Silica-based three-dimensional heterogeneously-integrated radio frequency microsystem and manufacturing method thereof

A micro-system and radio-frequency technology, which is applied in the manufacture of micro-structure devices, micro-structure technology, micro-structure devices, etc., can solve the problems of interconnection occupation area, signal transmission length and delay increase, and difficult to meet, so as to reduce the size, Good performance consistency, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

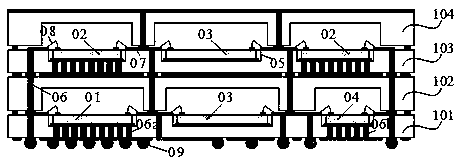

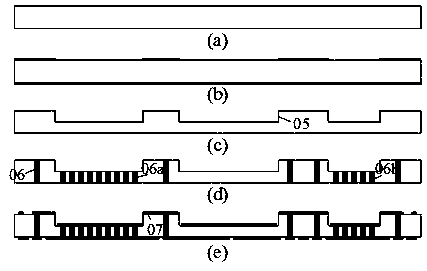

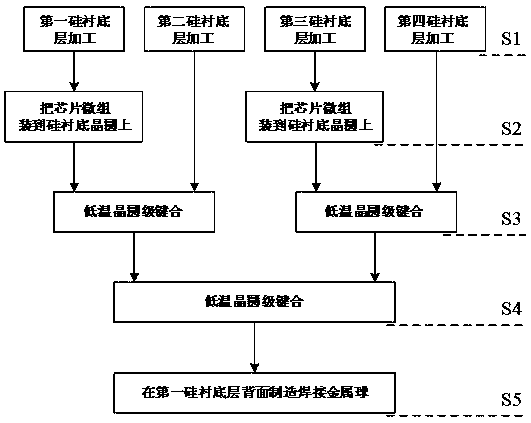

[0033] as attached figure 1 As shown, it is a schematic structural diagram of a silicon-based three-dimensional heterogeneous integrated radio frequency microsystem of the present invention, including a first silicon substrate layer 101, a second silicon substrate layer 102, a third silicon substrate layer 103, a fourth silicon substrate layer 104, RF power amplifier chip 01, RF low noise amplifier chip 02, RF filter 03 and RF switch 04; the front of the first silicon substrate layer 101 and the third silicon substrate layer 103, the second silicon substrate layer 102 and the fourth silicon substrate layer 104 The back side of each is provided with an etched cavity 05; the first silicon substrate layer 101, the second silicon substrate layer 102, the third silicon substrate layer 103 and the fourth silicon substrate layer 104 are all provided with throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com