Attrition mill grinding bin capable of automatic feeding

A technology of automatic feeding and grinding, which is applied in the field of grinding bins of grinding machines, can solve the problems of inability to realize automatic feeding and discharging, waste of human resources, and low production efficiency, so as to save manpower, improve production efficiency, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the content protected by the present invention is not limited to the following description.

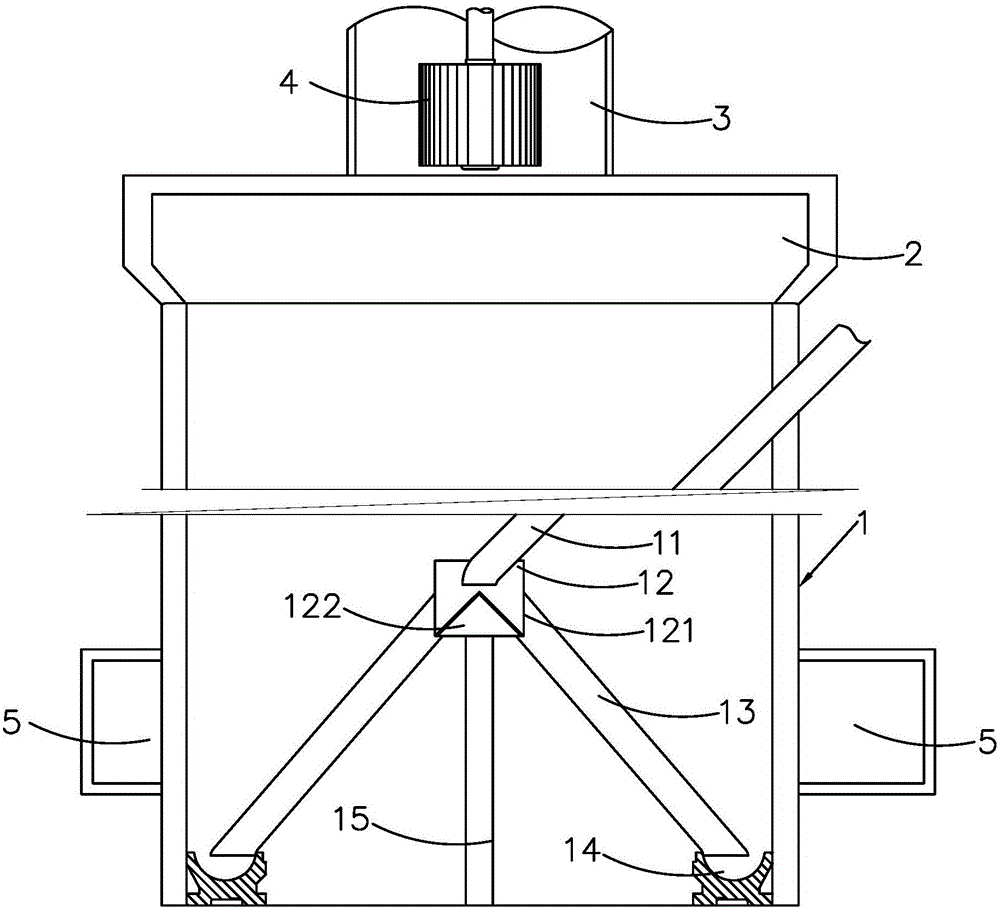

[0019] Such as figure 1 As shown, a grinder grinding bin capable of automatic feeding includes a grinding bin body 1, a decompression chamber 2 located above the grinding bin body 1, an air outlet pipe 3 located at the top of the decompression chamber 2, and a grinding chamber surrounding the grinding chamber. The air inlet pipe 5 on the outside of the chamber body 1, and the side where the air inlet pipe 5 meets the grinding chamber body 1 is provided with a plurality of air inlet holes;

[0020] The grinding bin body 1 includes a feed pipe 11, a feed bin 12, a discharge pipe 13 and a U-shaped ring groove 14 arranged inside. The discharge port of material pipe 11 links to each other with the feed port of feed bin 12, feed bin 12 is fixedly install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com