Patents

Literature

419results about How to "Improve performance consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

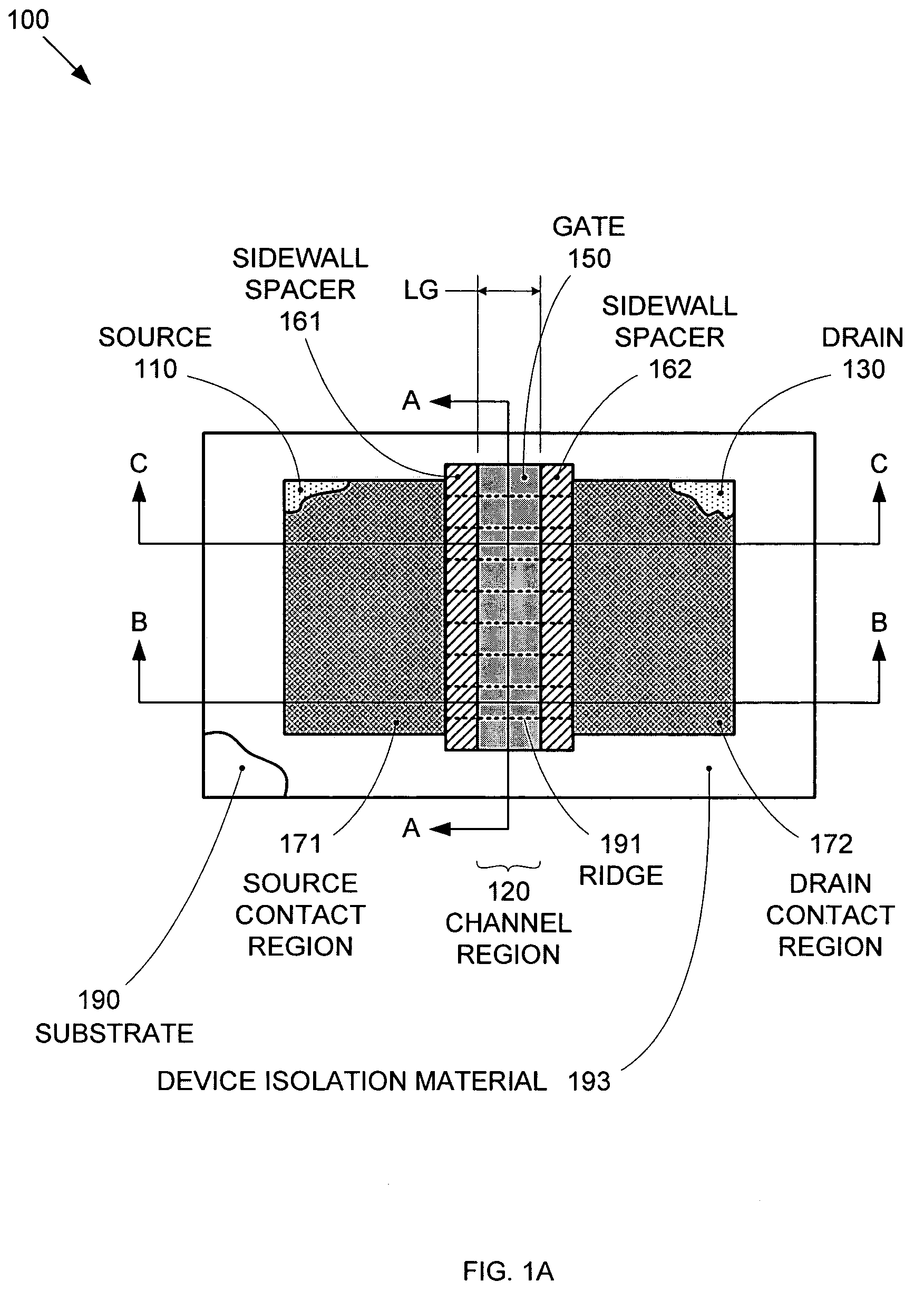

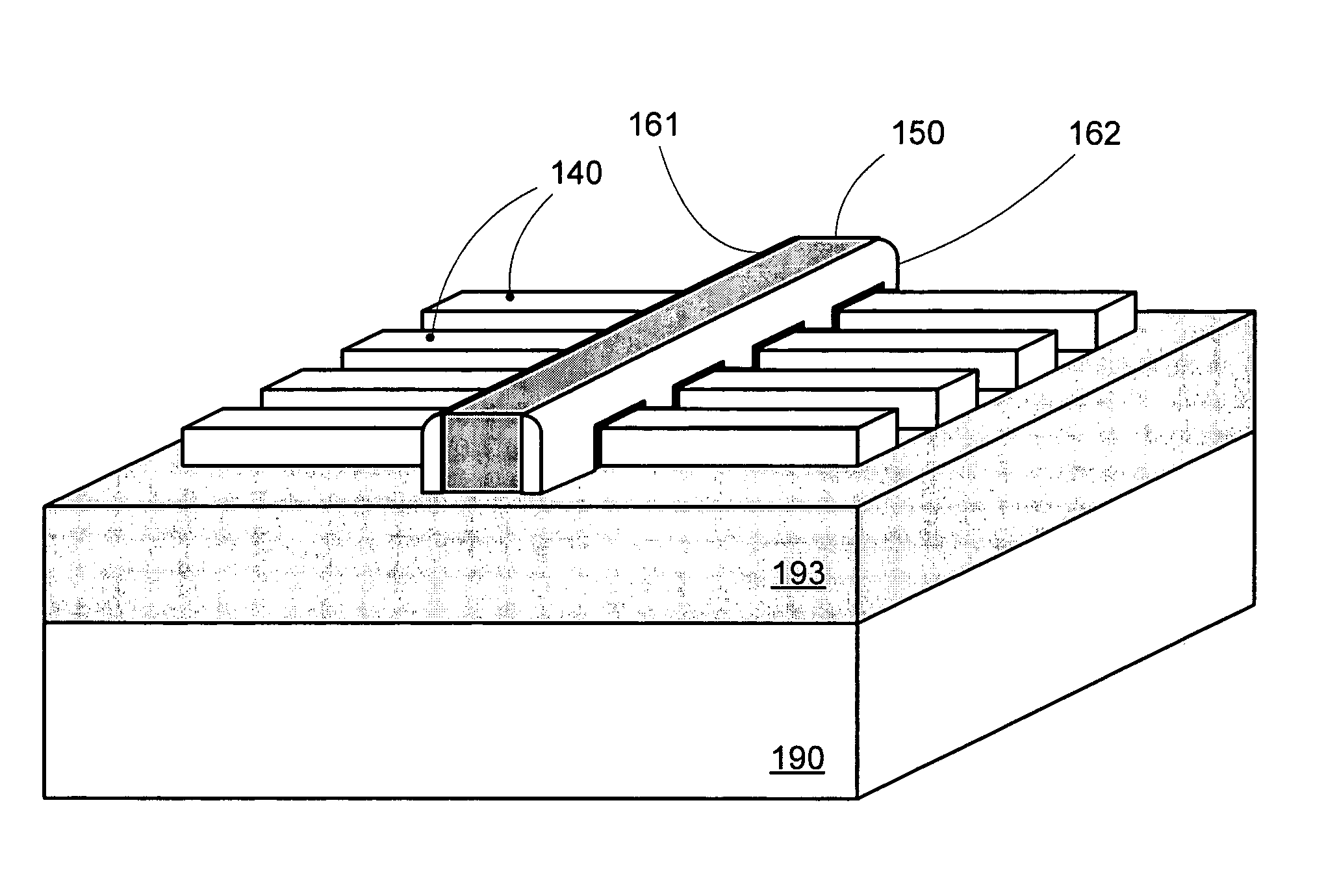

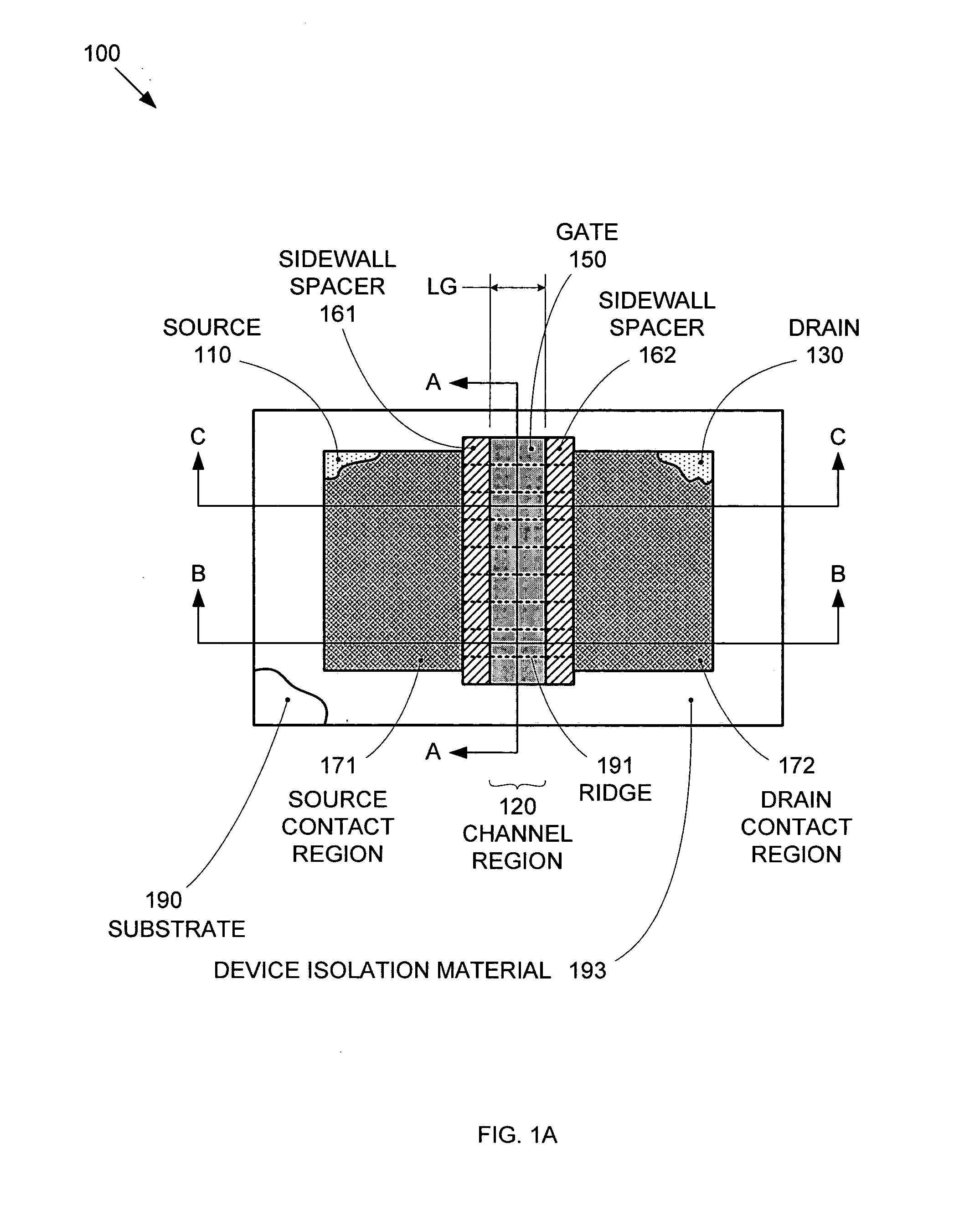

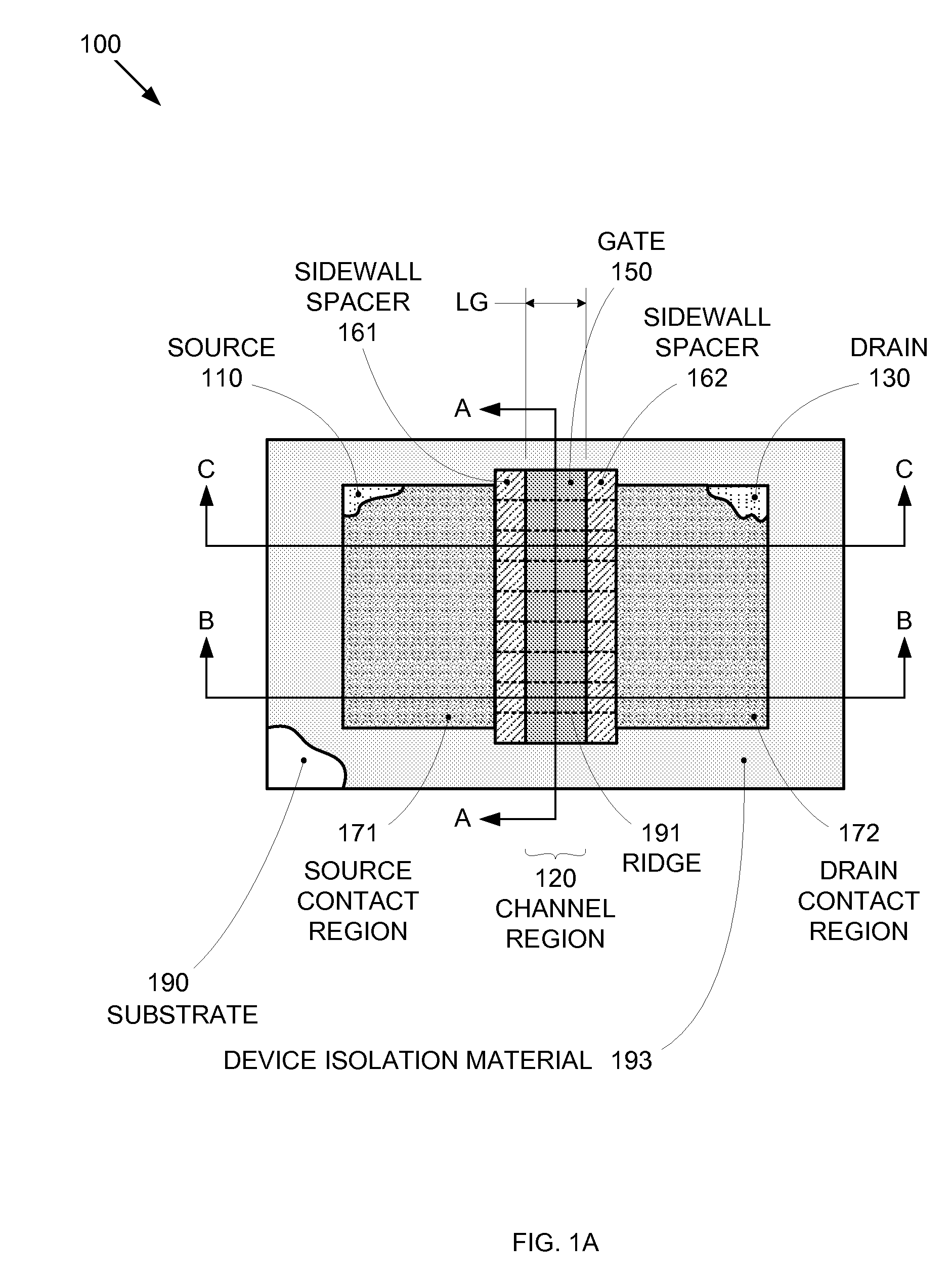

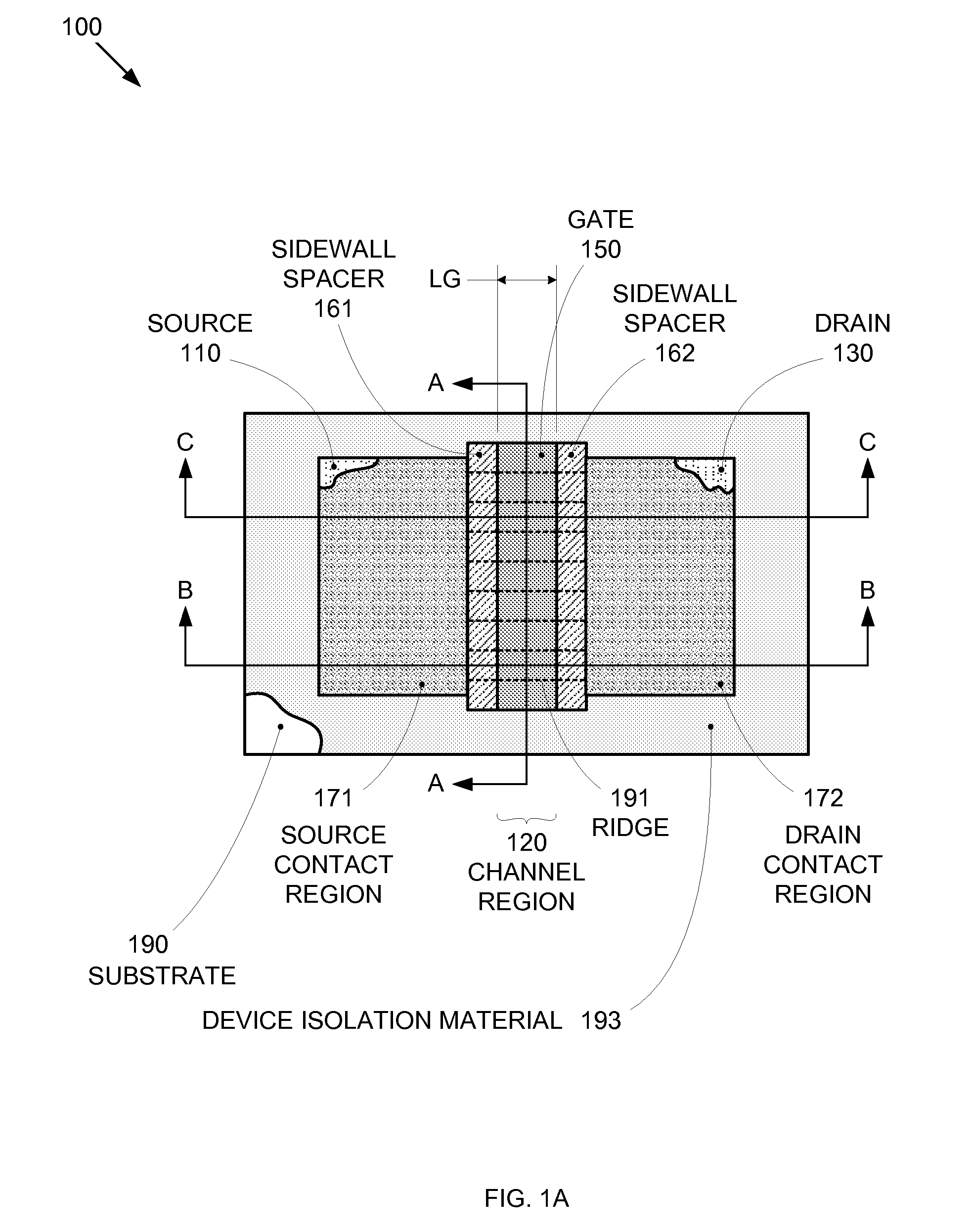

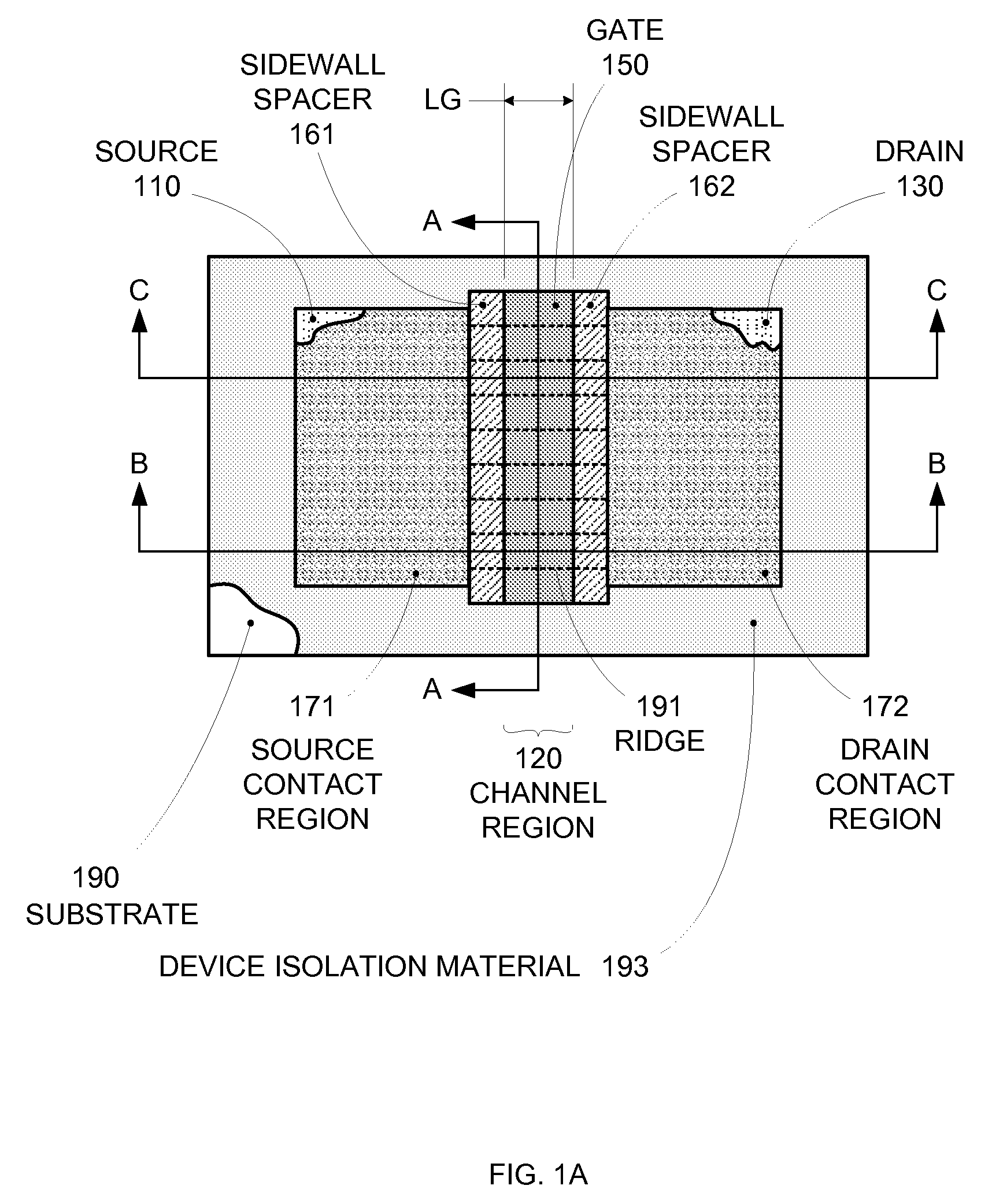

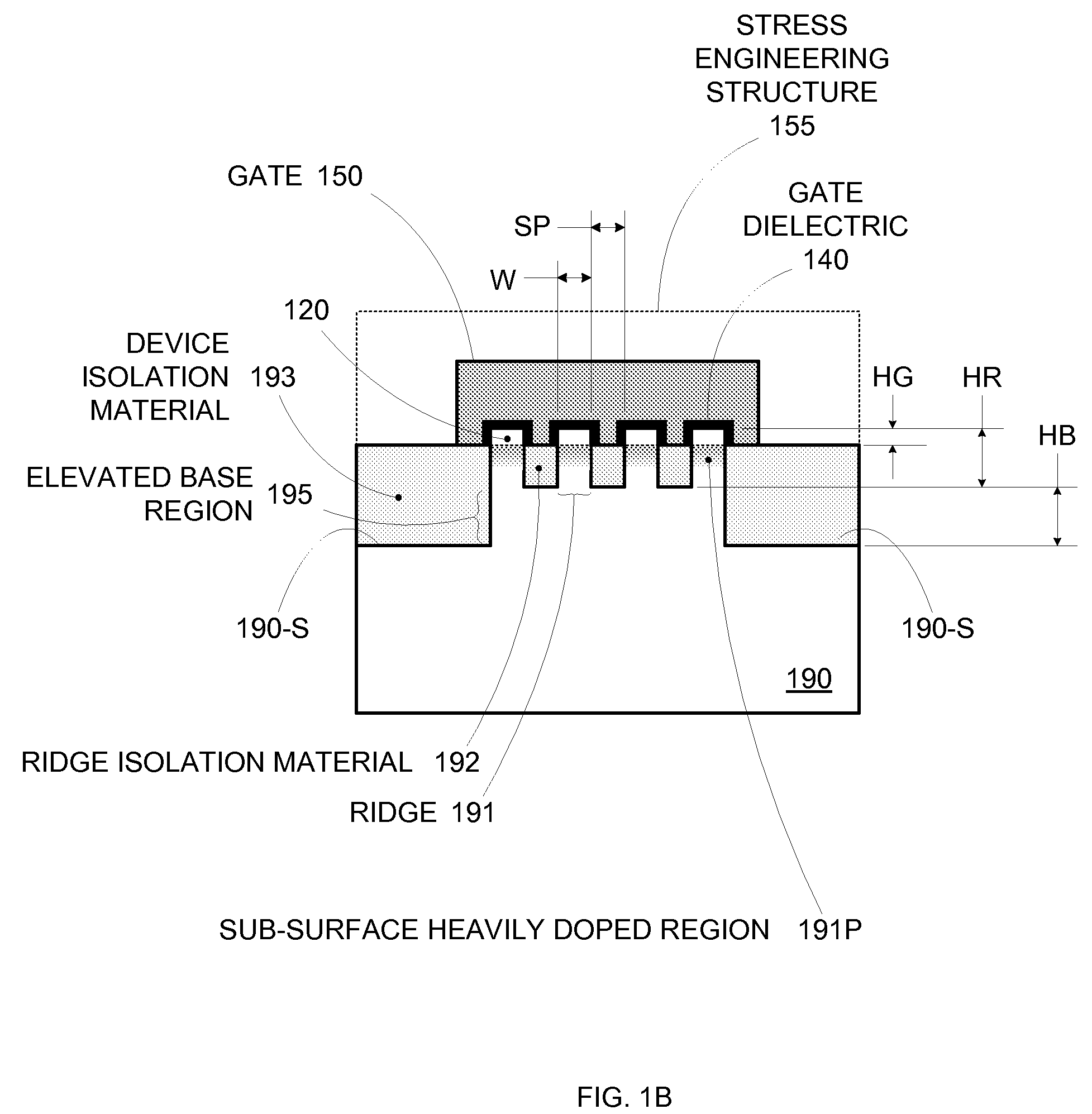

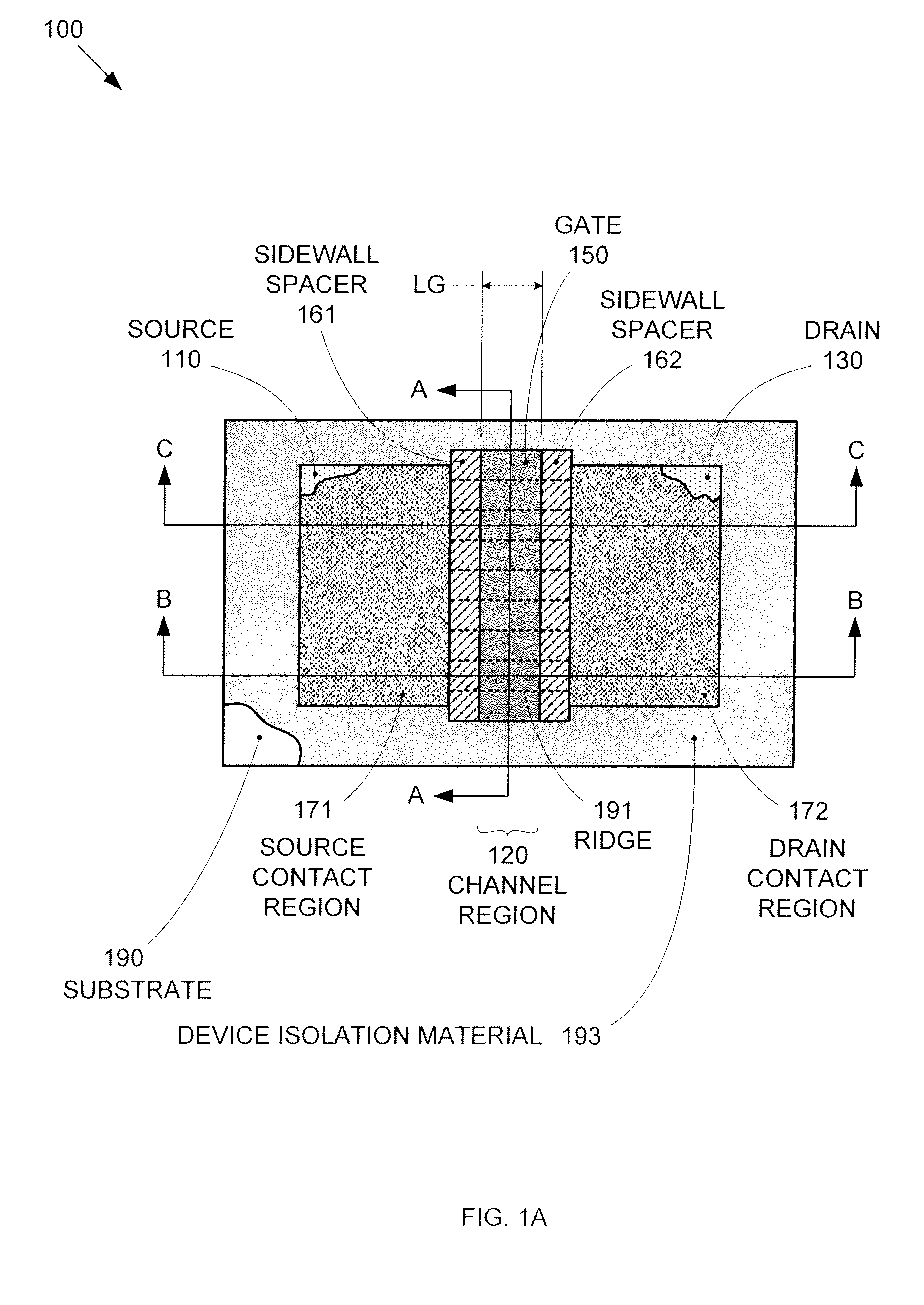

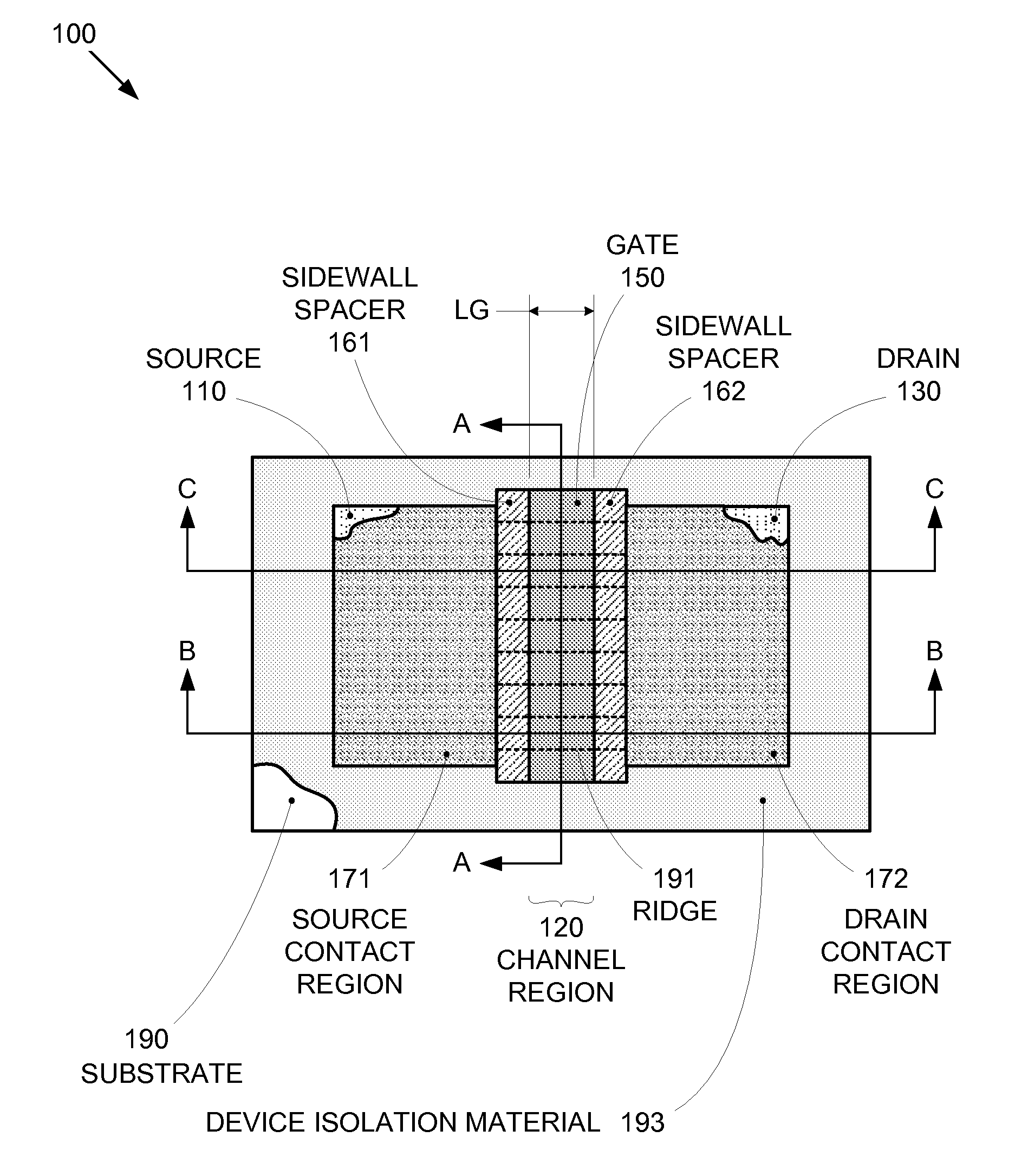

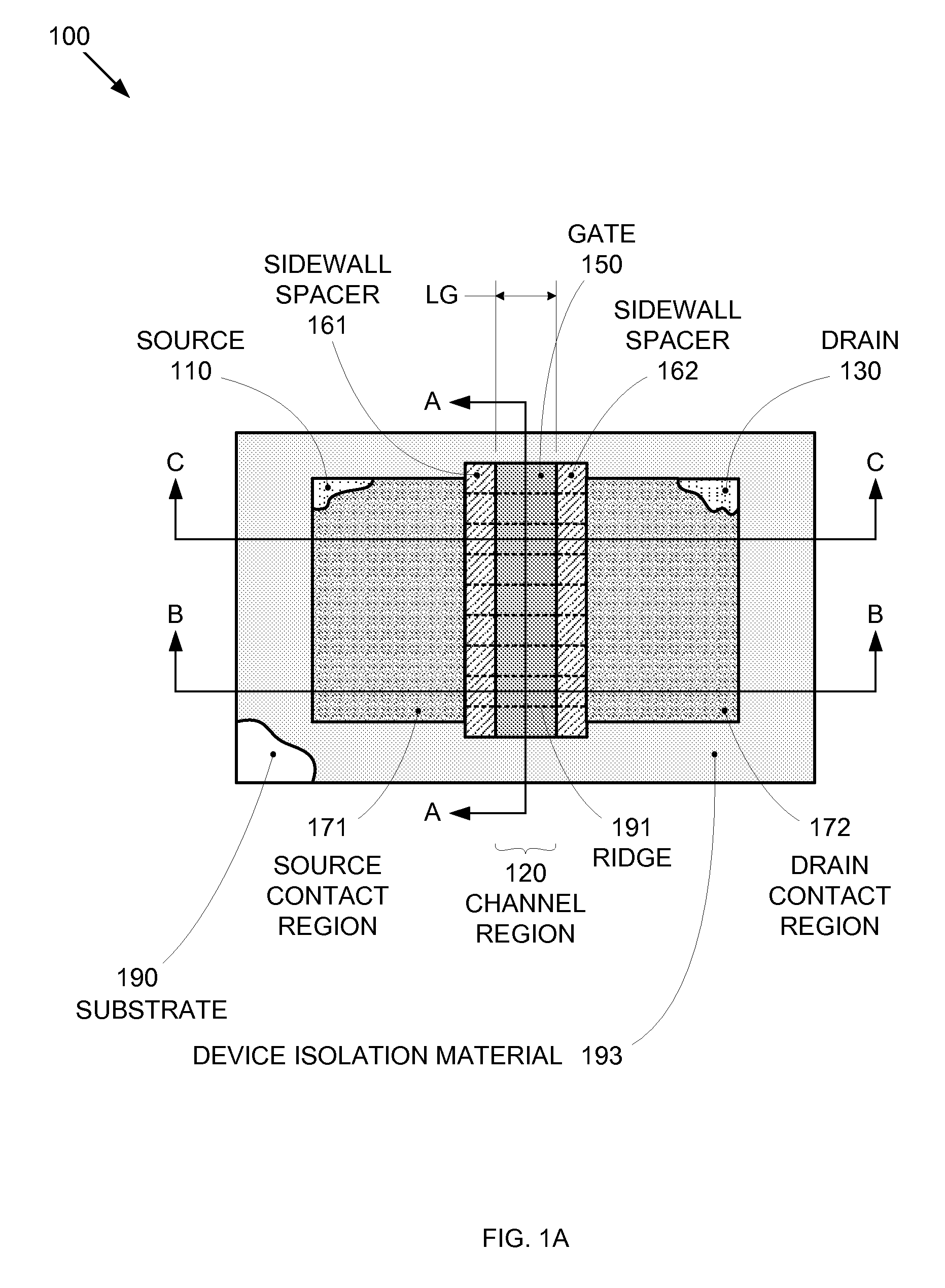

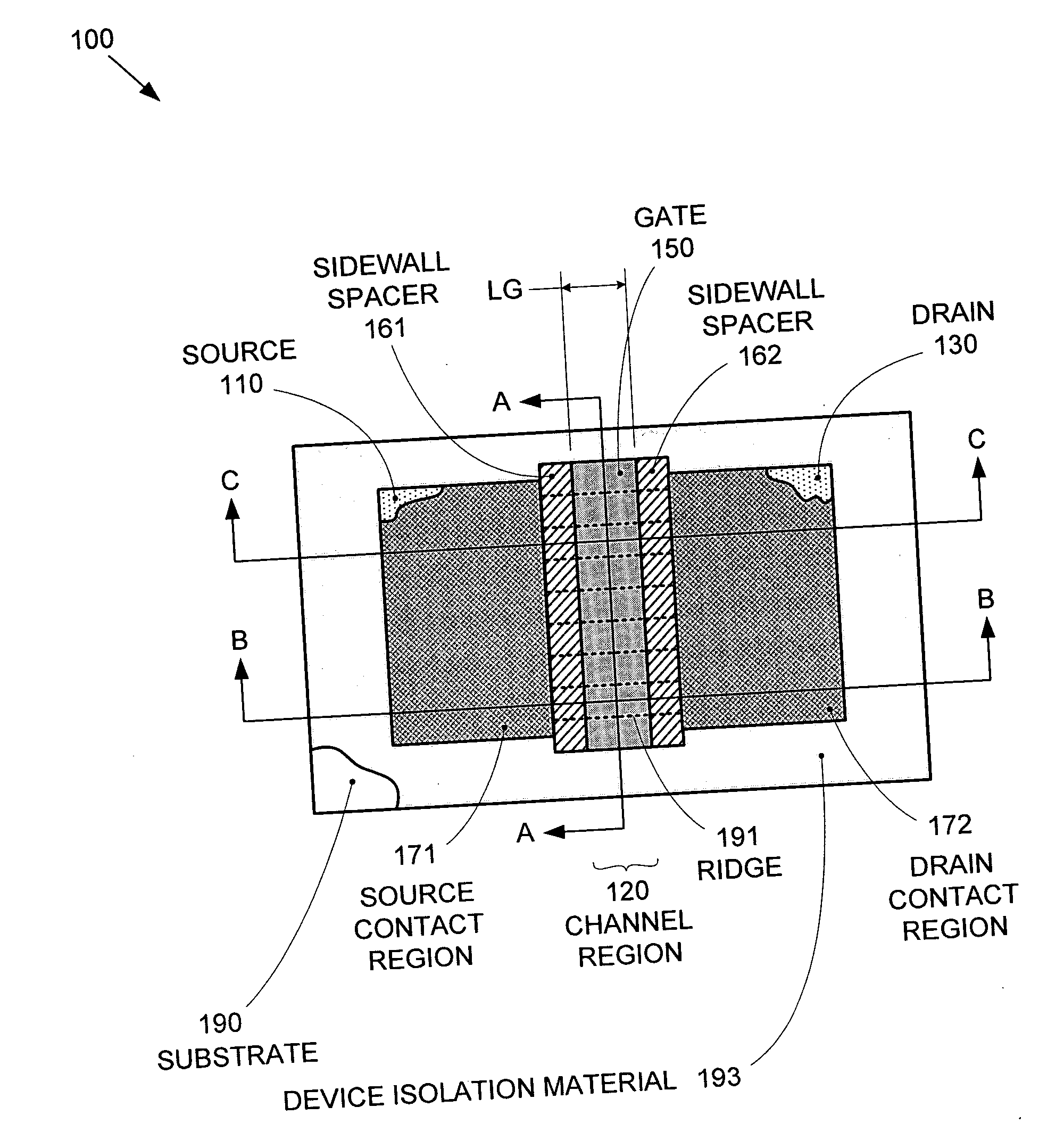

Segmented channel MOS transistor

ActiveUS7247887B2Improve performance consistencyImprove performanceTransistorSolid-state devicesMOSFETLithographic artist

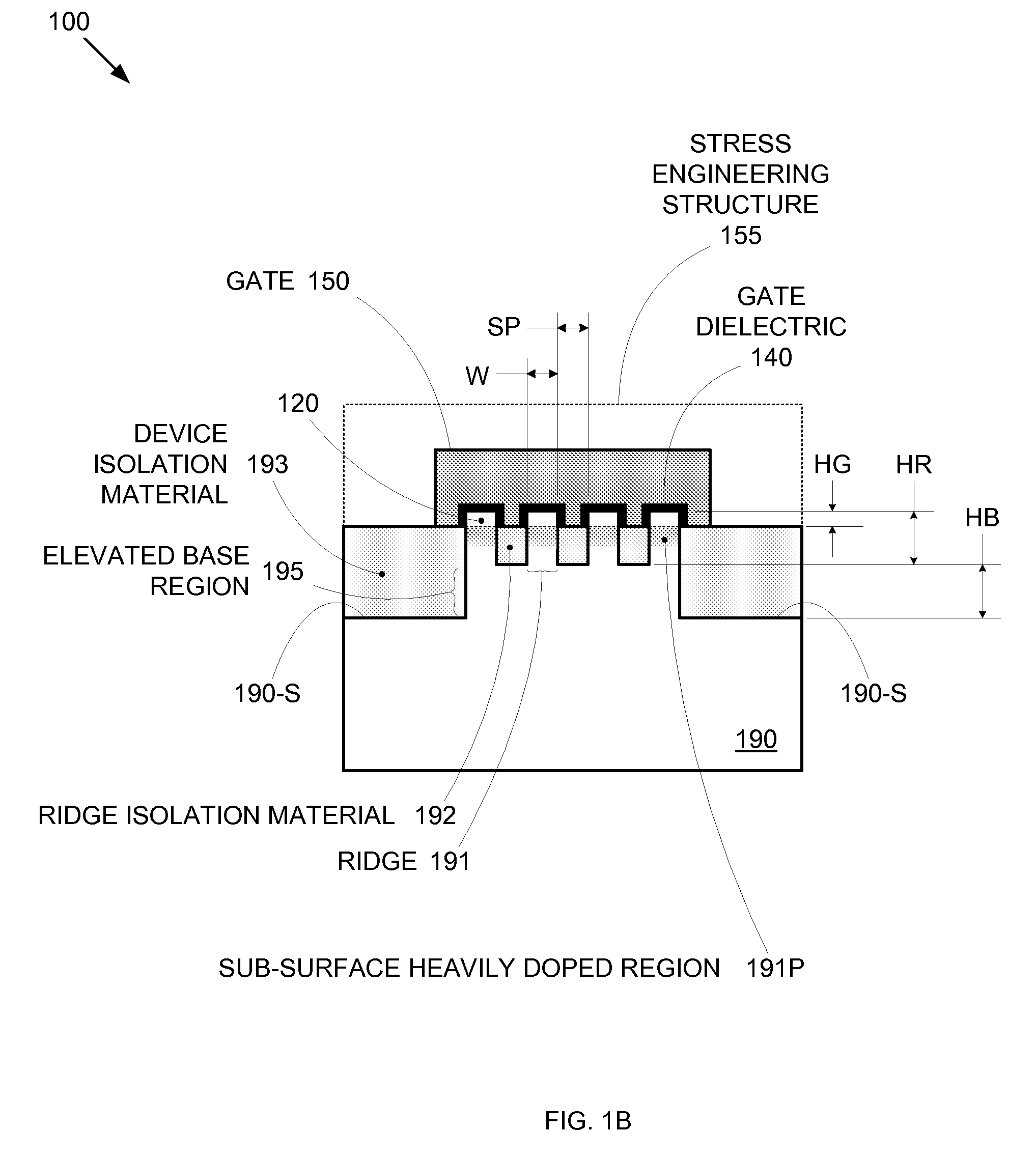

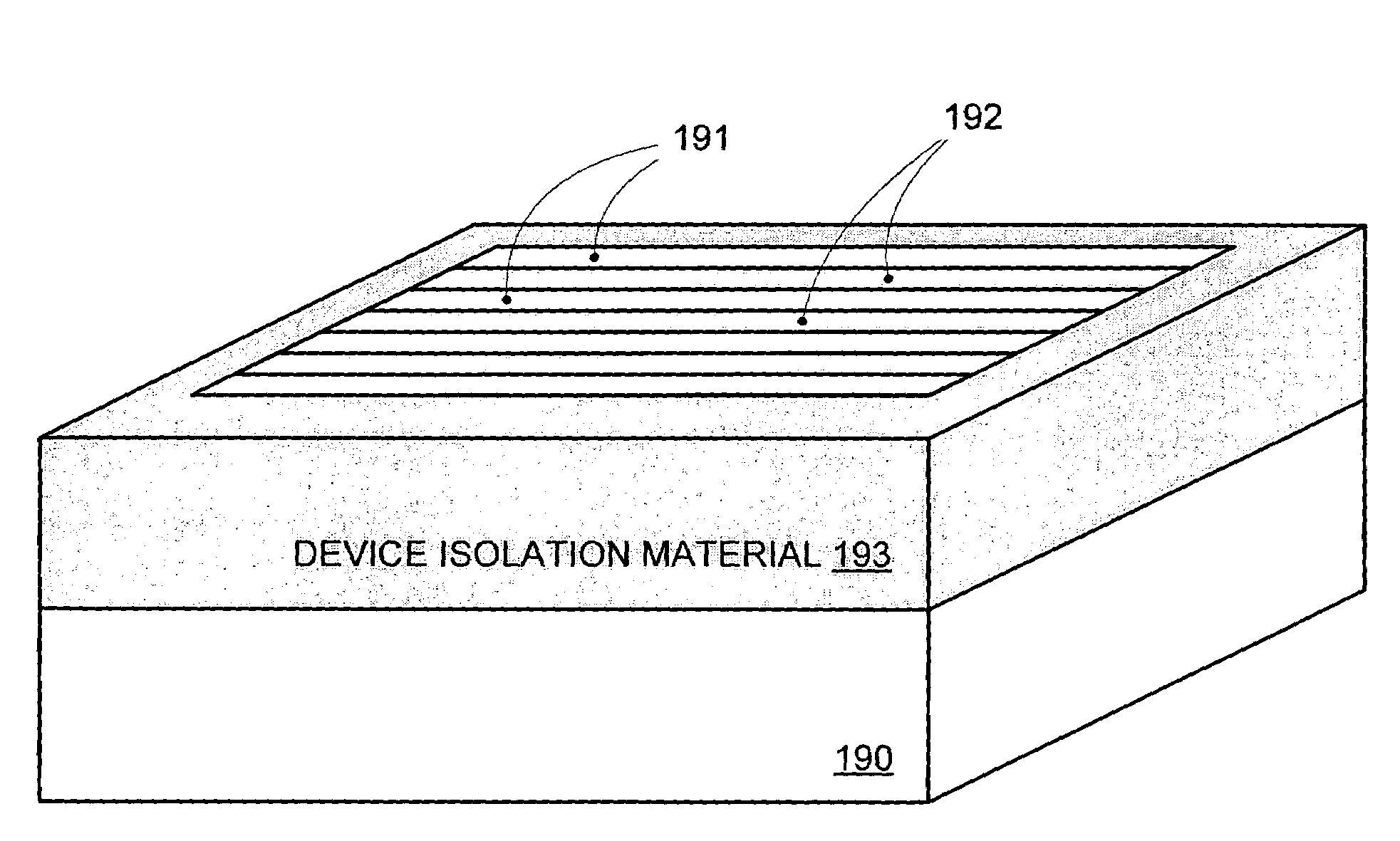

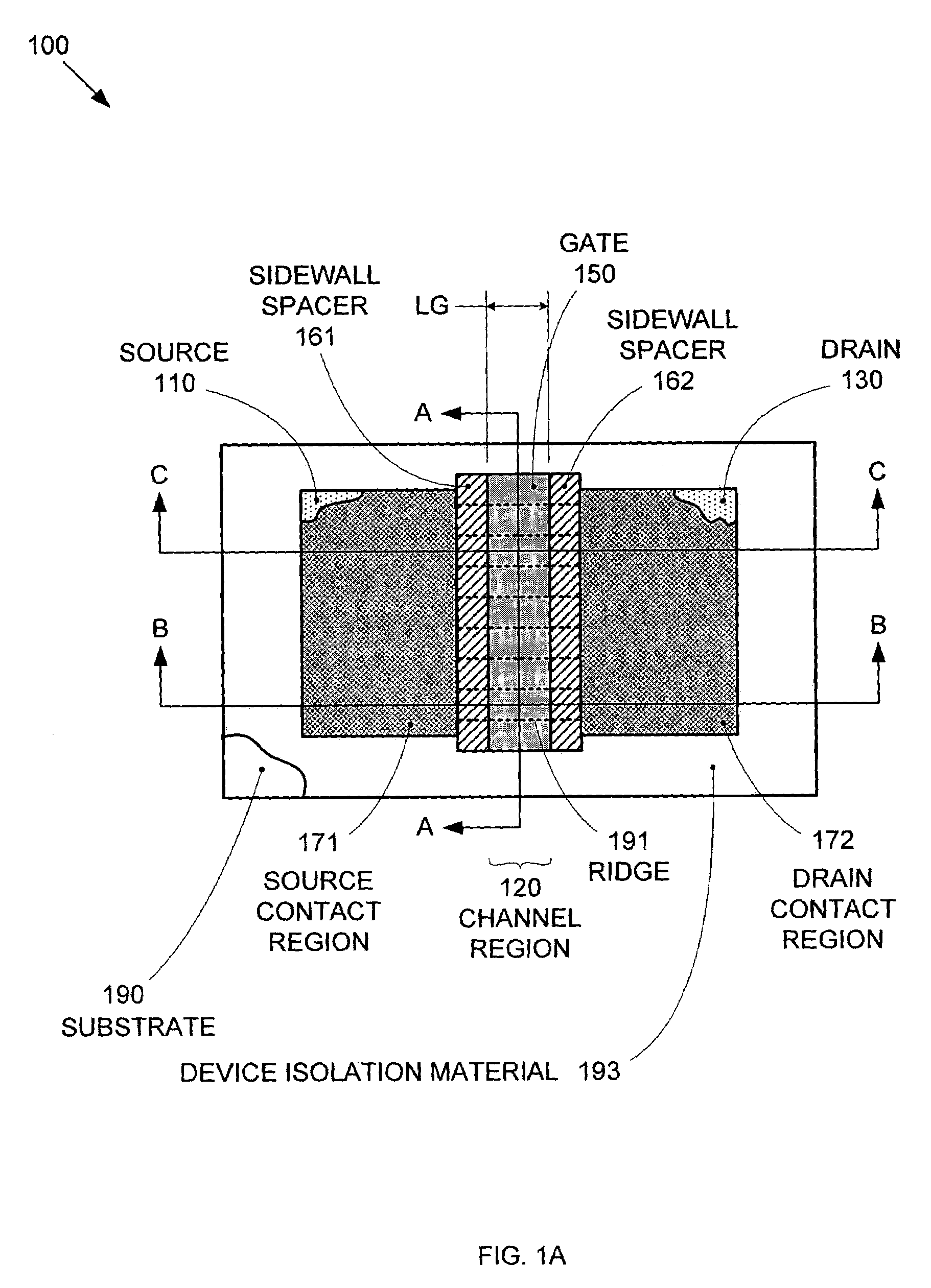

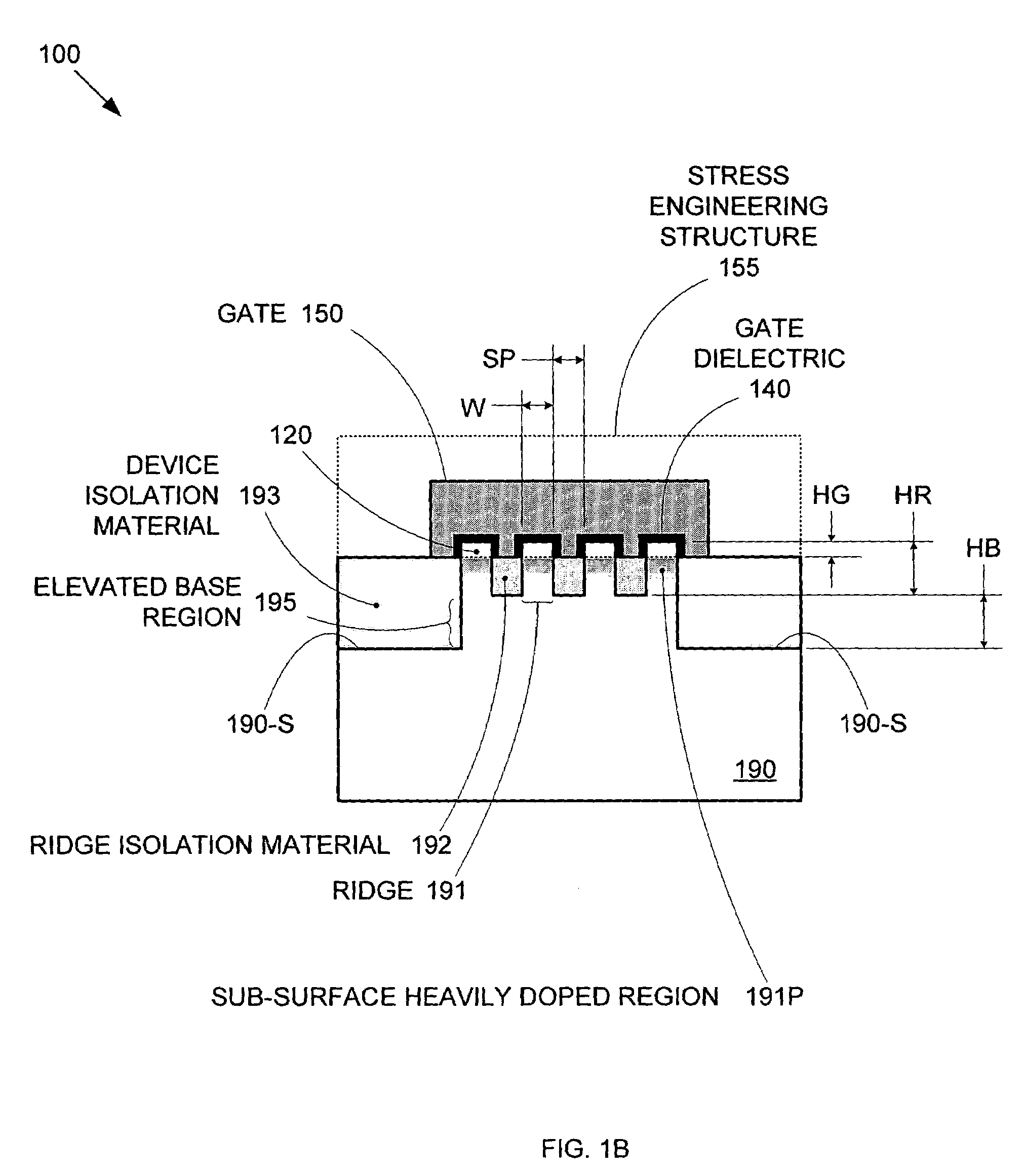

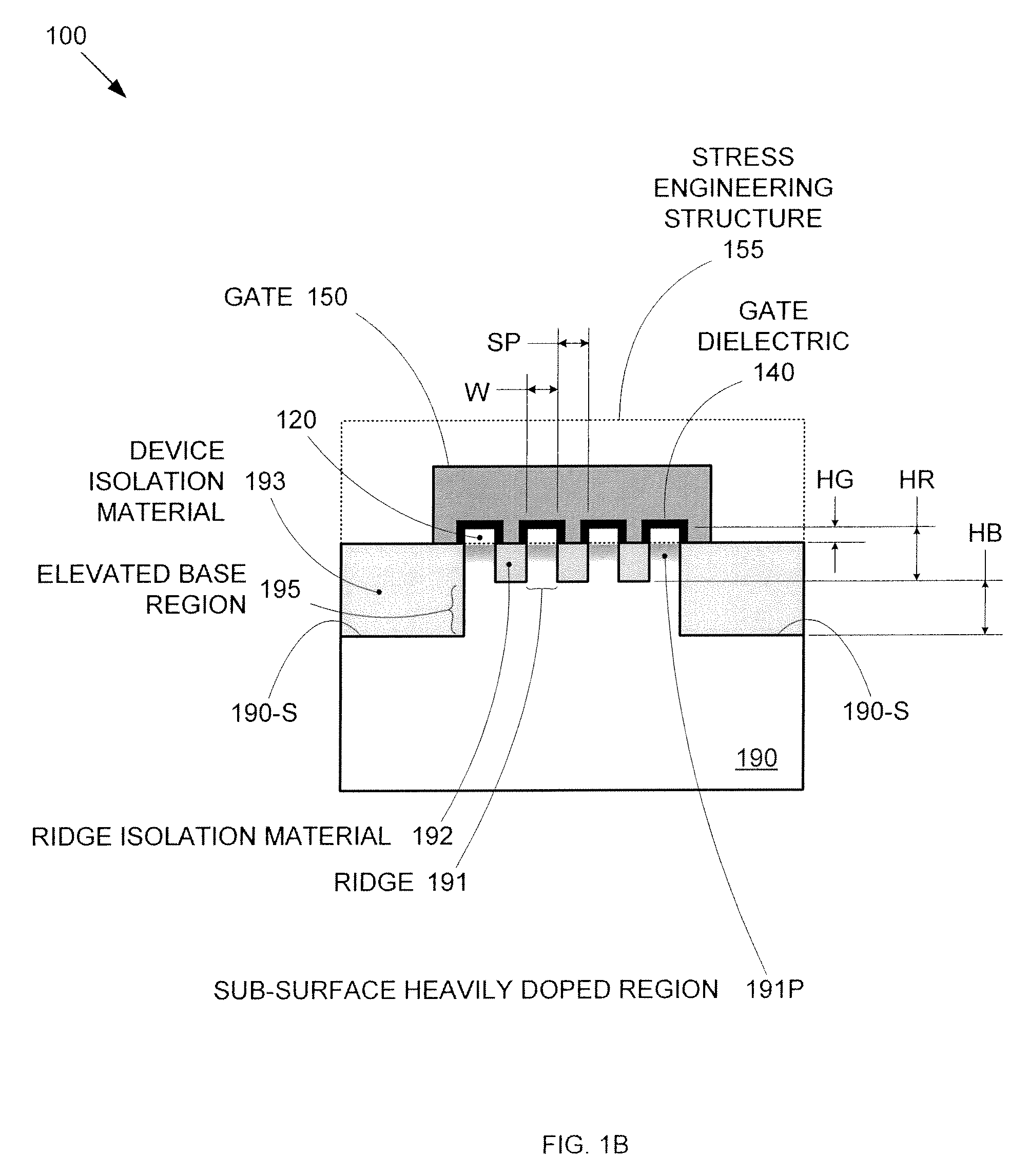

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping and “wrapped” gates can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

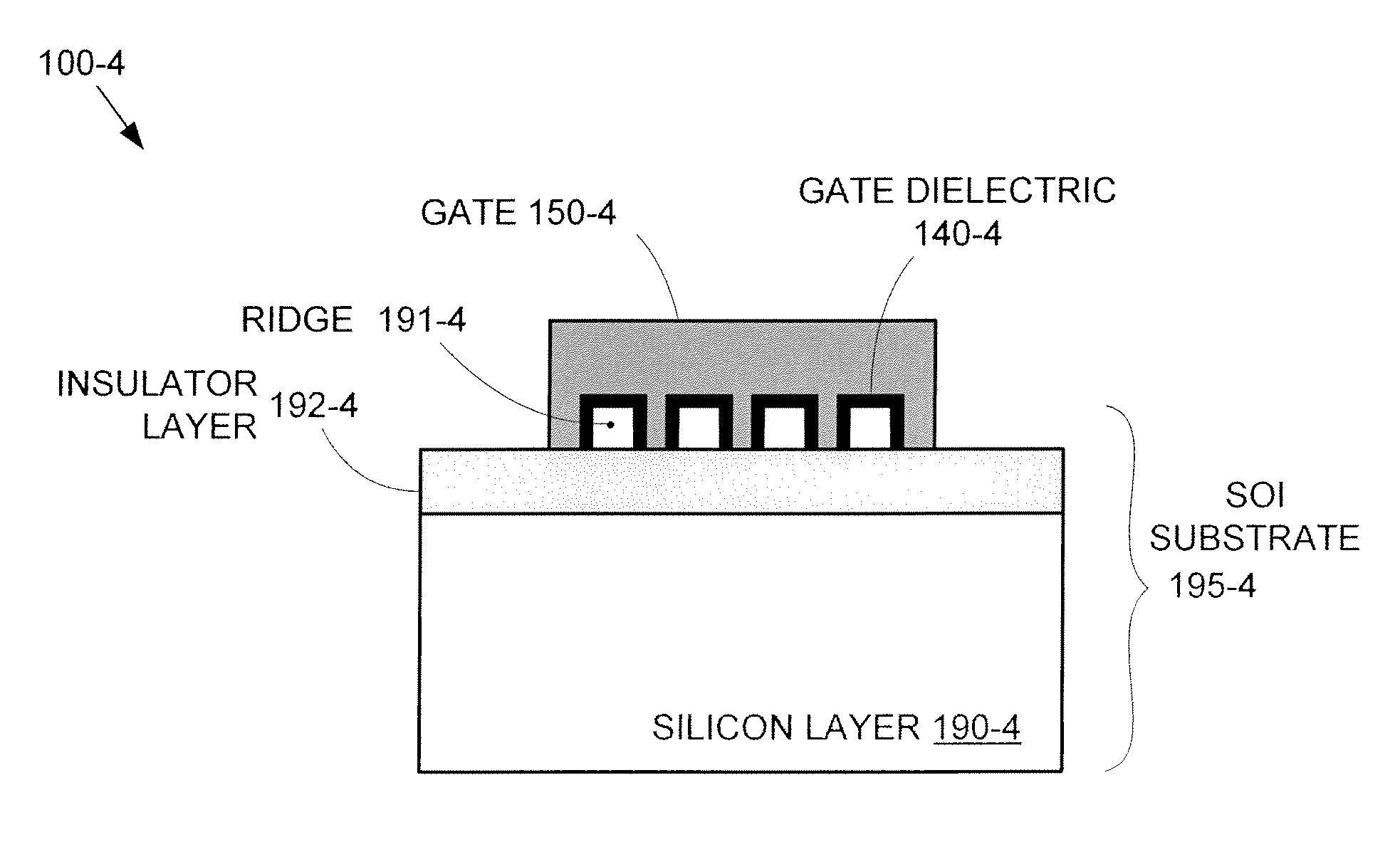

Integrated circuit on corrugated substrate

ActiveUS7190050B2Improve performance consistencyImprove performanceTransistorSemiconductor/solid-state device detailsMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping and “wrapped” gates can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

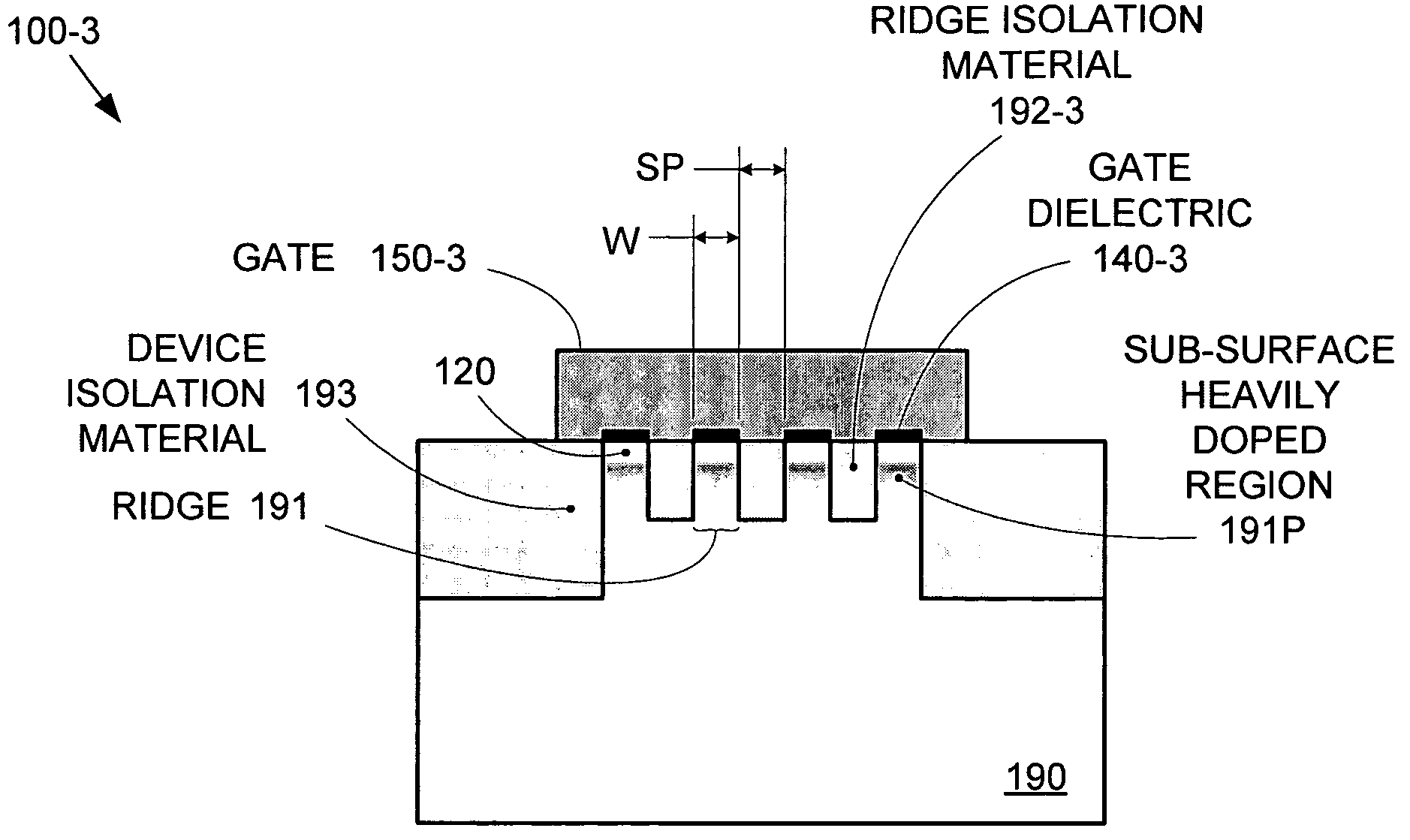

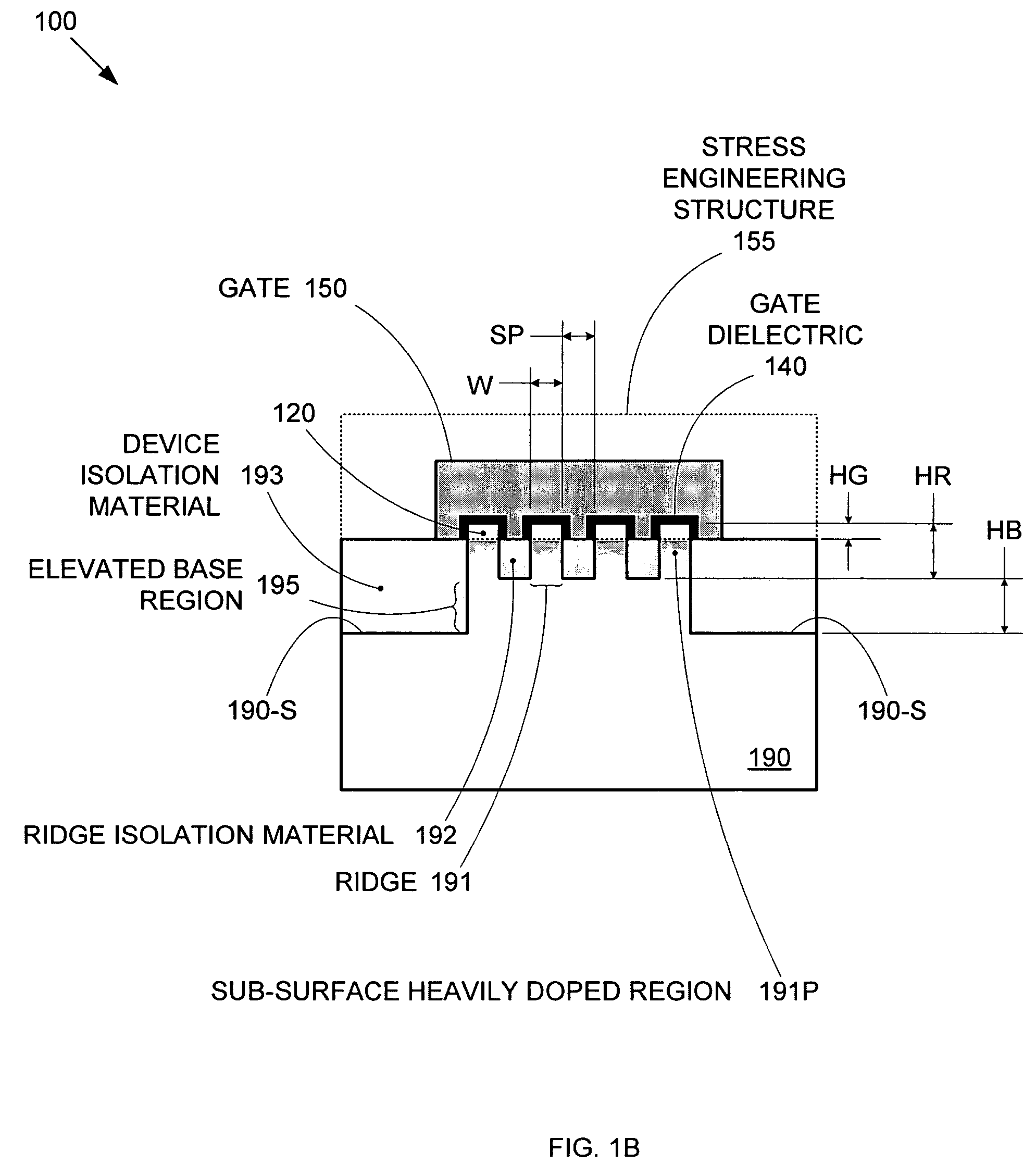

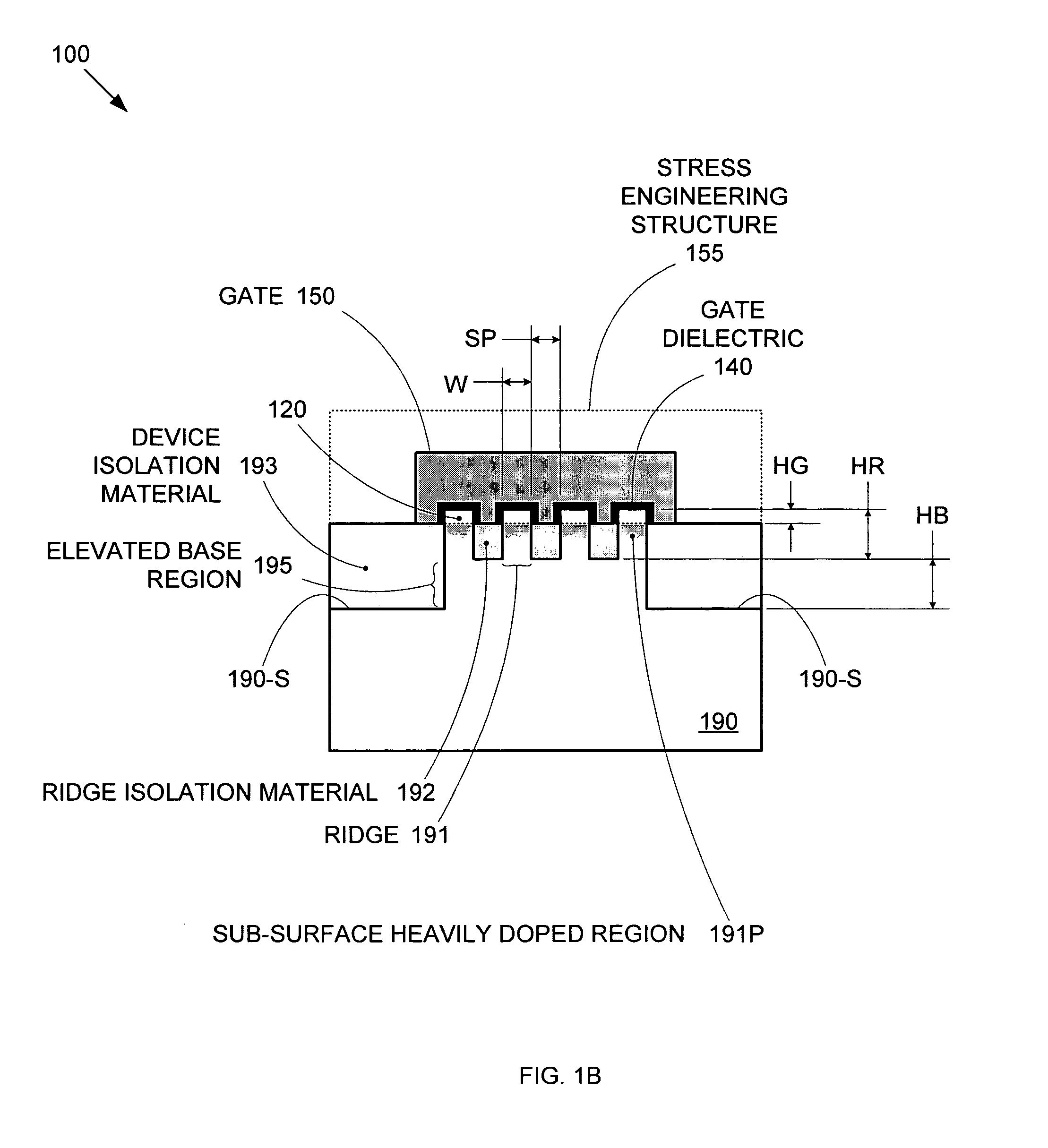

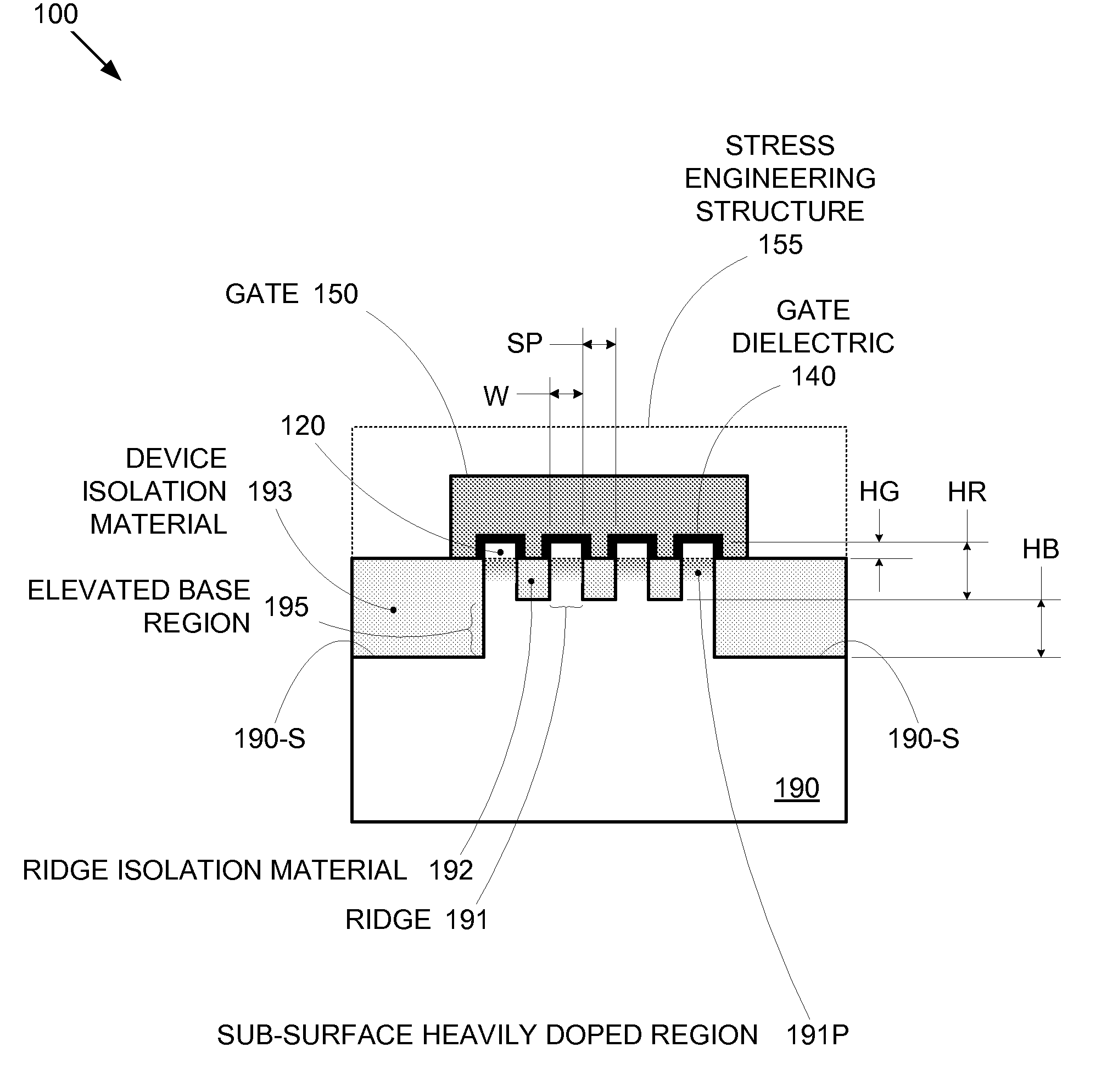

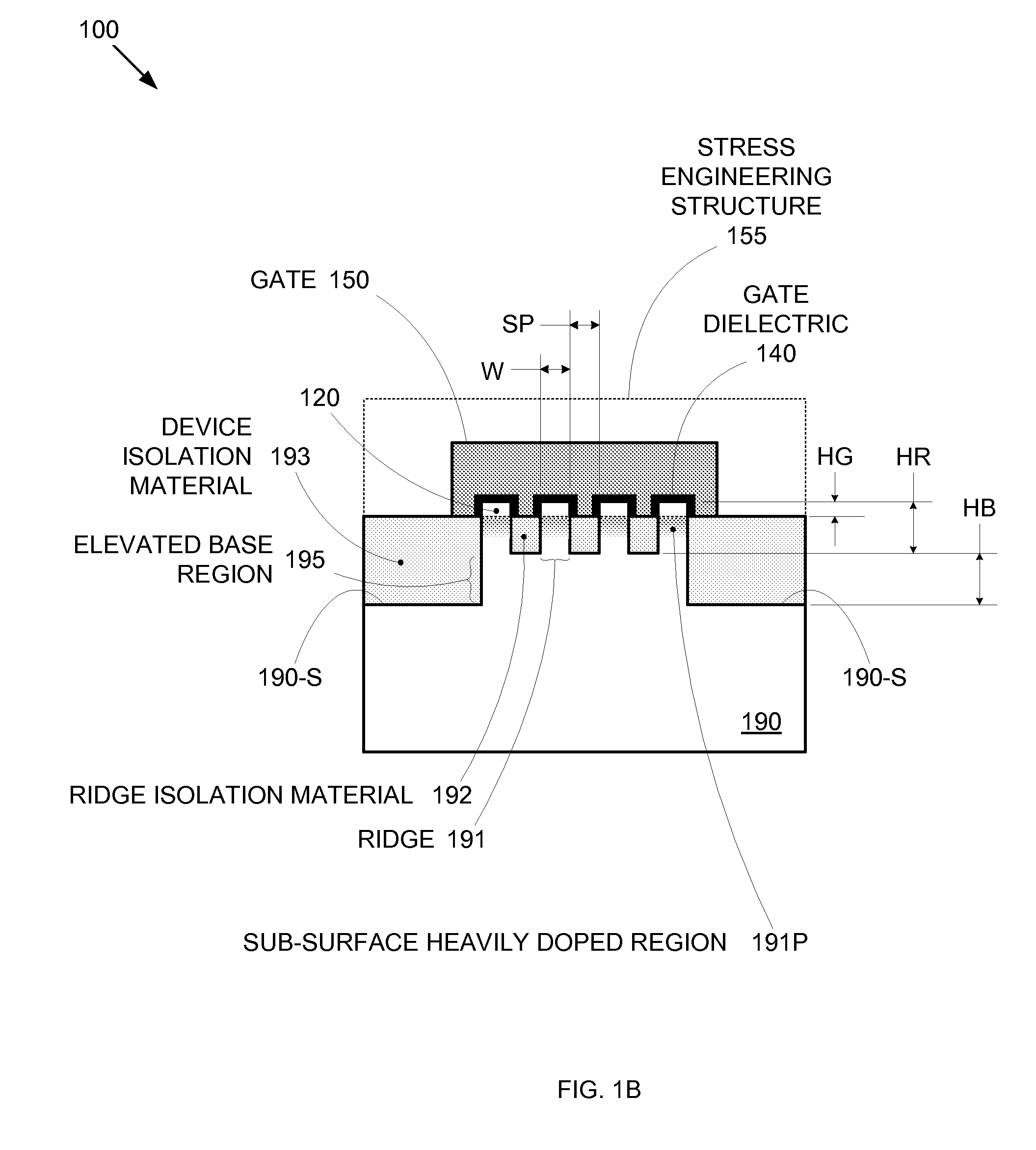

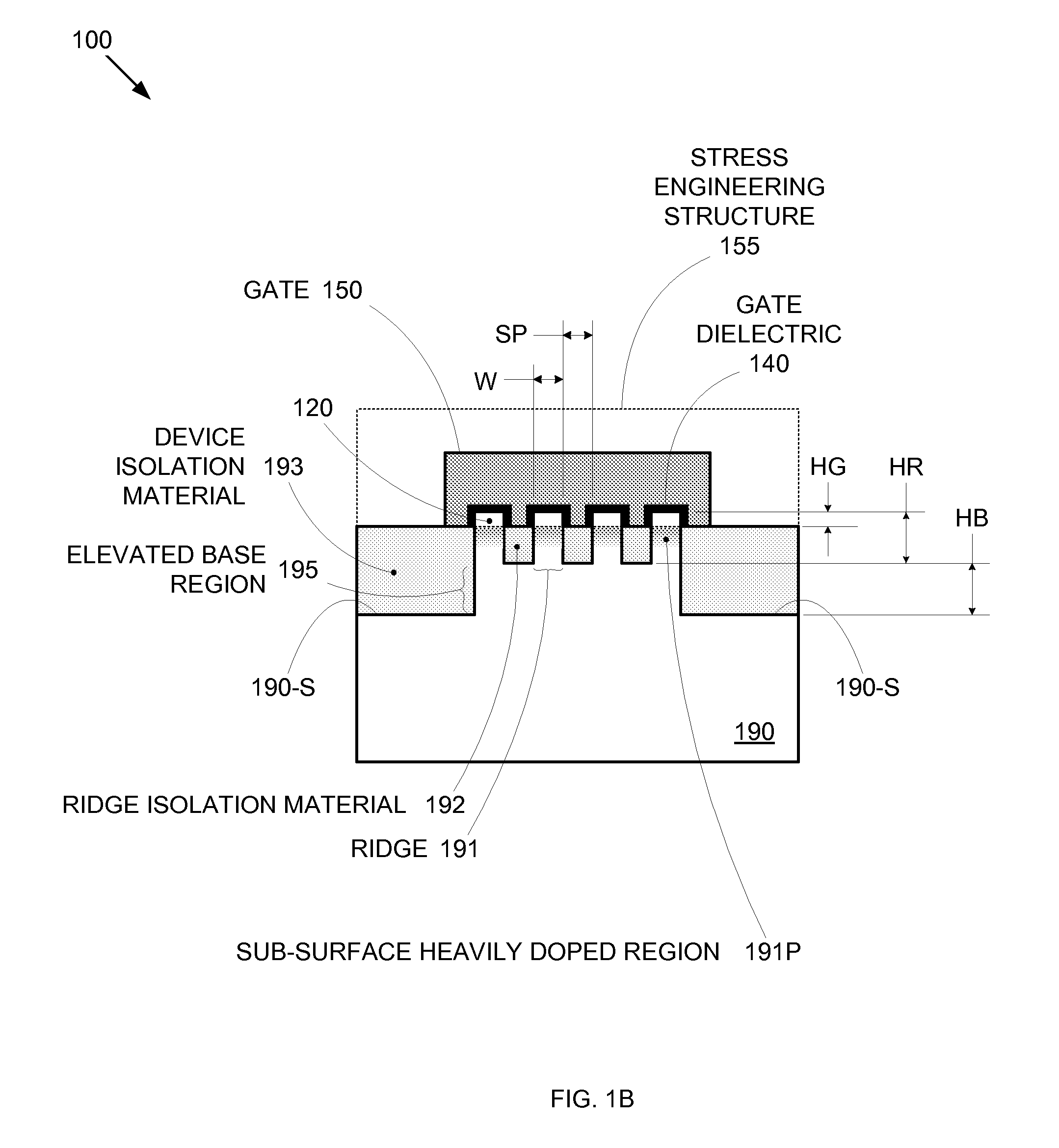

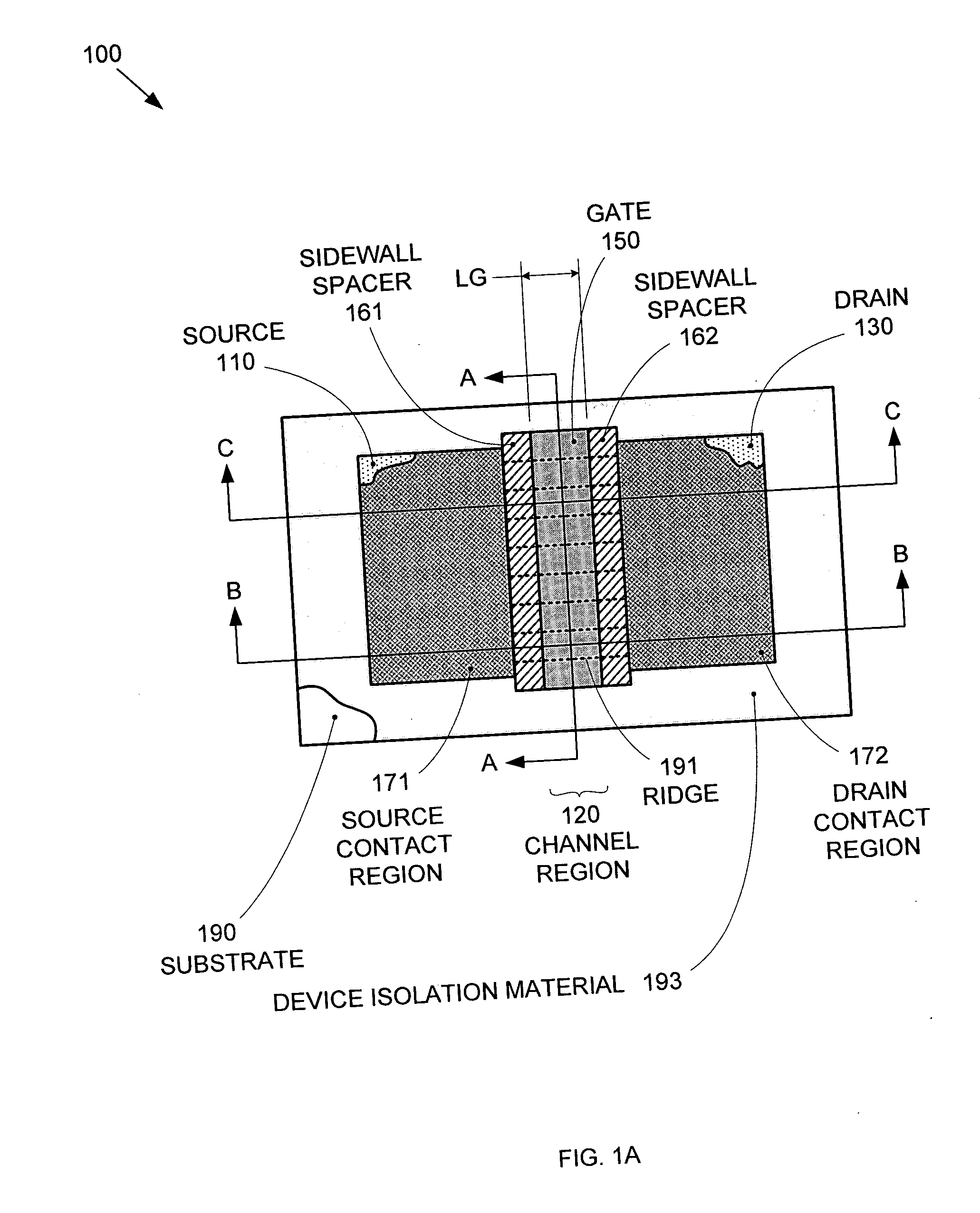

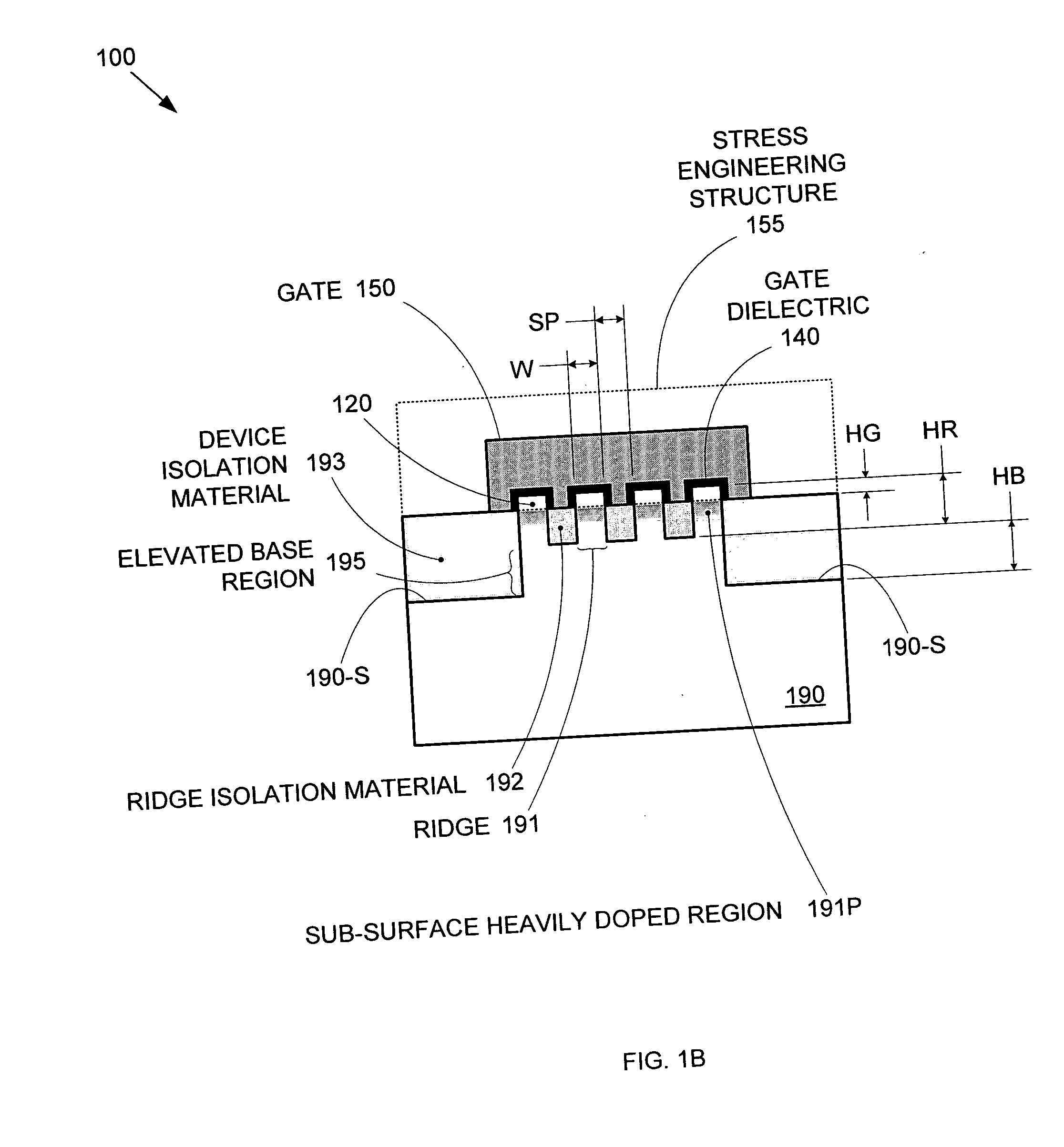

Enhanced Segmented Channel MOS Transistor with Multi Layer Regions

ActiveUS20070120156A1Increase costImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping, “wrapped” gates, epitaxially grown conductive regions, epitaxially grown high mobility semiconductor materials (e.g. silicon-germanium, germanium, gallium arsenide, etc.), high-permittivity ridge isolation material, and narrowed base regions can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

Method of IC production using corrugated substrate

ActiveUS7265008B2Improve performance consistencyImprove performanceLaser detailsSolid-state devicesMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping and “wrapped” gates can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

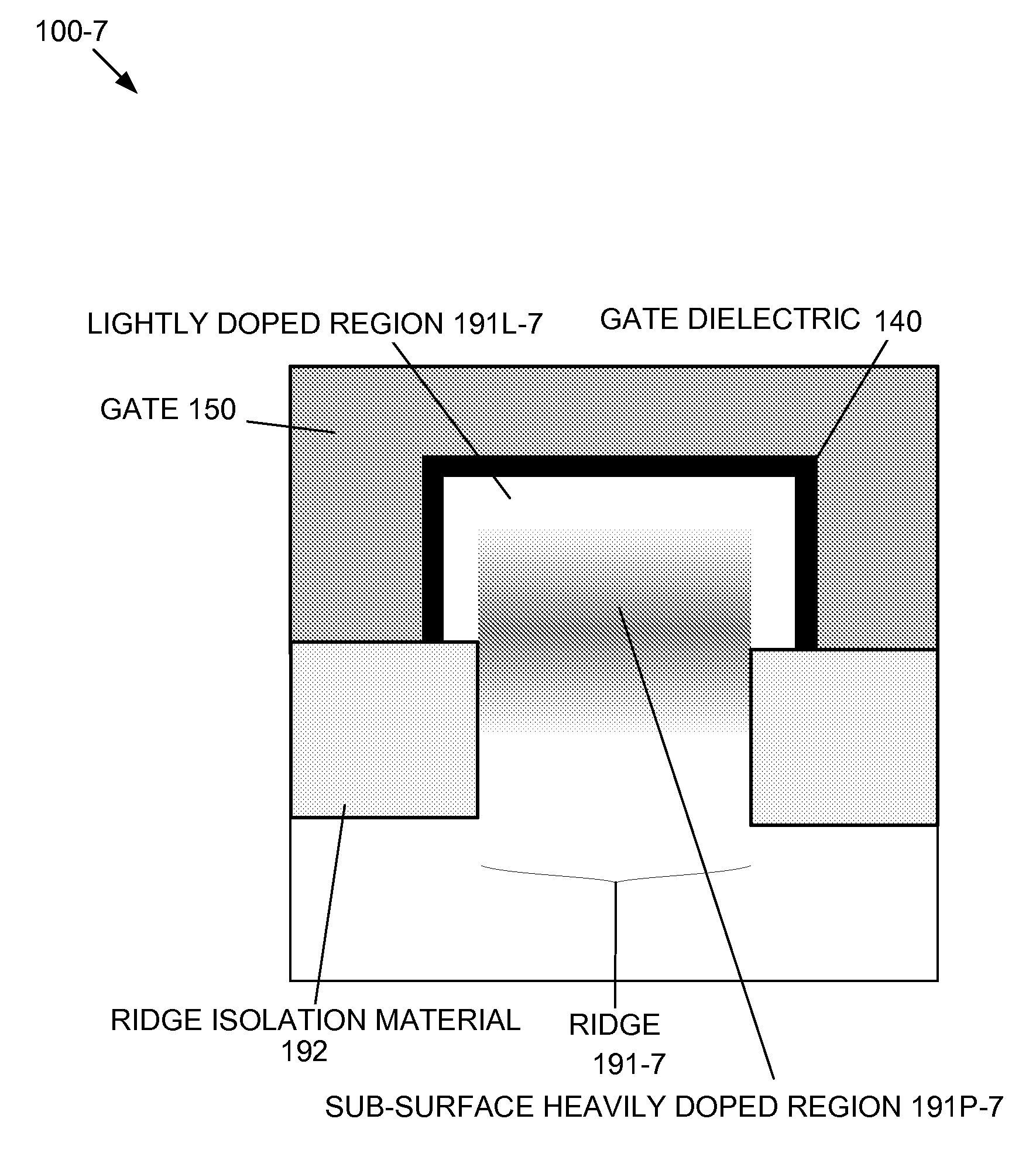

Enhanced segmented channel MOS transistor with narrowed base regions

ActiveUS7508031B2Improve performance consistencyImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably produced. Ridges on the corrugated substrate can be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping, “wrapped” gates, epitaxially grown conductive regions, epitaxially grown high mobility semiconductor materials, high-permittivity ridge isolation material, and narrowed base regions can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

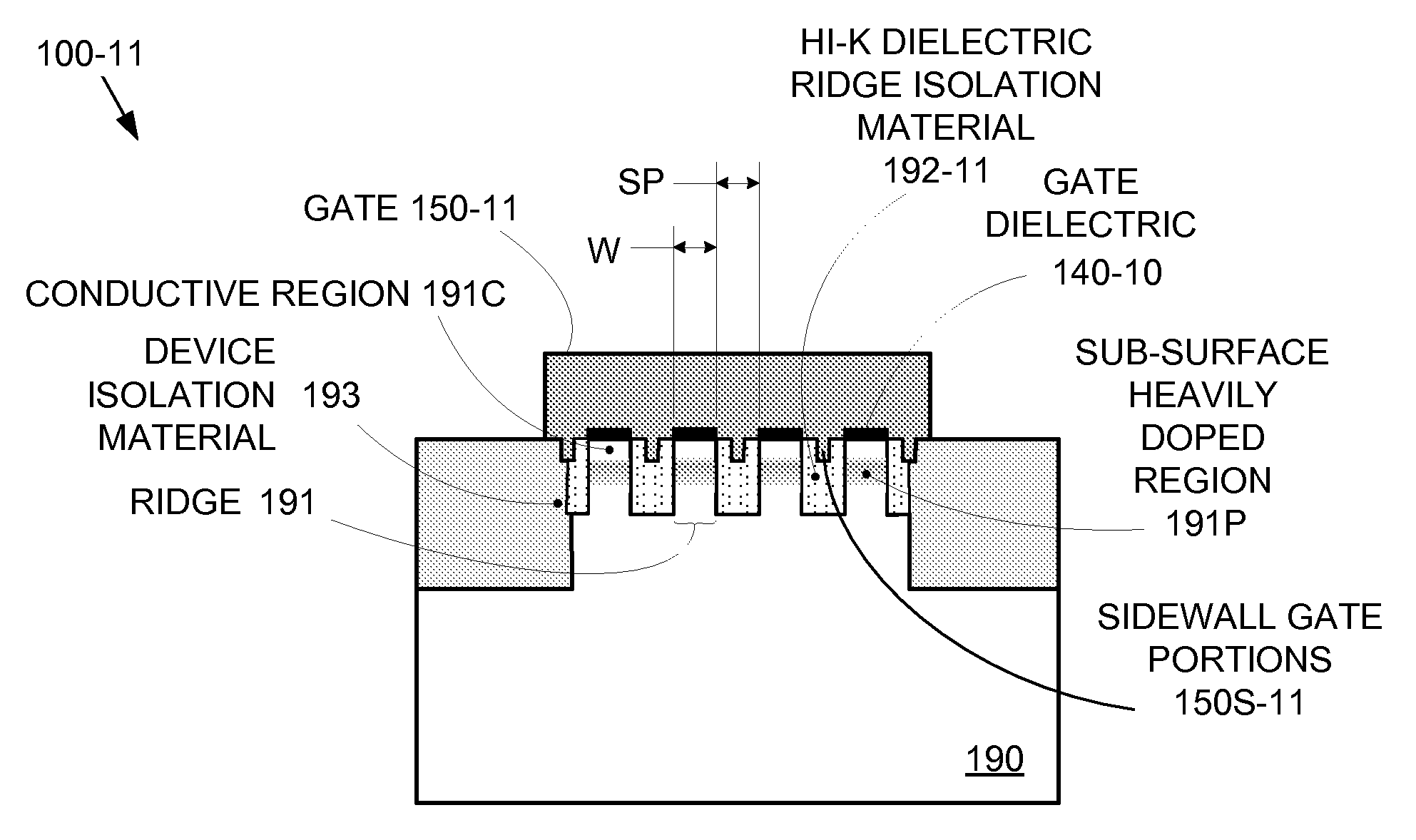

Enhanced segmented channel MOS transistor with high-permittivity dielectric isolation material

ActiveUS7605449B2Improve performance consistencyImprove performanceTransistorSolid-state devicesMOSFETPerformance enhancement

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping, “wrapped” gates, epitaxially grown conductive regions, epitaxially grown high mobility semiconductor materials (e.g. silicon-germanium, germanium, gallium arsenide, etc.), high-permittivity ridge isolation material, and narrowed base regions can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

Integrated Circuit On Corrugated Substrate

ActiveUS20070132053A1Improve performance consistencyImprove performanceTransistorSemiconductor/solid-state device detailsMOSFETSemiconductor materials

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping and “wrapped” gates can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

Closure device

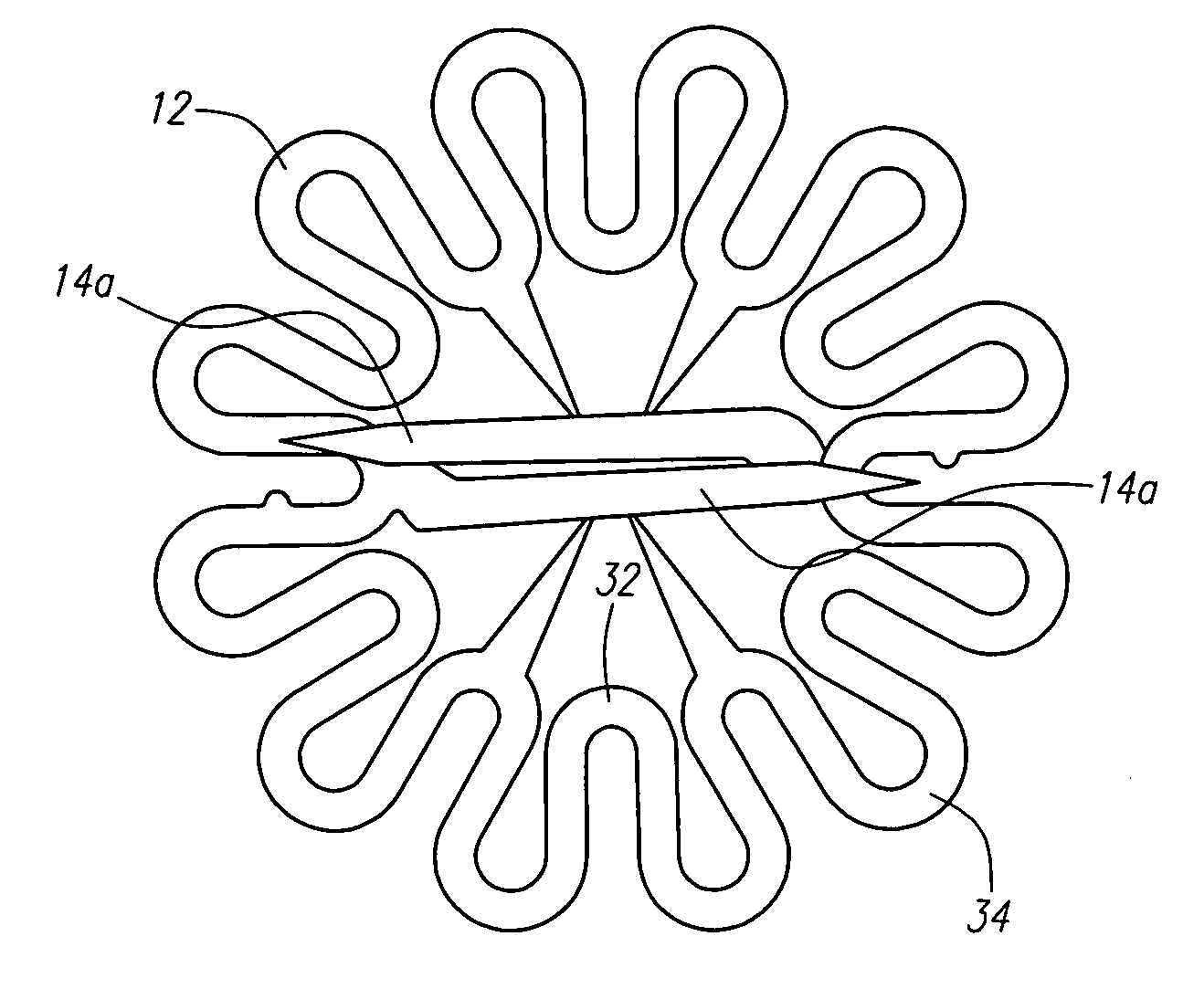

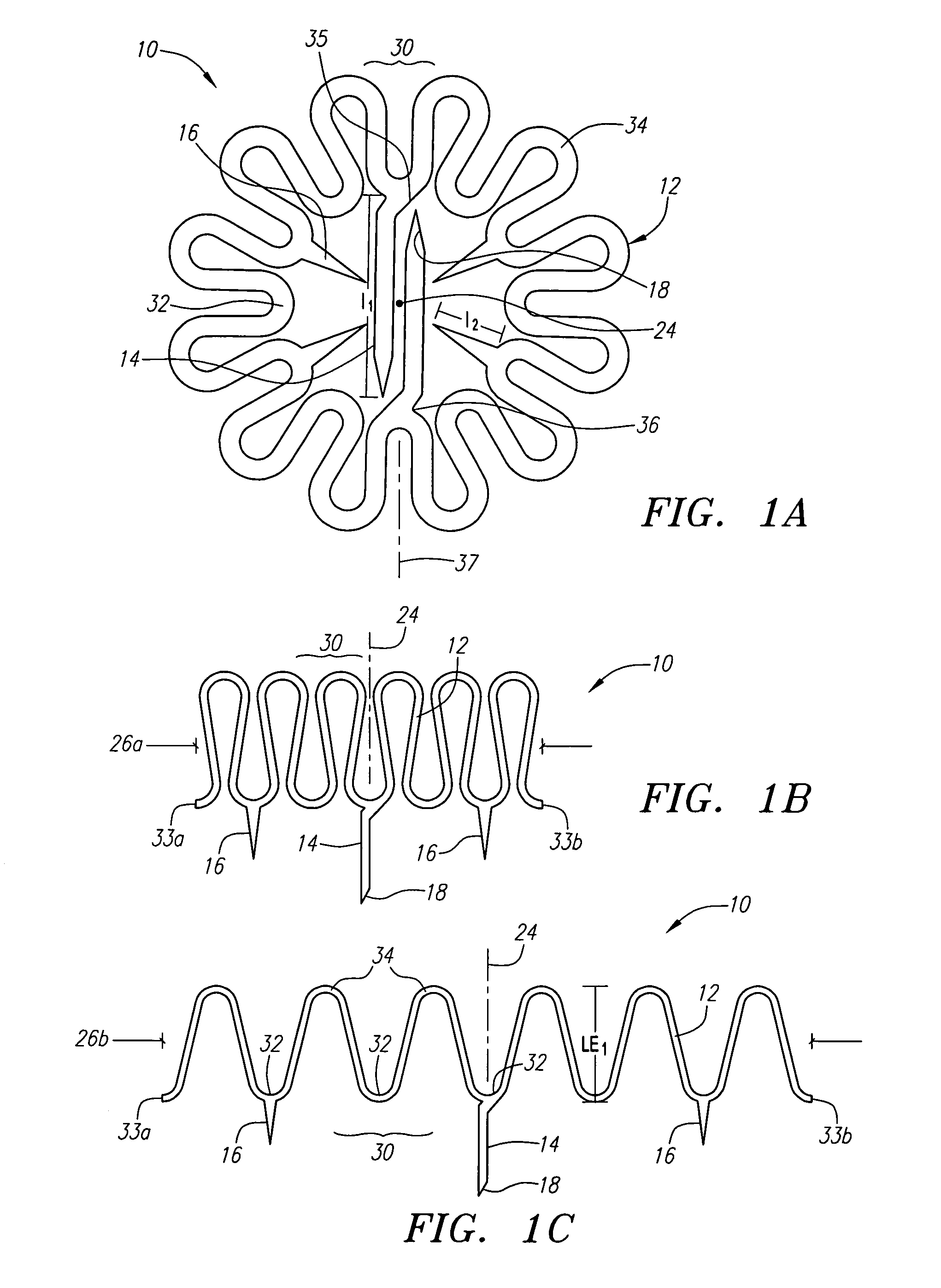

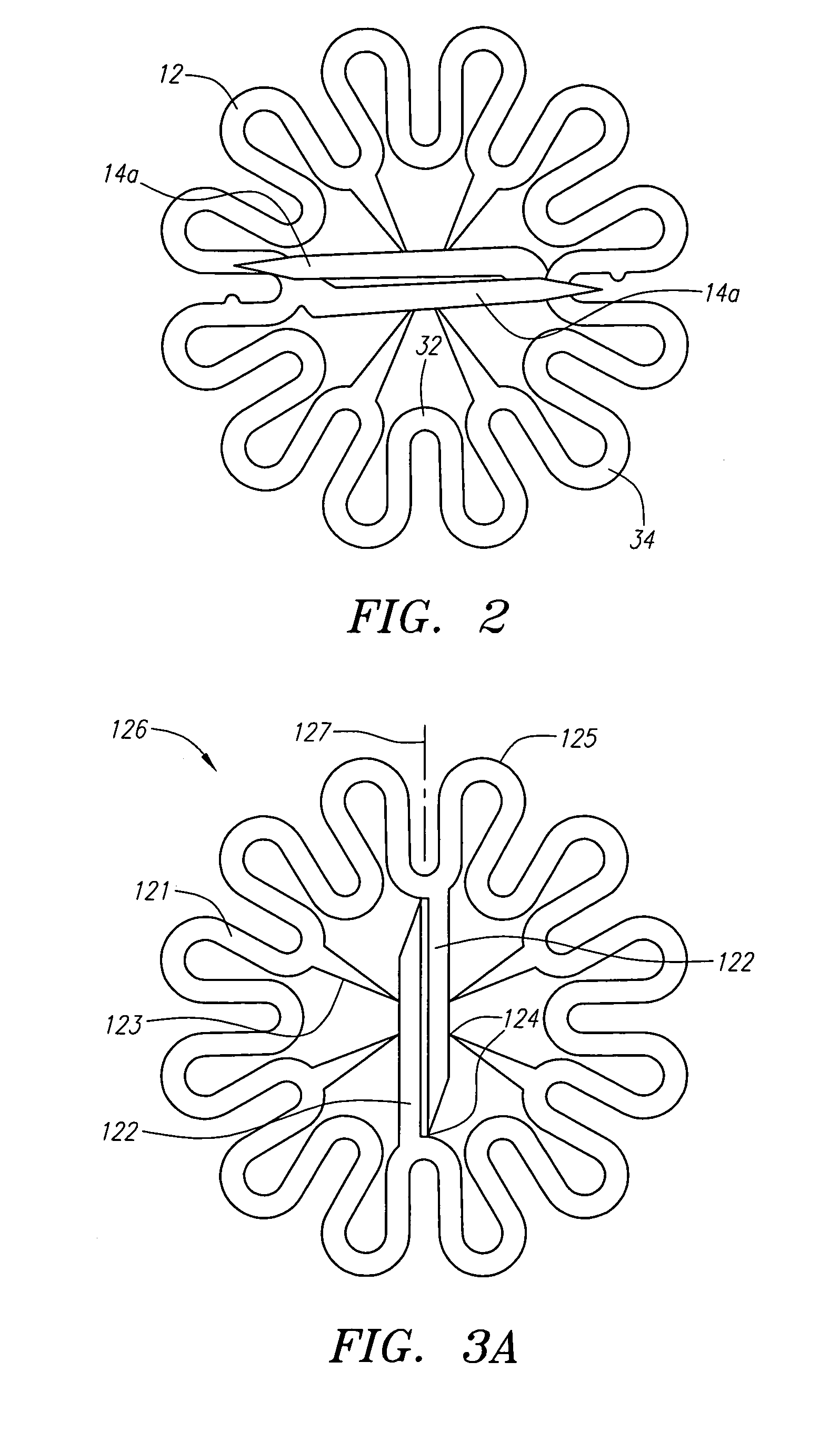

InactiveUS7806904B2Improve deformationStress minimizationDiagnostic markersStaplesLinear regionAxis of symmetry

A clip for engaging tissue includes a generally annular-shaped body defining a plane and disposed about a central axis extending normal to the plane. The body includes alternating inner and outer curved regions, defining a zigzag pattern about a periphery of the clip. The body is biased towards a planar configuration lying in the plane and deflectable towards a transverse configuration extending out of the plane. Tines extend from the inner curved regions, the tines being oriented towards the central axis in the planar configuration, and parallel to the central axis in the transverse configuration. The tines include primary tines and secondary tines that are shorter than the primary tines. The primary tines may be disposed on opposing inner curved regions and oriented towards one another. The primary tines are configured such that they are offset from the axes of symmetry of the curved regions from which they extend and are connected to the curved regions by curved or linear regions or are connected directly to the curved regions. The primary tines may overlap the body and may be of different lengths.

Owner:INTEGRATED VASCULAR SYST

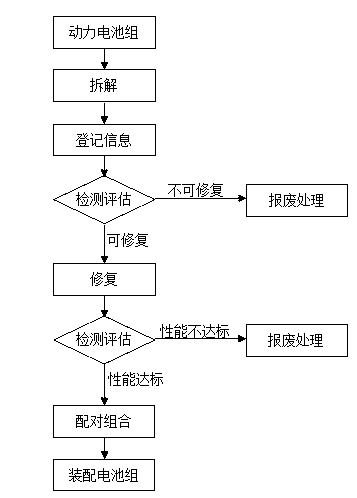

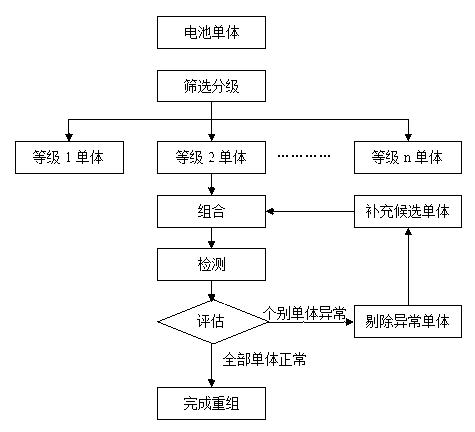

Waste energy echelon utilization method of power battery for electric vehicle

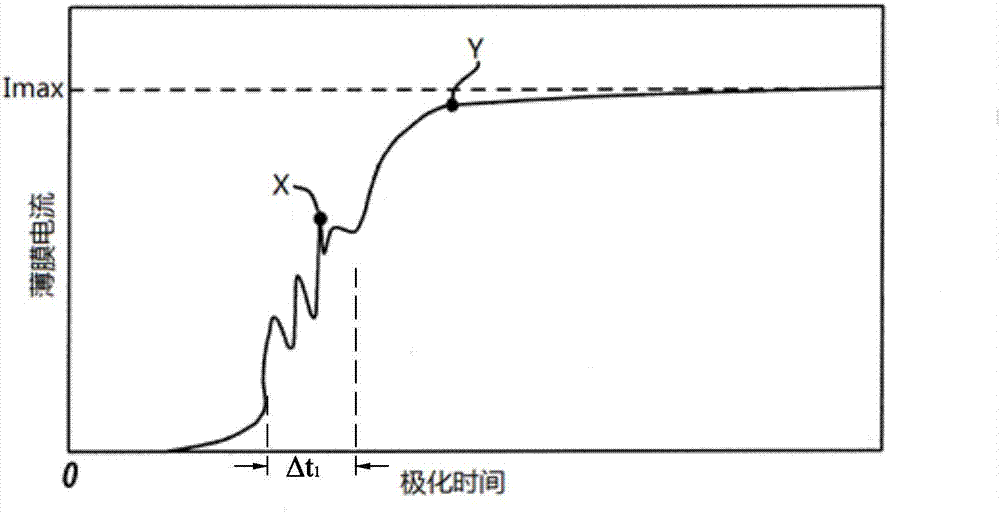

ActiveCN103138019AGood performance consistencyEasy to operateWaste accumulators reclaimingSecondary cells servicing/maintenancePower batteryElectrical battery

The invention discloses a waste energy echelon utilization method of a power battery for an electric vehicle. The waste energy echelon utilization method of the power battery for the electric vehicle comprises the following steps: firstly, a waste power battery set is disassembled; secondly, performance detection is conducted on battery monomers without damaged appearance to screen out battery monomers capable of being directly used and ensure that a fifth step is accessed, the battery monomers capable of being repaired and reused are screened out, and processed in a third step, and unrepairable battery monomers are processed in a discarded mode; thirdly, the battery monomers capable of being repaired and reused are repaired; fourthly, performance detection is conducted on repaired battery monomers to screen out battery monomers with the difference of nominal voltage and virtual voltage not larger than 0.02V and the virtual capacity not lower than 70% of nominal capacity, the battery monomers with the difference of the nominal voltage and the virtual voltage not larger than 0.02V and the virtual capacity not lower than 70% of the nominal capacity are processed according to the next step, and the repaired battery monomers not capable of reaching the standards are processed in a discarded mode; and fifthly, a new power battery set is assembled. Because waste capacity of a monomer battery of the power battery is reasonably utilized, and is recombined to a new power battery applied to different occasions, the waste energy echelon utilization method of the power battery for the electric vehicle not only satisfies requirements of using occasions, but also utilizes performance of the power batteries.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

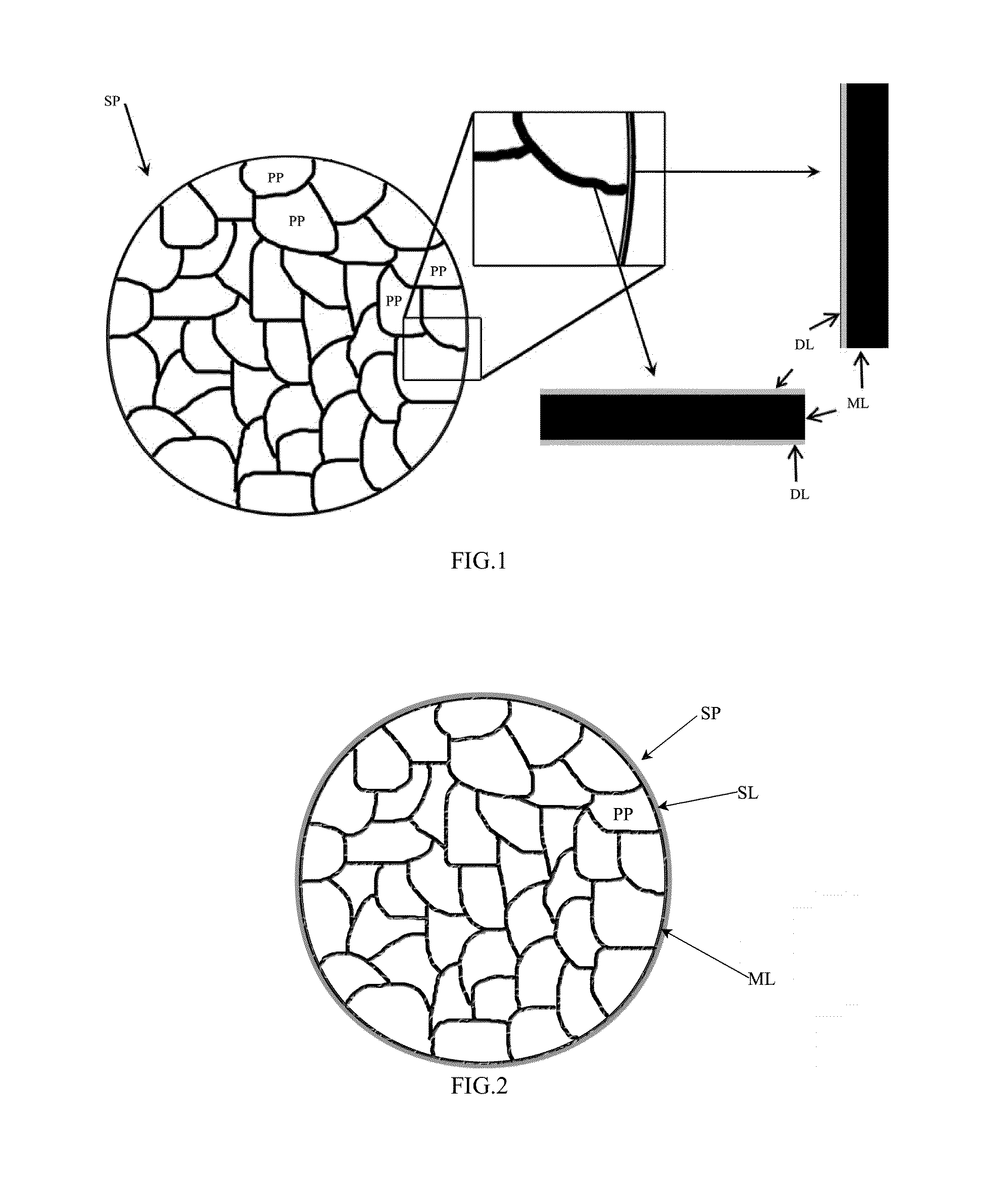

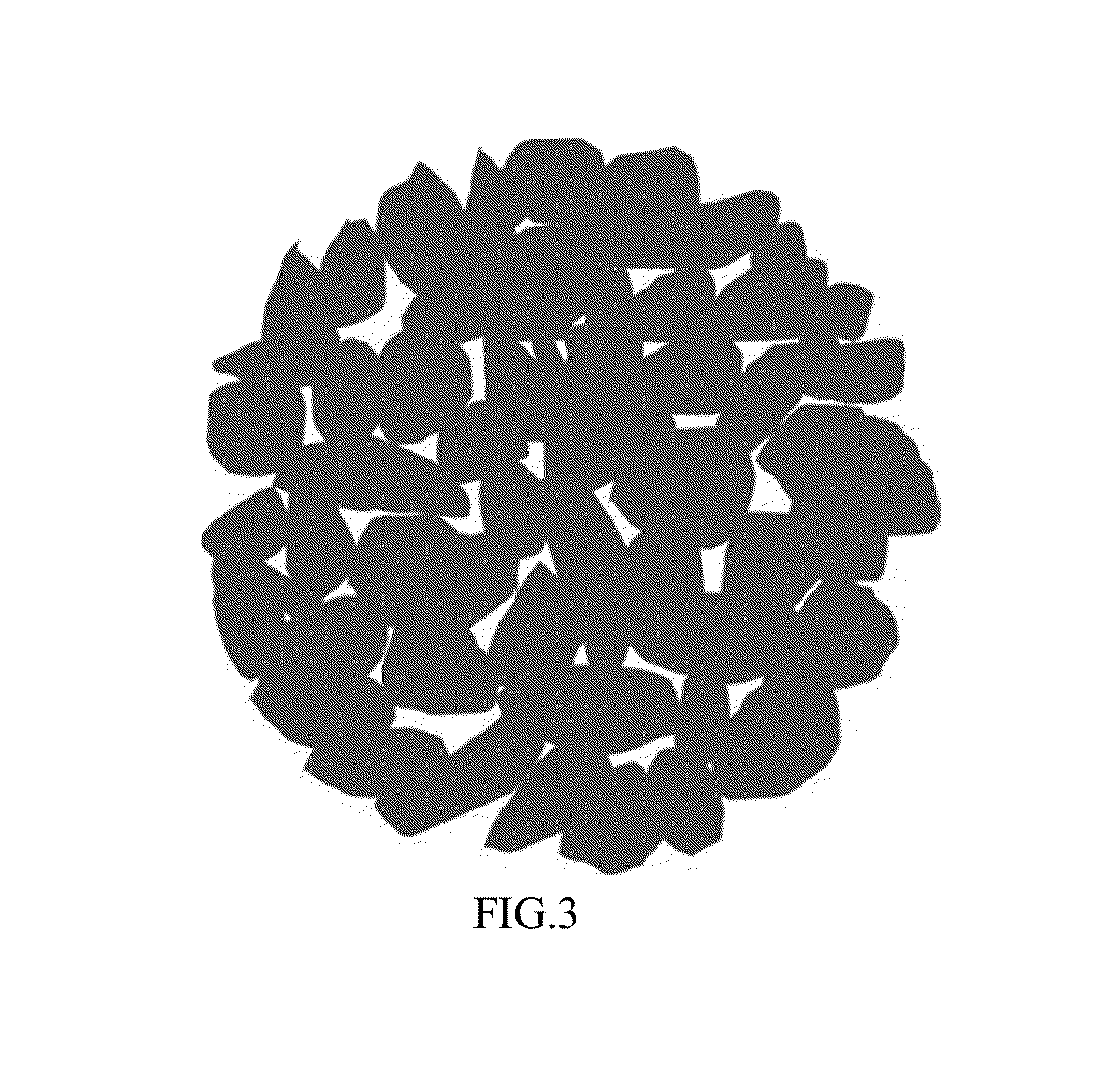

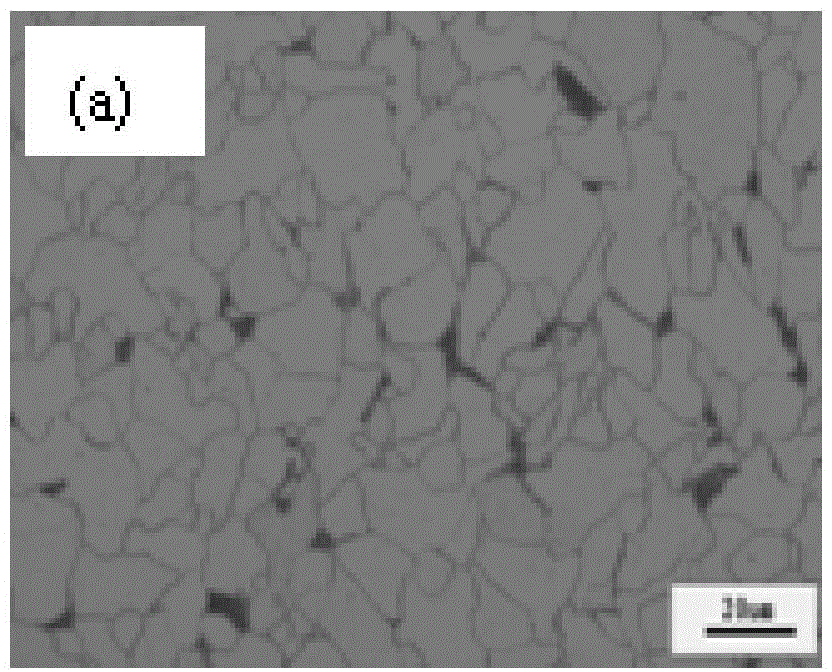

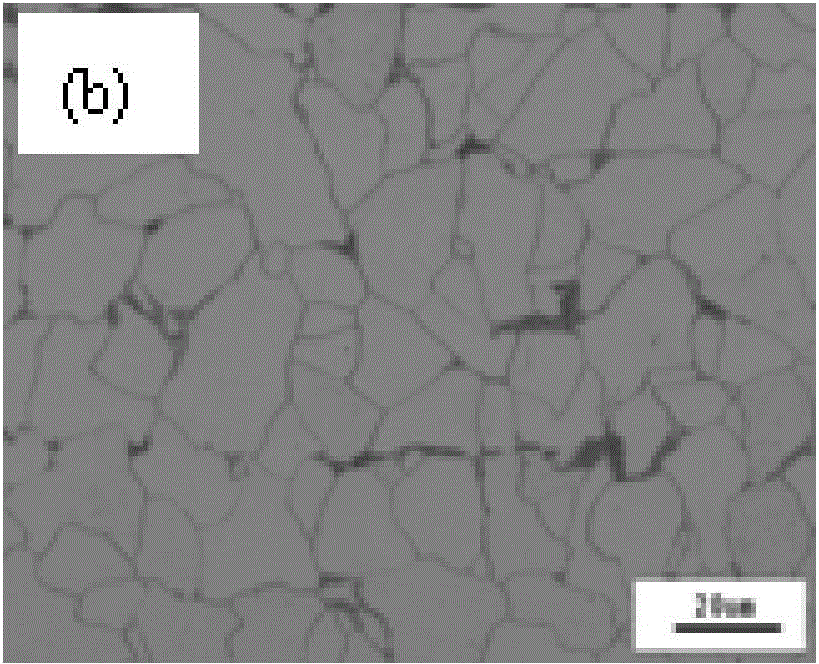

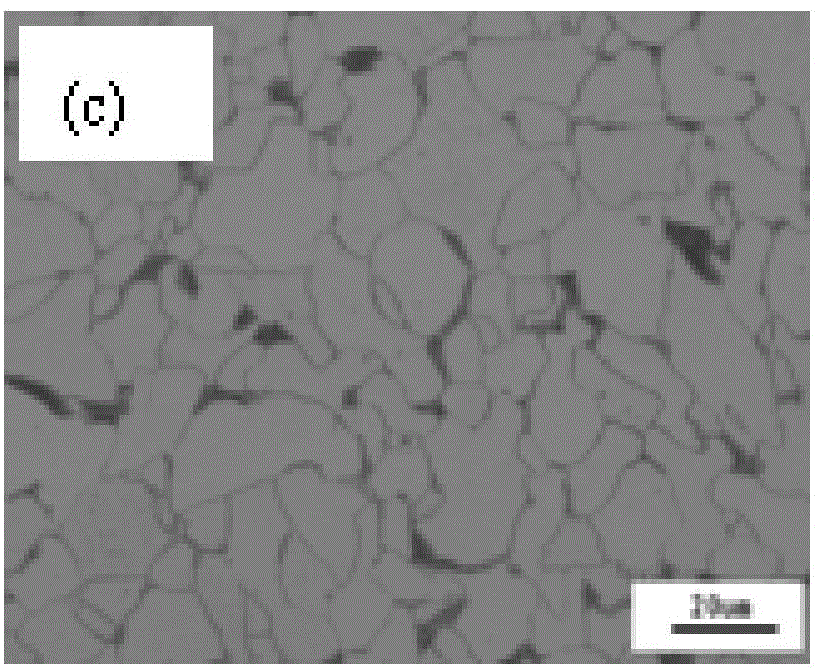

Lithium-ion battery positive electrode material and preparation method thereof

InactiveUS20150079471A1Good stretchabilityGood ductibilitySilver accumulatorsPositive electrodesLithium-ion batteryDiffusion layer

The present disclosure provides a lithium-ion battery positive electrode material and a preparation method thereof. In the lithium-ion battery positive electrode material, a secondary particle comprises lithium-containing multi-element transition metal oxide primary particles and a second phase material, a second phase material forms a second phase material layer distributed on a surface of the primary particle and forms a diffusion layer together with the lithium-containing multi-element transition metal oxide by means of atoms mutual diffusion to make the second phase material layer combined with the primary particle during formation of the secondary particle from the primary particles, thereby effectively suppressing chalking of the secondary particle along boundary among the primary particles, and effectively controlling size of the primary particles and the secondary particles, and improving specific capacity, cycling performance and safety performance of a lithium-ion battery to which the lithium-ion battery positive electrode material is applied.

Owner:NINGDE AMPEREX TECH +1

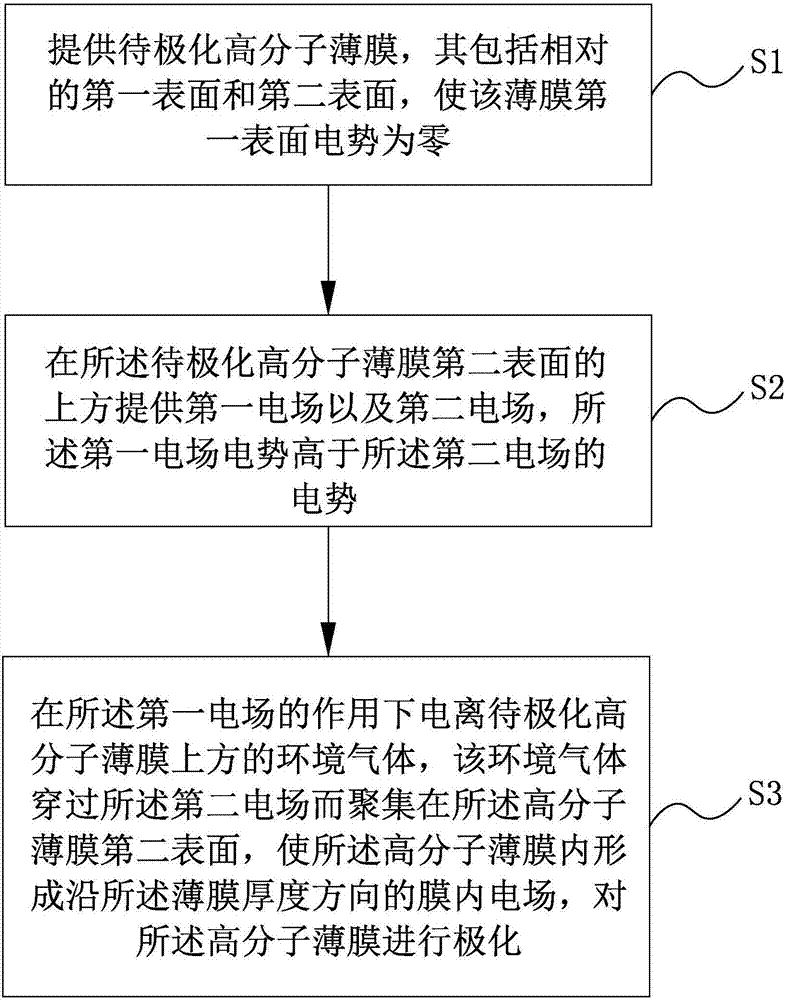

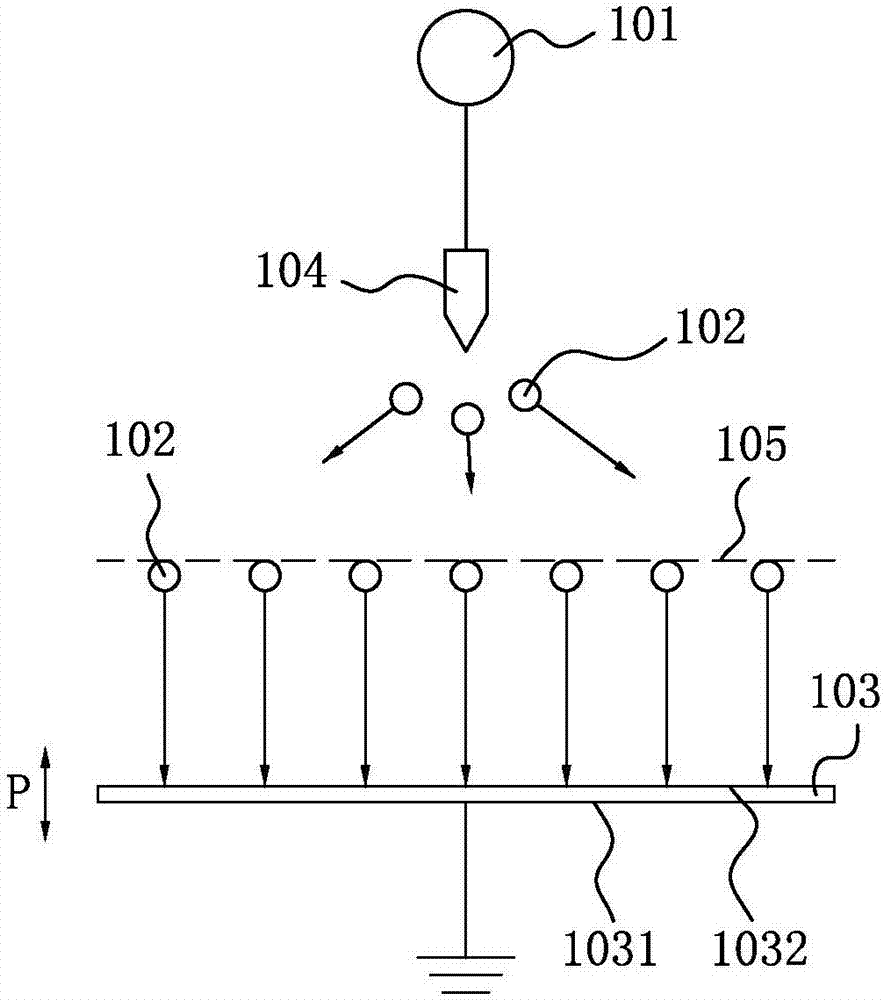

Polymeric thin film polarization method, polarizing film and electronic device

ActiveCN107104179APrevent breakdownImprove production pass ratePiezoelectric/electrostrictive devicesProduction rateElectricity

A method for polarizing a polymer film is disclosed. An ambient gas above a polymer film under the action of a first electric field is ionized, the ambient gas accumulates on the second surface of the polymer film through the second electric field, an organic electric field in the film thickness direction is formed in the molecular thin film, and the polymer film is polarized. The polymer film polarization method can avoid the breakdown of the polymer film, effectively improve the production rate of the polarized film, can achieve large-scale production; and the resulting polarized film has a strong piezoelectric effect and longer Service life. The present invention also provides a polarizing film prepared by the above-described method of polymer film polarization, which has a strong piezoelectric effect and a long service life. The present invention also provides an electronic device comprising a substrate and a polarizing film as described above.

Owner:科锐昇微系统(苏州)有限公司

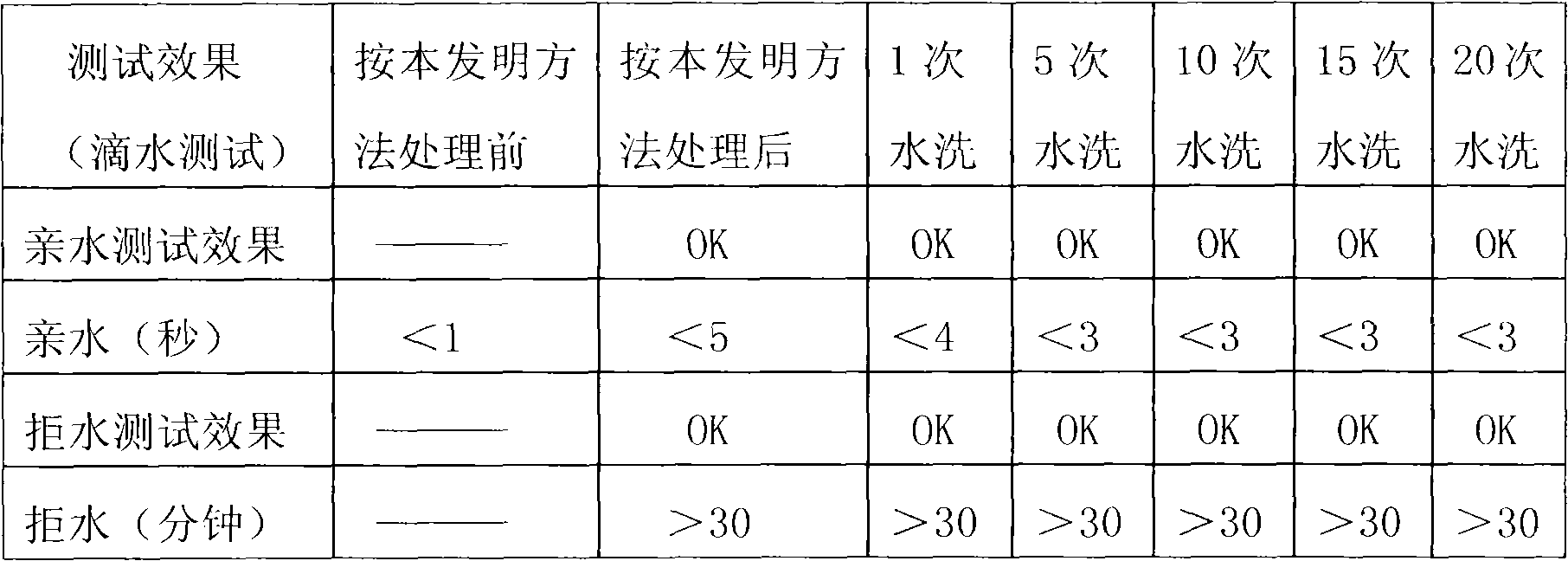

Processing method of one-way moisture-guiding fabric

InactiveCN101845702ASimple fabric specification requirementsGood one-way moisture transfer effectWeft knittingWarp knittingYarnEngineering

The invention relates to a processing method of one-way moisture-guiding fabric, which comprises the following basic steps of: preparing gray fabric; singeing; blanching; presetting; mercerizing; whitening / dying / printing; forming or drying; carrying out single-face finishing; carrying out hydrophilic finishing; washing with water; and forming. In the method, the single-face finishing is carried out by adopting a circular screen decorating machine or a flat screen decorating machine, and padding finishing liquor can be carried out by adopting an open-width pad dyeing machine or a boarding machine. The gray fabric of the one-way moisture-guiding fabric manufactured in the method can be formed by various common clothes fiber. Compared with other processing technology, the method for processing the one-way moisture-guiding fabric has simple requirement on fiber, yarns and fabric and is suitable for most shell fabrics. The one-way moisture-guiding fabric has obvious moisture-guiding effect, is produced stably and has good consistence of performance. When a person wears clothes made of the one-way moisture-guiding fabric in sports, sweat on the skin surface inside the clothes can be guided to the outer surface of the clothes through the shell fabric and is continuously evaporated, thereby the degree of sticking the body of the shell fabric is reduced, and the wearing comfort is effectively improved.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

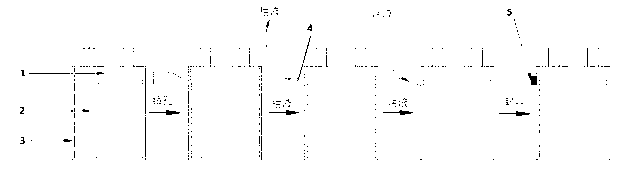

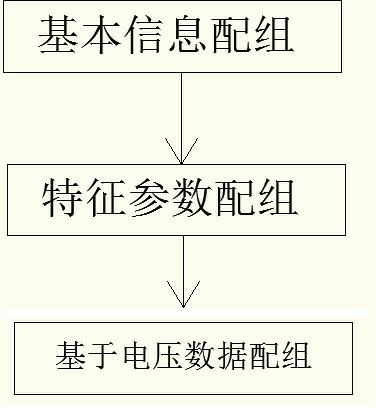

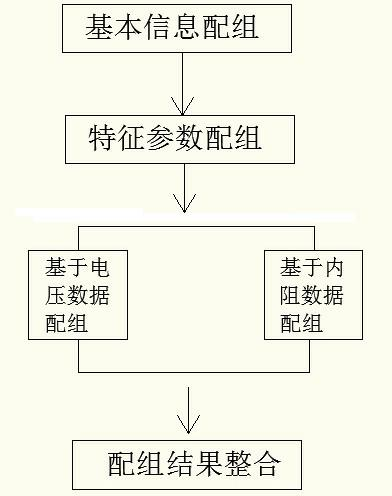

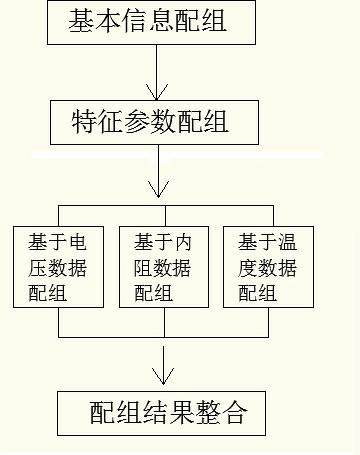

Cluster analysis based lithium battery unit matching method

ActiveCN102544606AExtended service lifeReduce the probability of performance mutationSecondary cells servicing/maintenanceSpecial data processing applicationsNameplate capacityInternal resistance

The invention relates to a cluster analysis based lithium battery unit matching method which comprises the following steps of: (1) classifying battery units according to the types and the rated capacities of batteries, dividing the batteries with the same type and rated capacity in a group, and then furthering matching all battery unit sets with more than one battery unit; (2) selecting more than one factor combination of health status, self-discharge rate, internal resistance, open-circuit voltage, charging efficiency and cycle index for matching the battery unit sets; and after classification, completing matching of all battery unit sets with more than one battery unit, or further matching. The cluster analysis based lithium battery unit matching method can be used for comprehensively estimating all factors influencing the performance of the batteries, thus improving the consistency of the initial performance of the batteries; abd meanwhile, the probability of battery performance mutation in the using process of the batteries can be effectively reduced, the service efficiency of the battery units can be improved, and the service life of groups of battery units can be prolonged.

Owner:HANGZHOU GOLD ELECTRONICS EQUIP CO LTD

Electromechanical transducer and method of manufacturing the same

InactiveUS20120091543A1High normal stiffnessImprove consistencySemiconductor/solid-state device manufacturingMechanical vibrations separationElectrical conductorSemiconductor

An electromechanical transducer includes multiple elements each including at least one cellular structure, the cellular structure including: a semiconductor substrate, a semiconductor diaphragm, and a supporting portion for supporting the diaphragm so that a gap is formed between one surface of the substrate and the diaphragm. The elements are separated from one another at separating locations of a semiconductor film including the diaphragm. Each of the elements includes in a through hole passing through a first insulating layer including the supporting portion and the semiconductor substrate: a conductor which is connected to the semiconductor film including the diaphragm; and a second insulating layer for insulating the conductor from the semiconductor substrate.

Owner:CANON KK

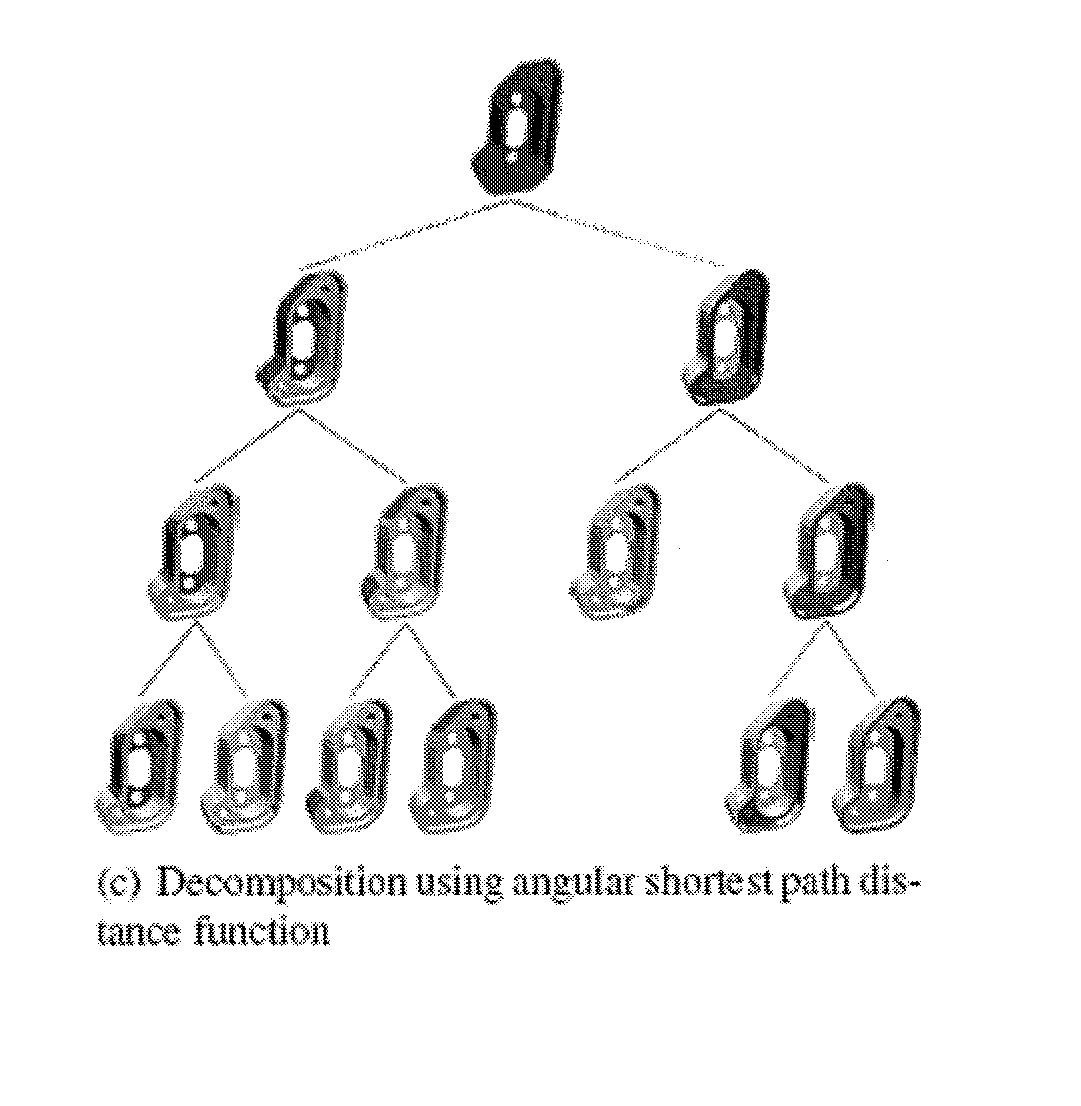

Multi-scale segmentation and partial matching 3D models

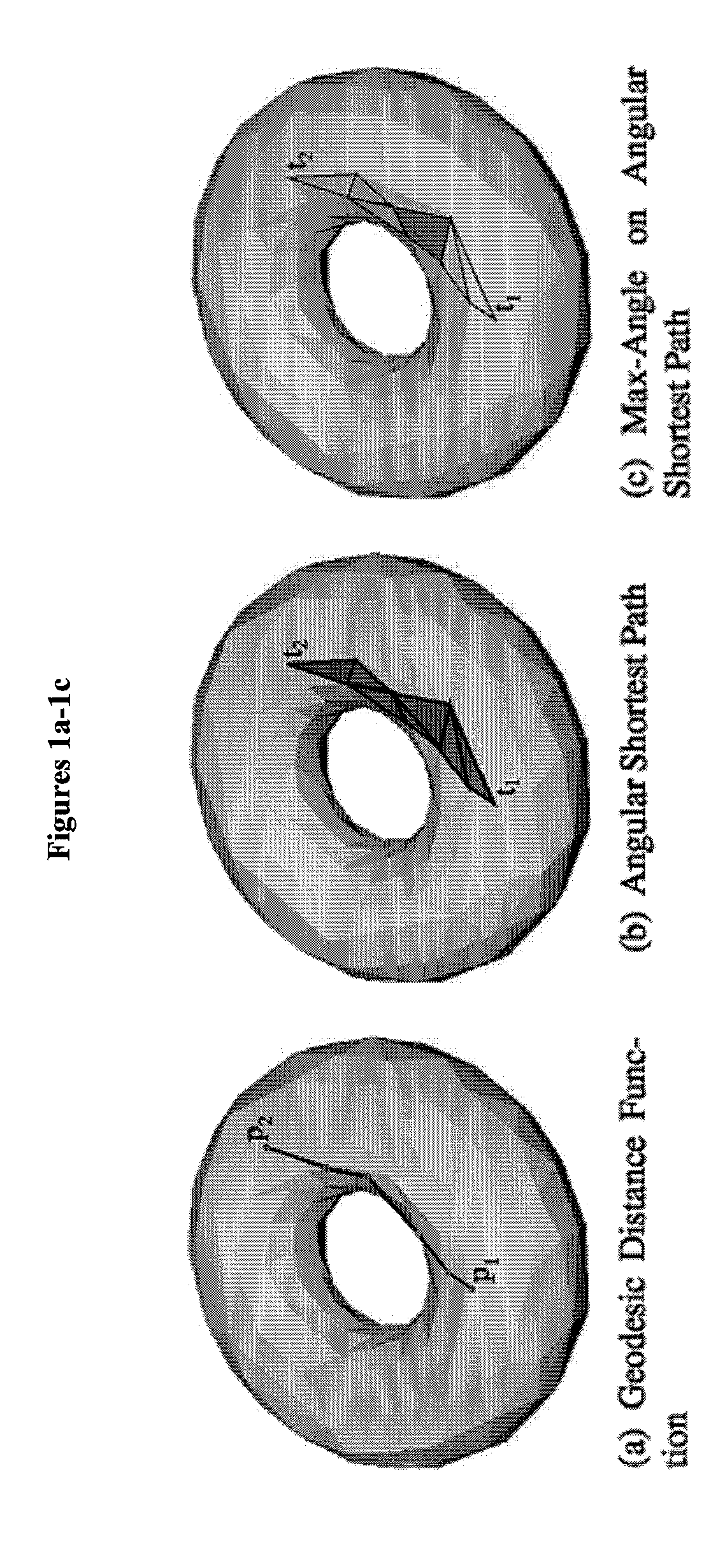

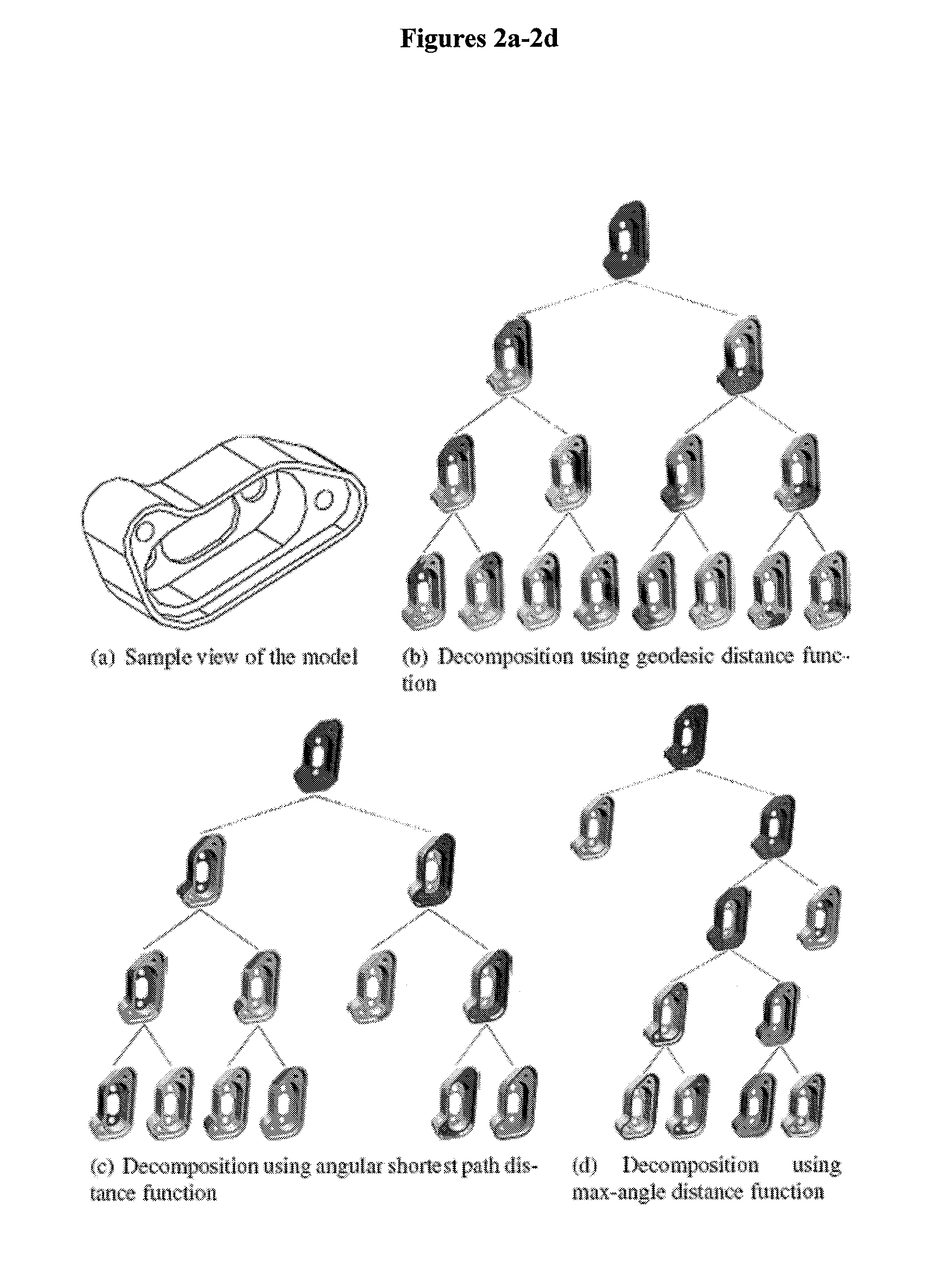

ActiveUS20080215510A1Improve performance consistencyConsistency in its performanceDigital data information retrievalDigital computer detailsViewpointsDecomposition

A scale-Space feature extraction technique is based on recursive decomposition of polyhedral surfaces into surface patches. The experimental results show that this technique can be used to perform matching based on local model structure. Scale-space techniques can be parameterized to generate decompositions that correspond to manufacturing, assembly or surface features relevant to mechanical design. One application of these techniques is to support matching and content-based retrieval of solid models. Scale-space technique can extract features that are invariant with respect to the global structure of the model as well as small perturbations that 3D laser scanning may introduce. A new distance function defined on triangles instead of points is introduced. This technique offers a new way to control the feature decomposition process, which results in extraction of features that are more meaningful from an engineering viewpoint. The technique is computationally practical for use in indexing large models.

Owner:DREXEL UNIV

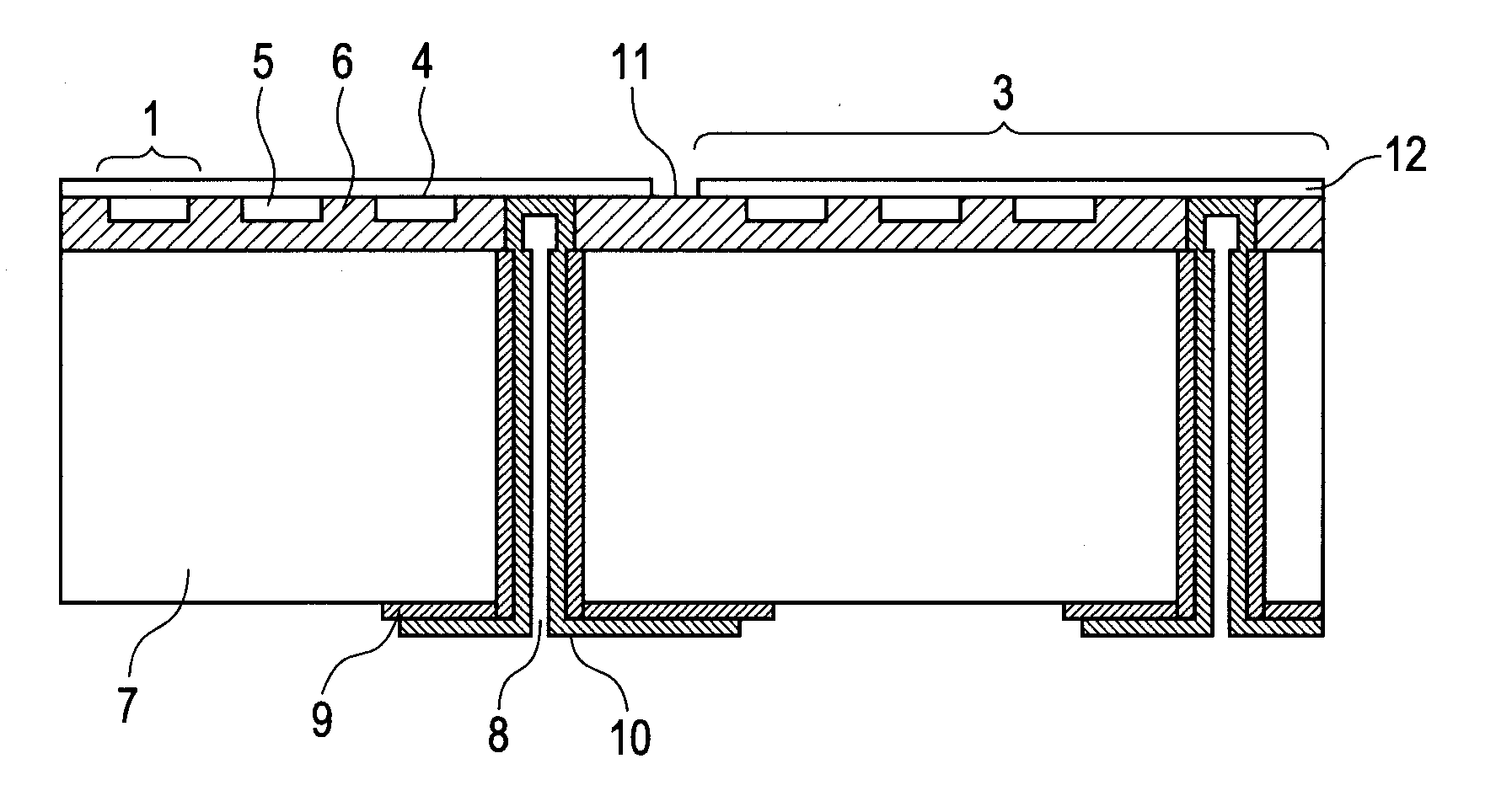

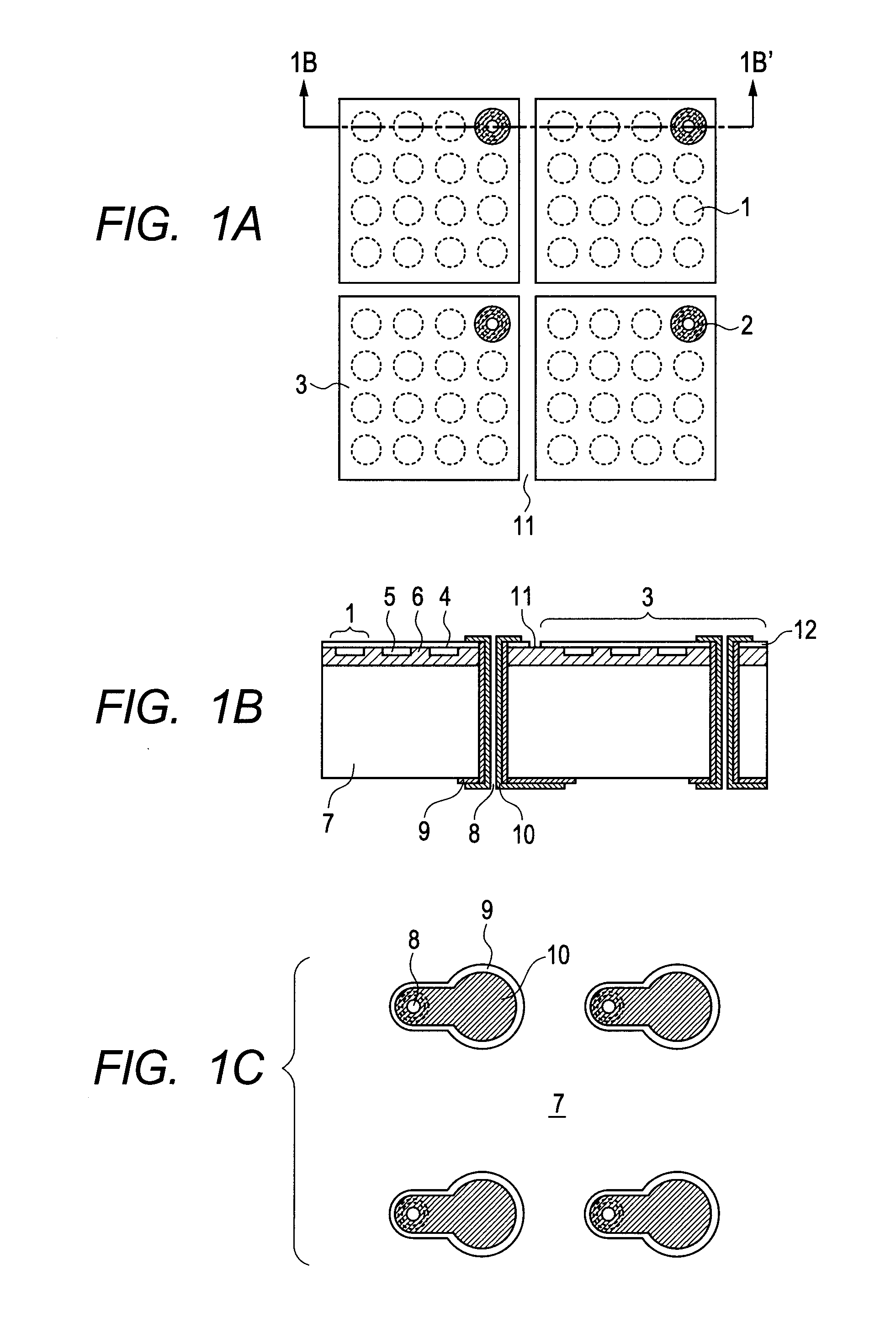

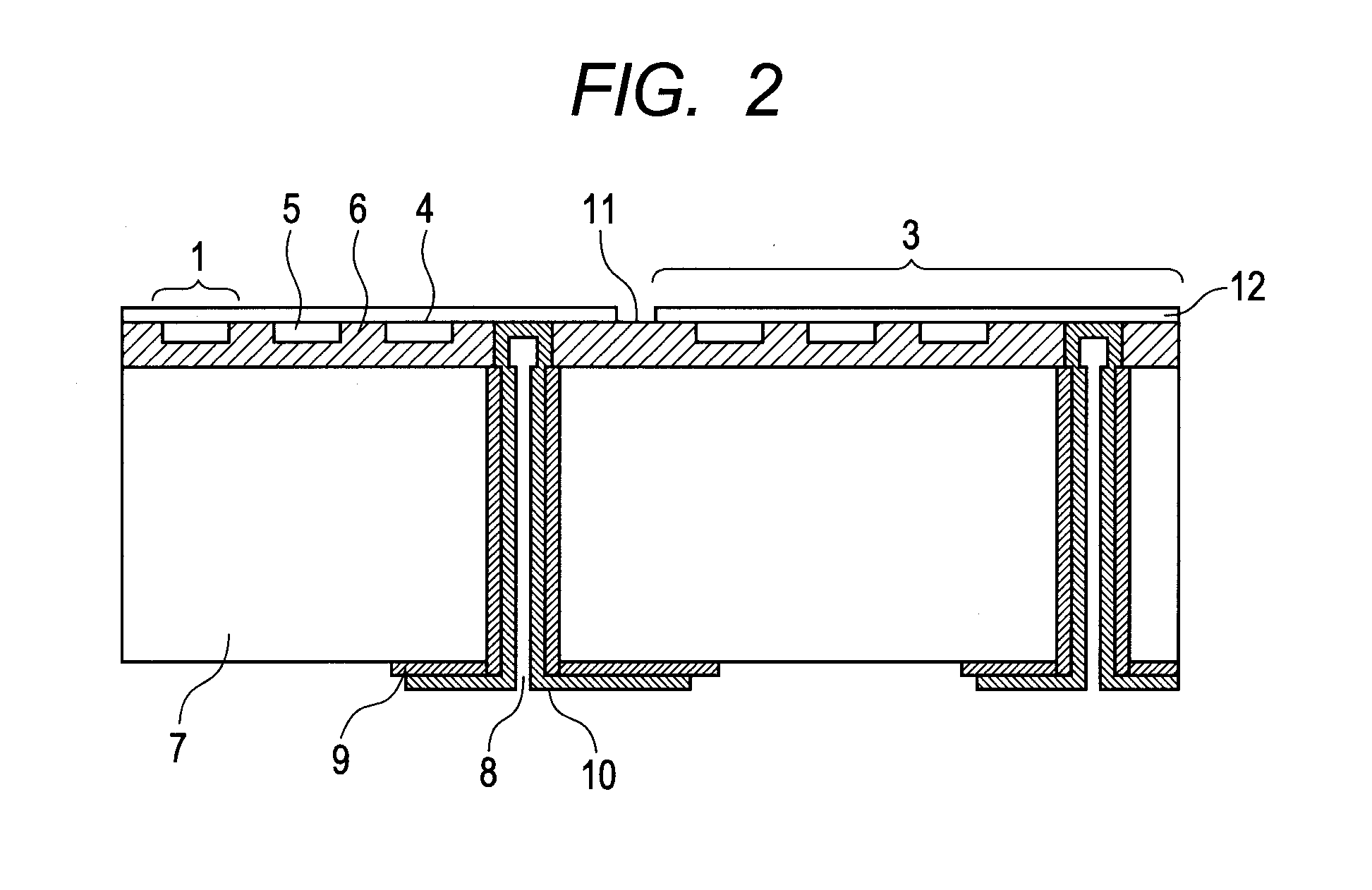

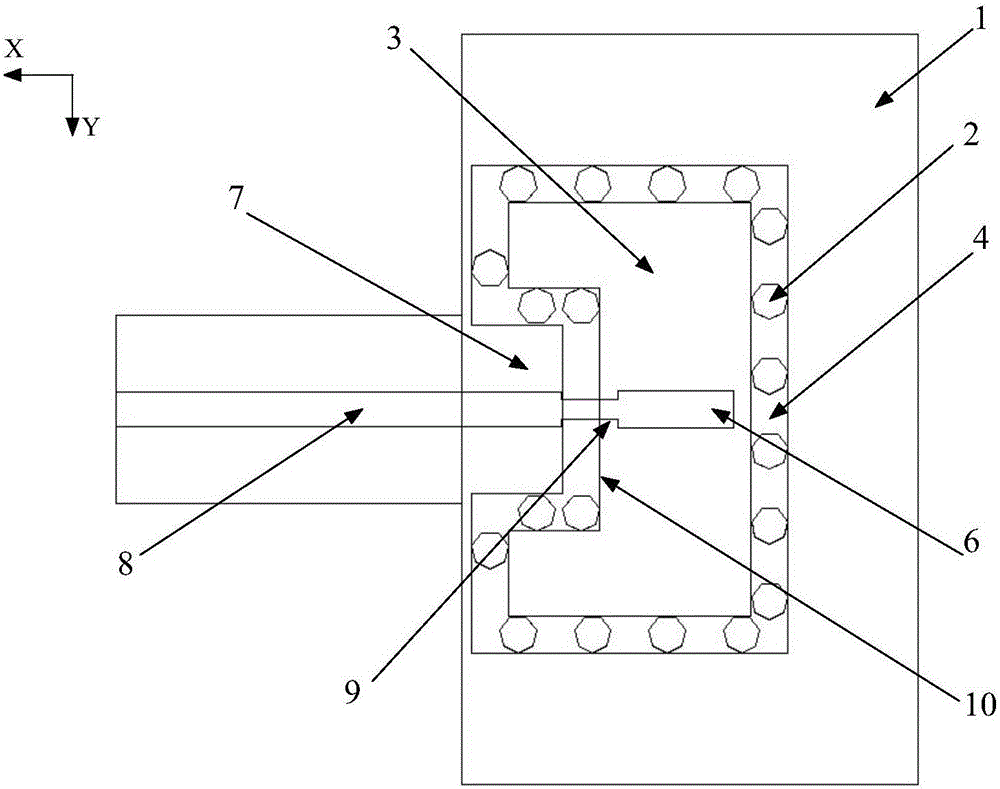

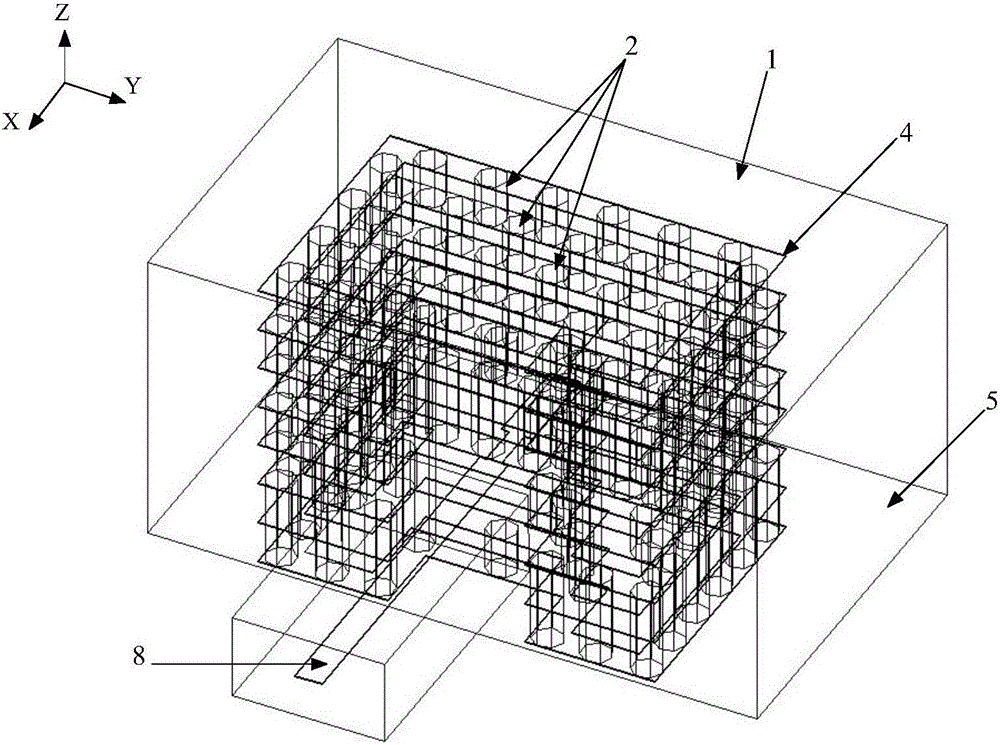

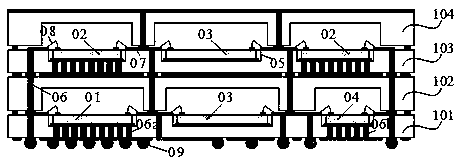

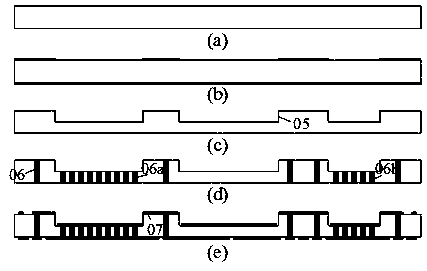

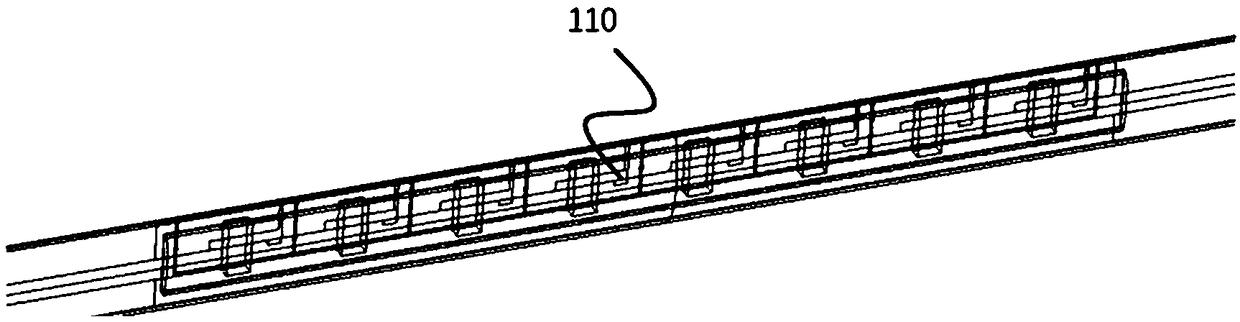

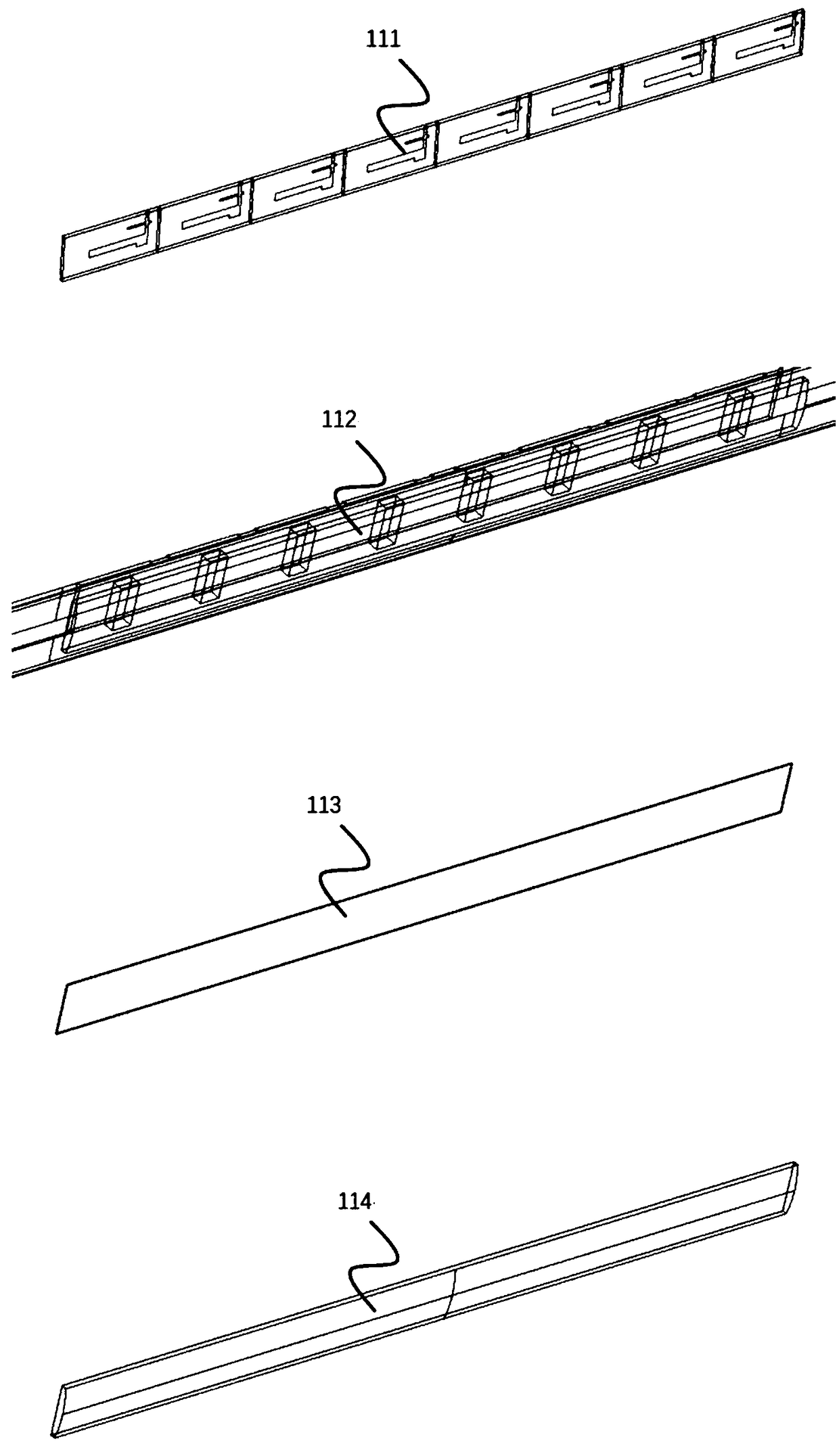

Inter-board perpendicular interconnection circuit structure for substrate integrated ridge waveguide

The invention provides an inter-board perpendicular interconnection circuit structure for a substrate integrated ridge waveguide (SIRW), and aims to provide a millimeter wave inter-board perpendicular interconnection circuit structure with small volume, easy integration, high interconnection property and long-term reliability. The inter-board perpendicular interconnection circuit structure is implemented by the following technical scheme: the SIRW (3) perpendicular to the surface of a base board is integrated on an LTCC multilayered circuit board (1); a substrate integrated ridge waveguide opening is etched in a corresponding outlet in the metal ground on the surface of the LTCC multilayered circuit board (1); Z-direction metalized filling holes (2) are arranged to form a metal hole gate array to equivalently form the waveguide wall and single-side ridges in the waveguide; metallic shield holes and probe restraining cavities (7) on the two sides of a 50-ohm strip line (8) are arranged at the equal spacing; and the alignment pressing and connection of the SIRW interfaces on the opposite sides between two boards is realized through pin hole alignment, so that the perpendicular interconnection transition of the millimeter wave signal between two boards in a way of 50-ohm strip line-SIRW-SIRW-50-ohm strip line is realized consequently.

Owner:10TH RES INST OF CETC

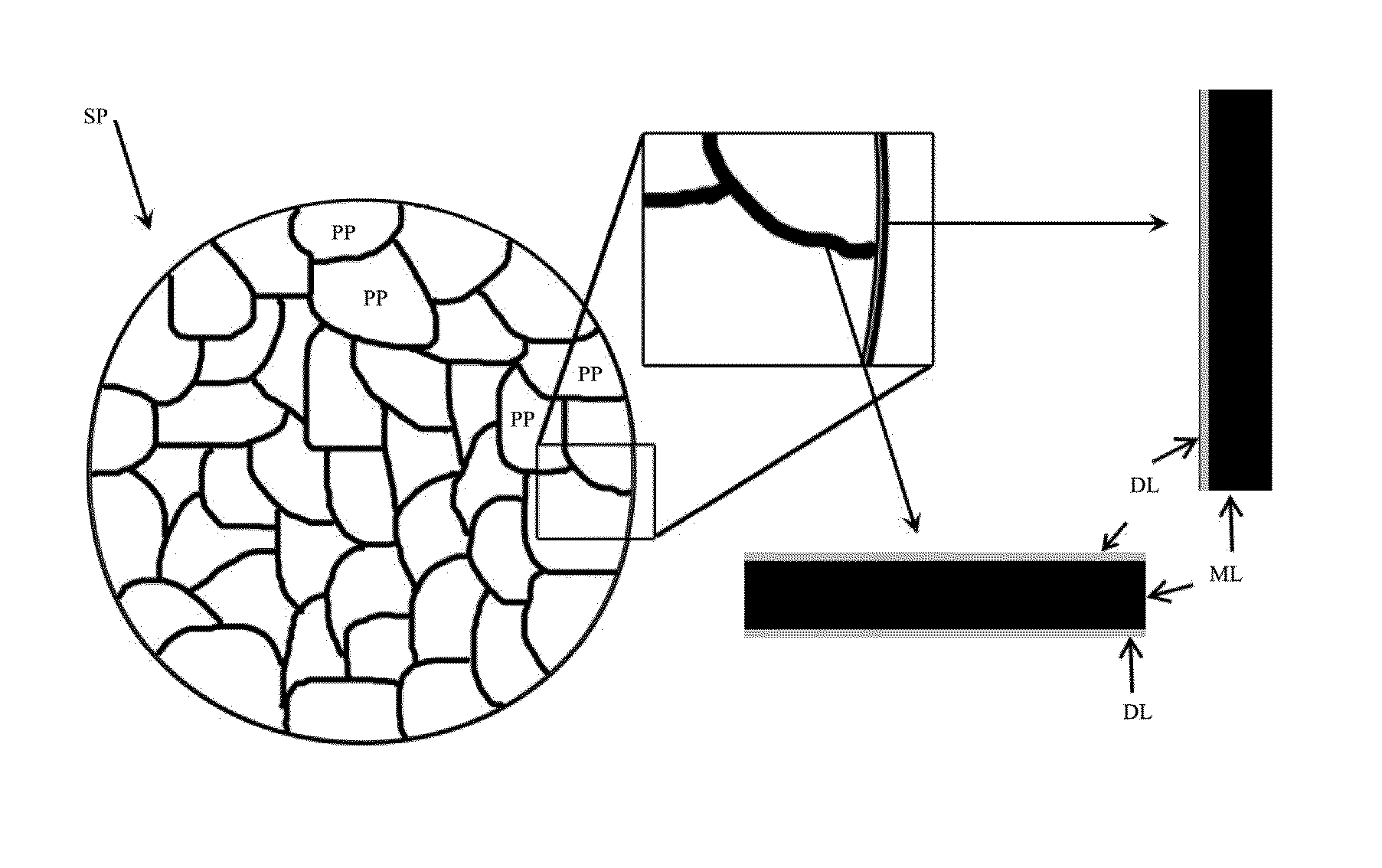

Sequential selective epitaxial growth

ActiveUS7807523B2Improve performance consistencyImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingMOSFETCMOS

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. A multi step epitaxial process can be used to extend the ridges with different dopant types, high mobility semiconductor, and or advanced multi-layer strutures. For CMOS integrated circuits a capping layer is formed over the a first region. Epitaxial layers are formed in a second region. Then the capping layer is removed from the first region and a capping layer is formed over the second region. Epitaxial layers can than be formed in the first region.

Owner:SYNOPSYS INC

Method for processing double face fabric with single-side moisture transferring and cooling functions

ActiveCN102134777APrevent backflow of moistureModerate costFabric breaking/softeningWeft knittingSpecial effectsMoisture transfer

The invention relates to a method for processing a double face fabric with single-side moisture transferring and cooling functions, which is characterized in that the yarn for weaving the inner layer of the fabric is made of cool nylon fiber FLYCOOL, and the yarn for weaving the outer layer of the fabric is made of all common garment fiber. The method comprises the basic processing steps of gray fabric preparing, pretreating, dyeing or whitening, softening and thermosetting finishing. The fabric obtains the single-side moisture transfer property through thermosetting finishing. The fabric with single-side moisture transfer property has simple technological design, stability in production, easiness for operation, high working efficiency, large-scale production and an obvious single-side moisture transfer effect, the product has good performance uniformity, and the fabric shows a composite special effect function, i.e. the fabric shows a single-side moisture transfer and moisture absorption fast dry mechanism and a cooling function. The wearing comfortableness of sports wear is increased, and the sports wear is cool and comfortable to wear, has strong wearability and can especially meet the wearing requirement of people doing a large amount of exercises in summer.

Owner:QINGDAO JIFA GROUP

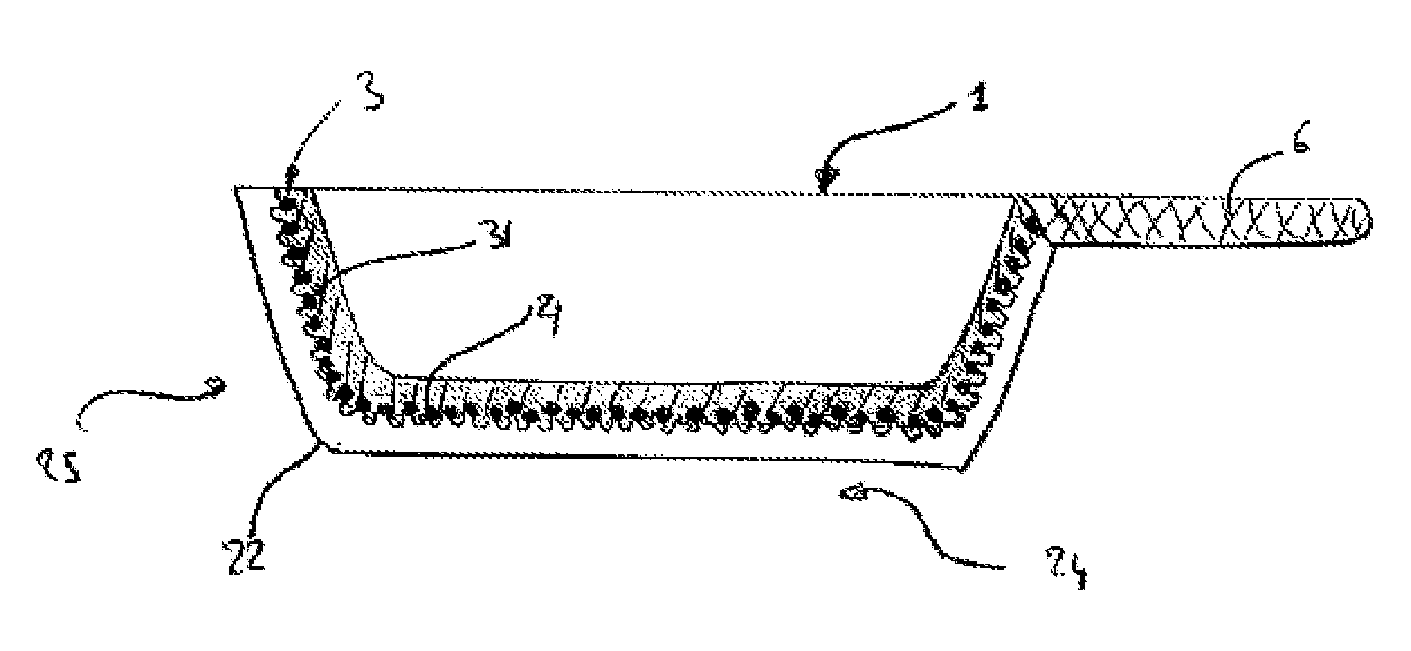

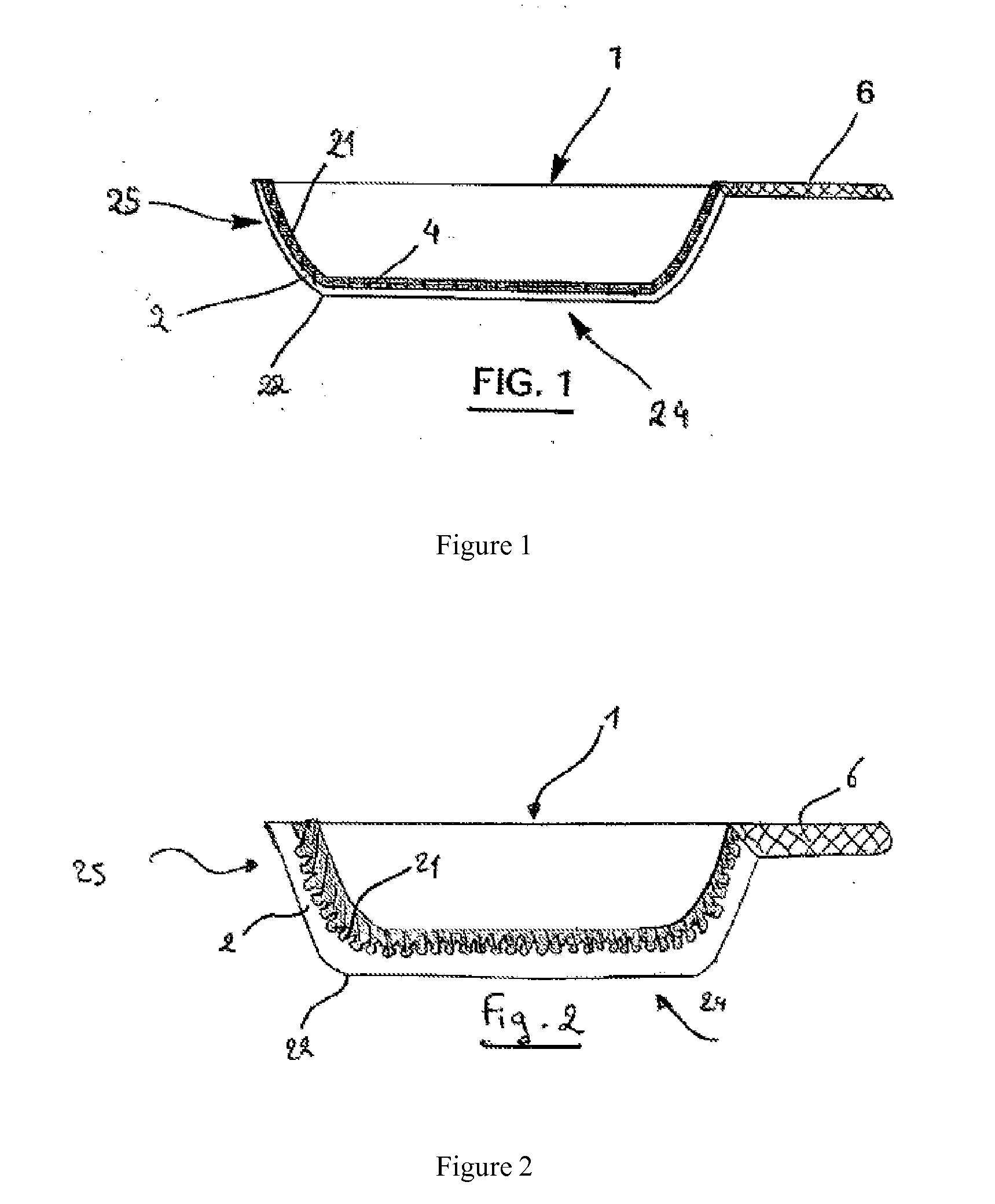

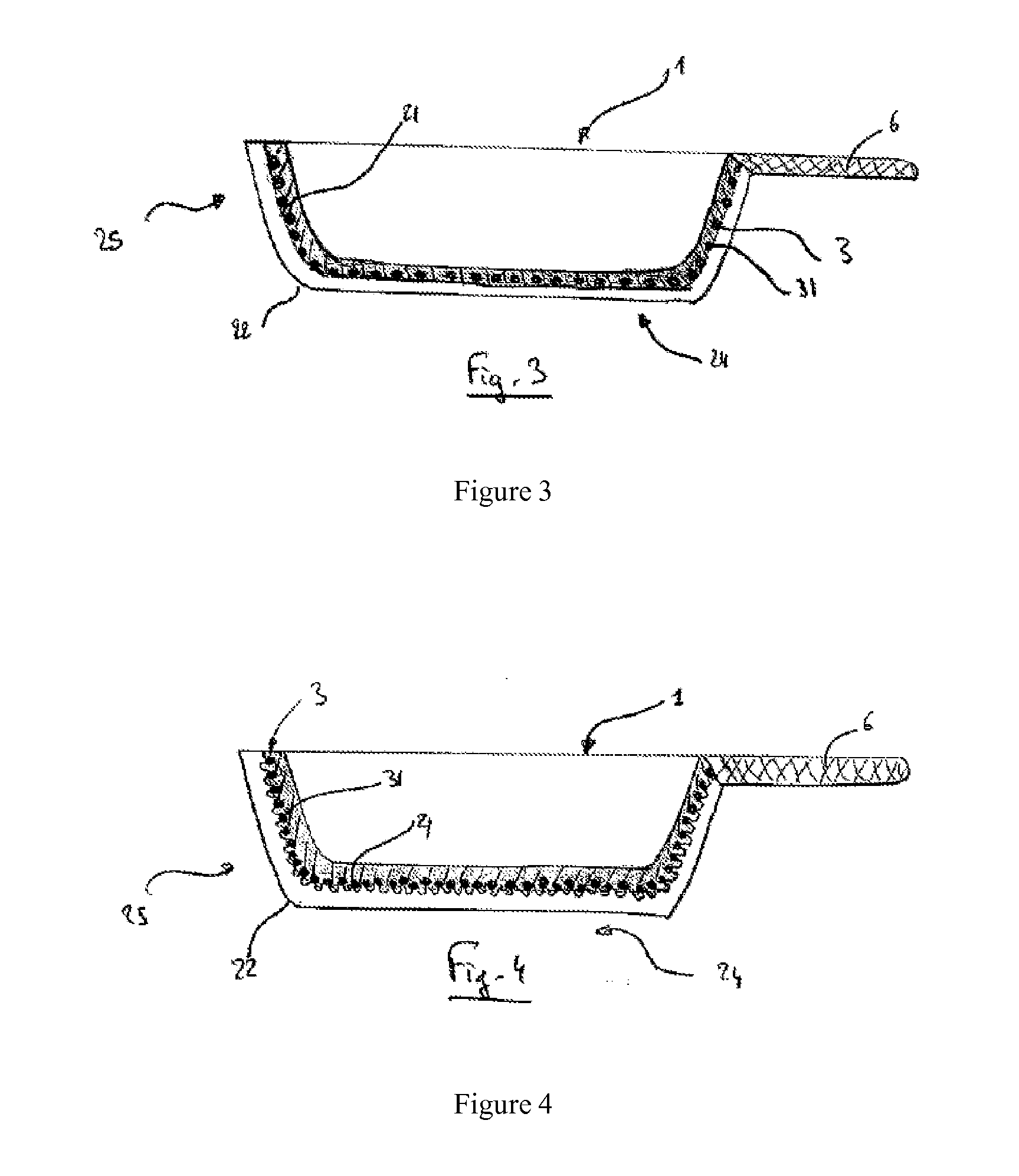

Cooking item comprising a non-stick coating with improved properties of adhesion to the substrate

InactiveUS20110174826A1High hardnessGood dispersionLayered productsSpecial ornamental structuresPulp and paper industryImpact resistance

Owner:SEB SA

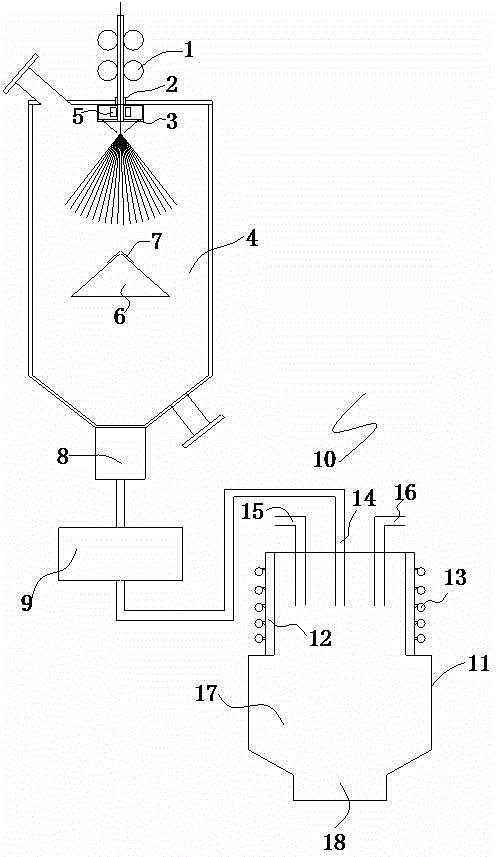

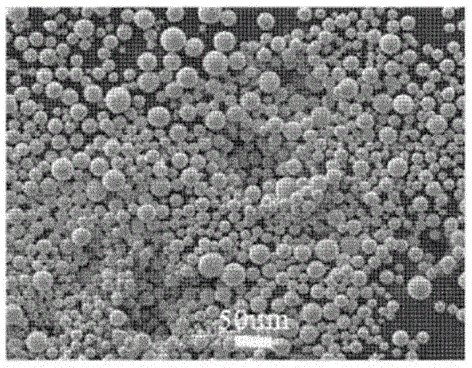

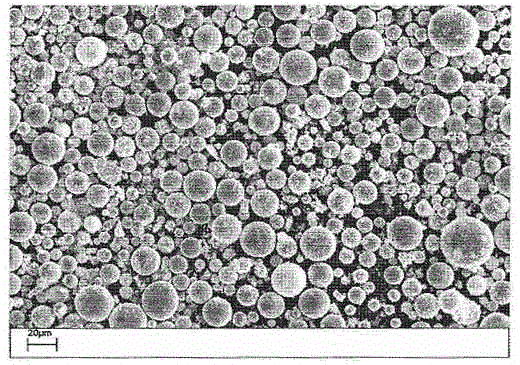

Device and method for preparing superfine micro-spherical titanium powder for 3D printing

InactiveCN105057689AGood sphericityHigh purityAdditive manufacturing apparatusPlasma torchRadio frequency plasma

The invention relates to a device for preparing superfine micro-spherical titanium powder for 3D printing. The device for preparing the superfine micro-spherical titanium powder for 3D printing comprises an automatic feeding system, an insulation dynamic seal unit, an annular gas atomization nozzle, an atomization chamber, an arc cathode smelting well, a radiating cover, a protection cover, a powder collection tank, a supersonic gas crushing mill and a radio frequency plasma reactor. The invention further relates to a method for preparing the superfine micro-spherical titanium powder for 3D printing. The method comprises the steps that firstly a gas atomization unit is used for performing initial powder production on raw titanium powder; then crushing is used for further reducing the granularity of the titanium powder; a plasma unit is used for further processing the titanium powder; the high-energy characteristic of radio frequency plasma is used for injecting carrying gas for irregular-shaped titanium powder particles into a plasma torch, the irregular titanium powder is heated rapidly and melted, the melted particles form drops with high sphericity degree under the action of surface tension, and the drops are solidified rapidly under an ultra-high temperature gradient to form the superfine micro-spherical titanium powder good in sphericity degree, high in purity and low in oxygen content.

Owner:SHANXI ZHUOFENG TITANIUM IND

Low-weight rare earth high-coercivity sintered neodymium-iron-boron magnet and production method thereof

ActiveCN103824668AGood performance consistencyReduced use of heavy rare earthsPermanent magnetsInductances/transformers/magnets manufactureAlloyBoron

The invention relates to the technical field of rare earth neodymium-iron-boron permanent magnet material, in particular to a low-weight rare earth high-coercivity sintered neodymium-iron-boron magnet and a production method thereof. Composition of the low-weight rare earth high-coercivity sintered neodymium-iron-boron magnet is expressed as: Re Alpha Fe(100-Alpha-Beta-NuB Beta)MNu. The production method includes: mixing alloy powder and rare earth micro powder, pressing the mixture under the orientation field with intensity not smaller than 1.5T to obtain a blank; sintering at the temperature of 1050-1120 DEG C to obtain low-weight rare earth high-coercivity sintered neodymium-iron-boron magnet. The rare earth neodymium-iron-boron permanent magnet material produced by the method and products of the material have well uniform properties, heavy rare earth consumption is low, and coercivity is high.

Owner:浙江东阳东磁有限公司

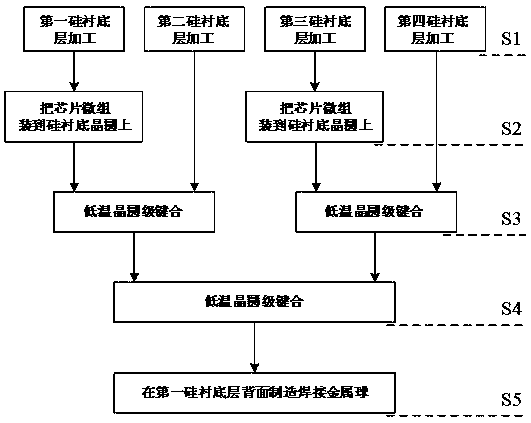

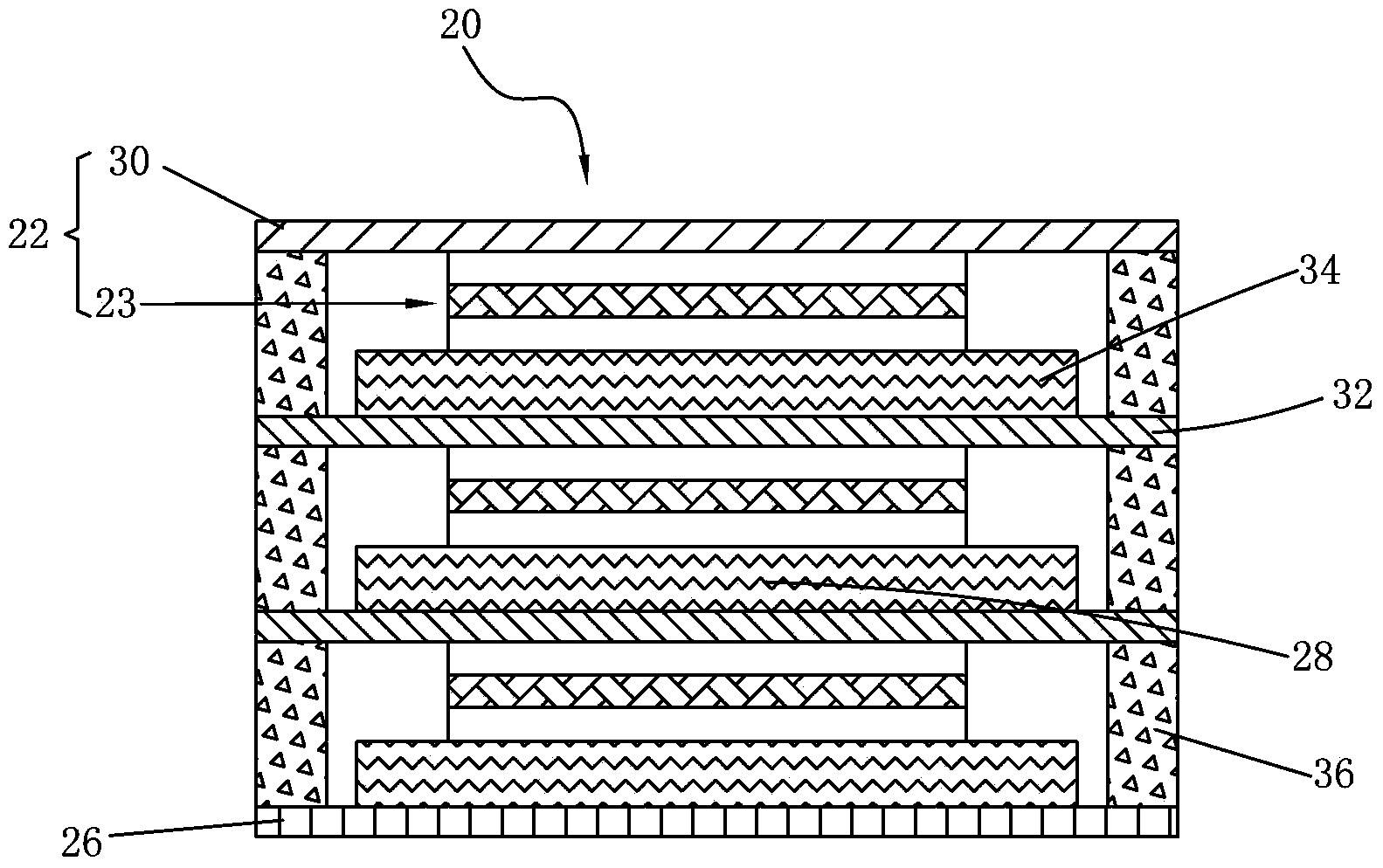

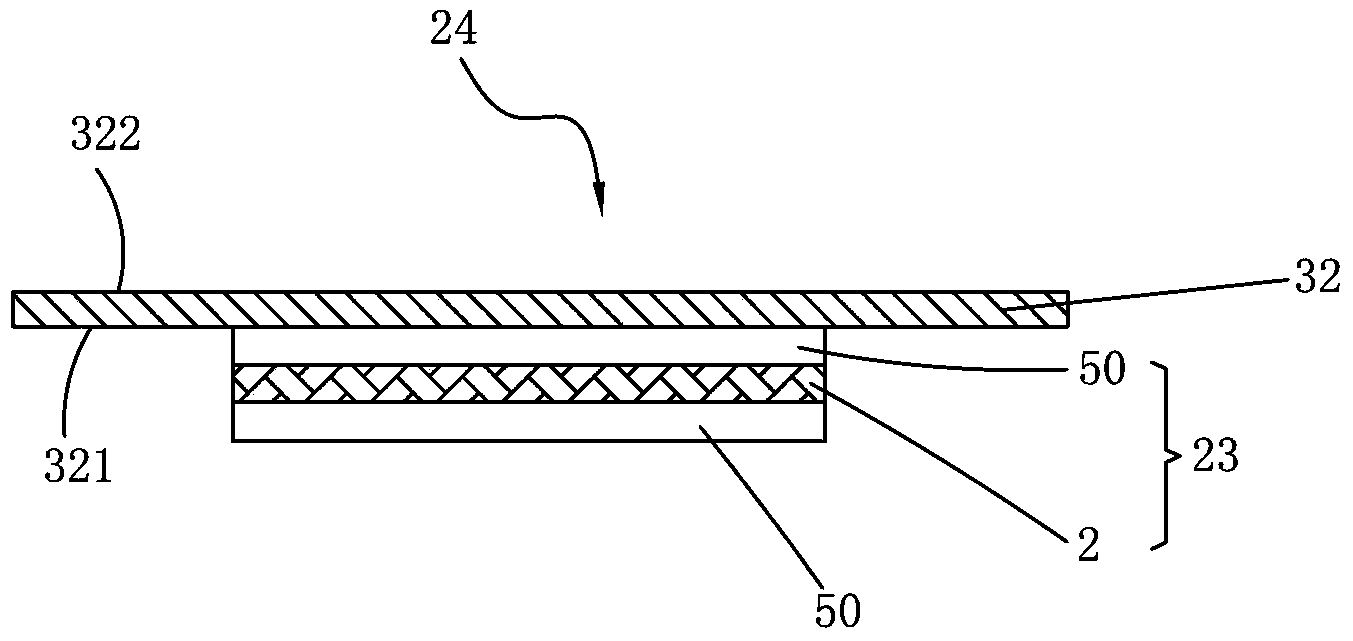

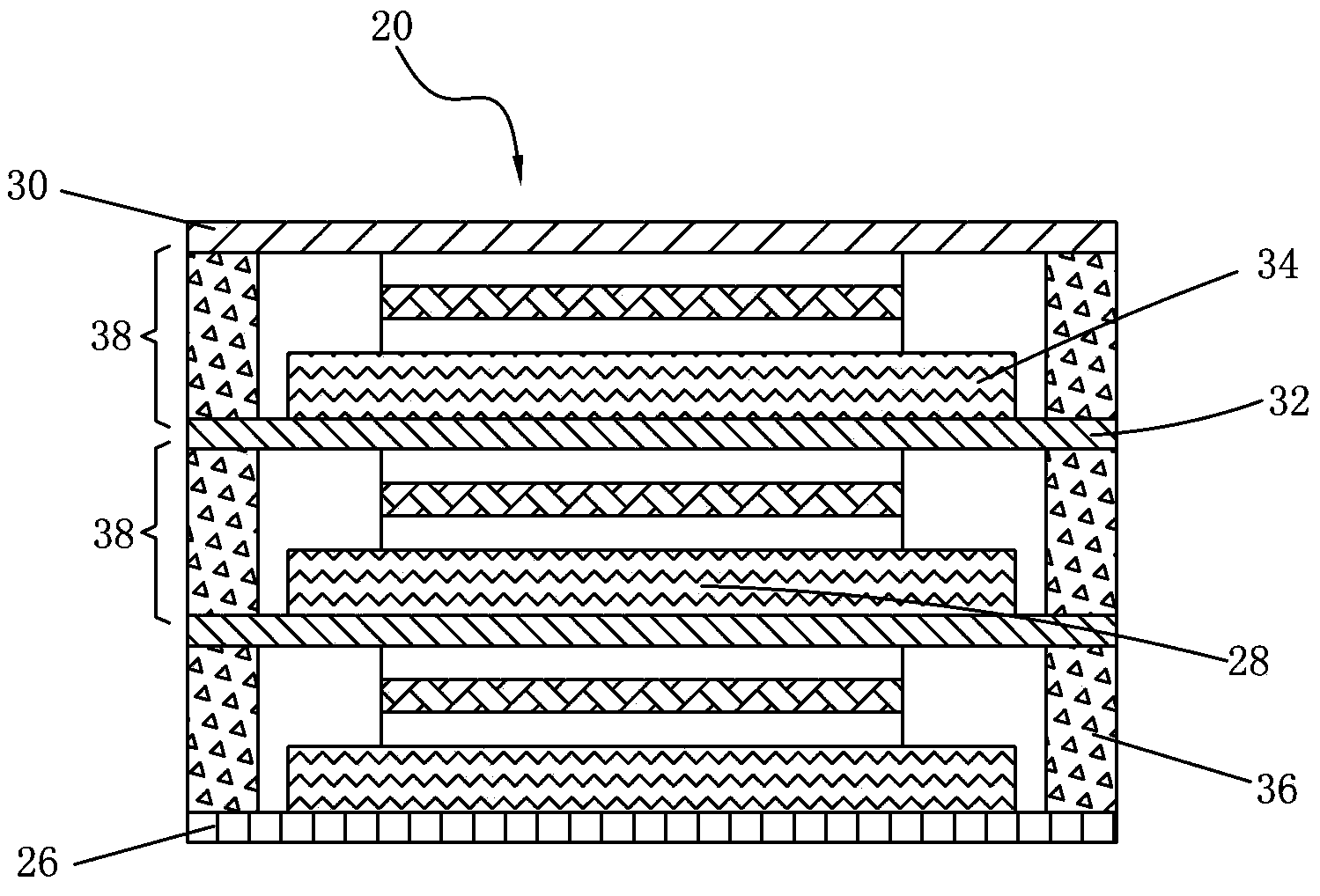

Silica-based three-dimensional heterogeneously-integrated radio frequency microsystem and manufacturing method thereof

PendingCN108083223AImprove performanceAchieve mass productionDecorative surface effectsSolid-state devicesLow noiseHigh resistance

The invention discloses a silica-based three-dimensional heterogeneously-integrated radio frequency microsystem and a manufacturing method thereof. The silica-based three-dimensional heterogeneously-integrated radio frequency microsystem comprises a first silica substrate layer, a second silica substrate layer, a third silica substrate layer, a fourth silica substrate layer, a radio frequency power amplification chip, a radio frequency low noise amplification chip, a radio frequency filter and a radio frequency switch, wherein the silica substrate layers are high-resistance silicon wafers; radio frequency chips and devices are made of different substrate materials through different processes; the radio frequency chips and devices are assembled inside cavities pre-etched in the first silicasubstrate layer and the third silica substrate layer; the first silica substrate layer, the second silica substrate layer, the third silica substrate layer and the fourth silica substrate layer are processed through low-temperature wafer-scale bonding into a whole and vertically connected through silicon through holes to form the silica-based three-dimensional heterogeneously-integrated radio frequency microsystem. The silica-based three-dimensional heterogeneously-integrated radio frequency microsystem achieves tree-dimensional integration of heterogeneous radio frequency chips and devices,thereby reducing the size, increasing the packaging density, reducing transmission loss of wire connection and enhancing the properties.

Owner:GREAT MICROWAVE TECH CO LTD

Battery

InactiveCN104253283ALow priceGood cycle performanceFinal product manufactureSecondary cells manufactureIonCurrent collector

The invention discloses a battery, which includes an anode, a cathode and an aqueous electrolyte solution. The anode comprises a composite current collector and an anode sheet. The composite current collector comprises an anode current collector and a conductive film coating the anode current collector. The anode sheet includes an anode active substance, which can realize reversible prolapse and embedding of ions. The cathode is a metal, alloy or carbon based material. The aqueous electrolyte solution includes an electrolyte, which can at least ionize active ions. The active ions are reduced and deposited at the cathode to form a cathode active substance during charging, and the cathode active substance is oxidized and dissolved in the aqueous electrolyte solution during discharging. The battery provided by the invention has good cycle performance and high energy, and is hopeful to be widely applied in large energy storage, power grid peak shaving and other fields.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD +1

Method of IC production using corrugated substrate

ActiveUS20070004113A1Enhance their performance and costReduce static power consumptionSolid-state devicesSemiconductor/solid-state device manufacturingMOSFETPre-existing

By forming MOSFETs on a substrate having pre-existing ridges of semiconductor material (i.e., a “corrugated substrate”), the resolution limitations associated with conventional semiconductor manufacturing processes can be overcome, and high-performance, low-power transistors can be reliably and repeatably produced. Forming a corrugated substrate prior to actual device formation allows the ridges on the corrugated substrate to be created using high precision techniques that are not ordinarily suitable for device production. MOSFETs that subsequently incorporate the high-precision ridges into their channel regions will typically exhibit much more precise and less variable performance than similar MOSFETs formed using optical lithography-based techniques that cannot provide the same degree of patterning accuracy. Additional performance enhancement techniques such as pulse-shaped doping and “wrapped” gates can be used in conjunction with the segmented channel regions to further enhance device performance.

Owner:SYNOPSYS INC

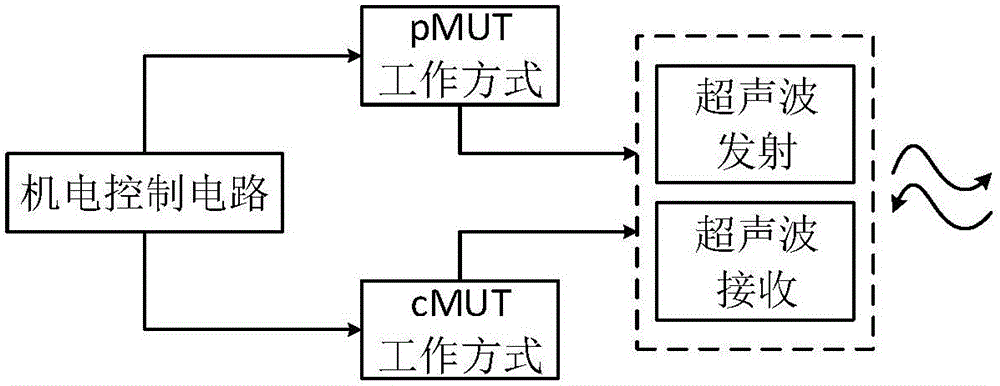

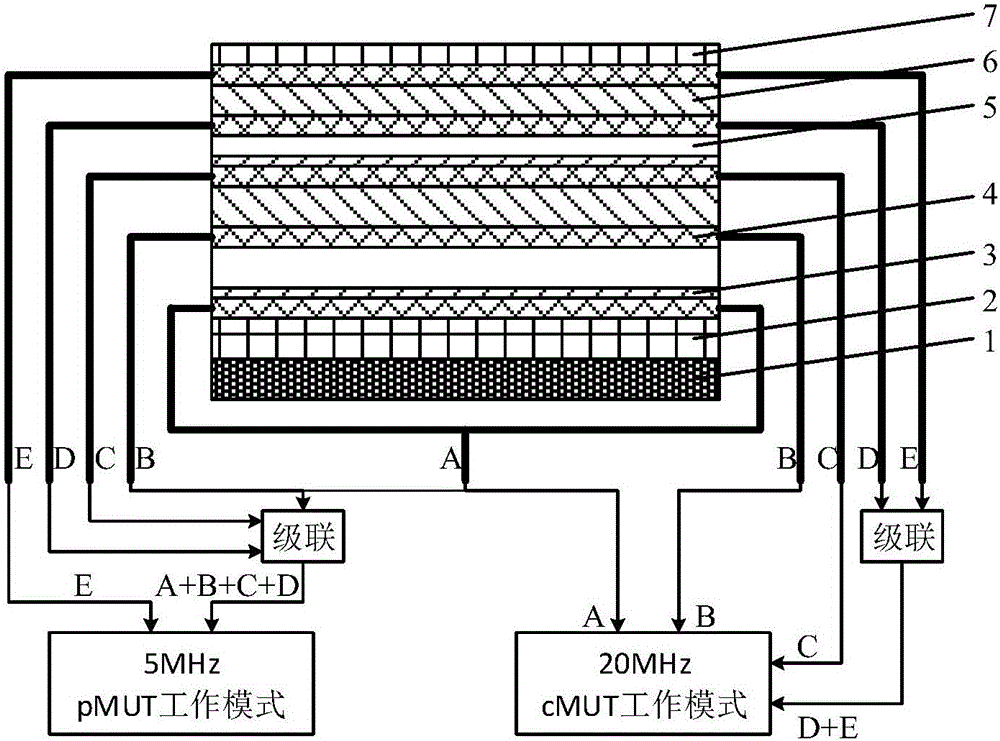

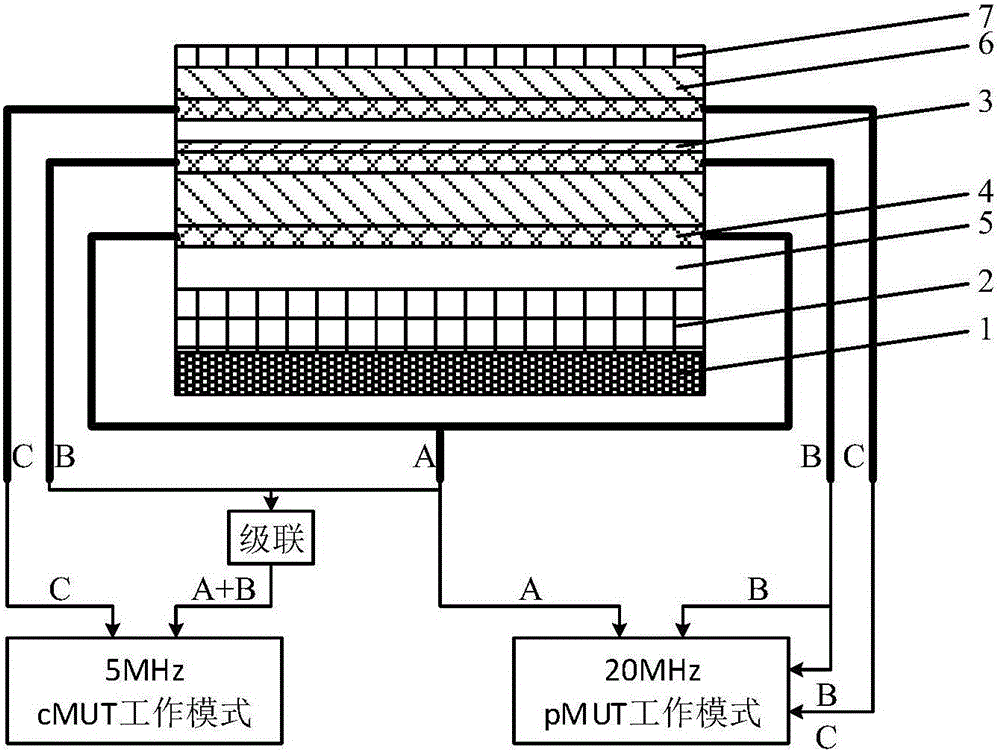

Novel multi-stable ultrasonic detection sensor

ActiveCN106198724AReduce volumeEasy to integrateAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesSolid phasesImage resolution

The invention relates to a novel multi-stable ultrasonic detection sensor which is used in the field of ultrasonic detection and includes: an acoustic resistance matching layer, a metal electrode, a piezoelectric film, a high-voltage-resistant insulating layer, a hollow chamber sealing layer, a back lining layer, and an electromechanical control circuit board. The ultrasonic detection sensor can achieve a multi-stable working mode of combination of piezoelectric ultrasonic sensing and capacitive ultrasonic sensing on one ultrasonic transducer unit through the electromechanical control circuit board, wherein each stable working mode can be designed according to optional ultrasonic frequencies, for example, a design scheme of capacitive low frequency ultrasonic sensing and piezoelectric high frequency ultrasonic sensing, thus considering both the depth and resolution of ultrasonic detection. The multi-stable ultrasonic detection sensor can be flexibly applied in ultrasonic detection on gas-phase, liquid-phase and solid-phase mediums, is simple in resistance matching, is small in size and is easy to integrate, can be produced in large scale and is low in cost, and has application prospects in the fields of underwater acoustic detection, bio-medical imaging, industrial ultrasonic non-destructive testing, etc.

Owner:CHONGQING UNIV

Low-cost high-conductivity magnet based amorphous nanocrystalline magnetically soft alloy and preparation method thereof

ActiveCN105861958ARaise the crystallization temperatureEnhanced Amorphous Formation AbilityMagnetic materialsProcess efficiency improvementRare earthAlloy

The invention discloses low-cost high-conductivity magnet based amorphous nanocrystalline magnetically soft alloy and a preparation method thereof. The molecular formula of the magnetically soft alloy is FeaSibBcMdCueNbfM'g, wherein M is Al or Zn, and M' is selected from one or more of Y, Gd or Er; and a, b, c, d, e, f and g are the mass percent, the value ranges meet the conditions that a is larger than or equal to 79 and less than or equal to 88.5, b is larger than or equal to 8 and less than or equal to 11, c is larger than or equal to 0.05 and less than or equal to 2, d is larger than or equal to 0.8 and less than or equal to 1.5, e is larger than or equal to 0.7 and less than or equal to 2.5, f is larger than or equal to 2 and less than or equal to 4, and g is larger than or equal to 0.008 and less than or equal to 0.02. On the basis that the high magnetic conductivity, high Bs and low coercive force and consumption of the magnetically soft alloy are all achieved, the low-cost Al or the Zn is adopted to replace copper partially, the content of Nb is decreased, and trace rare-earth metal is mixed, so that the production cost is reduced. The low-cost high-conductivity magnet based amorphous nanocrystalline magnetically soft alloy is obtained through the preparation method which is simple in process and disclosed by the invention.

Owner:NEW MATERIALS TECH JIANGSU AMORPHD

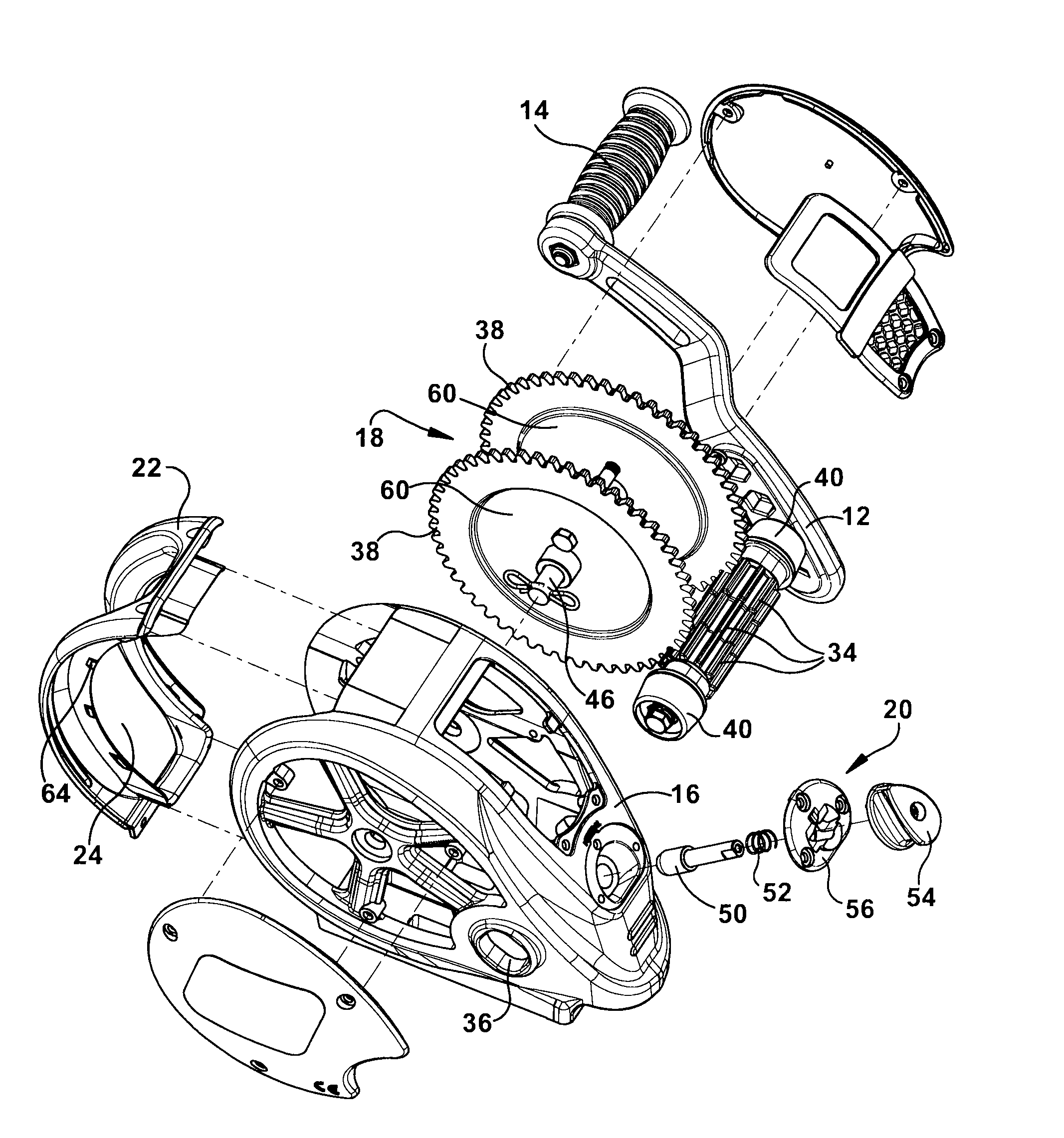

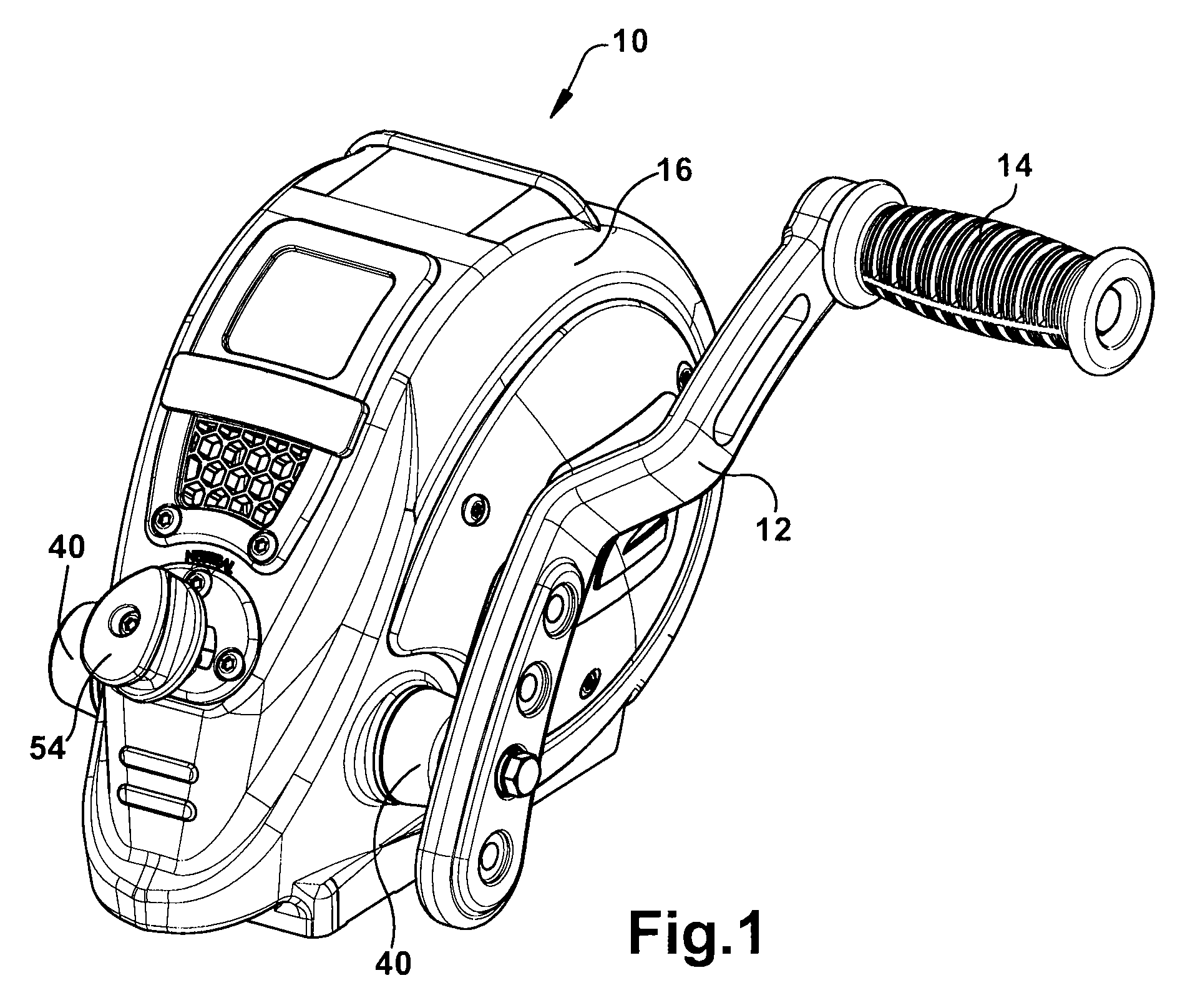

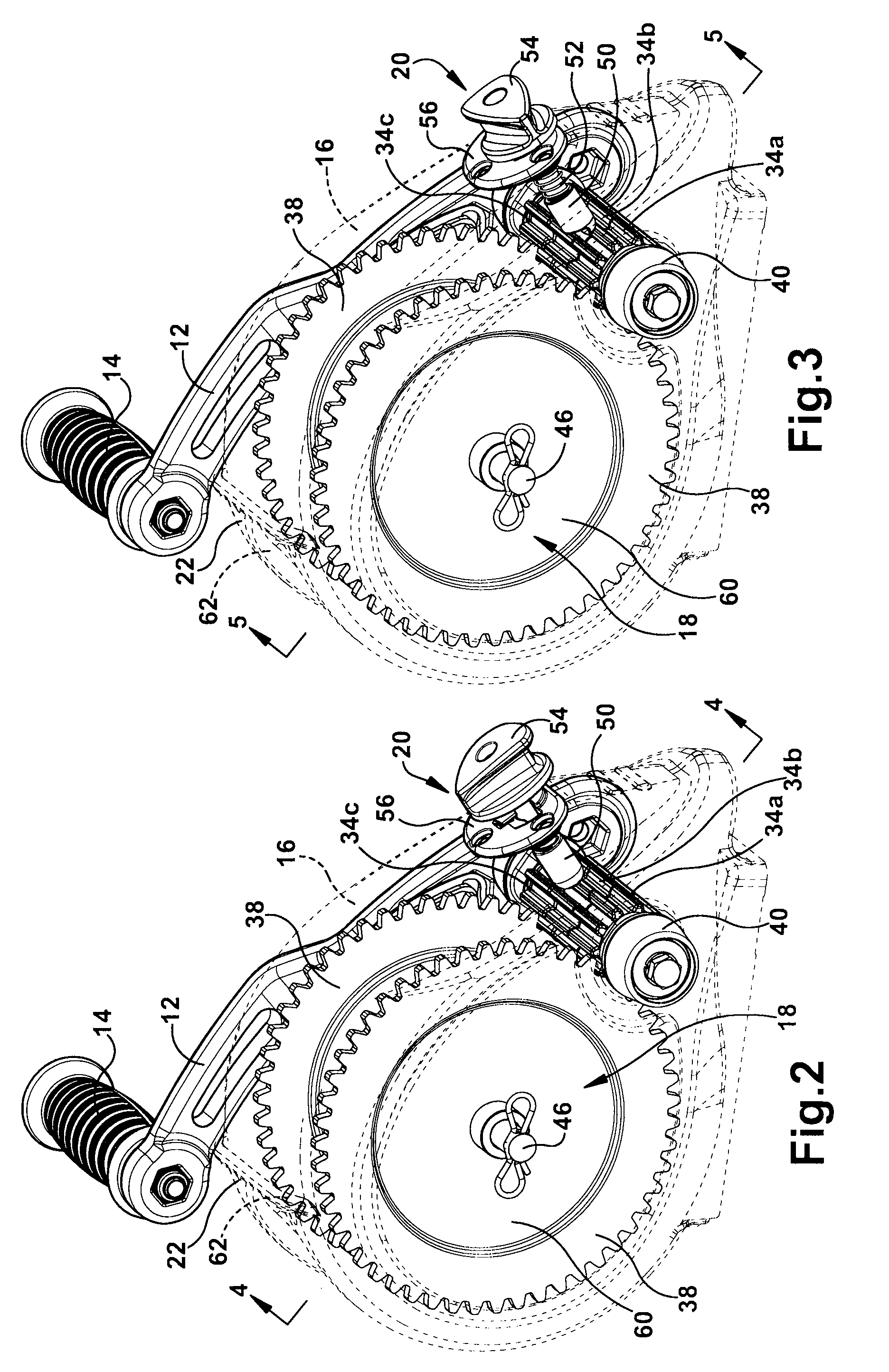

Winch assembly

ActiveUS7967278B2Easy to assembleEasy to useItem transportation vehiclesWinding mechanismsEngineeringWinch

The present invention is directed to apparatus for a winch assembly. The winch assembly may be secured to a towing trailer and arranged to assist in loading and unloading cargo from the trailer. The winch assembly may include mechanisms, systems, and features to make the winch assembly easy to assemble and use, increase the service life of the winch assembly, and improve the consistency of the performance of the winch assembly. Embodiments of a winch assembly disclosed include novel drive systems, novel ratchet and pawl systems, novel systems for guiding a winch strap, novel systems for securing the winch assembly to a towing trailer, and a novel frame member for a winch assembly.

Owner:HORIZON GLOBAL AMERICAS INC

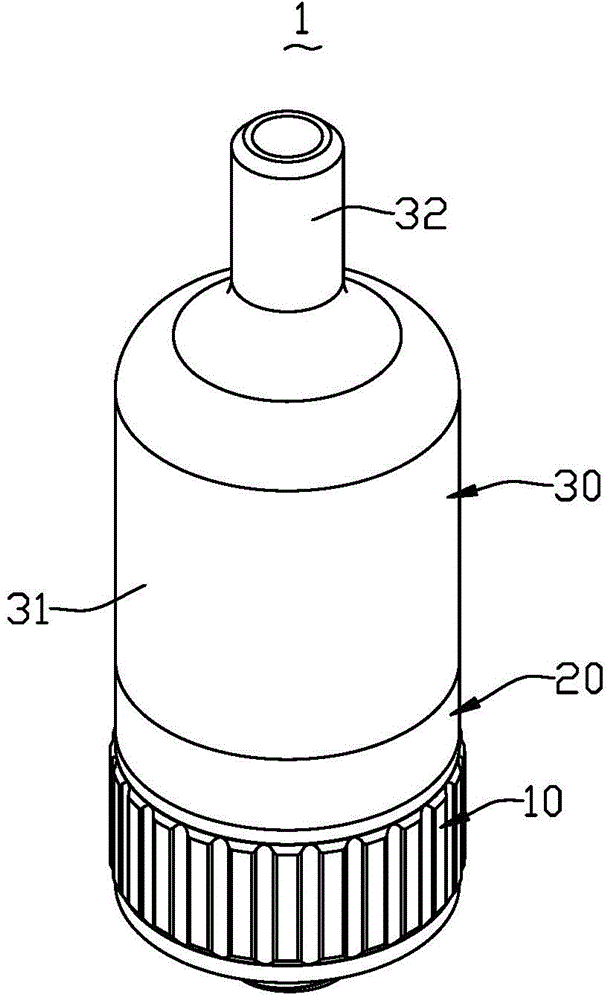

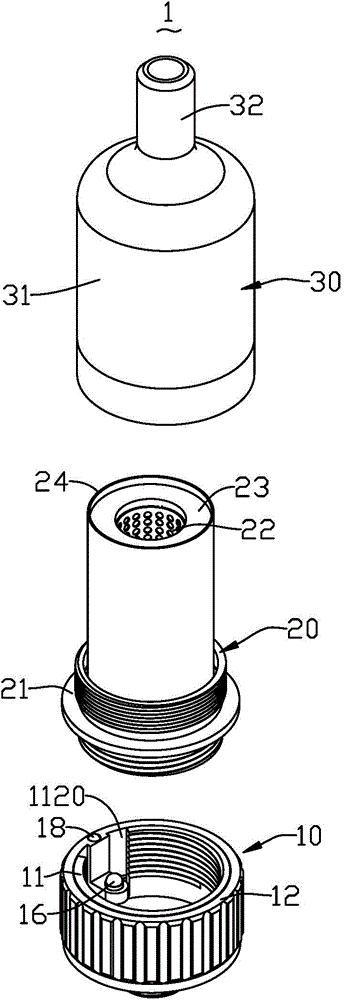

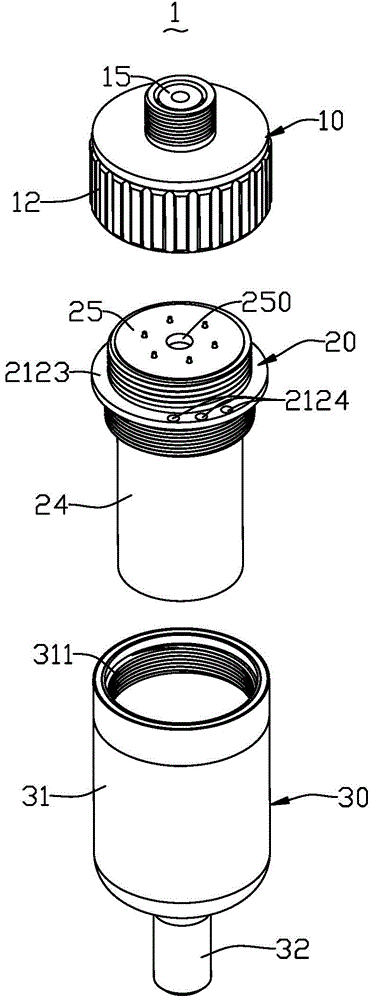

Electronic cigarette

The invention relates to an electronic cigarette, comprising an atomizing device and a power supply device matched with the atomizing device; the atomizing device comprises a mounting seat, a heating element and a control device, wherein the heating element is arranged on the mounting seat and comprises at least two heating parts, each heating part is cylindrical and defines an axial airflow channel, a plurality of through holes are formed in the side wall of each heating part, and the airflow channel is communicated with the outer sides of the heating parts by the through holes; the control device is electrically connected between the heating element and the power supply device in order to selectively control the at least two heating parts to be electrically conducted with the power supply device. The electronic cigarette atomizes cigarette juice by the cylindrical heating element and forms the airflow channel, and the diameter of the heating element easily makes consistent, therefore the consistence of performance of product can be improved; furthermore, different heating parts are controlled respectively, and the smoke amount can be adjusted as required.

Owner:SHENZHEN SMOORE TECH LTD

Hot rolling method for wide and thin size high-strength cold-rolled base plate for automobile

InactiveCN105478472AGuaranteed MicrostructureGuaranteed mechanical propertiesMetal rolling arrangementsStructure propertySheet steel

The invention discloses a hot rolling method for a wide and thin size high-strength cold-rolled base plate for an automobile. After continuous casting billets are assembled in a heating furnace in a hot state, the Cu accumulation amount of iron oxide scales and steel substrates is reduced by adopting high-temperature preheating and high-temperature rapid heating technologies; after rough rolling, the thickness of an intermediate billet is reduced, a heat holding cover is used for reducing temperature drop and temperature differences of all parts, so that the finish rolling entry temperature of the intermediate billet is increased; and loads of all racks for finish rolling are reduced, and the stability of finish rolling is improved. In the process from finish rolling to steel belt coiling, a controlled rolling and controlled cooling technology is adopted, so that the cold-rolled base plate has excellent uniformity between the shape and the structure property. According to the method, the cold-rolled base plate with the thickness of 1.5-2.5 mm and the width of 1650-2000 mm can be obtained; the convexity degree of a steel belt is controlled to be in a range between 45-15 mu m and 45+15 mu m; the straightness is controlled to be 30I; the thickness accuracy is in a range between -30 mu m and +30 mu m; the structure property of different edges of the head, the middle, the tail of the steel belt is uniform; and the yield and the production efficiency of the wide and thin size high-strength cold-rolled base plate can be increased and improved, so that the cold-rolled base plate meeting the requirements of the actual product quality and the performance is provided for steel plates with the grade of 450-590 MPa for automobile covering parts.

Owner:ANGANG STEEL CO LTD

A millimeter wave antenna system and a communication device

InactiveCN109066054AAvoid taking up spaceSmall footprintParticular array feeding systemsAntenna supports/mountingsDielectricElectricity

The invention discloses a millimeter wave antenna system and a communication device. The millimeter wave antenna system comprises a frame / housing equipped with an antenna slot; a high dielectric coverlayer arranged on the outside of the antenna slot; a signal transmission unit provided on the inner side of the antenna slot; a signal transceiver assembly electrically connected to the signal transmission unit; and an intermediate frequency and baseband processing unit electrically connected to the signal transceiver assembly; The dielectric resonant antenna array of millimeter wave antenna system is composed of the high dielectric cover layer, the antenna slot and the signal transmission unit. The invention provides an antenna system, which has the characteristics of small occupying space,many correctable factors and high working efficiency.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com