Green soybean automatic peeling production line

A production line and automatic technology, applied in the fields of application, food processing, food science, etc., can solve the problems of increased labor costs, time-consuming, labor-intensive, low efficiency, and inability to meet large-scale automated production, so as to achieve large-scale production and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

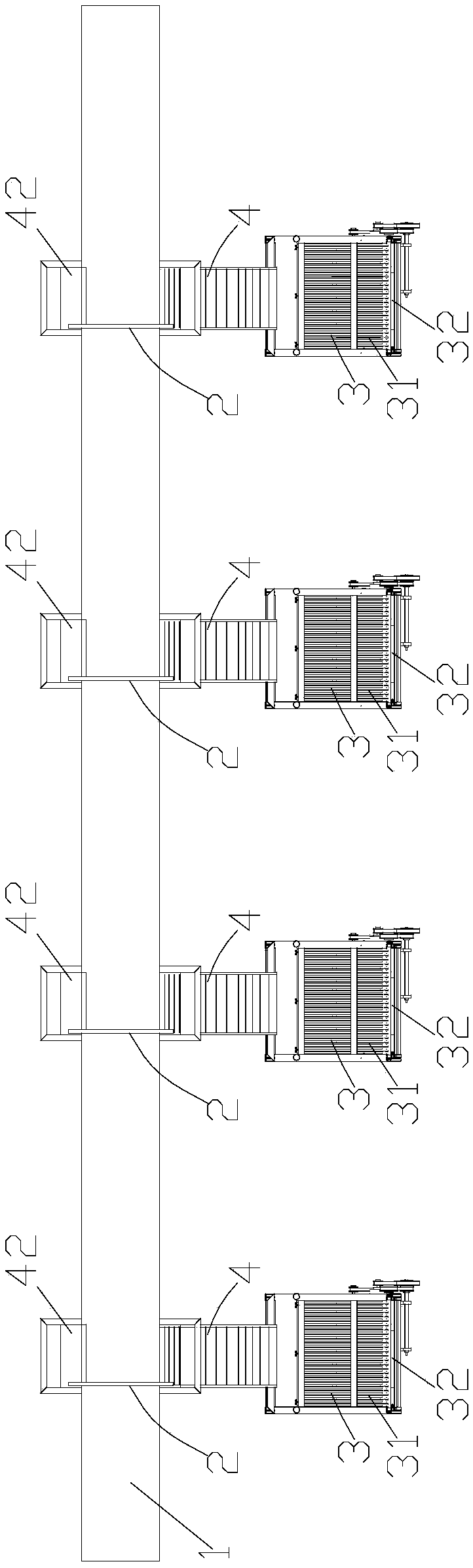

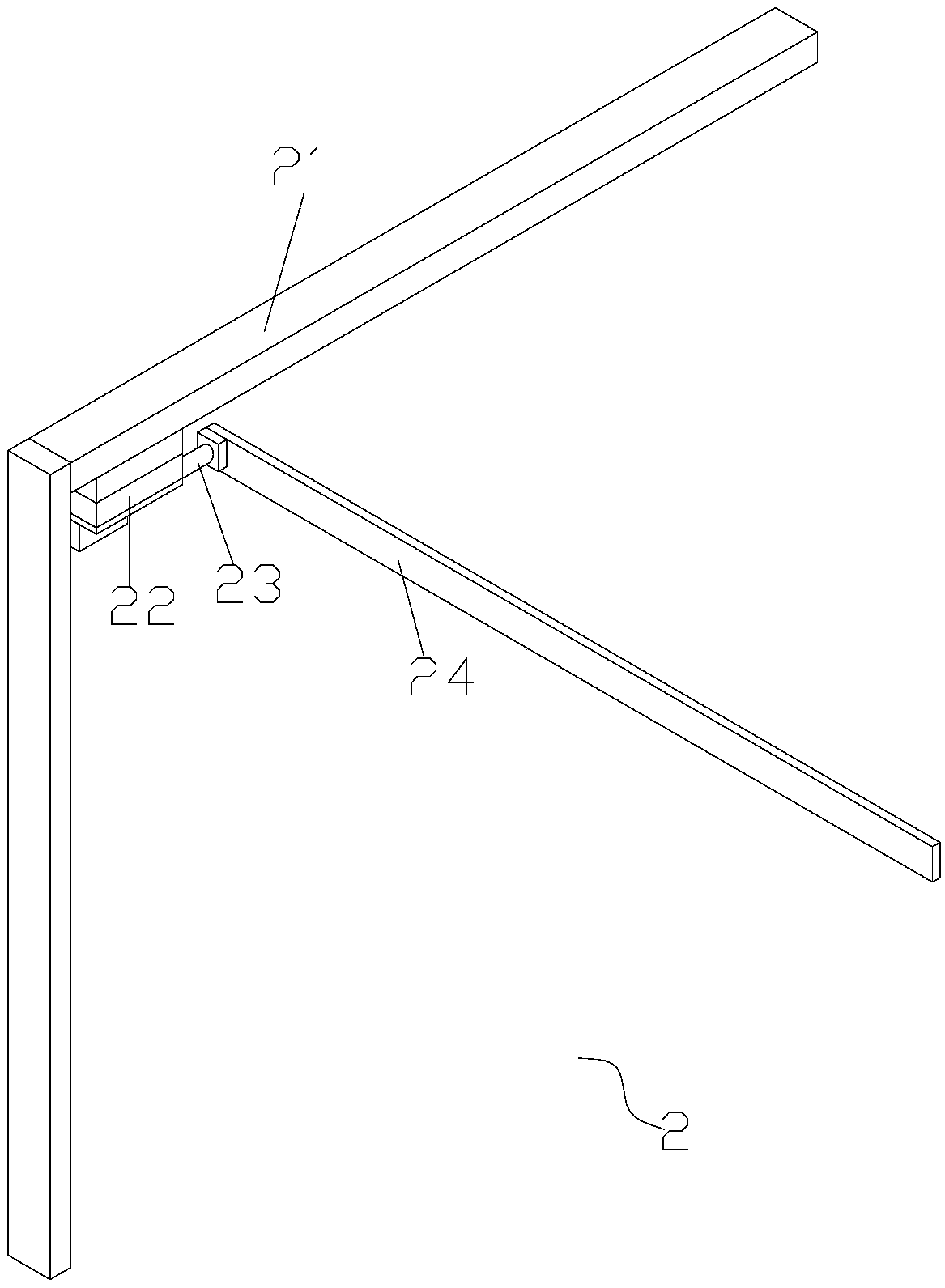

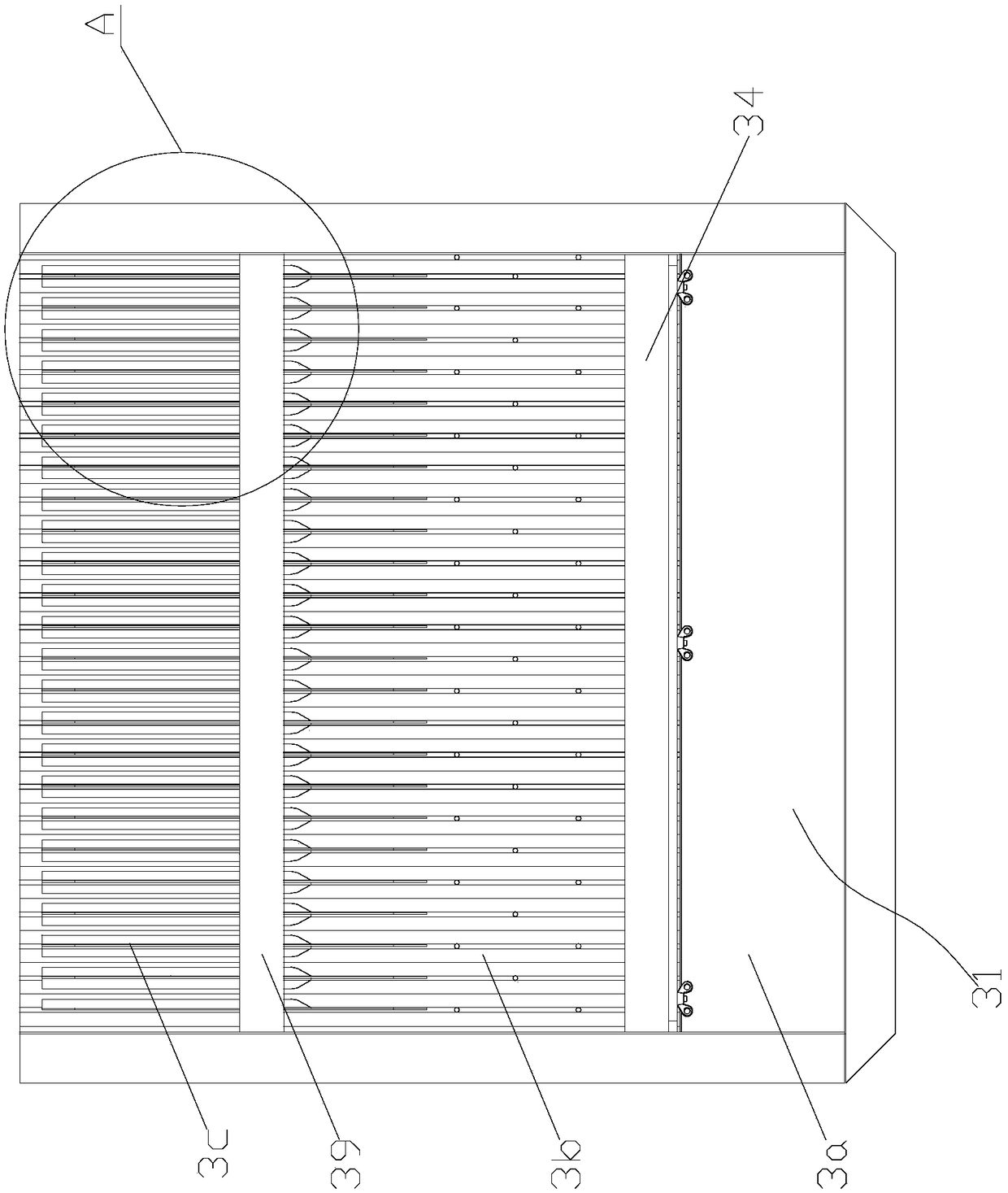

[0032] The invention discloses an automatic peeling production line of edamame, such as Figure 1 to Figure 9 As shown, a conveyor belt 1 is included, and multiple groups of pushing mechanisms 2 are arranged along the length direction of the conveyor belt 1, and each group of pushing mechanisms 2 corresponds to at least one peeling machine 3, and the pushing mechanism 2 includes The width direction straddles the stand 21 of the conveyor belt 1, the cylinder 22 that can move up and down is installed on the stand 21, the electric push rod 23 arranged along the width direction of the conveyor belt 1 is installed on the cylinder 22, the electric push rod 23 is fixedly connected with a push plate 24, the push plate 24 is arranged along the length direction of the conveyor belt 1, and the push plate 24 is driven by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com