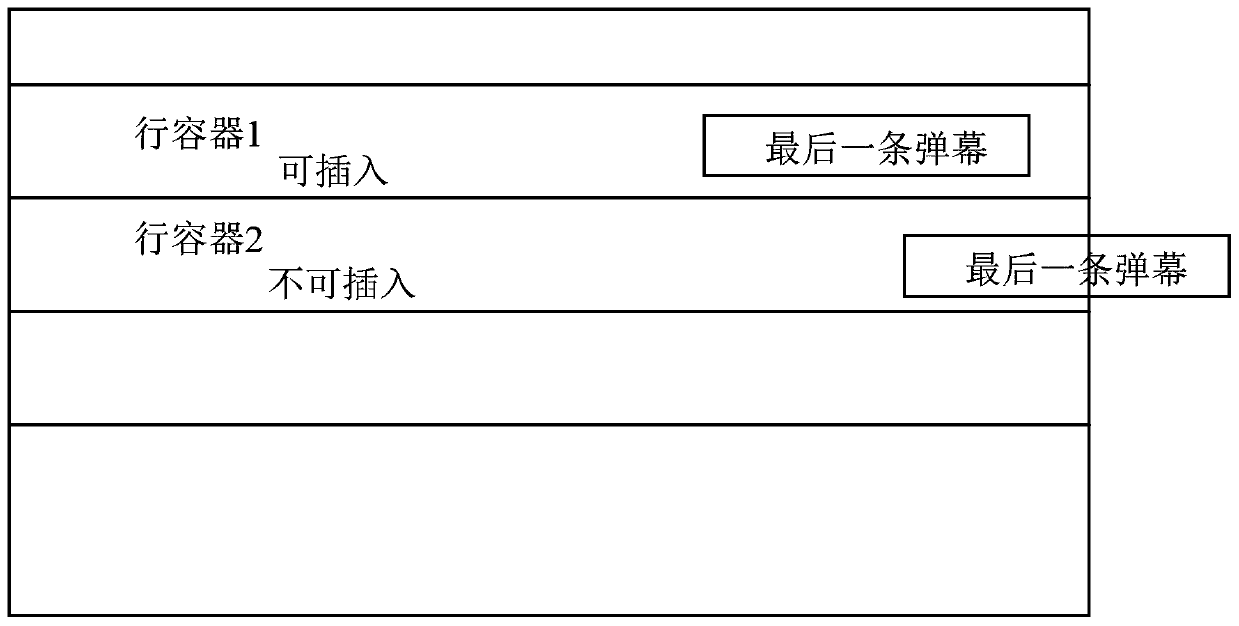

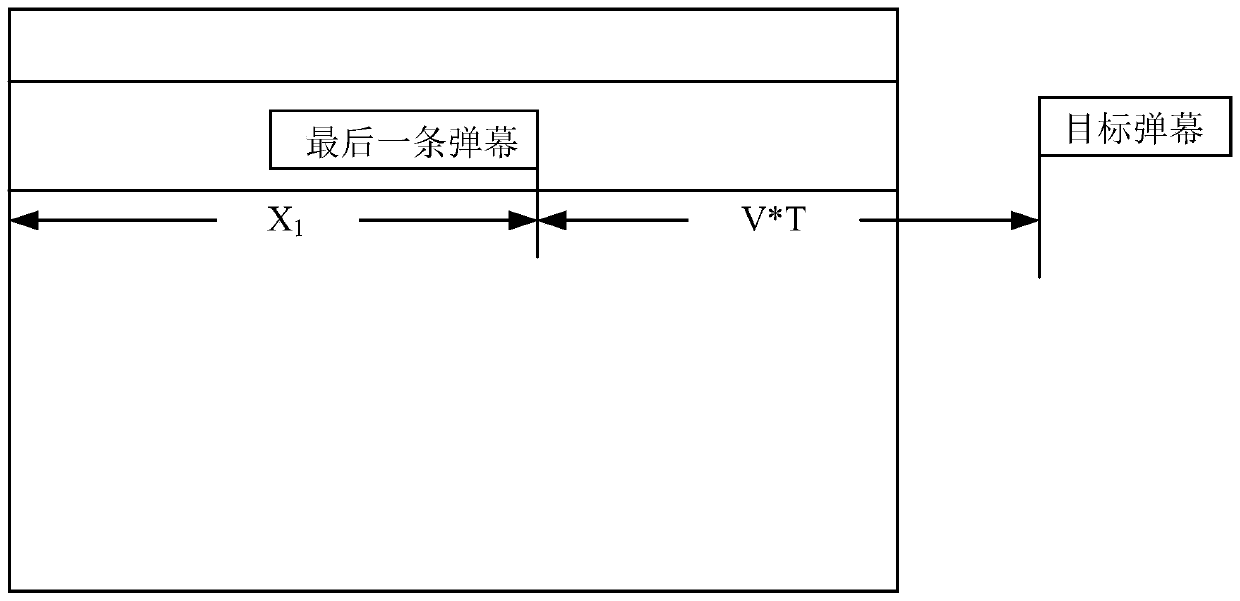

Bullet screen display method, device and equipment and storage medium

ActiveCN110012306APrevent stackingImprove the display effectSelective content distributionComputer hardwareVideo image

The embodiment of the invention discloses a bullet screen display method, device and equipment and a storage medium. The method comprises the steps of obtaining a target row container meeting a new bullet screen insertion condition in a video screen, and obtaining the last bullet screen in the target row container as a reference bullet screen; obtaining a target bullet screen in a bullet screen queue according to the moving speed of the reference bullet screen in the video screen and / or the current display position, and determining the initial emission coordinate of the target bullet screen; and controlling the target bullet screen to move according to the matched moving speed from the initial launching coordinate, so that the target bullet screen is not overlapped with the reference bullet screen in the moving process. According to the invention, a large number of bullet screens can be prevented from being simultaneously displayed in the video screen at the same time, so that the burden of a display card is reduced, the problems of video image jamming and the like are prevented, the bullet screens can be prevented from being stacked, and the bullet screen display effect is optimized.

Owner:GUANGZHOU HUYA INFORMATION TECH CO LTD

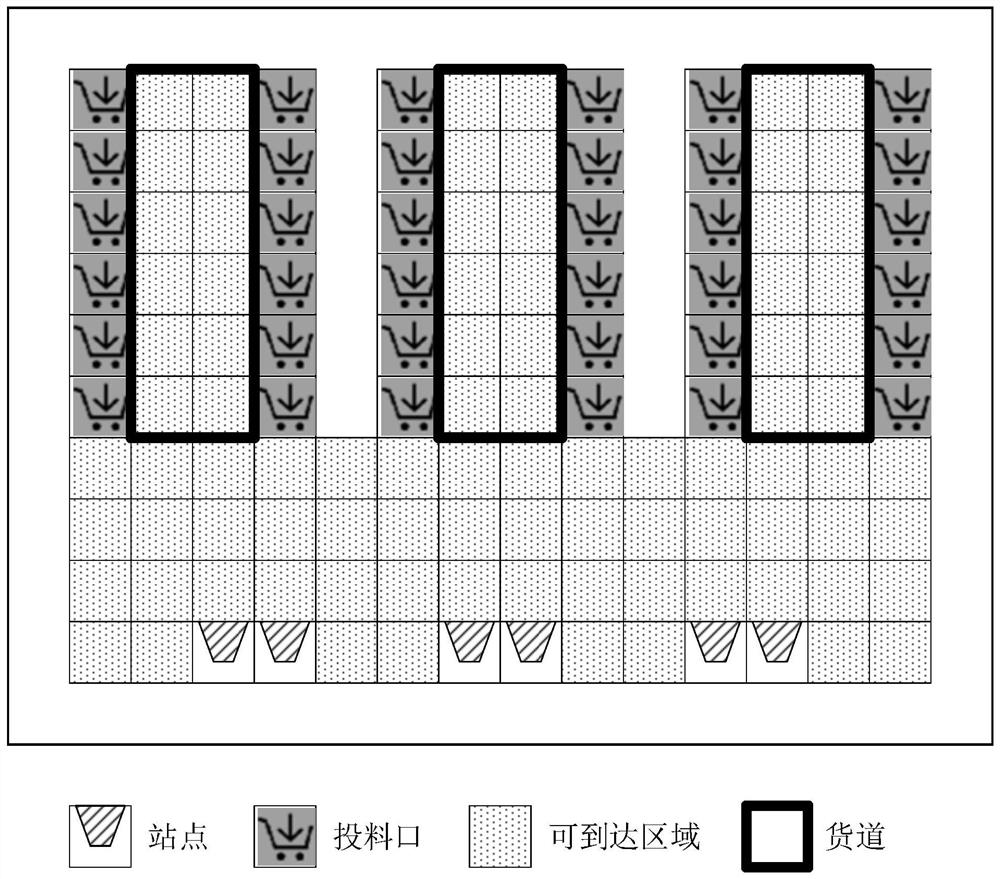

Order processing method and device in warehouse, medium, electronic equipment and system

PendingCN111652408AEasy to carryOptimize order allocationForecastingBuying/selling/leasing transactionsOrder processingEngineering

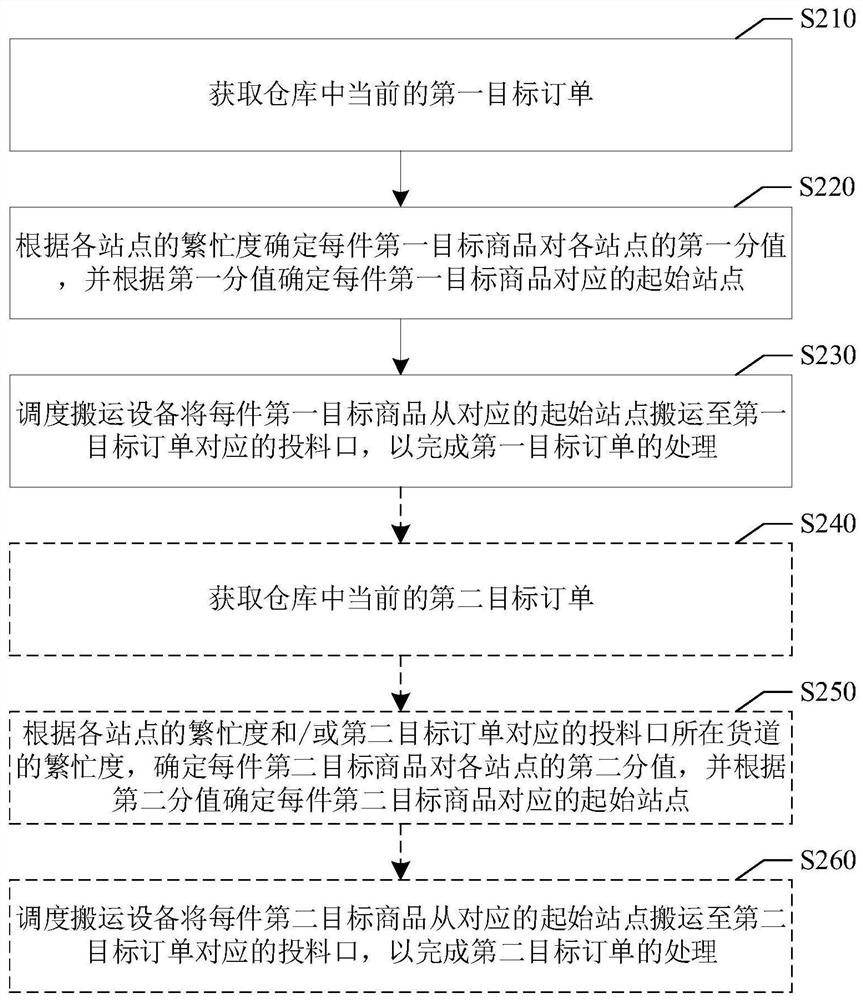

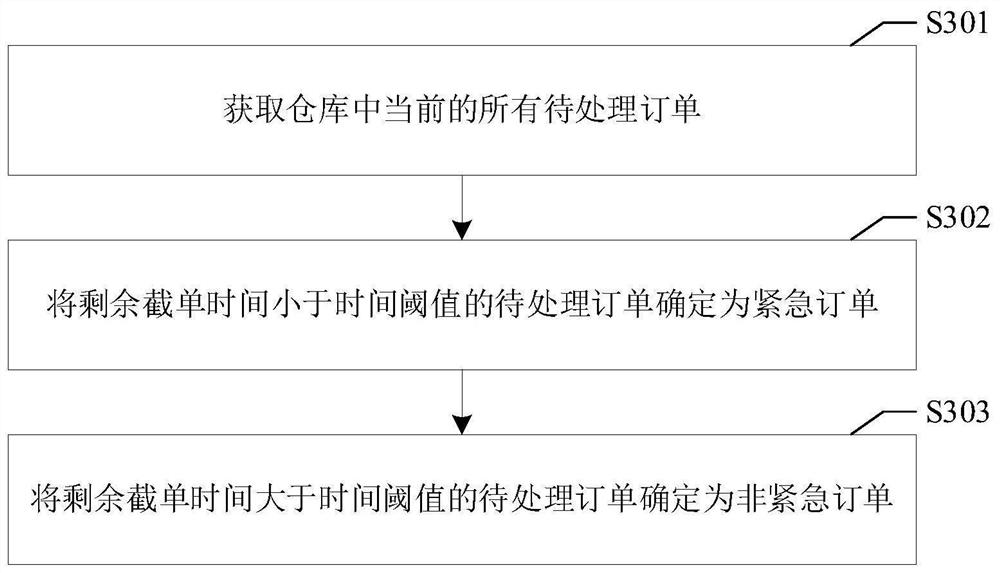

The invention provides an order processing method and device in a warehouse, a storage medium, electronic equipment and a warehouse management system, and relates to the technical field of logistics storage. The method comprises the steps of obtaining a current first target order in a warehouse; determining a first score of each first target commodity to each station according to the busy degree of each station, and determining a starting station corresponding to each first target commodity according to the first score, the first target commodity being a commodity in the first target order; and scheduling carrying equipment to carry each first target commodity from the corresponding starting station to a feeding port corresponding to the first target order, thereby finishing processing ofthe first target order. According to the invention, order allocation can be optimized globally, the situation of local task accumulation is avoided, and the order processing efficiency is improved.

Owner:BEIJING KUANGSHI ROBOTICS TECH CO LTD

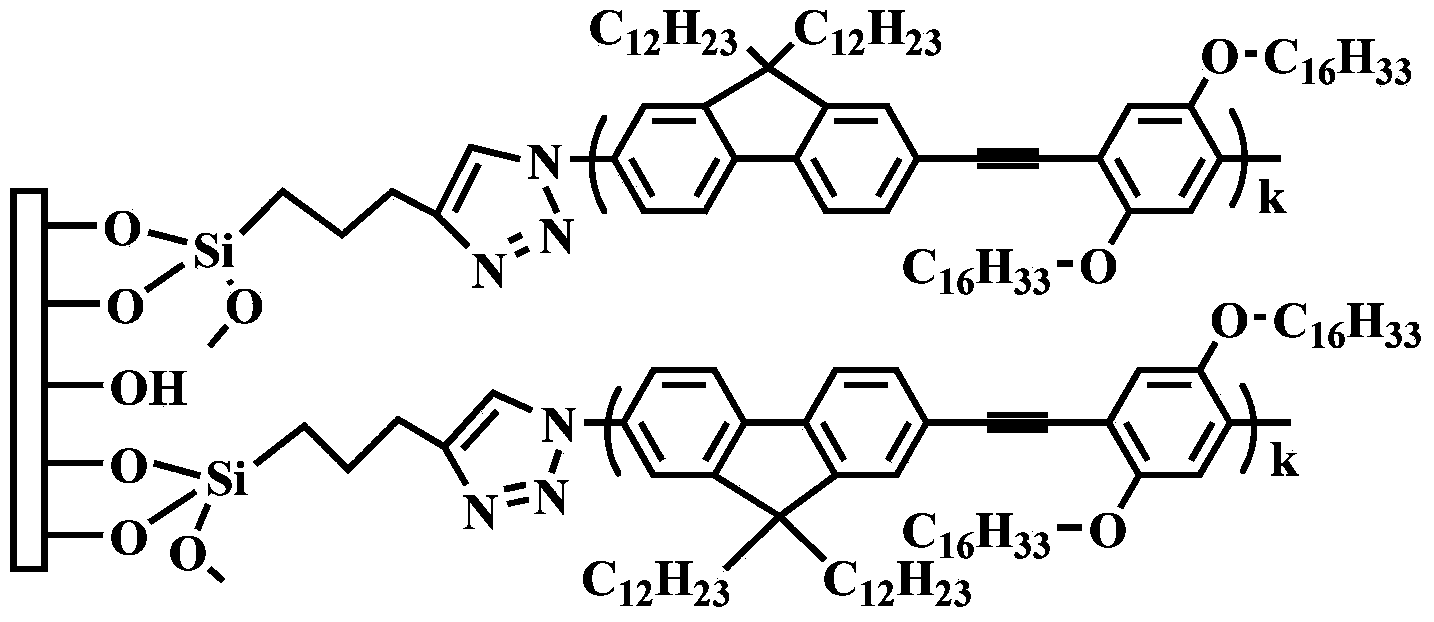

Single-layer fluorescent conjugated polymer membrane and preparation method thereof

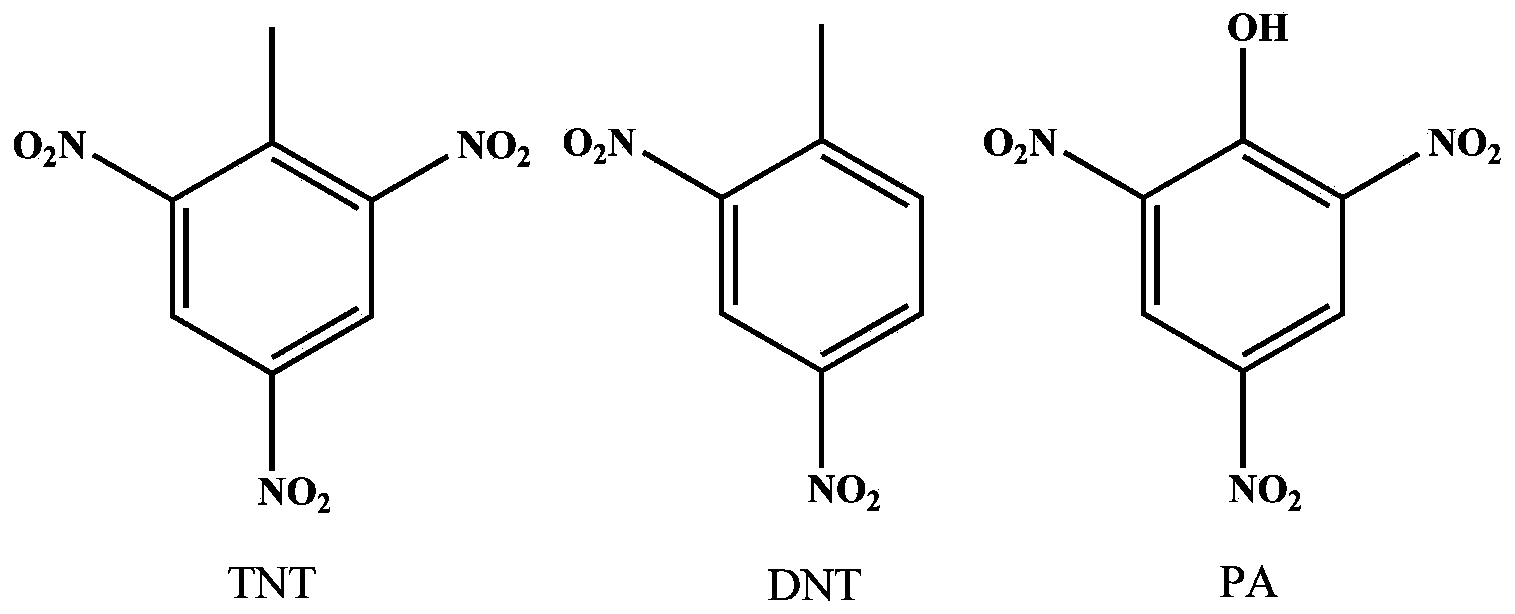

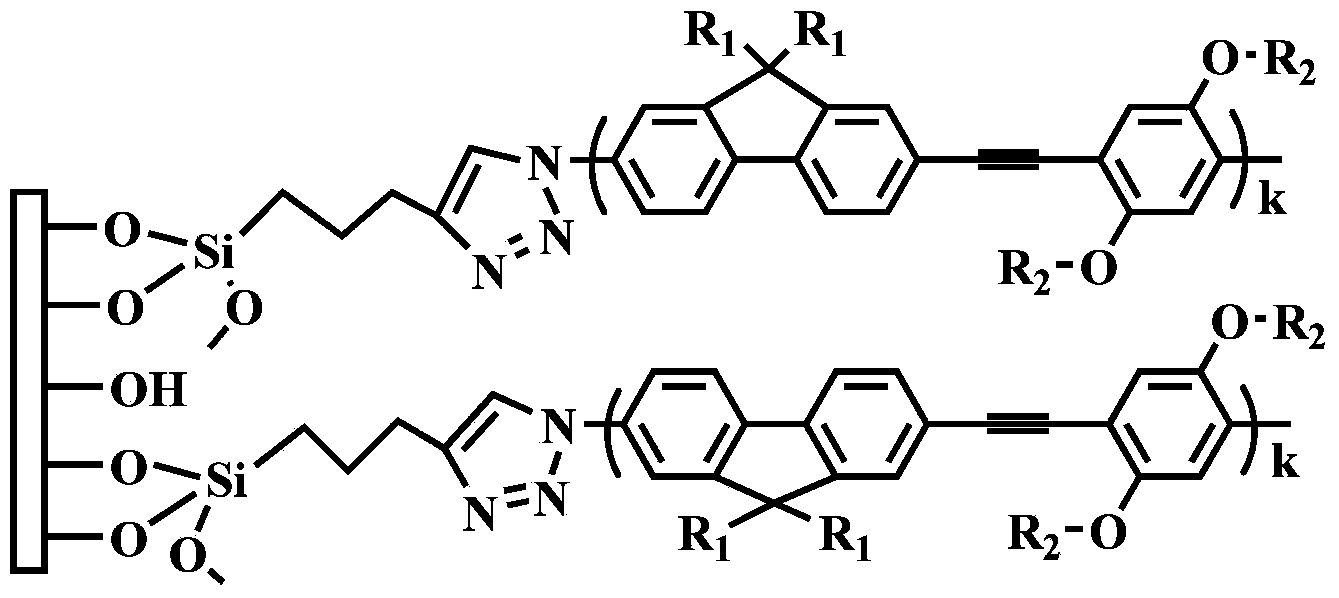

The invention discloses a single-layer fluorescent conjugated polymer membrane and a preparation method thereof. Long-chain aliphatic groups are introduced in carbon-9 and carbon-9' of fluorene; long-chain alkoxy groups are introduced in carbon-2 and carbon-5 of 1, 4-paradiiodobenzene; the two monomers are copolymerized to form a polymer; meanwhile, the polymer is immobilized on the surface of a substrate material to form a single-layer fluorescent conjugated polymer membrane material. The single-layer fluorescent conjugated polymer membrane material has excellent detection sensitivity to 1, 3, 5-trinitrotoluene, 2, 4-dinitrotoluene and 1, 3, 5-trinitrophenol.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

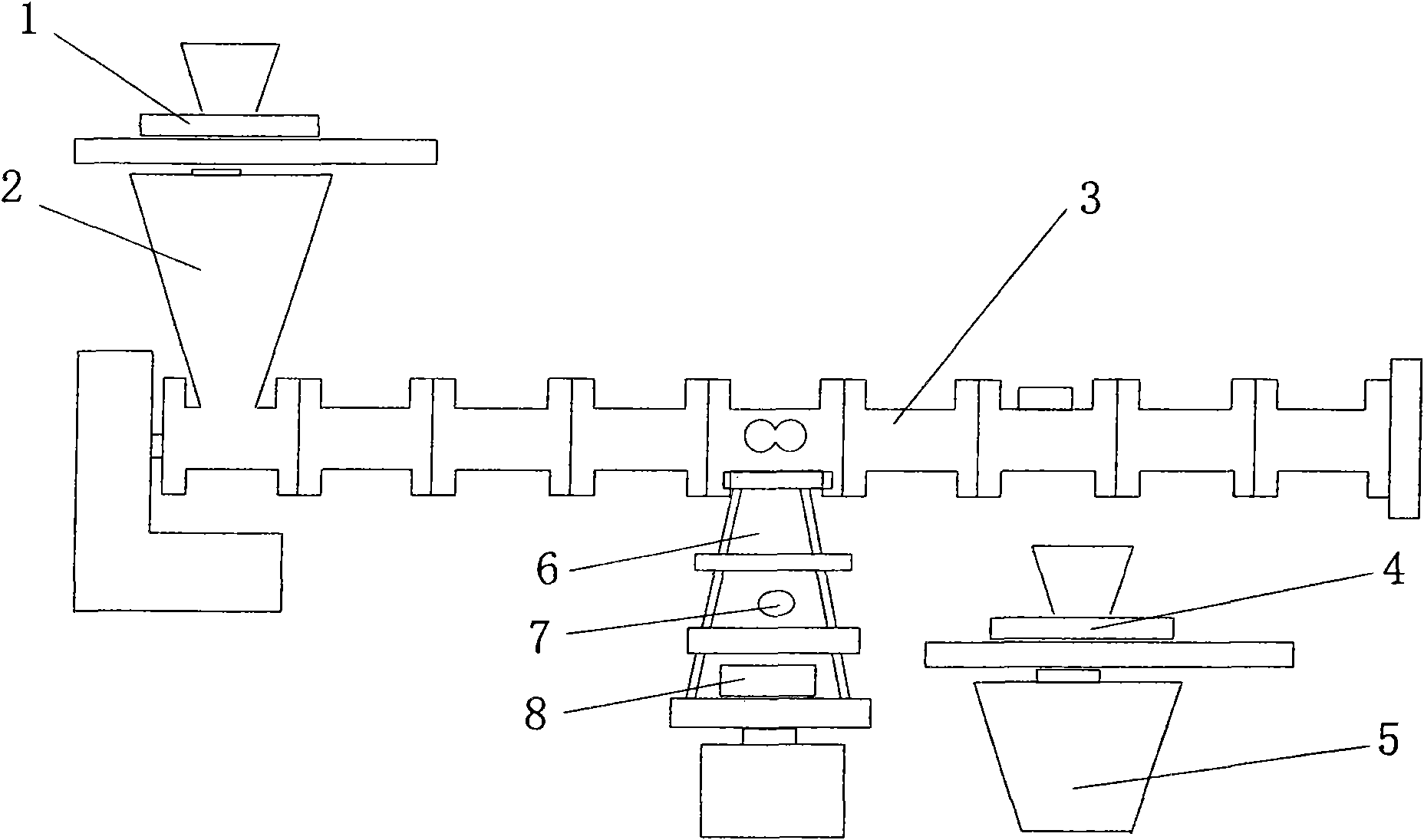

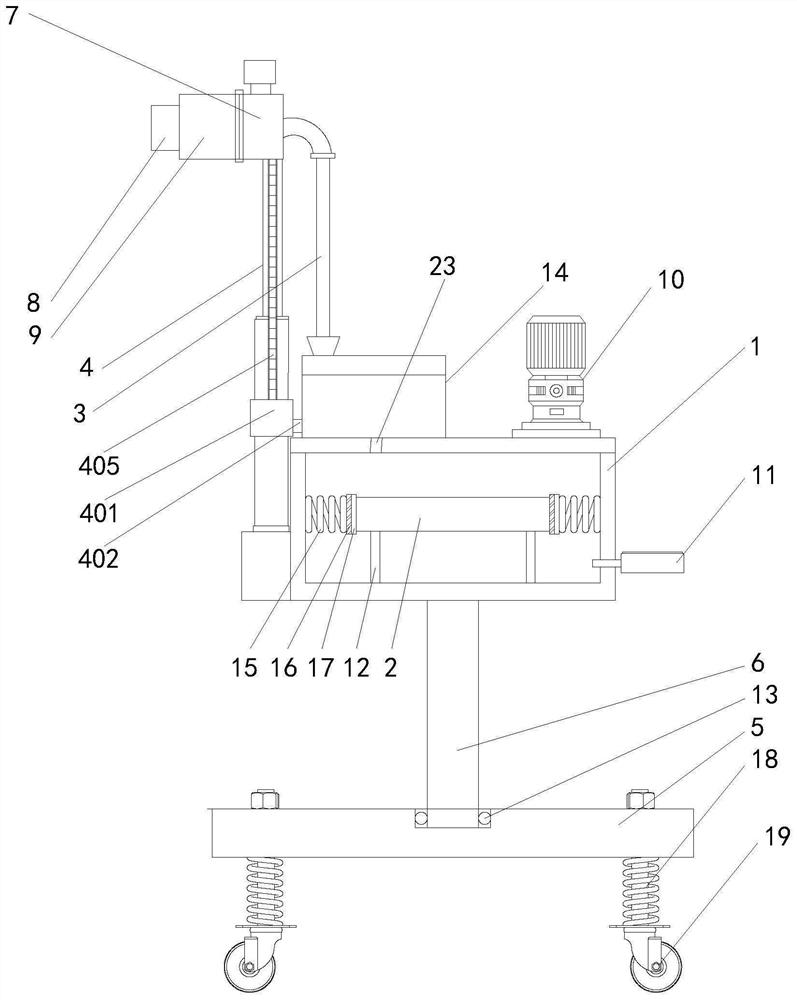

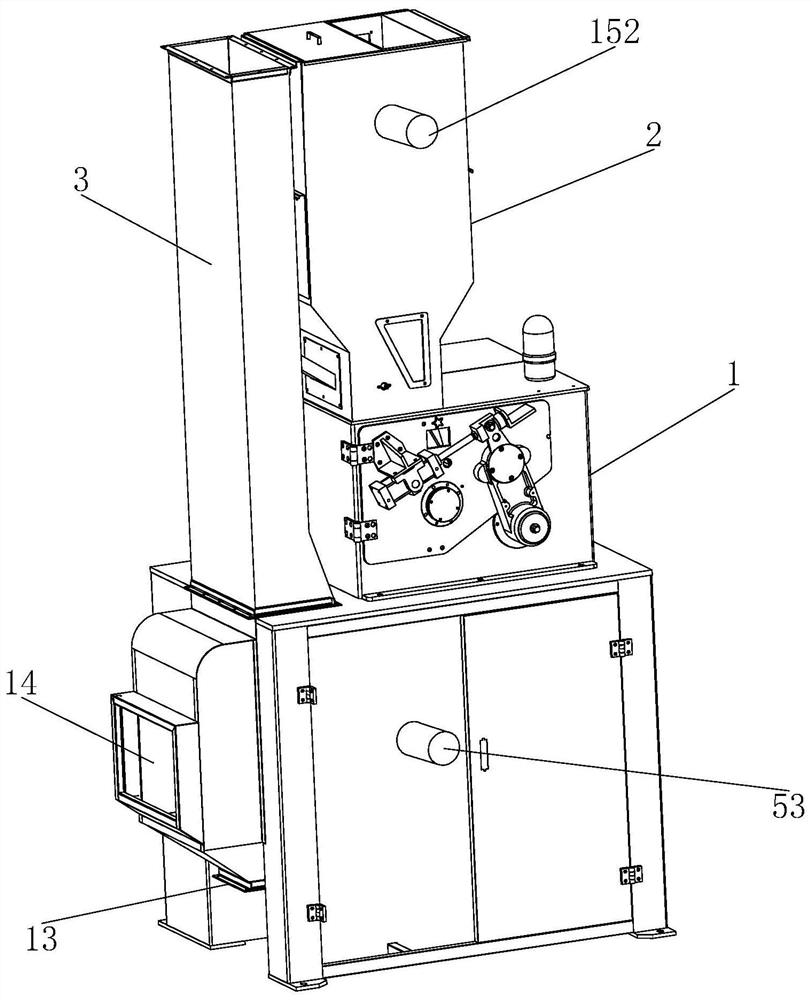

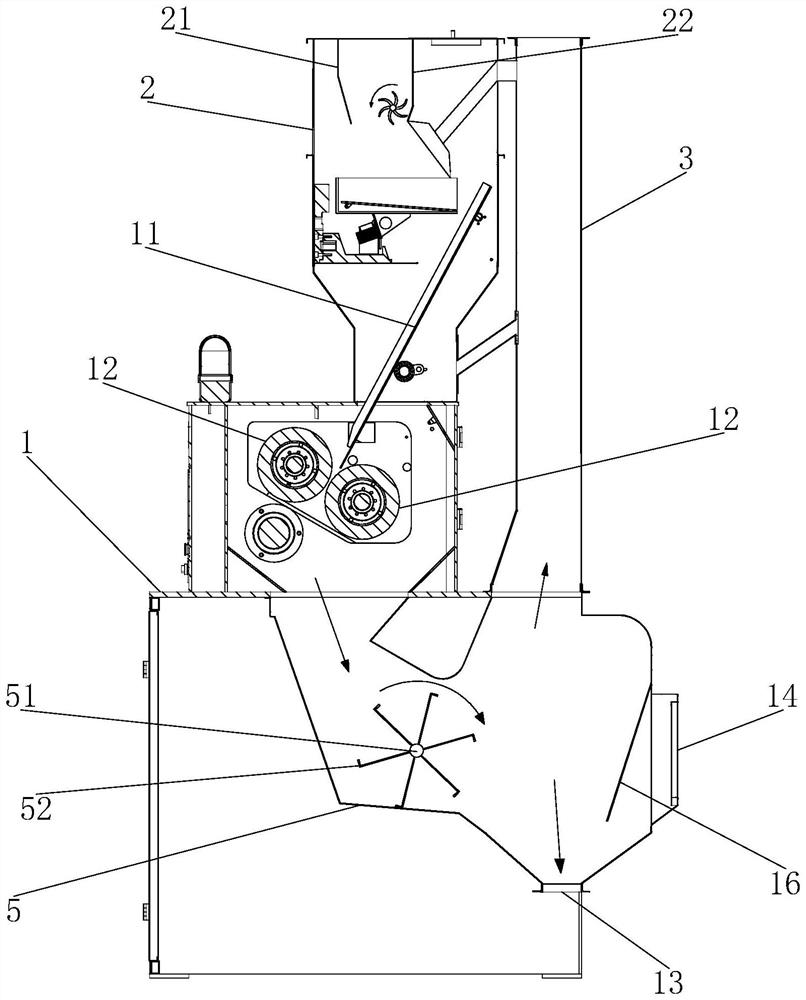

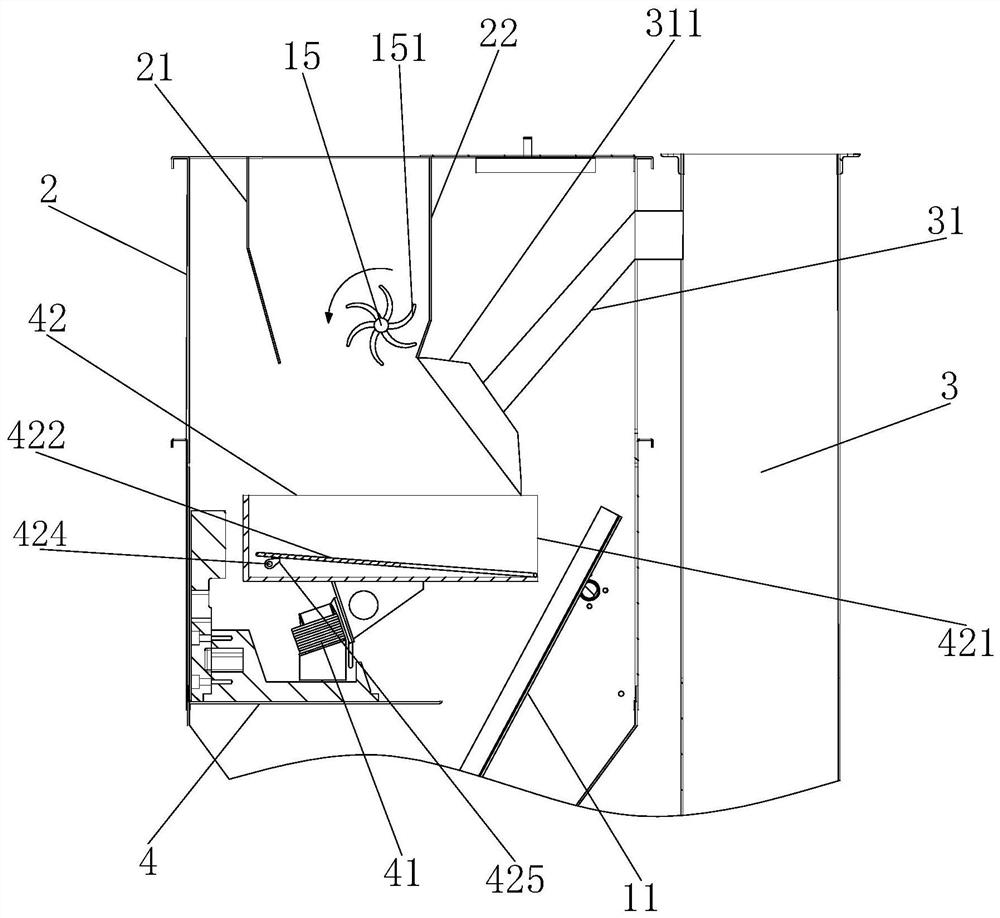

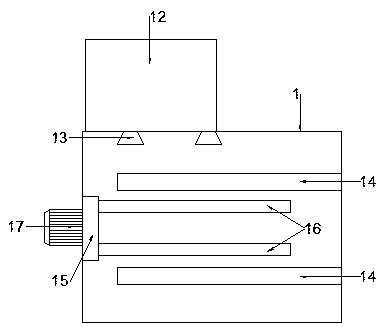

Rice huller with variable-frequency vibration feeding function

InactiveCN112774764AConvenient whereaboutsAccurate whereaboutsGrain huskingGrain polishingAnimal scienceElectric machinery

The invention relates to the technical field of rice huller design, and discloses a rice huller with a variable-frequency vibration feeding function. The rice huller comprises a machine body, a feeding hopper, a falling plate, two rubber rollers, a discharge port, an extraction pipe and an air inlet, a first guide plate is arranged at the upper end in the feeding hopper, and a second guide plate is further arranged at the position, located at one side of the first guide plate, in the feeding hopper. The lower end of the first guide plate inclines towards one side of the second guide plate, a rotating shaft is arranged at the position, located at the lower end of the second guide plate, in the machine body, feeding paddles are arranged at the peripheral side of the rotating shaft, and a driving motor used for being connected with the rotating shaft is arranged at the outer side of the feeding hopper. After rice enters the feeding hopper, the driving motor is used for driving the rotating shaft and the feeding paddles to rotate, and at the moment, the feeding paddles can turn over the rice between the first guide plate and the second guide plate and apply downward acting force to the rice, so that the possibility that the rice is blocked between the first guide plate and the second guide plate can be reduced.

Owner:浙江粮工机械科技有限公司

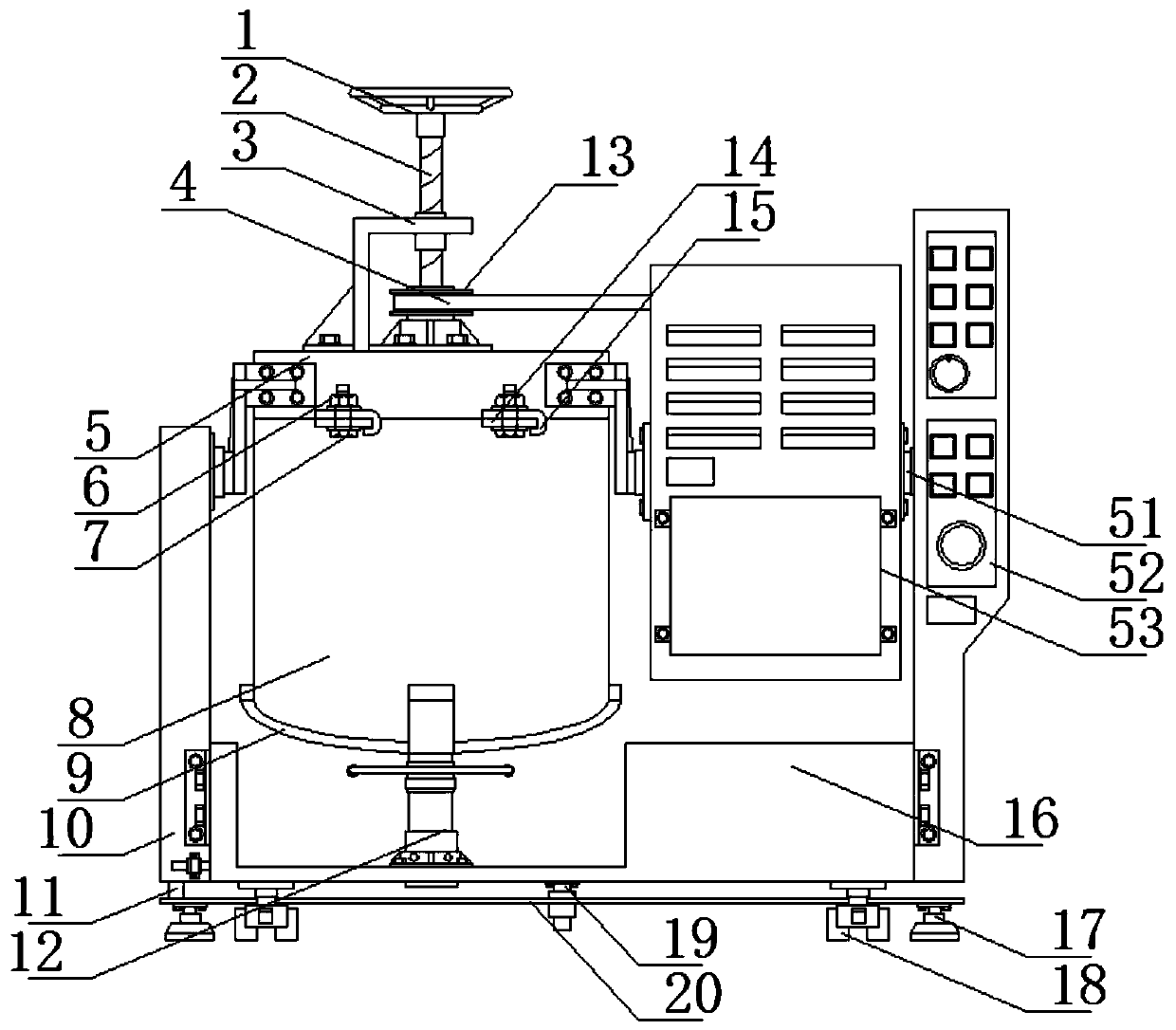

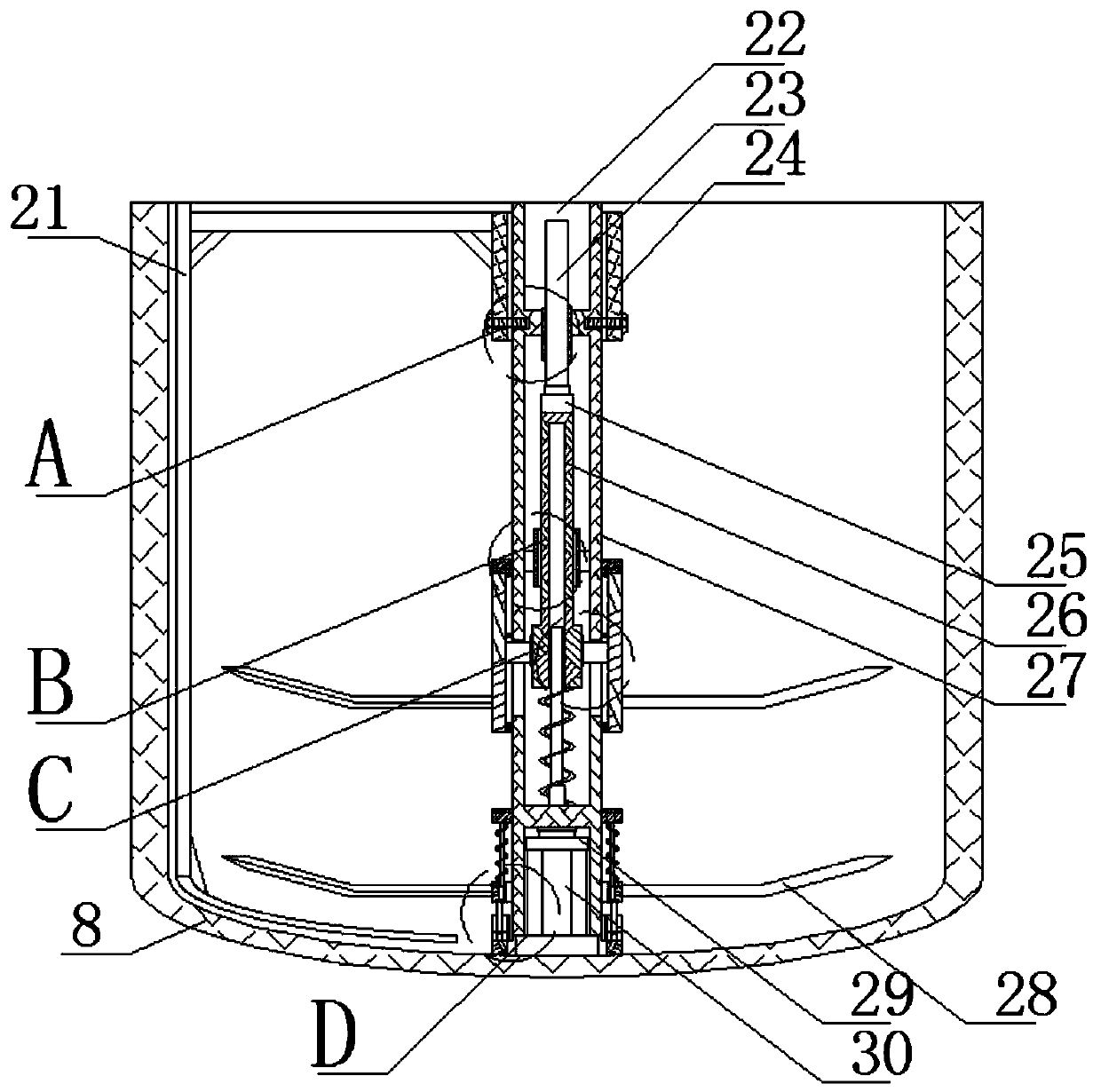

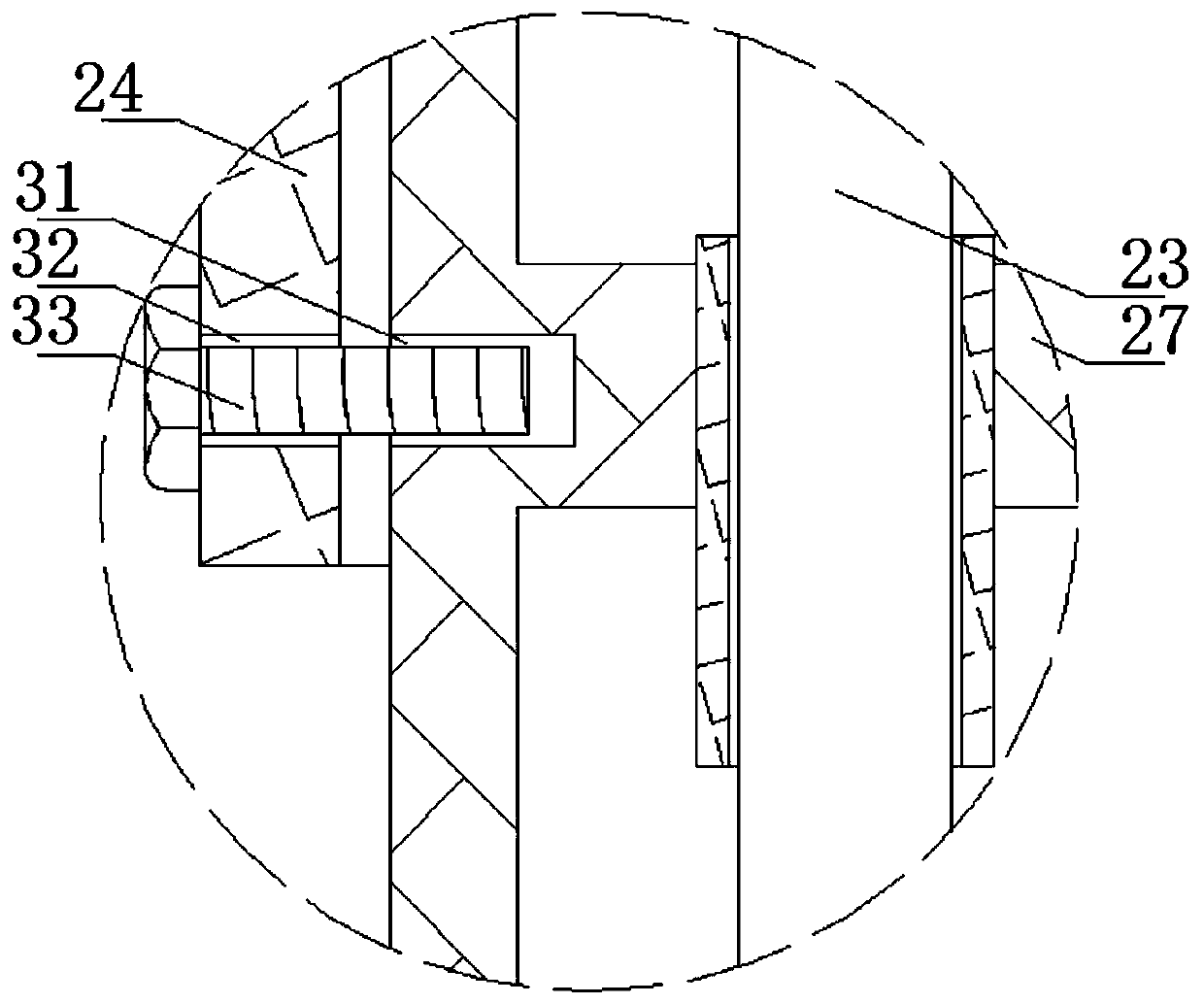

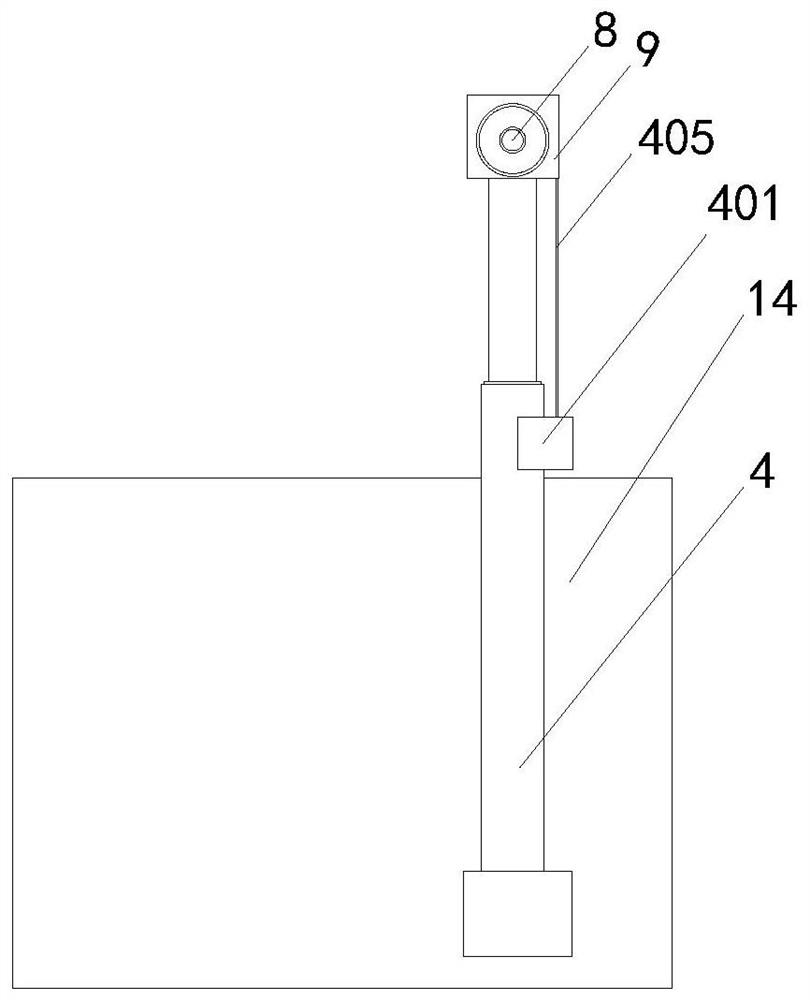

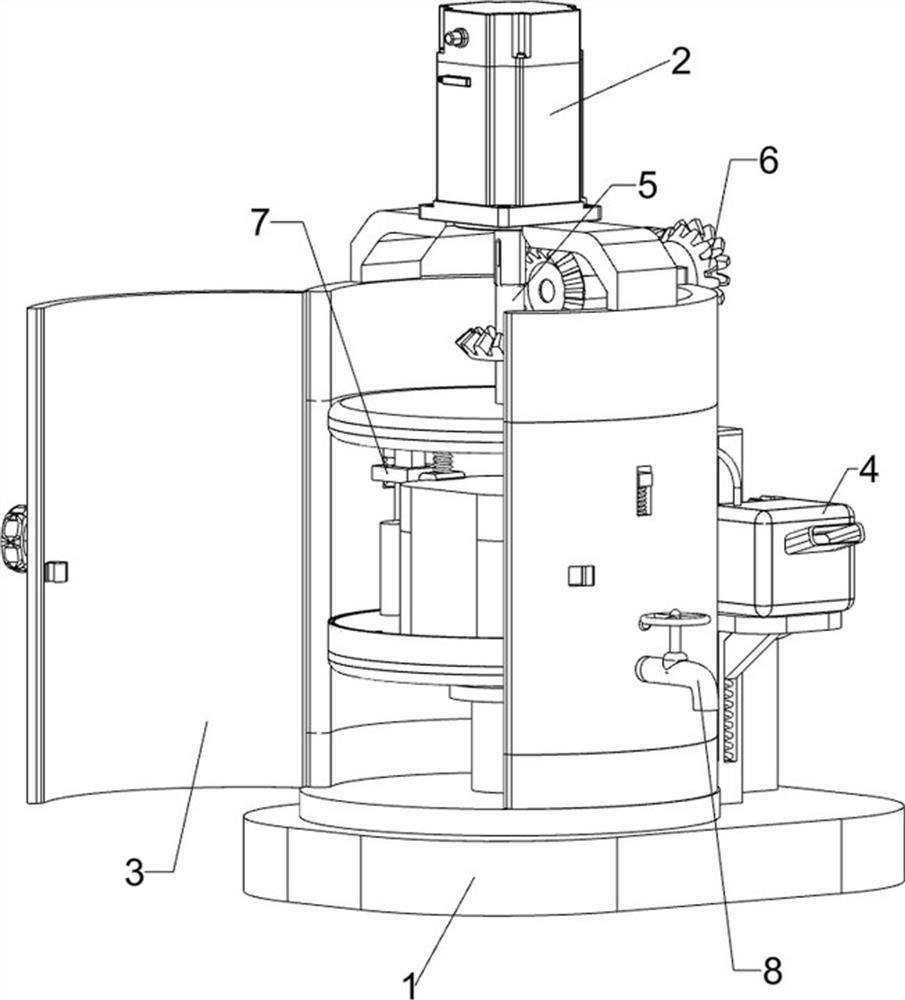

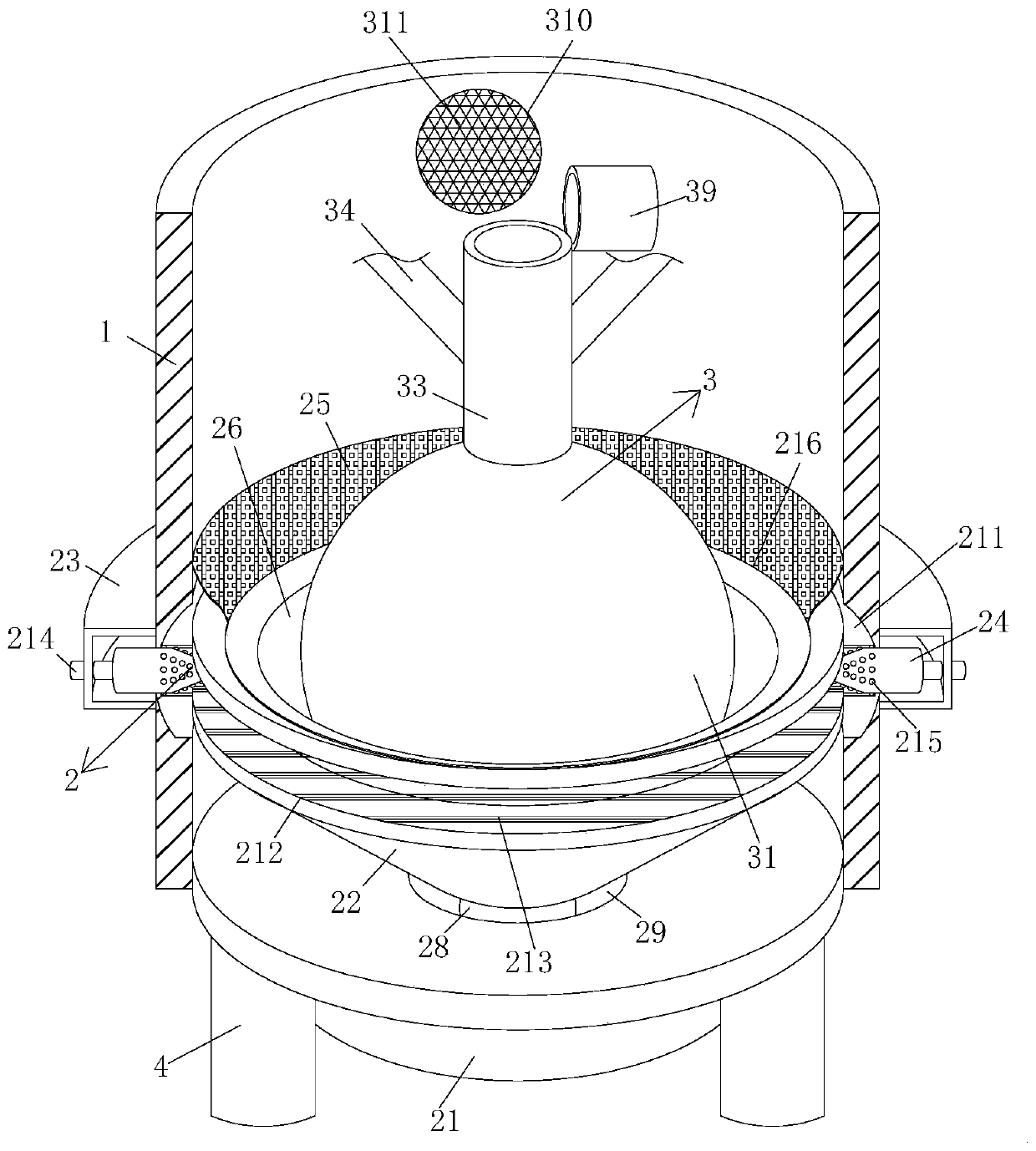

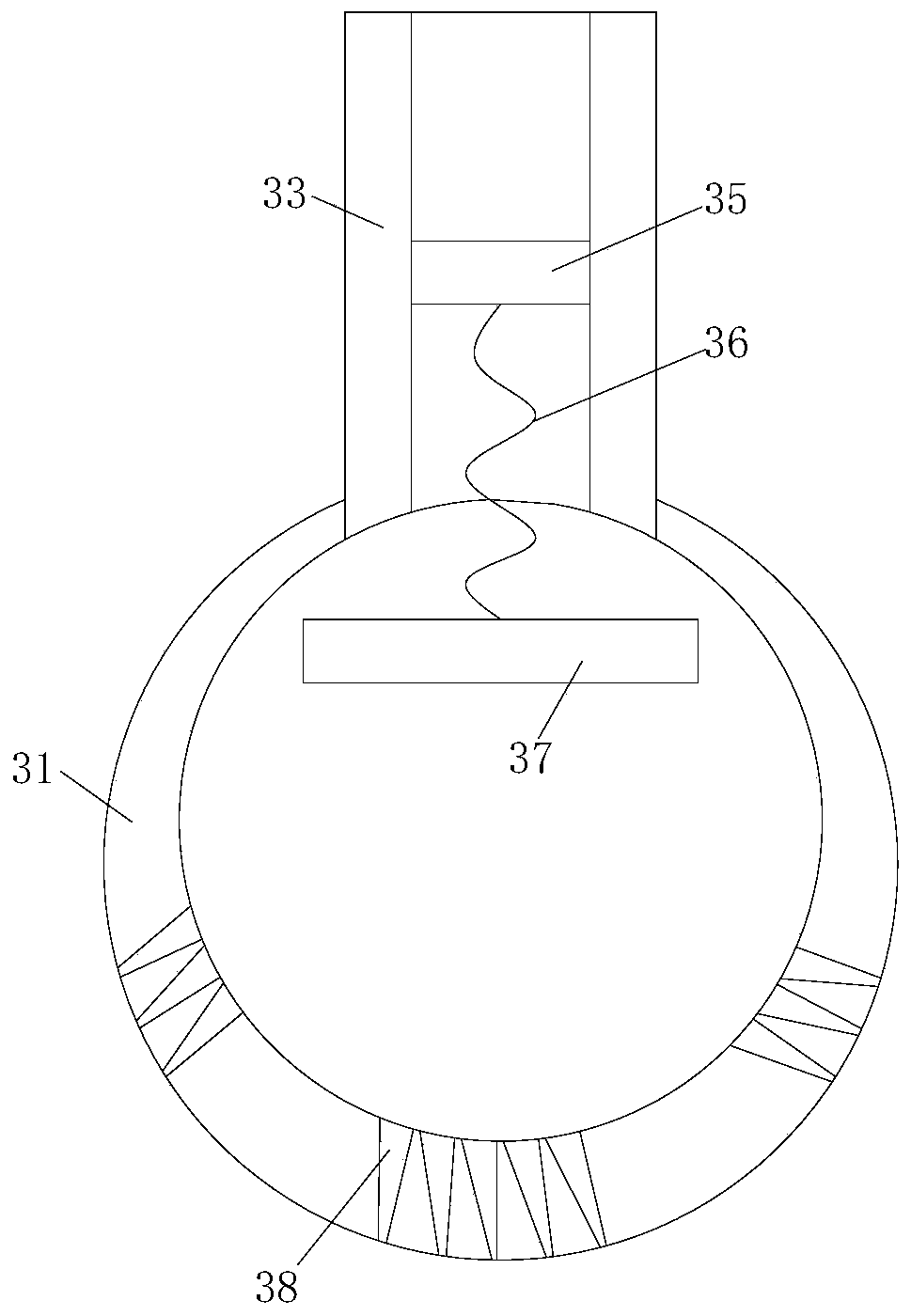

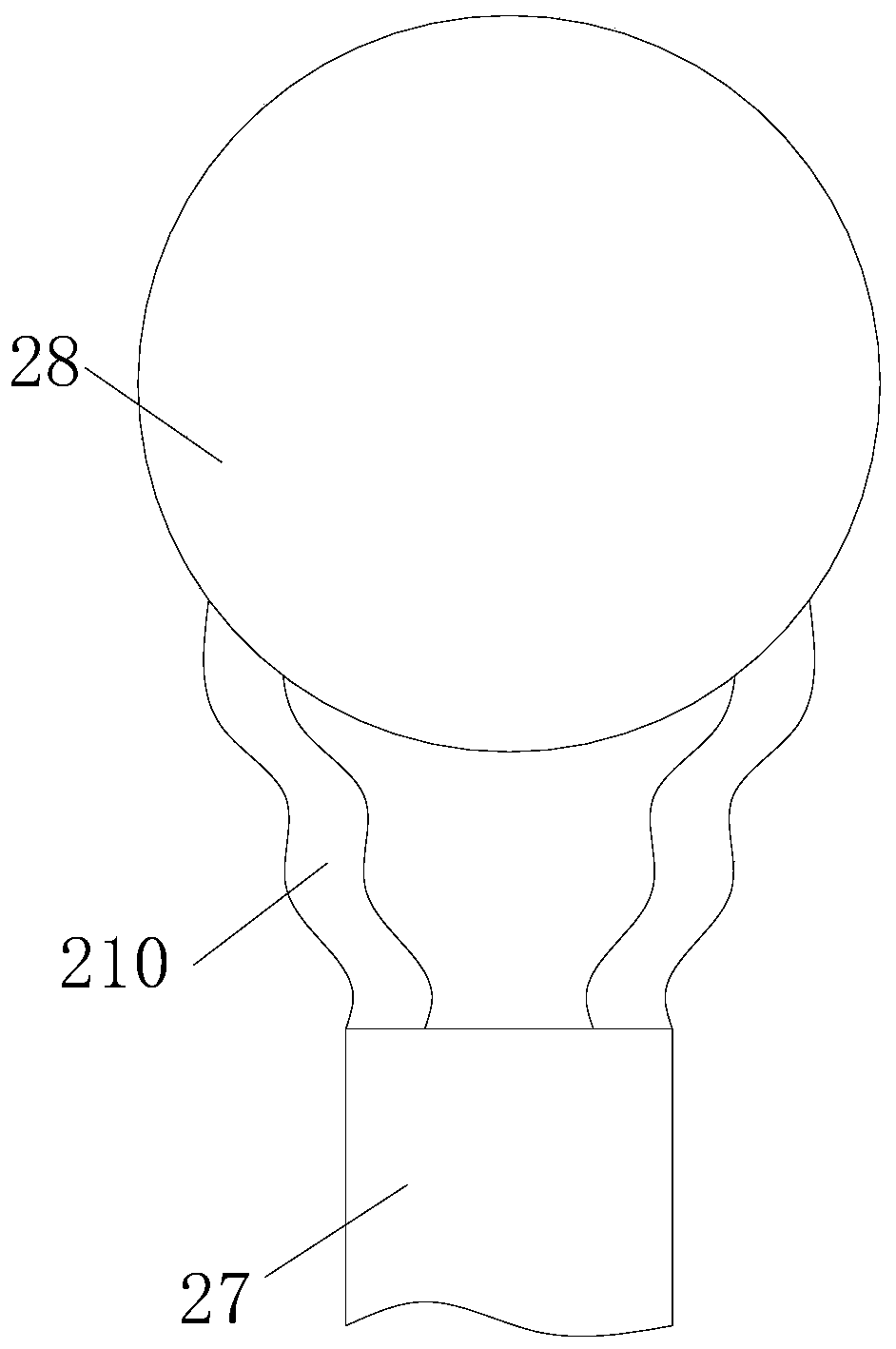

Attrition mill grinding bin capable of automatic feeding

InactiveCN105032588AGood dispersionEvenly distributedGrain treatmentsDecompression chamberMechanical engineering

The invention discloses an attrition mill grinding bin capable of automatic feeding. The grinding bin comprises a grinding bin body, a decompression chamber, an air outlet pipe and air inlet pipes, wherein a plurality of air inlets are formed on one side of a connecting part between each air inlet pipe and the grinding bin body; the grinding bin body comprises a feed pipe, a stock bin, discharge pipes and U-shaped circular grooves; a feed port of the feed pipe stretches out of the side surface of the grinding bin body; a discharge port of the feed pipe is connected with a material inlet of the stock bin; the stock bin is fixedly mounted on a rotating shaft; at least one stock bin discharge port is formed in the side surface of the stock bin and fixedly connected with the discharge pipes; discharge ports of the discharge pipes are connected with the U-shaped circular grooves; the stock bin is in a cylinder structure with both the bottom surface and the top surface being in regular polygon shapes; one storage bin discharge port is formed in each rectangular side surface of the stock bin; and the stock bin is internally provided with a cone taking the bottom surface of the stock bin as the bottom surface. The grinding bin is provided with the cone taking the bottom surface of the stock bin as the bottom surface, so that the situation that material accumulation of the stock bin occurs due to the fact that a material does not slide down timely can be avoided, and the material can enter the U-shaped circular grooves fully.

Owner:CHENGDU CHENHONG TECH

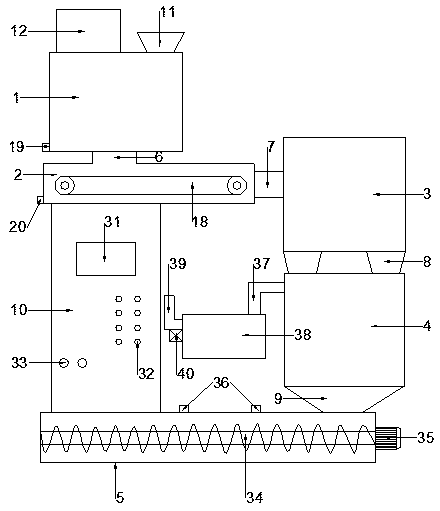

High-efficiency waste plastic processing and regenerating equipment

InactiveCN110435049AImprove cleaning efficiencyAvoid many and incomplete problemsPlastic recyclingMechanical material recoveryEngineeringMechanical engineering

The invention discloses high-efficiency waste plastic processing and regenerating equipment. The high-efficiency waste plastic processing and regenerating equipment comprises a cleaning work box, a feeding box, a crushing box, a stirring box and a spiral extrusion box, wherein the feeding box is arranged at the bottom of the cleaning work box; the cleaning work box and the feeding box are connected by a first discharge port; the crushing box is arranged at one side of the feeding box; the crushing box and the feeding box are connected by a second discharge port; the stirring box is arranged below the crushing box; the stirring box and the crushing box are connected by third discharge ports; the third discharge ports are respectively arranged at the two ends of the bottom of the crushing box; the spiral extrusion box is arranged at the bottom of the stirring box; the spiral extrusion box and the stirring box are connected by a fourth discharge port; a control cabinet is arranged betweenthe feeding box and the spiral extrusion box; and the feeding box and the spiral extrusion box are connected to the control cabinet. The high-efficiency waste plastic processing and regenerating equipment solves the problem that waste plastic is not completely cleaned and the plastic is not fully crushed, fully crushes the plastic and ensures the crushing quality.

Owner:陶媛媛

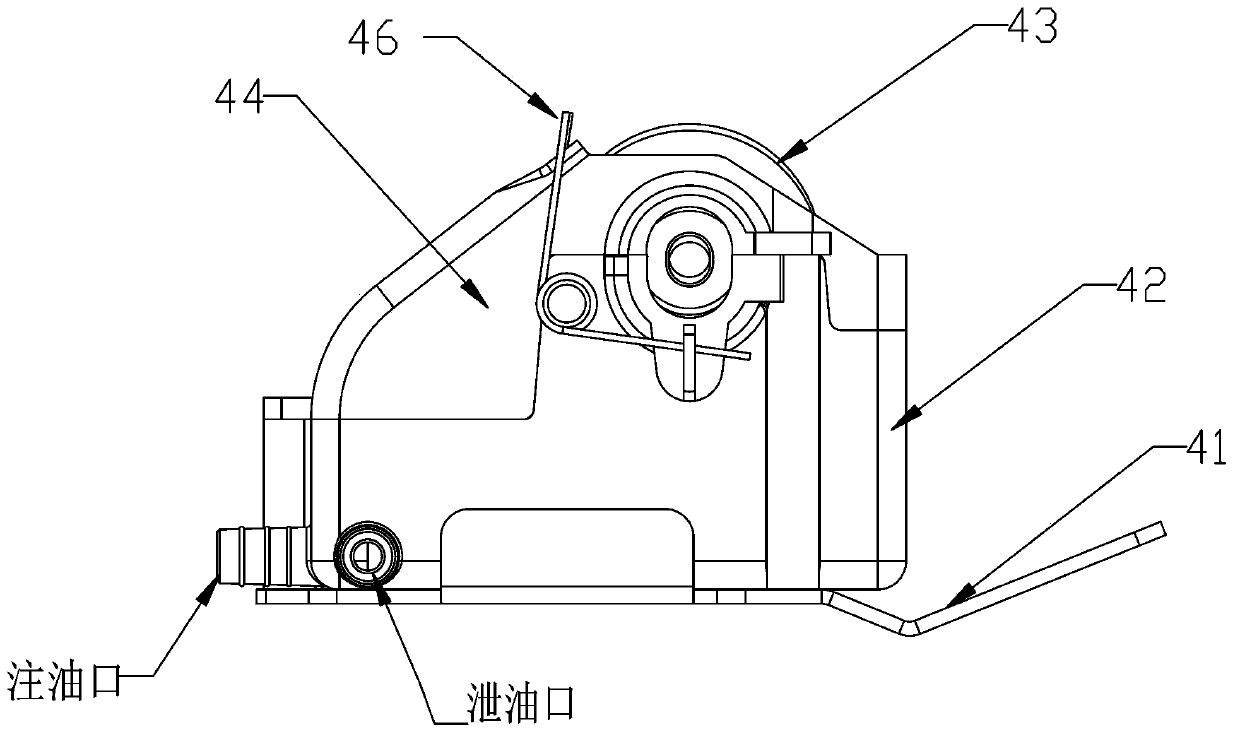

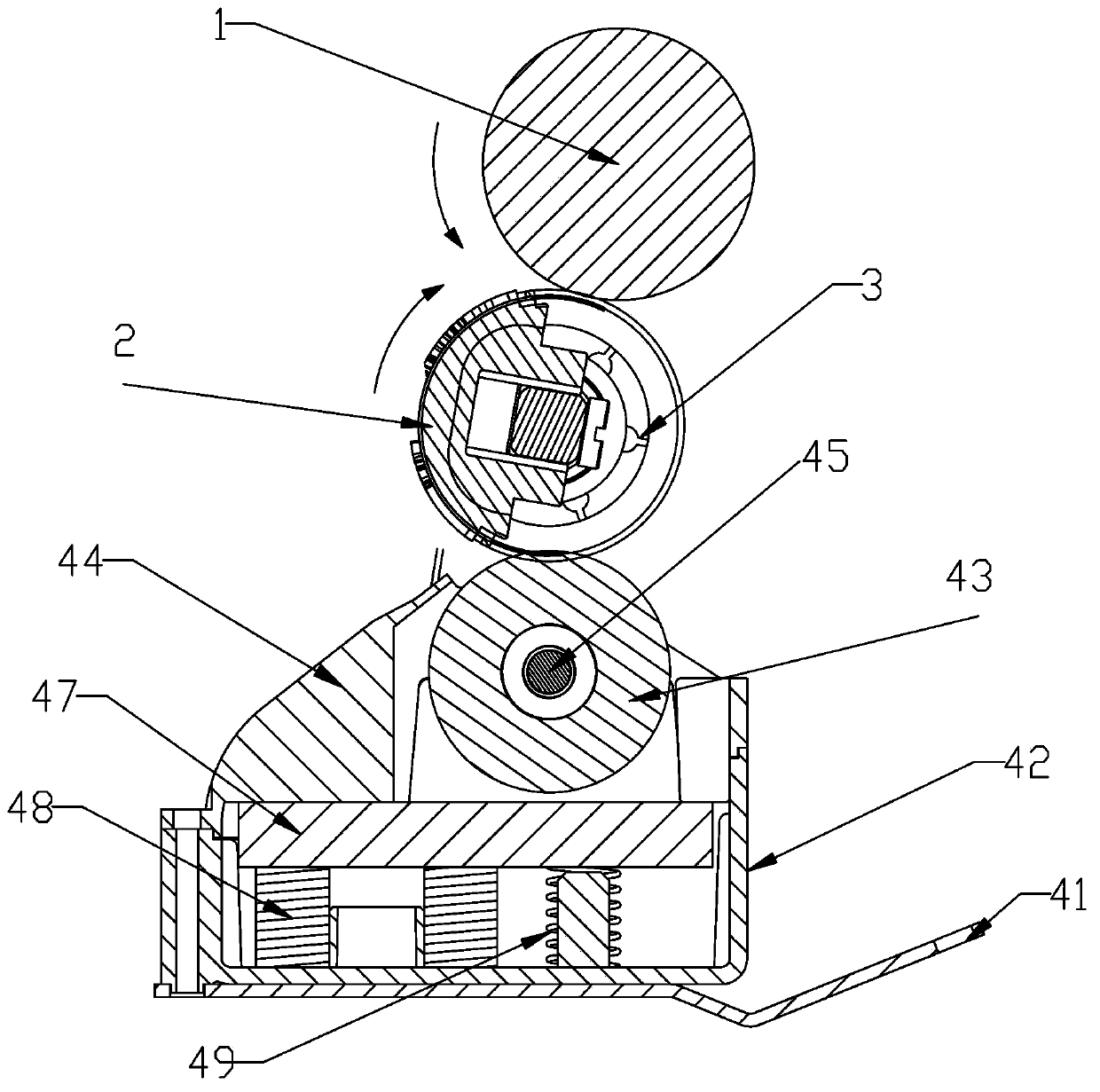

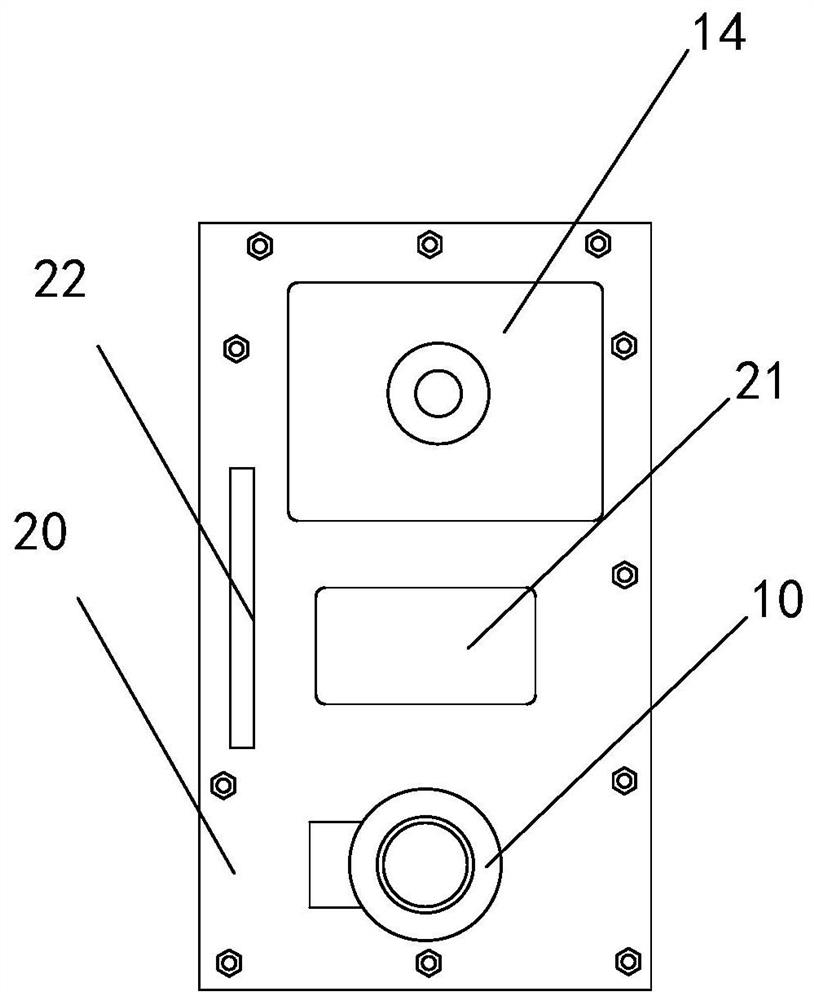

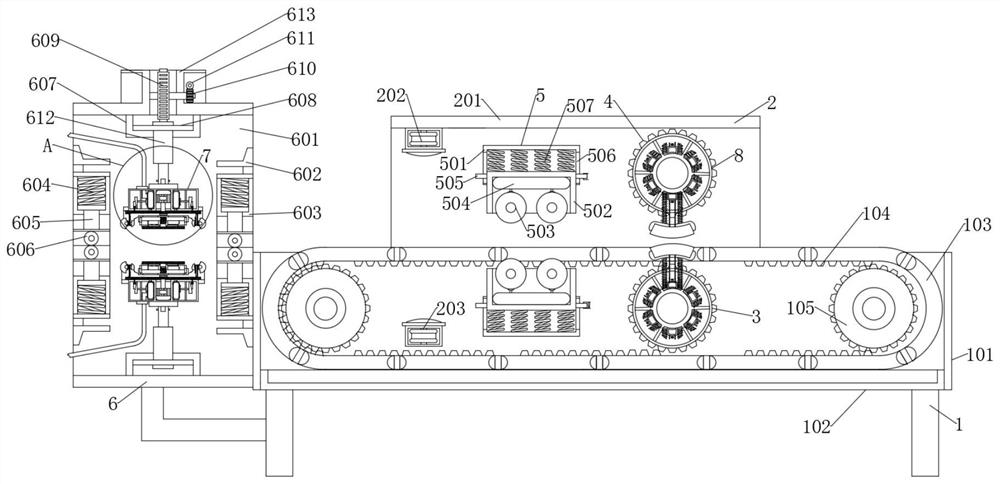

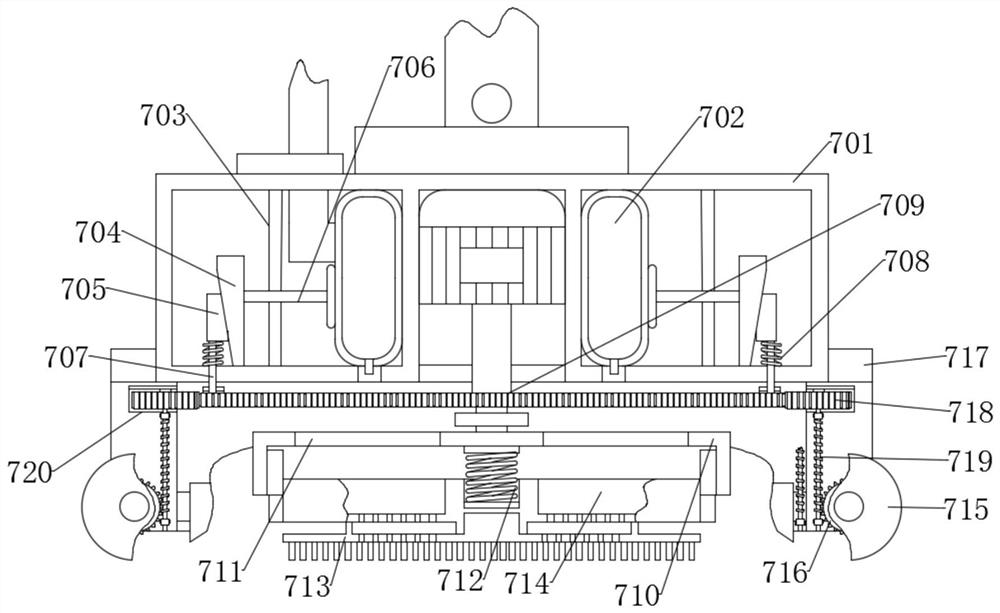

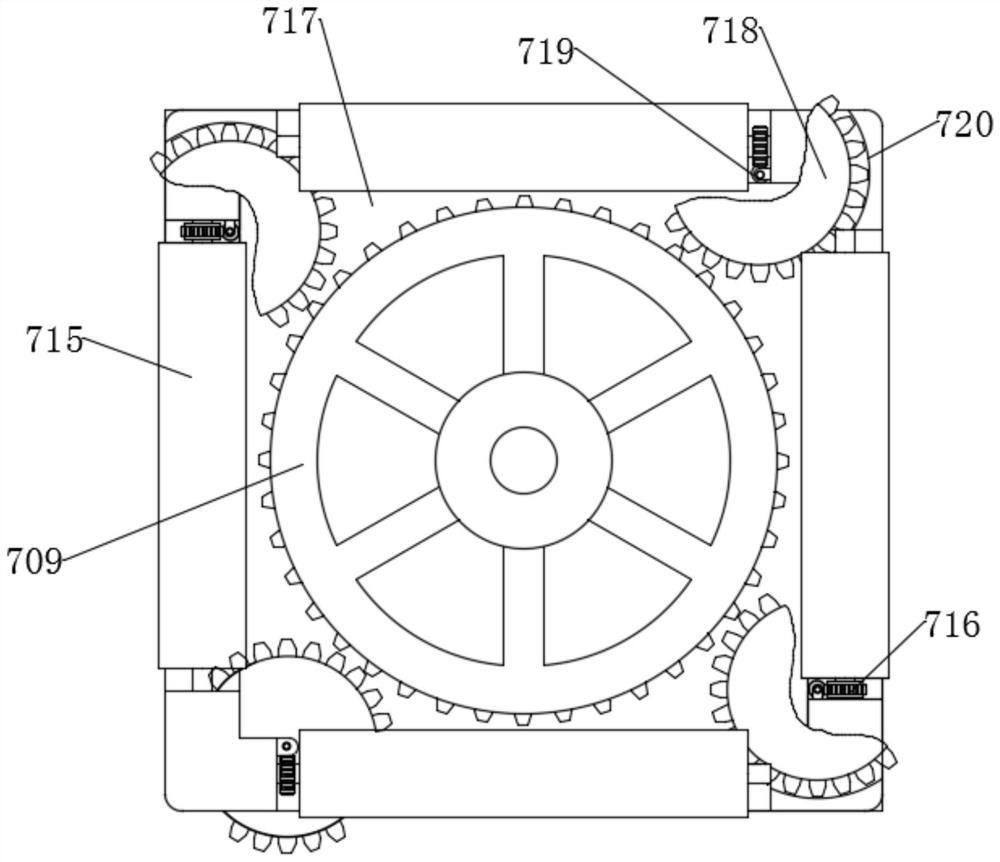

Detection oiling mechanism for big-data slide rail automatic production line and using method thereof

InactiveCN111957523APrevent stackingAvoid wasteful situationsLiquid surface applicatorsCleaning using toolsProduction lineGear wheel

The implement of the invention discloses a detection oiling mechanism for a big-data slide rail automatic production line. The detection oiling mechanism comprises a main body frame; a fixing shield is arranged on the upper part of the main body frame; an upper surface detector is arranged on the fixing shield; a main oiling component which is used for dusting and oiling an upper surface of a workpiece is arranged on a right side of the upper surface detector; a sub oiling component is connected to one side of the main body frame; the main oil component and the sub oiling component are arranged on the equipment, so that two times of oiling is performed on the surface of the workpiece, and the condition that partial zone is not oiled is avoided; besides, when the workpiece is subjected to sufficient oiling operation, an oil storage bag can only output oil when being pressed, so that the amount of oiling can be controlled; when an oiling disc is used for oiling, the oiling disc rotates for oiling in a manner of clinging to the surface of the workpiece; meanwhile, when a driving gear rotates, an oil baffling oiling wheel is driven to rotate, so that after primary oiling is performed by the oiling disc, the oil baffling oiling wheel is used for oiling again; and therefore, oil covering the surface of the workpiece is more uniform.

Owner:韶关市华思迅飞信息科技有限公司

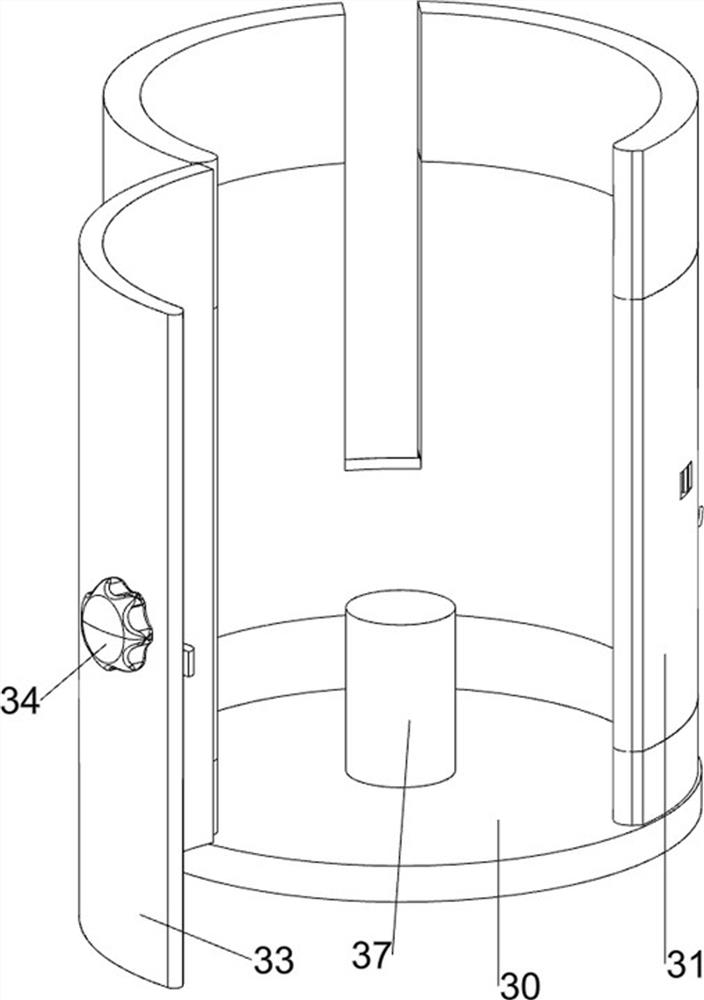

Wire winding device for electric cloth hanger and electric cloth hanger

ActiveCN107458979AAvoid knotsPrevent rope skipping (i.e. the thread does not wrap around the specified trajectory)Other drying apparatusWinding mechanismsElectric machineryControl theory

The invention discloses a wire winding device, which comprises a wire winding component, a driving component, and a wire winding clutch component; the wire winding component is used for making a cable wind; the driving component is used for driving the wire winding component to rotate; the wire winding clutch component is used for detecting if the cable is under a loosening state; if it is detected that the cable is under the loosening state, generating a stopping signal for stopping the running of the driving component, so that the driving component stops running according to the stopping signal. The wire winding device and the electric cloth hanger with the wire winding device can avoid cable knotting and blocking in the process of winding, thus the cable can be orderly wound on the rotary cylinder side by side under the driving of the motor.; meanwhile, when the cable is under the loosening state, the motor can automatically stop running and prevent more serious cable knotting, skipping and other status.

Owner:JIAXING HUATE MECH ELECTRICAL

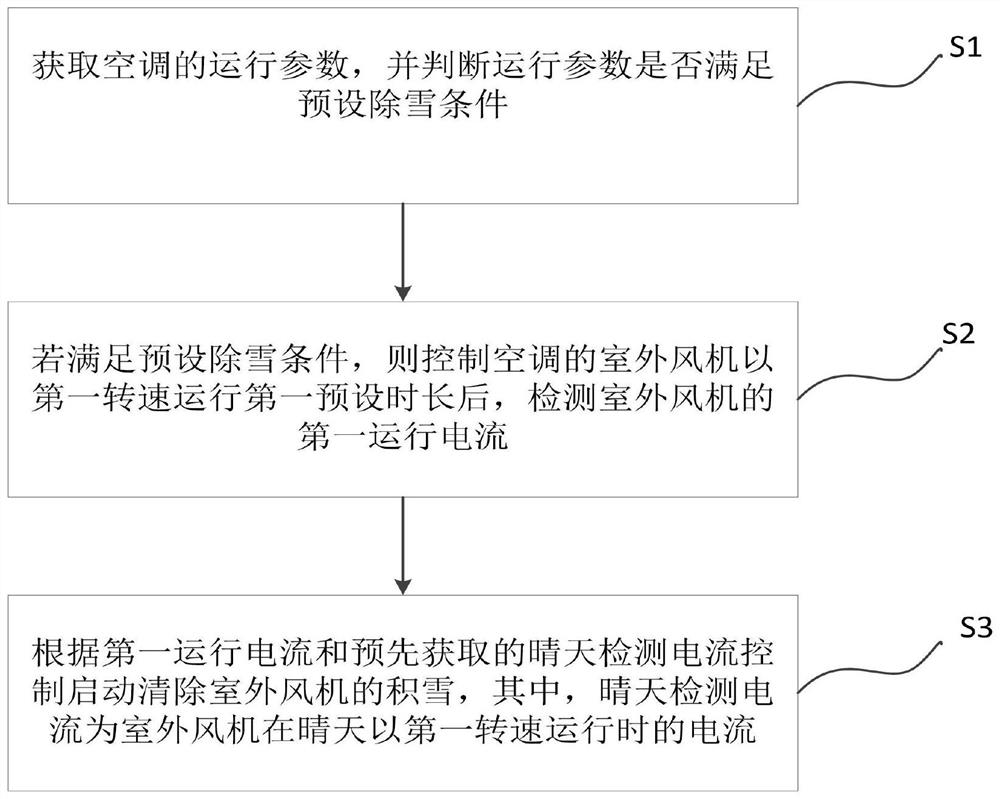

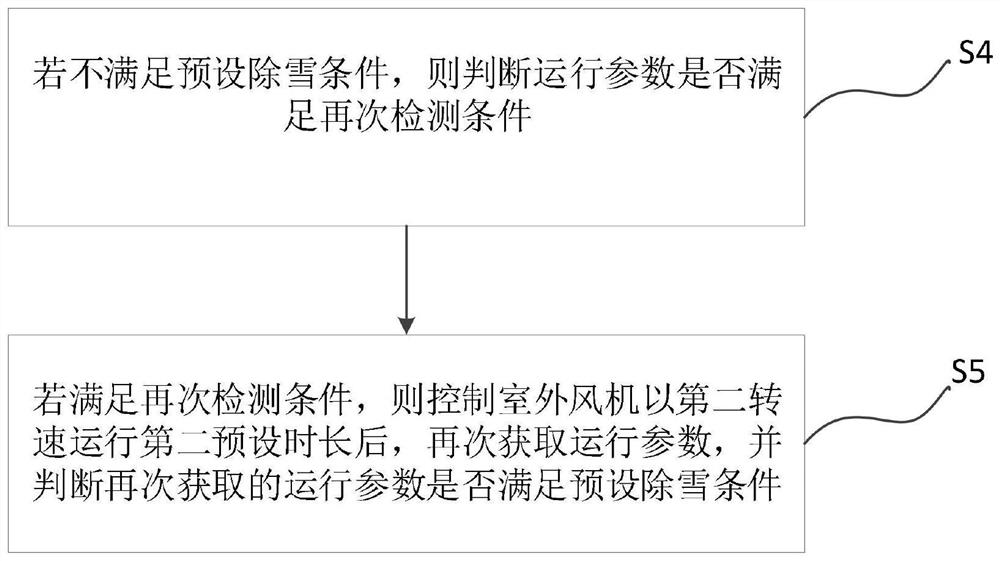

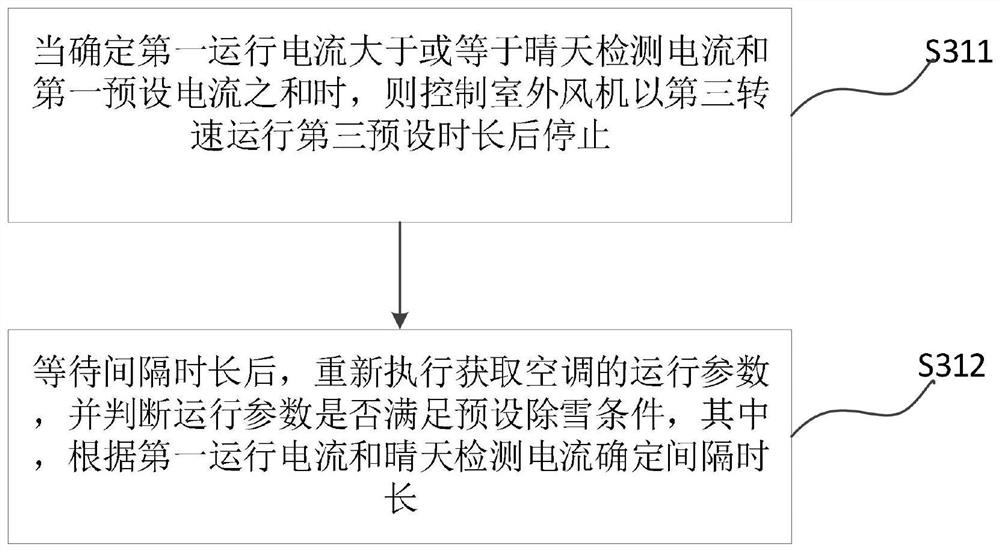

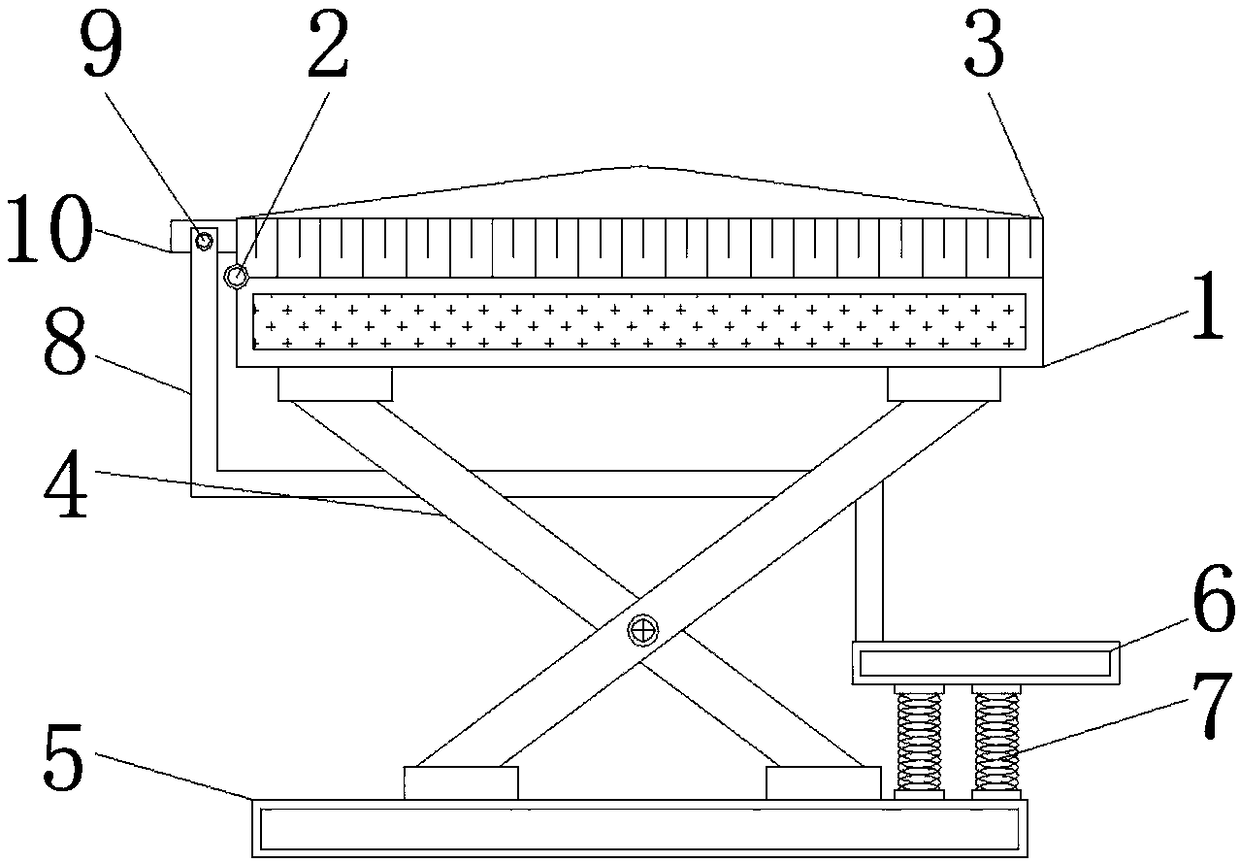

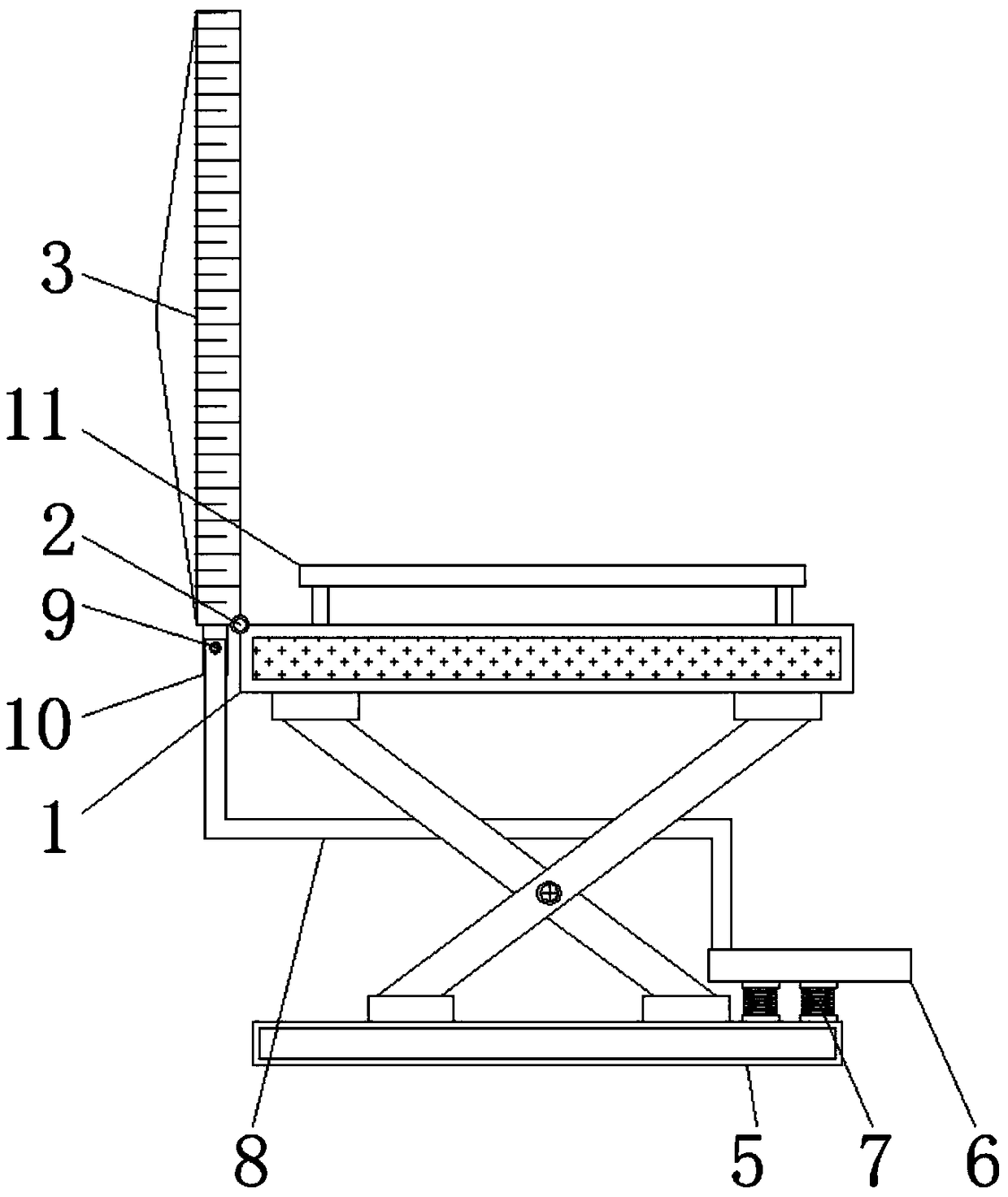

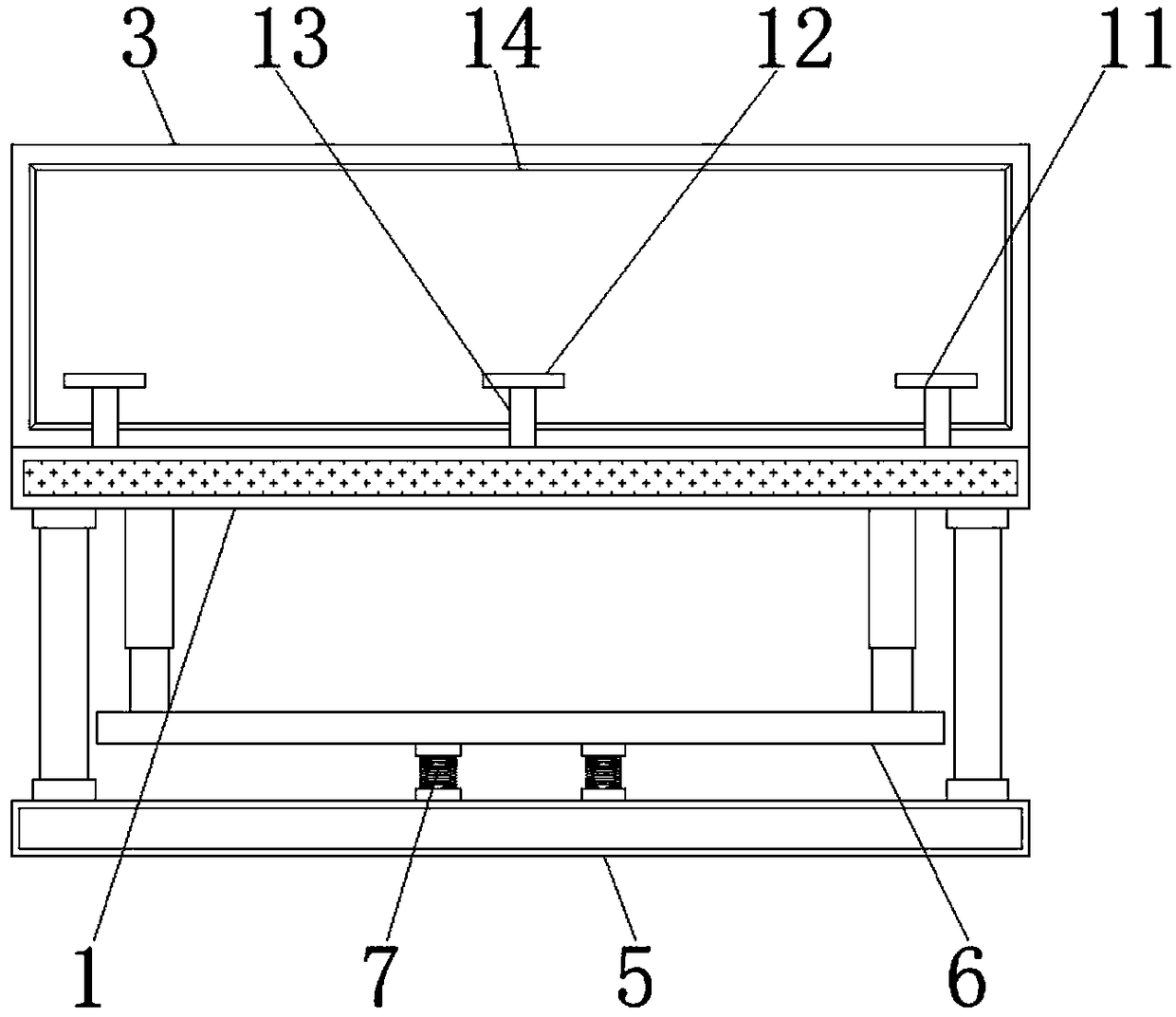

Air conditioner snow accumulation prevention control method and device, air conditioner and storage medium

ActiveCN111854059AEffectively judge the load statusGuaranteed intelligenceMechanical apparatusSpace heating and ventilation safety systemsSnow removalSnowpack

The invention provides an air conditioner snow accumulation prevention control method and device, an air conditioner and a storage medium and relates to the technical field of air conditioners. The air conditioner snow accumulation prevention control method comprises the steps of obtaining operation parameters of the air conditioner and judging whether the operation parameters satisfy a preset snow removing condition or not; if the preset snow removing condition is satisfied, after controlling an outdoor fan of the air conditioner to operate for a first preset time at a first rotation speed, detecting a first operation current of the outdoor fan; and controlling starting to clear accumulated snow of the outdoor fan according to the first operation current and a pre-obtained sunny day detection current. According to the air conditioner snow accumulation prevention control method and device, the air conditioner and the storage medium, by combining the operation parameters, the entering of accumulated snow clearing operation can be accurately recognized; the load state of the outdoor fan can be effectively judged according to the first operation current and the sunny day detection current; and therefore, the accumulated snow clearing operation is accurately controlled by accurately recognizing the snow accumulation situation, the intelligence, timeliness and high efficiency of airconditioner snow removal are guaranteed, and the situation that air conditioner accumulated snow is stacked is prevented so that the air conditioner can also normally operate in a severe and cold weather to facilitate the use of users.

Owner:NINGBO AUX ELECTRIC +1

Turnover type garden chair with protection function

The invention discloses a turnover type garden chair with the protection function. The turnover type garden chair comprises a chair plate, a pedal, fixed armrests, sliding blocks and a sliding groove,one end of the chair plate is provided with a turnover shaft, connecting springs connected under the pedal are arranged on a base plate, the upper portion of the pedal is fixed to one ends of connecting rods, the other ends of the connecting rods are connected to fixing blocks through connecting shafts, the fixing blocks are welded to a dustproof plate, the fixed armrests are symmetrically fixedto the two sides of the upper portion of the chair plate, a containing groove is formed in a dustproof plate, sliding blocks are fixed to side edge rods, and the sliding groove is reserved in the inner side wall of the chair plate. The turnover type garden chair with the protection function has the advantages that the dustproof plate of a turnover structure is arranged, so that when the device isnot used, the surface of the chair plate can be well covered and protected, and therefore the influence of external dust dirt or rainwater on the surface of the chair plate can be effectively avoided,and the dustproof plate can be used as a backrest when the chair plate is used.

Owner:芜湖天之梦工业技术有限公司

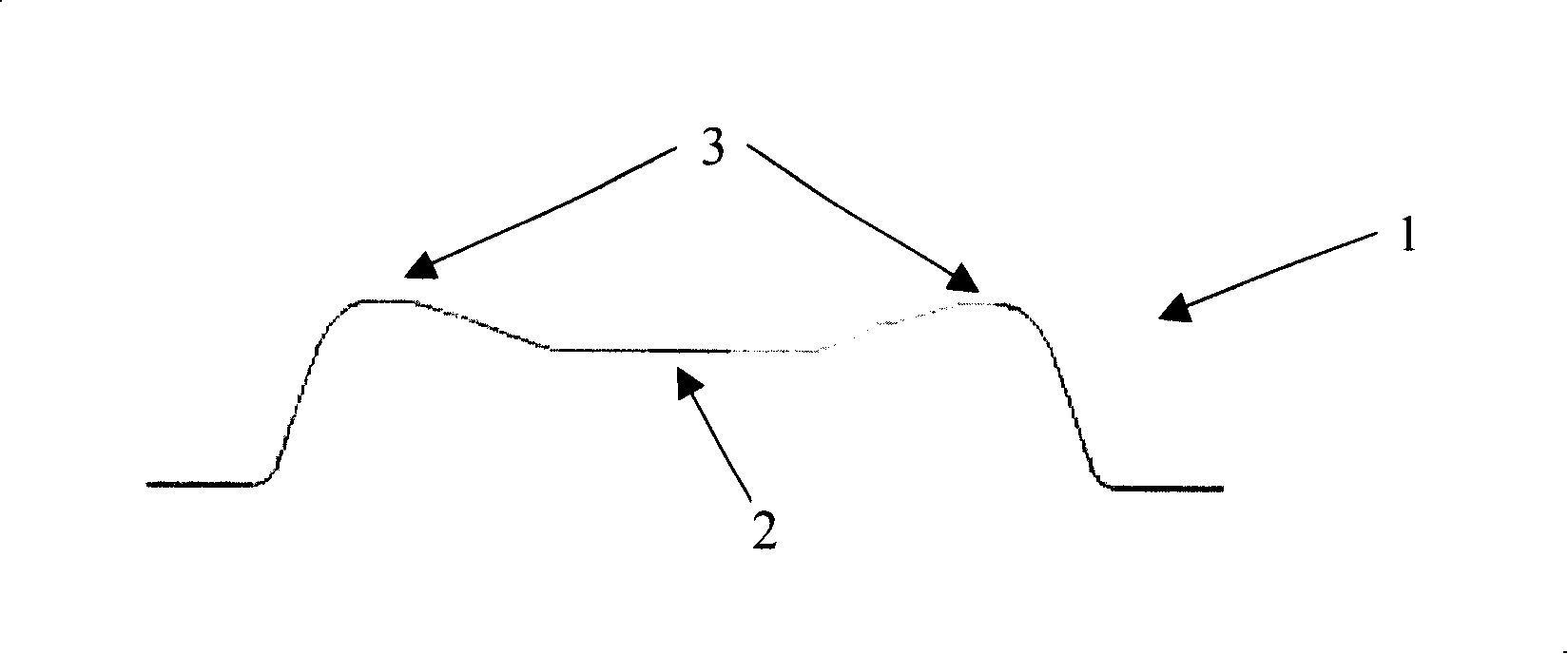

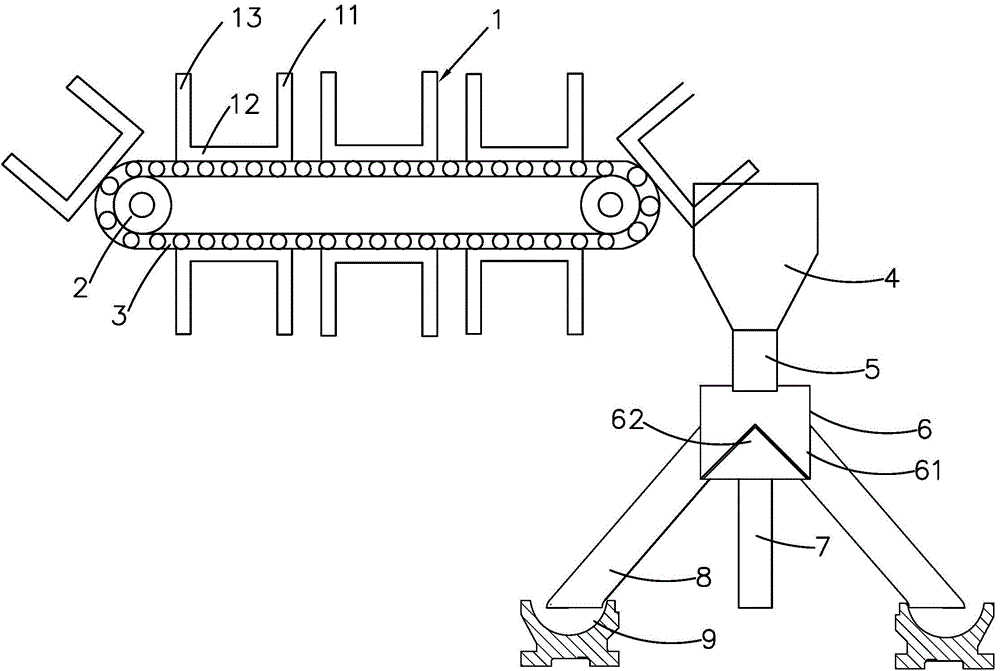

Roller cutting grinding mill automatic feeding device capable of enabling materials to be free of remaining

The invention discloses a roller cutting grinding mill automatic feeding device capable of enabling materials to be free of remaining. A transmission device comprises a belt (3), belt wheels (2) and feeding clamping grooves (1) fixedly connected with the belt (3); the feeding device comprises a first stock bin (4) connected with the feeding clamping grooves (1) and a feeding pipe (5) fixedly connected with a discharging opening of the first stock bin (4); a discharging opening of the feeding pipe (5) is fixedly connected with a feeding opening of a second stock bin (6), and a plurality of second stock bin discharging openings (61) are formed in the side face of the second stock bin (6) and are fixedly connected with corresponding discharging pipes (8) respectively; and discharging openings of the discharging pipes (8) are connected with U-shaped annular grooves (9) respectively. According to the device, materials can be automatically fed into the feeding device, and it also can be ensured that the phenomenon that the materials are stacked in the stock bins, and the materials cannot smoothly slide is avoided; a machine tool can effectively run, and feeding efficiency and stability are ensured; and workloads of an operator are reduced, and the production efficiency is improved.

Owner:CHENGDU CHENHONG TECH

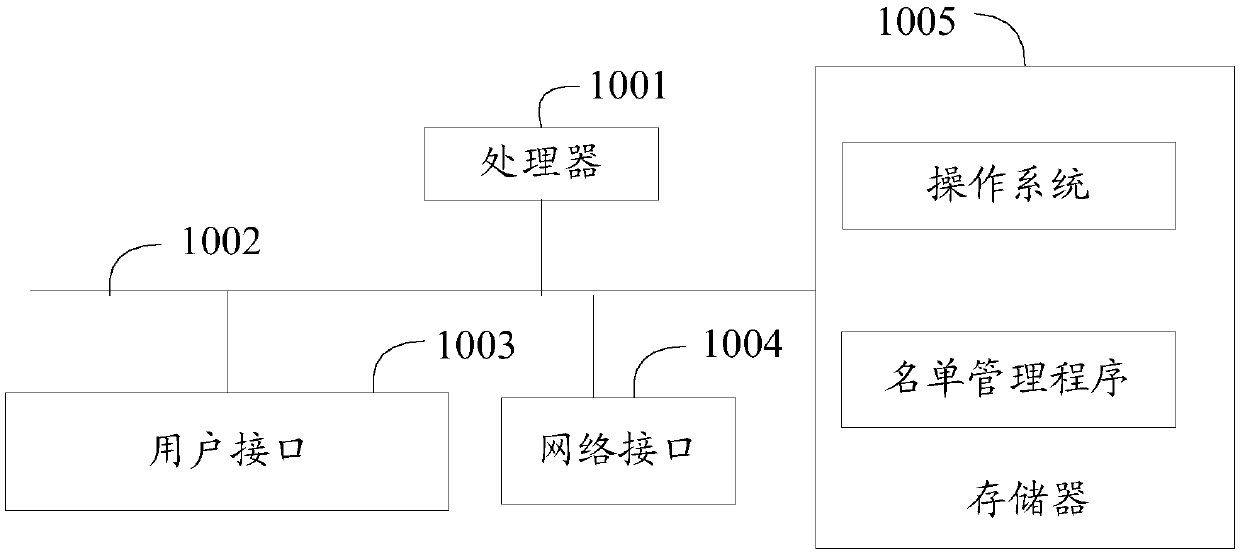

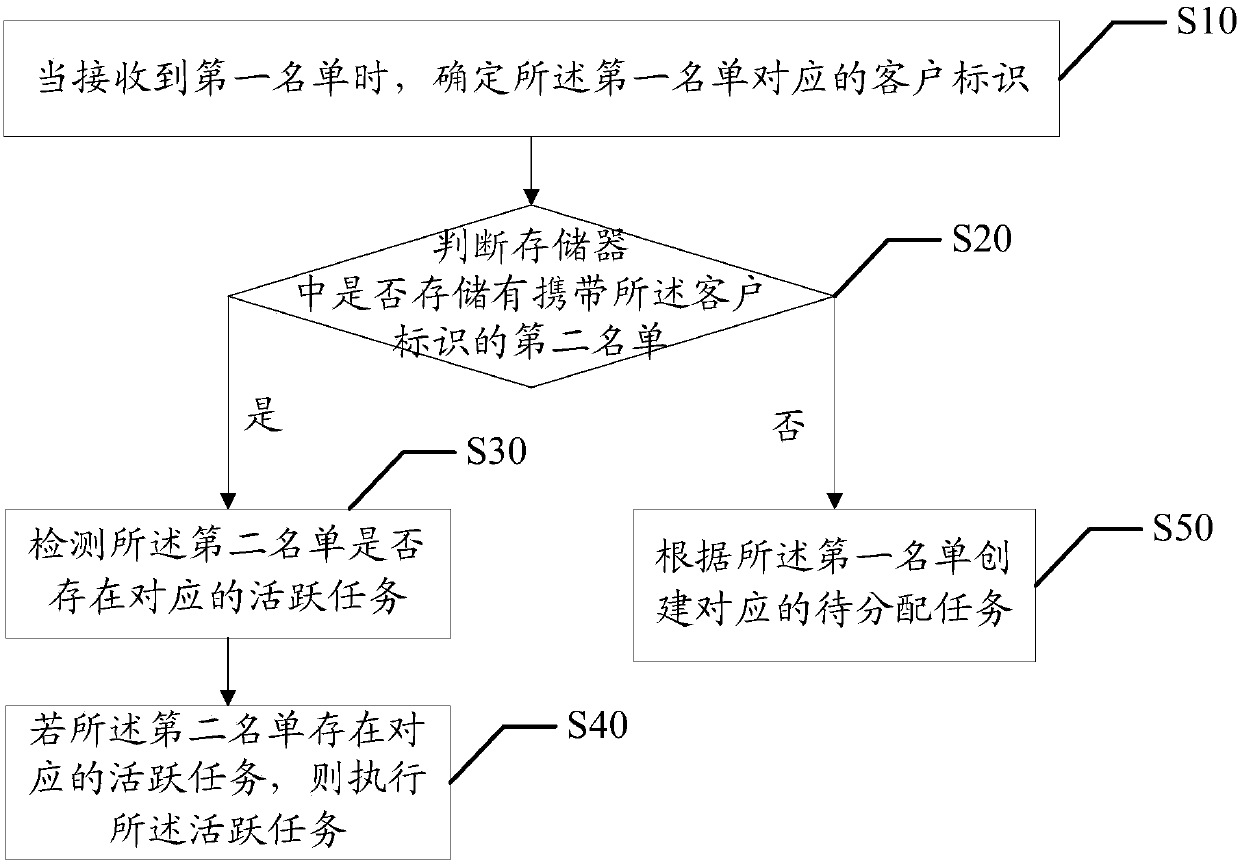

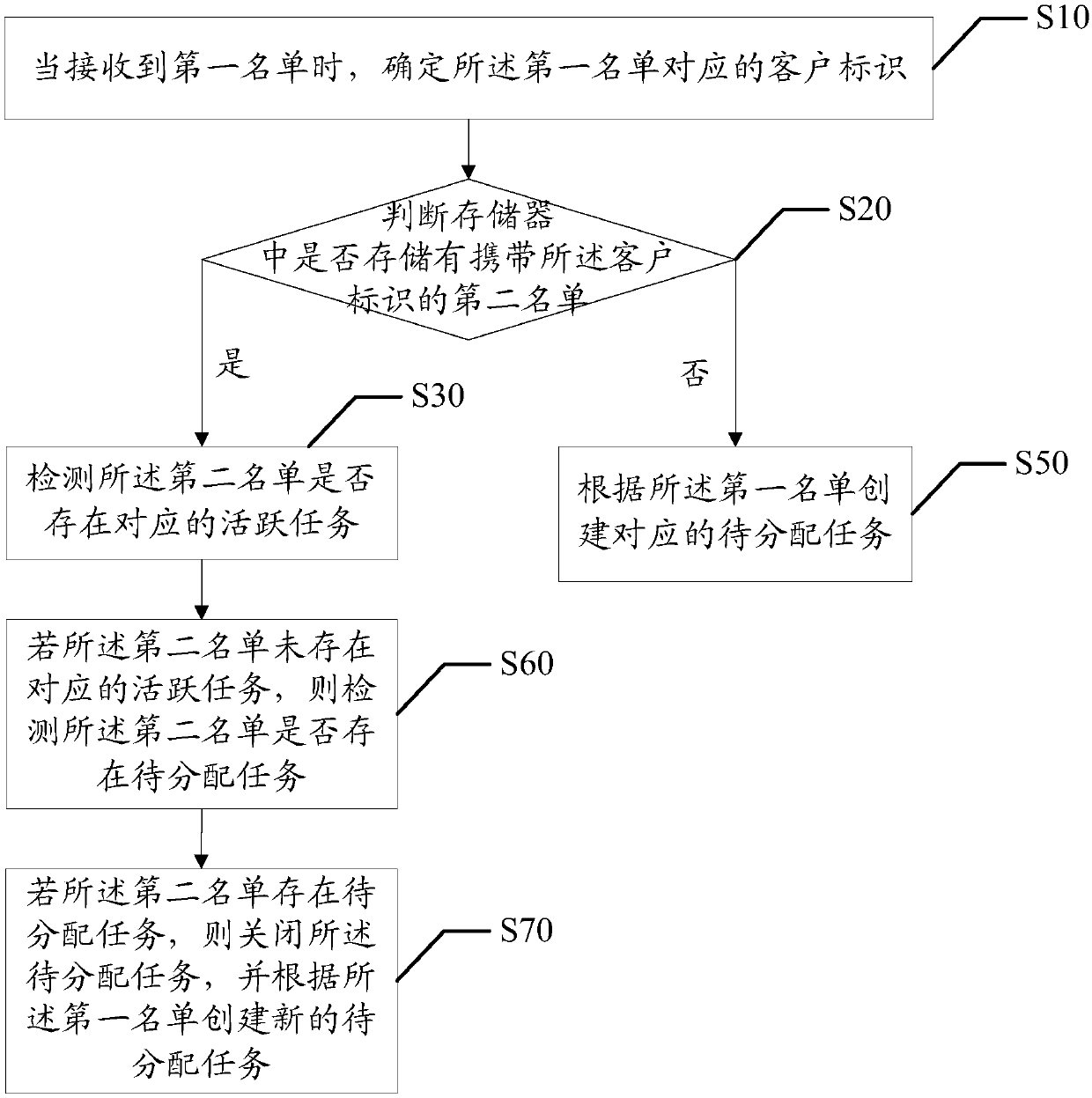

List management method, device, system and computer readable storage medium

The invention discloses a list management method, device, system and a computer readable storage medium. The method includes steps of determining a client mark corresponding to a first list after receiving the first list; judging whether a second list carrying the client mark is stored in the storage or not; creating a corresponding to-be-allocated task according to the first list if the second list carrying the client mark is not stored; detecting whether the second list has corresponding active tasks or not if the second list carrying the client mark is stored; and performing the active taskif the second list has the corresponding active task. According to the invention, after the list is received, whether the list of the client corresponding to the received list is in presence in the system or not is judged in advance, so that a condition of list accumulation in the system when one client has multiple tasks is avoided.

Owner:PING AN TECH (SHENZHEN) CO LTD

Grinding apparatus for hard carbon nano material production

ActiveCN110947487APrevent stackingImprove work efficiencyGrain treatmentsCleaning processes and apparatusHigh energyCooling effect

The invention provides a grinding apparatus for hard carbon nano material production, which comprises a grinding chamber for grinding hard carbon, an active grinding mechanism for controlling the grinding of the hard carbon and a passive grinding mechanism for promoting the cyclic grinding of hard carbon powder, wherein the bottom of the grinding chamber is fixedly connected with supporting legs and the active grinding mechanism is arranged on the grinding chamber. The invention relates to the field of hard carbon processing. The grinding apparatus for hard carbon nano material production carries out analysis and research according to the grinding characteristics and current problems of the hard carbon material, is provided with the mechanism that can promote the sufficient and cyclic grinding of the hard carbon powder material, makes full use of a grinding space, has an additional cooling effect and an energy-efficient and environment-friendly effect, thereby solving the problem thatthe grinding space of a conventional grinding apparatus ofor hard carbon nano material processing is likely to be occupied by hard carbon powder piece for a long time, which seriously influences the using efficiency of the grinding space of the grinding apparatus and causes insufficient and inhomogeneous grinding and high energy consumption.

Owner:宁波禾木纳米科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com