Patents

Literature

173results about How to "No manual feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

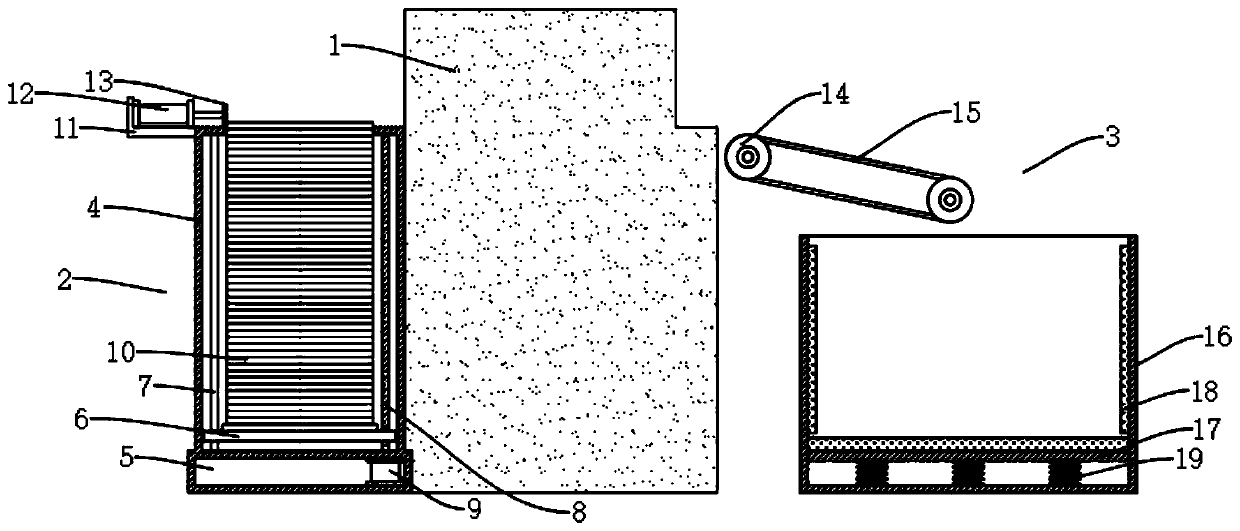

Garbage treatment apparatus for environmental protection engineering

InactiveCN107755038AIncrease workloadIncrease the feeding speedNon-rotating vibration suppressionGrain treatmentsEnvironmental resistanceDrive shaft

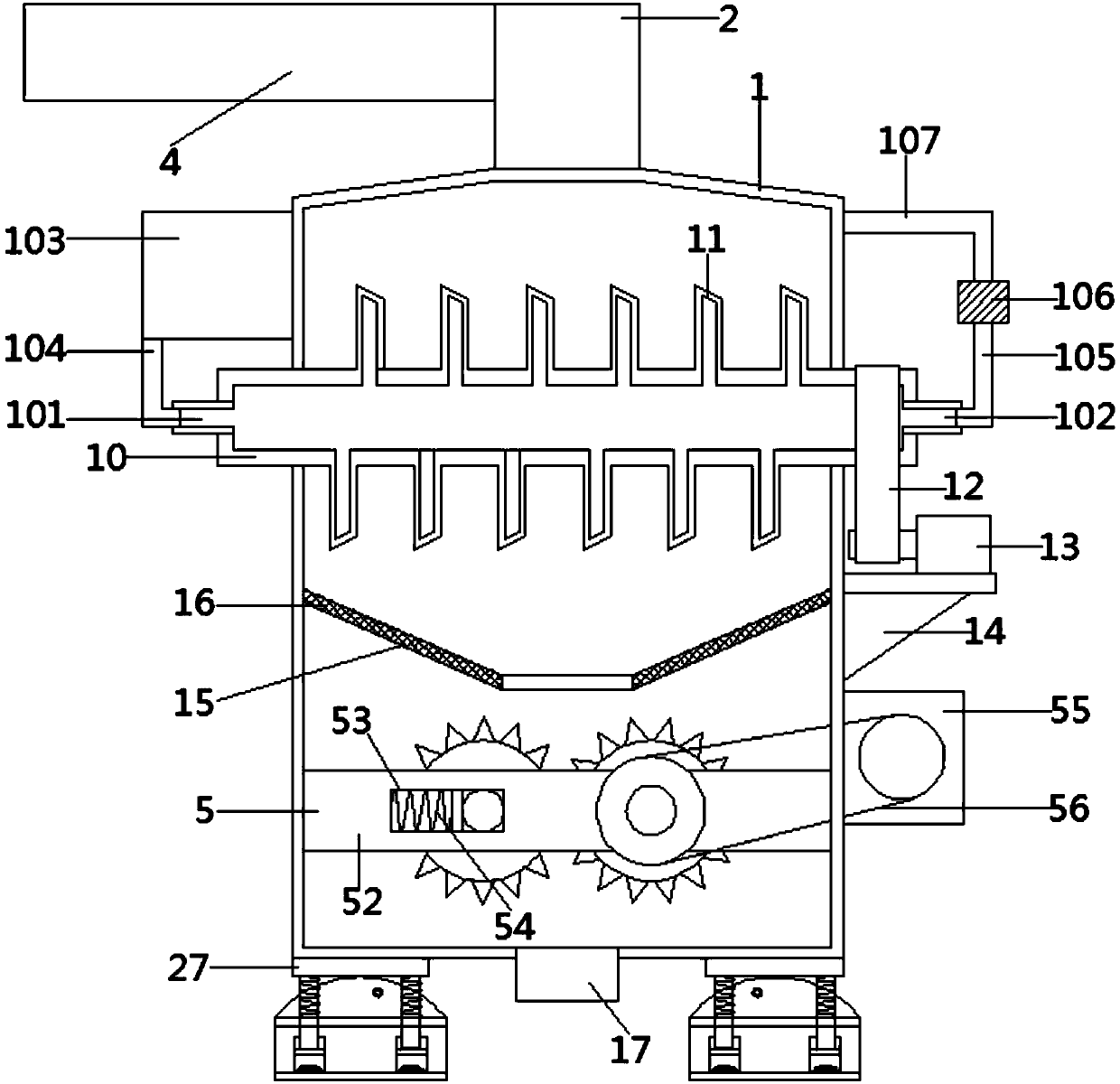

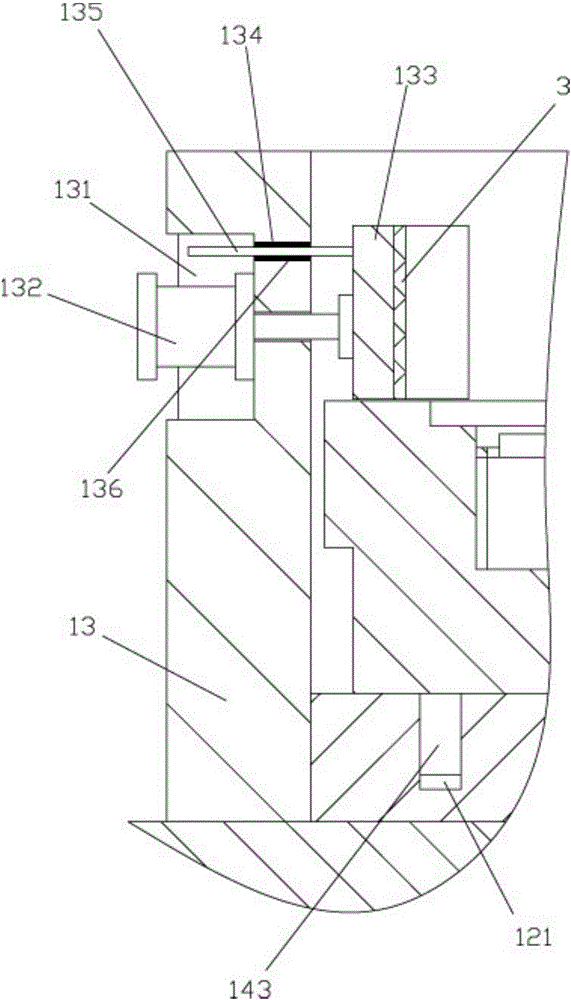

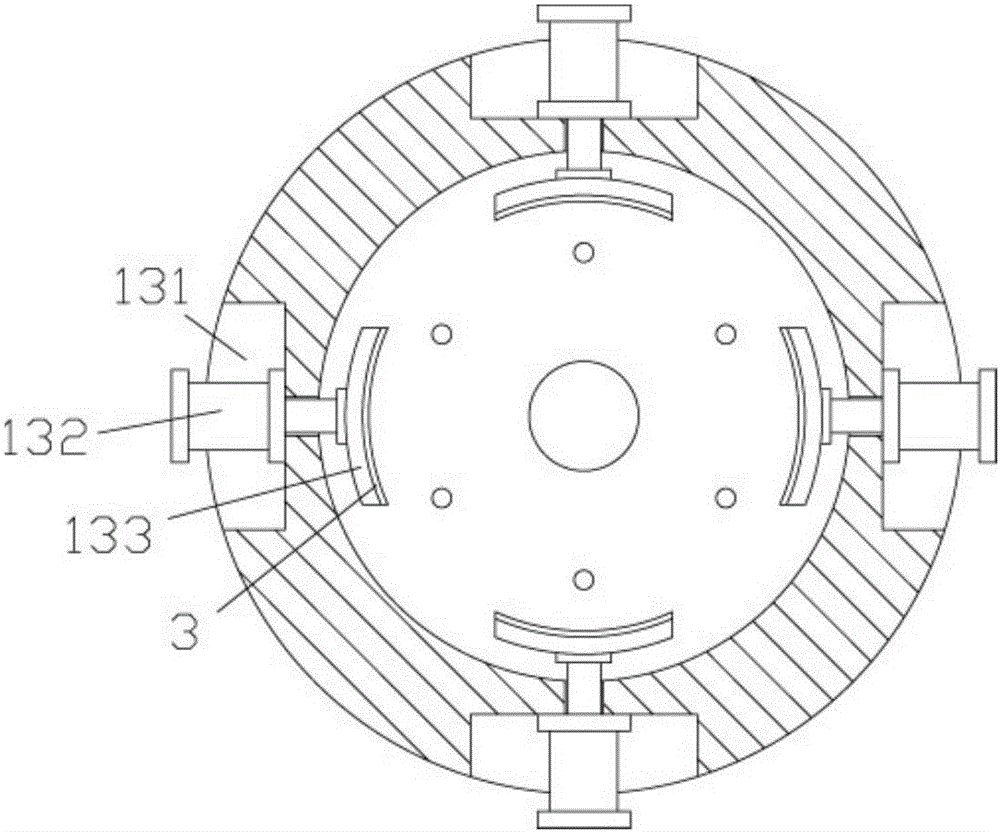

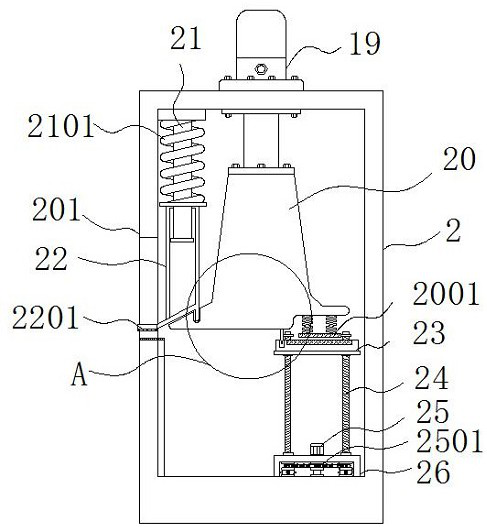

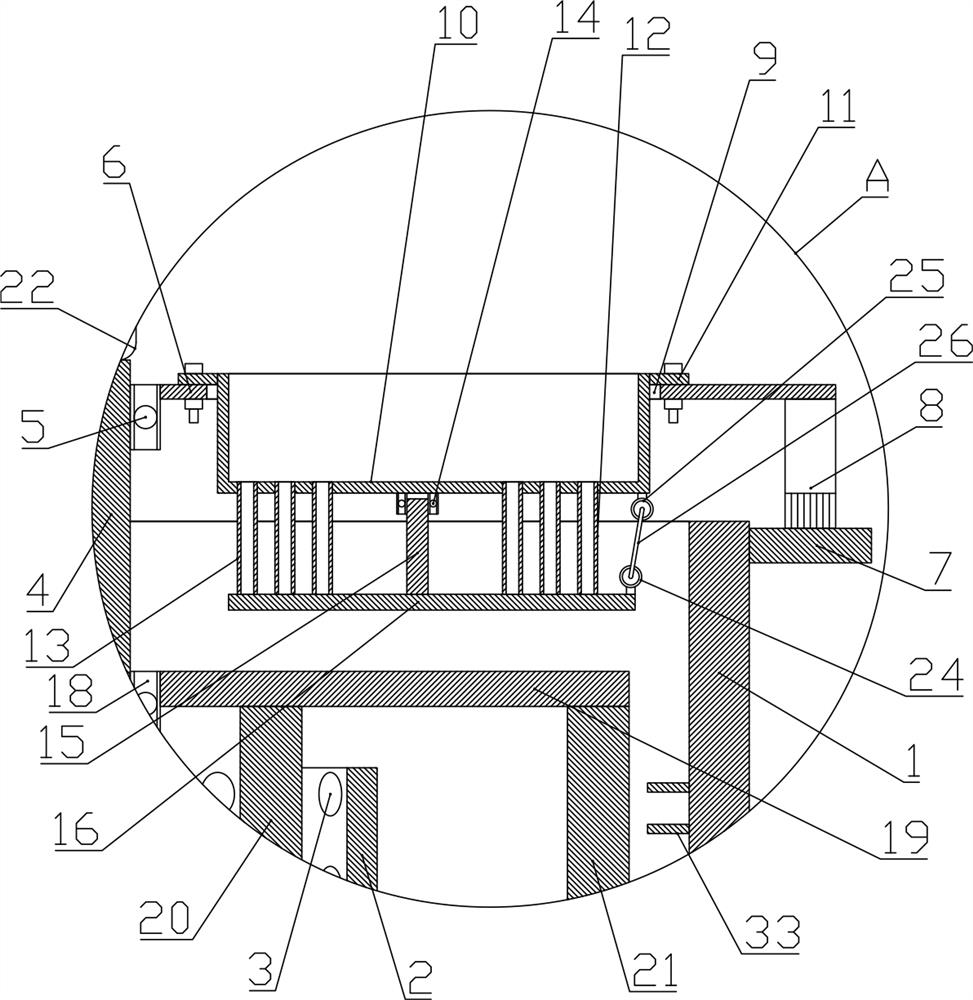

The invention discloses a garbage treatment apparatus for environmental protection engineering. The garbage treatment apparatus comprises a machine body, wherein the upper side of the machine body isprovided with a material inlet, the water inlet is connected with a material inlet pipe, the left side of the material inlet pipe is connected with a belt loading apparatus, and the belt loading apparatus comprises frame bodies as well as a driving roller, a driving shaft, three supporting rollers and a tension roller which are arranged between the frame bodies by virtue of a bearing seat frame from left to right. By adopting the belt loading apparatus to automatically load materials, the working efficiency is increased; moreover, the automatic discharging can be realized; by arranging an upper crushing mechanism and a lower crushing mechanism, and the crushing effect is ensured, the crushing efficiency is increased; water circularly flowing inside a rotating shaft can bring away the heatgenerated by the friction, the cooling can be performed without stopping, the crushing machine can work continuously, the excessive feeding can be prevented from damaging the rolling rollers, and theservice life is prolonged; the vibration of the machine body can be greatly reduced, and the stability is improved.

Owner:邓雨佳

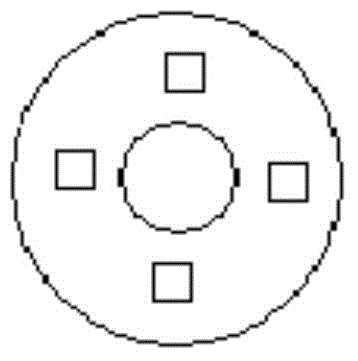

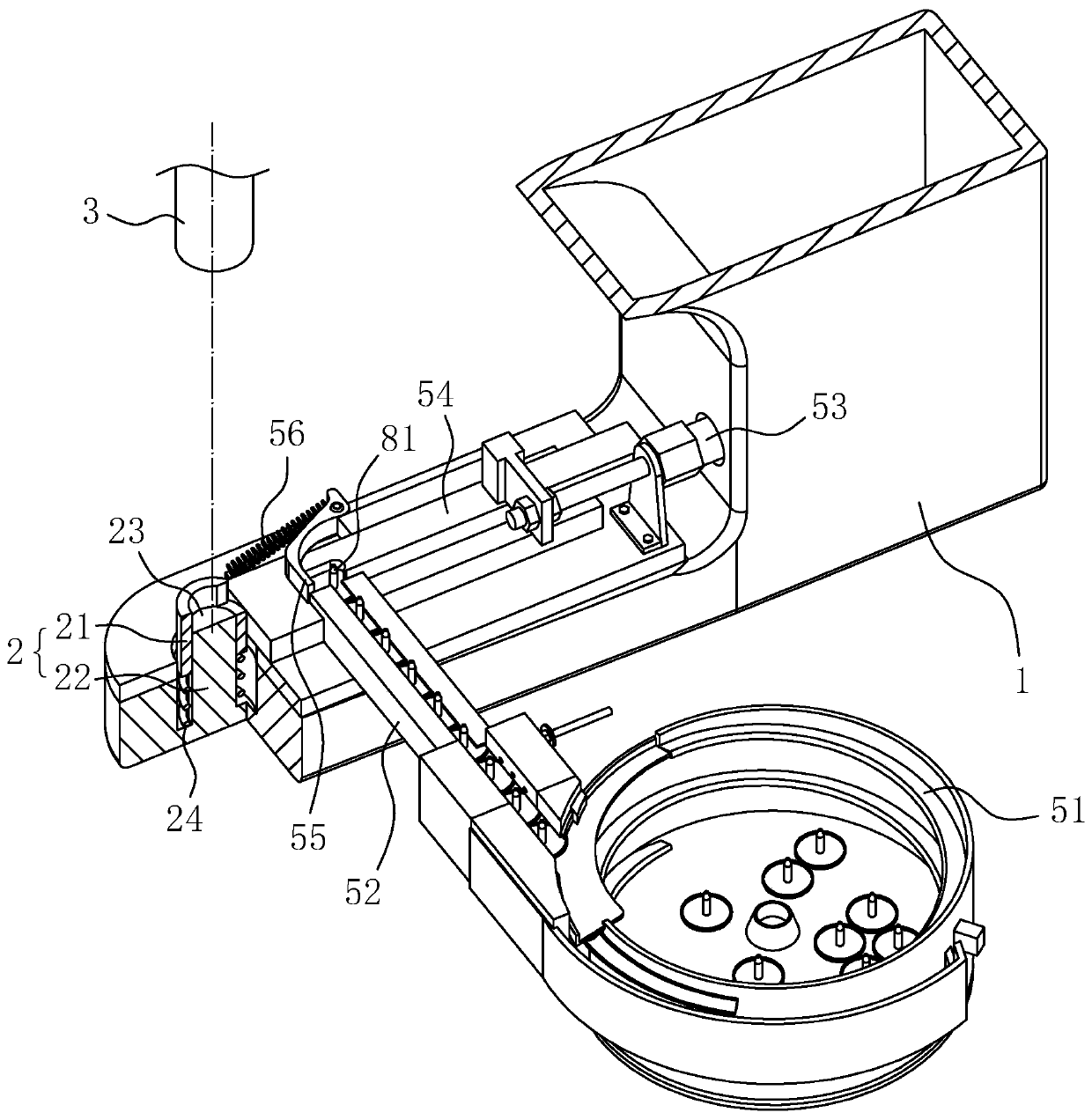

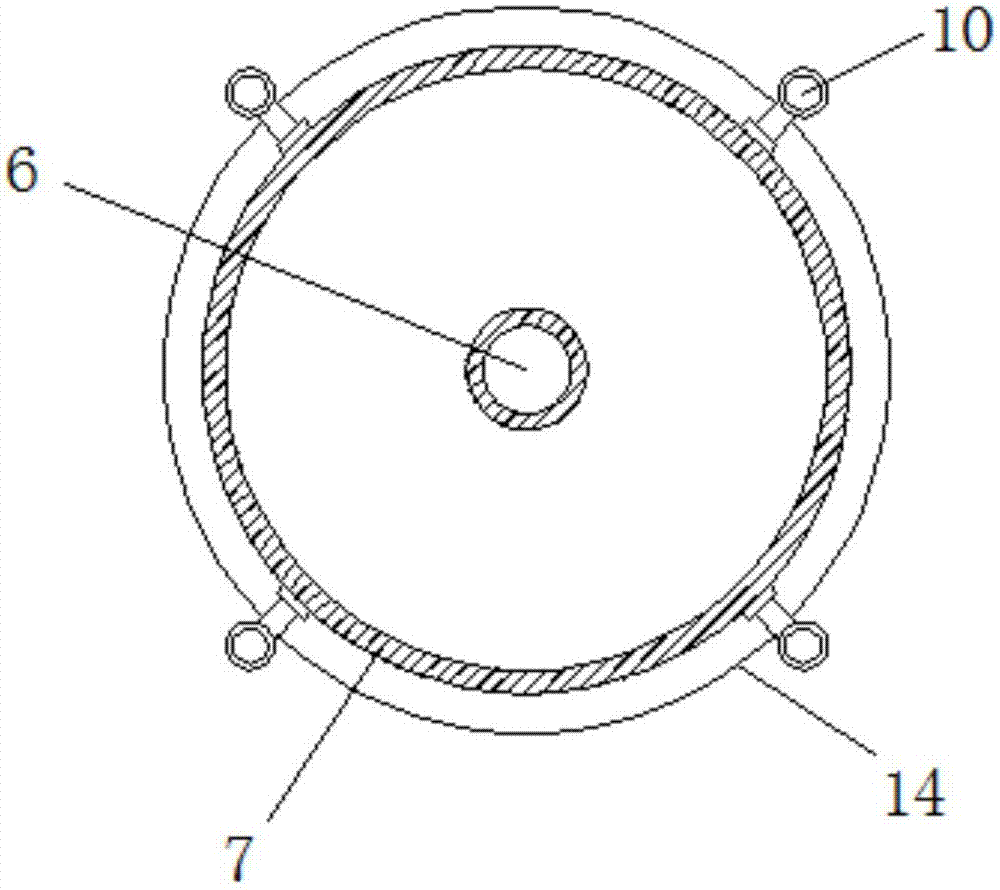

Automatic taking, feeding and molding mechanism for circular sheet applied to new-energy automobile

The invention discloses an automatic taking, feeding and molding mechanism for a circular sheet applied to a new-energy automobile. The automatic taking, feeding and molding mechanism comprises a frame; an upper supporting frame is fixedly arranged at the right side of a top plate of the frame; a material bucket is arranged at the left side of the top plate of the frame; a rotary cylinder frame is fixedly arranged on the part, positioned between the material bucket and the upper supporting frame, of the top plate of the frame; a rotary cylinder is fixedly arranged on the top surface of the rotary cylinder frame; a rotating rod is fixedly arranged at the end part of a rotating shaft of the rotary cylinder; a vacuum sucker is fixedly arranged at the bottom surface of the end part of the rotating rod; the vacuum sucker is positioned over the material bucket; a connecting bump part is molded at the middle part of the top plate of the frame; an annular sleeve body is fixedly arranged on the part, positioned on the outer sidewall of the connecting bump part, of the top plate of the frame. The automatic taking, feeding and molding mechanism can be used for automatically catching the circular sheet in the material bucket, placing the circular sheet on a mold supporting seat and subsequently automatically adjusting the circular sheet, manual feeding is not needed and convenient feeding is realized, so the machining efficiency and the machining effect of the circular sheet are improved.

Owner:浙江蓝天知识产权运营管理有限公司

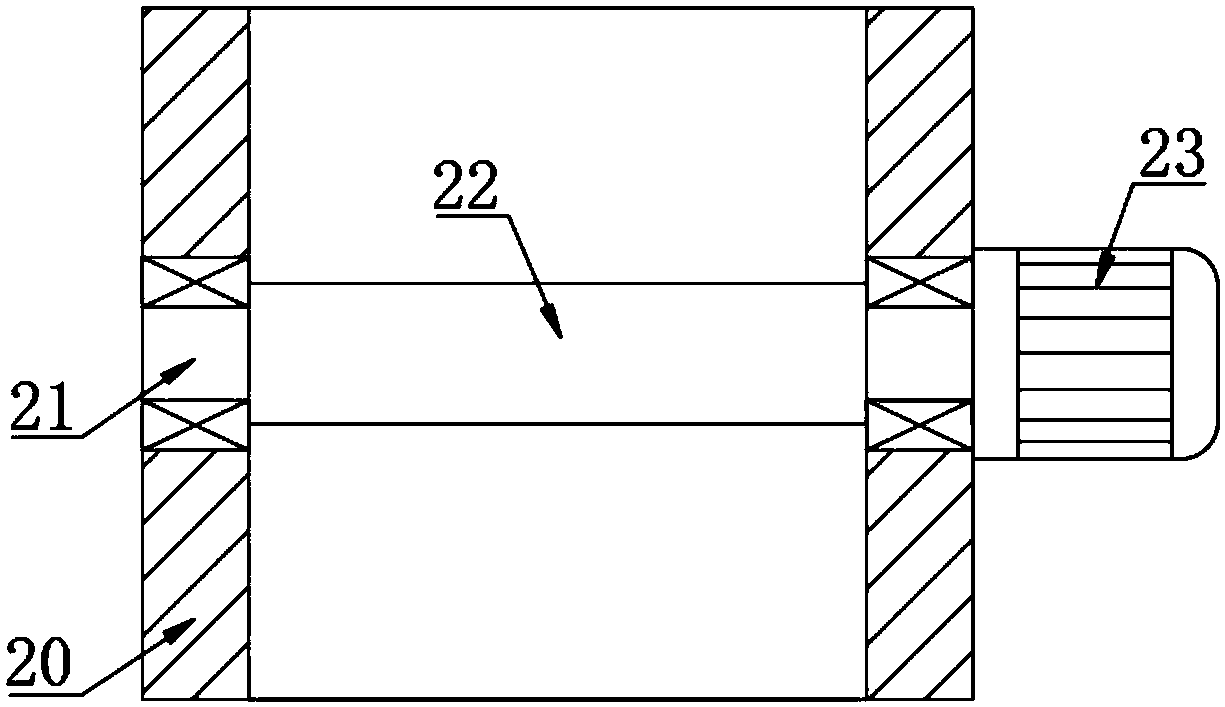

Rubbish sorting device

InactiveCN104138841AEasy loadingNo manual feedingGas current separationMagnetic separationEngineeringMechanical engineering

The invention relates to a rubbish sorting device which comprises a storage hopper, a feeding conveyer, a bag-breaking machine and a separating device which are connected with each other in turn, wherein the separating device comprises a solid-liquid separating device and a sorting separating device; the solid-liquid separating device comprises a solid-liquid separating motor, a driving gear set, a rotary screen and a liquid collecting hopper; the rotary screen is driven by the solid-liquid separating motor through the driving gear set, and the solid-liquid separating motor is under a rotating state along the axial direction of the rotary screen; more than one spiral flow-guiding plate which extends from the head end to the tail end of the rotary screen is arranged on an inner wall of the rotary screen; the liquid collecting hopper is arranged under the rotary screen corresponding to the rotary screen; the sorting separating device comprises a heavy mass collecting hopper, a light mass collecting hopper and a sorting fan; the heavy mass collecting hopper is arranged under the tail end of the rotary screen and is under the state of collecting rubbish sent out of the tail end of the rotary screen; the light mass collecting hopper is arranged for collecting light rubbish blown by the sorting fan from the rubbish sent out of the tail end of the rotary screen corresponding to an air-feeding direction of the sorting fan.

Owner:JIANGSU YUNJIANG BIOLOGICAL ENERGY TECH

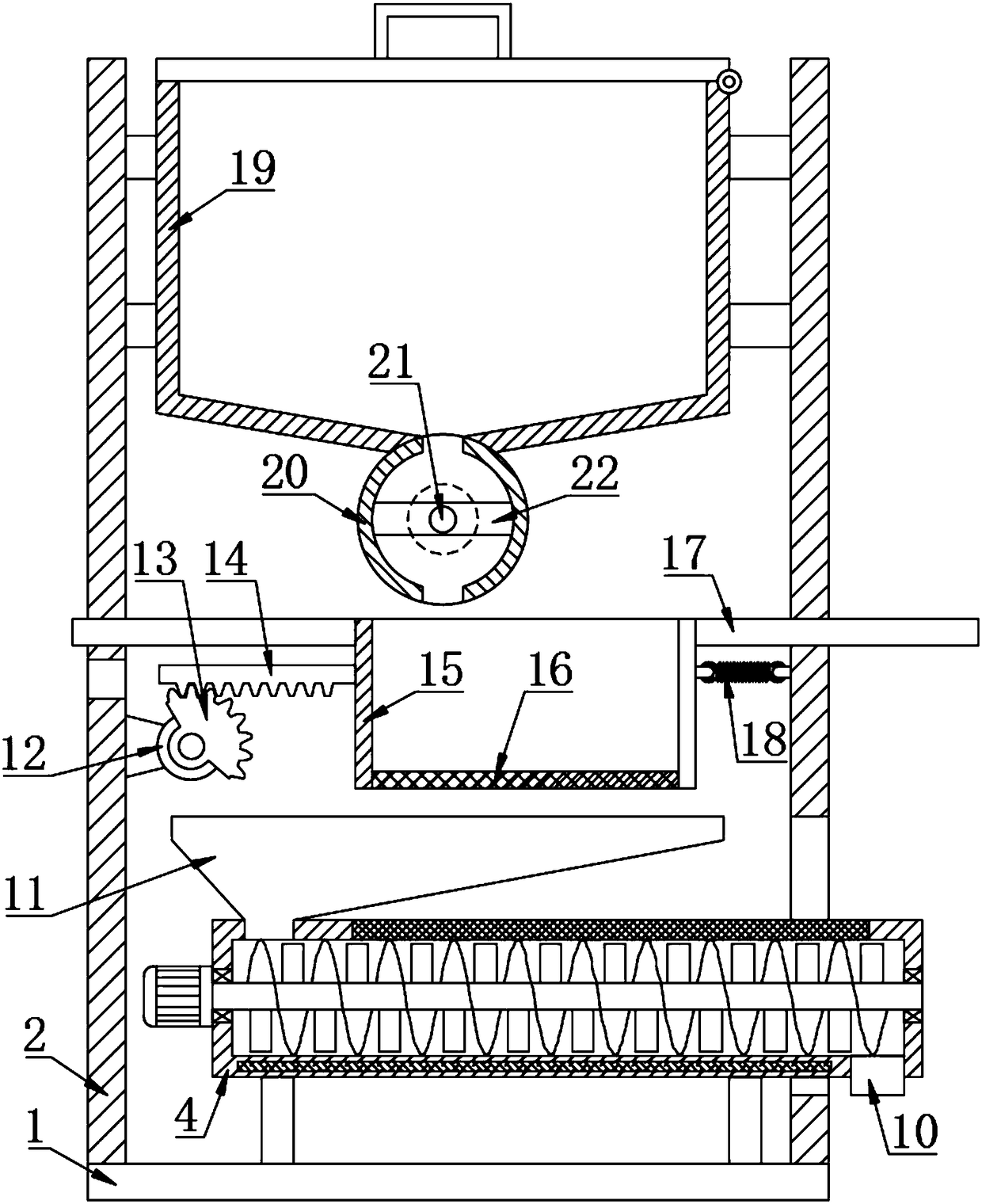

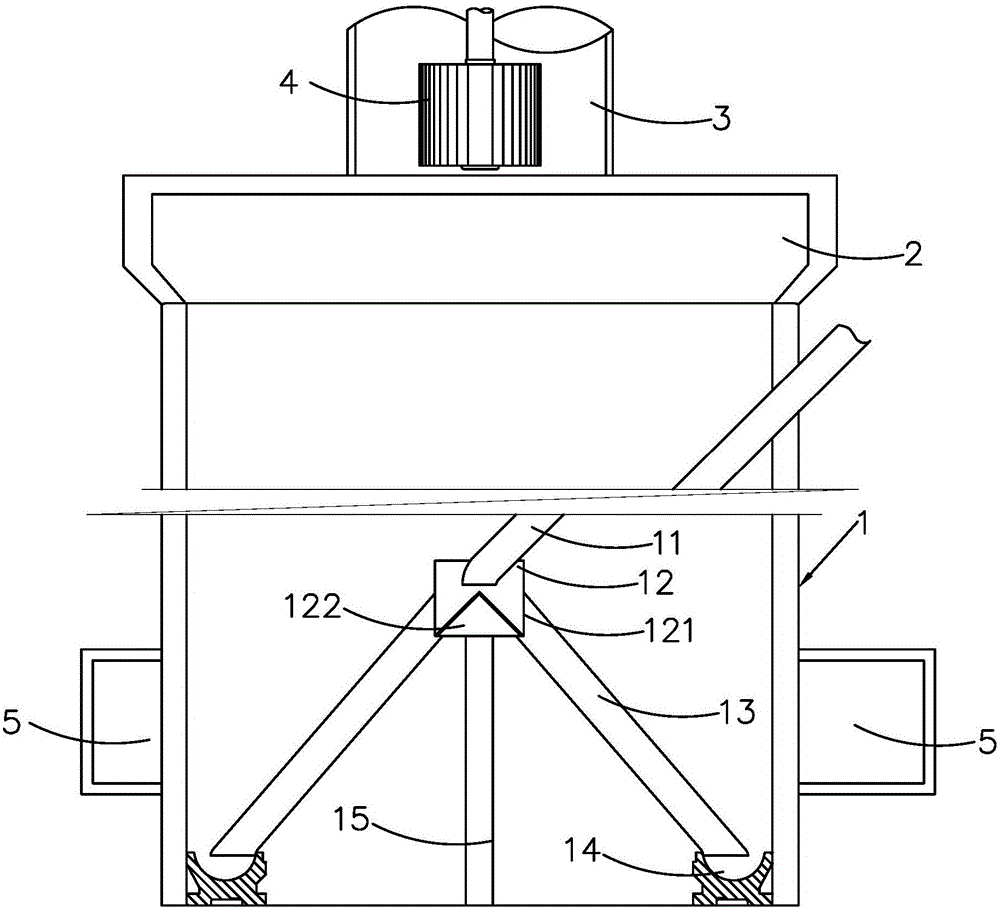

Stirring equipment used for municipal construction

InactiveCN107053470AExtended service lifeAchieve circular flowMixing operation control apparatusPretreatment controlElectric machineryWaste management

The invention discloses stirring equipment used for municipal construction. The equipment comprises an equipment body. A feeding barrel is arranged on the upper side of the equipment body. A feeding hopper is arranged at the left end of the upper side of the feeding barrel. A feeding mechanism is arranged in the feeding barrel and comprises a feeding screw and a screw blade arranged on the outer wall of the feeding screw. The left end of the feeding screw is connected with a motor. A pre-crushing mechanism is arranged on a right section of the feeding barrel. According to the stirring equipment used for municipal construction, automatic feeding can be achieved, raw materials are pre-crushed in the feeding process, the stirring efficiency is improved, circulating flowing of concrete is achieved through vertical moving of vibro-rammers and the guiding effect of an inner barrel, stirring screws are used for stirring the concrete and driving the concrete to rise in the stirring process, and the stirring effect is greatly improved; and in addition, a damping bracket can be used for achieving effective shock absorption and prevention, and the service life of the stirring equipment is prolonged.

Owner:FUNAN GAOFUXING INTELLIGENT TECH CO LTD

Food material processing equipment

ActiveCN111053091AImprove processing efficiencyRealize the processing effectBaked article fillingBaking ovenManufacturing efficiencyManufacturing engineering

The invention provides food material processing equipment which comprises a food material storage device used for storing a first food material and a second food material, wherein the food material storage device is provided with a first burdening port for discharging the first food material and a second burdening port for discharging the second food material; a baking mechanism with a baking gap,wherein the baking mechanism is at least partially arranged below the food material storage device, and the first batching opening is arranged to be corresponding to the baking gap; a frying and baking mechanism with a heating cavity, wherein the frying and baking mechanism is at least partially arranged below the food material storage device, and the second burdening port is arranged to be corresponding to the frying and baking mechanism; a conveying mechanism, wherein the baking mechanism and the frying and baking mechanism are arranged at intervals in the extending direction of the conveying mechanism, an output port of the baking gap and an output port of the heating cavity are both arranged to be corresponding to a conveying belt of the conveying mechanism, the first food material isloaded and conveyed to the position below the frying and baking mechanism through the conveying belt, so that the second food material is stacked on the first food material to form at least part of afood material to be packaged, and the problem that in the prior art, the hamburger food materials are low in manufacturing efficiency is solved.

Owner:GUANGDONG ATHENE ROBOTIC TECH CO LTD

Ecological culture and proliferation method of live oyster reef area algae-shellfish-sea cucumber

ActiveCN106234266AImprove product quality and nutritional valueHigh economic and social benefitsClimate change adaptationPisciculture and aquariaSeawaterMariculture

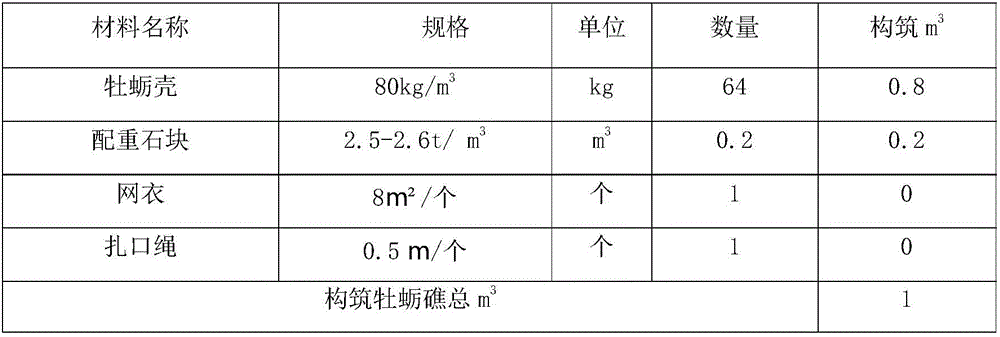

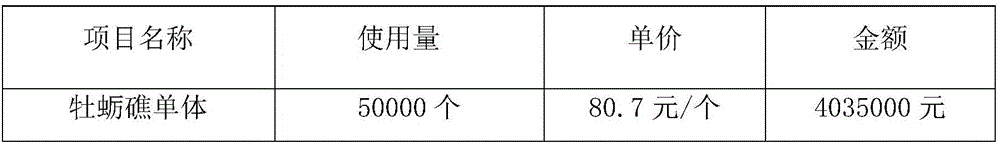

The invention relates to the field of mariculture, in particular to an ecological culture and proliferation method of live oyster reef area algae-shellfish-sea cucumbers. The method comprises the following steps: (1) constructing a live oyster reef: manufacturing a single reef body, unit reef group putting, and oyster reef group putting implementation; (2) performing algae transplantation; (3) putting offspring seeds; (4) fishing and catching; (5) monitoring reef area environment; (6) monitoring reef area culture organisms. The live oyster reef area is constructed in a nearshore neritic area to carry out the research of ecological composite and efficient culture and proliferation technology of precious marine products including economic algae classes, filter-feeding shellfish classes, sea cucumbers and the like. Through the design releasing of the live oyster reef, the proper culture and proliferation proportion parameter of different class groups including algae, shellfish, sea cucumbers and the like is researched to reduce the growth environment of the precious marine products under a natural state, a complete ecological chain is established, artificial food provisioning is not required, the product quality and the nutrition value of the precious marine products can be obviously improved while the marine ecological environment is repaired, the requirement of people on high-end environmental-friendly pollution-free precious marine products can be met, and meanwhile, the method has the advantages of high economic benefit and social benefit.

Owner:QINGDAO JINSHAHAI PROD CULTURE CO LTD

Conveyer belt type dispensing mechanism

ActiveCN105032714AImprove efficiencySpeed blockLiquid surface applicatorsCoatingsEngineeringCompressed air

Owner:南通江海港建设工程有限公司

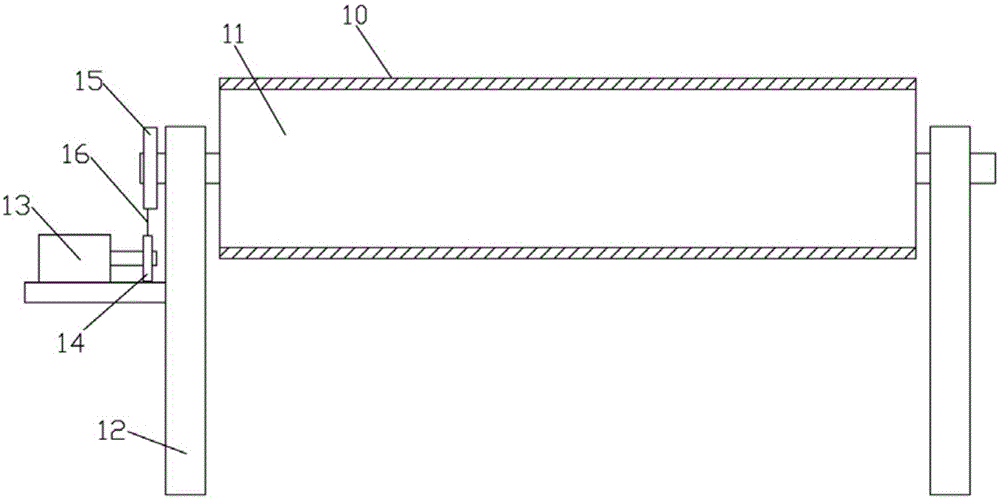

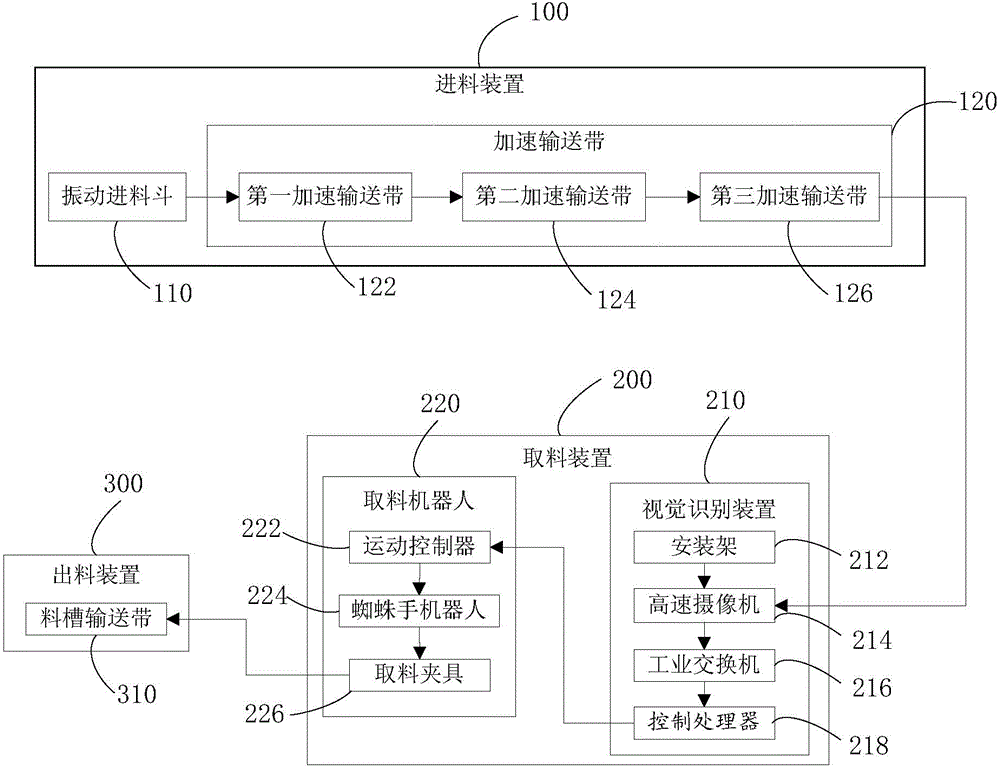

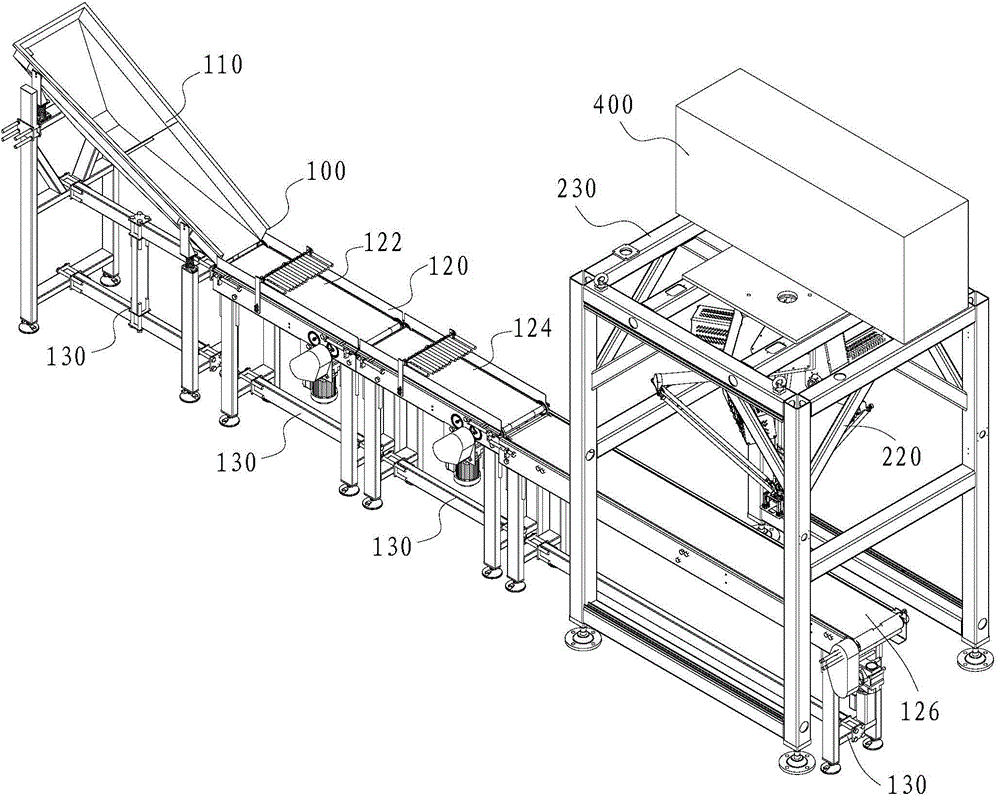

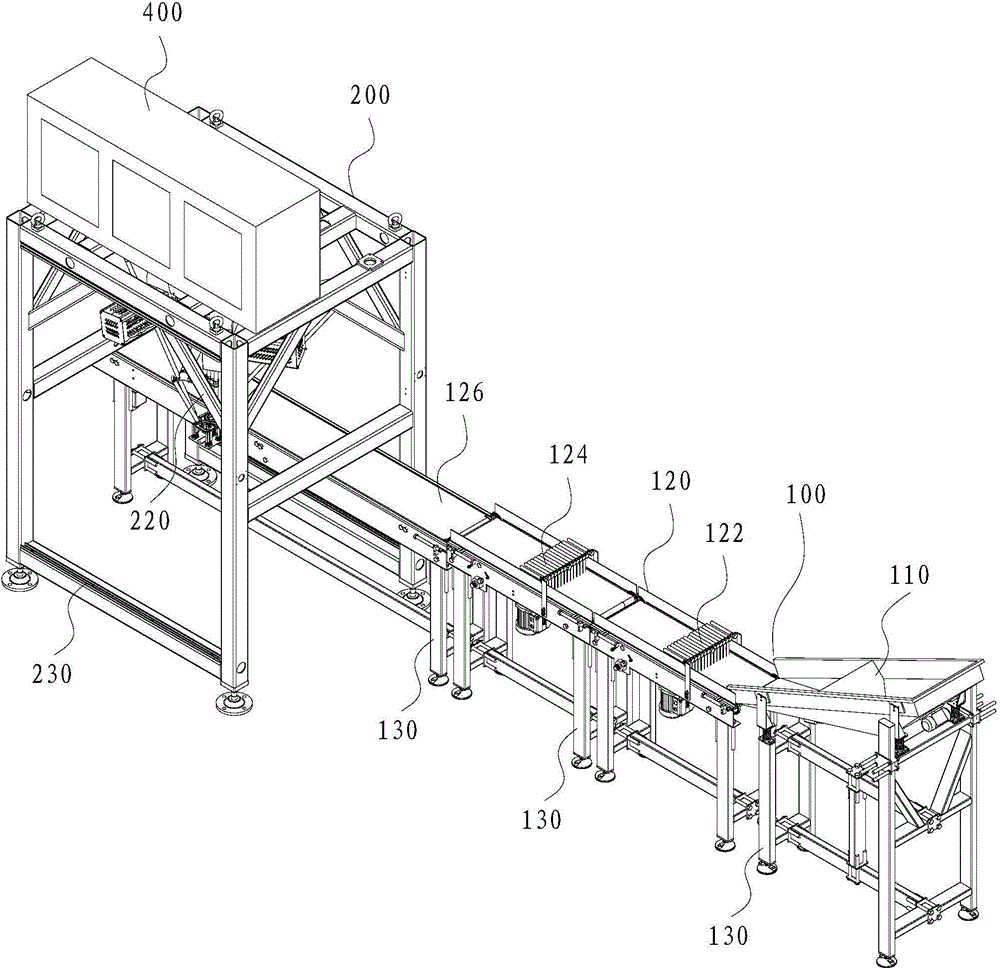

Feeding system and method for block-shaped food

ActiveCN104890936AEnsure food hygiene and safetyGuaranteed quantityPackaging automatic controlEngineeringRobot

The invention provides a feeding system and method for block-shaped food. The feeding system comprises a feeding device, a reclaiming device and a discharging device which are arranged in sequence. The feeding device comprises a vibration feed hopper and an acceleration conveying belt connected with the vibration feed hopper. The reclaiming device comprises a rack arranged at the end of the acceleration conveying belt in a covering mode, a visual identity device arranged above the rack and above the acceleration conveying belt and a reclaiming robot arranged inside the rack. The reclaiming robot is in communicating connection with the visual identity device. The discharging device comprises a trough conveying belt. The end of the trough belt is arranged inside the rack and is arranged below the reclaiming robot. According to the technical scheme provided by the feeding system and method for the block-shaped food, the problems that manually feeding cost for the block-shaped food is high, the efficiency is low, the quality is bad, and the sanitation is bad in the traditional technology in the traditional technology are solved.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

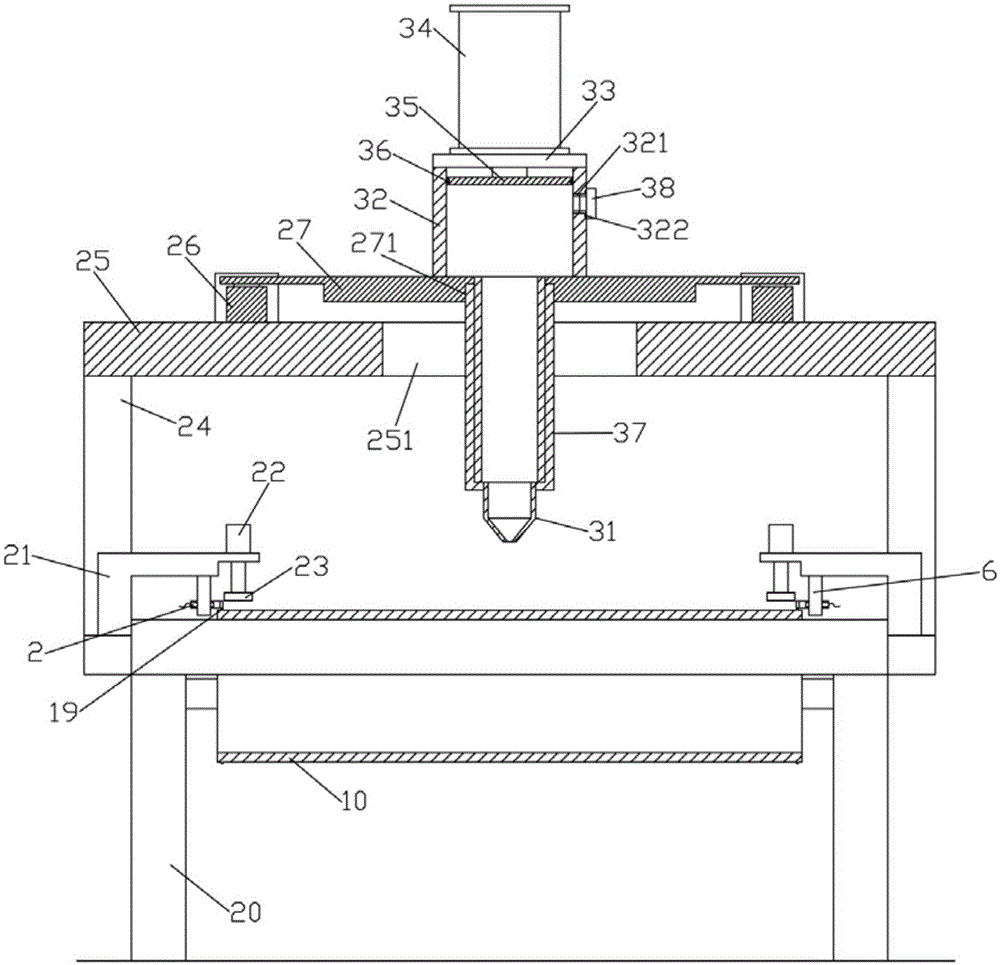

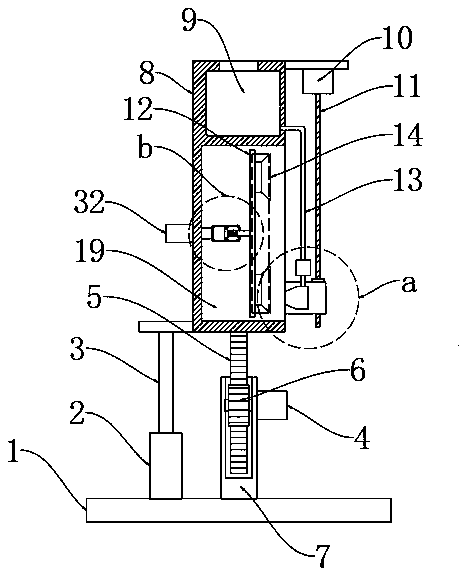

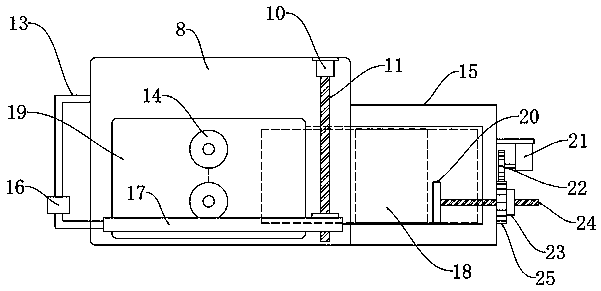

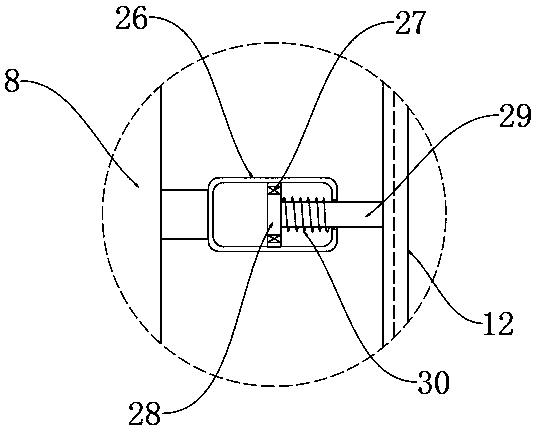

Vertical type automatic wall brick pasting device for building construction

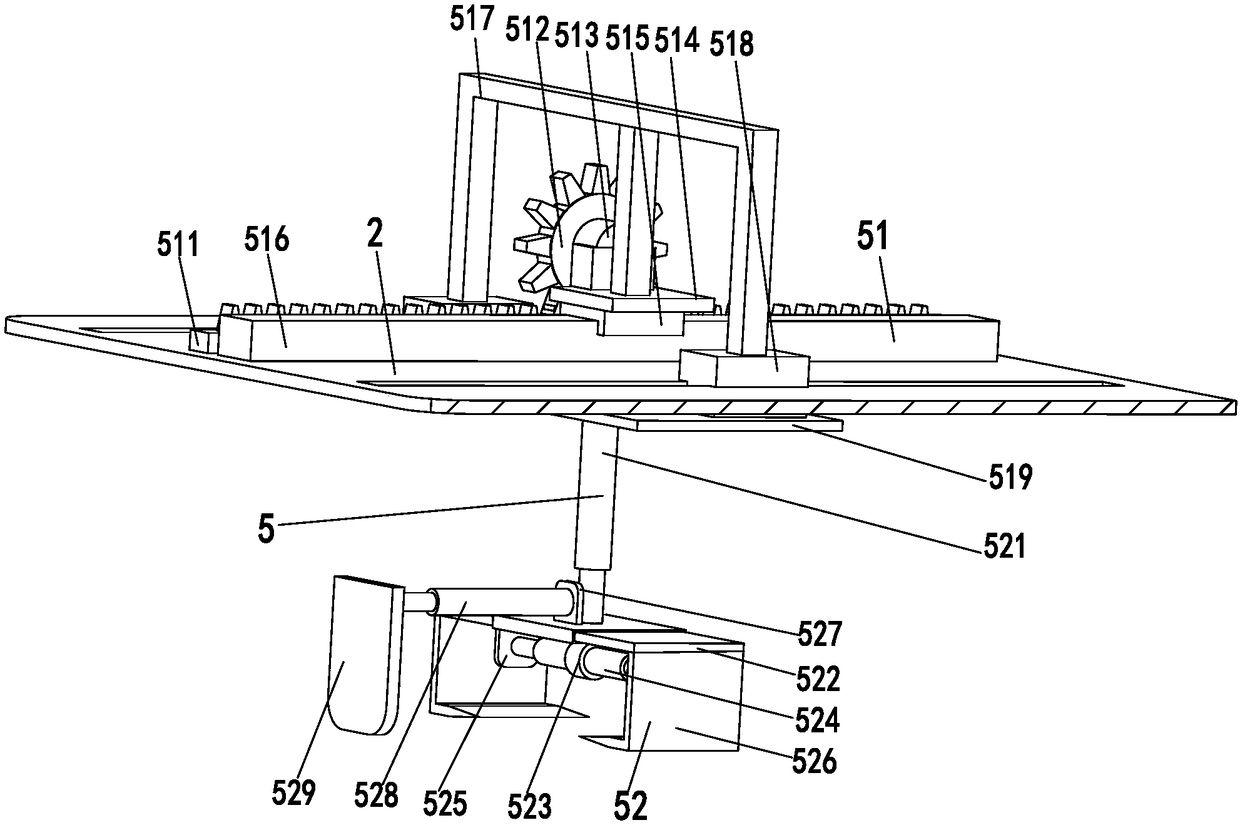

ActiveCN111424933ANo manual feedingImprove work efficiencyBuilding constructionsBrickArchitectural engineering

The invention discloses a vertical type automatic wall brick pasting device for building construction. The device comprises a base, the upper end of the base is fixedly connected with a shell with theside face provided with a containing groove through a guide device, a pushing mechanism for pushing the shell to move up and down is mounted on the base, a push plate is mounted in the shell, a suction cup for sucking ceramic tiles is mounted at the position, on an opening of the shell, of the push plate, a power mechanism used for pushing the push plate to move is fixedly connected with the sidewall of the shell, a claying mechanism for claying the wall bricks is mounted on the side wall of the shell, manual loading is not needed, multiple wall bricks can be pasted at one time, work efficiency is greatly improved, through the suction cup on the side wall of the push plate, the wall bricks are sucked, the wall bricks cannot be damaged due to flexible contact, through a buffer mechanism,the wall bricks can be effectively prevented from being damaged due to pressing during pasting, manual claying is not needed, and claying is more uniform.

Owner:山东兴源建设工程有限公司

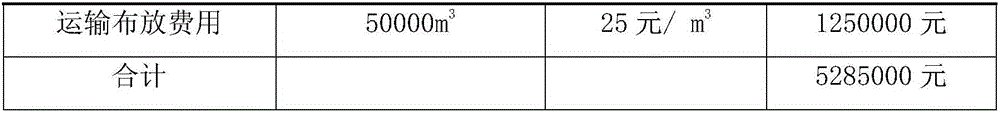

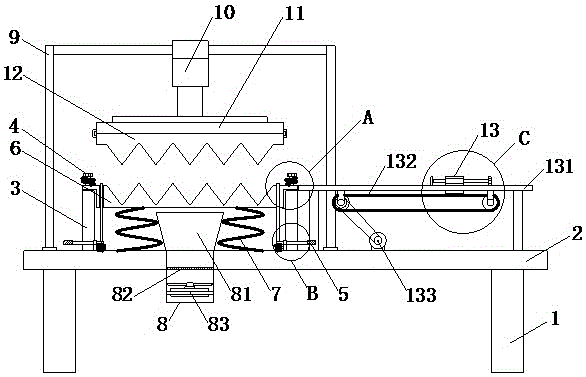

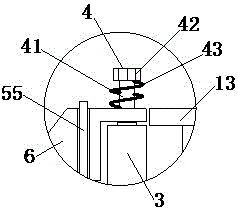

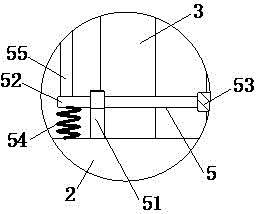

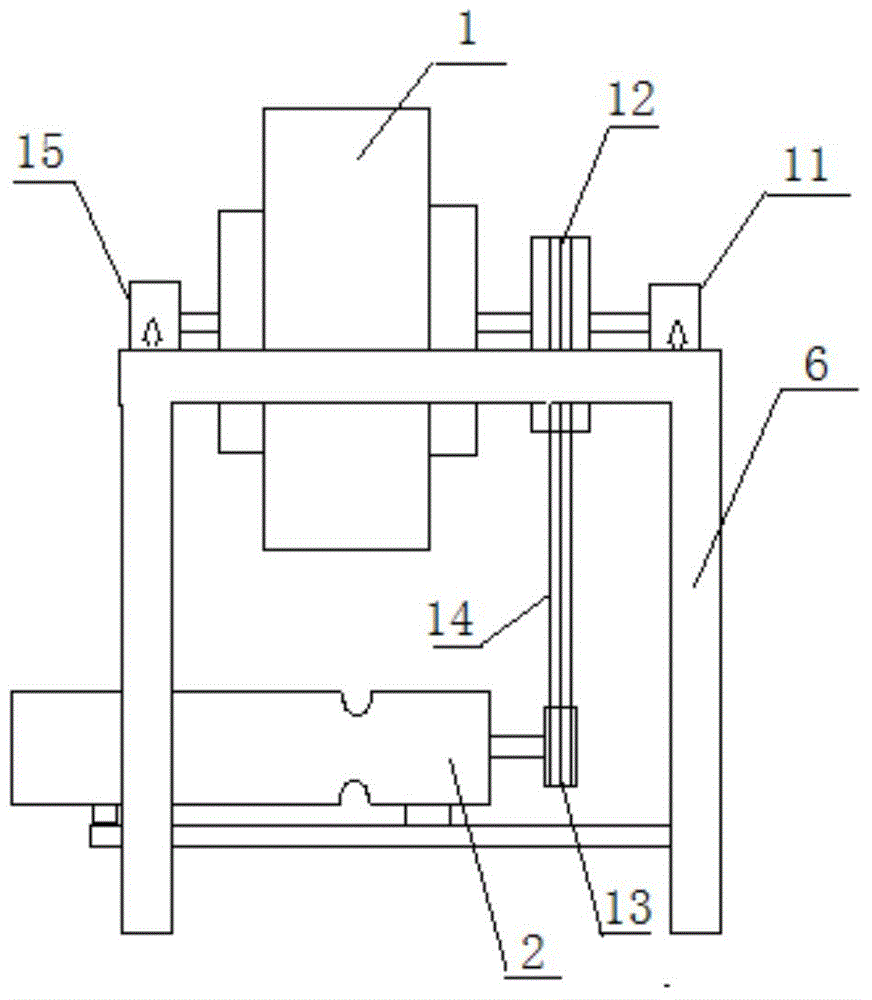

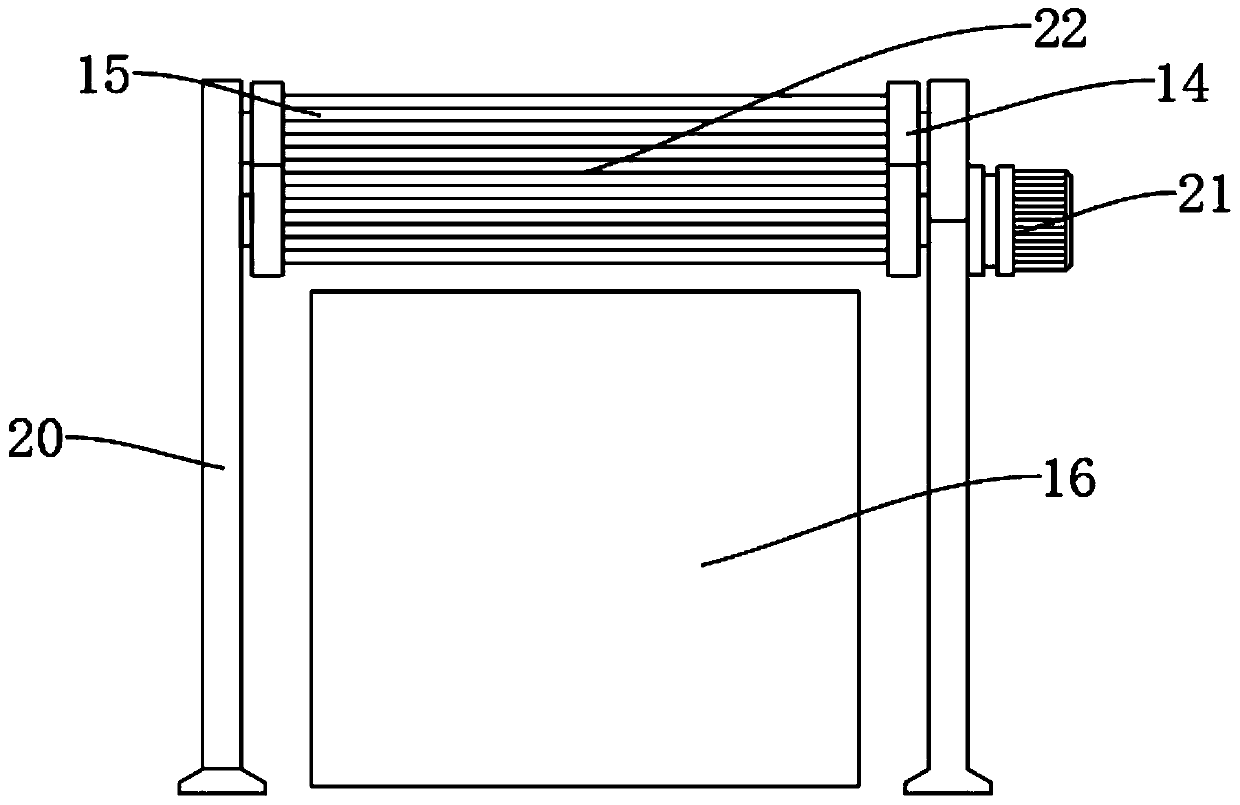

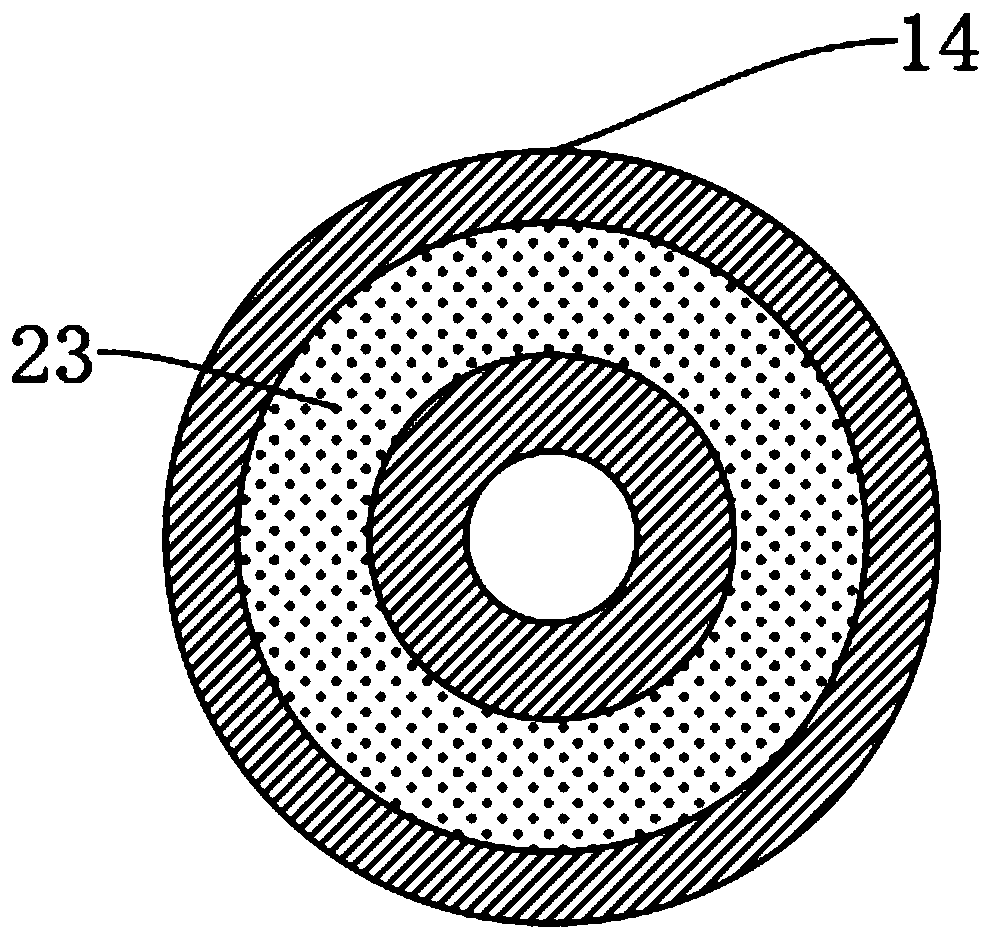

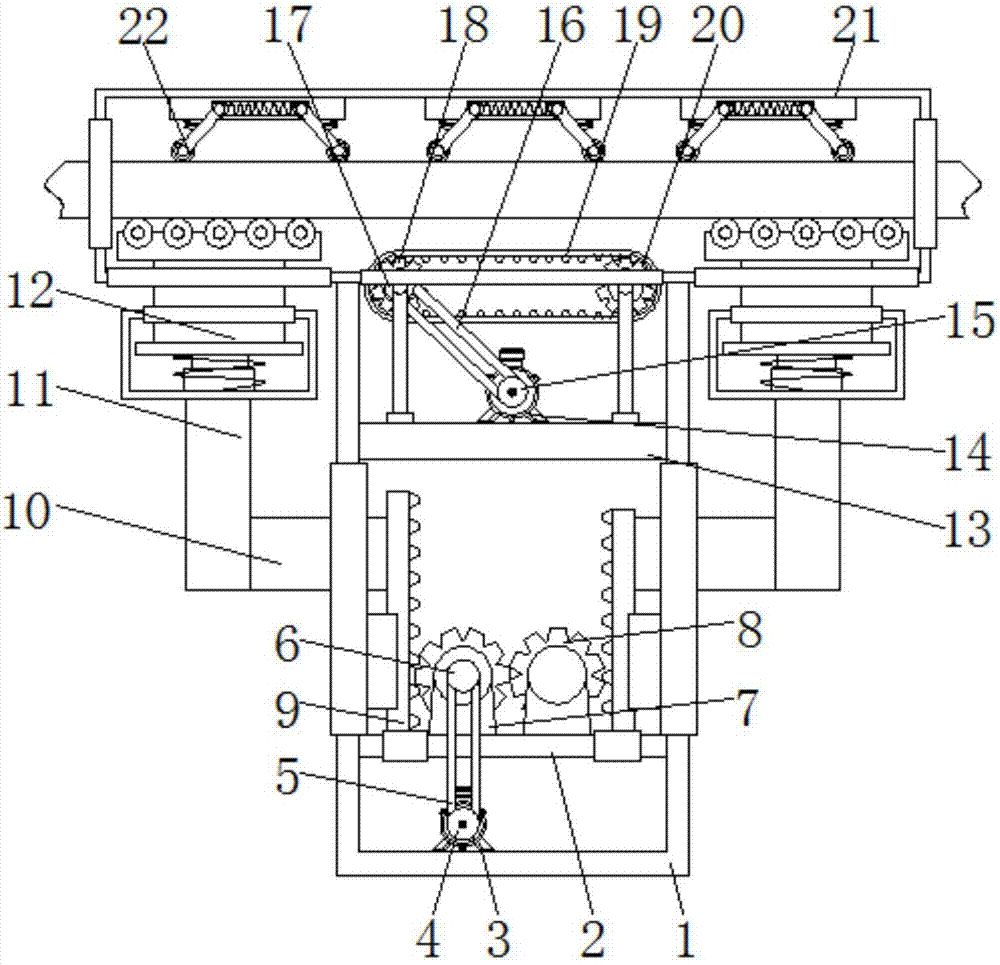

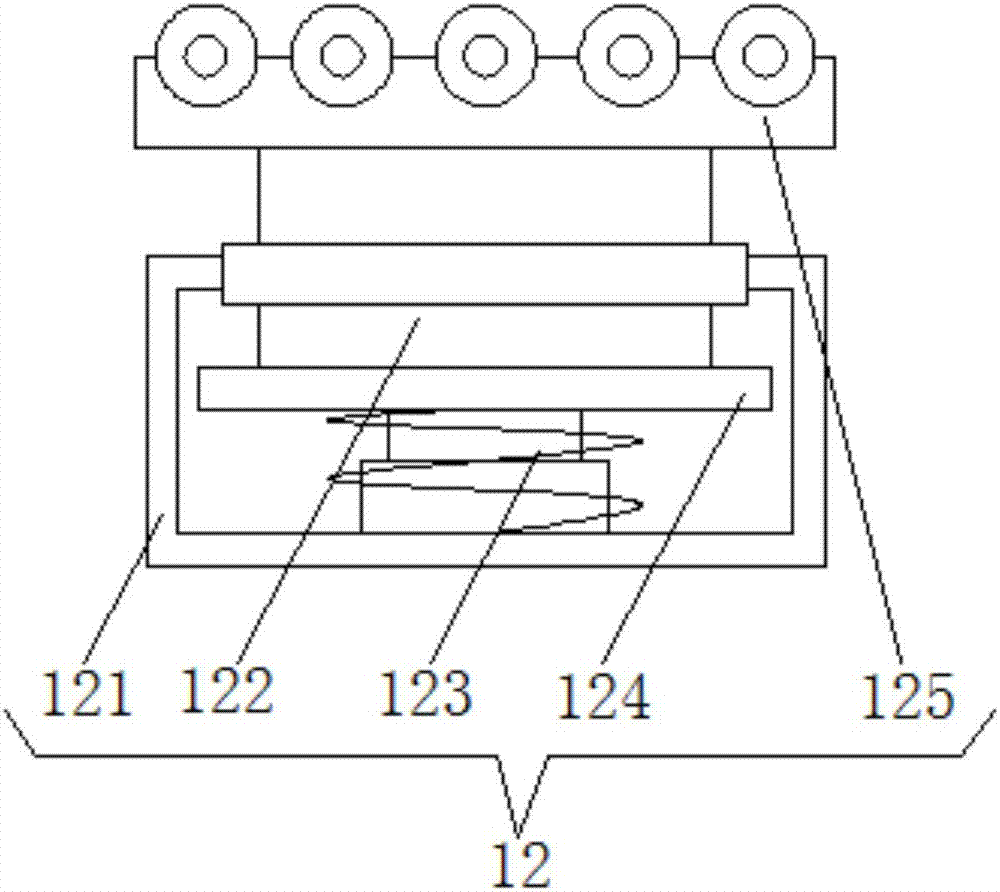

Novel preforming press for corrugated paper

InactiveCN105835410AEasy to replaceImprove personal safetyMechanical working/deformationPhysical paper treatmentEngineeringMechanical engineering

The invention discloses a novel preforming press for corrugated paper. The novel preforming press comprises support legs, wherein a worktable is fixed at the tops of the support legs, four prepressing braces are fixedly arranged at the upper surface of the worktable, a detaching device is fixedly arranged at the tops of the prepressing braces, a lower die is fixedly arranged at the junction of the detaching device and the prepressing braces, a demoulding device with top end running through the lower die is fixedly arranged on the worktable at the inner side of the prepressing braces, two ends of the bottom of the lower die are both movably connected with support springs with one ends fixedly connected with the worktable, and a drying device is sleeved and fixed on the worktable between the support springs. According to the novel preforming press used for corrugated paper, manual demoulding can be carried out on the corrugated paper prepressed on the lower die by utilizing the demoulding device, the operation is convenient; and due to arrangement of the feeding device, automatic feeding can be realized by a push plate just by putting to-be-machined paper on the feeding plate, manpower loading is not needed, and safety accidents are avoided.

Owner:CHANGZHOU WUJIN GOLDEN SUNSHINE ELECTRONICS

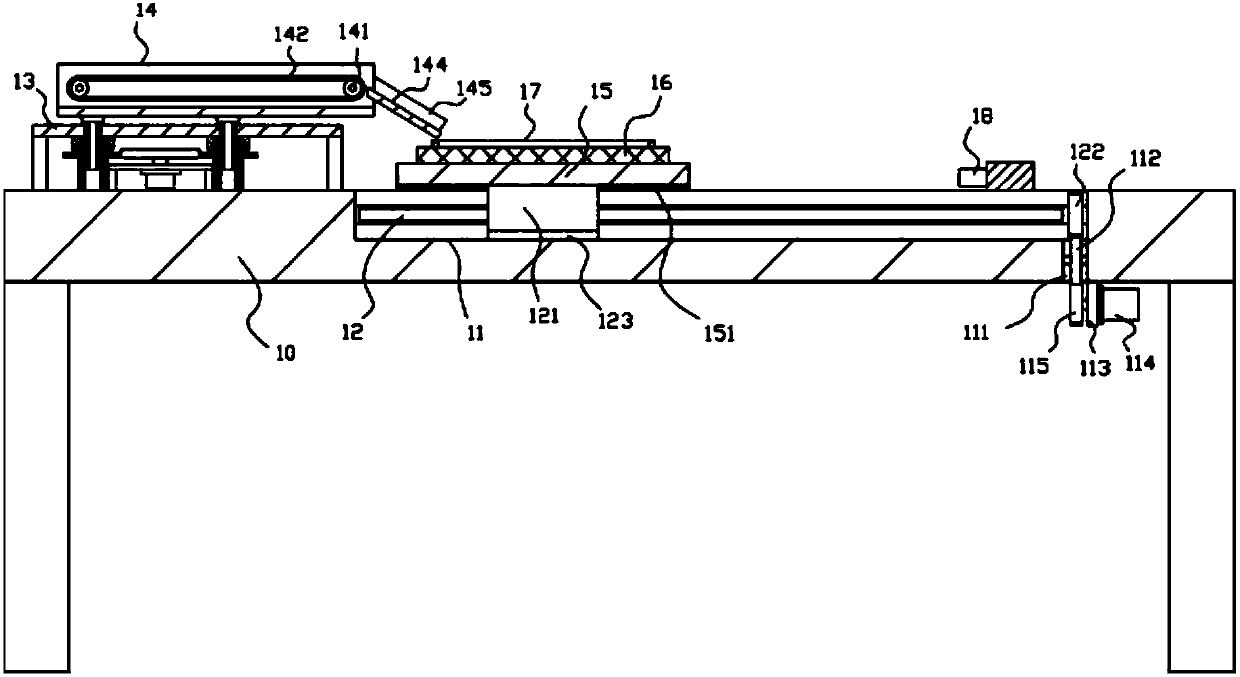

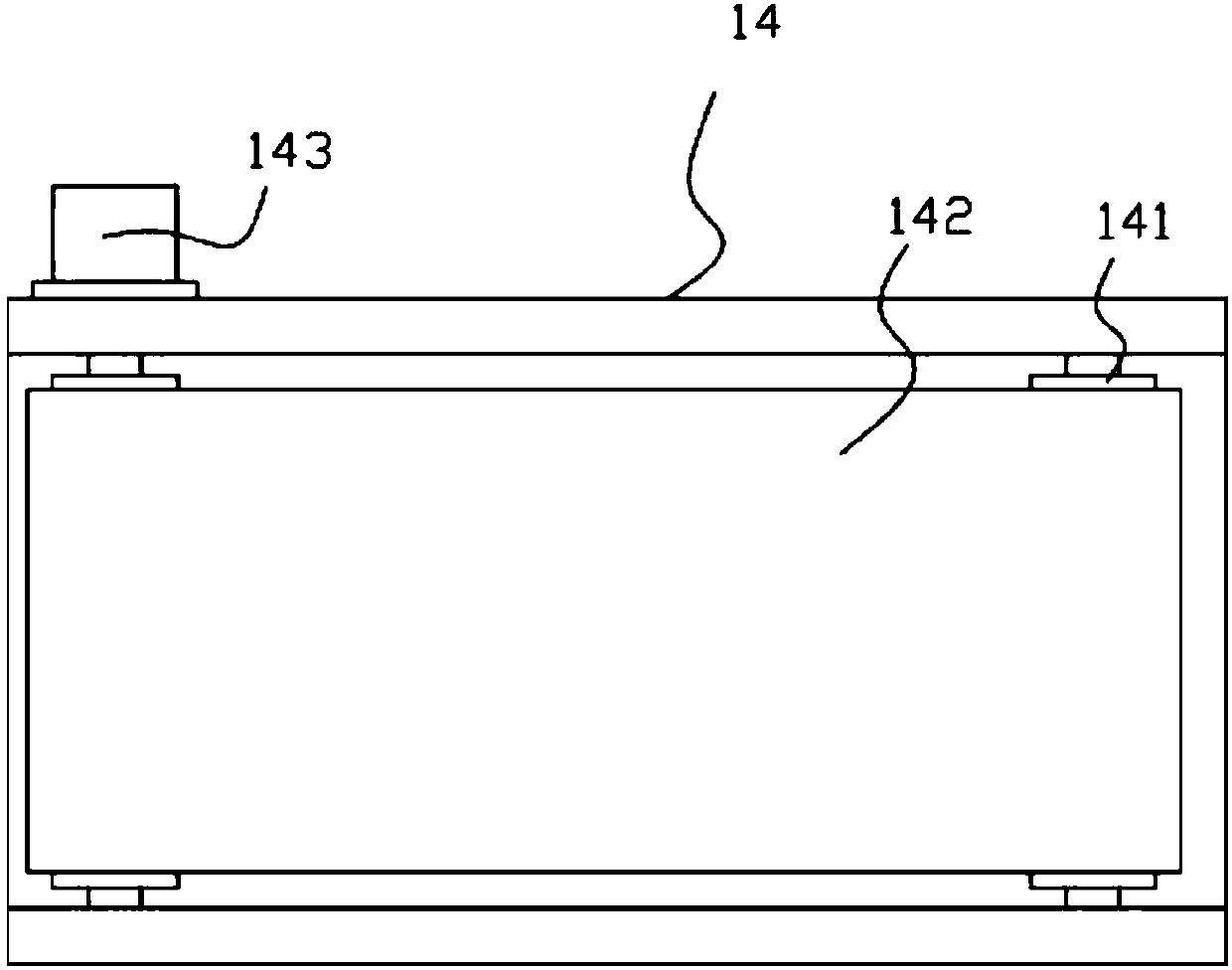

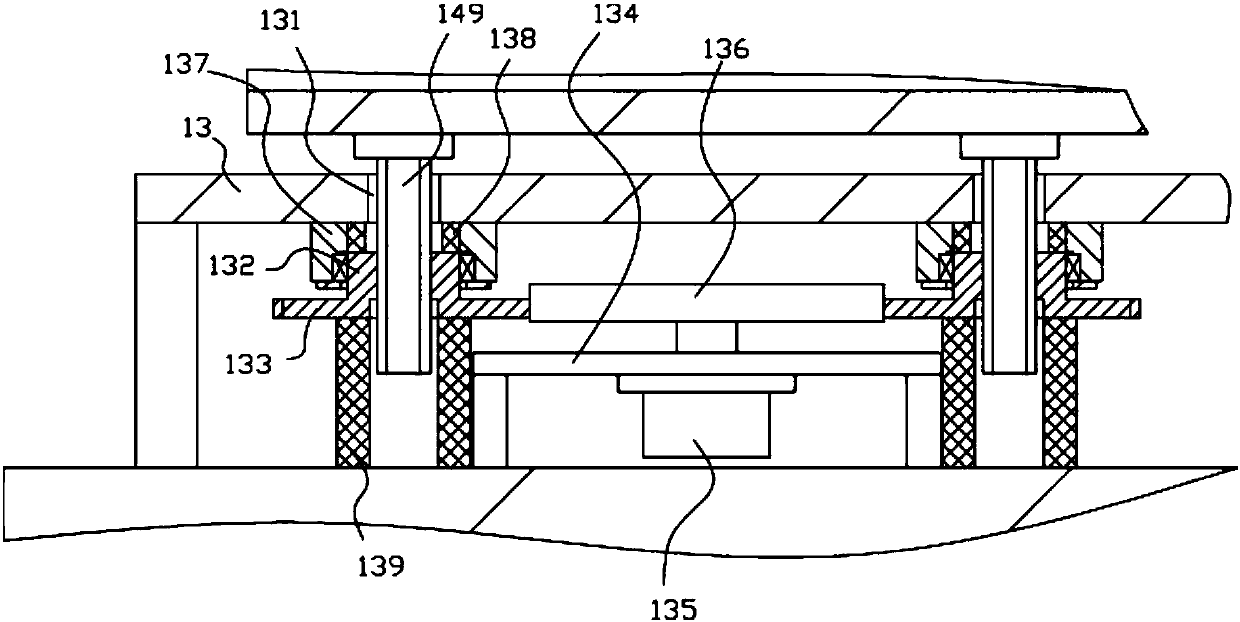

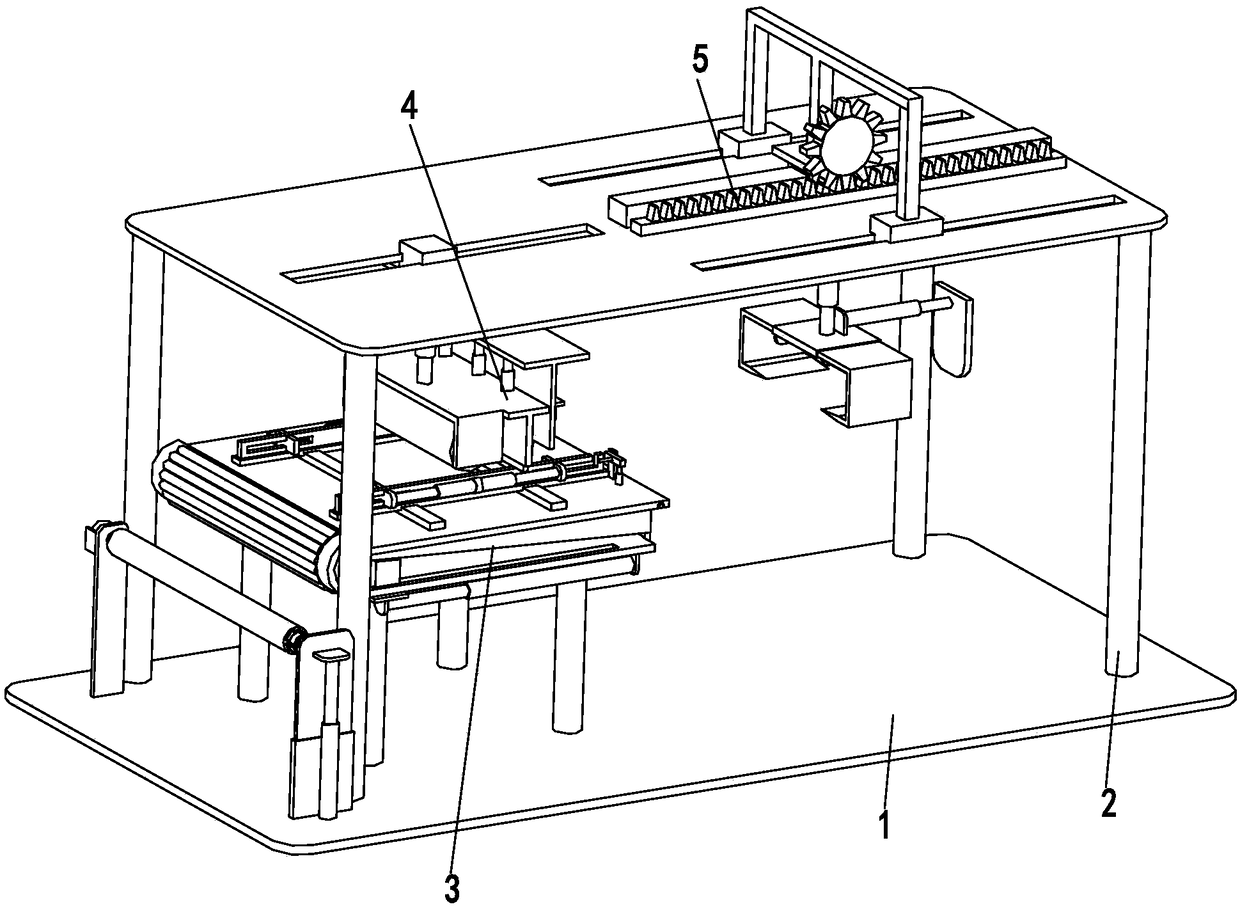

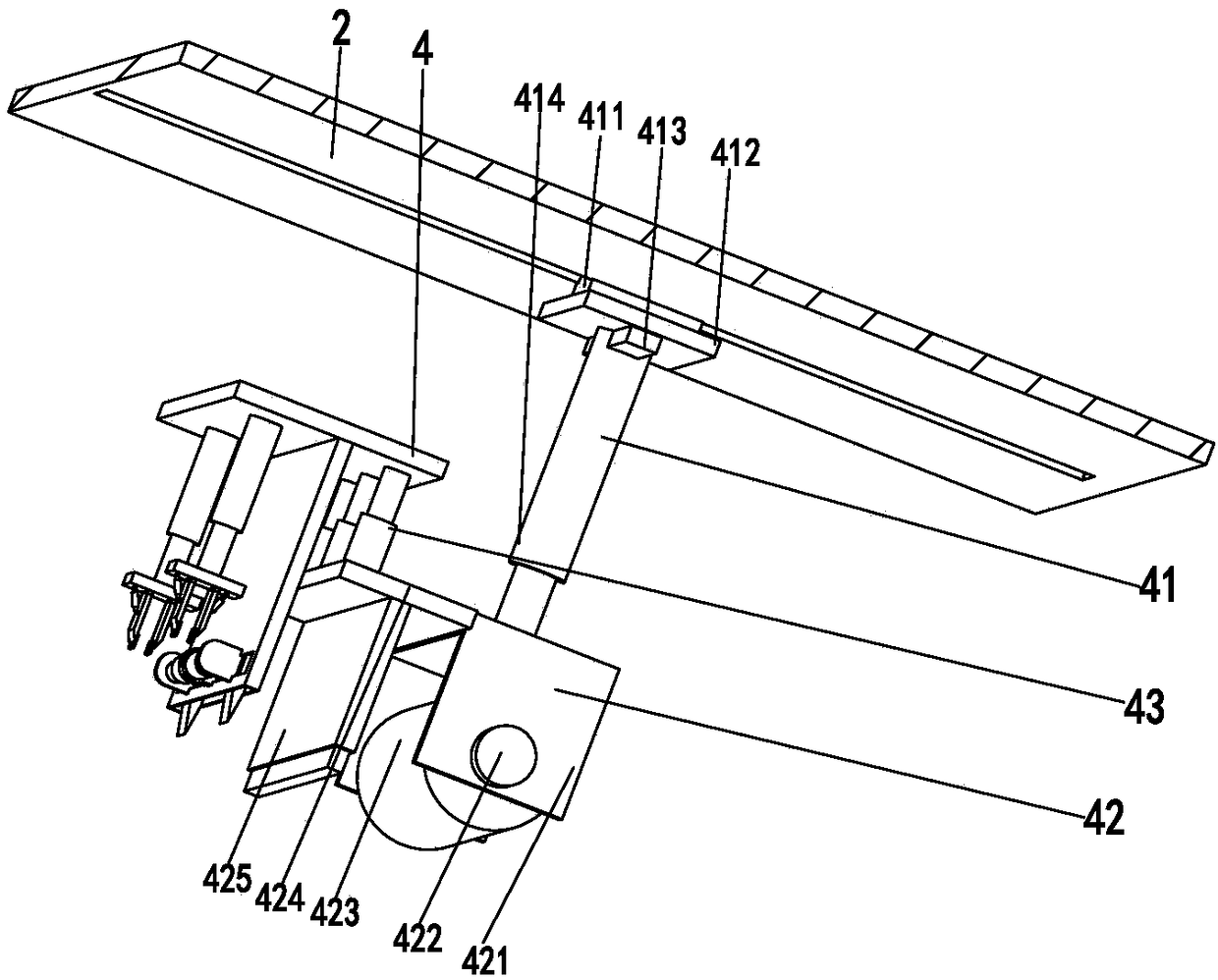

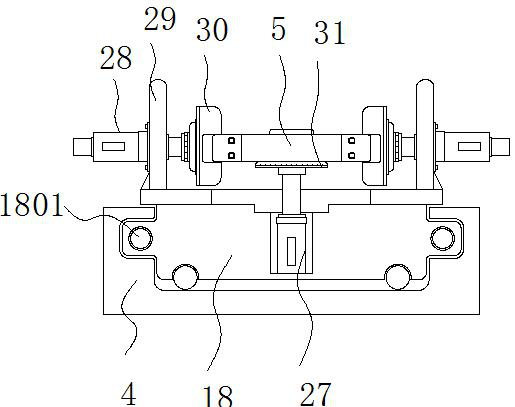

High-precision automatic conveying mechanism for metal plates

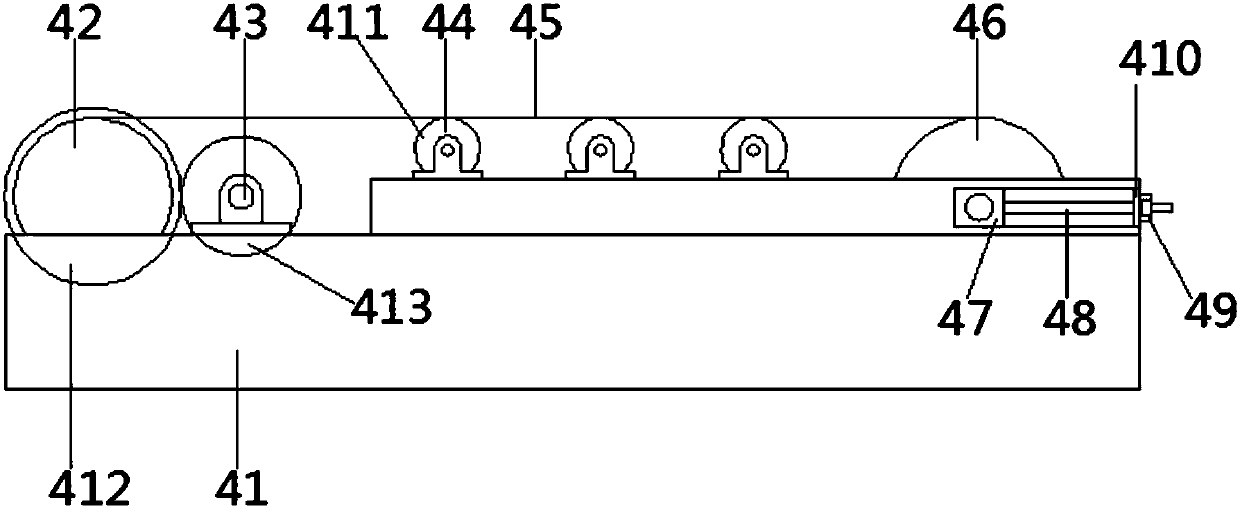

InactiveCN107672991AMeet high requirementsHigh precisionConveyorsConveyor partsAutomatic transmissionEngineering

The invention discloses a high-precision metal plate automatic conveying mechanism, which comprises a frame, the middle part of the top plate of the frame has a mounting groove, and a horizontal screw is inserted in the mounting groove, and the two ends of the horizontal screw are hinged on the installation On the two left and right inner walls of the groove, the moving block is screwed into the horizontal screw rod, the right end of the horizontal screw rod is fixed with the main transmission gear, the bottom surface of the right end of the installation groove has an installation empty slot, and the middle transmission gear is inserted into the installation empty slot , the two ends of the middle shaft of the intermediate transmission gear are hinged on the two inner walls of the installation cavity, the intermediate transmission gear meshes with the main transmission gear, and the bottom surface of the top plate of the frame is fixed with a lower connecting plate; it can adjust the feeding and conveying The high and low position of the plate ensures that it meets the height requirements of conveying different material plates and reduces bumps. It can automatically transport metal plates, and it is transported through a horizontal screw. convenient.

Owner:FOSHAN XINJUNAN SMART HOME CO LTD

Plastic film automatic covering system

The invention relates to a plastic film automatic covering system. The plastic film automatic covering system comprises a bottom plate, a mounting rack, an auxiliary device, a film covering device, and a feeding device; the mounting rack is arranged on the bottom plate; the film covering device and the feeding device are arranged on the lower end of the mounting rack from left to right successively; the auxiliary device is arranged below the film covering device, and is arranged on the bottom plate; the auxiliary device comprises a material loading mechanism, supporting columns, a supporting plate, an arc-shaped plate, an adjusting mechanism, and a spacing mechanism; the film covering device comprises a positioning adjusting mechanism, a laminating mechanism, and a cutting mechanism; the feeding device comprises a moving mechanism and a grabbing mechanism. The plastic film automatic covering system is capable of solving problems in the prior art that artificial cost is high, working efficiency is low, labor intensity is high, using range is small, and working stability is poor in conventional straw plate film covering process, is capable of realizing automatic film covering of straw plates, is low in artificial cost, low in labor intensity, high in working efficiency, wide in using range, and high in working stability.

Owner:潘学英

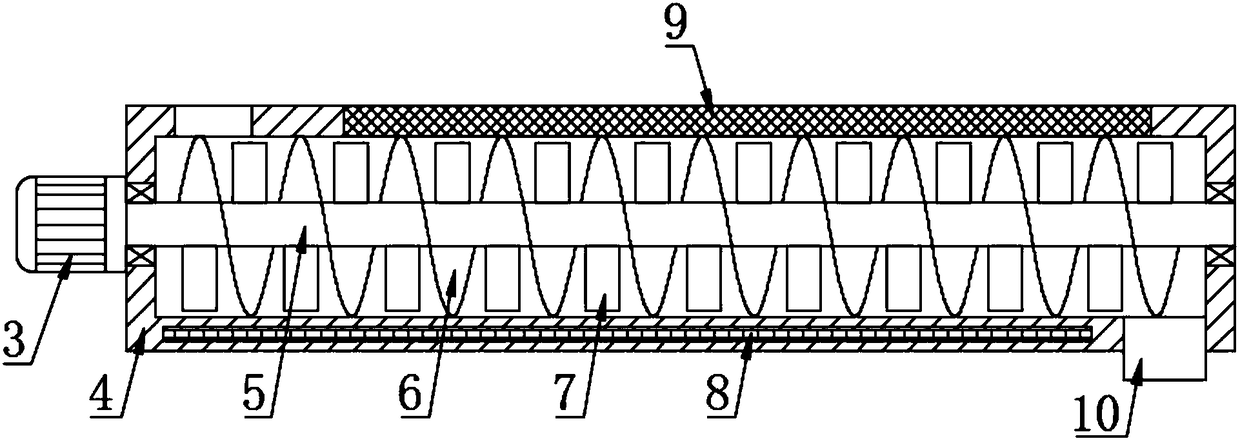

Feed automatic supply type feed drying device

InactiveCN108523185AEasy to useEasy to processFeeding-stuffDrying solid materialsSpiral bladeEngineering

The invention discloses a feed automatic supply type feed drying device. A drying barrel is fixedly arranged at the top of a base through a bracket, a discharge pipe is connected with the left lower corner of the drying barrel, and an arc electric heating plate is embedded in the side wall of the drying barrel; a first rotating shaft is arranged on the axis in the drying barrel, left and right ends of the first rotating shaft are respectively connected with left and right walls of the drying barrel in a rotating manner; a spiral blade is fixedly arranged on the side wall of a second rotating shaft; a vibrating and dispersing tank is arranged between left and right supporting plates, and is positioned on a collecting hopper; and the bottom of the vibrating and dispersing tank is opened, andis fixedly connected with a screen. According to the device, feed in the drying tank can be dried through the arc electric heating plate, the spiral blade is used for driving the feed to move leftward when rotating, the feed is discharged from the discharge pipe, and the feed can be constantly dried with high drying efficiency; and caked feed can be vibrated and dispersed by left-right shaking ofthe vibrating and dispersing tank, and subsequent drying is facilitated.

Owner:HEFEI TOTEM LONG MACHINERY DESIGN CO LTD

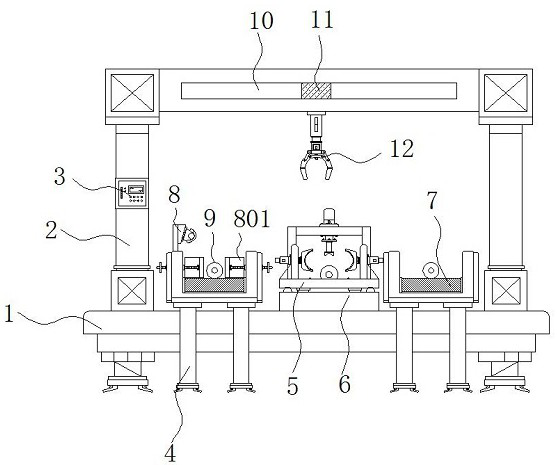

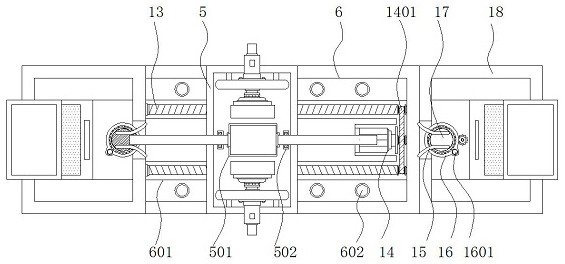

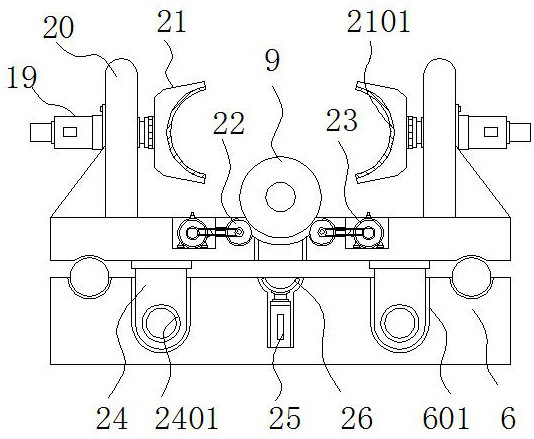

Diode pin bending device capable of conducting surface scratch detection on diode

InactiveCN112091128AImprove processing efficiencyImprove work efficiencySortingStructural engineeringWorkbench

The invention discloses a diode pin bending device capable of conducting surface scratch detection on a diode. The diode pin bending device particularly comprises a base, a workbench, a moving rail and a functional seat; a frame body is mounted at the top end of the base, a control panel is mounted in the middle of one side of the frame body, and an electromagnetic sliding rail is arranged in themiddle of the top end in the frame body; a sliding block is mounted in the electromagnetic sliding rail, and a grabbing mechanism is fixed to the bottom end of the sliding block; and the moving rail is mounted in the middle of the top end of the base, and the workbench is mounted on the moving rail. According to the diode pin bending device capable of conducting surface scratch detection on the diode, by arranging the functional seat, a bending seat and a cutting seat are arranged in the functional seat, a cutting knife on the cutting seat can cut pins of the diode, the bending seat can bend the pins, that is, the diode can be bent and cut off only by fixing the diode once, and the working efficiency is higher.

Owner:广州市金点子机电科技发展有限公司

Tool structure for wood cutting

InactiveCN108098935AInnovative designEasy to operateProfiling/shaping machinesConveyor beltWood cutting

The invention discloses a tool structure for wood cutting. The tool structure comprises a workbench, a support, a cutting mechanism and a feeding mechanism; the right end of the workbench is providedwith the feeding mechanism, and the feeding mechanism comprises a transmission wheel, a bevel gear C, a bevel gear D and a third motor; a conveyor belt is arranged at the left end of the workbench; and the support is fixedly arranged at the upper end of the workbench, a cutting mechanism is arranged on the inner side of the support, and comprises a threaded sleeve, a cutting knife, a first motor and a supporting plate. According to the tool structure for wood cutting, the design is novel, the operation is simple, the first motor is arranged to drive a threaded rod to rotate in the threaded sleeve by the meshing action of a driven gear and a driving gear to realize the up-down movement of the cutting knife, meanwhile, the cutting knife rotates under the action of the meshing action of a bevel gear A and a bevel gear B, rapid cutting is realized, the feeding mechanism is arranged, the automation degree of the tool structure is improved, manual feeding is not needed, the cutting efficiency is high, the practicability is high, and the tool structure is worthy of popularization.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

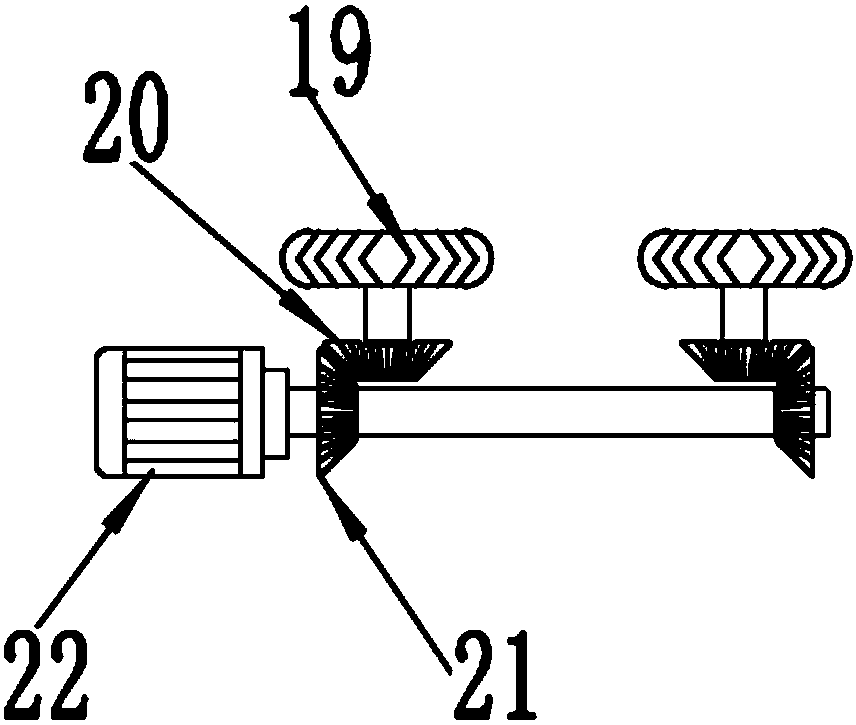

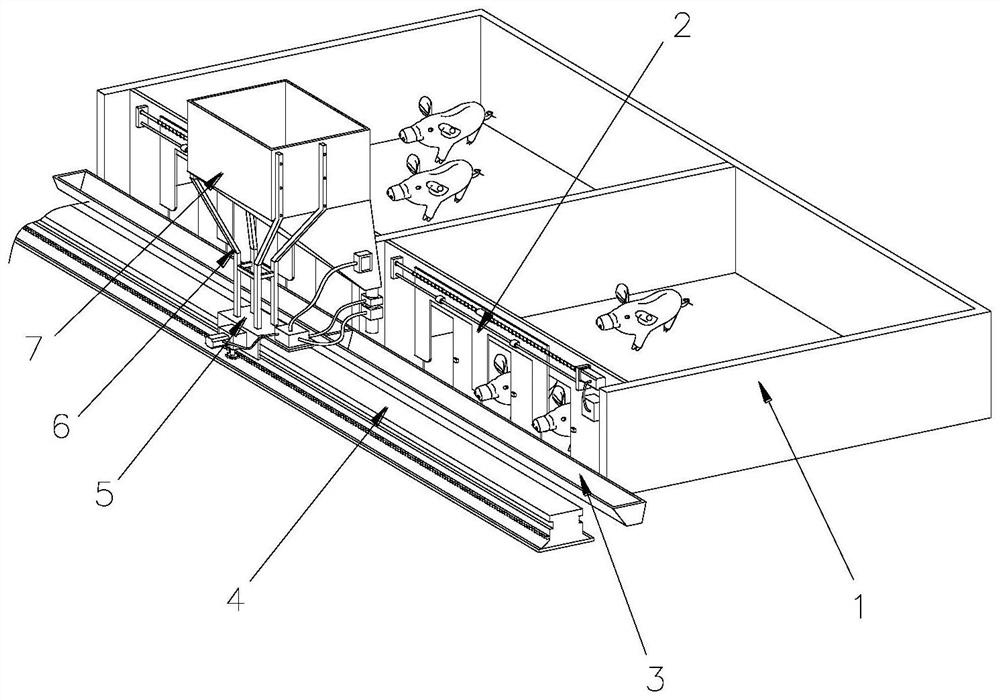

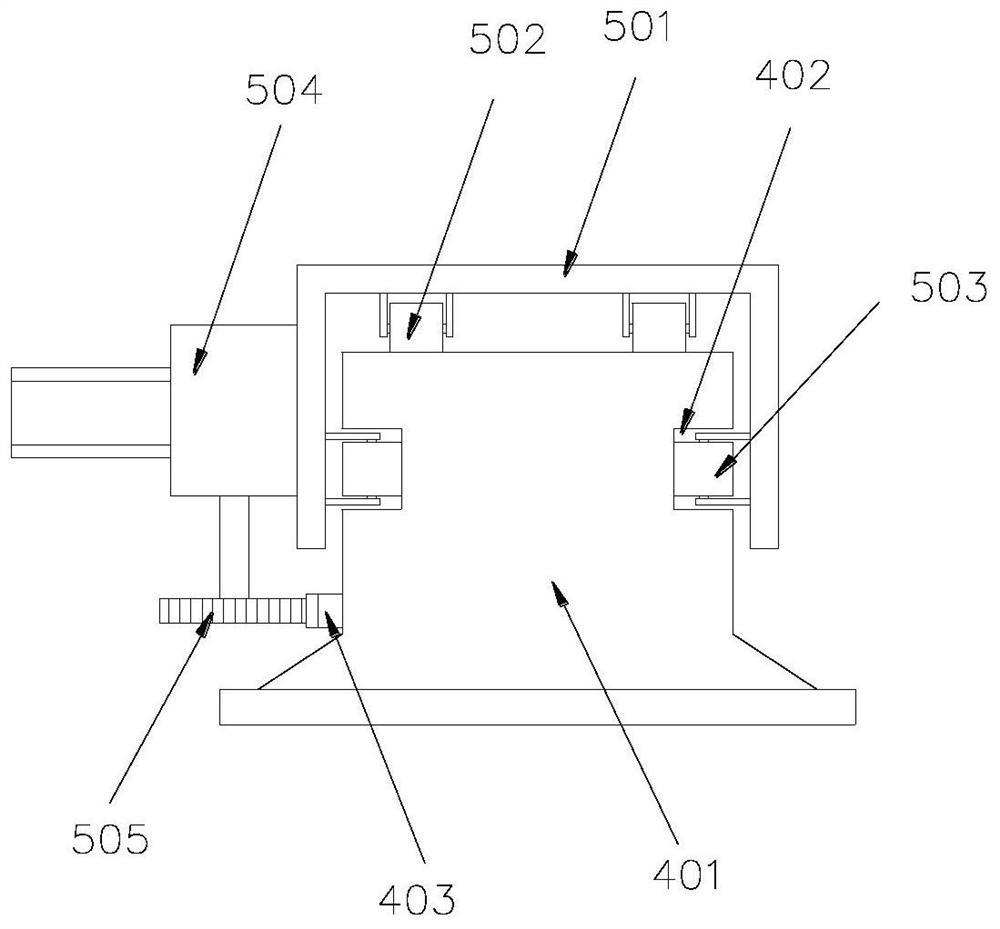

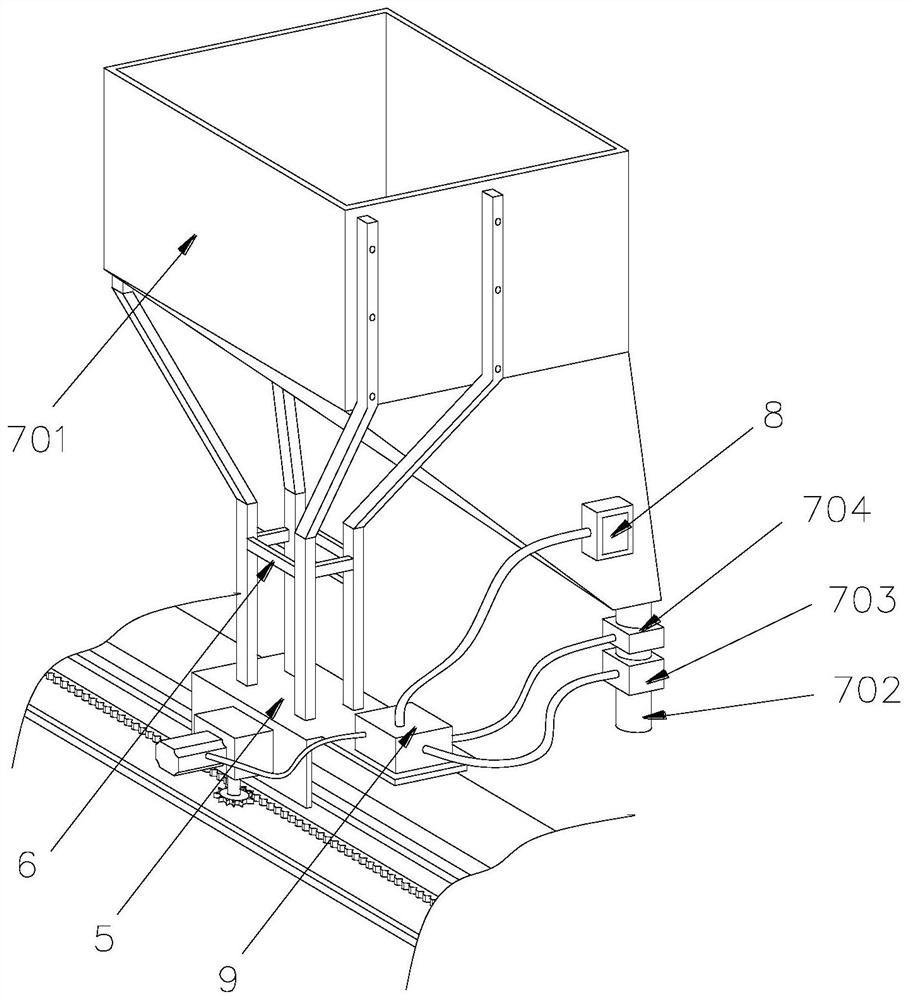

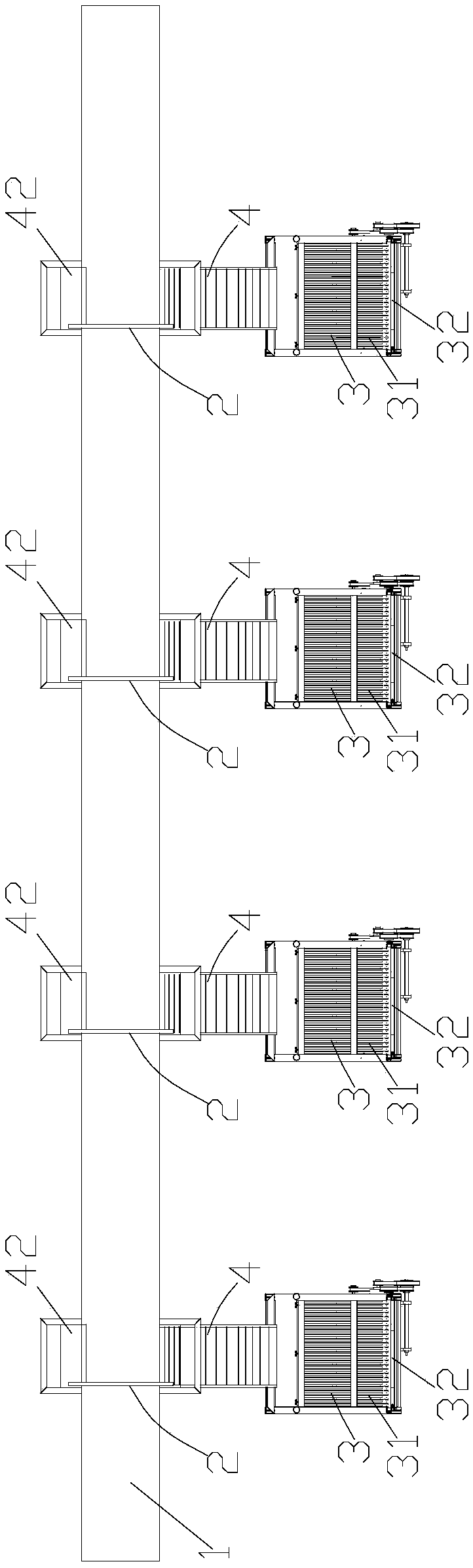

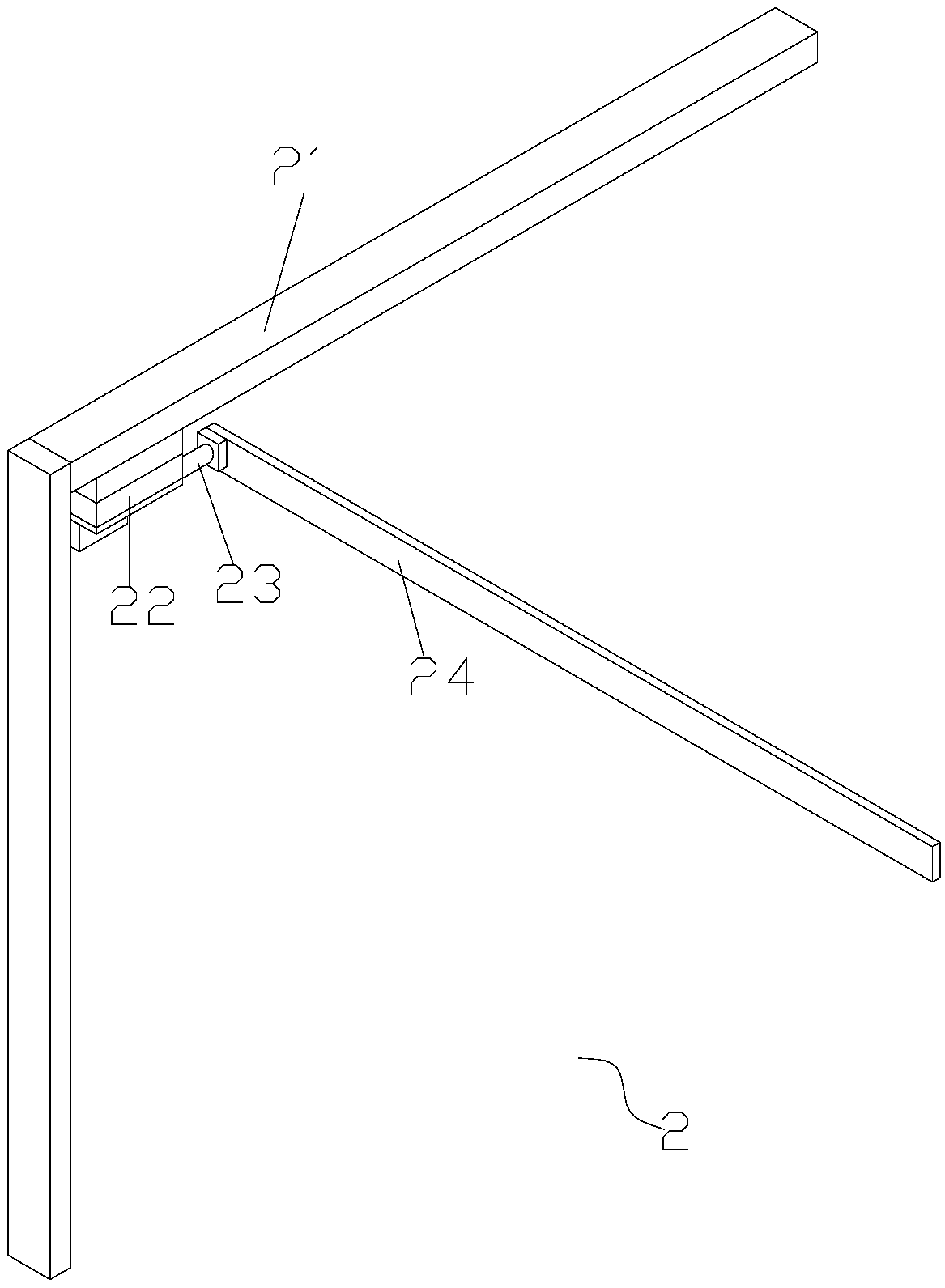

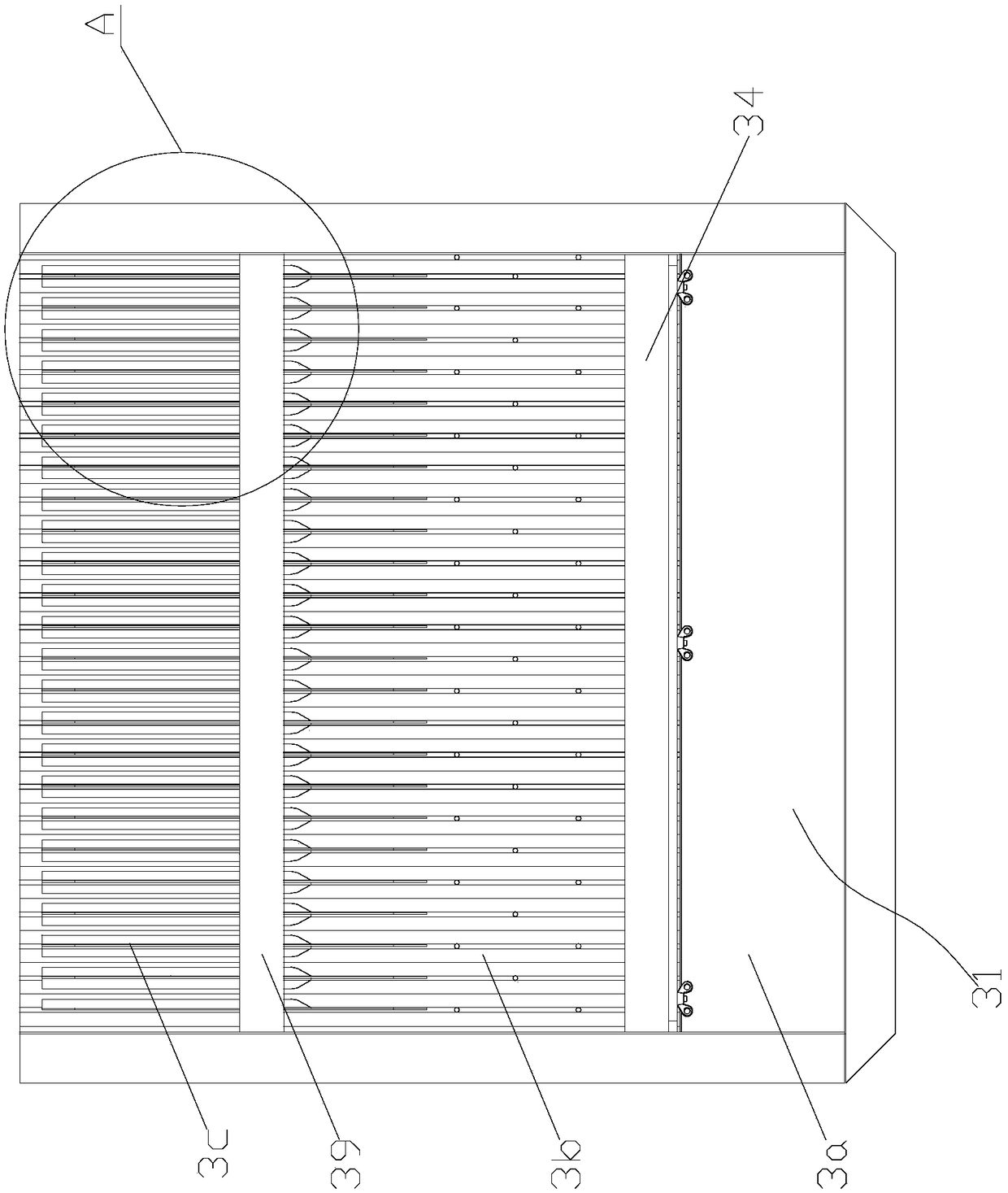

Intelligent automatic feeding system and feeding method for live pigs

ActiveCN111869578AThe feeding process is controllableAccurately control food intakeAnimal feeding devicesAnimal scienceEngineering

The invention discloses an intelligent automatic feeding system for live pigs. The intelligent automatic feeding system comprises feeding fences, wherein each feeding fence is provided with a guardrail and is characterized in that hole channels allowing the heads of live pigs to penetrate through are formed in the guardrail, a feeding trough is formed in the outer side of the guardrail, a guide rail is arranged on the outer side of the feeding trough, a sliding mechanism is mounted on the guide rail, and a feeding device is mounted on the sliding mechanism. The feeding device comprises a hopper and a discharging pipe connected to the lower part of the hopper, wherein the discharging pipe is located over the feeding trough, an electromagnetic valve is mounted on the discharging pipe, in addition, an RFID reader-writer is further mounted at the lower part of the hopper, a control host is mounted on the sliding mechanism, the RFID reader-writer is electrically connected with the control host, and the electromagnetic valve is connected with and controlled by the control host. The system can realize differentiated automatic feeding of feeds in each feeding fence, is scientific and reasonable, avoids feed waste to the maximum extent, does not need manual feeding, and saves time and labor. The system can accurately control the food intake of each pig, so that the breeding quality of the live pigs is improved.

Owner:潘建文

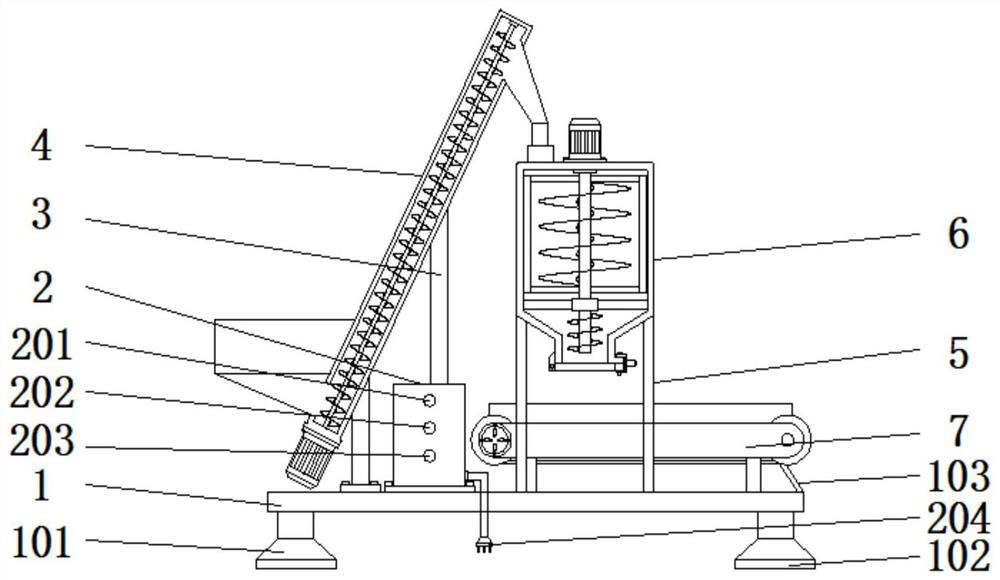

Automatic feed device with pre-processing function for forage production

InactiveCN108855534ARealize the purpose of heating and dryingRealize automatic feeding processNon-rotating vibration suppressionPackagingGround contactEngineering

The invention discloses an automatic feed device with a pre-processing function for forage production. The automatic feed device with the pre-processing function comprises a fixing sleeve, a first motor, a cylinder, a second motor and a base plate. Through the fixing sleeve, a user can conveniently rotate a screw rod to drive the base to move downwards and be contact with the ground to fix the base to the ground and achieve the aim of fixing the position of equipment, avoid moving of the equipment, and improve practicability of the equipment. Through the first motor, spiral conveying blades ata conveying rotating shaft are driven to rotate, and therefore materials are lifted to be discharged from a discharging pipe. In this way, automatic feeding is achieved, manual feeding is not required, and feeding efficiency is improved. A piston rod is driven by a cylinder to stretch out and retract back, and therefore the aim of adjusting the inclination angle of a first cylinder body is achieved, and requirements to the inclination angles of the first cylinder body under different circumstances are met.

Owner:张孝法

Pin machining and production equipment capable of detecting lengths of capacitor pins

InactiveCN112077227AImprove work efficiencySimple structureMeasurement devicesSortingCapacitanceStructural engineering

Owner:东莞市夯牛机电科技有限公司

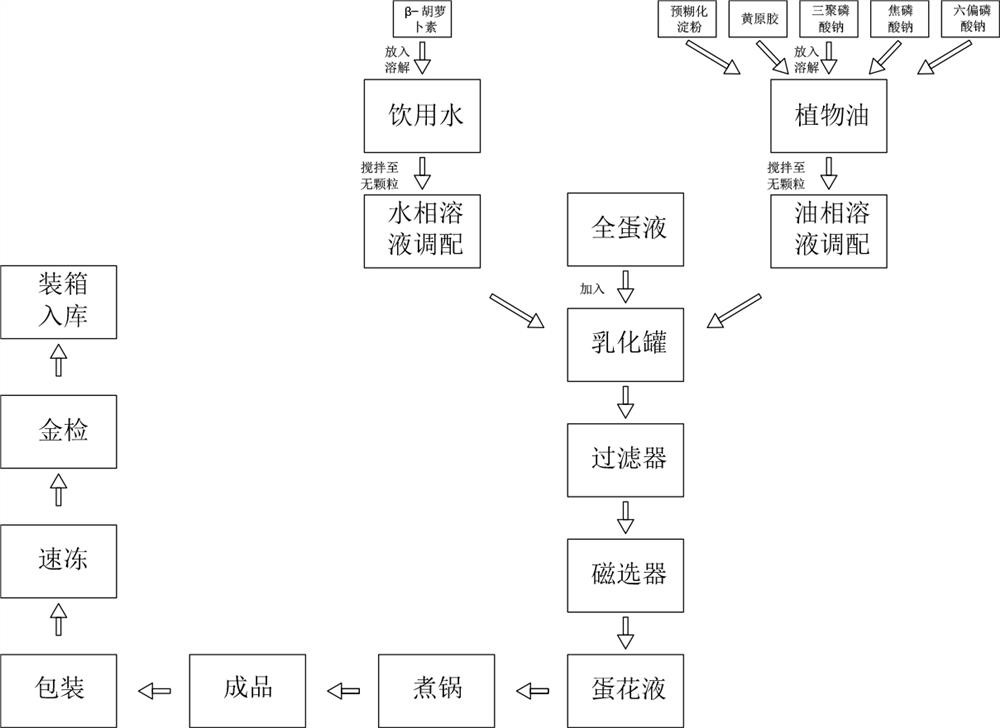

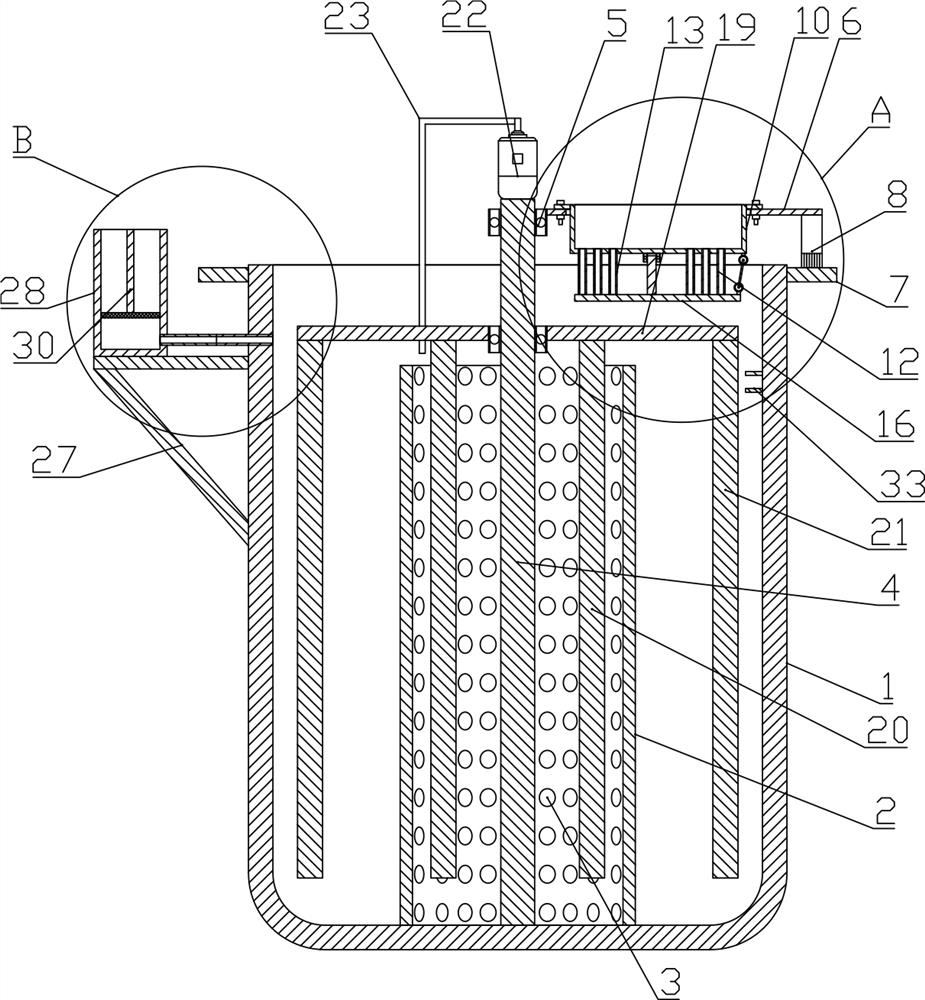

Frozen egg drop processing method and egg drop cooking device

ActiveCN112042892AWell mixedExtended shelf lifeFood freezingFood thermal treatmentBiotechnologySODIUM METAPHOSPHATE

The invention discloses a frozen egg drop processing method and an egg drop cooking device. The method comprises the step of preparing egg drop fluid, wherein the egg drop fluid comprises the raw materials: 3%-8% of vegetable oil, 85%-95% of egg pulp, 1%-5% of pre-gelatinized starch, 0.01%-0.5% of xanthan gum, 0.01%-0.3% of beta-carotene, 0.01%-0.3% of sodium tripolyphosphate, 0.01%-0.3% of sodiumpyrophosphate, 0.01%-0.3% of sodium hexametahposphate, 1%-10% of drinking water, 0.01%-0.05% of beta-carotin, 1%-5% of potato starch and the balance of filtering water. The method comprises the processing steps: oily-phase solution blending, aqueous-phase solution blending, egg drop fluid emulsifying, filtering magnetic separation, egg drop cooking, packaging, quick freezing, metal detecting andboxing and warehousing. The egg drop cooking device can be used for stirring egg drop and perform automatic charging. The method and the device have the beneficial effects that hand charging is not required, and uniform charging can be carried out, so that the working efficiency is increased; and working personnel can be prevented from scalding, so that potential safety hazards are reduced.

Owner:JILIN JINYI FOOD CO LTD

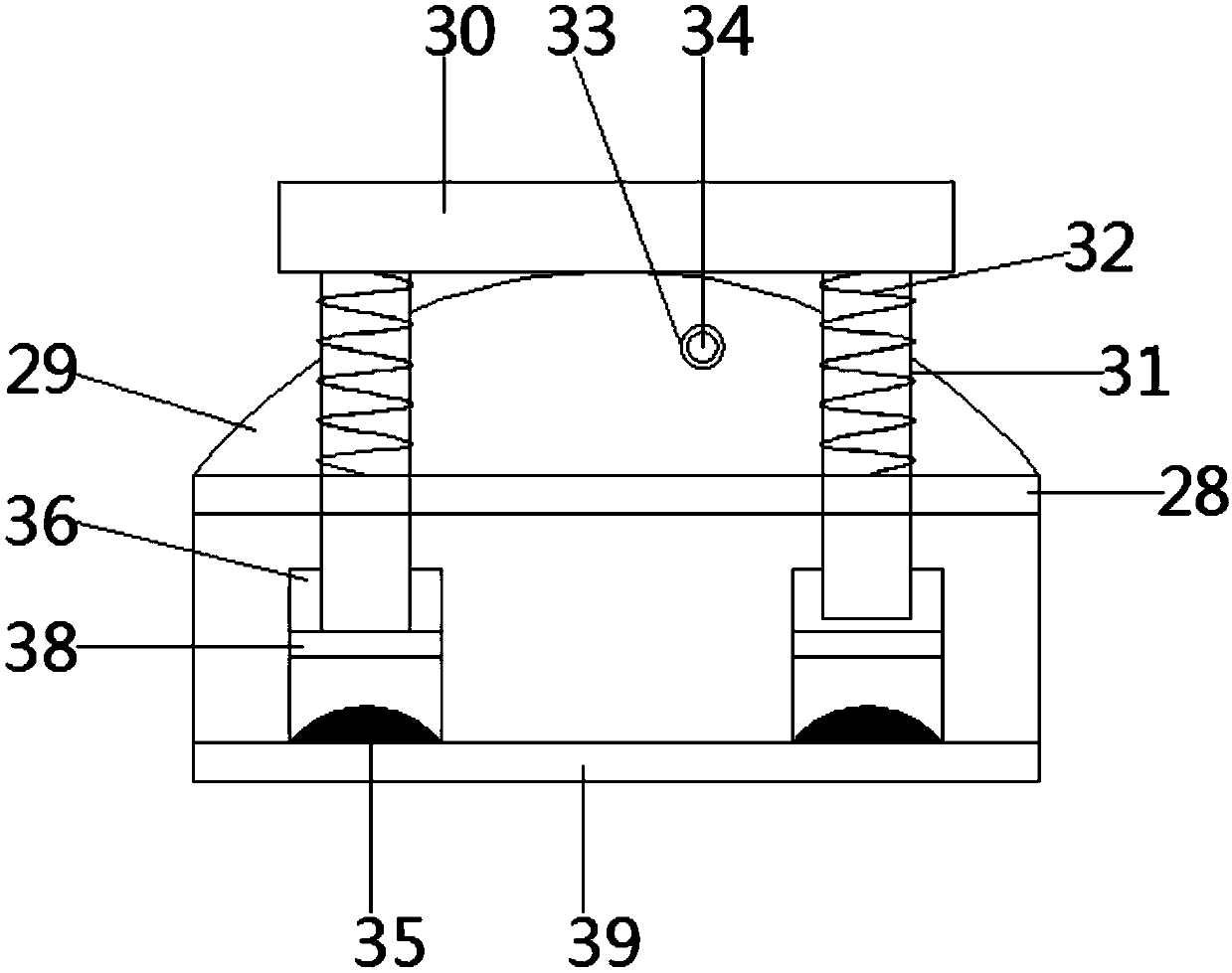

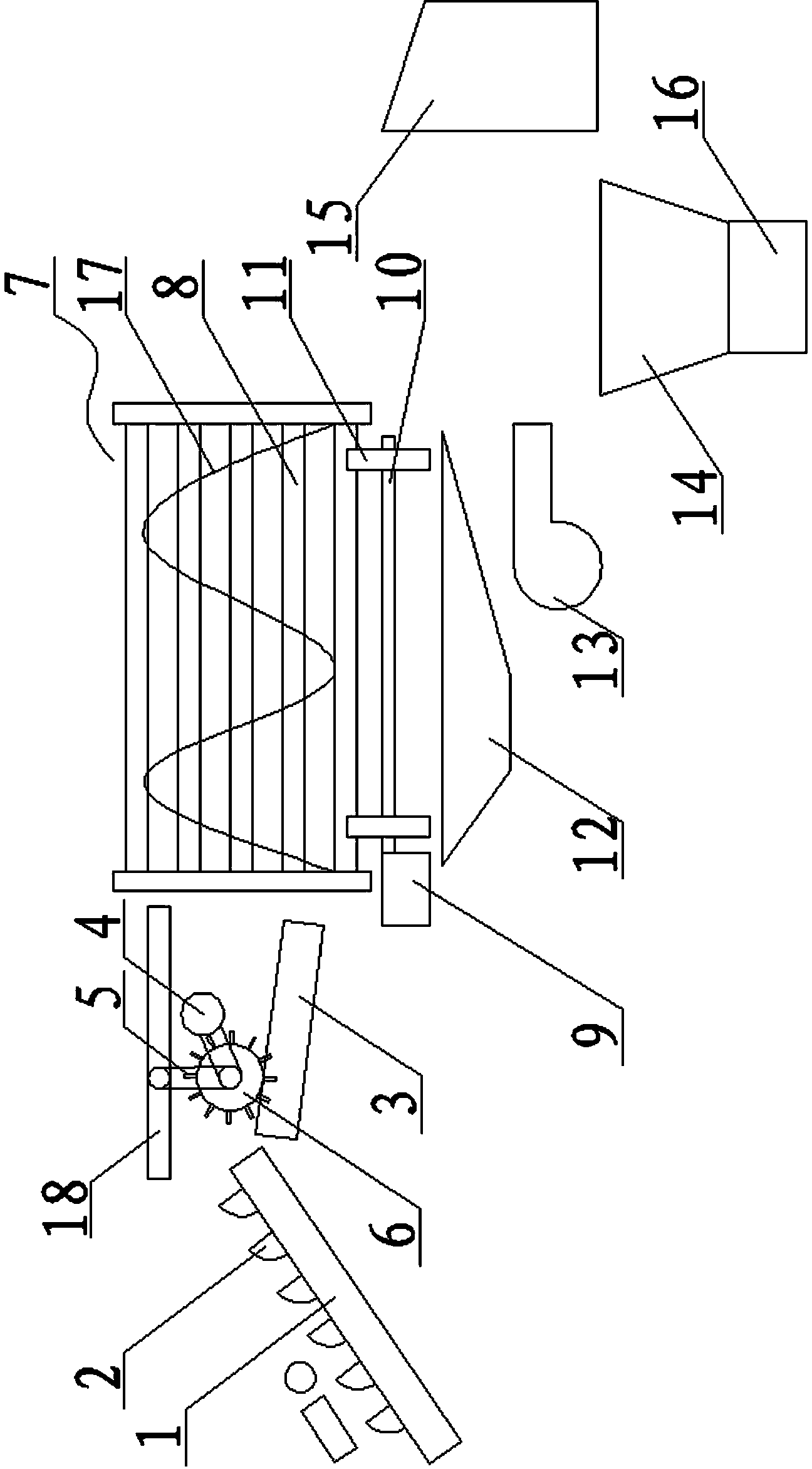

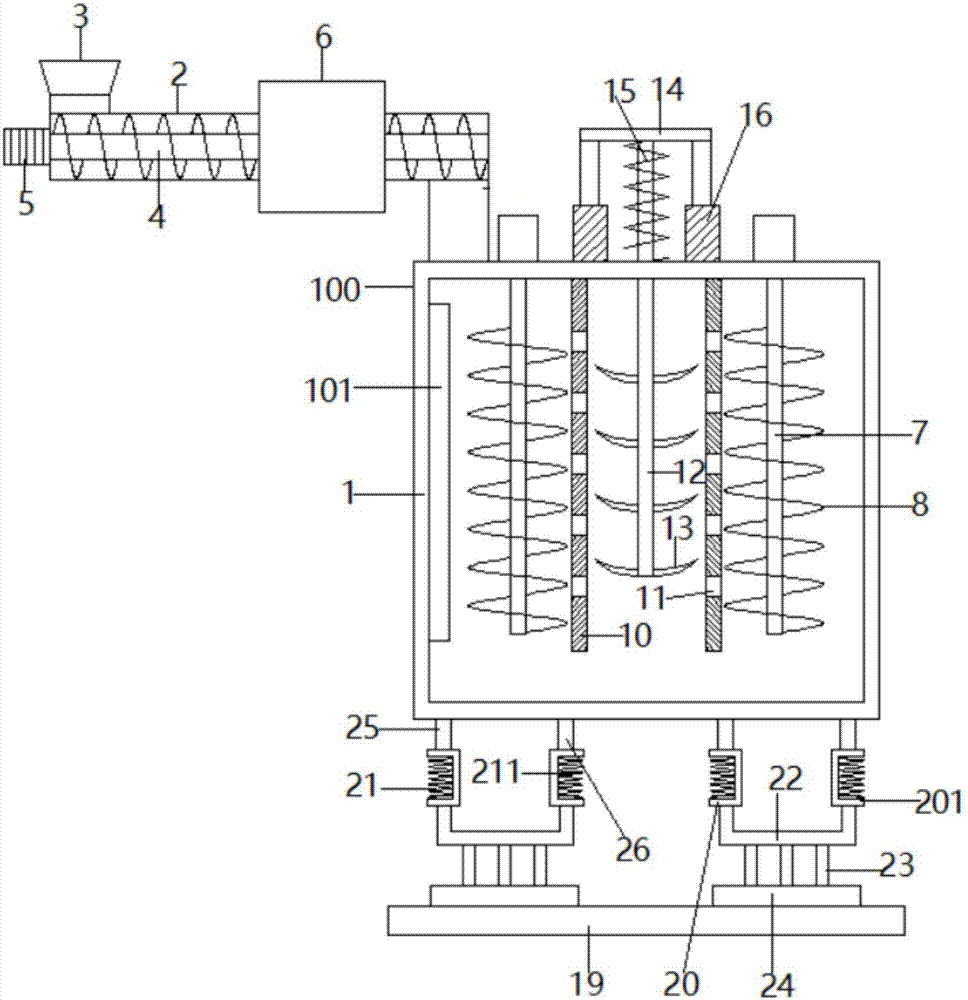

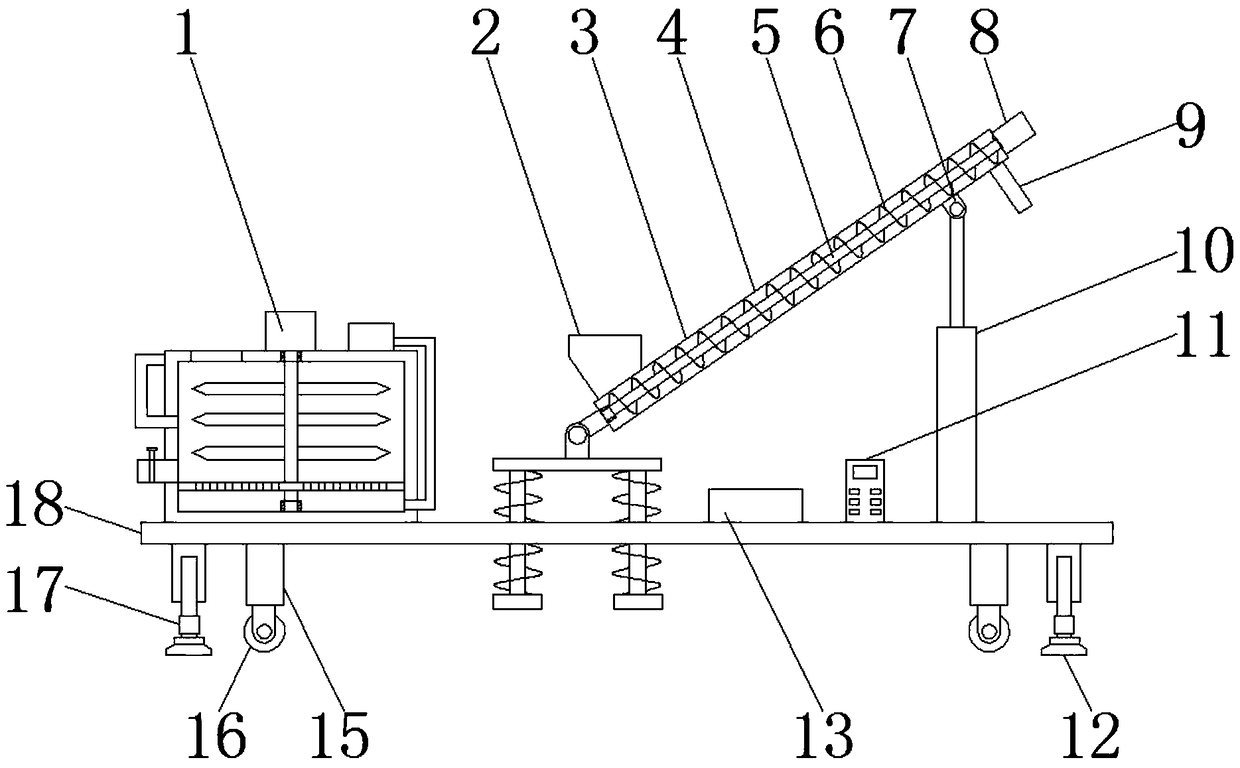

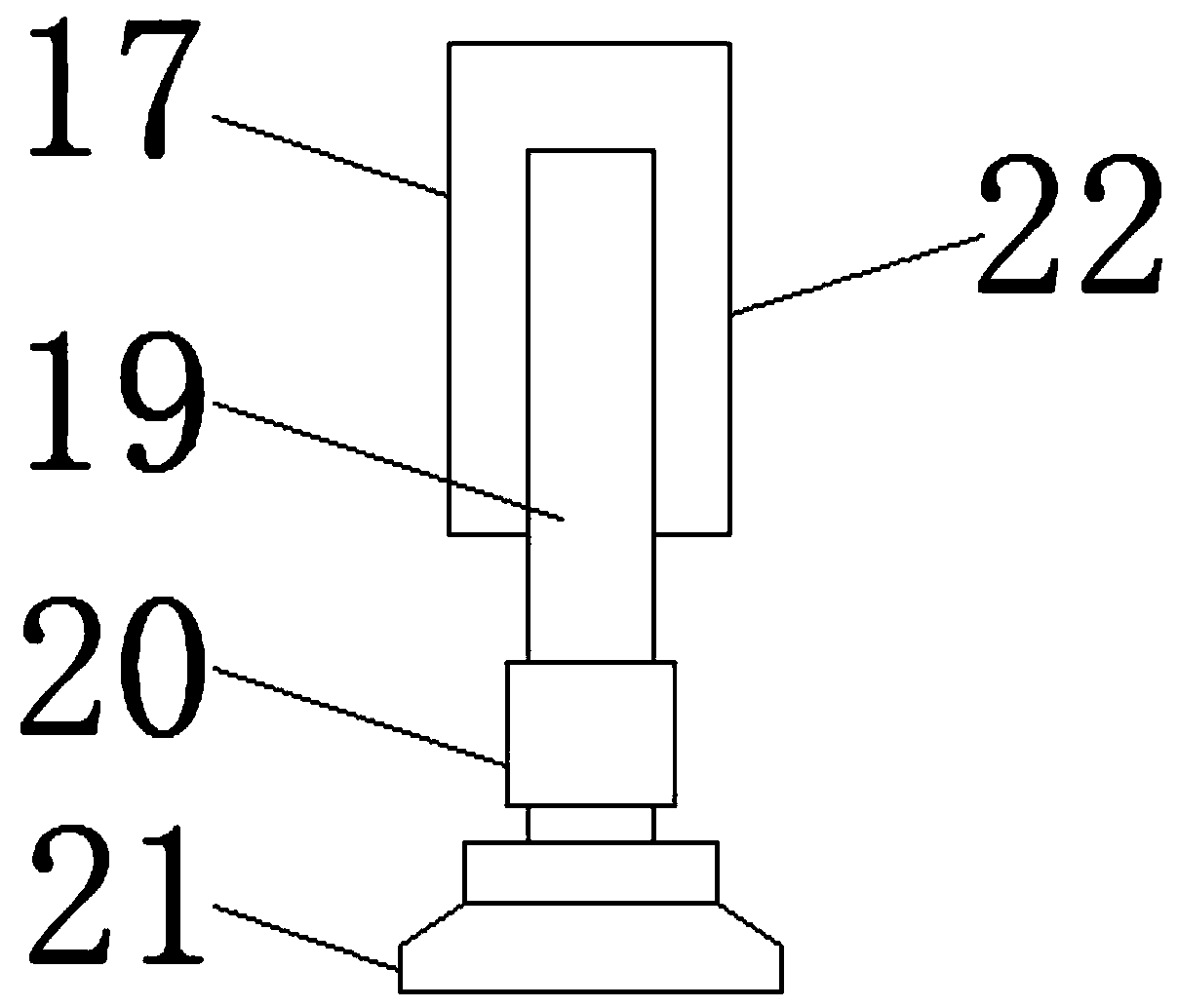

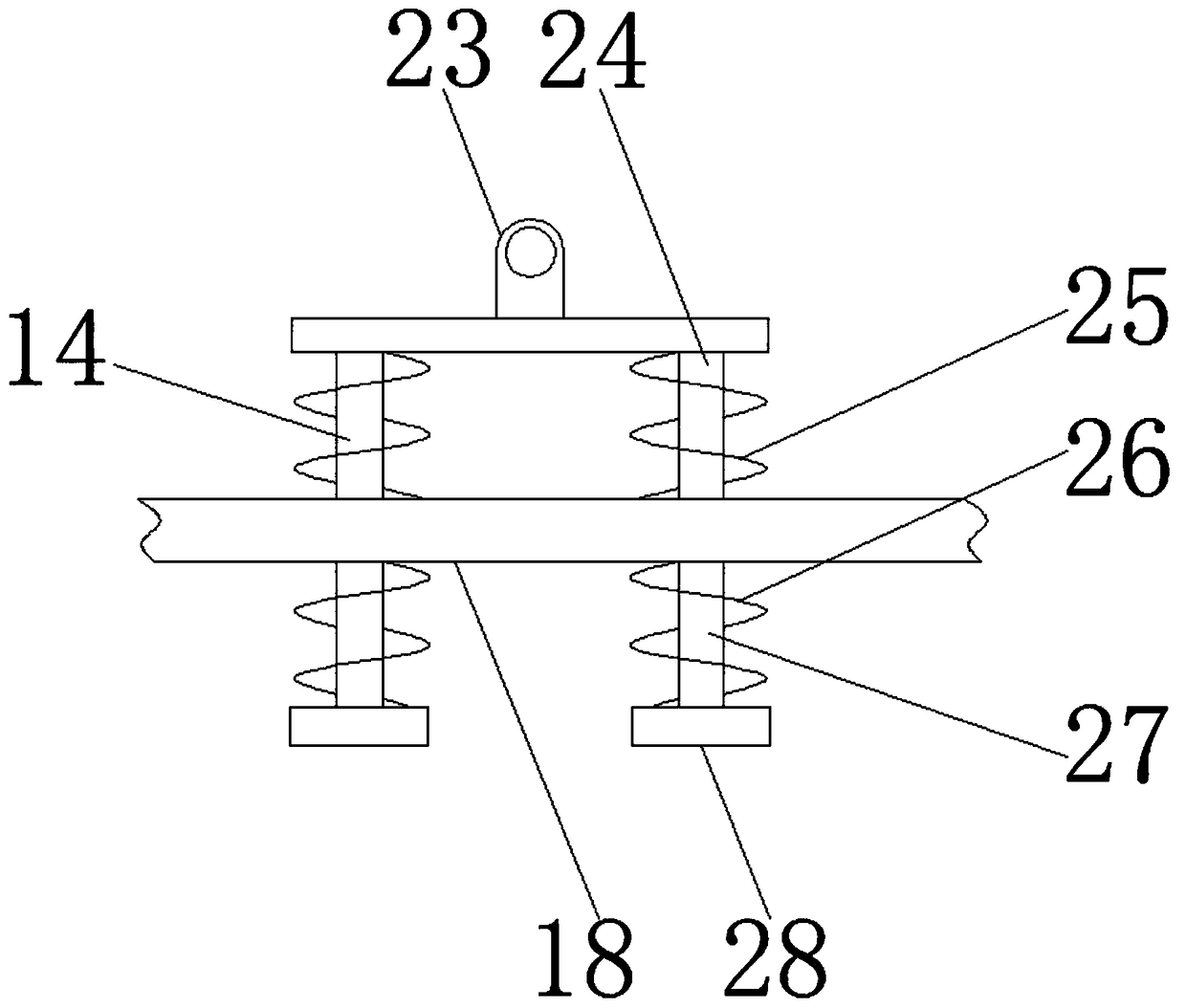

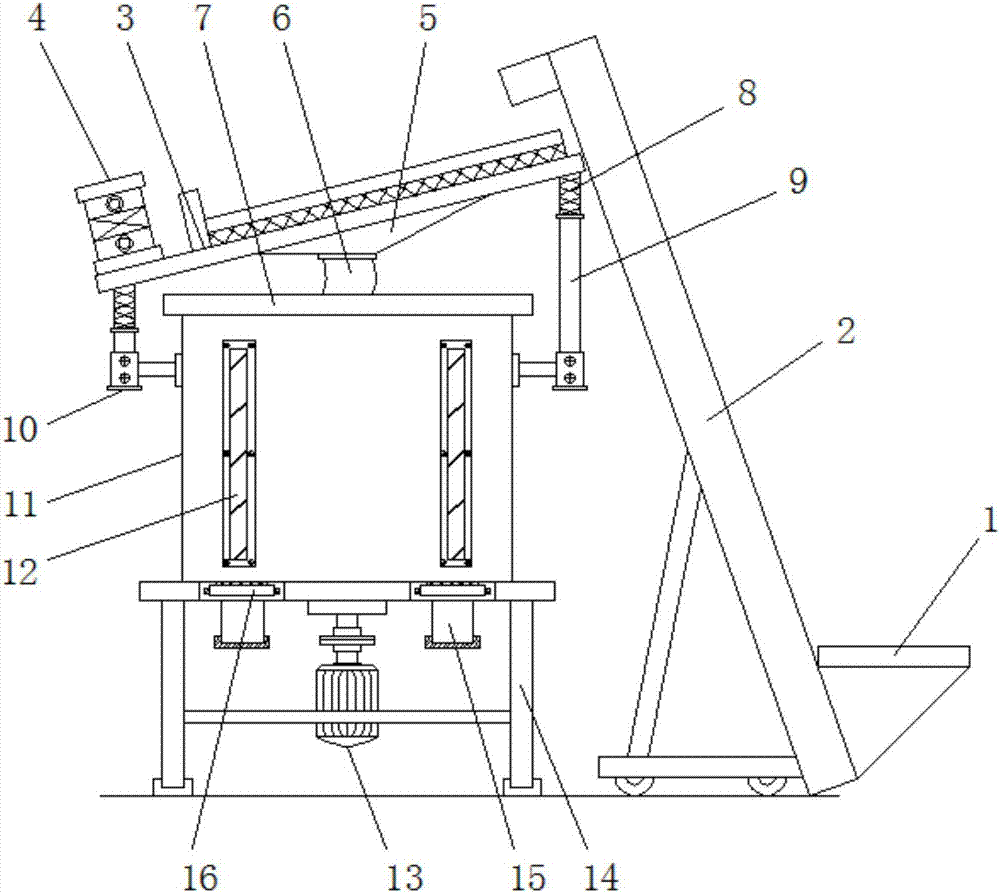

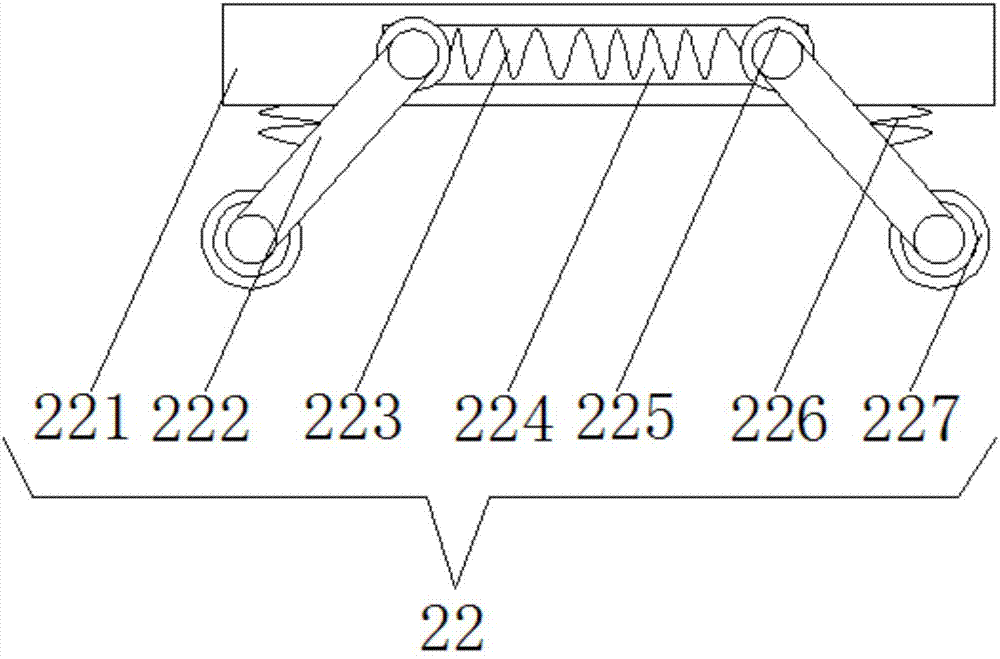

Mixing device with damping bracket for plastic production

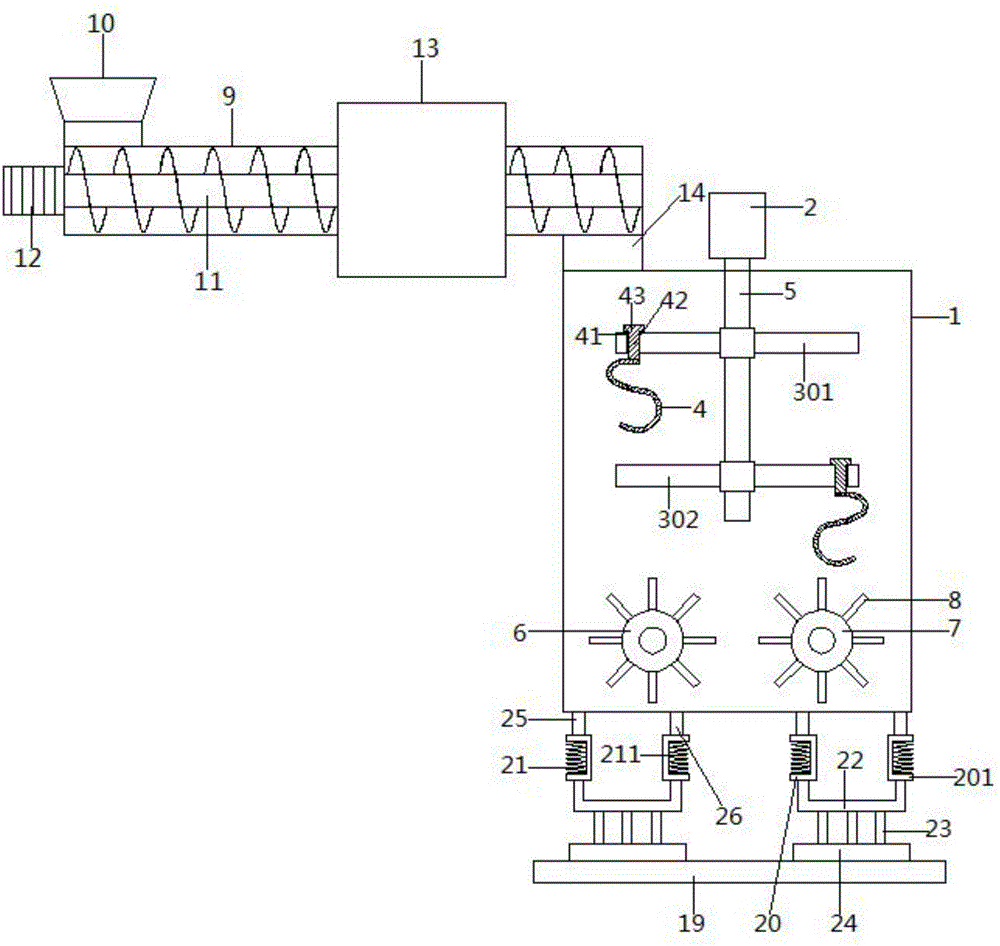

InactiveCN106626136AReduce workloadExtended service lifeNon-rotating vibration suppressionGrain treatmentsEngineeringMechanical engineering

The invention discloses a mixing device with a damping bracket for plastic production. The mixing device comprises a body, wherein a feeding cylinder is arranged on the upper side of the body; a feeding mechanism is arranged in the feeding cylinder and comprises a feeding screw and a screw blade arranged on the outer wall of the feeding screw; and a pre-crushing mechanism is arranged on a right section of the feeding cylinder and comprises four semispherical grooves symmetrically formed in the outer wall of the feeding cylinder, rolling cutting rotary shafts arranged at the centers of the semispherical grooves and rolling cutting blades arranged on the outer walls of the rolling cutting rotary shafts. The mixing device with a damping bracket for plastic production disclosed by the invention can realize automatic feeding; in the feeding process, the raw materials are pre-crushed, the crushing effect is good while the efficiency is high, and the stirring effect is good while the efficiency is high; the materials at the bottom in the body can be stirred and mixed, and the working efficiency of the mixer is improved; and the additional damping bracket can realize effective damping and shock prevention, and the service life of the mixer is prolonged.

Owner:ZHENGZHOU HAOEN ELECTRONICS INFORMATION TECH CO LTD

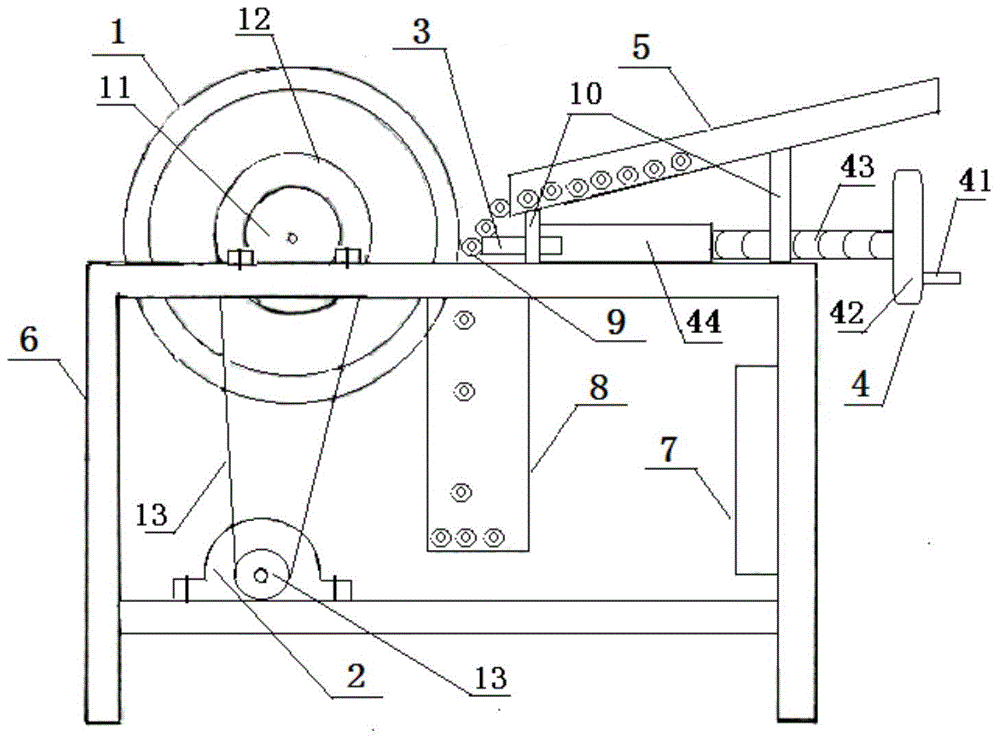

Code rolling machine conducting code pressing on workpiece based on extruding principle and using method thereof

The invention discloses a code rolling machine conducting code pressing on a workpiece based on an extruding principle and a using method of the code rolling machine and belongs to the technical field of code printing machines. The code rolling machine conducting code pressing on the workpiece based on the extruding principle comprises a reducer, a feeding groove, a frame-shaped support, an electric box and a discharging port and further comprises an inertia flywheel, a steel code and an extruding adjusting mechanism. The circle center of the inertia flywheel and the circle center of an upper belt pulley are located on the same axis, and the inertia flywheel and the upper belt pulley are connected through a rotating shaft and fixed in a bearing A and a bearing B which are arranged on a front beam and a rear beam of the frame-shaped support respectively. A lower belt pulley and the upper belt pulley are in transmission connection through a belt. A discharging port of the feeding groove is right opposite to the peripheral face of the inertia flywheel, an embossed steel code is arranged on the left end face of the steel code, and an extrusion opening is formed between the left end face of the steel code and the peripheral face of the inertia flywheel. The using method of the code rolling machine conducting code pressing on the workpiece based on the extruding principle is simple in operation, high in automation degree and production efficiency, clear in code printing and high in operation safety.

Owner:MAANSHAN CITY ZHIFENG MACHINERY

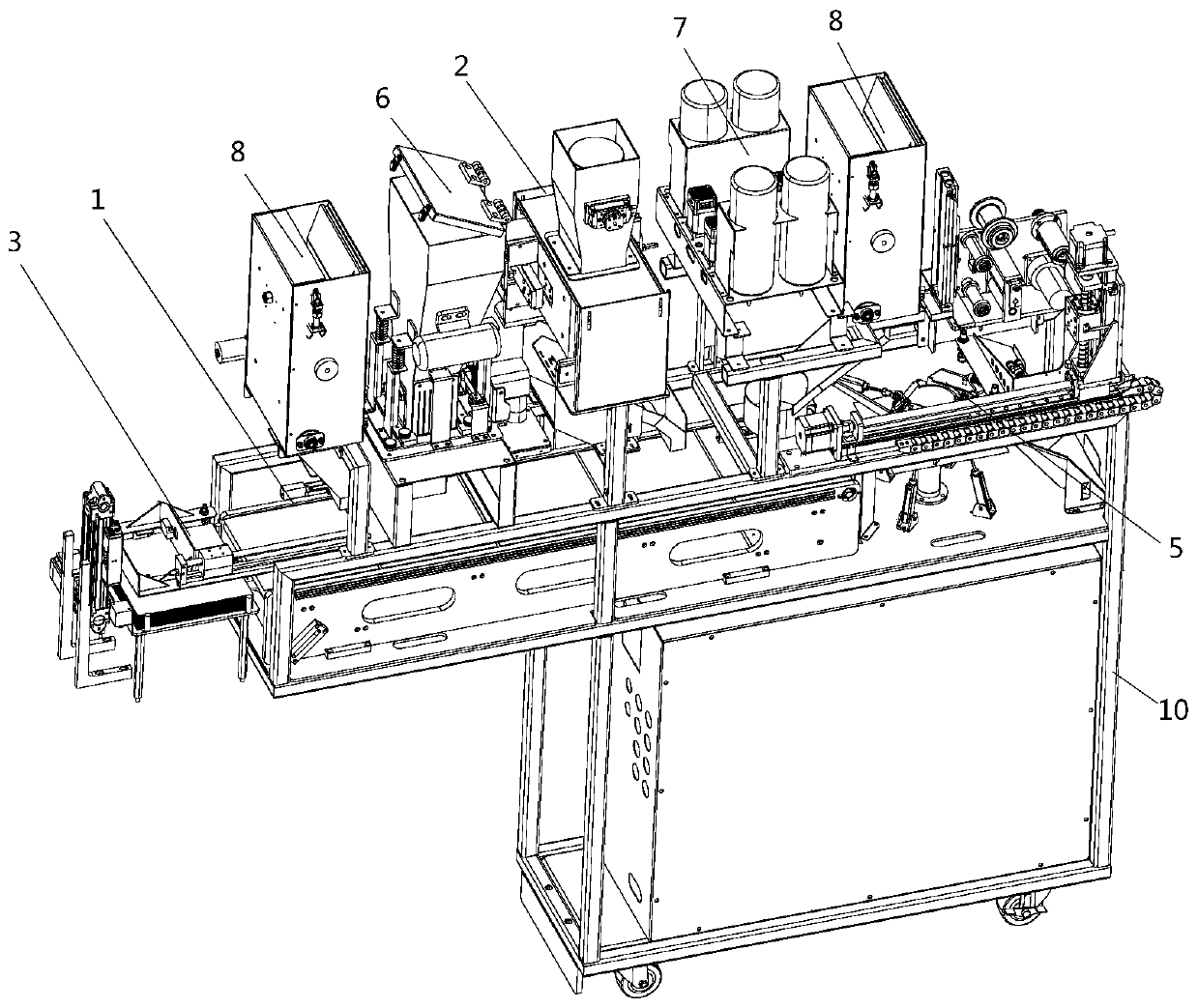

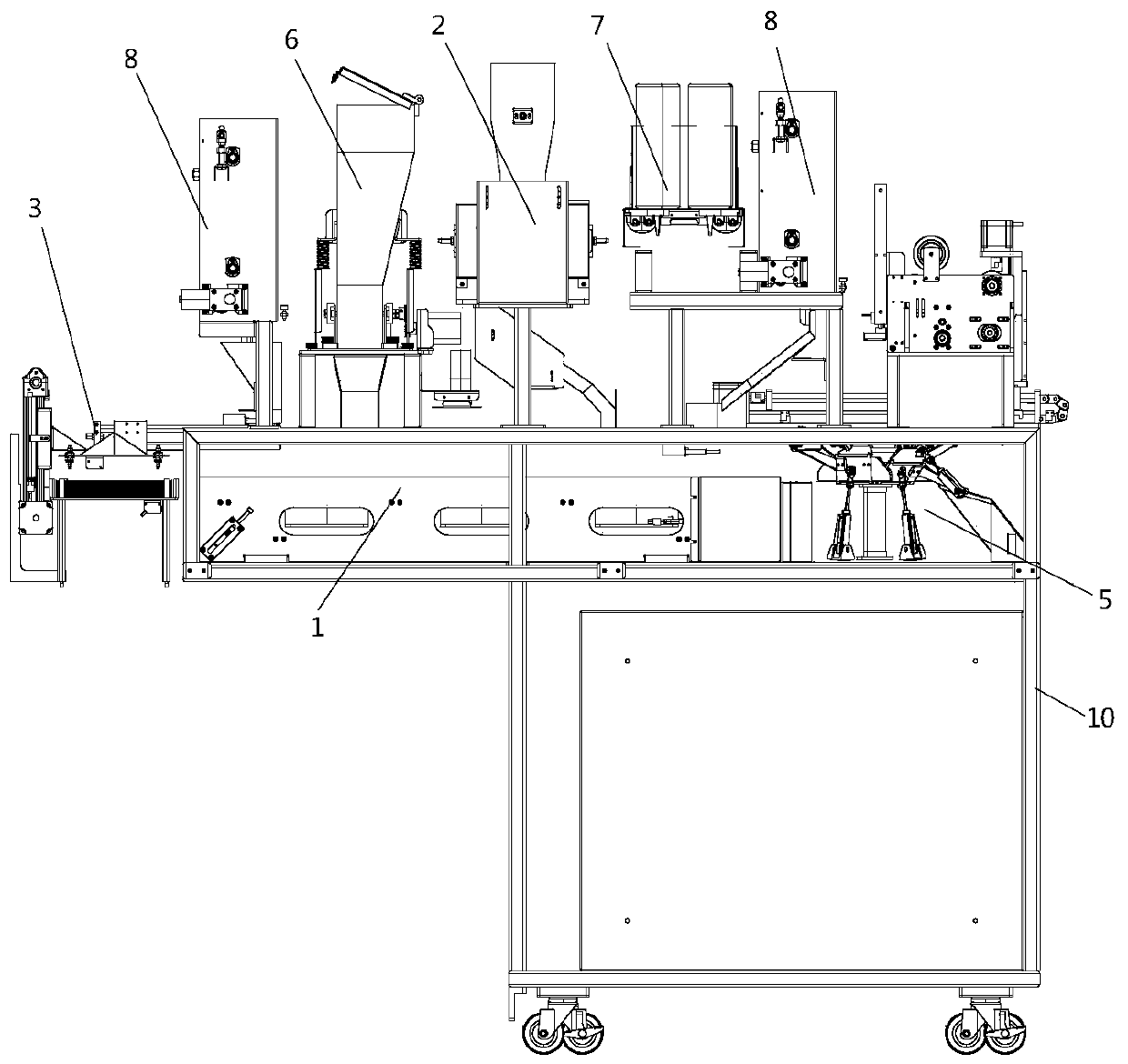

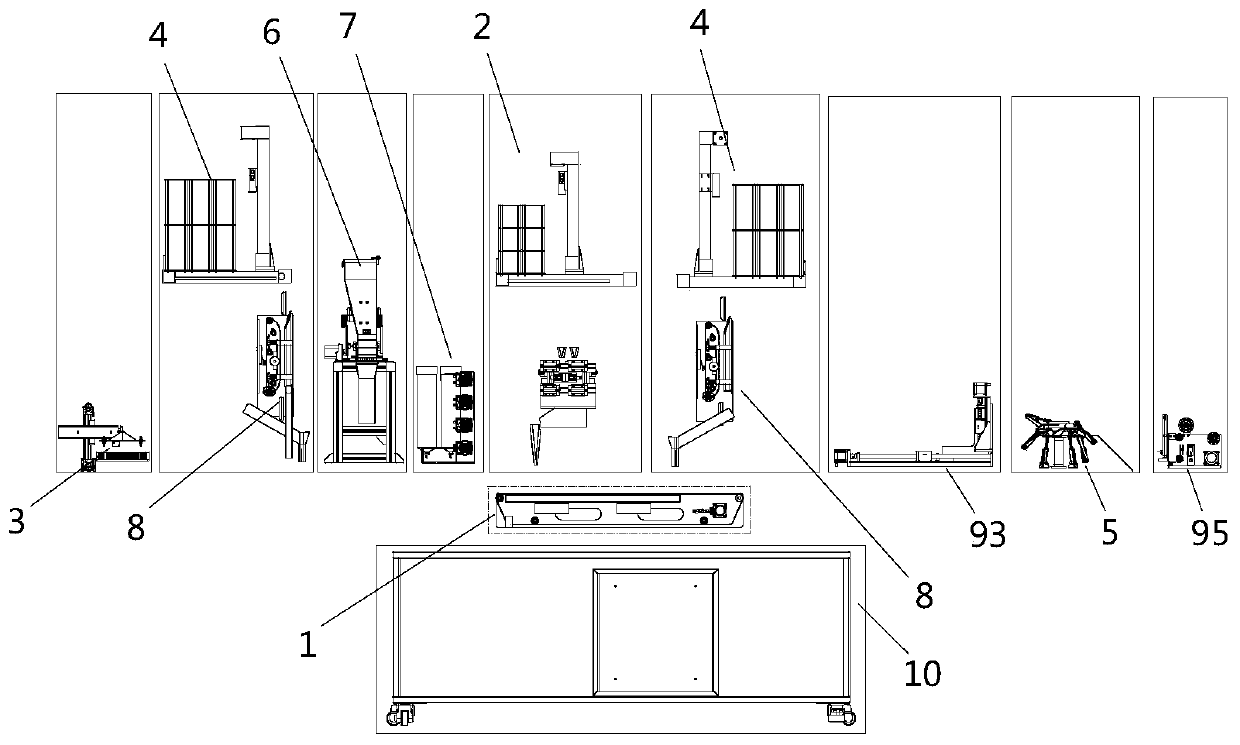

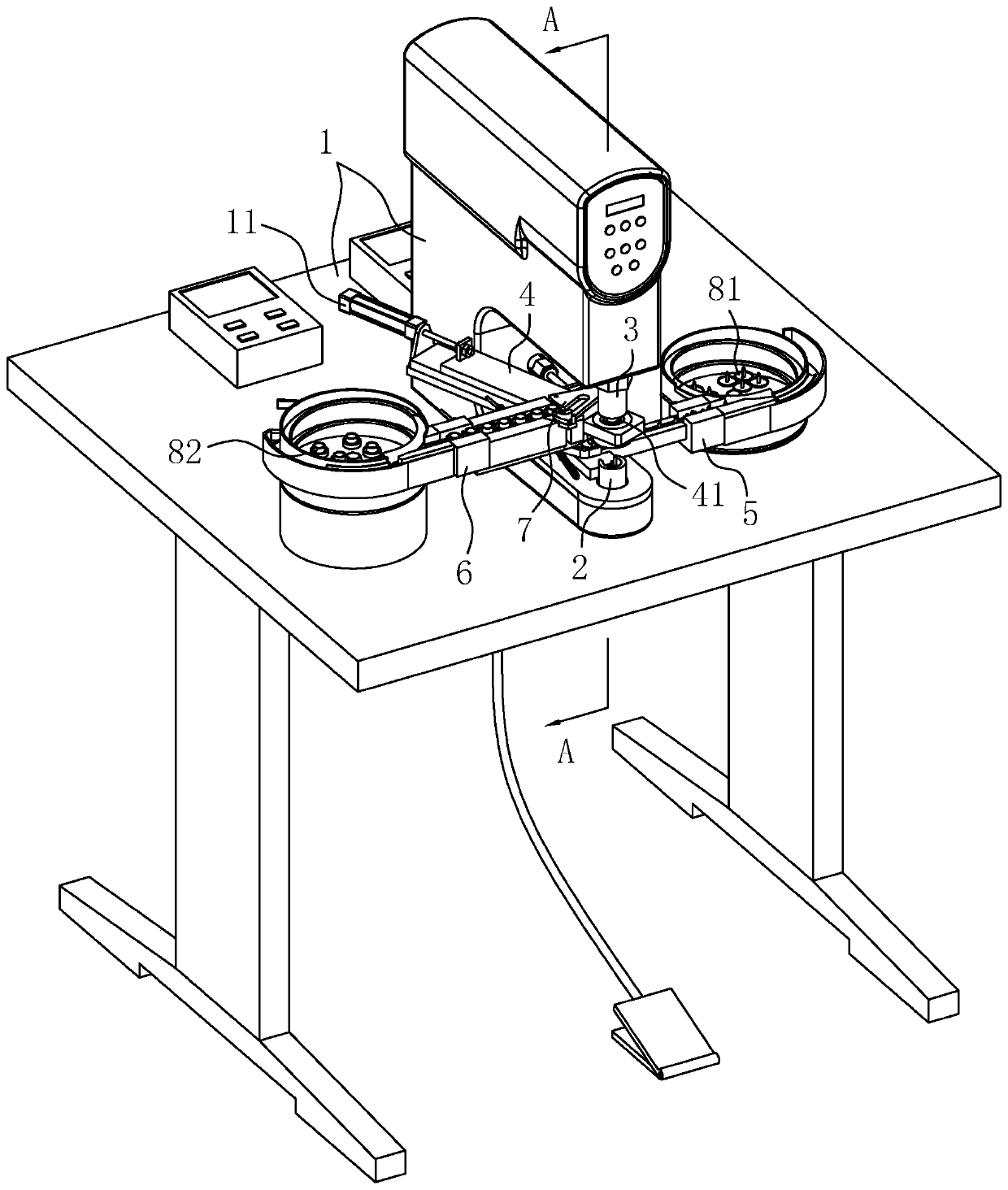

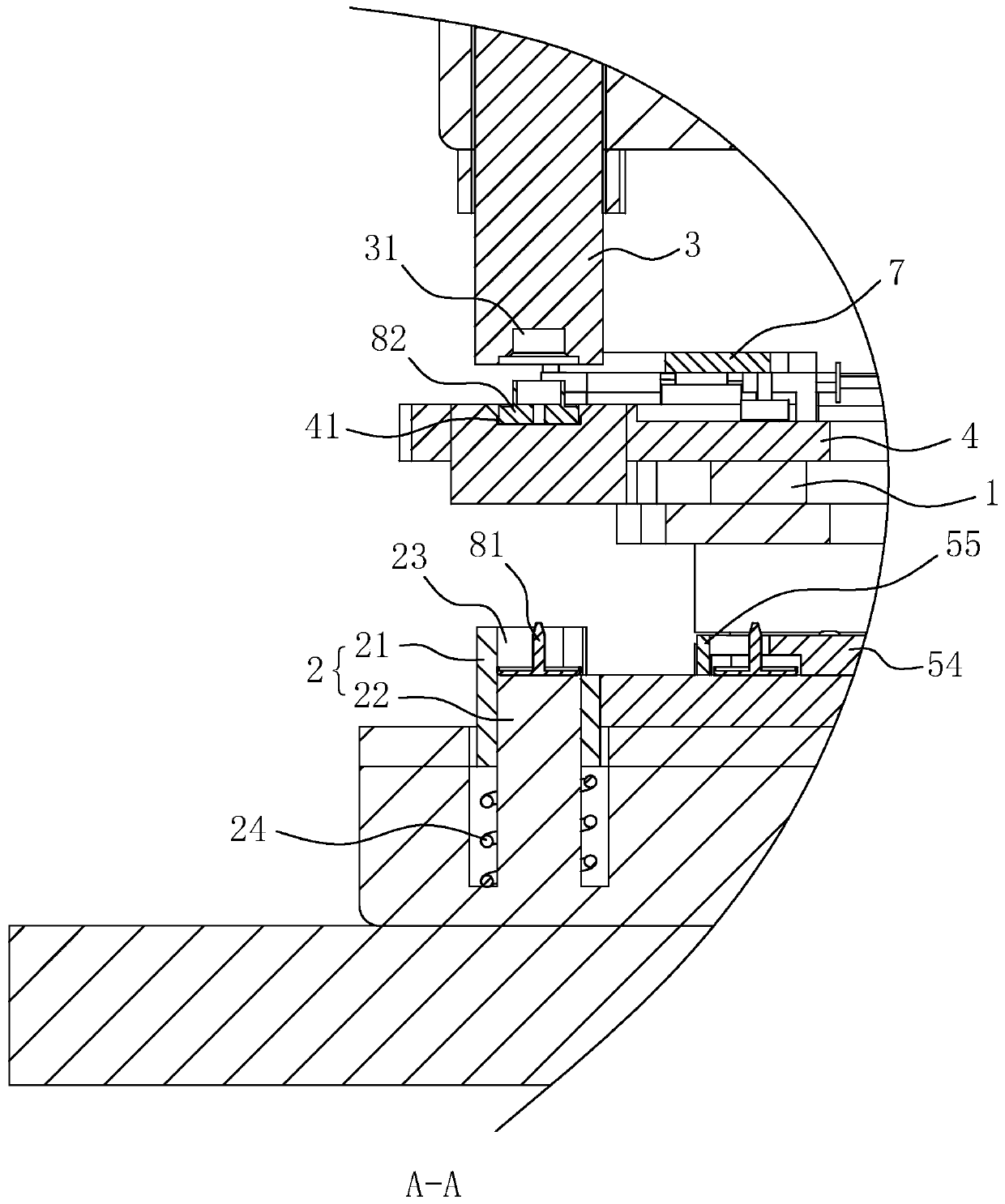

Automatic button attaching machine

The invention discloses an automatic button attaching machine, and relates to automation equipment. The key points of the technical scheme are that the automatic button attaching machine comprises a machine seat, wherein the machine seat is provided with a base and a pressing head aligned to the base, and the base is used for placing bottom buttons; the automatic button attaching machine also comprises a feeding mechanism I used for outputting the bottom buttons and a feeding mechanism II used for outputting top buttons; the feeding mechanism I is used for conveying the bottom buttons to the base one by one; the machine seat is provided with a driving part I and a sliding seat driven to slide by the driving part I; the sliding seat is provided with a middle positioning groove for placing the top buttons; and the pressing head faces the base and is provided with an upper positioning groove for embedding the top buttons; the feeding mechanism II conveys the top buttons to the middle positioning groove one by one, the sliding seat can slide between the base and the pressing head, and the middle positioning groove faces the upper positioning groove; and when the pressing head presses the sliding seat, the top buttons can be embedded into the upper positioning groove. The automatic button attaching machine can automatically complete button attaching each time, the waiting time between adjacent button attaching procedures is short, the top buttons and the bottom buttons can be automatically sent to the positions to be attached, manual feeding is not needed, and the automatic button attaching machine has the advantage of high production efficiency.

Owner:台州新同创科技有限公司

Attrition mill grinding bin capable of automatic feeding

InactiveCN105032588AGood dispersionEvenly distributedGrain treatmentsDecompression chamberMechanical engineering

The invention discloses an attrition mill grinding bin capable of automatic feeding. The grinding bin comprises a grinding bin body, a decompression chamber, an air outlet pipe and air inlet pipes, wherein a plurality of air inlets are formed on one side of a connecting part between each air inlet pipe and the grinding bin body; the grinding bin body comprises a feed pipe, a stock bin, discharge pipes and U-shaped circular grooves; a feed port of the feed pipe stretches out of the side surface of the grinding bin body; a discharge port of the feed pipe is connected with a material inlet of the stock bin; the stock bin is fixedly mounted on a rotating shaft; at least one stock bin discharge port is formed in the side surface of the stock bin and fixedly connected with the discharge pipes; discharge ports of the discharge pipes are connected with the U-shaped circular grooves; the stock bin is in a cylinder structure with both the bottom surface and the top surface being in regular polygon shapes; one storage bin discharge port is formed in each rectangular side surface of the stock bin; and the stock bin is internally provided with a cone taking the bottom surface of the stock bin as the bottom surface. The grinding bin is provided with the cone taking the bottom surface of the stock bin as the bottom surface, so that the situation that material accumulation of the stock bin occurs due to the fact that a material does not slide down timely can be avoided, and the material can enter the U-shaped circular grooves fully.

Owner:CHENGDU CHENHONG TECH

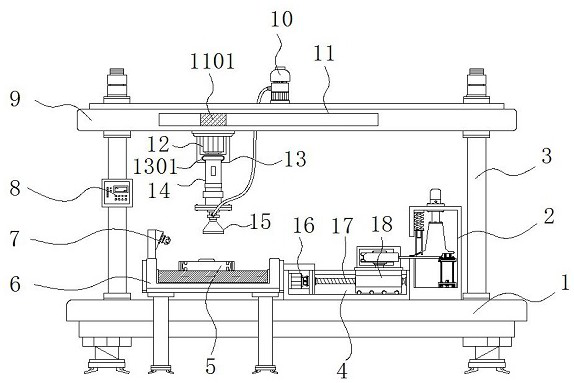

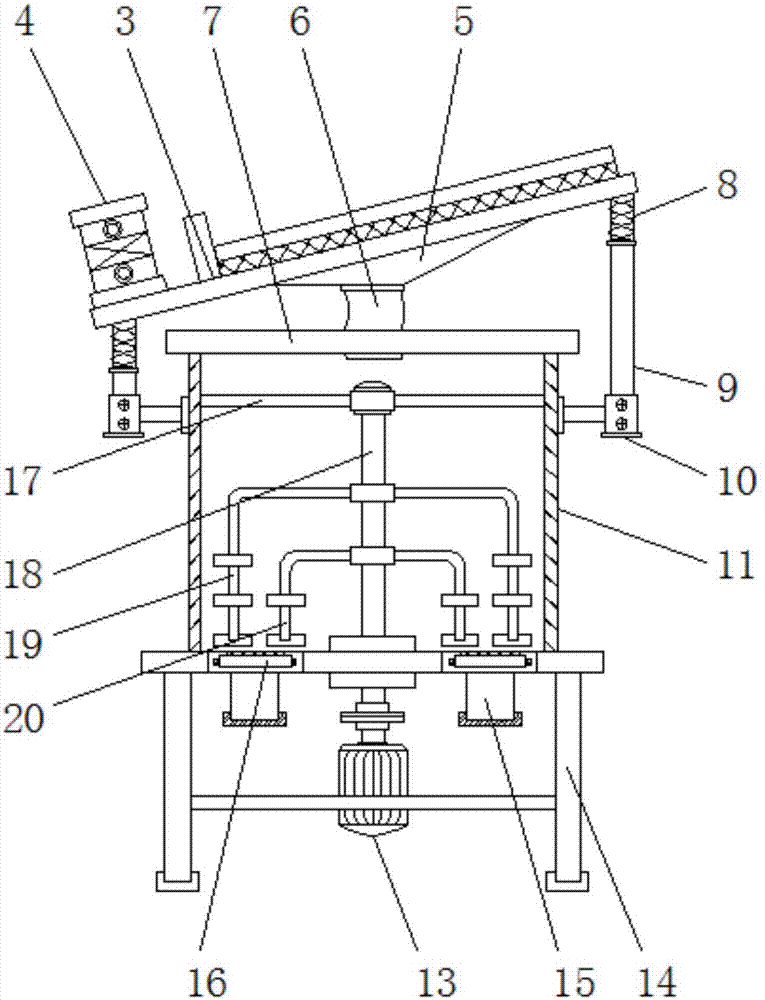

Vertical concrete mixer with screening function

InactiveCN107160556AImprove qualityFully contactedSievingDischarging apparatusFixed frameArchitectural engineering

The invention discloses a vertical concrete mixer with a screening function. The vertical concrete mixer comprises a spiral conveyor, a mixing motor, a slide plate, a first mixing rod and a second mixing rod; a feed hopper is arranged at the lower end of the spiral conveyor; a vibration motor is fixed at one end of a screening plate; two ends of the screening plate are connected through a vibration reducing spring and a support column; an observation window is mounted on a mixing barrel; the slide plate is fixed rightly above a discharge port; the mixing motor is positioned under the mixing barrel; a mixing shaft on the mixing motor penetrates through the mixing barrel to connect with a mixing shaft fixed frame; and the first mixing rod and the second mixing rod are both mounted on the mixing shaft. The vertical concrete mixer with the screening function needs no manual loading, is simple in operation, can remove impurities and large-size particles in raw materials, improves the concrete quality, can perform all-directional mixing to enable the raw materials to fully contact with water so as to achieve high mixing efficiency, and is convenient to quickly take the materials.

Owner:安徽新兴翼凌机电发展有限公司

Concrete material processing equipment for reducing material adhesion

InactiveCN111716525AAvoid cloggingAvoid wastingDischarging apparatusHollow article cleaningElectric machineSpiral blade

The invention discloses concrete material processing equipment for reducing material adhesion. The concrete material processing equipment comprises a bottom plate, an electric control box, a feeding pipe, a processing box and a feeding plate, the electric control box is fixedly mounted at the front end of one side of the top of the bottom plate, the feeding pipe is fixedly mounted on one side of the top of the bottom plate through a first mounting rod, a feeding rod is fixedly mounted in the feeding pipe, a third spiral blade is fixedly installed on the surface of the feeding rod, a third YS motor is fixedly installed at the bottom of the feeding pipe, the output end of the third YS motor is fixedly connected with the bottom end of the feeding rod through a rotating shaft, and the third YSmotor is electrically connected with the electric control box through a wire. According to the concrete material processing equipment, the feeding plate is arranged, a sealing cover is opened, then concrete falls onto a transmission belt, and then a first YS motor drives the transmission belt to rotate through a roller shaft, so that the concrete falling onto the transmission belt is conveyed, and the concrete is conveniently fed.

Owner:黄初祥

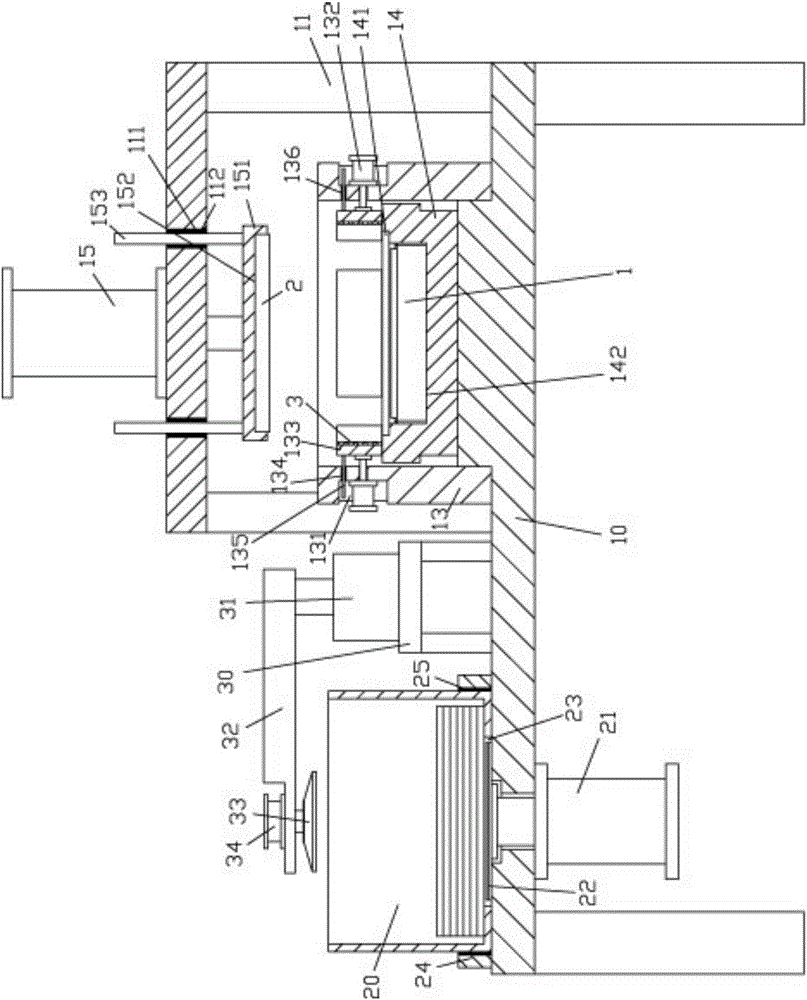

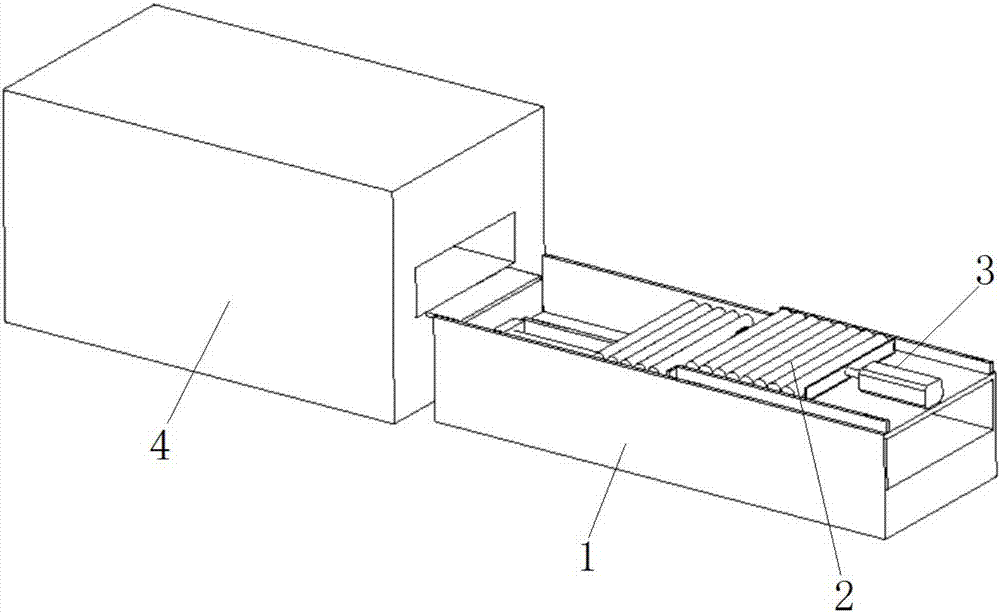

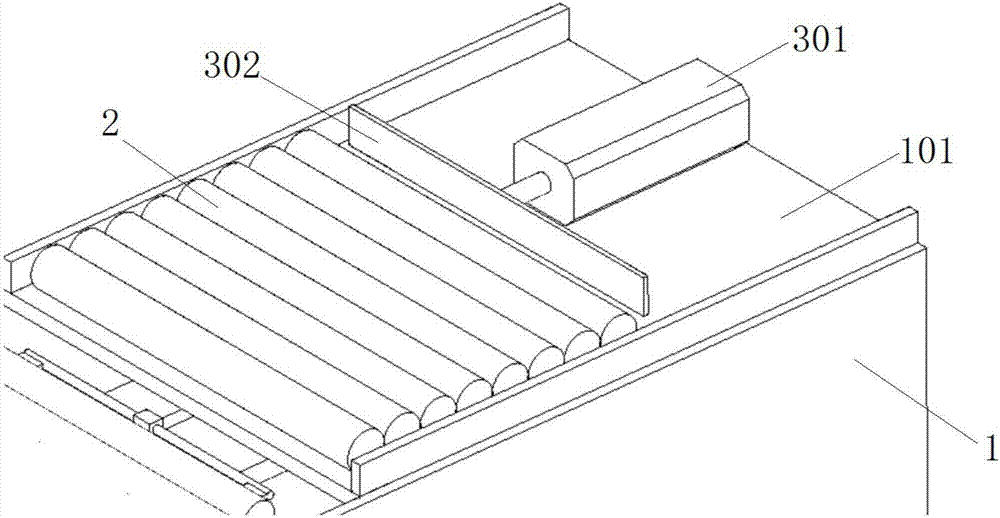

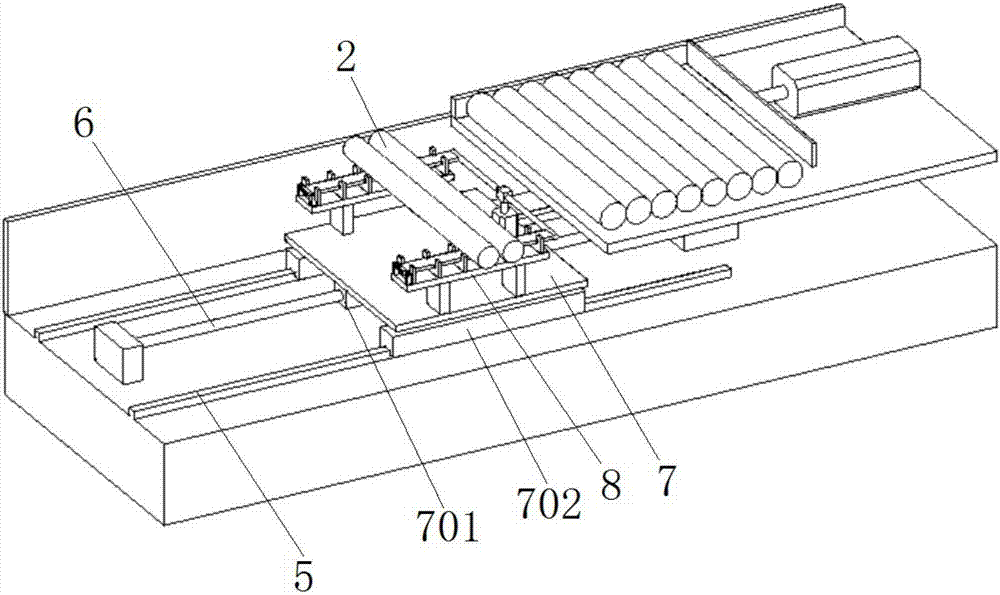

Combined type feeding device for annealing furnace

ActiveCN107419080AReduce manufacturing costImprove shipping efficiencyFurnace typesHeat treatment furnacesMaterials science

The invention discloses a combined type feeding device for an annealing furnace, and belongs to the technical field of processing and treatment of metal parts. The combined type feeding device comprises a base, an accommodating groove, a placement table, a material pushing device and a feeding device body, wherein the feeding device body comprises an X-direction movement mechanism, a forging piece positioning table and a jacking mechanism; the forging piece positioning table comprises a pair of supporting seats; the jacking mechanism comprises a first turnover plate, a second turnover plate and a driving air cylinder; one end of each of the first turnover plate and the second turnover plate is rotatably connected with the corresponding supporting seat; the other ends of the first turnover plate and the second turnover plate are mutually connected through a cross rod; the output end of the driving air cylinder is connected with the cross rod; and each of the first turnover plate and the second turnover plate is accommodated in the corresponding supporting seat when in the horizontal position. According to the combined type feeding device for the annealing furnace, the material pushing device with an air cylinder and the feeding device body with translation and jacking functions are arranged, so that circular forging pieces can be quickly and automatically fed into the annealing furnace, the cost is reduced, and the feeding efficiency is improved.

Owner:浙江星辉工贸有限公司

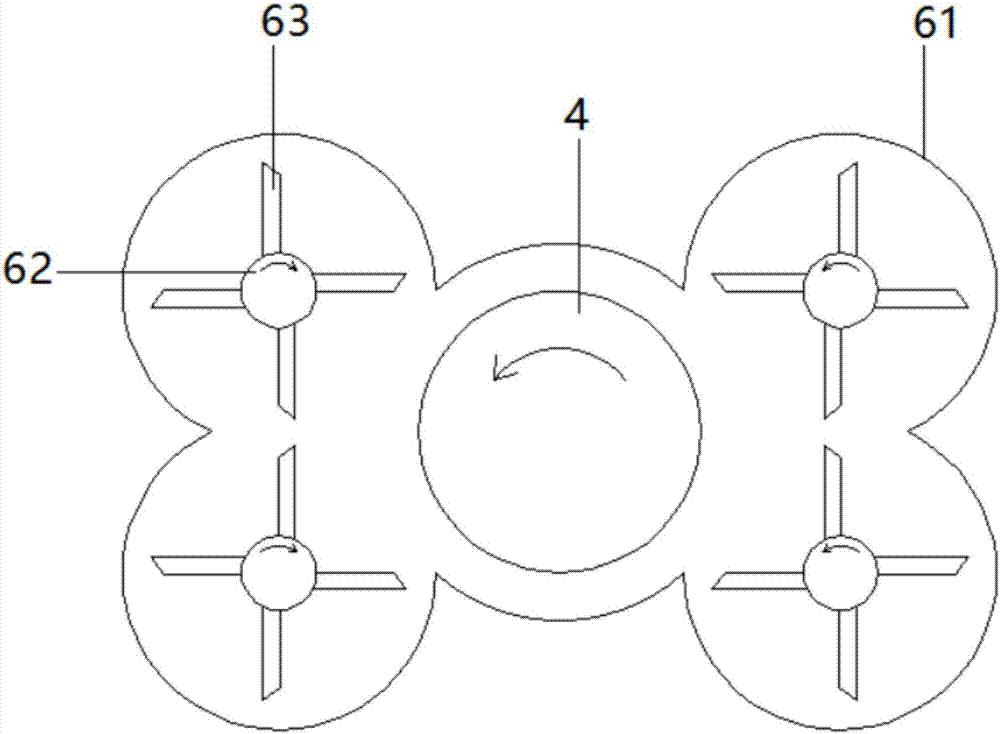

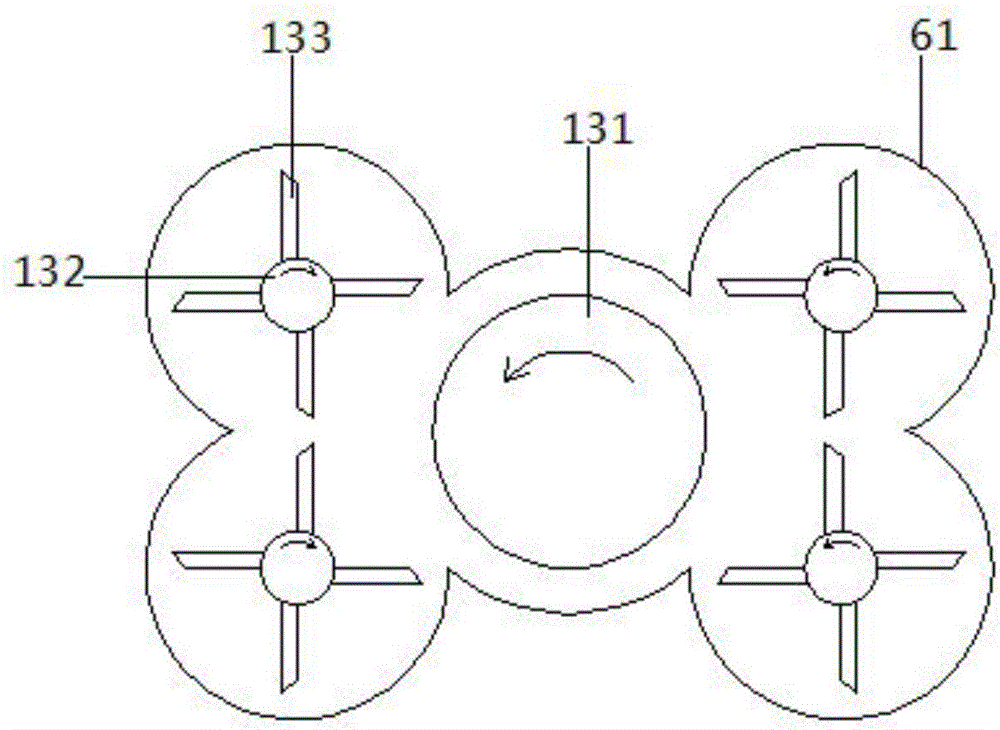

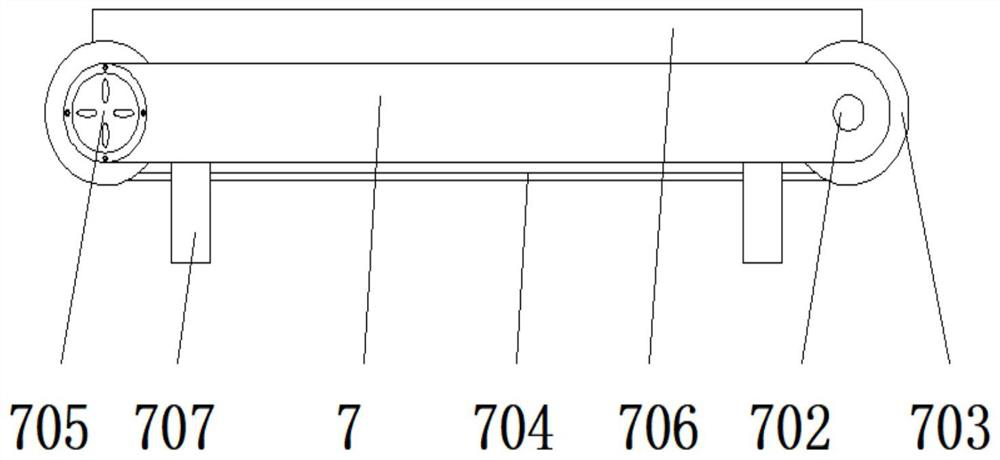

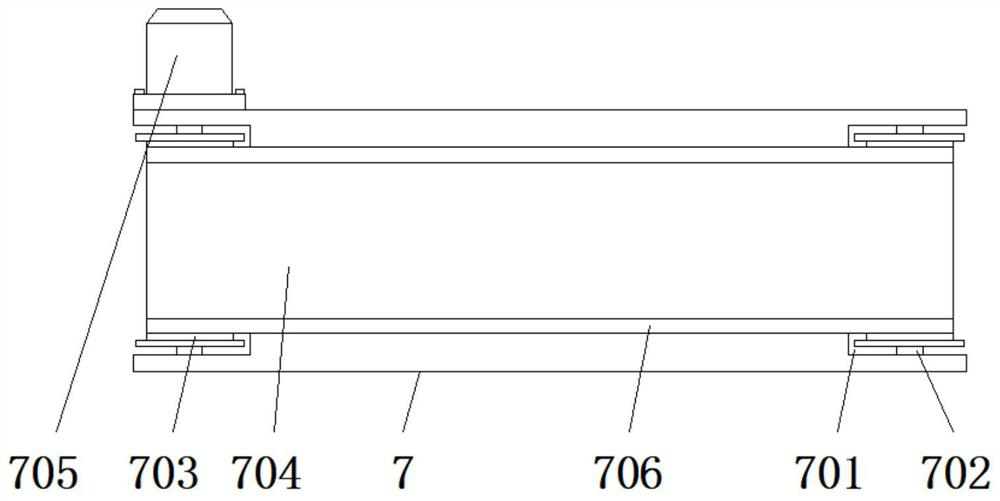

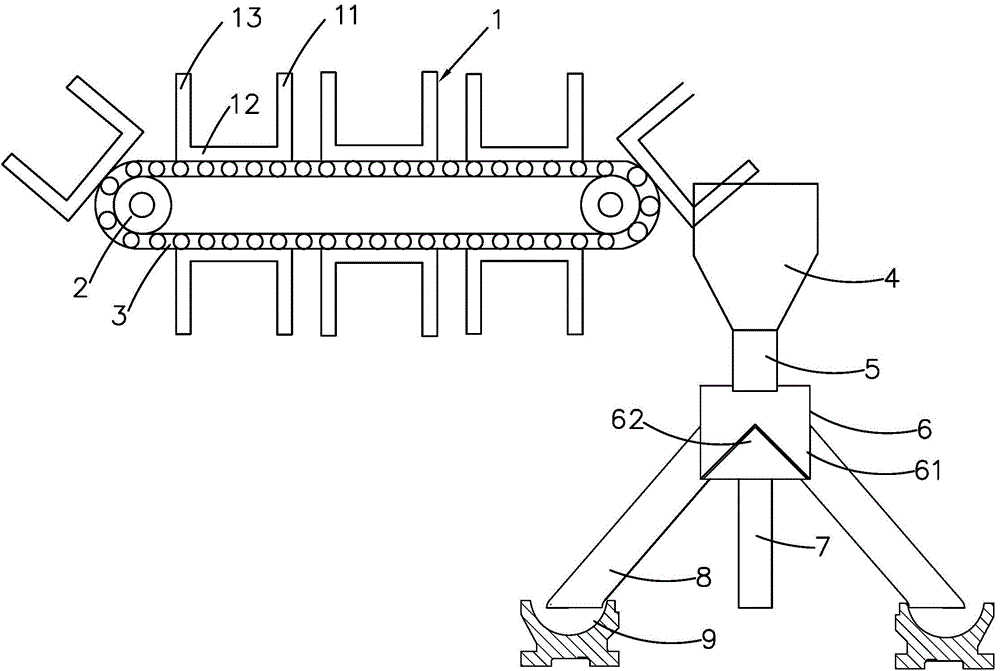

Roller cutting grinding mill automatic feeding device capable of enabling materials to be free of remaining

The invention discloses a roller cutting grinding mill automatic feeding device capable of enabling materials to be free of remaining. A transmission device comprises a belt (3), belt wheels (2) and feeding clamping grooves (1) fixedly connected with the belt (3); the feeding device comprises a first stock bin (4) connected with the feeding clamping grooves (1) and a feeding pipe (5) fixedly connected with a discharging opening of the first stock bin (4); a discharging opening of the feeding pipe (5) is fixedly connected with a feeding opening of a second stock bin (6), and a plurality of second stock bin discharging openings (61) are formed in the side face of the second stock bin (6) and are fixedly connected with corresponding discharging pipes (8) respectively; and discharging openings of the discharging pipes (8) are connected with U-shaped annular grooves (9) respectively. According to the device, materials can be automatically fed into the feeding device, and it also can be ensured that the phenomenon that the materials are stacked in the stock bins, and the materials cannot smoothly slide is avoided; a machine tool can effectively run, and feeding efficiency and stability are ensured; and workloads of an operator are reduced, and the production efficiency is improved.

Owner:CHENGDU CHENHONG TECH

Green soybean automatic peeling production line

The present invention discloses a green soybean automatic peeling production line. The green soybean automatic peeling production line comprises a conveyor belt and a plurality of groups of material pushing mechanisms arranged along the length direction of the conveyor belt. Each group of the material pushing mechanism corresponds to at least one shelling machine; each material pushing mechanism comprises a vertical frame spanning the conveyor belt along the width direction of the conveyor belt; the vertical frame is provided with an air cylinder capable of vertical moving; the air cylinder isprovided with an electric push rod arranged along the width direction of the conveyor belt; a free end of the electric push rod is fixedly connected with a push plate; the push plate is arranged along the length direction of the conveyor belt; and the push plate reciprocates along the width direction of the conveyor belt under the driving of the electric push rod. The green soybean automatic peeling production line can realize the automatic material feeding of the plurality of groups of the shelling machines, realizes mass production, and improves production efficiency.

Owner:JINHUA AGRI MACHINERY RES INST

Material guiding device for stamping parts

PendingCN110883258ARealize automatic feeding actionNo manual feedingMetal-working feeding devicesShaping safety devicesElectric machineryStructural engineering

The invention discloses a material guiding device for stamping parts, and relates to the technical field of the stamping parts. The material guiding device for the stamping parts aims to solve the existing problem of being time-consuming and labor-intensive due to the fact that manual feeding and collection of the stamping parts are required in the stamping process. A first material guiding mechanism is arranged on one side of a press machine, and a second material guiding mechanism is arranged on the other side of the press machine. The first material guiding mechanism includes a material storage box, and a bottom box is installed at the lower end of the material storage box. A steel plate placing table is installed in the material storage box, and a plurality of steel plate bodies are placed at the upper end of the steel plate placing table. A guiding rod is installed on one side in the steel plate placing table, and a screw rod is installed on the other side in the steel plate placing table. A stepper motor is installed at the lower end of the screw rod, and the upper end of the screw rod is connected with the material storage box through a bearing. The stepper motor is locatedin the bottom box, and the bottom box is connected with the stepper motor through a screw. A fixing plate is installed above one side of the outer part of the material storage box.

Owner:苏州苏宏模具有限公司

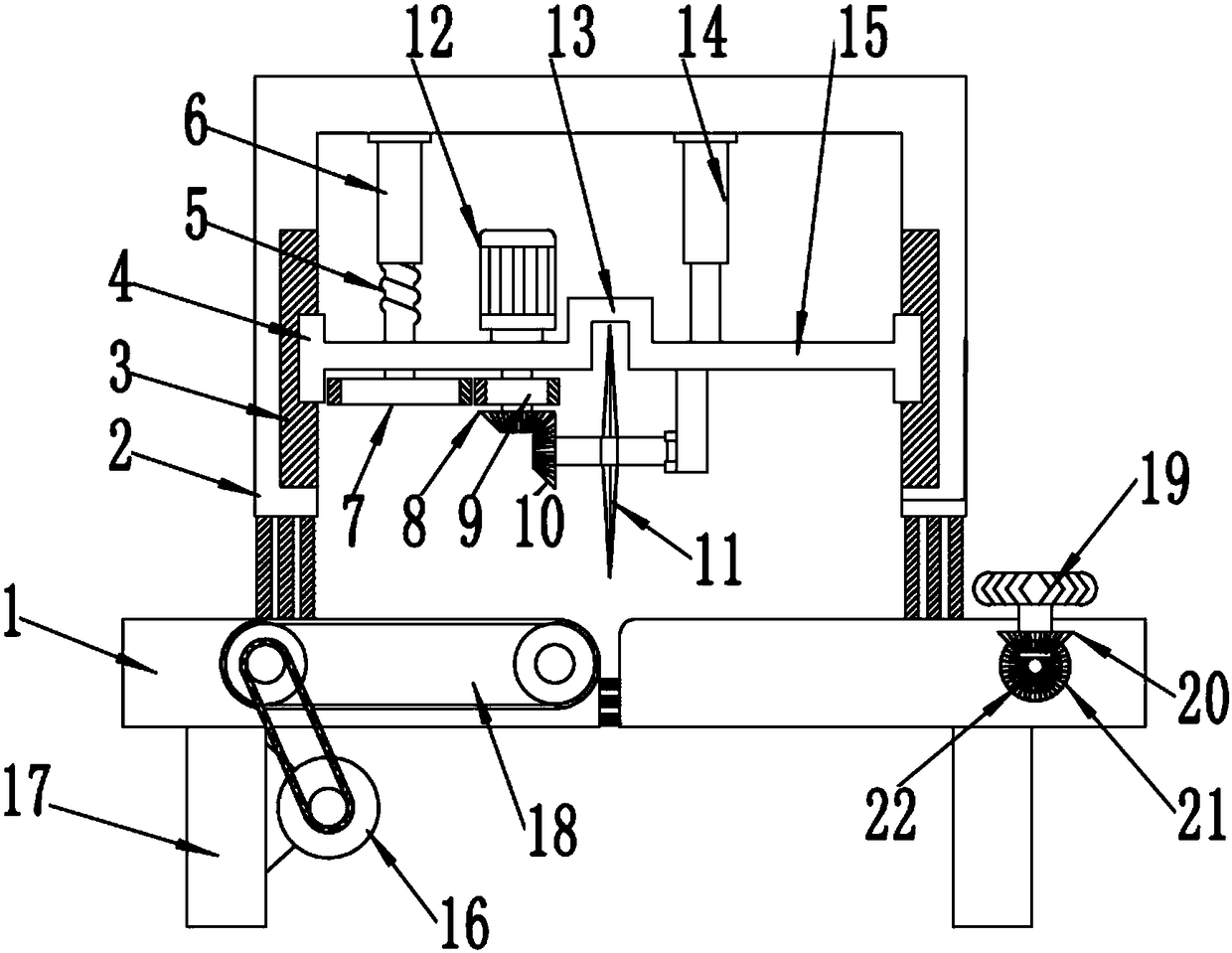

Automatic pipeline feeding device

ActiveCN107570576AEasy deliveryEasy to operateConveyorsMetal-working feeding devicesEngineeringMachining

The invention discloses an automatic pipeline feeding device and relates to the technical field of pipeline machining equipment. The automatic pipeline feeding device comprises an outer frame. A top plate and a bottom plate are fixedly connected between the two sides of the inner wall of the outer frame in sequence from top to bottom. The bottom of the inner wall of the outer frame is fixedly connected with a first motor. One end of an output shaft of the first motor is fixedly connected with a first belt wheel. The surface of the first belt wheel is in transmission connection with a second belt wheel through a belt. The back face of the second belt wheel is fixedly connected with a first gear. One side of the first gear is engaged with a second gear. According to the automatic pipeline feeding device, a pipeline can be clamped and fixed to be prevented from deviating in the cutting process, and the fixing effect is improved; manual clamping and manual feeding are not needed, operationis easy, the labor quantity of workers is relieved, and using of people is facilitated; and feeding is facilitated, the using performance of the device is improved, feeding precision is guaranteed, and errors caused by manual feeding are avoided.

Owner:GUANGDONG JUNCHI TECH HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com