Method for processing double face fabric with single-side moisture transferring and cooling functions

A one-way moisture-wicking and double-sided fabric technology, which is applied in the directions of fabric surface trimming, fabric heating/cooling, fabric kneading/softening, etc., can solve the problem of limited simplicity of production process design, insufficient process design, and product functionality. Limitation and other problems, to achieve the effect of good product performance consistency, no energy pollution, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

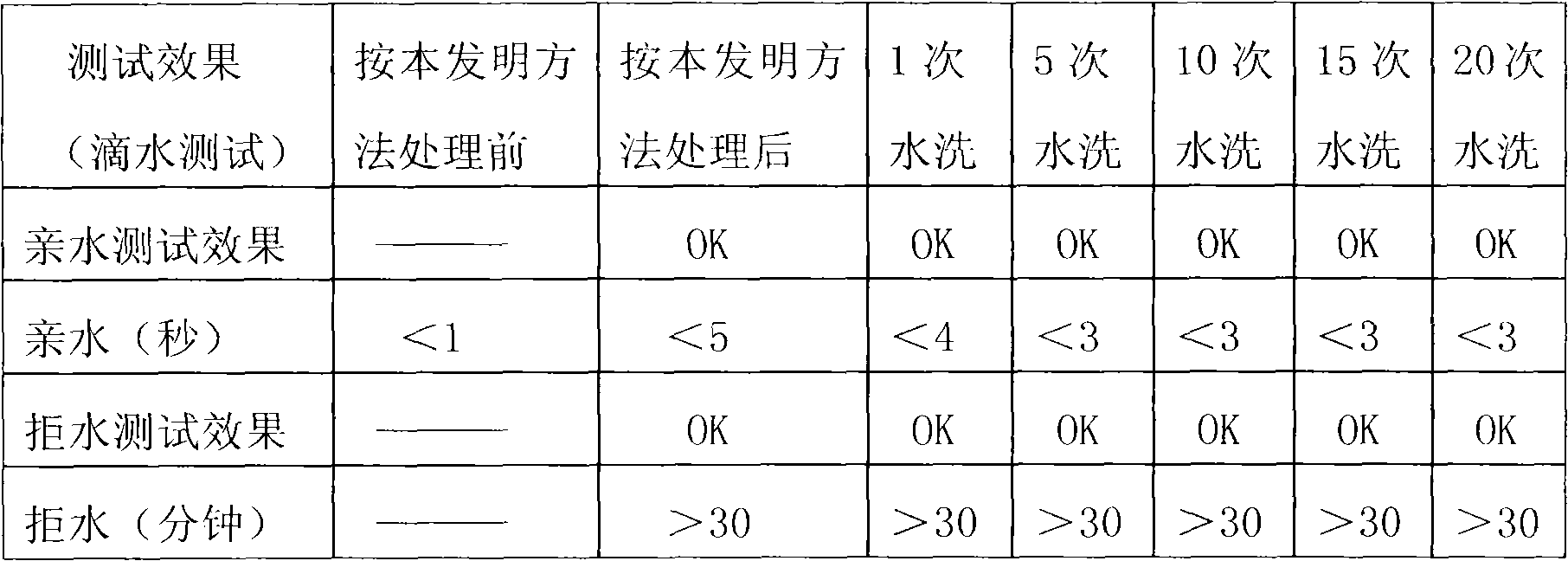

Examples

Embodiment 1

[0033] Double-sided fabric example 1: a polyester-covered nylon FLYCOOL jacquard rib knitted fabric, the outer layer of the fabric is made of 75D / 72F polyester filament, the inner layer of the fabric is made of 70D / 48F FLYCOOL nylon filament, and the weight of the finished garment is 165g / m 2 ;

Embodiment 2

[0034] Double-sided fabric embodiment 2: a cotton-covered nylon FLYCOOL plain knitted fabric, the outer layer of the fabric is made of 40 combed pure cotton staple fibers, the inner layer of the fabric is made of 70D / 48F FLYCOOL nylon filaments, and the weight of the finished garment is 155g / m 2 ;

Embodiment 3

[0035] Double-sided fabric example 3: a modal cover nylon FLYCOOL mesh knitted fabric, the outer layer of the fabric is made of 40 modal staple fibers, the inner layer of the fabric is made of 70D / 48F FLYCOOL nylon filaments, and the weight of the finished garment is 150g / m 2 ;

[0036] The double-sided fabric of above-mentioned embodiment 1-3, its processing method embodiment is as follows:

[0037] The processing method of the double-sided fabric of embodiment 1:

[0038] A method for processing double-sided fabrics with one-way moisture guide and cool function, specifically comprising the following steps:

[0039] Step 1, fabric pretreatment: first prepare the gray fabric, such as: cloth distribution, sewing, etc.; in the overflow jet dyeing machine, use the degreasing agent "DK-808", according to the weight percentage of the gray fabric, the dosage is 1%, in the gray fabric In the pre-treatment stage, degreaser was used to degrease the gray cloth. The bath ratio of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com