Rubbish sorting device

A technology of garbage sorting and separation device, which is applied in the directions of magnetic separation, solid separation, and separation of solids from solids by air flow, which can solve the problems of poor sanitation and safety in sorting operations, time-consuming and labor-intensive waste sorting, and low efficiency. , to achieve the effect of convenient feeding, improved bag breaking efficiency and high sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

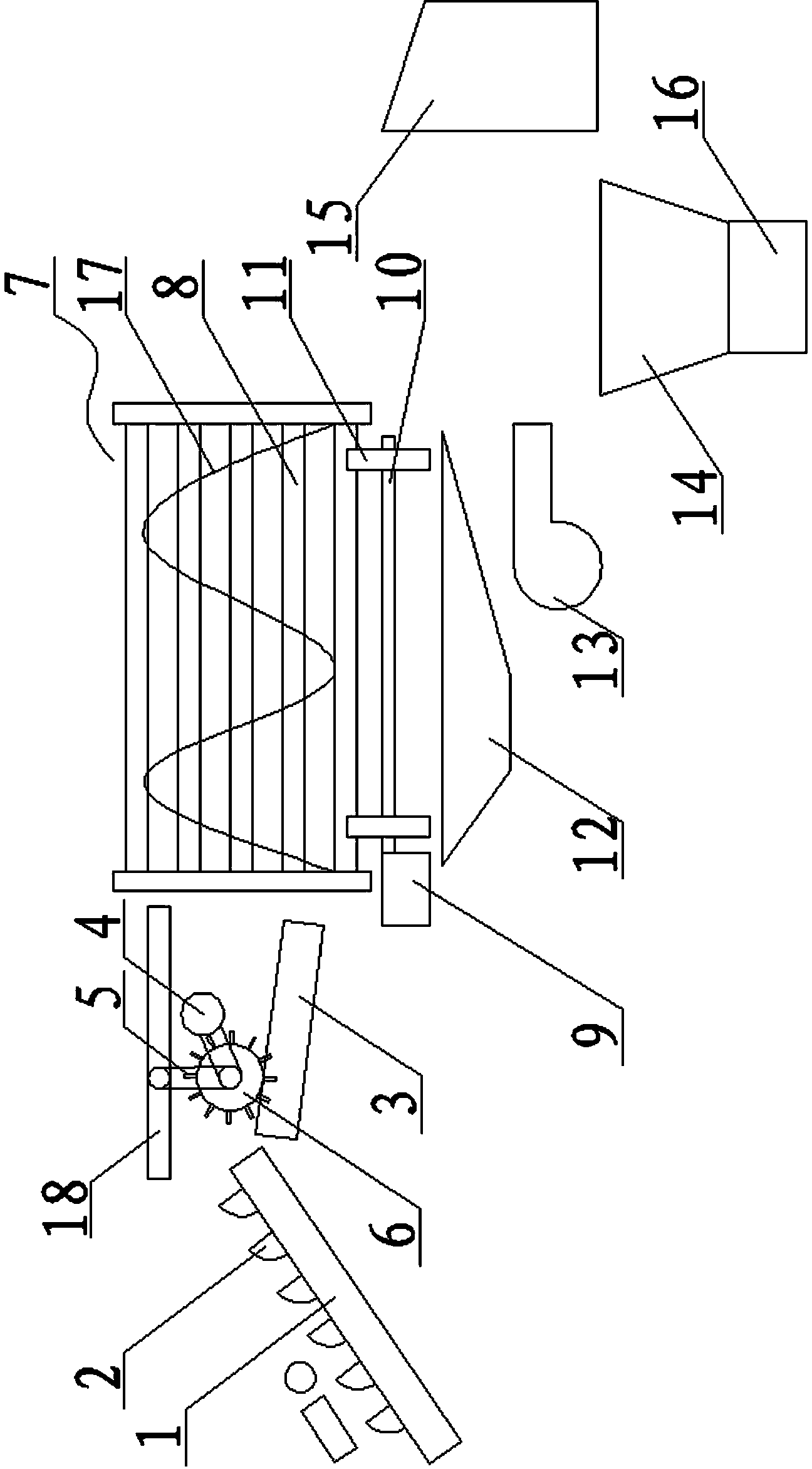

[0022] figure 1 As shown, a garbage sorting device includes a feeding conveyor belt 1, a conveyor bucket 2, a bag breaking conveyor trough 3, a bag breaking motor 4, a bag breaking roller 5, a bag breaking blade 6, a drum screen 7, and a solid-liquid separation motor 9 , transmission rod 10, gear 11, liquid collection bucket 12, sorting fan 13, heavy collection bucket 14, light collection bucket 15, pulverizer 16 and spiral deflector 17. The feeding conveyor is an inclined feeding conveyor belt 1, the lower end of the feeding conveyor belt 1 is connected to the storage hopper, an explosive detection alarm device and a powerful electromagnetic iron remover are installed above the feeding conveyor belt 1, and the upper edge of the feeding conveyor belt 1 The conveying direction is evenly provided with a plurality of conveying buckets 2 facing the conveying direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com