Frozen egg drop processing method and egg drop cooking device

A processing method, egg flower technology, applied in mixing methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of staff burns, fragility, and small process capacity, and achieve the effect of ensuring product quality and extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

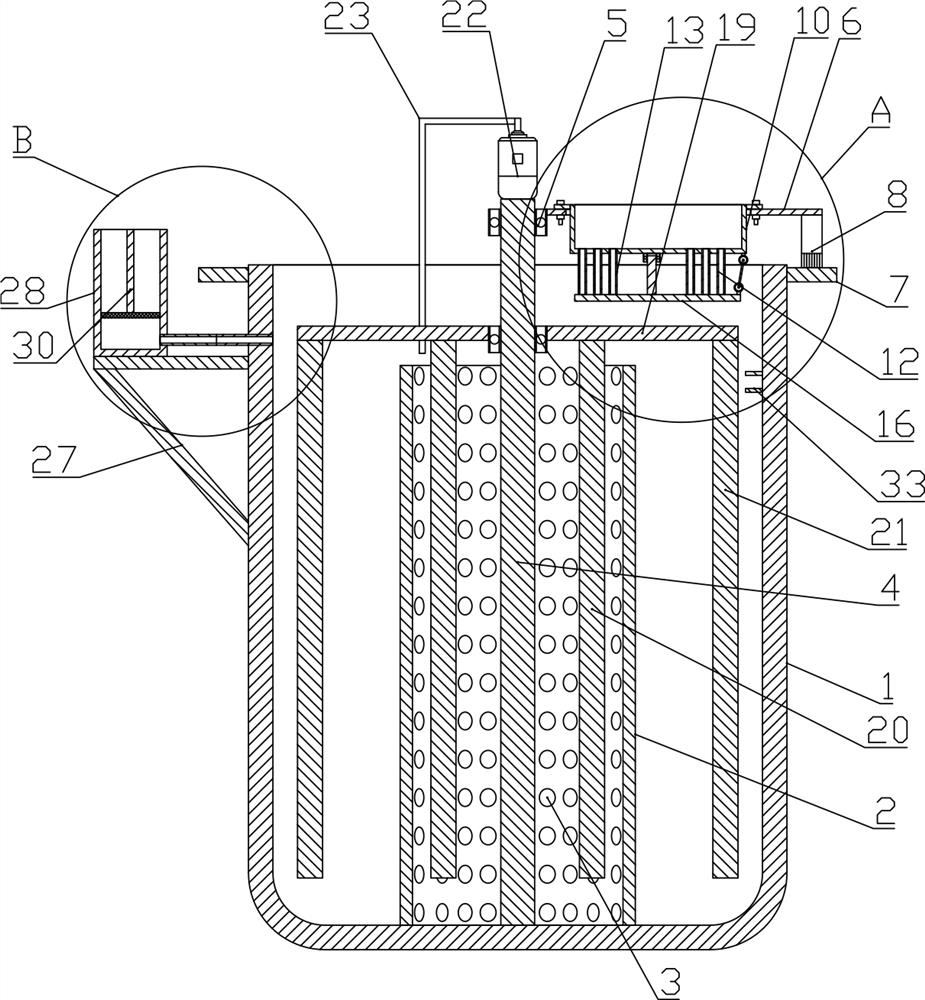

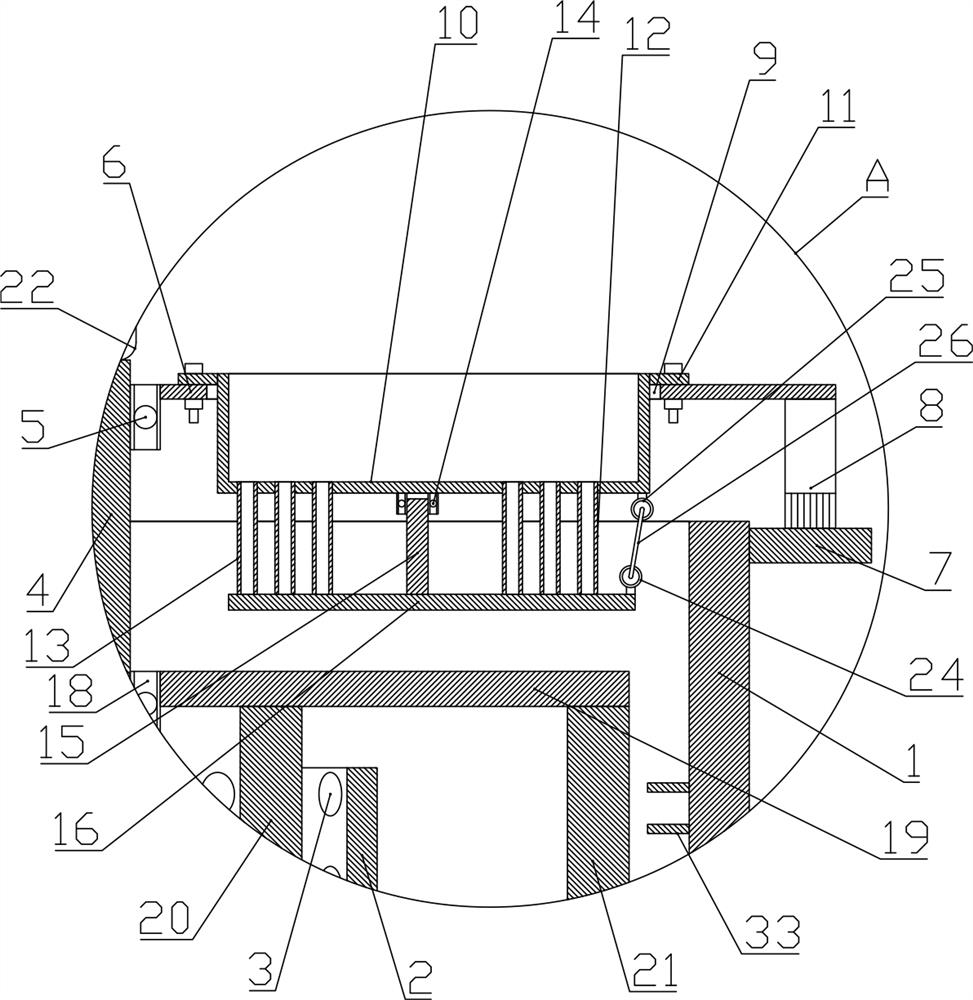

[0034] The present invention will be further described below in conjunction with specific embodiment:

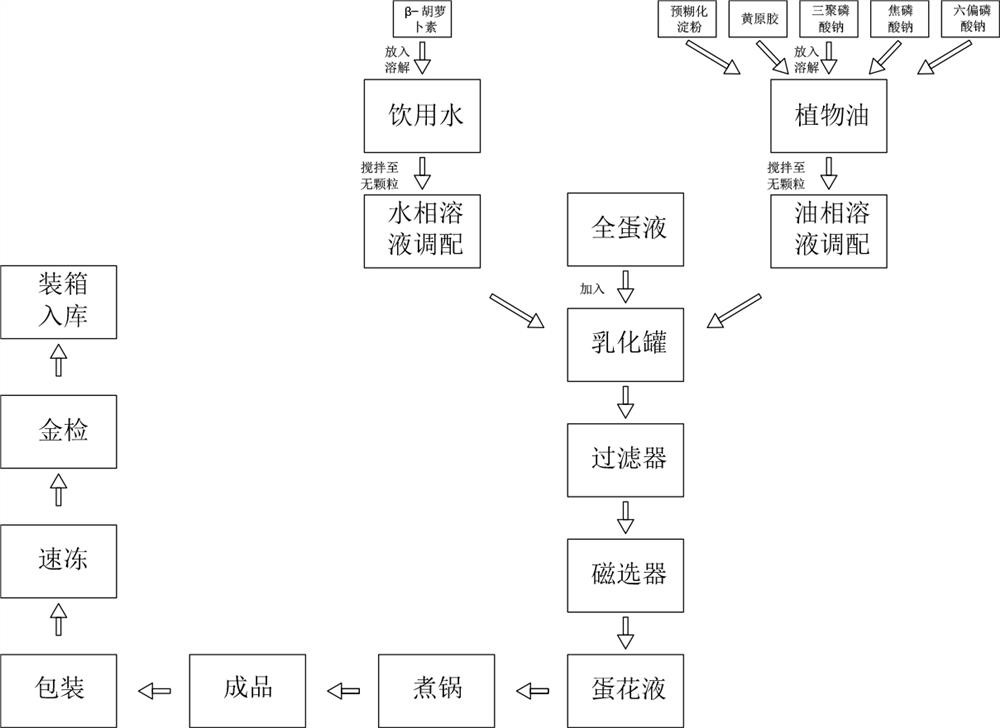

[0035] A method for processing frozen egg flower, comprising egg flower liquid, the raw material ratio of the egg flower liquid is 3-8% of vegetable oil, 85-95% of whole egg liquid, 1-5% of pregelatinized starch, and 0.01% of xanthan gum -0.5%, β-carotene 0.01-0.3, sodium tripolyphosphate 0.01-0.3%, sodium pyrophosphate 0.01-0.3%, sodium hexametaphosphate 0.01-0.3%, drinking water 1-10%, β-carotene 0.01 -0.05%, potato starch 1%-5%, some filtered water, the processing steps include: oil phase solution preparation, water phase solution preparation, egg flower liquid emulsification, filtration magnetic separation, boiled egg flower, packaging, quick freezing, golden Inspection, packing and warehousing;

[0036] Step 1. Oil phase solution preparation: Dissolve pregelatinized starch, xanthan gum, sodium tripolyphosphate, sodium pyrophosphate and sodium hexametaphosphate with abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com